Page 1

Remote Cooler Accessory

Installation Instructions

Part Numbers 00EFN900003000A, 00EFN900003100A

30XA080-350

60 Hz

CONTENTS

SAFETY CONSIDERATIONS . . . . . . . . . . . . . . . . . . . . . . 1

GENERAL . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-3

INSTALLATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-16

Cooler and Economizer Removal. . . . . . . . . . . . . . . . . 4

Remote Cooler and Economizer Installation. . . . . 10

SAFETY CONSIDERATIONS

Installing, starting up, and servicing air-conditioning

equipment can be hazardous due to system pressures, electrical

components, and equipment location. Only trained, qualified

installers and service technicians should install, start-up, and

service this equipment.

When working on air-conditioning equipment, observe

precautions in the literature and on tags, stickers, and labels

attached to the equipment. Follow all safety codes. Wear safety

glasses and work gloves. Use care in handling equipment.

Be sure power to equipment is shut off before performing

maintenance or service. Lock out and safety-tag all

disconnects.

GENERAL

The remote cooler accessory allows for the indoor relocation of the cooler on 30XA080-350 units as another means of

freeze protection. When the cooler is located in a heated space,

an anti-freeze solution is not needed and the performance

degradation associated with antifreeze solution can be avoided.

Maximum separation of the 30XA base unit and cooler is

limited to 50 lineal ft (15.25 m) or 75 equivalent ft (22 m) of

piping. For more information, refer to the Carrier Piping Design manual.

The liquid and economizer lines between the exteriorinstalled unit and the remote, interior-installed cooler must

have pressure relief devices installed in accordance with

ASHRAE 15 (American Society of Heating, Refrigeration, and

Air Conditioning Engineers) and local codes.

Units to be modified for a remote cooler application must

have the following options:

• Factory-installed suction service valve option.

• Condenser coil type:

— Aluminum fin and copper tube

— Pre-coat aluminum fin and copper tube

— E-coat aluminum fin and copper tube

— Copper fin and copper tube

— E-coat copper fin and copper tube

NOTE: The microchannel heat exchanger option can NOT use

the remote cooler accessory.

The application is limited to the following constraints:

• Operating chilled water temperature is between 40 and 55 F

(4.4 and 12.8 C). When the remote cooler is applied, the

cooler heaters will not function, so it is critical to maintain the

water temperature above the freezing point at all times. If the

water temperature falls below the freezing point, the cooler

does not have protection to keep the water from freezing.

• The interior space temperature where the cooler will be

installed must be maintained at a minimum of 50 F (10 C).

• Underground refrigerant piping is NOT permitted for this

application.

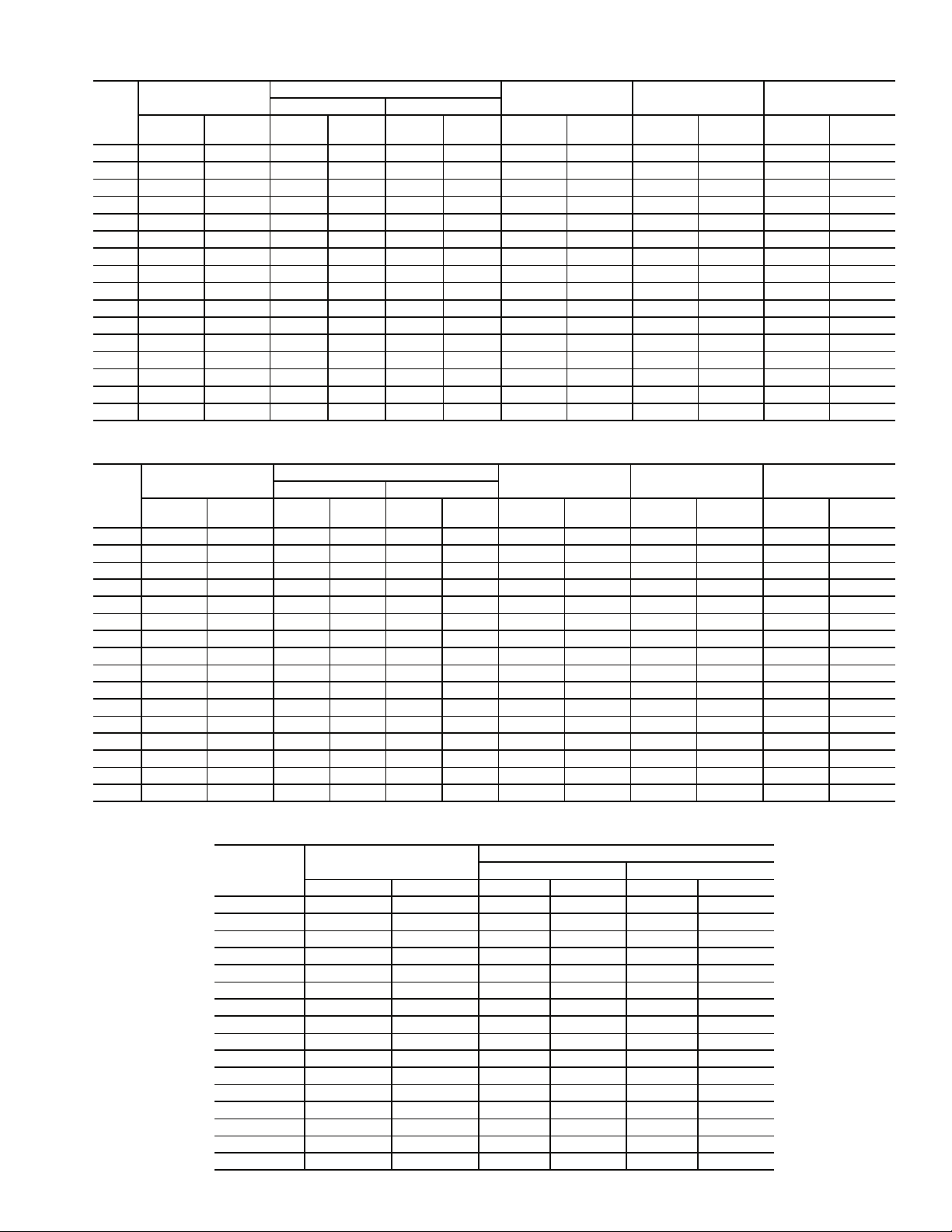

See Table 1 for accessory package usage and see Table 2 for

accessory package contents. In addition to the parts supplied

with each accessory package, the following material must be

field-supplied:

• Refrigerant grade liquid and suction line copper piping for

30XA080-120: circuits A and B and 30XA140-160: circuit

B (length determined by installation). See Tables 3A and 3B

for pipe sizes.

• Schedule 40 steel pipe for 30XA140-160: circuit A and

30XA180-350: circuits A and B (length determined by

installation). See Tables 3A and 3B for pipe sizes.

• 350 psig pressure relief valves and fittings (2 per circuit)

• Suction line tubing insulation (length determined by

installation)

• Economizer line tubing insulation (length determined by

installation)

1

•

/2 in. strain relief (2)

• Conduit (length determined by installation)

• ASME (American Society of Mechanical Engineers) B16.9

stub end (4 in. [102 mm]), Schedule 40 Steel (one needed

for 30XA140-160, two needed for 30XA180-350)

• ASME B16.5 Class 600 pipe flange (4 in. [102 mm]) with

field-modified extra mounting hole (one needed for

30XA260-300, two needed for 325, 350)

• Flange mounting hardware

• Extra flange gaskets (if necessary)

The 30XA units use R-134a refrigerant. No other refrigerant may be used in this system. Suction tubing design pressure is 220 psig (1517 kPa). Economizer and liquid tubing

design pressure is 350 psig (2413 kPa). Failure to use gage

set, hoses, and recovery systems designed to handle

R-134a refrigerant may result in personal injury and equipment damage. If unsure about equipment, consult the

equipment manufacturer.

Table 1 — Accessory Package Usage

30XA UNIT SIZE PACKAGE REQUIRED

080-200 00EFN900003000A

220-350 00EFN900003100A

Manufacturer reserves the right to discontinue, or change at any time, specifications or designs without notice and without incurring obligations.

Book 2

Ta b 5 c

Catalog No. 04-53300012-01 Printed in U.S.A. Form 30XA-7SI Pg 1 1-07 Replaces: New

Page 2

Table 2 — Accessory Package Contents

ACCESSORY PACKAGE

PART NO.

00EFN900003000A

00EFN900003100A

ITEM NO. DESCRIPTION PART NO. QTY

1 Economizer shutoff valve - 1

2 Liquid line shutoff valve - 1

3 5 Wire jacketed cable RM02EJ200

4 Cable assembly 32GB404694 5

5 Junction box HX30FZ001 2

6 Junction box cover HX38ZZ001 2

7 M6 Screws 00PPN500000302A 8

8 Cooler pipe flange - 3

10 Flex connector flange - 4 in. (102 mm) 00PSG000213300A 2

11 Loose pipe flange - 4 in. (102 mm) 00PSG000205100A 2

12 Cooler flange O-ring KK71EW256 4

13 Flex connector flange O-ring KK71EW250 2

14 Compressor flange gasket - 3 in. (76 mm) 00PPG000011702A 2

15 Compressor flange gasket - 4 in. (102 mm) 00PSG000011703A 4

16 Transducer wiring harness - 100 ft (30.5 m) 00PSN500180500A 2

1 Economizer shutoff valve - 1

2 Liquid line shutoff valve - 1

3 5 Wire jacketed cable RM02EJ200

4 Cable assembly 32GB404694 5

5 Junction box HX30FZ001 2

6 Junction box cover HX38ZZ001 2

7 M6 Screws 00PPN500000302A 8

8 Flex connector flange O-ring KK1EW250 2

9 Compressor flange gasket - 4 in. (102 mm) 00PSG000011703A 4

10 Compressor flange gasket - 5 in. (127 mm) 00PPG000011704A 4

11 Loose pipe flange - 5 in. (127 mm) 00PSG000211900A 2

12 Loose pipe flange - 4 in. (102 mm) 00PSG000205100A 2

13 Flex connector flange - 4 in. (102 mm) 00PSG000213300A 2

14 Transducer wire harness - 100 ft (30.5 m) 00PSN500180500A 2

1

/8 in. (29 mm) 00PPG000023501A 2

3

/8 in. (35 mm) EP71BA393 2

1

/8 in. (79 mm) 00PSN500091400A 2

1

/8 in. (29 mm) 00PPG000023501A 2

3

/8 in. (35 mm) EP71BA393 2

200 ft

(61 m)

200 ft

(61 m)

Choose a space that can support the weight of the cooler and

economizer with service clearances and area for refrigerant

piping. Field-supplied piping must be limited to less than

50 lineal ft (15.25 m) or 75 equivalent ft (22 m) in length.

Suction and liquid line risers must be limited to less than 15 ft

(4.5 m) vertical riser elevation. Suction lines and economizer

lines must be insulated to prevent condensation. Relocating the

cooler introduces minimal line losses if correct piping practices

are followed. Buried lines are not permitted.

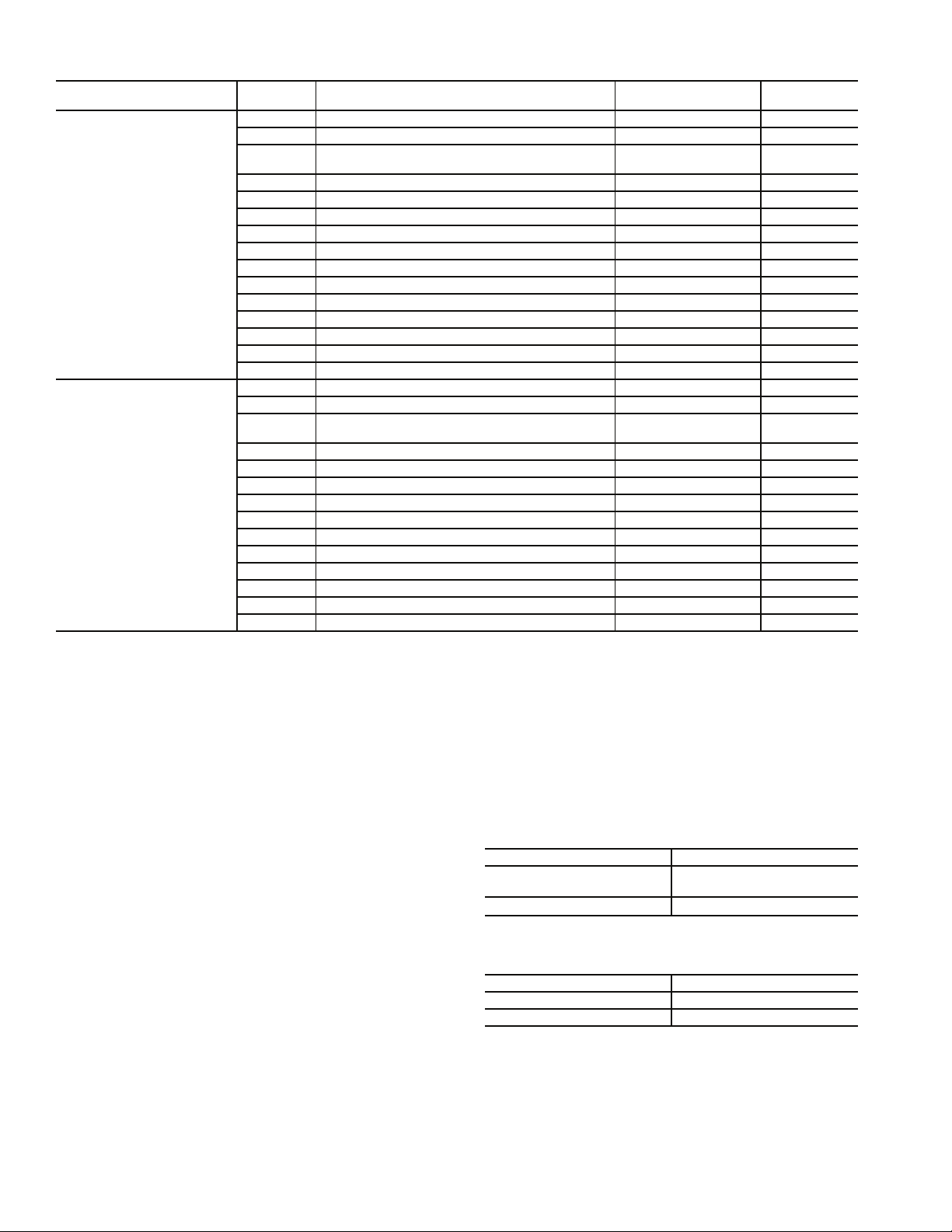

The remote cooler system can be applied in three different

configurations. See Fig. 1-3. In Fig. 1, the remote cooler and

the outdoor unit are at the same elevation. The suction, liquid,

and economizer lines run parallel between the cooler and the

outdoor unit. In Fig. 2, the outdoor unit and remote cooler are

at the same elevation, but the interconnecting piping has an elevation of up to 15 ft (4.5 m) above the base elevation of the

cooler. This could be result of running piping over a wall or

through the ceiling in a building. In Fig. 3, the remote cooler is

located below the outdoor unit. The interconnecting piping has

an elevation of up to 15 ft (4.5 m) above the base elevation of

the remote cooler. This could occur if the remote cooler is installed in a basement.

NOTE: Unit 30XA refrigeration piping can be either copper

tubing or steel tubing with flanged connections. All units are

factory charged with compressor oil to the required level.

However, when the double riser is constructed with U-bends or

street elbows, a substantial amount of oil can be trapped in the

U-bend during prolonged minimum load operation. If this

occurs, additional oil is needed to add to the system to prevent

the oil level from dropping below the minimum level in the oil

separator. Add 1 gallon of oil to each circuit. Refer to Controls,

Start-up, Operation, Service, and Troubleshooting Guide for

recommended oil type.

Table 3A — Refrigeration Piping and

Connections Material (English)

PIPE SIZE (in.) MATERIAL

5

/8, 7/8, 11/8, 13/8, 15/8,

1

2

/8, 25/8, 31/

1

2, 2

/2, 3, 31/2, 4 Schedule 40 Steel

8

Refrigeration copper

Table 3B — Refrigeration Piping and

Connections Material (SI)

PIPE SIZE (mm) MATERIAL

16, 22, 29, 35, 41, 54, 67, 79 Refrigeration copper

51, 64, 76, 89, 102 Schedule 40 Steel

2

Page 3

INDOOR LOCAT ION

LEGEND

............ Liquid Line

Economizer Line

Suction Line

a30-4509

LEGEND

............ Liquid Line

Economizer Line

Suction Line

a30-4510

30X A

REMOTE COOLER

Fig. 1 — 30XA Unit and Cooler Level, Piping Parallel (Single Circuit Shown)

INDOOR LOCAT ION

30XA

15 FT MAX

REMOTE COOLER

Fig. 2 — 30XA Unit and Cooler Level, Piping Elevated (Single Circuit Shown)

SUCTION

SERVICE

VALV E

SUCTION

SERVICE

VALV E

ECONOMIZER

ECONOMIZER

LEGEND

............ Liquid Line

Economizer Line

Suction Line

30X A

INDOOR LOCATION

15 FT MAX

REMOTE COOLER

a30-4511

Fig. 3 — 30XA Unit with Cooler Located Below Unit (Single Circuit Shown)

3

SUCTION

SE R VICE

V A L VE

ECONOMIZER

Page 4

INSTALLATION

Shut off all power to this equipment prior to installation.

There may be more than one disconnect switch. Tag all

disconnect locations to alert others not to restore power

until work is completed. Failure to disconnect power from

equipment prior to installation could result in serious

personal injury or death.

1. Inspect package contents for missing or damaged parts.

File a claim with the shipping agency if parts are

damaged and notify your local Carrier representative if

any item is missing.

2. Determine the new location for the cooler. Ensure that the

new location supports the cooler and economizers

weights and that there is enough room for service access

and tube removal. See Tables 4A and 4B to determine

refrigeration line sizes. See Table 5 for cooler and

economizers weights. See Fig. 4A-5B for cooler and

economizers dimensions, tube removal clearances, and

service areas.

3. Open and tag all electrical disconnects.

Cooler and Economizer Removal — The cooler and

economizers are accessible from the cooler side of the unit. To

remove the cooler and economizers from the unit, complete the

following steps:

1. Remove refrigerant from all circuits using standard

refrigeration practices. Refer to unit nameplate or installation instructions for refrigerant quantities.

2. Disconnect the cooler heater wiring, and conduit if

equipped.

3. Remove entering and leaving chilled water temperature

thermistors. Make sure to label thermistors as they are

removed. See Fig. 6.

4. Disconnect and label the chilled water flow switch cable

from the chilled water flow switch located on the leaving

water nozzle. See Fig. 6.

5. Disconnect the suction pressure transducer cables from

the transducers. Make sure to label cables as they are

removed. See Fig. 6.

NOTE: The suction pressure transducers (SPT) do not necessarily need to be removed. However, use care in protecting the

SPTs throughout the removal and remote installation processes,

as the SPTs are an important part of the remote installation.

6. Disconnect the electronic expansion valve (EXV) cables

from the EXVs at each economizer. Make sure to label

cables as they are removed. See Fig. 6.

NOTE: The 30XA080 units do not utilize an economizer.

In this case, only the EXVs are present.

7. Unbolt the cooler suction flanges from the cooler. Temporary supports may be needed to support the suction pipes.

See Fig 6.

8. At each circuit’s economizer, cut the liquid lines going to

the economizer assembly before the manual shutoff valve

(see Fig. 6, cut 1, circuits A and B). Cut the cooler liquid

lines between the manual shutoff valve and the cooler

(see Fig. 6, cut 2, circuits A and B). Cut the economizer

lines between the manual shutoff valve and the sensors

(see Fig. 6, cut 3, circuits A and B).

9. Remove the screws from the feet of each economizer.

Save all of the screws. Remove the economizers by carefully sliding them out the cooler side of the unit.

10. Remove the screws from the cooler feet. Save all of the

screws. Slide the cooler slightly to the left to clear the

refrigerant tubing.

11. Remove the cooler by carefully sliding the cooler out the

cooler side of the unit.

Because 30XA systems use polyolester oil, which can absorb moisture, it is important to minimize the amount of

time that the refrigeration system is left exposed to the atmosphere. Minimizing the exposure time will reduce the

amount of moisture that could possibly damage the unit.

The removal instructions minimize the exposure time to

prevent this type of damage. The remote installation instructions outline a dehydration process to counteract any

exposure that might have occurred.

Before installation of the field-supplied piping, the piping

must be thoroughly cleaned and free of dirt, debris, oil, and

welding residue. Presence of these objects will cause severe

damage to the compressors or other components of the refrigeration system.

4

Page 5

Table 4A — Refrigeration Line Sizes (English)

30XA

UNIT

SIZE

080 3

090 3

100 31/

110 31/

120 31/

140 43

160 43

SUCTION LINE

Circuit A

(in.)

1

/

8

1

/

8

8

8

8

Circuit B

(in.)

31/

8

31/

8

31/

8

31/

8

31/

8

1

/

8

1

/

8

180 4423

200 4423

220 4423

240 4423

260 442

280 442

300 442

325 442

350 442

DOUBLE SUCTION RISERS

Circuit A Circuit B

Riser A

(in.)

Riser B

(in.)

15/

15/

15/

15/

15/

23

23

1

1

1

1

1

25/

8

8

8

8

8

/

2

/

2

/

2

/

2

/

2

8

25/

8

25/

8

25/

8

25/

8

1

/

2

1

/

2

1

/

2

1

/

2

1

/

2

1

/

2

323

323

323

32

32

Riser A

(in.)

15/

15/

15/

15/

15/

15/

15/

8

8

8

8

8

8

8

Riser B

(in.)

25/

25/

25/

25/

25/

25/

25/

23

23

23

23

1

/

2

1

/

2

8

8

8

8

8

8

8

1

/

2

1

/

2

1

/

2

1

/

2

1

/

2

1

/

2

1

/

2

31

31

COOLER

LIQUID LINE

Circuit A

(in.)

11/

8

11/

8

11/

8

11/

8

11/

8

13/

8

13/

8

13/

8

13/

8

13/

8

13/

8

15/

8

15/

8

15/

8

5

/

8

5

/

8

Circuit B

(in.)

11/

8

11/

8

11/

8

11/

8

11/

8

11/

8

11/

8

13/

8

13/

8

13/

8

13/

8

13/

8

13/

8

13/

8

15/

8

15/

8

CONDENSER

LIQUID LINE

Circuit A

(in.)

11/

8

11/

8

11/

8

11/

8

11/

8

13/

8

13/

8

13/

8

13/

8

13/

8

13/

8

15/

8

15/

8

15/

8

15/

8

15/

8

Circuit B

(in.)

11/

8

11/

8

11/

8

11/

8

11/

8

11/

8

11/

8

13/

8

13/

8

13/

8

13/

8

13/

8

13/

8

13/

8

15/

8

15/

8

ECONOMIZER

LINE

Circuit A

(in.)

Circuit B

——

7

/

8

7

/

8

7

/

8

7

/

8

11/

8

11/

8

11/

8

11/

8

11/

8

11/

8

11/

8

11/

8

11/

8

11/

8

11/

8

Table 4B — Refrigeration Line Sizes (SI)

30XA

UNIT

SIZE

SUCTION LINE

Circuit A

(mm)

Circuit B

(mm)

DOUBLE SUCTION RISERS

Circuit A Circuit B

Riser A

(mm)

Riser B

(mm)

Riser A

(mm)

Riser B

(mm)

080 79 79 41 67 41 67 29 29 29 29 — —

090 79 79 41 67 41 67 29 29 29 29 22 22

100 79 79 41 67 41 67 29 29 29 29 22 22

110 79 79 41 67 41 67 29 29 29 29 22 22

120 79 79 41 67 41 67 29 29 29 29 22 22

140 102 79 51 89 41 67 35 29 35 29 29 22

160 102 79 51 89 41 67 35 29 35 29 29 22

180 102 102 51 89 51 89 35 35 35 35 29 29

200 102 102 51 89 51 89 35 35 35 35 29 29

220 102 102 51 89 51 89 35 35 35 35 29 29

240 102 102 51 89 51 89 35 35 35 35 29 29

260 102 102 64 76 51 89 41 35 41 35 29 29

280 102 102 64 76 51 89 41 35 41 35 29 29

300 102 102 64 76 51 89 41 35 41 35 29 29

325 102 102 64 76 64 76 41 41 41 41 29 29

350 102 102 64 76 64 76 41 41 41 41 29 29

COOLER

LIQUID LINE

Circuit A

(mm)

Circuit B

(mm)

CONDENSER

LIQUID LINE

Circuit A

(mm)

Circuit B

(mm)

ECONOMIZER

LINE

Circuit A

(mm)

Circuit B

(in.)

7

/

8

7

/

8

7

/

8

7

/

8

7

/

8

7

/

8

11/

11/

11/

11/

11/

11/

11/

11/

11/

(mm)

8

8

8

8

8

8

8

8

8

Table 5 — Cooler and Economizer Weights

30XA

UNIT SIZE

COOLER OPERATING

WEIGHT

lb kg lb kg lb kg

080 1277 580 — — — —

090 1323 601 45 20 45 20

100 1323 601 45 20 45 20

110 1357 617 45 20 45 20

120 1396 634 45 20 45 20

140 1622 737 45 20 55 25

160 1665 757 45 20 55 25

180 1860 845 55 25 55 25

200 1920 872 55 25 55 25

220 1980 900 55 25 60 27

240 2031 923 60 27 60 27

260 2261 1027 55 25 70 32

280 2321 1055 60 27 70 32

300 2411 1095 60 27 75 34

325 2458 1117 70 32 70 32

350 2523 1146 70 32 75 34

ECONOMIZER WEIGHT

Circuit A Circuit B

5

Page 6

13/16

(20)

117-3/4

(2991)

52-1/4

(1327)

1/2

(13)

DETAIL A

SCALE 2:1

TYP 6 PLACES

NOTES:

1. Measurements are shown in inches (millimeters).

2. Recommended service clearance around the cooler is 36 in. (914 mm).

3. Recommended cooler tube removal area (either end) is 109 in. (2769 mm).

8-9/32

(210)

SEE DETAIL A

14-11/32

(364)

57

(1447)

Fig. 4A — 30XA080-120 Cooler Dimensions

52-1/4

(1327)

SIDE VIEW

14-11/32

BOTTOM VIEW

(364)

52-1/4

(1327)

21-1/32

(534)

14-11/32

(364)

18-21/32

(474)

a30-4512

13/16

(20)

1/2

(13)

A

DETAIL

SCALE 2:1

TYP 6 PLACES

10-23/32

(272)

SEE DETAIL

15-5/16

(389)

A

64

(1625)

NOTES:

1. Measurements are shown in inches (millimeters).

2. Recommended service clearance around the cooler is 36 in. (914 mm).

3. Recommended cooler tube removal area (either end) is 109 in. (2769 mm).

Fig. 4B — 30XA140, 160 Cooler Dimensions

118-13/16

(3017)

52-1/4

(1327)

52-1/4

(1327)

SIDE VIEW

BOTTOM VIEW

15-5/16

(389)

45-1/4

(1149)

19-21/32

15-5/16

(389)

a30-4513

23-1/32

(585)

(499)

6

Page 7

13/16

(20)

119-9/32

(3030)

52-1/4

(1327)

11-3/16

1/2

(13)

A

DETAIL

SCALE 2:1

TYP 6 PLACES

NOTES:

1. Measurements are shown in inches (millimeters).

2. Recommended service clearance around the cooler is 36 in. (914 mm).

3. Recommended cooler tube removal area (either end) for 30XA180, 200 is 109

4. Recommended cooler tube removal area (either end) for 30XA220, 240 is 1085/8 in. (2758 mm).

(284)

SEE DETAIL

18-3/8

(466)

52-1/4

(1327)

A

57

(1448)

SIDE VIEW

18-3/8

(466)

BOTTOM VIEW

3

/8 in. (2779 mm).

Fig. 4C — 30XA180-240 Cooler Dimensions

52-1/4

(1327)

25-1/16

(636)

22-11/16

18-3/8

(576)

(466)

a30-4514

13/16

(20)

1/2

(13)

DETAIL

SCALE 1:1

TYP 6 PLACES

NOTES:

1. Measurements are shown in inches (millimeters).

2. Recommended service clearance around the cooler is 36 in. (914 mm).

3. Recommended cooler tube removal area (either end) for 30XA260-300 is 188

4. Recommended cooler tube removal area (either end) for 30XA325, 350 is 232

11-7/16

2

(290)

(50)

A

SEE DETAIL

A

20-11/32

(516)

16-3/8

(416)

52-1/4

(1327)

118-5/32

(3002)

64-7/8

(1648)

52-9/32

(1328)

SIDE VIEW

16-3/8

(416)

BOTTOM VIEW

3

/8 in. (4784 mm).

21

/32 in. (5910 mm).

20-11/32

(516)

57

(1448)

20-11/32

(516)

16-3/8

(416)

a30-4515

27-1/8

(689)

24-21/32

(626)

Fig. 4D — 30XA260-350 Cooler Dimensions

7

Page 8

22-7/8

(581)

23-1/2

(598)

30-3/8

(770)

SIDE VIEW END VIEW

6-1/2

(166)

5/8

2 x Ø 7/16 (11)

29-3/8

(746)

7/16

(12)

(17)

TOP VIEW

NOTES:

1. Measurements are shown in inches (millimeters).

2. Recommended service clearance around the economizer is 36 in. (914 mm).

Fig. 5A — 30XA090-160 Economizer Dimensions

7-7/8

(200)

7/16

(11)

a30-4516

7/8

(21)

23-1/32

(585)

30-3/4

(781)

SIDE VIEW END VIEW

2-1/4

8-3/4

(56)

(222)

4 x Ø 7/16 (11)

29-3/8

(746)

7/16

(12)

5/8

(17)

TOP VIEW

NOTES:

1. Measurements are shown in inches (millimeters).

2. Recommended service clearance around the economizer is 36 in. (914 mm).

Fig. 5B — 30XA180-350 Economizer Dimensions

8

7-7/8

(256)

7/16

(11)

24-1/4

(611)

a30-4517

7/8

(21)

Page 9

CUT 1

(LIQUID LINE)

CUT 3

(ECONOMIZER

LINE)

CIRCUIT A

ELECTRONIC

EXPANSION

VALV ES (2)

MANUAL SHUTOFF

VALVE

CHILLED WATER

FLOW SWITCH

1. Circuit A uses steel suction piping.

2. Circuit B uses copper suction piping.

NOTES:

SUCTION PRESSURE

TRANSDUCER

SUCTION PRESSURE

(HIDDEN)

CUT 3

(ECONOMIZER

CUT 2

(COOLER

TRANSDUCER

(HIDDEN)

LINE)

LIQUID LINE)

ENTERING CHILLED WATER

ELECTRONIC

EXPANSION

VALV ES (2)

COOLER

SUCTION

FLANGES

LEAVING CHILLED WATER

THERMISTORS

CIRCUIT A

(CONT.)

Fig. 6 — Typical Cooler Piping-Cooler Side View (30XA140, 160 Shown)

CUT 4

(SUCTION

LINE)

CUT 1

(LIQUID LINE)

MANUAL

SHUTOFF

VALVE

CUT 2

(COOLER

LIQUID LINE)

9

CIRCUIT B

a30-4518

Page 10

Remote Cooler and Economizers Installation —

location by following this procedure:

NOTE: Throughout the Remote Cooler and Economizers

Installation steps, the two accessory package part no.

(00EFN900003000A, 00EFN900003100A) have been shortened to 3000A and 3100A. When a specific part is referred to

in each accessory’s package, the package no. is mentioned followed by the item no. For item no. identification and accessory

package contents, refer to Table 2.

NOTE: The 30XA080 units do not utilize an economizer. In

this case, keep the EXV as close to the cooler as possible.

NOTE: The original flanges on the cooler and cut from the

30XA base unit may still be usable. However, Carrier recommends and has provided in the accessory kit, parts necessary to

replace both the cooler pipe flange and the suction flange.

When the extended piping is installed, these flanges should be

replaced.

Install the cooler and economizers in a remote

1. After removing the cooler from the base unit, strip back

the insulation on the cooler tube sheets (if required) and

use the two large holes in the top corners for lifting.

2. Transport the cooler and economizer assemblies to the

new location and secure them into position. Keep the

economizer assemblies as close to the cooler as possible.

Also, ensure there is sufficient room to install and remove

cooler tubes from either end of the cooler. See Fig. 4A4D for tube removal clearances.

3. Install the accessory-supplied economizer shutoff valves

(3000A or 3100A: Item 1) and liquid line shutoff valves

(3000A or 3100A: Item 2) on the two economizer lines

and liquid lines at circuits A and B on the 30XA base

unit. See Fig. 7.

4. At the new cooler location, connect the field-supplied

cooler liquid line piping between the factory-installed

manual shutoff valve at the two economizer assemblies

and at the cooler. See Fig. 7.

5. Following good piping practices, install additional fieldsupplied liquid and economizer line piping in the required

length to reconnect the two economizer assemblies to the

30XA base unit. See Fig. 8 for double suction riser construction detail.

Do NOT close both manual shutoff valves in one liquid

line. Pressure can build up in the trapped area. To avoid the

possibility of personal injury or property damage, the new

liquid lines between the manual shutoff valves must each

have field-supplied and installed pressure relief valves.

6. For 30XA080-120: all circuits and 30XA140-160: circuit

B, cut the suction pipe (copper) at the 30XA base unit and

discard (see Fig. 6, cut 4, circuit B). Following good

piping practices, install field-supplied copper suction line

piping from the 30XA base unit to the cooler. Use the

accessory-supplied cooler pipe flange (3000A: Item 8),

cooler flange O-ring (3000A: Item 12), and loose pipe

flange (3000A: Item 11) to connect the field-supplied

copper suction line piping at the cooler. See Fig. 9.

7. For 30XA140-160: circuit A and 30XA180-350: all

circuits, unbolt (DO NOT CUT) the portion of the steel

suction pipes that connected the flex connector flanges to

the cooler at the 30XA base unit and discard. See Fig. 10.

Refer to Table 6 for parts required (field-supplied or

accessory-supplied) to make new connections at the

cooler and the 30XA base unit with the field-supplied

steel suction line. See Fig 11. Follow good piping

practices to install field-supplied steel suction line piping

between the cooler and the flex connector at the 30XA

base unit.

When field-supplied flanges and gaskets are used, an

extra M16 mounting hole must be drilled and tapped to

connect a mounting bracket at the 30XA base unit. See

Fig. 10 and 11 for mounting bracket placement. See

Fig. 12 for mounting hole locations.

If additional gaskets are needed for installation, they must

1

be

/16 in. non-asbestos fiber with synthetic rubber binder

compressed gasket sheet. An extra mounting hole also

needs to be field modified for any additional gaskets. See

Fig. 12 for mounting hole locations. Field-supplied

mounting nuts and bolts are also needed for fieldsupplied gaskets.

8. All of the piping connections are now complete. Leak test

the unit and then pull a deep dehydration vacuum. Connect the vacuum pump to the high-flow access fitting at

the bottom of the cooler, the liquid line service valves,

and the economizer line service valves. For best results, it

is recommended that a vacuum of at least 500 microns

(0.5 mm Hg) be obtained. To perform a standing vacuum

rise test, observe the rate-of-rise of the vacuum in the

system. If the vacuum rises by more than 50 microns in a

30-minute time period, then continue the dehydration

process until the standing vacuum requirement is met.

This will ensure a dry system.

By following this dehydration procedure, the amount of

moisture present in the system will be minimized, and the

factory-supplied filter driers will provide adequate

moisture protection. It is highly recommended that the

filter drier cores be replaced after 24 hours of operation.

This is to ensure that any foreign debris that is captured

during start-up is removed from the system. Additional

moisture removal capacity is also provided.

9. After setup is leak tested and deep dehydration vacuum is

completed, install field-supplied suction and economizer

line insulation between the economizer and the unit. If

necessary, reinstall the insulation on the cooler head.

10. To reconnect the EXV cables, use the accessory-supplied

cable assemblies (3000A or 3100A: Item 4). Two cables

are needed for the 30XA080 unit, and four cables are

needed for 30XA090-350 units. Take one cable assembly,

and label both ends with “EXV-A” for the circuit A main

EXV. Then label another three cable assemblies the same

way with “EXV-B”, “ECEXV-A”, “ECEXV-B” for the

circuit B main EXV, circuit A economizer EXV, and

circuit B economizer EXV, respectively (economizer

EXV does not apply to 30XA080 units).

Plug one side of the electrical connectors of the EXV

labeled cables into their corresponding EXV plugs. Run

the cables to the 30XA base unit, and plug the other side

of the cable connectors into their corresponding EXV

leads. Coil excess cables and wire tie in a convenient

location.

11. To reconnect the flow switch cable, use the accessorysupplied cable assembly (3000A or 3100A: Item 4). Take

one cable assembly and label both ends with “CWFS.”

Plug one side of the electrical connector of the labeled

cable into the flow switch plug. Run the cable to the base

unit, and plug the other side of the cable connector into

the flow switch lead. Coil excess cables and wire tie in a

convenient location.

10

Page 11

12. Using the accessory-supplied M6 screws (3000A or

3100A: Item 6), install the accessory-supplied junction

box (3000A or 3100A: Item 5) at the desired location

where the entering and leaving water thermistor cables

can be conveniently spliced. One or two knockouts can

be used. Follow all local codes. Remove one knockout

from the junction box and install the field-supplied strain

relief at the knockout hole. If using field-supplied conduit

to provide mechanical protection to the thermistor wires

between the cooler and the 30XA base unit, remove

another knockout.

13. To reconnect the thermistors, locate the entering water

thermistor and leaving water thermistor and cut both

leads where they can be spliced in the installed junction

box. Cut, strip, and label both sides of the entering water

thermistor lead “EWT.” Cut, strip, and label the leaving

water thermistor lead the same way, with “LWT” on both

sides. See Fig. 13.

14. Run the labeled thermistor leads connected to the unit

into the installed junction box and tighten the fieldsupplied strain relief. Strip back the lead jackets to expose

the two wires in each lead.

15. Take one of the accessory-supplied 5-wire jacketed cables (3000A or 3100A: Item 3) to connect the thermistor

leads in the installed junction box to the cooler location.

Each wire in the jacketed cable is a different color. Cut

the cable into two pieces so that each has a maximum

length of 100 ft (30.5 m).

16. Select one jacketed cable and strip back the jacket on

both ends to expose the five wires. Pick any two wires

and label both ends of each wire “EWT.” Pick another

pair of wires and label both ends “LWT.” The fifth wire is

not used. See Fig. 14.

17. Run one end of the accessory-supplied 5-wire jacketed

cable into the installed junction box and splice the identically labeled thermistor leads. Solder the splices and insulate them to prevent shorting. Tighten the field-supplied

strain relief for the cables.

18. Run the other end of the accessory-supplied 5-wire

jacketed cables back to the cooler. Splice the labeled

jacketed cable wires to the matching thermistors. If a

second junction box is necessary at the cooler location,

use the second accessory-supplied junction box (3000A

or 3100A: Item 5).

19. Reinstall the thermistors in the correct cooler wells.

20. To reconnect the suction pressure transducers (SPT),

locate the SPT plugs for circuits A and B, and cut the

leads where they can be conveniently spliced in the

installed junction box at the 30XA base unit. Label the

leads “SPTA” for the circuit A lead, and “SPTB” for the

circuit B lead.

21. Take the two pieces of accessory-supplied transducer

wire harness (3000A: Item 16 or 3100A: Item 14). One

side of the harness is a plug and the other side is three

wires in red, black, and green. Label both sides of one

harness “SPTA,” and label the other harness “SPTB.”

Remove one knockout from an installed junction box and

install a field-supplied strain relief valve at the knockout

hole. If using field-supplied conduit to provide mechanical protection to the transducer wires between the cooler

and the 30XA base unit, remove another knockout.

22. Run the labeled transducer leads connected to the unit

into the installed junction box at the 30XA base unit and

tighten the field-supplied strain relief. Strip back the lead

jackets to expose the three wires, black, red, and white.

23. Run the lead end of accessory-supplied transducer wire

harnesses into the junction box and splice the identically

labeled leads. The red wire should go with red wire, the

black wire with the black wire, and the white wire with

the green wire. Solder the splices and insulate them to

prevent shorting. Tighten the field-supplied strain relief

for the cables and secure the accessory-supplied junction

box cover (3000A or 3100A: Item 6) with accessorysupplied M6 screws.

24. Run the plug end of the accessory-supplied transducer

wire harness back to the cooler. Connect the “SPTA” plug

into the circuit A transducer. Connect the “SPTB” plug

into the circuit B transducer. See Fig. 13.

25. Charge the unit to the amount of refrigerant as specified

on the 30XA base unit nameplate. Because of longer

field-installed liquid, economizer, and suction lines, additional charge is needed. Refer to Table 7 to calculate the

additional charge for each circuit and then add it to the

nameplate charge. Additional charge for the economizer

line is NOT required.

26. Perform all pre-start-up and start-up procedures specified

in the unit operation instructions. Follow the checklist

provided with the unit operation instructions.

27. Verify unit operation.

11

Page 12

Table 6 — Materials Required for Steel Piping Flange Connections

UNIT

SIZE

140 Field supplied:

ASME B16.9 Stub End 4 in.

(102 mm)

Accessory supplied:

Compressor Flange Gasket

(3000A: Item 15),

Loose Pipe Flange

(3000A: Item 11)

160 Field supplied:

ASME B16.9 Stub End 4 in.

(102 mm)

Accessory supplied:

Compressor Flange Gasket

(3000A: Item 15),

Loose Pipe Flange

(3000A: Item 11)

180 Field supplied:

ASME B16.9 Stub End 4 in.

(102 mm)

Accessory supplied:

Compressor Flange Gasket

(3000A: Item 15),

Loose Pipe Flange

(3000A: Item 11)

200 Field supplied:

ASME B16.9 Stub End 4 in.

(102 mm)

Accessory supplied:

Compressor Flange Gasket

(3000A: Item 15),

Loose Pipe Flange

(3000A: Item 11)

220 Field supplied:

ASME B16.9 Stub End 4 in.

(102 mm)

Accessory supplied:

Compressor Flange Gasket

(3100A: Item 9),

Loose Pipe Flange

(3100A: Item 11)

240 Field supplied:

ASME B16.9 Stub End 4 in.

(102 mm)

Accessory supplied:

Compressor Flange Gasket

(3100A: Item 9),

Loose Pipe Flange

(3100A: Item 11)

260 Field supplied:

ASME B16.9 Stub End 4 in.

(102 mm)

Accessory supplied:

Compressor Flange Gasket

(3100A: Item 9),

Loose Pipe Flange

(3100A: Item 11)

COOLER PIPE FLANGE CONNECTION FLEX CONNECTOR FLANGE CONNECTION

Circuit A Circuit B Circuit A Circuit B

N/A* Accessory supplied:

N/A* Accessory supplied:

Field supplied:

ASME B16.9 Stub End 4 in.

(102 mm)

Accessory supplied:

Compressor Flange Gasket

(3000A: Item 15),

Loose Pipe Flange

(3000A: Item 11)

Field supplied:

ASME B16.9 Stub End 4 in.

(102 mm)

Accessory supplied:

Compressor Flange Gasket

(3000A: Item 15),

Loose Pipe Flange

(3000A: Item 11)

Field supplied:

ASME B16.9 Stub End 4 in.

(102 mm)

Accessory supplied:

Compressor Flange Gasket

(3100A: Item 9),

Loose Pipe Flange

(3100A: Item 12)

Field supplied:

ASME B16.9 Stub End 4 in.

(102 mm)

Accessory supplied:

Compressor Flange Gasket

(3100A: Item 9),

Loose Pipe Flange

(3100A: Item 11)

Field supplied:

ASME B16.9 Stub End 4 in.

(102 mm)

Accessory supplied:

Compressor Flange Gasket

(3100A: Item 9),

Loose Pipe Flange

(3100A: Item 12)

LEGEND

3000A — Accessory Package Part No. 00EFN900003000A (30XA080-200)

3100A — Accessory Package Part No. 00EFN900003100A (30XA220-350)

Item — Item No. (See Table 2)

*Copper connection.

Flex Connector Flange

(3000A: Item 10),

Flex Connector Flange

O-ring

(3000A: Item 13)

Flex Connector Flange

(3000A: Item 10),

Flex Connector Flange

O-ring

(3000A: Item 13)

Accessory supplied:

Flex Connector Flange

(3000A: Item 10),

Flex Connector Flange

O-ring

(3000A: Item 13)

Accessory supplied:

Flex Connector Flange

(3000A: Item 10),

Flex Connector Flange

O-ring

(3000A: Item 13)

Accessory supplied:

Flex Connector Flange

(3100A: Item 13),

Flex Connector Flange

O-ring

(3100A: Item 8)

Accessory supplied:

Flex Connector Flange

(3100A: Item 13),

Flex Connector Flange

O-ring

(3100A: Item 8)

Field supplied:

ASME B16.5 Class 600

Flange 4 in. (102 mm)

Accessory supplied:

Compressor Flange Gasket

(3100: Item 10)

N/A*

N/A*

Accessory supplied:

Flex Connector Flange

(3000A: Item 10),

Flex Connector Flange

O-ring

(3000A: Item 13)

Accessory supplied:

Flex Connector Flange

(3000A: Item 10),

Flex Connector Flange

O-ring

(3000A: Item 13)

Accessory supplied:

Flex Connector Flange

(3100A: Item 13),

Flex Connector Flange

O-ring

(3100A: Item 8)

Accessory supplied:

Flex Connector Flange

(3100A: Item 13),

Flex Connector Flange

O-ring

(3100A: Item 8)

Accessory supplied:

Flex Connector Flange

(3100A: Item 13),

Flex Connector Flange

O-ring

(3100A: Item 8)

12

Page 13

Table 6 — Materials Required for Steel Piping Flange Connections (cont)

UNIT

SIZE

280 Field supplied:

ASME B16.9 Stub End 4 in.

(102 mm)

Accessory supplied:

Compressor Flange Gasket

(3100A: Item 9),

Loose Pipe Flange

(3100A: Item 11)

300 Field supplied:

ASME B16.9 Stub End 4 in.

(102 mm)

Accessory supplied:

Compressor Flange Gasket

(3100A: Item 9),

Loose Pipe Flange

(3100A: Item 11)

325 Field supplied:

ASME B16.9 Stub End 4 in.

(102 mm)

Accessory supplied:

Compressor Flange Gasket

(3100A: Item 9),

Loose Pipe Flange

(3100A: Item 11)

350 Field supplied:

ASME B16.9 Stub End 4 in.

(102 mm)

Accessory supplied:

Compressor Flange Gasket

(3100A: Item 9),

Loose Pipe Flange

(3100A: Item 11)

COOLER PIPE FLANGE CONNECTION FLEX CONNECTOR FLANGE CONNECTION

Circuit A Circuit B Circuit A Circuit B

Field supplied:

ASME B16.9 Stub End 4 in.

(102 mm)

Accessory supplied:

Compressor Flange Gasket

(3100A: Item 9),

Loose Pipe Flange

(3100A: Item 11)

Field supplied:

ASME B16.9 Stub End 4 in.

(102 mm)

Accessory supplied:

Compressor Flange Gasket

(3100A: Item 9),

Loose Pipe Flange

(3100A: Item 11)

Field supplied:

ASME B16.9 Stub End 4 in.

(102 mm)

Accessory supplied:

Compressor Flange Gasket

(3100A: Item 9),

Loose Pipe Flange

(3100A: Item 11)

Field supplied:

ASME B16.9 Stub End 4 in.

(102 mm)

Accessory supplied:

Compressor Flange Gasket

(3100A: Item 9),

Loose Pipe Flange

(3100A: Item 11)

LEGEND

3000A — Accessory Package Part No. 00EFN900003000A (30XA080-200)

3100A — Accessory Package Part No. 00EFN900003100A (30XA220-350)

Item — Item No. (See Table 2)

*Copper connection.

Table 7 — Additional Refrigerant Charges Required

Field supplied:

ASME B16.5 Class 600

Flange 4 in. (102 mm)

Accessory supplied:

Compressor Flange Gasket

(3100: Item 10)

Field supplied:

ASME B16.5 Class 600

Flange 4 in. (102 mm)

Accessory supplied:

Compressor Flange Gasket

(3100: Item 10)

Field supplied:

ASME B16.5 Class 600

Flange 4 in. (102 mm)

Accessory supplied:

Compressor Flange Gasket

(3100: Item 10)

Field supplied:

ASME B16.5 Class 600

Flange 4 in. (102 mm)

Accessory supplied:

Compressor Flange Gasket

(3100: Item 10)

Accessory supplied:

Flex Connector Flange

(3100A: Item 13),

Flex Connector Flange

O-ring

(3100A: Item 8)

Accessory supplied:

Flex Connector Flange

(3100A: Item 13),

Flex Connector Flange

O-ring

(3100A: Item 8)

Field supplied:

ASME B16.5 Class 600

Flange 4 in. (102 mm)

Accessory supplied:

Compressor Flange Gasket

(3100: Item 10)

Field supplied:

ASME B16.5 Class 600

Flange 4 in. (102 mm)

Accessory supplied:

Compressor Flange Gasket

(3100: Item 10)

LINE SIZE

LIQUID LINE

lb (kg) OF

R-134a REFRIGERANT

PER FOOT (305 mm)

SUCTION LINE

lb (kg) OF

R-134a REFRIGERANT

PER FOOT (305 mm)

in.mmlbkg lbkg

1

/

1

1

1

3

29 0.41 0.186 — —

8

3

/

35 0.64 0.2903 — —

8

5

/

41 0.89 0.4037 — —

8

1

/

79 — — 0.05 0.0227

8

4 102 — — 0.09 0.0408

13

Page 14

A

30XA

MANUAL

SHUTOFF

VALVE

FLANGE

CONNECTION

PRESSURE RELIEF

VALV ES (FIELD-

SUPPLIED)

ECONOMIZER

LINE

LIQUID LINE

(30XA TO

ECONOMIZER)

FLANGE

CONNECTION

COOLER LIQUID LINE

(ECONOMIZER TO COOLER)

SUCTION LINE

MANUAL SHUTOFF

VALV E

NOTE: All shaded piping is field supplied and installed.

Fig. 7 — Line Piping and Connections (1 Circuit Shown)

TO 30X

ECONOMIZER

COOLER

a30-4519

LOOSE PIPE FLANGE

(ACCESSORY-SUPPLIED)

A

RED.

TEE

FROM

COOLER

45 DEGREE

STR ELLS

LEGEND

RED. TEE — Reducing Tee

STR ELLS— Street Elbows

Fig. 8 — Double Suction Riser

Construction Detail

B

90 DEGREE

STR ELLS

a30-4507

O-RING

(ACCESSORY-SUPPLIED)

COOLER PIPE FLANGE

(ACCESSORY-SUPPLIED)

a30-4520

Fig. 9 — Connect Copper Suction Line at the Cooler

(30XA080-120: All Circuits and

30XA140-160: Circuit B)

14

Page 15

Fig. 10 — Unbolt Portion Between Flex Connector and Cooler

(30XA140, 160: Circuit A and 30XA180-350: All Circuits)

22.5°

45.0°

a30-4521

ASME B16.9

STEEL STUB END

(FIELD-SUPPLIED)

PIPE FLANGE

(ACCESSORY-SUPPLIED,

SEE TABLE 6)

MOUNTING

BRACKET

EXISTING FLANGE

ON FLEX

CONNECTOR AT

30XA BASE UNIT

a30-4522

Fig. 11 — Connect Steel Suction Line at the 30XA

Base Unit (Shown) and Cooler

(30XA140, 160: Circuit A and

30XA180-350: All Circuits)

8-1/2 (215.9)

8 HOLES 1 (25)

EQUALLY SPACED

1 EXTRA HOLE M16

a30-4523

NOTES:

1. Measurements are shown in inches (millimeters).

2. Accessory-supplied flanges and gaskets connecting to the flex

connector: extra hole has been factory-drilled and tapped. See

Table 2 (3000A: Item 10, 14, 15 and 3100A: Item 9, 10, 13).

3. Field-supplied flanges and gaskets connecting to the flex connector: extra hole must be field-drilled and tapped (M16).

4. The extra hole allows a bolt to slide through and mount the flanges

and gaskets of the suction line on a mounting bracket at the 30XA

base unit. See Fig. 10 and 11.

Fig. 12 — Flange and Gasket Mounting Locations

15

7-7/8 (200)

Page 16

MAIN

BASE

BOARD

a30-4524

LEGEND

DPT — Discharge Pressure Transducer

LWT — Leaving Water Temperature

OAT — Outdoor Air Temperature

SPT — Suction Pressure Transducer

Fig. 13 — Thermistor Connections

EWT

EWT

LWT

LWT

STRAIN RELIEF

(FIELD-SUPPLIED)

EWT

LWT

EWT

LWT

LWT

EWT

JUNCTION

BOX

(ACCESSORYSUPPLIED)

5-WIRE CABLE

(ACCESSORY-SUPPLIED)

CONDUIT

(FIELD-SUPPLIED)

a30-4508

Fig. 14 — Typical Junction Box Connections

(EWT and LWT Thermistors Shown)

Copyright 2007 Carrier Corporation

Manufacturer reserves the right to discontinue, or change at any time, specifications or designs without notice and without incurring obligations.

Book 2

Ta b 5 c

Catalog No. 04-53300012-01 Printed in U.S.A. Form 30XA-7SI Pg 16 3-07A 1-07 Replaces: New

Loading...

Loading...