Additional Items Needed

4-channel (or more) Radio Control Set

CA or Epoxy glue (large)

1/2oz. Thin CA glue

.40 to .61 (.90 4-cycle) R/C engine

13 running ft of covering material ( two

79”

rolls of material)

Paint (fuel-proof, quantity

depends on desired finish)

one 1-1/4” and two 3-1/4” Wheels

1/2” x8” x12” CG R/C Foam Rubber

Optional T

ools

CG Engine Test Stand (no. 293)

Propeller balancer

Combination prop/glow-plulg wrench

CG Hinge Slotting Kit (no. 269)

Engine Mounting Option

Drill & Tap, Size No. 43

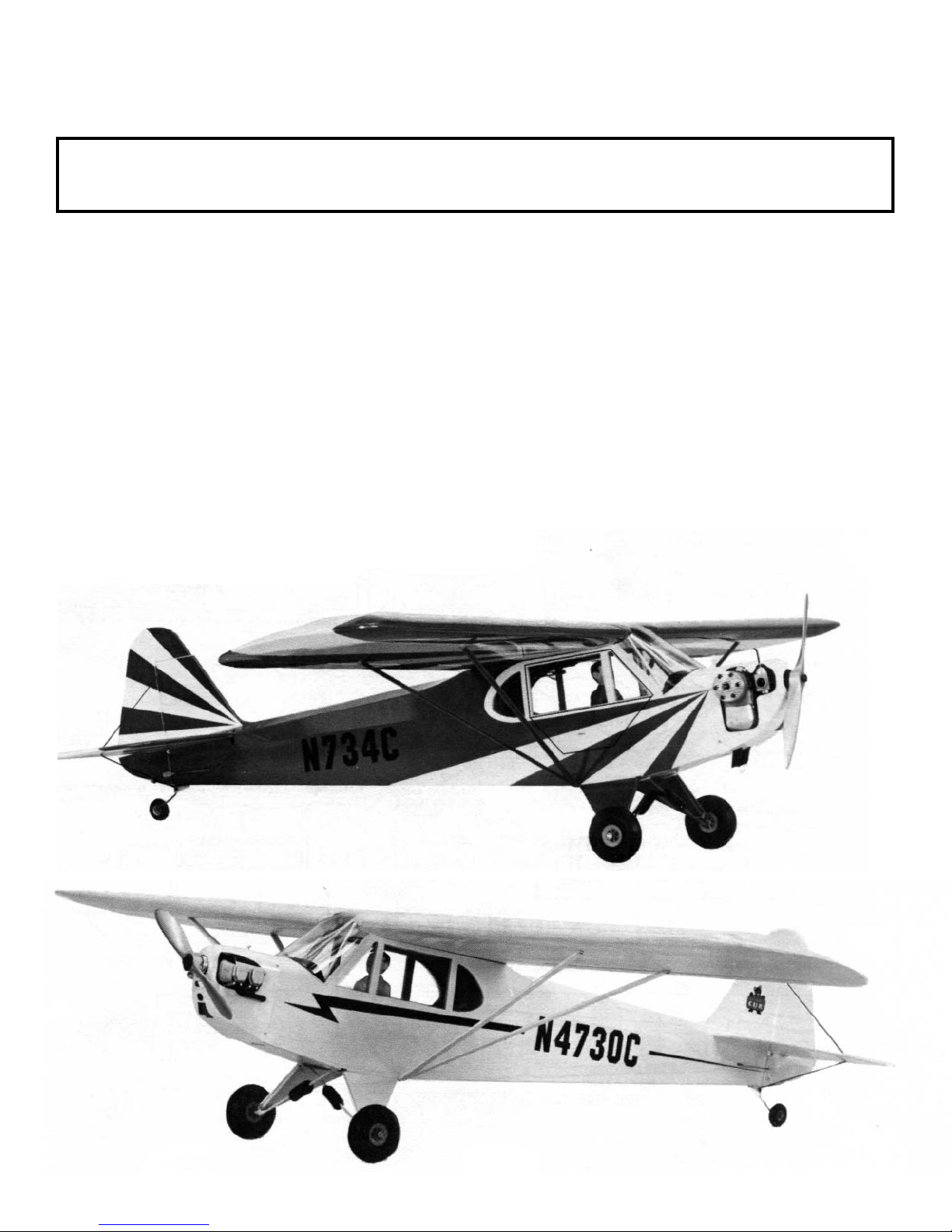

There really is nothing like a “Cub”! The C.G. version retains the honest, easy to fly qualities that made the full size airplane famous.

With the standard long wing, the model is a very graceful, realistic flyer. It’s aerobatic performance tends to be big,round, and slow.

Like the full size airplane, the model can be modified into an aerobatic version byshortening the wings. This “Clipped Wing” option

is a thrilling aerobatic machine that will provide outstanding performance, including point rolls, inside and outside

maneuvers, snaps and spins.

Building is easy, but to prevent simple mistakes, the step-by-step instructions should be followed. Many a modeler has made two

right fuselage sides instead of one right and one left as a results of not following the directions.

The Cub can be finished in any of the unlimited color schemes of of the original airplane.We show three popular types; standard,

sport, and military. Color scheme information's provided later in the instructions.

We’re sure that you will enjoy countless hours of flying fun with your Goldberg Cub, just as generations of pilots have had with

theirs!

Optional Parts

For Door Details

1/16” black CG Color-Stripe tape

Pilot figure (2” Scale)

“Pitts” type muffler (2-cycle only)

Small tube silicone caulk

Zap Formula 560 canopy glue

For optional “Military L-4” Scheme

WWII decals (various manufacturers)

Paint for Fuse Interior

Small spray can (gray)

Paint for Engine Detail

Artist’s acrylics, etc.

For simulating tail bracewires

1/16” nom. x36” elastic cord

Optional “Scale” Gear Struts

.025 x1/4” x2” brass strip

CG 1/16” Threaded Couplers (No.

217)

CG Mini-Snaps (No. 210)

5/32” O.D. dia. x 10” brass tube

3/32” O.D. dia. x 7” brass tube

Soldering iron, etc.

Tools & Supplies Needed

(You probably already have most of these)

Miscellaneous rubber bands

Wax paper or plastic wrap

Modeling knife or single edge razor blade

Sandpaper block & sandpaper; any grade 100

to 200, and any grade 240 to 320

A few dozen straight pins (“T” pins best)

Light power or hand drill & drill bits (sizes

1/16”,

3/32”, 1/8”, 5/32”, 3/16”, & 1/4”)

Three Allen wrenches (1/16” for #6 set screw

and 3/32” for #4 & 7/64” for #6 socket head

screws)

Flat building board (that you can push pins

into)

24” x 60”

Pliers

Small screwdrivers (1/8” and 3/16” blade tips)

Iron for applying covering (small household or

travel iron may be okay.

Masking, drafting, or scotch tape (for Holding

parts during assembly)

Carl Goldberg Products, Ltd.

P.O. Box 818 Oakwood, Ga. 30566 Phone 678-450-0085 Fax 770-532-2163 www.carlgoldbergproducts.com

©copyright 1985 Carl Goldberg Products, Ltd. Pt. #2077 issue #2 4-1-94

Instructions

Cub

2

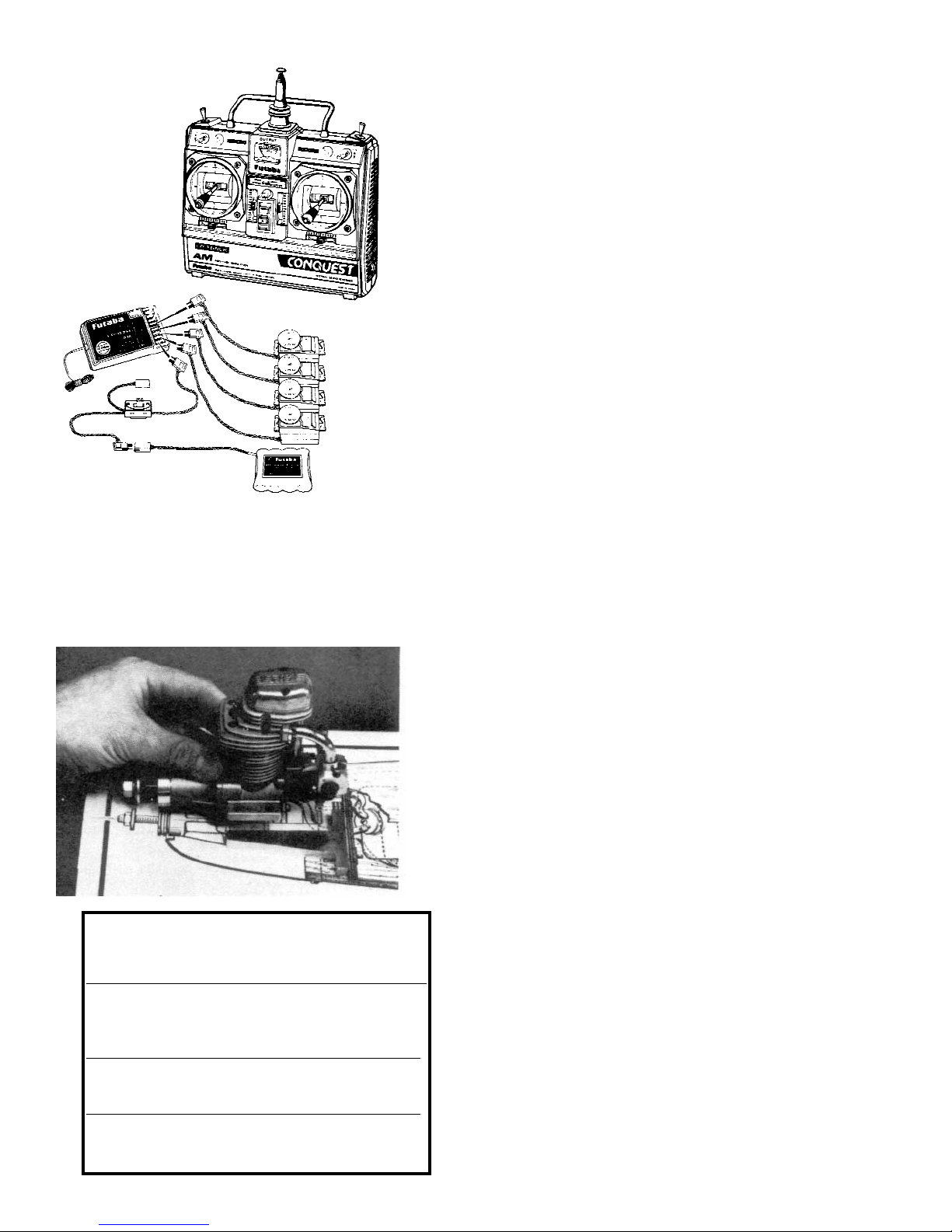

Digital proportional

Radio Control

One of many systems available,

please see your local dealer or

club for advice on selecting

your radio.

PROP AND FUEL TANK CHART

NUMBERS IN PARENTHESIS

REFER TO 4-CYCLE ENGINES

___________________________________________

FOR USE AND

ENGINE PROP TANK

SIZE SIZE SIZE

___________________________________________

.40-.51 10/6, 11/4, 11/6 8-10 OUNCE

(.40-.49) (12/6) (8)

___________________________________________

.60-.61 12/6 12 OUNCE

(.60-.91) (14/6) (10-12)

Selecting Radio Control Equipment

The Cub is designed for 4-channel radio control equipment. Many of the

radio systems now available feature “servo reversing” switches which allow you to

reverse the response of the servo. This feature simplifies radio installation and is a

worthwhile consideration when selecting a radio system.

Engine & Propeller

The Cub flies well using any engine size from .40 to .61 (.90 4-cycle). cubicinch

displacement. If you live in a warm climate, or your flying field is approximately

3,000 feet or more above sea level, you should use a .49 engine or larger. The propeller size must be matched with the engine. For example, a .40 engine may use a

10” diameter prop, while a .61 uses 11”. Refer to the prop and fuel tank chart at

lower left.

Balancing your propeller helps to protect your radio from the damaging

effects of vibration. Good balancers are on the market, and generally are

easy to use. We recommend sanding or scraping the heavy blade on the

curved face rather than the flat face, and out near the tip. Try to maintain the normal

airfoil curvature. And avoid scratches which might cause the prop to break.

Adhesives

All our test models were built using cyanoacrylate glue(CA) which is

specially formulated to firmly glue the plywood, hardwood, plastic, and balsa used

in your Cub, and we strongly recommend it. Other good glues to use are“15 Minute

Epoxy” or Aliphatic Resin. They will, however, add considerably to the assembly

time required (they dry a lot slower than CA). Also, Aliphatic Resin does not glue

plastic, so you will need one of the adhesives mentioned above (or similar) for the

plastic parts.

IMPORTANT!

In a few specific areas of assembly we suggest the use of thin type of instant glue (

CA) for example, sheeting the leading edge of the wing.

Other than when specifically recommended, these thin types of glue

should not be used since they do not glue plywood adequately and also

require that your work must be near perfect. Be careful when using instant glue to

install windows, as applying too much glue can sometimes cause fogging to occur.

This can be easily wiped off with a damp rag. A sure way to avoid fogging is to use

either epoxy or Zap Formula 560 canopy glue.

After you have finished gluing the model together, go back and re-glue all the

joints for added strength, and just in case some joints may have been

missed the first time. Be careful not to use too little glue. Too little leaves a

model weak. Since CA almost eliminates waiting for glue joints to dry, you can

work straight through and finish each assembly by following the step-by -step building sequence. If you use epoxy, you can save time while waiting for one assembly to

dry (the stabilizer, for example) by turning a few pages ahead and starting another

part (the fuselage, perhaps). Check-off boxes are provided at each step so you can

tell at a glance what steps you have completed.

Tack-Cementing. Sometimes it is necessary to temporarily glue a part

in place that must later be removed. To provide for easy removal of the part

without damage, it should have been glued in place using only a small dab of glue.

This is referred to as “tack-cementing” later on in the instructions.

Using Cyanoacrylate Glue. CA lets you b uild almost as fast as your hands

can press parts toghether! When pressed into a very thin layer, it sets almost instantly. So be careful, read instrluctions thoroughly and use check-off boxes to avoid

errors (like building two right-hand wings-instead of a left and a right)! CA allows

only for momentary positioning of parts. So be sure to trial fit parts toghether to

check fit and placement before applying glue. After its initial bond, CA continues to

strengthen. CA sets up a bit slower with plywood and hardwood, so hold such joints

together a little longer than you would for balsa. CA in corners takes a while longer

to dry because of its not being a thin layer. The tendency for all instant glues to set

slower on hardwood or plywood and when in a thick layer can be elilminated by

using Kicker, an accelerator for cyanoacrylate glue. Kicker bridges greater gaps,

speeds up slow bonds, and provides strong joint fillets.

Using Epoxy. Epoxy comes in two parts which need to be mixed before

using. Paper cups and wood coffee stirrers are useful for ixing. When

buying epoxy, check the package to see how long it takes to set (some formulas\

set in 5 minutes, others may take hours). We recommend 15 minute

3

epoxy. Disposable wood strips, cotton swabs, cheap stiff bristle brushes, or acid brushes from auto stores make good applicators.

Because epoxy is so thick, it’s easy to apply too much. If you use epoxy to build the entire model be especially careful to use sparingly

when assembling fin, stabilizer, and wing.

Caution

Some people may experience allergic reactions when exposed to fumes from instant glue or epoxy. This is very rare. However, it is always

important that such glues, and also paints, thinners and solvents, be used with adeqquate ventilation to carry fumes away.

Windshield

The Cub windshield was carefully designed to realistically duplicate the distinctive lines of the original, yet still be easy to install. For good final

appearance, follow instructions carefully, especially those dealing with removing scrap plastic from windshield base and its’ installation. If tinted

windows are desired, do not try to dye them (the plastic does not dye well).Instead, we recommend “transparent” spray enamels be carefully

applied to the inside window surface (they are not fuel proof).

Covering The Model

The full size Cub is of wood and metal construction, which is covered with fabric. The fabric is then painted. For your model, fabric types of covering duplicate the fabric appearance of the full size airplane quite realistically. There are many good covering materials available that have good

resistance to tearing and punctures. General information on applying iron-on covering can be found on page 22. Because of specific differences in

the application of various brands of covering, make sure instructions have been provided by the manufacturer of the covering you select.

Clipped Wing Option

The shortened wing for this option is accomplished by cutting the spars, leadings edges, etc. to the shorter lengths shown on the plan. This is

fully described at the beginning of the wing assembly.

4

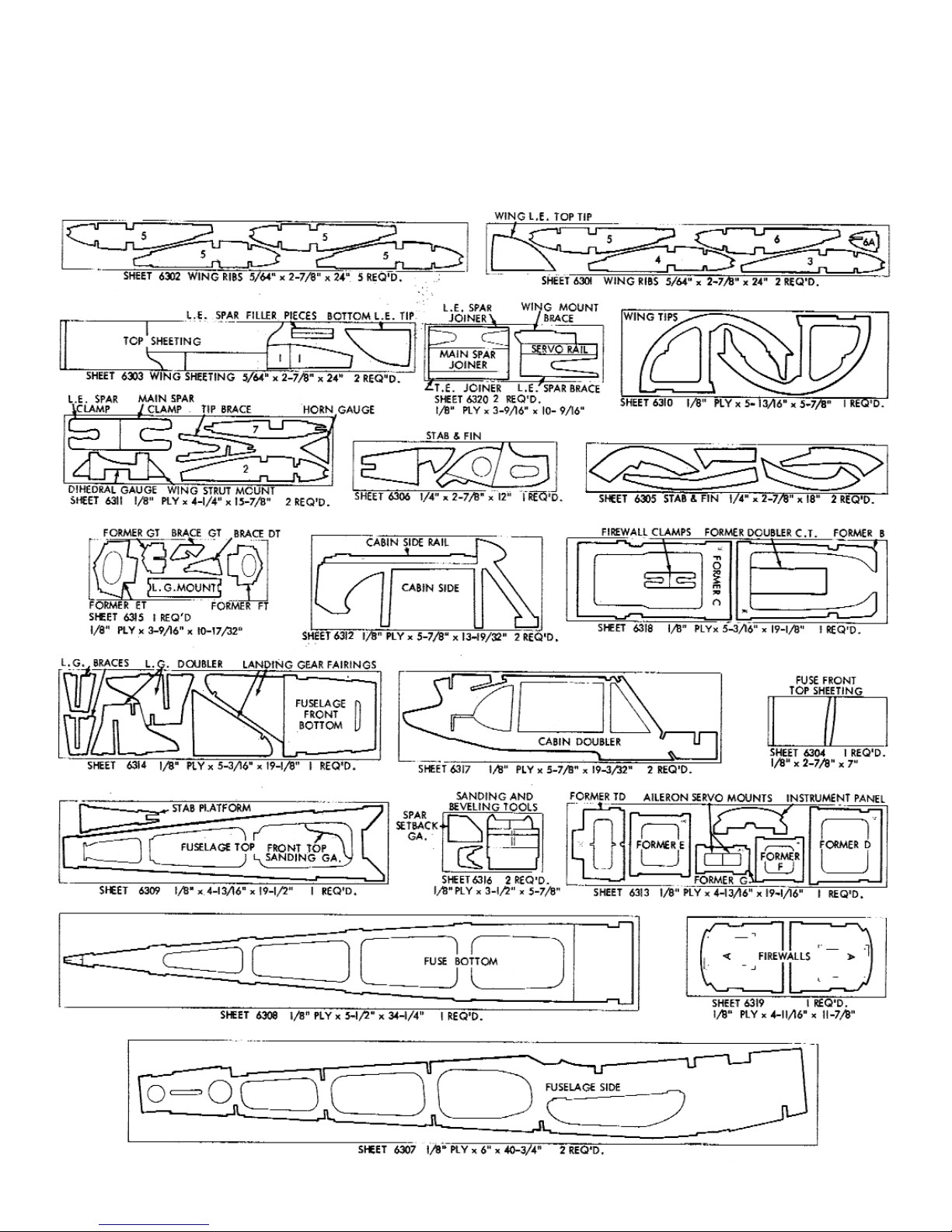

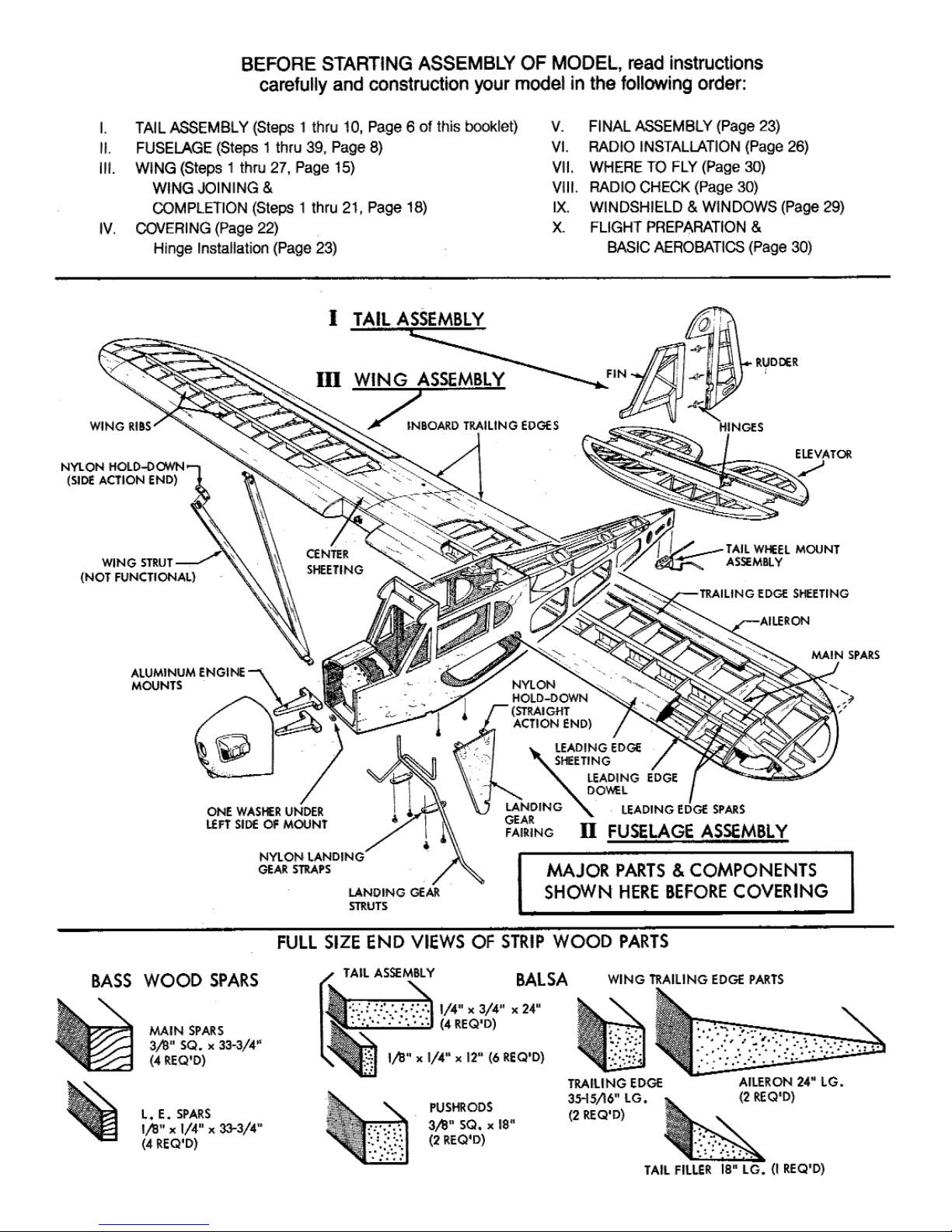

Be careful when removing parts (such as fuselage sides)

from die-cut sheets. Long parts are fragile until glued into a

structural unit. If necessary, use a razor knife or razor saw

to assist in the removal of parts from sheet. Sometimes a

little trimming and sanding can improve parts where

desired. Save scrap until model is completed, in case you

should miss a part. Scrap is used also in some building

steps on the plan. Other easily recognized parts, such as

engine bearers, are not shown here.

Wood Parts Identification

5

6

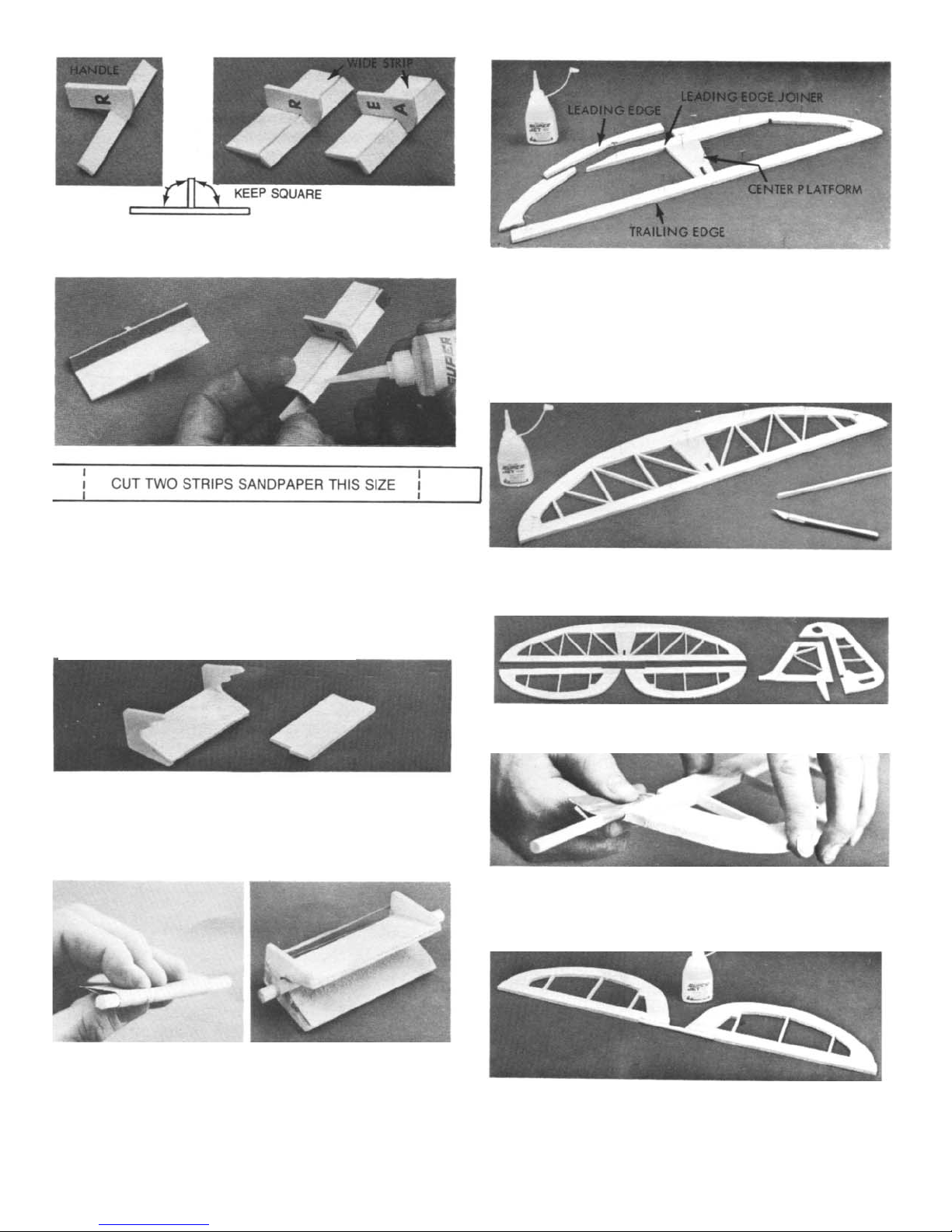

1. First, glue narrow strip to handle, keeping them

square, as shown above left. Then glue wide strip to

handle and narrow strip, again keeping things square.

2. Cut two strips of 100-200 grit sandpaper to size shown

above. Tack-cement sandpaper to tools as shown.

Die-Cut Sanding Tool

1. Glue one strip into handles notches keeping them

square. Then glue remaining strip to other half of handles.

2.

Cut one piece of 100-200 grit sandpaper to size of

2-1/4” x 3”.

Center 1/4” dowel over grit side of sandpaper. Roll

sandpaper around it as shown above left.

Slide dowel and sandpaper into tool and hold with

rubber band as shown at right. Glue sandpaper to tool.

1. From 1/4” x3/4” balsa stick material, make stabilizer

(stab) trailing edge (T.E.). Cut balsa carefully to match

with plan at ends. Pin in place.

Position and pin die-cut center platform over plan. Cut

stab leading edge (L.E.) joiner from 1/4” x 3/4” balsa to

match with plan and pin in position.

Assemble die-cut curved L.E. segments to form stab

outline, glue all parts together.

2. From 1/8”x 1/4” strip balsa, cut all trusses to size over

plan. Trim to fit well-don’t force into place. Glue in place.

Let dry thoroughly.

3. Assemble elevator halves, fin and rudder in same

manner as stab, using die-cut and stick parts.

4. Wrap 100-200 grit sandpaper around 1/4” x4-1/2”

dowel. Carefully sand recessed area in elevator L.E. so

dowel will fit flush with front of elevator.

Repeat for other elevator half.

Carefully align L.E.’s of elevators over plan and pin in

place. Join them with the 1/4” dowel, glue it securely in

place! Let dry thoroughly.

7

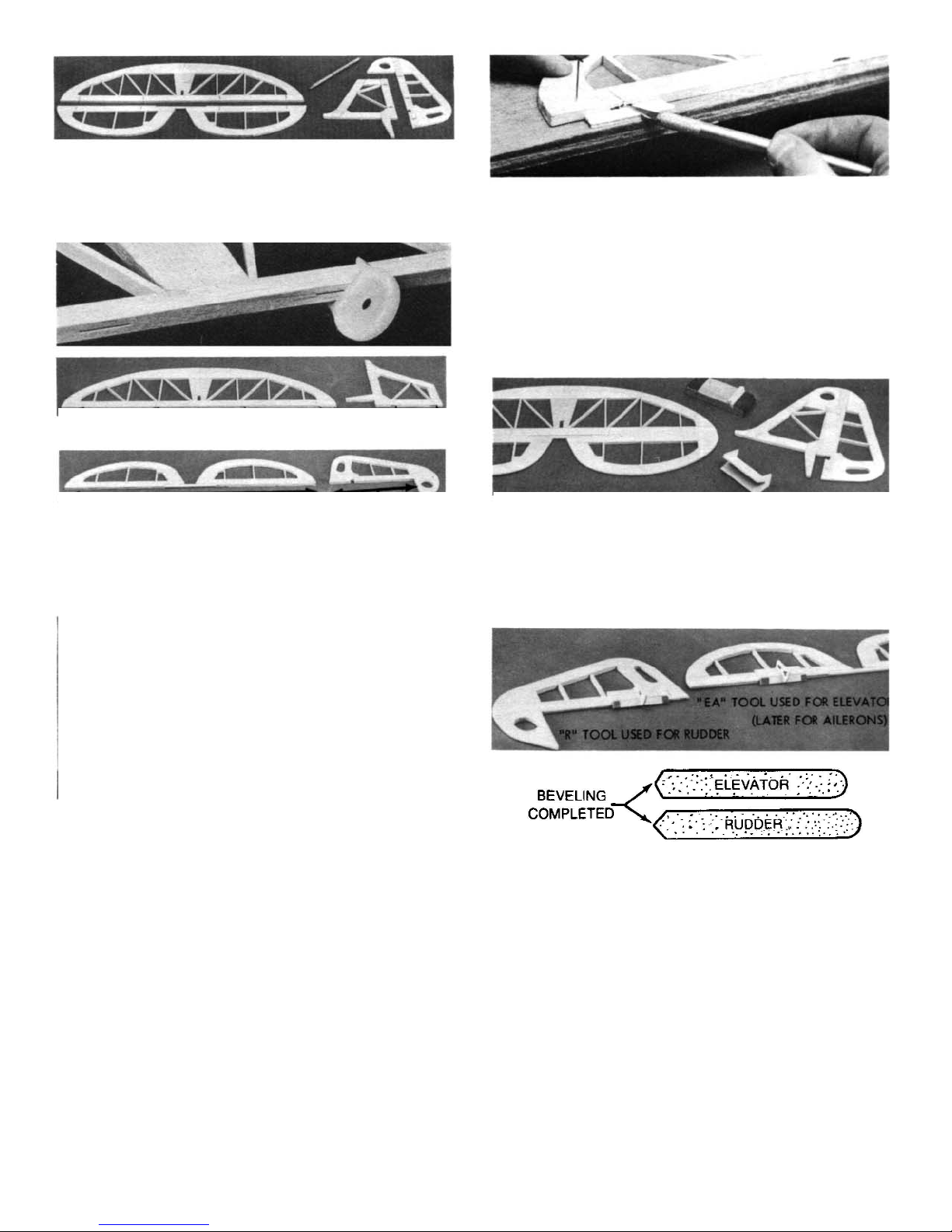

5. Place fin and rudder over plan and mark hinge location

Mark hinge locations for stab and elevator.

On stab & fin, mark center lines at hinge locations

On elevator & rudder, mark center lines along entire L.E.

6.

Using CG Center-Line marker provided, mark center-

lines along edges of parts as shown above. Tilt marker so

guide pegs touch the wood., then lightly pass the marker

back and forth. Point will scribe center line.

Using scrap ply from “sanding tool” sheet as a shim,

cut slots for hinges as shown. Sand ply if necessary so

blade cuts on center.

8.

Repeat this method in step 7 for fin and rudder.

First break corners with the sanding block. Then,

follow with stab sanding tool, rounding off all outside

edges except bottom of fin and the rudder L.E. Blend stab

and elevator at tips.

IMPORTANT! The hinges are not

9. Using a sanding block, flat sand stab, elevator, fin

and rudder, smoothing out surfaces.

Using no glue, TEMPORARILY attach elevator to stab

and fin to rudder with hinges in place. Hold parts together

with tape.

10. Remove tapes and separate elevator and rudder from

stab and fin.

Tape T.E. of elevator and rudder to work surface,

using

appropriate beveling tool, sand L.E. to center line.

Turn parts over and repeat beveling for other side.

THIS COMPLETES THE TAIL ASSEMBLY

CONSTRUCTION.

8

II FUSELAGE ASSEMBLY

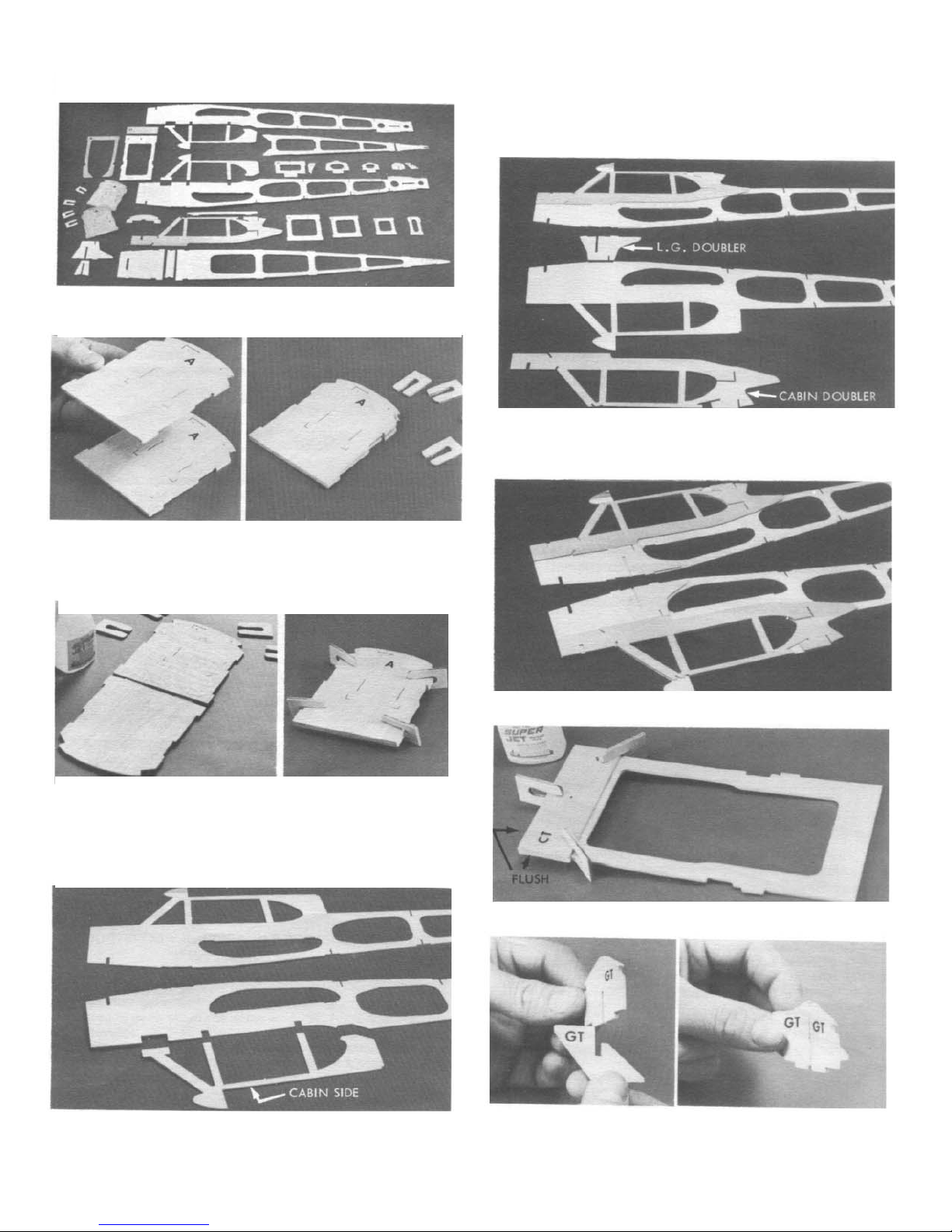

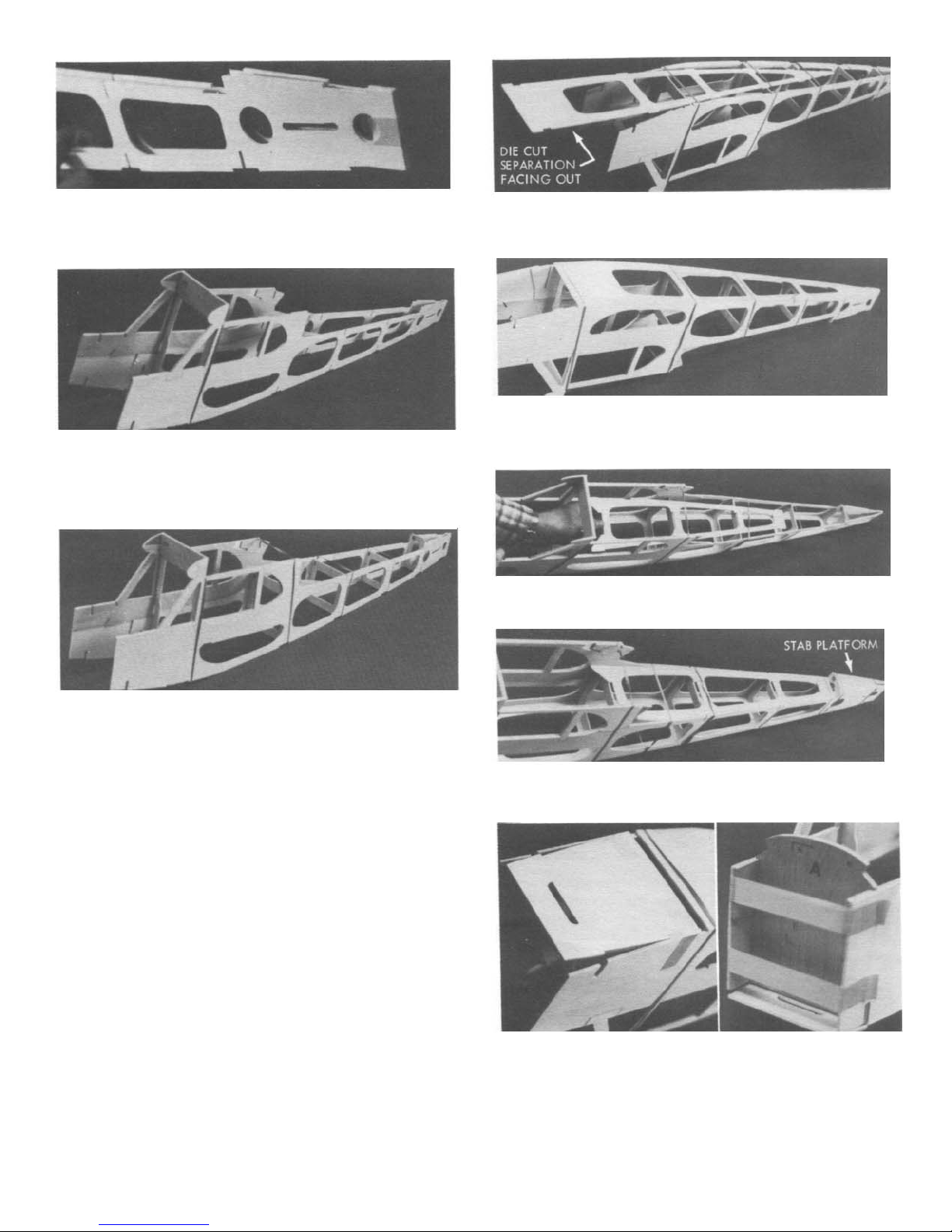

1. Carefully remove all fuselage (fuse) parts from die-cut

sheets. Lightly sand any rough edges.

2. With side stamped “A” facing out, position two 1/8”

ply formers (firewall) together, matching all edges. To hold

them in alignment, tape them securely together along one

edge as shown at right. Have four ply clamps ready for

next operation.

3. Open firewalls and apply a liberal amount of glue to

one part as shown at left.

Keep edges aligned as you close firewalls and tape

opposite edges together, squeeze firewalls together using

die-cut clamps. When dry, remove clamps and tapes; set

clamps aside for use later.

Temporarily position cabin sides in notches. Check

f it and ;placement of parts before gluing.

Glue cabin sides to fuse.

Temporarily position cabin and landing gear (L.G.)

doublers on fuse side, checking fit and placement before

gluing.

Glue cabin and L.G. doublers in place.

5.

Glue former doubler “CT” to former C.

Slide brace GT fully into former GT. Hold brace

square to former and glue.

9

Glue former brace DT to rear of former DT.

Drill a 1/4” diameter hole through CT & C at punch

mark location.

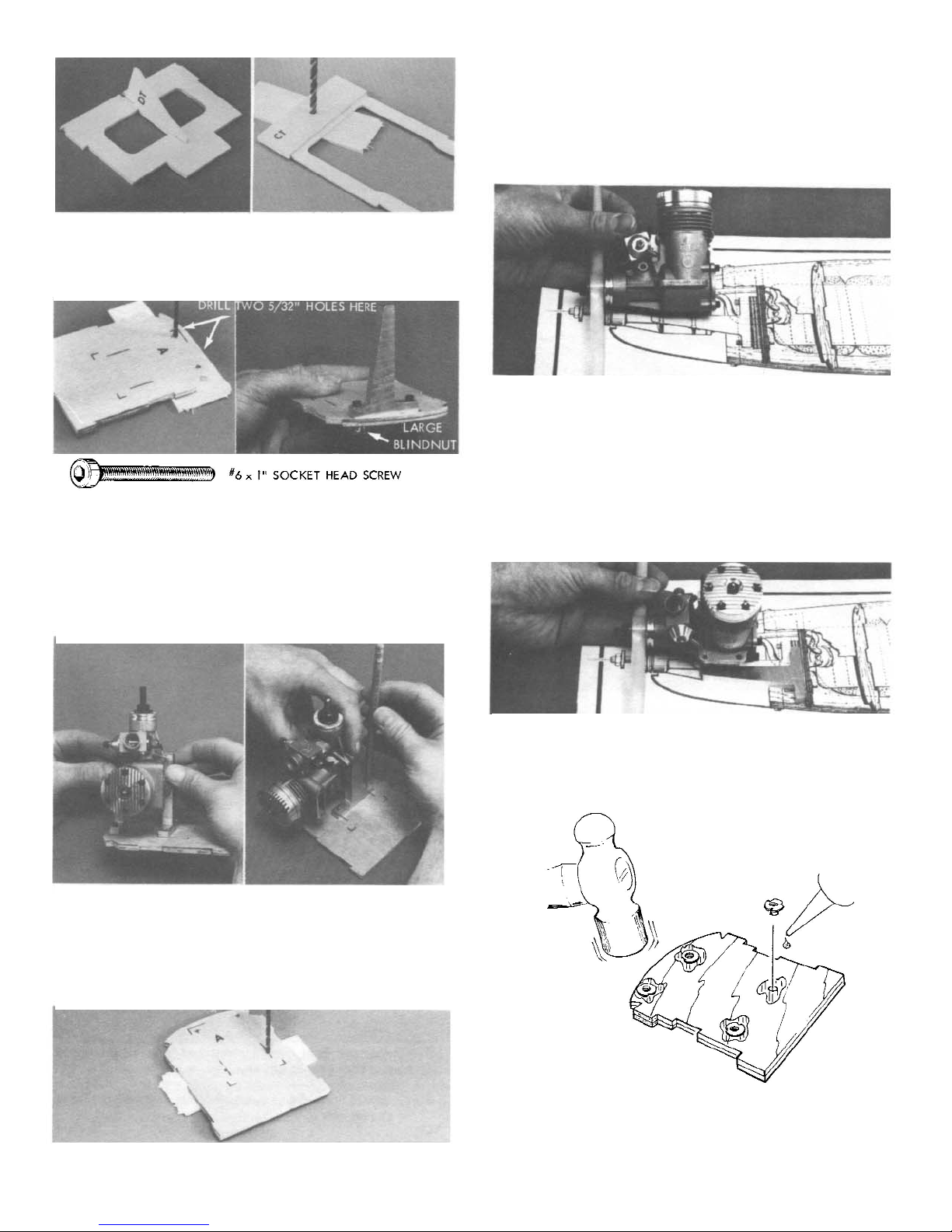

6. Drill two 5/32” diameter holes through firewall at

upper punch mark locations (place scrap wood under

backside while drilling to avoid splitout).

Temporarily install one of the motor mounts, using (2)

#6x1” socket head bolts and blindnuts. Do not pull the

blindnuts into firewall at this time, since they may need to

be removed at a later time.

7. Position the engine between both mounts, holding it

vertical to firewall and parallel to mounts. Spread mounts

apart to match engine mounting holes (there are two

stamped reference lines for positioning mount directly

under the upper one.)

Mark straight down through holes in lower mount.

8. Remove engine and mounts. Drill two more 5/32”

holes at lower mount location.

NOTE: Your kit may include an non-updated plan. The

1/4” ply motor mount extension is no longer needed with the

change to the fiber filled engine mounts now included with

the kit. If you have an older plan, please disregard any

reference to the ply extension.

9. Mount propeller on your engine. Position engine over

fuse top view on plan and compare it to the installation

shown. Back of your prop should protrude 1/8” to 1/4”

beyond the cowl front as shown on the plan. Hold engine

in this location.For long 4-cycle engines, check for at

least 1/8” clearance between engine rear and firewall; to

obtain this clearance the engine may have to be shifted

forward as required. Measure the distance from the

engine rear to the firewall. Write this measurement down,

it will be used later for engine mounting.

10. Position one engine mount, butting its rear flange

against the firewall location shown on the plan. Observe

how the front engine mounting holes relate to the engine

mount.

11. Insert the four blind nuts into the holes on the BACK

side of the firewall. CA glue the nuts to the ply and seat

them into the firewall with a hammer.

10

12a. Place fuse sides one on the other, tape rear

together around the back end. Spread fuse fronts apart,

and plug former “C” into holes in body sides. Hold parts

together with a rubber band.

12b. Hold fuse tail end up, carefully spread fuse rear

open,and plug former “G” in place, hold with a rubber

band. Working towards front, install formers “F”, “E”

and “D” in same manner, using rubber bands to hold

parts.

12c. With die-cut separation facing out, insert bottom

sheet under rubber bands at former “C”, and work it

towards tail, slipping it under bands as you go.

12d. Lock tabs at sides and ends of bottom sheet into

corresponding notches in fuse sides. Hold parts with

tape.

12e. Working through former C, position top sheet in

same manner, sliding it towards rear.

12f. Position stab platform between fuse ends, and hold

parts in place with tape or rubber bands.

13. Position front bottom sheet and tape it securely to

fuse at rear only as shown.

14.

Install firewall and pull fuse fronts toghether with tape

as shown.

Loading...

Loading...