Page 1

Compressors and Condensing Units

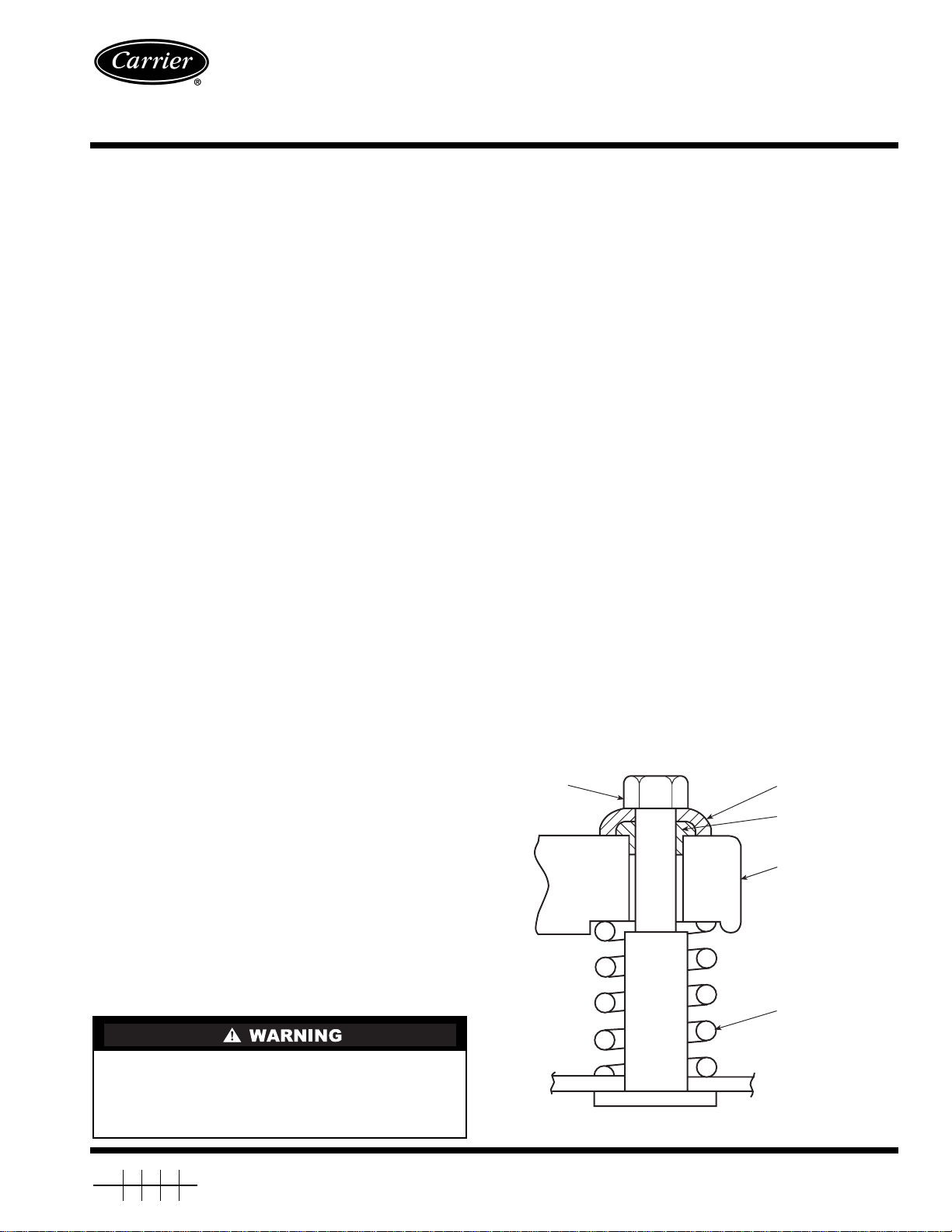

SELF-LOCKING

BOLT

SNUBBER FLANGED

WASHER

NEOPRENE

SNUBBER

COMPRESSOR FOOT

ISOLATION SPRING

Fig. 1 — Compressor Mounting

Installation, Start-Up and

Service Instructions

Hermetic, Water-Cooled

06E,07E

CONTENTS

SAFETY CONSIDERATIONS

INSTALLATION

Receive and Inspect Unit

Place Unit in Position

Check Compressor Mounting

Piping Connections

Electrical Connections

PRE-START-UP

Evacuate, Dehydrate, and Leak Test

Oil Charge

START-UP

Start Compressor

Timer Functions

SERVICE

Protection Devices

Compressor Thermal Protection

Capacity Control System

Removing, Inspecting and Replacing

Components

Lubrication System

Cylinder Heads

Pressure Relief Valve

Suction and Discharge Valve Plate Assembly

Terminal Plate Assembly

Compressor Running Gear Removal

Compressor Running Gear Replacement

Motor Removal

Motor Replacement

Motor Burnout (Clean-Up Procedure)

Condenser Maintenance

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-6

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7,8

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-18

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

. . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

. . . . . . . . . . . . . . . . . . . . . . 1

. . . . . . . . . . . . . . . . . . . . . . . . . 1

. . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

. . . . . . . . . . . . . . . . . . . . 1

. . . . . . . . . . . . . . . . . . . . . . . . . . . 2

. . . . . . . . . . . . . . 7

. . . . . . . . . . . . . . . . . 9

. . . . . . . . . . . . . . . . . . . . . . . . . 9

. . . . . . . . . . . . . . . . . . . . . . . . 14

. . . . . . . . . . . . 14

. . . . . . . . 15

. . . . . . . . . . . . 17

. . . . . . . . . . . . . . . . . . . . . . . . 17

Page

. . . 14

INSTALLATION

Receive and Inspect Unit —

damage. File claim with the shipping company if shipment is

damaged or parts are missing.

Local water conditions can cause excessive fouling or

pitting of condenser tubes. If such conditions are anticipated, a

water treatment analysis is recommended. Refer to Carrier

System Design Manual, Part 5, for general water conditioning

information.

Place Unit in Position —

well-ventilate d area. Instal l unit where i t will be war mer than

conditioned area. Position it to allow sufficient space for refrigerant and water connections and to service compressor. Allow

space at one end of condenser for tube cleaning or replacement.

Place unit so suction and discharge valves can be easily

reached and so oil level can be checked.

Make provision in piping layout to drain and vent condenser

if system is to be shut down in winter.

Level unit and bolt firmly to foundation.

Check Compressor Mounting —

sor mounting bolts and remove shipping blocks from under

compressor. Ti ghten all 4 bolts on compressor. Loosen each

bolt just enough until the flanged washer can be moved

sideways with finger pressure. See Fig. 1.

NOTE: Be sure that compressor floats freely on mounting

springs.

Inspect shipment for

Locate unit on floor in a

Loosen compres-

SAFETY CONSIDERATIONS

Installing, starting up, and servicing this equipment can be

hazardous due to system pressures, electrical components, and

equipment location (roofs, elevated structures, etc.). Only

trained, qualified installers and service mechanics should

install, start up, and service this equipment.

When working on the equipment, observe precautions in the

literature, tag s, stickers and labels at tached to the equipment,

and other safety precautions that apply. Follow all safety codes.

Wear safety glasses and work gloves. Use care when handling,

rigging, and setting bulky equipment.

Electrical shock can cause personal injury and even death.

Be sure power to equipment is shut off before installing or

servicing this equipment. There may be more than one disconnect. Tag disconnect(s) to alert others not to turn power

on until work is completed.

Manufacturer reserves the right to discontinue, or change at any time, specifications or designs without notice and without incurring obligations.

Book 2244

Tab 1b2a2b3a

PC 802 Catalog No. 530-607 Printed in U.S.A. Form 06/07E-2SI Pg 1 7-02 Replaces: 06/07E-1SI

Page 2

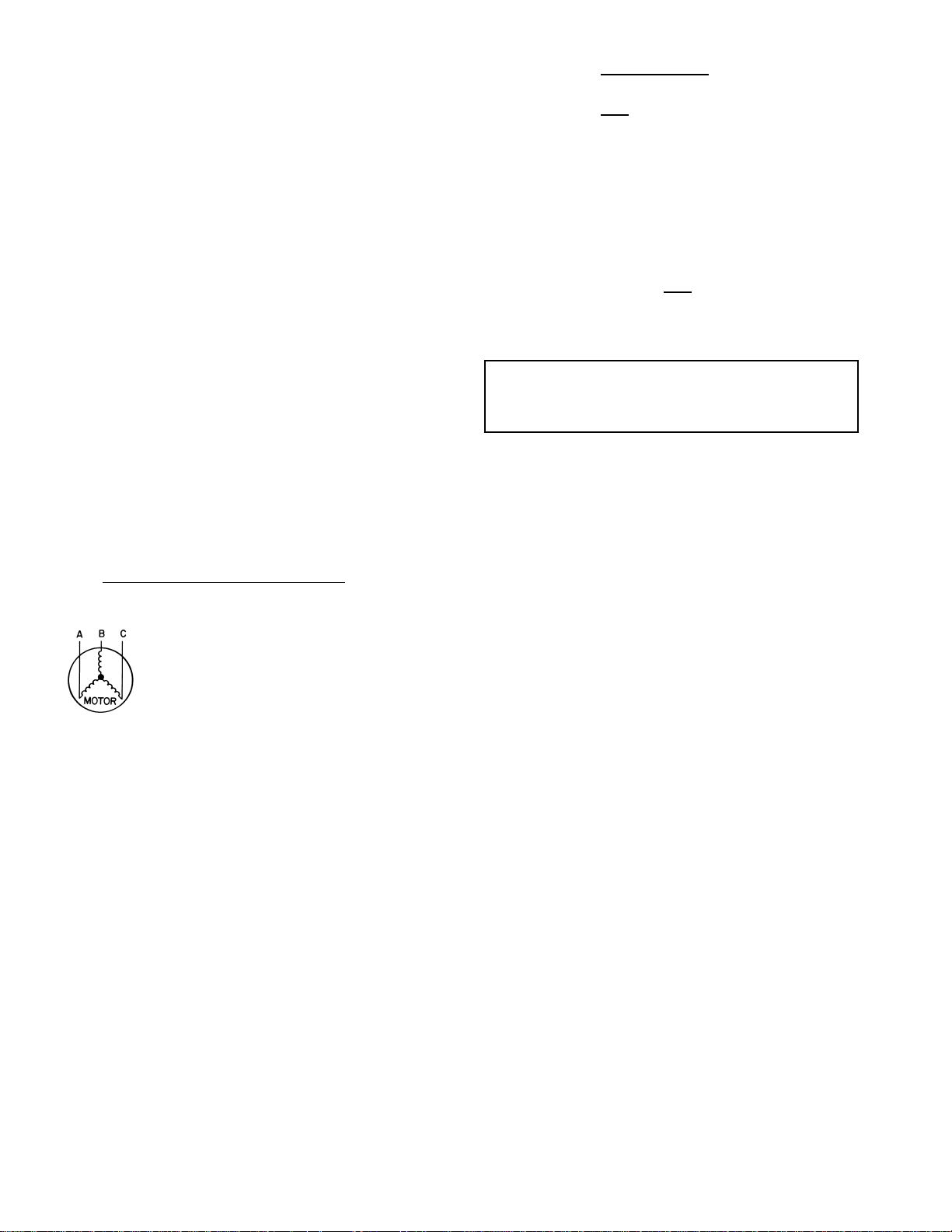

Piping Connections —

lines to connections indicated on condensing unit (Fig. 2).

Wat er leaving condenser should not be conne cted di rectly into

sewer lines; check local codes.

Attach refrigerant liquid and suction lines to condensing

unit (Fig. 2); suction and discharge lines to compressor unit

(Fig. 3 and 4). Discharge line muffler and check valve are

factory supplied with 06E compressor units. Install the muffler

as close to shutoff valve as possible and install the check valve

in the discharge line close to the muffler, on the downstream

side. When soldering or brazing piping to valves, disassemble

the valve or wrap it in wet cloth to prevent damage by heat.

Allow flexibility in suction line so compressor suction valve

may be moved aside for access to suction strainer.

A solenoid valve is necessary for single pumpout control

used on 06E and 07E units. Install the valve (field supplied) in

the liquid line, just before expansion valve. A filter drier of

adequate size should be installed in liquid line between condenser and solenoid valve.

Pressure relief valve located on top of condenser will open

to relieve excessive pressure, allowing refrigerant to escape.

Most local codes require piping from valve to outdoors.

Refer to Carrier System Design Manual for standard piping

techniques.

Attach water supply and return

Electrical Connections

UNBALANCED 3-PHASE SUPPLY VOLTAGE — Never

operate a motor where a phase imbalance in supply voltage

is greater than 2%. Use the following formula to determine

the % voltage imbalance:

% Voltage Imbalance =

100 x

Example: Supply voltage is 240-3-60

max voltage deviation from avg voltage

average voltage

AB = 243 volts

BC = 236 volts

AC = 238 volts

A verage Voltage =

Determine maximum deviation from average voltage:

(AB) 243 – 239 = 4 volts

(BC) 239 – 236 = 3 volts

(AC) 239 – 238 = 1 volt

Maximum deviation is 4 volts. Determine % voltage

imbalance:

% Voltage Imbalance = 100 x

This amount of phase imbalance is satisfactory as it is below

the maximum allowable 2%.

IMPORTANT: If the supply voltage phase imbalance is

more than 2%, contact your local electric utility company

immediately. Allowing the unit to operate with a voltage

imbalance in excess of 2% may void the warranty.

POWER SUPPLY — Field wiring must comply with local

and national codes. See Table 1.

Install a branch circuit fused disconnect of adequate size to

handle starting current. The disconnect must be within sight

from the unit and readily accessible, in compliance with

National Electrical Code (NEC), Section 440-14.

Line power is brought into control center through indicated

opening. Connect line power supply to terminal block TB1;

connect power leads to terminals L1, L2 and L3. Connect

control circuit power supply (115 volts) to terminals 1 and 15

on terminal block TB2. Refer to Fig. 5.

Wiring connections for field-supplied equipment are shown

on wiring diagram. See Fig. 6.

ACCESSORIES — Field-installed accessories for the 06E

and 07E units are control circuit transformer and gage

panel (3 gages). Refer to accessory literature for installation

instructions.

243 + 236 + 238

717

=

3

=

239 volts

3

4

= 1.7%

239

2

Page 3

8

16

16

16

16

/

5

5

9

16

/

9

9

121 5

2

/

1

34 27

4

/

3

3

2

4

/

3

3

/

9

16

/

34 26 1 21 5

4

/

2

4

/

16

/

5

9

16

/

9

121 5

2

/

1

34 27

4

/

3

2

4

/

3

/

5

5

9

16

/

9

9

121 5

2

/

1

34 27

4

/

3

3

2

4

/

3

3

/

9

16

/

34 26 1 21 5

4

/

2

4

/

DIMENSIONS (in.)

5

9

3

3

16

/

9

16

/

34 26 1 21 5

4

/

2

4

/

/

5

5

8

8

/

1

1

121 4

2

/

1

1

34 27

4

/

3

3

2

4

/

3

3

49

8

/

8

8

/

121 4

2

/

34 27

4

/

2

4

/

49

2

2

/

/

1

1

208/230 78 49

208/230 66 49

460, 575 66 43

A022

UNIT 07E VOLTS A B C D E F G H I

460, 575 78 43

B027

208/230 78 49

460, 575 78 43

B033

208/230 69

460, 575 69

D044

shooting and refrigerant charging, allow a minimum

1. For standard service practices, such as trouble-

NOTES:

clearance around the unit.

″

-6

′

2

removal is one condenser length at either end.

2. Recommended service space for condenser tube

wide

′

access aisle to and from the unit.

clearances.

3. For compressor removal, allow a minimum 3

4. Local codes or jurisdiction may prevail for unit

Fig. 2 — 07E Water-Cooled Condensing Units

3

Page 4

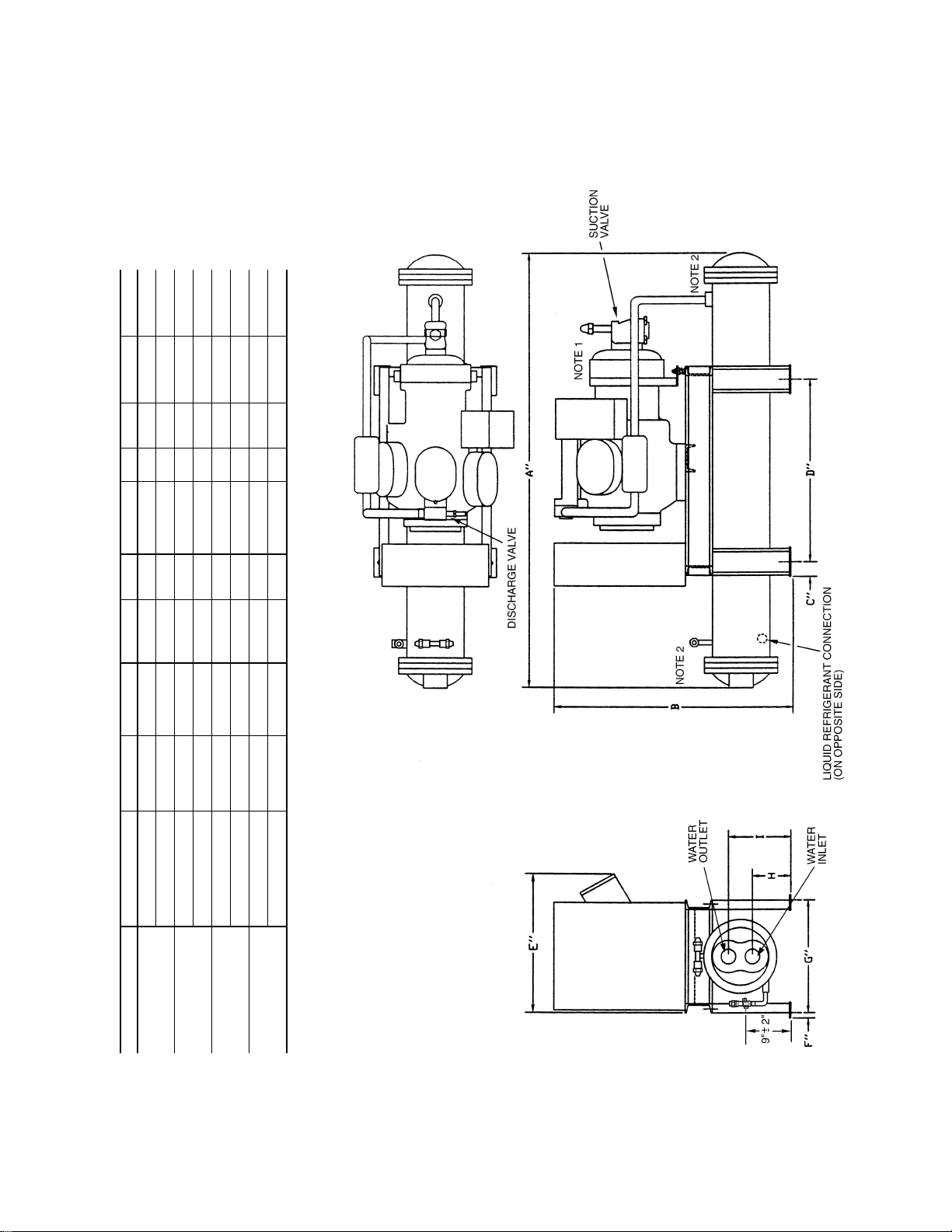

NOTES:

1. For standard service practices, such as troubleshooting

and refrigerant charging, allow a minimum 2′-6″ clearance

around the unit.

2. For compressor removal, allow a minimum 3′ wide access

aisle to and from the unit.

3. Local codes or jurisdiction may prevail for unit clearances.

DIMENSIONS (in.)

06E UNIT VOLTAGE A B C D E F G

V022

W027

W033

W044

208/230 48

460,575 481/

208/230 50

460,575 501/

208/230 50

460,575 501/

208/230 50

460,575 501/

1

/

4

4

1

/

4

4

1

/

4

4

1

/

4

4

35 367/

29 367/

35 367/

29 367/

35 367/

29 367/

35 367/

35 367/

8

8

8

8

8

8

8

8

11/

11/

11/

11/

11/

11/

11/

11/

2

2

2

2

2

2

2

2

271/

2

119

26 1 191/

271/

2

119

26 1 191/

271/

2

119

26 1 191/

271/

271/

2

2

119

119

Fig. 3 — 06E Hermetic Compressor Units

1

/

2

2

1

/

2

2

1

/

2

2

1

/

2

1

/

2

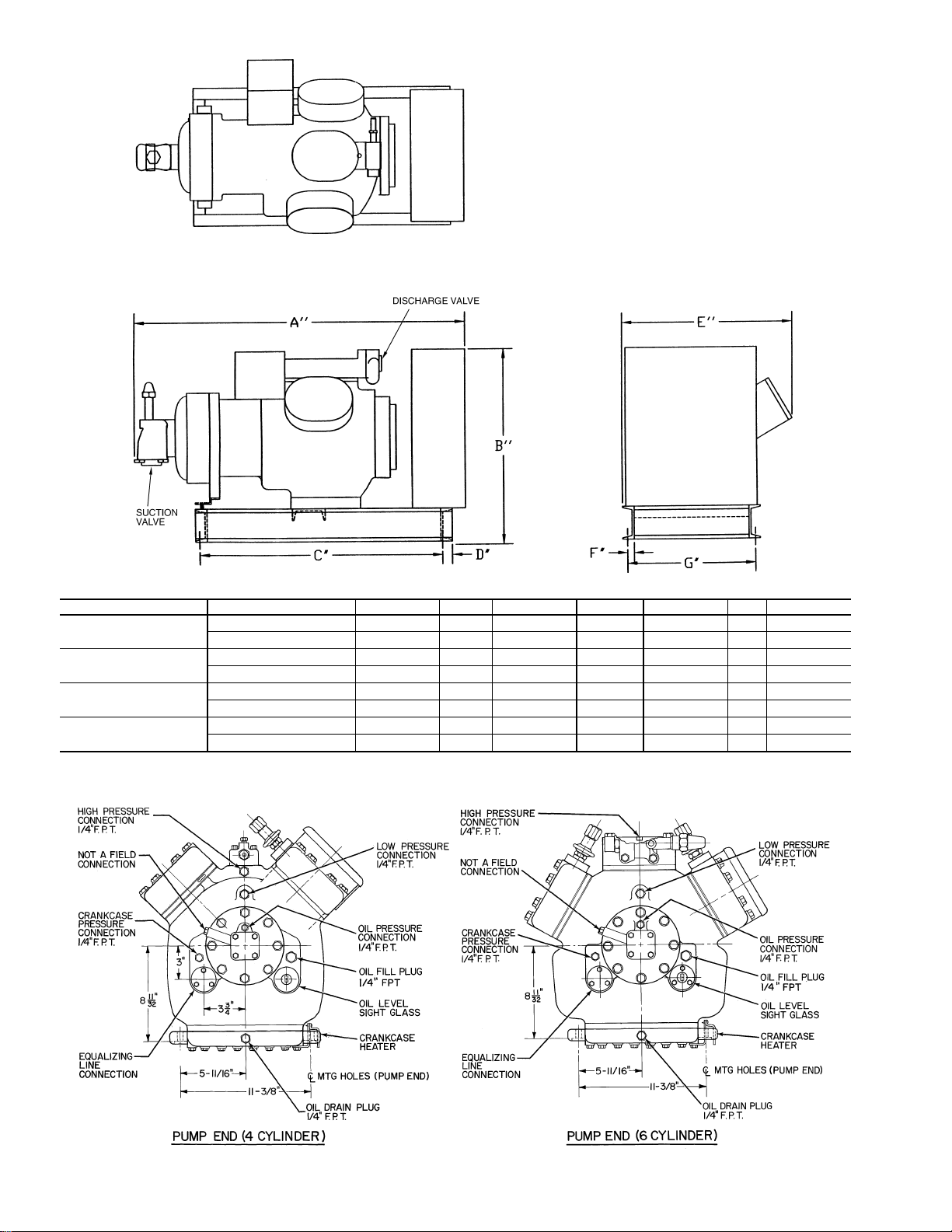

Fig. 4 — 06E Compressors

4

Page 5

Table 1 — Electrical Data — Compressor Motor With Circuit Breaker

COMPRESSOR MOTOR DATA CIRCUIT BREAKER

Compressor

Par t Num ber

06E*

250

265

A

275

299

LRA —

MHA —

MTA —

PW —

RLA —

XL —

*Refer to physical data table to match compressor with correct com-

pressor or water-cooled condensing unit.

NOTES:

1. Compressor MTA and RLA values are maximum figures.

2. LRA values for PW second winding =

3. 3-Pole XL circuit breakers shown, other 3-Pole XL alternates

and 6-Pole PW breakers available. Terminal lugs for circuit

breakers available in package 06EA660152 (not shown).

Vo lt a ge

(3 Ph - 60 Hz)

208/230

575 45 36 120 72 2.2 XA461 33 38 124 27.1

460 54 44 173 104 1.3 XA424 42 49 175 35.0

208/230

575 57 46 164 98 1.6 XA469 46 53 164 37.9

460 70 56 223 134 1.1 XA426 55 643 210 45.7

208/230

575 65 52 176 106 1.3 XA430 50 58 168 41.4

460 84 68 253 152 0.9 XA425 63 73 210 52.1

208/230

575 94 75 276 165 1.0 XA551 74 85 236 60.7

460 118 95 345 207 0.58 XA550 92 106 295 75.7

LEGEND

Locked Rotor Amps

Must Hold Amps

Must-Trip Amps

Part-Winding (Start)

Rated Load Amps

Across-the-Line (Start)

Maximum

Hp

Must Trip

Amps

108 87 345 207 0.32 HH83XB336 91 104 350 74.3

20

140 112 446 268 0.27 HH83XC509 110 127 420 90.7

25

168 135 506 304 0.22 HH83XC539 142 163 507 116.4

30

236 189 690 414 0.15 HH83XC537 187 215 636 153.6

40

Maximum

RLA

1

/2 the LRA – XL value.

LRA-XL

LRA-PW

(first

winding)

Motor

Winding

Resistance

(Ohms)

4. Recommended RLA value shown is determined by: circuit

breaker must trip value ÷ 1.40. Use this recommended (and

minimum) RLA value to determine nameplate stamping, minimum contactor sizing, and wire sizing. RECOMMENDED RLA

FOR 06E COMPRESSORS EQUALS: MUST-TRIP (MTA) OF

CARLYLE APPROVED OVERCURRENT DEVICE BEING

USED ÷ 1.40

5. Compressor operating amps at any specific condition can only

be determined from a performance curve.

6. Ohm values for resistance are approximate and shown for reference purposes only. Motors from different vendors and

motors of different efficiencies can differ up to 15% from data

shown.

7. Electrical data for compressor part numbers 06ER, 06EM and

50 Hz models (not shown) are available from Carrier Sales

Representative.

Recommended

Circuit Breaker

Part No.

MHA MTA LRA

Recommended

RLA

C1 —

C2 —

CCB —

CHR —

CR —

FU —

GND —

HPS —

LPS —

NEC —

NEMA —

OPS —

POR —

TB —

TDR —

TM —

TR —

LEGEND

Compressor Contactor

Compressor Contactor (PW)

Compressor Circuit Breaker

Crankcase Heater Relay

Control Relay

Fuse

Ground

High-Pressure Switch

Low-Pressure Switch

National Electrical Code

National Electrical

Manufacturer’s Association

Oil Pressure Switch

Pumpout Relay

Terminal Block

Time Delay Relay

Timer Motor

Timer Relay

Fig. 5 — Component Location

5

Page 6

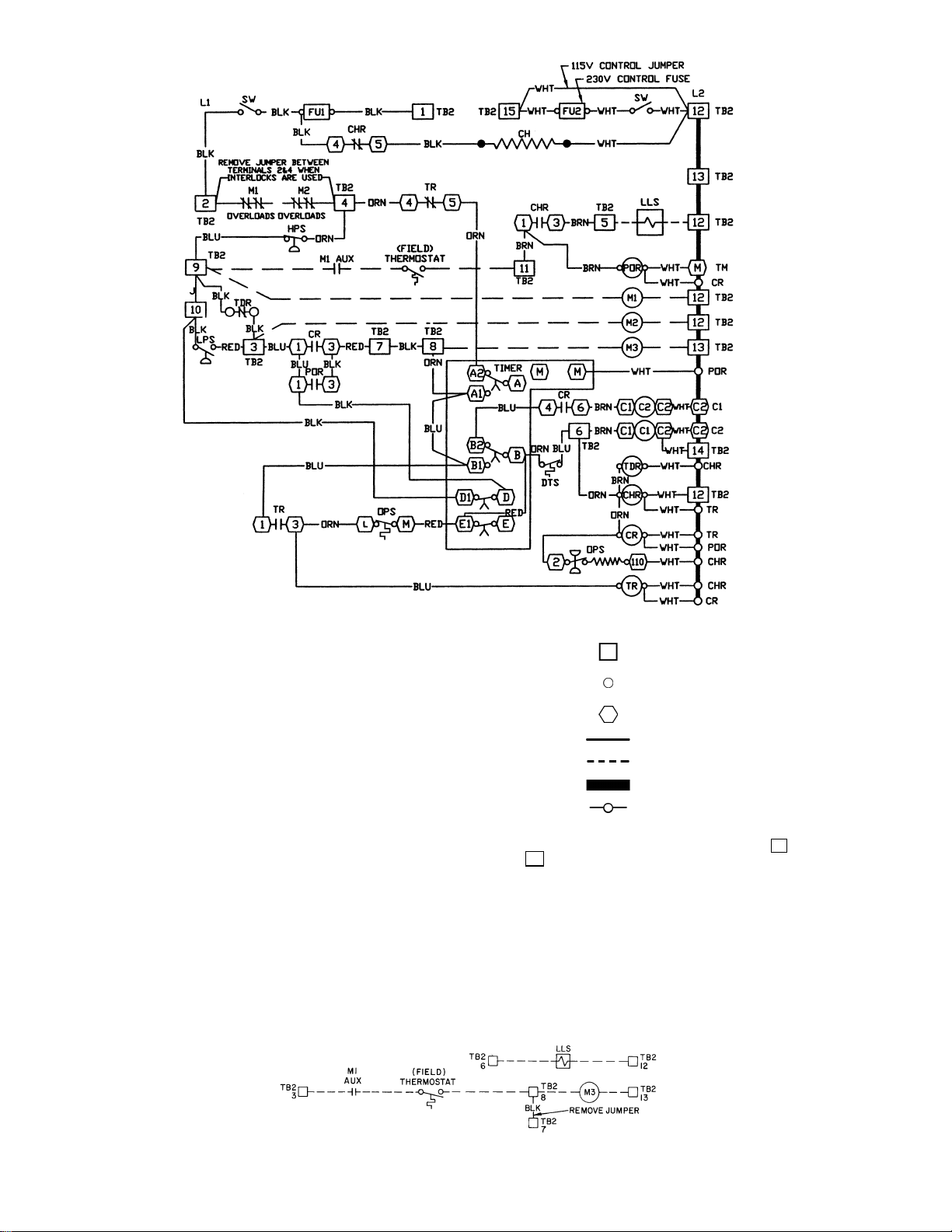

AUX —

C—

C1 —

C2 —

CH —

CHR —

CR —

DTS —

DX —

FU —

HPS —

LLS —

LPS —

Auxiliary

Compressor Contactor

Compressor Contactor

(XL start and first step of PW start)

Compressor Contactor

(PW second step)

Crankcase Heater

Crankcase Heater Relay

Control Relay

Discharge Temperature Sensor

Direct Expansion

Fuse

High-Pressure Switch

Liquid Line Solenoid Valve

Low-Pressure Switch

M1 —

M2 —

M3 —

NEC —

OPS —

POR —

PW —

SW —

TB —

TDR —

TM —

TR —

XL —

LEGEND

Evaporator Fan or

Chilled Water Pump

Cooling Tower Pump

Cooling Tower Fan

National Electrical Code

Oil-Pressure Switch

Pumpout Relay

Par t Wind

Start-Stop-Reset Switch

Terminal Block

Time Delay Relay

Timer Motor

Timer Relay

Across-the-Line

Terminal Block Connector

Unmarked Terminal

Marked Terminal

Factory Wiring

Field Control Wiring

To indicate common potential only;

not to represent wiring.

Splice

NOTES:

1. Factory wiring is in compliance with NEC. Any field modifications

or additions must be in compliance with all applicable codes. Use

copper, copper-clad aluminum for field power supply only.

2. Field power supply wiring must be 75 C minimum.

3. Compressor thermally protected. Three-phase motors are protected against primary single-phasing condition.

4. Pilot duty control must be field supplied. Minimum contact rating

must be 25 va.

5. 60 Hz units have 120 volt control circuit. 50 Hz units have 230 volt

control circuit. A separate source of supply at the correct voltage

must be field supplied through a fused disconnect device with a

Fig. 6 — Control Circuit Wiring for 06E/07E Units

maximum rating of 15 A to TB2 connections (Hot Side)

and (Neutral).

6. Open control circuit disconnect switch for servicing only. Discon-

7. A transformer of the following rating may be field supplied for

8. Transformer must be fused and grounded per applicable codes.

9. If any of the original wiring furnished must be replaced, it must be

10. Wiring is shown for single pumpout control. Single pumpout

L2

nect must remain closed for crankcase heater to operate.

60 Hz units: 350 va.

replaced with 90 C wire or its equivalent.

control should not be used on direct-expansion (DX) cooler applications (see lower diagram for wiring when applied with DX

cooler).

L1

6

Page 7

PRE-START-UP

When charging, or when removing charge, circulate water

through water-cooled condenser and cooler continuously to

prevent freezing. Freezing damage is considered abuse and

is not covered by Carrier warranty.

Evacuate, Dehydrate, and Leak Test —

refrigerant system must be evacuated, dehydrated and leak tested by methods described in Carrier Standard Service Techniques Manual, Chapter 1, Section 1-6 and 1-7. Use sight glass

method to charge system. See Section 1-8 of Service Techniques Manual fo r det ails.

Charge the system to a clear sight glass while holding

saturated condensing pressure constant at 125 F (air-cooled

systems) or 105 F (water-cooled systems). Add additional

refrigerant to fill condenser subcooler coils for air-cooled

applications.

Oil Charge (See Tables 2 and 3) —

factory charged with oil. If oil is visible in sight glass, start

compressor. Observe level and add oil, if required, to bring

level in crankcase

1

/8 to 3/8 of bull’s-eye during steady

The entire

All units are

operation. To add or remove oil, see Carrier Standard Service

T echniques Manual, Chapter 1, Refrigerants.

IMPORTANT: Use only Carrier approved compressor oil.

Do not reuse oil that has been drained and do not use oil

that has been exposed to atmosphere.

Approved compressor oils*:

Petroleum Specialties, Inc. . . . . . . . . . . . . . . . . . . . . . Cryol 150

T exaco, Inc. . . . . . . . . . . . . . . . . . . . . . . . . . . . . Capella WR-32

Witco Chemical Co.. . . . . . . . . . . . . . . . . . . . . . . . . Suniso 3GS

*Approved for R-12, R-22, R-502 refrigerants. Contact Carrier

Factory Sales Representative for other refrigerants.

TO ADD OIL — Close suction shutoff valve and pump down

crankcase to 2 psig. (Low-pressure cut-out must be bypassed.)

W ait a few minutes and repeat as needed until pressure remains

at 2 psig. Remove oil fill plug above bull’s-eye, add oil through

plug hole and replace plug. Run compressor for about 20 minutes and check the oil level.

TO RE MOVE OIL — Pump down compressor to 2 psig.

Loosen the

1

/4-in. pipe plug in compressor base and allow the

oil to seep out past the threads of the plug. The crankcase will

be under slight pressure. Be car eful not to re move the plug; the

entire oil char ge may be lost.

Table 2 — 06E Physical Data

UNIT 06E V022 W027 W033 W044

OPERATING WEIGHT (lb)

REFRIGERANT

COMPRESSOR — 06E*

Cylinders

Bore (in.)

Stroke (in.)

Displacement (cfm at 1750 rpm)

Maximum Rpm

Oil Charge (pt)

High Side Maximum Pressure (psi)

Low Side Maximum Pressure (psi)

CONNECTIONS (in.)

Suction Valve (ODF)

Discharge Valve (ODF)

LEGEND

ODF —

*Compressors listed are for R-22 applications. For R-134a an 06EM compressor

is standard offering; an 06ER compressor is standard for R-507/404A. Factory

compressor substitutes may be made. Contact Carrier Sales Representative.

Outside Diameter Female

600 640 650 670

R-134a, R-22, R-507/404A

A250 A265 A275 A299

46 6 6

11

2

/

16

3

2

/

16

50 68 75 99

14 19 19 19

5

1

/

8

1

1

/

8

211/

16

22

450 PSIG

245 PSIG

15/

8

13/

8

1750

211/

21/

13/

16

3

/

16

8

8

211/

27/

21/

15/

16

8

8

8

7

Page 8

Table 3 — 07E Physical Data

Fig. 7 — Timer Cycle

UNIT 07E A022 B027 B033 D044

OPERATING WEIGHT (lb)

REFRIGERANT

COMPRESSOR — 06E*

Cylinders

Bore (in.)

Stroke (in.)

Displacement (cfm at 1750 rpm)

Maximum Rpm

Oil Charge (pt)

High Side Maximum Pressure (psi)

Low Side Maximum Pressure (psi)

CONDENSER (Shell and Tube)† Part Number

Refrigerant Storage

Capacity (lb)

Min Refrigerant Operating

Charge (lb)

REFRIGERANT CONNECTION (in. ODF)

Inlet

Outlet

WATER CONNECTION (in. FPT)

Inlet/Outlet

LEGEND

FPT —

ODF —

*Compressor listed is the standard compressor for R-22, air conditioning duty. An 06ER compressor is standard equipment

for low temperature (R-507/404A) applications. For medium temperature (R-134a) applications, an 06EM compressor is

standard. Factory substitutions may be made. Contact Carrier Sales Representative.

†The condenser listed is for R-22, air conditioning duty and may change based on the application. Maximum condenser

operating pressure: 350 psi refrigerant side, 150 psi water side.

Female Pipe Thread

Outside Diameter, Female

R-134a

R-22

R-507/404A

1090 1200 1250 1410

R-134a, R-22, R-507/404A

A250 A265 A275 A299

4666

11

2

/

16

3

2

/

16

50 68 75 99

14 19 19 19

P701-0840AX P701-0850AX P701-0850AX P701-1065AX

71.3 85.90 85.90 112.70

15.4 18.67 18.67 23.77

70.4 84.80 84.80 111.20

15.1 18.30 18.30 23.30

61.1 73.60 73.60 96.50

15.1 18.30 18.30 23.30

1

2

/

8

3

1

/

8

1

2

/

2

211/

16

22

1750

21/

8

13/

8

21/

2

450

245

211/

3

21/

13/

21/

16

/

16

8

8

2

211/

27/

25/

15/

16

8

8

8

3

START-UP

Energize crankcase heater at least 24 hours prior to start-up.

Check to see that oil level is approximately

compressor sight glass.

Open water supply valve and allow water to reach condenser. (T urn condenser fan on when the compressor unit is applied

with air-cooled condenser.)

Backseat the compressor suction and discharge shutoff

valves; open liquid line valve at receiver.

Start evaporator fan or chilled water pump.

Do not attempt start-up with terminal cover removed from

compressor. Bodily injury or death may result from

explosion and/or fire if power is supplied to compressor

with the terminal cover removed or unsecured. See

warning label on terminal cover.

Start Compressor —

Push the control circuit STARTSTOP-RESET switch to START. The timer motor starts

immediately. Depending on the position of the timer, the

compressor start is delayed for 12 seconds to a pproximately

8 minutes. Check oil pressure after compressor has run a few

minutes; the pressure should be 12 to 18 psi above the suction

pressure. After about 20 minutes of operation, stop the compressor. Allow it to be idle for about 5 minutes, then observe

the oil leve l in the sight glass. Refer to the Carrier Standard

Service Techniques Manual, Chapter 1, Section 1-11, for

adding oil. The proper oil level for the 06E compressor is

approximately

1

/3 up on sight glass.

1

/3 up on the

Timer Functions

(See Fig. 7 — Timer Cycle.)

1. Switch A (contacts A-A1 and A-A2) provides Time

Guard® function. Start of compressor is delayed approximately 5.5 minutes after shutoff. The minimum time

between starts of compressor is 8 minutes.

2. Switch B (contacts B-B1 and B-B2) starts compressor

and deenergizes the crankcase heater. These contacts also

provide one-second time delay for part-winding start.

3. Switch E (contacts E-E1) provides approximately

40-second bypass of oil pressure switch (OPS) at start-up.

Compressor will shut off if sufficient oil pressure does

not build up.

4. Switch D (contacts D-D1) bypasses the low-pressure

switch (LPS) for 2.5 minutes at start-up for winter start

control.

8

Page 9

SERVICE

CONTROL

SET POINT

ADJUSTMENT

NUT

VALVE BODY

SEALING CAP

(COVERS PRESSURE DIFFERENTIAL

ADJUSTMENT SCREW)

Fig. 9 — Capacity Control Valve

TIMER

CONTACTS

BLU

ORN

B2

B1

CR

46

RED

C1C2C2

DTS

BLU

YEL

TB2

6

C2

C1

B

LEGEND

Fig. 8 — Discharge Temperature Sensor (DTS)

C—

Compressor Contactor

CR —

Control Relay

DTS —

Discharge Temperature Sensor

TB —

Terminal Block

•

Splice (in compressor junction box)

Protection Devices

HIGH-PRESSURE SWITCH — Check by throttling condenser water or blocking airflow on air-cooled units, allowing

head pressure to rise gradually. Check discharge pressure

constantly throughout procedure. Compressor should shut off

within 10 psi of values shown in Table 4.

LOW-PRESSURE SW ITCH — Check by slowly closing

suction shutoff valve or by completely closing liquid line

shutoff valve. A decrease of suction pressure will follow.

Compressor should shut off within 4 psi of values shown in

T able 4.

OIL PRESSURE SWITCH (OPS) — The oil pressure switch

protects against damage from loss of oil or loss of oil pressure

during unit start-up. If the oil pressure differential sensed by the

OPS is 6 psig or less on unit s tart-up, the switch remains closed

and the OPS heater is energized.

The switch time delay is approximately 45 seconds. If after

45 seconds the oil pressure differential sensed by the OPS is

less than 11 psig, the heater remains energized. The OPS

temperature actuated switch then opens and the compressor is

deenergized. If the differential reaches 11 psig, the OPS opens

and deenergizes the heater and the system operates normally.

See Table 4.

IMPORTANT: If the oil pressure switch caus es unit lockout, determine and correct the cause of the lockout (such as

loss of compressor oil or flooded compressor) before

restarting the unit. Failure to correct the cause of OPS

lockout may constitute abuse. Equipment failure due to

abuse is not covered by warranty.

exceeds 295 ± 5 F, the sensor contacts open and the compressor

shuts down. The sensor reset temperature is 235 F minimum.

See Fig. 8 for control circuit connections.

Capacity Control System

CAPACITY CONTROL VALVE (Fig. 9) — Valve is controlled by suction pressure and actuated by discharge pressure.

Each valve controls 2 cylinders. On start-up, controlled

cylinders do not load up until differential between suction and

discharge pressures is approximately 25 psi. See T able 5.

IMPORTANT: Do not use automatic pumpdown control

on 06E,07E units equipped with unloader valves. Use

single pumpout or solenoid drop (minimum protection)

control.

CAPACITY CONTROL VALVE ADJUSTMENTS

Control Set Point (Cylinder Load Point)

0 to 86 psig. Pressure differential between cylinder load-up

point and cylinder unload point is adjustable from 6 psi

to 16 psi.

— Adjustable f rom

To restart the unit, push the OPS reset button and then push

the control circuit switch on the unit control box to O FF and

then to ON.

NOTES:

1. Values for the high- and low-pressure switches based on R-22.

2. Values for oil pressure are above operating suction pressure

Table 4 — Factory Switch Settings

PRESSURE CHANGE AFFECTING

SWITCH TYPE

High Pressure

Low Pressure

Oil Pressure

For other refrigerants, reset to pressure corresponding to saturation temperatures indicated by the listed pressures.

(pressure differential between suction and discharge pressures

of oil pump).

SWITCH POSITION (psig)

Closed Open

210 (±10) 290 (±10)

70 (±4) 60 (±4)

611

TIME GUARD® CONTROL — The Time Guard control

protects against short cycling. See Start Compressor.

CRANKCASE HEATER — The crankcase heater prevents

absorption of liquid refrigerant by oil in crankcase during brief

or extended shutdown periods. Source of 115-volt power is the

auxiliary control power, independent of the main unit power.

This assures compressor protection even when main unit

power disconnect switch is off.

IMPORTANT: Never open any switch or disconnect that

will deenergize the crankcase heater unless unit is being

serviced or is to be shut down for a prolonged period. After

a prolonged shutdown or a service job, energize the crankcase heater for 24 hours before starting the compressor.

Compressor Thermal Protection —

temperature sensor, installed in one cylinder head, detects an

overtemperature condition. If the discharge temperature

A discharge

9

Page 10

To Regulate Control Set Point

— Turn adjustment nut

clockwise to its bottom stop. In this position, set point is

86 psig. Control set point is then regulated to desired pressure

by turning adjustment nut counterclockwise. Each full turn

decreases set point by approximately 7.2 psi. Approximately

12 turns counterclockwise lowers the control set point to

0 psig. See T able 5.

Table 5 — Capacity Control

% Full Load Capacity

UNIT 06E,07E

ALL 4 CYLINDER

MODELS

ALL 6 CYLINDER

MODELS

NOTE: Capacity control valve factory settings for 4-cylinder units

are: 59 psig control set point (cylinder load point), 10 psi differential

(59 psig cylinder unload point). Settings for 6-cylinder units are: left

cylinder bank control set point is 70 psig, differential is 10 psi; right

cylinder bank control set point is 68 psig, differential is 10 psi.

NO. OF

CONTR

CYL

24— 2 —

464— 2

100 67 49 32

% Full Load kW

100 73 57 46

Number of Active Cylinders

Pressure Differential Adjustment — Turn differential adjusting screw counterclockwise to its back-stop position. In this

position, differential is 6 psi. Pressure differential is set by

turning adjusting screw clockwise. Each full turn increases

pressure differential by approximately 0.8 psi. Approximately

10 turns increases differential to 16 psi.

SUCTION CUTOFF UNLOADER OPERATION — The capacity control valve shown in Fig. 9 is the pressure operated

type. Refer to Fig. 10 and the following description for val ve

operation.

Loaded

— When suction pressure rises high enough to overcome control set point spring, the diaphragm snaps to the left

and relieves pressure against the poppet valve. The drive spring

moves poppet valve to the left and it seats in the closed

position. See Fig. 10.

With poppet valve closed, discharge gas is directed into the

unloader-piston chamber and pressure builds up against the

piston. When pressure against unloader piston is high enough

to overcome the unloader valve spring, piston moves valve to

the right, opening suction port. Suction gas can now be drawn

into the cylinders and the bank is running fully loaded.

Unloaded

— As suction pressure drops below set point, control spring expands, snapping diaphragm to right. This forces

poppet valve open and allows gas from di scharge manifold to

vent thru base of control valve to suction side. Loss of full

discharge pressure against unloader piston allows unloader

valve spring to move valve left to closed position. The suction

port is blocked, isolating the cylinder bank from the suction

manifold. The cylinder bank is now unloaded. See Fig. 10.

Service Replacement Compressors

— These compressors are

not equipped with capacity control valves. One side-bank

cylinder head is a bypass unloading type, plugged with a

spring-loaded piston plug assembly. As received, the compressor will run fully loaded.

Replacing Suction Cutoff Unloading Heads

— When the

original compressor is equipped with suction cutoff unloading

head(s), the complete cylinder head and control valve assemblies must be transferred to the service (replacement) compressor. See Fig. 10 for typical suction cutoff installation. Where

one step of unloading is required, remove the bypass-type

unloader head and valve plate assembly from replacement

compressor (cylinder head next to terminal box). Remove

check valve from the valve plate. Using new gasket s, reinstall

the valve plate assembly and install the suction cutoff head

from the original compressor. Torque the cylinder head

holddown bolts to 90 to 100 lb-ft. For 6-cylinder 2-step suction

cutoff unloading, transfer the second unloading head and

control valve from the original compressor to the re placement

compressor, using the valve plate assembly from the replacement compressor. Use new gaskets.

Be sure the new cylinder head gasket is the one shown in

Fig. 11, Item 33, when installing suction cutoff unloader head.

Install parts removed from replacement compressor on

original compressor and seal all openings to prevent

contamination.

Removing, Inspecting and Replacing

Components (Fig. 11)

Do not remove the compressor terminal box cover until all

electrical power is disconnected and pressure is relieved.

Terminal pins may blow out causing injuries, death, and/or

fire.

SERVICE NOTES

1. All compressors have interchangeable valve plate assemblies, unloader valves and oil pump bearing head

assemblies. For replacement items use Carrier Specified

Parts.

2. Before compressor is opened, the refrigerant must be

removed from it by the Pumpdown method:

a. Start compressor, close suction shutoff valve, and

reduce crankcase pressure to 2 psig. (Bypass low

pressurestat with a jumper.)

b. Stop compressor and isolate from system by

closing discharge shutoff valve.

c. Bleed any residual refrigerant. Drain oil if

necessary.

3. After disassembly, clean all parts with solvent. Use

mineral spirits, white gasoline or naphtha.

4. Before assembly, coat all parts with compressor oil and

clean and inspect all gasket surfaces. R eplace all gaskets

with new factory-made gaskets. See Table 6 for torque

values.

5. After reassembly, evacuate compressor and open suction

and discharge valves. Restart compressor and adjust

refrigerant charge.

10

Page 11

NOTE: Pressure-operated control valve shown. A solenoid-operated control valve can also be used.

Fig. 10 — Suction Cutoff Unloader Operation

11

Page 12

3

4

5

6

1

2

789

14 15 16 17

18

19 10

20

21 23 22

31

32

33

31

34

35

36

37

38

40

41

29

30

32

39

31

32

33

38

26

25

24

41

Stator (Compressor Motor)

1—

Rotor (Compressor Motor)

2—

Motor Key

3—

Rotor Plate Washer

4—

Rotor Lock Washer

5—

Rotor Lock Bolt

6—

Motor Lock Bushing

7—

Roll Pin

8—

Acorn Nut and Gasket

9—

Compressor Crankcase

10 —

Bottom Cover Plate

11 —

Crankcase Oil Filter Screen

12 —

Pump End Bearing Head Assembly

13 —

Motor End Cover

14 —

Oil Sight Glass Assembly

15 —

Oil Sight Glass O-Ring Gasket

16 —

28 27

Oil Sight Glass Screw

17 —

Oil Sight Glass Lock Washer

18 —

Pipe Plug (Hex Head)

19 —

Crankshaft

20 —

Ring Spacer (when required)

21 —

Bearing Washer

22 —

Connecting Rod and Piston Assembly

23 —

Connecting Rod and Cap Assembly

24 —

Piston, Piston Pin and Retaining Ring

25 —

Package

Piston Rings (Oil and Compression)

26 —

Terminal Plate Assembly

27 —

Terminal Bolt Assembly

28 —

Ter m in al B ox

29 —

Terminal Box Mounting Screw (4)

30 —

Suction Valve

31 —

LEGEND

13

11

12

Fig. 11 — Compressor Components (06E Shown)

12

Valve Plate Assembly (includes dis-

32 —

charge valves)

Cylinder Head Gasket

33 —

Cap Screw, Valve Stop

34 —

Valve Stop Support

35 —

Discharge Valve Stop

36 —

Discharge Valve

37 —

Cylinder Head (Capacity control,

38 —

side bank)

Cylinder Head (Center bank)

39 —

Cylinder Head Bolt (8 per head)

40 —

Capacity Control Valve (Pressure

41 —

type shown)

Page 13

Table 6 — Torque Values

REMOVE 8 CAP

SCREWS

DRIVE SEGMENT

CAP SCREWS

OIL FEED GUIDE VANE

AND SPRING

OIL

PRESSURE

TAP

PUMP END

BEARING HEAD

COVER

PLATE

Fig. 12 — Removing Pump End Bearing Head

LEGEND

Fig. 13 — Pump End Bearing Head Assembly

1—

Pump End Bearing Head

2—

Drive Segment

3—

Oil Feed Guide Vane

4—

Oil Feed Guide Vane Spring

5—

Cover Plate

SIZE

THREADS

DIAM

PER IN.

(in.)

1

27 (pipe) 8-12 Pipe Plug — Crankshaft

/

16

1

18 (pipe) 20-25 Pipe Plug — Crankcase

/

4

1

/

4

1

/

4

5

18 (pipe)

/

16

3

/

8

3

18 (pipe) 30-40 Pipe Plug — Junction Box

/

8

7

/

16

1

/

2

5

/

8

5

/

8

3

/

4

No. 6

No. 10

TORQUE

RANGE

(lb-ft)

20

28

16

14

13

11

18 60-75 Oil Drain Plug

16 105 Stator Lock

32 1-2 Check Valve Body — Crankcase

32

8-10 Conn. Rod Cap Screw

8-12 Junction Box

3-5 Sight Glass

14-18 Oil Pump Drive Segment

14-18 Unloader Valve

14-18 Discharge Valve Stop

12-15 Head Gasket Positioning Screw

Cover Plate — Pump End Bearing

15-24

Head

15-24 Discharge Service Valve (4 cyl)

30-40 Bottom Plate — Crankcase

30-40 Compressor Foot

30-40 Terminal Plate

25-30 Oil Plug — Pump End Bearing Head

2-4 Terminal Bolts

55-65 Motor End Cover

55-65 Pump End Bearing Head

90-100 Cylinder Head

90-120 Discharge Service Valve (6 cyl)

90-120 Suction Service Valve (4 cyl)

90-120 Suction Service Valve (6 cyl)

90-120 Rotor Lock — Crankshaft

4-6 Oil Pump Drive Segment

4-6 Terminal Screw

USAGE

Lubrication System

TESTING OIL PUMP — An oil pressure tap is located above

oil pump cover plate (Fig. 12). Oil pressure should be 12 to

18 psi above suction pressure.

Oil Filter Screen

plate. Remove and inspect strainer for holes and dirt. Clean it

with solvent and replace.

OIL PUMP AND BEARING HEAD — The oil pump a s sembly is contained in the pump end bearing head aluminum

casting. (The pump end main bearing is a machined part of this

casing — no insert bearing.)

Remove Bearing Head

case and disassemble oil pump. Drive segment cap screws

must be removed before bearing head can be removed

(Fig. 12). Remove pump vane assemblies from both sides of

the bearing head by pushing against the bearing side of the

rotor. Check all parts (Fig. 13) for wear and damage.

Replace Bearing Head

1. Install the rotor retaining ring in the ring groove of the

pump rotor with chamfered edge toward compressor.

Compress retaining ring, and insert pump rotor into

bearing head.

2. Place the pump vanes, pump vane spring with guides, and

snap rings into the bearing head. Compress the springs

and force the snap rings into their grooves. (Insert snap

rings with flat side against casting.)

3. Bolt bearing head to crankcase (use 55 to 65 lb-ft torque).

Bolt drive segment to crankshaft.

4. Insert the oil feed guide vane with large diameter inward.

Place oil feed guide vane spring over small diameter of

guide vane.

5. Install pump cover plate.

— Screen is accessible through bottom cover

— Remove bearing head from crank-

1

2

3

4

5

13

Page 14

Cylinder Heads (See Fig. 11) —

TERMINAL

PLATE

ASSEMBLY

ALLEN HEAD

SCREWS (1/4”)

Fig. 14 — Pressure Relief Valve Removal

Fig. 15 — Valve Plate Removed

Fig. 16 — Removing Terminal Plate Assembly

inder heads by removing cap screws, and prying up on side

lifting tabs to break heads loose from valve plates. Do not hit

cylinder heads to break loose.

Check heads for warping, cracks and damage to gasket

surfaces. When replacing cylinder head, torque cap screws

90 to 100 lb-ft (prevents high to low side leak in center portion

of cylinder head gasket).

Pressure Relief Valve —

This internal safety device is

located in center cylinder bank (6-cylinder compressors,

Fig. 14) or under discharge service valve (4-cylinder compressors). The valve relieves refrigerant pressure from hi gh to low

side at 400 psi pressure differential. Check valve for evi dence

of leaking. Change if defective or if valve has ever opened due

to excessive pressure. Use a standard socket-type screwdriver

to remove and replace valve.

Suction and Discharge Valve Plate Assembly

TEST — Leak test for leaking discharge valves by pumping

compressor down and observing suction and discharge pressure equalization. If a discharge valve is leaking, pressures will

equalize rapidly. Maximum allowable discharge pressure drop

is 3 psi per minute.

If there is an indicated loss of capacity and discharge valves

check properly, remove suction and discharge valve plate

assembly and inspect suction valves.

DISASSEMBLE — Remove cylinder head.

1. Remove discharge valve assembly: cap screws, valve

stops, valve stop supports and valves.

2. Pry up on side lifting tab to remove valve plate and

expose suction valves (Fig. 15). Remove suction valves

and backers from dowel pins.

Inspect valves and valve seats for wear and damage (see

Wear Limits, Table 7). Replace valves if cracked or worn. If

valve seats are worn, replace complete valve plate assembly.

REASSEMBLE — Do not interchange valves. Install brackets and suction valves on dowel pins (backer is under the valve;

see Fig. 15). Place valve plate on cylinder deck and reinstall

discharge valve assembly. Retorque discharge valve stop cap

screws to 16 lb-ft. Replace cylinder head. (Be sure tab on

cylinder head gasket is lined up with tabs on cylinder head and

valve plate.)

Terminal Plate Assembly —

If there is a refrigerant

leak between the terminal plate and the compressor, remove

plate assembly and replace gasket.

If any terminal is shorted to the terminal plate, replace

complete plate assembly, using a new gasket.

Do not remove the terminal plate assembly except for the

above conditions.

REMOVAL — Remove junction box from terminal plate, and

remove cap screws holding terminal plate to compressor. Mark

all motor leads so they can be reassembled correctly to terminal

plate. Loosen Allen head screws holding motor leads to terminal plate (Fig. 16). Remove terminal plate.

REIN STALL — In reverse sequence, reinstall making sure

motor leads are correct. Torque terminal plate cap screws per

T able 6.

Compressor Running Gear Removal

CONNECTING R OD/PI ST O N ASSE MBLY — Remove cylinder heads, valve plate assemblies, crankcase bottom cover

plate, oil filter screen, and connecting rod caps (Fig. 17). Label

caps and rods so they may be reinstalled in same place on

crankshaft. Push connecting rod and piston assemblies up

through cylinder deck. Disassemble connecting rods from

pistons by removing retaining rings and piston pins. Remove

oil and compression rings from piston.

Disassemble cyl-

Keep each connecting rod and piston assembly together for

proper reassembly. Check all parts and crankpins for wear

(refer to Table 7 for wear limits).

PRESSURE RELIEF VALVE

VALVE PLATE

SECTION VALVE

SEATS

(VALVE PLATE)

SUCTION VALVES

(BACKER IS

UNDER THE

VALV E)

SUCTION VALVE STOPS

(CYLINDER DECK)

14

SUCTION

VALV E

BACKER

DOWEL

PINS

TAB

TAB

Page 15

CRANKSHAFT

RETAINING

RING GROOVE

(BOTH SIDES)

CHAMFER MUST

BE ON THIS SIDE

POSITION RETAINING

RING GAP APPROXIMATELY

ON THIS CENTERLINE

TOWARD SUCTION VALVE

DOWELS IN CYLINDER DECK

Fig. 18 — Connecting Rod/Piston Assembly

CONNECTING

RODS AND

CAPS

OIL DRAIN

PLUG

(MAGNETIC)

BOTTOM

COVER

PLATE

OIL FILTER

SCREEN

Fig. 17 — View with Bottom Cover Plate Removed

CRANKSHAFT — Remove pump end bearing head and

rotor. If connecting rod and piston assemblies are still in place.

remove connecting rod caps and push piston assembly up into

cylinder for crankshaft clearance. Pull crankshaft out through

pump end opening. Inspect crankshaft journals for wear and

tolerances shown in Table 7. Check oil passages and clean if

clogged.

PUMP END MAIN BEARING — This bearing is a machined

part of the oil pump and bearing head casting. Disassemble

bearing head. If bearing is scored or worn, replace the complete

bearing head.

CRANKCASE AND MOTOR END MAIN BEARINGS — These bearings are not field replaceable. If bearings

are worn or damaged, replace compressor.

Table 7 — Wear Limits — 06E Compressor

Compressor Running Gear Replacement

CRANKSHAF T — Be sur e c om p re ss o r e n d b ea ri n g w a sh er i s

in place on dowel pin. Install crankshaft through pump end,

carefully guiding it through main bearings. Replace rotor.

CONNECTING R OD/ PIS T ON ASSE MBLY (Fig. 18) — The

assembly of the connecting rod with contoured-crown piston

must be as shown. Note the relationship of the piston crown

pattern with the chamfered side of the rod bearing. This ensures

that the rods in the outer positions on crankpins have the

chamfers toward crankpin fill ets. On 6-cylinder compressors,

the position of the chamfer of center rod on crankpin has no

significance.

Lock the piston pin in place with retaining rings as shown in

Fig. 18.

The retaining rings should be tight enough that they cannot

be rotated by finger pressure.

Rings

1. Check ring gap by inserting each ring separately in cylinder approximately

between 0.002 in. and 0.007 inch.

2. Install compression ring in top piston groove with either

side up (no difference). Install oil ring below compression

ring with notched end on bottom. Stagger ring gaps

180 degrees.

3. Measure side clearance between ring and piston

(T able 6). Check rings for free action.

Installation of Connecting Rod/Pist on A ssemb ly

connecting rod/piston assemblies into cylinders with pistons

positioned as shown in Fig. 18 and 19.

This is necessary so that the suction valve and backer lie

properly over the contour ed piston cr own.

Be sure that the outer rod on each crankpin has the

chamfered side toward the crankpin fillet (this is a double

check on the connecting rod/piston assembly).

Install caps to matching connecting rods with chamfered

sides aligned. Caps are secured with Nylock cap screws.

Tighten with 8 to 10 lb-ft torque.

3

/8 in. from top. Ring gap should be

— Insert the

COMPRESSOR PART

MOTOR END

Main Bearing Diameter

Journal Diameter

PUMP END

Main Bearing Diameter

Journal Diameter

CONNECTING ROD

Bearing Diameter

(After Assembly)

Crankpin Diameter

THRUSTWASHER

(Thickness)

CYLINDERS

Bore

Piston Diameter

Wrist Pin Diameter

Con. Rod Wrist Pin ID

Piston Ring End Gap

Piston Ring Side Clearance

VALVE

THICKNESS

END CLEARANCE

*Maximum allowable wear above maximum or below minimum factory

tolerances shown. For example: difference between main bearing diameter and journal diameter is .0035 in. (1.8760 – 1.8725) per factory tol-

erances. Maximum allowable difference is .0045 in. (.0035 + .001).

FACTO RY TO L .

(in.)

Max Min

1.8760 —

— 1.8725

1.6260 —

— 1.6233

1.7515 —

— 1.7483

— 0.155 —

2.6885 — 0.002

— 2.6817 0.002

— 0.8748 0.001

0.8755 — 0.001

0.007 0.002 0.015

0.003 0.001 0.002

Suction

Discharge

0.0315 0.0305

0.0255 0.0245

0.0225 0.0215 0.002

0.031 — 0.010

MAXIMUM

ALLOWABLE

WEAR* (in.)

0.001*

0.001*

0.002*

0.002

15

Page 16

DOWEL

Fig. 20 — Removing Rotor

Fig. 21 — Removing Stator

HOLES

DOWEL

HOLES

BACKER

SUCTION

VALV E

PLACE AGAINST

CYLINDER DECK,

UNDER SUCTION VALVE

TOP VIEW OF PISTON

Fig. 19 — Piston, Suction Valve and

Backer Positions

DOWELS IN

CYLINDER DECK

FOR SUCTION

VALVE AND BACKER

IN CYLINDER

Push stator into housing until it lines up correctly with rotor

(Fig. 22).

Line up keyways in stator and crankcase and repl ace stator

locking assembly, then drive key into keyway and stake over

keyway in stator to secure key. When a new motor is being

installed, the stator must be drilled and a new locking pin and

motor lock bushing used (see Fig. 23 and instructions).

Connect stator leads to proper terminals on terminal plate.

Refasten terminal plate and junction box to compressor.

Replace motor end bell using studs for support. Remove rubber

plug (if used) from piston head. Replace valve plate assembly,

cylinder head, and terminal plate assembly. Torque 12 bolts

holding terminal plate to crankcase at 30 to 40 lb-ft.

VALVE PLATE

Turn crankshaft to be sure there is no binding between

bearing surfaces and journals. Replace oil screen, bottom cover

plate, valve plates and cylinder heads.

Motor Removal

MOTOR END BELL — Remove motor end bell carefully to

prevent damage to the stat or. Use three 7/16 - 14- x 5-in. studs

for guides and support. Inspect suction strainer in end bell.

Clean it with solvent or replace if broken or corroded.

REMOVE ROTOR — Bend rotor lock washer tab backward

and remove rotor lock bolt. If crankshaft turns, preventing lock

bolt from being loosened, remove a cylinder head and valve

plate and place a rubber plug (06R suction plug) on top of one

piston (Fig. 20). Replace valve plate assembly and cylinder

head (only 2 bolts required to hold cylinder head in place). Proceed to remove rotor lock bolt, lock washer and plate washer.

Use a jackscrew to remove rotor (Fig. 20). Insert a brass

plug into rotor hole to protect end of crankshaft from jackscrew. Support rotor while it is being removed to prevent stator

damage. Remove ring spacer between rotor and crankshaft

(if used).

Clean rotor thoroughly with solvent. If stator is to be

replaced, a matching rotor must be used.

REM OVE STATOR (Fig. 21 ) — Stator is a slip fit in motor

housing. It is held in place by both an axial key and a locking

assembly consisting of an acorn nut, locking pin, motor lock

bushing and a washer (see Fig. 21). Remove acorn nut and

washer. Back out locking pin and bushing and slide stator out.

Axial key positions stator and crankcase. If necessary, heat

crankcase motor housing (not over 20 to 30 F above stator

temperature).

Check stator for damage to windings and l ead wire s. Use a

megohmmeter to check for grounds or shorts between

windings.

Motor Replacement

STATOR AND ROTOR — Install stator halfway into housing. Insert the terminal leads first, guiding them to terminal

plate opening as stator is being inserted.

Replace ring spacer (Fig. 11, item 21) on crankshaft. Ease

rotor onto shaft until it begins to feel snug. Insert rotor key, and

push rotor the remainder of the way on shaft. Replace rotor

lock bolt with lockwasher and plate washer.

RUBBER PLUG

JACKSCREW

LOCKING PIN BOSS

ACORN

NUT

STATOR LOCKING

ASSEMBLY

STAT OR

ROTOR

ROTOR LOCK BOLT

STAT OR

KEY

MOTOR LOCK

BUSHING

Do not push stator in completely until rotor is in place.

16

WASHER

LOCKING PIN

Page 17

STAT OR

ROTOR

Fig. 22 — Motor Alignment

BUSHING

LOCKING PIN

PEENED ENDS

END

TURN

END

RING

ROTOR CENTER LINE

ACORN NUT

WASHER

2. Remove burned motor from compressor, and drain compressor oil. Clean crankcase and motor housing with

solvent. Ensure that all metal particles are wire-brushed

free and removed.

On severe burnouts, disassemble compressor heads and

valve plate assemblies. Clean them in same manner as

crankcase and motor housing.

3. Determine cause of burnout a nd remedy. Check control

box for welded starter contacts, welded overload contacts

or burned out heater elements. Check terminal plate for

burned or damaged terminals, insulation, and shorted or

grounded terminals.

4. Reassemble compressor with new stator and rotor. Install

new liquid line filter drier, and place new oil charge in

crankcase.

5. Evacuate and dehydrate compressor.

Do not attempt start-up with terminal cover removed.

Bodily injury or death may result from explosion and/or

fire if power is supplied to compressor with the terminal

cover removed or unsecured. See warning label on terminal cover.

COMPRESSOR

2 1/16"

STATOR CORE

3/8"

CASTING

Fig. 23 — Stator Locking Assembly

Remove

1. Acorn nut and washer.

2. Back out locking pin and bushing.

Replace

1. Screw in locking pin bushing until it rests on stator core.

2. Wrap a piece of tape around

3

/8-in. drill bit, 21/16 in. from

cutting edg e .

Before drilling, be sure stator vent holes do not line up with

locking pin hole. Vent holes are drilled horizontally

through stator, and can be seen from end bell side.

3

3. Ream out bushing (

until tape is flush with top of bushing. (Remove drill

chips.) Back off locking pin bushing

4. Tap locking pin into position. (Top of bushing should be

approximately

/8-in. drill) and drill into stator core

1

/8 of a turn.

1

/16 in. above top of pin.)

5. Peen top of bushing over roll pin.

6. Replace washer and acorn nut.

Motor Burnout (Clean-Up Procedure) —

When a

hermetic motor burns out, the stator winding decomposes

forming carbon, water and acid which contaminate refrigerant

systems. Remove these contaminant s from system to prevent

repeat motor failures.

1. Close compressor suction and discharge service valves,

and bleed refrigerant from compressor. Save remaining

refrigerant in system.

6. Place compressor in operation. After 2 to 4 hours of

operation, check compressor oil for discoloration and/or

acidity. If oil shows signs of contamination, replace oil

charge, filter driers, and clean suction strainer with

solvent.

7. Check oil daily for discoloration and acidity. If oil stays

clean and acid-free, the system is clean. If oil shows signs

of contamination, change oil, filter drier, and clean

suction strainer. If filter drier or suction strainer is dirty or

discolored, repeat this step until system is clean.

Condenser Maintenance (07E Units) —

To inspect

and clean condenser, drain water and remove condenser heads.

To drain condenser, shut off water supply and disconnect inlet

and outlet piping. Remove drain plugs and vent plug.

With condenser heads removed, inspect tubes for refrigerant

leaks. (Refe r to Carrie r Refr igerant Service Techniques Manu al.)

Clean condenser tubes with nylon brush (available from

Carrier Service Department). Flush water through tubes while

cleaning. If hard scale has formed, clean t ubes chemically. Do

not use brushes that will scrape or scratch tubes.

Because the condenser water circuit is usually an open

system, the condenser tubes may be subject to contamination

by foreign matter. Local water conditions may cause excessive

fouling or pitting of tubes. Condenser tubes, therefore, should

be cleaned at least once a year or more often i f the water is

contaminated.

Proper water treatment can minimize tube fouling and

pitting. If such conditions are anticipated, water treatment

analysis is recommended. Refer to the Carrier System Design

Manual, Part 5, for general water conditioning information.

If hard scale has formed, clean the tubes chemically. Consult an experienced and reliable water treatment firm in your

area for treatment recommendations. Clean the condenser by

gravity or by forced circulation as shown in Fig. 24 and 25.

IMPORTANT: If the ambient temperature is below 32 F

during a shutdown period, protect the condenser from

freezing by draining the water from the system or by adding antifreeze to the water.

17

Page 18

FILL CONDENSER WITH

Fig. 25 — Forced Circulation

CLEANING SOLUTION. DO

NOT ADD SOLUTION

MORE RAPIDLY THAN

VENT CAN EXHAUST

GASES CAUSED BY

CHEMICAL ACTION.

VENT

PIPE

3’ TO 4’

1”

PIPE

5’ APPROX

CENTRIFUGAL PUMP 1/2 HP

30 GPM AT 35’ HEAD

PUMP

SUCTION

PUMP

SUPPORT

TANK

PRIMING

CONN.

GAS VENT

GLOBE

VALV ES

1” PIPE

CLOSE VENT PIPE

VALVE WHEN

PUMP IS

RUNNING

CONDENSER

REMOVE WATER

REGULATING VALVE

Fig. 24 — Gravity Circulation

CONDENSER

FINE MESH

SCREEN

RETURN

18

Page 19

Page 20

Copyright 2002 Carrier Corporation

Manufacturer reserves the right to discontinue, or change at any time, specifications or designs without notice and without incurring obligations.

Book2244

Tab 1b2a2b3a

PC 802 Catalog No. 530-607 Printed in U.S.A. Form 06/07E-2SI Pg 20 7-02 Replaces: 06/07E-1SI

Loading...

Loading...