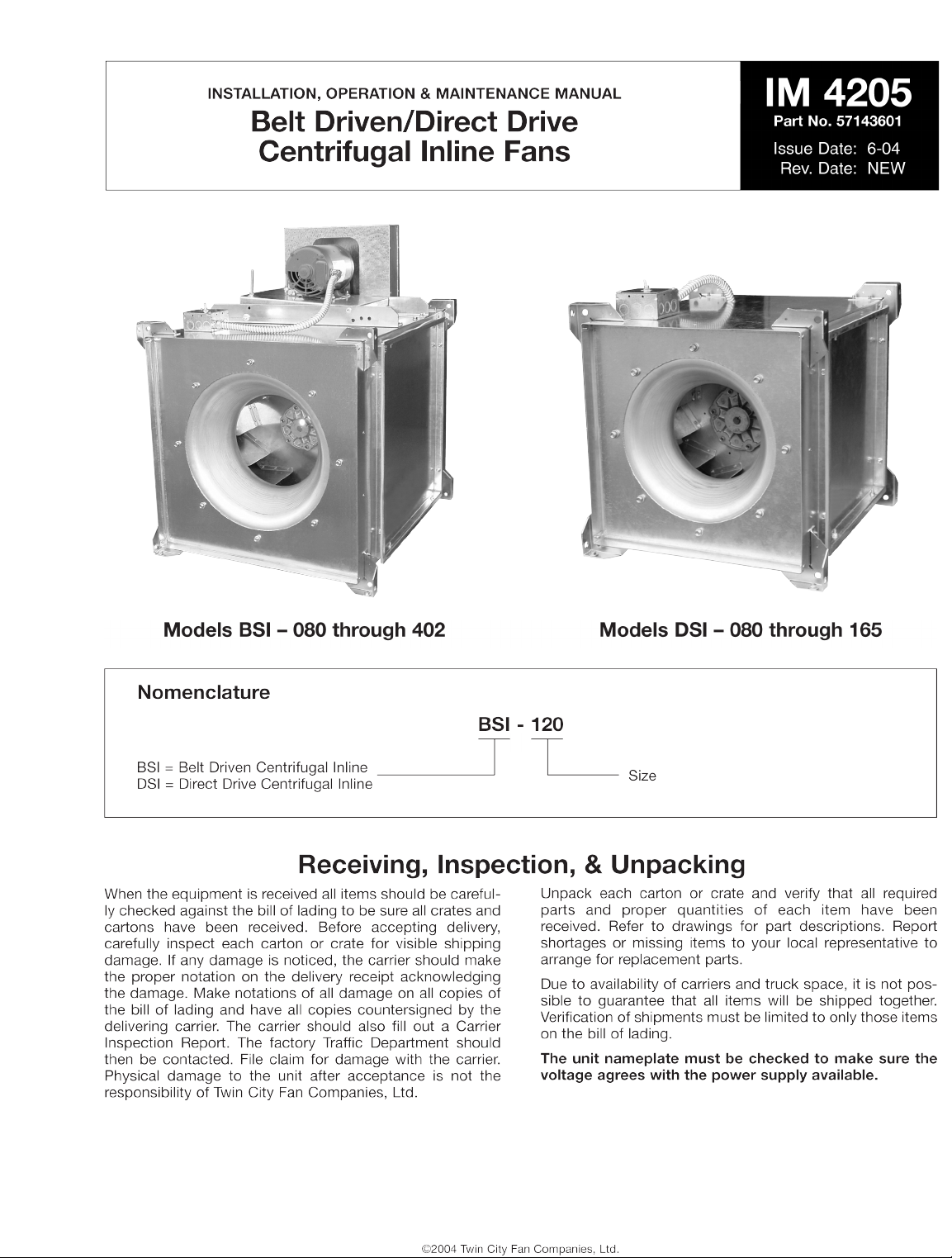

Page 1

Page 2

2 Tw in Ci ty IM 4 20 5

Installation

General

CAUTION: Sheet metal parts, screws, clips and similar

items inherently have sharp edges, and it is necessary

that the installer and service personnel exercise caution.

The installation of this equipment shall be in accordance

with the regulations of authorities having jurisdiction and

with all applicable codes.

This equipment is to be installed by an experienced installation company and fully trained personnel.

The mechanical installation of the inline centrifugal fan consists of making final connections between the unit, building

services, and duct connections.

1. These units have been run at the factory to insure excellent operation.

2. Before installing unit in ductwork (if damper is to be used)

make sure the damper is correctly installed. Refer to

Ta bl e 6 f or co rr ec t d am pe r s iz e .

3. Connect supply leads to the disconnect switch.

4. Check power supply to insure it is proper for the motor

supplied.

5. Determine if wheel is free to rotate and not subject to

misalignment in shipping or installation.

6. Install belts and adjust tension and lock capscrew in slot.

Te ns i on sh ou l d b e c he c ke d an d re se t , i f n ec e ss a ry, af t er

48 hours of operation. (BSI models only.)

7. Apply power and check wheel for proper rotation. Also

check unit RPM, motor volts and amperes, to insure

proper operation.

Check, Test & Start Procedure

WARNING

Electric shock hazard. Could cause severe injury or death. Failure to bond the frame of this equipment to the building

electrical ground by use of the grounding terminal provided or other acceptable means may result in electrical shock.

Disconnect electric power before servicing equipment. Service to be performed only by qualified personnel.

BEFORE STARTUP: Disconnect power to this unit before

servicing the unit.

1. Check to verify that the wheel is free to rotate.

2. Verify that supply voltage on the line side of disconnect

agrees with voltage on unit identification plate and is within the utilization voltage range as indicated in Table 1.

Tabl e 1. U ti li za ti on Vo lt ag e Ra ng es

3. On three-phase units check and calculate phase unbalance as follows:

% Voltage Unbalance = 100 x max. voltage deviation

from avg. voltage ÷ avg. voltage

Example: Determine the percent voltage unbalance given

voltages of 220, 216 and 213.

How To Use The Formula:

a. Avg. Voltage = 220 + 216 + 213 = 649 ÷ 3 = 216

b. Max. Voltage Deviation From Avg. Voltage =

220 – 216 = 4

c. % Voltage Unbalance = 100 x (4 ÷ 216) = 1.8%

Voltage unbalanc e sh oul d no t ex ceed 2%.

4. Apply power to unit and check rotation of wheel with the

directional arrow on the unit.

WARNING: All units run in a clockwise direction when viewed

from the air intake. If allowed to operate in the wrong direction, the motor will be overloaded and burn out

.

WARNING: Special attention should be paid to checking

three-phase units for rotation. For three-phase, rotation can

be changed by interchanging any two of the three line leads.

If unit is installed on temporary wiring, it should be rechecked

when permanently installed. Motor burn-out or tripped overload protection devices are usually the result of incorrect rotation.

5. Electrical Input Check: Perform check of fan ampere

draw and verify that motor nameplate amps are not

exceeded. Take account of the service factor range if

motor is nameplated above a 1.0 service factor.

6. Fan RPM Check: Fan the RPM should be checked and

verified with a tachometer. Refer to Table 2 for maximum

fan RPM values.

WARNING: Running the fan at an RPM greater than the maximum RPM value in Table 4 will overload the fan motor and

lead to premature motor failure.

WARNING: Do not replace motor sheave with one larger in

diameter. Do not replace fan sheave with one smaller in

diameter. The sheave ratios are set so that the motor will not

be overloaded within the range of the adjustable sheave.

SYSTEM VOLTAGE/ UTILIZATION VOLTAGE

UNIT NAMEPLATE MIN. MAX.

115/60/1 104 127

208-230/60/1 or 208-230/60/3 187 253

230/60/1 or 230/60/3 207 253

277/60/1 249 305

200/60/3 180 220

380/60/3 342 418

460/60/3 414 506

575/60/3 517 633

110/50/1 99 121

220/50/1 198 242

380-415/50/3 342 456

440/50/3 396 484

Page 3

Tw in Ci ty IM 4 20 5 3

MODEL MOTOR MAXIMUM

BSI HP FAN RPM

1/4 2250

1/3 2500

080 1/2 2860

3/4 3260

13590

1/4 2015

1/3 2230

090 1/2 2550

3/4 2920

13205

1/4 1565

1/3 1725

100 1/2 1980

3/4 2255

12480

1/4 1290

1/3 1420

120

1/2 1630

3/4 1865

12045

1-1/2 2345

1/4 1450

1/3 1600

120HP

1/2 1840

3/4 2105

12315

1-1/2 2655

1/4 1075

1/3 1190

135

1/2 1370

3/4 1565

11720

1-1/2 1970

1/4 1200

1/3 1350

135HP

1/2 1550

3/4 1765

11945

1-1/2 2225

1/4 920

1/3 1020

1/2 1170

150 3/4 1335

11465

1-1/2 1680

21845

1/3 1140

1/2 1320

150HP

3/4 1510

11660

1-1/2 1900

22090

1/3 875

1/2 1005

3/4 1150

165 11260

1-1/2 1445

21590

31820

1/2 1130

3/4 1290

165HP

11415

1-1/2 1620

21785

32040

Tabl e 2. M ax im um Fan R PM ( BS I)

MODEL MOTOR MAXIMUM

BSI HP FAN RPM

1/3 750

1/2 865

3/4 985

180 11085

1-1/2 1240

21365

31560

1/2 970

3/4 1105

180HP

11215

1-1/2 1390

21530

31750

1/3 630

1/2 720

3/4 825

210 1905

1-1/2 1040

21140

31305

1/2 810

3/4 925

210HP

11015

1-1/2 1165

21280

31465

1/3 520

1/2 600

3/4 685

225

1750

1-1/2 865

2950

31085

51285

3/4 785

1860

225HP

1-1/2 985

21085

31240

51470

1/2 505

3/4 575

1630

245

1-1/2 725

2795

3910

51080

7-1/2 1235

1730

1-1/2 835

245HP

2915

31050

51245

7-1/2 1425

1/2 420

3/4 480

1525

270

1-1/2 605

2665

3760

5900

7-1/2 1030

MODEL MOTOR MAXIMUM

BSI HP FAN RPM

1605

1-1/2 695

270HP

2760

3870

51030

7-1/2 1185

1450

1-1/2 515

300

2565

3645

5770

7-1/2 880

1515

1-1/2 590

300HP

2650

3745

5880

7-1/2 1010

1380

1-1/2 435

2475

330 3545

5650

7-1/2 745

10 820

1-1/2 500

2550

330HP

3630

5745

7-1/2 855

10 940

1320

1-1/2 370

2405

365 3465

5550

7-1/2 630

10 695

1-1/2 420

2460

365HP

3530

5625

7-1/2 720

10 790

1-1/2 310

2340

402

3390

5465

7-1/2 535

10 585

1-1/2 355

2390

3445

402HP 5530

7-1/2 605

10 670

15 765

Page 4

4 Tw in Ci ty IM 4 20 5

1. The motors in these units are equipped with permanently sealed ball bearings. They require no lubrication for the

life of the motor.

2. Fan shaft pillow block bearings on larger units are

equipped with grease gun fittings. These bearings are

factory lubricated and, with normal operation, will need

no lubrication for 3 to 6 months. (BSI models only.)

3. For pillow block bearings, use a low pressure grease gun

with Alvania #2 or #3 grease or equivalent. Only a few

strokes of the gun are required. Excess grease will be

forced out through the bearing pressure relief holes. Use

of a high pressure gun, however, is liable to blow the

bearing seals.

4. Belt tension is adjusted at the factory. It should be readjusted after a break-in period of 24 hours of actual operation. (BSI models only.)

5. To adjust belt tension, loosen the hex head screw in the

tab of the motor plate. Snug belts by pulling on the motor

with a force of 15 lbs. for single belts and 30 lbs. for double belts. Retighten screw before releasing motor.

6. Belt condition and tension should be checked every 3 to

6 months depending on service. If belt tension is too

tight, there is a possibility of overloading the motor as

well as causing undue belt wear. If the belt tension is too

slack, then the wheel will fall off in RPM, air delivery will

decrease and the belts will wear quite rapidly. (BSI models only.)

7. If the air handled by the unit is dust or grease laden, a

regular inspection and cleaning of the backdraft damper

and the wheel will ensure smooth, efficient operation.

Maintenance

Speed Control (Field Installed Only) — DSI Models (Optional)

Speed control is available for DSI models using 115/60/1

open type PSC or shaded pole motors. The speed controllers are of solid-state (tri-ac) design. The speed control

features include RFI filter, minimum speed trim adjustment

capability, and built-in on/off line switch. The controller is

designed to start motor on high speed for better start-up

characteristics.

Installation

Connect speed controller in series with motor and AC line

(115V only). Never connect speed controller across AC line.

See Figure 2.

Minimum Speed Setpoint

All controls are factory set to 65V±3V output as standard

with an input voltage of 120V. If different minimum speed is

desired, the control may be adjusted by turning minimum

speed pot clockwise to decrease minimum speed and

MOTOR DSI MOTOR PART NO. SPEED CONTROLLER

AMP

RPM HP MODEL ODP TE PART NO.

1/6 080, 090, 100, 120, 135N – 73505106

66805601 5

1075

1/4 135, 150N 73500214 73505210

1/2 150, 165N 73500413 73505408

66805701 10

3/4 165 73500510 73505506

1/4 080, 090 73500215 – 66805601 5

1/3 100 73500316 73505311

66805701 10

1/2 120 73500415 73505409

1650 1 135 73500610 73505606 66806001 15

3/4 135N 73500509 73505507 66805701 10

1 1/2 150 73500705 73505606

66806001 15

1 150N 73500610 73505706

Figure 1. Low End Setpoint Adjustment

Figure 2. Connection Diagram, Speed Control

SETPOINT ADJUSTMENT

SCREW

SPEED CONTROLLER

AC

LINE

(115V)

SWITCH

TRI-AC

MOTOR

counterclockwise to increase minimum speed. Refer to

Figure 1.

Warning: If minimum speed is readjusted, verify unit

ampere draw does not exceed motor nameplate amps. Do

not operate unit in range where amp draw exceeds motor

nameplate.

Warning: Certain failure modes of solid-state controls

such as half-waving can cause high levels of DC, motor

overheating and motor burn-out. Therefore, a thermal overload protection (integral with motor) is required to limit the

maximum motor temperature under such a failure.

Caution: These motors operate more efficiently in the

ranges set from the factory. Operating motors outside these

ranges may cause motors to run hotter and substantially

shorten motor life.

Note: Lowering the minimum speed setpoint may

adversely affect motor start-up characteristics.

Tabl e 3. S pe ed Con tr ol le r Si ze ( DS I Mod els )

Page 5

Tw in Ci ty IM 4 20 5 5

Hanger Brackets

Shown on pages 5 and 6 are the typical dimensions (E and

F) for the hanger brackets that are supplied with these units.

The

9

⁄16" holes in these brackets can readily be used for

installing the units. To obtain optimum isolation, the BSI unit

should be installed with the motor above or below the fan

body.

Overhead Mounting

Floor Mounting

2.15

2.72

3.0

3.69

5.25

Neoprene

Isolator

Hanger Rod, Nuts &

Washe rs (B y I nstall er)

Bolt, Nuts &

Washe rs (I nclu ded)

Hanger Housing

Spring

Isolator

BSI/DSI

Unit

Hanger Bracket

NEOPRENE ISOLATOR SPRING ISOLATOR

BSI/DSI

Unit

Finished Floor

3.50

1.50

BSI: Belt Driven Centrifugal Inline Fans

MODEL B C F DAMPER AVG. SHIP

BSI

A

SQ. SQ.

DE

MAX. SIZE WT. (LBS.)

080 22.50 13.00 11.25 20.19 14.50 12.00 11.00 x 11.00 111

090 23.00 15.25 13.50 20.69 16.75 12.00 13.00 x 13.00 116

100 26.00 17.81 16.06 23.69 19.31 12.00 16.00 x 16.00 135

120/120HP 25.50 19.38 17.62 23.19 20.88 12.00 17.50 x 17.50 151

135/135HP 28.00 21.53 19.75 25.75 23.03 12.00 19.50 x 19.50 161

150/150HP 30.50 23.69 21.94 28.25 25.19 12.00 21.50 x 21.50 200

165/165HP 36.00 26.38 24.62 33.75 27.88 14.50 24.50 x 24.50 232

180/180HP 39.25 28.88 27.12 37.00 30.38 14.50 27.00 x 27.00 266

210/210HP 43.00 32.19 30.44 40.75 33.69 14.50 30.00 x 30.00 300

225/225HP 45.50 34.00 32.25 43.25 35.50 14.50 32.00 x 32.00 385

245/245HP 48.50 37.50 35.75 46.25 39.00 16.00 35.50 x 35.50 468

270/270HP 54.50 40.00 38.25 52.25 41.50 16.00 38.00 x 38.00 551

300/300HP 59.50 44.00 42.25 57.25 45.50 16.00 42.00 x 42.00 634

330/330HP 65.00 48.69 46.94 62.75 50.19 17.00 46.50 x 46.50 792

365/365HP 65.00 50.00 48.25 62.75 51.50 17.00 48.00 x 48.00 892

402/402HP 71.50 55.25 53.50 69.25 56.75 20.00 53.00 x 53.00 1022

BELT

GUARD

B SQ.

E

C SQ.

F MAX.

B + 3.13

MOTOR

COVER

DISCONNECT

SWITCH

1.13

C SQ.

D

A

AIRFLOW

1.13

DIMENSIONS ARE NOT TO BE USED FOR CONSTRUCTION.

Page 6

Loading...

Loading...