Cardinal Health MedSystem III Service bulletin

Cardinal Health

San Diego, CA

Authorized EU Representative

Cardinal Health

Basingstoke, UK

Service Bulletin 404D P/N 10999653

Service Bulletins are supplements to Cardinal Health Technical Service/Maintenance Manuals.

A list of Service Bulletins can be found at cardinalhealth.com/alaris.

Model Affected: MedSystem III® Infusion Pump Multi-Channel, Model 286X

Date: June 2008

Subject: Level of Testing Guidelines/Functional Test Updates

This supersedes Service Bulletin 404C, to provide information related to the use of Model 1561C

and

1565C AC Adapters.

PURPOSE

The purpose of this bulletin is to provide Biomedical Technicians the following:

• A Level of Testing Guidelines table, to replace all existing references to testing required after repair

(reference “Repair” chapter of Service Manual).

• A new Audio Test, and updated procedures for Electrical Safety and Run-In tests (reference “System

Functional Tests” chapter, and “Procedures Following Repair” section in “Repair” chapter of Service

Manual).

• Procedures to help troubleshoot:

NiCad battery problems (reference “NiCad Battery Problems Table” in “Troubleshooting” chapter

of Service Manual).

Instrument memory loss problems.

• Information related to release of Model 1561C and 1565C AC Adapters.

This is reference information only

Technical Inquiries: United States: 888.876.4287

Canada: 800.387.8309

United Kingdom: 0800.389.6972

International: cardinalhealth.com/alaris (for contact information)

and is not intended to suggest a need for component changes.

ALARIS® and MedSystem III® are registered trademarks of Cardinal Health, Inc. or one of its subsidiaries.

All other trademarks belong to their respective owners.

©1996, 20004, 2008 Cardinal Health, Inc. or one of its subsidiaries. All rights reserved.

Page 1 of 12

Service Bulletin 404D P/N 10999653

EXPLANATION

• The tests currently specified in the service manual as being required after repair/reassembly might

not reflect current testing requirements or recommendations. To help provide the most current

minimum test requirements and recommended tests, a Level of Testing Guidelines table has been

provided.

• The Electrical Safety and Run-In tests currently specified in the service manual have been replaced

to provide the current test procedures (Electrical Safety Test, Run-In On AC Power). An Audio Test

procedure has been provided to check the audio volume.

• Procedures have been provided to verify:

NiCad battery is being charged within specification (NiCad Battery Charge Current Test).

Current drawn from NiCad battery, when instrument is operating on battery power, is within

specification (Standby Current Test).

NiCad battery can provide sufficient instrument operating time after being discharged and

recharged (Battery Functional Test).

Current drawn from backup battery, when instrument is off, is within specification (RAM Standby

Current Test).

Models 1561/1565 (see illustrations in “Electrical Safety Test” section)

power, is double insulated as a medical grade power adapter and does not require a connection to earth

ground. Models 1561/1565 are compatible with all previously released MedSystem III

has only two connections to AC

®

Infusion Pumps.

Certification to the applicable standards for ElectroMagnetic Compatibility (EMC) has been validated by

TÜV America.

NOTE: Model 1561 is ordered as 143032 and or Model 1565 is ordered as 2861089

REFERENCES

Model 2860/2863 Technical Service Manual (identified as P/N 139981; ordered as P/N 2863012)

Applicable Field Maintenance Software Operating Instructions (FMS DFU)

Applicable Instrument's Directions For Use (DFU).

PARTS AND TOOLS REQUIRED*

• Equipment referenced, as necessary, under each test procedure in this Service Bulletin.

• Appropriate field Maintenance Software (FMS) Kit.

* These are in addition to parts, tools, and equipment referenced in the service manual.

Page 2 of 12

Service Bulletin 404D P/N 10999653

RECOMMENDED ACTION

CAUTION

Turn the instrument off and disconnect it from AC power before disassembly. Static

charges will damage instrument circuitry. Observe proper grounding techniques (use

grounding strap) to prevent possible harm to static-sensitive components.

Add this Service Bulletin to the Technical Service Manual, as a supplement to the “System Functional

Tests”, “Troubleshooting”, and “Repair” Chapters.

NOTE: Restoration of Configured Parameters, Battery History Log Memory contents,

serial number, and special message can be corrupted during repair. Field Maintenance

Software (FMS) may have been used to customize configuration settings or program drug

lists for Dose Rate Calculator. All settings should always be verified for accuracy after

repair. For reprogramming instructions, refer to the appropriate FMS DFU.

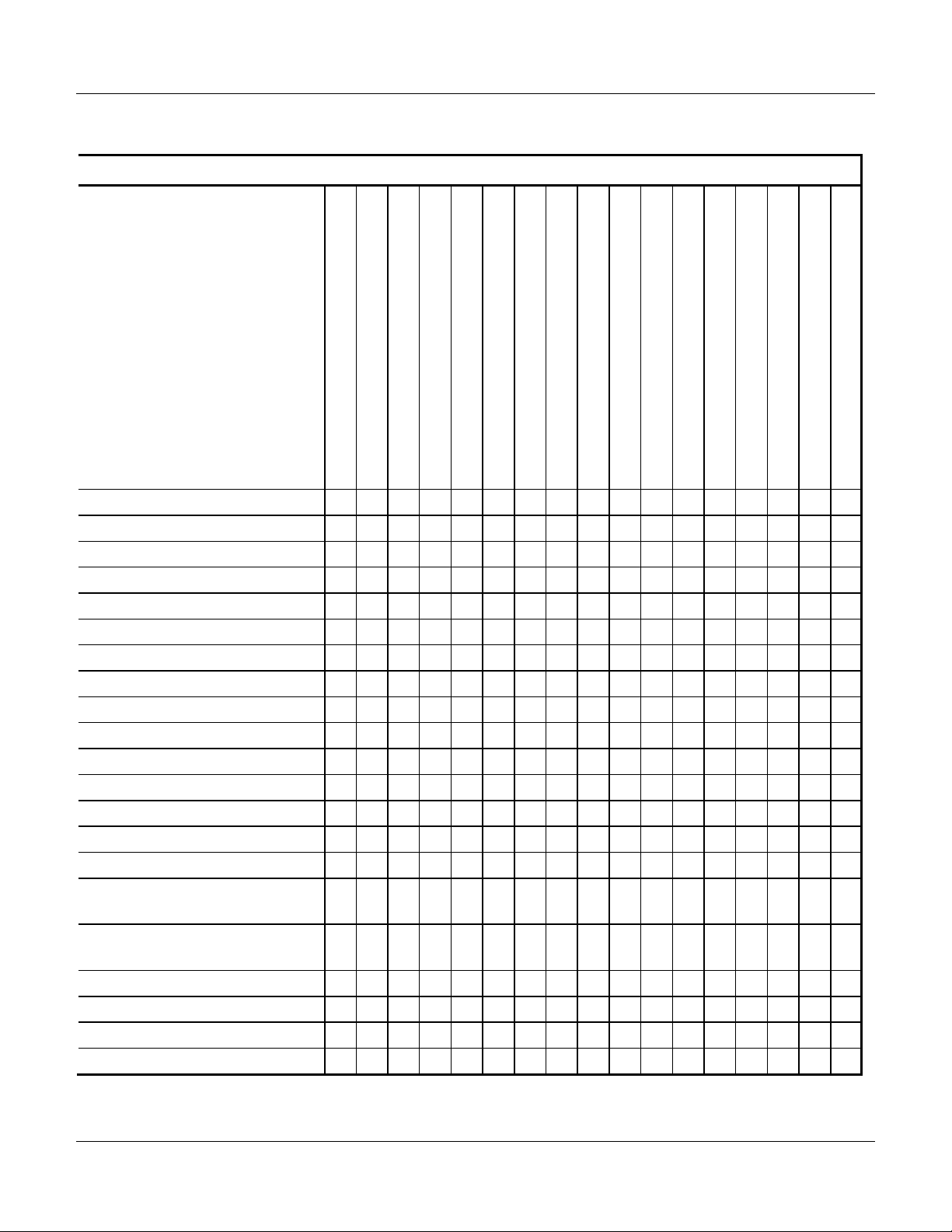

1. Level of Testing Guidelines

Any instrument repair or disassembly requires testing, determined by the level of the repair/

disassembly. Use the Level of Testing Guidelines, Table 1, in place of the test requirements

specified in the “Repair” chapter of the Service Manual.

Repair or replacement of the following parts does not require testing unless part of a higher level

repair, as listed in Table 1.

• Chassis Mounts

• Dust Cap

• Lower Housing Assembly

• Universal Pole Clamp

Page 3 of 12

Service Bulletin 404D P/N 10999653

RECOMMENDED ACTION (Continued)

Table 1 Level of Testing Guidelines

Tests to Perform ·

O = Required

= Optional

Repair/Replacement of Ð

No Fault Found

Adapter

Air-in-Line Sensor

Audio PCBA (Side Bd. Assy.)

Backup Battery

Battery Pack

Display Module

Drive Module Assembly

EPROM Module

Main Housing Assembly

MEA (Logic Board Assy.)

Optomodule

Power Supply Board Assembly

Power Supply Fuse

Pressure Transducer

Pump Latch Assembly and Shaft

Seal (case was removed)

Battery Charge Current Test

Standby Current Test

RAM Standby Current Test

Pump Latch Height Adjustment (7.3.2)

Valve Actuator Height Verification (7.3.6)

Full Calibration using FMS (5.0)

O O

O O

O

O O O O O O O O

O O

O

O O O O

O O O

O O O O O O O O O O

O O O O

O O O

O O O O O

O O O O O O

Electrical Safety Test (3.1)

Power Tests (3.2)

Cassette and Sensor Test (3.3)

O O

O O

O O

O O

O O

O O

O O

O O

PSOD Test (3.4)

FSOD Test (3.5)

AIL Test (3.6)

Volume Accuracy Test (3.7)

Watchdog Audio Test (3.9)

Audio Test

Battery Functional Test

Run-In AC Power

O

O

O

O

Pump Latch Assy. and Shaft Seal

(case was not removed)

Pump Latch Movable Jaw

Pump Shaft

Slide Link

Valve Actuator Assembly

O

O O O O O O O O

O

O O O O O O O O

Page 4 of 12

O O

O O

O O

O

O

O

O

Loading...

Loading...