Page 1

PORTABLE PLATFORM

SCALES

BEAM TYPE

SERIES 854F/954F

Owner’s Manual

0066-M110-O1 Rev H PO Box 151 y Webb City, MO 64870

09/11 Ph: 417-673-4631 y Fax: 417-673-5001 Printed in USA

Technical Support: Ph: 866-254-8261 y techsupport@cardet.com

CARDINAL SCALE MFG. CO.

www.detectoscale.com

Page 2

Page 3

TABLE OF CONTENTS

SCALE ASSEMBLY DIAGRAM AND INSTRUCTIONS ..................... 2

BASE ASSEMBLY PARTS DIAGRAM AND LIST .............................. 3

COLUMN ASSEMBLY PARTS DIAGRAM ......................................... 4

COLUMN ASSEMBLY PARTS LIST .................................................. 5

BEAM ASSEMBLY PARTS DIAGRAM............................................... 6

BEAM ASSEMBLY PARTS LIST........................................................ 7

854DB DOUBLE BEAM PARTS DIAGRAM....................................... 8

854DB DOUBLE BEAM PARTS LIST ................................................ 9

Thank you for purchasing our Detecto 854F/954F Series Scale. Manufactured with

Detecto quality and reliability at our factory in Webb City, Missouri U.S.A., this scale

has been calibrated and tested before leaving our factory to insure accuracy and

dependability for years to come.

Remove your scale from its packing and inspect it for signs of damage such as

exterior dents and scratches. Keep the carton and packing for return shipment or

relocation if it should become necessary. It is the responsibility of the purchaser to

file all claims for any damage or loss incurred during transit, unless this

responsiblity has been accepted by the Seller in its proposal.

NOTICE

All rights reserved. Reproduction or use, without express permission, of editorial or

pictorial content, in any manner, is prohibited. No patent liability is assumed with

respect to the use of the information contained herein. While every precaution has

been taken in the preparation of this book, the Seller assumes no responsibility for

errors or omissions. Neither is any liability assumed for damages resulting from the

use of the information contained herein. All instructions and diagrams have been

checked for accuracy and ease of application; however, success and safety in

working with tools depend to a great extent upon the individual accuracy, skill and

caution. For this reason the Seller is not able to guarantee the result of any

procedure contained herein. Nor can they assume responsibility for any damage to

property or injury to persons occasioned from the procedures. Persons engaging

the procedures do so entirely at their own risk.

1

Page 4

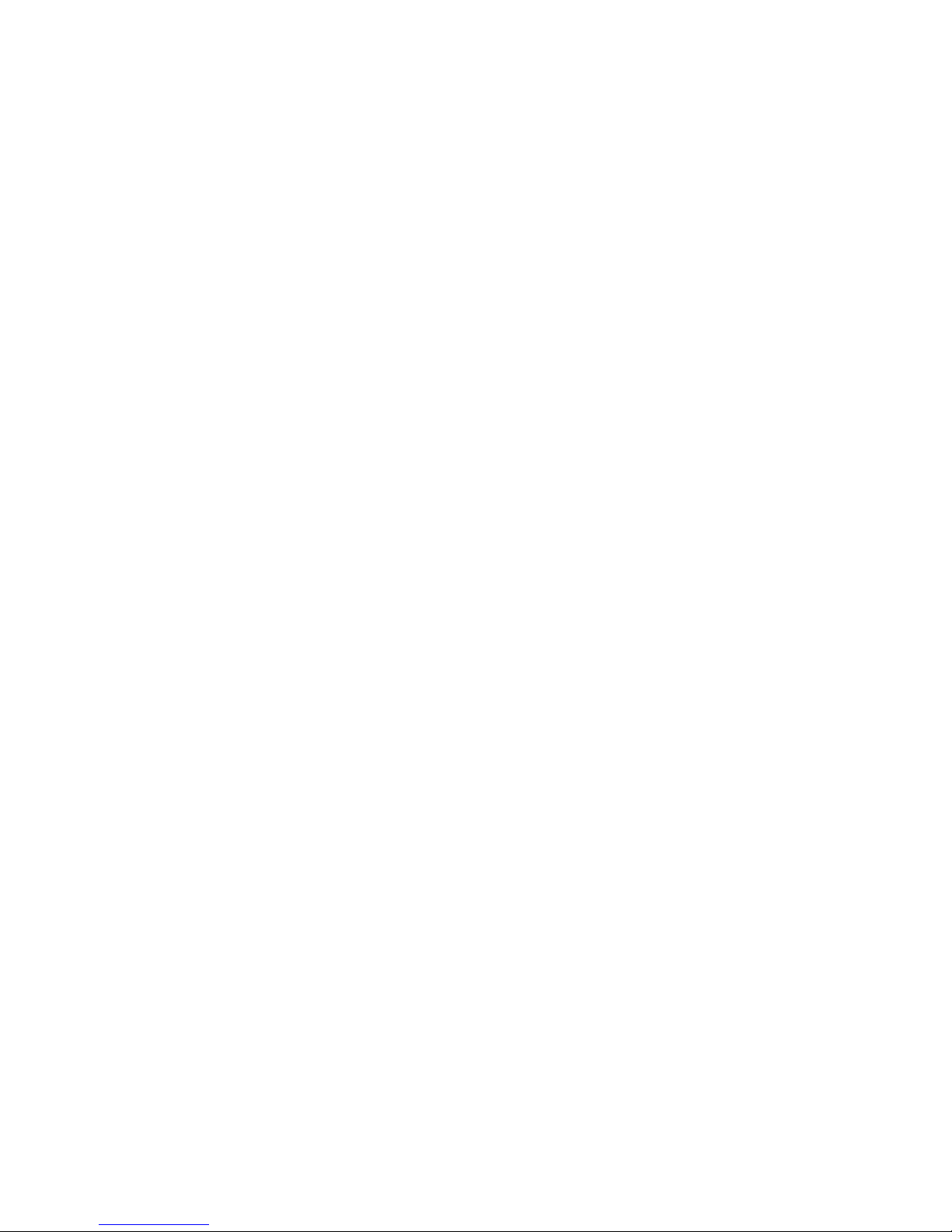

SCALE ASSEMBLY INSTRUCTIONS

Refer to Figure Number 1 and follow the instructions below for scale assembly.

H

G

L

K

Figure Number 1

SCALE ASSEMBLY

DIAGRAM

A

J

E

D2

D1

D

F

C

B

C1

1. Assemble wheels to scale base

with four 5/8-11 x 3 1/2" hex head

bolts, four sleeves and eight 5/8 flat

washers. To secure the wheel,

J

tighten the bolt against the sleeve

to the scale base.

2. Insert column (B) into scale

base assembly (A) and secure with

two 3/8 split lock washers and two

3/8 -16 hex nuts. NOTE: Detecto

decal should be facing toward the

platform.

3. Lower steelyard rod assembly

(C) into column (B).

4. Hook hanger bearing (C1) into

pivot (A1).

5. Column cap (H) may now be

placed over column (B) together

with weight racks (J). NOTE: If

using only one weight rack, we

recommend it be assembled to the

back of the column. Secure with

four 1/4 - 20 x 3/4" hex head bolts

and four 1/4 split lock washers.

6. Attach trig loop (G) to column

A1

8. Attach steelyard rod (C) onto the load loop assembly (F).

9. Secure the fulcrum loop assembly (E) to the column cap (H) with one 1/4-20 x 1" hex head

bolt, one 1/4 split lock washer and one 1/4 flat washer.

10. Hook counterpoise (K) into beam loop assembly (L). Scale assembly is now complete.

FINAL SEALING AND ADJUSTING INSTRUCTIONS

1. Place capacity poise at Zero, move balance ball (D2) to center of adjusting area by turning

zero adjust screw (D1).

2. Remove screw from counterpoise cup (K). Remove sufficient shot from cup (K) until scale is in

balance. NOTE: Screw must be used as part of weight when removing shot.

3. Replace and tighten screw into counterpoise cup (K). NOTE: Beam must arc freely, otherwise,

all bearings and hook connections must be rechecked for proper assembly. Scale is now ready for

operation. (Note: Scale must be set up and operation must be on a level surface. The scale is level

when the air bubble is in the target on the bulls-eye level.)

cap (H) with two 1/4 - 20 x 3/4"

carriage bolts, two 1/4 split lock

washers and two 1/4 - 20 hex nuts.

7. Guide beam assembly (D)

through the trig loop (G) and back

into the column (B) opening.

2

Page 5

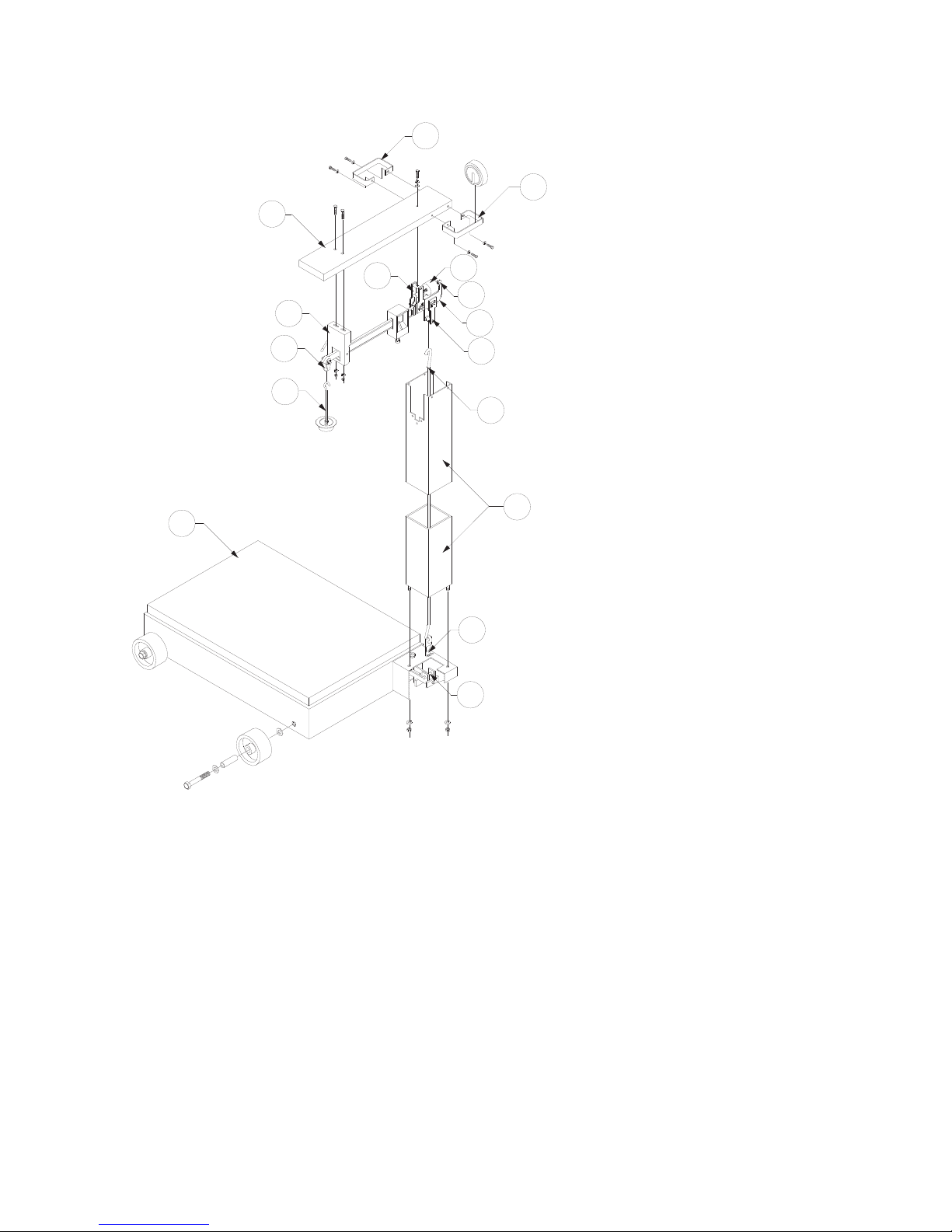

Figure Number 2

BASE ASSEMBLY

PARTS DIAGRAM

BASE ASSEMBLY

8

6

7

4

1

2

3

9

11

10

5

8

12

17

15

14

13

16

Item No. 854F Part No. 954F Part No. Part Name Quantity

1 0066-C017-08 0066-D057-0A Deck Plate 1

2 0066-D012-0A 0066-D107-0A Weighbridge Assembly 1

3 0066-D006-0A 0066-D060-0A Long Lever Assembly 1

4 0066-D007-0A 0066-D061-0A Short Lever Assembly 1

5 0066-B004-0A 0066-B004-0A Long Hanger Assembly 2

6 0066-B005-0A 0066-B005-0A Short Hanger Assembly 2

7 0066-B008-0A 0066-B008-0A Center Hanger Assembly 1

8 0066-B003-08 0066-B003-08 Bearing 4

9 0066-B010-0A 0066-B010-0A Nose Iron Assembly 1

10 6021-1458 6021-1458 5/16 -18UNC x 1 3/4" Hex head Bolt 1

11 6021-1833 6021-1833 5/16 -18UNC x 4" Hex head Bolt 1

12 0066-D002-0A 0066-D067-0A Base Weldment 1

13 0066-B199-08 0066-B199-08 5" Rubber Wheel 4

14 6007-0240 6007-0240 5/8 -11 x 3 1/2" Hex head Bolt 4

15 0066-B200-08 0066-B200-0A Sleeve 4

16 6024-0015 6024-0015 5/8 Flat Washer 8

17 6690-0001 6690-0001 Bulls-eye Level 1

3

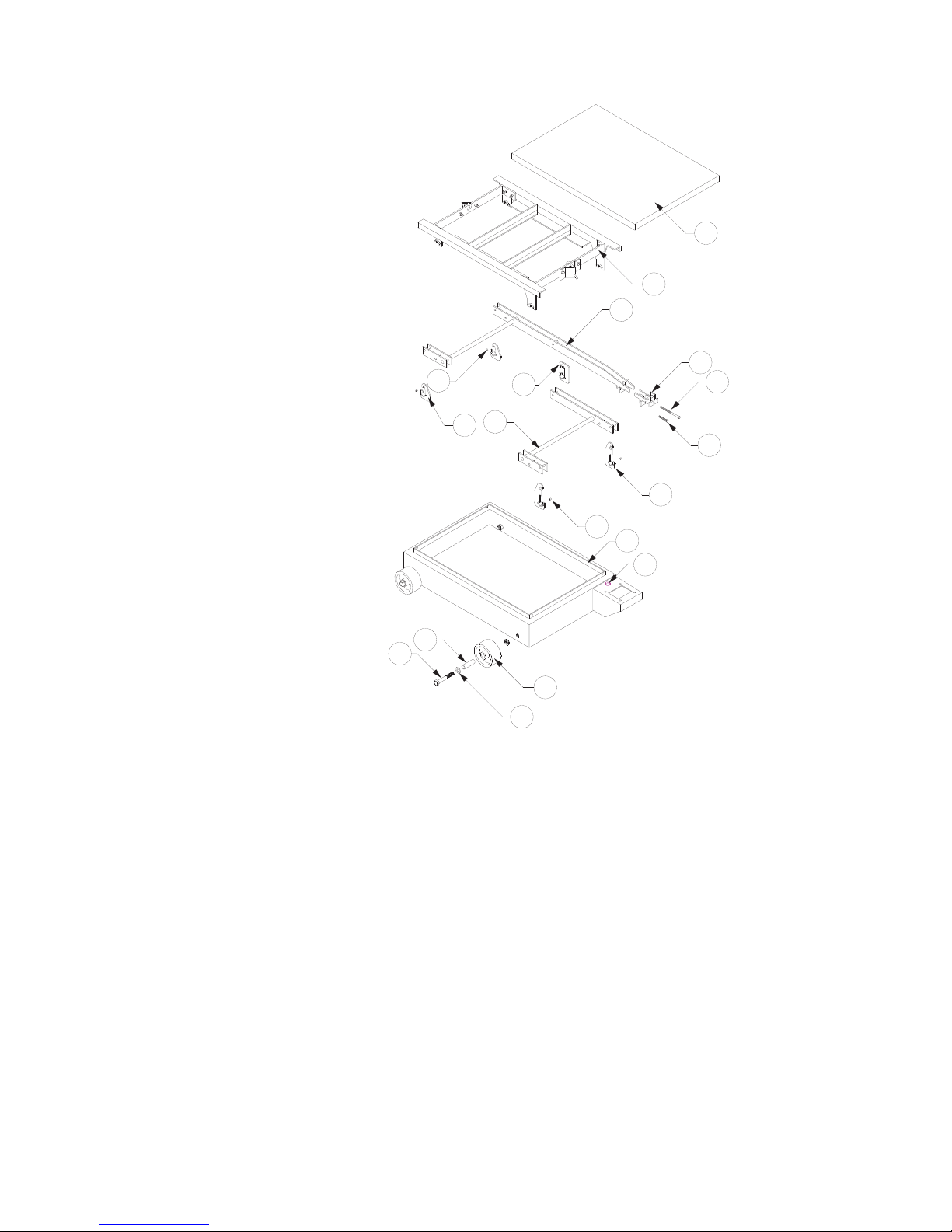

Page 6

27

28

35

36

34

29

28

21

25

26

31

30

24

28

32

Figure Number 3

COLUMN ASSEMBLY PARTS DIAGRAM

37

22

23

33

4

Page 7

COLUMN ASSEMBLY

Item No. Part No. Part Name Quantity Model No.

21 0066-C036-18 Column Cap 1 854F/954F

22 0066-C042-0A Column Assembly 1 854F/954F

23 6P33X Steelyard Rod Assembly 1 854F/954F

24 6P2009X Trig Loop 1 854F/954F

25 345MV0406 1/4 - 20 X 3/4" Carriage Bolt 2 854F/954F

26 6013-0045 1/4 - 20 Hex Nut 2 854F/954F

27 6021-1454 1/4 - 20 x 3/4" Hex Head Bolt 4 854F/954F

28 6024-0039 1/4 Split Lock Washer 7 854F/954F

29 6021-1428 1/4-20 x 1" Hex Head Bolt 1 854F/954F

30 6024-0003 1/4 Flat Washer 1 854F/954F

31 6P1007 Weight Rack 1 or 2 854F/954F

as required

32 6024-0045 3/8 Split Lock Washer 2 854F/954F

33 6P23 3/8 - 16 Hex Nut 2 854F/954F

34 593M729 Serial No. Plate 1 854F/954F

35 6680-0073 Pop Rivet 2 854F/954F

36 6PSS1002 Detecto Logo Decal 1 854F/954F

37 6PP3000X Weight Pack Assembly 1000lb 1 854F100P

6PP3050X Weight Pack Assembly 500lb 1 854F50P

6PK2500X Weight Pack Assembly 500kg 1 854F50K

6PK2550X Weight Pack Assembly 1000lb/500kg 1 854F100PK

6PL1000X Weight Pack Assembly 1000 libra/500kg 1 854FFS

6PK10 Weight 1

0066-C241-1A Weight 1

6PK20 Weight 1

0066-C239-1A Weight 1 854F-50PK

0066-C234-1A Weight 1

0066-C236-1A Weight 1

0066-C233-1A Weight 1

0066-C234-1A Weight 1

0066-C236-1A Weight 2 954F100P

0066-C237-1A Weight 3

0066-C239-1A Weight 1

0066-C241-1A Weight 1 954F50K

0066-C242-1A Weight 4

0066-C239-1A Weight 1

0066-C241-1A Weight 1

0066-C242-1A Weight 4 954FFS

0066-C234-1A Weight 1

0066-C236-1A Weight 2

0066-C237-1A Weight 3

}

}

2000 lb

1000 lb

}

1000 kg

}

500 lb/

200 kg

2000 libra

2000 libra/

1000 kg

5

Page 8

65

58

59

57

53

55

56

67

51

60

61

54

60

52

62

63

54

66

64

Figure Number 4

BEAM ASSEMBLY PARTS DIAGRAM

6

Page 9

BEAM ASSEMBLY

Item No. 854F Part No. 954F Part No. Part Name Quantity Model No.

51 6P10037 6P10037 Beam 1

52 & 53 6P11037 6P11037 Insert 100lb (Rear) 1 854F100P/954F100P

6P11137 6P11137 Insert 100lb (Front) 1 854F100P/954F100P

6P11042 Insert 50lb (Rear) 1 854F50P

6P11142 Insert 50lb (Front) 1 854F50P

6P11038 6P11038 Insert 50kg (Rear) 1 854F50K/954F50K

6P11138 6P11138 Insert 50kg (Front) 1 854F50K/954F50K

6P11044 Insert 20kg (Rear) 1 854F50PK

6P11142 Insert 50lb (Front) 1 854F50PK

6P11043 Insert 100lb (Rear) 1 854F100PK

6P11138 Insert 50kg (Front) 1 854F100PK

6P11039 6P11039 Insert 100 libra (Rear) 1 854FFS/954FFS

6P11138 6P11138 Insert 50kg (Front) 1 854FFS/954FFS

54 0066-B040-08 0066-B040-08 Pivot 3

55 0066-D112-0A 0066-D112-0A Poise Assembly 1 854F100P/954F100P

6P1031X 6P1031X Poise Assembly 1 854F50P

854F50PK

0066-D112-3A 0066-D112-3A Poise Assembly 1 854F50K/954F50K

854F100PK

854FFS/954FFS

56 2P60 2P60 Adjusting Spring 1

57 6029-0032 6029-0032 Snap Ring 1

58 6P27 6P27 Balance Weight 1

59 6P22 6P22 Adjusting Screw 1

60 6029-0022 6029-0022 Snap Ring 2

61 6P72 6P72 Pin 1

62 6P74 6P74 Pin 1

63 0066-C041-1A 0066-C041-1A Beam Loop Assem. 1

64 6P10021X 0066-B109-0A Counter Poise Assem. 1

65 0066-B126-1A 0066-B126-1A Fulcrum Loop Assem. 1

66 0066-B125-0A 0066-B125-0A Load Loop Assem. 1

67 6024-1043 6024-1043 Washer Nylon 1

7

Page 10

854DB DOUBLE BEAM SCALE

DOUBLE BEAM ASSEMBLY PARTS DIAGRAM

Figure Number 5

8

Page 11

854DB DOUBLE BEAM SCALE

(Assembly for avoirdupois, unit available in metric)

Only 1700 Demountable Heads can be used with these scales.

ITEM PART PART NAME QUANTITY

NUMBER NUMBER

1 6P7037X Beam W/Pivots 1

2 6P6042 Tare Beam 1

3 6P11138 Insert 50K Front 2

4 6P11038 Insert 50K Rear 2

5 6P11137 Insert 100P Front 2

6 6P11037 Insert 100P Rear 2

7 6P11142 Insert 50P Front 2

8 6P11042 Insert 50P Rear 2

9 6P10021X C-Poise Assy. 1

10 0066-B109-0A C-Poise Assy. 1

11 0066-C041-1A Beam Loop Assy. 1

12 0066-B125-0A Load Loop Assy. 1

13 0066-B126-1A Fulcrum Loop Assy. 1

14 6P166X Balance Wt. Assy. 1

15 6560-1061 Loctite #262 or Equal A/R

16 6P22 Adjusting Screw 1

17 6P27 Balance Weight 1

18 6029-0022 E-Ring 3/8” 2

19 6029-0032 E-Ring 5/16” 1

20 6P167 Spacer 1

21 548R590810 Roll Pin 4

22 6013-0295 Nut Hex #10-32 4

23 6021-1001 Scw Rd Head #10-32 4

24 6024-1010 Washer Lock #10 4

25 6021-1454 Scw Hex Hd 1/4-20 2

26 6024-0039 Washer Lock 1/4 2

27 6024-1043 Washer Flat 5/16 1

28 6007-0011 Blt Hex Head 1/4-20 1

29 6024-0003 Washer Flat 1/4 1

30 2P60 Spring 1

31 6P1065 Poise Screw REF

32 6P65X Poise Screw Assy REF

33 6P5042X Beam W/Pivots 1

34 0066-D112-0A Poise Assy (Uses Item 32) 2

35 6P1031X Poise Assy Alum (Uses Item 31) 1

36 0066-D112-3A Poise Assy (Uses Item 32) 1

9

Page 12

STATEMENT OF LIMITED WARRANTY

j

Detecto Scale warrants its equipment to be free from defects in

material and workmanship as follows: Detecto warrants to the

original purchaser only that it will repair or replace any part of

equipment which is defective in material or workmanship for a

period of one (1) year from date of shipment. Detecto shall be the

sole judge of what constitutes a defect.

During the first ninety (90) days Detecto may choose to supply all

necessary replacement parts and service during normal weekday

working hours at no charge to the buyer.

After the first ninety (90) days Detecto will supply parts and

service at the job site provided the owner agrees to pay the Dealer

for all travel time, including mileage and test equipment, as well as

any expenses incurred over the direct labor of the technician at the

ob site. This limited warranty honors only labor performed by

Detecto authorized dealers.

This warranty does not apply to peripheral equipment not

manufactured by Detecto; this equipment will be covered by certain

manufacturer’s warranty only.

This warranty does not include replacement of expendable or

consumable parts. This does not apply to any item which has

deteriorated or damaged due to wear, accident, misuse, abuse,

improper line voltage, overloading, theft, lightning, fire, water or acts

of God, or due to extended storage or exposure while in purchaser’s

possession. This warranty does not apply to maintenance service.

Purchased parts will have a ninety (90) day repair or replacement

warranty only.

Detecto may require components be returned to the factory; they

must be properly packed and shipping charges prepaid. A return

authorization number must be obtained for all returns and marked

on the outside of all returned packages. Detecto accepts no

responsibility for loss or damage in transit.

Page 13

STATEMENT OF LIMITED WARRANTY

g

Conditions Which Void Limited Warranty

This warranty shall not apply to equipment which:

A.) Has been tampered with, defaced, mishandled or have had

repairs and modifications not authorized by Detecto.

B.) Has had serial number altered, defaced, or removed.

C.) Has not been grounded according to Detecto’s recommended

procedure.

Freight Carrier Damage

Claims for equipment damaged in transit must be referred to the

freight carrier in accordance with freight carrier regulations.

This warranty sets forth the extent of our liability for breach of any

warranty or deficiency in connection with the sale or use of the

product. Detecto will not be liable for consequential damages of any

nature, includin

whether based on tort or contract. Detecto reserves the right to

incorporate improvements in material and design without notice and

is not obligated to incorporate improvements in equipment

previously manufactured.

The foregoing is in lieu of all other warranties, express or implied

including any warranty that extends beyond the description of the

product including any warranty of merchantability or fitness for a

particular purpose. This warranty covers only those Detecto

products installed in the forty-eight (48) contiguous continental

United States.

but not limited to, loss of profit, delays or expenses,

Ph. (800) 641-2008

E-mail: detecto@cardet.com

203 E. Daugherty

Webb City, MO 64870

D268-WARRANTY-DET

02/06

Printed in USA

Page 14

2

Page 15

2

Page 16

Loading...

Loading...