Page 1

Digital Counting Scale

Models 2240 and 2241

Operation Manual

8526-M231-O1 Rev C PO BOX 151 WEBB CITY, MO 64870 Printed in USA

10/99 PH 417-673-4631 FAX 417-673-5001

Page 2

INTRODUCTION

We wish to thank you for your purchase of our

Digital Counting Scale. This instrument has been

designed and manufactured at our factory in Webb

City, MO U.S.A. with quality and reliability.

This manual will help aquaint you with the features

of this instrument and instruct you in the proper

installation, operation and maintenance of your

new scale. Please read it before attempting to use

the scale and keep it handy for future reference.

FCC COMPLIANCE STATEMENT

WARNING! This equipment generates, uses and

can radiate radio frequency and if not installed and

used in accordance with the instruction manual,

may cause interference to radio communications. It

has been tested and found to comply with the limits

for a Class A computing device pursuant to Subpart

J of Part 15 of FCC rules, which are designed to

provide reasonable protection against such

interference when operated in a commercial

environment. Operation of this equipment in a

residential area may cause interference in which

case the user will be responsible to take whatever

measures necessary to correct the interference.

You may find the booklet "How to Identify and Resolve

Radio TV Interference Problems" prepared by the

Federal Communications Commission helpful. It is

available from the U.S. Government Printing Office,

Washington, D.C. 20402. Stock No. 001-000-00315-4.

All rights reserved. Reproduction or use, without

expressed written permission, of editorial or

pictorial content, in any manner, is prohibited. No

patent liability is assumed with respect to the use of

the information contained herein. While every

precaution has been taken in the preparation of this

manual, the Seller assumes no responsibility for

errors or omissions. Neither is any liability assumed

for damages resulting from use of the information

contained herein. All instructions and diagrams

have been checked for accuracy and ease of

application; however, success and safety in

working with tools depend to a great extent upon

the individual accuracy, skill and caution. For this

reason the Seller is not able to guarantee the result

of any procedure contained herein. Nor can they

assume responsibility for any damage to property

or injury to persons occasioned from the

procedures. Persons engaging the procedures do

so entirely at their own risk.

TABLE OF CONTENTS

Introduction ................................ 1.

Specifications ............................. 2.

Installation ................................ 3.

Components and Controls ................. 4.

Precautions ............................... 5.

Interconnections

...........................6.

Key Functions ............................. 8.

Reset Function ............................10

Annunciators ..............................10

Operation Without ID ......................12

Standard Sampling and Counting .......12

Counting with an Insufficient Sample ...12

Adjusting the Sample Quantity ..........13

Counting Out of A Container ...........13

Accumulator ............................13

Weight Display .........................14

Push Button Tare ......................14

Tare Weight Entry

......................

15

Metric Conversion ......................15

Operation Using ID(S) .....................15

Adding and Deleting ID Numbers .......16

Selecting the ID Number ...............17

Verifying Active (Current) ID Number ...17

Turning Off The Active ID Number ......17

Operation With Stored Tare Weigh .....18

Standard Sampling and Counting .......18

Counting with an Insufficient Sample ...19

Adjusting the Sample Quantity ..........19

Counting Out from a Container .........20

Accumulators

..........................

21

Calibration and Setup .....................24

Calibration Seal Installation ................30

Sampling and Count Accuracy .............31

Error and Status Displays ..................33

Before You Call Service ...................33

Care and Cleaning ........................33

Optional Battery Pack Operation ...........34

Thermal Label Formats ....................36

Parts Identification .........................37

1

PRECAUTIONS

Before using this instrument, read this

manual and pay special attention to all

"WARNING" symbols:

IMPORTANT ELECTRICAL

WARNING

Serial Number_____________________

Date of Purchase __________________

Purchased Form___________________

_________________________________

_________________________________

RETAIN THIS INFORMATION FOR FUTURE USE

Page 3

SPECIFICATIONS

Power Requirements .......... 115VAC 50/60Hz (2240) 220/240 VAC 50/60Hz (2241)

Power Consumption ........... 20 Watts (maximum)

Power Cord .................... 2240: 6 foot, 3-pin polarized - 2241: 6 foot

Operating Temperature ........ 14º F to 104º F (-10º C + 40º C)

Internal Resolution

............

1,000,000

Weight Displayed Resolution .. 10,000 divisions

Sample Rate .................. 2 samples per second

Load Cell Excitation ...........9.3 VDC

ID Number Capacity .......... 300

Dimensions ...................13½" W x 13¼" D x 4" H (345mm W x 339mm D x 102mm H)

Shipping Weight .............. 28 lbs (incl. optional battery)

MODEL Capacity x Division Value Commodity Tray Dimensions

2240-5

2241-5*

5 lb x 0.0005 lb or 2 kg x 0.0002kg 13½" W x 10¼" D

2240-10

2241-10*

10 lb x 0.001 lb or 5 kg x 0.0005kg 13½" W x 10¼" D

2240-20

2241-20*

20 lb x 0.002 lb or 10 kg x 0.001kg 13½" W x 10¼" D

2240-50

2241-50*

50 lb x 0.005 lb or 20 kg x 0.002kg 13½" W x 10¼" D

2240-100

2241-100*

100 lb x 0.01 lb or 40 kg x 0.005kg 13½" W x 10¼" D

* 220/240 VAC 50/60Hz models

Standard Features:

0.6" high red LED 6 Character Count/Data display

0.6" high red LED 5 Character Weight Display

LED Operating Status Annunciators

Metric (lb/kg) Conversion

Bi-Directional RS-232 Printer Port

Fixed Printer Port Data Format, 9600 baud, 8 data bits, No parity and 1 stop bit

Mechanical Overload Protection

Adjustable Leveling Feet and Bubble Level Indicator

User-accessible Setup Parameters

Digital Calibration

Auto Recall of Last Piece Weight

Simplified Operation Selection

Automatic Recomputation of Average Piece Weight

Manual Count Accumulators

Auto Shut-Off Feature

Auto Selection of Optional Remote Scale

Switch between Local and Remote Scale during Sample or Count Operation

Non-volatile Memory stores up to 300 ID's and retains associated data base

Optional Features:

Battery Operation using readily available Sealed Lead-Acid Camcorder battery

Approximately 10 hours use on fully charged battery (without remote scale)

Remote Scale

Label Printer

2

Page 4

INSTALLATION

Unpacking

Before beginning installation of your Digital Counting Scale, make certain the instrument has

been received in good condition. Carefully remove the instrument from the shipping carton and

inspect it for any evidence of damage (such as exterior dents or scratches) that may have taken

place during shipment. Keep the carton and packing material for return shipment if it should

become necessary. It is the responsibility of the purchaser to file all claims for any damages or

loss incurred during transit. Refer to the Counting Scale Unpacking and Re-Packing

Instructions, 8526-M246-01, for additional information.

Placement

Place the scale on a stable, vibration-free level surface away from direct sunlight and from any

rapidly moving air source (heating/cooling vents, fans, etc.). Make certain the power cord and

peripheral cables are routed out of the way of normal traffic.

CAUTION! DO NOT place the scale on any unstable cart, stand or table. The

scale may fall causing injury to the operator, and seriously damage the unit,

or proper operation of the scale may be inhibited.

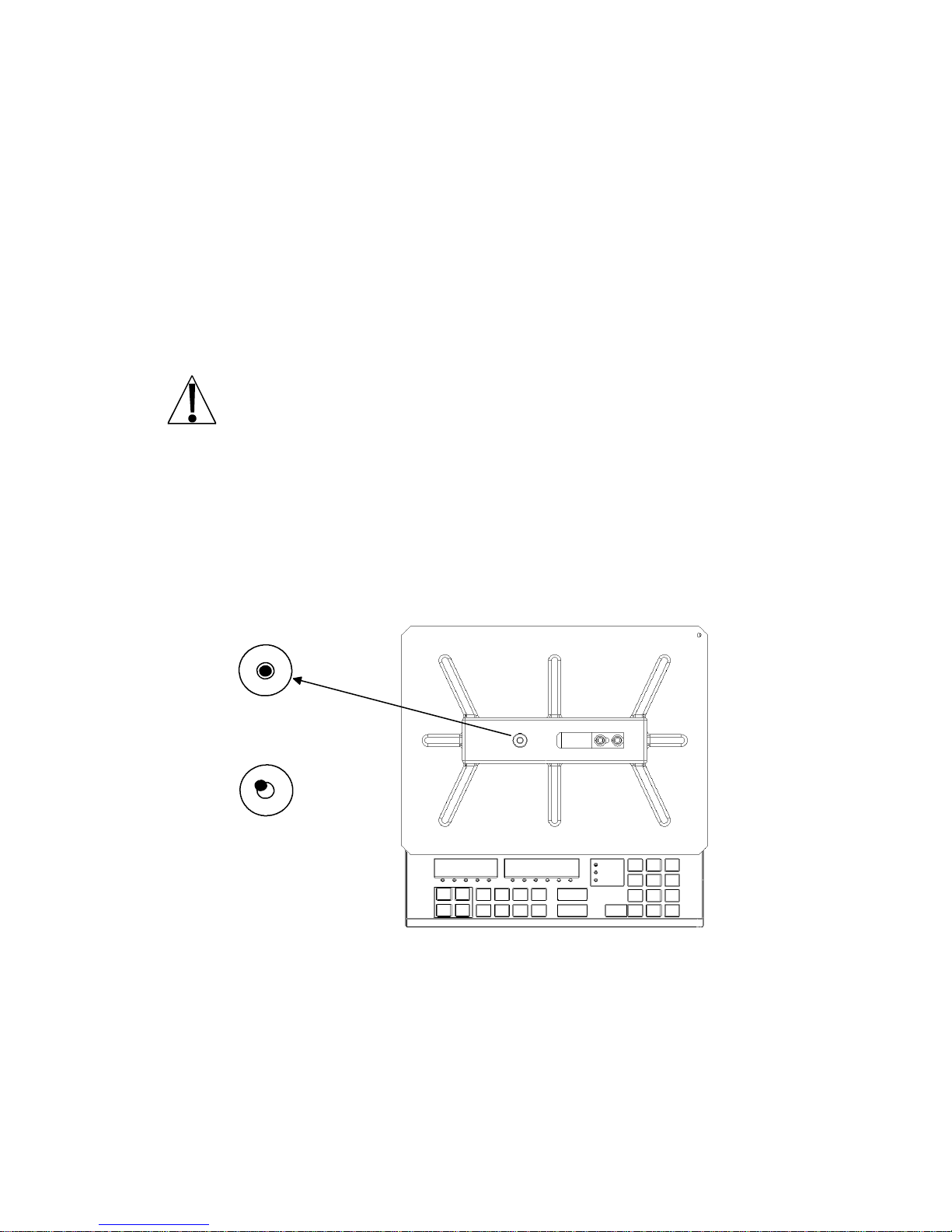

Level Adjustment

Check to make certain the scale is level. The level indicator is located in the center of the

weighbridge under the Stainless Steel commodity tray. Remove the commodity tray and

observe the level bubble (see Figure No. 1). If the scale is not level (the bubble will not be

centered), loosen the locking nut on all four (4) mounting feet (see Figure No. 2) and adjust

them as required to center the bubble and attain a level scale. Once a level condition has

been obtained, lock the mounting feet in place by tightening the adjustment nuts against the

bottom of the scale.

Figure No. 1

Power Connection

The scale contains a power supply which converts the 110/120/220/240 VAC 50/60Hz wall

supply to the power required by the scale circuitry. The power supply also contains the circuitry

necessary to monitor and recharge the optional battery and is capable of operating the scale and

recharging the battery simultaneously.

3

Leveled

Not Leveled

Page 5

INSTALLATION, Cont.

AC Operation (Model 2240)

Plug the power cord into a grounded, polarized wall receptacle that supplies 110/120 VAC

50/60Hz power. If it is necessary to use an extension cord, make certain it is a 3-wire, fully

grounded type using a minimum of 18 gauge wire. Be certain the power cord is routed out of the

way of normal traffic. If only a ungrounded wall receptacle is available, it is the customer's

responsibility to contact a qualified electrician to replace the ungrounded receptacle with a

properly grounded polarized wall receptacle or have a grounding adapter properly installed.

CAUTION! To avoid electrical hazard, DO NOT under any circumstances, cut,

remove, alter, or in any way bypass the power cord grounding prong.

AC Operation (Model 2241)

It is the responsibility of the customer to contact a qualified electrician to install the proper

power cord connector. Plug the power cord into a grounded, polarized wall receptacle that

supplies 220/240 VAC 50/60Hz power. Be certain the power cord is routed out of the way of

normal traffic.

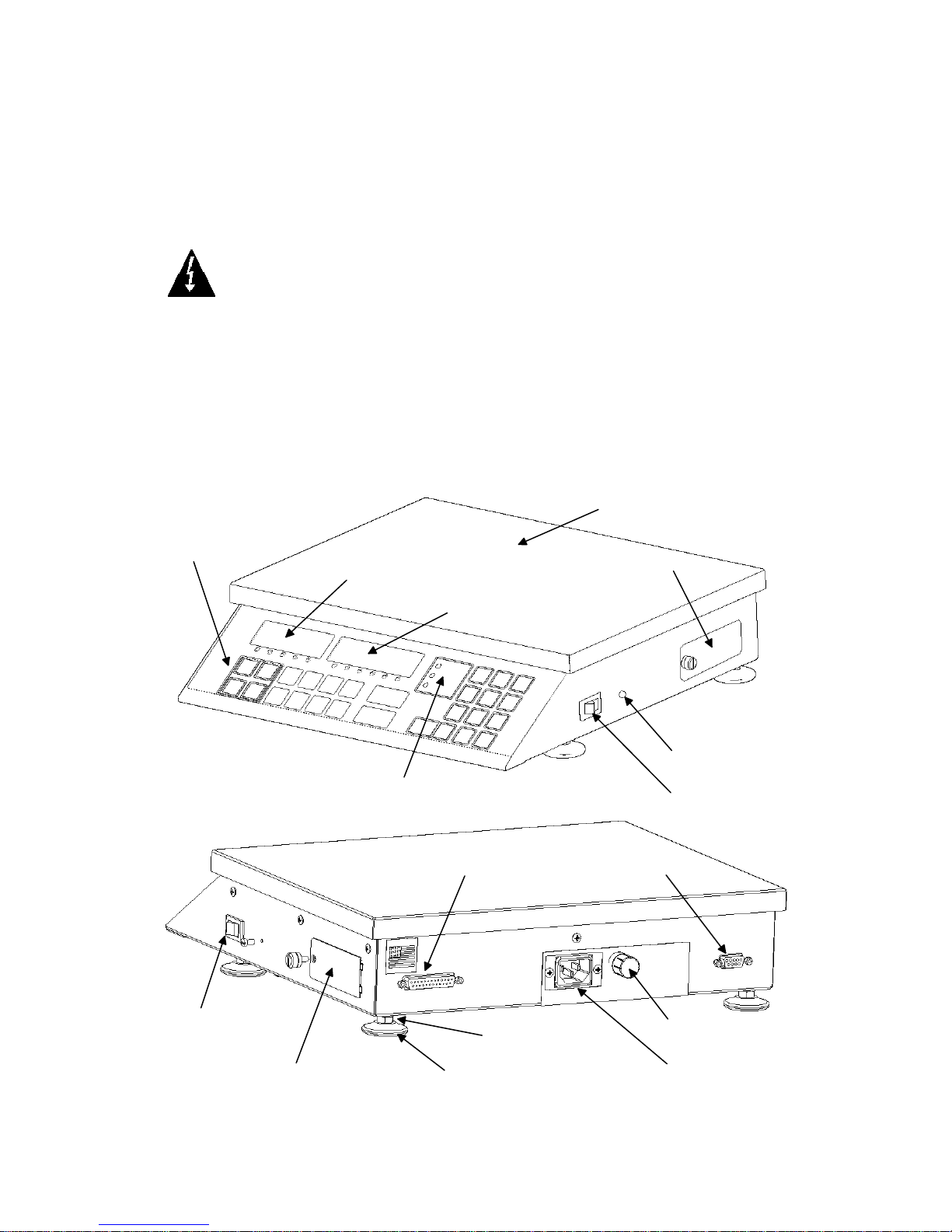

COMPONENTS and CONTROLS

Figure No. 2

4

Remote Scale

On/Off

Switch

Battery

Access

Locking Nut

Mounting Feet

Fuse

AC Power

Socket

Connector

Printer

Connector

Calibration

Sealing Screw

On/Off Switch

Weight Display

Count/Data Display

Battery Low and

Insufficient Sample

Annunciators

Quick

Count

Keys

Battery

Access

Commodity Tray

Page 6

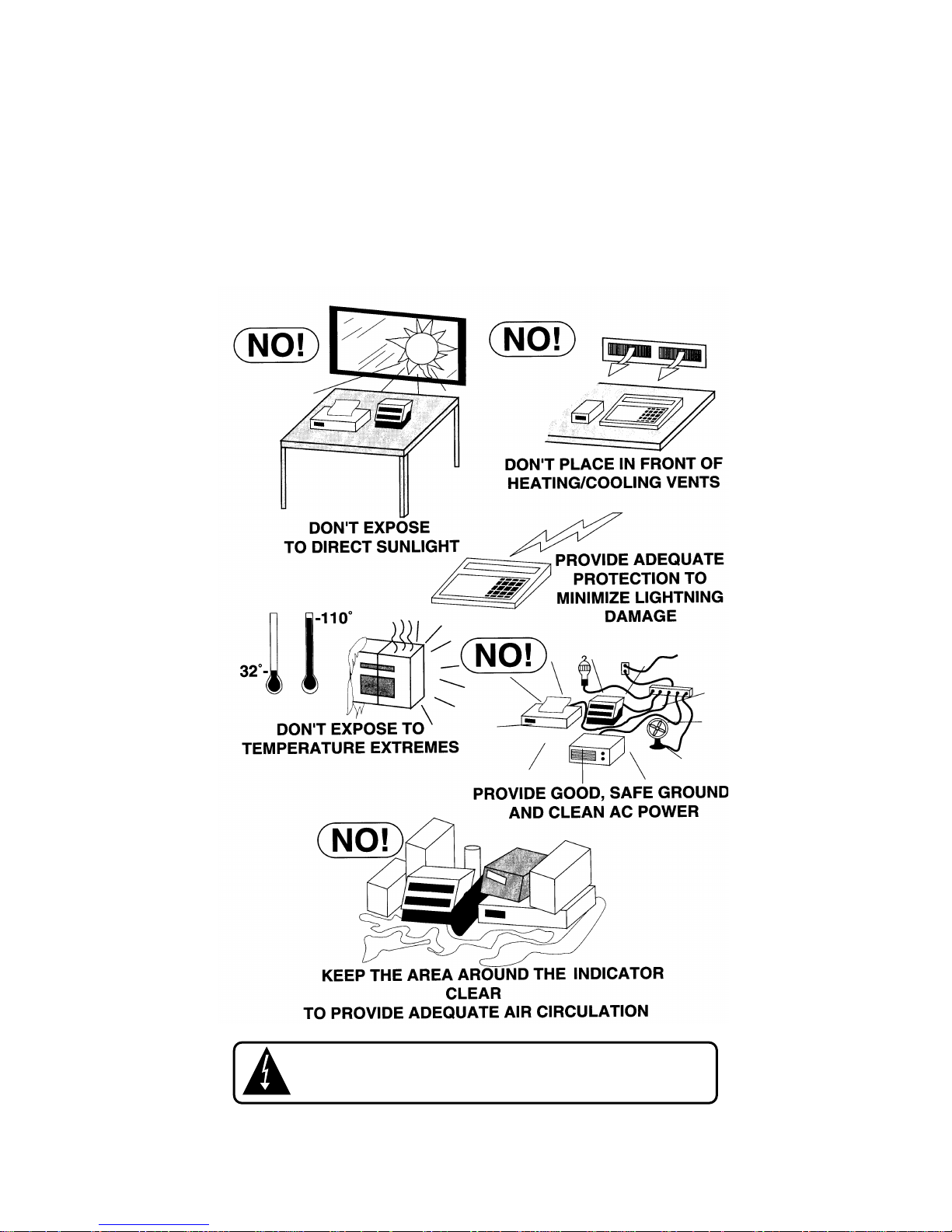

PRECAUTIONS

Most scales are designed for an office type environment. The Digital Counting Scale is no

exception to that rule. Such an environment is free of excessive dust and moisture and provides

a comfortable temperature. In general, the scale will perform well over a temperature range of

32° to 104° F (0° to +40° C). In order to keep cooling requirements to a minimum, the scale

should be placed out of direct sunlight and to provide adequate air circulation, keep the area

around the scale clear. Make certain the scale is not directly in front of a heating or cooling vent.

Such a location will subject the scale to sudden temperature changes and air currents which may

result in unstable weight readings. Insure that the scale has good, clean AC power and is

properly grounded. In areas subject to lightning strikes, additional protection to minimize

lightning damage, such as surge suppressors, should be installed.

5

CAUTION! When in parallel runs, locate external Load Cell

cables a minimum of 24 inches away from all AC wiring.

Page 7

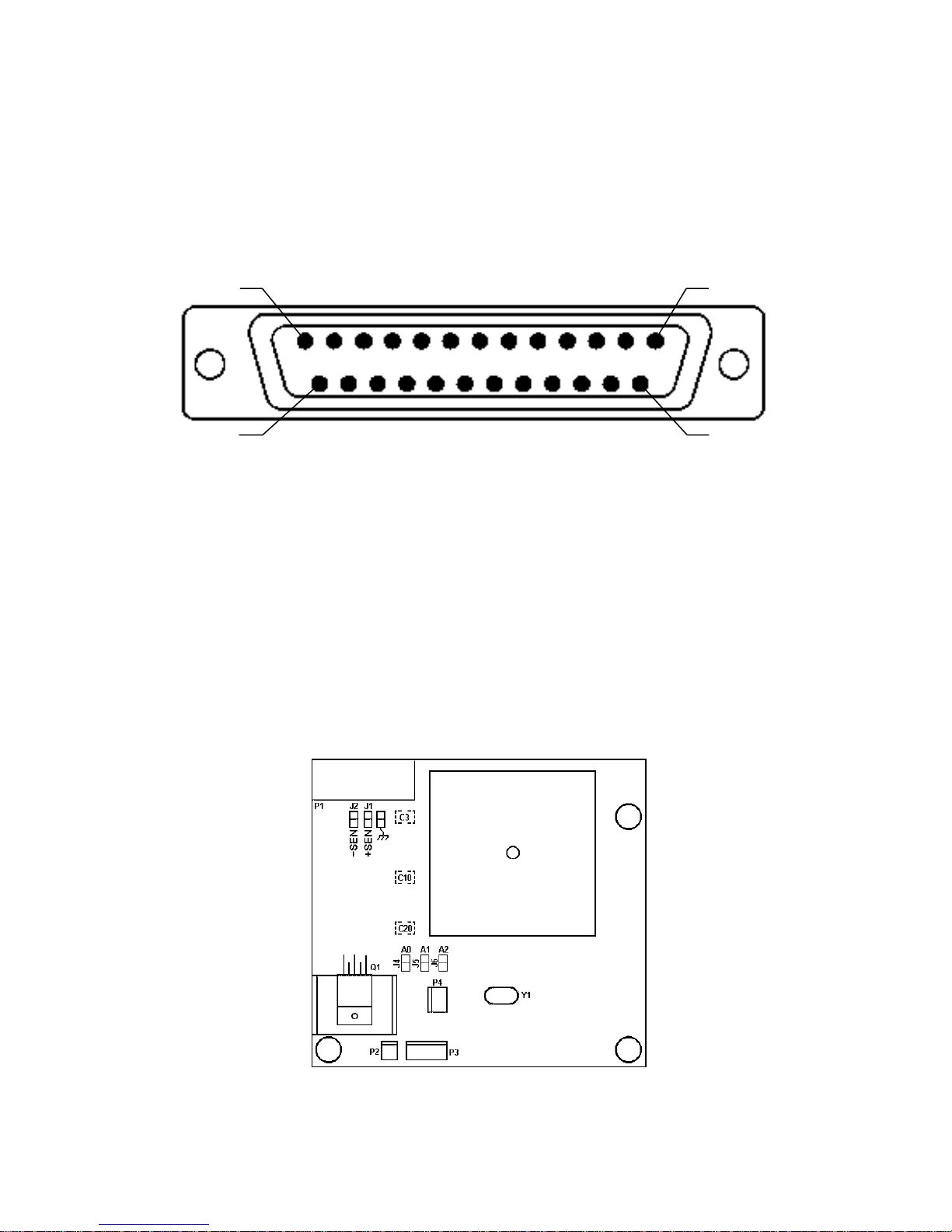

INTERCONNECTIONS

Remote Scale Connection

If a remote scale is used, it connects to the counting scale via a 9-pin "D" connector (REMOTE

SCALE) located on the rear panel of the scale (see Figure No. 2). Before connecting your

remote scale to the counting scale, verify that your scale cable is correctly wired. Refer to Figure

No. 3 for pin identification of the remote scale connector.

The Digital Counting Scale ships from the factory configured for remote scales that do not use

load cells with sense leads (4 wire load cells). The sense jumpers, J1 and J2 are installed for

proper operation with 4 wire load cells. If your remote scale uses load cells with sense leads (6

wire load cells), jumpers J1 and J2, located on the printed circuit board (see Figure No. 5) should

be placed on one pin only or disconnected.

Make certain that the connector retaining screws are used to hold the remote scale cable

connector securely to the rear panel.

Figure No. 3

MATING CONNECTOR INFORMATION

PART NO. VENDOR PART NO.

6610-2379 DE-9P CONNECTOR

6610-1131 DE-24657 SHELL

6

REMOTE SCALE

PIN LOCATION AS VIEWED FROM CABLE ATTACHMENT SIDE

1

69

5

Page 8

INTERCONNECTIONS, Cont.

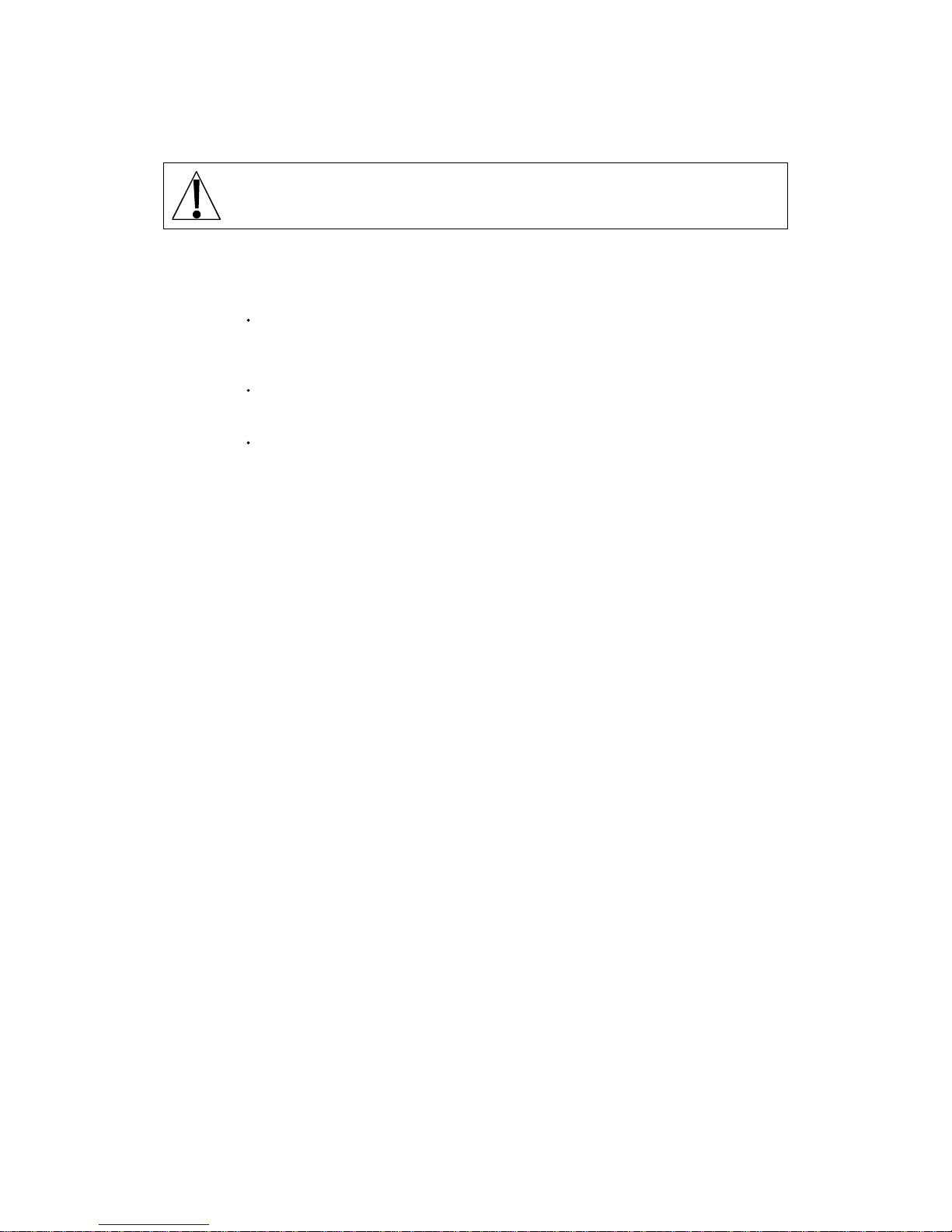

Printer Port Connection

The Digital Counting Scale has a serial printer port that may be used to print weight and

associated data. The data is sent to the printer on demand when the PRINT key is pressed. The

printer connects to the counting scale via the 25-pin "D" connector (PRINTER) located on the

rear panel of the scale. Refer to Figure No. 4 for pin identification of the printer port connector.

NOTE: The serial printer port has a fixed data format, configured for 9600 baud, 8 data bits, No

parity and 1 stop bit (9600,8,N,1) operation.

Printer Port Rs-232 Connector Pin Definitions

3 TXD Output to printer (Transmit)

2 RXD Input from printer (Receive, not used)

7 COMMON Common (Signal Ground)

19 CTS Input from printer (Clear To Send)

MATING CONNECTOR INFORMATION

PART NO. VENDOR PART NO.

6610-2047 DB-25P CONNECTOR

6610-2218 BACKSHELL

Figure No. 5

7

PIN LOCATION AS VIEWED FROM CABLE ATTACHMENT SIDE

PRINTER

PIN 13

PIN 1

PIN 14

PIN 25

Figure No. 4

ON for

4 Wire

Load Cells

OFF for

6 Wire

Load Cells

J2 & J1

Remote Scale

Analog Board

Page 9

KEY FUNCTIONS

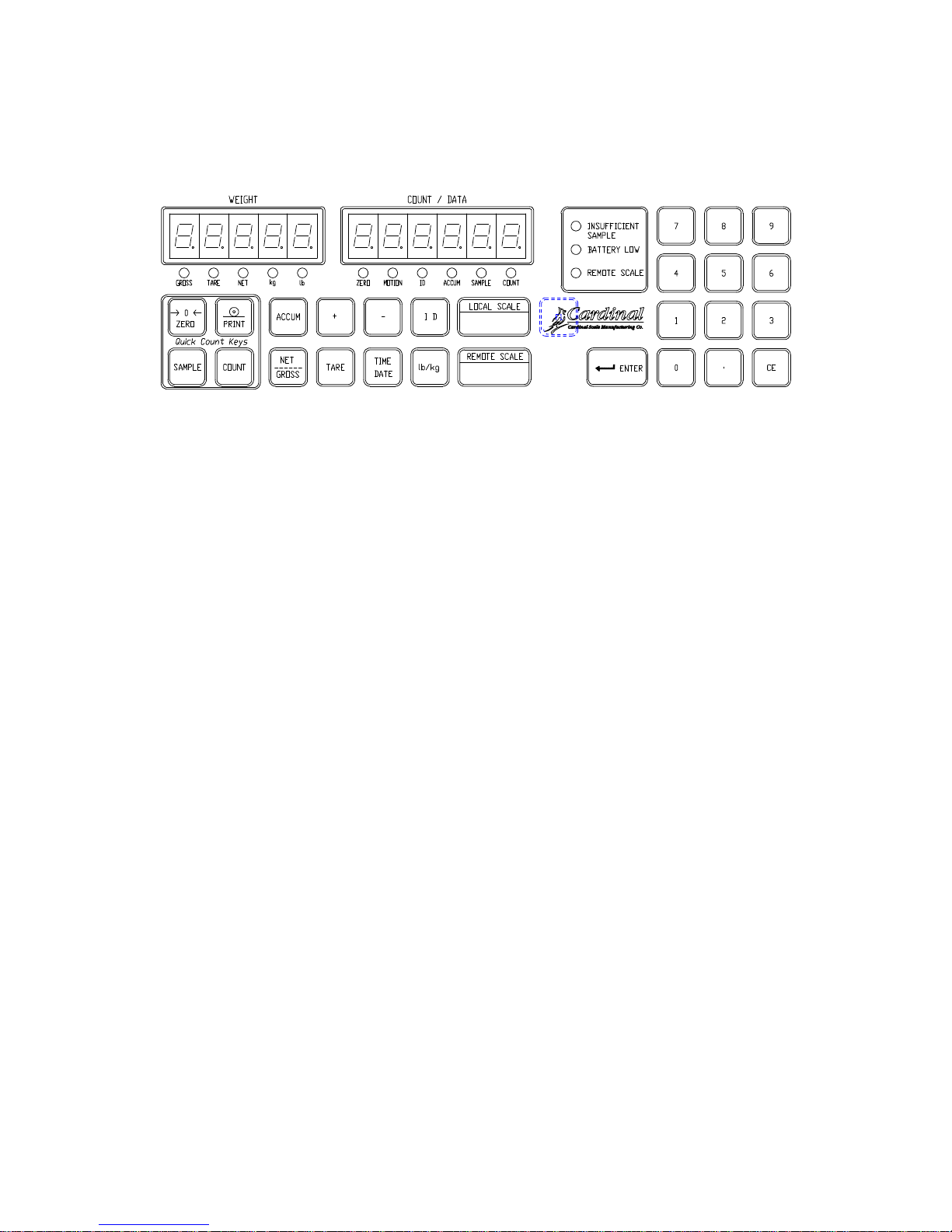

This section describes the use of each of the keys on the Digital Counting Scale. It will be helpful

to refer to the scale keyboard or Figure No. 6 when reading this section.

ZERO The ZERO key is used to perform a variety of functions depending on the current

mode of operation:

Weight Display Mode (lb or kg annunciator on): Pressing the ZERO key will set

the weight display to zero and turn on the ZERO annunciator if the displayed

weight is within ± 4% of scale capacity.

Count Mode (COUNT annunciator on): Pressing the ZERO key while in the Count

mode will reset the count quantity to zero.

Accumulator Mode (ACCUM annunciator on): Pressing the ZERO key while in the

Accum mode will reset the contents of the currently selected accumulator to zero.

PRINT Pressing the PRINT key will transmit RS-232 data to an optional printer,

recording time, date, weight, piece count and ID or part number. Refer to the

Thermal Label Formats section of this manual and Figure No. 12 for typical print

formats.

SAMPLE The SAMPLE key is used to weigh a known number of pieces to be added or

removed from the scale in preparation for a new counting operation. The SAMPLE

key is also used to change the sample quantity. Pressing the SAMPLE key

repeatedly will cause the sample size to step through pre-established sample sizes

of 5, 10, 25, 50 and 100 pieces. In this manner sample quantities other than the

first one requested by the scale can be used for counting operations. Sample

quantities may also be entered using the numeric keypad in any quantity desired.

COUNT The COUNT key is pressed after removing or adding the requested sample, and

will place the scale in the COUNT mode and start the counting operation.

ACCUM Pressing the ACCUM key will cause the scale to display the contents of the

accumulator (the number of pieces accumulated since the last time the accumulator

was zeroed) for the currently selected identification (ID) number.

+ (plus) The + (plus) key is used to add the current piece count value to the accumulator of

the currently selected identification (ID) number. The ACCUM annunciator will flash

to indicate the accumulation has taken place.

- (minus) The - (minus) key is used to substract the current piece count value from the

accumulator of the currently selected identification (ID) number. The ACCUM

annunciator will flash to indicate the subtraction has taken place.

ID Pressing the ID key will cause the scale to display the currently selected

identification (ID) number and allow the entry of a new ID number.

LOCAL Pressing this key while displaying any weight information will select the

SCALE instrument platform (LOCAL) for sampling, counting or weighing operations.

8

The membrane keyboard is not to be operated with pointed objects (pencils, pens,

fingernails, etc). Damage to keyboard resulting from this practice will NOT be

covered under warranty.

Page 10

KEY FUNCTIONS, Cont.

NET Pressing this key will toggle the weight display between the Net and Gross weight

GROSS display modes. NOTE: If a valid tare weight has not been entered, pressing this

key will toggle between Net and Gross modes (illuminating the appropriate

annunciator) with no change on the display.

TARE The TARE key is used to display the current tare weight (or zero if no tare has

been entered) and/or using the numeric keypad, to enter a new tare weight. It is

also used when entering a tare under a specific indentification (ID) number.

TIME Pressing this key will allow the entry of hours-minutes-seconds (6 digits) followed

DATE by the entry of the month-day-year (6 digits). NOTE: The time and date formats

are selected during setup of the counting scale.

lb/kg Pressing this key will toggle the weighing units between pounds (lb) and kilograms

(kg). NOTE: The currently selected weighing unit is indicated by illuminating either

the lb or kg annunciator (LED).

REMOTE Pressing this key while displaying any weight will select the optional external

SCALE scale (REMOTE) for sampling, counting or weighing operations. The Remote

Scale annunciator (LED) will illuminate to indicate the external (REMOTE) scale is

in use. NOTE: The REMOTE scale cannot be selected until it has first been

enabled in Setup and then calibrated.

ENTER The ENTER key is used to signal the completion of the data entry process and

starts the scale processing the data entered.

0 These keys are used to enter numeric data during setup and calibration as well

through as during normal operations. NOTE: The 1 and 0 keys have dual functions. They

9 are used to enter numeric data during setup and calibration as well as during

normal operations and are also used to answer Yes (1=YES) or No (0 = NO)

to various prompts.

This is the decimal point key used to enter a decimal point where required when

entering numeric data.

CE The CE key is used to perform different functions depending on the current mode of

operation:

Data Entry: The CE key is used to clear an incorrect entry from the display without

processing the data. If an incorrect entry is made, press the CE key and re-enter

the correct data. NOTE: The CE key must be pressed before the ENTER key to

ensure the data is not procesed.

Sample Mode (SAMPLE annunciator on): Pressing the CE key while in the Sample

mode during the initial Add display will reset the Add value to 5. This display

indicates the number of sample pieces to be added to (or removed from) the scale

platform.

NOTE: An invalid key entry will produce a long tone and no change on the

display.

9

Page 11

RESET FUNCTION

A hidden key (under the Cardinal bird emblem) is provided to be used as an reset function to

abort the current operation and return the scale to the weight display mode. This allows the

operator to start the operation again from the beginning.

Figure No. 6

ANNUNCIATORS

The annunciators are turned on to indicate that the scale is in the mode corresponding to the

annunciator label or that the status indicated by the label is active. It will be helpful to refer to

the scale keyboard or Figure No. 6 when reading this section. The following describes the

functions of each annunciators.

GROSS

The GROSS annunciator is turned on to show that the weight displayed is the gross weight.

Gross weight may be displayed only when in the weight mode and a zero tare weight (or no tare

weight) value is stored. Note that the GROSS annunciator is only active when the display is in

the weight mode as shown by the illumination of the lb or kg annunciator.

TARE

The TARE annunciator is turned on to show that the scale is in a weight mode in which a known

tare (container) weight may be keyed in via the numeric keypad, or in a mode that will display the

current TARE weight.

NET

The NET annunciator is turned on to show that the weight displayed is the net weight. Net weight

is determined by subtracting the stored tare weight from the gross or scale weight. The tare

weight, usually the weight of the container, is entered using the tare key. Note that the NET

annunciator is only active when a zero tare weight or tare weight value is stored and the display

is in the weight mode as shown by the illumination of the lb or kg annunciator.

kg

The kg annunciator is turned on to show that the weight displayed is in kilograms. The lb/kg key

may be used to select kilogram as the weighing units.

lb

The lb annunciator is turned on to show that the weight displayed is in pounds. The lb/kg key

may be used to select pounds as the weighing units.

ZERO

The ZERO annunciator is turned on to show that the scale gross weight is within ± ¼ of a

division of true zero (center-of-zero).

10

Page 12

ANNUNCIATORS, Cont.

MOTION

The MOTION annunciator shows that the scale weight is unstable. An unstable weight reading

may be caused by motion on the scale platform. Accumulation of piece counts, Zero and printing

cannot take place when the MOTION annunciator is illuminated.

ID

The ID annunciator is used to show the status of the Identification Number mode. During

operation, the ID annunciator will be ON (not flashing) to indicate that an ID number is active.

When the scale is in the ID ADD, EDIT or DELETE modes of operation, the ID annunciator will

be flashing.

ACCUM

The ACCUM annunciator shows that the display is in the Accumulator mode and that the value

displayed is the current contents of the accumulator. Individual counts are adjusted via the ( + )

and ( - ) keys or optionally, any count may be entered using the numeric keypad. Note, a flashing

ACCUM annunciator indicates that the current count has been added to the accumulator (count

annunciator is also lit).

SAMPLE

The SAMPLE annunciator shows that the display is in the Sample mode and that the value

displayed is the sample quantity requested in pieces.

COUNT

The COUNT annunciator shows that the display is in the Count mode and the value displayed is

the count quantity of either the pieces removed from the scale platform (reverse counting) or the

number of pieces added to the scale platform (normal counting). The count value is determined

by dividing the net or gross weight (as selected) by the average piece weight.

INSUFFICIENT SAMPLE

The INSUFFICIENT SAMPLE annunciator is located between the display and the numeric

keypad and shows that the sample selected is too small to calculate an accurate piece weight. If

a counting function is continued by pressing the COUNT key a second time without increasing

the sample size, the INSUFFICIENT SAMPLE annunciator will flash. Note that increasing the

sample size by the amount indicated prior to pressing the COUNT key a second time, will turn off

the INSUFFICIENT SAMPLE annunciator and result in an accurate piece weight.

BATTERY LOW

The BATTERY LOW annunciator is used with the battery operation and will flash slowly to

indicate that the internal battery requires charging. If continued use furthers drains the battery,

the annunciator will stop flashing and stay on continuously. No change in operation will occur

until just before the battery voltage drops to a level where operation is affected. At this level, the

scale will automatically turn itself off. Note that when the scale is charging the battery,

BATTERY LOW annunciator will flash until charging has been completed.

REMOTE SCALE

The REMOTE SCALE annunciator is illuminated when the optional remote scale platform has

been selected for use. The remote scale is selected by pressing the REMOTE SCALE key.

POWER ON

The Power Switch is located on the right side panel towards the front of the scale. Place the

power switch in the on position. The scale will perform a brief lamp test. This test consists of

illuminating all display segments and annunciator LED's for approximately three (3) seconds to

allow the operator to make a visual verification that the display is operational. After completion

of the lamp test, the scale will display the model number and software revision level, then the

weight display will show zero weight, indicating the scale is ready for use.

11

Page 13

OPERATION WITHOUT ID

Standard Sampling and Counting

1. With the scale on and warmed up (on for approximately

10 minutes) and in the Weight mode (Count display is

blank) press the SAMPLE key.

2. Add the number of pieces indicated on the count display

and press the COUNT or ENTER key.

3. Add the pieces to be counted and read the total count.

4. Press the ENTER key to complete the counting

operation and return to the Weight mode.

Automatic Average Piece Weight Re-Computation

Immediately after a standard sampling operation, if a quantity of pieces, less than the original

sample size is added to the scale platform, a new average piece weight will be calculated

automatically. This new average piece weight is based on a larger sample than that used initially

therefore improving the accuracy of the count.

NOTE: The automatic recomputation of the average piece weight occurs only once for each new

sample. Note also that the recalculation of the average piece weight will not take place if the

quantity of pieces added is equal to or greater than the original sample quantity, nor will it take

place if the display mode is changed before the pieces are added.

Counting With an Insufficient Sample

1. With the scale on and warmed up (on for approximately

10 minutes) and in the Weight mode (Count display is

blank) press the SAMPLE key.

2. Add (or remove) the number of pieces indicated on the

count display and press the COUNT or ENTER key.

3. If the sample weight is too small, the INSUFFICIENT

SAMPLE annunciator will flash and the display will show

the number of pieces to be added or removed.

4. Add or remove the number of pieces requested and

press the COUNT or ENTER key or if Manual Count

Override* is enabled, press the COUNT key to force a

count function. Note that if the pieces are not added or

removed, the INSUFFICIENT SAMPLE annunciator will

continue to flash to show the out-of-tolerance count.

NOTE: If the Manual Count Override is not enabled

and less than the displayed number of pieces are

added or removed when requested to add additional

pieces, the counting operation will terminate and the

scale will return to the weight display.

5. Add or remove the pieces to be counted and read the

count.

6. Press the ENTER key to complete the counting

operation and return to the Weight mode.

* Refer to Calibration and Setup section

12

or

5

I I 0

Add 5

Add 25

Add 5

INSUFFICIENT

SAMPLE

30

INSUFFICIENT

SAMPLE

ll0

5

0.000

lb

0.000

lb

SAMPLE

COUNT

COUNT

SAMPLE

COUNT

COUNT

Page 14

OPERATION WITHOUT ID, Cont.

Adjusting the Sample Quantity

1. Press the SAMPLE key. Press the SAMPLE key again

to step to the next sample quantity.

Note, pressing the SAMPLE key repeatedly will cause

sample quantity to step in the following sequence: 5, 10,

25, 50, 100, 5, 10, etc. OR

3. Using the numeric keypad, key-in any desired sample

value, then press the COUNT or ENTER key.

4. Add or remove indicated sample quantity and press the

COUNT or ENTER key.

5. Add or remove the pieces to be counted and read total

the count.

6. Press the ENTER key to complete the counting

operation and return to the Weight mode.

Counting Out From a Container

1. Place the filled container on the scale platform and

press the SAMPLE key.

2. Remove the number of pieces shown on the display and

press the COUNT or ENTER key.

3. Press the ZERO key to zero the count, then remove the

pieces from the container and read the total number

removed.

4. Press the ENTER key to complete the counting

operation and return to the Weight mode.

Accumulator

Displaying the Accumulator.

With scale in the Weight mode (Count display is blank)

or in the Count mode (COUNT annunciator ON), press

the ACCUM key (ACCUM annunicator illuminates) to

display the contents of the accumulator. Press the

ACCUM key again to return to the previous display or

press the SAMPLE key to go to the sample display.

Clearing the Accumulator.

With scale in the Weight mode (Count display is blank)

or in the Count mode (COUNT annunciator ON), press

the ACCUM key (illuminating the ACCUM annunicator)

to display the contents of the internal accumulator.

Press the ZERO key to reset the accumulator to zero,

then press the ACCUM key to return to the previous

display.

13

then

Add 5

Add I0

0.000

Add 5

II0

0.000

0.000

lb

COUNT

SAMPLE

II0

COUNT

lb

lb

0

ACCUM

1 2 3 4 5

6 7 8 9 0

SAMPLE

SAMPLE

0

COUNT

0.000

lb

2583I

ACCUM

ACCUM

25831

Page 15

OPERATION WITHOUT ID, Cont.

Accumulator, Cont.

Manually Adding to the Accumulator.

1. With the display showing the current count (COUNT

annunciator ON), press the ++ key to add to (or the - key

to subtract from) the displayed count of the accumulator.

2. The ACCUM annunciator will flash to show that the

adjustment to the accumulator has taken place and will

continue to flash until all pieces are removed from

platform and the display returns to zero in preparation

for the next counting operation.

3. Press the ENTER key to complete the counting

operation and return to the Weight mode.

NOTE: Additional accumulator adjustments can

not take place until the next counting operation

has been completed.

Weight Display

Displaying Weight.

Press the ENTER key. The display will show the weight

on the scale platform. The GROSS and lb or kg

annunciator will illuminate to indicate which unit of

weight has been selected and that the scale is in the

Weight mode. Note, the count display will be blank.

Zero the Weight Display.

With the display in the Gross Weight mode (GROSS

annunciator illuminated), press the ZERO key. The

weight display will return to zero. The ZERO

annunciator will illuminate, indicating a center-of-zero

gross weight condition.

Push Button Tare

1. With the display in the Gross Weight mode (GROSS

annunciator illuminated and the Count display blank),

place the empty container on the scale platform.

2. Press the TARE key, then the ENTER key. The weight

display will change to zero and the NET annunciator

illuminates, indicating net weight is being displayed. The

empty container's weight has been entered as "tare

weight".

3. To return to a zero tare, simply remove all material from

the scale platform and press the TARE key, then the

ENTER key, which will reset the the tare weight to zero.

4. Press the NET/GROSS key, to return to the Gross

weight mode. Note, the selection of Gross weight mode

is indicated by illumination of the GROSS annunciator.

14

25

25

COUNT

ACCUM

I.I6I

GROSS

0.000

lb

lb

GROSS

ZERO

0.000

0.000

GROSS

0.I25

lb

0.000

TARE

0.000

NET

GROSS

0.000

Page 16

OPERATION WITHOUT ID, Cont.

Tare Weight Entry

1. With the scale in the Gross Weight mode (GROSS

annunciator illuminated and the Count display blank),

press the TARE key. The display will show zero or the

previously entered tare (if any) and the TARE

annunciator will turn on.

2. Using the numeric keypad, enter the desired tare

(container) weight. Note: When entering tare values, a

maximum of 4 digits can be entered and that the

numbers advance from right to left in the display. The

number of leading or trailing zeros required to obtain

your desired tare entry is dependent upon the DIVISION

VALUE selected in the calibration procedure.

For example:

Division Value: 0.001

Desired Tare Value: 0.50lb

Key Sequence: 5

Division Value: 0.01

Desired Tare Value: 1.5lb

Key Sequence: 1 5

3. After the desired tare value has been entered, press the

ENTER key. The display will show the Net weight

(Gross minus tare) and the NET annunciator will

illuminate.

4. Proceed with the counting or weighing operation.

Metric Conversion

To change weighing units, simply press the lb/kg key to

toggle between pounds and kilograms.

Note that either the lb or kg annunciator will illuminate to

indicate which weighing unit is selected.

OPERATION USING ID(S)

This section describes the various operating procedures of the Digital Counting scale using the

ID mode. The ID (identification number) function may be thought as a catalog of stored values for

up to 300 separately identifiable counting operations. Those values, stored under an assigned ID

number, are: the TARE WEIGHT1 (if used), the UNITS (Average Piece Weight) and the

ACCUMULATED COUNT of a counting operation. They are accessed by entering the assigned

ID number.

1

A TARE WEIGHT value can be stored for both the Local and Remote scale, allowing the

operator to use a small container for the sample and a pallet, tote or the shipping box for the

final item count. If required, the stored Tare weight value for an ID can be added or updated

before or during a Count or Sample operation.

15

or

1 2 3 4 5

6 7 8 9 0

tArE=

.5

0.000

GROSS

0.I25

TARE

-I.000

NET

2.000

0.9075

lb

kg

Page 17

OPERATION USING ID(S), Cont.

Adding ID Numbers

NOTE: If a stored tare weight is desired for an ID, it is recommended to select

the scale (Local or Remote) and place the empty container to be used for the

tare on the appropriate scale before pressing the ID key in step 1.

1. With the counting scale on, and in the Weight mode

(the Count display is blank), press the ID key.

2. The ID annunciator will flash and the weight display will

show id=id=. NOTE: If this is the first ID to be added, the

count display will be blank, otherwise the current active

ID number will be shown in the count display.

3. Key-in up to a 12 digit identification number and press

the ID key. Note, that when entering an ID number, the

digits start displaying on the left side of the count

display and proceed to the right. When an ID greater

than 6 digits is used, the digits will automatically scroll

off the left side of the count display to show the

additional digits on the right as they are entered.

4. The display will change to TARE=TARE= and show the current

tare weight (the weight of the empty container). Press

the ENTER key if the current scale weight is to be used

for the tare or using the numeric keypad, key-in the tare

and press the ENTER key. Note, entering a 0 (zero) for

tare and pressing the ENTER key will select no tare.

5. The display will change to UNITSUNITS. If the Average Piece

Weight is known, use the numeric keypad to key-in the

value and press the ENTER key OR if the average

piece weight isn't known press the ENTER key.

6. The display will change to ACCU=ACCU= and show the current

value of the accumulator associated with the ID number.

If the displayed value is to remain unchanged, press the

ENTER key OR using the numeric keypad, key-in the

desired accumulator value and press the ENTER key.

7. The ID annunciator will stop flashing and stay on,

indicating the ID has been stored and is now the current

active ID. Counts will accumulate from this point.

8. Repeat the above steps for all ID numbers to be added.

When completed, proceed to the "Standard Sampling

and Counting" section of this manual.

Deleting ID Numbers

1. With the counting scale on, and in the Weight mode

(the Count display is blank), press the ID key.

2. The ID annunciator will flash, the weight display will

show id=id=, and the count display will show the current

active ID.

NOTE: If 7 to 12 digit ID numbers have been used, press the "-" (minus) key to

scroll the number displayed to the right and the "+" (plus) key to scroll the

number displayed to the left to view the complete ID number.

16

0.000

lb

id=

I524

1 2 3 4 5

6 7 8 9 0

tArE=

0.000

ID

Accu= 0

unitS 0.000

0.000

ID

id=

I524

0.000

ID

Page 18

OPERATION USING ID(S), Cont.

Deleting ID Numbers, Cont.

3. If the current ID is to be deleted, key-in the displayed

number and press the ID key OR if another ID is to be

deleted, key-in that ID number and press the ID key.

4. The weight display will change to delid delid and the count

display will change to nono.

5. Press the YES/1 key to toggle the count display to yesyes,

then press the ENTER key to delete the ID.

6. The ID number entered and its associated accumulator

will be deleted. The ID annunciator will stop flashing

and remain off and the scale will return to the Weight

mode.

Selecting The ID Number

1. With the counting scale on, and in the Weight mode

(the Count display is blank), press the ID key.

2. The ID annunciator will flash, the weight display will

show id=id=, and the count display will show the current

active ID.

3. If the current ID is to be used, press the ENTER key

OR if another ID is to be used, using the numeric

keypad, key-in the desired identification number and

press the ENTER key.

NOTE: If the ID does not exist, the scale will

beep and return to the weight mode.

5. The ID annunciator will stop flashing and stay on, and

the scale will return to the Weight mode.

Verifying Active (Current) ID Number

1. With the counting scale on, and in the Weight mode

(the Count display is blank), press the ID key.

2. The ID annunciator will flash, the weight display will

show id= id=, and the count display will show the current

active ID.

3. Press the ENTER key. The ID annunciator will stop

flashing and stay on, and the scale will return to the

Weight mode.

Turning Off The Active (Current) ID Number

1. With the counting scale on, and in the Weight mode

(the Count display is blank), press the ID key.

2. The ID annunciator will flash, the weight display will

show id=id=, and the count display will show the current

active ID.

3. Press the CE key, then the ENTER key.

4. The ID annunciator will stop flashing and remain off

and the scale will return to the Weight mode.

17

ID

1 2 3 4 5

6 7 8 9 0

dEL id

no

dEL id

YES

0.000

id= I524

lb

0.000

lb

id= I524

1 2 3 4 5

6 7 8 9 0

ID

0.000

ID

0.000

ID

id= I524

ID

0.000

0.000

ID

id= I524

0.000

lb

Page 19

OPERATION USING ID(S), Cont.

Operation With Stored Tare Weight Values

The Digital Counting Scale can store separate Tare weight values for each ID for both the Local

and Remote scale. This allows the operator to use a smalll container for sampling and a larger

container such as a pallet, tote or the shipping box for the final item count.

The TARE WEIGHT value can be programmed (stored) when first adding an ID or it can be

added to the ID before or during a Count or Sample operation. Note, that if an ID has a stored

Tare weight value and the Tare weight is updated during a Count or Sample operation, the

updated value will become the stored Tare Weight value.

NOTE: When an ID is selected that has a stored Tare weight, the scale will

automatically switch to the Net mode operation when the SAMPLE key or the COUNT

key is pressed and display a negative weight (the Tare) if the container is not on the

scale.

Standard Sampling and Counting

1. With the counting scale on, unloaded, warmed up (on for

approximately 10 minutes), and in the Weight mode (the

Count display is blank), press the ID key.

2. The ID annunciator will flash, the weight display will

show id=id=, and the count display will show the current

active ID.

3. If the current ID is to be used, press the ENTER key

OR if another ID is to be used, using the numeric

keypad, key-in the desired identification number and

press the ENTER key.

4. The ID annunciator will stop flashing and stay on, and

the scale will return to the Weight mode.

5. Press the SAMPLE key.

6. Add or remove the number of pieces indicated on the

display and press the COUNT or ENTER key.

7. Add the pieces to be counted and read the total count.

8. Press the ENTER key to complete the counting

operation and return to the Weight mode.

Automatic Average Piece Weight Re-Computation

Immediately after a standard sampling operation, if a quantity of pieces less than the original

sample size is added to the scale platform, a new average piece weight will be calculated

automatically. This new average piece weight is based on a larger sample than that used initially

therefore improving the accuracy of the count.

NOTE: The automatic recomputation of the average piece weight occurs only once for each new

sample. Note also that the recalculation of the average piece weight will not take place if the

quantity of pieces added is equal to or greater than the original sample quantity, neither will it

take place if the display mode is changed before the pieces are added.

18

1 2 3 4 5

6 7 8 9 0

ID

id= I524

0.000

lb

Add 5

SAMPLE

5

COUNT

I I 0

COUNT

0.000

lb

Page 20

OPERATION USING ID(S), Cont.

Counting With an Insufficient Sample

1. With the counting scale on, unloaded, warmed up (on for

approximately 10 minutes), and in the Weight mode (the

Count display is blank), press the ID key.

2. The ID annunciator will flash and the weight display will

show id=id=, and the count display will show active ID.

3. If the current ID is to be used, press the ENTER key

OR if another ID is to be used, using the numeric

keypad, key-in the desired identification number and

press the ENTER key.

4. The ID annunciator will stop flashing and stay on, and

the scale will return to the Weight mode.

5. Press the SAMPLE key, then add the number of pieces

indicated on the display and press the COUNT or

ENTER key.

6. If the sample weight is too small, the INSUFFICIENT

SAMPLE annunciator will flash and the display will show

the number of additional pieces to be added.

7. Add or remove the pieces requested, then press the

COUNT or ENTER key or if Manual Count Override* is

enabled, press the COUNT or ENTER key to force a

count function. If the pieces are not added or removed,

the INSUFFICIENT SAMPLE annunciator will continue

to flash to show the out-of-tolerance count.

NOTE: If the Manual Count Override is not enabled

and less than the displayed number of pieces are

added or removed when requested to add additional

pieces, the counting operation will terminate and the

scale will return to the Weight mode.

8 Add or remove the pieces to be counted and read the

count.

9. Press the ENTER key to complete the counting

operation and return to the Weight mode.

* Refer to Calibration and Setup section

Adjusting the Sample Quantity

1. With the scale in the Weight mode (the Count display is

blank), press the ID key.

2. The ID annunciator will flash, the weight display will

show id=id=, and the count display will show the current

active ID.

3. If the current ID is to be used, press the ENTER key

OR if another ID is to be used, using the numeric

keypad, key-in the desired identification number and

press the ENTER key.

4. The ID annunciator will stop flashing and stay on, and

the scale will return to the Weight mode.

19

or

1 2 3 4 5

6 7 8 9 0

Add 5

5

II0

0.000

lb

id= I524

ID

Add 25

INSUFFICIENT

SAMPLE

SAMPLE

30

COUNT

INSUFFICIENT

SAMPLE

COUNT

0.000

lb

0.000

lb

id= I524

ID

1 2 3 4 5

6 7 8 9 0

0.000

ID

Page 21

OPERATION USING ID(S), Cont.

Adjusting the Sample Quantity, Cont.

5. Press the SAMPLE key. Press the SAMPLE key again

to step to the next sample quantity. Note that pressing

the SAMPLE key repeatedly will cause the sample

quantity to step in the following sequence:

5, 10, 25, 50, 100, 5, 10, etc. OR

6. Using the numeric keypad, key-in any desired sample

value, then press the ENTER key.

7. Add or remove the indicated sample quantity and press

the COUNT or ENTER key.

8 Add or remove the pieces to be counted and read the

total count.

9. Press the ENTER key to complete the counting

operation and return to the Weight mode.

Counting Out From a Container

1. With the scale in the Weight mode (the Count display is

blank), press the ID key.

2. The ID annunciator will flash, the weight display will

show id=id=, and the count display will show the current

active ID.

3. If the current ID is to be used, press the ENTER key

OR if another ID is to be used, using the numeric

keypad, key-in the desired identification number and

press the ENTER key.

4. The ID annunciator will stop flashing and stay on, and

the scale will return to the Weight mode.

5. Place the filled container on the scale platform and

press the SAMPLE key.

6. Remove the number of pieces shown on the display and

press the COUNT or ENTER key.

7. Press the ZERO key to zero the count, then remove the

pieces from the container and read the total number

removed.

8. Press the ENTER key to complete the counting

operation and return to the Weight mode.

20

then

Add 5

SAMPLE

Add 10

SAMPLE

1 2 3 4 5

6 7 8 9 0

II0

0.000

lb

COUNT

0.000

lb

id= I524

ID

1 2 3 4 5

6 7 8 9 0

Add 5

SAMPLE

II0

COUNT

0

COUNT

0.000

lb

Page 22

OPERATION USING ID(S), Cont.

Accumulators

Displaying the Accumulator for the Active ID.

1. With scale in the Weight mode (the Count display is

blank), press the ID key.

2. The ID annunciator will flash, the weight display will show

id=id=, and the count display will show the current active ID.

Press the ENTER key.

3. The ID annunciator will stop flashing and stay on, and the

scale will return to the Weight mode.

4. Press the ACCUM key to display the contents of the

accumulator. The ACCUM annunicator will illuminate.

5. Press the ACCUM key to return to the Weight mode.

Clearing the Accumulator for the Active ID.

1. With scale in Weight mode (the Count display is blank),

press the ID key.

2. The ID annunciator will flash, the weight display will

show id=id=, and the count display will show the current

active ID. Press the ENTER key.

3. The ID annunciator will stop flashing and stay on, and

the scale will return to the Weight mode.

4. Press the ACCUM key (illuminating the ACCUM

annunicator) to display the contents of the accumulator

for the ID entered.

5. Press the ZERO key to reset the accumulator to zero.

6. Press the ACCUM key to return to the Weight mode.

Displaying the Accumulator for a Non-Active ID.

NOTE: The following steps change the Non-Actve ID to

the Active ID to Display the Accumulator.

1. With scale in the Weight mode (the Count display is

blank), press the ID key.

2. The ID annunciator will flash, the weight display will

show id=id=, and the count display will show the current

active ID.

3. Using the numeric keypad, key-in the desired

identification number and press the ID key.

4. The ID annunciator will stop flashing and stay on, and

the scale will return to the Weight mode.

5. Press the ACCUM key to display the contents of the

accumulator. The ACCUM annunicator will illuminate.

6. Press the ACCUM key to return to the Weight mode.

21

0.000

2583I

ACCUM

id= I524

ID

0.000

ID

id= I524

ID

2583I

ACCUM

0

ACCUM

0.000

lb

id= 1524

1 2 3 4 5

6 7 8 9 0

ID

2583I

ACCUM

ID

ID

Page 23

OPERATION USING ID(S), Cont.

Clearing the Accumulator for a Non-Active ID.

NOTE: The following steps change the Non-Actve ID to

the Active ID to Clear the Accumulator.

1. With scale in Weight mode (the Count display is blank),

press the ID key.

2. The ID annunciator will flash, the weight display will

show id=id=, and the count display will show the current

active ID.

3. Using the numeric keypad, key-in the desired

identification number and press the ENTER key.

4. The ID annunciator will stop flashing and stay on, and

the scale will return to the Weight mode.

5. Press the ACCUM key to display the contents of the

accumulator. The ACCUM annunicator will illuminate.

6. Press the ZERO key to reset the accumulator to zero.

7. Press the ACCUM key to return to the Weight mode.

manual accumulator Adjustment

Adding to the Accumulator for the Active ID.

1. With scale in the Weight mode (the count display is

blank), press the ID key.

2. The ID annunciator will flash, the weight display will show

id=id=, and the count display will show the current active ID.

Press the ENTER key.

3. The ID annunciator will stop flashing and stay on, and the

scale will return to the Weight mode.

4. Press the SAMPLE key, then add or remove the number

of pieces indicated on the display.

5. Press the COUNT or ENTER key, add or remove the

pieces to be counted and read the total count.

6. With the display showing the current count (COUNT

annunciator ON) press the ++ key to add to (or the - key to

subtract from) the displayed count of the accumulator.

The ACCUM annunciator will flash to show that the

adjustment to the accumulator has taken place and will

continue to flash until all pieces are removed from

platform and the display returns to zero in preparation for

the next counting operation.

7. Press the ENTER key to return to the Weight mode.

NOTE: Additional accumulator adjustments can not take place until the next

counting operation has been completed.

22

0.000

lb

id= I524

ID

1 2 3 4 5

6 7 8 9 0

0.000

ID

id= I524

ID

1 2 3 4 5

6 7 8 9 0

0.000

lb

2583I

0.000

ID

ACCUM

0

ACCUM

Add 5

SAMPLE

II0

COUNT

II0

ACCUM

Page 24

OPERATION USING ID(S), Cont.

Adding to the Accumulator for a Non-Active ID.

NOTE: The following steps change the Non-Actve ID to the

Active ID to ADD to the Accumulator.

1. With scale in the Weight mode (the Count display is

blank), press the ID key.

2. The ID annunciator will flash, the weight display will

show id=id=, and the count display will show the current

active ID.

3. Using the numeric keypad, key-in the desired

identification number and press the ENTER key.

4. The ID annunciator will stop flashing and stay on, and

the scale will return to the Weight mode.

5. Press the SAMPLE key, then add or remove the number

of pieces indicated on the display.

6. Press the COUNT or ENTER key, add or remove the

pieces to be counted and read the total count.

7. With the display showing the current count (COUNT

annunciator ON) press the ++ key to add to (or the - key to

subtract from) the displayed count of the accumulator.

The ACCUM annunciator will flash to show that the

adjustment to the accumulator has taken place and will

continue to flash until all pieces are removed from

platform and the display returns to zero in preparation for

the next counting operation.

8. Press the ENTER key to return to the Weight mode.

NOTE: Additional accumulator adjustments can not take place until the next

counting operation has been completed.

23

id= 1524

ID

Add 5

0.000

SAMPLE

II0

COUNT

ACCUM

II0

0.000

lb

1 2 3 4 5

6 7 8 9 0

ID

0.000

Page 25

CALIBRATION and SETUP

This scale was calibrated at the factory and should not require adjustment. In the event that the

scale should need recalibration, the following describes the Calibration of the Digital Counting

Scale. A qualified technician should perform this function to maintain the instrument's high

degree of accuracy.

Before beginning calibration, the following equipment is required:

Calibrated test weights (Full capacity for all models, e.g. 5 lbs for 5 lb, . . . 100 lbs for 100 lb)

Small Flat Blade screwdriver (to remove calibration sealing screw)

If sealing wires require breaking for purposes of calibration, proper procedures under

National Institue of Standards and Technology Handbook 44 must be adhered to.

CALIBRATION PROCEDURE - LOCAL SCALE

1. With the scale power off, remove the calibration sealing screw on the right side panel, see

Figure No.7.

2. With the screw removed, place the power switch in the ON position. The scale will perform a

brief lamp test. This test consists of illuminating all display segments and annunciator LED's

for approximately three (3) seconds to allow the operator to make a visual verification that

the display is operational. After completion of the lamp test, the scale will display the model

number and software revision level, then the weight display will change to SCALESCALE.

3. Select the LOCAL scale by pressing the LOCAL SCALE key.

4. The weight display will change to LOAD LOAD and the count display will change to xxxxxx. Note

that xxxxxx is the capacity of the scale and the load required to calibrate the scale. This will

vary depending on the capacity of the scale and the units of measurement selected.

5. Press the lb/kg key to select the units of measurement for calibration. Note that the "lb" or

"kg" annunciator will be illuminated to indicate which unit of measurement has been selected

and the count display will show the corresponding load.

6. Press the + key to cycle up through or the - key to cycle down through the folowing

capacity values: 5, 10, 20, 50, 100 for pounds (lb) or 2, 5, 10, 20, 40 for kilograms (kg).

CAUTION: The capacity value selected must match the load cell installed in the

scale. Proper operation of the scale may be inhibited and the warranty will be

voided if the required load cell is not used. Refer to the Load Cell Table in the

Parts Identification section of this manual for the required load cell for the

capacity selected.

7. Place the required calibrated test weight on the scale platform, wait about 5 seconds for the

scale to stabilize, then press the ENTER key to start calibration.

24

Calibration Sealing Screw

Figure No. 7

Page 26

CALIBRATION and SETUP, Cont.

CALIBRATION PROCEDURE - LOCAL SCALE, CONT.

8. The display will start to fill with dashes from the left of the weight display and proceed to the

right of the count display. When finished, the unit will display UNLOAD UNLOAD on the count display.

9. Remove the weight from the scale, wait about 5 seconds for the scale to stabilize, then

press the ENTER key to finish calibration.

10. The display will start to fill with dashes from the left of the weight display and proceed to the

right of the count display. When finished, the display will change to calib doNEcalib doNE.

11. If operational setup is required (or a remote scale is to be used) proceed to the Operational

Setup procedure.

12. If only calibration was required and the LOCAL (integral) scale is the only scale, turn the

scale off and replace the calibration sealing screw on the right side panel of the scale. Place

the power switch in the ON position. The scale is now ready for use.

OPERATIONAL SETUP

The Operational Setup of the Digital Counting Scale is accomplished entirely by using the scale

keypad and can easily be performed using one of the following methods:

Calibration Method (sealing screw REMOVED)

At the completion of the Calibration procedure (Local or Remote scale), the display will

change to calib doNEcalib doNE. Press the ENTER key. The weight display will show SCALESCALE . Press

the ENTER key again. The weight display will change to scal2scal2, the first setup prompt.

The scale is now ready to begin setup.

Operation Method (sealing screw INSTALLED)

With the scale power off, apply power by placing the power switch in the ON position.

While the weight display is showing 2240 2240 or 2241 2241 (the model number) and the count

display is showing xx r?.?r?.? (the capacity and the software revision level), press the

ENTER key. The weight display will change to the first setup prompt, scal2scal2. The scale is

now ready to begin setup.

During the setup process it will be necessary to enter operational parameters using the

counting scale's keypad. Pressing the ENTER key will cause the data entered or

displayed to be retained and the setup process will advance to the next prompt.

NOTE: If an incorrect entry is made, pressing the CE key will clear the display and

allow re-entering the correct data.

ZERO TRACKING

The display will show 0trac0trac, the prompt to enable or disable the automatic Zero Tracking

feature and display the current setting. This feature, when enabled will automatically maintain

the center-of-zero within one division. To change the setting, press the YES/1 key to enable

or the NO/0 key to disable, then press the ENTER key to save the setting and proceed to the

next prompt.

FOUR PERCENT ZERO RANGE LIMIT

The display will show 4 Pct4 Pct, the prompt to select whether a 4% limit be placed on the push

button zero and display the current setting. If enabled, the push button zero is limited to 4%

of the scale capacity. If disabled, the push button zero will operate up to the full capacity of

the scale. Press the YES/1 key to enable or NO/0 to disable, then press the ENTER key to

save the setting and proceed to the next prompt.

UNITS OF MEASUREMENT

The display will show unitsunits , the prompt to select the Units of Measurement and display the

current setting. To change the setting, use the keypad to select a new value (1 to 3) for the

units, then press the ENTER key to save the setting and proceed to the next prompt.

1 = Pounds (lb) only 2 = Kilograms (kg) only 3 = Pounds/Kilograms (lb/kg)

25

Page 27

CALIBRATION and SETUP, Cont.

OPERATIONAL SETUP, Cont.

SCALE 2 (Optional remote scale)

The display will show scal2scal2, the prompt to enable or disable the optional remote scale and

display the current setting. To change the setting, press the YES/1 key to enable or the NO/0

key to disable, then press the ENTER key to save the setting and proceed to the next prompt.

NOTE: The REMOTE scale cannot be used until it has been calibrated (refer to the

Calibration Procedure - Remote Scale section).

AUTO LOCAL-TO-REMOTE SWITCH

The display will show a suta sut, the prompt to enable or disable the Auto Switching from the

sample scale to the bulk scale for counting operations and display the current setting. This

feature, when enabled will use the integral (local) scale for the sample then automatically

switch to the bulk (remote) scale for counting with the acceptance of the sample. To change

the setting, press the YES/1 key to enable or the NO/0 key to disable, then press the ENTER

key to save the setting and proceed to the next prompt.

AUTO RECALL OF LAST AVERAGE PIECE WEIGHT

The display will show a RcLa RcL, the prompt to enable or disable the Auto Recall of the Average

Piece Weight on power up and display the current setting. This feature, when enabled will

automatically recall the last average piece weight after turning the scale on. To change the

setting, press the YES/1 key to enable or the NO/0 key to disable, then press the ENTER key

to save the setting and proceed to the next prompt.

AUTO ACCUMULATION

The display will show a acca acc , the prompt to enable or disable Auto Accumulation of counts

and display the current setting. This feature, when enabled will automatically accumulate the

counts after a counting operation. If disabled, the operator must press the ACCUM key to

accunulated the counts. To change the setting, press the YES/1 key to enable or the NO/0

key to disable, then press the ENTER key to save the setting and proceed to the next prompt.

BEEPER

The display will show beeprbeepr, the prompt to enable or disable the internal beeper and display

the current setting. This feature, when enabled will sound the beeper each time a key is

pressed and when an error occurs. If disabled, the beeper will only sound when an error

occurs. To change the setting, press the YES/1 key to enable or the NO/0 key to disable,

then press the ENTER key to save the setting and proceed to the next prompt.

STORE ID

The display will show str idstr id, the prompt to enable or disable the Identification Number (ID)

feature and display the current setting. To change the setting, press the YES/1 key to enable

or the NO/0 key to disable, then press the ENTER key to save the setting and proceed to the

next prompt.

12 HOUR CLOCK

The display will show 12 hr12 hr, the prompt to enable or disable the 12 Hour clock feature and

display the current setting. This feature, when enabled will select the 12 hour time format for

printing the time on tickets. Note that an "a" for am or an "p" for pm will not print on the ticket.

If disabled, the time will be in the 24 hour (military) time format. To change the setting, press

the YES/1 key to enable or the NO/0 key to disable, then press the ENTER key to save the

setting and proceed to the next prompt.

NOTE: The 12 Hour Clock feature only affects how the time is printed on tickets. The time is

set using the 24 hour (military) format whether the 12 Hour clock feature is enable or

disabled.

26

Page 28

CALIBRATION and SETUP, Cont.

OPERATIONAL SETUP, Cont.

EUROPEAN DATE

The display will show europeurop, the prompt to enable or disable the European Date format and

display the current setting. This feature, when enabled will print the date on tickets in the

European (International) format of day/month/year (DD/MM/YYYY). If disabled, the date on

the tickets will print in the month/day/year (MM/DD/YYYY) format. To change the setting,

press the YES/1 key to enable or the NO/0 key to disable, then press the ENTER key to save

the setting and proceed to the next prompt.

MANUAL COUNT OVERRIDE

The display will show n cntn cnt, the prompt to enable or disable the Manual Count Override and

display the current setting. This feature, when enabled will allow a counting operation to

continue while the Insufficient Sample annunciator is illuminated. If disabled, the counting

operation can not be contiuned until additonal sample pieces are placed on the scale

platform. To change the setting, press the YES/1 key to enable or the NO/0 key to disable,

then press the ENTER key to save the setting and proceed to the next prompt.

PRINTER OUTPUT

The display will show prntrprntr, the prompt to enable or disable the Printer output and display

the current setting. To change the setting, press the YES/1 key to enable or the NO/0 key to

disable, then press the ENTER key to save the setting and proceed to the next prompt.

If printer output is enabled, additional setup prompts (TICKET FORMAT and PRINT

BARCODE) will be displayed. If printer output is disabled, the setup procedure will

advance to the UNITS OF MEASUREMENT prompt.

TICKET FORMAT

If Printer Output was enabled, then the display will show ticfrticfr, the prompt to select the

format for ticket printing and display the current setting. The available formats are:

1 = Vertical Printing (The printed line is parallel with the print head)

2 = Horizontal Printing (The printed line is at right angle to the print head)

3 = Generic Text Printer (ASCII text ouptut with CR/LF control codes only)

To change the setting, on the numeric keypad press the YES/1 key to select the vertical

format, the 2 key to select the horizontal format or the 3 key to select the Generic Text

Printer. Press the ENTER key to save the setting and proceed to the next prompt.

NOTE: The maximum number of digits in an ID number is dependent upon the Ticket Format

selected. When using format 1, the maximum is 10 digits. When using format 2, the maximum

length of an ID number is 12 digits.

PRINT BARCODE

If Printer Output was enabled, and Ticket Format 1 or 2 was chosen, then the display will

show barcobarco , the prompt to enable or disable printing barcode on the ticket and display the

current setting. To change the setting, press the YES/1 key to enable or the NO/0 key to

disable, then press the ENTER key to save the setting and proceed to the next prompt.

NOTE: Barcode printing is available only when Ticket Format 1 or 2 have been selected.

Ticket Format 3 (Generic Text Printer) does not support bardocde.

27

Page 29

CALIBRATION and SETUP, Cont.

OPERATIONAL SETUP, Cont.

COUNT ACCURACY

The display will show C acrC acr , the prompt to select the Count Accuracy percentage and

display the current setting. This refers to the set-point for the INSUFFICIENT SAMPLE

annunciator. There are two pre-selected values, .1 and .5 percent. If the weight of a sample

is less than .1% or .5% of the gross capacity of the scale, (.1 lb or .5 lb for a 100 lb capacity

scale) sample accuracy is not guaranteed. The Insufficient Sample annunciator will

illuminate, and the scale will calculate the minimum additional number of pieces required to

raise the sample weight to the .1% or .5% preset and display the quantity.

To change the setting, use the numeric keypad to key-in a new value (1 or 5, with no decimal)

for the count accuracy, then press the ENTER key to save the setting and proceed to the

next prompt.

AUTO SHUTOFF

The display will show a offa off, the prompt to enable or disable the Auto Shutoff feature and

display the current setting. This feature, when enabled will automatically turn the scale off

after a select period of inactivity to prolong battery life. To turn the instrument back on you

must toggle the power switch from the ON position to the OFF position and then back to the

ON position.

To change the setting, using the numeric keypad, key-in the number of minutes (1 through 9,

time approximate) of inactivity before turning the scale off, then press the ENTER key to save

the setting and proceed to the next prompt. Note, that entering a zero (0) disables the

Automatic Shutoff feature.

DISPLAY INTENSITY

The display will show britebrite, the prompt to adjust the display intensity and display the current

setting. This feature allows the display intensity (brightness) to be adjusted to compensate for

lighting conditions at the scale's location. Also, when operating from the battery, lowering the

display intensity decreases the load on the battery, increasing operating time before

recharging is required. To change the setting, use the numeric keypad to key-in a new value

(1 to 3) for the display intensity, then press the ENTER key to save the setting and proceed to

the next prompt.

1 = DIM 2 = NORMAL (default setting) 3 = HIGH

CLEAR MEMORY

The display will show clr rclr r, the prompt to enable the Clear Memory operation and display

the current (default) setting NO. This operation, when enabled will clear all ID's and

associated accumulators from the scale memory. The Clear Memory operation is performed

after turning the scale OFF and back ON with YES selected for the setup prompt. After

clearing memory, the setup prompt will automatically return to NO, the default setting.

NOTE: The Clear Memory operation does not clear the Calibration or Setup

information from the scale. The Calibration and Setup data are stored in non-volatile

memory (NOVRAM) and can only be changed using their respective procedures.

To enable the Clear Memory operation, press the YES/1 key, then press the ENTER key to

save the setting and proceed to the next prompt.

28

Page 30

CALIBRATION and SETUP, Cont.

OPERATIONAL SETUP, Cont.

PRINT SETUP

The display will show prsetprset, the prompt to enable printing a record of the scale's current

Operational Setup and display the current (default) setting NO. This operation, when enabled

and with a printer connected to the printer port will print a summary of the Operational Setup.

To print the summary, press the YES/1 key, then press he ENTER key. The summary will

begin to print immediately after pressing the ENTER key. Upon completion of printing, the

setup prompt will automatically return to NO, the default setting and then proceed to the next

prompt.

Please note, that in order to print the Operational Setup, a serial dot matrix printer and

8½" x 11" paper must be used NOT the thermal label printer used for printing labels.

The serial dot matrix printer must have a RS232 serial interface configured for 9600

baud, 8 data bits, No parity and 1 stop bit (9600,8,N,1).

SETUP DONE

If Setup was performed using the Calibration Method (sealing screw REMOVED), the display

will change to setup doNE setup doNE when completed. Place the power switch in the OFF position

and replace the calibration sealing screw on the right side panel of the scale. Return the

power switch to the ON position. The scale will power up to the Weight Display mode and is

now ready for use.

When using the Operation Method (sealing screw INSTALLED), at the completion of Setup,

the scale will return to Weight Display mode and is ready for use.

CALIBRATION PROCEDURE - REMOTE SCALE

If sealing wires require breaking for purposes of calibration, proper procedures under

National Institue of Standards and Technology Handbook 44 must be adhered to.

1. With the scale power off, remove the calibration sealing screw on the right side panel, see

Figure No.7.

2. With the screw removed, place the power switch in the ON position. The scale will perform a

brief lamp test. This test consists of illuminating all display segments and annunciator LED's

for approximately three (3) seconds to allow the operator to make a visual verification that

the display is operational. After completion of the lamp test, the scale will display the model

number and software revision level, then the weight display will change to SCALESCALE.

3. Select the REMOTE scale by pressing the REMOTE SCALE key.

NOTE: The REMOTE scale cannot be selected until it has first been enabled in

Setup (refer to Operational Setup section).

4. The weight display will change to cap =cap = (capacity).

5. Key-in the scale capacity (max 6 digits) and press the ENTER key.

6. The display will change to int =int = (interval or division).

7. Key-in the interval (division value) (max 4 digits) then press the ENTER key. The following

values are allowable for the interval: 1, 2, 5, .1, .2, .5, .01, .02, .001, .002, .005, .0001,

.0002 and .0005.

29

Page 31

CALIBRATION and SETUP, Cont.

CALIBRATION PROCEDURE - REMOTE SCALE, Cont.

NOTE: When selecting the interval, the total number of divisions can not exceed

10,000 divisions. To calculate the total number of divisions, divide the capacity of the

scale by the interval. For example:

10 lb (scale capacity) ÷ .001 (interval) = 10,000 (divisions).

8. The weight display will change to units units (units), the prompt to select the Units of

Measurement. Press the lb/kg key to select the units of measurement for calibration. Note

that the "lb" or "kg" annunciator will be illuminated to indicate which unit of measurement has

been selected and the count display will show the corresponding load.

9. The weight display will change to LOADLOAD. Place a known calibrated test weight on the

Remote scale platform, key-in the weight (max 6 digits), wait about 5 seconds for the scale

to stabilize, then press the ENTER key to start calibration.

10. The display will start to fill with dashes from the left of the weight display and proceed to the

right of the count display. When finished, the unit will display UNLOAD UNLOAD on the count display

11. Remove the weight from the scale, wait about 5 seconds for the scale to stabilize, then