Page 1

Cardinal®

OPERATION MANUAL

MSB-25 Series

25 Pound Capacity

Counter Type

Electronic Scale

8540-M222-O1 Rev

07/10

C

© Cardinal Scale Manufacturing Company

P.O. Box 151, Webb City, MO 64870

PH: (417) 673-4631

Printed In U.S.A.

Page 2

Page 3

TABLE OF CONTENTS

PART 1 Description

1.1 Introduction

1.2 Purpose

1.3 Description of scale

1.4 Principles of operation

1.5 Precautions

PART 2 Specifications

PART 3 Unpacking, Installation and

Preparation for use

3.1 Unpacking

3.2 Placement

3.3 Level adjustment

3.4 Power supply connection

PART 4 Operation

4.1 Key functions

4.2 LED indicator functions

4.3 Operation: weighing, sampling and counting

4.4 Test mode

PART 5 Calibration

PART 6 Serial Interface

6.1 Purpose

6.2 Interconnection

6.3 Message format

PART 7 Care and Maintenance

PART 8 Parts Breakdown

8.1 Exploded View

8.2 Parts list

1

Page 4

1.0 DESCRIPTION

1.1 Introduction

This manual provides descriptive data, specifications, operating instructions, calibration procedures, care and

maintenance instructions and information on interchangeable parts for the Detecto model MSB-25 scale.

This scale is manufactured by Detecto Scale Co., Webb City, MO 64870.

1.2 Purpose

This scale is designed for the following functions:

1. General purpose weighing of mailable objects up to 25 pounds in weight.

2. Displaying weight of a single mailpiece, number of mailpieces per pound or number of pieces on the

scale after a number of identical pieces have been weighed.

3. Manual entry of a tare weight or automatic zeroing of weight on the scale, for purpose of using a

container for weighing.

4. Ability to display weight digitally in pounds and ounces or in pounds only.

5. Perform all of the above functions with an input from a remotely located weighing device.

6. Direct output of data to a printer or other device.

1.3 Description of scale

The Detecto MSB-25 is a ruggedized, fully-electronic digital weight indicator employing a single-point load

cell, stainless steel weighing platform, digital electronics, full-travel keypad, LED annunciators to indicate

scale mode, twenty character alphanumeric dot matrix display with 7/16 inch high characters, and serial

interface. Operating instructions are readily visible on a pull-out instruction placard.

1.4 Principles of operation

The scale may be used to display weight; either gross weight or net weight (gross minus tare). Displayed

units may be either pounds or pounds-ounces format. Known container tare weight may be entered via the

keyboard. Unknown container tare weight may be zeroed off. An average weight per piece of identical mail

pieces may be taken from a known sample quantity. The sample quantity must be large enough to total 0.2

lbs of weight. The default sample quantity is 10 pieces, however a more convenient sample quantity may be

selected via the keyboard. The weight per piece or pieces per weight may be displayed. Number of pieces

(count) may also be displayed.

1.5 Precautions

Before using this instrument read this manual and pay special attention to all "WARNING" symbols:

IMPORTANT ELECTRICAL WARNING

2

Page 5

Power requirements: 110/120 VAC, 60 Hz

Count capacity: 999,999

Weight resolution: 1 part in 8,000

2.0 SPECIFICATIONS

Computing resolution: 1 part in 16 x 10

6

with floating decimal

Dimensions: 5" H x 17" W x 21" D

Weight: 28 lb

Operating temperature: 32° F - 104° F (0° C - 40° C)

Weighing accuracy: This equipment is manufactured in

accordance with the recommendations

set forth by Handbook #44, issued by the

United States Department of Commerce,

National Insitute of Standards and

Technology.

Capacity: 25 lb x 0.05 oz (0.005 lb)

3

Page 6

3.0 UNPACKING, INSTALLATION AND

PREPARATION FOR USE

3.1 UNPACKING

Inspect the scale for any signs of damage due to shipping such as loose

screws or exterior dents and scratches on the covers and case. Keep

carton and packing for return shipment of scale if necessary. It is the

responsibility of the purchaser to file all claims for any damages or loss in

transit incurred, unless this responsibility has been accepted by the Seller

in its proposal.

3.2 PLACEMENT

Place the scale on a stable, vibration-free location away from direct

sunlight and away from any rapidly moving air source.

CAUTION!!! DO NOT place the scale on any unstable

cart, stand or table. The scale may fall causing injury to

the operator, and seriously damage the scale, or proper

operation of the scale may be inhibited.

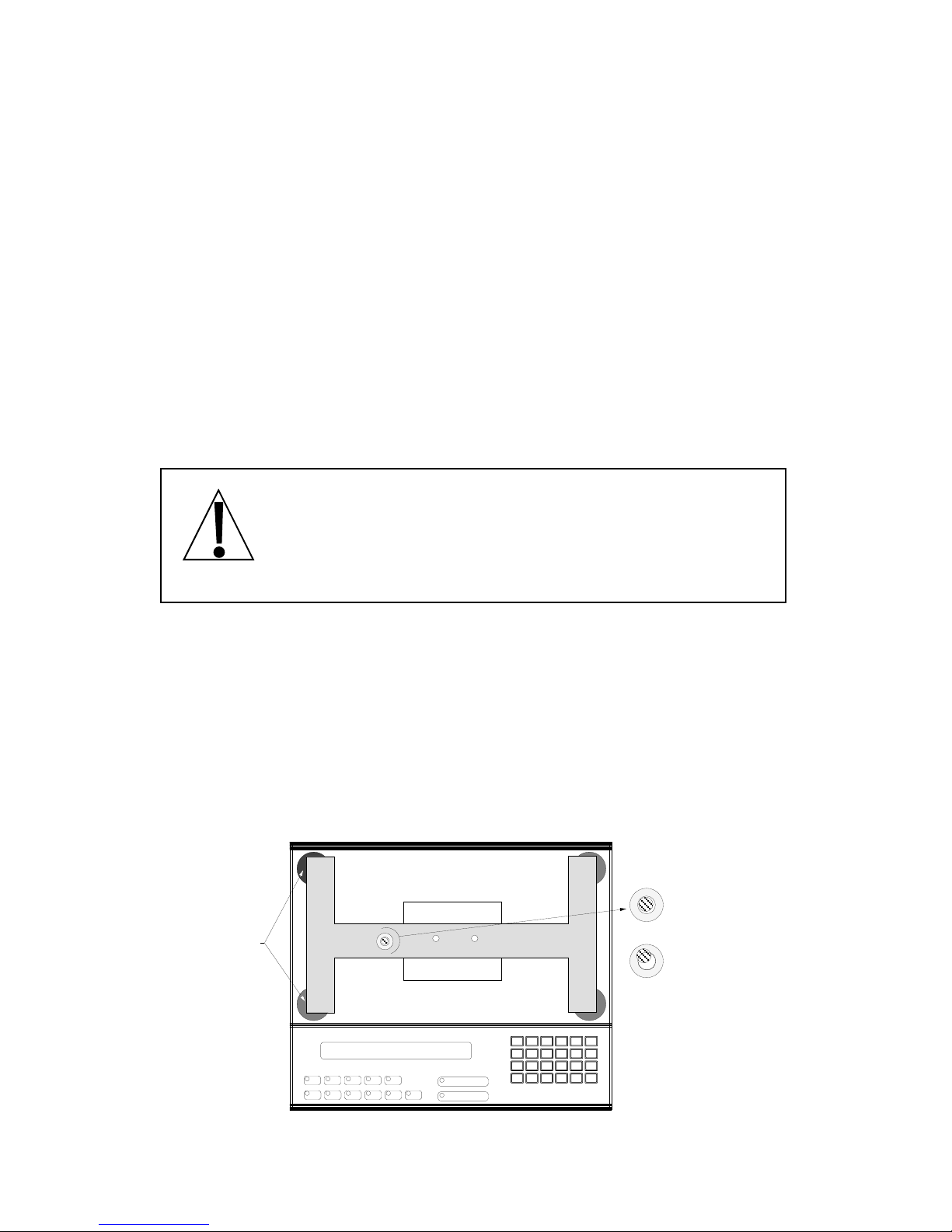

3.3 LEVEL ADJUSTMENT

Before mounting the commodity tray onto the scale, level the scale if

necessary by adjusting the four legs on scale bottom, up or down, until the

bubble in the level gage located on the top cover is centered as shown in

the illustration below. After level is achieved, lock legs in place by

tightening lock nuts on legs against the scale bottom.

Leveled

Adjusting

Legs

(on bottom

of scale)

Not Leveled

4

Page 7

3.4 POWER SUPPLY CONNECTION

3.4.1 Plug power cord into a grounded, 3-pronged wall receptacle that

supplies 115 VAC power. If an extension cord must be used, it should be

a 3-wire, grounded type.

3.4.2 If a 2-pronged wall receptacle is encountered, it is the responsibility

of the customer to contact a qualified electrician to replace the 2-pronged

receptacle with a properly grounded 3-pronged wall receptacle or to have

a grounding adapter properly installed.

CAUTION!!! - To avoid electrical hazard, DO NOT under

any circumstances, cut, remove, alter, or in any way

bypass the power cord grounding prong. Be certain

power cord is routed out of the way of normal traffic.

CAUTION!!! - If it becomes necessary to replace a fuse,

use only fuses of type 3AG 1/4 ASB for 115 VAC

operation. ALWAYS UNPLUG THE POWER CORD

BEFORE CHANGING THE FUSE.

3.4.3 START-UP

When the power switch is turned ON the scale will perform a brief display of

model and version numbers. On conclusion, the display will show zero

weight, signaling that the scale is ready for use.

When the unit is plugged in and turned OFF, power is provided to the load

cell and circuitry, so that the unit will be ready to weigh accurately

immediately after power-up.

If plugging the unit in after an extended period, allow the unit to warm up for

approximately 15 minutes.

5

Page 8

4.0 OPERATION

CAUTION!!! - Dropping packages weighing more than 3

pounds onto the scale platform can cause permanent

damage to the load cell.

4.1 KEY FUNCTIONS

This section describes the use of each of the keys on the keypad of the MSB-25 Scale.

The TARE key is used to enter a known tare (container) weight via the

TARE

WEIGHT

numeric keypad. Pressing the TARE key will display zeros or the previously

entered tare (if any) and illuminate the TARE annunciator.

The WEIGHT key is used to place the scale in the weight display mode.

Pressing the WEIGHT key will display the scale weight as indicated by

illumination of either the lb or lb-oz indicator. If a tare was previously entered

via the TARE key, the net weight will be displayed and the NET annunciator

will illuminate. If no tare has been entered, the weight displayed will be gross

weight, and the GROSS annunciator will illuminate.

ZERO

7

4

1

0

8

5

2

.

.

.

9

6

3

CLEAR

Pressing the ZERO key with weight on the scale, will set the gross weight to

zero, and clear the tare weight, if any. If the display is in count mode, the

count will be set to zero.

The NUMERIC KEYS are used to enter numeric values required in the

various operational modes and calibration procedures of the scale. The 1 and

0 keys are also used to answer YES and NO questions displayed in certain

operations. The 1 and 2 keys are also used to select between scale #1 (local)

and scale #2 (remote).

The DECIMAL key is used to enter a decimal point where desired when

keying in a number sequence.

6

Page 9

SAM

PLE

COUNT

WT/PC

KEY FUNCTIONS, Cont.

The SAMPLE key is used to weigh a specific number of pieces to be added to

or removed from the scale in preparation for a new counting operation. The

SAMPLE key is also used to change the sample quantity. Pressing the

SAMPLE key repeatedly will cause the sample size to step in multiples of 10

from 10 to 250. In this manner sample quantities other than the first one

requested by the instrument may be used for counting operations. Sample

quantities may optionally be entered via the numeric keypad in any desired

quantity. The SAMPLE key may be used to return the display to a sample

display from any weight or count display mode.

The COUNT key is pressed after removing or adding the sample requested,

to initiate the counting operation and place the display in the COUNT mode.

The COUNT key will return the display to the count mode from any weight

display or sample mode.

Pressing the WT/PC key will:

• display the calculated average piece weight from a current sampling and

counting operation

• allow the entry of a known piece weight to be used in a counting operation.

PRINT

XMIT

1

2

Pressing the PRINT XMIT key will transmit RS-232 data to an optionally

installed printer, printing data which is currently shown on the scales display,

along with descriptive headings. See section 6.0 for further information.

Pressing the 1 key while displaying any weight or count information will select

the instrument platform (LOCAL, SCALE #1) for use in all weighing and

counting operations. The SCALE ID digit in the display will show a "1". If a

non-zero tare was previously entered, the net weight will be displayed and the

NET annunciator will illuminate. If no tare has been entered, the weight

displayed will be gross weight, and the GROSS annunciator will illuminate.

Pressing the 2 key while displaying any weight or count information will select

an external weight indicator platform (REMOTE, SCALE #2) for use in all

weighing and counting operations. The SCALE ID digit in the display will

show a "2". If a non-zero tare was previously entered, the net weight will be

displayed and the NET annunciator LED will illuminate. If no tare has been

entered, the weight displayed will be gross weight, and the GROSS

annunciator LED will illuminate.

7

Page 10

KEY FUNCTIONS, Cont.

CLEAR

lb

lb-oz

PC/WT

The CLEAR key is used to erase an erroneous entry, and return the cursor

back to the first character in the entry field.

The lb key is used to select the mode whereby weights are to be displayed in

decimal pounds format, pp.ppp pounds. The lb annunciator LED will

illuminate.

The lb-oz key is used to select the mode whereby weights are to be displayed

in pounds-ounces format, pp pounds oo.oo ounces. The lb-oz annunciator

LED will illuminate.

Pressing the PC/WT key will display the calculated number of pieces per

pound. This number is calculated as the reciprocal of the WT/PC value. The

PC/WT annunciator will illuminate.

The ENTER key is used when keying in some calibration and operational

ENTER

data, to accept or terminate the entry.

The TEST key is located on the bottom of the scale enclosure. Pressing this

switch will place the scale in the test mode as indicated by a "T" displayed in

the right edge of the display. In this mode of operation, the weight is displayed

either in 0.01 ounce or 0.001 pound graduations to check how closely the

scale approaches zero tolerance error.

8

Page 11

4.2 LED INDICATOR FUNCTIONS

The following describes the functions of each of the LED indicators and

associated legends contained on the face of the instrument display.

MOTION

ZERO

lb

GROSS NET

lb - oz

SAMPLE

TARE

COUNT

WT/PC PC/WT

NET

The NET indicator shows the weight displayed is the net weight. Net weight is

determined by subtracting the stored tare weight from the gross or scale weight. The tare

weight, usually the weight of the empty container, is entered using the tare operation key.

Note that the NET indicator is only active when the display is in the weight mode as

shown by the illumination of either the lb or lb-oz indicator.

TARE

The TARE indicator shows that the scale is in a weight mode in which a known tare

(container) weight may be keyed in via the numeric keypad, or in a mode that will display

the current TARE weight.

lb

The lb indicator shows that the display is in the weight mode and that the weight

displayed is in decimal pounds.

lb-oz

The lb-oz indicator shows that the display is in the weight mode and the weight displayed

is in pounds and ounces.

MOTION

The MOTION indicator shows that the scale weight is unstable. An unstable weight

reading may be caused by motion on the scale platform. The ZERO and PRINT/XMIT

functions are disabled while the MOTION indicator is illuminated.

ZERO

The ZERO indicator is active during any mode and is used to indicate that the scale

gross weight is within ± 1/4 of a graduation of true zero.

SAMPLE

The SAMPLE indicator shows that the display is in the sample mode and that the value

shown is the sample quantity requested in pieces.

9

Page 12

INDICATOR FUNCTIONS, Cont.

COUNT

The COUNT indicator shows that the display is in the count mode, and that the value

shown is the count quantity of either the pieces removed from the scale platform (reverse

counting) or the number of pieces added to the scale platform (normal counting). The

count value is determined by dividing the net weight by the average piece weight.

WT/PC (WEIGHT PER PIECE)

The indicator shows that the displayed value is the average weight of a single part (from

a previous sampling operation; or entered via the numeric keypad ). The data display will

show a message in the form PP.PPPP with the lb LED lit, or PP oo.oooo with the lb-oz

LED lit.

GROSS

The GROSS indicator shows that the weight displayed is the gross weight. Gross weight

may be displayed only when the WEIGHT key is pressed and a zero tare weight (or no

tare weight) value is stored. The net weight (used in all sampling and counting functions)

is determined by subtracting the stored tare weight from the gross weight. Note that the

GROSS indicator is only active when the display is in the weight mode as shown by the

illumination of either the lb or lb-oz indicator.

PC/WT

The PC/WT indicator shows that the indicator is displaying the calculated number of

pieces per pound, based on the last sample taken. The data display will show a message

in the form PC/LB XXX.XXX, and is the calculated number of pieces per pound,

calculated as the reciprocal of the WT/PC value.

The SCALE ID character in the display's rightmost character indicates which scale is

operational for weighing, sampling and counting. A "1" indicates the internal scale, and a

"2" indicates an external scale. A "T" indicates that the internal scale is being used in

"TEST" mode (.01 oz divisions).

The message "INSUFFICIENT ADD XXX" when seen during a sampling operation,

indicates that the sample size placed on the scale was insufficient to calculate an

accurate piece weight.

10

Page 13

4.3 OPERATION: WEIGHING, SAMPLING AND COUNTING

4.3.1 STANDARD SAMPLING AND COUNTING

1. With the scale in any mode...

2. Press the SAMPLE key and place on scale the number of pieces indicated on

display. (A different sample size may be selected by following procedure below).

3. Press the ENTER key. The display will change to count mode and the COUNT

indicator will illuminate.

4. Add to scale the number of additional pieces to be counted and read the total

count on display.

5. When sampling, if the weight is too small, the display will show "INSUFF. ADD

XXXXXX", where XXXXXX is the number of additional pieces required for a

sufficient sample.

6. Add to scale the number of additional parts requested and press the ENTER

key. The display will change to count mode and the COUNT indicator will

illuminate.

7. Add to scale the additional pieces to be counted and read the total count.

4.3.2 ADJUSTING THE SAMPLE QUANTITY

1. Press the SAMPLE key.

2. Press the SAMPLE key again to step to the next sample quantity. Pressing the

SAMPLE key repeatedly will cause the sample quantity to step in multiples of 10

from 10 through 250; OR

3. Key in the desired sample value via the numeric keypad.

4. Place on scale the indicated sample quantity and press the ENTER key. The

display will change to count mode and the COUNT indicator will illuminate.

5. Add to or remove from scale pieces to be counted and read the total count.

4.3.3 SAMPLING AND COUNTING OUT FROM A CONTAINER

1. Place the filled container on the scale platform and press the SAMPLE key.

2. Remove the number of pieces shown in the display and press the ENTER key.

3. Remove the pieces from the container and read the total number removed.

4.3.4 TO DISPLAY WEIGHT

1. Press the WEIGHT key. The display will show the gross weight if tare is zero, or

the net weight if tare is non-zero. Either the lb or lb-oz indicator will illuminate.

4.3.5 COUNTING WITH INSUFFICIENT SAMPLE

If the weight of a sample is below 0.2 pounds, the message "INSUFF. ADD

XXXXXX" will be displayed. Although not recommended, it is possible to override

this message and proceed with counting by pressing the COUNT key when the

message is displayed. The unit will save the weight per piece and proceed to

COUNT mode.

11

Page 14

4.3 OPERATION WEIGHING,SAMPLING AND COUNTING, Cont.

4.3.6 TO ZERO THE GROSS WEIGHT

1. With the display in weight or count mode...

2. Press the ZERO key. The tare weight will be set to zero and a new gross weight

center of zero point will be established. If the display was in count mode, the

count will be set to zero. If the display was in the weight mode, a zero gross

weight will be displayed and the GROSS indicator will illuminate. In either case,

the ZERO indicator will illuminate.

4.3.7 TO ENTER A KNOWN TARE WEIGHT

1. With the scale in any weight or counting mode...

2. Press the TARE key. The display will show the previously entered tare weight

and the TARE indicator will illuminate.

3. Key in desired tare: pounds with decimal point followed by ENTER; or

pounds-ENTER, ounces-ENTER (depending upon the weight units in effect).

4. The scale will change to weight mode. Gross weight will be displayed if the tare

is zero, and the GROSS indicator will illuminate. If the tare is non-zero, net

weight will be displayed (gross minus tare) and the NET indicator will illuminate.

4.3.8 COUNTING WITH A KNOWN AVERAGE WEIGHT PER PIECE

1. Press the WT/PC key.

2. Key-in desired average piece weight value in decimal pounds format only via the

numeric keypad followed by ENTER. Place items to be counted on scale then

press the COUNT key.

3. Read count on display.

4.3.9 TO DISPLAY WEIGHT PER PIECE OR PIECE PER WEIGHT

1. To display the average weight per piece, based on the most recent sample,

press the WT/PC key.

2. To display the average number of pieces per pound, press the PC/WT key. The

appropriate indicator will illuminate.

4.4 TEST MODE OPERATION

4.4.1 To Enter the Test Mode

1. Press the test mode pushbutton located on the bottom of the scale. It will be

necessary to lift one side of the scale to gain access to this button. (see figure

8.1)

2. The selection of the test mode is indicated by a "T" shown at the rightmost

display position.

3. While in the test mode note that the only keys that are active are the lb, lb-oz,

and zero keys. All others are disabled.

4. While in the test mode the weight will be displayed in graduations of 0.01 ounce

or 0.001 pound.

4.4.2 To Exit The Test Mode

1. Press the test mode pushbutton a second time to resume normal operation. The

"T" in the display will be replaced by a "1" to indicate selection of the normal

operating mode and scale no.1. (see figure 8.1)

12

Page 15

5.0 CALIBRATION

The following describes the Calibration of the MSB-25 scale in the event that the scale

should need recalibration. A qualified technician should perform this function to maintain

the instrument’s high degree of accuracy.

1. Unplug the scale from the power outlet. This unit applies power to the load cell and

circuits even when the power switch is OFF. .

2. Ensure that the bulls-eye level indicates that the scale platform is level. Adjust if

necessary. Refer to section 3.3.

IF BREAKING THE SEALING WIRES IS REQUIRED FOR PURPOSES OF

CALIBRATION, PROPER PROCEDURES COVERED UNDER NIST

HANDBOOK 44 MUST BE ADHERED TO.

3. Remove the weighing platform and weighbridge. Remove the eight screws securing the

top cover and remove the cover. Refer to the drawing in section 8.1 for location of parts.

4. Referring to the drawing in section 5.1, locate the calibration seal (plastic cover) and

remove it by removing the two (2) small slotted screws on the bottom of the scale. This

will expose the calibration switch. Refer to the drawing in section 8.1 for location.

5. Using a small screwdriver or pencil, push the switch lever to the opposite setting (toward

the front of scale).

6. Replace the weighbridge with the two hex-drive bolts and lock washers. Replace the

weighing platform.

7. Plug in the power cord and turn the scale ON. The display will show "LOAD SCALE TO

25 LB". If it is desired to bypass calibration and only change AUTOZERO, press the

CLEAR key at this point, and proceed to step 9. Allow load cell and electronics to

stabilize for at least 5 minutes if power had previously been off 30 minutes or more.

8. Apply an accurate 25 pound test weigh to the platform and press the ENTER key. The

scale will go through a brief display sequence and the show "UNLOAD SCALE".

9. Remove the test weight and press the ENTER key. The scale will again go through a

brief display sequence and display "AUTOZERO?".

10. Press the 1 key to enable Autozero, or the 0 key to disable. It is recommended that

Autozero should be disabled only for testing purposes. When Autozero is enabled,

weights below 0.005 lb (0.08 oz) are automatically zeroed off within 3 seconds after

weight is applied or removed.

11. The display will show "DONE". Turn the scale OFF and unplug the power cord from the

wall outlet.

12. Remove the weighing platform and weighbridge. Return the calibration switch lever to

the original setting (toward the rear of the scale). Replace the calibration seal (plastic

cover) by re-installing the two (2) small slotted screws on the bottom of the scale.

13. Replace the top cover and eight (8) screws. Replace the weighbridge and weighing

platform. The scale is ready for use.

14. The test mode may be used to determine how closely the scale's performance

approaches zero tolerance error. Refer to section 4.4.

13

Page 16

5.1 CALIBRATION SEAL

14

CALIBRATION SEAL

(PLASTIC COVER)

Page 17

6.0 SERIAL INTERFACE

A serial data communication interface is provided on the MSB-25 scale. This interface serves as the means to

receive weight data from a remote scale, to respond to enquiry from auxiliary computer o r to print displayed data

with descriptive identifiers on a serial printer such as an Epson MX100 or compatible. Note: Requires cable

8510-C304-GA. Available from our Parts Department at 1-800-641-2045 or by e mail at parts@cardet.com.

The signal characteristics conform to the definitions of ANSI/EIA-232D.

When the unit is ready to recognize received data on its RX line (pin 3), it will change the voltage on its DTE-

Ready line (pin 20) from an 'OFF' to an 'ON'. When transmission is initiated by pressing the PRINT XMIT key on

the keypad, or by receipt of an ENQ character (05 hex) on the receive RX line, the unit will transmit data on its TX

line (pin 2) only if it receives an 'ON' signal on its DCE-Ready line (pin 6).

Signal levels

Mark -3V to -12VDC (Logic 1)

Space 3V to 12VDC (Logic 0)

Data format

1200 baud (standard), 1 start bit, 7 data bits, no parity, 2 stop bits on transmit, 1 stop bit on receive

Record formats (depending upon current mode of MSB-25)

WEIGHT

SWWWWWW_lb_M_CC_<CR><LF>

SPP_lb_00.00_oz_M_CC_<CR><LF>

COUNT

COUNT_NNNNNN_<CR><LF>

PIECES PER POUND

PC/LB_NNNNNN_<CR><LF>

AVERAGE WEIGHT PER PIECE

WT/PC_SPPPPPP_lb_<CR><LF>

WT/PC_SPP_lb_oo.oo_oz_<CR><LF>

Signal identification

PIN 1 CHS Protective ground

PIN 2 TX Transmitted data, from MSB-25

PIN 3 RX Received data, to MSB-25

PIN 6 DSR Data set ready, to MSB-25

PIN 7 COM Signal ground

PIN 20 DTR Data terminal ready, from MSB-25

S =

P =

W =

O =

M =

CC =

N =

<CR> =

<LF> =

_=

Space (positive) or - (negative)

Pounds, Leading zero suppressed to space,

embedded decimal point (if any)

WEIGHT VALUE in decimal pounds

Ounces, decimal always present as shown

Modes: G = gross, N = net, T = tare

MO = Motion

CZ = Center of zero*

OC = Over capacity*

BZ = Below zero

*(reflects state of gross weight only)

Number for count or pieces per pound, decimal

point (if any)

Carriage return (OD hex)

Linefeed (OA hex)

space (20 hex)

INTERCONNECTIONS

1 13

14 25

PIN LOCATION AS VIEWED FROM MSB-25 REAR PANEL

DATA OUTPUT CONNECTION DIAGRAM

15

Page 18

7.0 CARE AND MAINTENANCE

1. DO NOT subject the commodity tray to sudden shocks.

2. DO NOT submerge the scale in water or spray water directly on the

scale. The scale may be cleaned using a damp soft cloth and mild

detergent. Be certain power is removed before cleaning is begun.

DO NOT use an abrasive cleaner on this instrument.

3. DO NOT replace a fuse with the power cord plugged in or use fuses of

sizes other than specified.

4. DO NOT use acetone or other volatile solvents for cleaning.

5. DO NOT use any sharp or pointed instrument to depress keys.

6. DO follow all warnings and instructions marked on this product and listed

in this manual.

16

Page 19

PARTS DIAGRAM

17

Page 20

8.2 PARTS LIST

This section lists parts which are interchangeable by field or factory service personnel. Refer

to the MSB-25 exploded view in section 8.1 for the location of each item. Unless otherwise

noted, the quantity of each item is 1.

Item Description Part

1 Enclosure bottom housing 8540-C201-0A

2 Enclosure trim panel, silkscreened 8540-D215-08

3 Subpanel 8540-D214-08

4 Top cover 8540-C204-0A

5 Weighing platform 8540-C211-08

6 Weighbridge 8540-C208-0A

7 Level Indicator 6690-0001

8 Load cell, 25 lb, with cable 2950-C009-4A

9 Adjustable leveling foot (4 per assembly) 6540-1011/6540-1012

10 Pull-out instruction placard 8540-C213-0A

11 Keypad, 24 key, full travel 8540-D207-0A

12 LED display board 8540-D206-0A

13 Display, alphanumeric, dot matrix, 20 char. 8542-D013-1A

14 Controller board 8540-D034-2A

15 Serial I/O board 8540-D205-0A

16 Analog board 584GR670

17 Calibration set-up switch 8540-B033-08

18 Power cord, grounding, molded plug, SJO, 12' length 8540-B049-1A

19 Power switch, rocker 6910-5095

20 Fuse holder 6610-4046

21 Fuse, 3AG, 1/4 ASB 6610-4019

22 Identification plate 593M729

23 Serial interface connector 8540-C216-0A

24 Test button 8540-B226-0A

18

Page 21

Page 22

U

N

A

M

&

E

D

S

I

G

U

N

E

D

F

A

C

T

R

E

D

I

N

U

S

A

.

.

.

U

N

A

M

&

E

D

S

I

G

U

N

E

D

F

A

C

T

R

E

D

I

N

U

S

A

.

.

.

Loading...

Loading...