Page 1

T2000 SERIES

PID TEMPERATURE

CONTROLLER

CARLO GAVAZZI

Automation Components

CGI Tempware Software Manual

Page 2

INDEX

KEY TO PROGRAM ICONS 2

OVERVIEW 3

INSTALLATION/CABLING

RS232 4

RS485 5

Termination resistors 6

Bias resistors 7

RS232/RS485 features 8

INSTRUMENT COMMS SETTINGS 9

CONFIGURING INSTRUMENT COMMS SETTINGS 10-11

INSTALLING SOFTWARE 12-13

GETTING STARTED 14

INSTRUMENT SCREENS 15

PC COM PORT SETTINGS 16-17

INSTRUMENT PARAMETER CONFIGURATION 18

SOFTWARE ALARMS 18

SETPOINT ADJUSTMENT 19

INSTRUMENT CLONING 20

SAVING SETTINGS TO FILE 21

SECURITY LOCKOUTS 22-23

LOGGING AND CHARTING 24-27

LOG ON CHANGE 28-29

EXPORTING LOG FILES 30

TROUBLE SHOOTING 31

GLOSSARY OF TERMS 32-33

Index

1

Page 3

Key to Program Icons

Change comms settings &

start monitoring

Toggle Modbus comms

de-bug window

Add new instrument

Add new instrument

Arrange instruments in grid

Make instruments larger

Make instruments smaller

Set security locks

Add new chart recorder

Close program

Create new file

Print chart recorder

Scroll chart up 100%

Scroll chart up 10%

Find chart zero

Scroll chart down 10%

Scroll chart down 100%

Expand verticle scaling range

Decrease verticle scaling range

Increase time/division

Decrease time/division

Open existing file

Export file in text format

Select units to record

Toggle grid density

Select background colour

Select primary grid colour

Select grid colour

Make chart bigger

Make chart smaller

Program Icons

2

Page 4

OVERVIEW

CGI T empware is a graphic WINDOWSTMbased software

package designed for PC supervision of Model T20321 /

T20161 and Model T20162 controllers. It offers the

capability of remote adjustment, instrument configuration,

cloning, saving and retrieving instrument settings to files

together with logging and charting in real time.

Communication uses the MODBUS

®

protocol via either a

fully isolated RS232 or RS485 link depending on the number

of instruments and the transmission distances involved in the

application.

PC Requirements

To gain the full benefit of CGI Tempware software, it is

recommend that the PC is fitted with a Pentium processor

and is running WINDOWS 95 or Windows NT programs. A

minimum of 16 Mb RAM is recommended to run the

program, together with enough free hard disc space to

meet logging requirements.

This manual assumes that a mouse or other pointing device

will be employed, but alternatively or in an emergency the

standard WINDOWS key convention can be used to

operate or close the program.

Because the controllers are “stand alone” they do not

need PC supervision for their normal function, and will

continue to control the process unaffected by failure of

any part of the communications loop.

Overview

3

Page 5

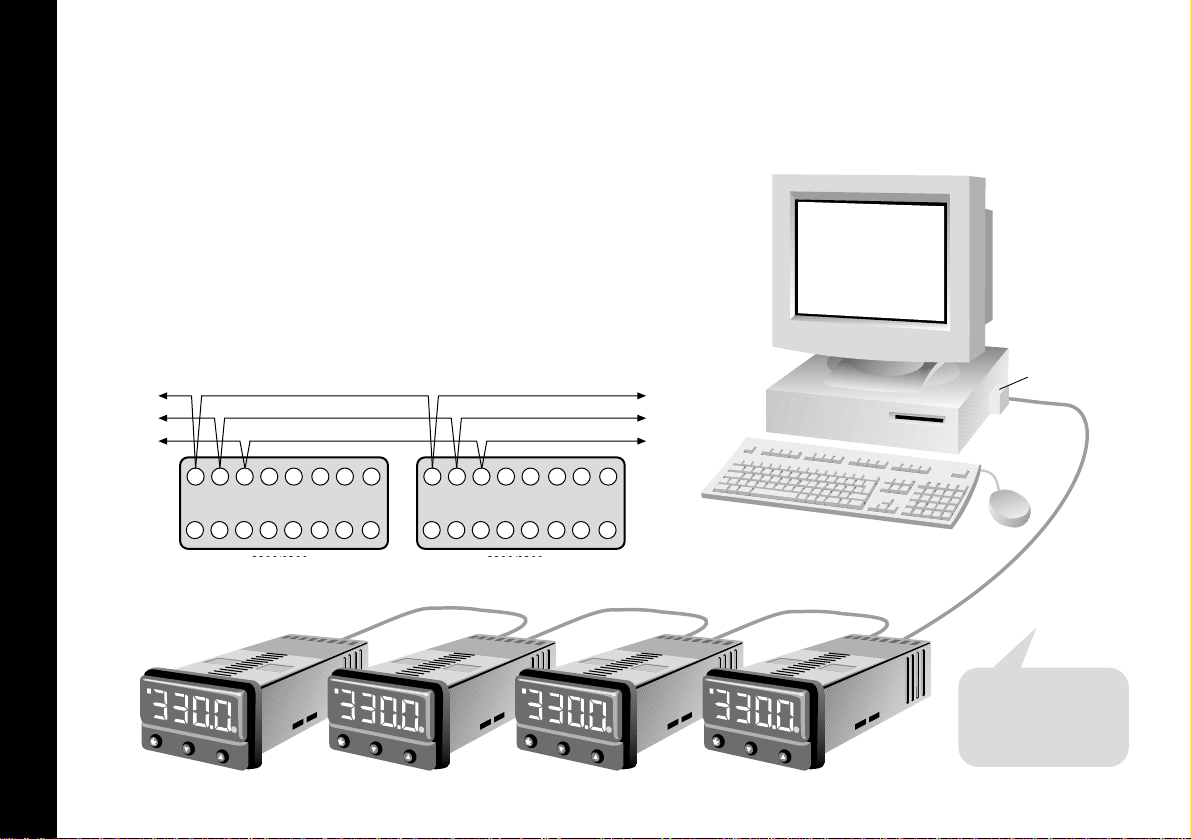

1 2 3 4 5 6 7 8

9 10 11 12 13 14 15 16

3300/9300

rear terminal

1

5

69

PC Com 1

DB-9 Pin

Tx

Rx

Gnd

COM port

Installation/Cabling

Installation/Cabling

4

RS-232 Is the standard most widely used for interfacing

peripherals to PC's and is designed for serial

communications with single instrument up to a distances

of 15 metres, in a low electrical noise environment.

Connection is via a screened two core cable where the

voltage signal on each line is referenced to the screen

which is grounded. Most PC's have one or two RS-232

compatible ports fitted as standard.

RS232 Connections

Port

Page 6

Installation/Cabling

Installation/Cabling

5

Tx Rx (+)

1 2 3 4 5 6 7 8

9 10 11 12 13 14 15 16

To

additional

units

1 2 3 4 5 6 7 8

9 10 11 12 13 14 15 16

3300/9300

unit 2

Tx Rx (-)

3300/9300

unit 1

Gnd

Tx Rx (+)

Tx Rx (-)

Gnd

Daisy chained connections

Connections if PC 485 card used

To RS 485 Interface

Either plug in board or

separate converter

Note:

Where separate RS 485

interface is used, refer to

manufacturers instructions for

connection details

To

RS 485

interface

COM port

RS485 Connections

RS-485 Is a half duplex serial communications link and is the

standard most commonly used for industrial applications due

to it's high noise immunity and multi-drop capability. It

enables a PC to communicate with up to 128 instruments

over distances up to 1200 metres, and requires the addition

of an RS-485 interface card, or a separate RS-232/485

converter.

Unit 2 Unit 1

Page 7

Installation/Cabling

Installation/Cabling

6

Termination resistors

–

120Ω

Tx

Rx

+

+

–

+

–

+

–

Tx

Rx

+

–

+

–

Tx

Rx

+

–

+

–

Tx

Rx

120Ω

Instrument 1 Instrument 2 Instrument ‘N’

Each RS485 interface has specific connection and

termination biasing requirements which will be detailed in

their installation instructions. The general principles are as

follows.

Terminations Because each wire is a transmission line, it

must be properly terminated to prevent reflections. Where

multiple instruments are daisy-chained together, a 120 ohm

terminating resistor should be fitted at the connection to

the PC and to the last instrument in the chain.

Page 8

Installation/Cabling

Installation/Cabling

7

Bias resistors

–

Tx

Rx

+

+

–

+

–

+

–

Tx

Rx

+

–

+

–

Tx

Rx

+

–

+

–

Tx

Rx

Instrument 1 Instrument 2 Instrument ‘N’

+5V

620Ω

-5V

620Ω

Bias resistors When transmission lines are not transmitting,

they remain in an indeterminate state which can allow

receivers to receive invalid data bits due to electrical noise

on the cable. To prevent this, the the lines should be forced

into a known state by fitting two 620 ohm bias resistors to

one point (node).

If an RS-485 interface card is being fitted to the PC,

separate bias resistors may not be needed because they

may already be fitted to the card. Check the manufacturers

specification.

Page 9

Installation/Cabling

Installation/Cabling

8

For a continually updated list of recommended RS-485

interface cards, contact Carlo Gavazzi.

Feature

Type of transmission lines Unbalanced

132

321

15M

19.2Kb/sec 19.2Kb/sec

+/- 25V + 12 to - 7V

1200M

Differential

Maximum number of drivers

Maximum number of receivers

Maximum cable length

Maximum data rate

Maximum CMV

RS232 RS485

Table lists the features of both RS-232 and RS-485

standards.

Cable To ensure data integrity over long transmission

distances, it is recommended that good quality RS-485 cable

is used.

Page 10

Instrument Comms Settings

Instrument Comms Settings

9

Immediately after power-up, both instrument, and PC comms

settings need to be made compatible before communication

between them is possible. Instrument defaults are shown

below together with the available options.

ADDR (Address) This is a unique

identification number that must be

allocated to each instrument

connected to the network.

Default =0. Options;

1 to 247

BAUD (Baud rate) The setting determines

the serial communication data

transmission rate in bits/sec, and must

match the PC settings

Default =

9600

.

Options;

1200;2400;4800;9600 and 19200

DATA (Data) Sets the transmission format, and

must match the PC settings.

Data Format Table

Settings Start bits

1

1

1

Data bits

8

8

8

Parity

n (none)

e (even)

o (odd)

Stop bits

1

1

1

Default

Option 1

Option 2

DBUG (Debug). Commissioning and

troubleshooting aid. Display shows

when the instrument is transmitting or

receiving data by rapidly flashing the

three horizontal segments of the first

and last digit of the display.

First digit = Tx; last digit = Rx

Default = Off. Options

off; on

Only use dbuG during commissioning or trouble-shooting

because it shares display segments and therefore

corrupts the normal display.

!

Page 11

Instrument Comms Address

Configuring Instrument Comms Settings

10

This should also be done immediately after power-up, and

is only possible from the instrument front panel.

On power-up the controller will display the self test

sequence followed by Alternating INPT and

nonE

INPT

CAL 3300

INPT

CAL 3300

INPT

CAL 3300

NONE

CAL 3300

NONE

CAL 3300

NONE

CAL 3300

INPT

CAL 3300

NONE

CAL 3300

Note: During the following procedure the display will revert

to alternating INPT and

nonE

after 60 seconds of

keying inactivity, but will retain any settings already

completed. Should this occur, or in the event of becoming

"lost" in the program, please start again from the alternating

INPT and

nonE

display

To select Level C (communications settings)

Press ▼ once display alternates LEVL and

5

Press and hold ✱ and press ▼ five times to reach level C

display alternates LEVL and

C

!

Note: Level C is only visible when the comms interface

board is fitted to the unit

To set up Instrument comms address

Press ▲ once display alternates ADDR and

0

Press and hold ✱ and press ▲ to index to chosen address

number

(1 to 247)

Note: In the absence of any conflicting information the

following comms settings should be left as the default

values. (see details on page 6).

To read or adjust comms settings

Baud rate

Press ▲ once display alternates BAUD and

9600

(Default setting)

Press and hold ✱ and use ▲ or ▼ keys to select preferred

value

Data format

Press ▲ once display alternates DATA and

18n1

(Default setting)

Press and hold ✱ and use ▲ or ▼ keys to select preferred

setting (see table page 6)

Debug setting

Press ▲ once display alternates DBUG and

oFF

(Default setting)

Press and hold ✱ and use ▲ key to select

on

Page 12

Instrument Comms Settings

Configuring Instrument Comms Settings

11

To enter settings into memory

Press and hold ▲ and ▼ for 3 seconds display alternates

INPT and

nonE

To check settings; repeat the above procedure

The unit is now ready to be configured from the PC.

Note: Where more than one instrument is connected to the

system, it is useful at this point to list them by location, title

and comms address. The list can then be used as a reference

to ensure that the the instruments are given the same identity

when configuring the comms link from the PC.

Page 13

Installing Comms Software

Installing CGI Tempware Software

12

1. From the Windows screen, click the Start button and

point to Settings.

2. Click the Control Panel icon then double click on the

Add/Remove Programs icon.

3. Click on the Install button and follow the screen

prompts.

When installation is complete, CGI Tempware should appear

in the Windows program menu.

To Uninstall CGI Tempware, repeat the above procedure.

To create a shortcut and put the CGI Tempware icon on

your desktop

Right click anywhere on the desktop.

Point to New then Click Shortcut

Type in Command line panel using syntax

exactly as shown:

"c:\Program Files\Carlo Gavazzi\

CGI Tempware\CGI Tempware.exe"

Click Next

In Select name for shortcut panel the

text will appear; CGI Tempware.exe

Click Finish, and this will place the title and

the CGI Tempware icon on the desktop.

Alternatively;

Overtype your preferred title in the Command line

panel then

Click Finish.

Check that the CGI Tempware logo appears

correctly titled.

An alternative method of defining the file path in the Create

shortcut window is to use the Browse function to find

CGI Tempware.exe

Click Browse

Double Click Program Files folder.

Double click CGI Tempware folder

Double click CGI Tempware.exe logo, then

Click Next, then

Click Finish, and check the CGI Tempware

icon and title.

Page 14

Installing Comms Software

Installing Comms Software (continued)

13

To delete a shortcut,

Click on the desktop icon then press the delete key

Page 15

Getting Started

Getting Started

14

Start the program running from either;

a. Windows Start menu

b. Shortcut icon (if created during

CGI T empware installation)

This will open the CGI Tempware window. The

screen can be sized using standard Windows

controls.

Note; As CGI Tempware is a supervisory program it is not

designed to be minimised

!

ADDING INSTRUMENTS

Click the appropriate Add New Instrument icon to

call up the type and number of instruments that

are to be shown on the screen. Each click

produces a new instrument which can also be

deleted by using the Close button in the

instrument title bar immediately above the

instrument screen. Mixed instrument types can be

displayed on the same screen.

Click the Arrange Instruments in a grid icon and

use the screen prompt to arrange them in the

preferred layout.

Click the Make Instruments Larger icon or;

Click the Make Instruments Smaller icon to size

them as required.

See screen illustrations overleaf.

Page 16

CGI Tempware Instrument Screens

Getting Started

15

Page 17

will automatically configure the com port settings. Where an

RS485 PC card is being used, refer to the manufacturers

installation instructions.

To open communication with the instruments in preparation for

Instrument configuration.

Click Change comms settings and start

monitoring icon, then select the comms

port that the instruments are connected

to.(eg comm 1 or comm 2) then Select

Baud rate to match the instrument settings,

(eg 9600) then Select Data Frame to match

the instrument settings, (eg 18n1)

Click Open Comms button

Comms Settings (on PC)

PC Com Port Settings

16

When the instruments are positioned on the screen, they are

automatically numbered in sequence Inst.1, Inst.2 etc. Each

one can be individually named in it's own title bar, and must

be given the same unique comms address (1 to 247) given

manually to the instrument during the Instrument Set-Up

procedure.

(CHECK your list!)

.

Right click in the display window of Inst.1 to open

the Internal Parameters for Inst1 screen.

If not already in User Level;

Click User Level tab to open page, then;

Point to instrument/name and if required,

change inst1 by typing in a preferred

instrument title.

Check Modbus address and if necessary

correct it to the given comms address

(1 to 247) by using the spin buttons or

by swipe and type.

(CHECK your list!)

Click on Update button and then Yes button

in Confirm / Update Instruments with

new parameters panel.

Instrument 1 should now have the correct comms

settings. The above procedure

must

be

repeated for all instruments on the

screen before starting Instrument

Parameter Configuration.

Note; If using an RS232 or RS485 converter plugged into

comm port 1 or comm port 2, the CGI Tempware software

Page 18

Comms Settings (on PC)

17

PC Com Port Settings (continued)

Wait!! For update to be fully completed by

observing the Uploading bar turning

from red to green in the CGI Tempware

Instrument screen.

This may take several seconds.

Check Virtual instrument display readings

against real instrument readings.

If the check is satisfactory, proceed with

Instrument Parameter Configuration

Page 19

Parameter Configuration

Instrument Parameter Configuration

18

The instrument(s) will not be operational until configured

with the following basic settings.

* Sensor type

* Units of measurement

* Allocation of output devices to the main output SP1 and

second output SP2

To configure the basic settings to Instrument 1

Right Click in the display window of Inst.1 (or new

given name) to open the Internal

Parameter screen

Click Level 2 tab to open page, then

Click Input sensor box, and select required

sensor from the drop down menu (eg

K

)

Click Process unit box, and select required

unit from the drop down menu (eg

o

C)

Click Level 3 tab to open page, then

Click SP1 output device box, and select

choice of output device from drop

down menu (eg

rLy

)

Note: That SP2 output device box registers the

alternative output device (eg

SSd

) and if

OK, Click the Yes button to confirm

selection.

Click User Level tab to open page, and enter

a setpoint value in Set Point 1/SP1 Value

box using spin buttons or swipe and

type.

Check The Enable Display Mimics box if you

want the virtual instrument to mimic all

actual instrument displays as well as

reading setpoint and process values.

NB This may slow down communications

and should only be used if it serves a

useful purpose.

SOFTWARE ALARMS

This feature provides a screen alarm indication if the

measured value falls below the low alarm and/or rises above

the high alarm settings.

The alarm appears as a red band across the lower fascia of

the instrument.

Page 20

Parameter Configuration

19

Instrument Parameter Configuration (continued)

To set Software Alarms (in User Level)

Adjust Spin buttons in Low Alarm/ High Alarm

boxes to set the required high/low level

Check The Enabled boxes.

TO ENTER THE ABOVE INSTRUMENT PARAMETER SETTINGS

Click on Update button and then Yes button

in Confirm/Update Instruments with new

parameter panel.

Wait For update to be fully completed as

indicated by the Uploading bar turning

from red to green after it temporarily

appears in the CGI Tempware Instrument

screen.

This may take several seconds.

After a few seconds more the Heat-On

LED in the top left hand corner of the

Inst.1 screen will light indicating that the

power is applied to the output.

Instrument 1 will control with factory

PID settings and pre-set proportional

cycle times. For optimum performance

the instrument may require Tuning to

match the characteristics of the

application. For full instruction in setting

the controller functions, please consult

the main manual.Autotune routines can

be found on page 7.

SETPOINT ADJUSTMENT

During normal use, instrument setpoints can be adjusted

from the CGI Tempware instrument screen, by using the

three buttons shown on the virtual instrument lower fascia.

✱ button highlighted with red circle in program

Click The ✱ button, and while the red circle

shows around it, click either the ▲ or

▼ button to increase or decrease the

setpoint value. This setting will be

implemented when the red circle

disappears after a few seconds.

Note: When more than one instrument is being configured,

the outputs of the other instruments can be temporarily

turned off using the

ParK

option of the TUNE function in

level 1.

Page 21

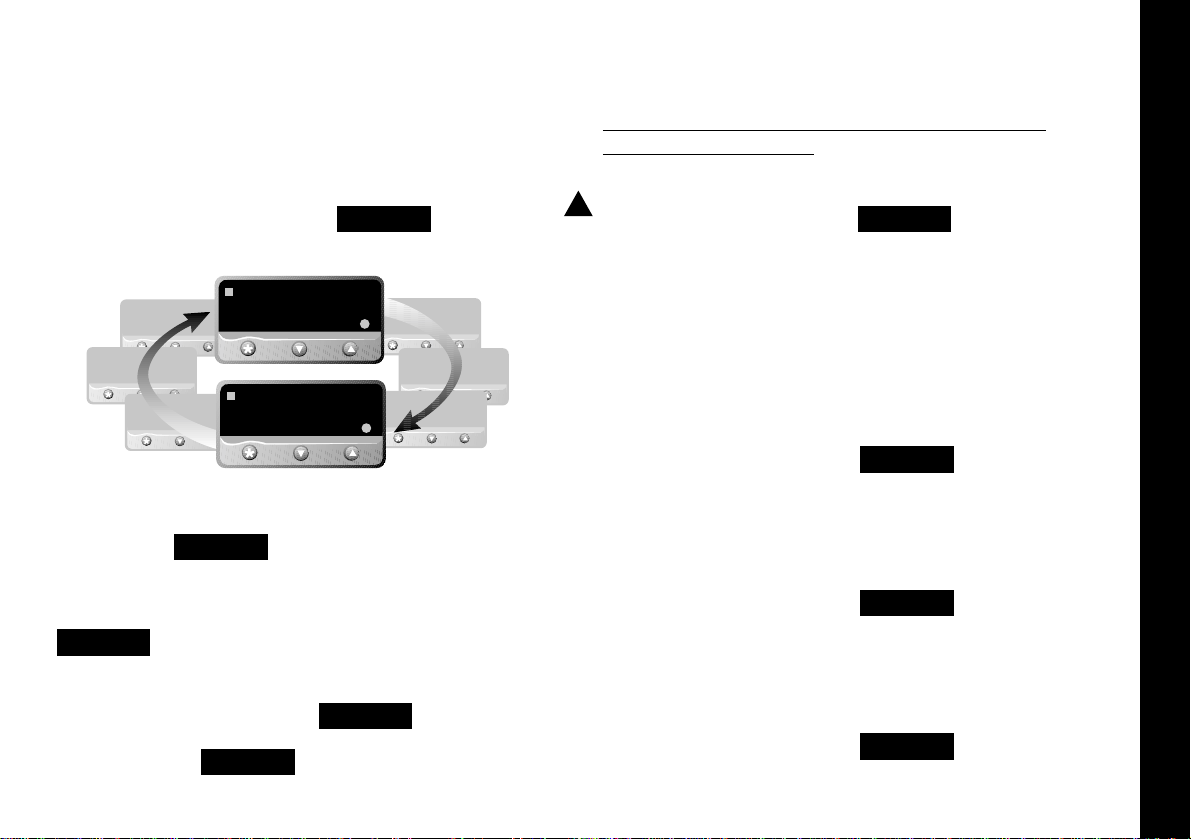

Instrument Cloning

Instrument Cloning

20

When a satisfactory instrument configuration has been

achieved, either from the initial configuration with the basic

parameter settings, following Autotune or other further

adjustments, these settings can be cloned to other

instruments on the network or saved in a file for later use.

Suites of settings of all the instruments in an application can

similarly be saved to a file making it possible to re-configure

all of the instruments on a machine or process in a matter of

seconds, to optimise them to different task.

Cloning Settings to another instrument on the bus.

Right Click in the display window of the instrument

that settings are to be cloned from.

Click the clone button in any of the pages of

the Internal Parameters for instrument

(n) screen to call up the Clone data

page. The Instruments on line panel will

list all of the instruments on line by it's

Modbus address and either the default

instrument number or name/location

given during Instrument Comms Setting

procedure.

To transfer an instrument or group of

instruments to the Instruments to Clone

panel;

Click anywhere on instrument title, to

highlight, or

Click/hold a group of instrument titles, then

Click the button to transfer the highlighted

instruments to the Instruments to clone

panel, then

Click the OK button to clone them with the

settings from the original instrument.

Page 22

Saving/Retrieving Instrument/Application Settings

Saving Settings to File

21

Saving the settings of a single instrument

Click Save in the menu bar of the Internal

Parameters for Inst.n screen

Type Your filename in the File name box

Click the Save box

This will save the instrument settings to an instrument file

with the extension .ins

Opening an existing instrument file

Click Load in the menu bar of the Internal

Parameters for Inst.n screen

Click the Yes button in the Confirm panel to

Load inst.n from file?

This will load instrument n settings to the new instrument.

Saving an Application File

In the CGI T empware Instruments screen

Click File in the menu bar, then Save

Application from the menu.

Type Your new filename in the File name box.

Click Save

This will save the settings of all the instruments on the

screen to an application file with the extension .app. Check

that the file is correctly named Yourtitle.app.

Opening an Existing Application File

Click File in the menu bar, then Open

Application from menu

Click File name to select application from the

list then click Open

This will automatically configure the instruments to the

settings saved in the selected file

Starting a New Application File

Click File in the menu bar and select New

Application from menu

Click Yes to confirm Start a new application

Note: When instrument settings are loaded from an

application file, remember to re-start comms

Page 23

Security Lockouts

Security Lockouts

22

When the instrument parameters have been established you may wish to password protect the settings against accidental or

unauthorised adjustment. It is possible to make individual protection for each instrument function at each level, and for each

instrument on the network

Please study the lock hierarchy diagram below before implementing your security strategy.

When correcting errors, start again from supervisor level, lock none, and clear the locked settings in the correct hierarchical

sequence

Supervisor

All of the controller functions are available to the supervisor

who can deny adjustment of any number of them to lower

levels in the hierarchy. These settings will be protected by

the supervisor’s password.

Operator

The operator can adjust all controller functions not locked

by the supervisor, and can in turn lock any of these to deny

adjustment to a user, and then protect them with the

operator’s password.

User

Any remaining functions are available for adjustment by the

end user. These functions can be locked and unlocked

without the use of a password.

All Controller Functions

Supervisor

Controller Functions Available to Operator

Operator

Controller Functions Available

for User Adjustment

Lock Hierarchy

!

Page 24

parameters you want to lock, or the All

box or the None box.

Click OK then

Click the tab for the next level, and repeat the

procedure until all levels of Inst.1 have

been protected.

Repeat for all of the remaining

instruments on the network, then return

to CGI Tempware instrument screen.

Click double lock icon in the menu bar to

bring up the Password panel, then

Click the arrow in the User type box and

select Locked from the drop down

menu.

Type your password in the Password box and

click OK. The selected levels of the

selected instruments are now locked

and protected by your password which

can be changed at any time using the

Change feature.

NB: Once communication has been established and routine

function adjustments under PC control, it is highly

recommended that the instrument controls are manually

locked to prevent unauthorised local adjustment. When

locked, it will still be possible to make adjustments from

the PC.

If you forget your password, please contact Carlo Gavazzi.

Security Lockouts

23

Lock Hierarchy

Right click in the display window of Inst.1 to open

the Internal Parameters for

Click the tab for a level that contains any

settings that you wish to protect, and

Click the Lock button, and in the Lock User

Level Parameter window,

Check either the individual boxes of all the

To implement your security lockout

strategy, begin from the CGI Tempware

instrument screen, supervisor mode.

Page 25

Logging and Charting

24

The CGI Tempware software is capable of logging readings

from up to 128 instruments which it stores in data files. The

data can be exported into text files which will enable the

data to be displayed in c.s.v. format, as columns of readings

against dates and times, for each of the 128 instruments. In

addition, the readings of up to 12 of the instruments can be

presented graphically and in color, by the chart recorder

facility.

As in other sections of the manual, it is assumed that a

mouse or pointing device is being used. Where only a

keyboard is available, the standard

Windows

key

conventions can be used to operate the program.

GETTING STARTED

From the CGI Tempware instrument screen.

Click the add new chart recorder icon in the

menu bar, and in the Chart recorder

screen;

Click the create new file icon, and in the File

name box of the Select File to Create

panel;

Type your chosen file name, then Click the

Save button.

In the Select Units to Chart screen;

Click to highlight all of the units that are to be

logged from, in the Available

instruments list.

Logging and Charting

Page 26

Logging and Charting

25

using the Add to Custom Color feature.

Click the OK box in the color screen.

In the Sample Frequency panel,

Click the spin buttons to set the log reading

frequency.

Click the OK button to open the Chart

Recorder screen.

In the Chart Recorder screen, check that

the Active File panel shows the correct

file name, then make the following chart

recorder settings to suit your application,

starting with the Scaling panel;

Logging and Charting (continued)

Click the transfer button to list them in the

Instruments to record table. For each

instrument to be charted from, double

click in the Plot? column to change the

No to Yes.

Double click in each instrument color panel, and

from the standard Windows

TM

color

chart, select contrasting colors that will

effectively display all of the instruments

listed. Additional shades can be added

Page 27

Logging and Charting

26

Click the buttons in the deg C/F box to set up

a suitable temperature scale in the chart

Y axis.

Click the buttons in the time/div box to set

chart speed in the time interval per minor

division of the X axis.

Click the Start button to commence logging

and run the chart recorder with default

chart settings.

Note: Chart scale settings are determined by the settings

chosen for the first instrument (or instrument 1)

Traces can be vertically positioned on the chart by using

the chart scroll buttons.

Click the buttons to move the chart up or

down by 10%

Click the buttons to move the chart up or

down by 100%

Click the button to zero the chart

The appearance and colors of the chart can be changed

as follows;

Click select background color icon, and

chose another color from the color

chart.

Click the toggle grid intensity icon to add

minor divisions to the Y axis.

Click the select primary grid color icon to

change the color of the grid major

divisions.

Click the select grid color icon to change

the color of the grid minor divisions.

Note: Because the chart is re-drawn after each plot, a

setting of less than 5 minutes/div is recommended, to avoid

extravagant use of system resources while logging. Longer

settings can be used to review the full chart history in view

plot mode.

!

Page 28

Logging and Charting

27

Click the make chart bigger or make chart

smaller icons to adjust the size of the

chart on your screen.

Click in the chart recorder blue title band, and

drag to adjust the position of the chart

recorder on your screen. Repeat this for

the CGI Tempware instrument screen,

and trim both adjustments so that both

are visible.

If you prefer using full screens for both

chart and instruments, toggle between

screens using the instruments menu bar

option in the chart screen and the chart

option in the instruments screen.

Click the pause button to stop logging and

stop the chart recorder.

Click the Resume button to re-start logging

and charting.Note that a grey vertical

band appears on the right of the chart to

signify the break in readings.

Click the auto plot button to pause the chart

and allow the chart history to be viewed

using the horizontal scroll bar controls.

(normal logging continues meanwhile)

Click the view plot button to return to

automatic chart update state and normal

charting is resumed.

During charting, the current value is

displayed to the right of the chart, in the

trace color. When in view plot mode

Point and Click to any point on the trace. A

dashed vertical line will appear and cut

the trace at this point, and the value will

appear to the right of the chart in place

of the current value.

If used in auto plot mode the reading will

be set to current value at the next plot.

Page 29

Log on Change

28

LOG-ON-CHANGE (ONLY LOG/CHART OUT OF LIMITS

READINGS)

This feature reduces the size of log and chart files by

ignoring readings that are within adjustable specified limits.

To specify the limits;

Double click in the inst.1 Min column and enter the

value

below

which readings are to be

logged. Repeat in the

Max

column, and

enter the value above which readings

are to be logged.

Check the radio button record when out of

tolerance, and Click the OK button.

The chart will now only register

out of

limits

readings which will be separated

by grey vertical bands signifying periods

of

in limit

readings. It will still be

necessary to set the Sample Frequency

buttons.

Check the radio button record all readings to

return to normal logging/charting.

Factor and Offset adjustments

A factor adjustment can be made to enable readings of

differing orders of magnitude to be charted on the same

scale. For example, a X10 factor applied to ambient

temperature readings would enable them to be charted

alongside process temperatures of 200

o

/400oC -

400

o

/1470oF. Factor adjustments can be greater or less than

one.

Offset adjustments can be applied to any trace to adjust its

position with respect to the scale. For example, the readings

from a particular instrument may be known to be 4

o

low

due to poor siting of the sensor. An adjustment of +4 in the

Offset column will remove this error.

Sizing and positioning your chart

Click to make the chart smaller or larger.

If required, it is possible to super-impose

a small chart screen on top of or beside

the CGI Tempware screen so that both

are visible.

Other Logging and Charting Options

Page 30

Log on Change

29

Saving Charts

To stop recording

Click Either the close button or from the

menubar chose File then Exit. The file

will automatically be saved with the

name given earlier as Givenname.cht

Files can be recalled to view, or to add additional data using

the Append feature.

Click the Open existing file icon, and select

the name of the file to be opened from

the list in the file box.

Click Open button.

The chart recorder screen will open with

the chart settings returned to default. If

preferred, reset the chart to your

original settings, then;

Click Append button to add the new readings

to the chart. The new readings will be

separated by a vertical gray bar.

Multiple Charts

It is possible to open a number of charts simultaneously. The

menu will register the number of charts open under the

chart heading. These can be arranged on the screen, in or

out of view, and moved or sized as required.

Page 31

Exporting Log Files

30

Exporting Log Files as Text Files

Log files can be exported as "Comma Separated Variable"

(csv) text files, which appears as column of logged

instrument readings, set against its time, date and line

number.

In this form the data can be exported into other

applications such as spreadsheets or data bases for use in

the preparation of reports or other management

documents.

To export data to a text file, in the Chart Recorder screen,

Click the export file in text format icon, and

in the Export Text File screen, type your

file name in the File name box.

Click the Save button to save your file as a

Filename.txt file

To check that your file has been correctly saved, open

Windows Explorer

And from the C:\ directory click Program Files then Carlo

Gavazzi then CGI Tempware

From the list contained under the filepath

C:\Program Files\Carlo Gavazzi\CGI Tempware\

Double click Select Filename.txt

Depending on the size of the file, it will be opened in either

Notepad or WordPad

Printing Charts

Charts can be printed in full color, depending on the

specification of the printer.

From the Chart recorder screen use either the print icon or

the print chart command from Options in the menu bar. This

will open the Windows

TM

print screen. Click the properties

button to select landscape setting. If changes in appearance

are required, review the logging and charting section.

Page 32

Trouble Shooting

31

Trouble Shooting

Error Message Fault Suggested remedy

ASK Comms error Check that the comms

address setting of the

real

and the

virtual

instruments are the

same.

_ _ _ _ Comms inactive Make sure that comms is

open.

Click Change comms

settings and start

monitoring icon.

Page 33

Glossary of Terms

32

Glossary of Terms

The following definitions apply to terms as they are use in

this manual, and have been worded for ease of

understanding. They may differ in detail to definitions

found elsewhere.

Address The unique number given to each

instrument on the network that enables

the PC to transmit individual instructions,

and receive individual data from it.

Application In this manual it defines the application of

an instrument or group of instruments to

control temperatures or other variables

on a machine or process.

Application file The stored settings of all of the

instruments on a machine or process.

Baud Serial communication consists of a stream

of on/off signals called bits. Baud rate is a

measure of the speed of communications

in bits/second.

Bus The electrical connection linking together

the instruments and the PC.

Charting Placing logged readings on a graph

format to form a continuous trace of

readings where the vertical or Y axis

measures the magnitude of the reading

and the horizontal or X axis measures

elapsed time.

Cloning Copying settings or groups of settings

from one instrument to another.

Comms Abbreviation of serial communications.

Daisy chain The method of connecting instruments

together.

Data format Defines the structure of the message.

Functions The main features available in the

controller.

Icon Small picture on a PC screen that

describes a CGI Tempware function that

can be clicked on to open or close the

function.

Level The instruments' functions are grouped

on five levels of adjustments for ease of

use and protection.

Logging Datalogging; Recording readings against

time and or date, into a file.

Modbus Generic name given to the format

(protocol) that defines the structure of

the coherent groups of signals in serial

communications.

Multi drop When several instruments are connected

together on a network using RS 485

standard.

Options The choice of settings for the Functions.

Password protect The arrangement that enables the user

to lock the system settings against

unauthorised adjustment with the use of

a word or code.

Continued over the page

Page 34

Glossary of Terms

33

Glossary of Terms

Glossary of Terms (continued)

P.C. Personal computer, desktop or laptop.

Protocol See Modbus.

Radio button A PC "screen" switch shaped like a push

button that can be clicked

on and off

RS232/RS485 Sometimes EIA232/EIA485 defines the

two standards for serial communication.

More detail can be found under

Installation/Cabling.

Serial Link Another name for the wiring between

two communicating devices.

Virtual Instrument Image of the instrument on the PC

screen.

Page 35

CARLO GAVAZZI INC.

Automation Components

750 Hastings Lane, Buffalo Grove, IL 60089-6904

Phone 847.465.6100 Fax 847.465.7373

email: sales@carlogavazzi.com

CARLO GAVAZZI

Automation Components

Control It

Current Monitors • Panel Meters

Phase Monitors • Timers

Transducers • Voltage Monitors

Distributed I/O

Dupline

®

Field and Installation Bus

Over a Twisted Pair • Up to 6 Miles (10km)

Send It

Sense It

Capacitive Proximity

Inductive Proximity • Level Controls

Photoelectric

Electromechanical Relays • Integral DIN

Mounted SSRs • Motor Controllers

Solid State Relays

Switch It

A Global Force in Industrial Automation

T2000 Manual 33058/01/0200

Loading...

Loading...