Page 1

Compressors and Condensing Units

Installation, Start-Up and

Service Instructions

Hermetic, Water-Cooled

06D,07D

CONTENTS

Page

SAFETY CONSIDERATIONS

BEFORE INSTALLATION

Check Shipment

Unit Location Considerations

INSTALLATION

Mount Unit

Piping Connections

Electrical Connections

Limitations

Refrigerant Charging

INITIAL START-UP

To St a rt C om p r es s o r

CHECKING OPERATION

Oil Charge

High-Pressure Switch

Low-Pressure Switch

Oil Pressure Switch

Time Guard® Control

CAPACITY CONTROL

Control Set Point

To Regulate Control Set Point

Pressure Differential Adjustment

Capacity Control Pressure

CONDENSER MAINTENANCE

SERVICE

Service Notes

Testing Oil Pump

Cylinder Heads

Service Replacement Compressors

Suction and Discharge Valve Plate Assembly

Cleaning Suction Strainer

Motor Replacement

Terminal Plate Assembly

Compressor Running Gear Removal

Compressor Running Gear Replacement

COMPRESSOR MOTOR BURNOUT

Clean-Up Procedure

TROUBLESHOOTING

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12-17

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-8

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

. . . . . . . . . . . . . . . . . . . . . . . . . .18,19

. . . . . . . . . . . . . . . . . . . . . . 1

. . . . . . . . . . . . . . . . . . . . . . . . . 1

. . . . . . . . . . . . . . . . . . . . 1

. . . . . . . . . . . . . . . . . . . . . . . . . . . 4

. . . . . . . . . . . . . . . . . . . . . . . . .8,9

. . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

. . . . . . . . . . . . . . . . . . . . . . . . . .9,10

. . . . . . . . . . . . . . . . . . . . 9

. . . . . . . . . . . . . . . . . 9

. . . . . . . . . . . . . . . . . . . . . . 10

. . . . . . . . . . . . . . . . .10,11

. . . . . . . . . . . . . 14

. . . 15

. . . . . . . . . . . . . . . . . . . . . . . 16

. . . . . . . . . . . . . . . . . . . . . . . . 16

. . . . . . . . . . . . 16

. . . . . . . . 17

. . . . . . . . . . . . . . 17

SAFETY CONSIDERATIONS

Installing, starting up and servicing this equipment can be

hazardous due to system pressures, electrical components and

equipment location (roofs, elevated structures, etc.). Only

trained, qualified installers and service mechanics should

install, start up and service this equipment.

When working on the equipment, observe precautions in the

literature, tags, stickers and labels attached to t he equipment

and any other safety precautions that apply. Follow all safety

codes. Wear safety glasses and work gloves. Use care in

handling, rigging and setting bulky equipment.

Electrical shock can cause persona l injury and even death.

Be sure power to equipment is shut off before installing or

servicing this equipment. There may be more than one

disconnect. Tag disconnect(s) to alert others not to turn

power on until work is completed.

BEFORE INSTALLATION

Check Shipment —

if shipment is damaged or incomplete.

Unit Location Considerations —

floor in a well-v entil ated ar ea. Pos itio n unit t o allow sufficien t

space for refrigerant and water connections and to service

compressor. Place unit so suction and discharge valves can be

easily reached and oil level checked. Do not install condensing

unit where temperature will fall below freezing.

Local water can cause excessive fouling or sealing of

condenser tubes. If such conditions are anticipated, a water

treatment analysis is recommended. Refer to Carrier System

Design Manual, Part 5, for general water conditioning

information.

Make provision in piping layout to drain and vent condenser

if system is to be shut down in winter.

File claim with shipping company

Locate unit on

INSTALLATION

Mount Unit —

Loosen compressor mounting bolts and remove shipping

blocks from under compressor. Tighten all 4 bolts on compressor. Next, loosen each bolt until the flanged washer can be

moved sideways with finger pressure.

NOTE: Be sure that compressor floats freely on mounting

springs.

Piping Connections —

lines to connections indicated on condenser unit (Fig. 1). Water

leaving condenser should not be connected directly into sewer

lines. Check local codes.

Attach refrigerant liquid and suction lines to condensing

units (Fig. 1); suction and discharge to compressor unit

(Fig. 2). When soldering or brazing piping to valves, disassemble valve or wrap it in a wet cloth to prevent heat damage.

Allow flexibility in suction line so compressor suction valve

may be moved aside for access to suction strainer.

Level unit and bolt firmly to foundation.

Attach water supply and return

Manufacturer reserves the right to discontinue, or change at any time, specifications or designs without notice and without incurring obligations.

Book 2244

Tab 1b2a2b3a

PC 802 Catalog No. 530-608 Printed in U.S.A. Form 06/07D-3SI Pg 1 802 7-02 Replaces: 06/07D-2SI

Page 2

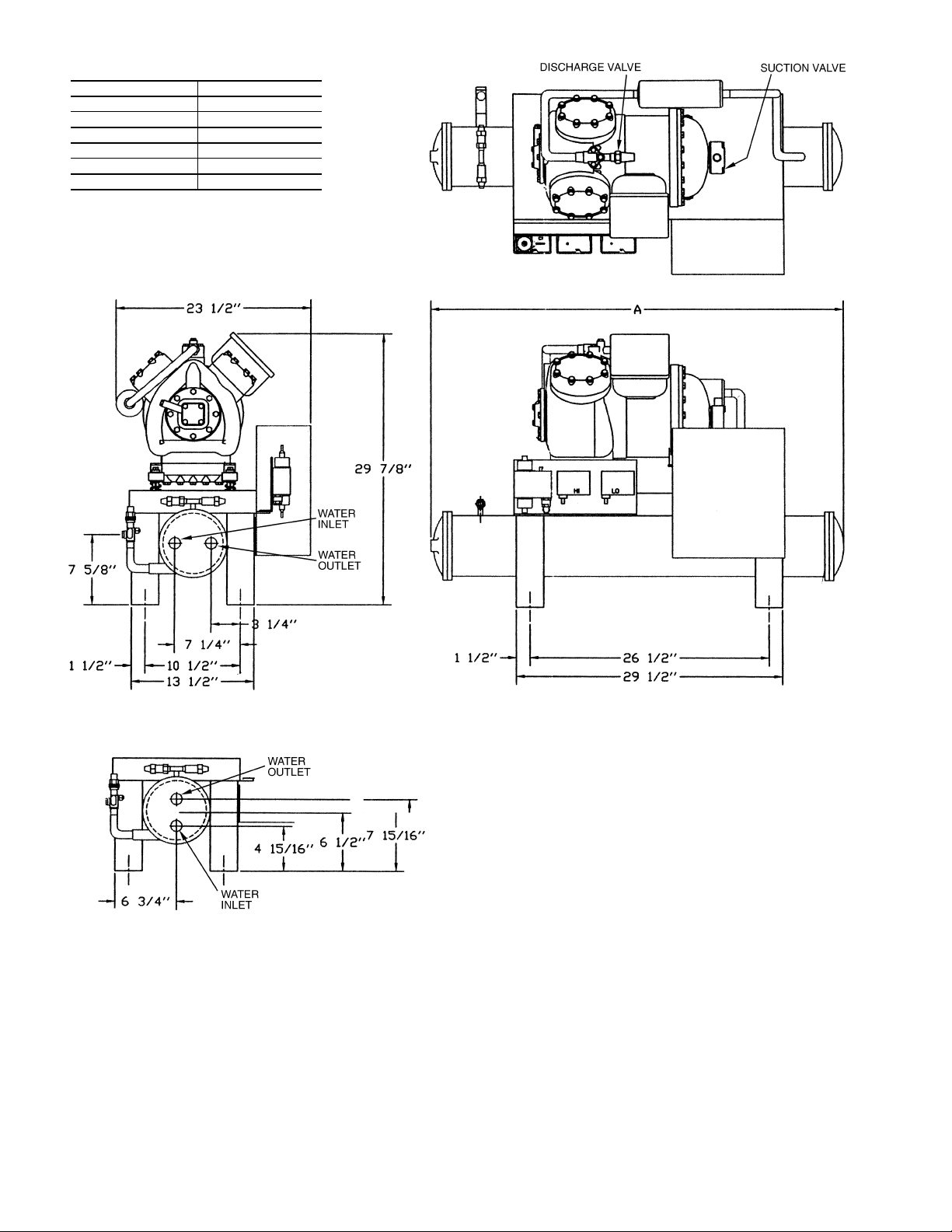

DIMENSIONS (in.)

UNIT 07D WIDTH A

A203

B205

A208

B210

B212

B215

63

39

51

51

30

30

9

/

16

9

/

16

9

/

16

13

/

16

WATER CONNECTIONS FOR 07DB215 UNIT ONLY.

Fig. 1 — 07D Condensing Unit Dimensions

NOTES:

1. For standard service practices, such as troubleshooting and refrigerant charging, allow a minimum

2′-6″ clearance around the unit.

2. Recommended service space for condenser tube

removal is one condenser length at either end.

3. For compressor removal, allow a minimum 3′ wide

access aisle to and from the unit.

4. Local codes or jurisdiction may prevail for unit

clearances.

2

Page 3

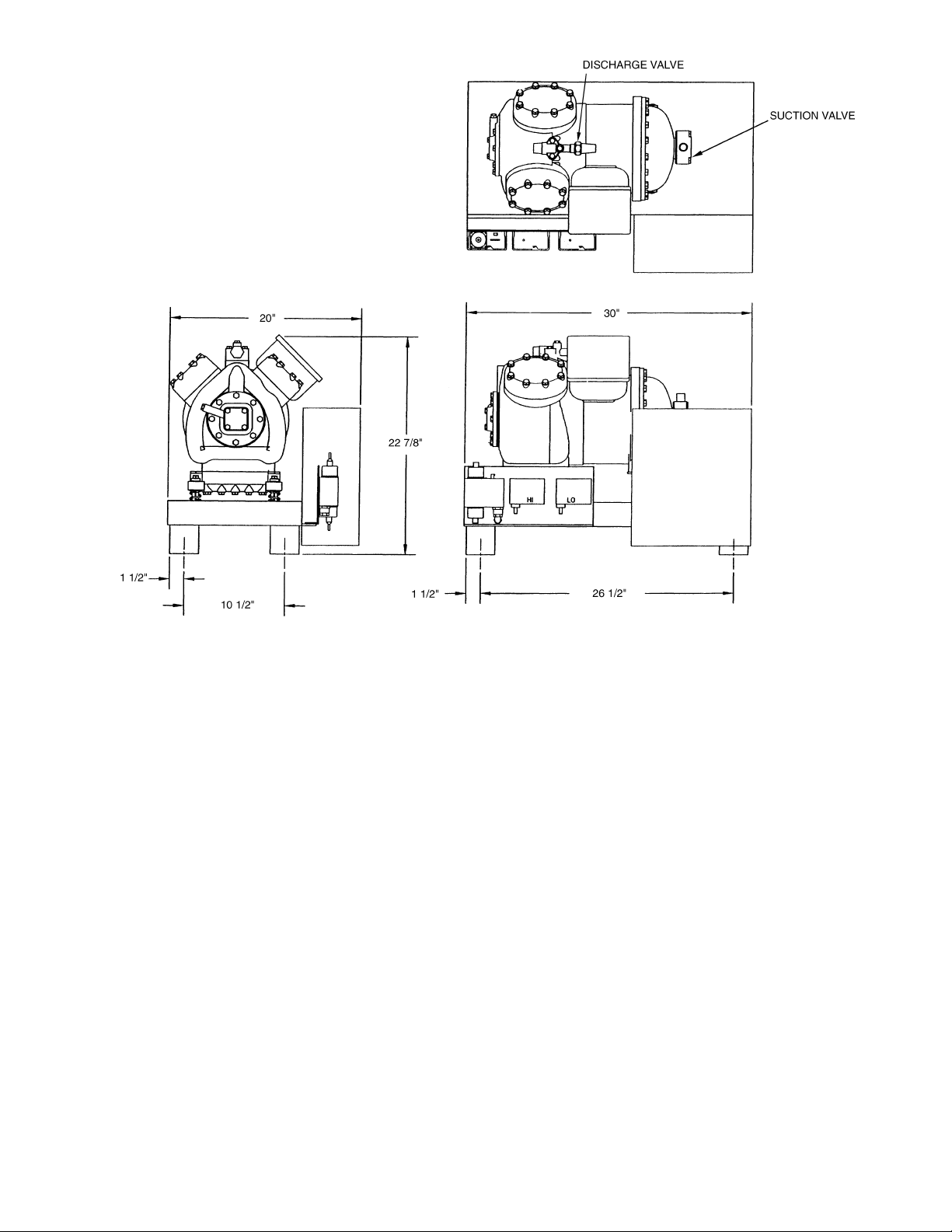

NOTES:

1. For standard service practices, such as troubleshooting and refrigerant charging, allow a minimum

2′-6″ clearance around the unit.

2. For compressor removal, allow a minimum 3′ wide

access aisle to and from the unit.

3. Local codes or jurisdiction may prevail for unit

clearances.

Fig. 2 — 06D Compressor Unit Dimensions

3

Page 4

Install a solenoid valve (field supplied) in liquid line directly

before expansion valve. Solenoid valve is necessary for single

pumpout control used on 06D, 07D units. Refrigerant filter

drier and moisture indicator are shipped with 07D condensing

units for field installation. Install in liquid line according to

manufacturer’s instructions.

Relief valve located on top of condenser (07D units) will

open to relieve excessive pressure, allowing refrigerant to

escape. Most local codes require piping from safe ty device to

outdoors.

Refer to Carrier System Design Manual, Part 3, for standard

piping techniques.

COMPRESSOR UNITS — Connect high- and low-pressure

switch capillary tubes from control box to compressor. See

Fig. 2.

Install discharge line muffler (accessory) in discharge line

as close to compressor shutoff valve as possible.

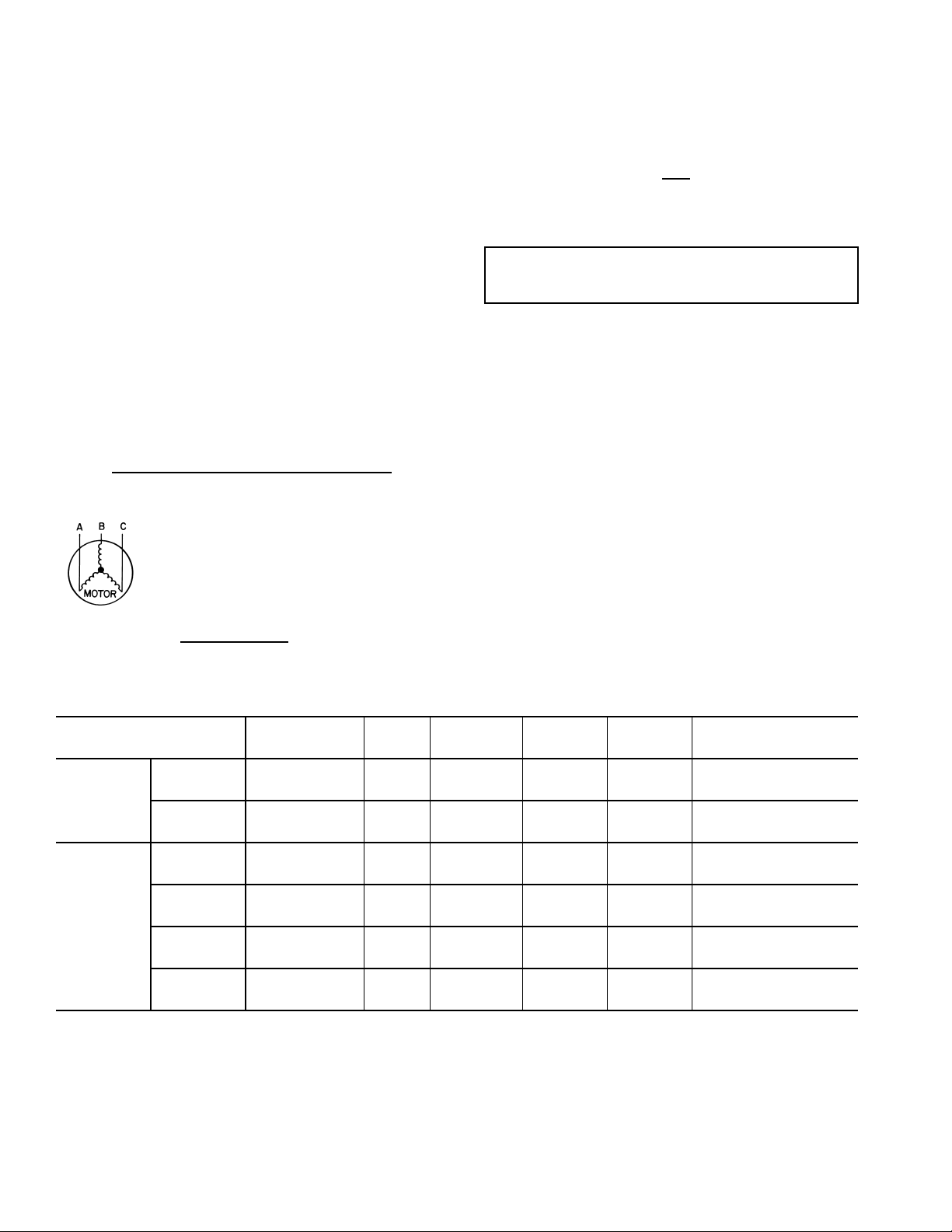

Electrical Connections

UNBALANCED 3-PHASE SUPPLY VOLTAGE — Never

operate a motor where a phase imbalance in supply voltage

is greater than 2%. Use the following formula to determine

the % voltage imbalance:

% Voltage Imbalance =

100 x

Example: Supply voltage is 230-3-60

A verage Voltage =

max voltage deviation from average voltage

average voltage

AB = 236 volts

BC = 229 volts

AC = 234 volts

236 + 229 + 234

3

= 233 volts

Determine maximum deviation from average voltage:

(AB) 236 – 233 = 3 volts

(BC) 233 – 229 = 4 volts

(AC) 234 – 233 = 1 volt

Maximum deviation is 4 volts. Determine % voltage

imbalance:

% Voltage Imbalance =100 x

4

233

= 1.7%

This amount of phase imbalance is satisfactory as it is below

the maximum allowable of 2%.

IMPORTANT: If the supply voltage phase imbalance is

more than 2%, contact your local electric utility company

immediately.

ELECTRICAL DATA NOTES

1. All 06D and 07D units are across-the-line start.

2. Wire sizes are based on TW type copper wire. Maximum

wire lengths based on data from Table 1 will result in a

1% voltage drop to compressor. Where up to 3% voltage

drop is allowed, the run length can be increased to 3 times

the length calculated from data in Table 1.

3. The 06D compressor unit electrical data shown in Table 1

does not apply for 06D compressors used as an integral

part of other Carrier equipment. See proper installation

book for electrical information.

WIRI NG — Power supply must correspond with unit nameplate electrical characteristics (units are internally wired at

factory for nameplate voltage). Field wiring must comply with

local and national codes.

Install a branch circuit fused disconnect of adequate size to

handle starting current.

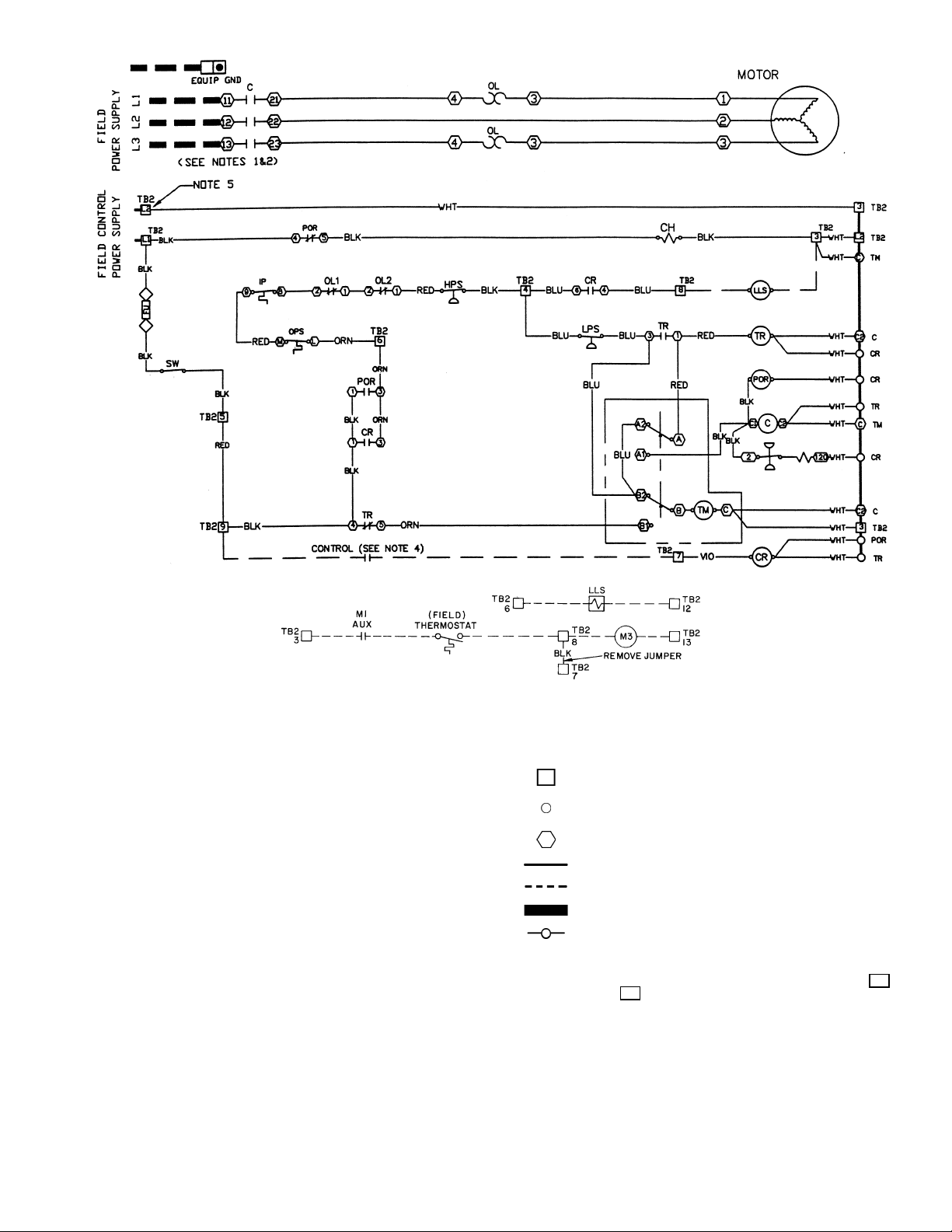

LIN E POWER — Connect line power to the compressor con-

tactor C. For example, connect L1 to terminal 11, L2 to terminal 12 and L3 to terminal 13. See Fig. 3.

Table 1 — Compressor Electrical Data

COMPRESSOR

PART NUMBER

06D*

808

M

313

818

825

A

328

537

LEGEND

LRA —

MCC —

RLA —

*Refer to physical data table to match compressor with correct com-

pressor unit or water-cooled condensing unit.

NOTES:

1. RLA (rated load amps) value shown is: MCC ÷ 1.40 = RLA.

2. For minimum contactor sizing, use RLA value determined by:

Locked Rotor Amps

Maximum Continuous Current

Rated Load Amps

MCC ÷ 1.40 = RLA.

VO LTAGE

(3 Ph-60 Hz)

575

208/230 17.4 12.4 71 0.78

460 8.7 6.2 35.5 3.1

575

208/230 27 19.3 100 0.5

460 13.5 9.6 50 2.1

575

208/230 44 31.4 160 0.42

460 22 15.7 80 1.7

575

208/230 55.5 39.6 198 0.31

460 27.8 19.8 99 1.3

575

208/230 62 44.3 228 0.26

460 31 22.1 114 1.0

575

208/230 89 63.6 266 0.18

460 40 28.6 120 0.72

HP MCC RLA LRA

3

5

6.5

7.5

10

15

MOTOR WINDING

RESISTANCE

(Ohms)

7 5 28.4 5.0

10.8 7.7 40 3.3

17.6 12.6 64 2.6

22.2 15.9 79 2.0

25 17.9 91 1.7

32 22.9 96 1.2

3. For wiring sizing, the RLA value can be determined by: MCC

÷

1.56 = RLA.

4. Compressor operating amps at any specific conditions can only

be determined from a performance curve.

5. RLA values for 06D compressor protected by a calibrated

circuit breaker will depend on must-trip value of circuit breaker.

6. Ohm values shown for resistance are approximate and shown

for reference only. Motors from different vendors and motors of

different efficiencies can differ up to 15% from data shown.

7. Electrical data for compressor part numbers 06DR and

50 Hz models (not shown) are available from Carrier Sales

Representative.

4

Page 5

AUX —

C—

CH —

CR —

DX —

EQUIP —

FU —

GND —

HPS —

IP —

LLS —

LPS —

M3 —

NEC —

OL —

OPS —

POR —

SW —

Auxiliary

Compressor Contactor

Crankcase Heater

Control Relay

Direct Expansion

Equipment

Fuse

Ground

High-Pressure Switch

Internal Protector

Liquid Line Solenoid Valve

Low-Pressure Switch

Cooling Tower Fan

National Electrical Code

Overload

Oil-Pressure Switch

Pumpout Relay

Start-Stop-Reset Switch

LEGEND

TB —

TM —

TR —

Terminal Block

Timer Motor

Timer Relay

Terminal Block Connector

Unmarked Terminal

Marked Terminal

Factory Wiring

Field Control Wiring

To indicate common potential only;

not to represent wiring.

Splice

NOTES:

1. Factory wiring is in compliance with NEC. Any field modifications

or additions must be in compliance with all applicable codes. Use

copper, copper-clad aluminum for field power supply only.

2. Field power supply wiring must be 75 C minimum.

3. Compressor thermally protected. Three-phase motors are protected against primary single-phasing condition.

4. Pilot duty control must be field supplied. Minimum contact rating

must be 25 va.

5. 60 Hz units have 120-volt control circuit. 50 Hz units have

230-volt control circuit. A separate source of supply at the correct

voltage must be field supplied through a fused disconnect device

Fig. 3 — Unit Label Diagram — 06D,07D Units

with a maximum rating of 15 A to TB2 connections

(Hot Side) and (Neutral).

6. Open control circuit disconnect switch for servicing only. Disconnect must remain closed for crankcase heater to operate.

7. A transformer of the following rating may be field supplied for

60 Hz units: 350 va.

8. Transformer must be fused and grounded per applicable codes.

9. If any of the original wiring furnished must be replaced, it must

be replaced with 90 C wire or its equivalent.

L2

5

L1

Page 6

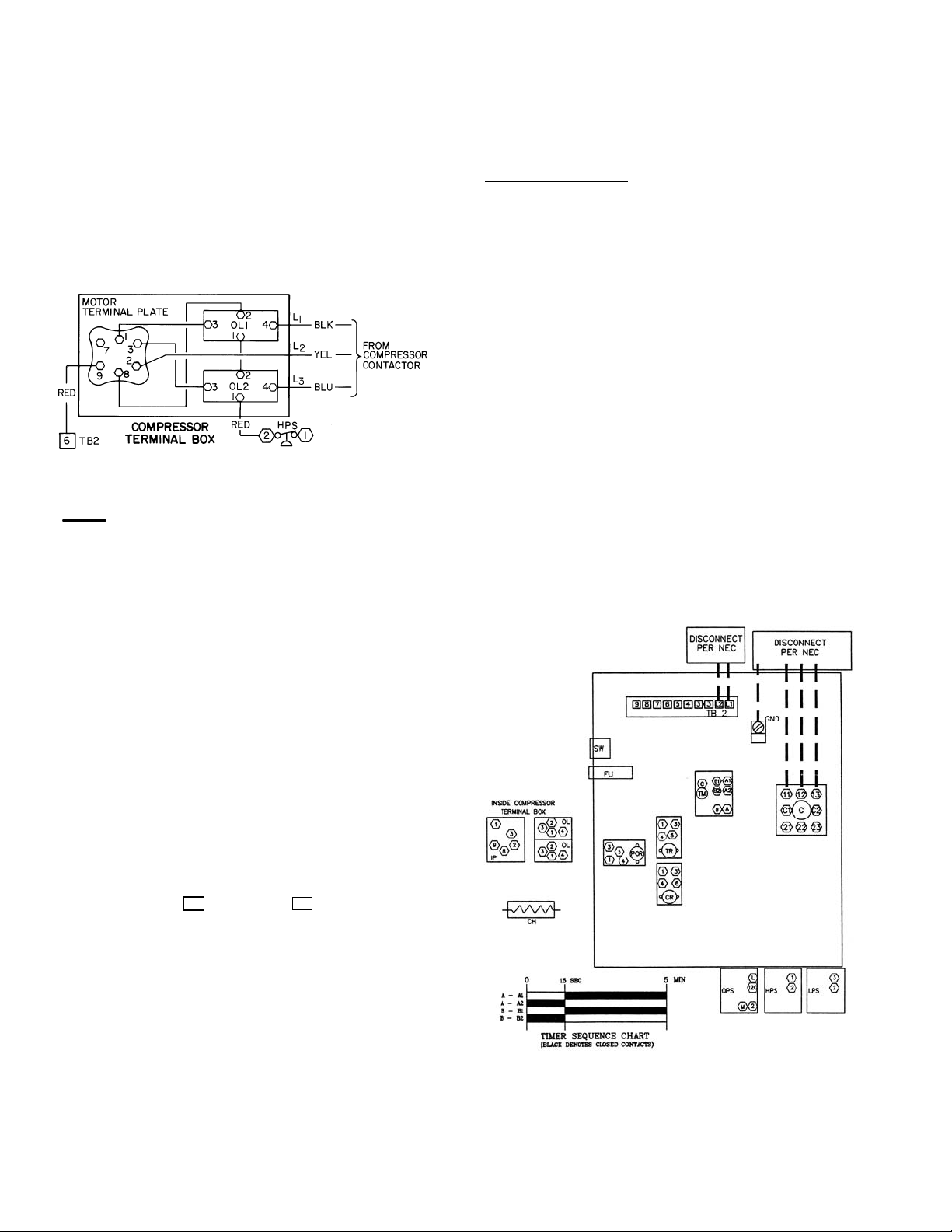

Compressor Unit Connections

— Extend power leads from

control center (contactor terminals) to compressor terminal box

and make connections as shown in Fig. 4.

Terminals 8 and 9 on motor terminal plate are for internal

protector connections. As shown in Fig. 4, run a wire from terminal 9 to terminal 6 on TB2 in control center and a wire from

terminal 1 on OL2 to terminal 2 on HPS in control center.

Run crankcase heater power wiring into control center.

Connect leads to terminal 5 on pumpout relay and terminal 3

on terminal block TB2. See Fig. 5.

Affix power warning label supplied in the installer ’s packet

to fused disconnect which energizes crankcase heater (see unit

label diagram).

LEGEND

HPS —

OL —

TB —

High-Pressure Switch

Overload Relay

Terminal Block

Factory Wiring

Fig. 4 — Compressor Terminal Diagram

CONT ROL WIRING — Control circuit power is 115 volts,

energized from an external source or from unit voltage through

field-supplied transformer. Transformer size required is 350 va

for 60 Hz units. External control power source must be

supplied through a 15-amp fused disconnect. Connect control

circuit power leads to terminal block TB2, terminals L1 and

L2. Terminal L2 is neutral potential (ground).

Compressor Protection

— The 06D and 07D units are factory

wired for single-pumpout control. Field addition and wiring of

line voltage remote control and liquid line solenoid valve is

required. (See unit Fig. 3 and Fig. 6.) Remote control minimum

contact rating must be 25 va. Solenoid valve must have a

maximum load rating of 50 va holding; 200 va inrush. For

applications with cooling tower, air-cooled or evaporative

condensers, add necessary auxiliary contacts in line between

compressor contactor and terminal A1 on timer. Insert desired

interlocks and overloads between terminals 5 and 9 on terminal

block TB2.

Control wiring may be modified as shown in Fig. 6 for

automatic pumpdown control; remove low-pressure switch

between timer relay and terminal 4 on TB2. Wire low-pressure

switch between terminals 9 and 6 on TB2. Add necessary

auxiliary contacts between compressor contactor and ter minal

A1 on timer. Remove wire between terminal 6 on TB2 and

terminal 3 on pumpout relay. Insert required interlocks and

overloads between terminals 5 and 9 on TB2.

Limitations —

Do not use automatic pumpdown control

on direct expansion cooler applications or when compre ssors

are equipped with pressure-type unloader valves. Pressure

unloader valves have built-in high to low passage which allows

compressor to cycle with automatic pumpdown.

LEGEND

C—

CH —

CR —

FU —

GND —

HPS —

IP —

LPS —

NOTES:

1. Factory wiring is in compliance with NEC. Any field modifications or

2. Field power supply wiring must be 75 C minimum.

3. Compressor thermally protected. Three-phase motors are protected

4. Pilot duty control must be field supplied. Minimum contact rating must

5. 60 Hz units have 120-volt control circuit. 50 Hz units have 230-volt con-

6. Open control circuit disconnect switch for servicing only. Disconnect

7. A transformer of the following rating may be field supplied for 60 Hz

8. Transformer must be fused and grounded per applicable codes.

9. If any of the original wiring furnished must be replaced, it must be

Contactor, Compressor

Crankcase Heater

Control Relay

Fuse

Ground Connection

High-Pressure Switch

Internal Protector

Low-Pressure Switch

additions must be in compliance with all applicable codes. Use copper,

copper-clad aluminum for field power supply only.

against primary single-phasing condition.

be 25 va.

trol circuit. A separate source of supply at the correct voltage must be

field supplied thru a fused disconnect device with a max rating of 15 A

to TB2 connections (Hot Side) and (Neutral).

must remain closed for crankcase heater to operate.

units: 350 va.

replaced with 90 C wire or its equivalent.

L1

NEC —

OL —

OPS —

POR —

SW —

TB —

TM —

TR —

National Electrical Code

Overload Relay

Oil Pressure Switch

Pumpout Relay

Switch

Terminal Block

Timer Motor

Timer Relay

L2

Fig. 5 — 06D/07D Control Box Components and Connections (3-Phase)

6

Page 7

AUX —

C—

CR —

HPS —

LLS —

LPS —

M3 —

M4 —

M5 —

Auxiliary

Contactor

Control Relay

High-Pressure Switch

Liquid Line Solenoid Valve

Low-Pressure Switch Factory Wiring

Evaporator Fan or Chilled Water Pump Field Wiring

Cooling Tower Pump, Air-Cooled or

Evaporative Condenser Fan

Cooling Tower Fan or

Evaporative Condenser Pump

LEGEND

OL —

POR —

SW —

TB —

TR —

*Optional.

Overload Relay

Pumpout Relay

Switch

Terminal Block

Timer Relay

Fig. 6 — Recommended Field Wiring

7

Page 8

Refrigerant Charging

When charging, or when removing charge, circulate water

through water-cooled condenser(s) and cooler continuously

to prevent freezing. Freezing damage is considered abuse

and is not covered by Carrier warranty.

EVACUA TE, DEHYDRATE AND LEAK TEST — Entire refrigerant system must be evacuated, dehydrated and leak tested

by methods described in Carrier Standard Service Techniques

Manual, Chapter 1, Sections 1-6 and 1-7. Use sight glass method to charge system. See Section 1-8 of manual for details.

CHARGE THE SYSTEM — Charge to a clear sight glass

while holding saturated condensing pressure constant at 125 F

(air-cooled systems) or 105 F (water-cooled systems). Add

additional refrigerant to fill condenser subcooler coils, where

applicable, for air-cooled applications.

06D Compressor Units

charge required to fill subcooler after clear sight glass is

obtained.

— See condenser data for additional

INITIAL START-UP

CHECKING OPERATION

Refer to Carrier Standard Service Techniques Manual,

Chapter 2 for complete instructions on checking electrical

components.

Oil Charge (See Tables 2A and 2B) —

level in compressor sight glass after 15 to 20 minutes of

operation. If oil level is low, add oil according to methods

described in Carrier Standard Service Techniques Manual,

Chapter 1 (Section 1-11). Add oil through suction manifold

connection on 4-cylinder compressors, and oil port on

6-cylinder compressors.

The preferred method for a complete recharge is to

glass with compressor shut down.

When additional oil, or a complete charge, is required, use

only Carrier-approved compr essor oil.

Approved* oils are:

Witco. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ..Suniso 3GS

T exaco, Inc. . . . . . . . . . . . . . . . . . . . . . . . . . . . . Capella WF-32

*Oils approved for R-12, R-22, R-502 Carrier refrigerants.

For other refrigerants, contact Carrier Factory Sales

Representative.

IMPORTANT: Do not reuse drained oil and do not use oil

that has been exposed to atmosphere.

Check oil

1

/2 sight

Do not attempt start-up with terminal cover removed.

Bodily injury or death may result from explosion and/or

fire if power is supplied to compressor with the terminal

cover removed or unsecured. See warning label on terminal cover.

Crankcase heater should be energized a minimum of

24 hours before starting unit. Do not permit crankcase heaters

to be deenergized during normal shutdown periods.

1

Check to see t hat oi l leve l is

glass.

Open water supply valve and allow water to reach condenser. Open pressure line valve of water regulating valve, if used.

(Turn condenser fan on when the compressor unit is applied

with air-cooled condenser.)

Backseat (open) the compressor suction and discharge shutoff valves; open liquid line valve at receiver.

Start evaporator fan or chilled water pump.

To Start Compressor —

control power switch, and unit ON-OFF switch. Time Guard®

control circuit causes a short delay before compressor starts.

Recheck oil level and check oil pressure. See Oil Charge for

details.

With unit operating, voltage at compressor terminals must

be within limits shown on nameplate. Phases must be balanced

within 2% of voltage (refer to Electrical Connections section).

Contact local power company for correction of improper line

voltage or phase imbalance. Operation of unit on improper line

voltage or with excessive phase imbalance constitutes abuse

and is not covered by Carrier Warranty.

NOTE: The 06D, 07D unit safety controls are of the

automatic-reset type. If compressor is shut off by a safety

control, do not permit control to reset more than once before

determining cause of shutdown.

/3 to 2/3 up on compressor sight

Close main power switch,

High-Pressure Switch —

er water or blocking airflow on air-c ooled units, allowing head

pressure to rise gradually. Check discharge pressure constantly

throughout procedure. Compressor should shut off within 10 psi

of values shown in Ta ble 3.

Low-Pressure Switch —

tion shutoff valve or by completely closi ng liquid line shutoff

valve. A decrease of suction pressure will follow. Compressor

should shut off within 4 psi of values shown in Table 3.

Oil Pressure Switch (OPS) —

protects against damage from loss of oil or loss of oil pressure

during unit start-up. If the oil pressure differential sensed by the

OPS is 6 psig or less on unit start-up, the switch remains closed

and the OPS heater is energized.

The switch time delay is approximately 45 seconds. If after

45 seconds the oil pressure differential sensed by the OPS is

less than 11 psig, the heater remains energized. The OPS temperature actuated switch then opens and the compressor is

deenergized. If the differential reaches 11 psig, the OPS opens

and deenergizes the heater and the system operates normally.

IMPORTANT: If the oil pressure switch causes unit lockout, determine and correct the cause of the lockout (such as

loss of compressor oil or flooded compressor) before

restarting the unit. Failure to correct the cause of OPS lockout may constitute abuse. Equipment failure due to abuse is

not covered by warranty.

To restart the unit, push the OPS reset button and then push

the control circuit switch on the unit control box to OF F and

then to ON.

Time Guard® Control —

approximately 5 minutes before restarting compressor after

shutdown for any reason. On starting, the Time Guard control

timer causes a delay of 15 seconds after thermostat closes

before compressor will start.

Check by throttling condens-

Check by slowly closing suc-

The oil pressure switch

Control provides a delay of

8

Page 9

Table 2A — 06D Physical Data

UNIT 06D A8081 H3131 A8181 E8251 E3281 E5371

OPERATING WEIGHT (lb)

REFRIGERANT

COMPRESSOR — 06D*

Cylinders

Bore (in.)

Stroke (in.)

Displacement (cfm at 1750 rpm)

Maximum Rpm

Oil Charge (pt)

High Side Maximum Pressure

Low Side Maximum Pressure

CONNECTIONS (in.)

Suction Valve (ODF)

Discharge Valve (ODF)

*Compressors listed are for R-22 applications. For R-134a and R-507/

404A an 06DR compressor is standard. Factory compressor substitutes

may be made. Contact Carrier Sales Representative.

180 250 265 325 325 330

R-134a, R-22, R-507/404A

M808 M313 A818 A825 A328 A537

2446 6 6

2222 2 2

1

/

1

4

8 13 18.3 23.9 28 37.1

11

34.55.5 8 8 8

7

/

8

5

/

8

7/

8

5/

8

→

7

/

16

11/

4

115/

32

115/

1750

450 PSIG

245 PSIG

11/

8

7/

8

NOTE: The 06DE8251 compressor unit with the 06DA825 compressor

replaces the 06DE8241 once inventory of the 06DA824 compressor is

depleted.

13/

7/

8

8

13/

8

7/

8

13/

11/

Table 2B — 07D Physical Data

UNIT 07D A203 B205 A208 B210 B212 B215

OPERATING WEIGHT (lb)

REFRIGERANT

COMPRESSOR — 06D*

Cylinders

Bore (in.)

Stroke (in.)

Displacement (cfm at 1750 rpm)

Maximum Rpm

Oil Charge (pt)

High Side Maximum Pressure

Low Side Maximum Pressure

CONDENSER (Shell and Tube)† Part Number

Refrigerant Storage

Capacity (lb)

R-134a

R-22

Min Refrigerant Operating

Charge (lb)

REFRIGERANT CONNECTION (in. ODF)

Inlet

Outlet

WATER CONNECTION (in. FPT)

Inlet/Outlet

R-507/404A

LEGEND

FPT —

ODF —

*Compressor listed is the standard compressor for R-22, air conditioning

duty. An 06DR compressor is standard equipment for low temperature

(R-507/404A) or medium temperature (R-134a) applications. Factory

substitutions may be made. Contact Carrier Sales Representative.

Female Pipe Thread

Outside Diameter, Female

270 395 420 545 595 620

R-134a, R-22, R-507/404A

M808 M313 A818 A825 A328 A537

244666

222222

1

/

1

4

8 13 18.3 23.9 28 37.1

11

34.55.58 8 8

7

/

16

1750

450 PSIG

245 PSIG

11/

4

115/

32

115/

P701-0605CX P701-0607CX P701-0610CX P701-0615CX P701-0620CX P701-0625AX

17.20 15.90 24.40 31.60 27.40 39.80

2.86 3.16 5.00 7.55 8.47 9.18

17.00 15.70 24.10 31.20 27.10 39.30

2.80 3.10 4.90 7.40 8.30 9.00

14.70 13.60 20.90 27.10 23.50 34.10

2.80 3.10 4.90 7.40 8.30 9.00

5

/

1

8

1

/

1

8

111

15/

8

11/

8

†The condenser listed is for R-22, air conditioning duty and may change

based on the application. Maximum condenser operating pressure:

350 psi refrigerant side, 300 psi water side (“CX” models); 350 psi

refrigerant side, 150 psi water side (“AX” models).

NOTE: The 07DB210 with the 06DA825 compressor replaces the

→

07DB210 with the 06DA824 once the compressor inventory is depleted.

15/

11/

8

8

1

/

4

15/

11/

11/

8

8

4

15/

11/

11/

8

8

4

15/

11/

16

8

8

16

8

8

2

Table 3 — Factory Switch Settings

PRESSURE CHANGE AFFECTING

SWITCH TYPE

High Pressure

210 (±10) (psig) 290 (±10) (psig)

Low Pressure

Oil Pressure

LEGEND

psid —

psig —

pounds per square inch differential

pounds per square inch gage

NOTES:

1. Values for the high- and low-pressure switches based on R-22.

For other refrigerants, reset to pressure corresponding to saturation temperatures indicated by the listed pressures.

2. Values for oil pressure are above operating suction pressure

(pressure differential between suction and discharge pressures

of oil pump).

SWITCH POSITION

Closed Open

70 (±4) (psig) 60 (±4) (psig)

6 (psid) 11 (psid)

CAPACITY CONTROL (Suction Cutoff Type)

Control Set Point (Cylinder Load Point) —

point is adjustable from 0 to 86 psig. Pressure differential

between cylinder load-up point and cylinder unload point is

adjustable fr om 7 to 19 p si.

To Regulate Control Set Point —

Turn adjustment nut clockwise to its bottom stop (with nut in

this position, set point is 86 psig). Control set point is then

regulated to desired pressure by turning adjustment nut counterclockwise. Every full turn decreases set point by 7.2 psi.

Approximately 12 turns in counterclockwise direction will decrease control set point to 0 psig. Table 4 shows steps of control

for the compressor and condensing unit.

Pressure Differential Adjustment —

ential adjusting screw counterclockwise to its back-stop position (differential in this position is 7 psi). Pressure differential is

set by turning adjustment screw clockwise. Every full turn

increases differential by 1.2 psi. Approximately 10 turns in

clockwise direction will increase pressure differential to 19 psi.

9

Refer to Fig. 7.

Turn differ-

Set

802

Page 10

CONTROL

SET POINT

ADJUSTMENT

NUT

POWER

HEAD

PRESSURE

DIFFERENTIAL

ADJUSTMENT

SCREW

VALVE BODY

BYPASS

PISTON RING

BYPASS PISTON-USED

WITH HOT GAS BYPASS

TYPE OF UNLOADING ONLY.

NOT REQUIRED WITH

SUCTION CUTOFF TYPE

UNLOADING.

DIFFERENTIAL SCREW

SEALING CAP (CAP MUST

BE REPLACED TO PREVENT

REFRIGERANT LEAKAGE)

Fig. 7 — Capacity Control Valve

(Pressure Type)

Table 4 — Capacity Control Reduction Steps

% Full Load Capacity

100 67 49 32

% Full Load kW

100 73 57 46

Number of Active Cylinders

24—2—

464—2

UNIT 06D,07D

ALL 4 CYLINDER

MODELS

ALL 6 CYLINDER

MODELS

NO. OF

CONTR

CYL

Capacity Control Pressure (Fig. 8)

LOADED OPERATION — Pressure-operated control valve

is controlled by suction pressure and actuated by discharge

pressure. Each valve controls 2 cylinders (one bank). On

start-up, controlled cylinders do not load up unt il differential

between suction and discharge pressures is approximately

25 psi.

When suction pressure rises high enough to overcome

control set point spring, the diaphragm snaps to the left and

relieves pressure against the poppet valve. The drive spring

moves the poppet valve to left and it seats in the closed

position.

With poppet valve closed, discharge gas is directed into the

unloader-piston chamber and pressure builds up against the

piston. When pressure against unloader piston is high enough

to overcome the unloader valve spring, piston moves valve to

the right, opening suction port. Suction gas can now be drawn

into the cylinders and the bank is running fully loaded.

UNLOADED OPERATION — As suction pressure drops

below set point, control spring expands, snapping diaphragm to

right. This forces poppet valve open and allows gas from

discharge manifold to vent through base of control valve to

suction side. Loss of full discharge pressure against unloaded

piston allows unloader valve spring to move valve left to

closed position. The suction port is blocked, isolating the

cylinder bank from the suction manifold. The cylinder bank is

now unloaded.

CONDENSER MAINTENANCE

To inspect and clean condenser, drain water and remove

condenser heads. To drain condenser , shut off water supply and

disconnect inlet and outlet piping. Remove drain plugs and

vent plug.

With condenser heads removed, inspect tubes for refrigerant

leaks. (Refer to C arrier Refr igerant Ser vice T e chniques Manual.)

Clean condenser tubes with nylon brush (available from

Carrier Service Department). Flush water through tubes while

cleaning. If hard scale has formed, clean t ubes chemically. Do

not use brushes that will scrape or scratch tubes.

Because the condenser water circuit is usually an open

system, the condenser tubes may be subject to contamination

by foreign matter. Local water conditions may cause excessive

fouling or pitting of tubes. Condenser tubes, therefore, should

be cleaned at least once a year or more often i f the water is

contaminated.

Proper water treatment can minimize tube fouling and

pitting. If such conditions are anticipated, water treatment

analysis is recommended. Refer to the Carrier System Design

Manual, Part 5, for general water conditioning information.

If hard scale has formed, clean the tubes chemically. Consult an experienced and reliable water-treatment firm in your

area for treatment recommendations. Clean the condenser by

gravity or by forced circulation as shown in Fig. 9 and 10.

IMPORTANT: If the ambient temperature is below 32 F

during a shutdown period; protect the condenser from

freezing by draining the water from the system or by adding antifreeze to the water.

10

Page 11

LEGEND

Fig. 11 — Compressor

(Bottom Plate Removed)

1—

Oil Pressure Relief Valve

5—

Eccentric Shaft

2—

Piston and Eccentric

Strap Assembly

6—

Eccentric Strap Side

Shield

3—

Motor End Counterweight

7—

Oil Suction Tube

4—

Oil Return Check Valve

8—

Pump End Counterweight

FILL CONDENSER WITH

SUCTION

PUMP

SUPPORT

TANK

FINE MESH

SCREEN

RETURN

GAS VENT

PUMP

PRIMING

CONN.

GLOBE

VALV ES

1” PIPE

CONDENSER

REMOVE WATER

REGULATING VALVE

CENTRIFUGAL PUMP 1/2 HP

30 GPM AT 35’ HEAD

CLOSE VENT PIPE

VALVE WHEN

PUMP IS

RUNNING

CLEANING SOLUTION. DO

NOT ADD SOLUTION

MORE RAPIDLY THAN

VENT CAN EXHAUST

GASES CAUSED BY

CHEMICAL ACTION.

3’ TO 4’

1”

VENT

PIPE

PIPE

5’ APPROX

Fig. 9 — Gravity Circulation

Fig. 8 — Capacity Control Valve Operation

CONDENSER

Fig. 10 — Forced Circulation

11

Page 12

SERVICE

LEGEND

Fig. 11 — Compressor

(Bottom Plate Removed)

1—

Oil Pressure Relief Valve

5—

Eccentric Shaft

2—

Piston and Eccentric

Strap Assembly

6—

Eccentric Strap Side

Shield

3—

Motor End Counterweight

7—

Oil Suction Tube

4—

Oil Return Check Valve

8—

Pump End Counterweight

Do not remove the compressor terminal box cover until

all electrical power is disconnected and pressure is

relieved. Terminal pins may blow out causing injuries,

death, and/or fire.

Service Notes

1. Where compressor components are shown, they are in

normal order of removal from compressor.

2. For replacement items, use Carrier specified parts.

See Carrier 06D Specified Parts list for c ompressor part

interchangea b ilit y.

3. Before compressor is opened, the refrigerant must be

removed from it by the Pumpdown method.

a. Start compressor, close suction shutoff valve, and

reduce crankcase pressure to 2 psig (bypass low

pressurestat with jumper).

b. Stop compressor and isolate from system by

closing discharge shutoff valve.

c. Bleed any residual refrigerant. Drain oil if

necessary.

4. After disassembly, clean all parts with solvent. Use

mineral spirits, white gasoline or naphtha.

5. Before assembly, coat all parts with compressor oil and

clean and inspect all gasket surfaces . Replace all gaskets

with new standard specified gaskets, coated with

compressor oil. See Table 5 for typical torque values.

6. After reassembly, evacuate compressor and open suction

and discharge valves. Restart compressor and adjust

refrigerant charge.

Table 5 — Torque Values

Testing Oil Pump —

Observe oil level sight glass. The

oil pressure relief valve line is positioned to discharge oil

against sight glass. When oil does not discharge from this line,

it is an indication of low oil pump pressure.

If oil pump pressure is low, remove and check oil filter

screen, oil pressure regulator and oil return check valve.

OIL PRESSURE RELIEF VAL VE (Fig. 1 1) — Uns cr ew re-

lief valve assembly from motor partition plate, and be sure

assembly is not clogged or the plunger is not stuck.

OIL RETURN CHECK VALVE (Fig. 11) — Unscrew check

valve from motor partition plate. Be sure flutter valve is not

sticking and that it seats tightly .

OIL FILTER SCREEN (Fig. 12) — Screen is accessible

through bottom cover plate. Remove and inspect strainer for

holes and dirt. Clean it with solvent and replace.

OIL PUMP AND BEARING HEAD (Fig. 12) — The oil

pump assembly is contained in the pump end bearing head

aluminum casting. The pump end main bearing is a machined

part of this casting. An insert bearing is not required.

Remove Bearing Head Assembly from Crankcase

— Remove

in sequence (refer to Fig. 12 and 13): oil pump cover, oil feed

guide retaining spring, oil feed guide, pump drive segment. If

damage to the oil pump or main bearing is found, a new pump

end bearing head assembly should be installed.

Replace (Refer to Fig. 12 and 13)

— For torque values, refer

to Ta ble 5. Following steps are used to replace bearing head:

1. Bolt bearing head to crankcase. Place pump drive segment into position and secure to end of crankshaft with

cap screws and lock washers that were removed (see

Fig. 13).

2. Insert oil feed guide with large diameter inward and place

guide retainer spring over small diameter of guide.

3. Install gasket and oil pump cover.

SIZE

DIAM

(in.)

1

/

16

1

/

8

1

/

4

5

/

16

3

/

8

7

/

16

1

/

2

5

/

8

No. 10

1

1

/

2

NEF —

THREADS

PER IN.

27 (pipe) 8-12 Pipe Plug — Crankshaft

20 (pipe) 6-10

20 (pipe) 20-25 Pipe Plug — Press. Gage Conn.

20 10-12 Connecting Rod Capscrew

28

18

16

14 55-60 Motor End Cover — Crankcase

13 80-90 Suction Service Valve

11 25-30 Crankshaft Spinner Tube

32 4- 6 Oil Pump Drive Segment

18 NEF 35-45 Oil Level Sight Glass

LEGEND

National Extra Fine

TORQUE

RANGE

(lb-ft)

Oil Return Check Valve —

Crankcase

12-15 Baffle Plate — Crankcase

12-15 Side Shield

12-15 Oil Pump Drive Segment

12-15 Unloader Valve

16-20

16-20 Terminal Block Cap Screws

20-25 Suction Service Valve

20-25 Discharge Service Valve

30-35 Pump End Bearing Head

30-35 Bottom Plate — Crankcase

30-35 Compressor Foot

30-35 Cylinder Head

30-35 Motor End Cover — Crankcase

Cover Plate — Pump End

Bearing Head

USAGE

1

8

7

6

5

2

3

4

12

Page 13

87 6 5 4

9

10

11

12

13

3 26 2

24

23

22

PHASE BARRIER

POSITIONING

KEY (SEE FIG. 19)

1

25

14

44 42 41 16 38 37 36 35

15

394043

16

15

45

17

18

46

47

48 49 27

Fig. 12 — 06D Compressor Components (4-Cylinder with Eccentric Shaft Shown)

2019

34 33 32 31 30

21

29

28

13

Page 14

CAPACITY

CONTROL

VALV E

CAP SCREWS

(NONINTERCHANGEABLE

WITH FLANGE COVER

CAP SCREWS)

BYPASS PISTON PLUG

SPRING

TAB

FLANGE COVER

CAP SCREWS

(NONINTERCHANGERABLE

WITH CONTROL VALVE

CAP SCREWS)

GASKET

GAS PORT

Fig. 14 — Removal of Capacity Control Valve

Fig. 15 — Removal of Bypass Piston Plug

Motor Cover Gasket

1—

Motor End Cover

2—

Discharge Manifold Connection

3—

Valve Plate Gasket

4—

Valve Plate Assembly

5—

Cylinder Head Gasket

6—

Cylinder Head

7—

Cylinder Head Washer

8—

and Cap Screw

Suction Manifold Connection*

9—

Suction Valve Positioning Spring

10 —

Suction Strainer

11 —

Bearing Head Gasket

12 —

Oil Pump Inlet Passage

13 —

Bearing Head Washer

14 —

and Cap Screw

Oil Pump Cover

15 —

Pump End Bearing Head

16 —

LEGEND FOR FIG. 12

Oil Drain Plug

17 —

Crankcase

18 —

Bottom Plate Gasket

19 —

Bottom Plate

20 —

Bottom Plate Washer and Cap Screw

21 —

Oil Filter Screen

22 —

Oil Return Check Valve

23 —

Oil Level Sight Glass

24 —

Motor Terminal Plate

25 —

Dowel Pins (For Suction Valve

26 —

Positioning)

Equalizing Tube and Lock Screw Assembly

27 —

Lockwasher

28 —

Rotor Lockwasher

29 —

Rotor Drive Key

30 —

Piston Pin Lock Ring

31 —

Piston Pin

32 —

Piston

33 —

Oil Ring

34 —

Compression Rings

35 —

Eccentric Strap

36 —

Eccentric Strap Side Shield

37 —

Pump End Counterweight

38 —

Oil Pump Drive Segment

39 —

Drive Segment Cap Screws

40 —

and Lockwashers

Oil Feed Guide

41 —

Oil Feed Guide Retainer Spring

42 —

Cover Gasket

43 —

Pump Cover Cap Screw and Washer

44 —

Counterweight Bolt

45 —

Eccentric Strap Side Shield

46 —

Motor End Counterweight

47 —

Locknut

48 —

Eccentric Shaft (or Crankshaft)

49 —

*Used to add compressor oil.

TOP

8

Suction Strainer

1—

Assembly

Oil Pump Bearing Head

2—

Assembly

Rotor Retaining Ring

3—

Oil Pump Drive Segment

4—

Fig. 13 — Removing Pump End Bearing Head

LEGEND

Oil Pump Rotor

5—

Drive Segment Cap

6—

Screws

Bearing Head Cap

7—

Screws

Oil Pump Inlet Passage

8—

Three Allen head cap screws hold capacity control valve in

1

place (Fig. 14). Remove screws using a cut-down

wrench, and pull valve from cylinder head.

3

/16-in. Allen

Remove same number of piston plugs from replacement

compressor as number of unloaders supplied with original

compressors. Three Allen head cap screws hold piston plug

2

assembly in place. Remove flange cover, gasket, spring and

bypass piston plug (Fig. 15). A tapped hole is provided in

piston to allow it to be pulled out. Hole has same thread

3

4

5

6

7

diameter as cap screws removed above.

Cylinder Heads —

Disassemble cylinder heads by re-

moving cap screws and prying up on side between cylinder

head and valve plate to break heads loose from valve plate. Do

not strike cylinder heads to break loose.

Check heads for warping, cracks and damage to gasket

surfaces. When replacing cylinder head, torque cap screws

30 to 35 lb-ft to prevent high to low side leak in center portion

of cylinder head gasket.

Service Replacement Compressors —

ment compressors are not equipped with control valves. One or

both side bank cylinder head(s) is plugged with a spring loaded

plug piston assembly. Compressor will run fully loaded with

piston plug(s) in place.

compressor (ensures proper val ves are used with correct set-

Transfer original capacity control valve(s) to replacement

ting). For sealing purposes, install a plug piston assembly into

each cylinder head of original compressor f rom which a control valve was removed.

Replace-

14

Page 15

Suction and Discharge Valve Plate Assembly

CYLINDER HEAD

GASKET

VALVE PLATE

GASKET

DISCHARGE VALVE

SCREW AND

LOCK WASHER

DISCHARGE

VALV E

VALVE PLATE

VALVE PLATE ASSEMBLY

DISCHARGE

VALVE STOP

DISCHARGE

PORT

HIGH-PRESSURE

CONNECTION

LOW-PRESSURE

CONNECTION

SUCTION

VALV E

VALVE PLATE

DOWEL PIN

SUCTION VALVE

POSITIONING

SPRING

Fig. 16 — Valve Plate Assembly

Fig. 17 — Suction Valve and Positioning

Springs in Place

(Fig. 16) —

compressor down and observing suction and discharge

pressure equalization. If a discharge valve is leaking, the

pressures will equalize rapidly. Maximum allowable discharge

pressure drop is 3 psi per minute after an initial drop of 10 to

15 psi in the first half minute.

If there is an indicated loss of capacity and discharge valves

check properly, remove suction and discharge valve plate

assembly and inspect suction valves.

IMPORTANT: This test procedure is not applicable to

compressors equipped with pressure actuated or solenoid

unloader valves due to rapid pressure equalization rate.

Check suction and discharge valves by disassembling

valve plate (see Fig. 16).

DISASSEMBLY — Remove cylinder head.

1. Remove discharge valve assembly: cap screws, valve

stops, valve stop supports and valves.

2. Pry up on side of valve plate, between valve plate and

cylinder deck, to remove valve plat e and expose suction

valves. Remove suction valves and suction valve positioning springs from dowel pins.

Inspect valves and valve seats for wear and dam age. See

Table 6. Check cylinder deck valve stops for uneven wear.

Replace valves if cracked or worn. If valve seats are worn,

replace complete valve plate assembly. If cylinder deck valve

stops are worn, replace compressor.

REAS S E M BLY — Do not interchange valves. Install suction

valve positioning springs on dowel pins. Assemble positioning

springs with spring ends bearing against cylinder deck

(Fig. 17). Springs bow upward. Place suction valves on dowel

pins, over positioning springs. Place valve plate on cylinder

deck, and reinstall discharge valve plate assembly. Retorque

discharge valve stop cap screws to 16 lb-ft. Replace cylinder

head. Be sure cylinder head gasket is lined up correctly with

cylinder head and valve plate.

Test for leaking discharge valves by pumping

COMPRESSOR PART

MOTOR END

Main Bearing Diameter Max

Journal Diameter Min

PUMP END

Main Bearing Diameter Max

Journal Diameter Min

CRANKPIN DIAMETER Min

THROW Max

THRUSTWASHER Max

ECCENTRIC DIAMETER Max

CONN. ROD DIAMETER Max

PISTON PIN BEARING Min

CYLINDERS

Bore Max

Piston Diameter Min

Piston Pin Diameter Min

Piston Pin Bearing

Piston Ring Gap Max

Piston Ring Side Clearance Max

*Maximum allowable wear above maximum or below minimum factory tolerances

shown. For example: difference between pump end main bearing diameter and

journal diameter is .001 in. (1.3745 – 1.3735) per factory tolerances. Maximum

allowable difference is .004 in. (.002 + .002).

†Tolerance for the 06DA825 same as 06DA824.

Table 6 — Compressor Wear Limits (Factory Tolerances) (in.)

COMPRESSOR MODEL

06DM808 06DM313 06DA818 06DA825† 06DA328 06DA537

1.3755 1.6240 0.002

1.3735 1.6233 0.002

1.3745 0.002

1.3735 0.002

2.2030 1.3735 2.2030 1.3735 0.0025

1.2500 1.0000 1.4374 1.2500 1.9396 —

Min

Min

Min

Min

1.2460 — 1.4344 1.246 —— —

— 0.1570 0.025

— 0.1550 0.025

2.2035 — 2.2035 — 0.002

— 1.3755 — 1.3755 0.002

0.6878 0.001

2.0005 0.002

1.996 0.002

0.6873 0.001

Press Fit —

0.0130 0.025

0.0050 0.025

0.0020 0.002

0.0010 0.002

15

MAX* ALLOW

WEAR

Page 16

Cleaning Suction Strainer

Fig. 18 — Motor End Cover Assembly

ACROSS-THE-LINE APPLICATION (5 TERMINALS)

Fig. 19 — Terminal Plate Assembly

1. Pump down compressor.

2. Remove motor end cover and screws holding disc type

strainer (Fig. 1 8) to c ove r.

3. Clean strainer with solvent or replace if broken or

corroded.

4. Replace strainer and motor end cover. Purge or evacuate

compressor before starting.

Motor Replacement —

replaceable. Stator is a press fit into motor housing. If compressor motor is damaged, replace compressor.

Terminal Plate Assembly —

bly is shown in Fig. 19. Do not disassemble for any reason except to replace the phase barrier, which may become damaged.

If refrigerant leakage or a ground short occurs, the entire terminal plate assembly must be replaced.

If it becomes necessary to remove the phase barrier, proceed

as follows:

1. Loosen and remove all terminal nuts.

2. Remove lock washers and wire terminals.

3. Loosen and disengage the center screw. (Do not try to

remove the screw.)

4. Lift the phase barrier off the terminal screws (the spacers

and the center screw are removed with the phase barrier).

IMPORTANT: Do not disturb the jam nuts on which the

phase barrier rests.

S

tator and rotor are not field

The terminal plate assem-

STRAINER SCREWS & WASHERS

SUCTION STRAINER

MOTOR END COVER

SUCTION SERVICE VALVE

BARRIER POSITIONING KEY (THIS SIDE IS

ADJACENT TO THE CYLINDER HEAD)

PHASE BARRIER

NO TERMINAL IN

THIS SECTION

TERMINAL NUMBERS ON

THIS SURFACE

VALVE GASKET

VALVE CAP

SCREW

TERMINAL

NUT(TYP)

Procedure for reassembling the phase barrier:

1. Place phase barrier over the terminal screws. B e sure po-

sitioning key is in the recess in the terminal plate before

proceeding further.

2. Place the spacers and wire terminals on the terminal

screws.

3. Place the lock washers and terminal nuts over the wire

terminals and tighten to specified torque (18 to 30 lb-in.).

4. Install the center screw through the phase barrier and

tighten to the specified torque (15 to 25 lb-in.).

NOTE: The design allows for clearance between the center

screw head and the phase barrier. Thus, the torque limit may

be reached before the screw head contacts the phase barrier.

This condition is acceptable.

Compressor Running Gear Removal

1. Remove pump end bearing head.

2. Remove motor end cover carefully to prevent damage to

stator. Support cover and lift of f horizontally until it clears

windings.

3. Remove bottom cover plate.

4. Remove equalizer tube assembly from motor end of

crankshaft (or eccentric shaft). If shaft turns , preventing

tube assembly from being loosened, block shaft with a

piece of wood.

5. Remove rotor using a jackbolt. Insert a brass plug into

rotor hole to protect end of crankshaft from jackbolt.

Support rotor while it is being removed to prevent stator

damage.

6. Remove connection rod caps from compressors using

connecting rods and crankshafts. Label caps and rods so

they may be reinstalled in same plate on crankshaft.

BLACK JAM NUTS

ON TERMINALS 8 & 9;

BRASS JAM NUTS ON

TERMINALS 1, 2 AND 3

CENTRAL SCREW (THREADS

INTO TERMINAL PLATE)

SPACER

(TYP)

LOCK WASHER

(TYP)

7. Remove bolts holding counterweights and eccentric strap

side shields to eccentric shaft. Remove eccentric strap

side shields. Remove pump end counterweight through

pump end bearing head opening. Motor end counterweight will remain on eccentric shaft until shaft is

removed.

8. Pull eccentric shaft or crankshaft out through pump end

opening. Guide eccentric straps from eccentric shaft

during removal process. Rotate shaft and tap it lightly to

prevent straps from jamming.

9. Remove eccentric straps or connecting rods and pistons

through bottom cover plate opening.

10. Disassemble connecting rods or eccentric straps from

pistons by removing lock ring(s) and piston pins. Remove

oil and compression rings from piston. Keep each piston

assembly together for proper reassembly.

Check all parts for wear and tolerances shown in Ta ble 6.

Check crankshaft (eccentric shaft) oil passages and clean if

clogged.

16

Page 17

PUMP END MAIN BEARING — This bearing is a machined part of the new aluminum oil pump and bearing head

casting. Disassemble bearing head. If bearing is scored or

worn, replace complete bearing head.

CRANKCASE AND MOTOR END MAIN BEARINGS — These bearings are not field replaceable. If bearings

are worn or damaged, replace compressor.

Compressor Running Gear Replacement

CRANKSHAFT — Install crankshaft through pump end,

carefully guiding it through main bearings. Replace rotor.

Attach equalizer tube assembly to motor end of shaft.

Eccentric shafts must be installed after piston assemblies.

Place motor end counterweight on shaft before inserting shaft

into compressor. See Piston Assembly Replacement.

PISTON ASSEMBLY — Attach connecting rods or eccentric

straps to pistons with piston pins and lock in place with piston

pin lock rings. Place lock rings with gap on the side.

They should be tight enough so they cannot be rotated by

finger pressure.

RINGS

1. Check ring gap by inserting each ring separately in

cylinder, approximately

be between .013 and .005 inch.

2. Install compression rings in top piston grooves with side

marked “Top” toward piston head. Install oil ring below

compression ring with notched end on bottom. Stagger

ring gaps around piston.

3. Measure side clearance between ring and piston

(T able 6). Check for free action.

PISTON ASSEMBLY REPLACEMENT

Compressors Using Crankshafts

and piston assemblies into cylinders. Place chamfered sides of

connecting rods against radius of crankpins. Install connecting

rod caps to matching connecting rods through bottom of crankcase. Be sure chamfered sides of caps are against radius of

crankpins. Caps are locked in plac e with cap screw s. Use 8 to

10 lb-ft to tighten cap screws.

Compressors Using Eccentric Shafts

strap and piston assemblies into cylinders. Install eccentric

shaft through pump end, carefully guiding it through

eccentric straps and main bearings. Install pump end counterweight to eccentric shaft and replace eccentric strap side

shields.

Turn crankshaft or eccentric shaft to be sure there is no

binding between bearing surfaces and journals. Replace oil

screen, bottom cover plate, valve plates and cylinder heads.

3

/8 in. from top. Ring gap should

— Install connecting rod

— Install eccentric

COMPRESSOR MOTOR BURNOUT

Do not attempt start-up with terminal cover removed.

Bodily injury or death may result from explosion and/or

fire if power is supplied to compressor with the terminal

cover removed or unsecured. See warning label on terminal cover.

Clean-Up Procedure —

the stator winding decomposes, forming carbon, water and acid

which contaminate refrigerant systems. Remove these contaminants from system to prevent repeat motor failures.

1. Close compressor suction and discharge service valves,

and bleed refrigerant from compressor. Save remaining

refrigerant in system.

2. Check control box for welded contactor contacts, welded

overload contacts or burned out heater elements. Che ck

terminal plate for burned or damaged terminals, insulation, and shorted or grounded terminals. Repair or replace

where nece ssa ry.

3. Remove suction and discharge shutoff valve bolts and all

other connections to damaged compressor. Remove

damaged compressor and replace with new compressor.

Replace liquid line filter drier with a drier of one size

larger.

4. Purge new compressor . Tri ple-evacuate, using the following procedure:

a. Evacuate to 5000 microns.

b. Break vacuum with system refrigerant. Pressurize

to 15 psig. Wait 20 minutes to remove moisture.

c. Re-evacuate to 5000 microns.

d. Repeat Step b.

e. Evacuate to 1000 microns or below if possible.

5. Place compressor in operation. After 2 to 4 hours of

operation, check compressor oil for signs of discoloration

and/or acidity. If oil shows signs of contamination,

replace oil charge, filter driers, and cl ean suction st rainer

with solvent. Repeat this procedure until oil stays clean

and acid free for 48 hours of operation.

If a hermetic motor burns out,

17

Page 18

PROBLEM CAUSE REMEDY

Compressor does not run.

Compressor cycles on low-pressure

control.

Compressor cycles on high-pressure

control.

Insufficient capacity.

Unit operates long or continuously.

LEGEND

Thermostatic Expansion Valve

TXV —

TROUBLESHOOTING

Read Safety Considerations on page 1 before proceeding

with troubleshooting.

Main power line open. Replace fuse or reset circuit breaker.

Safety thermostat tripped. Reset thermostat.

Condenser water pump not running — power off. Restart.

Pump binding. Free pump.

Incorrect wiring. Rewire.

Motor burned out. Replace.

Control stuck open. Replace control.

Loose terminal connection. Check connections.

Improperly wired controls. Check wiring and rewire.

Low line voltage. Check line voltage — determine location of

Compressor motor defective. Check motor winding for open or short.

Seized compressor. Replace compressor.

Low-pressure control erratic in action. Raise differential setting, check capillary for

Suction shutoff valve partially closed. Open valve.

Low refrigerant charge. Add refrigerant.

Plugged suction strainer. Clean strainer.

Defective TXV. Replace.

High-pressure control erratic in action. Check capillary tube for pinches. Set control as

Discharge valve partially closed. Open valve.

Air in system. Purge.

Condenser scaled (or airflow restricted). Clean condenser.

Receiver not properly vented, refrigerant backs

up into evap condenser.

Condenser water pump or fans not

operating.

Refrigerant overcharge. Purge.

Low refrigerant charge. Add refrigerant.

Control set too high. Reset control.

Expansion valve plugged. Clean or replace.

Inefficient compressor. Check valves and pistons.

Expansion valve setting too high. Lower setting.

Iced or dirty evaporator. Defrost or clean.

Evaporator too small. Add surface or replace.

Condensing unit too small. Add unit or replace.

Expansion valve too small. Raise suction pressure with larger valve.

Restricted or small gas lines. Clear restriction or increase line size.

Low refrigerant charge. Add refrigerant.

Control contacts fused. Replace control.

Air in system. Purge.

Partially plugged or plugged expansion valve or

strainer.

Defective insulation. Replace or repair.

Service load. Keep doors and windows closed.

Inefficient compressor. Check valves.

Condenser scaled. Clean condenser.

Restricted evaporator air. Defrost coil, clean filters and ductwork.

voltage drop.

Replace compressor if necessary.

pinches, replace control.

required.

Repipe as required.

Start pump or fans.

Clean or replace.

18

Page 19

PROBLEM CAUSE REMEDY

System noises.

Compressor loses oil.

Frosted suction line.

Hot liquid line.

Frosted liquid line.

Frosted expansion valve.

LEGEND

Thermostatic Expansion Valve

TXV —

Piping vibration. Support piping as required, check for loose pipe

Expansion valve hissing. Add refrigerant, check for plugged liquid line

Compressor noisy. Check valve plates for valve noise, replace

Insufficient compressor oil. Add oil.

Leak in system. Repair leak.

Plugged or stuck compressor oil return

check valve.

Oil trapping in line. Check piping for oil traps.

Crankcase heaters not energized during

shutdown.

Expansion valve admitting excess

refrigerant.

Shortage of refrigerant. Repair leak and recharge.

Receiver shutoff valve partially closed or

restricted.

Restricted catchall. Replace.

Restricted strainer drier. Replace.

Ice plugging TXV orifice. Apply hot wet cloth to TXV.

Moisture indicated by increase in suction

pressure.

Plugged TXV strainer. Clean strainer or replace TXV.

connectors.

strainer.

compressor (worn bearings), check for loose

compressor holddown bolts.

Repair or replace.

Replace heaters.

Adjust expansion valve.

Open valve or remove restriction.

Install drier.

19

Page 20

Copyright 2002 Carrier Corporation

Manufacturer reserves the right to discontinue, or change at any time, specifications or designs without notice and without incurring obligations.

Book2244

Tab 1b2a2b3a

PC 802 Catalog No. 530-608 Printed in U.S.A. Form 06/07D-3SI Pg 20 802 7-02 Replaces: 06/07D-2SI

Loading...

Loading...