Page 1

Models QS12 & QS24

Modular Grills

Operating Instructions

050559--M

2/20/01

Page 2

Complete this page for quick reference when service is required:

r

Taylor Distributor:

Address:

Phone:

Service:

Parts:

Date of Installation:

Information found on data plate:

Model Number:

Serial Number:

Electrical Specs: Voltage Cycle

Phase

Maximum Fuse Size: Amps

Minimum Wire Ampacity: Amps

Part Number:

E February, 2001 Taylo

All rights reserved.

050559-M

Taylor Company

The word Taylor and the Crown design

are registered trademarks in the United States

of America and certain other countries.

a division of Carrier Commercial Refrigeration, Inc.

750 N. Blackhawk Blvd.

Rockton, IL 61072

Page 3

Table of Contents

Section 1 To the Installer 1............................................

Air Clearance 1.........................................................

Electrical Connections 1.................................................

Ventilation and Clearance 2..............................................

Leveling Procedures 2...................................................

Section 2 To the Operator 5...........................................

Section 3 Safety 6....................................................

Section 4 Operator Parts Id en t ificatio n 8...............................

QS12 8................................................................

QS24 9................................................................

QS12 Accessories 10.....................................................

QS24 Accessories 12.....................................................

Section 5 Important: To the Operator 14.................................

Release Material (units with upper cook surfaces only) 14.....................

Temperature Controls 15..................................................

Control Board 15.........................................................

Keypad and Display 15...................................................

Operating Screen and Controls 15.........................................

Maintenance Menu 17....................................................

Maintenance Menu Flowchart 20...........................................

Section 6 Operating Procedures 21.....................................

Opening Procedures 21...................................................

Cooking Procedures 23...................................................

Cleaning Between Product Runs 24........................................

Cleaning the Grease Tray Partition 25......................................

Closing Procedures 26...................................................

Weekly Cleaning Procedures 28...........................................

Table of Contents Models QS12 & QS24

Page 4

Table of Contents -- Page 2

r

Section 7 Troubleshooting Guide 29....................................

Section 8 Warranty Explanation 31......................................

Parts 31................................................................

Labor 31................................................................

Section 9 Parts List 32.................................................

Wiring Diagrams 39......................................................

Note: Continu in g research results in steady improvements; therefore, information

in this manual is subject to change without notice.

E February, 2001 Taylo

All rights reserved.

050559-M

Taylor Company

The word Taylor and the Crown design

are registered trademarks in the United States

of America and certain other countries.

Models QS12 & QS24 Table of Contents

a division of Carrier Commercial Refrigeration, Inc.

750 N. Blackhawk Blvd.

Rockton, IL 61072

Page 5

Section 1 To the Installer

This machine is designed for indoor use only.

DO NOT install the machine in an area where

a water jet could be used to clean or rinse the machine.

Failure to follow this instruction may result in serious

electrical shock.

Air Clearance

Clearances from the grill to other surfaces are required

for proper air circulation:

The required minimum clearances from the grill to

combustible construction is: 4” (102 mm) bottom, 3”

(76 mm) rear, and 3” (76 mm) sides.

Bottom: 4 inches (102 mm) minimum

Rear: 3 inches (76 mm) minimum

Sides: 3 inches (76 mm) to combustible

surfaces

0 inches (0 mm) to non-combustible

surfaces;

0 inches (0 mm) between grills in multiple

installations.

Failure to comply with these minimum clearance

requirements will affect grill performance, and

may cause component damage and overheating

of combustible surfaces.

proper maintenance will result in an installation

essentially free from hazard!

In all other areas of the world, equipment should be

installed in accordance with the existing local codes.

Please contact your local authorities.

Stationary appliances which are not equipped with a

power cord and a plug or other device to disconnect

the appliance from the power source must have an

all--pole disconnecting device with a contact gap of at

least 3 mm installed in the external installation.

This equipment is provided with a grounding lug

that is to be properly attached to the rear of the frame

by the authorized installer. The installation location is

marked by the equipotential bonding symbol (5021 of

IEC 60417--1) on the removable panel and the frame.

The proper wire size and fused circuit should be

selected according to grill data label information.

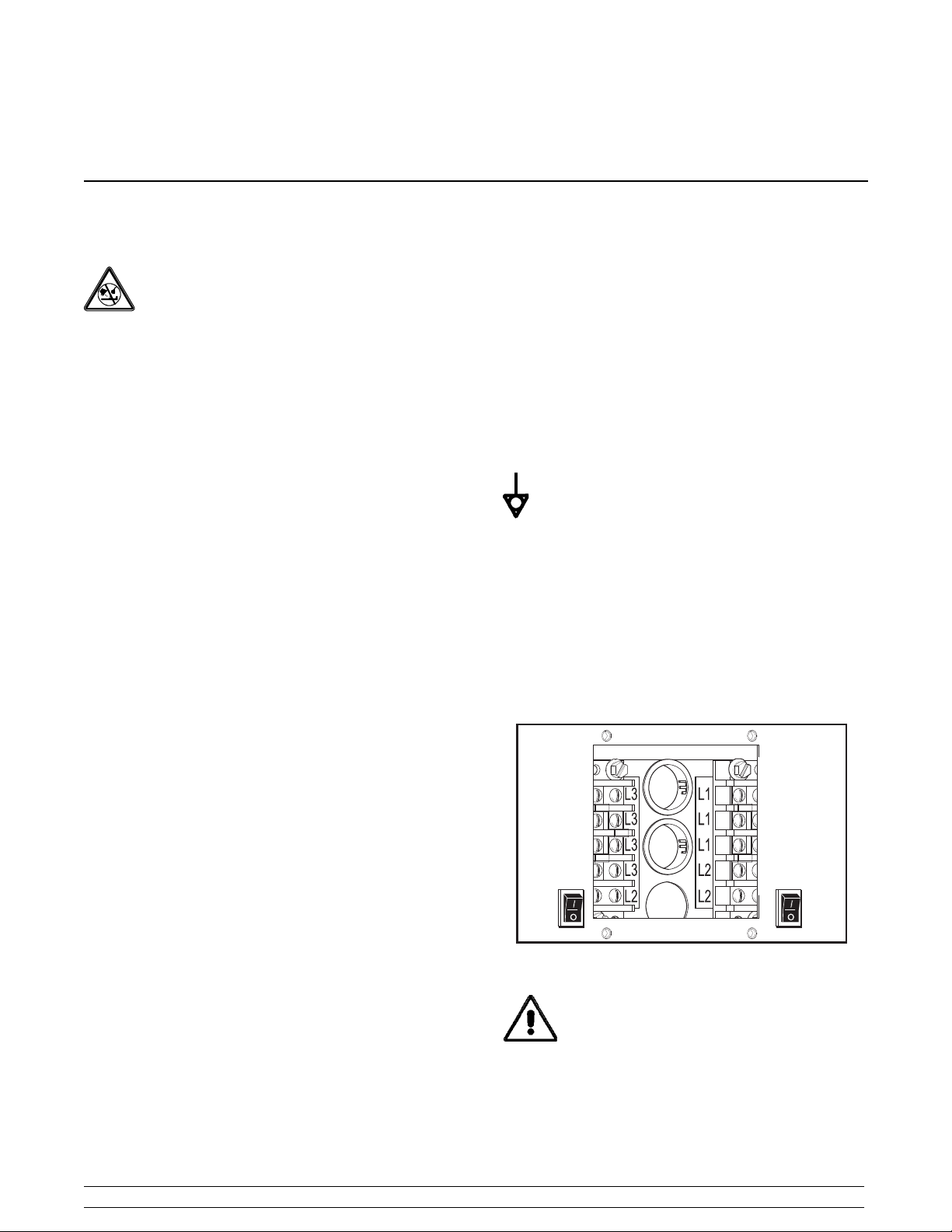

Incoming power must be connected to the terminals

with black characters on a white background, as

shown:

14092

Electrical Connections

The QS Series grills have one electrical connection.

Check the data plate on the grill for voltage, cycle,

phase and electrical specifications. The power

connection is located behind the access line cover on

the front of the grill.

In the United States, this equipment is intended to be

installed in accordance with the National Electrical

Code (NEC), ANSI/NFPA 70--1987. The purpose of

the NEC code is the practical safeguarding of persons

and property from hazards arising from the use of

electricity. This code contains provisions considered

necessary for safety. Compliance therewith and

Models QS12 & QS24 To the Installer

THE GRILL DURING A POWER OUTAGE. Grills

require electrical power for operation. In the event of

a prolonged power outage, place the unit in the “OFF”

position.

1

CAUTION: DO NOT ATTEMPT TO USE

Figure 1

050831

Page 6

Ventilation and Clearance

To ensure proper operation of this appliance it must be

installed so that the products of combustion are

efficiently removed. Do not store anything on top of the

grill.

Most service can be performed from the front of the

grill. When inspecting heating elements, the unit must

be disconnected and pulled out of the hood enclosure.

Allow four feet in front of the appliance for this purpose.

Leveling Procedures

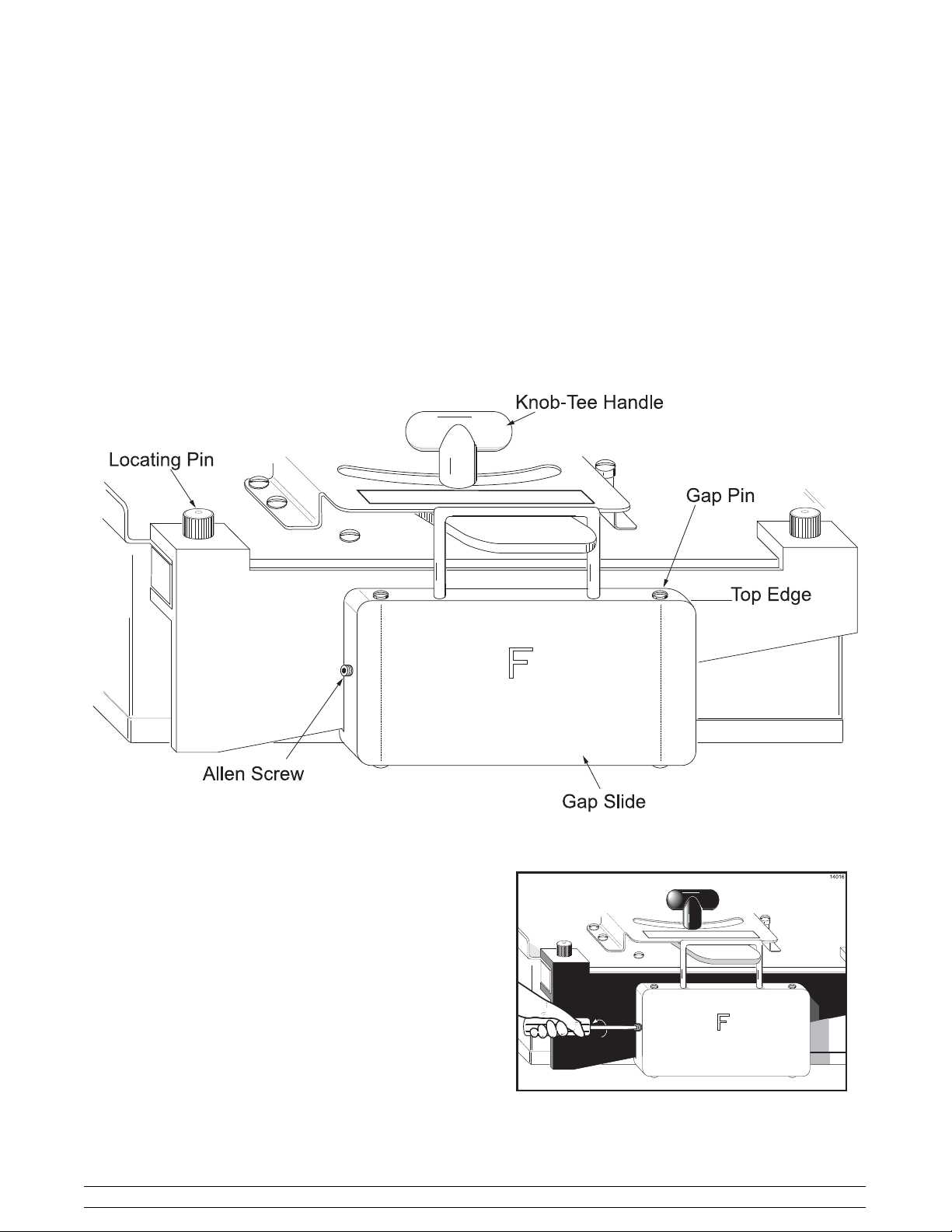

Step 1

The leveling adjustment needs to be performed while

the grill is at operating temperature. Remove the cook

surface shroud and release sheet.

Step 2

To allow adjustment of the gap pins, loosen the two set

screws located on the side of the front and rear gap

slide.

To the Installer

Figure 2

2

Figure 3

Models QS12 & QS24

Page 7

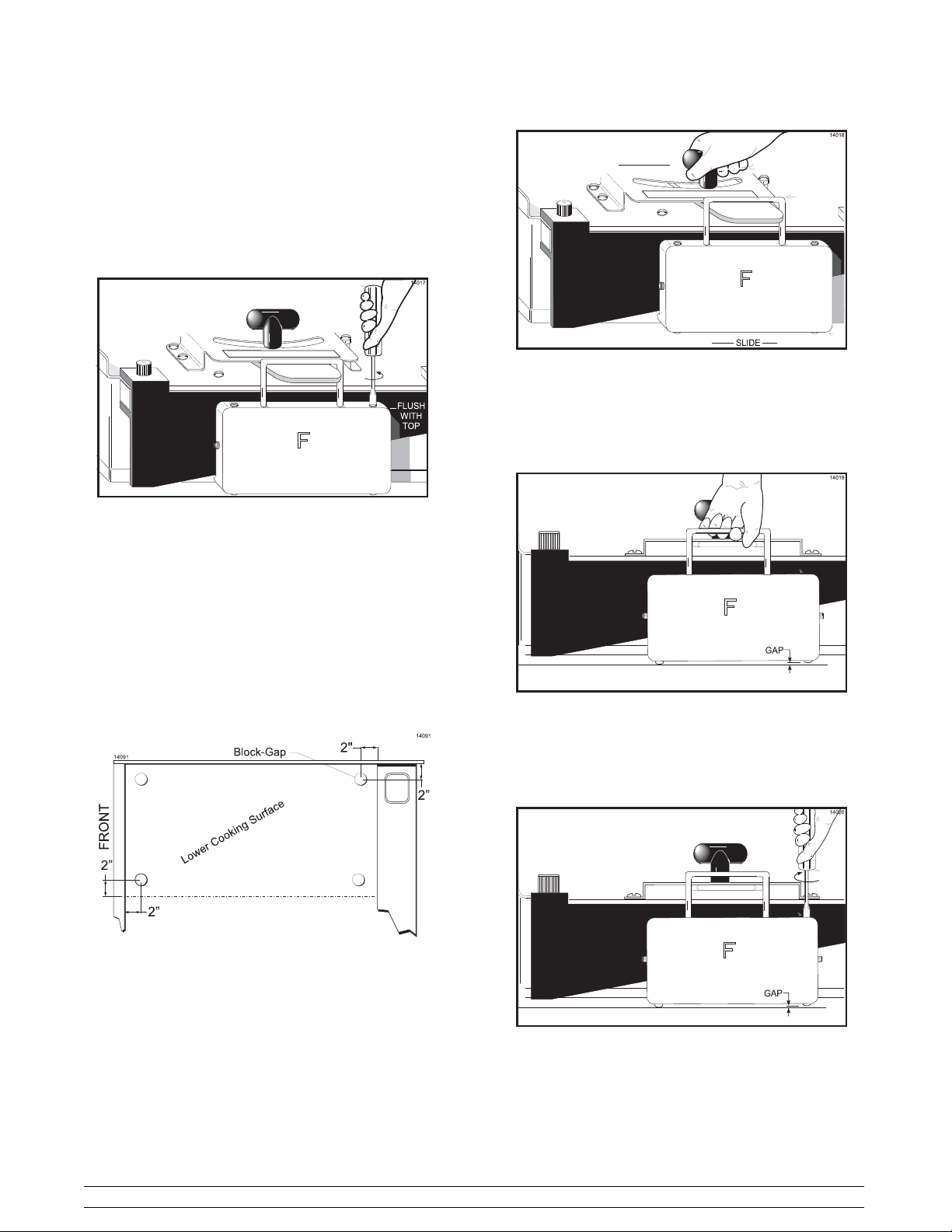

Step 3

Raise or lower both gap pins on the front gap slide until

they are flush with the top edge of the gap slide.

Repeat this step for the rear gap slide. Slide the gap

slide to the right.

Figure 4

Figure 6

Step 6

Wearing proper protection, carefully attempt to raise

the gap slide to evaluate which gap pin is in need of

adjustment.

Step 4

For each cook surface requiring adjustment, place 4

gap blocks on the cook surface, approximately 2”

(51 mm) in from each corner.

Figure 5

Step 5

Lower the cook surface assembly. Loosen and slowly

move the T-handle to the left until the gap pins in the

gap slides touch the cook surface, and tighten the

T-handle.

Figure 7

With the gap slide raised, slowly turn the gap pin

needing adjustment until it makes contact with the

cook surface. Repeat these steps for both gap

slides.

Figure 8

Step 7

Raise the upper cook surface and remove the four gap

blocks.

Models QS12 & QS24 To the Installer

3

Page 8

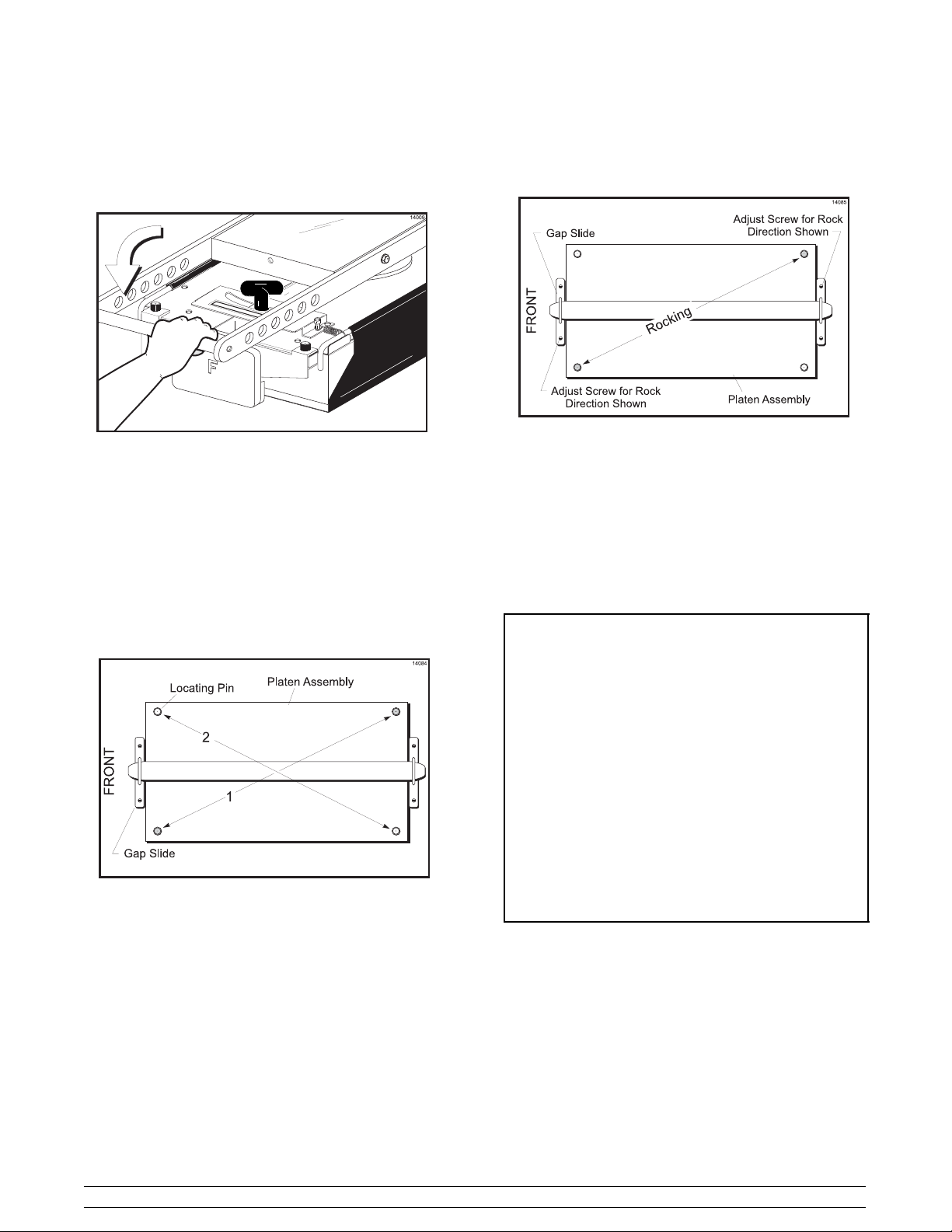

Step 8

Lower the upper cook surface into the COOK position.

Figure 9

Step 10

If the unit rocks, split the adjustment for gap pins

across the uneven corners, as shown in Figure 1 1.

Figure 11

Step 11

After adjusting, verify the unit for stability.

Step 9

Wearing proper protection, attempt to rock the cook

surface assembly. Apply pressure on the locating pins

at opposite corners to each other as shown in Figure

10.

Figure 10

Step 12

If all adjustments on the cook surface are correct, and

no rocking occurs, tighten the two screws located on

the side of the front and rear gap slides to lock all

adjustments from moving.

It is highly recommended that the gap

slides and the gap slide retainers be

removed at least weekly for cleaning these

parts and the cook surface shroud behind

these parts.

These parts are easily removed by

removing the locating pins and holding

both parts, because they are not attached

together, and pulling them from the cook

surface.

Take the gap slides to the sink for

cleaning. (Be sure to re-install the gap

slides as they were removed, i.e., “F”

front.) See Weekly Cleaning Procedures

on page 28.

090401

To the Installer

4

Models QS12 & QS24

Page 9

Section 2 To the Operator

The grill you have purchased has been carefully

engineered and manufactured to provide dependable

operation. This grill is designed to deliver

“cook-to-order” menu items. The two-sided cooking

method increases speed of service and assures safe

product integrity.

The Taylor Grill, when properly operated and

maintained, will produce a consistent quality product.

Like all mechanical products, this machine will require

cleaning and maintenance. A minimum amount of care

and attention is necessary if the operating procedures

in this manual are followed closely.

This Operator’s Manual should be read before

operating or performing any maintenance on your

equipment.

It is strongly recommended that all personnel

responsible for the equipment’s operation and

cleaning, review these procedures for proper training

and assurance that no misunderstandings exist.

In the event that you require technical assistance,

please contact your local authorized Taylor Distributor.

If the crossed out wheeled bin symbol is

affixed to this product, it signifies that this product is

compliant with the EU Directive as well as other similar

legislation in effect after August 13, 2005. Therefore,

it must be collected separately after its use is

completed, and cannot be disposed as unsorted

municipal waste.

The user is responsible for returning the product to the

appropriate collection facility,as specified by your local

code.

For additional information regarding applicable local

laws, please contact the municipal facility and/or local

distributor.

050831

Models QS12 & QS24 To the Operator

5

Page 10

Section 3 Safety

We at Taylor are deeply concerned about the safety of

the operator when he or she comes in contact with the

grill and its parts. Taylor has gone to extreme efforts to

design and manufacture built-in safety features to

protect both you and the service technician. As an

example, warning labels have been attachedto the grill

to further point out safety precautions to the operator.

To Operate Safely:

3” (76 mm) from all combustible materials

(0” to non--combustible materials).

Failure to comply could result in a fire hazard.

Failure to comply may result in personal injury or

equipment damage.

Grill clearance must be maintained at least

This grill must be placed on a level surface.

DO NOT operate the grill without reading this

operator’s manual. This manual should be kept in a

safe place for future reference.

This equipment is provided with a grounding lug

that is to be properly attached to the rear of the frame

by the authorized installer. The installation location is

marked by the equipotential bonding symbol (5021 of

IEC 60417--1) on the removable panel and the frame.

S DO NOT operate the grill unless it is

properly grounded.

S DO NOT use the cord if it is frayed.

S DO NOT attempt any repairs unless the

power supply to the grill has been

disconnected.

S DO NOT operate the grill unless all service

panels are restrained with screws.

S Stationary appliances which are not

equipped with a power cord and a plug or

other device to disconnect the appliance

from the power source must have an

all--pole disconnecting device with a contact

gap of at least 3 mm installed in the external

installation.

Failure to follow these instructions may result in

electrocution. Contact your local Taylor Distributor for

authorized service.

DO NOT use a water jet to clean or rinse the

grill. Failure to follow this instruction may result in the

following:

S serious electrical shock

S burns from hot steam

S liquid collecting inside the grill and

destroying electrical components.

S DO NOT prepare or remove product without

proper equipment.

S DO NOT allow untrained personnel to

operate this grill.

S USE EXTREME CAUTION when cleaning

the grill.

Failure to follow these instructions may result in severe

burns from high temperatures.

Taylor recommends Sizzler Grill Bun and

Toaster Cleaner, a Kay Chemicalr product. Sizzler

is an alkaline detergent and is not environmentally

harmful. Take caution to protect eyes, lungs, and all

parts of the body from potential harm. See the Kay

Chemicalr MSDS for further details.

070116

Safety

6

Models QS12 & QS24

Page 11

DO NOT slide the grill with the legs attached. Failure

to follow this instruction may damage the grill.

DO NOT obstruct air intake and discharge openings:

4” (102 mm) minimum air space on the bottom and 3”

(76 mm) at the rear of the unit. Failure to comply will

affect grill performance and may cause component

damage.

NOISE LEVEL: Airborne noise emission does not

exceed 70 dB(A) when measured at a distance of 1.0

meter from the surface of the machine and at a height

of 1.6 meters from the floor.

Models QS12 & QS24 Safety

7

Page 12

Section 4 Operator Parts Identification

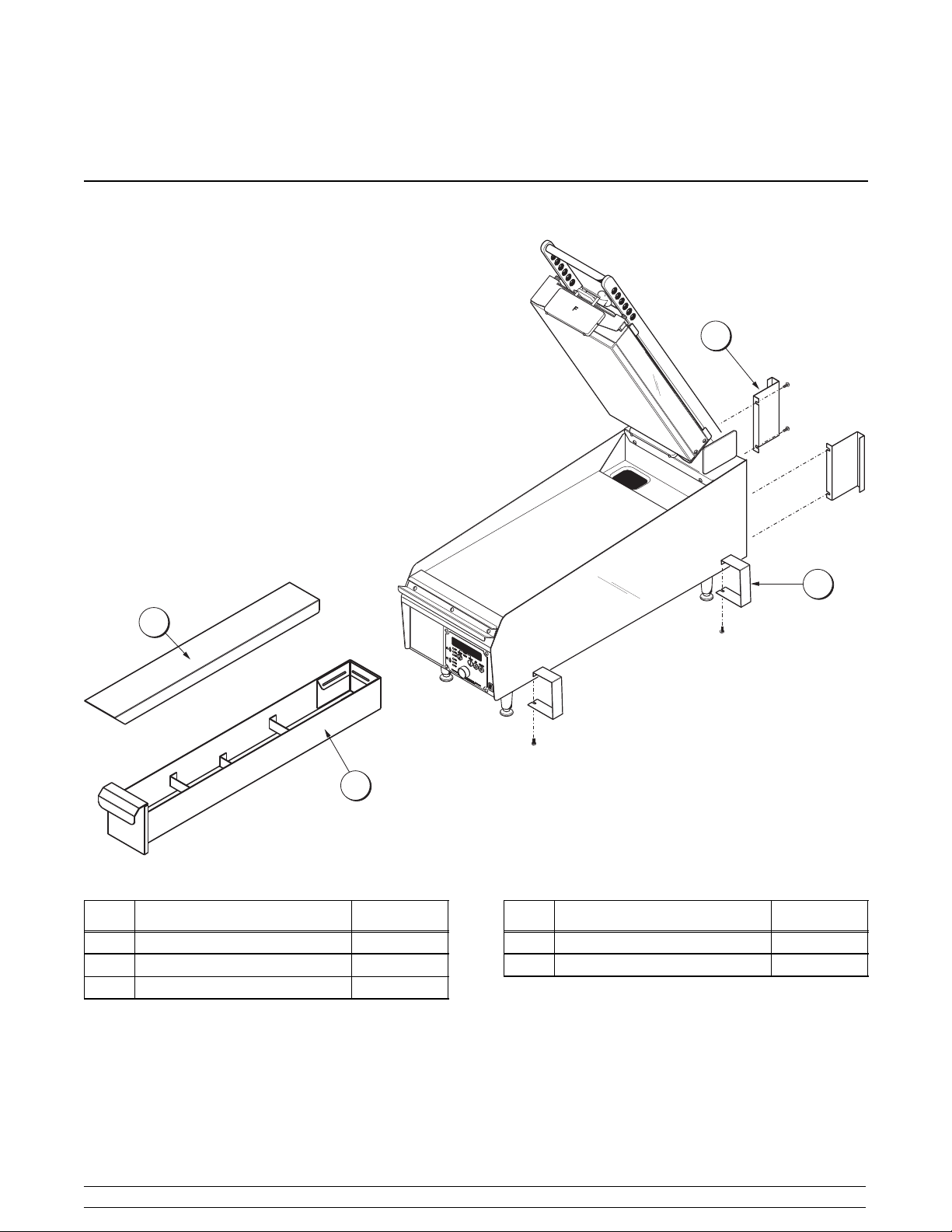

QS12

1

2

4

3

ITEM DESCRIPTION PART NO.

1 STANDOFF-REAR 079288

2 STANDOFF-FRONT 079289

3 TRAY A. - GREASE X79940-SER

O

N

O

F

F

Figure 12

ITEM DESCRIPTION PART NO.

4 COVER-TOP 079969

* CLEANER-SIZZLE 079896

*NOT SHOWN

071102

Operator Parts Identification

8

Models QS12 & QS24

Page 13

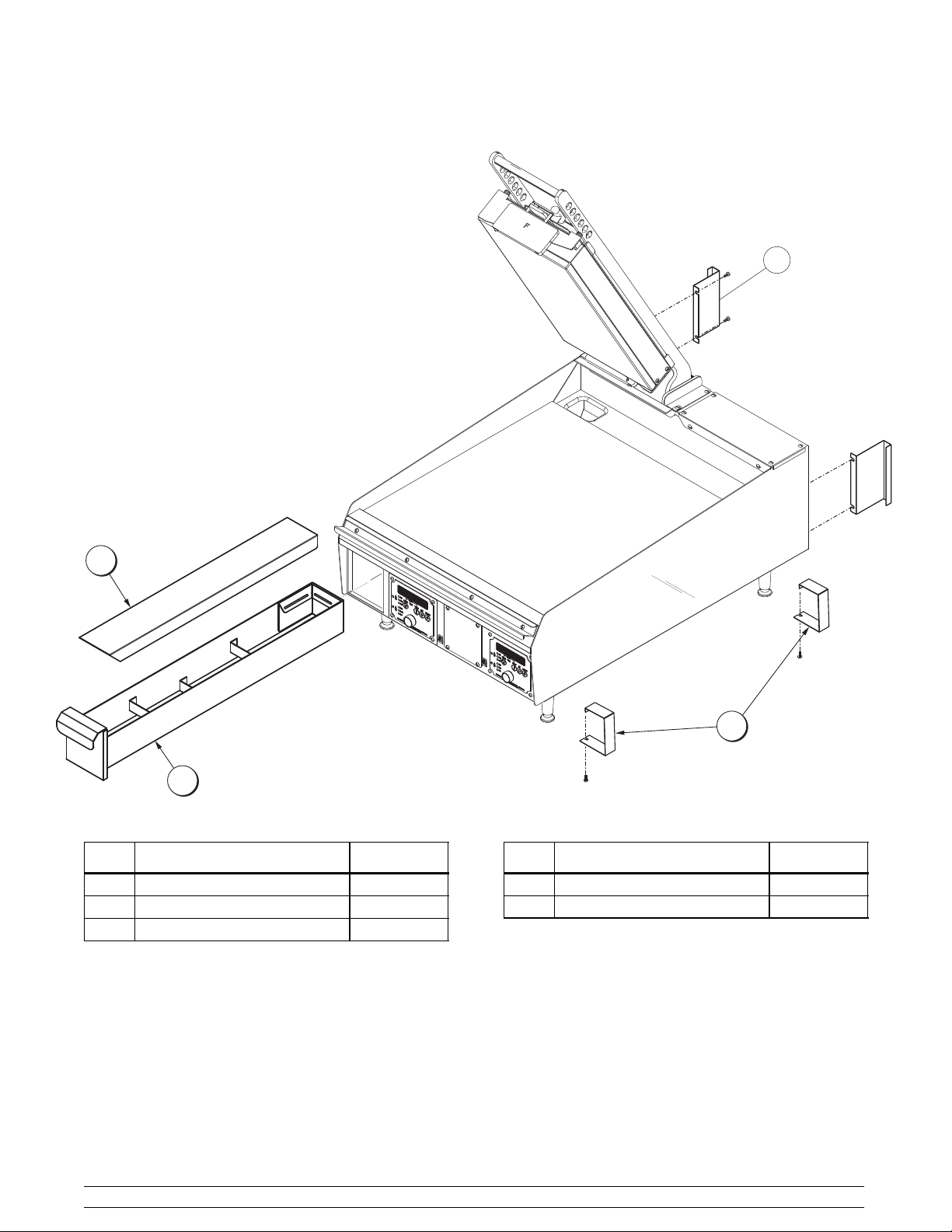

QS24

2

4

1

ITEM DESCRIPTION PART NO.

1 TRAY A.--GREASE X79940--SER

2 COVER--TOP 079969

3 STANDOFF--FRONT 079289

ON

OFF

ON

OFF

Figure 13

3

ITEM DESCRIPTION PART NO.

4 STANDOFF--REAR 079288

* CLEANER--SIZZLE 079896

*NOT SHOWN

071102

Models QS12 & QS24 Operator Parts Identification

9

Page 14

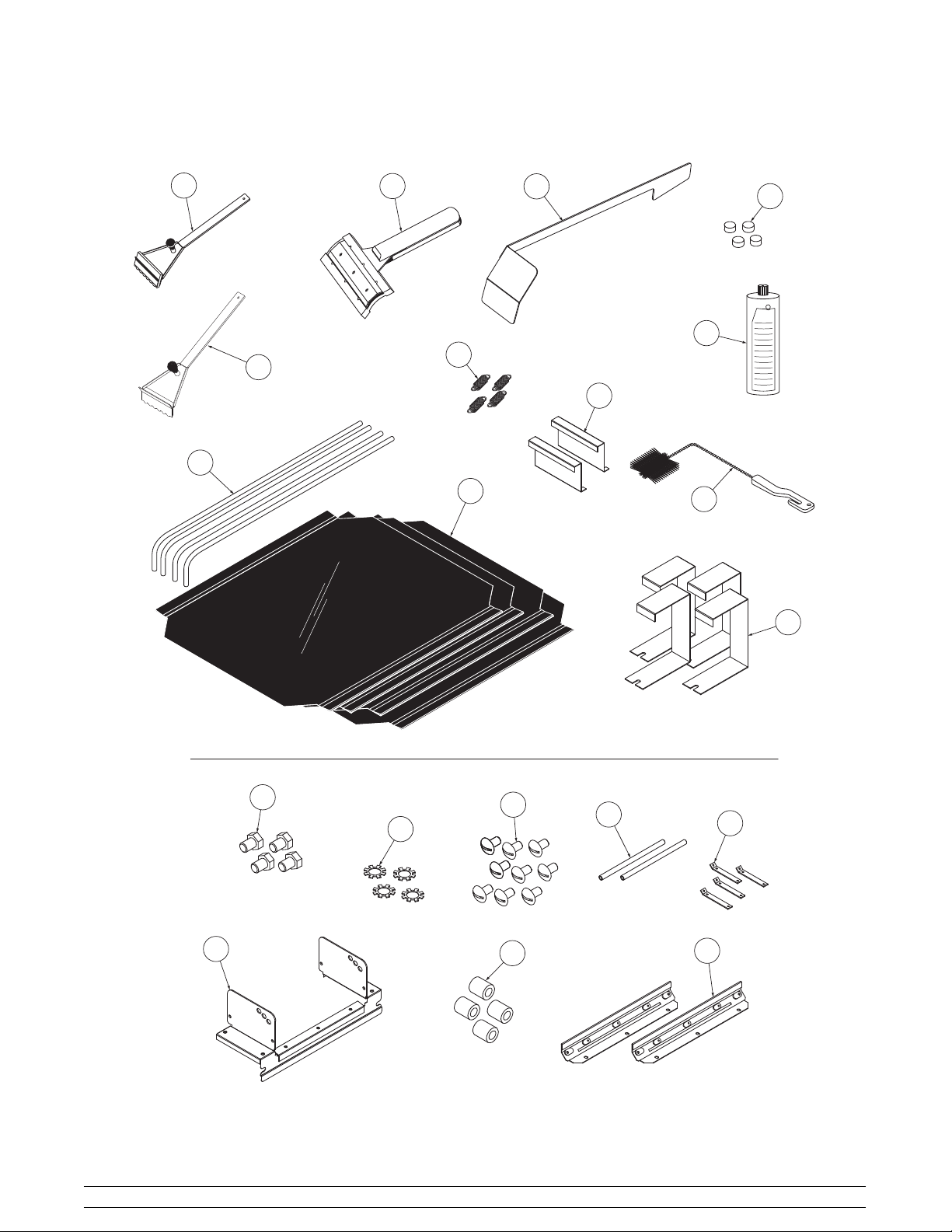

QS12 Accessories

1

3

4

9

S

I

Z

E

Z

L

10

7

2

8

5

6

11

12

13

20

071102

Operator Parts Identification

14

Figure 14

10

15

19

16

17

18

Models QS12 & QS24

Page 15

QS12 Accessories -- Parts Identificatio n

ITEM DESCRIPTION PART NO.

1 SCRAPER A.-GROOVE X79246

2 SCRAPER A.-GROOVE X79668

3 SCRAPER-TEFLON WIPER 075887

4 SCRAPER-TROUGH 079726

5 BAR-RELEASE SHEET 079930

6 SHEET-SEAMED RELEASE 078804

7 SPRING-.438OD X .046 X 1.75 079704

8 STANDOFF-REAR 079288

9 BLOCK-GAGE PLATEN KIT 079912

10 CLEANER-SIZZLE 1 QT 545A 079895

11 BRUSH-.625 X 1.500 074166

12 STANDOFF-FRONT 079289

* CARD-CHECKOUT-GRILL GM 049990

* GUIDE-CHECK OUT-QS 051934

ITEM DESCRIPTION PART NO.

ITEMS 13-20 ARE INCLUDED IN X79689 KIT

13 SCREW-3/8-16X1/2 HEX HEAD 001081

14 WASHER-3/8 EXTERNAL 001087

15 SCREW-10-32X3/8SLTD 024298

16 BAR-STOP 079673

17 BAR-REAR-COVER SUPPORT 079855

18 GUARD A.-FRONT X79426-SP

19 SLEEVE-STOP BAR 079688

20 COVER A.-REAR X79674

*NOT SHOWN

Models QS12 & QS24 Operator Parts Identification

11

Page 16

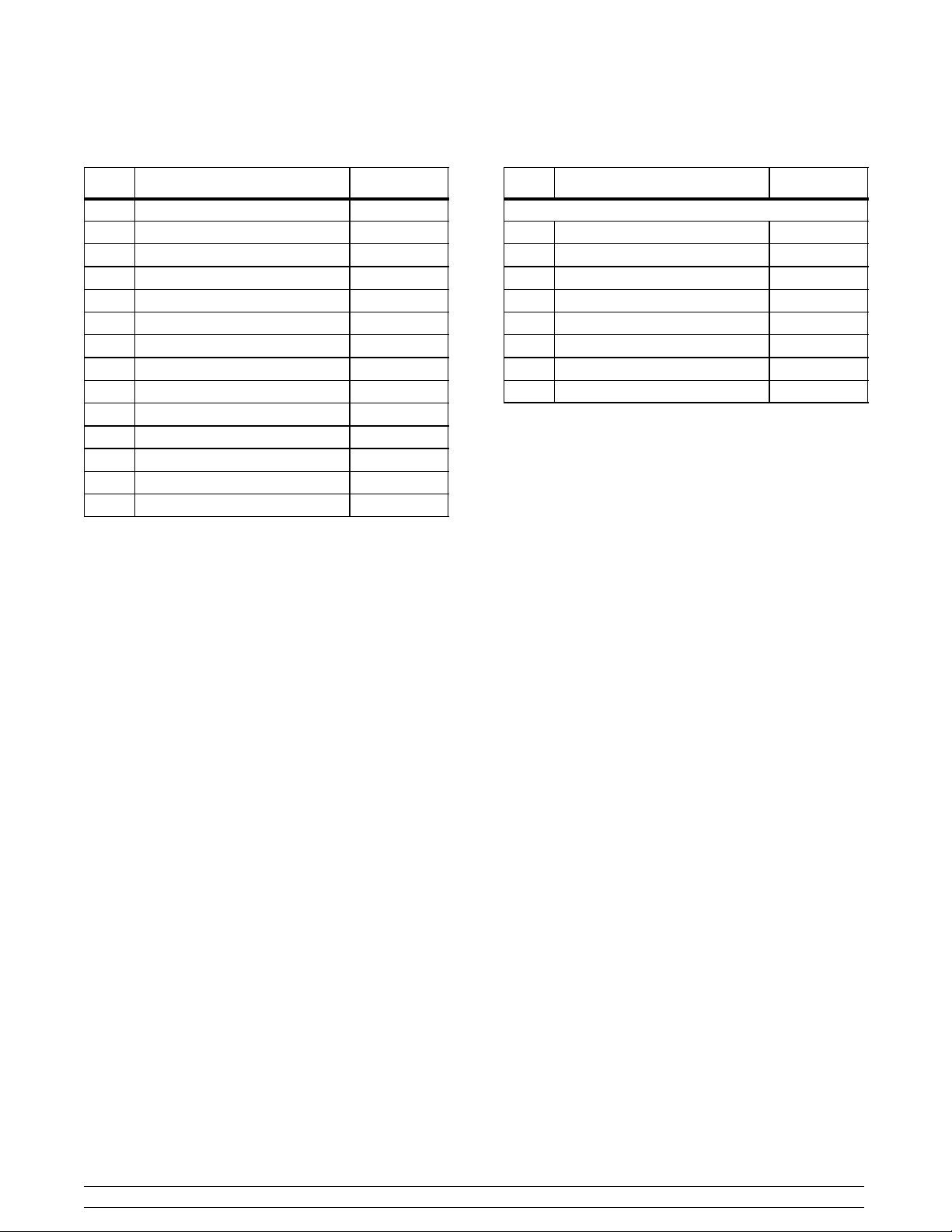

QS24 Accessories

1

3

4

9

2

10

S

I

Z

E

Z

L

7

8

5

6

11

15

12

13

14

Figure 15

071102

Operator Parts Identification

12

Models QS12 & QS24

Page 17

QS24 Accessories -- Parts Identificatio n

ITEM DESCRIPTION PART NO.

1 SCRAPER A.-GROOVE X79246

2 SCRAPER A.-GROOVE X79668

3 SCRAPER-TEFLON WIPER

4 SCRAPER-TROUGH 079726

5 BAR-RELEASE SHEET 079930

6 SHEET-SEAMED RELEASE 078804

7 SPRING-.438OD X .046 X 1.75 079704

8 STANDOFF-REAR 079288

9 BLOCK-GAGE PLATEN KIT 079912

75887

ITEM DESCRIPTION PART NO.

10 CLEANER-SIZZLE 1 QT 545A 079895

11 BRUSH-.625 X 1.500 074166

12 SCREW-10-32X3/8SLTD 024298

13 BAR-REAR-COVER SUPPORT 079855

14 GUARD A.-FRONT X79426-SP

15 COVER A.-REAR X74332

* CARD-CHECKOUT-GRILL GM 049990

* GUIDE-CHECK OUT-QS 051934

* INSTRUCTION-GRILLOPER 053656-INS

*NOT SHOWN

Models QS12 & QS24 Operator Parts Identification

13

Page 18

Section 5 Important: To the Operator

3

UF

MENU

UM

UR

4

LR

LM

LF

MANUFACTURED BY THE TAYLOR COMPANY

ROCKTON, ILLINOIS U.S.A.

5

ITEM DESCRIPTION

1 Power Switch

2 Keypads

3 LED Display

4 Indicator Lights

5 Timer Button

Power Switch (Rocker)

When placed in the “ON” position, the power switch

allows control panel operation for the applicable side

of the grill. The power switches are located on the front

panel.

EXIT

TIME

TEMP

UP

DOWN

1

I

0

2

Release Material (units with upper

cook surfaces only)

Step 1

Lay the release material sheet on the lower plate and

carefully lower the upper cook surface.

Step 2

Starting with the spring side, slide the straight end of

the release material rod through the front spring,

continue through the hemmed end of the release

sheet, and through the rear spring.

Indicator Light

The lights on the front panel indicate when the heaters

are operating.

Heating Zones

Each side (zone) of the grill is equipped with three

independent heating elements. The independent

elements assure even temperatures and quick

temperature recovery.

Timer Button

Used to start and stop the cook timer.

071102

Important: To the Operator

Step 3

Insert the second rod through the opposite hemmed

side of the release material sheet. Grasp both ends of

the rod, pull the release material up and around the

non-spring side of the upper cook surface and attach

the rod ends to the retaining clips. Turn the rods so that

the hooked end is facing downward.

Step 4

Raise the upper cook surface and assure that the

release material sheet fits evenly and snugly on the

upper cook surface. Rotate the release material sheet

on an every other day basis.

14

Models QS12 & QS24

Page 19

Temperature Controls

Operating Screen and Controls

The Model QS12 is equipped with one temperature

control and the Model QS24 is equipped with two

individual temperature controls. They control both the

upper and the lower temperatures. The lower cook

surface temperatures can be set manually from 150_

- 400_F(65_ - 204_C). The upper cook surface

temperatures can be set manually from 150_ - 425_F

(65_ - 219_C). The left and right sides (zones) of the

Model QS24 grill operate independently.

Control Board

This unit is equipped with a microprocessor control,

programmable by the operator.

Keypad and Display

Located on the front panel, beneath each cook zone,

is an alpha-numeric LED display and a group of keys

used for operating, programming, and servicing the

grill and its microprocessor control.

The keys are illustrated with icons, descriptive of their

functions, and referred to in these instructions as

follows:

The VERSION SCREEN is viewed when a grill is

powered for normal operation. It indicates the version

of software the microprocessor is using.

VER 1.01B

Note: If the grill is not equipped with the upper cook

surface option, the words “NO PLTN” will appear on

the display for two seconds before the version screen

appears.

The MEMORY INITIALIZATION SCREEN appears if

the grill has never been used or in the rare event that

set-up parameter memory has been lost.

MEM INIT

=MENU

=TEMP

= UP ARROW

= DOWN ARROW

The display is a visual message center for the user,

operator (maintenance personnel or manager), and

the service technician.

When this screen appears on the display, the

parameters previously programmed by the operator

will revert back to the factory default values. Pressing

the MENU key will advance the display to the

VERSION screen.

Factory defaults:

Upper 400_FTM130

Lower 325_FTM20

If set-up parameter memory is lost, programmed

names will revert back to the “ITEM” messages.

After the VERSION SCREEN is displayed and a key

is pressed, the grill will enter the COOK mode of

operation.

Models QS12 & QS24 Important: To the Operator

15

Page 20

Cook Temperatures

Step 1

To set cook temperatures, press the up or down arrow

to select the item to be changed. Press and hold the

temperature key for five seconds. After releasing the

key, the message “SU1” and the current set

temperature will be displayed. (See example below .)

SU1 400 F

(Set upper item 1)

Step 2

Use the arrow keys to adjust the desired cook

temperature setting for the upper cook surface.

Temperatures may be set for 150_F to 425_F(66_to

218_C).

Step 3

Press the MENU key and the message “SL1” and the

current temperature will appear on the display. (See

example below.)

middle of the cook cycle. Timer two should then be

programmed for 15 seconds. Once the cook cycle

begins, a tone will sound 15 seconds after the first

timer starts, alerting the operator to season the

product. Press the timer key to stop the tone. The first

timer will continue to measure the full 30 second cook

cycle.

A tone will sound 5 seconds before the time elapses,

and will continue to sound until the timer key has been

pressed. (This timer can be adjusted from 0 -- 10

seconds.)

Note: The factory default settings are 30 seconds for

the first (cook cycle) timer, and 0 seconds for the

second (alert) timer. The timers can be set from 0 to

3,600 seconds. The second timer cannot be

programmed for a longer time setting than the first

timer.

To adjust the timers, press the up or down arrow to

select the item to be changed. Press and hold the time

key for five seconds. Release the key and the

message “TM1” will appear next to the current time

setting. (See the example below.)

SL1 325 F

(Set lower item 1)

Step 4

Use the arrow keys to adjust the desired cook

temperatures for the lower cook surface. The range for

the lower cook surface temperatures is 150_Fto

400_F(66_to 204_C).

Press the MENU key again to return to the selected

item display.

Cook Timers

Each item selection has two programmable cook

timers. The first timer is the cook cycle timer. This timer

measures the amount of time the product should be

cooked.

The second timer is an alert timer. This timer can be

set to alert the operator to add seasonings, to turn the

product, or to start warming buns for the cooked

product.

For example, item one has been programmed to cook

for 30 seconds. The operator wishes to add salt in the

TM1 30

Step 1

Press the UP or DOWN arrows to adjust the time

setting for the total cook cycle.

Step 2

Once the desired cook time has been set, press the

MENU key and the message “TM2” will appear next to

the current time setting. (See the example below.)

TM2 0

Step 3

Press the UP or DOWN arrows to adjust the time

setting for the alert timer (timer 2).

Step 4

Once the desired alert timer has been set, press the

MENU key to return to the selected item display.

Repeat this step for each item.

080429

Important: To the Operator

16

Models QS12 & QS24

Page 21

Fault Screen

Maintenance Menu

If the grill experiences a system failure, a fault

message will appear on the display, and a tone will

sound.

FLT HTUM

An example of the FAULT SCREEN is illustrated in the

previous figure. The screen appears when the

controller has detected a fault in the system. The code

letters “FLT” is an abbreviation for “fault”. The next set

of code letters indicate the type of fault and the zone

affected. Following is a list of possible codes that may

appear on the screen:

HTUF High Temperature Upper Front zone exceeded

HTUM High T emperature Upper Mid zone exceeded

The Maintenance Menu provides five screens to allow

managers and service technicians to monitor grill

performance.

To enter the Maintenance Menu while any item is

displayed, press and hold the MENU key for

approximately 5 seconds and release. The following

screen will appear on the display.

CODE 0000

Press TIME until the first digit is “5”.

Example: CODE 5000.

Press TEMP until the next digit is “3”.

Example: CODE 5300.

Press the UP Arrow until the next digit is “7”.

Example: CODE 5370.

Press the DOWN Arrow until the last digit is “6”.

Example: CODE 5376.

Press the MENU key to accept the access code and

the following screen will appear:

HTUR High Temperature Upper Rear zone exceeded

HTLF High Temperature Lower Front zone exceeded

HTLM High T emperature Lower Mid zone exceeded

HTLR High Temperature Lower Rear zone exceeded

TCUF Upper Front thermocouple fault

TCUM Upper Mid thermocouple fault

TCUR Upper Rear thermocouple fault

TCLF Lower Front thermocouple fault

TCLM Lower Mid thermocouple fault

TCLR Lower Rear thermocouple fault

The user must press the MENU and TEMP keys to

acknowledge the fault. The fault description and item

name will appear alternately on the display. The zone

that has the fault will shut down while the rest of the grill

will be operational. (Refer to the Fault Screen

information in the Service Manual, Controls and

Systems Section.)

CALIBRAT

Note: If an incorrect code is entered, the display will

return to the cook screens.

Step 1

Press the MENU key to enter the calibrate mode and

the following message will appear on the screen.

UFXX X F

There are three lower heating elements in each cook

zone and three heating elements in the upper cook

surface (if applicable). The calibrating screens allow

calibration of each independent heating element.

Calibrating verifies proper temperatures of heating

elements.

Models QS12 & QS24 Important: To the Operator

17

Page 22

Note: A calibrated pyrometer must be used for

calibration.

Note: Calibration is allowed only when the item1

temperatures are within 50_ F(28_ C) of the set point.

Step 2

Place the pyrometer disc on the upper front heating

element of the grill. Using the arrow keys, enter the

temperature reflected on the pyrometer for the upper,

front heating element.

Note: The indicating lights should be lit when

calibration adjustments are made.

Figure 16

Step 3

Press the MENU key to display the calibration screen

for the upper middle heating element. Place the

pyrometer on the upper middle heating element. Using

the arrow keys, enter the temperature reflected on the

pyrometer for the middle of the upper heating element.

Step 1

Press the MENU key to display the current

temperature scale:

SCALE F or C

Step 2

If Fahrenheit is the desired temperature scale, press

the MENU key while SCALE F is displayed. If Celsius

is desired, press the UP arrow to display SCALE C.

Step 3

Press the MENU key to accept the scale and return to

the SCALE message.

Step 4

If desired, the names of specific products can be

programmed to appear on the display instead of ITEM

numbers. While at the SCALE message display, press

theUParrowtodisplaytheNAMES message.

NAMES

Step 4

Repeat this procedure for the remaining upper rear,

and lower heating elements. When the last zone has

been calibrated, press the MENU key to return to the

CALIBRAT screen.

Step 5

Press the UP arrow to display the “SCALE” message.

SCALE

Note: The CALIBRAT screen is the base

maintenance screen. All other maintenance

functions are accessible through the CALIBRAT

screen.

Important: To the Operator

Step 5

While at the NAMES message display, press the

MENU key and the message “NAME1” will appear on

the display. This message indicates that the operator

can program a specific product name to appear for the

first item on the menu.

NAME1

18

Models QS12 & QS24

Page 23

Step 6

Press the MENU key again, and the message “ITM1”

will appear on the display. The letter “I” will be flashing

above the cursor.

ITM1

Step 9

Use the UP arrow key to display the message

“NAME2.”

Repeat Steps 6-9 until all desired item names have

been entered.

Step 10

After entering the desired characters in the NAMES

screens, the control will return to “NAME1”.

Step 7

Using the UP and DOWN arrow keys, enter the

desired letter (A - Z) or number (0 - 9) ( -- _ ). Once the

character letter is entered, press the MENU key to

move the cursor to the next position. Up to four

characters may be entered.

POM1

PORK

Step 8

After the last character has been entered, press the

MENU key to return to the message “NAME1”.

Press the DOWN arrow to display “NAMES”.

Step 11

Press the UP arrow to display “LANGUAGE”, and

press the MENU key to display “ENGLISH”.

Press the MENU key to return to the “LANGUAGE”

display.

Step 12

Press the UP arrow to display “MONITOR”.

Press the MENU key to display “UF XXX F” to monitor

the upper front temperature.

Step 13

Continue to press the UP arrow to monitor the

remaining five zones.

Step 14

Press the UP arrow to display “CANCEL”, and press

the MENU key to display “MONITOR”.

Press the MENU and TEMP keys at the same time to

return to the main cook screen.

Models QS12 & QS24 Important: To the Operator

19

Page 24

Maintenance Menu Flowchart

Important: To the Operator

20

Models QS12 & QS24

Page 25

Section 6 Operating Procedures

The Model QS12 has one, 12” (305 mm) lower cook

surface and the option of an 11” (279 mm) upper cook

surface. The Model QS24 has two, 12” (305 mm) lower

cook surfaces and the option of one 11” (279 mm)

upper cook surface or two 1 1” (279 mm) upper cook

surfaces. The QS24 is also available with a grooved

lower cook surface for product sear. The two-sided

cooking concept ensures quick, even cooking of both

sides of products placed on the lower surface.

We begin our instructions with the opening

procedures, assuming product set-up procedures

(outlined in the “Important to the Operator” section of

this manual) are complete.

Opening Procedures

Before operating the grill, a release material sheet

must be installed on the upper cook surface.

CAUTION: Make sure the grill is cool

before attempting to install or remove release

material.

Perform the following steps for installing release

material:

Step 1

Lay the release material sheet on the lower plate and

carefully lower the upper cook surface.

Step 2

Starting with the spring side, slide the straight end of

the release material rod through the front spring,

continue through the hemmed end of the release

sheet, and through the rear spring.

Figure 18

Step 3

Insert the second rod through the opposite hemmed

side of the release material sheet. Grasp both ends of

the rod, pull the release material up and around the

non-spring side of the upper cook surface and attach

the rod ends to the retaining clips. Turn the rods so that

the hooked end is facing downward.

Figure 17

Models QS12 & QS24 Operating Procedures

21

Figure 19

Page 26

Step 4

Raise the upper cook surface and assure that the

release material sheet fits evenly and snugly on the

upper cook surface. Rotate the release material sheet

on an every other day basis.

Note: It is not necessary to replace the release

material sheet if small pinholes develop.

Operating Procedures

Figure 20

22

Models QS12 & QS24

Page 27

CAUTION: Release material sheets must be

replaced if:

S Release material is torn.

S Release material substance is worn from the

release material sheet.

S Product sticks to the release material.

Cooking Procedures

Step 1

Make sure the release material is installed.

Step 2

Place the power switches in the ON position. The

screen will scroll through information messages and

then advance to the first cook screen.

Step 4

Allow the grill to heat for approximately 15 minutes or

until all indicating lights are no longer illuminated.

DO NOT begin cooking until the grill has reached set

temperature. If the grill is not at cook temperature, the

display will alternate between the item number and the

words, “TOO COOL”. If the grill is too hot to cook the

selected product, the display will alternate between the

item number and the words “TOO HOT”. When the

words “TOO COOL” or “TOO HOT” stop appearing on

the display, and all indicator lights have cycled off, the

grill is ready to cook product.

Step 5

To adjust the gap between the upper cook surface and

lower cook surface, loosen the “T” handle and slide the

gap adjusting bar to the right for a smaller gap or to the

left for a larger gap.

Figure 21

Note: If there is no upper cook surface, the words

“NO CLAM” will appear on the screen prior to the

software version number.

Step 3

Press the UP arrow until the desired item number

appears on the display.

14293

UF

UM

UR

LR

LM

LF

MANUFACTURED BY THE TAYLOR COMPANY

EXIT

TIME

TEMP

MENU

ROCKTON, ILLINOIS U.S.A.

UP

DOWN

I

0

Figure 22

Figure 23

Step 6

While the upper cook surface is in the raised position,

place the product on the lower cook surface. Lower the

upper cook surface, and press the TIME key. A tone

will sound for two seconds, alerting the operator that

the cook cycle has been initiated.

Figure 24

Models QS12 & QS24 Operating Procedures

23

Page 28

CAUTION: The grill is hot. To prevent

personalinjury, always use the handle to lowerthe

upper cook surface.

Step 7

If the timer is programmed, press the large red TIMER

button. A tone will sound for two seconds, alerting the

operator that the COOK cycle has been initiated. The

timer will count down in seconds. When five seconds

are left in the cook time, a tone will sound to alert the

operator that product is ready for serving. Raise the

upper cook surface. (If a second timer is entered,

subtract that amount from the total time and a tone will

sound. Press the large red TIMER button to stop the

tone and the control will continue to count down.)

14294

UF

UM

UR

LR

LM

LF

MANUFACTURED BY THE TAYLOR COMPANY

EXIT

TIME

TEMP

MENU

ROCKTON, ILLINOIS U.S.A.

UP

DOWN

I

0

Cleaning Between Product Runs

After each run of product, the grill must be cleaned to

ensure proper cooking.

Step 1

Using a grill scraper, scrape residue from the lower

cook surface (scrape from front to back only).

Figure 26

Step 2

Use a rubber wiper squeegee to clean release material

on the upper cook surface. Hold the handle at a slight

upward angle with wiper end facing downward. Wipe

the material using a downward motion. DO NOT use

extreme pressure or force. Improper procedures will

tear or crease the release material.

Figure 25

To cancel the tone, press the large red TIMER button.

Step 8

Carefully remove product with a safe cooking utensil

in the same order the product placed on the grill.

071102

Operating Procedures

Figure 27

Note: DO NOT use a scraper, sharp utensils, or

abrasives for cleaning the upper cook surface.

24

Models QS12 & QS24

Page 29

Step 3

Using the rubber wiper squeegee, push the grease to

the rear of the lower surface into the grease trough. DO

NOT use the grill scraper for this step.

Step 4

When necessary, use a grill cloth to clean the back

splash shield and the bullnose areas.

Step 5

Repeat Steps 1 through 4 for other side of the grill

(QS24 only).

Note: Whenever the grill is idle and product is not

being cooked, keep the upper cook surface in the

raised position.

When necessary, use the trough scraper to clean the

rear grease trough. If a buildup of carbon is starting in

the grease chute, use the hook end of the trough

scraper to push the carbon down into the grease tray.

Periodically, check the grease drawer for excess

grease and empty it as needed.

Figure 29

Step 5

Carefully remove the grease tray partition. Take it to

the sink for cleaning.

Figure 30

Figure 28

Cleaning the Grease Tray Partition

Occasionally, the grease tray partition must be

cleaned.

Step 1

Place the power switch in the OFF position.

Step 2

Carefully unplug the unit from the wall receptacle.

Step 3

Remove the grease tray.

Step 4

Remove the four screws that secure the grease tray

partition.

Models QS12 & QS24 Operating Procedures

Note: For installation of the grease tray partition,

carefully reverse the above steps.

It is highly recommended that the gap

slides and the gap slide retainers be

removed at least weekly for cleaning these

parts and the cook surface shroud behind

these parts.

These parts are easily removed by

removing the locating pins and holding

both parts, because they are not attached

together, and pulling them from the cook

surface.

Take the gap slides to the sink for

cleaning. (Be sure to re-install the gap

slides as they were removed, i.e., “F”

front.) See Weekly Cleaning Procedures

on page 28.

090401

25

Page 30

Closing Procedures

Step 1

Raise the upper cook surface to the “raised” position.

Step 2

Turn the power switches to the OFF position.

Step 7

Dampen the gap slide brush with an approved, full

strength cleaner/degreaser (i.e., Sizzler Grill Bun and

Toast Cleaner, a Kay Chemicalr product).

Step 8

Clean the shroud by brushing between the platen

shroud and the gap slides.

Figure 31

Step 3

Wipe the release material sheet thoroughly while still

attached to the upper cook surface, using the rubber

wiper squeegee.

CAUTION: The upper cook surface and

release material sheets are very hot. To prevent

burn injuries, wear protective gloves and use

extreme care when performing this procedure.

Step 4

Remove the release material sheet from the upper

cook surface by pulling the release rods from the

release material sheet. Temporarily place the release

material sheet on a clean, flat surface for further

cleaning. DO NOT fold or crease the material or lay it

on sharp objects.

Step 5

Take the release material rods to the sink for cleaning.

Step 6

Clean the upper cook surface(s) with the special

rubber squeegee.

Note: DO NOT use metal scrapers, abrasive pads,

screens or wire brushes to clean the upper cook

surface.

Figure 32

Step 9

Repeat Steps 7 and 8 with warm water.

CAUTION: Protect eyes, lungs, and all

parts of the body from potential harm when using

any chemical cleaner.

Step 10

Starting from the top of the upper cook surface, spray

full strength cleaner/degreaser (i.e., Sizzler Grill Bun

and Toaster Cleaner, a Kay Chemicalr product.) from

6” (152 mm) away. (Use a cleaner that will not

damagealuminum.)Spray one ounce of cleaner over

each upper cook surface and two ounces on the lower

cook surface. Let the cleaner soak for 3 -- 5 minutes.

Note: One ounce of cleaner equals approximately

thirty squirts.

Step 11

Starting from the top of the upper cook surface and the

rear of the lower cook surface, rinse both surfaces with

a mist of water from a spray bottle.

CAUTION: Use care not to spray water or

cleaner/degreaser on any part of the grill, other

than the cook surfaces. Improper procedures will

cause permanent electrical and mechanical

damage to internal parts.

Operating Procedures

26

Models QS12 & QS24

Page 31

IMPORTANT: Do not use a jet of water to

clean or rinse the grill.

Step 12

Use the rubber wiper squeegee to remove excess

liquid from the upper and lower surfaces.

IMPORTANT! Do not scrape the upper surface

with metal utensils.It is aluminum and will scratch

very easily.

Step 13

Repeat Steps 10 and 11if necessary, but apply cleaner

only to soiled areas.

Step 14

Remove any small carbon spots with the rubber

squeegee.

Step 15

Using a damp cloth, wipe down all exterior stainless

steel of the upper cook surface (especially behind the

rear of the upper cook surface, next to arm assembly).

Note: Grills should be removed from cooking alcoves

in order to clean the rear section of the upper cook

surface.

CAUTION:

S Never use cold water or ice to cool the

upper cook surface or lower grill plate.

S Never use grill screens on the upper cook

surface or lower grill plate.

S Never use any other abrasives or cleaners

other than approved food service cleaners

and degreasers.

S Never spray excessive amounts of water on

the grill.

S Never pour or spray liquid of any type on

the top of the upper cook surface.

Step 21

Place release material sheet(s) on the warm lower grill

plate and thoroughly wipe down both sides with a

clean, damp grill cloth.

Step 16

Clean lower grill by pouring warm water carefully on

the surface while brushing with sturdy brush.

CAUTION: Wear rubber gloves to avoid

hot steam.

Step 17

Continue to add water and brush the surface until the

grill is cool enough to squeegee dry.

Step 18

Wipe the cook surface(s) twice with a clean, damp

towel.

Step 19

Wipe all areas of the grill with a clean, damp towel.

Step 20

Wipe all exterior stainless steel panels around the

entire grill.

CAUTION:

S Never attempt to clean release material

sheets on a cold surface.

S Never use a hot hose for cleaning release

material, or soak release material sheets in

liquid.

S Never fold, crease or touch release material

sheets with sharp objects.

S Never allow the grill scraper or abrasive

cleaning materials to come in contact with

release material sheets.

Step 22

Apply a light coat of shortening to the entire lower grill

plate.

Models QS12 & QS24 Operating Procedures

27

Page 32

Weekly Cleaning Procedures

Step 1

Loosen, but do not remove the four locating pins that

attach both sets of Gap Slide Retainers. One set is

located at the front and one set is located at the rear

of the upper platen.

Step 2

Lift the upper platen to the raised position. Remove

the four locating pins on both ends of the platen.

Step 3

Removeboth setsof the GapSlideRetainers andGap

Slides. Take them to the sink for washing, rinsing and

sanitizing. Wipe dry with a clean, sanitized towel.

Step 4

Re-install the Gap Slide Retainers and the GapSlides

in their original locations.

Note: The front Gap Slide set will be marked with an

(F ) todesignate thefrontlocation. The rearsetwillnot

be marked.

090401

Operating Procedures

28

Models QS12 & QS24

Page 33

Section 7 Troubleshooting Guide

PROBLEM PROBABLE CAUSE REMEDY

1. Grill will not heat. a. Power cord is not connected. a. Check power connection.

b. Circuit breaker is tripped. b. Reset the circuit breaker.

2. One heat zone will not heat.

(Indicator light is not on,

display flashing “TOO COOL”.)

3. One heat zone will not heat.

(Indicator light is on, display

flashing “TOO COOL”.)

c. Power switch is in the OFF

position.

d. Power switch is faulty. d. Contact a service technician.

e. Faulty relay or relay board. e. Contact a service technician

a. Control is not set correctly. a. Check temperature setting.

b. Faulty relay or relay board b. Contact a service technician.

c. Unit displays a fault. c. Clear the fault. If action is

d. Faulty thermocouple. d. Contact a service technician.

a. Heater is faulty . a. Contact a service technician.

b. Thermocouple is faulty. b. Contact a service technician.

c. Thermo overload is faulty. c. Contact a service technician.

d. Relay or relay board is faulty. d. Contact a service technician.

e. Unit displays a fault. e. Clear the fault. If action is

c. Place the power switch in the

ON position.

ineffective, contact a service

technician.

ineffective, contact a service

technician.

4. One heat zone is overheating.

(Display is flashing “TOO

HOT”.)

5. Upper cook surface will not

stay in the raised position.

Models QS12 & QS24 Troubleshooting Guide

a. Thermocouple is faulty. a. Contact a service technician.

b. Relay or relay board is faulty. b. Contact a service technician

c. Unit displays a fault. c. Clear the fault. If action is

ineffective, contact a service

technician.

a. Defective gas filled cylinder(s). a. Contact a service technician.

29

Page 34

PROBLEM PROBABLE CAUSE REMEDY

6. Product is under-cooked,

overcooked, or cooking

unevenly.

7. Control is displaying fault. a. Refer to “fault screens”,

8. Grease drips from under the

grease drawer.

a. Release material sheet is

worn.

b. Incorrect cooking time. b. Adjust cook time accordingly.

c. Incorrect temperature setting. c. Adjust temperature setting.

d. Incorrect gap setting. d. Adjust gap.

e. Heat zone not heating. e. Contact service technician.

f. Upper cook surface has carbon

build-up.

g. Incorrect temperature

calibration.

h. Cook surfaces are not parallel. h. Call a service technician to

i. Incorrect item selected. i. Select proper item.

page 17.

a. Grease tray is full. a. Empty the grease tray.

a. Replace the release material

sheet.

f. Closing procedures must be

followed to remove carbon

build-up.

g. Calibrate the grill accordingly.

level the grill or refer to leveling

procedure in front of manual.

a. Clear the fault. If action is

ineffective, contact service

technician.

9. The grease drawer will not

close.

a. Product has built up in back of

grease partition.

a. Refer to “Cleaning the Grease

Tray Partition” instructions.

Troubleshooting Guide

30

Models QS12 & QS24

Page 35

Section 8 Wa rranty Explanation

Parts

Class 103 Parts

The warranty for new equipment is one year, with a

replacement parts warranty of three months.

Class 000 Parts

Wear items -- no warranty.

Class 212 Parts

The warranty for new equipment parts is two years,

with a replacement parts warranty of 12 months. This

includes the microprocessor control, relays, and the

upper cook surface (aluminum casting and shroud).

Labor

The Taylor warranty is valid only if the required service

work is performed by an authorized T aylor technician.

For more details, see the warranty/checkout card.

Contact your local Taylor Distributor regarding

Extended Service Contract options.

Models QS12 & QS24 Warranty Explanation

31

Page 36

Section 9 Parts List

143

UPDATE

REMARKS PARTS

FOR SERVICE -- USE X74036--SER

WARR.

CLASS

QTY.

QS24

QTY.

QS12

NUMBER

DESCRIPTION PART

X79838 1 103 LEFT SIDE -- J8050000/UP (50HZ & 60HZ)

X79839--23R 1 103 RIGHT SIDE -- J8050000/UP (60HZ)

1 2 103

X40788--SER

PCB A . --CONTROL (BASE BOARD) X53319--SER 1 2 212

CHIP-- SOFTWARE (VERSION 1.01)

+BRACKET ”E” RELAY 074040 6 12 103

RELAY--30A--277V--12VDC 074041 6 12 103

STRAP A.GROUNDING *QS24* X74123 1 2 000

CONNECTOR-- MATE LOK 6 CIR--SKT 029248 1 2 103

CONNECTOR-- MATE LOK 6 CIR--SKT 029248 2 4 103

SOCKET-- 084 OD/14-- 2 0 AWG-- STRIP 021625 9 18 103

HARNESS--WIRE (RELAY BOX) 074039 1 2 103

PCB A.--CONTROL X53512--SER 1 2 212

BAR--RELEASE SHEET *QS24* 079930 2 2 103 137

BLOCK--GAGE PLATEN KIT 078095 4 4 103

BLOCK-- TERMINAL--5P SCREW

W/JUMPERS

BLOCK-- TERMINAL--5P SCREW

W/JUMPERS

BLOCK-- TERMINAL--5P SCREW 079045 1 103 LEFT SIDE -- PRIOR TO J8050000

BLOCK-- TERMINAL--5P SCREW 079045--23R 1 103 RIGHT SIDE -- PRIOR TO J8050000

BLOCK-- TERMINAL--6P SCREW 076943 1 103

BOX A. --RELAY *QS12/QS24* (NEW) X74036--SER 1 2 212 J9054573/UP -- 50HZ & 60HZ

+ Available Separately

Parts List Models QS12 & QS24

32

SOCKET-- 084 OD/14-- 2 0 AWG-- STRIP 021625 3 6 103

BOX A. --RELAY *QS12/QS24* (OLD) X79678--SER 1 2 212 USE X74036--SER IN ALL APPLICATIONS 122, 143

HARNESS--WIRE RELAY BOX *QS24* 078616 1 2 103 INTERFACE TO KEY PAD BOX

PCB A.-- CONTROL GRILL X48604--SER 1 2 212 USE X74036-- SER

CHIP-- SOFTWARE *QS24* CONTROL X40863 1 2 103

PCB A . --INTERFACE GRILL X49540--SER 1 2 212 USE X74036--SER

RELAY--SPDT--200/240 VAC 079690 3 6 103 J7100000--J9054572 (for 1800 WATT heater) 122

STRAP A.GROUNDING *QS24* X74123 1 2 000

BOX A. --RELAY -- (OLD) X78757 1 2 212 USE X74036--SER IN ALL APPLICATIONS 143

BOX A. --REMOTE KEY PAD *QS12 & QS24* X78579 1 2 212

BEEPER--WITH WIRE HARNESS *QS 078617 1 2 103

Page 37

UPDATE

REMARKSWARR.

CLASS

QTY.

QS24

X50412--SER PCB. A & X74320-- SER DECAL

QTY.

QS12

PART

NUMBER

DESCRIPTION PARTS

BUMPER--.500 DIA X .090 THK 079499 1 2 000

DECAL-- KEY PAD *QS24* X74320--SER 1 2 000

BUMPER--.500 DIA X .090 THK 079499 1 2 000

FILTER--CORCOM 2VR1 032567 1 2 103 PRIOR TO J9054573 143

GASKET-- BOX A. 074060 1 2 000 J9054573/UP 143

HARNESS--WIRE REMOTE *QS24* 078614 1 2 103

PAD A. --KEY REMOTE *QS24* X78573 1 2 103

PCB A.-- REMOTE GRILL X50412--SER 1 2 212 J6041233/UP

CHIP-- SOFTWARE QSDSP CONTROL X40908 1 2 103

PCB A.-- REMOTE GRILL J6041232/PRIOR MUST UPDATE WITH

SWITCH-- MEMBRANE--5 P OSITION--8”L 044520 1 2 103

BRACKET-- FRONT TRAY *QS12* 079272 1 103

BRACKET-- FRONT TRAY *QS24* 078527 1 103

BRUSH--.625X1.500 QS12/24 074166 1 1 000 J9110000/UP 147

+PIN-- MALE .084”DIA-- MATE-- N--LOK 021624 3 6 103

CLEANER--SIZZLE #545A 079896 1 1 000 CASE OF 6 QUARTS W/SPRAY BOTTLE

CONNECTOR-- MATE LOK 6 CIR--PIN 028594 2 4 103

CORD A.--POWER X79291 1 103

+BUMPER--.500 DIA X .090 THK 079499 1 000

CORD A.--POWER X79877 1 103 GROOVED PLATEN ONLY

COVER A. --PLATEN *QS24* X78798 1 1 103

COVER A. --REAR *QS12* X79444 1 103

COVER A. --REAR *QS24* X74332 1 103 REPLACES X79423

COVER--LINKAGE *QS24* 079441 1 103

CYLINDER-- GAS DUEL SEAL QS24 074313 2 2 103 REPLACES 079215

DECAL A.--KEYPAD QS SERIES X74320 --SER 1 1 000 GREEN (Replaces Old Red Decal -- 078612)

DECAL-- MIN CLEARANCE *QS24* 079061 1 1 000

DECAL-- TERMINAL BLOCK--LEFT 079046--23L 1 000

DECAL-- TERMINAL BLOCK--RIGHT 079046--23R 1 000

DIAGRAM-- WIRING 074063-- 1 1 000 J9054573/UP 143

DIAGRAM-- WIRING 079691-- 1 1 000 J7100000 TO J9054573 122

DIAGRAM-- WIRING 078807-- 1 1 000 PRIOR TO J7100000 122

+ Available Separately

Models QS12 & QS24 Parts List

33

Page 38

UPDATE

REMARKSWARR.

CLASS

BOX

143

ZONES) REPLACE WITH 074178 -- T/C

LOWER FRONT QS, 074179 -- T/C LOWER

MIDDLE QS, 074180 -- T/C LOWER REAR QS

AS REQUIRED OR ALL 3 TO REPLACE

HARNESS.

ZONES) REPLACE WITH 074178 -- T/C

LOWER FRONT QS, 074179 -- T/C LOWER

MIDDLE QS, 074180 -- T/C LOWER REAR QS

AS REQUIRED OR ALL 3 TO REPLACE

HARNESS.

(PRIOR TO J9054573)

QTY.

QS24

QTY.

QS12

PART

NUMBER

DESCRIPTION PARTS

GASKET-- ACCESS COVER 074059 1 000 J9054573/UP 143

078620 1 2 103 POWER SWITCH TO INTERFACE BOARD

+CONNECTOR-- HOUSING 3 PIN 078596 1 2 103

HARNESS-- CONTROL TO REMOTE QS24 078618 1 2 103 CONTROL BOARD TO REMOTE KEY PAD

HARNESS--T/C LOWER *QS12* 079292 1 103 THERMOCOUPLES (6 L OWER COOKING

HARNESS--T/C LOWER *QS24* 078643 1 103 THERMOCOUPLES (6 LOWER COOKING

HARNESS--T/C UPPER #4 078622--4 1 1 103 THERMOCOUPLES (UPPER PLATEN ASSY.)

HARNESS--T/C UPPER #5 078622--5 1 1 103 THERMOCOUPLES (UPPER PLATEN ASSY.)

HARNESS--T/C UPPER #6 078622--6 1 1 103 THERMOCOUPLES (UPPER PLATEN ASSY.)

HARNESS-- WIRE--LOWER POWER 074006 1 2 103 J9054573/UP 143

HARNESS--WIRE --LOWER P OWER*QS24*

(OLD)

HARNESS-- WIRE--UPPER POWER 074007 1 1 103 1 PER UPPER PLATEN

HEATER--CAST -- 1800 WATT 079639-- 3 6 103 J7100000/UP 122

HEATER--CAST -- 1400 WATT 078409-- 3 6 103 PRIOR TO J7100000 122

KIT A.--T-- HANDLE *QS12-- QS24* X74326--KIT 1 1 103

+WASHER 078638 1 1 000

KIT A.--RELAY BOX A. (60HZ--OLD) X79897--SER 103 USE X74036--SER 135/143

LABEL-- CAUTION --HOT SYMBOL 075717--SYM 1 1 000 J9080000 TO K0100000

LABEL-- PRODUCT 079714 1 1 000

LABEL-- PRODUCT STOP BULLS EYE 079894 1 000 GROOVED PLATEN ONLY

LABEL-- WARN--NO SPRAY SURFACE--SYM 074148--SYM 1 2 000 J9110000/UP

LEG--4”--3/8--16 STUD 036397 4 4 103

MAN--OPER QS24 050559 --M 1 1 000

PANEL A.--CONTROL *QS12* X79265 1 103

PANEL A.--CONTROL *QS24* X78405 1 103

+ Available Separately

Parts List Models QS12 & QS24

34

Page 39

UPDATE

REMARKSWARR.

147

CLASS

QTY.

QS24

QTY.

QS12

PART

NUMBER

SEALED

MODELS)

DESCRIPTION PARTS

ARM--PLATEN *QS24* 078520 2 2 103

ARM--PLATEN LINKAGE *QS24* 079192 2 2 103

BEARING-- CYL MOUNT *QS24* 079214 2 2 103

BEARING-- LINKAGE ARM *QS24* 079213 2 2 103

BEARING-- OPEN END NEEDLE *Q524* 078522 8 8 103

BEARING-- OPEN END NEEDLE *Q524* 078523 2 2 103

BEARING-- OPEN END NEEDLE *QS24* 078652 2 2 103

BEARING-- PLATEN ARM PIVOT QS24 078541 2 2 103

CAP--BEARING PLATEN ARM *QS24* 078548 2 2 103

CYLINDER-- GAS DUEL SEAL QS24 074313 2 2 103 REPLACES 079215

E-- RING 3/4 077046 4 4 000

E-- RING 3/8 038958 16 16 000

E--RING EXTERNAL 1/2 024908 16 16 000

HANDLE--PLATEN LIFT *QS24* 078592 1 1 103

LINKAGE-- PIVOT UPPER *QS24* 078760 2 2 103

MOUNT-- CYLINDER LIFT *QS24* 079193 1 1 103

PIN-- LINKAGE ARM *QS24* 078664 2 2 103

PIVOT A.--PLATEN *QS24* X78759 1 1 103

PIVOT-- PLATEN ARM *QS24* 078556 2 2 103

PLATE--PLATED LINKAGE PIVOT LH 078560 1 1 103

PLATE-- PLATED LINKAGE PIVOT RH 078559 1 1 103

RETAINER-- BEARING *QS24* 079191 2 2 103

GASKET-- GREASE PARTITION 074154 1 1 000 J9101783/UP (CAN ADAPT TO EXISTING

PANE L A . - -SIDE L EFT NONE NOT AVAILABLE FOR REPLACEMENT --

PANEL A.-- SIDE RIGHT NONE UNIT TO PREVENT GREASE MIGRATION

PANEL--REAR *QS12* 079280 1 103

PANEL--REAR *QS24* 079044 1 103

PARTITION A.--GREASE X79944 1 1 103 Replaces X78402 137

+ Available Separately

Models QS12 & QS24 Parts List

PIN-- LOCATING 078544 4 4 103

PIVOT A.--PLATEN COMPLETE *QS24 X78758--SER 1 1 103

35

ROD-- LINKAGE 3/4 DIA *QS24* 079216 1 1 103 ROD W/GEAR UNIT

Page 40

UPDATE

REMARKSWARR.

CLASS

QTY.

QS24

078643 HARNESS

078643 HARNESS

078643 HARNESS

QTY.

QS12

PART

NUMBER

DESCRIPTION PARTS

ROD--PLATEN LINKAGE MID *QS24 079194 1 1 103

ROD--PLATEN LINKAGE MID *QS24* 078549 1 1 103

ROD--PLATEN LINKAGE UPPER *QS24 078550 1 1 103

PLATEN ASSEMBLY 208V 1400W X79629--23 1 1 212 208VOLT -- 60HZ 123

PLATEN ASSEMBLY 208/230V 1400W X79629--33 1 1 212 208-- 230VOLT -- 60HZ 123

SCRAPER--TEFLON WIPER 075887 1 1 000

SCRAPER--TROUGH 079726 1 1 000

SCREW--1/4 --20X1/4 ALLEN SET 001801 2 2 000

SCREW--10--24 X 3/8 SET SS 078863 2 2 000 PRIOR TO J8020000

PIN-- GAP--SLIDE--ADJ. 078789 2 2 103

SCREW--10--32X1/2 THUMB STAINLES 078651 2 2 103 THUMB SCREWS

SHEET--SEAMED RELEASE *QS24* 078804 2 2 000

SHIELD-- GREASE FRONT *QS24* 079433 1 1 103

SHIELD-- GREASE REAR *QS24* 079434 1 1 103

SLIDE A.--GAP -- FRONT X78864--F 1 1 103 1 PER PLATEN

SLIDE A.--GAP -- REAR X78864--R 1 1 103 1 PER PLATEN

PIN-- GAP--SLIDE--ADJ. 078789 2 2 103

SCREW--1/4 --20X1/4 ALLEN SET 001801 2 000

SCREW--10--24 X 3/8 SET SS 078863 2 2 000 PRIOR TO J8020000

SPRING .375 OD X .037 X 1.500 079704 2 2 103 RELEASE BAR (Replaces 078805) 125

SPRING-- 3/16 BELLEVILLE DISC 079127 2 2 103 PRIOR TOJ7010000

STANDOFF-- FRONT 079289 4 103

STANDOFF-- REAR 079288 2 103

SWITCH-- ROCKER SPST OFF --ON 078418 1 2 103 POWER

THERMOSTAT--475F 078410 3 6 103

TRANS.-- CONT.-- 40VA 120/200/240V 045754 1 2 103

TRAY A. --GREASE *QS24* X79940--SER 1 1 103 Replaces X78428 137

T/C LOWER FRONT QS 074178 1 1 103 THERMOCOUPLE -- REPLACES 079292 OR

T/C LOWER MIDDLE QS 074179 1 1 103 THERMOCOUPLE -- REPLACES 079292 OR

T/C LOWER REAR QS 074180 1 1 103 THERMOCOUPLE -- REPLACES 079292 OR

VIDEO-- TRAIN QS12 & QS24 OPERATIONS 051170--V 1 1 000

+ Available Separately

Parts List Models QS12 & QS24

36

Page 41

UPDATE

REMARKSWARR.

CLASS

QTY.

QS24

QTY.

QS12

PART

NUMBER

DESCRIPTION PARTS

WIPER-- SIDE LEFT *QS24* 079437 1 1 103

WIPER-- SIDE RIGHT *QS24* 079438 1 1 103

WIPER--FRONT *QS24* 079439 1 1 103

WIPER-- REAR *QS24* 079440 1 1 103

ACCESSORIES:

SCRAPER A.--GROOVE -- RUBBER X79246 1 1 103 RUBBER -- FOR GROOVED PLATEN

SCRAPER A.--GROOVE--METAL X79668 1 1 103 METAL -- FOR GROOVED PLAT EN

OPTIONS:

CART-- SEE BREAKDOWN

BRACKET A.--LEG SUPPORT X79994 4 103

CASTER--SWIVEL 3/4-- 10 021279 2 2 103

CASTER--LOCKING 3/4--10 030307 2 2 103

LEG--INSERT 079990 4 4 103

PIN-- LEG HEIGHT 079991 4 4 103

KIT A.-- PRODUCT STOP X79916 1 1 103

KIT A.--REAR COVER STOP BAR X79689 1 103 HOOD STOP

KIT A.--REAR COVER STOP BAR X79873 1 103 HOOD STOP -- 2 PLATENS

KIT A.--REAR COVER STOP BAR LH X79900 1 103 HOOD STOP -- LEFT PLATEN

KIT A.--REAR COVER STOP BAR RH X79902 1 103 HOOD STOP -- RIGHT PLATEN

LEG--2--1/2 IN 3/8-- 16 STUD 079715 4 4 103 DISCONTINUED

50HZ

BOX A. --RELAY (OLD) X79678--75 1 2 212 50HZ & 60HZ USE X74036--SER 143

RELAY--SPST--200/240VAC (OLD) 079690 6 6 103

X79839--62R 1 103 RIGHT SIDE -- J8050000/UP

BLOCK-- TERMINAL--5P SCREW

W/JUMPERS

BLOCK-- TERMINAL--5P SCREW 079045--62R 1 103 RIGHT SIDE -- PRIOR TO J8050000

DECAL-- SWITCH *QS24* SYMBOL 079454 1 2 000

DECAL-- TERMINAL BLOCK *QS24 079046--62L 1 000

DECAL-- TERMINAL BLOCK *QS24 079046--62R 1 000

CONTROL-- HI --LIMIT 550F NO RESET 074165 12 12 103 K0010000/ UP

+ Available Separately

Models QS12 & QS24 Parts List

37

Page 42

UPDATE

REMARKSWARR.

CLASS

150

X74189; QS24 --X74190 (FLAT), X74188

(SINGLE CLAM), OR X74186 (DUAL CLAM)

QTY.

QS24

QTY.

QS12

PART

NUMBER

DESCRIPTION PARTS

DIAGRAM-- WIRING (NEW) 074063--75 1 1 000 J9054573/UP 143

DIAGRAM-- WIRING (OLD) 079691--75 1 1 000

FILTER A.--*M22* X79163 1 1 103

HARNESS--POWER LOWER *QS24* (NEW) 074065 1 2 103 J9054573/UP

HARNESS--POWER LOWER *QS24* (OLD) 079496 1 2 103

HARNESS--POWER UPPER (NEW) 074007 1 1 103 1 PER PLATEN (REPLACES 079497)

HEATER--CAST 230V 1800W *QS24* 079639-- 26 3 6 103

PLATEN ASSEMBLY 230/400V 1400W X79629--75 1 1 212 230/400VOLT -- 50HZ 123

THERMOSTAT--500F 079471 12 12 103 PRIOR TO K0010000 -- UPDATE W/QS12--

+ Available Separately

Parts List Models QS12 & QS24

VIDEO-- TRAIN QS24 OPS 051170--PAL 1 1 000

38

Page 43

QS12/24

074063--22

Page 44

QS12/24

074063--23

Page 45

QS12/24

074063--75

Rev . 4/01

Page 46

QS24

078807--23

Page 47

QS24

079691--77

J710000 -- J9050000

Loading...

Loading...