Caron 6545 User Manual

PO Box 715

Marietta, OH 45750

800-648-3042 740-373-6809

Fax 740-374-3760

www.caronproducts.com

service@caronproducts.com

MODEL 6540/6545

PHOTOSTABILITY CHAMBER

OPERATIONS MANUAL

Dear Valued Customer:

Thank you for purchasing CARON Products & Services equipment. We appreciate

your business and look forward to being your preferred supplier of controlled

environment equipment products in the future.

At CARON, we are committed to continuous quality improvement. Our goal is to

supply our customers with highly reliable equipment at a fair price. In order to

openly monitor our performance, we would appreciate your feedback on our

products and services.

If you have questions, or any suggestions for improvement based on the installation

or operation of the equipment you have purchased, please contact our service

department at service@caronproducts.com or 740-373-6809.

Thanks again for your business!

6540 Series Operations Manual Rev_I.docx 4/7/2014 2

WARRANTY INFORMATION

EQUIPMENT LIMITED WARRANTY

Please review this section before requesting warranty service. At CARON, one of our primary goals is to

provide customers with high levels of personal service and top quality products, delivered on time, backed

by technical service and supported for the life of the product.

Before contacting us for warranty service, please be aware that there are repairs that are not covered

under warranty.

WARRANTY DEFINED

Caron Products & Services, Inc. (herein after CARON) hereby warrants that equipment manufactured by

CARON is free from defects in materials and workmanship when the equipment is used under normal

operating conditions in accordance with the instructions provided by CARON.

COVERED:

Parts and labor for a period of one (1) year from date of shipment.

Any part found defective will be either repaired or replaced at CARON's discretion, free of charge, by

CARON in Marietta, OH. Parts that are replaced will become the property of CARON.

If CARON factory service personnel determine that the customer's unit requires further service CARON

may, at its sole discretion, provide a service technician to correct the problem, or require the return of the

equipment to the factory or authorized service depot.

CARON will have the right to inspect the equipment and determine the repairs or replacement parts

necessary. The customer will be notified, within a reasonable time after inspection, of any costs incurred

that are not covered by this warranty prior to initiation of any such repairs.

NOT COVERED:

Calibration of control parameters.

Improper installation; including electrical service, gas and water supply tubing, gas supplies, room

ventilation, unit leveling, facility structural inadequacies or ambient conditions that are out of

specification.

Cost of express shipment of equipment or parts.

Any customer modifications of this equipment, or any repairs undertaken without the prior written

consent of CARON, will render this limited warranty void.

CARON is not responsible for consequential, incidental or special damages; whether shipping damage or

damages that may occur during transfer to the customer’s point of use. When the equipment is signed for

at the customer’s site, ownership is transferred to the customer. Any damage claims against the shipping

company become the responsibility of the customer.

Repairs necessary because of the equipment being used under other than normal operating conditions or

for other than its intended use.

Repair due to the customer's failure to follow normal maintenance instructions.

Parts considered consumable; including: light bulbs, filters, gases, etc.

Damage from use of improper water quality.

Damage from chemicals or cleaning agents detrimental to equipment materials.

Force Majeure or Acts of God.

6540 Series Operations Manual Rev_I.docx 4/7/2014 3

This writing is a final and complete integration of the agreement between CARON and the customer.

CARON makes no other warranties, express or implied, of merchantability, fitness for a particular purpose

or otherwise, with respect to the goods sold under this agreement. This warranty cannot be altered unless

CARON agrees to an alteration in writing and expressly stated herein shall be recognized to vary or modify

this contract.

Ohio Law governs this warranty.

EQUIPMENT INTERNATIONAL LIMITED WARRANTY

6540 Series Operations Manual Rev_I.docx 4/7/2014 4

Please review this section before requesting warranty service. At CARON, one of our primary goals is to

provide customers with high levels of personal service and top quality products, delivered on time, backed

by technical service and supported for the life of the product.

Before contacting your distributor for warranty service, please be aware that there are repairs that

are not covered under warranty.

WARRANTY DEFINED

Caron Products & Services, Inc. (herein after CARON) hereby warrants that equipment manufactured by

CARON is free from defects in materials and workmanship when the equipment is used under normal

operating conditions in accordance with the instructions provided by CARON.

COVERED:

Parts for a period of two (2) years from date of shipment.

Any part found defective will be either repaired or replaced at CARON's or their authorized

representative’s discretion. Parts that are replaced will become the property of CARON.

If CARON or their authorized representatives determine that the customer's unit requires further service,

CARON or the representative may, at its sole discretion, provide a service technician to correct the

problem, or require the return of the equipment to the an authorized service depot.

CARON or their authorized representative will have the right to inspect the equipment and determine the

repairs or replacement parts necessary. The customer will be notified, within a reasonable time after

inspection, of any costs incurred that are not covered by this warranty prior to initiation of any such

repairs.

NOT COVERED:

Calibration of control parameters.

Improper installation; including electrical service, gas and water supply tubing, gas supplies, room

ventilation, unit leveling, facility structural inadequacies or ambient conditions that are out of

specification.

Cost of express shipment of equipment or parts.

Any customer modifications of this equipment, or any repairs undertaken without the prior written

consent of CARON, will render this limited warranty void.

CARON and their representative are not responsible for consequential, incidental or special damages;

whether shipping damage or damages that may occur during transfer to the customer’s point of use.

When the equipment is signed for at the customer’s site, ownership is transferred to the customer. Any

damage claims against the shipping company become the responsibility of the customer.

Repairs necessary because of the equipment being used under other than normal operating conditions or

for other than its intended use.

Repair due to the customer's failure to follow normal maintenance instructions.

Parts considered consumable; including: light bulbs, filters, gases, etc.

Damage from use of improper water quality.

Damage from chemicals or cleaning agents detrimental to equipment materials.

Force Majeure or Acts of God.

This writing is a final and complete integration of the agreement between CARON and the customer.

CARON makes no other warranties, express or implied, of merchantability, fitness for a particular purpose

or otherwise, with respect to the goods sold under this agreement. This warranty cannot be altered unless

6540 Series Operations Manual Rev_I.docx 4/7/2014 5

CARON agrees to an alteration in writing and expressly stated herein shall be recognized to vary or modify

this contract.

Ohio Law governs this warranty.

Caron Products & Services, Inc.

PO Box 715 · Marietta, OH 45750

740-373-6809

6540 Series Operations Manual Rev_I.docx 4/7/2014 6

TABLE OF CONTENTS

SECTION PAGES

INTRODUCTION ................................................................................ 8

INSTALLATION ............................................................................... 10

Power requirements ....................................................................... 11

Water connections ......................................................................... 12

OPERATION ....................................................................................... 17

Start up ........................................................................................... 17

Light control .................................................................................. 19

Manual control ................................................................... 19

Dimming ............................................................................ 20

Testing ........................................................................................... 21

Test setup ........................................................................... 21

Run test .............................................................................. 23

Test status .......................................................................... 25

Test details ......................................................................... 27

Power failure ..................................................................... 29

Temperature set point .................................................................... 30

Humidity set point ......................................................................... 31

Alarms .......................................................................................... 33

Setup menu .................................................................................... 37

Language ....................................................................................... 37

Lamp life ....................................................................................... 38

Screen lock-out .............................................................................. 39

Information .................................................................................... 41

Calibration ..................................................................................... 44

Configuration menu ....................................................................... 46

Door switch ................................................................................... 47

Graph ............................................................................................. 49

Extended range options ................................................................. 50

MAINTENANCE ............................................................................... 51

Routine maintenance ..................................................................... 51

Brief Troubleshooting ................................................................... 52

Replace lamps ................................................................................ 54

Component access ......................................................................... 56

Replacement Parts ......................................................................... 58

APPENDIX .......................................................................................... 60

A - Validation/Qualification .......................................................... 60

B - Light intensity characteristics .................................................. 61

C - Chart recorder parameters ....................................................... 64

D - Declaration of conformity ....................................................... 68

6540 Series Operations Manual Rev_I.docx 4/7/2014 7

INTRODUCTION

CARON’s 6540 series photostability chambers are designed specifically to meet ICH, FDA EMEA, and

Health Canada requirements for photostability testing according to ICH Q1B option II. UVA (black) and

VIS (cool white) lamps provide sequential light exposure.

The chamber conditions are conveniently displayed at eye-level and controlled through the touch-screen

display. Calibrated photon detectors measure light intensity. Lights can be manually turned on/off or

automatically based on exposure level (W-hr/m2 or Lux-hr) or time. To enhance reliability, temperature and

humidity (optional) conditions are monitored and controlled throughout the test.

Specifications

Lamp Type, UVA Fluorescent, near UV (black lamp)

Lamp Type, VIS Fluorescent, cool white

Temperature Range 10 to 35C

Temperature Control 0.2C

Humidity Range (model 6545) 40 to 70% RH

Humidity Control (model 6545) 3%

Interior Dimensions 683 W x 610 D x 711 H mm (296 L; includes lamp space)

Features

Controls

● Icon based, easy to use, eye-level, touch-screen interface

● Automatically turns off lights at end of programmed exposure

● Alerts operator when lamps need changed

● Temperature and humidity deviation alarms

● Security lockout to prevent accidental tampering

Light Detectors VIS and UVA, calibrated

Shelves Two, sliding, 22 lbs (10kg) maximum load each

Construction, Interior Stainless steel

Reflective Interior Surfaces Specular aluminum

Chamber Footprint 955 W x 767 D mm

Chamber Height 1168 mm with leveling feet

Power 115V 60Hz, 208/230V 60Hz, or 230V 50Hz

Access Port Two (44 W x 51 H mm each)

Door Light tight, magnetic gasket seal

Room ambient conditions must be 20ºC to 25ºC, non-condensing. Exceeding 25ºC can result in operational

failure. The temperature and humidity ranges can be extended (optional). Humidity limited by 6ºC dew

point.

Models 6540-1 and 6545-1 were formerly models 6540A and 6545A respectively.

Models 6540-3 and 6545-3 were formerly models 6540E and 6545E respectively.

6540 Series Operations Manual Rev_I.docx 4/7/2014 8

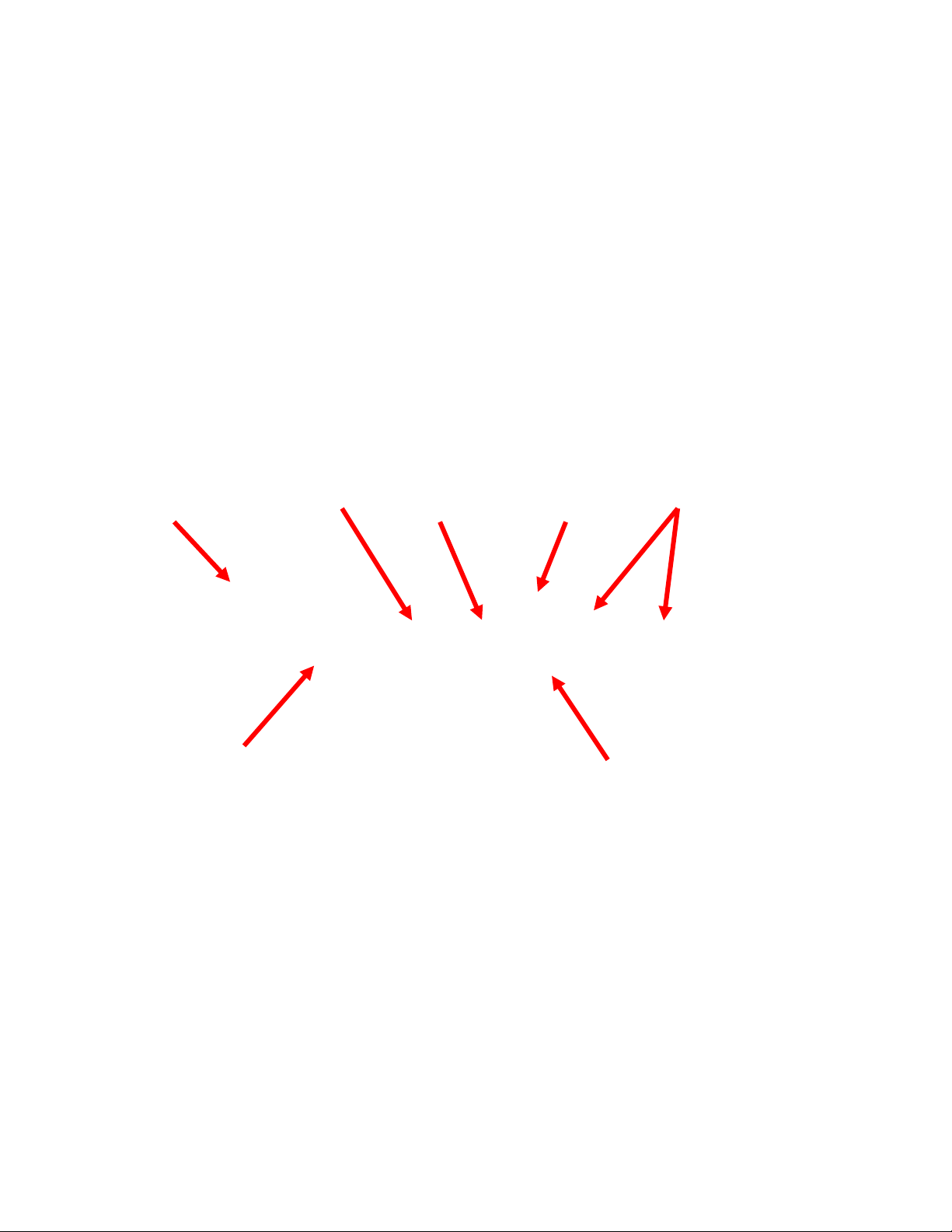

Warning of hazardous area

Warning of dangerous electric voltage

Earth (ground) protective conductor

Local government may require proper lamp disposal

INTERNATIONAL SYMBOLS AND DEFINITIONS

WARNINGS

Use eye protection, gloves and aprons if exposure to hazardous materials could occur

6540 Series Operations Manual Rev_I.docx 4/7/2014 9

INSTALLATION

Unpacking

This product has been completely tested, cleaned and packed for shipment. Carefully remove all packing

material. Please examine the chamber completely. Should any damage be found, notify the delivering

carrier immediately. Report any shortages to your local distributor or contact CARON customer service at

740-373-6809, 800-648-3042 (USA only) or service@caronproducts.com.

Chamber Location

The photostability chamber is an instrument and should be treated accordingly. The chamber must be

located in a dry, clean, and level area. Allow a 2 inch (51 mm) clearance from the back of chamber for

proper air circulation. Locate the chamber in an area out of direct sunlight and away from heating and

cooling ducts. Ambient temperature should be 18°C - 25°C and avoid locations where there are excessive

ambient air temperature fluctuations. The chamber can exhaust 4000 BTU/hr (1170 W) into the

surroundings. The chamber operates quietly around 60 dBA at 6 ft (2 m) away.

Caution: Do not put more than 10 lbs (4.5 kg) on top of unit.

The figure below shows a right view of the chamber with access port locations. Install rubber stoppers into

both access ports. Press in firmly.

6540 Series Operations Manual Rev_I.docx 4/7/2014 10

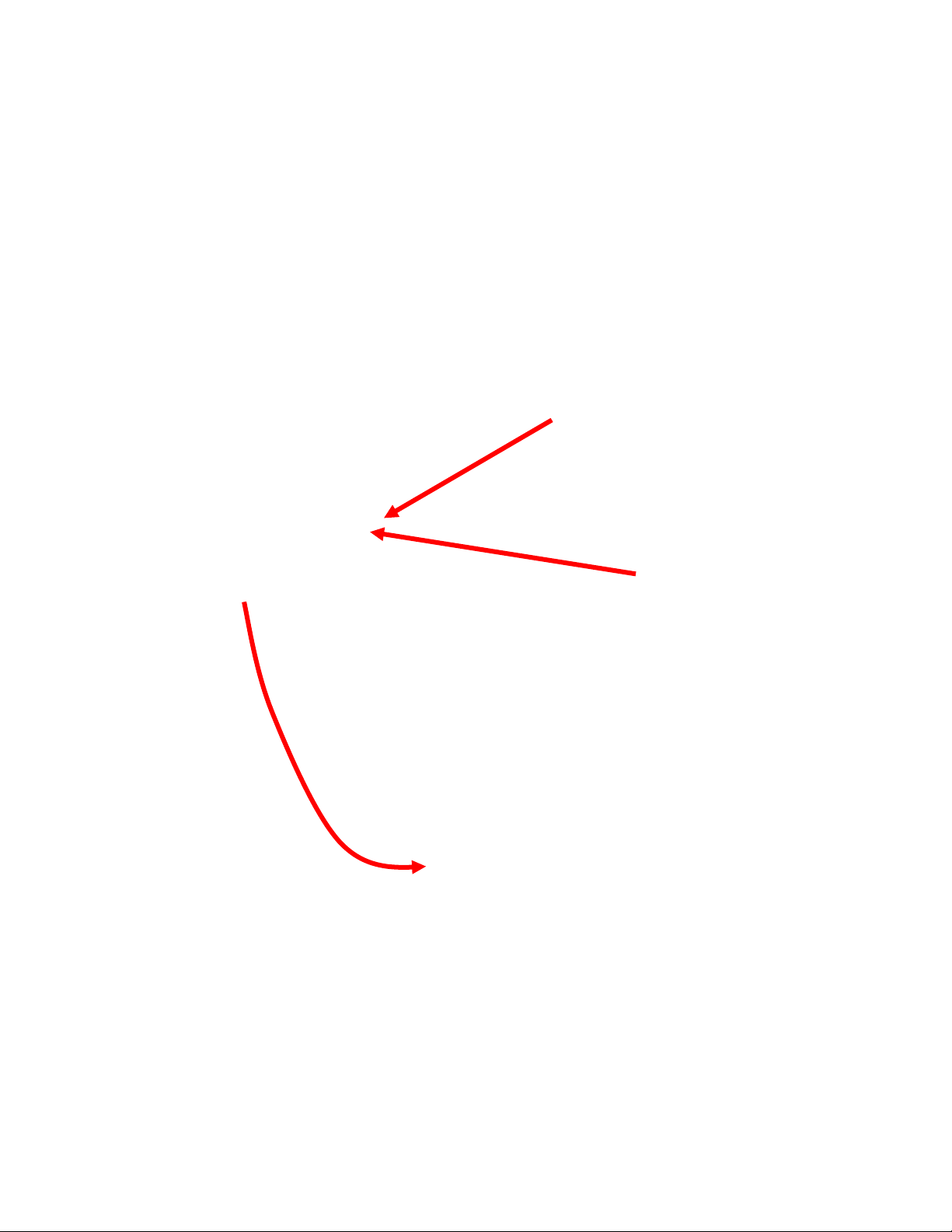

Style C14

Style C20

Power Requirements

The Power Cord of this chamber is equipped with a grounded plug to minimize the possibility of electrical

shock from the chamber. CARON recommends that the chamber have a dedicated wall outlet. Verify

correct power supply required for particular unit.

Models 6540-1 and 6545-1

Plug is NEMA configuration 5-15P for 115V, 15A (Hubbell 5266C).

Models 6540-2 and 6545-2

Plug is NEMA configuration 6-15P for 208/230V, 15A (Hubbell 5666C).

Models 6540-3 and 6545-3

Modular cord set has continental European CEE 7/7 10/16A plug. Connector type is IEC 60320 C14 (or C20

with options).

6540 Series Operations Manual Rev_I.docx 4/7/2014 11

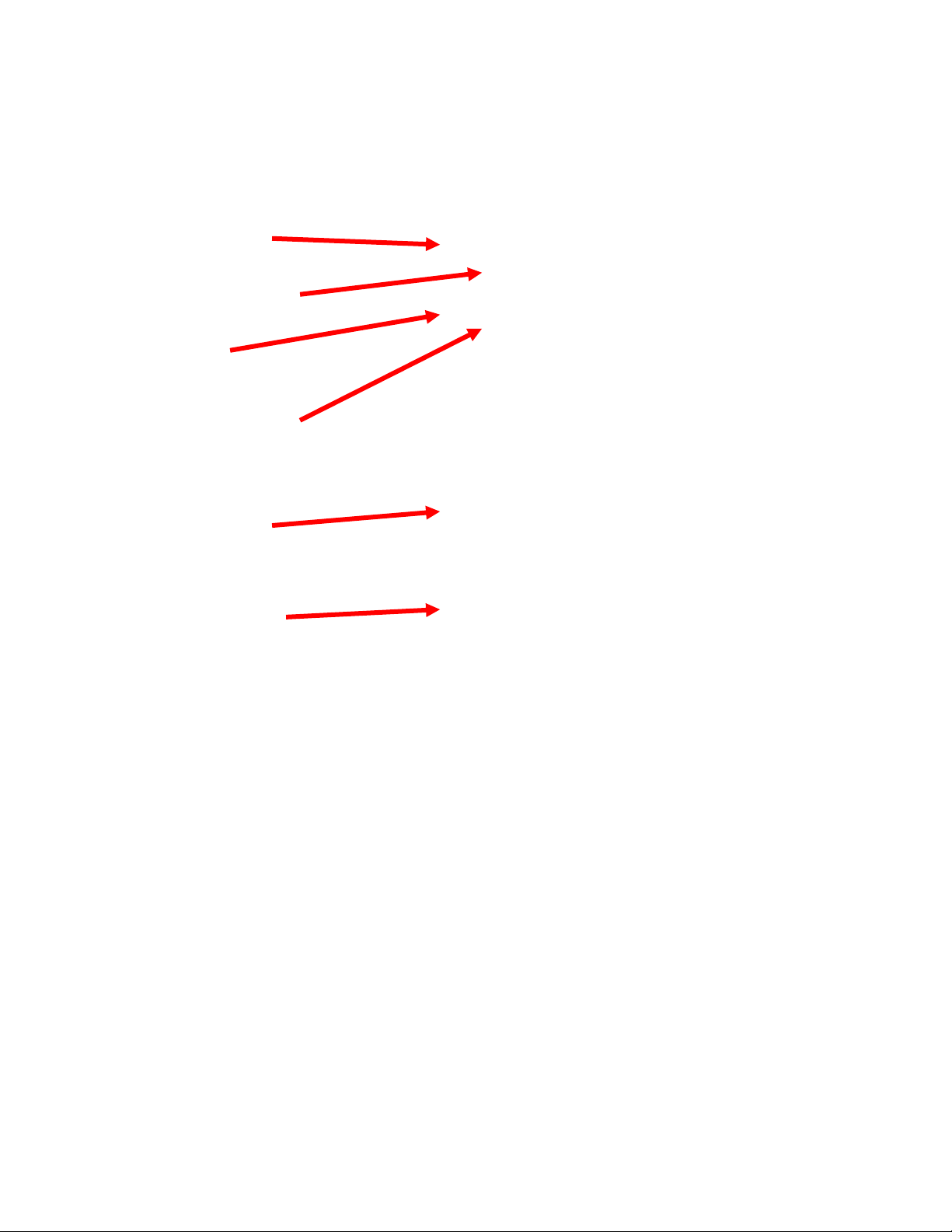

Water supply

(optional)

Water drain

(all units)

Ethernet

(service)

Chart recorder

(signal)

Chart recorder

(power)

Power cord

(6545-1 shown)

Options

Water Drain

Plumb the water drain connection to a facility drain. The drain should handle 1 liter per day.

6540-1, 6540-2, 6545-1, 6545-2 Connect to 1/4FPT fittings on back of unit with 1/4MPT fitting.

6540-3, 6545-3 Connect to 1/4BSPP male (British Standard Pipe Parallel, also known

as ISO parallel) on back of unit with a 1/4BSPP female fitting.

Note: Under certain ambient (room) temperature and humidity conditions, the cooling system will condense

moisture from the air. A drain is required, even if the chamber does not have humidity control.

Water Supply (optional)

The chamber requires distilled or deionized water with resistivity between 0.05 & 1 Mega Ohmn-cm and pH

above 6.5. Using water outside this range will void the warranty. Typical water usage is 0.4 gallons/day

(1.5 liters/day) with a maximum of 3.2 gallons/day (12 liters/day).

6545-1, 6545-2 Connect to 1/4FPT fittings on back of unit with 1/4MPT fitting.

6545-3 Connect to 1/4BSPP male (British Standard Pipe Parallel, also known

as ISO parallel) on back of unit with a 1/4BSPP female fitting.

6540 Series Operations Manual Rev_I.docx 4/7/2014 12

Condensate Recirculating System: CRSY102 (optional)

The Condensate Recirculating System can be used in conjunction with CARON’s 6540 series chambers as a

water delivery system. This system is typically used in facilities where a drain or in-house source of distilled

or deionized water is not available. The system provides continuous, clean, filtered water to the chamber’s

humidity injection system, collects and recycles the condensate that forms in the base of the chamber. Refer

to instructions with the CRSY102 for connection details.

6545-1-2 CRSY102 CONNECTION FITTINGS 6545-3 CRSY102 CONNECTION FITTINGS

Ethernet (service only)

For service or diagnostic purposes, the chamber can be monitored and controlled via the 10x base Ethernet

link provided. If service support is needed contact CARON for details.

6540 Series Operations Manual Rev_I.docx 4/7/2014 13

Chart recorder

signal plug

Chart recorder

Install recorder on

left side of cabinet

Chart Recorder (optional)

The circular chart recorder (REC203 and REC204) monitors and records UVA light intensity, VIS light

intensity, temperature and humidity (optional). The mounting brackets can be used to mount the recorder on

a wall. Connect the chart recorder signal and power cables into the back of the chamber. Electrical ratings

for the power outlet receptacle are:

115V, 60Hz (models 6540-1, 6545-1)

208/230V, 60Hz (models 6540-2, 6545-2)

230V, 50Hz (models 6540-3, 6545-3)

power plug

6540 Series Operations Manual Rev_I.docx 4/7/2014 14

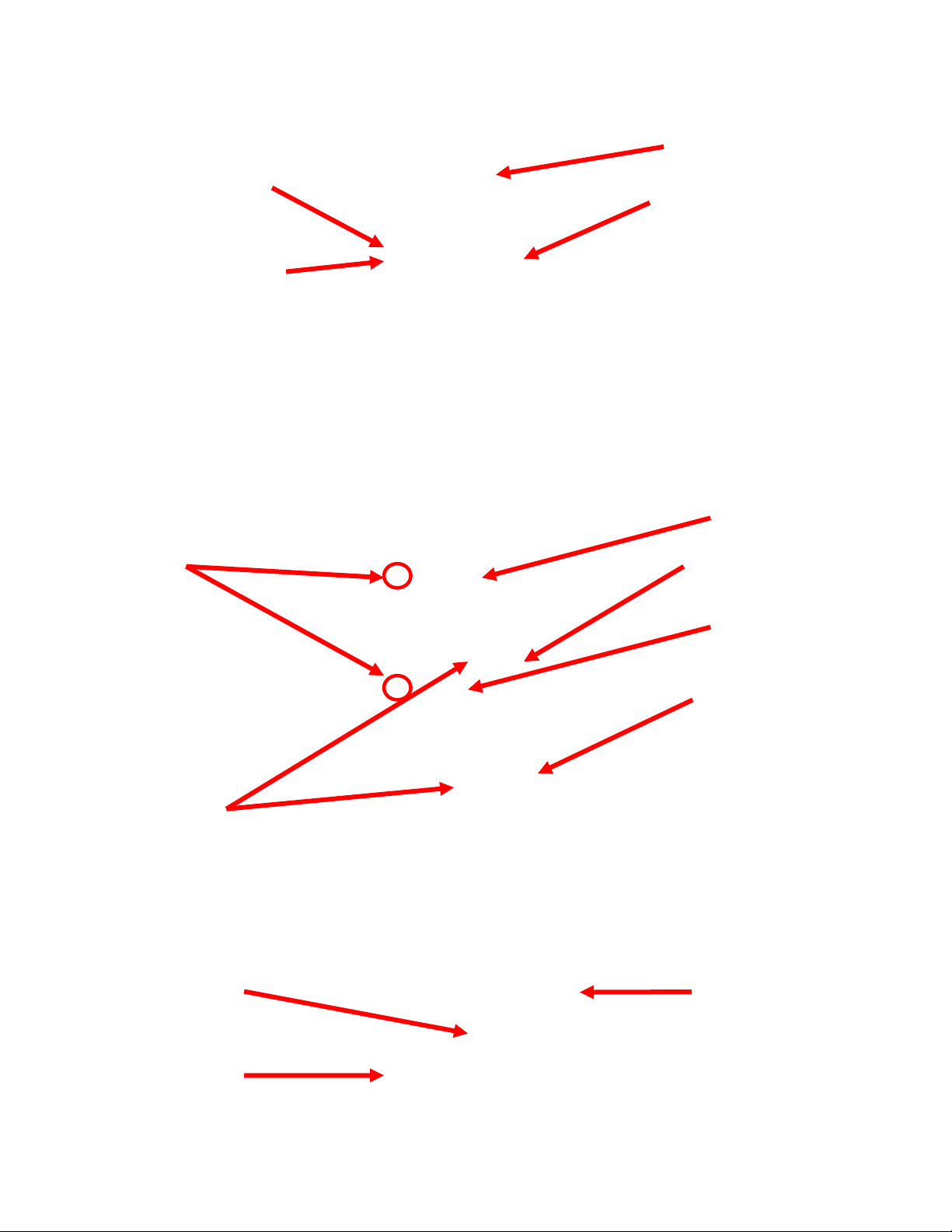

Top light bank

mating connector

Bottom light bank

mating connector(s)

Top light bank track

Bottom light

bank track

Install top light

bank

Install bottom

light bank

Install Lamps and Lamp Banks (Chamber must be off while installing light banks!!)

1. Locate the top lamp bank with 6 lamp holders (the bottom bank will have 10 or 14 lamp holders).

2. Turn the top lamp bank upside down and insert ‘black’ lamps into light bank by installing bi-pin

lamps into lamp holders and rotate a ¼ turn.

3. Locate the top lamp bank track.

4. With the black connector going in first, slide the top light bank into the chamber.

5. Press light bank firmly into place to seat rear connector.

6. Locate the bottom lamp bank with 10 (models 6540-1 or 6545-1) or 14 (models 6540-2, 6540-3,

6545-2 or 6545-3) lamp holders.

7. Insert ‘white’ lamps into light bank

6540-1/6545-1: Press one end of lamp into ‘plunger’ lamp holder. Press the other lamp

end into ‘fixed’ lamp holder. Repeat for other 9 lamps.

6540-2, -3/6545-2, -3: Install bi-pin lamp into lamp holders and rotate a ¼ turn. Repeat for

other 13 lamps.

6540 Series Operations Manual Rev_I.docx 4/7/2014 15

Note: Picture shown

with top shelf

already installed.

Top light bank

installed

Bottom lamp

bank track

Top shelf track

Top light bank

installed

Detector cut-out

Handle (toward

Usable shelf

Removable

top light

When

installing, press

Removable

bottom light

Shelf handle (toward

front)

8. Locate the bottom lamp bank track.

9. Install the bottom light bank and press firmly into place to seat rear connector.

Note: If one lamp is not installed properly or burned out, it will affect the performance of other lamps.

Install Shelves

Insert both shelves into the shelf tracks (see picture above). Orient the shelf handle toward the front.

Maximum shelf load is 22lbs (10kg) per shelf.

area

(insert this end in

first)

6540 Series Operations Manual Rev_I.docx 4/7/2014 16

front)

Door key lock

Touch screen

Power switch

‘Power On’

OPERATION

Start Up

Turn on unit by pressing the power switch. The ‘power on’ indicator light and display screen will illuminate.

indicator light

control panel

6540 Series Operations Manual Rev_I.docx 4/7/2014 17

Active display screen

Temperature

Relative humidity

Alarm button

UVA light intensity

VIS light intensity

UVA status

VIS status icon

Setup menu button

Humidity set

(optional)

% UVA test complete

% VIS test complete

UVA light test

VIS light test

Temperature set

VIS status description

UVA status

UVA light

on/off icon

VIS light

Main Screen Display

After initializing, the main screen (shown below) will display.

icon & description

(optional)

on/off icon

(hidden)

setup button

setup button

point button

point button

Units

The units displayed are as follows:

UVA light intensity W/m2

VIS light intensity klux

Temperature ºC

Relative humidity %RH (6545-1, 6545-2, 6545-3 only)

For light exposure tests, corresponding units are:

UVA light exposure (or dose) W-hr/m2

VIS light exposure (or dose) klux-hr

The touch screen will go into screen saver mode (blank) after being un-touched for 30 minutes. To reactivate the touch screen (while the unit is still on), simply press anywhere on the screen and the screen will

illuminate. The power indicating light (illuminated blue ‘O’ in CARON) indicates when the unit is on.

6540 Series Operations Manual Rev_I.docx 4/7/2014 18

Exit button

Turn lights on

Selected lamp type icon

Turn lights off

‘Check’ indicating

Intensity control

View testing

Test setup button

Test control buttons

Light Control

& screen description

(manual) button

lights status

(manual) button

button (optional)

details button

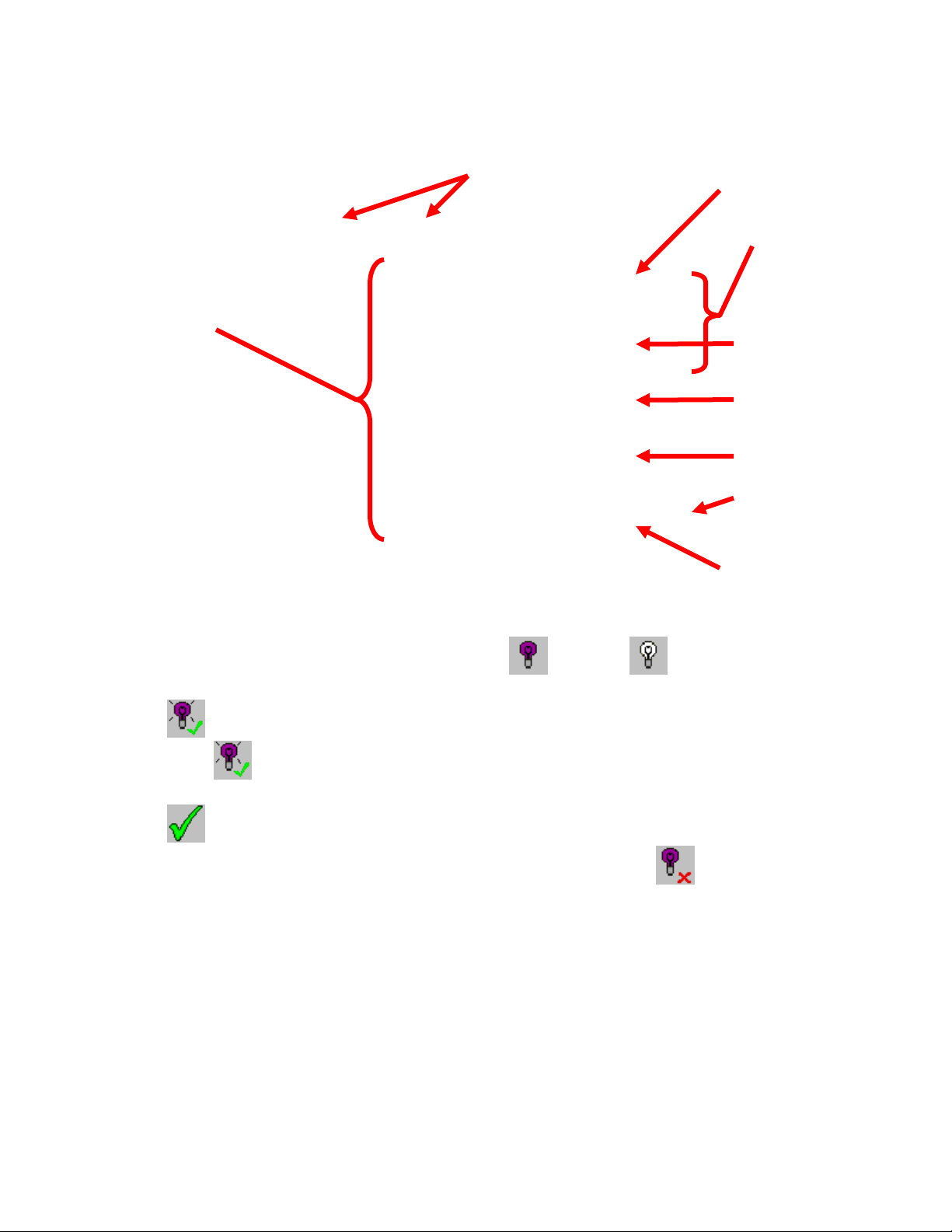

Control Lights Manually

1. From the main screen, press desired light test setup (UVA) or (VIS) button. (UVA used

in example)

2. Press (TURN LIGHTS ON) button. Lights should come on.

Note: If the (TURN LIGHTS ON) icon is not a button and the corresponding description is

grey, then a test is running. The lights can’t be controlled manually during a test.

3. Press (EXIT) button.

To manually turn lights off, repeat the same procedure except in step #2, press (TURN LIGHTS OFF).

6540 Series Operations Manual Rev_I.docx 4/7/2014 19

‘Check’ indicating

status

Forces light on

Light intensity

Allows dimming and

Light Dimming Control (6540-2, 6540-3, 6545-2, 6545-3)

1. From the main screen, press desired light test setup (UVA) or (VIS) button. (UVA used

in example)

2. Press (LIGHT INTENSITY) button.

3. Press (DIMMING) button. The light intensity set point will display a value.

4. Using (UP) and (DOWN) arrow buttons, set the desired light intensity.

5. Press (EXIT) button

To turn lights on full power, repeat the same procedure except in step #3, press (FULL POWER).

maximum brightness

controls to set point

set point

lights dimming

6540 Series Operations Manual Rev_I.docx 4/7/2014 20

Page 1 of 2

Next button

Page 2 of 2

Exposure duration

Estimated time

current lamp brightness

Large increase /

level set point

Small increase /

level set point

Test Setup: Exposure Test

1. From the main screen, press desired light test setup (UVA) or (VIS) button. (UVA used

in example)

2. Press (TEST SETUP) button.

3. Choose (EXPOSURE TEST).

4. Press (NEXT) button.

5. Using (UP), (DOUBLE UP), (DOWN), and (DOUBLE DOWN) arrow

buttons, set the desired test conditions.

set point

decrease in exposure

remaining based on

decrease in exposure

6. Press (EXIT) button

6540 Series Operations Manual Rev_I.docx 4/7/2014 21

Loading...

Loading...