Page 1

30

I20618 - Subject to change. © Belimo Aircontrols (USA), Inc.

D001

AF24-MFT95 US

Proportional damper actuator, Spring Return Fail-Safe, 24 V for use with

Honeywell

®

electronic Series 90, or a 0 to 135Ω input

Technical Data AF24-MFT95 US

Power supply 24 VAC ± 20% 50/60 Hz

24 VDC ± 10%

Power consumption running: 6 W ; holding: 2 W

Transformer sizing 10 VA (class 2 power source)

Electrical connection 3 ft, 18 GA appliance cable

1/2” conduit connector

Overload protection electronic throughout 0 to 95° rotation

Operating range WRB 0 to 135Ω Honeywell electronic series

90, or a 0 to 135 Ω input

Feedback output U* 2 to 10 VDC, 0.5 mA max

Mech. angle of rotation* 95°, adjustable 35° to 95° w/ZDB-AF2

Torque 133 in-lb [15 Nm] constant

Direction of rotation* spring: reversible with cw/ccw mounting

motor: reversible with built-in switch

Position indication visual indicator, 0° to 95° (0° is spring

return position)

Manual override 3mm hex crank (shipped w/actuator)

Running time motor* 150 seconds constant

Running time spring <20 sec spring return fail safe position

Angle of Rotation Off (Default)

Adaptation*

Override control* Min. (Min Position) = 0%

- ZS

(Mid. Position) = 50%

- Max. (Max. Position) = 100%

Humidity 5 to 95% RH non-condensing

Ambient temperature -22°F to +122°F [-30°C to +50°C]

Storage temperature -40°F to +176°F [-40°C to +80°C]

Housing NEMA type 2 / IP54

Housing material zinc coated metal

Agency listings UL 873 listed, CE, CSA C22.2

No. 24 certified

Noise level max. 45 dB (A)

Servicing maintenance free

Quality standard ISO 9001

Weight 6.0 lbs (2.7 kg.)

* Variable when configured with MFT options

AF24-MFT95 US

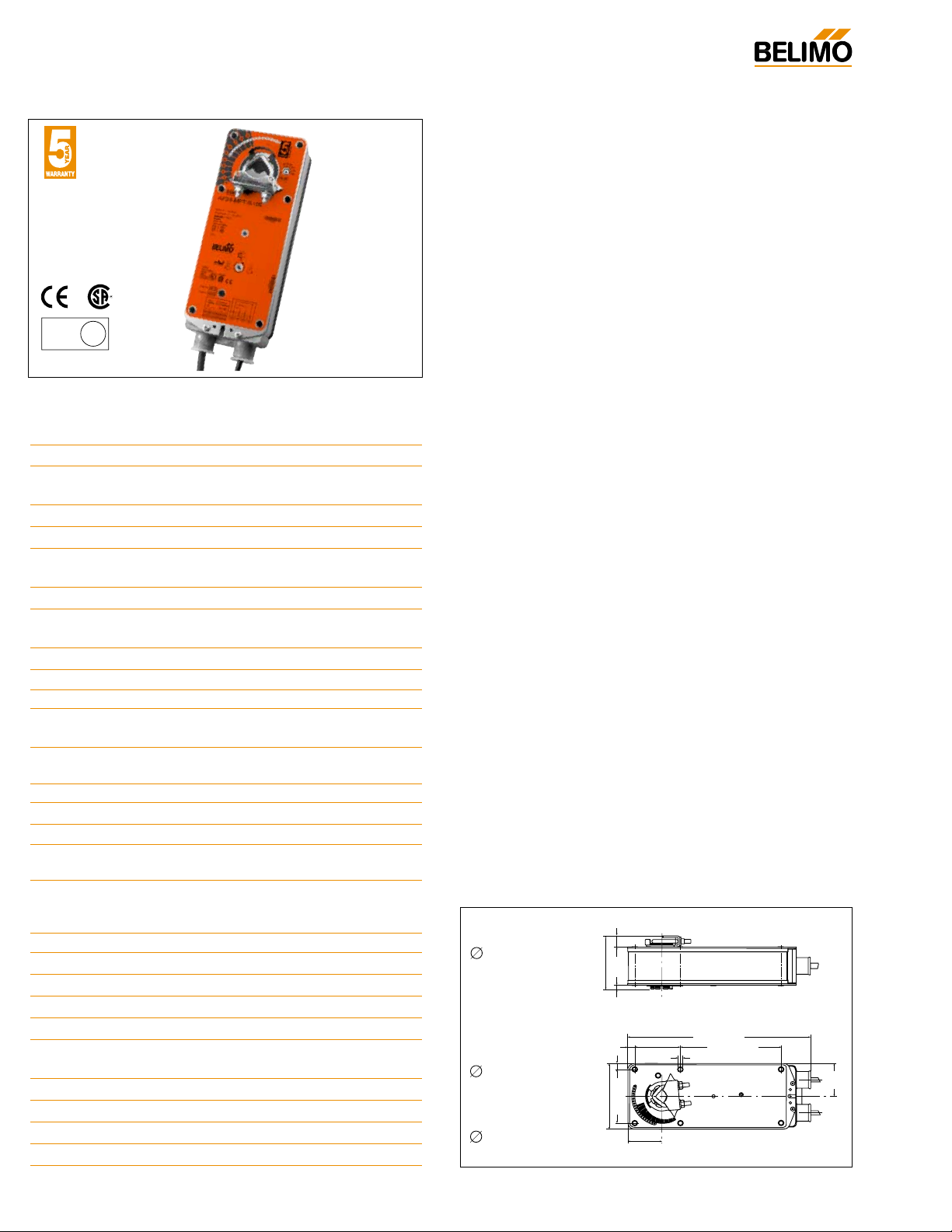

Dimensions [All numbers in brackets are in millimeters.]

• Torque min. 133 in-lb

• Control fixed, 0 to 135Ω input, or Honeywell series 90 (fixed)

• Feedback 2 to 10 VDC (DEFAULT)

Application

For proportional modulation of dampers and control valves in

HVAC systems. The AF24-MFT95 US provides mechanical

spring return operation for reliable fail-safe application.

Default/Configuration

Default parameters for 0 to 135Ω Input applications of the

AF24-MFT95 US actuator are assigned during manufacturing.

If required, custom versions of the actuator can be ordered.

However the control input cannot be modified via MFT-Handy tool

or PC-software. The parameters noted in the Technical Data

table are variable.

These parameters can be changed by three means:

• Pre-set configurations from Belimo

• Custom configurations from Belimo

• Configurations set by the customer using the MFT-Handy

®

or the MFT-Actuate™ PC software application.

Operation

The AF24-MFT95 US actuator provides 95° of rotation and is provided with a graduated position indicator showing 0° to 95°. The

actuator will synchronize the 0° mechanical stop or the physical

damper or valve mechanical stop and use this point for its zero

position during normal control operations. A unique manual override allows the setting of any actuator position within its 95° of

rotation with no power applied.This mechanism can be released

physically by the use of a crank supplied with the actuator. When

power is applied the manual override is released and the actuator

drives toward the fail-safe position.

The actuator uses a brushless DC motor which is controlled by an

Application Specific Integrated Circuit (ASIC) and a microprocessor. The microprocessor provides the intelligence to the ASIC to

provide a constant rotation rate and to know the actuator’s exact

position. The ASIC monitors and controls the brushless DC

motor’s rotation and provides a Digital Rotation Sensing (DRS)

function to prevent damage to the actuator in a stall condition.

The position feedback signal is generated without the need for

mechanical feedback potentiometers using DRS. The actuator

may be stalled anywhere in its normal rotation without the need of

mechanical end switches.

The AF24-MFT95 US is mounted directly to control shafts up to

1.05" diameter by means of its universal clamp and anti-rotation

bracket. A crankarm and several mounting brackets are available

for damper applications where the actuator cannot be direct coupled to the damper shaft. The spring return system provides minimum specified torque to the application during a power interruption. The AF24-MFT95 US actuator is shipped at +5° (5° from full

fail-safe) to provide automatic compression against damper gaskets for tight shut-off.

(Not selectable via MFT)

LISTED

94D5

TEMP. IND &

REG. EQUIP.

U

L

K4-2 US (supplied)

1/2" Centered

(Default)

3/4" Centered

(Field Selectable)

1.05" Centered

(Field Selectable)

K4-1 US (optional)

3/4" to 1.05"

Adjustable

K4 US (optional)

3/8" to 3/4"

Adjustable

0.65" [16.5]

3.10" [78]

0.19" [5]

0.39" [10]

0.35" [9]

3.86" [98]

[57]

2.24"

3.15" [80]

1.97"

[50]

2.64"

[67]

10.59" [269]

5.85" [148.5]

0.26" [6.5]

®

[49]

1.93"

Page 2

31

I20618 - Subject to change. © Belimo Aircontrols (USA), Inc.

AF

AF24-MFT95 US

Proportional damper actuator, Spring Return Fail-Safe, 24 V for use with

Honeywell

®

electronic Series 90, or a 0 to 135Ω input

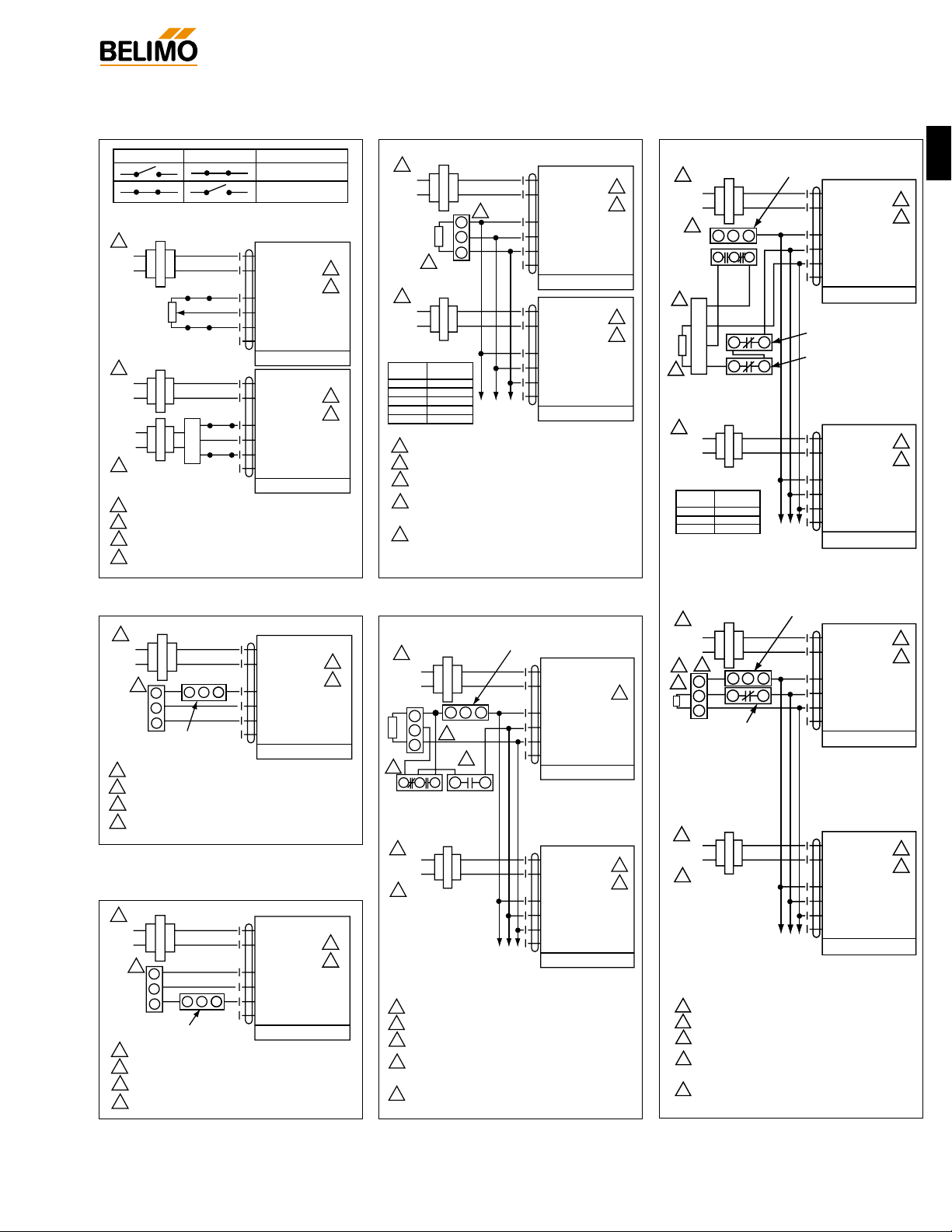

1

2

3

5

2

4

1 Common, Blk

2 + Hot, Red

3 W, Wht

4 R, Wht

5 B, Wht

6 ‘U5’

Output 2-10 VDC

AF24-MFT95 US

Line

Volts

24 VAC

Transformer

1

3

3

5

1 Common, Blk

2 + Hot, Red

3 W, Wht

4 R, Wht

5 B, Wht

6 ‘U5’

Output 2-10 VDC

AF24-MFT95 US

W

W

RR

Y

B

To other

actuators

Resistor Kit No. ZG-R06

Q209A

Minimum Position

Potentiometer

H205

Changeover

Controller

W973, W7100

Controller

Occupied

Contact

Honeywell T675A

Morning Warmup

Shunting

Resistor

Line

Volts

2

1

3

5

1 Common, Blk

2 + Hot, Red

3 W, Wht

4 R, Wht

5 B, Wht

6 ‘U5’

Output 2-10 VDC

AF24-MFT95 US

To other

actuators

Line

Volts

No. of

actuators Resistance

2 1300Ω

3 910Ω

4 768Ω

BR

W

W

R

B

1

3

2

5

4

1 Common, Blk

2 + Hot, Red

3 W, Wht

4 R, Wht

5 B, Wht

6 ‘U5’

Output 2-10 VDC

AF24-MFT95 US

Line

Volts

24 VAC

Transformer

Honeywell Q209A

Minimum Position

Potentiometer

Shunting

Resistor

RRB

W

W

W

R

B

Used with the W973 and W7100 controllers.

Honeywell

T675A Morning

Warmup

W973, W7100

T775

Override of AF24-MFT95 US

1

3

5

4

2

1 Common, Blk

2 + Hot, Red

3 W, Wht

4 R, Wht

5 B, Wht

6 ‘U5’

Output 2-10 VDC

AF24-MFT95 US

Line

Volts

24 VAC Transformer

1

1

2

3

3

5

5

4

1 Common, Blk

2 + Hot, Red

3 W, Wht

4 R, Wht

5 B, Wht

6 ‘U5’

Output 2-10 VDC

AF24-MFT95 US

W

R

B

To other

actuators

Resistor Kit No. ZG-R03

Series 90

Controller

Shunting

Resistor

Line

Volts

Provide overload protection and disconnect as required.

Actuators and controller must have separate transformers.

Consult controller instruction data for more detailed

installation information.

Resistor value depends on the type of controller and

the number of actuators. No resistor is used for one

actuator. Honeywell resistor kits may also be used.

To reverse control rotation, use the reversing switch.

No. of

actuators Resistance

2 140Ω

3 71.5Ω

4 47.5Ω

5 37.5Ω

6 28Ω

Switch A Switch B Damper Position

Damper Open

Damper Closed

The direction of rotation switch is set so that the fail safe position and the

position of the damper is closed with no signal at wire R.

1

3

4

1 Common, Blk

2 + Hot, Red

3 W, Wht

4 R, Wht

5 B, Wht

6 ‘U5’ Output 2-10 VDC

AF24-MFT95 US

A

B

Line

Volts

24 VAC Transformer

135Ω

1

1

2

2

3

3

4

4

1 Common, Blk

2 + Hot, Red

3 W, Wht

4 R, Wht

5 B, Wht

6 ‘U5’

Output 2-10 VDC

AF24-MFT95 US

A

W

R

B

Controller

B

Line

Volts

Line

Volts

24 VAC Transformer

Provide overload protection and disconnect as required.

Actuators and controller must have separate transformers.

Consult controller instruction data for more detailed

installation information.

To reverse control rotation, use the reversing switch.

1

3

2

2

5

4

1 Common, Blk

2 + Hot, Red

3 W, Wht

4 R, Wht

5 B, Wht

6 ‘U5’

Output 2-10 VDC

AF24-MFT95 US

Line

Volts

24 VAC

Transformer

1

1

2

3

3

5

5

4

1 Common, Blk

2 + Hot, Red

3 W, Wht

4 R, Wht

5 B, Wht

6 ‘U5’

Output 2-10 VDC

AF24-MFT95 US

To other

actuators

Series 90

Controller

S963A

Minimum Position

Potentiometer

H205 Changeover Controller

Occupied

Contact

Shunting

Resistor

Line

Volts

Provide overload protection and disconnect as required.

Actuators and controller must have separate transformers.

Consult controller instruction data for more detailed

installation information.

Resistor value depends on the type of controller and

the number of actuators. No resistor is used for one

actuator. Honeywell resistor kits may also be used.

To reverse control rotation, use the reversing switch.

RB

W

B

R

W

W

R

B

Wiring multiple actuators to a Series 90

controller using a minimum position

potentiometer.

1

2

3

4

1 Common, Blk

2 + Hot, Red

3 W, Wht

4 R, Wht

5 B, Wht

6 ‘U5’

Output 2-10 VDC

AF24-MFT95 US

Line

Volts

24 VAC Transformer

WBR

W

B

R

R

Series 90 low limit control

135Ω for 0 to 50% control

280Ω for 0 to 100% control

Series 90

Controller

1

2

3

4

Provide overload protection and disconnect as required.

Actuators and controller must have separate transformers.

Consult controller instruction data for more detailed

installation information.

To reverse control rotation, use the reversing switch.

AF24-MFT95 USused with a Series 90 controller and a Series 90 low limit control

1

2

3

4

1 Common, Blk

2 + Hot, Red

3 W, Wht

4 R, Wht

5 B, Wht

6 ‘U5’

Output 2-10 VDC

AF24-MFT95 US

Line

Volts

24 VAC Transformer

W B

W

B

R

R

Series 90 high limit control - 280Ω

Series 90

Controller

1

2

3

4

Provide overload protection and disconnect as required.

Actuators and controller must have separate transformers.

Consult controller instruction data for more detailed

installation information.

To reverse control rotation, use the reversing switch.

AF24-MFT95 USused with a Series 90 controller and a Series 90 high limit control

Typical wiring diagrams for multiple

actuators used with the W973, W7100

and T775 controllers.

Proportional Potentiometric Control

Wiring multiple actuators to a Series 90

controller.

W015

W018

W020

W016

W019

W017

®

Provide overload protection and disconnect as required.

1

Actuators and controller must have separate transformers.

2

Consult controller instruction data for more detailed

3

installation information.

Resistor value depends on the type of controller and

4

the number of actuators. No resistor is used for one

actuator. Honeywell resistor kits may also be used.

5

To reverse control rotation, use the reversing switch.

Loading...

Loading...