Page 1

Carrier

fnsfallatîon Instructions^^

Air-Cooled Condensing Units

(includes 50BD Combination)

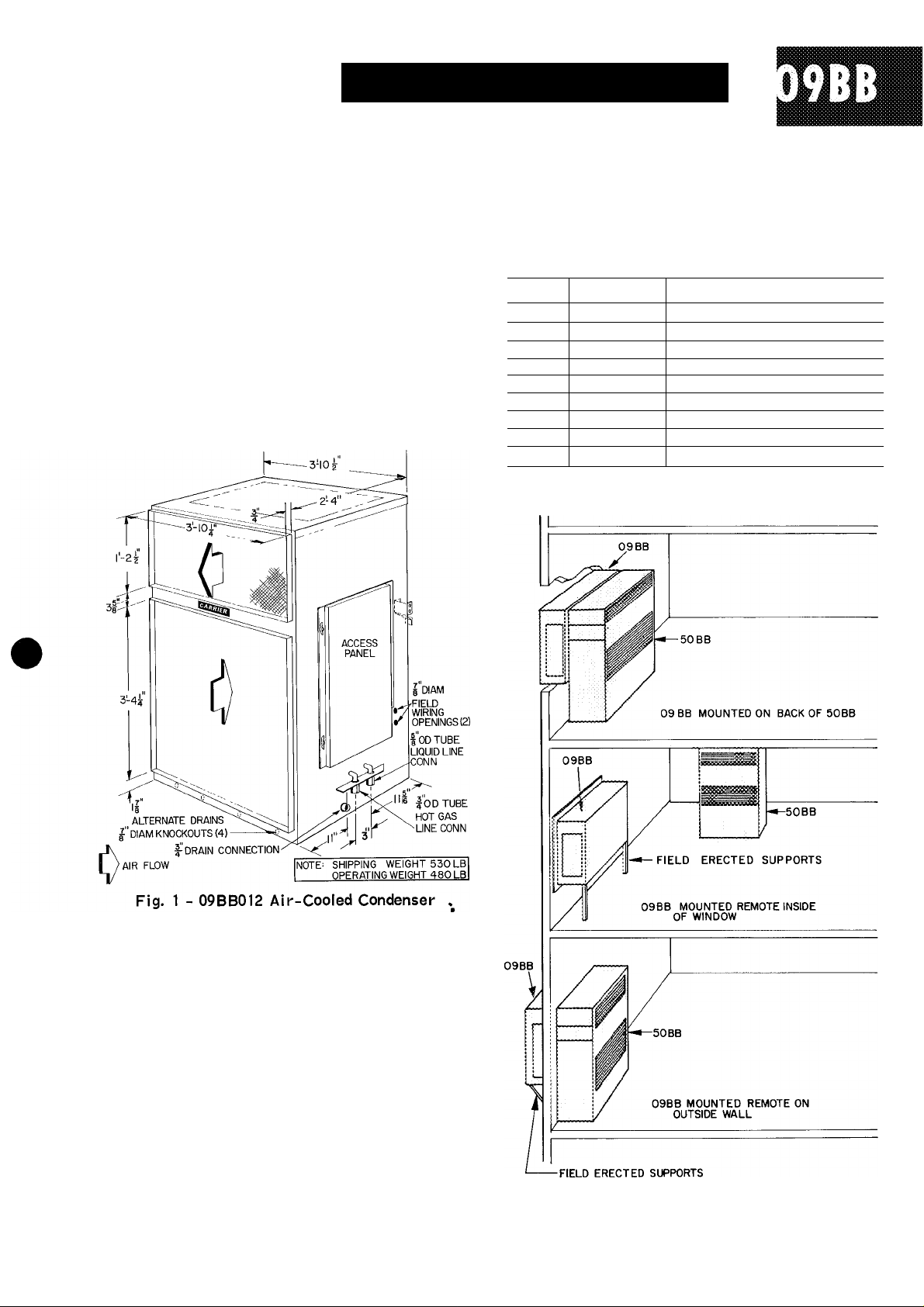

General - The 09BB012 condenser can be coupled

with a 50BB008 or 012 Weathermaker® unit to

form a 50BD combination.

The condenser is designed to match with, or

arranged to be field mounted to the back of

50BB units.

The condenser can also be mounted remote.

Air discharge can be vertical or horizontal, in

or out the same face.

Table 1 - Fastener Package Contents

UNIT

1

2

3 2

4

5

6

7 4

8 4

9

QUANTITY

4

2

2

2

2

2

Vibration isolators

Support bolt nuts 5/16-18

Channel bolts 3/8-16 x 1" hex hd

Lockwashers 3/8"

Plain washers 5/16"

DESCRIPTION

Locking bolt 1/4-20 1" hex hd

Support bolt 5/16-18 3" hex hd

Thd forming screws 1/4 x 1-1/4"

External locktooth washers 1/4"

Receiving the Unit ~ Inspect unit for shipping dam

age. Enter any claims directly with the transporta

tion company.

Carrier Air Conditioning Company will not be

responsible for damage incurred in transit.

Uncrating - Remove unit and hardware from ship

ping skid. Check to see that unit and component

parts conform to the bill of lading. Contents of

fastener package are listed in Table 1.

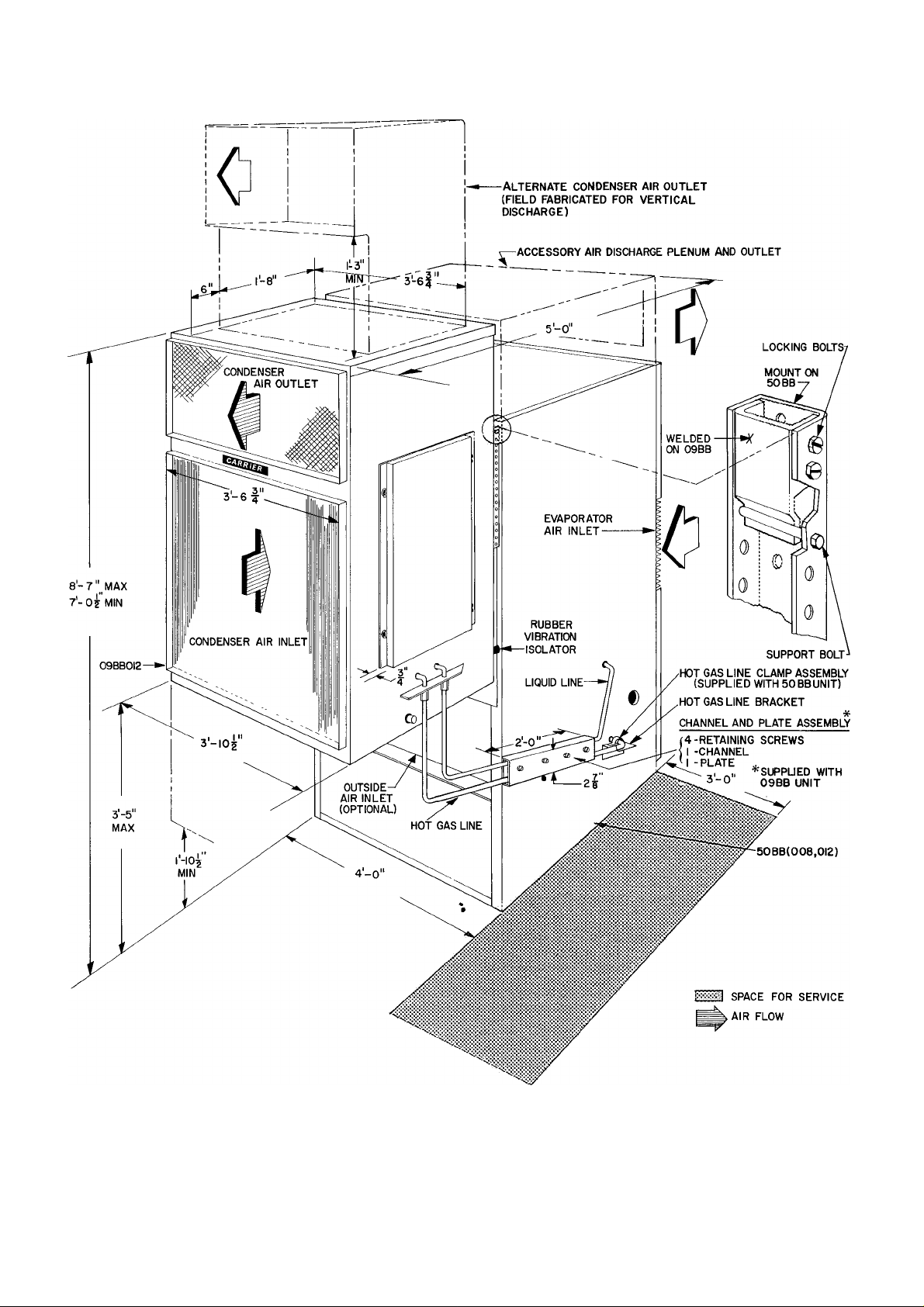

Before Installation - Check space requirements,

service clearances, floor strength, location of

piping, size of power supply, and location of duct

work (Fig. 2 and Fig. 3).

Make sure rigging equipment is adequate, Avoid

undue force against side and front panels when

lifting unit.

Carrier Corporation 1967

Printed in U.S.A.

Fig. 2 - Mounting Arrangements

6-67

09BB-1SI

Page 2

*1

V

Fig. 3 - 50BD Combination

©

Page 3

INSTALLATION

Mounting Brackets - Two mounting brackets are

supplied for mounting the 09 BB unit to the 50BB

unit (Fig. 4). These brackets have been designed

to provide adjustable heights for the 09BB to the

nearest 1/2 in. This is done by providing two sets

of mounting holes on the bracket, spaced 1-1/2 in.

apart. The upper mounting holes allow 09BB unit

height adjustment in 1-in. increments starting

1 ft 10-1/2 in. from the floor. The lower mounting

holes allow height adjustment in l-ir. increments

starting 2 ft from the floor.

Install brackets as follows:

1. Remove the top four retaining screws on each

side of the back panel of 50BB.

2. Select mounting holes and place bracket in

position. Install with retaining screws and

channel bolts in shipping holes (Fig. 4).

3.

Install support bolts as shown in Fig. 3.

4.

Install vibration isolators (supplied) in lowest

hole each side of 50BB back panel (Fig. 4). Re

move Tinnerman nut and install each vibration

isolator with 5/16 in. plain washer (supplied in

fastener package).

Vertical Discharge - 09BB unit can be mounted as

shown in Fig. 5. It will be necessary to relocate

the electrical junction box either external to unit

(as shown) or on an interior panel.

Also, provide a rain drain on back of unit.

Fig. 4 - Installation of Mounting Brackets

Positioning 09BB Unit

For typical installation

refer to Fig. 3.

WARNING: The 50EB unit will not balance the

09BB unit without additional support.

Once 09BB unit has been positioned in the

mounting brackets, install locking bolts as shown

in mounting bracket detail.

Before sliding units into final position, check

for clearance to access panels, and service area

to install piping.

PIPING

09BB hot gas and liquid line piping is factory

supplied when field mounting the 09BB to the 50BB.

The preformed piping is arranged for various

mounting heights. Cut the vertical rise of tubes

for height adjustment. No bending is required.

09BB units are factory charged with refrig

erant. Liquid and hot gas lines are installed

as follows:

Compatible Fittings - Liquid and hot gas lines are

installed from the 50BB unit to the 09BB unit with

Carrier compatible fittings and service valves.

These fittings may be used as sweat or mechanical

connections. Install either type as follows:

MECHANICAL CONNECTIONS

1. Cut tubing to length and remove burrs. Be care

ful not to expand tubing.

2. Remove plug from fitting and loosen nut one

turn.

3. Position tube. Remove cap and insert tube in

fitting to depth indicated on tag (1-1/4” depth

for 5/8” and 3/4” tube, 3/4” depth for 3/8”

and 5/16” tube).

4. Leave nut loose at condenser end of each tube.

Purge one line at a time using 50BB base unit

holding charge.

5. Tighten nut to a stop on unit fitting collar.

6. Open all service valves.

Page 4

SWEAT CONNECTIONS

1. Cut tubing to length and remove burrs. Be care

ful not to expand tubing.

2. Clean tubing. Remove plug and nut from fitting.

3. IMPORTANT - Remove O ring from inside

fitting. Wrap entire valve with wet rag.

4. Insert tubing in fitting and solder with lowtemperature solder (450 F) such as Allstate

430.

INTERNAL DRAINAGE - The base pan has a

3/4-in. coupling for an interior drain outlet (for

rainwater). Remove the plug from the drain out

let and install a trap in the piping if this system

is used.

IMPORTANT: For vertical discharge unit,

provide a rain drain on back of unit (Fig. 5).

On ail units, before connecting drains trim

away insulation blocking the hole{s).

NOTE: Make solder connection at 50BB

unit, then connect to 09BB unit except for

soldering. Purge with 50B3 holding charge,

then solder.

Brackets - After installing piping from 50BB to

09BB units, install the following:

HOT GAS LINE BRACKET - Install proper size

rubber-coated clamp assembly (furnished in 50BB

fastener package) to hot gas line bracket (Fig. 3).

CHANNEL AND PLATE ASSEMBLY - Figure 3

illustrates correct assembling and positioning for

this assembly.

Remote Piping - For 09BB remote installation,

select pipe sizes according to length from the

following table.

Table 2 - Remote Pipe Sizing (in.)

UINI 1

0-15 (ft) 16-25 (ft) 26-50 (ft) 51-75 (ft) 76-100 (ft)

50BB

008 3/4 5/8 7/8 5/8 7/8

012 3/4 5/8 7/8

HG — Hot Gas Line

Liq — Liquid Line

NOTES;

1. Normal number of elbows and fittings have been considered in

sizing pipes.

2. Pressure loss thru recommended hot gas line check valve has

been considered for 25-100 ft lengths.

3. Use of 0 hot gas line check valve is recommended on 50BB012

units with field-supplied piping.

HG

Liq

LENGTH OF PIPE

Liq

HG

7/8 1-1/8 7/8 1-1/8 7/8 1-1/8 7/8

HG

Liq

HG

5/8 1-1/8

Liq

7/8 1-1/8 7/8

HG

Liq

To connect piping, use instructions previously

given for compatible fittings. Use refrigerant

grade piping. If tubing size is other than unit con

nection sizes, use adapter fittings.

Refer to 50BB Installation Instructions to de

termine refrigerant charge adjustment for remote

piping.

Drains - The 09BB unit provides a choice of two

drain systems for installation. The choice is gov

erned by unit location.

EXTERNAL DRAINAGE - If unit is located with

front panel outside of building, there are four

7/8-in. knockouts that can be used for external

drainage (Fig. 1).

Pitch drain pipes downward for proper drain

age. Provide tees plugged one side for cleanouts.

Leave clearance for servicing. Observe local

sanitary codes.

For other piping details refer to Carrier Sys

tem Design Manual.

Ductwork - The 09BB unit is designed for use

without ductwork or rain louvers. If either is used,

care must be taken to eliminate air recirculation.

Recirculation can be minimized by blocking the

front discharge and discharging thru an extension

elbow. When properly designed, hinged discharge

louvers can be applied to ductwork, also to the con

denser air discharge. Fixed rain louvers over dis

charge outlets can cause excessive recirculation

and nuisance high-pressure switch cutouts. Ob

structions closer than 20 ft to the discharge air

pattern can cause significant recirculation.

If ductwork is used from standard discharge

openings and another "bird screen” is provided,

remove Carrier supplied screen to reduce static

pressure load.

CONDENSER AIR DUCT INSULATION

The condenser air duct must be insulated on

indoor installations to prevent moisture condensa

tion on the unit panels during cold weather. Insu

late as follows:

1. If metal ductwork is used, insulation should be

applied on the inside of the duct. This insulation

should be extended to cover the inside of the

09BB duct flanges.

It is necessary to insulate the inside of the

ducts at the duct flanges to reduce heat loss

from the metal cabinet by conduction thru the

duct flanges and into the cold duct. Interior

insulation allows the metal duct to approach

room temperature. It also prevents condensa

tion from forming and collecting under the in

sulation which will occur with exterior duct

insulation.

2. If insulation is applied to the outside of the

metal duct, the inside must be insulated for a

length of ten inches from the unit (including

the duct flanges) or up to the flexible duct

vapor barrier on the outside which must be

tightly sealed to prevent condensation under

the insulation.

Page 5

3. A high-density fiberglass (2 lb minimum den

sity) or semirigid foamed insulation such as

Styrofoam will be required inside the ducts to

prevent air erosion. The insulation must be

firmly secured in the discharge duct near the

blower discharge to withstand the high air

velocity.

Fan Adjustment - Check fan blade location before

start-up. Figure 6 indicates proper fan position

in relation to the fan orifice.

ELECTRICAL DATA

Fig. 6 - Position of Condenser Fan

TO DETERMINE WIRE SIZE USE

O Component Connections Unmarked

O Component Connections Marked

□ Terminal Board Connections

------

Field Wiring

Fig. 7 - Typical 50BD Wiring and Component Arrangement

LEGEND

C — Compressor Contactor

HPS - High Pressure Switch

F - Fan Contactor

FU - Fuse

HR - Holding Relay

5

LPS - Low Pressure Switch

TB - Terminal Block

TM - Timer Motor

Page 6

ELECTRICAL DATA (Cont)

MAINTENANCE

Refer to Table 3 for 09BB fan motor char

acteristics. Refer to Table 4 for wire and fuse

sizing. Refer to Fig. 7 for combination field

wiring.

Table 3 - 09BB Condenser Fan Motor

HORSEPOWER

1

FULL LOAD AMPS

7

Table 4 - Wire and Fuse Sizing

50BD*

COMBINATION

09BB012/50BB008

09BB012/50BB012

*When power is supplied to 09BB from 50BB terminal block, use

this table to size wires from fused disconnect to 50BB terminal

block.

t60° wire.

iBased on 1% voltage drop.

NOTES:

1. When power to 09BB is supplied from 50BB disconnect, refer

to 50BB Installation Instructions for wire sizes from fused

disconnect to 50BB

2. Power to 09BB can also be supplied from separate fused dis

connect. For this method, use 15 amp fuses and No 12 wire

3. Power supply voltage must be within ±10% of nameplate voltage.

VOLTAGE

(3-Phase,

60-Cycle)

208

230

208

230

LOCKED ROTOR AMPS

WIRE

SIZEt

(AWG)

WIRE MAX

LENGTH

(ft)r

6

4

2

6

4

2

4

2

4

2

140

117

175

100

119

18

MAX

FUSE

(Amps)

61

92

77

67

79

50

45

70

60

Cleaning - 09BB unit should be thoroughly cleaned

inside and out. Frequency of cleaning will depend

on unit location and area conditions.

Drains must be kept free of dirt and trash.

Coils can be cleaned with a stiff brush, vacuum

cleaner or compressed air. Coil can be reached

thru access panels.

Inspection - Check coil baffles for tight fit to pre

vent air from bypassing the coil.

Check panels for air leakage, particularly those

sealing the fan and coil compartments.

Check for loose electrical connections, oil

level, proper refrigerant charge and refrigerant

piping leaks.

NOTE: 09BB fan motor is permanently lubri

cated. Does not require further lubrication.

Before start-up, be sure all service valves ;

are open (backseated).

Tab 5 09BB-1S1 New

Manufacturer reserves the right to change any product specifications without notice

6-67 Codes C and MC Catalog No. 530-905

Loading...

Loading...