Page 1

Cardinal

Cardinal Scale Manufacturing Co.

®

DIGITAL HANGING SCALE

BATTERY OPERATED

HSDC SERIES

Operation Manual

8551-M256-O1 Rev J

06/05

PO BOX 151, WEBB CITY, MO 64870

PH 417-673-4631 • FAX 417-673-5001

Web site-http://www.cardinalscale.com

Printed in USA

Page 2

2

Page 3

TABLE OF CONTENTS

Introduction .................................................... 1

Specifications ................................................. 1

Battery Installation ......................................... 2

Scale Operation ............................................. 3

Tare Weight Entry ........................................... 4

Display Codes ................................................ 5

Calibration ...................................................... 6

Setup Review ................................................ 10

Sealing .......................................................... 10

Do’s And Don’ts............................................. 10

In Case Of Difficulty ...................................... 11

Office, Washington, DC 20402; Stock No. 004000-00345-4.

INTRODUCTION

Congratulations on selecting a Cardinal Series

HSDC digital hanging scale. This precision

weighing instrument is designed to provide

years of trouble-free operation while

maintaining a high degree of weighing

accuracy. This manual contains information on

the proper care and use of this instrument.

Serial Number_________________________

Date Of Purchase______________________

Purchased From_______________________

_____________________________________

Retain This Information For Future Use

WARNING! This equipment generates and uses

radio frequency energy and if not installed and

used properly, that is, in strict accordance with

the manufacturer’s instructions, may cause

interference to radio and television reception. It

has been type tested and found to comply with

the limits for a Class B computing device in

accordance with the specifications in Subpart J

of Part 15 of FCC Rules, which are designed to

provide reasonable protection against such

interference in a residential installation.

However, there is no guarantee that interference

will not occur in a particular installation. If this

equipment does cause interference to radio or

television reception, the user is encouraged to

try to correct the interference by one or more of

the following measures:

1. Reorient the receiving antenna.

2. Relocate the instrument with respect to the

receiver.

3. Move the instrument away from the

receiver.

4. Plug the instrument into a different outlet

so that the instrument and receiver are on

different branch circuits.

If necessary, the user should consult the dealer

or an experienced radio/television technician for

additional suggestions. The user may find the

following booklet prepared by the Federal

Communications Commission helpful: “How to

Identify and Resolve Radio-TV Interference

Problems.” This booklet is available from the U.S.

Government Printing.

Before using the instrument, read

this manual and pay special

attention to all “Warning”

Symbols.

NOTICE

All rights reserved. Reproduction or use of

editorial or pictorial content, in any manner,

without written, expressed permission is

prohibited. No patent liability is assumed with

respect to the use of the information contained

herein. While every precaution has been taken

in the preparation of this book, the Seller

assumes no responsibility for errors or

omissions. Neither is any liability assumed for

damages resulting from the use of the

information contained herein. All instructions

and diagrams have been checked for accuracy

and ease of application; however, success and

safety in working with tools depends to a great

extent upon individual accuracy, skill and

caution. For this reason, the Seller is not able

to guarantee the result of any procedure

contained herein. Nor can they assume

responsibility for any damage to property or

injury to persons occasioned from the

procedures. Persons engaging the procedures

do so entirely at their own risk.

SPECIFICATIONS

Capacity ......................... see table

Graduation size ..............see table

Tare/Rezero capacity ..... 4% or 100% of scale

capacity

Operating temperature ...-10˚ to +40˚C,

14˚ to 104˚F

Storage temperature ...... -10˚ to +60˚C,

14˚ to 140˚F

Display type....................4 digit, 1" high LCD

Battery requirements ...... 6 each “C” size

alkaline

Weight ............................5 lb

Ultimate safe overload .... 200%

1

Page 4

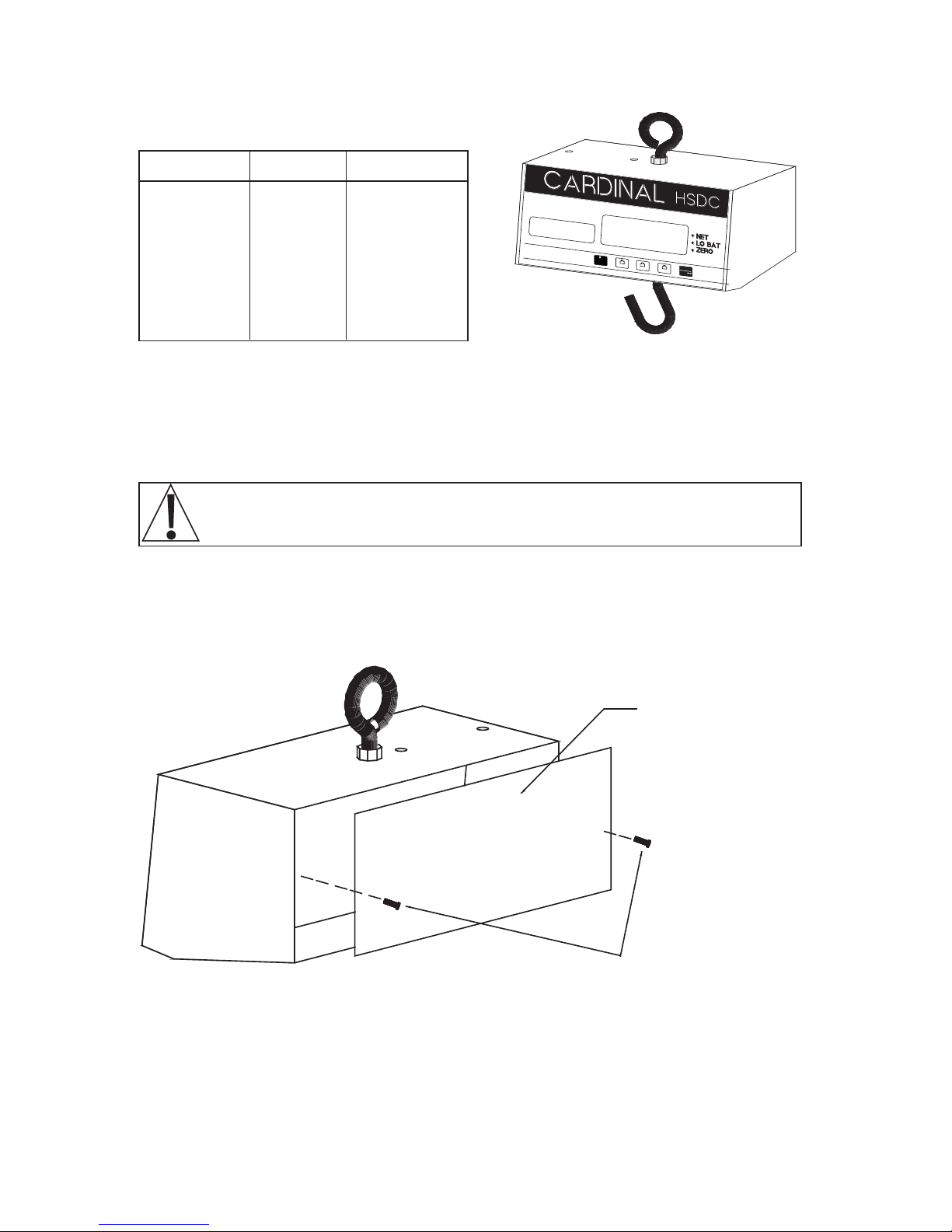

SPECIFICATIONS, Cont.

Model Capacity Graduation

HSDC-200 200 lb 200 x 0.1 lb

HSDC-100 100 lb 99.95 x 0.05 lb

HSDC-40 40 lb 40 x 0.02 lb

HSDC-20 20 lb 20 x 0.01 lb

HSDC-500 500 lb 500 x 0.2 lb

OFF

G

T

GROSS

N

TARE

ON

NET

ZERO

0

HSDC-100KG 100 kg 99.95 x 0.05 kg

HSDC-40KG 40 kg 40 x 0.02 kg

HSDC-20KG 20 kg 20 x 0.01 kg

BATTERY INSTALLATION

Before weighing operations can begin it will be necessary to install the batteries in the HSDC

hanging scale. This same procedure should also be followed when battery replacement becomes

necessary. Make certain that only “C” size alkaline batteries are used as replacements.

NOTE! Exposure of batteries to high temperatures (above 140

° F) will decrease

their capacity resulting in shorter operation time.

Step 1

Using a screwdriver, remove the two retaining screws from the back of the instrument. Remove the

battery compartment cover.

Battery Compartment

Cover

Step 2

Remove the old batteries, if present. Insert six new “C” cells making certain that each cell is

correctly positioned. Refer to the next diagram for proper battery placement.

Remove these screws

2

Page 5

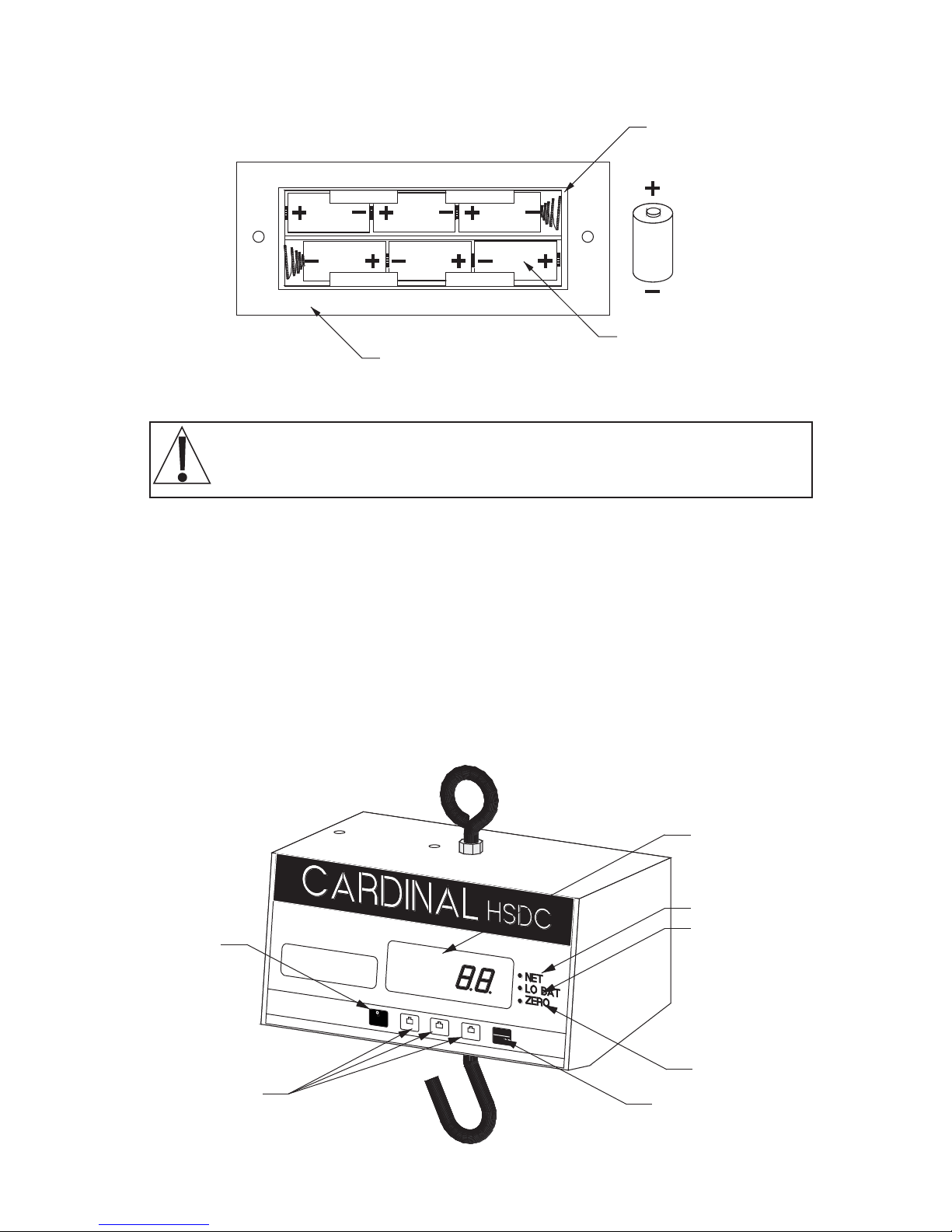

BATTERY INSTALLATION, Cont.

Battery Compartment Cover

Step 3

Replace the battery compartment cover and retaining screws.

NOTE! If the HSDC scale fails to operate after battery replacement check to

make certain that each of the six cells has been installed correctly. One cell

installed backward will prevent the scale from operating.

SCALE OPERATION

Battery Pack

Battery

Before weighing operations can begin it will be necessary to install batteries in the scale. Refer to

the battery installation section of this manual for additional information.

Hang the scale from a support that is strong enough to support the weight of the scale PLUS the

weight of the material that is to be weighed.

Hang the load receiving element on the hook on the bottom of the scale and press the ON/ZERO

key. Look at the weight display. If the display does not indicate zero weight, press the ON/ZERO

key again to reset the display to zero.

Place the material to be weighed in the receiving element and read the weight in the scale display.

Refer to the figure below for the identification of scale components:

Weight Display

Window

Net Annunciator

Low Battery

OFF Key

Indicator

GROSS, TARE

and NET Keys

OFF

G

T

GROSS

N

TARE

ON

NET

ZERO

0

Zero Indicator

ON/ZERO Key

3

Page 6

OFF

GROSS

TARE

N

NET

ON

ZERO

SCALE OPERATION, Cont

Scale Component Identification

Press to turn the scale off. The auto-shutoff feature will turn the scale off automatically after

a preselected time of inactivity (no motion).

Press to place the scale in the gross weight display mode (net indicator off).

G

Press to enter a new tare weight value equal to the current scale weight. The scale will

T

automatically enter the net weight display mode (net indicator on).

Press to enter the net weight display mode without entering a new tare weight value (net

annunciator on).

Press to turn the scale on. If on, press to zero the weight display up to the preset zero limit

0

(4% or 100% of the scale capacity).

The membrane keyboard is not to be operated with pointed objects (pencils, pens,

fingernails, etc). Damage to keyboard resulting from this practice will NOT be covered

under warranty.

Annunciators

NET Illuminated to indicate the scale is in the net weight mode. If it is off, it indicates that

•

the scale is in the gross weight mode.

LO BAT Illuminated to signal that the batteries should be replaced.

•

ZERO Illuminated to show that the scale weight is within 1/4 graduation of the center of zero.

•

TARE WEIGHT ENTRY

The HSDC has an automatic tare feature that allows you to enter tare weight up to the three least

significant digits of the scale capacity. This tare weight feature is often used to subtract the empty

container weight or other unwanted fixed weight values from the weight reading. See the PUSH

BUTTON TARE setup mode section to activate this feature.

The following table lists the maximum tare weight allowed for each model of the HSDC scale.

MODEL CAPACITY MAXIMUM TARE WT

HSDC-500 500 lb X 0.2 lb 99.8 lb

HSDC-200 200 lb x 0.1 lb 99.9 lb

HSDC-100 99.95 lb x 0.05 lb 9.95 lb

HSDC-40 40 lb x 0.02 lb 9.98 lb

HSDC-20 20 lb x 0.01 lb 9.99 lb

HSDC-100KG 99.95 kg x 0.05 kg 9.95 kg

HSDC-40KG 40 kg x 0.02 kg 9.98 kg

HSDC-20KG 20 kg x 0.01 kg 9.99 kg

TABLE 1

4

Page 7

TARE WEIGHT ENTRY, Cont.

Pressing the TARE key will cause the currently displayed gross weight to be stored as the new tare

weight and cause the scale to enter the net weight display mode. The net weight display mode is

indicated by turning on the net annunciator. For example, on a HSDC-20, if the displayed gross

weight is 2.00 lb and you press the TARE key, the 2.00 lb would be entered as the new tare weight.

The scale would then enter the net weight mode and subtract the 2.00 lb tare value from the gross

weight displaying a net weight of 0.00 lb. If you added another 2.00 lb to the platform, the display

would indicate 2.00 lb of net weight. Pressing the GROSS key would return the scale to the gross

weight display 4.00 lb. NOTE: Remember the scale will only weigh to its maximum capacity. Any

combination of NET plus TARE weights over the scale capacity will result in a overload condition

and display ot. For example, using the HSDC-20 from above, with tare weight of 2.00 lb, adding

19.00 lb to the platform will cause an overload condition. This is because 2.00 lb tare weight plus

19.00 lb load weight equals 21.00 lb gross weight, which exceeds the capacity of the scale.

DISPLAY CODES

During operation of the HSDC hanging scale you may encounter a special display message. The

following lists display codes and their meaning.

DISPLAY MEANING

-oC-

UnSt

UnLd

LoAd=

-oF-

CALb

Err

Scale overloaded, remove excess load to resume operation.

Motion is present when attempting to power-up, zero the weight display or enter a

tare value.

The weight on the scale exceeds the zero range on power-on. Remove the load.

The scale load is less than the zero range on power-on.

Attempting to display a negative number less than -999.

Indicates that the scale has not been calibrated or has been interrupted during the

calibration process.

Disallowed keyboard entry: attempted to zero with the weight outside the zero

range.

5

Page 8

CALIBRATION

Your HSDC hanging scale has been calibrated prior to shipment and should not require recalibration before it is placed in service. A regular check of the instrument’s calibration should be

made to ensure that its weighing accuracy is maintained.

To check the calibration of your HSDC hanging scale, you must have a calibrated test weight or

weights equal to the scale’s capacity. Begin by making certain that the scale is unloaded and that

the display is indicating zero weight. Load the scale with the test weight(s) and observe the weight

display. If the displayed weight is different from the total test weight value, calibration may be

necessary. Note that a qualified scale technician should be consulted before any attempt at

calibration is made.

NOTE! This scale is provided with a means of attaching a seal to prevent access

to the calibration switch.

Calibration Procedure

Step 1. Remove the seals (if present) from the calibration cover plate, then remove the two

retaining screws and cover plate.

Retaining Screw

Cover

Plate

Seals

Underside of

Scale

Step 2. Hang the scale from a suitable support and attach the load receiving device. Press the

OFF key. Using a straightened paper clip, press and hold the calibration switch while

pressing the ON/ZERO key. Release the calibration switch when the display shows

int=.

Step 3. Refer to the following steps and enter the required setup parameters.

INTERVAL

int=

Press the NET key to show the current setting. Then press the ON/ZERO key to select

the desired value: 1-2-5. Press the NET key to save.

6

Page 9

DECIMAL POINT

dPP=

CAPACITY

CAP=

WEIGHING UNITS

Unt=

Press the NET key to show the current setting. Then press the ON/ZERO key to

select the desired value:

Press the NET key to save.

Press the NET key to show the current capacity setting. Then press the ON/ZERO

key to advance the flashing digit from 0 through 9 (200.

press the TARE key to advance to the next digit location (20

process until the capacity has been entered. Press the NET key to save.

Press the NET key to show the current setting. Then press the ON/ZERO key to

select the desired value: 1-2 where 1=Pounds Only and 2=Kilograms Only. Press

the NET key to save it.

CALIBRATION, Cont.

0=XXXX 1=XXX.X

2=XX.XX 3=X.XXX

0). Select the value then

0.0). Repeat the

(Please note, although selection 3 will display and can be selected, it is

for the HSDC scale.)

CALIBRATION WEIGHT

Lod=

UnLod

ZERO TRACKING RANGE

trA=

4% ZERO TRACKING LIMIT

trL=

Press the NET key to show the current calibration weight. Then press the ON/

ZERO key to advance the flashing digit of calibration weight from 0 through 9

0). Select the value then press the TARE key to advance to the next digit

(150.

location (15

entered. Place this amount of calibration test weights on the scale, then press the

NET key. The display will show ---- then:

Remove the test weights and press the NET key. The display will show ---then proceed to the next prompt.

Press the NET key to show the current division setting. Values of 0 through 9 and

0.5 are valid for the zero tracking range. Press the ON/ZERO key to step through

and select 0.5 as the division value, then press the NET key to save. If a zero

tracking range division of 0 through 9 is desired, first press the ON/ZERO key to

select 0, then press the TARE key to advance to the next digit location and press

the ON/ZERO key to select 0 through 9 divisions. Press the NET key to save.

Press the NET key to show the current setting. Then press the ON/ZERO key to

toggle between yes and no. YES=4% limit, no=100% limit. Press the NET key to

save. (NOTE: 4% limit is for Canadian use)

INVALID

0.0). Repeat the process until the calibration weight has been

POWER UP ZERO

PUO=

FILTERING

FLt=

F=

Press the NET key to show the current setting. Then press the ON/ZERO key to

toggle between yes and no. YES=enable, no=disable. Press the NET key to save.

Press the NET key to show the current level of filtering. Then press the ON/ZERO

key to select the desired value:

0=no filtering 1=minimal filtering

2=moderate filtering 3=custom filtering

Press the NET key to save setting.

If you select level 3 then:

Press NET to show current filter weight setting. Press ON/ZERO to select filter

weight level (1 through 99,-99 being the greatest filtering and 1 the least). Press

the NET key to save setting.

7

Page 10

BREAKPOINT

b=

MOTION RANGE

UnS=

SAMPLE RATE

Sr=

AUTOMATIC SHUTOFF

ASh=

SLEEP MODE

SLP=

Press NET to show the current break point setting. Press ON/ZERO to select

break point setting (1 through 99). Press the NET key to save setting.

Press the NET key to show the current motion range in divisions. Then press the

ON/ZERO key to select the number of digits to change before motion: 0 through

9. Press the NET key to save.

Press the NET key to show the current sample rate setting. Values of 1 through

12 are valid for the sample rate. Press the ON/ZERO key to select 1 through 9

samples per second, then press the NET key to save. If a sample rate of 10

through 12 is desired, first press the ON/ZERO key to select 0 through 2, then

press the TARE key to advance to the next digit location and press the ON/ZERO

key to select 10 through 12 samples per second. Press the NET key to save.

Press the NET key to show the current setting. Then press the ON/ZERO key to

disable the feature or to select the number of minutes of inactivity before turning off

the scale. 0= disable, 1 to 9= minutes of inactivity before shutoff. Press the NET

key to save it.

Press the NET key to show the current setting. Then press the ON/ZERO key to

disable the feature or to select the number of minutes at zero before going to sleep.

0=disable, 1 to 9=minutes of inactivity before sleeping. Press the NET key to save

it.

CALIBRATION, Cont

PUSH BUTTON TARE

Pbt=

The display will display the software revision number and then the gross weight. The setup and

calibration process has been completed and the scale is ready to weigh. Place the test weight back

on the scale to verify calibration.

Press the NET key to show the current setting. Then press the ON/ZERO key to

toggle between yes and no. YES=enable, no=disable. Press the NET key to save.

8

Page 11

CALIBRATION, Cont

Model

HSDC

int=

dPP=

CAP=

Unt=

Calibration Switch

Table 1 -- Setup Settings for HSDC Models

500

200

2

1

5000

1

1 5 2 2

1 2 2 22 2

2000 2000 2000400040009995 9995

1 1 1 1 1 1 1

2

100

40

Front of Instrument

100kg

20

1 15

40kg

Underside of Scale

20kg

trA=

trL=

PUO=

FLt=

UnS=

0.5

no

1

no no no no no no no

no no no no no no nono

1 1 1 1 1 1 1

1 1 1 1 1 1 11

0.5 0.5 0.50.5 0.50.50.5

Sr=

ASh=

SLP=

Pbt=

End of Calibration Section. Go to Setup Review/Fine Span.

yyyyyyyy

1 1 1 1 1 1 11

2 2 22 2222

trL= YES is for Canadian

use

Skip if FLt= 1 or 2

9

Page 12

SETUP REVIEW

The HSDC allows several operational parameters to be reviewed and changed as necessary

without having to break the calibration seal and enter the setup and calibration mode. The setup

review allows changes to be made to the power up zero setting, the automatic shutoff and sleep

mode delay times, push button tare.

To enter the setup review mode, simply turn the HSDC off, then press and hold any key other than

ON/ZERO or the OFF keys and press the ON/ZERO key. The display will prompt for the power up

zero selection. Refer to the instructions listed in the Calibration Procedure section of this manual for

information on how to change these parameters.

The parameters in the setup review will be processed in the following sequence:

POWER UP ZERO

AUTOMATIC SHUTOFF TIME

SLEEP MODE TIME

PUSH BUTTON TARE

Fine Span

The span can be fine-adjusted while the indicator is on by pressing and holding the calibration

switch and pressing the ON/ZERO or NET key:

Calibration Switch + ON/ZERO = increase

Calibration Switch + NET = decrease

Go to Sealing Instructions

SEALING INSTRUCTIONS

To attach the seals, first make certain the two cover plate retaining screws are snug then thread the

seal wires through the hole in the screw heads as shown in the calibration section of this manual.

DO’S and DON’TS

1. DO hang the scale from a support that is strong enough to support the weight of the scale plus

the weight of the material to be weighed. The more rigid the support the better.

2. DON’T shock load your HSDC hanging scale with weights greater than 10 percent of the scale’s

capacity by throwing the weight on the scale.

3. DO replace batteries as soon as the weight display shows the low battery signal.

4. DON’T hose down or submerse the scale in any liquid.

5. DO use only a damp cloth and mild detergent to clean the outside of the scale.

6. DON’T disassemble the scale. There are no user-serviceable components within the scale.

10

Page 13

DO’S AND DON’TS, Cont.

7. DO use only high quality Alkaline “C” size replacement batteries.

8. DON’T use sharp objects to press the keys. Use only your finger tip.

9. DO check scale calibration regularly to ensure that the high degree of weighing accuracy is

maintained.

10.DON’T modify or replace the loading hook or hanging eye with lower capacity parts.

11.DO remove loads which produce the over capacity (-oC- ) display as soon as possible.

IN CASE OF DIFFICULTY

Your HSDC hanging scale has been designed to provide years of trouble free service. Should you

encounter a problem with your scale refer to the chart below before contacting your scale

technician.

Problem Possible Cause/Solution

1. Scale seems dead A. Batteries improperly installed, make certain each of the six batteries

is correctly installed.

No display B. Batteries are discharged completely, replace with fresh batteries.

2. Incorrect weight A. Scale not at zero prior to applying weight, remove load and reset

display to zero by pressing ON/ZERO key.

B. Scale is not calibrated. Refer to Calibration Section of this manual.

C. Scale in net mode. Press the GROSS key.

If you are unable to resolve the difficulty, contact the Cardinal Scale representive from whom you

purchased the scale. He will be able to provide you with information concerning the return and

repair of your scale. Make certain that you obtain a return authorization number prior to returning

the scale. This number should appear on the shipping carton and all correspondence referencing

the repair. Failure to obtain a return authorization number will result in unnecessary delay.

11

Page 14

2

Page 15

2

Page 16

U

N

A

M

&

E

D

S

I

G

U

N

E

D

F

A

C

T

R

E

D

I

N

U

S

A

.

.

.

U

N

A

M

&

E

D

S

I

G

U

N

E

D

F

A

C

T

R

E

D

I

N

U

S

A

.

.

.

Loading...

Loading...