Page 1

Technical Support: Ph: 866-254-8261 v techsupport@cardet.com

Waist-High

Dial Physician Scale

Models 090 and 090KG

Operating Instructions

CARDINAL SCALE MFG. CO.

0044-M323-O1 Rev B

PO Box 151 v Webb Cit

y

, MO 64870

07/06

Ph: 417-673-4631 v Fax: 417-673-5001

Printed in USA

www.detectoscale.com

Page 2

Page 3

SPECIFICATIONS

Capacity

Model 090

300 lb x 1 lb

Model 090KG

150 kg x .5 kg

UNPACKING INSTRUCTIONS

v

Remove scale from the carton by lifting up with equal

force on the column and platform base of the scale.

v

Check for any damage incurred in shipping. If the

scale has been damaged, place a claim with the

carrier. If the scale must be returned, use the original

carton and packing material.

v

Remove all plastic wrapping, banding and packing

material from the scale, as well as the cardboard

between the levers, and foam block inside the scale

base. The scale will not function properly if any of the

plastic wrap, the banding on the base, the cardboard

between the levers or foam block is still in place.

v

Set the scale on a flat, level floor or low cut carpet.

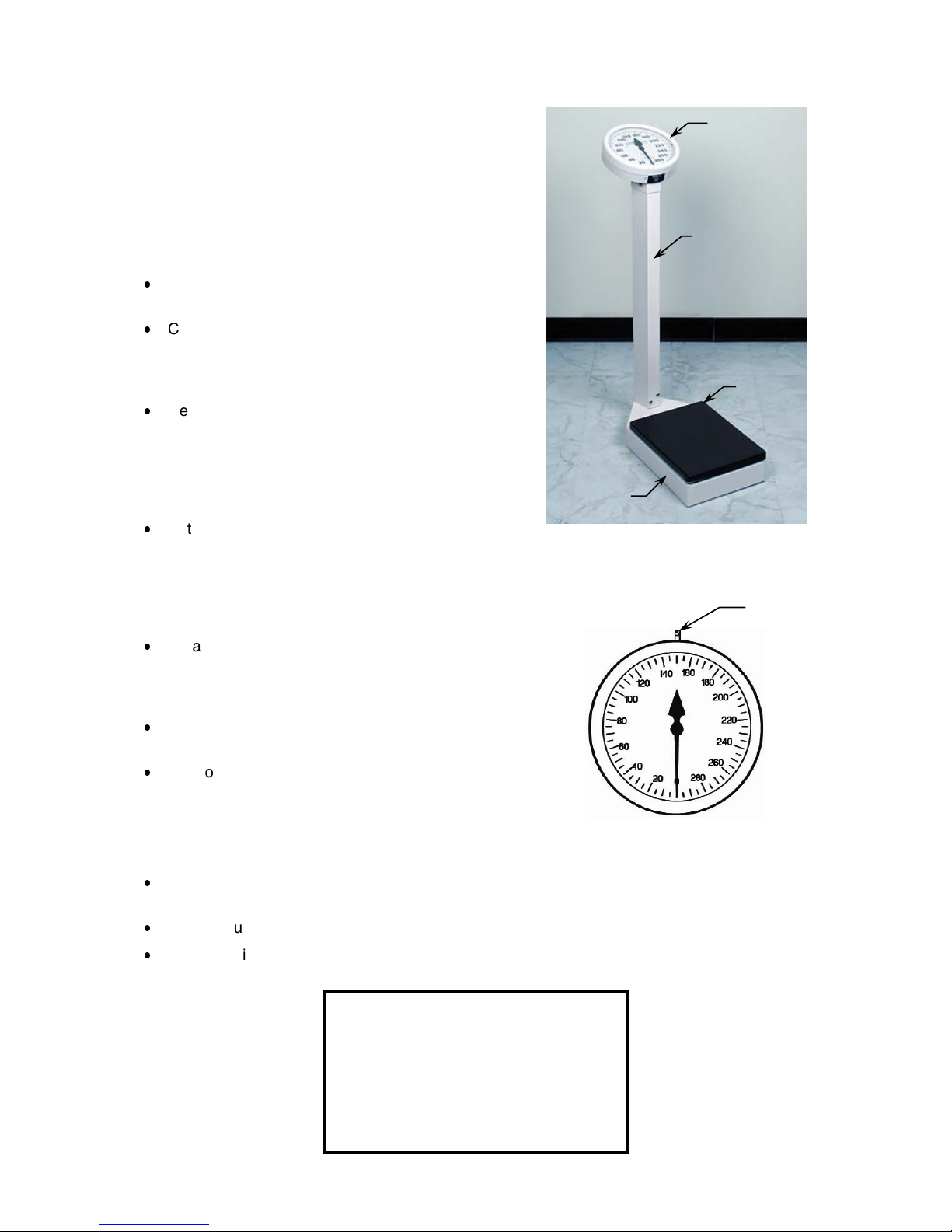

OPERATING INSTRUCTION

Zeroing the Scale

v

Rotate the zero adjust knob at the back edge of the dial

head to adjust the pointer until the “0” reading is obtained.

Weighing Procedure

v

Step onto the scale, position both feet firmly on the

platform. The pointer will indicate the current weight.

v

Step off the scale and re-zero the scale if necessary.

CARE AND CLEANING

v

DO NOT spray; water directly on the scale. The scale may be cleaned using a damp, soft

cloth and mild detergeant. NOTE! Some types of paper towels may scratch the dial lens.

v

DO NOT use acetone, alcohol, or other volatile solvents for cleaning.

v

DO NOT oil any parts of the scale.

Date of Purchase ________________

Purchased From _________________

_______________________________

_______________________________

Retain this information for future use.

Column

Dial Head

Platform

Platform

Base

Zero

Adjust

Knob

DIAL HEAD

1

Page 4

OPTIONAL WHEELS

How to setup the Detecto Waist-High

Dial Physican Scale with roller wheels.

1. Remove the two lower screws in

the back of the column.

2. Place the wheel bracket against

the back of the column and align

the holes in the bracket with the

holes in the column.

3. Install the two screws removed

in step 1, securing the wheel

bracket to the column.

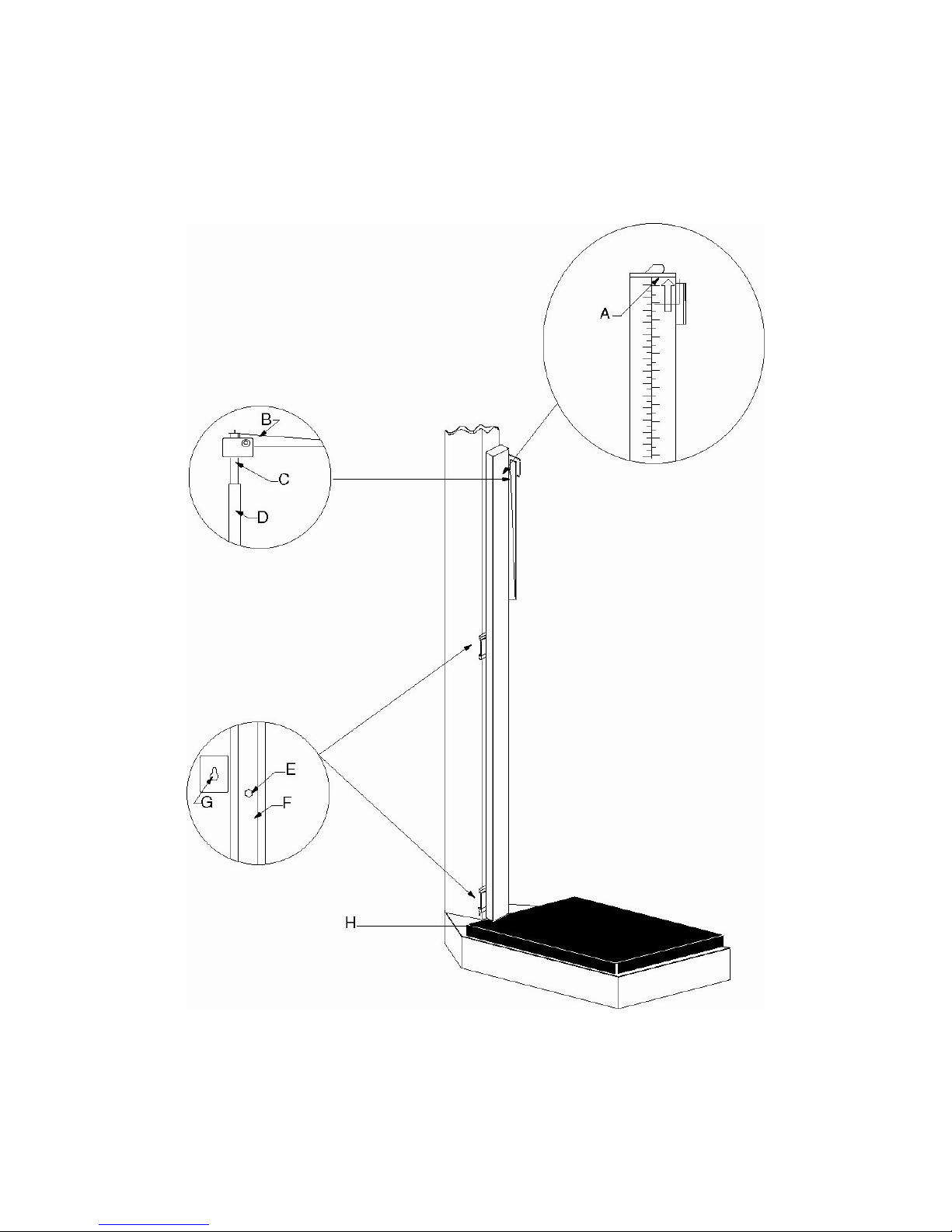

OPTIONAL HEIGHT ROD

Optional Height Rod Installation

1. Remove the height rod from the box.

2. If not already installed, insert the two hex head screws from the hardware pack into the

holes in the front of the column and tighten them with the included wrench until the hex

heads are 1/8" from the column.

3. Place both height rod brackets over the two pre-installed hex head screws and pull down.

4. Use the included wrench to tighten both hex head screws. Do not overtighten the screws.

Height Rod Operating Guide

1. Before the person steps onto the scale platform, the spoon should be rotated to the

horizontal position, and raised well above the person’s apparent height.

2. The person may now step onto the scale platform. The spoon should be held horizontal

and above the person’s head.

3. Carefully lower the spoon, while keeping it horizontal, until it rests gently upon the top of

the person’s head. If the person is shorter than 3' 4" (101.5 cm), push the latch to the right,

while simultaneously pushing down on the spoon, until the spoon rests horizontally upon

the top of the person’s head.

4. Read the height of the person as follows:

If the back of the spoon points to the outer height rod, then it points to the correct height.

If the back of the spoon points to the inner height rod, then the correct height is read at

the top of the outer height rod (see “Read” arrow on the outer height rod).

5. While holding the spoon horizontally, raise the spoon above the person’s head. The

person may now step off of the scale platform. Hold the spoon horizontal until the person

is clear of the height rod.

6. Rotate the spoon back to the vertical position and adjust the height rod back to the rest

position (i.e. the spoon should be locked in place within the inner height rod and the inner

rod should be at its lowest position).

Screws and

wheels bracket

2

Page 5

OPTIONAL HEIGHT ROD, Cont.

A = “Read” line

B = Spoon

C = Inner height rod

D = Outer height rod

E = Hex head screw

F = Column

G = Mounting bracket

H = Height rod sits on top of the scale base

3

Page 6

PARTS IDENTIFICATION

ITEM QTY PART NUMBER DESCRIPTION

1 1 3P1001X Base Weldment

2 1 430XG3R800 Column Weldment

3 1 3P2011X Platform Weldment

4 1 3P8068 Platform Cover

5 1 *0033-D203-0A Height Rod Assembly

6 4 6021-1629 Sheet Metal Screw #10 X 1/2”

7 2 6021-1058 THM Scw, #10-32 x .375

8 1 0044-C304-0A Pinion Assembly

9 1 3P8002X Long Lever Assembly

10 1 3P8003X Short Lever Assembly

11 1 0044-B294-08 Steelyard Rod

12 2 3P60 Check Plate

13 1 0044-C292-08 Column Top Adapter

14 8 6021-1423 THMS 1/4”-20 x 0.50

15 2 6013-0045 Hex Nut 1/4”-20

16 6 6021-2058 FHM Scw, Wht Nylon #6-32 x .5

17 6 6021-2043 RHM Scw, #6-32 x .25

18 2 0044-B172-08 Standoff

19 1 3P122 Bumper

20 2 6021-0985 Hex Washer Head Scw #10 X 1/2”

21 4 3P8059 Hanger

22 1 2U58 Center Loop

23 4 3P2087 Platform Load Bearing

24 1 0044-C305-0A Zero Adjust Assembly

25 6 6024-0047 Lock Washer 1/4”

26 4 63K1038 Base Leg

27 1 0044-C204-08 Bezel Ring

28 1 0044-B194-08 Friction Cap

29 4 6021-0622 RHM Scw, #8-32 x .25 Phil Drive

30 A/R 6560-0021 Locite #222-31

31 1 0044-C125-208 Lens

32 2 6024-1000 Internal Star Washer #8

33 1 0044-B223-08 Sash Mounting Plate

34 1 0044-C295-08 Base Plate

35 2 0044-D129-08 Sash Ring Half

36 1 0044-C321-08 Dial Chart for 090

37 1 0044-C322-08 Dial Chart for 090KG

38 1 0044-B141-08 Sash Ring Bracket

39 1 0044-C312-0A Driveline Assembly

40 1 0044-B151-08 Decal, Sash Button

41 1 6021-1836 PHM Scw, #8-32 x 3/16” Phil Drive

* Optional, Brackets Not Shown

4

Page 7

PARTS IDENTIFICATION, Cont.

5

Page 8

Loading...

Loading...