caron 6010, 6030, 6031, 6032, 6012 Operation Manual

...

CARON 6000 SERIES

ENVIRONMENTAL TEST CHAMBERS

MODELS 6010, 6011, 6012, 6030, 6031, & 6032

OPERATIONS MANUAL

TABLE OF CONTENTS

SE CTION

INTRODUCTION

Symbols and Warnings......................................................... 3

.............................................................. 3

P AG E S

SPECIFICATIONS ........................................................... 5

INSTALLATION ...............................................................

Chamber Location ................................................................ 7

Drain Connection ................................................................. . 8

Power ................................................................................... 8

OPERATION

CONTROLLERS

Temperature Deviation Alarm ............................................. 12

.................................................................. 10

..................................................................... . 12

7

OPTIONS . ..................................................................... 13

Humidity System & Controller ............................................. 13

Humidity Controller Calibration ........................................... 14

Humidity Water Inlet ........................................................... 14

Diurnal Lighting System...................................................... 15

Heatless Dryer Package ..................................................... 16

Dryer Package Installation ....................................... 16

Dryer Package Testing & Adjustments .................... 17

Circular Chart Recorder...................................................... 18

Setup, Installation .................................................... 18

Routine Maintenance ............................................... 21

Contact Closure Timer System ........................................... 22

Condensate Recirculating System...................................... 23

Remote Alarm Contact ....................................................... 25

Product Temperature Safety............................................... 25

Computer Communications ................................................ 12

Defrost Package............................................................................ 26

MAINTENANCE

TROUBLESHOOTING

APPENDIX A – Watlow 96

General Controller Operation.............................................. 30

Light & Contact Timer, Communications ............................ 31

APPENDIX B – Watlow SD

APPENDIX C – 230 V Optional

Light & Contact Timer ......................................................... 33

APPENDIX D – Declaration of

....................................................................... 27

GUIDE

..............................................

Controller

Controller

Unit

Conformance

...............................

..............................

.................................. 33

................ 34

29

30

32

6000 SERIES MANUAL_U.doc 12-12-07 2

INTRODUCTION

The CARON 6010 & 6030 series Environmental Test Chambers provide multiple capabilities to

create repeatable environmental conditions for numerous applications including:

Product shelf life

•

Stability and package testing

•

Light exposure and temperature evaluation studies

•

Electronic component burn-in

•

TAPPI testing

•

Photostability

•

Plant growth

•

Insect rearing

•

These chambers utilize environmentally friendly HFC refrigerant and CFC-Free insulation, and is

designed to meet NEC, UL and CSA standards for safety and performance.

Controlling the chamber temperature requires the ability to heat and cool. Heating of the chamber

is achieved by duct heaters, and cooling is achieved by a direct expansion/vapor compression

refrigeration heat exchanger mounted in the duct, combined with horizontal airflow pattern which

creates better air uniformity, and temperature control.

A bi-modal controller (single input - dual output) is necessary for proper control of the system that

can drive the process variable in either direction. The refrigeration system uses a single

condensing unit that will allow independent cooling and dehumidification. This insures continuous,

safe and reliable operation of the compressor even when no cooling is required. This also

prevents the compressor from rapid cycling “on” and “off” which shortens the compressor life.

SYMBOLS AND WARNINGS

Warning of hazardous area

Warning of dangerous electric voltage

Earth (ground) protective conductor

Local government may require proper electrical component disposal

CHAMBER CONSTRUCTION

The chamber is a custom designed sheet metal package. Exterior metal is Cold Rolled Steel

(CRS) with a powder coat finish for corrosion resistance. The chamber interior is constructed from

304 stainless steel, with all joints seam welded. The chamber face connecting the interior to the

exterior is magnetic stainless steel providing a sealing surface for the magnetic gasketed exterior

door as well as improved corrosion resistance. The control panel housing is constructed from

aluminum with a powder coat finish. The chamber is insulated on all sides with fiberglass

insulation rated at 70°C.

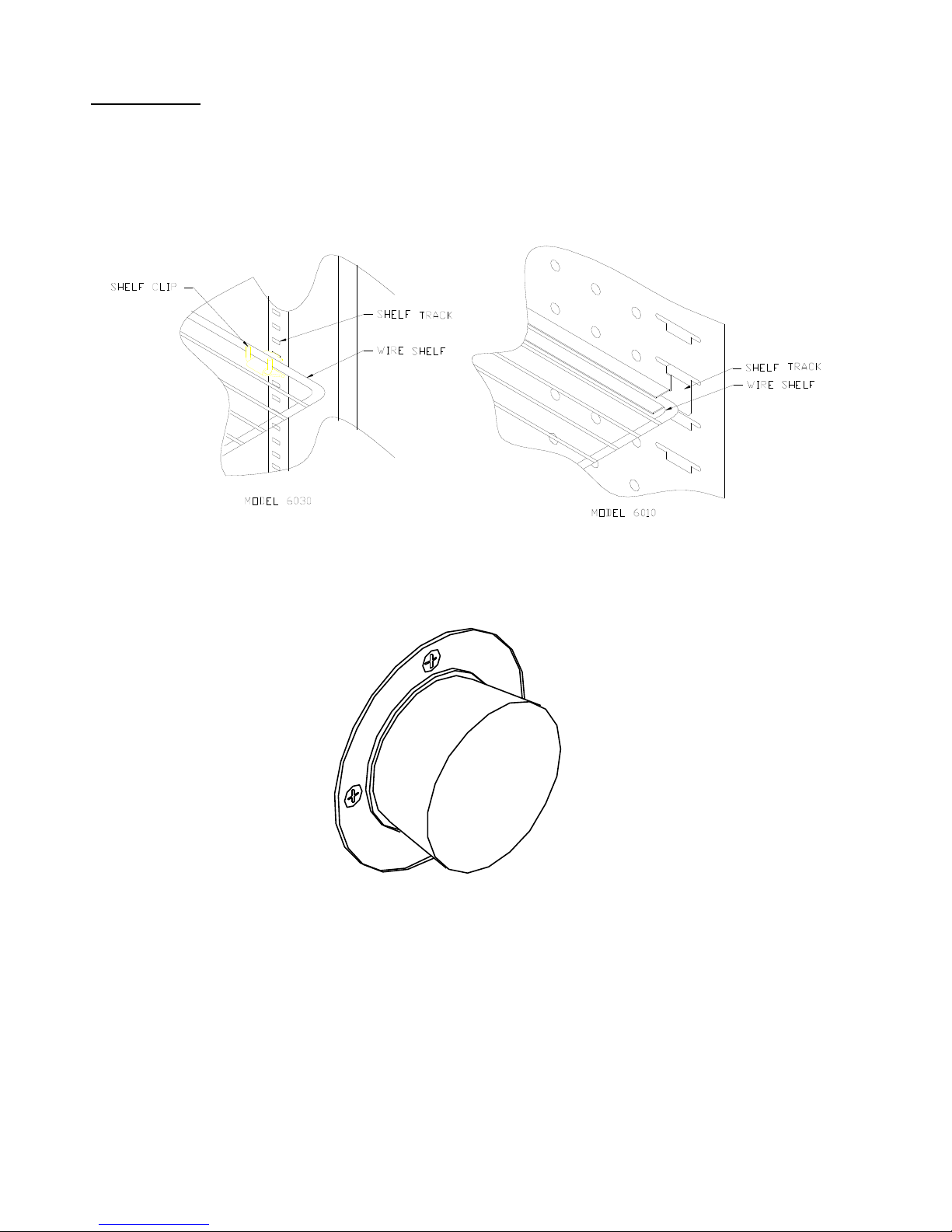

SHELF CONSTRUCTION (STANDARD)

The chamber shelves are polished, 304 stainless steel wire formed.

REFRIGERATION SYSTEM

A bi-modal refrigeration system allows for independent heating and cooling. This system is now

used to replace the less sophisticated type of refrigeration system which used heaters to buck

against the refrigeration system and assist in temperature control. The new design allows the

chamber to respond faster and controls the chamber more efficiently at a constant temperature.

CONTROL SYSTEM

The control system is comprised of a single channel, dual output controller. On/off outputs are

used to drive heaters and cooling solenoids.

SAFETIES

The CARON 6000 Series has a triple redundancy safety system. A temperature alarm in the

temperature controller sounds an alarm to alert the end user to the condition. A thermal snap

disk, high limit and a thermal fuse are provided to prevent run-away heating of the unit. The

compressor and blower motors are both protected by thermal overloads. The Condenser fan

motor is impedance protected.

MODEL 6010 SPECIFICATIONS

Temperature Range without lights 5°C to 70°C

Temperature Range with lights 10°C to 70°C

Temperature Control

Temperature Uniformity

Humidity 20 to 98% RH

Humidity Control ± 3%

Interior Dimensions 23”W x 25.8”D x 29.8”H

Exterior Dimensions 43.4”W x 30.6”D x 36”H

Work Space 10 cu.ft. (283.2 liters)

Shelves

Number of shelves 4 Stainless Steel, Wire Rod Standard

Shelf Spacing 1.5” on center (15 positions)

Shelf Size Each Shelf: 22.8”W x 25.4”D

Shelf Area 4ft.2 each, 16ft.2 total

Materials / Finishes:

Interior Chamber - all Stainless Steel

Exterior Chamber - Cold Rolled Steel and

Magnetic Stainless Steel, Powder

Exterior Door Aluminum, Powder Coat Finish

Feet Adjustable leveling pads

Electrical 115V/20A/60Hz (standard, 220V optional)

Shipping Weight 400 lbs.

Display Resolution:

Temperature 0.1°C

Relative Humidity 1% RH

± 0.1°C

± 0.3°C Relative

∗

(58cm x 65.5cm x 75.7cm)

(110cm x 77.7cm x 91.4cm)

(57.9cm x 64.5cm)

Interior door - Tempered glass

Coat Finish

∗

RH

levels limited by 4°C minimum dewpoint

Specifications were established at 20°C with 50% RH ambient conditions.

Chamber

ambient

conditions

2 0 °

C to

25 °

C.

Exceeding

2 5 °

C

can

result

in

For help with operation of the unit, call Customer Service at 1-740-373-6809.

chamber

failure.

MODEL 6030 SPECIFICATIONS

Temperature Range without lights 5°C to 70°C

Temperature Range with lights* 10°C to 70°C

Temperature Control

Temperature Uniformity

Relative Humidity* 20 to 98% RH

Humidity Control* ± 2%

Interior Dimensions 30”W x 27.5”D x 63.5”H

Exterior Dimensions 36”W x 39”D x 90”H

Work Space 30 cu.Ft. (850 liters)

Shelves

Number of shelves 5 Stainless Steel, Wire Rod Standard

Shelf Spacing 1.5” on center (37 positions)

Shelf Size Each Shelf: 29.25”W x 26.5”D

Shelf Area 5.4ft.2 each, 26.9ft.2 total

Materials / Finishes:

Interior Stainless Steel

Exterior Metal with powder coated finish

Feet Adjustable leveling pads

Electrical 115V/25A/60Hz 1Ph. (standard, 220V optional)

Shipping Weight 750 lb. (340kgs)

± 0.1°C

± 0.3°C

**

(76.2cm x 69.9cm x 161.3cm)

(91.4cm x 99.1cm x 228.6cm)

(74.3cm x 67.3cm)

*Optional items

**RH levels limited by 4°C minimum dewpoint

Specifications were established at 20°C with 50% RH ambient conditions.

Chamber

ambient

conditions

2 0 °

C to

25 °

C.

Exceeding

2 5 °

C

can

result

in

For help with operation of the unit, call Customer Service at 1-740-373-6809.

chamber

failure.

INSTALLATION

Unpacking

This product has been completely tested, cleaned and packed for shipment. Carefully remove all

packing material. Please examine the chamber completely. Should any damage be found, notify

the delivering carrier immediately.

Report any shortages to Customer Service at 1-740-373-6809.

Chamber Location

Chamber ambient conditions 20

C to 25

°

C. Exceeding 25

°

C can result in chamber failure.

°

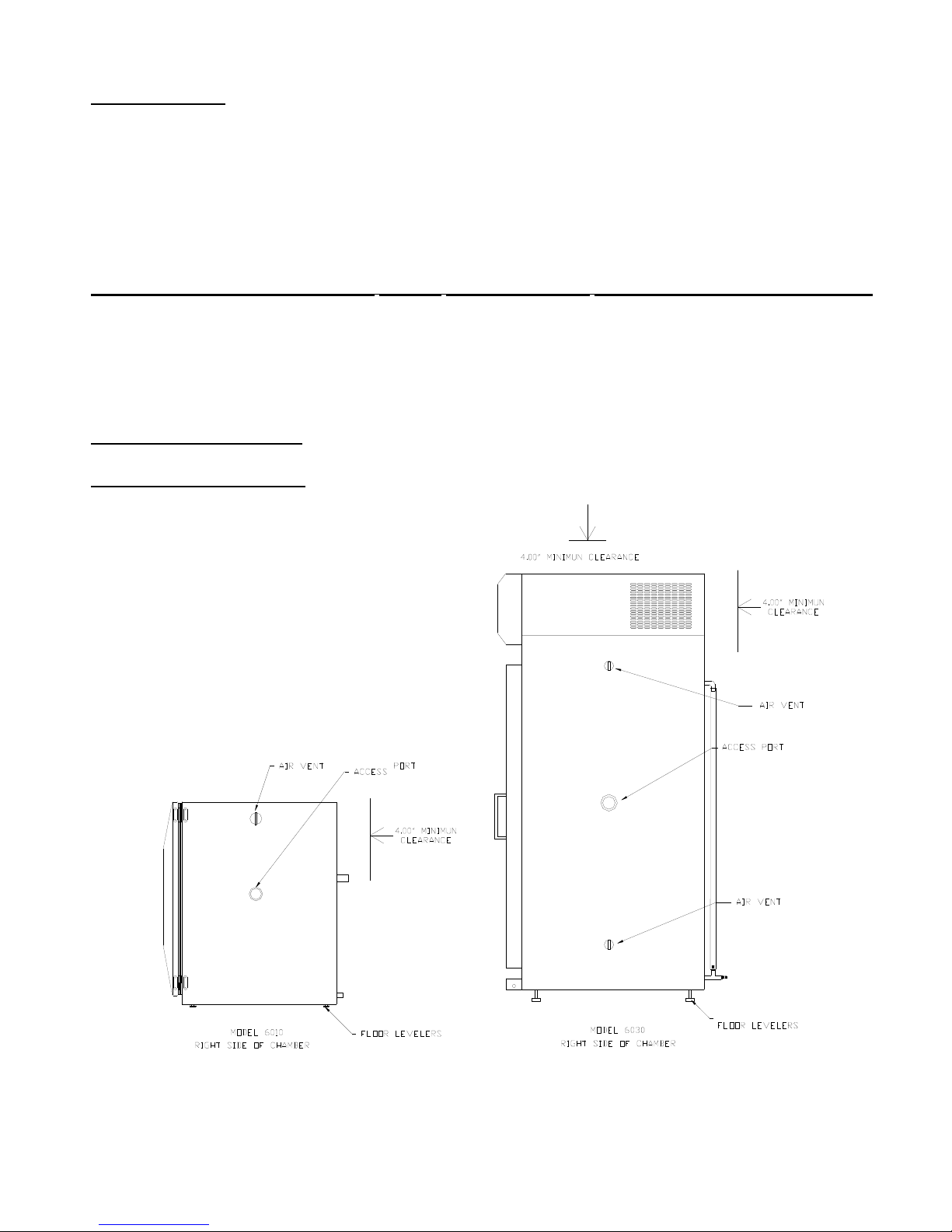

The chamber must be located in a dry, clean, and level area. Allow a 4” clearance from the back

and top of the chamber for proper air circulation and ease of installation. Locate the chamber in

an area out of direct sunlight and away from heating and cooling ducts. The 6010 & 6030

chambers can exhaust 2500 BTU/hr (730 W) and 4000 BTU/hr (1170 W) respectively into the

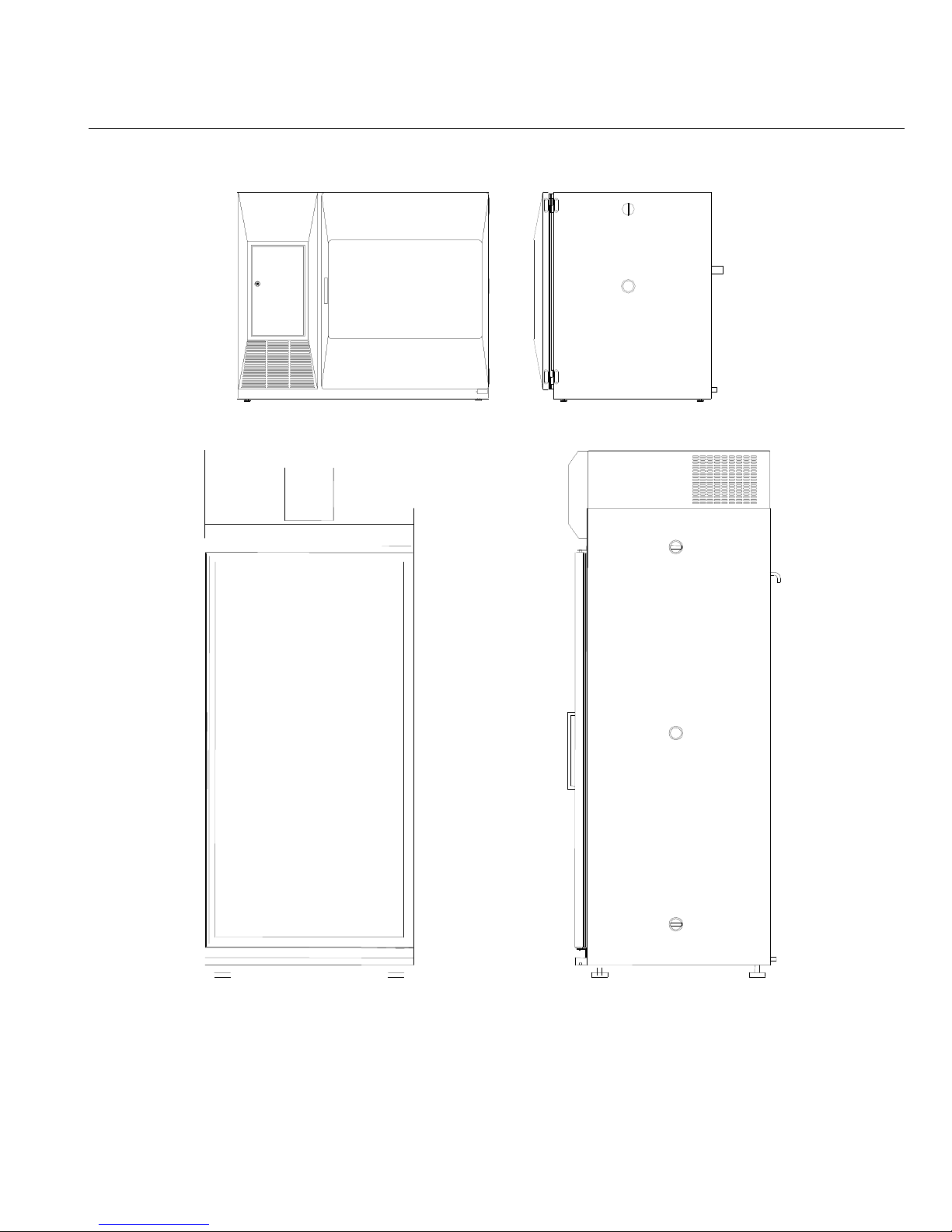

surroundings. The figure below shows a side view of the chamber with air vent and access port

locations.

Models

6030,

6031,

603 2 : Tilt the unit ½ of a level’s bubble toward the back for proper water

drainage

Models

6010,

6011,

6012: Unit should be completely level for proper water drainage

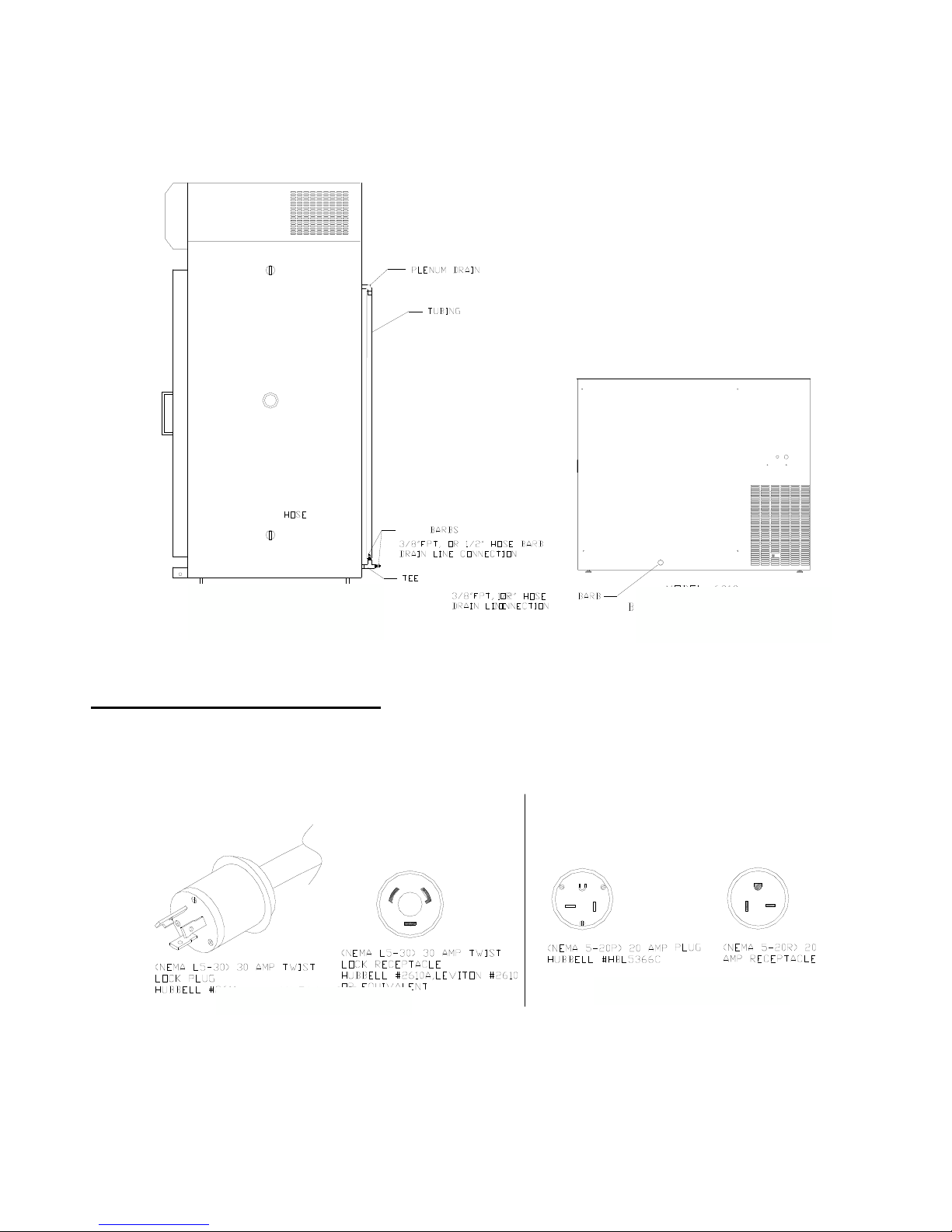

Drain connection

Connect a 3/8” NPT drain line to the drain connection located on the lower back side of the chamber. The figure

below shows the drain connection on the back of the chamber. For proper operation the drain hose should not be

kinked or bent. It should run down from the chamber and go into an open floor drain.

Models 6030, 6031, 6032

Right side of chamber

Models 6010, 6011, 6012

Back side of chamber

Power

PLEASE READ CAREFULLY!

For personal safety, this chamber must be properly grounded.

The Power Cord of this chamber is equipped with a grounded plug which mates with a

corresponding outlet to minimize the possibility of electrical shock from the chamber. CARON

recommends that the chamber have a dedicated wall outlet.

Models 6010, 6011, 6012

Models 6030, 6031, 6032

INSTALLATION cont.

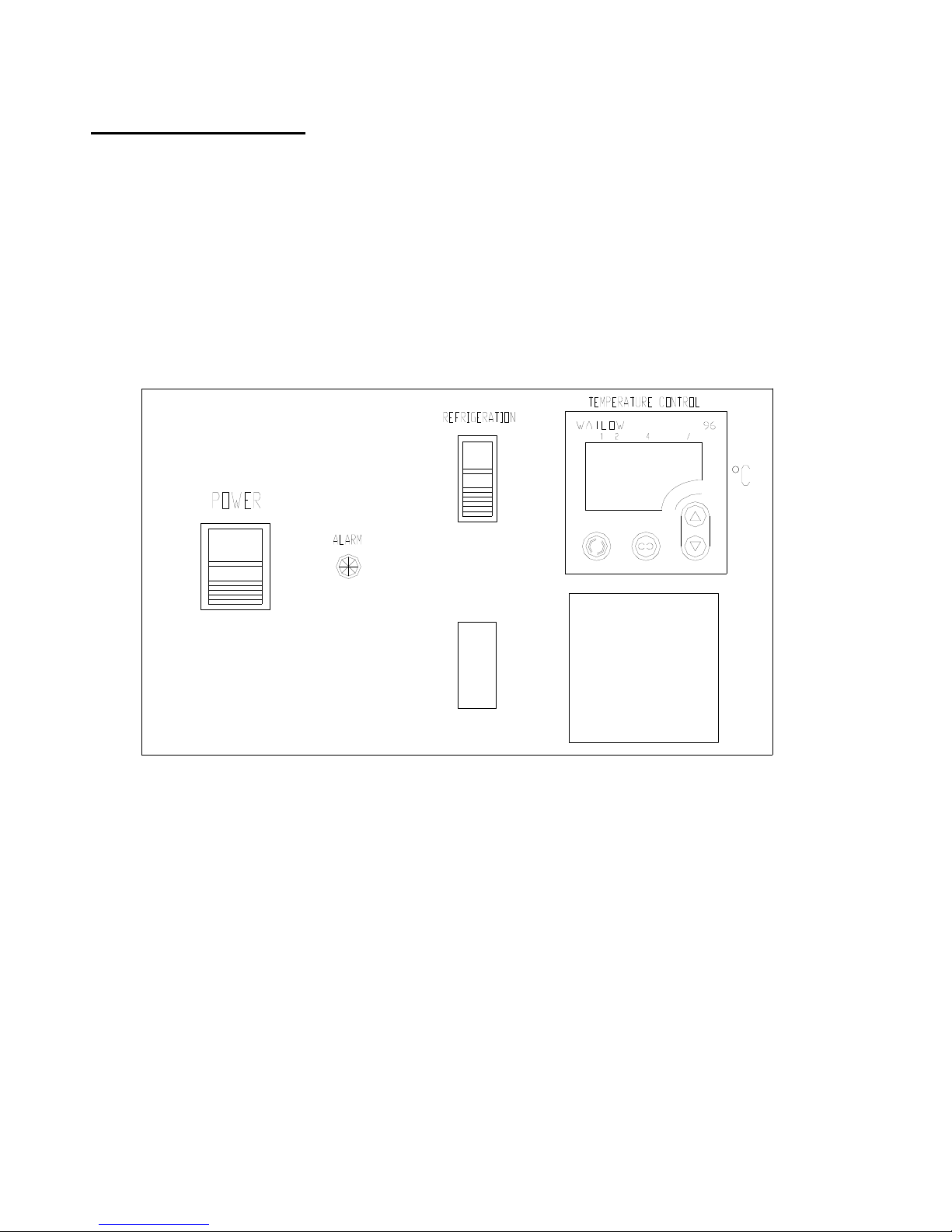

Control System

The control system is comprised of a 1/16 DIN temperature controller. The drawing below shows

the control panel (exact controller may vary). The display panel consists of a power switch,

refrigeration switch, and a temperature controller. The temperature controller’s unit is degrees

Celsius (°C). Refer to the figure below for the layout for the indicator lights as detailed below.

See appendix for controller operating instructions.

CONTROL PANEL

2 0

.

OPERATION

1. Connect the drain lines, and power cord as instructed in the INSTALLATION section of this

manual. (See Appendix C for additional drain connections. 6030 only)

2. Insert all shelf clips, and shelves. Check to see if they are properly installed.

3. Close the chamber door.

4. Install rubber stopper in access port on right side of cabinet.

5. Turn on power switch located on the control panel. This switch activates the heating unit and

temperature controller. The temperature controller will sound an alarm. The temperature alarm

will automatically reset after a few seconds.

6. *Turn on the refrigeration switch when operating at setpoints below 35°C. This switch

activates the refrigeration system.

7. Set the temperature controller to the desired setpoint. (See appendix if necessary).

8. Turn on the humidity switch. This switch activates the humidity system and the humidity

controller. (with humidity option only). Set the humidity controller to the desired setpoint. (See

appendix if necessary).

During normal refrigeration operation, a soft “clicking” sound can be heard. This sound is the

result of the solenoid control valves switching in the refrigeration system.

Chamber Loading

Air circulates through the chamber to maintain uniform conditions. When loading (putting product

into) the chamber, position samples so air can flow freely throughout the chamber. For best

temperature & humidity uniformity, keep samples away from surfaces as listed in table below. Do

not put product on the floor.

Between

Model Ceiling Back wall Side walls Front / door

shelves

6010, 6011, 6012 2 in (5 cm) 2 in (5 cm) 4.5 in (11 cm) 2 in (5 cm) 2 in (5 cm)

6030, 6031, 6032 6 in (15 cm) 6 in (15 cm) 3.5 in (9 cm) 3.5 in (9 cm) 3.5 in (9 cm)

Loading...

Loading...