Page 1

Carrier

installation, Start-Up ncsc H7F

and Service Instructions WOC,u/C

Compressors and Condensing Units

Hermetic, Water-Cooled

PRELIMINARY SURVEY

Inspect shipment for damage. File claim with

the shipping company if shipment is damaged or

incomplete.

Locate unit on floor in a well ventilated area.

Install unit where it will be warmer than condi

tioned area. Position it to allow sufficient space for

refrigerant and water connections and to service

compressor. Allow space at one end of condenser

for tube cleaning or replacement. Place unit so

suction and discharge valves can be easily reached

and so oil level can be checked.

Local water conditions can cause excessive

fouling or pitting of condenser tubes. If such

conditions are anticipated, a water treatment

analysis is recommended. Refer to Carrier System

Design Manual, Part 5, for general water condi

tioning information.

Make provision in piping layout to drain and vent

condenser if system is to be shut down in winter.

Level unit and bolt it firmly to foundation.

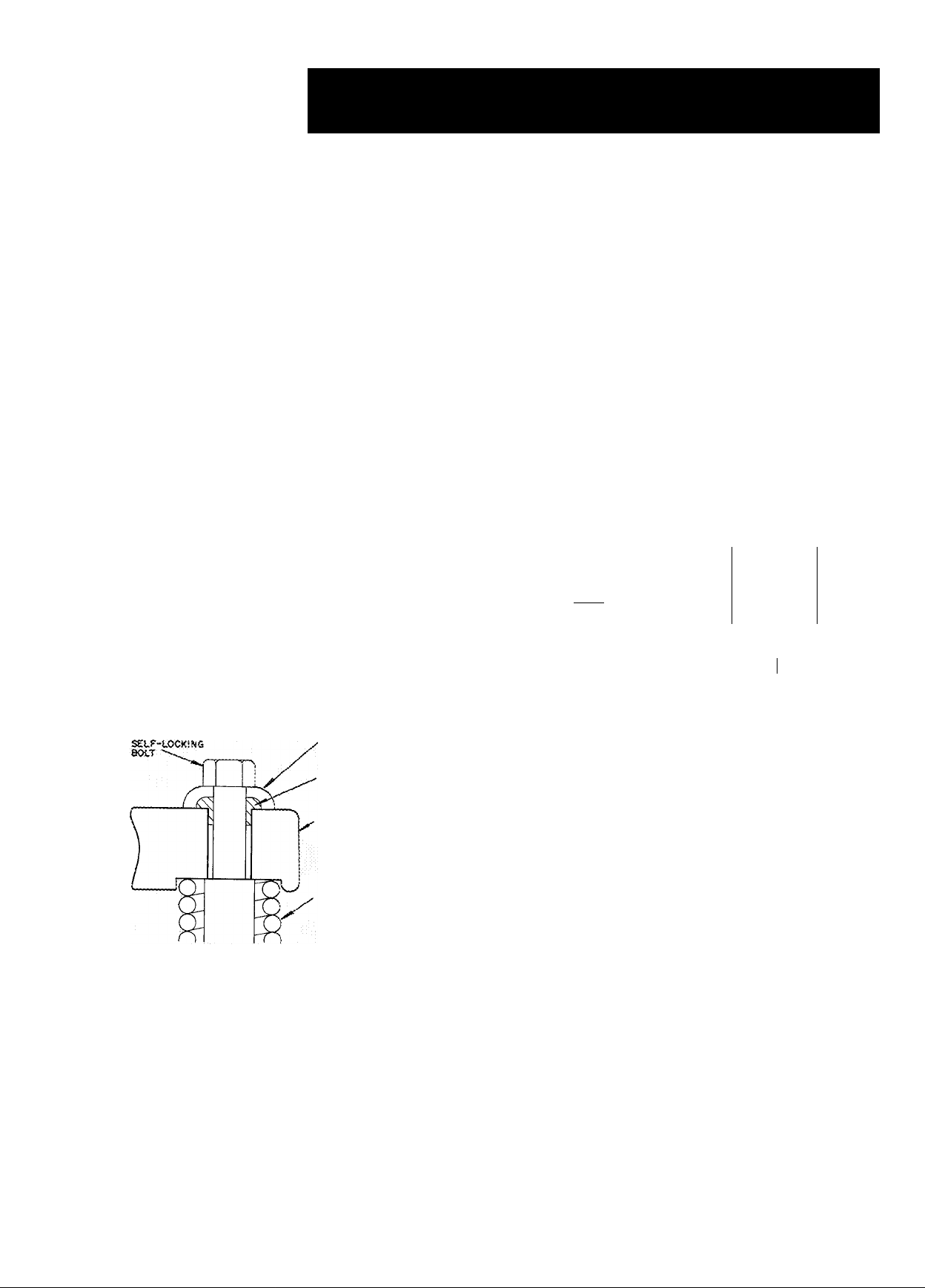

Remove 4 self-locking bolts from compressor

mounting springs, and reassemble them with

flanged washers and neoprene snubbers as shown in

Fig. 1. Flanged washers and neoprene snubbers are

shipped in a cloth bag tied to compressor. Tighten

all 4 bolts. Then, loosen each until the flanged

washer can be moved sidewise. Check compressor

to see that it floats freely on its mounting springs.

SMUBBER FLATBED

WASHER

MEOPRENE

SNUBBER

^COMPRESSOR FOOT

, tSOtATtON SPRiNO

Fig. 1 — Compressor Mounting

PIPING CONNECTIONS

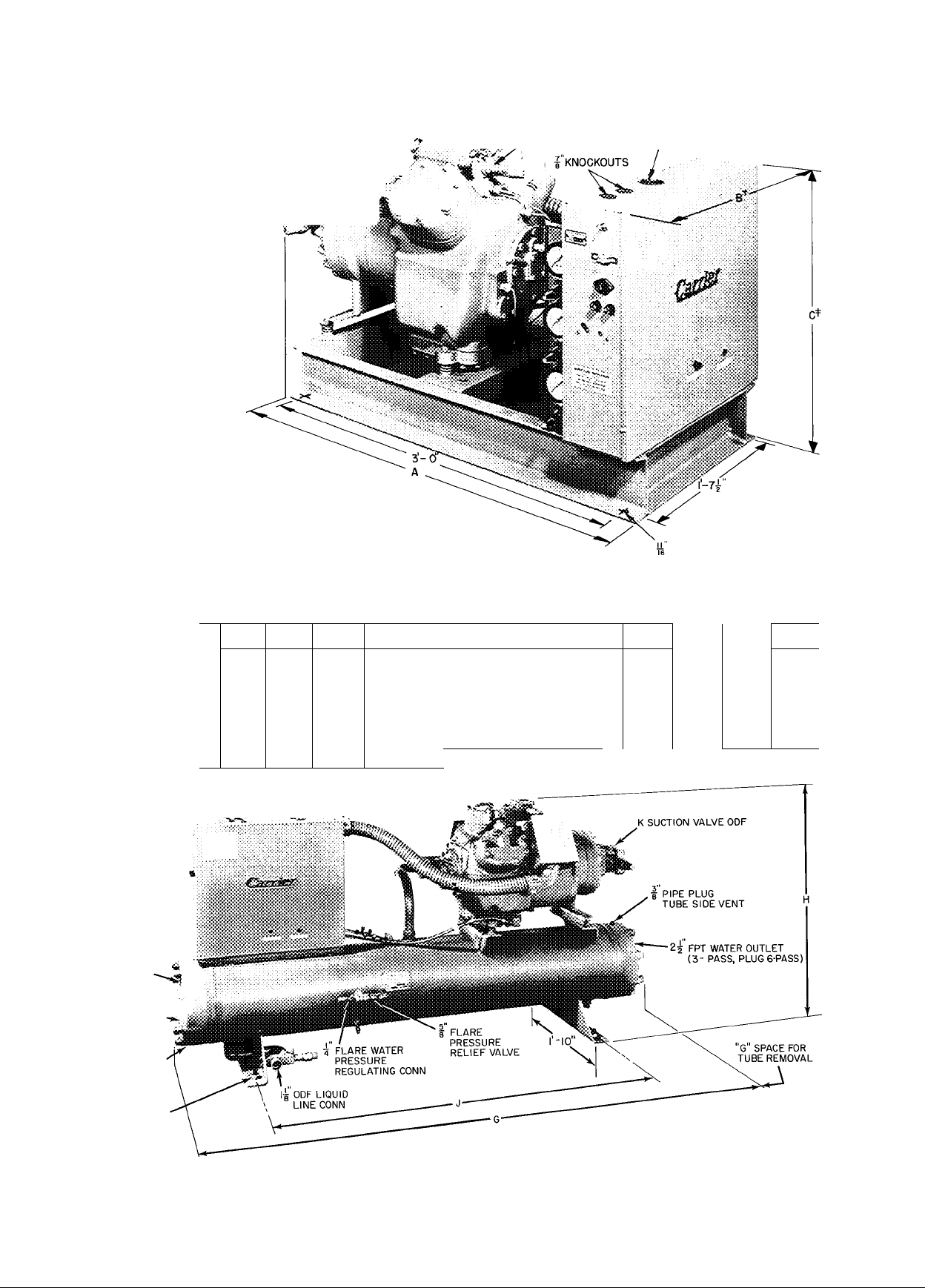

Attach water supply and return line to connec

tions indicated on condensing unit (Fig. 3). Water

leaving condenser should not be connected directly

into sewer lines; check local codes.

Attach refrigerant liquid and suction lines to

condensing unit (Fig. 3); suction and discharge

lines to compressor unit (Fig. 2). Discharge line

muffler supplied with 06EV,W compressor units is

installed in discharge line as close to shutoff valve

as possible. When soldering or brazing piping to

valves, disassemble the valve or wrap it in wet cloth

to prevent damage by heat. Allow flexibility in

suction line so compressor suction valve may be

moved aside for access to suction strainer.

Install a solenoid valve (field supplied) in liquid

hne directly before expansion valve. Solenoid valve

is necessary for single pumpout control used on

06E,07E units (refer to Start-Up and Service

Instructions). A filter-drier of adequate size should

be installed in liquid line between condenser and

solenoid valve.

Pressure relief valve located on side of con

denser will open to relieve excessive pressure,

allowing refrigerant to escape. Most local codes

require piping from valve to outdoors.

Refer to Carrier System Design Manual for

standard piping techniques.

Table 1 — Physical Data

COMPRESSOR UNIT 06E

d P E R A fjNjG W E (G H T (fb)

CONDENSING UNIT 07E

OPERATING WEIGHT (lb)

refrigeYnt

COMPRESSOR 06E

Oil Charge (pt) (PP33-2)

Normal Oil Pressure*

Oil Safety Switch Cut-In

High-Pressure Switch

Cutout Range

Differential (cutout, cut-in) f

Factory Settings f Cutout '

Low-Pressure Switch

Cutout Range

Differential (cutout, cut-in)

Factory Settings! Cutout

Low Side Max Pressure

CONDENSER DATA

Max Refrigerant (R-22)

Storage Capacity (lb) t

Min Refrigerant (R-22)

Operating Charge (Ib)

Max Operating Pressure

Refrigerant Side

Water Side

J 07E Conidensing Unit data

* Pressures noted are above operating suction pressure; i.e , pressure

differential between suction pressure and discharge pressure of oil

pump.

Î Pressure switch settings shown are for R-22. When using other

refrigerants, reset high- and low-pressure switch settings to

pressures corresponding to satuialion temperatures indicated by

the above pressures.

\ Condenser 80% filled with liquid refrigerant at 104 F,

Cutout

Cut-in i

Cut-in

V022

W027 1 W033 W044

6Ô0

BO 22

D250

D150 N265 ;

B027^

1275 1340 1 1350

R-22, R-502^

14

230 to 400 psiq (adj)

23G to 340 p'ji ;g (ccj)

, 80 ± 10 psi (fi xed)

370 ± 7 Dsig

28C i

290 + 7 psig

200 ± 7 psic

20 in Hg vac to 60 psig (adj)

20 in Hg vac to 70 psig (adj)

31 psi (adj 13 to 50)

650

B033 D044

.1,

0265 I F 275 E299

N175

16 i Î9

psig

12-18

psig

8-10

psig

4- 5

36 + 4 psig

67 + 4 psig

245 psig

135

' 33

335 psig

250 psig

' 670

1560

N599

193

37

© Carrier Corporation 1972

Form 06E,07E-4SI

Page 2

E SUCTION VALVE ODF

(ROTATES 360°AT ,

90° INTERVALS)

* Install pressure relief device in discharge line

Pressure relief setting is 465 psig

tOverall width includes projection of fuse

holders and/or switches

j.Maximum height is to top of unloader valve on

06EV022 and W044

F DISCHARGE VALVE ODF^

'• . (ROTATES 180°) n

D DIAM CONCEN

DIAM-4 HOLES

RIG KNOCKOUT

Fig. 2 — 06E Hermetic Compressor Units

06E Hermetic Compressor Unit Dimensions

UNIT 06E

DIMENSIONS (ff-in.)

CONNECTIONS (in.)

■k KNOCKOUTS .

2" FPT

OUTLET (6-PASS)

INLET (3-PASS)*

2 FPT INLET «”>■

(3-PASS*a6-PASS)~

V022

A

3-9V2

B

2-0 2-0

C

2-r/a 2-2Va

1% &

2V,

E

IVa

F

1 %

L DIAM CONCENTRIC

KNOCKOUT

W027

2-9%

2, 2%

& 3

IVs

1%

W033

3-11%

2- 0 1-1 1%

2- 1%

]% &

2%

2Va

1%

W044

4- 0%

2- 2

2, 2%

& 3

2Va

1%

07E Water-Cooled Condensing Unit Dimensions

2Va

2Va

D044

6- 7%

4-10%

2%a

2, 2Va

& 3

UNIT 07E

DIMENSIONS (ft-in.) G

CONNECTIONS (In.)

B022 B027 B033

6- 5 6- 5 6- 5

H

2-11% 2-1 r/2

J

4- 8%

K

L

1%

1% &

2%

4-IOV4

1%

2, 2%

& 3

2-1 1% 3- 2Va

4- 8%

1% &

I PIPE PLUG TUBE

SIDE DRAIN

EITHER END

DIAM-4 HOLES

WIDTH DIM I'-5"

ifc^TO

*Use both inlets for 3-pass operation.

Fig. 3 — 07E Water-Cooled Condensing Units

Page 3

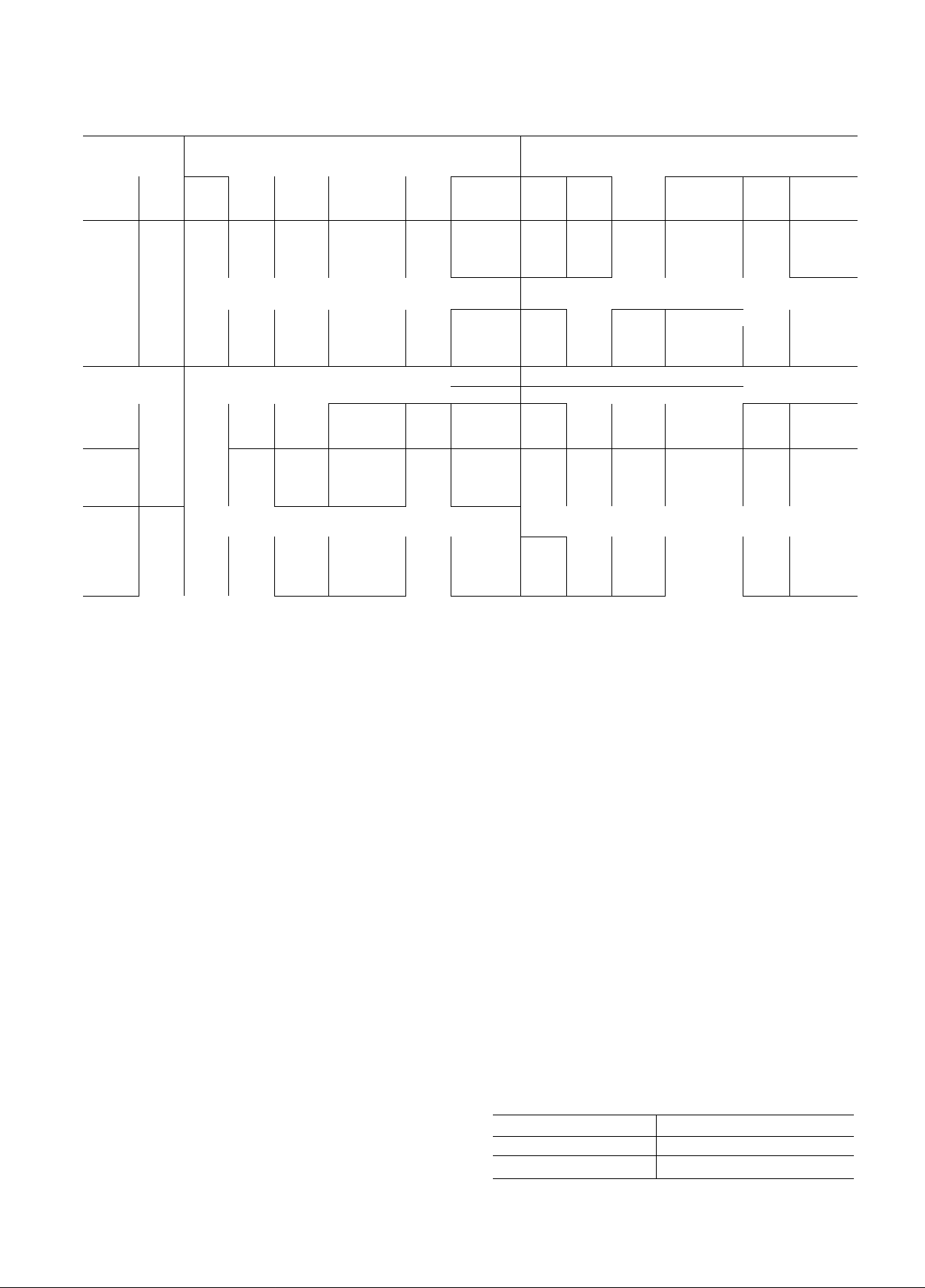

Table 2 — Electrical Data

volts/phaU

NDSV

COND

UNIT KW LRA FLA

07 E

B022

B027 31.4

B033 34 0

DO 44 50.4

COMPR

06 E

V022 24 8 387

W027

W033

W044 55.1

VOLTS/PHASE

NDSV

COND

UNIT KW LRA

07 E (AWG No.) Wire

B022

B027

B033 34 0 175 48 66 0

D044 50.4 265 61 85.4

COMPR

06 E

V022 24 8 175 35 48 3

WO 27

W033 37 6 210

W044 55 1 300 69 96.0

FLA — Full Load Amps

LRA — Locked Rotor Amps

IMDSV — Nominal Distribution System Voltage (Application Range)

OLTA — Overload Trip Amps

*Wire size to terminal box (line side)

NOTES:

1. 208-, 230-volt 06E compressor units and 07E condensing units

22 6

33.6 457

37 6

22 6

31 4

33 6 205 43 60 2

-- Motorsand controlswill operate satisfactorily 10% above

and 10% below the NDSV (Application Range)

have part-winding start 460-, 575-volt units have across-the-line

start, except 06EW044 and 07ED044 which have part-winding

start Control circuit voltage is 11 5 volts for all units.

310 71 99

457

387 105

586 126

464

664

FLA OLTA Size*

140

205

OLTA

86 121

78 109

93

115 160

137

32

44 5 8 102

41 57 8 6 122

52 71 6

208/3 230/3

208

Wire

Size*

(AWG No.)

146 00

176

129

192

00

00

00

460/3

440-480

Wire

4

6 143

6

4

2

0

1

0

2

2

Max Fusetron Wire

Ft

Wire

73 100

62 125

84

71 200 530

79

79 150 410

77 175 420

65

Max

Ft

158 70

132

116

145 75

121

220-240

Si ze

(Amps) (AWG No.)

150

110 350

200 600 137

Fusetron

Si ze

(Amps)

45

60 164

90 212 53 73.4 4 185

50 140 28 38 6

70

100 240 56 78 0

LRA

280 65 90 8

410

350 96 134 0 0

LRA

1 12

140 38 53 3 6 165 60

164 34

168

Factory wiring is in compliance with National Electrical Code.

Field wiring must comply with appiicable local codes Maximum

wire size to control center line terminal block is 250 MCM.

Where compressor FLA is under 100 amps, wire sizes are based

on type TW wire. Where compressor FLA is over 100 amps, wire

sizes are based on type TFIW wire

Maximum wire lengths tabulated will result in a 1% voltage drop

to compressor A 3% voltage drop is maximum allowed.Therefore,

the run length can be increased to three times the value given.

5.

Above 06E compressor unit electrical data does not apply for

06E compressors used as an integral part of other Carrier equip

ment See proper Start-Up and Service book for electrical

information

FLA OLTA

116 0

82

126 176.0 00

71

86

105 146

FLA

27 36 7 8 151

34 48 3

42

99

120

192 00

OLTA

48 3

58 0

Size* Ft Size

2

0

2 80 100

1 78

00

575/3

550-600

Wire

Size*

(AWG No.)

6 183

8 147 40

6

6 150 60

4 171 80

Max Fusetron

Wire

Max

Ft

Wire

183

(Amps)

88 100

78

87 150

80 200

94

72

125

125

150

200

Fusetron

Size

(Amps)

40

SO

80

50

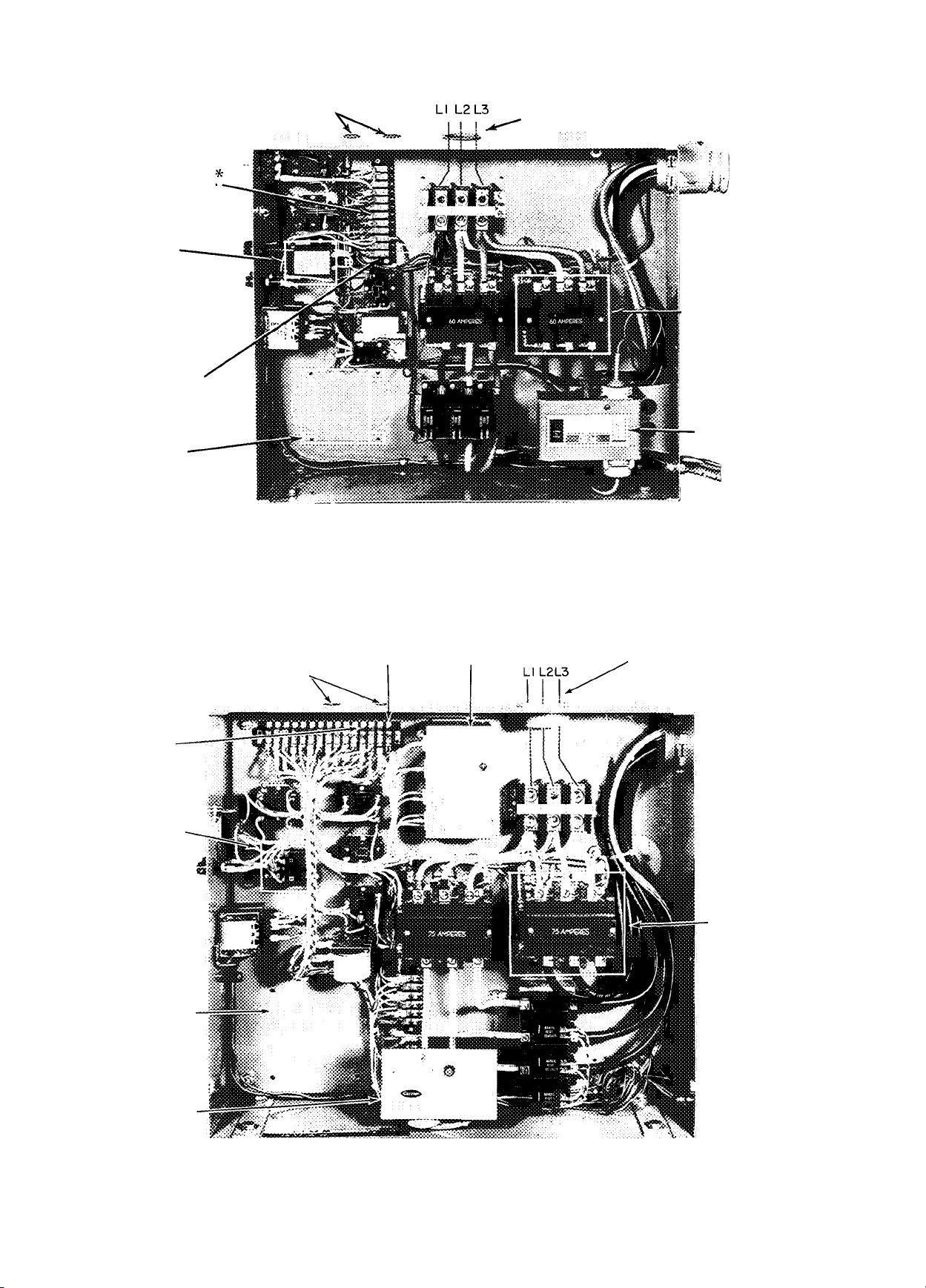

ELECTRICAL REQUIREMENTS

Field wiring must comply with local and

national codes.

Install a branch circuit fused disconnect of

adequate size to handle starting current.

Line power is brought into control center thru

indicated opening. Connect line power supply to

terminal block 1; connect power leads to terminals

LI, L2 and L3. Connect control circuit power

supply (115 volt) to terminals 1 and 2 on terminal

block 2. Refer to Fig. 4 and 5.

Wiring connections for field-supplied equip

ment are shown on diagram attached to unit (or in

wiring diagram booklet).

Discharge line limit thermostat supplied with

06EV,W compressor units is installed on discharge

hne as close to compressor as possible.

1. Place mounting

plate on discharge line and

solder in place.

2. Fasten the thermostat

to plate with screws

supplied.

3. Cover switch with insulation and secure insula

tion at each end with straps.

4. Connect thermostat leads to control circuit

terminals 4 and 5.

ACCESSORIES

PACKAGE NUMBER DESCRIPTION

07EA900021 Control Circuit Transformer

07EA900001

Gage Panel

Page 4

KNOCKOUTS

DISCHARGE LINE

THERMOSTAT CONN

PART-WINDING

START UNITS

ONLY

CONTROL CIRCUIT

POWER CONN.*

(TERMINAL BLOCK

N0.2)

ACCESSORY

TRANSFORMER

CONNECT TO LI a L2

TERMINALS ON LINE

SIDE OF CONTACTOR

*Refer to unit label wiring diagram for connections when accessory

transformer or interlocks are used

Fig. 4 - Control Center - Used on: 06EV022, 06EW033, 07EB022, 07EB033

FIELD POWER CONN.

(TERMINAL BLOCK NO. I)

PART-WINDING

START UNITS

ONLY

OIL PRESSURE

SAFETY SWITCH

DISCHARGE LINE

THERMOSTAT

CONN.*

PART-WINDING

START UNITS

ONLY

ACCESSORY

TRANSFORMER

CONNECT TO LI

a L2 TERMINALS

ON LINE SIDE OF

CONTACTOR

KNOCKOUTS

MOTOR PROTECTION MODULE

CONTROL CIRCUIT

POWER CONN.*

(TERMINAL

BLOCK N0.2)

FIELD POWER CONN.

(TERMINAL BLOCK N0.1)

PART-WINDING

START UNITS

ONLY

OIL PRESSURE

SAFETY SWITCH

*Refer to unit label wiring diagram for connections when accessory transtoriT.er or

interlocks are used

Fig. 5 - Control Center - Used on: 06EW027, 06EW044, 07EB027, 07ED044

Page 5

REFRIGERANT CHARGING

Evacuate, ' Dehydrate and Leak Test the entire

refrigerant system by methods described in Carrier

Standard Service Techniques Manual, Chapter 1,

Sections 1-6 and 1-7. Use sight glass method to

charge system. See section 1-8 of Service Tech

niques Manual for details.

CHARGE THE SYSTEM to a clear sight glass while

holding saturated condensing pressure constant at

125 F (air-cooled systems) or 105 F (water-cooled

systems). Add additional refrigerant to fill con

denser subcooler coils.

07E Condensing Units

obtained.

add charge

After clear sight glass is

until liquid refrigerant

reaches condenser liquid level test cock.

06E Compressor Units — See condenser data for

additional charge required to fill subcooler.

INITIAL START-UP

Crankcase heater should be energized a mini

mum of 24 hours before starting unit.

Check to see that oil level is 1/3 to 2/3 up on

compressor sight glass.

Open water supply valve and allow water to

reach condenser. (Turn condenser fan on when the

compressor unit is applied with air-cooled

condenser.)

Backseat the compressor suction and discharge

shutoff valves; open liquid line valve at receiver.

Start evaporator fan or chilled water pump.

To Start Compressor, place control center start-

stop switch in “Start” position, and push motor

protector relay start-reset button. (Time Guard

circuit will cause a short delay before compressor

starts.) If compressor does not start in a 5-minute

period, reset oil pressure safety switch and over

load relays.

Recheck oil level and check oil pressure which

should be 12-18 psig above suction pressure.

NOTE: If compressor is shut off by motor

protection relay, current overloads, oil safety

switch or if control circuit power is opened, reset

button(s) must be pushed before compressor will

restart. Do not reset safety controls more than

once before determining cause of shutdown.

CHECKING OPERATIONS

Refer to Carrier Standard Service Techniques

Manual, Chapter 2 for complete instructions on

checking electrical components.

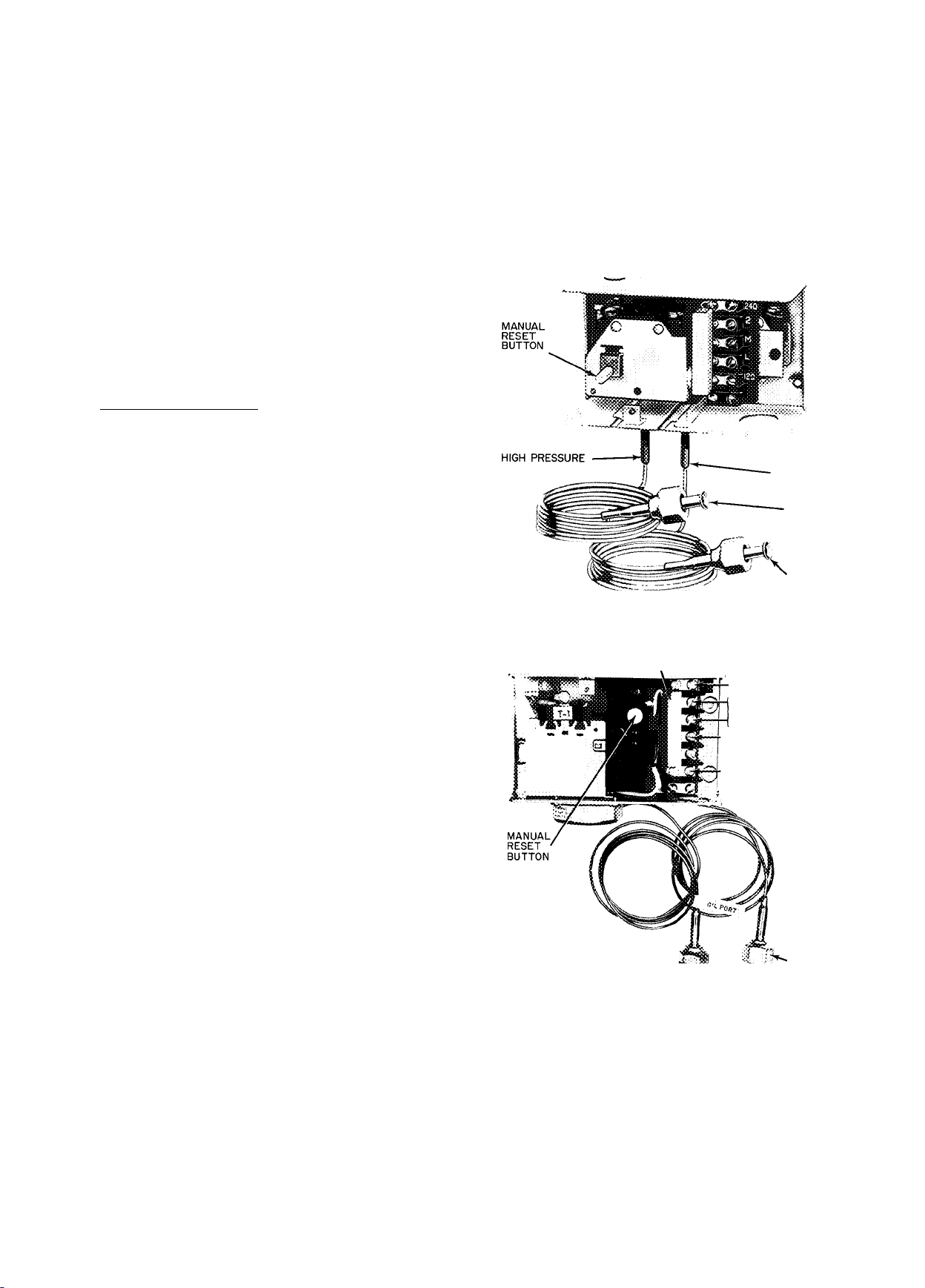

Oil Pressure Safety Switch (Fig. 6 and 7) may be

checked by moving arm on left side of switch

forward. Compressor should stop in approximately

45 seconds. (If compressor continues to run, check

wiring to safety switch. If wiring is correct, the

switch is faulty and should be replaced.)

After completing test, press reset button on

front of safety switch and restart compressor.

(Allow 3 minutes before attempting to reset

switch.)

NOTE Check oil level in compressor sight glass

after 15-20 minutes of operation. If oil level is low,

add oil according to methods described in Carrier

Standard Service Techniques Manual, Chapter 1

(Section 1-11).

LOW PRESSURE

CONNECT TO

OIL PUMP

DISCHARGE

CONNECT TO

(Switch shown is Penn Controls )

CRANKCASE

Fig. 6 — Oil Pressure Safety Switch Used on;

06EV022, 06EW033, 07EB022, 07EB033

RESISTANCE

I

■f

120

V^C

CONNECT IN 240

SERIES WITH VAC

CONTROL CIRCUIT

(REFER TO UNIT LABEL

WIRING DIAGRAM)

HIGH-PRESSURE

CONNECTION TO

0|LPUMP '" LOW-PRESSURE

DISCHARGE CONNECTION

TO CRANKCASE

Fig. 7 — Oil Pressure Safety Switch Used on:

06EW027, 06EW044, 07EB027, 07ED044

Dual Pressurestat (Fig. 8) — High-pressure safety

switch is checked by throttling condenser water or

blocking air flow on air-cooled units, allowing head

pressure to rise gradually. Check discharge pressure

constantly throughout procedure. Compressor

should shut off within 10 psi of values shown in

Table 1.

Page 6

Check low-pressure switch by slowly closing

suction shutoff valve or by completely closing

hquid line shutoff valve. A decrease of suction

pressure will follow. Compressor should shut off

within 4 psi of values shown in Table 1.

HIGH-PRESSURE

SAFETY SWITCH

DIFFERENTIAL ADJUSTMENT -TURN

■ № ■' CLOCKWISE TO DECREASE ONLY LOWER

SETTING WITHOUT CHANGING THE

HIGHER SETTING

*Hlgh — 38 PsI/Turn

Low — 7 Psi/Turn

Fig. 8 — Dual Pressurestat Adjustment

Time Guard Circuit for each compressor provides

LOW-PRESSURE

SAFETY SWITCH

RANGE ADJUSTMENT-TURN

CLOCKWISE TO RAISE BOTH

CUT-IN AND CUTOUT

for a 5-minute delay before restarting compressor

after shutdown for any reason. On starting, the

Time Guard Timer causes a delay of 15 seconds

after thermostat closes before compressor will

start. On compressor shutdown, the timer recycles

for 4 minutes 45 seconds. During this time the

compressor cannot restart.

Compressor Motor Protection on 06EW027,

06EW044, 07EB027 and 07ED044 consists of

three temperature sensors embedded in motor

windings and connected to a solid state module in

unit control box.

When an over-temperature condition causes

module to shut compressor off, push control

center STOP button. Investigate cause of com

pressor shutdown and correct. After compressor

cools (see Temperature Sensors below), push

ST ART-RESET button. Compressor will restart

after Time Guard delay period.

SOLID STATE MODULE is checked by applying

unit control voltage to terminals T1 and T2 (see

label diagram), then checking for continuity across

terminals Ml and M2. If no continuity between Ml

and M2, check temperature sensor and fuse resist

ance using a volt-ohmmeter (see below).

CAUTION; Do not use a fcattiary powered test

lamp to check sensors. Excessive current can

cause damage.

TEMPERATURE SENSORS are protected by

three 1/8-amp fuses (Carrier Part no. HYIOLFOIO)

in compressor terminal box. Fuse resistance should

be between 3.2 and 4.4 ohms. Replace defective

fuses only with 1/8-amp fuses specified above. If

all sensors check below 95 ohms (180 F), fuses are

good, and there is no continuity between module

terminals Ml and M2, replace module.

If one sensor fails, it can be jumpered out of

the circuit with a 75 ohm, 2-watt resistor across

the proper sensor terminal and common terminal.

If a short to ground in sensor circuit is indicated,

replace compressor motor.

CAPACITY CONTROL ADJUSTMENT

Control Set Point (cylinder load point) is adjust

able from 0 psig to 85 psig. Pressure differential

between cylinder load-up point and cylinder un

load point is adjustable from 6 psig to 22 psig.

To Regulate Control Set Point — Refer to Fig. 9.

Turn adjustment nut clockwise to its bottom stop

(with nut in this position set point is 85 psig).

Control set point is then regulated to desired

pressure by turning adjustment nut counterclock

wise; every full turn decreasing set point by 7.5 psig.

(Approximately 11-1/2 turns in counterclockwise

direction will decrease control set point to 0 psig.)

Table 3 shows the steps of control for the

compressor and condensing unit.

SEALING CAP

(CAP MUST BE REPLACED

TO PREVENT REFRIGERANT LEAKAGE)

Fig. 9 — Capacity Control Valve

Table 3 — Steps of Control

COMPRESSOR*

CONDENSING

UNIT*

06EV022

07EB022

06EW027

07EB027

06EW033

07EB033

06EW044

07ED044

^Capacity control valve (Fig 6) factory settings for 4-cylinder

units are: 69 psig control set point (cylinder load point), 10 psig

differential (59 psig cylinder unload point) Settings for

6-cylinder units are; leit cylinder bank control set point is

70 psig, differential is 10 psig; right cylinder bank control set

point is 68 psig, differential is 10 psig

—

No.

Cyl

4 100

6 100

6 100

6

1

%

Cap.

100 4

STEPS

No.

Cyl

2

4

4

2

%

Cap.

50

67

67

67

---------------

No.

Cyl

- -

2 33

2 33

2 33

-

3

%

Cap.

Page 7

Pressure Differential Adjustment — Turn differ

ential adjusting s,crew in counterclockwise direc

tion to its back-stop position (differential in this

position 6 psig). Pressure differential is set by

turning adjustment screw clockwise; every full turn

increasing differential by 1.5 psig. (Approximately

10 turns in clockwise direction will increase

pressure differential to 22 psig.)

acid cautiously. Clean condenser by gravity or

forced circulation (Fig. 10 and 11). For average

scale deposits allow acid solution to remain in

condenser overnight; for heavy deposits, allow 24

hours. Drain condenser and flush with clean water.

NOTE: Protect condenser from freezing when

ambient is below 32 F by draining water from

system or adding antifreeze to water.

CONDENSER MAINTENANCE (07E Units)

To inspect and clean condenser, drain water

and remove condenser heads. To drain condenser,

shut off water supply and disconnect inlet and

outlet piping. Remove drain plugs and vent plug.

With condenser heads removed, inspect tubes

for refrigerant leaks. (Refer to Carrier Standard

Service Techniques Manual, Chapter 1 Section 1-6,

Leak Testing, for instructions.)

Clean condenser tubes with nylon brush

(available from Carrier Service Department). Flush

water thru tubes while cleaning. If hard scale has

formed, clean tubes chemically. Do not use brushes

that will scrape or scratch tubes.

For chemical cleaning solution, use inhibited

hydrochloric acid solution (Oakite 32). Handle

C£NTfilFU<5AL <3AS VSNT30 GPM AT 35* BEAD GC03E

PUMP

SUCTION

PUMP^

SUPPORT

TANK-

PRIMING /VAUvesX

CONN, /

!

-RETURN

Fig. 11 — Forced Circulation

i CLOSE VENT PIPE

( VALVE WHEN

( PUMP IS

! RUNBiNG

REMOVE WATER

REGULATING VALVE

REMOVING, INSPECTING AND

REPLACING COMPONENTS (Fig. 12)

Service Notes

1.

Where compressor components are shown they

are in normal order of removal from compressor.

2.

All compressors have interchangeable valve

plate assemblies, unloader valves and oil pump

bearing head assemblies. For replacement items

use Carrier Specified Parts.

3.

Before compressor is opened, the refrigerant

must be removed from it by the Pumpdown

method.

a. Start compressor, close suction shutoff

valve, and reduce crankcase pressure to

2 psig. (Jumper low pressurestat.)

Table 4 — Torque Values

SIZE

THREADS

DIAM

(in.)

No. 6 32

No. 10

PER IN.

27 (pipe) 8-12

yi6

V4

‘/4

V4

18 (pipe)

%

18 (pipe)

\

Xe

Va

V»

%

%

18 20-25

20

28

16

14

13

11

18 60-75 Oi 1 Drain Plug

16 105 Stator Lock

32

TORQUE

RANGE

(ft-lb)

Pipe Plug — Crankshaft

Pipe Plug — Crankcase

8-10

Conn. Rod Cap Screw

8-12

Junction Box

3-5

14-18

14-18

14-18

15-24

15-24

30-40

30-40

30-40

25-30

30-40

55-65

55-65

100-120

90-120

90-120

90-120

90-120

Sight Glass

Oil Pump Drive Segment

Unioader Valve

Discharge Valve Stop

Cover Plate — Pump End

Bearing Head

Discharge Service Valve(4 cyl)

Bottom Plate — Crankcase

Compressor Foot

Terminal Block

Oil Plug — Pump End Bearing

2-4

1-2 Check Valve Body — Crankcase

4-6

4-6

Head

Terminal Bolts

Pipe Plug — Junction Box

Motor End Cover

Pump End Bearing Head

Cyl inder Head

Discharge Service Valve(6 cyl)

Suction Service Valve (4 cyl)

Suction Service Valve (6 cyl)

Rotor Lock — Crankshaft

Oil Pump Drive Segment

Terminal Screw

USAGE

Page 8

®®

'J /

^x V.

--------------

_ ?' i

^

@

06EV027, W044 AND 07EB022,033

: |-(S 1

^~® i

■•' 1

^ '

'■ .': mifr^ 1

{SEE LEGEND PAGE 9)

Fig. 12 — 06E Compressor Components

8

rfWIMMMh -- nji_i_ui_,

' ^ ' : ,3?^

^ .*,

Page 9

b. stop compressor and isolate from system by

closing discharge shutoff valve.

c. Bleed any residual refrigerant. Drain oil if

necessary.

4. After disassembly, clean all parts with solvent.

Use mineral spirits, white gasoline or naptha.

5. Before assembly, coat all parts with compressor

oil and clean and inspect all gasket surfaces.

Replace all gaskets with new factory-made

gaskets. See Table 4 for torque values.

6. After reassembly, evacuate compressor and

open suction and discharge valves. Restart

compressor and adjust refrigerant charge.

LUBRICATION SYSTEM

Testing Oil Pump — An oil pressure tap is located

above oil pump cover plate (Fig. 13). Oil pressure

should be 12 - 18 psi above suction pressure.

REMOVE 8 CAP SCREWS

OIL PRESSURE TAP

Compressor MotorStator and Rotor

Motor Key

©

Rotor Plate Washer

©

Rotor Lock Washer

©

Rotor Lock Bolt

©

Motor Lock Bushing

©

Roll Pin

©

Acorn Nut and Gasket

©

Ring Spacer

©

Junction Box

Fiame Arrestor

©

Terminal Plate Assembly

@

Terminal Bolt Assembly

0

Terminal Bolt Assembly

0

Terminal Bolt Assembly

0

Cover Plate

0

Hex Head Screw

©

Compressor Crankcase

0

Motor End Cover

©

Cylinder Head —

©

Center Bank

Cylinder Head - Ca

0

pacity Control Side Bank

Internal Relief Valve

0

Crankcase Oil Filter

0

Screen

Oil Sight Glass Assembly

0

Oil Sight Glass "O”

0

Ring Gasket

Oil Sight Glass Screw

0

Oil Sight Glass Lock

0

Washer

Pipe Plug Gasket

0

(hex head)

Bottom Cover Plate

(S)

Legend (Fig. 12)

(30) Pump End Bearing

(0 Pump Rotor

(3^ Pump Vane

(3^ Pump Vane Spring

(3^ Pump Vane Spring

(3^ Retaining Spring

(3^ Oil Feed Guide Vane

(3^ Oil Feed Guide Vane

(3^ Oil Pump Drive

(3^ Screw, Soc Head

^ 1/4 - 28 X 5/8 in.

(4^ Screw, Soc Head no 10

^ -32x1/2 in

(0 Cover Plate

(42) Cover Plate Cap Screw

(0) Crankshaft

(0 Bearing Washer

(0) Piston Ring (Oil and

(0) Piston, Piston Pin and

(0) Connecting Rod and

(0) Valve Plate Package

(0) Valve Plate

0) Discharge Valve Stop

(0) Discharge Valve

(0) Valve Stop Support

(0) Cap Screw, Valve Stop

(55) Suction Valve

Head Package

Guide

Spring

Segment

Oil Relief Piston

Compression)

Retaining Ring Package

Cap Assembly

PUMP END BEARING HEAD

ORIVE SEGMENT CAP SCREWS

Fig. 13 — Removing Pump End Bearing Head

OIL FEED GUIDE VANE

AND SPRING

COVER

PLATE

OIL FILTER SCREEN is accessible thru bottom

cover plate. Remove and inspect strainer for holes

and dirt. Clean it with solvent and replace.

Oil Pump and Bearing Head — The oil pump

assembly is contained in the pump end bearing

head aluminum casting. (The pump end main

bearing is a machined part of this casting — no

insert bearing.)

REMOVE bearing head from crankcase and

disassemble oil pump. Drive segment cap screws

must be removed before bearing head can be

removed (Fig. 13). Remove pump vane assemblies

from both sides of bearing head. Push the pump

rotor out of the bearing head by pushing against

the bearing side of the rotor. Check all parts

(Fig. 14) for wear and damage.

REPLACE

1. Install the rotor retaining ring in the ring groove

of the pump rotor with chamfered edge toward

compressor. Compress retaining ring, and insert

pump rotor into bearing head.

2. Place the pump vanes, pump vane springs with

guides, and snap rings into the bearing head.

Compress the springs and force the snap rings

into their grooves. (Insert snap rings with flat

side against casting.)

3. Bolt bearing head to crankcase (use 55 to 65

ft-lb torque). Bolt drive segment to crankshaft.

4. Insert the oil feed guide vane with large

diameter inward. Place oil feed guide vane

spring over small diameter of guide vane.

5. Install pump cover plate.

Page 10

f E f

Fig. 15 — Pressure Relief Valve Removal

o-^

LEGEND

o Cover Plate

Oil Feed Guide Vane Spring

® Oil Feed Guide Vane

® Drive Segment

® Pump Rotor

® Pump End Bearing Plead

Fig. 14 — Pump End Bearing Head Package

CYLINDER HEADS (Fig. 12)

© Pump Vane

® Pump Vane Spring

Pump Vane Spring Guide

(i^ Retaining Spring

© Pump End Main Bearing

(12) Oil Relief Piston

Disassemble cylinder heads by removing cap

screws, and prying up on side lifting tabs to break

heads loose from valve plates. Do not hit cylinder

heads to break loose.

Check heads for warping, cracks and damage to

gasket surfaces. When replacing cylinder head,

torque cap screws 100 to 120 ft-lb (prevents high

to low side leak in center portion of cylinder head

gasket).

Pressure Relief Valve — This safety device is

located in center cyhnder bank (6-cylinder

compressors, Fig. 15) or under discharge service

valve (4-cylinder compressors). The valve relieves

refrigerant pressure from high to low side at

400 psi pressure differential. Check valve for

evidence of leaking. Change if defective or if valve

has ever opened due to excessive pressure. Use a

standard socket-type screwdriver to remove and

replace valve.

Capacity Control Valve(s) are of the snap-action

type. They are controlled by suction pressure and

actuated by discharge pressure. Each valve controls

2 cylinders. On start-up, controlled cylinders do

not load up until differential between suction and

discharge pressure is 10 psi (see Fig. 16).

Do not use automatic pumpdown control on

06E, 07E units equipped with unloader valves. Use

single pumpout or solenoid drop (minimum

protection) control.

CAPACITY CONTROL VALVE OPERATION

Loaded Operation — When suction pressure is

above control point, the poppet valve will close.

Discharge gas bleeds into valve chamber, the

pressure closes bypass piston and cylinder bank

loads up. Discharge gas pressure forces check valve

open, permitting gas to enter discharge manifold.

Unloaded Operation — When suction pressure

* *

drops below valve control point, the poppet valve

will open. Discharge gas bleeds from behind bypass

piston to suction manifold. Bypass piston opens,

discharge gas is recirculated back to suction mani

fold and cylinder bank is unloaded. Reduction in

discharge pressure causes check valve to close,

isolating cylinder bank from discharge manifold.

SERVICE REPLACEMENT COMPRESSORS are

* not equipped with capacity control valves. Side

bank cylinder head(s) is plugged with spring loaded

plug piston assembly(ies). Compressor will run

fully loaded with piston plug(s) in place.

Transfer original capaeity control valve(s) to

replacement compressor (ensures proper valves are

used with correct setting). Install plug piston

assembly(ies) into original compressor for sealing

purposes.

Three alien head cap screws hold capacity

control valve in place (Fig. 17). Remove screws

using a “cut down” 3/16-in. alien wrench, and pull

valve from cylinder head.

Remove same number of piston plugs from

replacement compressor as number of unloaders

supplied with original compressor. Three alien head

10

Page 11

PRESSURE DIFFERENTIAL SEALING

BYPASS CYLINDER

-BYPASS PASSAGE

COMMUNICATES WITH

'SUCTION MANIFOLD

-SUCTION MANIFOLD

«

I DISCHARGE PRESSURE

Fig. 16 — Capacity Control Valve Operation

CAP SCREWS

(NONINTERCHANGEABLE

WITH FLANGE COVER

CAP SCREWS)

Fig. 17 — Removal of Capacity Control Valve

cap screws hold piston plug assembly in place.

Remove flange cover, spring, piston plug and seat

ring (Fig. 18). A tapped hole is provided in piston

to allow it to be pulled out. Hole has same thread

diameter as cap screws removed above.

LOADED OPERATION

BYPASS PISTON PLUG

SPRING —^

CAPSCREWS \

(NON INTERCHANGEABLE X

WITH CONTROL VALVE

CAP SCREWS)

-SEAT RING . .

FLANGE COVER

Fig. 18 — Removal of Bypass Piston Plug

SUCTION AND DISCHARGE VALVE

PLATE ASSEMBLY (Fig. 12)

Test for leaking discharge valves by pumping

compressor down and observing suction and

discharge pressure equalization. If a discharge valve

is leaking their pressures will equalize rapidly.

Maximum allowable discharge pressure drop is 3

psi per minute.

11

Page 12

If there is an indicated loss of capacity and

discharge valves check properly, remove suction

and discharge valve plate assembly and inspect

suction valves.

Disassembly — Remove cylinder head.

1. Remove discharge valve assembly: cap screws,

valve stops, valve stop supports and valves.

2. Pry up on side hfting tab to remove valve plate

and expose suction valves (Fig. 19). Remove

suction valves from dowel pins.

Inspect valves and valve seats for wear and

damage (see Wear Limits, Table 5). Replace valves

if cracked or worn. If valve seats are worn, replace

complete valve plate assembly.

Reassembly — Do not interchange valves. Install

suction valves on dowel pins. Place valve plate on

cylinder deck, and reinstall' dischârge valve

assembly. Retorque discharge valve stop cap screws

to 16 ft-lb. Replace cylinder head. (Ensure tab on

cylinder head gasket is lined up with tabs on

cylinder head and valve plate.)

MOTOR REMOVAL

Motor End Bell — Remove motor end bell carefully

to prevent damage to stator. Use 7/16 in. —

14 X 5 in. studs (3) for guides and support. Inspect

suction strainer in end bell. Clean it with solvent or

replace if broken or corroded.

Rotor — Bend motor lock washer tab backward

and remove rotor lock bolt. If crankshaft turns,

preventing lock bolt from being loosened, remove a

cylinder head and valve plate and place a rubber

plug (06R suction plug) on top of one piston

(Fig. 20.) Replace valve plate assembly and

cylinder head (only two bolts required to hold

cylinder head in place). Proceed to remove rotor

lock bolt, lock washer and plate washer.

Use a jackscrew to remove rotor (Fig. 20).

Insert a brass plug into rotor hole to protect end of

crankshaft from jackscrew. Support rotor while it

is being removed to prevent stator damage.

Remove ring spacer between rotor and crankshaft.

Clean rotor thoroughly with solvent. If stator is

to be replaced, a matching rotor must be used.

Table 5 — Wear Limits - 06E Compressor

COMPRESSOR PART

Main Bearing Diameter

Journal Diameter

PUMP END

Main Bearing Diameter

Journal Diameter

CONNECTING ROD

Bearing Diameter

(After Assembly)

Crankpin Diameter

THRUST y,ASHER

(Thickness)

CYLINDERS

Bore

Piston Diameter

Wrist Pin Diameter

Con. Rod Wrist Pin ID

Piston Ring End Gap

Piston Ring Side

Clearance

VALVE

THICKNESS

END CLEARANCE

"■Maximum allowable wear above maximum or below minimum fac

tory tolerances shown. For example: difference between main bear

ing diameter and journal diameter is 0035 in. (1.8760 — 1.8725)

per factory tolerances. Maximum allowable difference is 0045 in.

(.0035 -f.001).

Suction

Discharge

FCTY TOLER

ANCES (in.)

Max Min

1 8760

I 8725

1 6260

1.6233

1 7515

2 6885

8755

007

003

.03J5

^'0255

■ 0'225

.031

I 7483

.155

2 6817

8748

.002

001

.0305

'“70245"

MAX

ALLOWABLE

WEAR* (in.)

001’

OOP

.002*

002

002

.001

001

.015

002

.002

.010

VALVE PLATE

RUBBER PLUG

STATOR LOCKING

ASSEMBLY

JACKSCREW'

'ROTOR LOCK BOLT

Fig. 20 — Removing Rotor

Terminal Plate Assembly — Disassemble junction

box from terminal plate, and remove cap screws

holding terminal plate to compressor. Mark all

motor leads so they can be reassembled correctly

to terminal plate. Loosen alien head screws holding

motor leads to terminal plate (Fig. 21). Remove

terminal plate.

12

Page 13

POWER LEAD TERMINAL STLFD — Disassemble

only if leaking refrigerant or if resistance to ground

is low. If there‘is a short to ground, replace

complete terminal plate assembly.

Disassembly

1. Unscrew terminal, terminal locknut, and

terminal bolt assembly hex nut.

2. Push terminal bolt thru terminal plate and

remove insulating washers.

Inspect for grounds, insulation breakdown, and

sufficient life remaining in terminal seal bush

ings. It is recommended that disassembled termi

nal stud assemblies be replaced with new parts.

ALLEN HEAD

SCREWS (T)

Stator is a slip fit in motor housing. It is held in

place by both an axial key and a locking assembly

consisting of an acorn nut, locking pin, motor lock

bushing and a washer. Remove acorn nut and

washer. Back out locking pin and bushing. Withdraw

stator (Fig. 23). Axial key positions stator and

crankcase. If necessary, heat crankcase motor hous

ing (not over 20 to 30 degrees above stator temp).

Check stator for damaged windings or lead

wires. Use a megohmmeter to check for grounds or

shorts between windings.

LOCKING PIN BOSS

STATOR

MOTOR LOCK

BUSHING

WASHER

Fig. 23 — Removing Stator

LOCKING PIN

Fig. 21 — Removing Terminal Plate Assembly

Reassembly

Refer to Fig. 22 for position of terminal

1

Fig. 22

assembly parts (washers are color coded).

Tighten terminal bolt assembly hex nut only

2.

enough to stop escape of refrigerant gas

(maximum recommended torque is 4 ft-lb). Do

not tighten nuts so terminal insulation washers

are flush with mounting plate.

-TERMINAL BOLT ASSEMBLY

—TERMINAL INSULATION WASHER

--------

INSULATION WASHER

-TERMINAL INSULATION BUSHING

-TERMINAL SEAL BUSHING

TERMINAL INSULATION

WASHERS(GRAY)

TERMINAL INSULATION

WASHER

LOCK WASHER

(SPRING)

TERMINAL LOCKNUT

■TERMINAL SEAL WASHERS

(RED)

TERMINAL INSULATION

BUSHING

PLATE WASHER

HEX NUT

■TERMINAL

MOTOR REPLACEMENT

Stator and Rotor — Install stator halfway into

housing. Insert the terminal leads first, guiding

them to terminal plate opening as stator is being

inserted.

Replace ring spacer on crankshaft. Ease rotor

onto shaft until it begins to feel snug. Insert motor

key, and push rotor the remainder of the way on

shaft. Replace rotor lock bolt with lock washer and

plate washer.

CAUTION: Do not push stator in completely

until rotor is in place.

Push stator into housing until it lines up

correctly with rotor (Fig. 24).

T;

STATOR

\ ROTOR

END

TURN

END

RING

ROTOR CENTER LINE

Fig. 22 — Power Lead Terminal Stud Assembly

13

Fig. 24 — Motor Alignment

1272

Page 14

Line up keyways in stator and crankcase and

replace stator locking assembly, then drive key into

keyway and stake over keyway in stator to secure

key. When a new motor is being installed, the stator

must be drilled and a new locking pin and motor lock

bushing used (see Fig. 25 and instructions). Connect

stator leads to proper terminals on terminal plate.

Refasten terminal plate and junction box to com

pressor. Replace motor end bell using studs for

support. Remove rubber plug (if used) from piston

head. Replace valve plate assembly, cylinder head,

and terminal plate assembly. (Torque in 12 bolts

holding terminal plate to crankcase at 30-40 ft-lb.)

PEENEO

ENOS

rod caps (Fig. 26). (Label caps and rods so they

may be reinstalled in same place on crankshaft.)

Push connecting rod and piston assemblies up thru

cylinder deck. Disassemble connecting rods from

pistons by removing retaining rings and piston pins.

Remove oil and compressor rings from piston.

(Keep each connecting rod and piston assembly

together for proper reassembly.) Check all parts

and crankpin journals for wear (refer to Table 5 for

wear limits).

CONNECTING

RODS a CAPS

■? r

i »

CONN

t »•

ROD

CAPS

l' s

CRANKSHAFT

OIL DRAIN PLUG

(MAGNETIC)

BOTTOM COVER

PLATE

Fig. 25 — Stator Locking Assembly

REMOVE

1. Acorn nut and washer.

2. Back out locking pin and bushing.

REPLACE

1. Screw in locking pin bushing until it rests on

stator core.

2. Wrap a piece of tape around 3/8 in. drill bit,

2-1/16 in. from cutting edge.

3. Ream out bushing (3/8 in. drill) and drill into

stator core until tape is flush with top of

bushing. (Remove drill chips.) Back off locking

pin bushing 1/8 of a turn.

CAUTION: Before drilling, be sure stator

vent holes do not line up with locking pin

hols. Vent holes are drilled horizontaily

thru stator, and can be seen fro-n end bell

side.

4. Tap locking pin into position. (Top of bushing

should be approximately 1 /16 in. above top of

pin.)

5. Peen top of bushing over roll pin.

6. Replace washer and acorn nut.

COMPRESSOR RUNNING GEAR REMOVAL

Connecting Rod and Piston Assembly — Remove

cylinder heads, valve plate assemblies, crankcase

bottom cover plate, oil filter screen, and connecting

i *

I '

Fig. 26 Removing Connecting Rod and

Piston Assemblies

Crankshaft — Remove pump end bearing head and

rotor.^ If connecting rod and piston assemblies are

still in place, remove connecting rod caps and push

piston assembly up into cylinder for crankshaft

clearance. Pull crankshaft out thru pump end

opening. Inspect crankshaft journals for wear and

tolerances shown in Table 5. Check oil passages

and clean if clogged.

Pump End Main Bearing is a machined part of the

oil pump and bearing head casting. Disassemble

bearing head. If bearing is scored or worn, replace

the complete bearing head.

Crankcase and Motor End Main Bearings are not

field replaceable. If bearings are worn or damaged,

replace compressor.

COMPRESSOR RUNNING GEAR

REPLACEMENT

Crankshaft — Ensure compressor end bearing

washer is in place on dowel pin. Install crankshaft

thru pump end, carefully guiding it thru main

bearings. Replace rotor.

Connecting Rod and Piston Assembly (Fig. 12) —

Attach connecting rods to pistons with piston pins,

and lock in place with retaining rings. Place

retaining rings with the gap on the side. They

should be tight enough so they cannot be rotated

by finger pressure.

1272

14

Page 15

RINGS

1. Check ring gap* by inserting each ring separately

in cylinder approximately 3/8 in. from top. Ring

gap should be between .002 in. and .007 in.

2. Install compression ring in top piston groove

with side marked “Top” toward piston head.

Install oil ring below compression ring with

notched end on bottom. Stagger ring gaps

around piston.

3. Measure side clearance between ring and piston

(Table 5). Check rings for free action.

Install connecting rod and piston assemblies

into cylinders. Place chamfered sides of connecting

rods against radius of the crankpins. Install

connecting rod caps to matchmg connecting rods

thru bottom cover plate. Be sure chamfered sides

of caps are against radius of crankpins. Caps are

locked in place with nylock cap screws. Use 8-10

ft-lb torque to tighten cap screws.

Turn crankshaft to be sure there is no binding

between bearing surfaces and journals. Replace oil

screen, bottom cover plate, valve plates and

cylinder heads.

MOTOR BURNOUT

(Clean-Up Procedure)

When a hermetic motor burns out, the stator

winding decomposes forming carbon, water and

acid which contaminate refrigerant systems.

Remove these contaminates from system to

prevent repeat motor failures.

1. Close compressor suction and discharge service

valves, and bleed refrigerant from compressor.

Save remaining refrigerant in system.

2. Remove burned motor from compressor, and

drain compressor oil. Clean crankcase and

motor housing with solvent. Ensure that all

metal particles are wire-brushed free and

removed.

On severe burnouts, disassemble compressor

heads and valve plate assemblies. Clean them in

same manner as crankcase and motor housing.

3. Ascertain cause of burnout and remedy. Check

control box for welded starter contacts, welded

overload contacts or burned out heater

elements. Check terminal plate for burned or

damaged terminals, insulation, and shorted or

grounded terminals.

4.

Reassemble compressor with new stator and

rotor. Install new hquid line filter-drier, and

place new oil charge in crankcase.

5.

Evacuate and dehydrate compressor.

Place compressor in operation. After 2-4 hours

6.

of operation, check compressor oil for discolor

ation and/or acidity. If oil shows signs of

contamination, replace oil charge, filter-driers,

and clean suction strainer with solvent.

7. Check oil daily for discoloration and acidity. If

oil stays clean and acid-free, the system is clean.

If oil shows signs of contamination, change oil,

filter-drier, and clean suction strainer. If fUterdrier or suction strainer is dirty or discolored,

repeat this step until system is clean.

#

15

Page 16

For replacement items use Carrier Specified Parts.

Manufacturer reserves the right to change any product specifications without notice.

CARRIER AIR CONDITIONING COMPANY • SYRACUSE, NEW YORK

Tabs Form 06E,07E-4SI Supersedes 06E.07E-3SI and 06E,07E-6SS Printed in U.S A. 1274 6-72 CodesCandMB Cataiog No 530-61 6

Loading...

Loading...