Page 1

Carrier

06D,07D

Installation Instructions

7/

vO

o

o

CO

xn

■CQ

S

<0

O

cc

o

■H

a

Carrier Corporation 1965 Litho in U.S.A.

AND o:

07DA501005 6-65

Tab 4

Supersedes 6D21-1045 1-61

Page 2

06D,07D INSTALLATION

CONTENTS

Carrier

PAGE

Inspect the Site

Inspect Shipment for Loss and Damage

Set the Unit in Place

Code Compliance

Electrical Requirements

Piping and Accessories

Leak Test the System

Dehydrate the System

Check Refrigerant Charge

Initial Start-Up Instructions

Checking Operations

07DA210,112,215 Electrically Operated Capacity

Control Device

Check the Installation

13

15

15

15

15

20

24

24

26

27

27

28

32

SUCTION

SHUT-OFF VALVE

DISCHARGE MANIFOLD

PRE5SURESTAT CONN.

PUMP END BEARING

HEAD

OIL PUMP COVER

SUCTION MANIFOLD

PRESSURESTAT CONNECTION

(REMOVE FITTING TO

CHECK OIL LEVEL WITH

DIPSTICK)

COMPRESSOR NAMEPLATE

REGISTER TAG

FUSIBLE UNION

COOLING WATER

CONN

WATER REGULATOR VALVE

PRESSURE CONNECTION

LIQUID LINE CONNECTION

liquid line valve

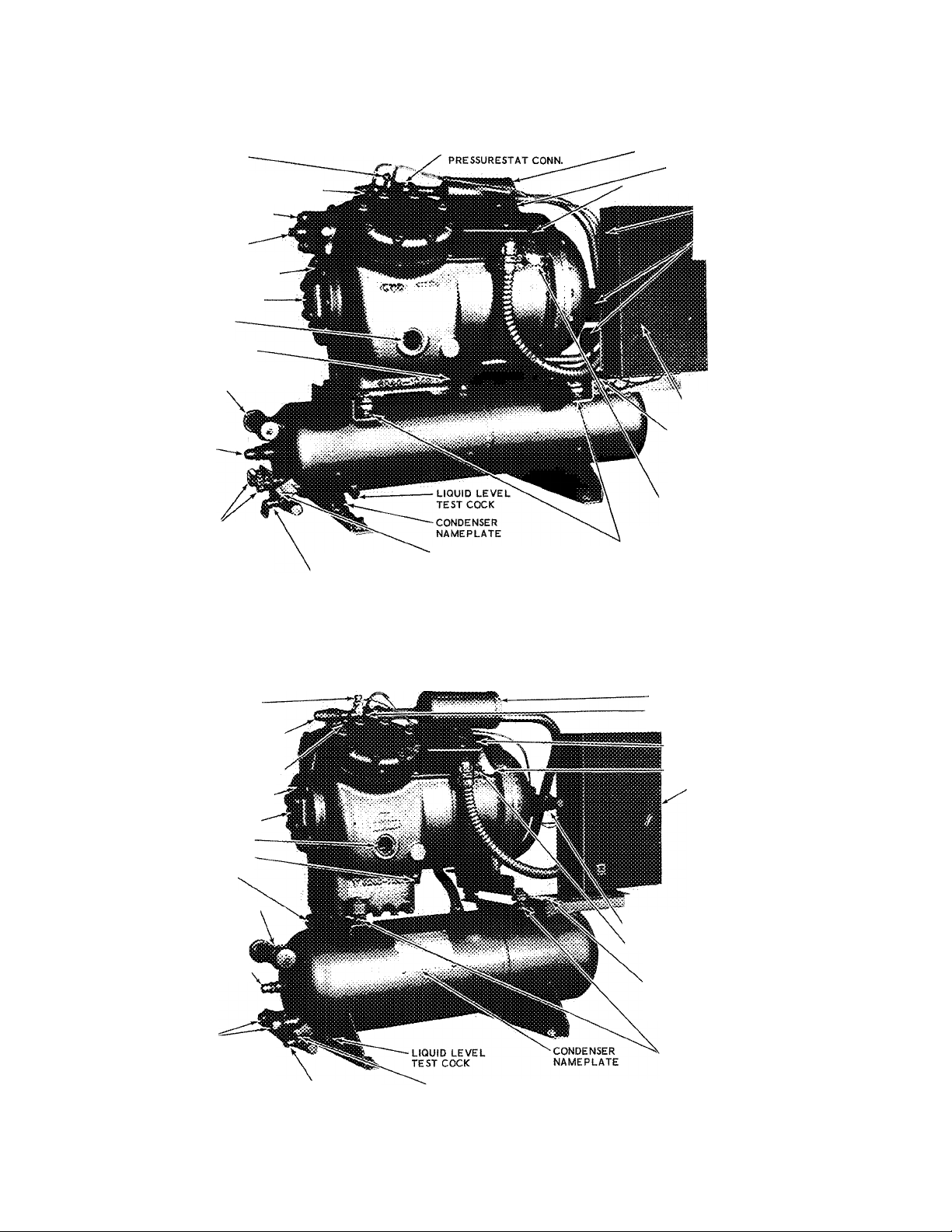

Fig. 1 - Typical 2 Cylinder Water-Cooled Condensing Unit

MOUNTING SPRINGS

(REMOVE BOLTS BEFORE STARTING)

CONDENSER NAMEPLATE

(07DA102, Single-Phase Illustrated)

TERMINAL BLOCK

discharge‘shut-off valve

DISCHARGE GAGE CONNECTION

RUN CAPACITOR

CONTROL BOX

DISCHARGE MUFFLER

CONDENSING UNIT

NAMEPLATE (USE

FOR WARRANTY

PURPOSES)

LIQUID LEVEL TEST

COCK

Page 3

Carrier

INSTALLATION 06D,07D

DISCHARGE

GAGE CONN.

SUCTION

PRESSURESTAT CONNECTION

SUCTION SHUT-OFF

VALVE

SUCTION GAGE

CONN.

PUMP END BEARING

HEAD

OIL PUMP COVER

BULL'S EYE

OIL DRAIN PLUG

WATER OUTLET

(COOLING TOWER ONLY)

FUSIBLE UNION

WATER INLET

(COOLING TOWER)

WATER INLET

AND OUTLET

(CITY WATER)

'LIQUID LINE CONN.

. DISCHARGE MANIFOLD

-WATER

REGULATING VALVE

PRESSURE CONN

DISCHARGE MUFFLER

TERMINAL BLOCK

COMPRESSOR NAMEPLATE

RUN

CAPACITORS

START

CAPACITORS

CONTROL BOX

CONDENSING UNIT

NAMEPLATE (USE

FOR WARRANTY

PURPOSES)

REFRIGERANT TAG

MOUNTING

SPRINGS (REMOVE

BOLTS BEFORE STARTING)

Fig. 2 - Typical 4 Cylinder Water-Cooled Condensing Unit

DISCHARGE GAGE

CONN.

DISCHARGE SHUT-OFF

VALVE

SUCTION MANIFOLD

PRESSURESTAT CONN,

PUMP END BEARING

HEAD

OIL PUMP COVER

BULL’S EYE

OIL DRAIN PLUG

PURGE COCK

WATER OUTLET

(COOLING TOWER

ONLY)

FUSIBLE UNION

WATER INLET

(COOLING TOWER)

WATER INLET AND

OUTLET (CITY

WATER

(07DA103, Single-Phase Illustrated)

'LIQUID LINE

CONN.

■WATER REGULATING

VALVE PRESSURE CONN.

DISCHARGE MUFFLER

DISCHARGE MANIFOLD

PRESSURESTAT CONN.

-TERMINAL BLOCK

REFRIGERANT TAG

CONTROL BOX

SUCTION SHUT-OFF VALVE

COMPRESSOR NAMEPLATE

CONDENSING UNIT

NAMEPLATE (USE FOR

WARRANTY PURPOSES)

MOUNTING

SPRINGS

(REMOVE BOLTS

BEFORE STARTING)

Fig. 3 - Typical 4 Cylinder Water-Cooled Condensing Unit

(07DA106, Three-Phase Illustrated)

Page 4

06D,07D INSTALLATION

DISCHARGE GAGE

CONN.

DISCHARGE SHUT-OFF

VALVE

DISCHARGE MANIFOLD

PRESSURESTAT CONN.

PUMP END BEARING

HEAD

OIL PUMP COVER

BULL'S EYE

WATER INLET AND

OUTLET HEADERS

(SEE FIG 18 FOR

PROPER CONNECTIONS)

MOUNTING SPRINGS

(REMOVE BOLTS BEFORE

STARTING)

LIQUID LEVEL

TEST COCK

DISCHARGE MUFFLER

SUCTION MANIFOLD

PRESSURESTAT CONN

TERMINAL BLOCK

SUCTION SHUT-OFF

VALVE

CONTROL BOX

REFRIGERANT

TAG

COMPRESSOR

NAMEPLATE

CONDENSING UNIT

NAMEPLATE

OIL FILL PLUG

LIQUID LINE CONN.

' WATER REGULATING VALVE

PRESSURE CONN

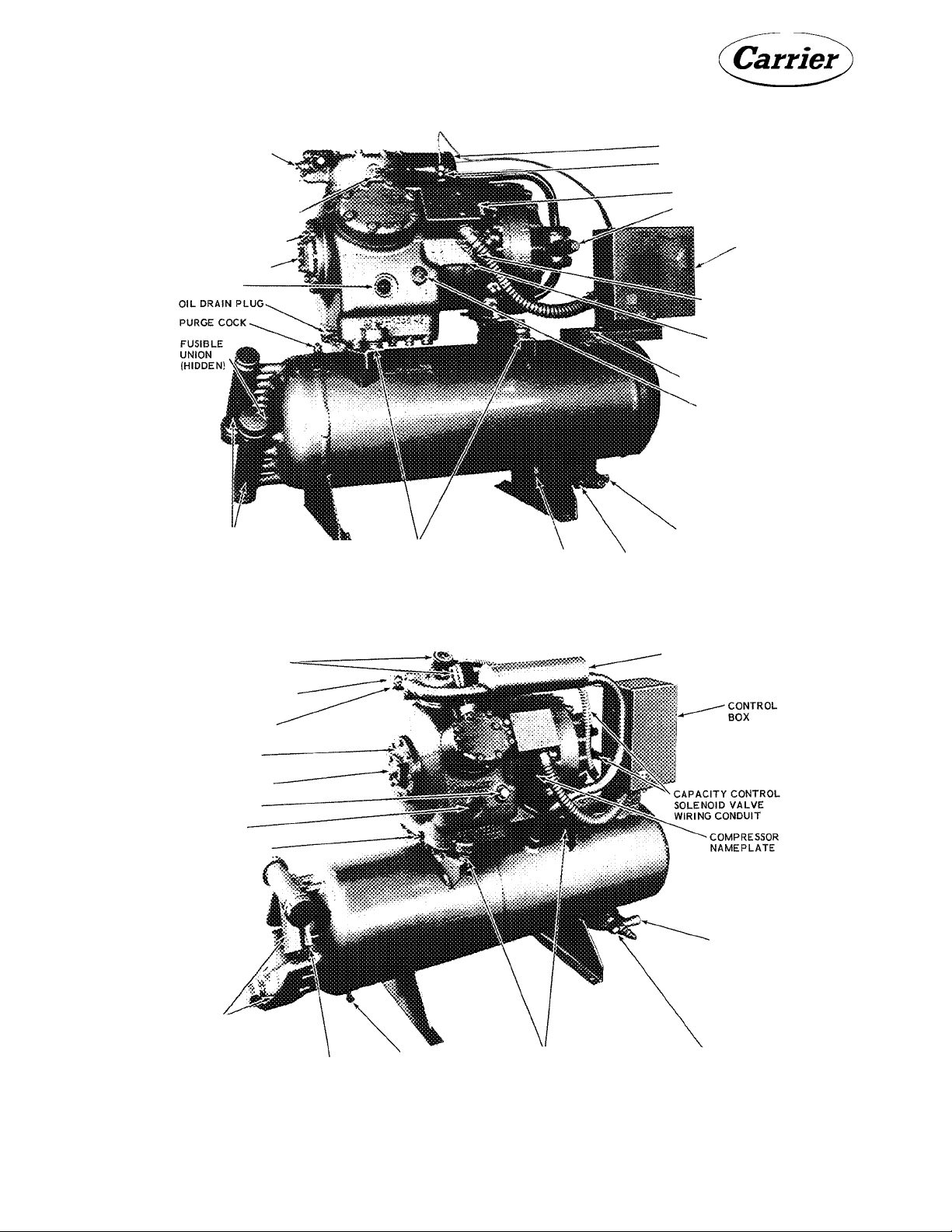

Fig. 4 - Typical 6 Cylinder Water-Cooled Condensing Unit

CAPACITY CONTROL

SOLENOID VALVES

DISCHARGE SHUT-OFF

VALVE

DISCHARGE GAGE

CONNECTION

PUMP END

BEARING HEAD

OIL PUMP COVER

OIL FILL PLUG

BULL'S EYE

OIL DRAIN PLUG

WATER INLET

AND OUTLET

HEADERS (SEE

FIG. 18 FOR

PROPER

CONNECTIONS)

(07DA210, Three-Phase Illustrated)

FUSIBLE

UNION (HIDDEN)

' LIQUID

LEVEL TEST

COCK

MOUNTING SPRINGS

(REMOVE BOLTS BEFORE

STARTING)

DISCHARGE MUFFLER

LIQUID LINE

CONNECTION

WATER REGULATING VALVE

PRESSURE CONN

Fig. 5 - Typical 6 Cylinder Water-Cooled Condensing Unit - Capacity Control

(07DA215, Three-Phase Illustrated)

Page 5

NOTES

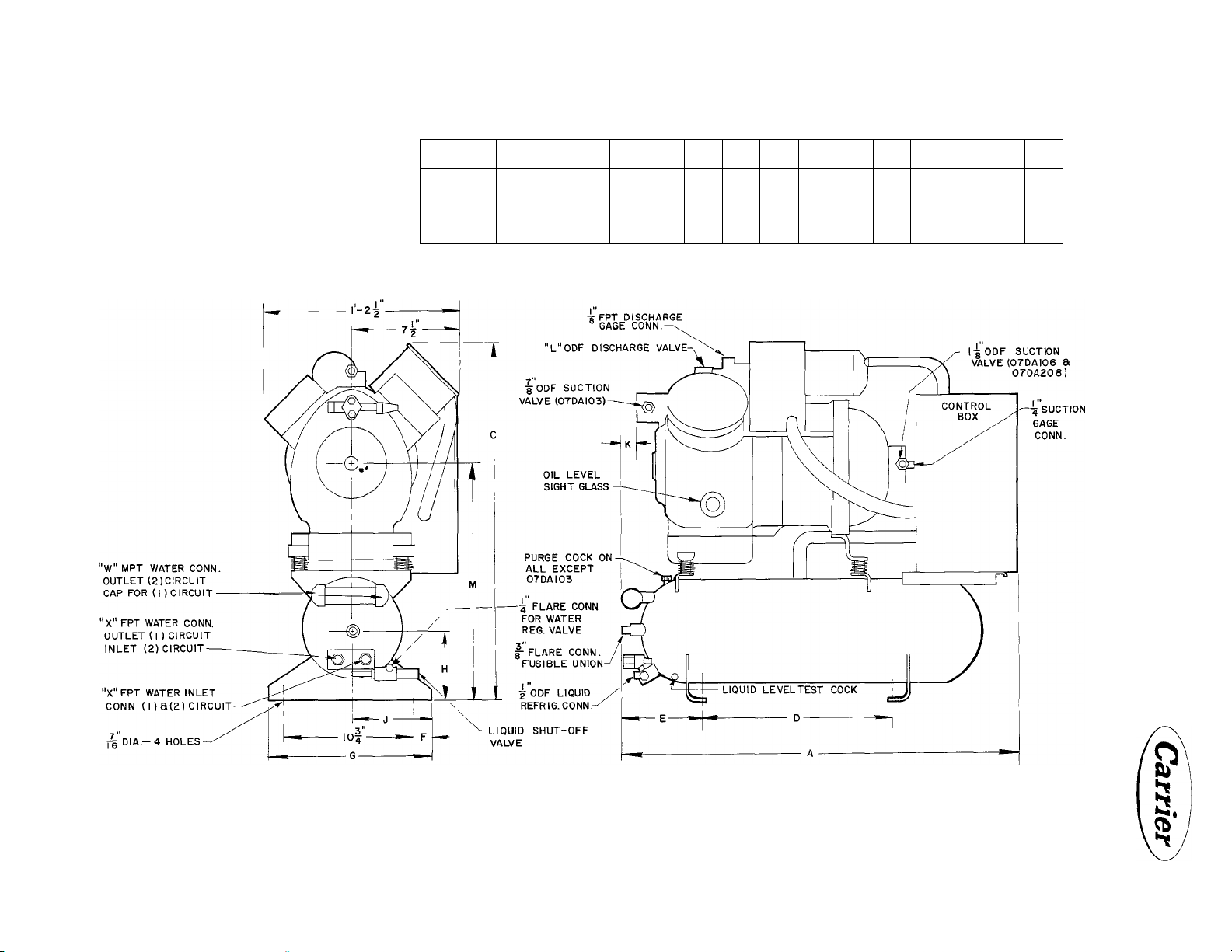

1. NET WEIGHT INCLUDES OIL BUT NOT REFRIG. CHARGE.

2. OIL PUMP IS AUTOMATICALLY REVERSIBLE FOR

EITHER DIRECTION OF ROTATION

3. CONTROL BOX DRAWING 06D-20I-EI

4. MUFFLER DRAWING ' 06D- 202-4

LIQUID STRAINER-DRIER

CRANKCASE HEATER PKG.

YES NO

UNIT

MODEL

07DAI02

07DA203

NET WEIGHT

(LBS)

181

190

A D E

2'-s|'

4''

2-7 C

if

3 i

z

(/)

>

>

5

z

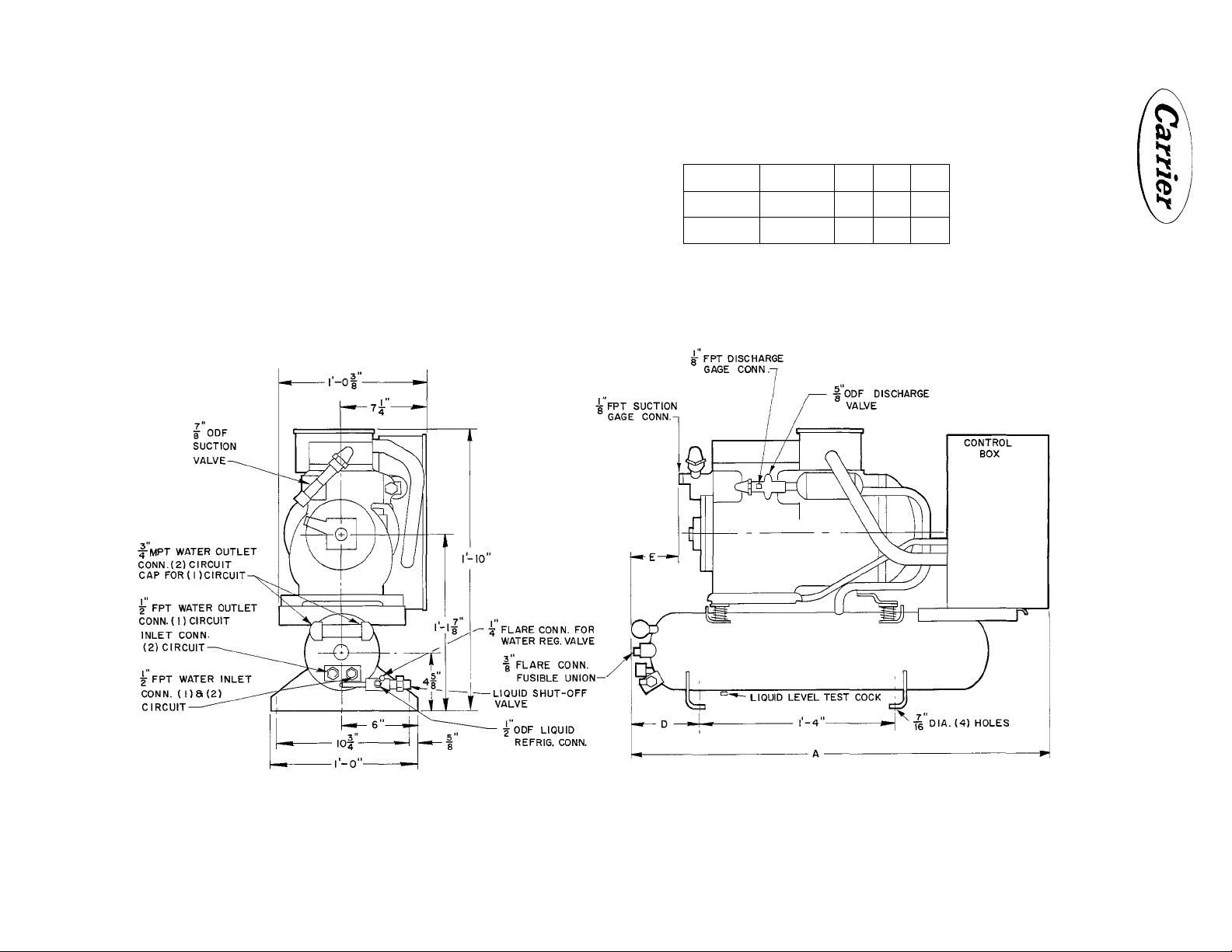

Dimensions are approximate. Certified dimension drawings are available on request.

Fig. 6 - Dimensions for 07DA102 and 07DA203

Page 6

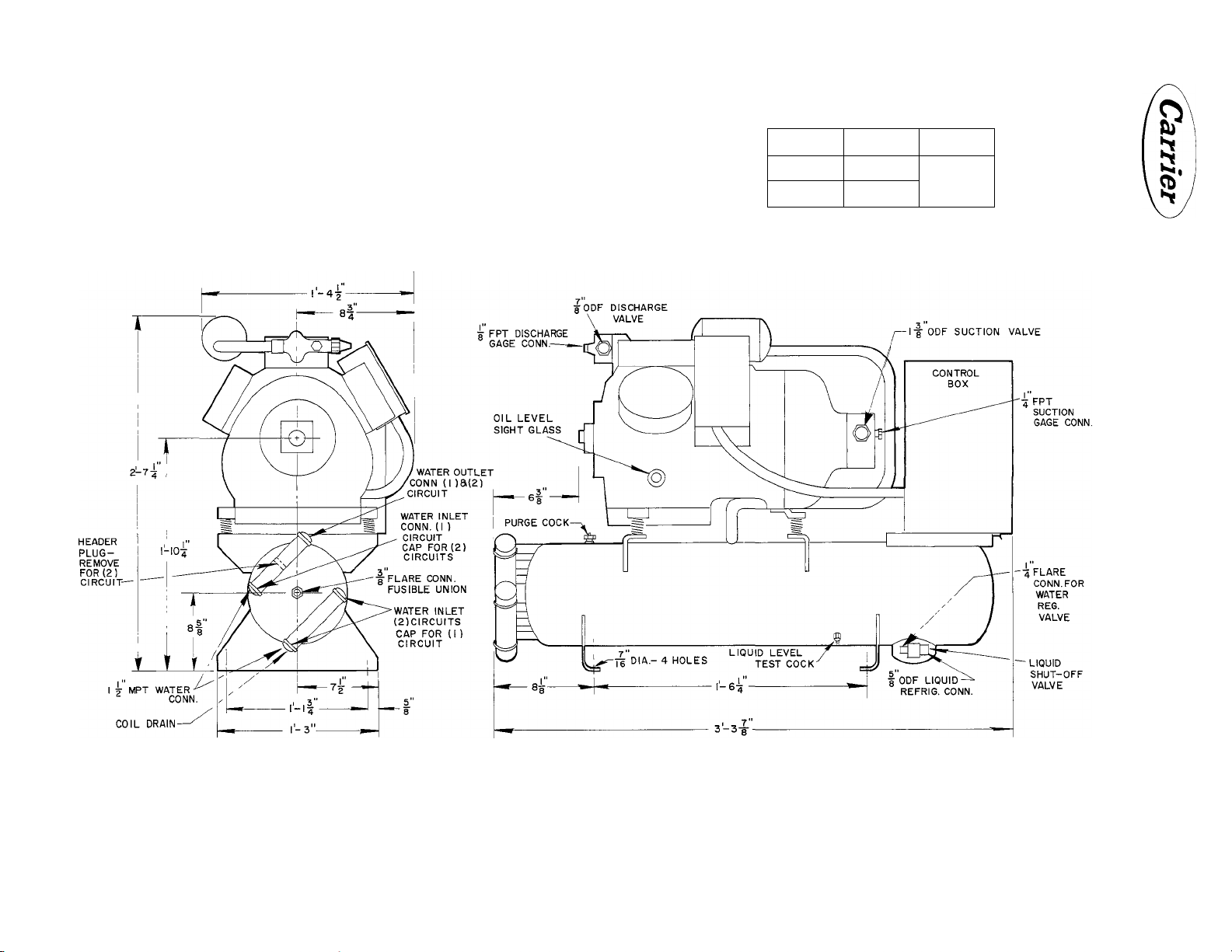

NOTES'

1. NET WEIGHT INCLUDES OIL BUT NOT REFRIG. CHARGE.

2. OIL PUMP IS AUTOMATICALLY REVERSIBLE FOR

EITHER DIRECTION OF ROTATION.

3. CONTROL BOX drawing: 06D-20I-EI

4. MUFFLER DRAWING • 06D- 202-4

LIQUID STRAINER-DRIER

CRANKCASE HEATER PKG.

YES NO

UNIT

MODEL

t

---------------------

07DAI03 247 2-9"

07DAI06 2 94

07DA208

NET WEIGHT

(LBS)

330

2'-9|"

3'-3|"

A

I'-iiir"

2-4 J,

c 0 E

l'-4"

.1 ...n

I-IO

6"

7"

F G H

5"

I'-O"

8

|J-''

I'-l"

' 8

4|"

5®"

^4

J K L

6"

s'"

bg

5 "

8

7”

8

M

I-2-L"

r 7"

w

MPTXFPT

3 "

4

1 "

1"

3"

4

>

>

5

Dimensions are approximate. Certified dimension drawings are available on request.

Fig. 7 - Dimensions for 07DA103,106 and 208

Page 7

#

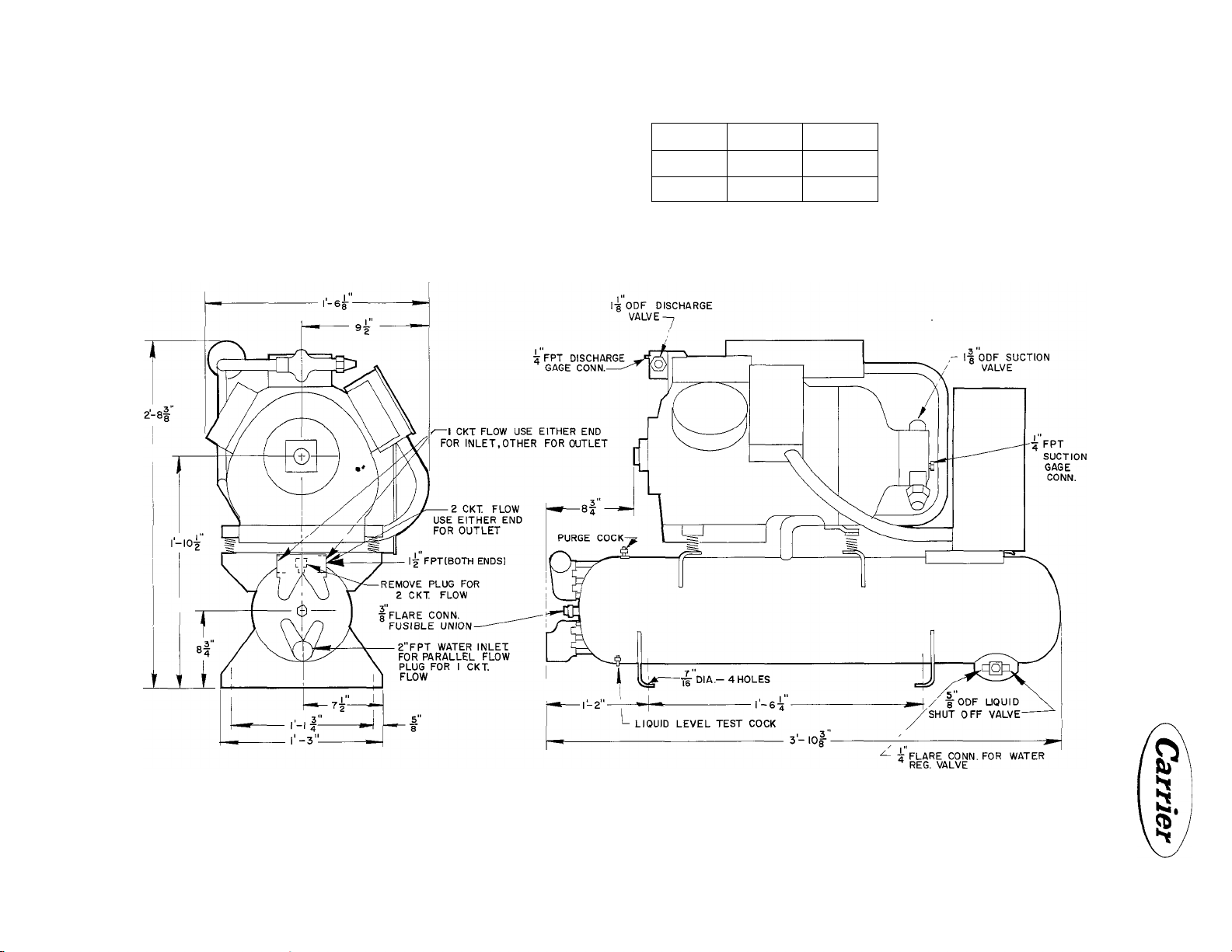

NOTES

1. NET WEIGHT INCLUDES OIL BUT NOT REFRIG. CHARGE.

2. OIL PUMP IS AUTOMATICALLY REVERSIBLE FOR

EITHER DIRECTION OF ROTATION.

3. CONTROL BOX DRAWING 06D-20I-EI

4. MUFFLER DRAWING 06D-202-4

PRESS. ACTUATED CONTROL VALVE(S)

LIQUID STRAINER- DRIER

CRANKCASE HEATER PKG.

YES NO

UNIT

MODEL

07DA2I0 WITHOUT

07DB2I0

CAPACITY

CONTROL

WITH

NET WEIGHT

(LBS)

475

z

>

>

5

z

Dimensions are approximate. Certified dimension drawings are available on request.

Fig. 8 - Dimensions for 07DA210 and 07DB210

Page 8

NOTES.

1. NET WEIGHT INCLUDES OIL BUT NOT REFRIG. CHARGE.

2. OIL PUMP IS AUTOMATICALLY REVERSIBLE FOR

EITHER DIRECTION OF ROTATION.

3. CONTROL BOX DRAWING OSD- 201-El

4. MUFFLER DRAWING OSD- 202-4

PRESS. ACTUATED CONTROL VALVEiS)

LIQUID STRAINER-DRIEF

CRANKCASE HEATER PKG.

YES_ NO

UNIT

MODEL

07DAII2

07DA2I5

07DBI 12

07DB2I5

CAPACITY

CONTROL

WITHOUT

WITH 590

NET WEIGHT

(LBS)

580

z

>

>

o

Dimensions are approximate. Certified dimension drawings are available on request.

Fig. 9 - Dimensions for 07DA,DB112 and 07DA,DB215

Page 9

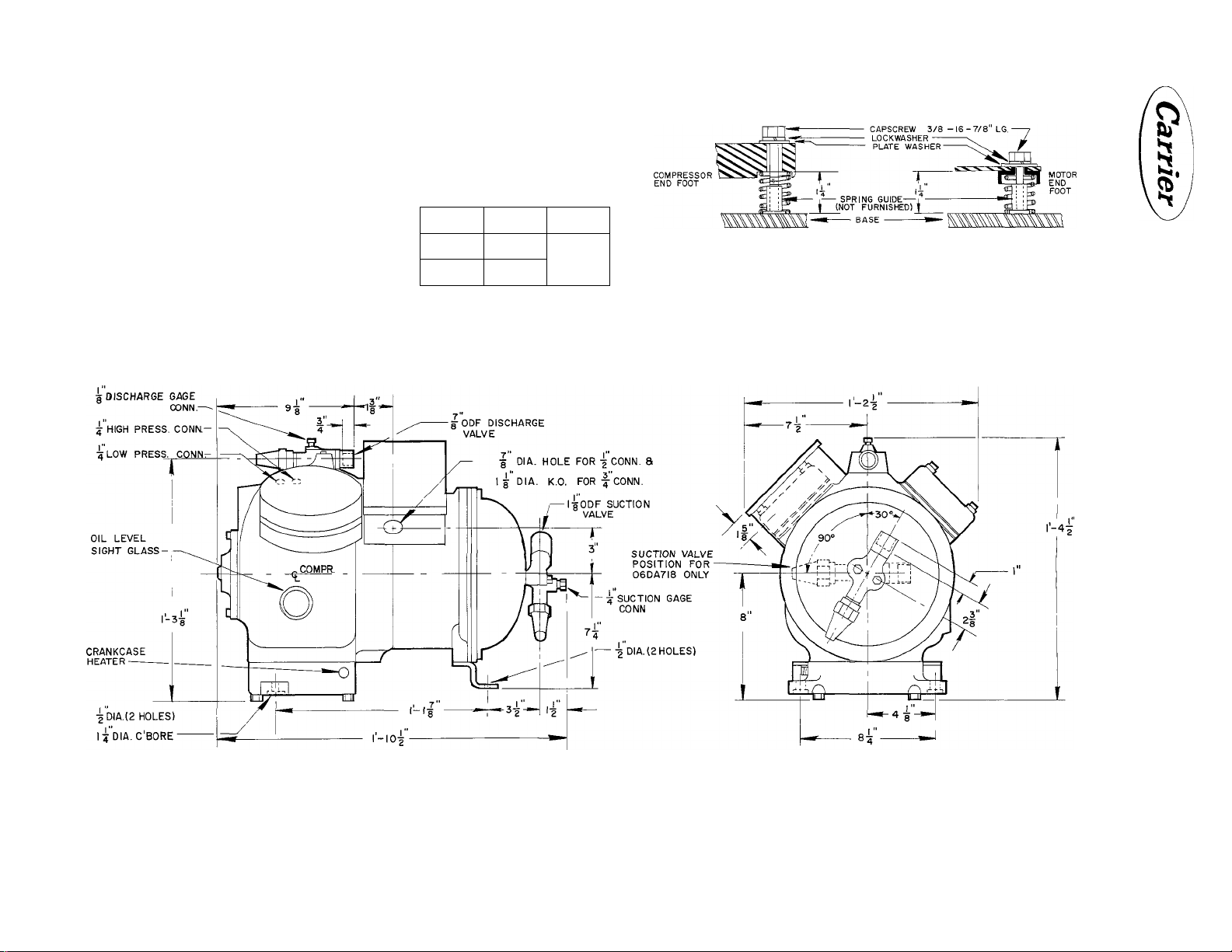

NOTES.

1. NET WEIGHT INCLUDES OIL BUT NOT REFRIG. CHARGE.

2. OIL PUMP IS AUTOMATICALLY REVERSIBLE FOR

EITHER DIRECTION OF ROTATION.

3. CONTROL BOX DRAWING 06D-201-El

4. MUFFLER DRAWING 06D-202-4

CONTROL BOX r

MOUNTING SPRINGS

MUFFLER

CRANKCASE HEATERS

YES NO

MODEL

06DA7I8 210 LBS.

06DA8I8

NET

WEIGHT

225 LBS.

OIL

CHARGE

7 PINTS

#

SPRING MOUNTING ARRANGEMENT

(TYPICAL)

z

(/>

>

>

Dimensions are approximate. Certified dimension drawings are availabie on request.

Fig. 10 - Dimensions for 06DA718 and 06DA818

5

z

Page 10

NOTES

I NET WEIGHT INCLUDES OIL BUT NOT REFRIG. CHARGE.

2. OIL PUMP IS AUTOMATICALLY REVERSIBLE FOR

EITHER DIRECTION OF ROTATION.

3. CONTROL BOX DRAWING 06D-20I-EI

4. MUFFLER DRAWING 06D-202-4

PRESS. ACTUATED

CONTROL VALVE(S)

CONTROL BOX

MOUNTING SPRINGS

MUFFLER

CRANKCASE HEATER

YES NO

NET WEIGHT 270 LBS.

OIL CHARGE 10 PTS.

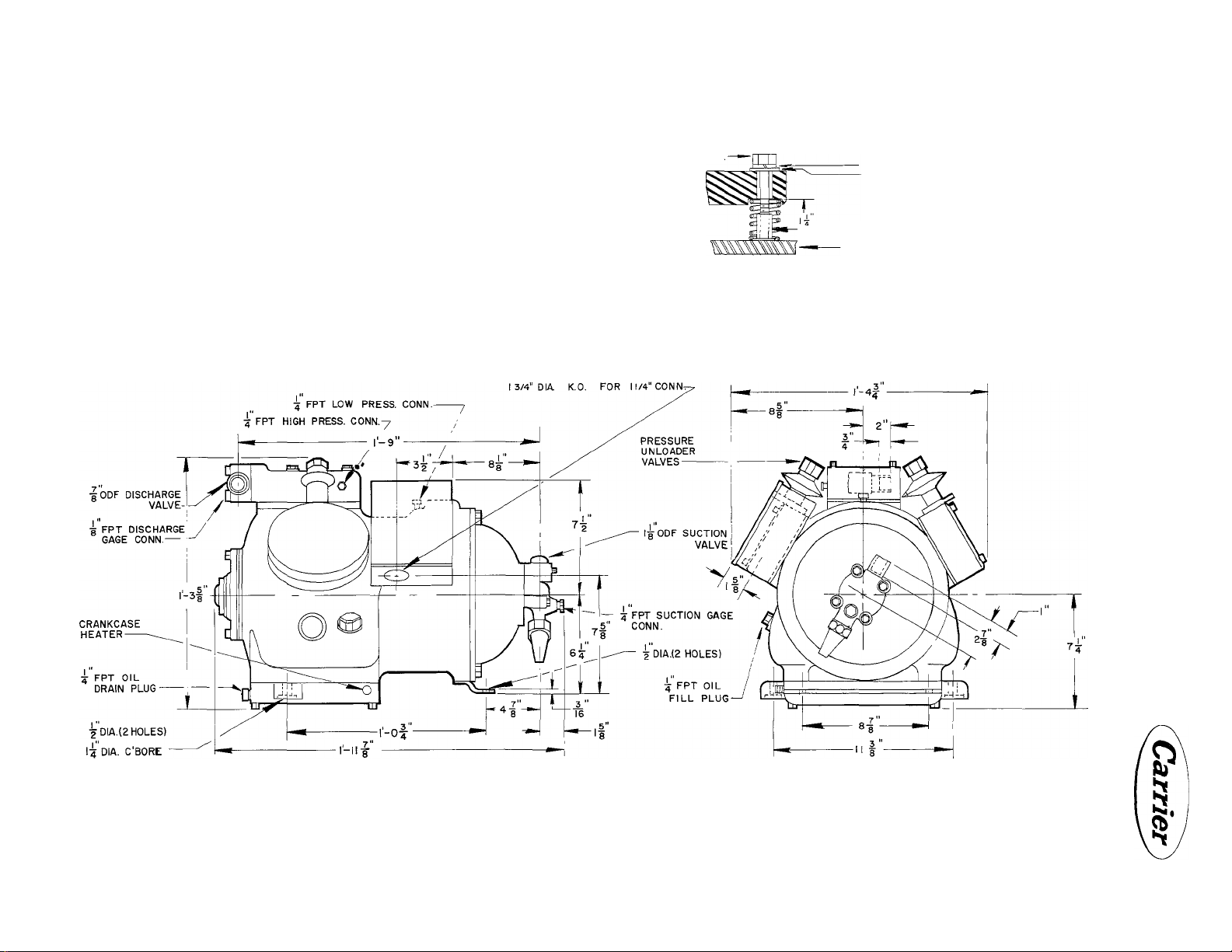

06DA DENOTES NO UNLOADERS

06DE DENOTES 2 STEP PRESSURE

ACTUATED UNLOADING

M/8" DIA. HOLE FOR 3/4“C0NN..

13/8“ DIA. K.O. FOR I" CONN. 8.

3Æ-I6 X 1 1/2 LG

CAPSCREW

COMPRESSOR

END FOOT

LOCKWASHER —

PLATE WASHER

SPRING GUIDE-

JL (NOT FURNISHED)

SPRING MOUNTING ARRANGEMENT

BASE-

(TYPICAL)

3/8 - 16-7/8‘‘LG. CAPSCREW

ai

MOTOR

END

FOOT

z

>

>

5

z

Dimensions are approximate. Certified dimension drawings are available on request.

Fig. 11 - Dimensions for 06DA824 and 06DE824

Page 11

NOTES

1. NET WEIGHT INCLUDES OIL BUT NOT REFRIG. CHARGE.

2. OIL PUMP IS AUTOMATICALLY REVERSIBLE FOR

EITHER DIRECTION OF ROTATION.

3. CONTROL BOX DRAWING OSD-201-El

4. MUFFLER DRAWING OSD-202-4

PRESS. ACTUATED

CONTROL VALVE(S)

CONTROL BOX

MOUNTING SPRINGS

MUFFLER

CRANKCASE HEATER

YES

NO

MODE L

*

06D( )337

06 D( Ì537

„ 06DA DENOTES NO UNLOADERS

06DE DENOTES 2 STEP PRESSURE

NET

WEIGHT

285 LBS.

ACTUATED UNLOADING

OIL

CHARGE

10 PINTS

ELECTRICAL

208-3-60

230-3-60

230-3-50

400-3-50

460-3- 60

SPRING MOUNTING ARRANGEMENT

D

1 3/8" DIA. HOLE FOR 1" CONN, a

8"

1 3/4" DIA. K.O. FOR 1 1/4" CONN.

1 1/8" DIA. HOLE FOR 3-4" CONN.,

13/8" DIA K.O. FOR l" CONN. 8

9"

1 3/4" DIA K.O. FOR 1 1/4" CONN.

(TYPICAL)

"E" CONNECTION SIZES

z

>

>

5

Dimensions are approximate. Certified dimension drawings are available on request.

Fig. 12 - Dimensions for 06DA337,06DE337 and 06DA537,06DE537

Page 12

FIGURE I

n FIGURE H

MUFFLER

PKG.

NO.

6D44-

882

6047-

882

6075-

882

FIG.

NO.

I

JL 10

IL

1-4"

A

9|''

DIMENSIONS

B

c D

5"

-

8

7"

if

8

4"3"4 4"

DIXH.

COND.

CONN.

INLET

MTG.

HORIZ.

OR

VERT

CONN.

INLET

E

—

-

I'ODF

^OOM

|-§ODF

|0DF

l-gODF

r

3"

4

2

7"

8

MODELS

USED

ON

06DA7I8

06DA8I8

06D_824

060—337

060 — 537

z

Ui

>

>

5

z

Dimensions are approximate. Certified dimension drawings are available on request.

Fig. 13 - Dimensions for 06D Muffler Assembly

Page 13

Carrier

INSTALLATION 06D,07D

m

Table 1 - 07D Condensing Unit Data

Condensing Unit A102 A203 A103 A106

Compressor Mo lei

Unit Type

Nominal Tons

Evap Temp Le\ el

No. of Cy 1 inders

Bore ond Stroke (in )

Compr Speed (rpm)

DispI at 1750 Rpm (cfm)

Suet Gas Conn

Disch Gas Conn. (ODF) 5/8 5/8

Liq Line Conn

Refrigerant 12

Optg Ref Charge (lbs)** 2

Cond Storoge Cap

(80% Liquid at 100 F)

Water Conn Inlet 1/2 FPT

Cooling Tower

Water Conn

City Water

Frangible Discs, M. Fl. 3/8

06DA109

H,M,L

2 X 1-3/8 2 X 1-1/4

1750

(ODF)

(ODF)

Outlet

Outlet 1/2 FPT 1/2 FPT 1/2 FPT

Inlet

1/2 FPT

1/2 FPT

06DA808

WC

2

H,M

2 2

1750 1750

8.69 7 96 13.1

7/8 7/8 7/8 1-1/8 1-1/8 1-1/8 1-3/8 1-3/8

1/2

18 18.5 20.5 39.5 35.8 45

1/2 FPT(2) 1/2 FPT(2) 1/2 FPT(2) 1/2 FPT(2) 3/4 FPT (2)

3/4 MPT 3/4 MPT 1 MPT 1 MPT 1 MPT *1-1/2 MPT 2 FPT 2 FPT

1/2 FPT 1/2 FPT 1/2 FPT

WC

3

1/2 1/2 1/2

22

2.5

3/8

06DA013 06DA718

WC WC WC

3

H,M H

4 4 4

1-13/16 X 1-1/4 2 X 1-7/16 2 X 1-7/16 2 X 1-7/16

5/8 7/8 7/8

12 12 22 22 22

2.7 2.0 1.9

3/8 3/8 3/8

5 5

1750

18.3

1/2 FPT

-------------------------

06DA818

M

1750 1750 1750

18.3 18 3 23.88 37 07 37 07

1/2 1/2 5/8 5/8 5/8

1/2 FPT

1/2 FPT 3/4 FPT 1-1/2 MPT 1-1/2 FPT 1-1/2 FPT

3/4 FPT 1-1/2 MPT 1-1/2 FPT

1

A .

A208

WC

7-1/2

H,M

4

7/8 7/8 1-1/8

2 7 3.2 4.3 4.3

3/8

210

B

06DA724 06DA337 06DA537

WC

10 10

H,M H,M

6 6 6

2 X 1-1/4 2 X 1-15/16

67

1-1/2 MPT

3/8

A

WC WC

2 X 1-15/16

1750

12 22

88 88

*1-1/2 FPT(2) *1-1/2 FPT(2)

1-1/2 FPT

3/8 3/8

'^215

B

15

H,M

1750

1-3/8

1-1/8

*Remove upper header plug for parallel circuiting for cooling tower application (See Fig. 18 )

**Condensing unit minimum operating refrigerant charge

WC — Water-Cooled

INSPECT THE SITE

Preliminary Survey

Before starting the installation, make a survey

to determine the following:

SPACE REQUIREMENTS

Dimensions for the 07D Condensing Units are

given in Table 2. Allow additional room to re

move the compressor heads and valve plates.

Place the unit so the suction and discharge shut

off valves can be easily reached and the oil

level checked.

Install the unit where it will be warmer than the

refrigerated space, to prevent refrigerant from

condensing in the compressor crankcase during

shutdown. Water-cooled condensing units must

be protected against freezing. Make provision

in the piping layout to drain and blow out the

condenser and water piping if the system is to

be shut down in winter.

Table 2 - Condensing Unit Dimensions

Length

Unit

07DÂ102 WC 0 0)

07DA102 WC (Poly 0)

07DA203 WC 0 </.)

(in.)

21-3/8 12 ■ 21-1/2

29-1/16 12 21-1/2

29-1/2

07DA203 WC (Poly 0) 31-3/16

07DA103 WC (1 </.)

07DA103 WC (Poly0)

07DA106 WC (All)

07DA208 WC (All)

07DA210 WC (All)

07DA112 WC (All)

31-3/32 14 22-5/8

32-3/4

33-1/4

39-5/8

39-11/16

46-3/8 17-7/16

07DA215 WC (All) 46-3/8

NOTE: WC - Water-Cooled

Width

(in.)

15-1/2

17-7/16

Height

(in.)

12

12

21-7/16

21-7/16

14 22-5/8

14 27-7/8

14 27-7/8

31-7/32

32-3/4

32-3/4

13

Page 14

06D,07D INSTALLATION

Table 3 - Electrical Data for 06D Compressor Units and

07D Water-Cooled Condensing Units

Carrier

06D 07D

Compressor Condensing

Unit

A808

A718

A818

¿824

*337

¿537

Unit

A102 208/3/60 7.9

A203 208/3/60

A103 208/3/60

A106 208/3/60 19.3

A208 208/3/60 35.0

*210

¿112

¿215

Full

Volt/Phase Load

Cycle (amps)

230/1/60 11.2

230/3/60

460/3/60 3.5

230/3/50 5.8

400/3/50 3.5

230/1/60 15.8

230/3/60

460/3/60 5.2

230/3/50

400/3/50

230/1/60

230/3/60

460/3/60

230/3/50 8.9

400/3/50 5.3

230/1/60 25.0 100.0 35.0

230/3/60 16.8

460/3/60 8.5

230/3/50

400/3/50 8.5

230/3/60

460/3/60

230/3/50 26.2

400/3/50 15.8

208/3/60 36.0

230/3/60

460/3/60 15.8

230/3/50

400/3/50

208/3/60 44.0

230/3/60 39.7

460/3/60 19.9

230/3/50

400/3/50 19.9

208/3/60

230/3/60 44.3

460/3/60 22.2

230/3/50

400/3/50 22.2

208/3/60 55.7

230/3/60 50.0

460/3/60 25.0

230/3/50 41.5

400/3/50 25.0

Locked

Rotor

(amps)

6.8

11.8

10.3

8.6

5.2

12.2

16.1 70.0 22.5 25.0

10.6

5.3 28.8 7.4 9.0

14.0

31.5

15.8

31.5

26.2

15.8

33.0

49.3 191.0 69.0 80.0 15.9 4

37.2 143.0 52.0 60.0 13.2

137.0 48.8 60.0 10.8

124.0

103.0

137.0 48.8 60.0

124.0

103.0 36.7 40.0

170.0 61.5 70.0 14.1

153.0

128.0 46.2 50.0

172.0 62.0 70.0

266.0

240.0

120.0

200.0

115.0

Overload Fusetron

(amps) (amps)

48.5

50.0

43.0 9.5 12.0 2.8

22.5 4.8

35.8

21.5 4.8

63.5

70.0

57.5 14.4

28.8

47.8

27.5 7.2 9.0 3.17

63.5 17.0 20.0 4.1

57.5 14.8 17.5 4.1

47.7 12.4 15.0 3.42

27.5 7.4 9.0 3.42

95.0 27.0 30.0 6.6

86.0 23.5 30.0 6.6

43.0

72.0 19.5 25.0 5.5

41.0

62.0

59.0 22.0 25.0 9.0

62.0

59.0 22.0 25.0 9.0

77.0 27.8 35.0 14.1

74.0 •

86.0

83.0

Trip Size

11.0 12.0 2.8

15.6 17.5

8.0 10.0 2.35

16.5 20.0 3.8

22.0 25.0 3.8

7.2

12.0

11.8 15.0

11.8 15.0 5.5

44.0

22.0

36.7 40.0 9.0

44.0

22.0

55.5 70.0 14.1

27,8

31.0

31.0

78.0 90.0 18.9

70.0

35.0 40.0 18.9

58.0

35.0

5.6

5.6

17.5 3.8 14 41

9.0 3.8

15.0 3.17

40.0 6.6

50.0 10.8 8

25.0

50.0

25.0

35.0

35.0

35.0 13.2

80.0

70.0

40.0

Max

Kw

2.8

2.8

2.35

4.1

4.1

6.6 14 100

10.8

10.8

10.8

10.8

9.0

11.7

11,7

15.9

15.9

18.9

15.7

15.7

Min

Branch

Circuit Wire Length Old

Size (AWG)

14

14

14 63

14 249

14

14 216

14 32

12 34

14

14

14 143

14 31

12 33

14 35

14 161

14

14 140

10 50

10 32

10 63

12 48

14 87

6

12

8 64

12 74

6

8 53

12

8 64

12 75

6

6

10 107

6 76

10 85

6 57

10

6 67

10

4

4

8 131

6

8

Max Wire

(ft)*

Reference

Number

49

29

74

164

50

36

63

53

85

63 6D67

85

41

63

69

96

83

61

75

60

115

6D21

6D28

6D40

6D47

6D48

6D68

6D73

6D75

*Wlre sizes are based on minimum wire size needed to

comply with Notional Electric Code for TW Type Wire.

Maximum wire length is based on a 1% voltage drop in the

branch circuit. Where up to 3% voltage drop is acceptable,

maximum wire lengths can be multiplied by 3.

14

Page 15

INSTALLATION 06D,07D

m

m

VENTILATION OF MACHINE SPACE

Ventilation must be provided to remove heat

from the compressor and allow refrigerant gas

to escape in case of a leak.

VIBRATION ISOLATION

Install the unit where the floor is strong enough

to support it. It is not necessary to install it on

a special foundation because vibration is ab

sorbed by the compressor mounting springs.

On critical installations it may be desirable to

enclose the unit in an equipment room to pre

vent direct transmission of sound to occupied

spaces. Place the unit where it will not be dam

aged by traffic or flooding. It may be necessary

to cage the unit.

NOTE: Remove the compressor hold

down bolts to allow the compressor to

float freely on the springs.

INSPECT SHIPMENT FOR LOSS AND DAMAGE

Check the shipping list immediately to see if

the shipment is complete. Inspect the unit for

damage. File a claim with the shipping company

immediately if damaged or lost.

Do not remove the tags until they are read and

understood. Save tags, instructions, installation

record card and shipping receipt. The person

starting machine may need them for reference.

CODE COMPLIANCE

Install these units in accordance with applicable

codes and ordinances. Refer to ASA-B9 1-1953,

American Standards Association's "Mechanical

Refrigeration Safety Code."

Frangible discs are provided to protect against

explosion in cases of extreme heat from an

external source.

Before installing the unit, check the electric

service to insure that it is adequate. The volt

age at the motor terminals must not vary more

than plus or minus 10% of the nameplate volt

age during start-up or while running.

Phase unbalance for three-phase units must not

exceed 2%. Where unbalance exists, connect the

two lines with the higher amperages thru the

switch heater elements.

Table 3 lists the minimum wire sizes for 6D

Water-Cooled Condensing Units.

Figure 14 - 16 are the unit wiring diagrams for

the water-cooled condensing units.

Water-Cooled Condensing Unit Control

T ransformers

ELECTRICAL REQUIREMENTS

SET THE UNIT IN PLACE

Set the unit in place. Level the condenser and

bolt the unit to the floor. For dimensions be

tween hold-down bolt holes, see Fig. 6 - 13.

Control transformers are not furnished with

the 440 condensing units. Recommended trans

former sizes are shown in Fig. 16. All 460/3/60

units have 115-volt control circuits. All other

units have 230-volt control circuits.

15

Page 16

06D,07D INSTALLATION

POWER AND CONTROL CIRCUIT SCHEMATIC

□ -TEKMINAL tLOCK CONNECTION

C - CONTACTOR

CR-CONTROL RELAY

r-FU8E

IT-INTERNAL MOTOR THERMOSTAT

HP-HI PRESSURESTAT

LP-LO PRESSURESTAT

HR-H0L0IN6 RELAY

OL-OVERLOAO (OVERCURRENT RELAY)

PO-PUMP OUT RELAY

TM’TIMER MOTOR

-----

FACTORY WIRINO

'•"FIELD WIRINO

I. CONTROL MUST BE FIELD SUPPLIED. j

MINIMUM CONTACT RATING MUST BE 25VA.

t. LIQUID LINE SOLENOID VALVE MUST BE

FIELD SUPPLIED. MAXIMUM LOAD'.

«OVA HOLDINOi 200 VA INRUSH.

S A60V AND 57SV UNITS HAVE A II5V

CONTROL CIRCUIT WHICH MUST BE

ENERGIZED AT LI AND L2 FROM AN

EXTERNAL SOURCE 400V UNITS HAVE

A 2SO V CONTROL CIRCUIT WHICH MUST

BE ENERGIZED AT LI AND L2 FROM

AN EXTERNAL SOURCE. ALL OTHER

UNITS HAVE A 2SOV CONTROL CIRCUIT

WHICH IS ENERGIZED THRU FACTORY

WIRING AT LI AND L2

4. A TRANSFORMER OF THE FOLLOWING

RATING MUST BE FIELD SUPPLIED FOR

400V, 4S0V AND B7SV UNITS*.

ALL 0TD()|I2, 070U2I5, OSDOSST,

0GD0S37 AND 060()S24 UNITS; ISO VA.

ALL OTHER units; 100 VA.

B.OPEN FUSED DISCONNECT SWITCH, ONLY

FOR SERVICING EQUIPMENT. DISCONNECT

MUST REMAIN CLOSED IN ORDER FOR

THE CRANKCASE HEATER TO OPERATE.

S.290V CONTROL CIRCUIT USES I/4 X

I '/4 SAMP FUSES.

IIS V CONTROL CIRCUIT USES 1/4 X

1^/4 10 AMP FUSES,

LEaCND

NOTES

Fig, 14 - Wiring Label 07D Condensing Units, 06D Compressor Units (3-Phase)

16

Page 17

INSTALLATION 06D,07D

(irc NOT! t)

#

I JUNCTION iOX

COMPREttOR

POWER AND CONTROL CIRCUIT SCHEMATIC

□ -TERMINAL BLOCK CONNECTION

C - CONTACTOR

CR-CONTROL RELAY

F-FUSE

IT-INTERNAL MOTOR THERMOSTAT

HP-HI PRESSURESTAT

LP-LO PRESSURESTAT

HR-HOLDING RELAY

OL-OVERLOAD (OVERCURRENT RELAY)

PO-PUMP OUT RELAY

TM-TIMER MOTOR

-----

FACTORY WIRING

-----

FIELD WIRING

RC-RUN CAPACITOR

SC-START CAPACITOR

SR-8TARTIN0 RELAY

1. CONTROL MUST BE FIELD SUPPLIED.

MINIMUM CONTACT RATING MUST BE 25VA.

a. LIQUID LINE SOLENOID VALVE MUST BE

FIELD SUPPLIED. MAXIMUM LOAD!

• OVA HOLDING^ 200 VA INRUSH.

•«OPEN FUSED DISCONNECT SWITCH, ONLY

FOR SERVICING EQUIPMENT. DISCONNECT

MUST REMAIN CLOSED IN ORDER FOR

THE CRANKCASE HEATER TO OPERATE.

0 CONTROL CIRCUIT IS 230V AND USES

*/4 X I '/4, S AMP FUSES

LEGEND

NOTES

CRANKCASE

HEATER

-AA/VW

i O-

• Al

V

Sl^

“tÍmer”

-0

VIEW

070ASOOOS3

Fig. 15 - Wiring Label 07D and 06D Units (1-Phase)

17

Page 18

06D,07D INSTALLATION

POWER WIRING

SINGLE PHASE

LI

FACTOR> WIRING IS IN ACCORDANCE WITH THE NATIONAL ELECTRICAL

CODE ANY FIELD MODIFICATIONS OR ADDITIONS MUST BE IN

COMPLIANCE WITH ALL APPLICABLE CODES

A6C VOLT UNITS HAVE 115 VOLT CONTROL CIRCUIT ENERGIZED

FROM EXTERNAL SOURCE AOO VOLT UNITS HAVE 250 VOLT

CONTROL CIRCUIT ENERGIZED FROM EXTERNAL SOURCE ALL

OTHER UNITS HAVE 230 VOLT CONTROL CIRCUIT ENERGIZED

THRU FACTORY WIRING AT L» AND L2

CONTROL CIRCUIT POWER REQUIREMENTS! ALL 07D( ) 112 8215 8

06D( )337,5378824 WITH 400V 8 460V DRAW 150 VA ALL

OTHER UNITS REQUIRE lOOVA WHEN CONTROL TRANSFORMERS ARE

REQUIRED THEY SHOULD BE SIZED ACCORDINGLY THESE RATINGS

APPLY TO DEVICES SHOWN ON CONTROL DIAGRAM, IF ADDITIONAL

ARE USED. TRANSFORMER SIZE MUST BE INCREASED PROPORTIONATELY

CONTROL CIRCUIT FUSES ARE 11/4" X 1/4" DIA CERAMIC TUBE RATED

AT -5 AMPS FOR 208 8 230V0LTS AND lOAMPS FOR 115 VOLTS

DO NOT SUBSTITUTE OVERLOAD RELAYS OF A HIGHER RATING THAN

ORIGINALLY SUPPLIED.

IF A CONTROL VOLTAGE POWER SUPPLY HAVING A GROUNDED SUPPLY

LEG IS USED, THE GROUNDED CONDUCTOR MUST BE CONNECTED TO

TERMINAL 3 AND F2 BYPASSED.

OPEN DISCONNECT ONLY WHEN SERVICING EQUIPMENT CRANKCASE

HEATER MUST REMAIN ENERGIZED WHEN EQUIPMENT IS SHUT DOWN

WIRING SHOWN IS FOR WATER-COOLED CONDENSING UNITS WITH

CONTROL BOX MOUNTED. COMPRESSOR UNITS ARE SHIPPED WITH

CONTROL BOX SEPARATE AND PIELD MUST SUPPLY INTERCONNECTING

WIRING WHERE NECESSARY

WOrning-DlSCONNECT ALL CIRCUITS BEFORE SERVICING THIS

ONE OVERLOAD ON SINGLE PHASE. TWO ON THREE PHASE

TIMER MOTOR (TM) CAM ROTATES AT 1/5 RPM WHEN TM IS

ENERGIZED TO PROVIDE 15 SEC. TIMING WITH SWITCHES (N A-A2,

B-B2, POSITION AND AMIN. 45 SEC, IN A-AI. B-BI, POSITION.

COMPLETE TIME GUARD CONTROL PROVIDES 15 SEC ADVANCE START

FOR CONDENSER AUXlUARIES AND PREVENTS COMPRESSOR RESTARTING

IN LESS THAN 5 MIN AFTER STOPPING

EQUIPMENT

Fig. 16 - Field Wiring for 06D, 07D Units

LEGEND

HR HOLDING RELAY

CR CONTROL RELAY

► C COMPRESSOR

M3 EVAPORATOR FAN OR

CHILLED WATER PUMP

M4 COOLING TOWER PUMP.AIR

COOLED OR EVAPORATIVE

CONDENSER FAN

M5 COOLING TOWER FAN OR

EVAPORATIVE CONDENSER PUMP

OL OVERLOAD

SV LIQUID LINE SOLENOID VALVE

SR STARTING RELAY

US UNLOADER SOLENOID

POR PUMP OUT RELAY

TM TIMER MOTOR

TERMINALS

Q MAIN TERMINAL STRIP

^ COMPRESSOR

18

MODEL

NUMBERS

070A102

07DA203

07DA103

060A7I8 A.B.C.D.E.F

07DA106 A.B. C.D, E, F

06DA6t8 A. C.D, E.F

07DA208

06D( )824 A, C. D. E. F

07D( )2I0 A. C.D. E, F

06D( )337 A. C.D,E.F

07D( )l 12

06 Di )537 A, C.D, E.F

07D( )2I5 A. C,D.e,F

A = 208/3/60

B • 230/1/60

C • 230/3/60

STANDARD

ELECTRICAL‘S

C HARACTERISTICS

A.B.C.D.E.F

A.B.C. D, E.F

A.B.C.D, E.F

A. C.D. E.F

A. C.D.E.F

D« 460/3/60

E» 230/3/50

F- 400/3/50

Page 19

INSTALLATION 06D,07D

[33 SINGLE PUMP OUT CONTROL WITH CITY WATER

1 FI Pel

=* CONTROL '

T'STAT t ,

---------------

------------

MS

--------

(>

' дих

____________

AUX

.CONTACT SV t

dd

^Z]

-INSERT SAFETY INTERLOCK

HERE (WHEN USED)

Q^single pump out control with:

tSEE NOTE 3

I I COOLING TOWER I 1 EVAPORATIVE

□ COOLING TOWER FAN ^ ^roRATiVE

I 1 AIR COOLED CONDENSER CONDENSER

-------

PUMP

syt

o-p—4^

LOW PRESS '

CUTOUT

•^OPTIONAL t SEE NOTE3

NOTES:

1 REMOVE WIRE FROM C TO LOW PRESSURE CUTOUT

AND ADD NECESSARY AUXILIARY CONTACTS

2 REMOVE WIRE FROM FI TO Щ AND INSERT DESIRED

INTERLOCKS AND OL'S

3 FIELD SUPPLIED T'STAT MUST HAVE MIN. CONTACT RATING

OF 25VA FIELD SUPPLIED SV MAX LOAD 60VA HOLDING;

200 VA INRUSH.________________________________________________

CONDUIT TO COMPRESSOR TERMINAL BOX ARRANGEMENT

Г“ " ■

a и

---

1 Г“

1

MOTOR TERM BOX

i

3 PHASE - 6 CYLINDER

ilfyXP)’

¿2 -] T|

03 OL 4СЯ-------------------

•O i

T Tj

“^2 1 T,

05 OL 40

--------------------

i COMPRESSOR

TERMINAL BOX ‘

I I PUMP DOWN CONTROL WITH CITY WATER

(SEE NOTES NO I THRU 6 BELOW)

.CONTROL T'STAT +

CONTACT SY»

I I PUMP DOWN CONTROL WITH.

I I COOLING TOWER [~~3 EVAPORATIVE CONDENSER

I ~1 COOLING TOWER FAN | ~| EVAPORATIVE CONDENSER

I 1 AIR COOLED CONDENSER

PUMP

l''l

CONTACT ®V T

M5 P

--------

[T]

|з

_

¿ *o—яй^—4-i>—

»OPTIONAL T SEE NOTE 6

NOTES FOR PUMP DOWN CONTROL DIAGRAMS:

1 REMOVE LOW PRESSURE CUTOUT BETWEEN C 8 Al AND CONNECT C TO Al

WITH ANY DESIRED INTERLOCKS

2 WIRE LOW PRESSURE SWITCH BETWEEN TERMINALS fil a [F].

3 REMOVE CONNECTION BETWEEN a CR NORMALLY OPEN CONTACT

A DO NOT USE PUMP DOWN CONTROL METHODS FOR COMPRESSORS LJUIPPED

WITH CAPACITY CONTROL USE SINGLE PUMP OUT CONTROL.

5 INSERT SAFETY INTERLOCKS HERE IWHEN USED)

6 FIELD SUPPLIED T'STAT MUST HAVE MIN. CONTACT RATING OF 25VA FIELD

SUPPLIED SV MAX LOAD 60 VA HOLDING ; 200 VA INRUSH

I I ELECTRIC UNLOADER CONTROL FOR COMPRESSORS FIELD EQUIPPED

WITH ELECTRIC CYLINDER UNLOADERS (TWO SHOWN)

PRESSURESTATS OR THERMOSTATS NOT FACTORY FURNISHED

--

0-

----------

ч:(^Ръ—

-B

MOTOR TERM BOX

a Ш

a в

OÎ

_____J_____

03 OL

-----

3 PHASE-2 0 4 CYLINDER

SINGLE PHASE

~05-

OL

!C

1

__

O?

40r

10

____1

COMPRESSOR

TERMINAL BOX

COMPRESSOR

TERMINAL BOX

4

CYLINDER

UNITS

2

CYLINDER

UNITS

USED ON SINGLE

PHASE UNITS ONLY

APPROXIMATE COMPONENT LOCATION IN CONTROL BOX

SIDE VIEW

Fig. 16 - Field Wiring for 06D, 07D Units (Confd)

19

OCDCTCCl IBCCTAT .

—В ^

TERMINAL

STRIP

------

(I PHASE

ONLY)

I HOLDING

TM KR

Л

’'ш

FRONT VIEW WITH COVER

REMOVED

RELAY

^AIN Ì

TERMINA®

STRIP I

Page 20

06D,07D INSTALLATION

PIPING AND ACCESSORIES

Elimination of Pipe Vibration

The liquid and suction lines are usually of soft

copper tubing. To absorb vibration, loop or

sweep tbe liquid and suction lines near the unit.

Fasten the tubing to walls or supports, using

vibration isolation type bangers as shown in

Fig. 17. Keep uninsulated lines away from hot

water or steam lines. Follow the piping prac

tices in Carrier System Design Manual, Part 3.

minute period has elapsed. On normal starts,

the control will operate 15 seconds before start

ing the compressor.

The heart of the control is the cycle timer. The

cam on the cycle timer completes one revolu

tion in five minutes. Whenever the compressor

is stopped the timer motor will automatically

run until the cam lever is operated, which in

turn actuates the necessary switches. When this

sequence is completed, the cycle timer is pre

pared to start the unit.

Table 4 shows the normal operating sequence

of the timer circuit. This table can be helpful

in diagnosing electrical problems.

Operation of the control circuit is generally the

same on all voltage units. However, wiring se

quences for the individual controls may vary,

such as overloads and safety devices.

The following is a general description of the

operating sequence of the control circuit. Refer

to the schematic wiring diagrams as a guide.

The functions of this control accessory are:

Fig. 17 - Refrigerant Line Hangers

Time Guard Control Operation

CONTROL CIRCUIT

This unit is equipped with controls which pro

vide automatic reset overload protection, time

delay in starting, and controlled cycling under

any cycling condition. Following shutdown of

the compressor for any reason (i.e., opening,

of the thermostat, functioning of a protective

device, power failure), the control permits re

starting of the compressor only after a five

1. To limit restart cycling of the compressor,

under any circumstance, to a minimum of

five minute intervals after stopping.

2. To allow time to run during normal "off

periods, thus utilizing this time as part of

the five minute timing interval described

above in No. 1.

3. To provide a 15 second delay on each com

pressor start before the compressor motor

starter is energized; to allow auxiliaries such

as condenser pump, condenser fan, chilled

water pump, etc. to be in operation before

the compressor starts. This feature will pre

vent nuisance cutouts due to momentary ac

tion of the high pressure switch or chilled

water flow switch during start-up.

20

Page 21

INSTALLATION 06D,07D

Table 4 - Recyling Control Circuit Normal Operation Chart

Unit at Rest

Control

Timer Relay

Coil 230 DE EN

Contacts N.O.

Contacts N.C.

Cycle Timer

Motor

Cam Up

Contacts A—A2 230

Contacts A—A]

Contacts B—B2 230

Contacts B —B|

Compressor Line DE

Accessories

Legend: EN - Energized CL

CL — Contacts Closed OP

DE — De-energized

*Accessories will continue to run if high or low pressurestat shuts off compressor.

Voltage

230

230

230 DE

230 OP OP

230 OP OP

230

Ready to Start

OP

CL

CL

CL

DE

Thermostat Closes

Instantaneous thru

15 Seconds

CL

OP

EN

Up

CL

CL

DE

EN

Contacts Closed and in Service

Contacts Open

Thermostat or

Safety Device

Normal

Run

EN DE DE

CL

OP CL

DE

Do wn

OP

CL CL

OP OP CL

CL CL OP

EN

EN

Opens —Instant

Thru 4-3/4 Min

OP OP

EN

Down

OP

DE

DE* DE

Unit Ready

to Restart

CL

DE

Up

CL

OP

DE

1. starting Sequence (Assuming evaporator in

terlocks and all operating safety controls

frigerant pressure rises and low-pressure

switch closes.

are in closed position)

Time: 0 Min 0 Sec - Timer switch plunger

is up at beginning edge of cam node

and contacts are in positions A-A2

and B-B2, as shown.*

Control thermostat closes, energizing liq

uid line solenoid valve (SV) and pump-out

relay (FOR), FOR N.O. contacts close. Re-

Condenser auxiliaries, such as condenser

water pump, tower fan, etc., start and their

auxiliary starter contacts close. Timer re

lay (TR) is energized thru timer switch con

tacts A-A2, closing TR N.O. contacts and

opening TR N.C. contacts. Timer motor (TM)

is energized thru timer switch contacts B-B2

and starts running.

* This is the position always reached by the cam each time after the compressor has stopped

and the timer motor has completed its 4 min and 45 sec timing run.

Starting Sequence of Time Guard Control (Single Pump-Out Arrangement Shown)

21

Page 22

06D,07D INSTALLATION

Carrier

■ L|

EVAPORATOR

---

SAFETY

DEVICE

CONTACTS,N.C.

INTERLOCK

CONTACTS,N.O.

----

LOW

PRESS.

SWITCH

CONTROL

THERMOSTAT

---------

*^^-0

------

M" AUX

CONTACTS,N.OT

CONTACTS,N.O.

J/_

POR

CONTACTS,N.C.

TR

2. Operating Condition

Time: 0 Min 15 Sec

Timer switch plunger has dropped off the

cam node and the contacts have switched to

positions A-Ai and B-Bi. Timer motor stops

running since TR N.C. contacts are open.

Operating Condition of Time Guard Control (Single Pump-Out Arrangement Shown)

TR

CONTACTS, N.O.

4^—

---------

TIMER MOTOR CAM

1/5 RPM, 15 SEC CAM NODE

Timer relay (TR) remains energized thru

TR N.O. contacts, which are now closed.

Compressor motor starter is energized thru

timer switch contacts A-Ai and compressor

starts. Compressor continues to run unless

circuit is broken by action of control ther

mostat or safety devices.

CONO AUX

PUMPOUT RELAY

LIQ SOL VALVE

COND AUX

AUX CONTACTS,NO.

—#—

OFF

O

O-

a

TIMER RELAY

■Ö

COMPRESSOR

TIMER MOTOR

O

—Cj-O—<•

HIGH

PRESS..

SWITCH

CONTACTS, N.C.

3. Stopping Sequence

Time: Any time after 15 seconds

Timer switch plunger is still in position of

having just dropped off the cam node, since

timer motor has not been running, and switch

contacts are in position A-Ai and B-Bi.

Thermostat opens when cooling load is sat

isfied. Liquid solenoid valve (SV) is de

energized and closes. Pumpout relay (POR)

is de-energized, and its contacts open. The

timer relay (TR) and compressor continue

to operate thru compressor starter auxiliary

contacts ”M" until system pumps down and

low-pressure switch opens. Then compres-

Stopping Sequence of Time Guard Control (Single Pump-Out Arrangement Shown)

TIMER MOTOR CAM

1/5 RPM, 15 SEC CAM NODE

sor and condenser auxiliaries stop and relay

TR is de-energized. TR N.C. contacts close

and timer motor (TM) is energized thru

switch contacts B-Bi and starts to run.

The TM timer will switch again to position

A-A2 and B-B2 after 4 min 45 sec elapse.

Thus, at least 4 min 45 sec must elapse after

a shutdown before the compressor can begin

its restart sequence, if the cooling thermo

stat is closed. A total of 5 min will elapse

before the compressor can restart. Each

compressor restart is preceded by 15 sec

operation of the condensing equipment.

This reverts to conditions at time 0 min 0 sec.

22

Page 23

INSTALLATION 06D,07D

#

Shut-Off Valves

The suction and discharge shut-off valves are

of the backseating type and have gage ports.

Frontseating the valve closes the refrigerant

line and opens the gage port to the pressure in

the compressor.

Backseating the valve shuts off pressure to the

gage port. To attach a gage or charging line to

the gage port, backseat the valve to prevent es

cape of refrigerant.

U se a square ratchet or box-end wrench to open or

close a valve. Do not use pliers or an adjustable

wrench. They are likely to round the valve stem.

Do not use excessive force to turn the stem. If

it turns hard, loosen the packing gland nut. If

the valve sticks on its seat, a sharp rap on the

wrench will usually break it loose.

Crankcase Heater

The crankcase heater is an internal cartridge-

type heater that is inserted in a blind hole in

the compressor bottom cover. It does not come

in direct contact with the oil. The heater draws

75 watts and is held in the hole by a clip. In

sure that the crankcase is held tightly in place

by the clip.

The heater is approved for wet locations.

The crankcase heater should be energized at

least 12 hours before start-up to insure that

the refrigerant is out of the oil.

Liquid Line Strainer-Drier

Install the liquid line strainer-drier in the liquid

refrigerant line. The drier should be installed

between the sight glass and the solenoid valve.

Flare Connections

Using too much force in tightening flare nuts

will damage the copper flare. Repeated tighten

ing will harden the copper. To soften copper

tubing, heat it to a dull red and allow it to cool.

Soldering and Brazing Piping to Valves

Disassemble the valve or wrap it in wet cloth

to prevent damage by heat.

Water Regulating Valves (Water-Cooled Units Only)

Install the water regulating valve with the cap

illary down and the arrow on the valve body in

the direction of water flow.

1. Backseat the liquid line shut-off valve.

2. Connect the capillary of the water regulating

valve to the 1 /4 inch flare connection on the

liquid line shut-off valve.

3. Open the shut-off valve one turn from the

backseated position. This allows refrigerant

pressure to reach the water regulating valve

and still leave the refrigerant line open.

NOTE: The water regulating valves for

R-12 and R-22 are not interchangeable.

Liquid Line Solenoid Valve (Field Supplied)

The puipose of this valve is to prevent dam

age to the compressor which would result from

flooding of the crankcase with refrigerant during

shutdown and to provide the pumpdown control

feature. Install this valve in the liquid refrig

erant line directly ahead of the expansion valve.

It must be installed in the vertical position and

wired as shown in the wiring diagrams.

Liquid Line Sight Glass

Install the liquid line sight glass between the

liquid line solenoid and expansion valve. Locate

the sight glass so that it is convenient to place

a light behind the glass when observing the liq

uid for proper charge.

Condenser Water Connections

When city water is used for condensing, the

condenser circuits are normally connected in

series.

When cooling tower water is used for condens

ing, the condenser circuits are normally con

nected in parallel. (See Fig. 18 for correct

connections.)

IMPORTANT: In the case of the 07DA210,

112, 215 WC Condensers, a plug in the upper

header must be removed to provide parallel

circuiting for cooling tower application. This

plug is accessible by removing the upper

header cap and unscrewing the Allen pipe

plug. (See Fig. 18 for proper wrench sizes.)

23

Page 24

06D,07D INSTALLATION

COOLING TOWER OR

CITY WATER

Carrier

The Halide Leak Detector

The halide leak detector in Fig. 19 consists of a

burner, needle valve, suction tube, and a chim

ney with a copper reaction plate. Some torches

use alcohol and others propane as fuel.

To use the leak detector:

1. Adjust the flame so the top of the flame cone

is level with or slightly above the chimney.

Place the end of the suction tube at the point

2.

to be tested. The tube pulls in a sample of

air to the burner where the refrigerant is

decomposed by reaction with the copper plate.

3. Observe color of the flame. Small leaks give

a greenish tint and large ones a vivid blue.

COOLING TOWER

COOLING TOWER

Fig. 18 - Water-Cooled Condensing Units

Condenser Water Connections

LEAK TEST THE SYSTEM

CITY WATER

CITY WATER

1. Charge the system to 40 psi with dry nitrogen

or carbon dioxide. Check all joints for large

leaks with soap solution.

2. Release the pressure and charge to 10 psi

with refrigerant.

3. Add dry nitrogen or carbon dioxide until the

pressure is 150 psi.

4. Check for leaks with a halide leak detector.

5. Repair leaks and purge system.

SUCTION

FEELER

TUBE

Fig. 19 - Halide Leak Detector

PRECAUTIONS: Do not use the compres

sor to build up pressure. If used to com

press air, overheating and damage may

result.

DO NOT USE OXYGEN TO BUILD UP PRES

SURE. Use a refrigerant or a dry stable gas

such as nitrogen or carbon dioxide instead.

DEHYDRATE THE SYSTEM

Preparation

Moisture in the system causes oil sludge and

corrosion. It is likely to freeze up the expansion

valve of a low temperature system. The best

means of dehydration is evacuation with a pump

especially built for this purpose.

24

#

Page 25

INSTALLATION 06D,07D

Before dehydrating a system make the following

preparations:

1. Obtain a pump that will produce a vacuum of

0.2 in. Hg absolute. Do not use the compres

sor as a vacuum pump. It is not designed for

such use and may be seriously damaged.

2. Pressure test the system to be sure it is

free of leaks.

3. Obtain a vacuum indicator similar to that

shown in Fig. 20 (available from Robinair

Manufacturing Corporation, Edgerton, Ohio).

4. Keep the ambient temperature above 60 F to

speed the evaporation of moisture.

TO

COMPRESSOR

TO VACUUM PUMP

SHUT-OFF VALVE

water in the tube. The temperature is related

to the absolute pressure in the tube. Table 5

gives the absolute pressures corresponding to

various temperatures.

Table 5 - Vapor Pressures of Water

Temp F Observed on

Vacuum Indicator

70

60 0.522

55 0 436

50 0 363

45 0.300

40

35

32 0.180

NOTE:

To determine the vacuum in inches of mercury,

subtract the absolute pressure from the barometer

reading.

Absolute Pressure

Inches of Mercury

0.739

0.248

0 204

Handle the vacuum indicator with care. It must

be vacuum tight to give a true reading. The top

seal of the indicator is not designed to support

a long run of connecting tubes. Faster the tubes

to supports to prevent damage.

Fig. 20 - Vacuum Indicator

Description and Use of the Vacuum Indicator

The vacuum indicator consists of a wet-bulb

thermometer in an insulated glass tube con

taining distilled water. Part of the tube is ex

posed so the thermometer can be read and the

water level checked. When the vacuum indicator

is connected to the vacuum pump suction line,

the thermometer reads the temperature of the

Use only distilled water in the indicator. Be

sure the wick is clean. Oil or dirt on the wick

causes erroneous readings.

To prevent loss of oil from the vacuum pump

and contamination of the indicator:

1. Install a shut-off valve in the suction line at

the vacuum pump.

2. Install a shut-off valve in the suction line at

the vacuum indicator (Fig. 20).

3. When shutting off the pump, close the indica

tor valve and the pump valve, and turn off

the pump in that sequence.

Procedure for Dehydrating the System

1. Connect the pump and vacuum indicator to

the system. Put a "jumper" line between

the high and low side so that the pump will

draw a vacuum on all portions of the system.

Open the compressor shut-off valves. Start

the pump.

2. Open the indicator connection shut-off valve

occasionally and take a reading. Keep the

25

Page 26

06D,07D INSTALLATION

Fig. 21 - Dehydration Pull-Down Curve

Carrier

valve open at least three minutes for each

reading. (Keep the valve closed at all other

times to decrease the amount of water the

pump must handle and hasten dehydration.)

When the pressure in the system drops to a

value corresponding to the vapor pressure of

the water in the indicator, the temperature

will start to drop. In the example shown in

Fig. 21, the ambient temperature and the

temperature of the water in the indicator

is 60 F. Starting at 60 F and 0 time, the

temperature of the water in the indicator

remains at 60 F until the pressure in the

system is pulled down to the pressure cor

responding to the saturation temperature of

the water (60 F). At this point the moisture

in the system will start to boil. The tem

perature drops slowly until the free mois

ture is removed, and then more rapidly until

the absorbed moisture is removed (35 F).

Dehydration is nearly completed at this point,

provided the ambient temperature remains

at 60 F or higher. If the ambient temperature

were lower than 60 F, ice might form before

moisture removal is complete.

3. Continue the dehydrating operation until the

vacuum indicator shows a reading of 35 F

which corresponds to a pressure of 0.204 in.

Hg absolute. This may take several hours. It

may be advantageous to run the pump all night.

4. With the pump still running, open the system

at a point farthest from the pump and admit

air thru a drier. Close system and repeat

Steps 2 and 3. Vapor in the system is thus

greatly diluted and almost completely re

moved by double dehydration.

5. After evacuation, turn off the pump suction

valve and break the vacuum by admitting

refrigerant.

6. Disconnect the pump and vacuum indicator.

CHECK REFRIGERANT CHARGE

After the system has been evacuated and dehy

drated, charge refrigerant in gas form into the

low side as follows:

1. Backseat the suction and discharge shut-off

valves. Install a gage in the discharge gage

port and turn the valve one turn from the

backseat position to allow pressure to reach

the gage.

2. Connect a refrigerant drum thru a drier and

tee connection with a compound gage, to the

suction gage port. Purge air from the lines

and tighten the connections.

3. Turn the suction shut-off valve a couple turns

from the backseat position and open the re

frigerant drum valve. Keep the refrigerant

drum in an upright position to prevent liquid

refrigerant from entering the compressor.

4. Start the compressor. See "INITIAL START

UP INSTRUCTIONS."

5. Check the refrigerant charge frequently while

charging, by observing the liquid line sight

glass. The refrigerant charge is sufficient

when flashing (bubbles) disappears. An al

ternate method of checking the charge is to

26

Page 27

INSTALLATION 06D,07D

crack open the liquid test cock. The charge

is sufficient if a mixture of liquid and vapor

comes from the test cock.

The sight glass method of checking the re

frigerant charge is more reliable, and should

be used whenever possible.

6. When the system is sufficiently charged, close

the valve to the refrigerant cylinder, back

seat the suction shut-off valve, disconnect

the charging line, plug the gage ports, and

recap the valve stems. If the pressure in

the cylinder drops to the level of the suction

pressure, all refrigerant can be drawn from

the cylinder by frontseating the suction shut

off valve and pulling a vacuum on the cylinder.

CAUTION: Be careful not to overcharge the sys

tem, Overcharging results in:

1. Higher discharge pressure due to excess liq

uid in the condenser. With water-cooled units

this means higher cooling water consumption.

2. Possible compressor damage,

3. Higher power consumption,

4. Increased flooding of refrigerant to the com

pressor during off-cycle if the expansion

valve is leaky.

To charge the system thru the liquid line, refer

to the Service Section of the Product Informa

tion Book.

3. Open the compressor discharge and suction

shut-off valves,

4. Open the liquid line valve at the receiver.

5. Open pressure line valve of the water reg

ulating valve.

6. Close the main power switch supplying cur

rent to the compressor starter,

7. Check the oil pressure. (See "Lubrication.")

8. Adjust the water regulating valve.

9. Check control settings.

10. Recheck the oil level in the crankcase.

11. Cap all valves tightly.

CHECKING OPERATIONS

When starting a newly Installed compressor, be

on the alert for any sign of trouble. Always in

stall suction and discharge pressure gages. The

water regulating valve on water-cooled units

may need adjustment.

Dual Pressurestat

A dual pressurestatis connected to both the high

side and low side to protect the compressor.

Settings are preset at the factory for use with

R-12 or R-22 as shown by the values in Table 6.

INITIAL START-UP INSTRUCTIONS

The compressor should be started up only by

a refrigeration mechanic who is familiar with

accepted operation practices for refrigeration

systems. Detailed instructions for checking and

adjusting the components will be found under

"CHECKING OPERATIONS."

Proceed as follows:

Water-Cooled Units

1, Check to see that the proper oil level appears

in the compressor sight glass, (A dipstick

must be used with two cylinder compres

sors.) See "Lubrication" under "CHECK

ING OPERATIONS,"

2, Open the main water supply valve and allow

water to reach the condenser.

Table 6 - Factory Pressurestat Settings (Psig)

High Pressure

Unit

07D Units 280 200

U6U Units 370 290

Cutout

Cut-in Cutout Cut-in

Low Pressure

36 67

36 67

The 07D condensing unit high pressurestat cut

out point is adjustable from 230-340 psig with

a fixed differential. The 06D compressor unit

high pressurestat cutout point is adjustable from

230-400 psig with a fixed differential. The low

pressurestat on all units have an adjustable cut

out from 20" vacuum to 70 psig and an adjust

able differential from 13-50psi. All adjustments

are made thru the back of the control box.

Check the high-pressure cutout by throttling

the condenser water on water-cooled units, or

27

Page 28

06D,07D INSTALLATION

blocking the air flow on air-cooled units, allow

ing the head pressure to rise gradually. The

cutout and cut-in pressures should be within

10- to 15-pounds of the values shown in Table 6.

If they are not, the pressurestat should be re

placed or adjusted if it is an adjustable type.

Check the low-pressure cutout by closing the

suction shut-off valve or by closing the liquid

line shut-off valve to allow the compressor to

pump down. The cut-in and cutout points may

be adjusted if necessary.

Lubrication

A properly adjusted compressor should run with

the crankcase warm to the touch. Check oil level

frequently to see that a sufficient amount of oil

remains in the crankcase. Check the oil pres

sure by looking thru the crankcase sight glass

at the oil pressure relief valve, (For 2 cylinder

compressors, see Fig, 22.) If oil is discharged

from the relief valve, pressure is adequate.

To check the oil charge on 2 cylinder 6D com

pressors, proceed as follows;

1. Pump down the compressor, turn off power

and close the shut-off valves.

2. Remove the suction manifold pressurestat

connection and half-union coupling.

3. Insert a dipstick in the hole and measure the

oil charge.

Below is a sketch of a simple dipstick that may

be used on 2 cylinder 6D compressors.

Table 7 - Factory Oil Charge (Pts)

Compressor Oil Charge

06DA109

06DA808 3-1/2

06DA013

06DA718 7

06DA518 7

06DA724 10

06DA337

06DA537

3-1/2

5

10

10

ADDING OIL

1. Pump down the compressor to 2-psi gage; stop

the compressor and close shut-off valves.

2. Add oil thru the low-side pressurestat con

nection or the oil fill plug on 6 cylinder

compressors.

NOTE: Be sure to connect the low-side

equipment and to size the piping, so oil

will return to the compressor under

all operating conditions.

Water Valve Adjustment (Water-Cooled Units Only)

Adjust the water regulating valve to the most

economical head pressure for the locality. Nor

mally this is between 120- and 140-psi for R-12

and between 200- and 230-psi for R-22,

Factory Oil Charge

The unit compressors are shipped with the oil

charges of PP33-2 oil shown in Table 7. Do not

assume that the charge is sufficient. Run the^

unit for 15- to 20-minutes until conditions have*

leveled off. Stop the compressor without pump

ing down and immediately check the oil level.

The oil level must be 1/3 to 2/3 of the way up

on the sight glass. If the oil level is low, add oil.

PRESSURESTAT BOSS TO END OF STICK

-------

MIN OIL LEVEL- 4^/16

NORMAL OIL LEVEL-3k4M AX OIL LEVEL - 3 ^''16 —

r

Fig. 22 - Oil Level Measurement 2 Cylinder

Compressors

07DA210,112,215 ELECTRICALLY OPERATED

CAPACITY CONTROL DEVICE

The Capacity Control Device is a cylinder head

bypass type, solenoid operated. Energizing the

control solenoid unloads a complete cylinder

bank and de-energizing the solenoid loads a

complete cylinder bank.

Controls to operate the solenoid valve are not

furnished with the 07DA210,112,215 condensing

units. They must be field furnished and may be

either temperature or pressure operated as per

job requirements.

Solenoid Valve Electrical Characteristics

208/220 volts 1 (/> 60 cycle 10 4 VA holding 41 6 VA inrush

220 volts 1 0 50 cycle 10 4 VA holding 41.6 VA inrush

115 volts 1 0 60 cycle 10.4 VA holding 41.6 VA inrush

28

Page 29

INSTALLATION 06D,07D

The control solenoids will be field wired to the

condensing unit control box (Fig. 16). All wiring

must comply with local codes.

3. REFRIGERANT PRESSURE WILL BE BLED TO THE SUCTION

MANIFOLD THROUGH THE OPENED GAS BYPASS PORT. A RE

DUCTION IN PRESSURE ON THE VALVE PISTON WILL TAKE

WITH THE SOLENOID VALVE ENERGIZED

THE SOLENOID VALVE STEM WILL OPEN

THE GAS BYPASS PORT.

PRESSURE FROM THE DISCHARGE

MANIFOLD PASSES THROUGH THE

STRAINER AND BLEED ORIFICE

TO THE BACK OF THE PISTON

BYPASS VALVE. UNLESS BLED

AWAY, THIS PRESSURE WOULD

TEND TO CLOSE THE PISTON

AGAINST THE PISTON SPRING

PRESSURE.

PLACE BECAUSE THE RATE OF BLEED THROUGH THE GAS BYPASS

PORT IS GREATER THAN THE RATE OF BLEED THROUGH THE

BLEED ORIFICE.

DISCHARGE PRESSURE IN THE

DlSCHARGE MANIFOLD WlLL

CLOSE THE DISCHARGE PISTON

CHECK VALVE ISOLATING THE

COMPRESSOR DISCHARGE MANIFOLD

FROM THE INDIVIDUAL CYLINDER

BANK MANIFOLD.

Figures 23 and 24 explain the operating sequence

of the 07DA210,112,215CapacityControlDevice.

WHEN THE PRESSURE BEHIND

THE PISTON HAS BEEN REDUCED

SUFFICIENTLY, THE VALVE

SPRING WILL FORCE THE VALVE

PISTON BACK. OPENING THE

GAS BYPASS FROM THE DIS

CHARGE MANIFOLD TO THE

SUCTION MANIFOLD.

-CYLINDER DISCHARGE VALVE

-VALVE PLATE

THE UNLOADED CYLINDER BANK

WILL CONTINUE TO OPERATE

FULLY UNLOADED UNTIL THE

SOLENOID VALVE CONTROL DE

VICE IS DE-ENERGIZED AND

THE GAS BYPASS PORT IS

CLOSED.

Fig. 23 - D7DA210,112,215 Compressor with Cylinder Head Unloading - Cylinder Bank Unloaded

2. WITH THE SOLENOID VALVE DE

ENERGIZED THE SOLENOID VALVE

STEM WILL CLOSE THE GAS

BYPASS PORT

1. DISCHARGE PRESSURE

BLEEDS FROM THE DIS

CHARGE MANIFOLD THROUGH

THE STRAINER AND BLEED

ORIFICE TO THE SOLENOID

VALVE STEM CHAMBER AND

THE BACK OF THE PISTON

BYPASS VALVE.

Dl SCHARGE

VALVE MANIFOLD

h. CYLINDER DISCHARGE PRES

SURE WILL FORCE OPEN THE

DISCHARGE PISTON CHECK

VALVE ASSEMBLY. REFRIG

ERANT GAS WlLL PASS INTO

THE COMPRESSOR DISCHARGE

MANIFOLD.

3. REFRIGERANT PRESSURE WILL

OVERCOME THE BYPASS VALVE

SPRING TENSION AND FORCE THE

PISTON FORWARD CLOSING THE

GAS BYPASS FROM THE DISCHARGE

MANIFOLD TO THE SUCTION

MANIFOLD.

CYLINDER DISCHARGE VALVE

-VALVE PLATE

.CYLINDER SUCTION

VALVE

5. THE LOADED CYLINDER

BANK WILL CONTINUE TO

OPERATE FULLY LOADED

UNTIL THE SOLENOID

VALVE CONTROL DEVICE

IS ENERGIZED AND THE

GAS BYPASS PORT IS

OPENED,

Fig. 24 - 07DA210,! 12,215 Compressor with Cylinder Head Unloading - Cylinder Bank Loaded

29

Page 30

06D,07D INSTALLATION

TURN CLOCKWISE TO INCREASE

ACTUATING PRESSURE}

COUNTERCLOCKWISE TO DECREASE

LOADING POINT MAY BE SET

ANYWHERE FROM 0-PSIG

TO 85-PSIG MAX.

Carrier

m

TT

DIFFERENTIAL ADJUSTMENT

REMOVE SEALING CAP AND

TURN CLOCKWISE TO INCREASE

DIFFERENTIAL j

COUNTERCLOCKWISE TO

DECREASE.

ONE TURN = 2-PSI

REPLACE AND TIGHTEN

SEALING CAP.

DIFFERENTIAL MAY BE

ADJUSTED FROM

6-PSI MIN. TO

22-PSI MAX.

(A) UNLOADED OPERATION

(B) LOADED OPERATION

Fig. 25 - Pressure Actuated Capacity Control System - 06D Compressors

30

Page 31

Carrier

INSTALLATION 06D,07D

Pressure Operated Capacity Control Valve Operation

This valve is self-contained in that no wiring

or external controls such as pressurestats or

thermostats are needed as on the solenoid ca

pacity control valve.

This valve is interchangeable with the sole

noid capacity control valve now used on the

6D compressors.

It is also interchangeable between the 06D and

06E compressors.

This valve is a self-actuated cylinder head by

pass type which is suction pressure operated.

The valve operation is such that the controlled

cylinders will not load up until a differential

of 25 psi between suction and discharge pres

sure is established.

There can be a control valve in each side bank

of the six cylinder compressors. Each of the

control valves will load or unload two cylinders

in a single bank of the compressor by allowing

the discharge gas to bypass to the suction side

thru the bypass port. The unloaded cylinders

then operate thru no pressure differential, thus

consuming very little power.

the compressor upon shutdown within 50 psi dif

ferential very quickly so that on start-up the

compressor will have very little head pressure

to start against. There is a possibility of short

cycling on pumpdown because of a short equal

ization time. Therefore, we recommend single

pumpout or liquid line solenoid drop with crank

case heaters.

The control load up or set point (Fig. 26) is ad

justable from -40 F (0-psig) to +50 F (85-psig)

and is set in the field for individual job require

ments. The set point adjustment is made by

turning clockwise to increase the control pres

sure (load up) and counterclockwise to decrease

the control pressure point.

SET POINT

ADJUSTMENT

When the suction pressure drops due to decrease

in load, the poppet valve will snap open, as shown

in Fig. 25A. The discharge gas behind the piston

will now bleed out to the suction manifold, re

ducing the pressure behind the bypass piston and

allowing the bypass piston spring to pull the pis

ton back against the valve body. The bypass pis

ton port will then open allowing discharge gas

to recirculate back to the suction manifold.

When the suction pressure is above the valve

set point, the poppet valve will be closed, as

shown in Fig. 25B. Discharge gas will now bleed

into the valve chamber. The pressure will then

overcome the bypass valve spring tension and

force the piston forward, sealing the bypass

port. The two cylinders controlled by this valve

will now run fully loaded.

The check valve in the valve plate will close

when the cylinder bank is unloaded, isolating the

individual cylinder bank from the discharge man

ifold. When the bank loads up, the discharge gas

pressure will force open the check valve, allow

ing the gas to pass into the discharge manifold.

Pumpdown control is NOT recommended when

using these valves because of a bleed in the

differential chamber. This device will equalize

DIFFERENTIAL

ADJUSTMENT

BYPASS

PISTON RING

DIFFERENTIAL SCREW

SEALING CAP

Fig. 26 - Capacity Control Valve

To Adjust - The set point head should be turned

clockwise down to the bottom stop. The coun

terclockwise turns can be determined by using

the curve in Fig. 27. If the desired load up point

is known, the number of turns can be picked

off the curve.

The differential adjustment (Fig. 26) will vary

the pressure difference between the cut-in and

cutout point from 6- to 22-psi. This differential

adjustment is made by removing the sealing

cap and turning the inside screw clockwise to

increase the differential and counterclockwise

to decrease the differential.

31

Page 32

06D,07D INSTALLATION

I 2 3 4 5 6 7 8 9 10 II 12

TURNS OUT FROM BOTTOM STOP-COUNTERCLOCKWISE

Fig. 27 - Control Set Point

234 56789 10

TURNS IN FROM BACKSTOP - CLOCKWISE

Fig. 28 - Differential Set Point

To Adjust - The differential screw should be

turned counterclockwise out to the back stop. If

the desired differential is known, the number of

turns can be determined from Fig, 28.

CHECK THE INSTALLATION

After the unit has been checked for leaks, put

into operation, and all adjustments made, check

the following:

1. Make sure the shipping bolts have been re

moved from the compressor.

07DA501005

2. See that the shut-off valves are backseated.

3, Tighten all shut-off valve packing nuts and

replace the caps.

4, Pick up all tools and clean up around the unit.

5. Make sure there is adequate air circulation

around the unit.

6. Instruct customer in the operation of the unit.

32

6-65

Loading...

Loading...