Page 1

DriveIT Low Voltage AC Drives

User’s Manual

ACH550-UH HVAC Drives (1

…150 Hp)

Page 2

2 ACH550-UH User’s Manual

ACH550 Drive Manuals

GENERAL MANUALS

ACH550-UH HVAC User's Manual (1…150 HP)

• Safety

•Installation

• Start-Up

• Diagnostics

• Maintenance

• Technical Data

ACH550-UH Installation Supplement (200...550 HP)

• Safety

•Installation

• Maintenance

• Technical Data

ACH550 Input Disconnect and Bypass Supplement

(1...550 HP)

• Safety

•Installation

• Start-Up

• Maintenance

• Technical Data

BACnet is a registered trademark of ASHRAE.

CANopen is a registered trademark of CAN in Automation

e.V.

ControlNet is a registered trademark of ControlNet

International.

DeviceNet is a registered trademark of Open DeviceNet

Vendor Association.

DRIVECOM is a registered trademark of DRIVECOM User

Organization.

Ethernet is a registered trademark of Xerox Corp.

Interbus is a registered trademark of Interbus Club.

LonWorks is a registered trademark of Echelon Corp.

Metasys is a registered trademark of Johnson Controls Inc.

Modbus and Modbus Plus are registered trademarks of

Schneider Automation Inc.

Profibus is a registered trademark of Profibus Trade Org.

Profibus-DP is a registered trademark of Siemens AG.

OPTION MANUALS

(Fieldbus Adapters, I/O Extension Modules etc., manuals

delivered with optional equipment)

Relay Output Extension Module (typical title)

•Installation

• Programming

• Fault tracing

• Technical data

© 2004 ABB Oy. All Rights Reserved.

Page 3

ACH550-UH User’s Manual 3

Safety

Warning! The ACH550 adjustable speed AC drive should ONLY be installed by

a qualified electrician.

Warning! Even when the motor is stopped, dangerous volt age is present a t the

Power Circuit terminals U1, V1, W1 and U2, V2, W2 and, where present, UDC+,

UDC-, BRK+ and BRK-.

Warning! Dangerous voltage is present when input power is connected. After

disconnecting the supply , wait at least 5 minutes (to let the intermediate circuit

capacitors discharge) before removing the cover.

Warning! Even when power is removed from the input terminals of the

ACH550, there may be dangerous voltage (from external sources) on the

terminals of the relay outputs R01

Warning! When the control te rminals of two or mo re drive units are connected

in parallel, the auxiliary voltage for these control connections must be taken

from a single source which can either be one of the units or an external

supply.

…R03.

Warning! The ACH550-UH is not a field repairable unit. Never attempt to repair

a malfunctioning unit; contact the factory or your local Authorized Service

Center for replacement.

Warning! The ACH550 will start up automatically after an input voltage

interruption if the external run command is on.

Warning! The heat sink may reach a high temperature. See "Technical Data" on

page 225.

Warning! If the drive will be used in a floating network, remove screws at EM1

and EM3 (Frame size R1

diagrams on page 14 and page 15 respectively.

Note! For more technical information, contact the factory or your local ABB sales

representative.

…R4), or F1 and F2 (Frame size R5 or R6). See

Safety

Page 4

4 ACH550-UH User’s Manual

Use of Warnings and Notes

There are two types of safety instructions throughout this manual:

• Notes draw attention to a particular condition or fact, or give information on a

subject.

• Warnings caution you about conditions which can result in serious injury or death

and/or damage to the equipment. They also tell you how to avoid the danger . The

warning symbols are used as follows:

Dangerous voltage warning warns of high voltage which can cause physical

injury and/or damage to the equipment.

General warning warns about conditions, other than those caused by

electricity, which can result in physical injury and/or damage to the equipment

Safety

Page 5

ACH550-UH User’s Manual 5

Table of Contents

Safety

Use of Warnings and Notes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Table of Contents

Installation

Installation Flow Chart . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Preparing for Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Installing the Drive . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Start-Up

HVAC Control Panel Features . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

Start-Up . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

Modes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

Application Macros . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

Parameter Descriptions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 51

Serial Communication – EFB

Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 143

Planning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 144

Mechanical and Electrical Installation – EFB . . . . . . . . . . . . . . . . . . . . . . . . . 145

Communication Set-up – EFB . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 146

Activate Drive Control Functions – EFB . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 147

Feedback from the Drive – EFB . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 151

Diagnostics – EFB . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 153

Modbus Protocol Technical Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 155

ABB Drives Profile Technical Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 162

N2 Protocol Technical Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 170

FLN Protocol Technical Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 179

BACnet Technical Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 192

Serial Communication – FBA

Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 193

Planning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 195

Mechanical and Electrical Installation – FBA . . . . . . . . . . . . . . . . . . . . . . . . . 196

Communication Set-up – FBA . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 197

Activate Drive Control Functions – FBA . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 197

Feedback from the Drive – FBA . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 200

Diagnostics – FBA . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 201

ABB Drives Profile Technical Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 203

Generic Profile Technical Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 210

Diagnostics

Diagnostic Displays . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 212

Table of Contents

Page 6

6 ACH550-UH User’s Manual

Correcting Faults . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 213

Correcting Alarms . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 218

Maintenance

Maintenance Intervals . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 221

Heatsink . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 221

Main Fan Replacement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 222

Internal Enclosure Fan Replacement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 223

Capacitors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 223

Control Panel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 224

Technical Data

Ratings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 225

Input Power Connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 228

Motor Connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 232

Control Connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 237

Efficiency . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 240

Cooling . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 240

Dimensions and Weights . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 241

Degrees of Protection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 244

Ambient Conditions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 244

Materials . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 245

Applicable Standards . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 245

Liability Limits . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 247

Index

Table of Contents

Page 7

ACH550-UH User’s Manual 7

Installation

Study these inst allation instructio ns carefully before proceeding. Failure to observe

the warnings and instructions may cause a malfunction or personal hazard.

Warning! Before you begin read "Safety" on page 3.

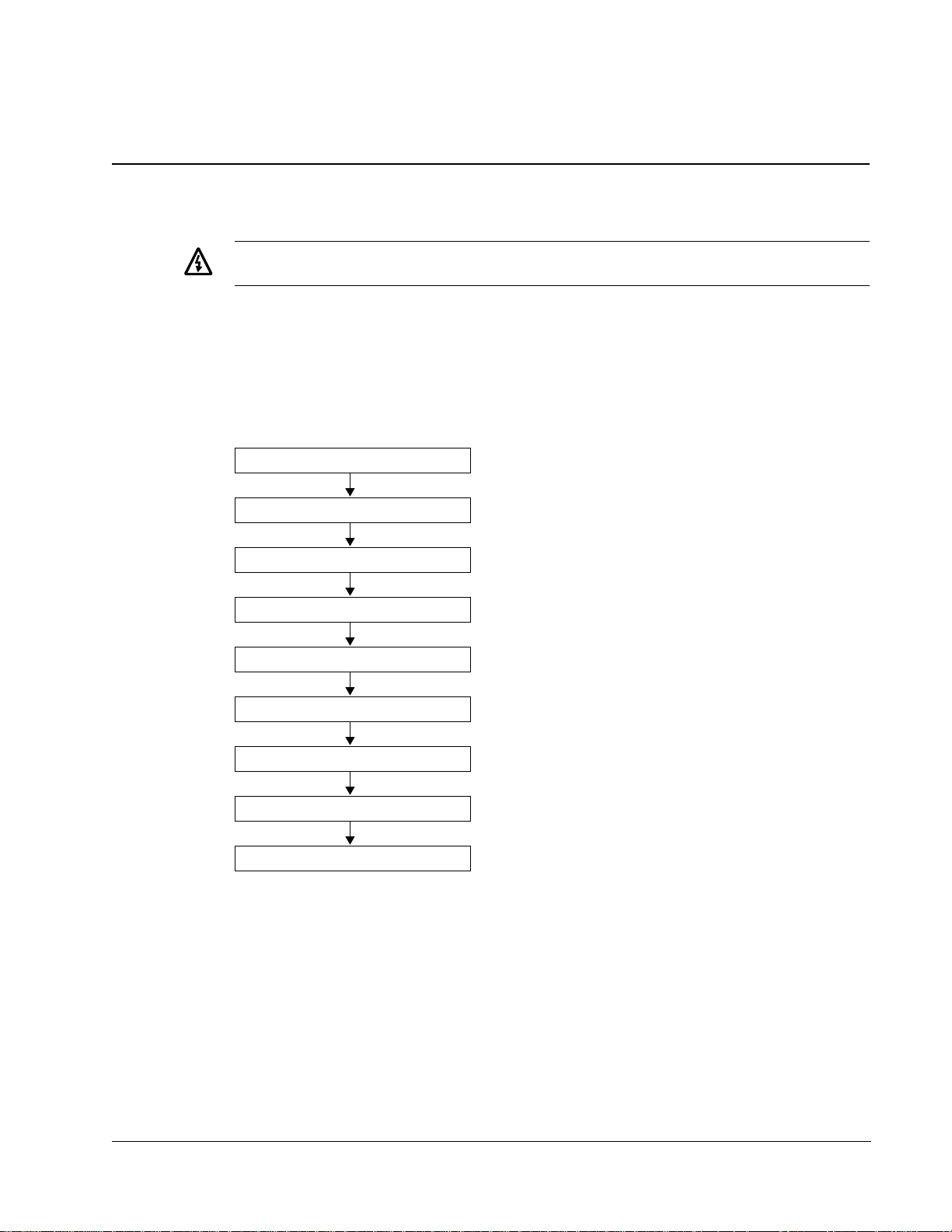

Installation Flow Chart

The installation of the ACH550 adjustable speed AC drive follows the outline below.

The steps must be carried out in the order shown. At the right of each step are

references to the detailed information needed for the correct installation of the unit.

Task See

PREPARE for installation "Preparing for Installation" on page 8.

PREPARE the Mounting Location "Prepare the Mounting Location" on page 11.

REMOVE the front cover "Remove Front Cover" on page 11.

MOUNT the drive "Mount the Drive" on page 12.

INSTALL wiring "Install the Wiring" on page 12.

CHECK installation "Check Installation" on page 18.

RE-INSTALL the cover "Re-install Cover" on page 18.

APPLY power "Apply Power" on page 19.

START-UP "Start-Up" on page 20.

Installation

Page 8

8 ACH550-UH User’s Manual

Preparing for Installation

Lifting the Drive

Lift the drive only by the metal

chassis.

Unpack the Drive

1. Unpack the drive.

2. Check for any damage and

notify the shipper immediately

if damaged components are

found.

3. Check the contents against

the order and the shipping label to verify that all parts have been received.

Drive Identification

Drive Labels

IP2040

To determine the type of drive you are installing, refer to either:

• Serial number label attached on upper part of the chokeplate between the

mounting holes.

ACH550-UH-08A8-4

U1

I2N

PN

3~ 380...480 V

8.8 A

4

Ser. no.

*2030700001*

• Type code label attached on the heat sink – on the right side of the unit cover.

Input U1

Output U2

I2N

f2

Motor PN

ACH550-UH-08A8-4

I1N

f1

3~ 380...480 V

8.8 A

48...63 Hz

3~ 0...U

8.8 A

0...500 Hz

4

V

1

Ser. no.

*2030700001*

Installation

Page 9

ACH550-UH User’s Manual 9

Type Code

Use the following chart to interpret the type code found on either label.

ACH550-UH-08A8-4+...

AC, HVAC Drive – 550 product series

Construction (region specific)

01 = Setup and parts specific to IEC installation and compliance

UH = Setup and parts specific to US installation and NEMA compliance

Output current rating

See Ratings chart for details

Voltage rating

2 = 208…240 VAC

4 = 380…480 VAC

Enclosure protection class

No specification = IP 21 / UL type 1

B055 = IP 54 / UL type 12

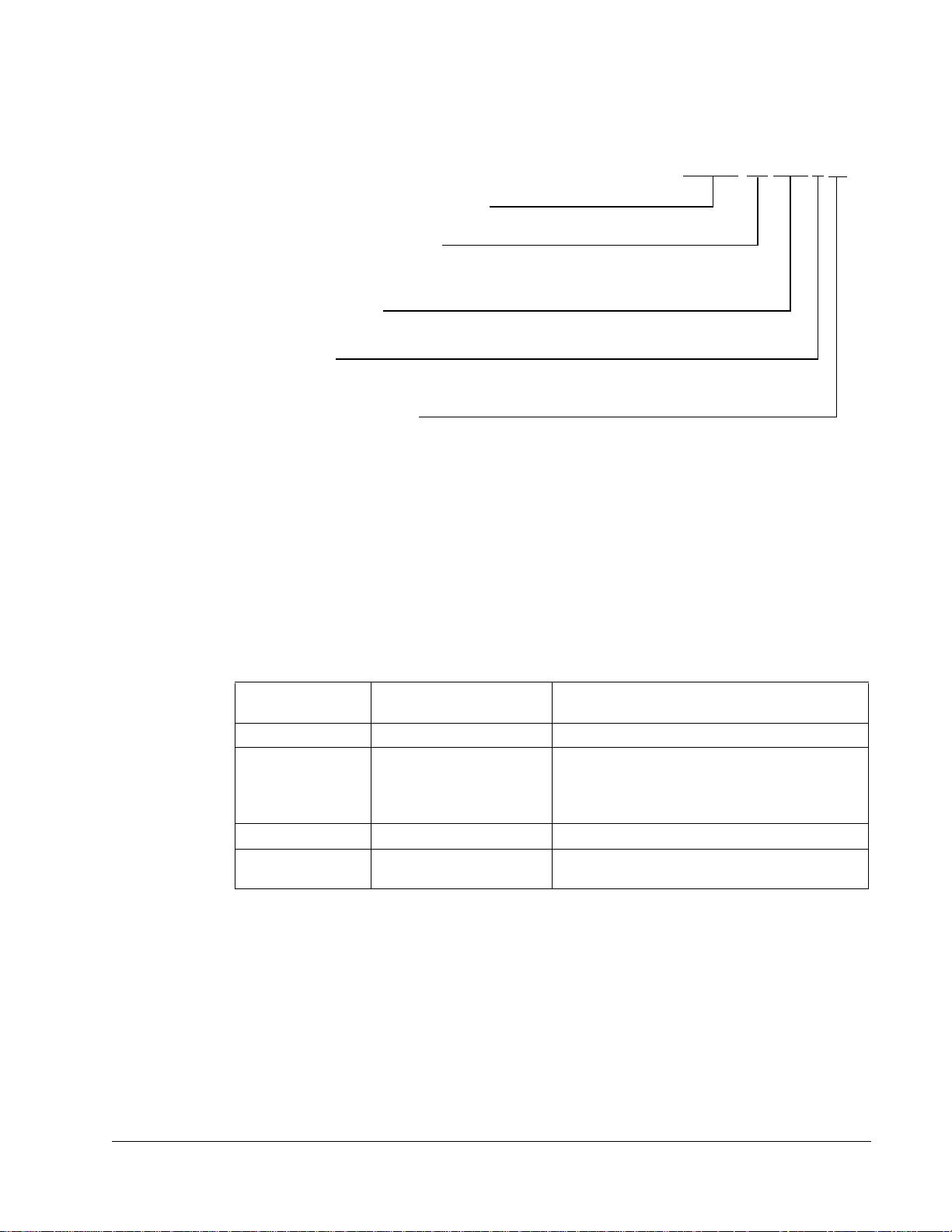

Ratings and Frame Size

The chart in "Ratings" on page 225 lists technical specifications, and identifies the

drive’s frame size – significant, since some instructions in this document, vary,

depending on the drive’s frame size. To read the Ratings table, you need the “Output

current rating” entry from the type code (see above). Also, when using the Ratings

tables, note that there are two tables based on the drive’s “Voltage rating”.

Motor Compatibility

The motor, drive, and supply power must be compatible:

Motor

Specification

Motor type 3-phase induction motor –

Nominal current Motor value is within this

range: 0.15…1.5 * I

(I

2N

Nominal frequency 10…500 Hz –

Voltage range Motor is compatible with

the ACH550 voltage range.

Verify Reference

• Type code label on drive, entry for Output I2N,

= normal use current)

2N

or

• Type code on drive and rating table in

"Technical Data" on page 225.

208…240 V (for ACH550-UH-XXXX-2) or

380…480 V (for ACH550-UH-XXXX-4)

Tools Required

To install the ACH550 you need the following:

• Screwdrivers (as appropriate for the mounting hardware used)

• Wire stripper

• Tape measure

•Drill

Installation

Page 10

10 ACH550-UH User’s Manual

• Frame Size R5 or R6 with IP 54 / UL type 12 enclosure: Punch for conduit

mounting holes

• Mounting hardware: screws or nuts and bolts, four each. The type of hardware

depends on the mounting surface and the frame size:

Frame Size Mounting Hardware

R1…R4 M5 #10

R5 M6

R6 M8 5/16 in

1/4 in

Suitable Environment and Enclosure

Confirm that the site meets the environmental requirements. To prevent damage

prior to installation, store and transport the drive according to the environmental

requirements specified for storage and transportation. See "Ambient Conditions"

244.

page

on

Confirm that the enclosure is appropriate, based on the site contamination level:

• IP 21 / UL type 1 enclosure. The site must be free of airborne dust, corrosive

gases or liquids, and conductive contaminants such as condensation, carbon

dust, and metallic particles.

• IP 54 / UL type 12 enclosure. This enclosure provides protection from airborne

dust and light sprays or splashing water from all directions.

Suitable Mounting Location

Confirm that the mounting location meets the following constraints:

• The drive must be mounted vertically on a smooth, solid surface, and in a suitable

environment as defined above.

• The minimum space requirements for the drive are the outside dimensions (see

"Outside Dimensions" on page 243), plus air flow space around the unit (see

"Cooling" on page 240).

• The distance between the motor and the drive is limited by the maximum motor

cable length. See either

"EN61800-3 Compliant Motor Cables" on page 235.

• The mounting site must support the drive’s modest weight. See "Weight" on p age

242.

Installing the Drive

Warning! Before installing the ACH550, ensure the input power supply to the

drive is off.

"Motor Connection Specifications" on page 232, or

Installation

Page 11

ACH550-UH User’s Manual 11

Prepare the Mounting Location

The ACH550 should only be mounted where all of the

requirements defined in "Prepa ring for Installation" on

page 8 are met.

1. Mark the position of the mounting holes.

1

2. Drill holes of appropriate size.

Note! Frame sizes R3 and R4 have four holes along the top. Use only two. If

possible, use the two outside holes (to allow room to remove the fan for

maintenance).

Note! ACH400 drives can be replaced using the original mounting holes. For R1 and

R2 frame sizes, the mounting holes are identical. For R3 and R4 frame sizes, the

inside mounting holes on the top of ACH550 drives match ACH400 mounts.

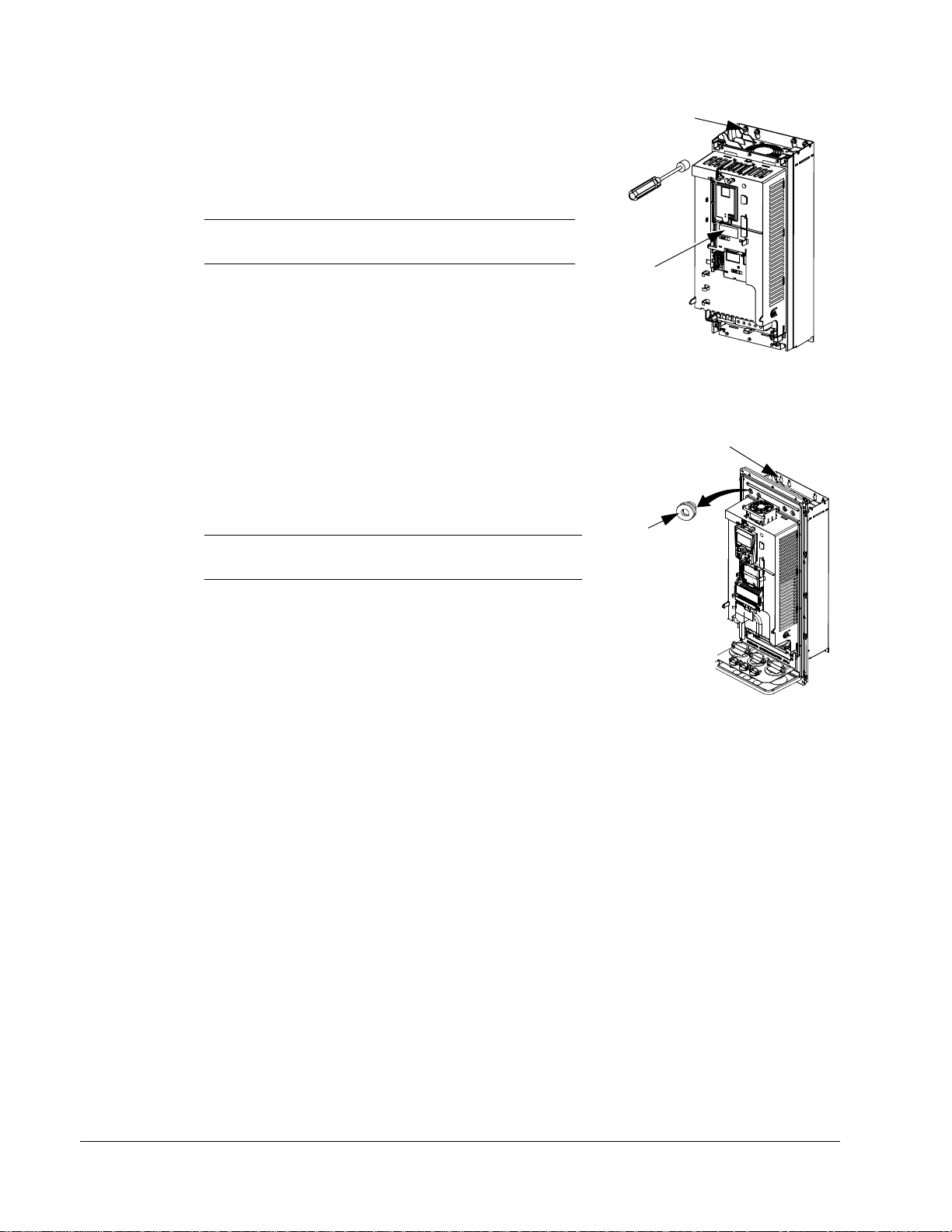

Remove Front Cover

IP 21 / UL Type 1

3

1. Remove the control panel, if attached.

2

2. Loosen the captive screw at the top.

3. Pull near the top to remove the cover.

X0002

IP 54 / UL Type 12

1. If hood is present: Remove screws (2) holding

the hood in place.

2. If hood is present: Slide hood up and off of the

cover.

3. Loosen the captive screws around the edge of

the cover.

4. Remove the cover.

1

IP2000

1

2

3

4

FM

Installation

Page 12

12 ACH550-UH User’s Manual

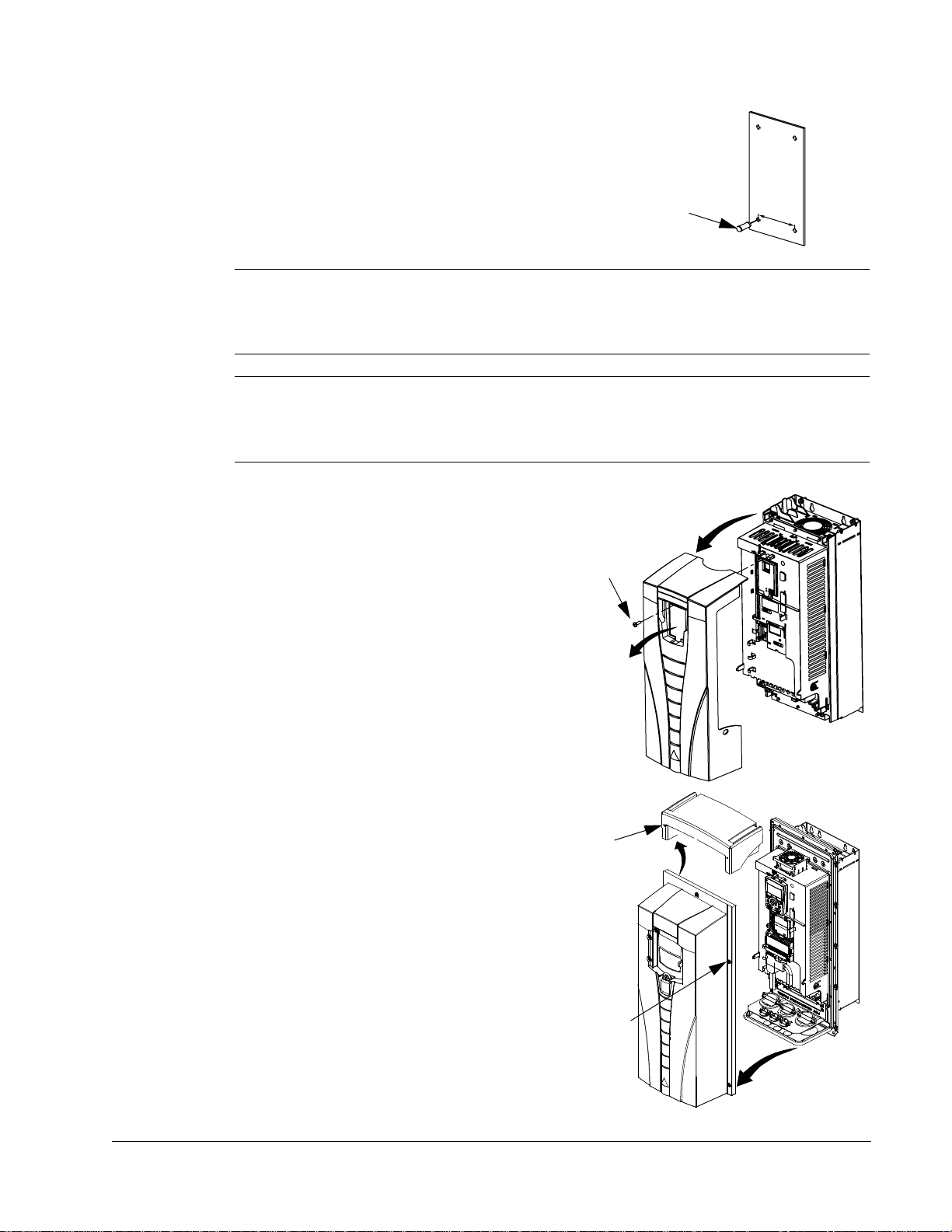

Mount the Drive

1

IP 21 / UL Type 1

1. Position the ACH550 onto the mounting screws

or bolts and securely tighten in all four corners.

Note! Lift the ACH550 by its metal chassis.

2

2. Non-English speaking locations: Add a warning

sticker in the appropriate language over the

existing warning on the top of the module.

IP 54 / UL Type 12

For the IP54 / UL Type 12 enclosures, rubber plugs are required in the holes

provided for access to the drive mounting slots.

1. As required for access, remove the rubber plugs.

Push plugs out from the back of the drive.

2. Position the ACH550 onto the mounting screws

or bolts and securely tighten in all four corners.

1, 3

Note! Lift the ACH550 by its metal chassis.

IP2002

2

3. Re-install the rubber plugs.

4. Non-English speaking locations: Add a warning

sticker in the appropriate language over the

existing warning on the top of the module.

Install the Wiring

Conduit Kit

Wiring drives with the IP 21 / UL type 1 Enclosure requires a conduit kit with the

following items:

• conduit box

•screws

• cover

The kit is included with IP 21 / UL type 1 Enclosures.

FM

Installation

Page 13

ACH550-UH User’s Manual 13

Wiring Overview

Warning! Ensure the motor is compatible for use with the ACH550. The

ACH550 must be installed by a competent person in accordance with the

considerations defined in

"Preparing for Installation" on page 8. If in doubt,

contact your local ABB sales or service office.

As you install the wiring, observe the following:

• There are two sets of wiring instructions – one set for each enclosure type (IP 21

/ UL type and IP 54 / UL type 12). Be sure to select the appropriate procedure.

• For the power connection points on the drive see the "Connection Diagrams"

section below.

• Use separate conduit runs to keep these three classes of wiring apart:

– Input power wiring.

– Motor wiring.

– Control/communications wiring.

• For details on power connections, refer to the following sections in "Technical

Data":

– "Input Power Connections" on page 228.

– "Motor Connections" on page 232.

• For floating networks (also known as IT, ungrounded, or high impedance

networks):

– Disconnect the internal RFI filter by removing both the EM1 and EM3 screws

(frame sizes R1…R4, see page

14), or F1 and F2 screws (frame sizes

R5…R6, see page 15).

– Do NOT install an external filter, such as one of the kits listed in the filter table

236. Using an EMC/RFI filter grounds the input power through the filter

on

capacitors, which could be dangerous and could damage the unit.

– Where EMC requirements exist, check for excessive emission propagated to

neighboring low voltage networks. In some cases, the natural suppression in

transformers and cables is sufficient. If in doubt, use a supply transformer with

static screening between the primary and secondary windings.

• For details on control connections, refer to the following sections:

– "Control Connections" on page 237.

– "Application Macros" starting on page 35.

• For electro-magnetic compliance (EMC), follow local codes and the requirements

"Motor Cable Requirements for CE & C-Tick Compliance" on page 234. For

in

example:

– Properly ground the wire screen cable shields.

– Keep individual un-screened wires between the cable clamps and the screw

terminals as short as possible.

– Route control cables away from power cables.

Installation

Page 14

14 ACH550-UH User’s Manual

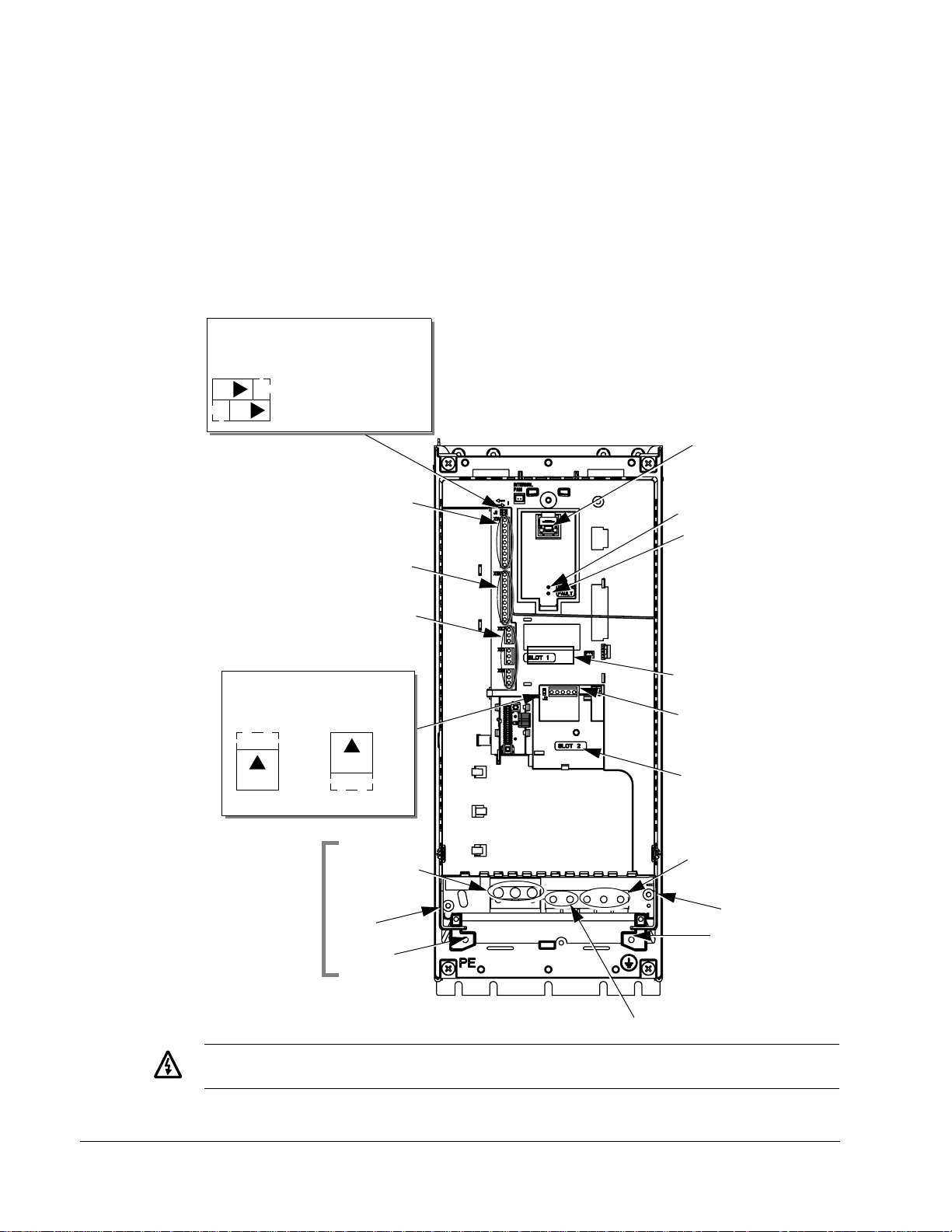

Connection Diagrams

The layout of connection terminals is similar for all frame sizes (R1…R6). The only

significant layout difference is in the power and ground terminals for frame sizes R5

and R6. The following diagrams show:

• Terminal layout for frame size R3, which, in general, applies to all frame sizes

except as noted above.

• Power and ground terminal layout for frame sizes R5 and R6.

R1…R4 (Diagram shows the R3 frame.)

J1 – DIP Switches

for Analog Inputs

J1

ON

X1 – Analog Inputs and Outputs

(and 10 V Ref. Voltage Output)

(and 24 V Aux. Voltage Output)

AI1: (in Voltage Position)

ON

AI2: (in Current Position)

X1 – Digital Inputs

Panel Connector

Power LED (Green)

Fault LED (Red)

X1 – Relay Outputs

J2 – DIP Switches

for RS485 Termination

J2

ON

off position on position

Frame Sizes

R5/R6 differ.

See next page.

J2

ON

Power Input

(U1, V1, W1)

EM1

Optional Module 1

X1 – Communications

(RS485)

Optional Module 2

Power Output to Motor

(U2, V2, W2)

EM3

GND

PE

X0003

Terminals Not Used

Installation

Warning! For floating (ungrounded) networks remove screws at EM1 and EM3.

Page 15

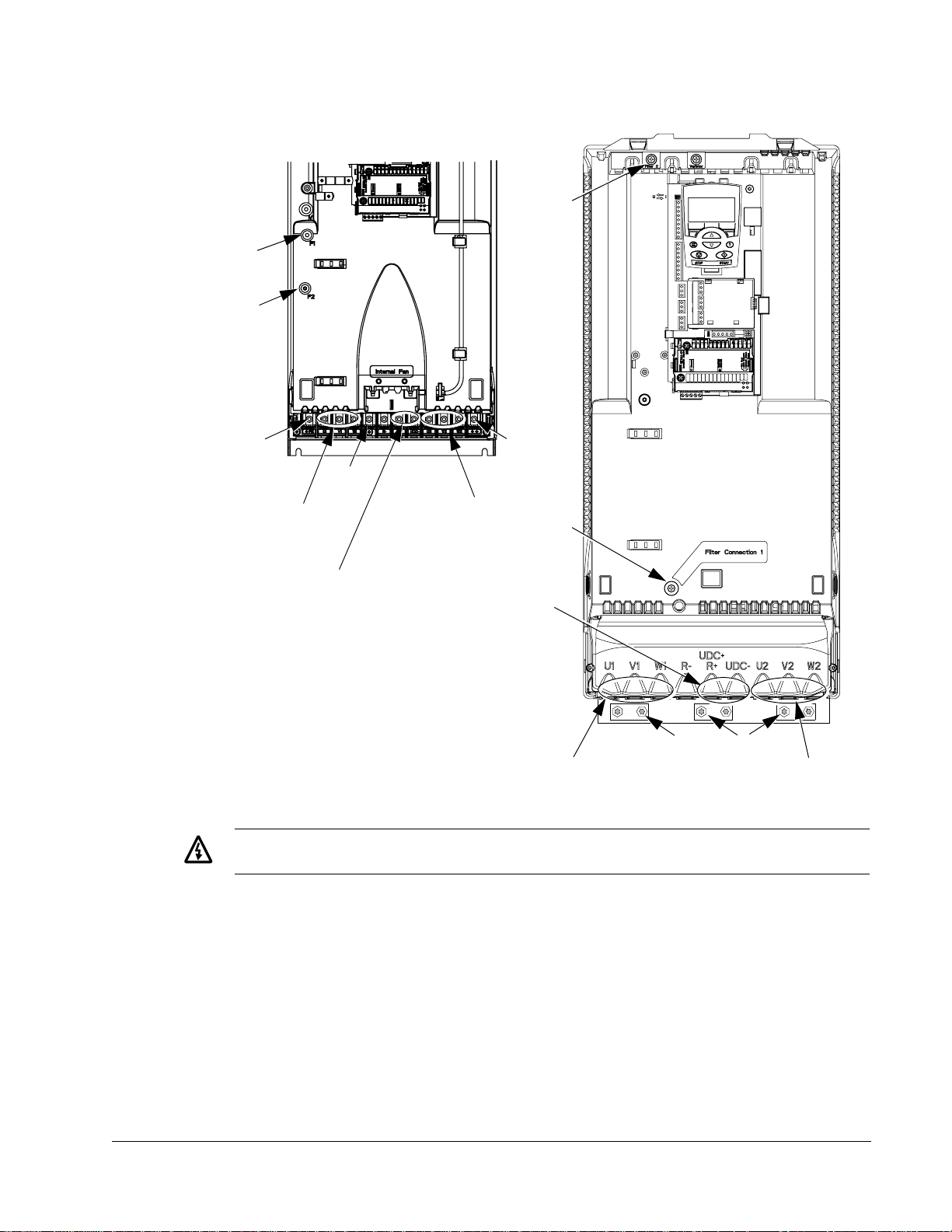

ACH550-UH User’s Manual 15

R5 R6

F2

F1

F2

PE

GND

X0011

GND

Power Input

(U1, V1, W1)

Power Output to Motor

(U2, V2, W2)

F1

Terminals Not Used

Terminals Not Used

X0013

Power Input

(U1, V1, W1)

PE

GND

Power Output to Motor

(U2, V2, W2)

Warning! For floating (ungrounded) networks remove screws at F1 and F2.

Installation

Page 16

16 ACH550-UH User’s Manual

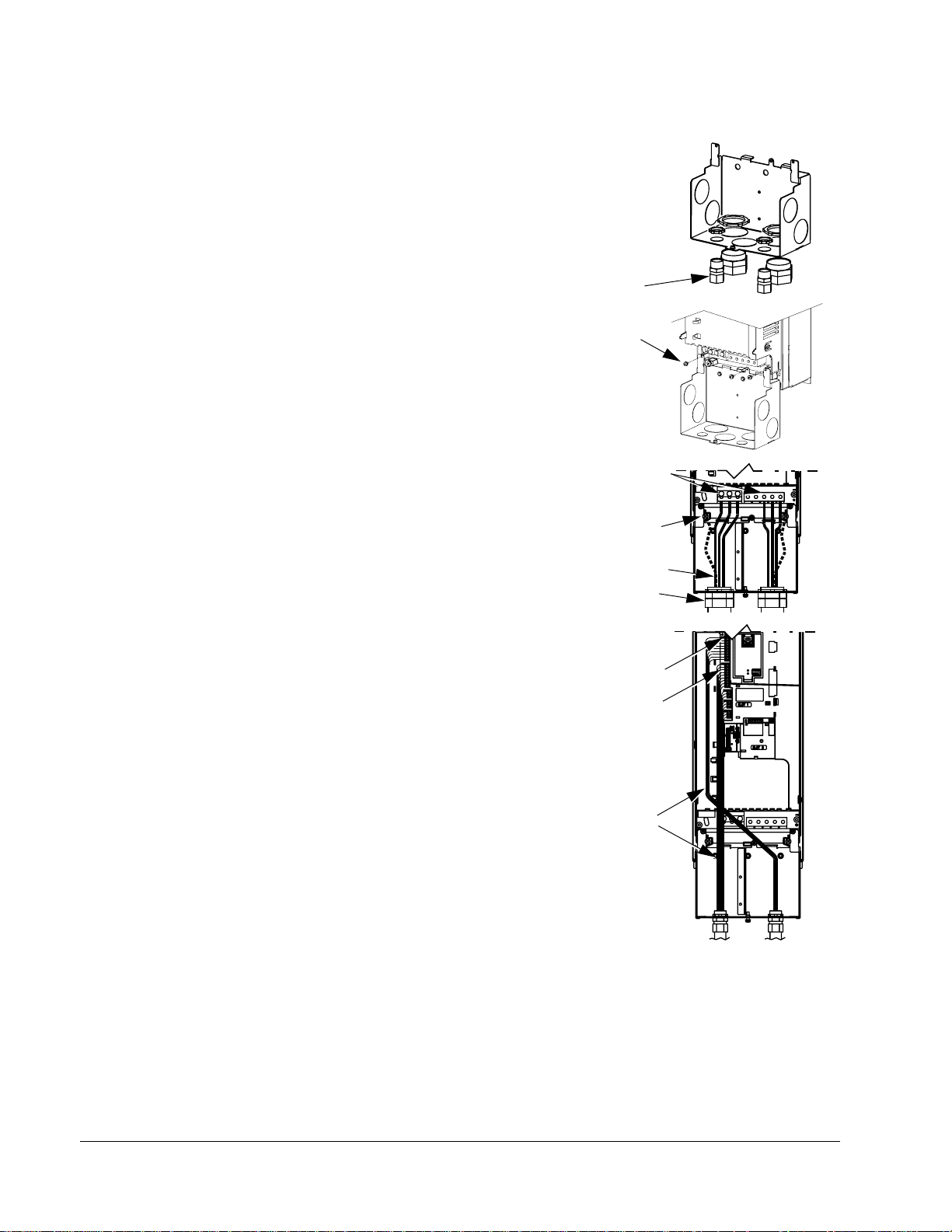

Wiring IP 21 / UL Type 1 Enclosure

1. Open the appropriate knockouts in the

conduit box. (See "Conduit Kit" above.)

2. Install thin-wall conduit clamps (not supplied).

3. Install conduit box.

4. Connect conduit runs for input power, motor

and control cables to the box.

5. Route input power and motor wiring through

separate conduits.

6. Strip wires.

7. Connect power, motor, and ground wires to

the drive terminals. See

"Wiring Overview" on

page 13.

8. Route the control cables through the conduit

(not the same conduit as either input power or

motor wiring).

9. Strip the control cable sheath ing and twist the

copper screen into a pig-tail.

2

3

7

7

5

4

10

12

X0007

X0005

IP2004

Installation

10. Connect the ground screen pig-tail for digital

and analog I/O cables at X1-1. (Ground only

at drive end.)

1 1. C onnect the ground screen pig -tail for RS485

cables at X1-28 or X1-32. (Ground only at

drive end.)

12. Strip and connect the individual control wires

to the drive terminals. See

"Wiring Overview"

on page 13.

13. Install the conduit box cover (1 screw).

8

IP2005

Page 17

ACH550-UH User’s Manual 17

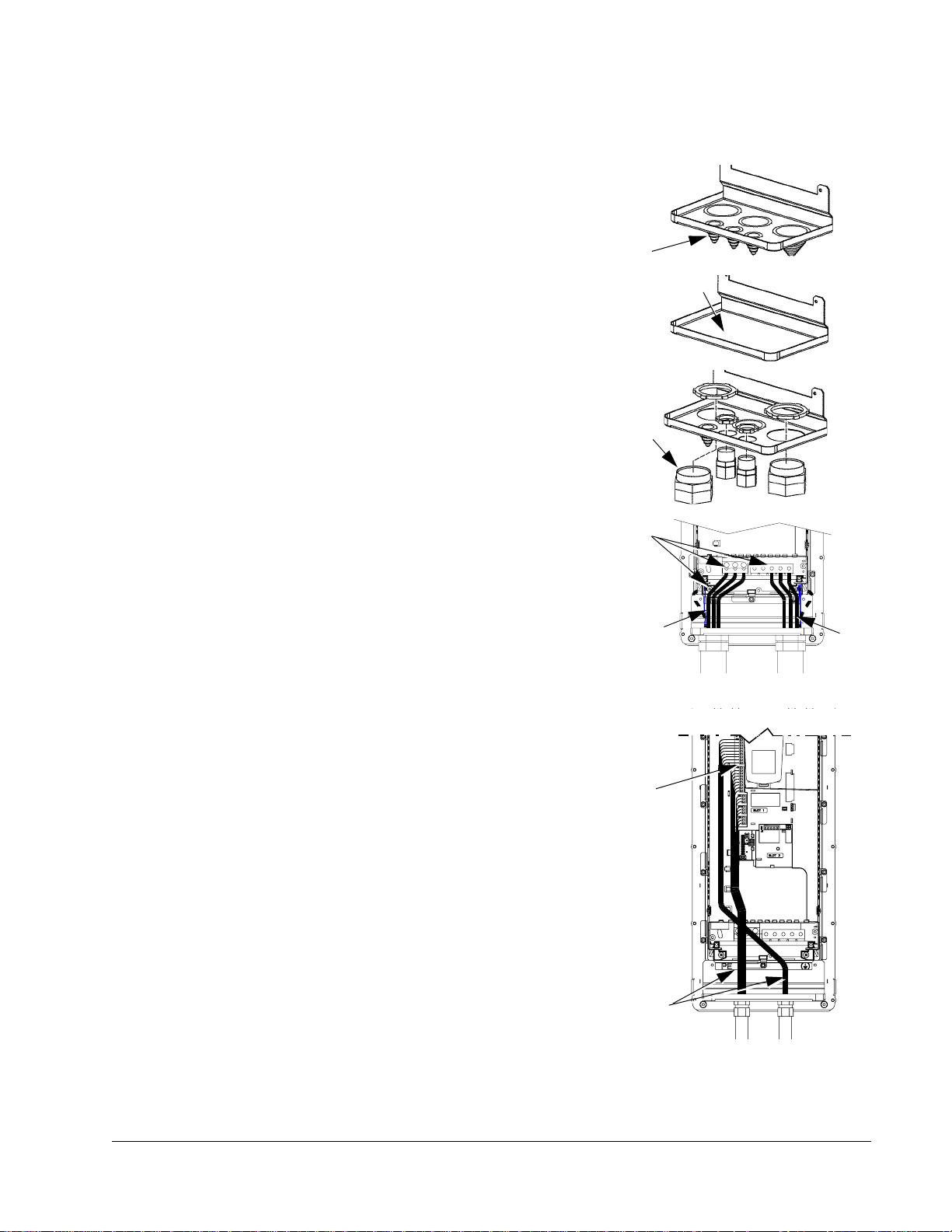

Wiring IP 54 / UL Type 12 Enclosure

1. Step depends on Frame Size:

• Frame Sizes R1…R4: Remove and

discard the cable seals where conduit will

be installed. (The cable seals are coneshaped, rubber seals on the bottom of the

drive.)

IP50131

• Frame Sizes R4 and R5: Use punch to

create holes for conduit connections as

needed.

2. For each conduit run (input power, motor and

control wiring must be separate), install water

tight conduit connectors (not supplied).

3. Route the power wiring through conduit.

4. Route the motor wiring through conduit (not

the same conduit as input power wiring run).

5. Strip the wires.

6. Connect the power, motor, and ground wires

to the drive terminals. See

"Wiring Overview"

on page 13, and "Connection Diagrams" on

page 14.

7. Route the control cables through the conduit

(not the same conduit as either input power or

motor wiring runs).

1

IP5023

2

IP5006

6

3

4

IP5007

8. Strip the control cable sheathing and twist the

copper screen into a pig-tail.

9. Connect the ground screen pig-tail for digital

and analog I/O cables at X1-1. (Ground only

at drive end.)

10. Connect the ground screen pig-tail for RS485

cables at X1-28 or X1-32. (Ground only at

drive end.)

11. Strip and connect the individual control wires

to the drive terminals. See

"Wiring Overview"

on page 13.

12. Install the conduit box cover (1 screw).

9…1 1

7

IP5008

Installation

Page 18

18 ACH550-UH User’s Manual

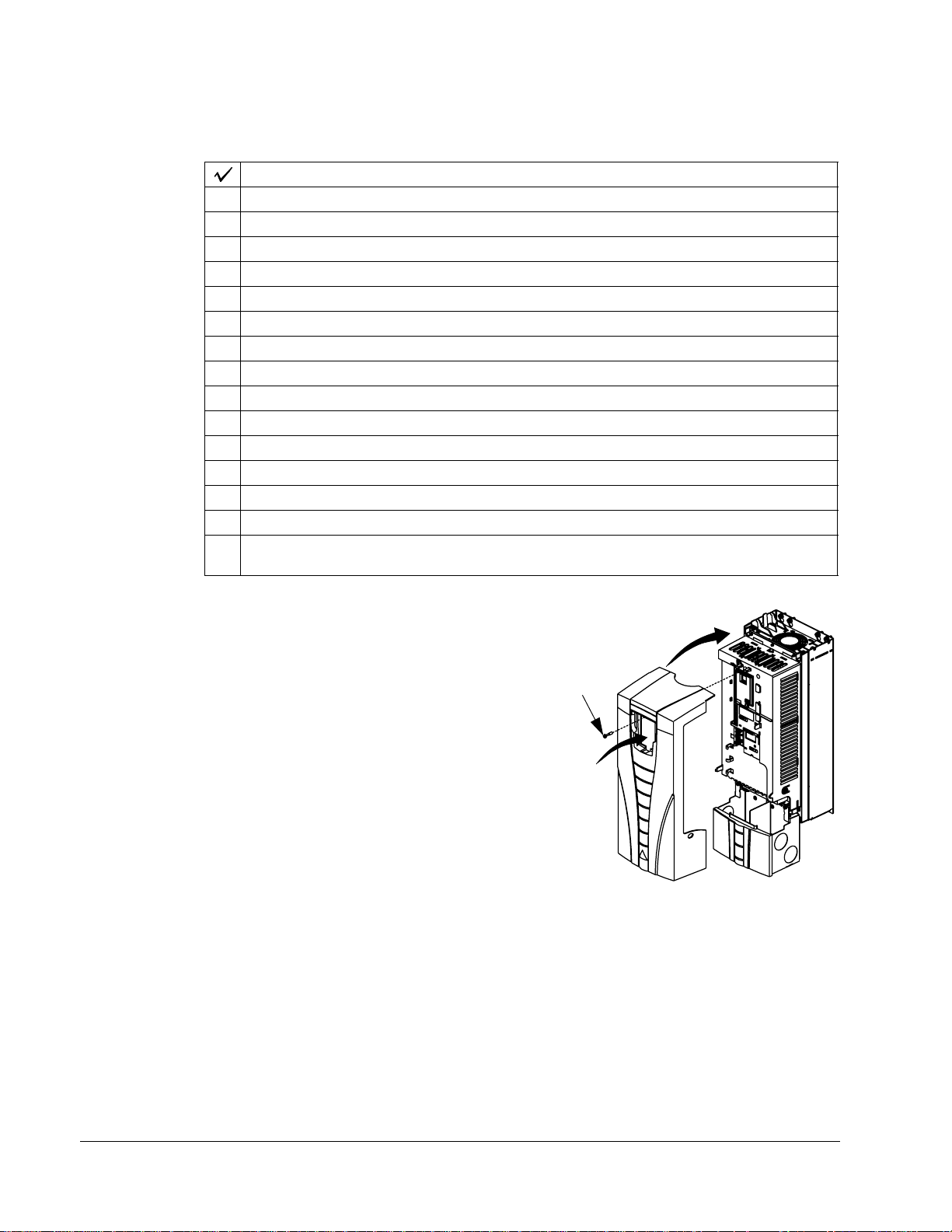

Check Installation

Before applying power, perform the following checks.

Check

Installation environment conf orms to the drive’s specifications for ambient conditions.

The drive is mounted securely.

Space around the drive meets the drive’s specifications for cooling.

The motor and driven equipment are ready for start.

For floating networks: The internal RFI filter is disconnected.

The drive is properly grounded.

The input power voltage matches the drive nominal input voltage range.

The input power connections at U1, V1, and W1 are connected and tightened as specified.

The input power branch circuit protection is installed.

The motor connections at U2, V2, and W2 are connected and tightened as specified.

The input power, motor and control wiring are routed through separate conduit runs.

NO power factor compensation capacitors are in the motor cable.

The control connections are connected and tightened as specified.

NO tools or foreign objects (such as drill shavings) are inside the drive.

NO alternate power source for the motor (such as a bypass connection) is connected – no

voltage is applied to the output of the drive.

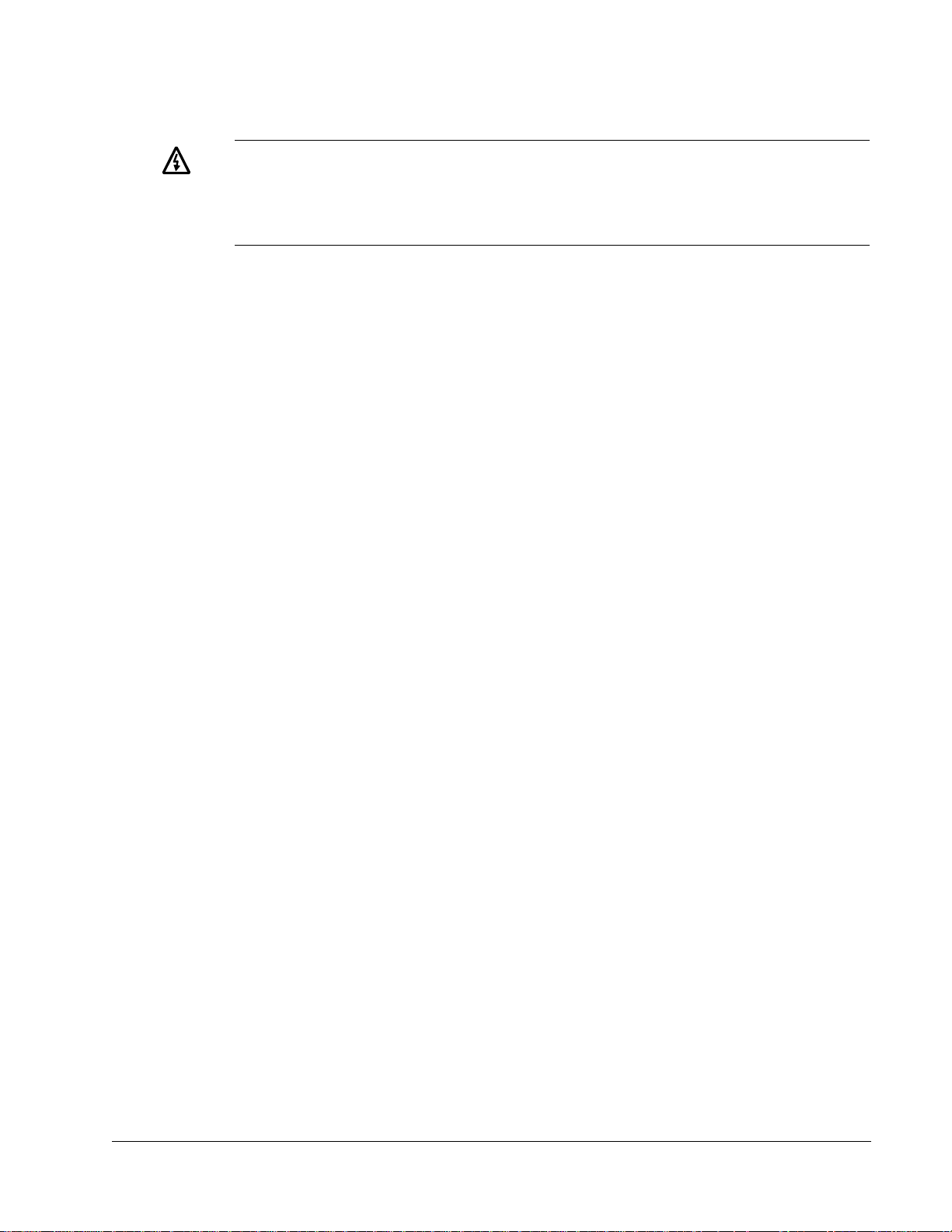

Re-install Cover

IP 21 / UL Type 1

1. Align the cover and slide it on.

2. Tighten the captive screw.

3. Re-install the control panel.

1

2

3

IP2009

Installation

Page 19

ACH550-UH User’s Manual 19

IP 54 / UL Type 12

1. Align the cover and slide it on.

4

2. Tighten the captive screws around the edge of

3

the cover.

3. Slide the hood down over the top of the cover.

4. Install the two screws that attach the hood.

5. Re-install the control panel.

5

Note! The control panel window must be

closed to comply with IP 54/UL type 12.

6

6. Optional: Add a lock (not supplied) to secure

the control panel window.

2

1

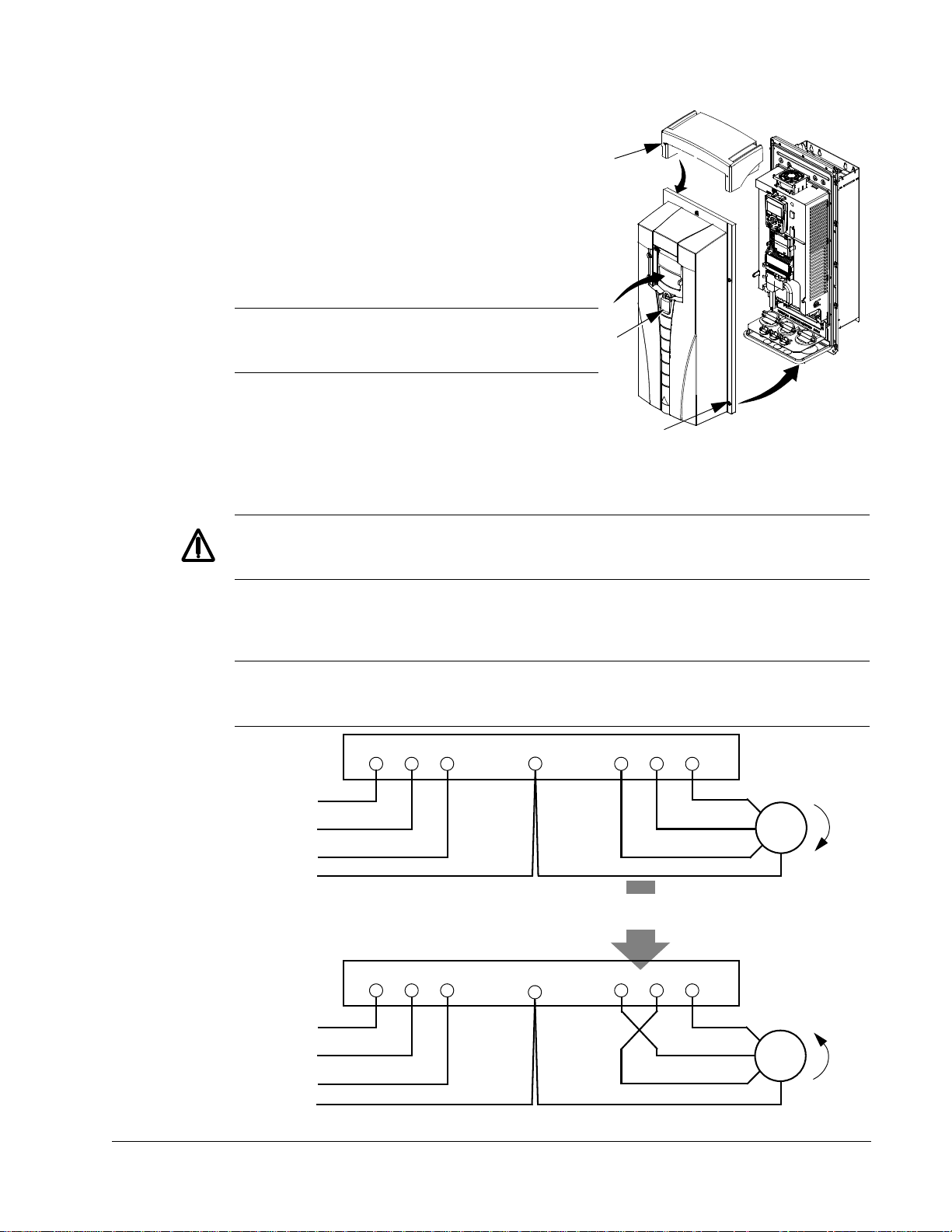

Apply Power

Always re-install the front cover before turning power on.

Warning! The ACH550 will start up automatically at power up, if the external

run command is on.

1. Apply input power.

When power is applied to the ACH550, the green LED comes on.

Note! Before increasing motor speed, check that the motor is running in the desired

direction.To change rotation direction, switch motor leads as shown below.

Drive

GND

Motor

Input

U1 V1 W1 U2 V2 W2

L1

L2

FM

Input

L3

GND

L1

L2

L3

GND

To change rotation direction,

switch motor leads

Drive

U1 V1 W1 U2 V2 W2

GND

Motor

FM

Installation

Page 20

20 ACH550-UH User’s Manual

Start-Up

The ACH550 has default parameter settings that are sufficient for many situations.

However, review the following situations. Perform the associated procedures as

appropriate.

Spin Motor

When first installed and started the control panel displays a welcome screen with the

following options.

• Press Exit to commission the drive as described in section “S tart-Up by Changing

the Parameters Individually” on page 23.

• Press Enter to move to the following options:

– Select “Commission Drive” to commission the drive as described in section

“Start-Up by Using the Start-Up Assistant” on page 23.

– Select “Spin Motor” to operate the motor prior to commissioning. This option

operates the motor without any commissioning, except entry of the motor data

as described below. Spin Motor is useful, for example, to operate ventilation

fans prior to commissioning.

Note! When using Spin Motor, the motor speed is limited to the range 1/3…2/3 of

maximum speed. Also, no interlocks are activated. Finally, once the drive is

commissioned, the welcome screen and this option no longer appear.

Motor Data

The motor data on the ratings plate may differ from the defaults in the ACH550. The

drive provides more precise control and better thermal protection if you enter the

rating plate data.

1. Gather the following from the motor ratings plate:

•Voltage

• Nominal motor current

• Nominal frequency

• Nominal speed

• Nominal power

2. Edit parameters 9905…9909 to the correct values.

• Assistant Control Panel: The Start-up Assistant walks you through this data entry

(see page

27).

• Basic Control Panel: Refer to "Parameters Mode" on page 26, for parameter

editing instructions.

Installation

Macros

Note! Selecting the appropriate macro should be part of the original system design,

since the control wiring installed depends on the macro used.

Page 21

ACH550-UH User’s Manual 21

1. Review the macro descriptions in "Application Macros" on page 35. Use the macro

that best fits system needs.

2. Edit parameter 9902 to select the appropriate macro. Use either of the following:

• Use the Start-up Assistant, which displays the macro selection immediately after

motor parameter setup.

• Refer to "Parameters Mode" on page 26, for parameter editing instructions.

Tuning – Parameters

The system can benefit from one or more of the ACH550 special features, and/or

fine tuning.

1. Review the parameter descriptions in "Parameter Descriptions" starting on page 51.

Enable options and fine tune parameter values as appropriate for the system.

2. Edit parameters as appropriate.

Fault and Alarm Adjustments

The ACH550 can detect a wide variety of potential system problems. For example,

initial system operation may generate faults or alarms that indicate set-up problems.

1. Faults and alarms are reported on the control panel with a number. Note the number

reported.

2. Review the description provided for the reported fault/alarm:

• Use the fault and alarm listings on pages 213 and 218 respectively, or

• Press the help key (Assistant Control Panel only) while fault or alarm is displayed.

3. Adjust the system or parameters as appropriate.

Installation

Page 22

22 ACH550-UH User’s Manual

Start-Up

HVAC Control Panel Features

The ACH550 HVAC control panel (ACS-CP-B) features:

Status LED

(Green when normal,

if flashing or red,

see Diagnostics.)

UP

SOFT

KEY 1

DOWN

AUTO

OFF

HAND

• Language selection for the display

• Drive connection that can be made or detached at any time

• Start-up assistant to facilitate drive commissioning

• Copy function for moving parameters to other ACH550 drives

• Backup function for saving parameter sets

• Context sensitive help

• Real-time clock

General Display Features

SOFT

KEY 2

HELP (always available)

X0201

Start-Up

Soft Key Functions

The soft key functions are defined by text displayed just above each key.

Display Contrast

To adjust display contrast, simultaneously press and or , as

appropriate.

Page 23

ACH550-UH User’s Manual 23

Start-Up

Start-Up can be performed in two ways:

• Using the Start-Up Assistant.

• Changing the parameters individually.

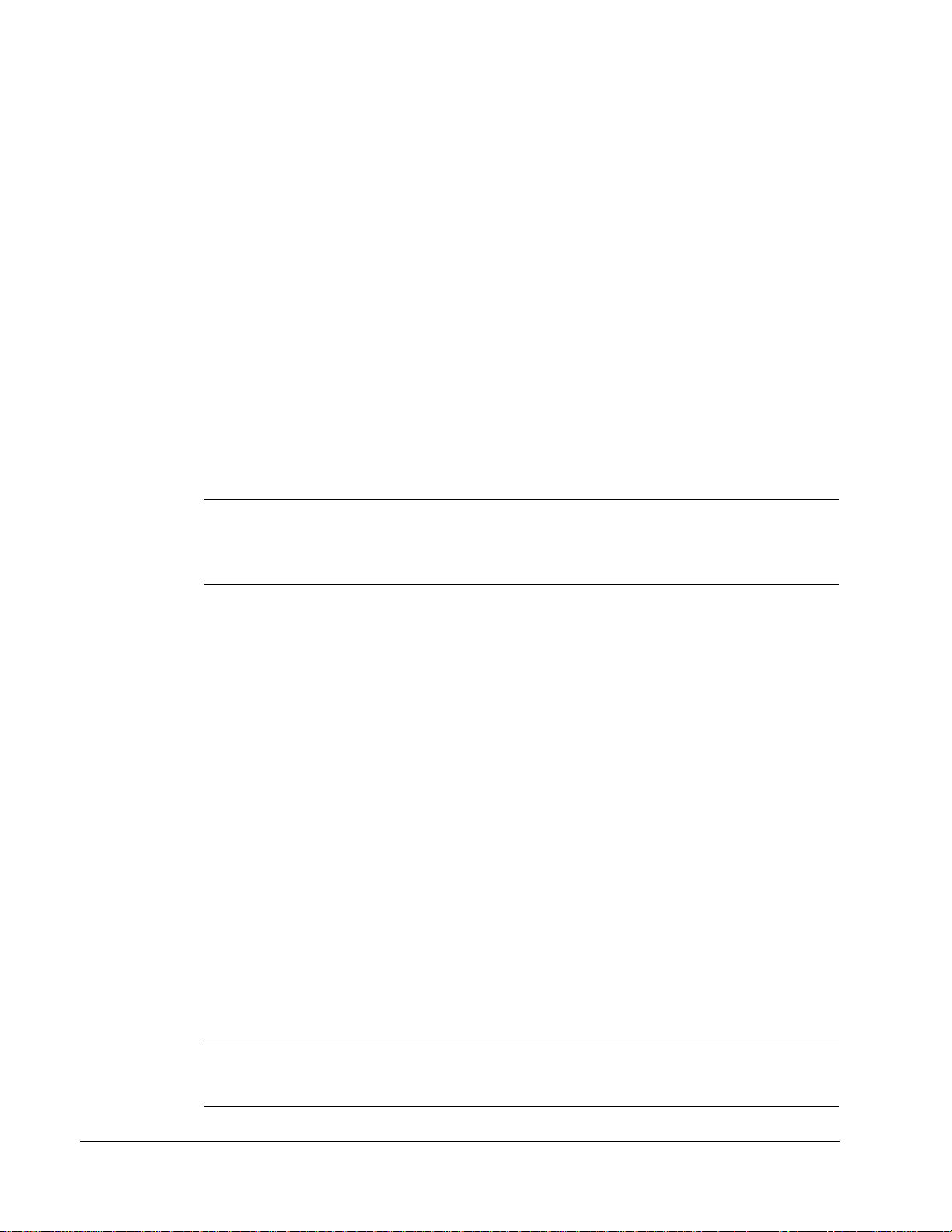

Start-Up by Using the Start-Up Assistant

To start the Start-Up Assistant, follow these steps:

Select MENU to enter the main menu

1

Select ASSISTANTS with the Up/Down

buttons and select ENTER.

2

Scroll to COMMISSION DRIVE with the

Up/Down buttons.

3

Change the values suggested by the

assistant to your preferences and then

press SAVE after every change.

4

The Start-Up Assistant will guide you through the start-up.

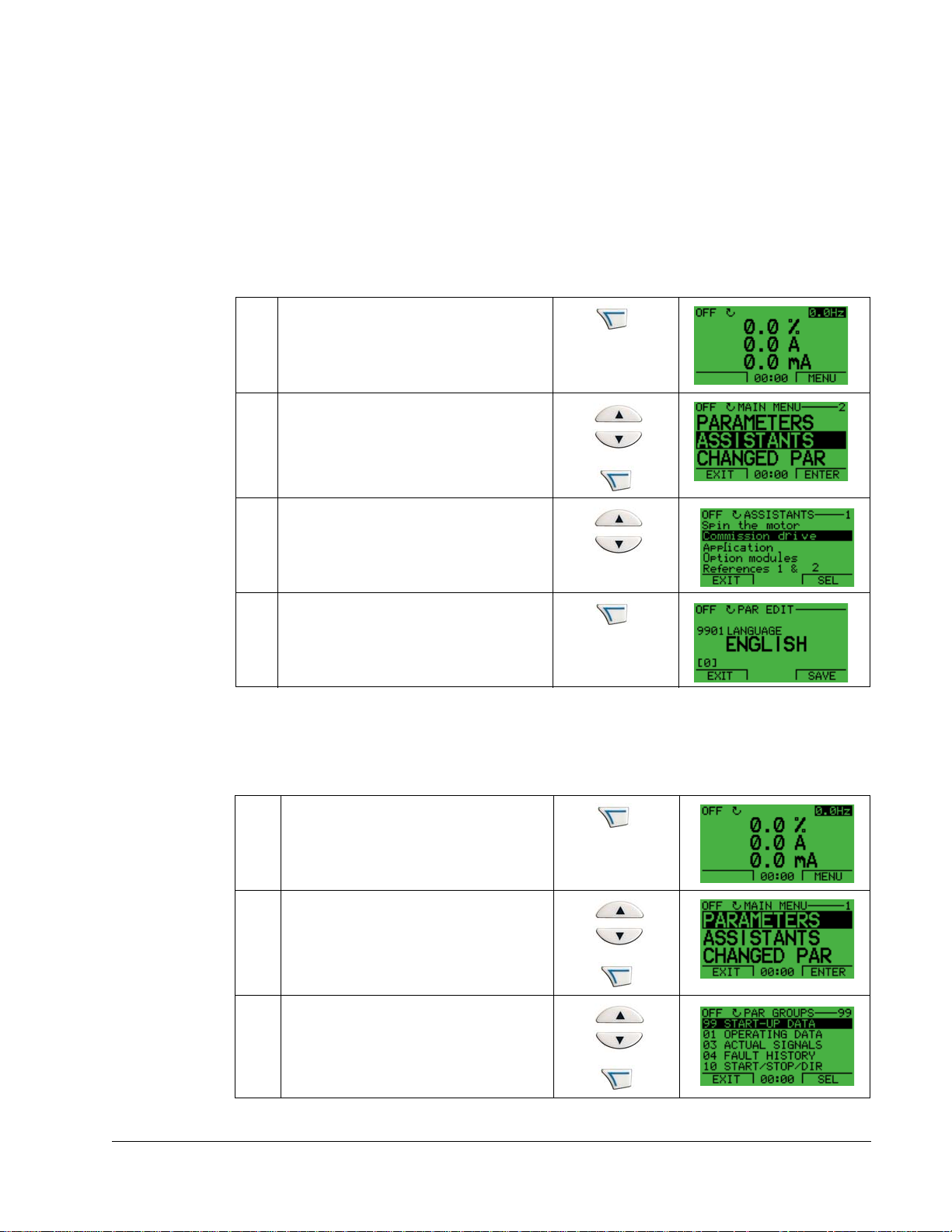

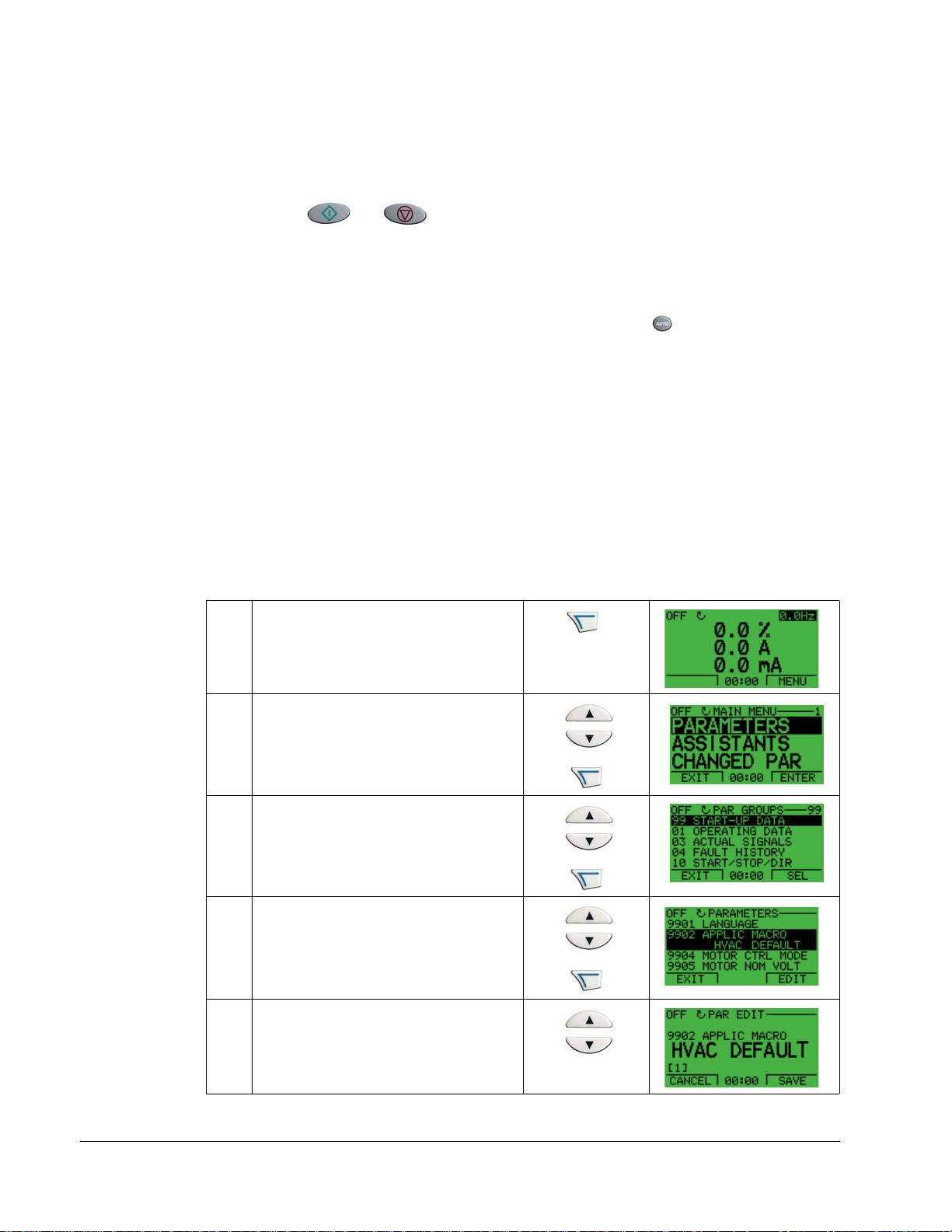

Start-Up by Changing the Parameters Individually

To change the parameters, follow these steps:

Select MENU to enter the main menu.

1

Select the Parameters mode with the UP/

DOWN buttons and select ENTER to

select the Parameters mode.

2

Select the appropriate parameter group

with the UP/DOWN buttons and select

SEL

3

Start-Up

Page 24

24 ACH550-UH User’s Manual

Select the appropriate parameter in a

group with the UP/DOWN buttons.Select

EDIT to change the parameter value.

4

Press the UP/DOWN buttons to change

the parameter value.

5

Select SAVE to store the modified value or

select CANCEL to leave the set mode.

Any modifications not saved are

6

cancelled.

Select EXIT to return to the listing of

parameter groups, and again to return to

the main menu.

7

To complete the control connections by manually entering the parameters, see

"Parameters Mode" in this section.

For detailed hardware description, see the "Technical Data" section.

Note! The current parameter value appears below the highlighted parameter.

Note! To view the default parameter value, press the UP/DOWN buttons

simultaneously.

Note! The most typical and necessary parameters to change are parameter groups

99 Start-up data, 10 Start/Stop/Dir, 11 Reference Select, 20 Limits, 21 Start/Stop, 22

Accel/Decel, 26 Motor Control and 30 Fault Functions.

Note! To restore the default factory settings, select the application macro HVAC

default.

Start-Up

Page 25

ACH550-UH User’s Manual 25

Modes

The HVAC control panel has several different modes for configuring, operating and

diagnosing the drive. The modes are:

• Standard display mode – Shows drive status information and operates the

drive.

• Parameters mode – Edits parameter values individually.

• Start-up assistant mode – Guides the start-up and configuration.

• Changed parameters mode – Shows changed parameters.

• Drive parameter backup mode – Stores or uploads the parameters.

• Clock set mode – Sets the time and date for the drive.

• I/O settings mode –Checks and edits the I/O settings.

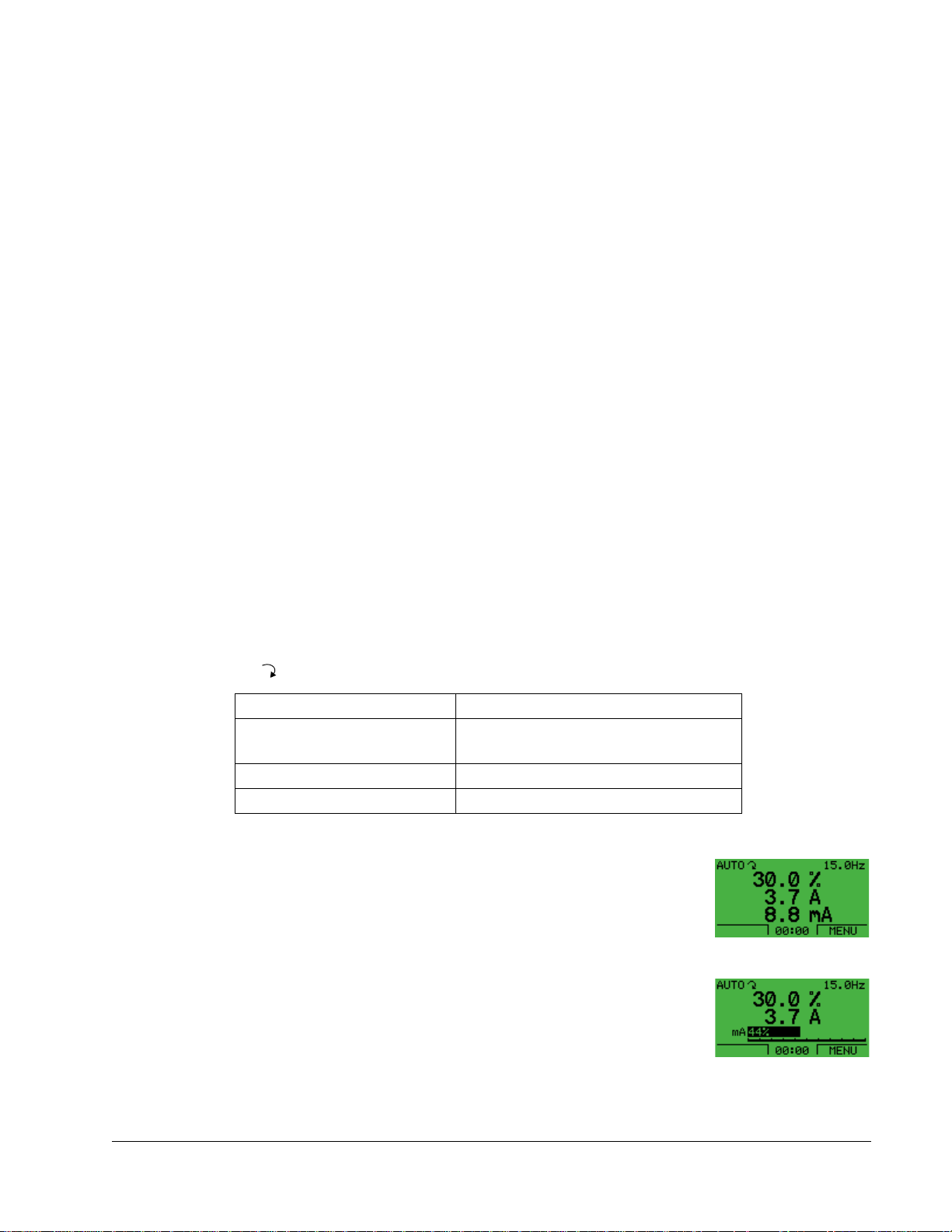

Standard Display Mode

Use the standard display mode to read information on the drive’s status and to

operate the drive. To reach the standard display mode, press EXIT until the LCD

display shows status information as described below.

Status Information

Top. The top line of the LCD display shows the basic status information of the drive.

•HAND – Indicates that the drive control is local, that is, from the control panel.

•AUTO – Indicates that the drive control is remote, such as the basic I/O (X1) or

fieldbus.

• – Indicates the drive and motor rotation status as follows:

Control panel display Significance

Rotating arrow (clockwise or

counterclockwise)

Rotating arrow blinking Drive is running but not at setpoint

Stationary arrow Drive is stopped

• Drive is running and at setpoint

• Shaft direction is forward or reverse

• Upper right – shows the active reference.

Middle. Using parameter group 34, the middle of the LCD

display can be configured to display:

• One to three parameter values – The default display shows

parameters 0103 (OUTPUT FREQ) in percentages, 0104

(CURRENT) in amperes and 0120 (AI1) in milliamperes.

• A bar meter rather than one of the parameter values.

Bottom. The bottom of the LCD display shows:

• Lower corners – show the functions currently assigned to

the two soft keys.

• Lower middle – displays the current time (if configured to show the time).

Start-Up

Page 26

26 ACH550-UH User’s Manual

Operating the Drive

AUTO/HAND – The very first time the drive is powered up, it is in the auto control

(AUTO) mode, and is controlled from the Control terminal block X1.

To switch to hand control (HAND) and control the drive using the control panel, press

and hold the

or button.

• Pressing the HAND button switches the drive to hand control while keeping the

drive running.

• Pressing the OFF button switches to hand control and stops the drive.

To switch back to auto control (AUTO), press and hold the button.

Hand/Auto/Off – To start the drive press the HAND or AUTO buttons, to stop the

drive press the OFF button.

Reference – To modify the reference (only possible if the display in the upper right

corner is in reverse video) press the UP or DOWN buttons (the reference changes

immediately).

The reference can be modified in the local control mode, and can be parameterized

(using Group 11 reference select) to also allow modification in the remote control

mode.

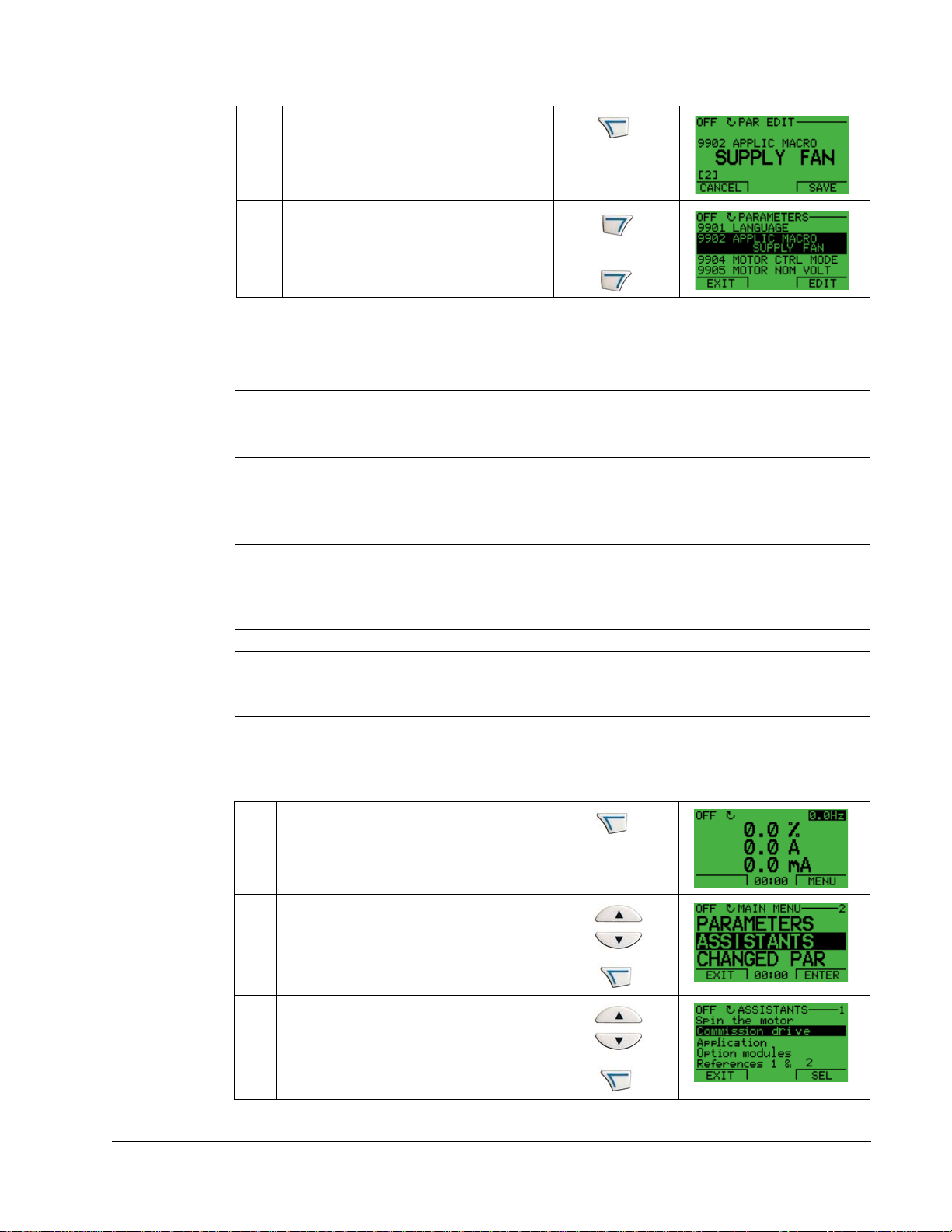

Parameters Mode

To change the parameters, follow these steps:

Select MENU to enter the main menu.

1

Select the Parameters mode with the UP/

DOWN buttons, and select ENTER to

select the Parameters mode.

2

Select the appropriate parameter group

with the UP/DOWN buttons and select

SEL

3

Select the appropriate parameter in a

group with the UP/DOWN buttons. Select

EDIT to change the parameter.

4

Start-Up

Press the UP/DOWN buttons to change

the parameter value.

5

Page 27

ACH550-UH User’s Manual 27

Select SAVE to store the modified value

or select CANCEL to leave the set mode.

Any modifications not saved are

6

cancelled.

Select EXIT to return to the listing of

parameter groups, and again to return to

the main menu.

7

To complete the control connections by manually entering the parameters, see

"Parameters Mode" in the this section.

For detailed hardware description, see the Appendix.

Note! The current parameter value appears below the highlighted parameter.

Note! To view the default parameter value, press the UP/DOWN buttons

simultaneously.

Note! The most typical and necessary parameters to change are parameter groups

99 Start-up data, 10 Start/Stop/Dir, 11 Reference Select, 20 Limits, 21 Start/Stop, 22

Accel/Decel, 26 Motor Control and 30 Fault Functions.

Note! To restore the default factory settings, select the application macro HVAC

default.

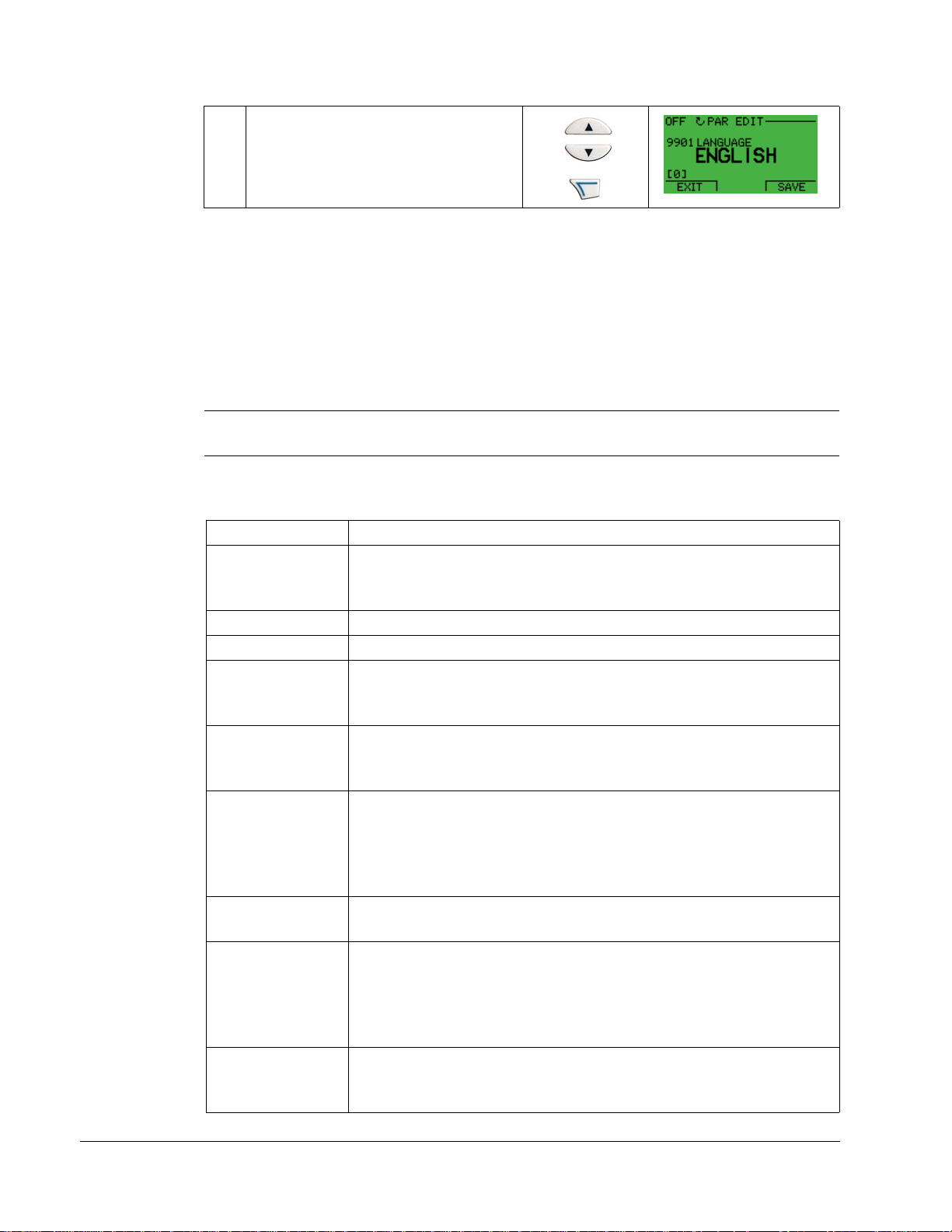

Start-Up Assistant Mode

To start the Start-Up Assistant, follow these steps:

Select MENU to enter the main menu

1

Select ASSISTANTS with the Up/Down

buttons and select ENTER.

2

Scroll to COMMISSION DRIVE with the

Up/Down buttons and select SEL.

3

Start-Up

Page 28

28 ACH550-UH User’s Manual

Change the values suggested by the

assistant to your preferences and then

press SAVE after every change.

4

The Start-Up Assistant will guide you through the start-up.

The Start-Up Assistant guides you through the basic programming of a new drive.

(You should familiarize yourself with basic control panel operation and follow the

steps outlined above.) At the first start, the drive automatically suggest s entering th e

first task, Language Select.The assistant also checks the values entered to prevent

entries that are out of range.

The St art-Up Assist ant is divided into tasks. You may activate the tasks one after t he

other, as the Start-Up Assistant suggests, or independently.

Note! If you want to set the parameters independently, use the Parameters mode.

The order of tasks presented by the S t art-up Assista nt depends on your entries. The

following task list is typical.

Task name Description

Spin the motor • Prompts for control panel display language selection.

• Prompts for motor data.

• Guides user through rotation check.

Commission drive Prompts for motor data.

Application Prompts for application macro selection.

References 1 & 2 • Prompts for the source of speed references 1 and 2.

• Prompts for reference limits.

• Prompts for frequency (or speed) limits.

Start/Stop Control • Prompts for the source for start and stop commands.

• Prompts for start and stop mode definition.

• Prompts for acceleration and deceleration times.

Protections • Prompts for current and torque limits.

• Prompts for the use of Run enable and Start enable signals.

• Prompts for the use of emergency stop.

• Prompts for Fault function selection.

• Prompts for Auto reset functions selection.

Constant Speeds • Prompts for the use of constant speeds.

• Prompts for constant speed values.

PID Control • Prompts for PID settings.

• Prompts for the source of process reference.

• Prompts for reference limits.

• Prompts for source, limits and units for the process actual value.

• Defines the use of Sleep function.

Low Noise Setup • Prompts for switching frequency.

• Prompts for definition of Flux optimization.

• Prompts for the use of Critical speeds.

Start-Up

Page 29

ACH550-UH User’s Manual 29

Task name Description

Panel Display Prompts for display variable and unit settings.

Timed Functions Prompts for the use of Timed functions.

Output • Prompts for the signals indicated through the relay outputs.

• Prompts for signals indicated through the analog outputs AO1 and AO2.

Sets the minimum, maximum, scaling and inversion values.

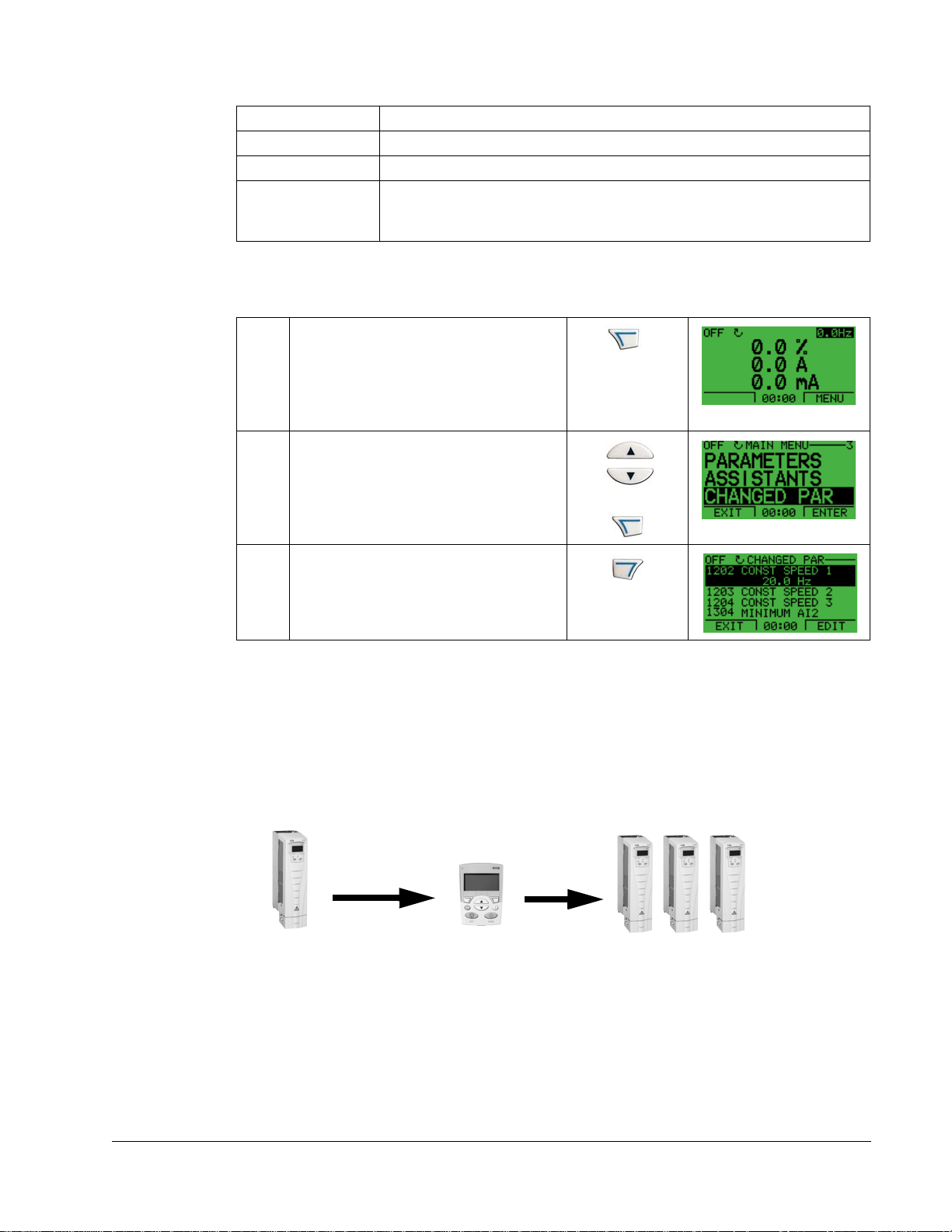

Changed Parameters Mode

To view changed parameters, follow these steps:

Select MENU to enter the menu.

1

Select CHANGED PAR with the UP/

DOWN buttons and select ENTER.

2

A list of changed parameters is displayed.

Select EXIT to exit the parameters mode.

3

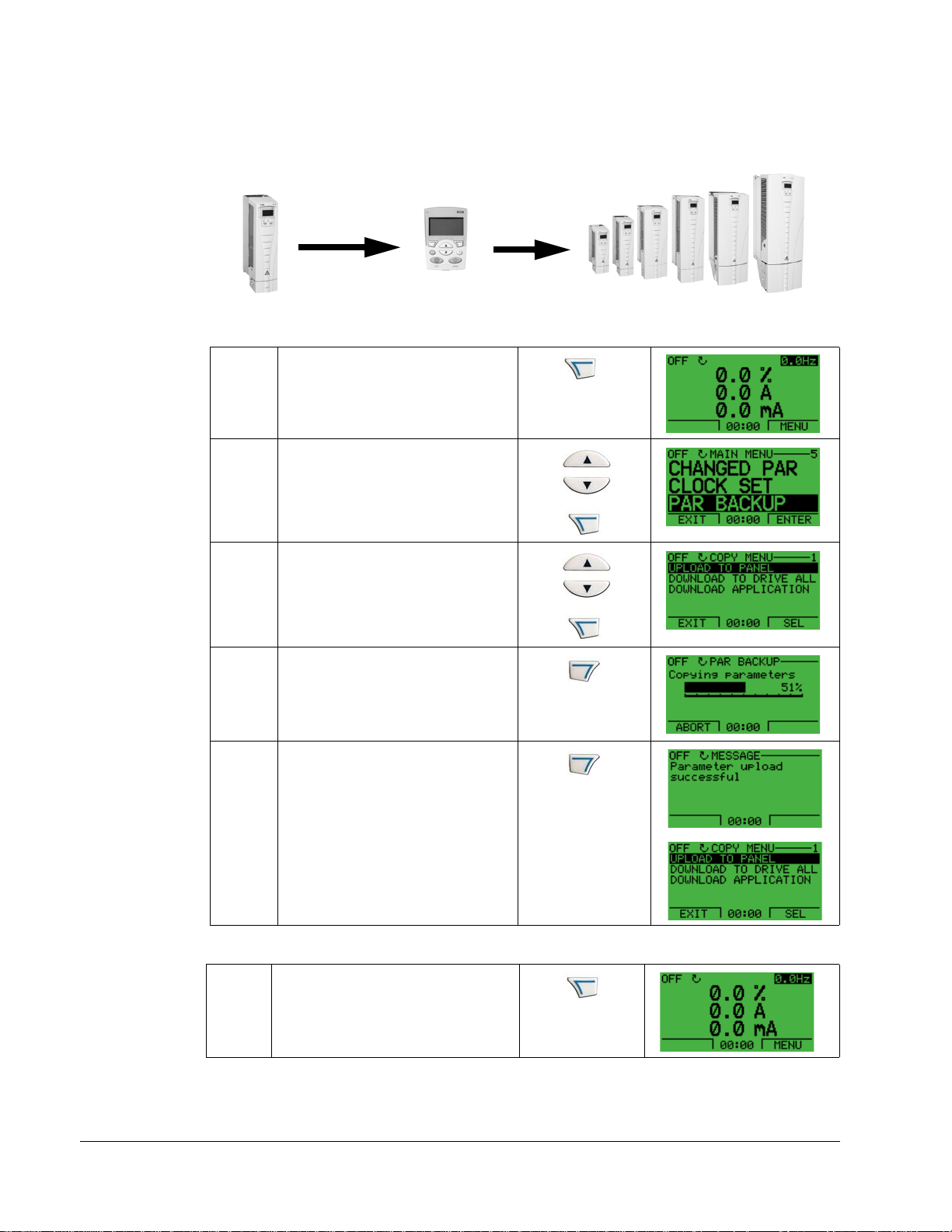

Drive Parameter Backup Mode

Use the parameter backup mode to export parameters from one drive to another.

The parameters are uploaded from a drive to the control panel and downloaded from

the control panel to another drive. Two options are available:

• Download all – copies all application and motor parameters to the drive. Useful

where drives of the same size use the same application. Also useful to create a

backup for recovery if drive parameters are corrupted or erased.

Control

Upload

to panel

IP2100

Panel

X0202

Download

all

IP2100

Start-Up

Page 30

30 ACH550-UH User’s Manual

• Download application – copies only the application to the drive. Useful where

drives of different sizes use the same application. Parameters 9905...9909, 1605,

1607, 5201, group 51 parameters and internal motor p arameters are NOT copied.

Control

IP2100

Upload

to panel

Panel

X0202

Download

application

IP2101

To upload parameters to control panel, follow these steps:

Select MENU to enter the main

menu.

1

Select PAR BACKUP with the UP/

DOWN buttons and select ENTER.

2

Scroll to Upload to Panel and select

SEL.

3

The text “Copying parameters” and a

progress diagram is displayed.

Select ABORT if you want to stop

4

the process.

The text “Parameter upload

successful” is displayed and the

control panel returns to the PAR

BACKUP menu. Select EXIT to

return to the main menu. Now you

can disconnect the panel.

5

To download all parameters to drive, follow these steps:

Select MENU to enter the menu.

Start-Up

1

Page 31

ACH550-UH User’s Manual 31

Select PAR BACKUP with the UP/

DOWN buttons.

2

Scroll to Download to drive all and

select SEL.

3

The text “restoring parameters” is

displayed. Select ABORT if you want

to stop the process.

4

After the download stops, the

message “Parameter download

successful” is displayed and the

control panel goes back to PAR

BACKUP menu. Select EXIT to return

to the main menu.

5

To download application to drive, follow these steps:

Select MENU to enter the menu.

1

Select PAR BACKUP with the UP/

DOWN buttons.

2

Scroll to DOWNLOAD APPLICATION

and select SEL.

3

The text “Downloading parameters

(partial)” is displayed. Select ABORT

if you want to stop the process.

4

Start-Up

Page 32

32 ACH550-UH User’s Manual

The text “Parameter download

successful” is displayed and the

control panel returns to P AR BACKUP

menu. Select EXIT to return to the

main menu.

5

Note! If upload or download of parameters is aborted, the partial p arameter set is not

implemented.

Clock Set Mode

The clock set mode is used for setting the time and date for the internal clock of the

ACH550. In order to use the timer functions of the ACH550, the internal clock has to

be set first. Date is used to determine weekdays and is visible in Fault logs.

To set the clock, follow these steps:

Select MENU to enter the main menu.

1

Scroll to Clock Set with the UP/DOWN

buttons and select ENTER to enter the

Clock Set mode.

2

Scroll to Clock Visibility with the UP/

DOWN buttons and select SEL to change

the visibility of the clock.

3

Scroll to Show Clock with the UP/DOWN

buttons and select SEL to make the clock

visible.

4

Scroll to Set Time with the UP/DOWN

buttons and select SEL.

5

Start-Up

Page 33

ACH550-UH User’s Manual 33

Change the hours and minutes with the

UP/DOWN buttons and select OK to save

the values. The active value is displayed

6

in inverted color.

Scroll to Time Format with the UP/DOWN

buttons and select SEL.

7

The different formats are displayed.

Select a format with the UP/DOWN

buttons and select SEL to confirm the

8

selection.

Scroll to Set Date with the UP/DOWN

buttons and select SEL.

9

Change the days, months and year with

the UP/DOWN buttons and select OK to

save the values. The active value is

10

displayed in inverted color.

Scroll to Date Format with the UP/DOWN

buttons and select SEL.

11

The Date formats are displayed . Sel e ct a

date format with the UP/DOWN buttons

and select OK to confirm the selection.

12

Select EXIT twice to return to the main

menu.

13

Start-Up

Page 34

34 ACH550-UH User’s Manual

I/O Settings Mode

To view and edit the I/O settings, follow these steps:

Select MENU to enter the main menu.

1

Scroll to I/O Settings with the UP/DOWN

buttons and select ENTER.

2

Scroll to the I/O setting you want to view

with the UP/DOWN buttons and select

SEL.

3

Select the setting you want to view with

the UP/DOWN buttons and select OK.

4

You can change the value with the UP/

DOWN buttons and save it by selecting

SAVE.

5

If you do not want to change the setting,

select CANCEL.

Select EXIT to return to the main menu.

6

Start-Up

Page 35

ACH550 User’s Manual 35

Application Macros

Overview

Macros change a group of parameters to new, predefined values designed for

specific applications. Use macros to minimize the need for manual editing of

parameters. Selecting a macro sets all other parameters to their default values,

except:

• Group 99: Start-up Data parameters

• The PARAMETER LOCK 1602

• The PARAM SAVE 1607

• Groups 50…52 serial communication parameters

• Group 29: Maintenance triggers

After selecting a macro, additional parameter changes can be made manually using

the control panel.

Application macros are enabled by setting the value for parameter 9902

MACRO. By default, HVAC default (value 1) is the enabled macro.

APPLIC

General Considerations

The following considerations apply for all macros:

• When using a direct speed reference in AUTO mode, connect the speed

reference to analog input 1 (AI1), and provide the START command using digital

input 1 (DI1). In HAND/OFF mode, the control panel provides the speed

reference and START command.

• When using process PID, connect the feedback signal to analog input 2 (AI2). As

a default, the control panel sets the Setpoint, but analog input 1 can be used as

an alternate source. You can set up process PID using parameters (Group 40) or

using the PID control assistant (recommended).

Application / Macro Listing

This section describes the following macros:

9902

Value

1 HVAC default

2 Supply fan 9 Internal timer with constant speeds

3 Return fan

4 Cooling tower fan

5 Condenser 12 Dual setpoint PID with constant speeds

6 Booster pump

7 Pump alternation

Macro

9902

Value

8 Internal timer

10 Floating point

11 Dual setpoint PID

13 E-bypass

14 Hand Control

Macro

Start-Up

Page 36

36 ACH550 User’s Manual

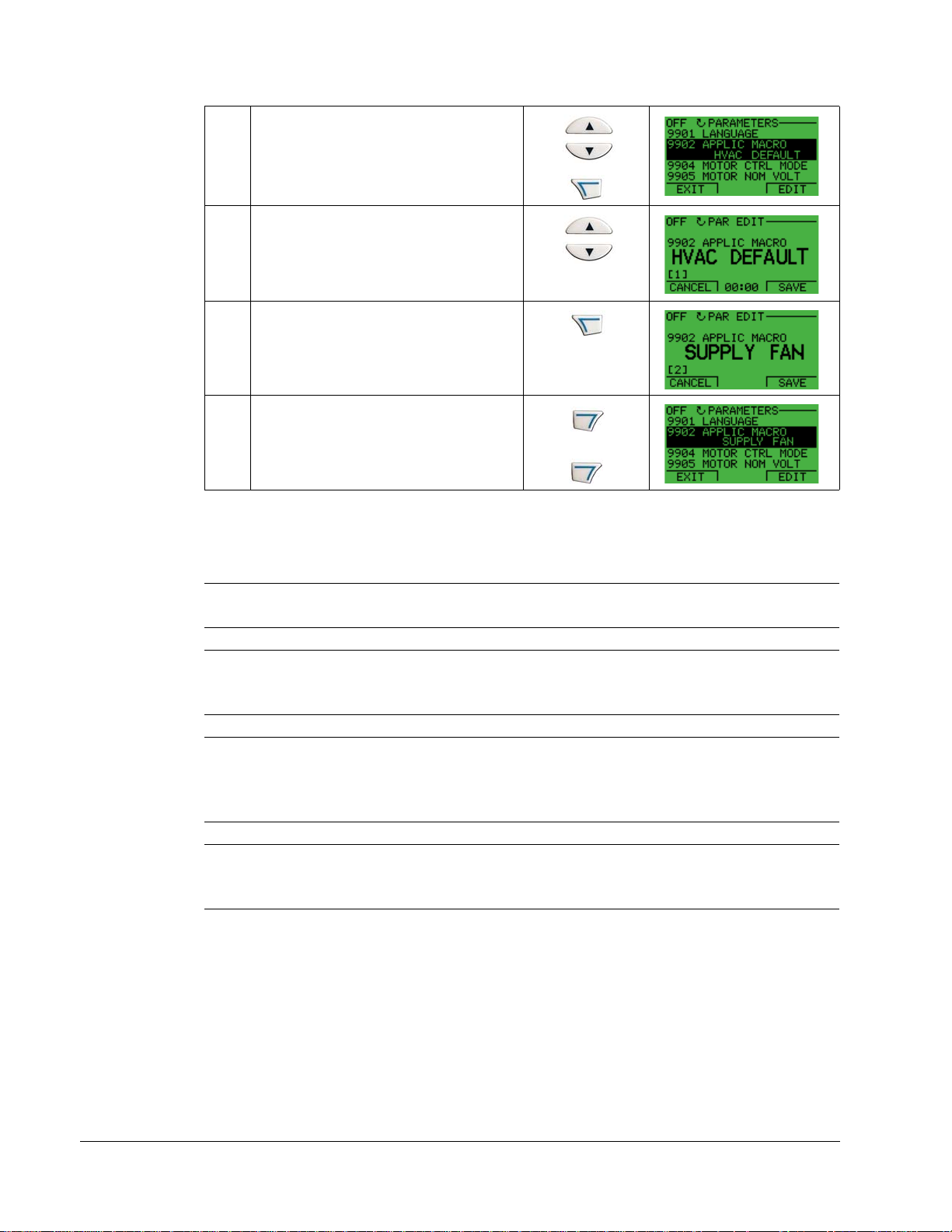

Selecting an Application Macro

To select a macro, follow these steps:

Select MENU to enter the main menu.

1

Select ASSISTANTS with the Up/Down

buttons and select ENTER.

2

Scroll to APPLICATION and select

ENTER.

3

Select a macro with the Up/Down buttons

and select SAVE.

4

Restoring Defaults

To restore the factory default settings, select the application macro HVAC Default.

Control Wiring

Each macro has specific requirements for control wiring. For general details about

the ACH550 control wiring terminals, see “Control Terminal Descriptions” on

page 238. Specific wiring requirements are included with each macro description.

Start-Up

Page 37

ACH550 User’s Manual 37

HVAC Default

This macro provides the factory default parameter settings for the ACS550-UH.

Factory defaults can be restored at any time by setting parameter 9902 to 1. The

diagram below shows typical wiring using this macro. When using direct speed

reference in AUTO mode or process PID, see "General Considerations" on page 35.

X1

1SCR

+

2AI1

3AGND

4 10V

+

5AI2

6AGND

mA

mA

7AO1

8AO2

9AGND

Signal cable shield (screen)

External reference 0(2)…10 V or 0(4)…20 mA

Analog input circuit common

Reference voltage 10 VDC

PID feedback: 0(2)…10 V or 0(4)…20 mA

Analog input circuit common

Output frequency: 0(4)…20 mA

Output current: 0(4)…20 mA

Analog output circuit common

ON

J1

Jumper Settings

AI1: 0(2)

ON

AI2: 0(4)

…10 V

…20 mA

10 24V

11 GND

12 DCOM1

13 DI1

14 DI2

15 DI3

16 DI4

17 DI5

18 DI6

19 RO1C

20 RO1A

21 RO1B

22 RO2C

23 RO2A

24 RO2B

25 RO3C

26 RO3A

27 RO3B

Parameter Value

None (Default macro)

Auxiliary voltage output +24 VDC

Common for DI return signals.

Digital input common for all

Start/Stop: Activate to start drive

Not configured

Constant (Preset) speed 1 (P 1202)

Safety interlock: Deactivate to stop drive (P 1608)

Not configured

Not configured

Relay output 1 (P 1401)

Default operation: Ready =>19 connected to 21

Relay output 2 (P 1402)

Default operation: Running =>22 connected to 24

Relay output 3 (P 1403)

Default operation: Fault (-1) =>25 connected to 27

(Fault => 25 connected to 26)

Parameters Changed Relative to HVAC Default

Parameter Value

Start-Up

Page 38

38 ACH550 User’s Manual

Supply Fan

This macro configures for supply fan applications where the supply fan brings fresh

air in according to signals received from a transducer. When using direct speed

reference in AUTO mode or process PID, see "General Considerations" on page 35.

X1

1SCR

+

2AI1

3AGND

4 10V

+

5AI2

6AGND

mA

mA

7AO1

8AO2

9AGND

10 24V

11 GND

12 DCOM1

13 DI1

14 DI2

15 DI3

16 DI4

17 DI5

18 DI6

19 RO1C

20 RO1A

Signal cable shield (screen)

External reference 0(2)…10 V or 0(4)…20 mA

Analog input circuit common

Reference voltage 10 VDC

PID feedback: 0(2)…10 V or 0(4)…20 mA

Analog input circuit common

Output frequency: 0(4)…20 mA

Output current: 0(4)…20 mA

ON

J1

ON

Analog output circuit common

Auxiliary voltage output +24 VDC

Common for DI return signals.

Digital input common for all

Start/Stop: Activate to start drive

Run permissive: Deactivate to stop drive (P 1601)

Constant (Preset) speed 1 (P 1202

1

)

Safety interlock 1: Deactivate to stop drive (P 1608)

Safety interlock 2: Deactivate to stop drive (P 1609)

Not configured

Relay output 1 (P 1401)

Default operation: Ready =>19 connected to 21

Jumper Settings

AI1: 0(2)

AI2: 0(4)

…10 V

…20 mA

21 RO1B

22 RO2C

23 RO2A

Relay output 2 (P 1402)

Default operation: Running =>22 connected to 24

24 RO2B

25 RO3C

26 RO3A

27 RO3B

Relay output 3 (P 1403)

Default operation: Fault (-1) =>25 connected to 27

(Fault => 25 connected to 26)

Parameters Changed Relative to HVAC Default

Parameter Value

9902

APPLIC MACRO 2 (SUPPLYFAN) 3207 SUPERV 3 PARAM 0103 (OUTPUT FREQ)

RELAY OUTPUT 17 (STARTED) 4001 GAIN 0.7

1401

1601

RUN ENABLE 2 (DI2) 4002 INTEGRATION TIME 10.0 s

1609

START ENABLE 25 (DI5) 4101 GAIN 1.0

Parameter Value

2202 ACCELER TIME 1 15.0 s 4102 INTEGRATION TIME 60.0 s

2203

DECELER TIME 1 15.0 s

Start-Up

Page 39

ACH550 User’s Manual 39

Return Fan

This macro configures for return fan applications where the return fan removes air

according to signals received from a transducer. When using direct speed reference

in AUTO mode or process PID, see "General Considerations" on page 35.

X1

1SCR

+

2AI1

3AGND

4 10V

+

5AI2

6AGND

mA

mA

7AO1

8AO2

9AGND

Signal cable shield (screen)

External reference 0(2)…10 V or 0(4)…20 mA

Analog input circuit common

Reference voltage 10 VDC

PID feedback: 0(2)…10 V or 0(4)…20 mA

Analog input circuit common

Output frequency: 0(4)…20 mA

Output current: 0(4)…20 mA

Analog output circuit common

ON

J1

Jumper Settings

AI1: 0(2)

ON

AI2: 0(4)

…10 V

…20 mA

10 24V

11 GND

12 DCOM1

13 DI1

14 DI2

15 DI3

16 DI4

17 DI5

18 DI6

19 RO1C

20 RO1A

Auxiliary voltage output +24 VDC

Common for DI return signals.

Digital input common for all

Start/Stop: Activate to start drive

Run permissive: Deactivate to stop drive (P 1601)

Constant (Preset) speed 1 (P 1202

1

)

Safety interlock 1: Deactivate to stop drive (P 1608)

Safety interlock 2: Deactivate to stop drive (P 1609)

Not configured

Relay output 1 (P 1401)

Default operation: Ready =>19 connected to 21

21 RO1B

22 RO2C

23 RO2A

Relay output 2 (P 1402)

Default operation: Running =>22 connected to 24

24 RO2B

25 RO3C

26 RO3A

27 RO3B

Relay output 3 (P 1403)

Default operation: Fault (-1) =>25 connected to 27

(Fault => 25 connected to 26)

Parameters Changed Relative to HVAC Default

Parameter Value

9902

APPLIC MACRO 3 (RETURNFAN) 3207 SUPERV 3 PARAM 0103 (OUTPUT FREQ)

RELAY OUTPUT 17 (STARTED) 4001 GAIN 0.7

1401

1601

RUN ENABLE 2 (DI2) 4002 INTEGRATION TIME 10.0 s

1609

START ENABLE 25 (DI5) 4101 GAIN 1.0

Parameter Value

2202 ACCELER TIME 1 15.0 s 4102 INTEGRATION TIME 60.0 s

2203

DECELER TIME 1 15.0 s

Start-Up

Page 40

40 ACH550 User’s Manual

Cooling Tower Fan

This macro configures for cooling tower fan applications where the fan speed is

controlled according to the signals received from a transducer. When using direct

speed reference in AUTO mode or process PID, see "General Considerations" on

page 35.

X1

1SCR

+

2AI1

3AGND

410V

+

5AI2

6AGND

mA

mA

7AO1

8AO2

9AGND

10 24V

11 GND

12 DCOM1

13 DI1

14 DI2

15 DI3

16 DI4

17 DI5

18 DI6

Signal cable shield (screen)

External reference 0(2)…10 V or 0(4)…20 mA

Analog input circuit common

Reference voltage 10 VDC

PID feedback: 0(2)…10 V or 0(4)…20 mA

Analog input circuit common

Output frequency: 0(4)…20 mA

Output current: 0(4)…20 mA

ON

J1

ON

Analog output circuit common

Auxiliary voltage output +24 VDC

Common for DI return signals.

Digital input common for all

Start/Stop: Activate to start drive

Run permissive: Deactivate to stop drive (P 1601)

Constant (Preset) speed 1 (P 1202

1

)

Safety interlock 1: Deactivate to stop drive (P 1608)

Safety interlock 2: Deactivate to stop drive (P 1609)

Not configured

Jumper Settings

AI1: 0(2)

AI2: 0(4)

…10 V

…20 mA

19 RO1C

20 RO1A

Relay output 1 (P 1401)

Default operation: Ready =>19 connected to 21

21 RO1B

22 RO2C

23 RO2A

Relay output 2 (P 1402)

Default operation: Running =>22 connected to 24

24 RO2B

25 RO3C

26 RO3A

27 RO3B

Relay output 3 (P 1403)

Default operation: Fault (-1) =>25 connected to 27

(Fault => 25 connected to 26)

Parameters Changed Relative to HVAC Default

Parameter Value

Parameter Value

9902 APPLIC MACRO 4 (CLNGTWRFAN) 3207 SUPERV 3 PARAM 0103 (OUTPUT FREQ)

1401

RELAY OUTPUT 17 (STARTED) 4101 GAIN 1.0

1601 RUN ENABLE 2 (DI2) 4102 INTEGRATION TIME 60.0 s

1609

START ENABLE 25 (DI5)

Start-Up

Page 41

ACH550 User’s Manual 41

Condenser

This macro configures for condenser and liquid cooler applications where fan speed

is controlled according to signals received from a transducer. When using direct

speed reference in AUTO mode or process PID, see "General Considerations" on

page 35.

X1

1SCR

+

2AI1

3AGND

410V

+

5AI2

6AGND

mA

mA

7AO1

8AO2

9AGND

10 24V

11 GND

12 DCOM1

13 DI1

14 DI2

15 DI3

16 DI4

17 DI5

18 DI6

Signal cable shield (screen)

External reference 0(2)…10 V or 0(4)…20 mA

Analog input circuit common

Reference voltage 10 VDC

PID feedback: 0(2)…10 V or 0(4)…20 mA

Analog input circuit common

Output frequency: 0(4)…20 mA

Output current: 0(4)…20 mA

ON

J1

ON

Analog output circuit common

Auxiliary voltage output +24 VDC

Common for DI return signals.

Digital input common for all

Start/Stop: Activate to start drive

Run permissive: Deactivate to stop drive (P 1601)

Constant (Preset) speed 1 (P 1202

1

)

Safety interlock 1: Deactivate to stop drive (P 1608)

Safety interlock 2: Deactivate to stop drive (P 1609)

Not configured

Jumper Settings

AI1: 0(2)

AI2: 0(4)

…10 V

…20 mA

19 RO1C

20 RO1A

Relay output 1 (P 1401)

Default operation: Ready =>19 connected to 21

21 RO1B

22 RO2C

23 RO2A

Relay output 2 (P 1402)

Default operation: Running =>22 connected to 24

24 RO2B

25 RO3C

26 RO3A

27 RO3B

Relay output 3 (P 1403)

Default operation: Fault (-1) =>25 connected to 27

(Fault => 25 connected to 26)

Parameters Changed Relative to HVAC Default

Parameter Value

Parameter Value

9902 APPLIC MACRO 5 (CONDENSER) 2203 DECELER TIME 1 10.0 s

1401

RELAY OUTPUT 17 (STARTED) 3207 SUPERV 3 PARAM 0103 (OUTPUT FREQ)

1601 RUN ENABLE 2 (DI2) 4005 ERROR VALUE INV 1 (YES)

1609

START ENABLE 25 (DI5) 4101 GAIN 1.0

2202

ACCELER TIME 1 10.0 s 4102 INTEGRATION TIME 60.0 s

Start-Up

Page 42

42 ACH550 User’s Manual

Booster Pump

This macro configures for booster pump applications where the pump speed is

controlled according to a signal received from a transducer . Whe n using direct speed

reference in AUTO mode or process PID, see "General Considerations" on page 35.

X1

1SCR

+

2AI1

3AGND

410V

+

5AI2

6AGND

mA

mA

7AO1

8AO2

9AGND

10 24V

11 GND

12 DCOM1

13 DI1

14 DI2

15 DI3

16 DI4

17 DI5

18 DI6

Signal cable shield (screen)

External reference 0(2)…10 V or 0(4)…20 mA

Analog input circuit common

Reference voltage 10 VDC

PID feedback: 0(2)…10 V or 0(4)…20 mA

Analog input circuit common

Output frequency: 0(4)…20 mA

Output current: 0(4)…20 mA

ON

J1

ON

Analog output circuit common

Auxiliary voltage output +24 VDC

Common for DI return signals.

Digital input common for all

Start/Stop: Activate to start drive

Run permissive: Deactivate to stop drive (P 1601)

Constant (Preset) speed 1 (P 12021)

Safety interlock 1: Deactivate to stop drive (P 1608)

Safety interlock 2: Deactivate to stop drive (P 1609)

Not configured

Jumper Settings

AI1: 0(2)

AI2: 0(4)

…10 V

…20 mA

19 RO1C

20 RO1A

Relay output 1 (P 1401)

Default operation: Ready =>19 connected to 21

21 RO1B

22 RO2C

23 RO2A

Relay output 2 (P 1402)

Default operation: Running =>22 connected to 24

24 RO2B

25 RO3C

26 RO3A

27 RO3B

Relay output 3 (P 1403)

Default operation: Fault (-1) =>25 connected to 27

(Fault => 25 connected to 26)

Parameters Changed Relative to HVAC Default

Parameter Value Parameter Value

9902

APPLIC MACRO 6 (BOOSTERPUMP) 2203 DECELER TIME 1 5.0 s

RELAY OUTPUT 17 (STARTED) 3207 SUPERV 3 PARAM 0 103 ( OUTPUT FREQ)

1401

1601

RUN ENABLE 2 (DI2) 4001 GAIN 1.0

1609

START ENABLE 25 (DI5) 4002 INTEGRATION TIME 60.0 s

ACCELER TIME 1 5.0 s

2202

Start-Up

Page 43

ACH550 User’s Manual 43

Pump Alternation

This macro configures for pump alternation applications, usually used in booster

stations. To adjust/maintain pressure in the network, the speed of the one pump

changes according to a signal received from a pressure transducer. When the

variable speed pump reaches a maximum speed limit, auxiliary pumps start as

needed. When using process PID, see "General Considerations" on page 35. To use

more than one (the default) Auxiliary pump, see parameter group 81.

X1

1SCR

+

2AI1

3AGND

410V

+

5AI2

6AGND

mA

mA

7AO1

8AO2

9AGND

10 24V

11 GND

12 DCOM1

13 DI1

14 DI2

15 DI3

16 DI4

17 DI5

18 DI6

Signal cable shield (screen)

External reference 0(2)…10 V or 0(4)…20 mA

Analog input circuit common

Reference voltage 10 VDC

PID feedback: 0(2)…10 V or 0(4)…20 mA

Analog input circuit common

Output frequency: 0(4)…20 mA

Output current: 0(4)…20 mA

ON

J1

ON

Analog output circuit common

Auxiliary voltage output +24 VDC

Common for DI return signals.

Digital input common for all

Start/Stop: Activate to start drive

Run permissive: Deactivate to stop drive (P 1601)

Not configured

PFA interlock 1: Deactivate to stop drive (P 1608)

PFA interlock 2: Deactivate to stop drive (P 1609)

Not configured

Jumper Settings

AI1: 0(2)

AI2: 0(4)

…10 V

…20 mA

19 RO1C

20 RO1A

Relay output 1 (P 1401)

Default operation: PFA (starts lag pump)

21 RO1B

22 RO2C

23 RO2A

Relay output 2 (P 1402)

Default operation: Running =>22 connected to 24

24 RO2B

25 RO3C

26 RO3A

27 RO3B

Relay output 3 (P 1403)

Default operation: Fault (-1) =>25 connected to 27

(Fault => 25 connected to 26)

Parameters Changed Relative to HVAC Default

Parameter Value

9902

APPLIC MACRO 7 (PUMPALTERN) 1609 START ENABLE 25 (DI5)

REF1 MAX 62Hz/1860rpm 2208 EM DEC TIME 62HZ

1105

Parameter Value

1201 CONST SPEED SEL 0 (NOT SEL) 2202 ACCELER TIME 1 5.0 s

1401

RELAY OUTPUT 1 31 (PFA) 2203 DECELER TIME 1 5.0 s

AO1 CONTENT MAX 62HZ 3207 SUPERV 3 PARAM 0103 (OUTPUT FREQ)

1503

1508

AO2 CONTENT MIN 0.0% 4101 GAIN 1.0

1509

AO2 CONTENT MAX 100.0% 4102 INTEGRATION TIME 60.0 s

RUN ENABLE 2 (DI2) 8123 PFA ENABLE 1 (ACTIVE)

1601

1608

START ENABLE 10 (NOT SEL)

Start-Up

Page 44

44 ACH550 User’s Manual

Internal Timer

This macro configures for applications where a built-in timer starts and stops the

motor. When the variable speed pump reaches a maximum speed limit, auxiliary

pumps start as needed. When using direct speed reference in AUTO mode or

process PID, see "General Considerations" on page 35.

Momentarily activating digital input 3 (DI3) provides a b oost fu nction which operates

the motor. See group 36, Timer Functions, for more information on setting up timers.

X1

1SCR

+

2AI1

3AGND

410V

+

5AI2

6AGND

mA

mA

7AO1

8AO2

9AGND

10 24V

11 GND

12 DCOM1

13 DI1

14 DI2

15 DI3

16 DI4

17 DI5

18 DI6

Signal cable shield (screen)

External reference 0(2)…10 V or 0(4)…20 mA

Analog input circuit common

Reference voltage 10 VDC

PID feedback: 0(2)…10 V or 0(4)…20 mA

Analog input circuit common

Output frequency: 0(4)…20 mA

Output current: 0(4)…20 mA

ON

J1

ON

Analog output circuit common

Auxiliary voltage output +24 VDC

Common for DI return signals.

Digital input common for all

Timer enable: Activate to start/stop drive from timer

Run permissive: Deactivate to stop drive (P 1601)

Timer override: Activate to start drive

Safety interlock 1: Deactivate to stop drive (P 1608)

Safety interlock 2: Deactivate to stop drive (P 1609)

Not configured

Jumper Settings

AI1: 0(2)

AI2: 0(4)

…10 V

…20 mA

19 RO1C

20 RO1A

Relay output 1 (P 1401)

Default operation: Started =>19 connecte d to 21

21 RO1B

22 RO2C

23 RO2A

Relay output 2 (P 1402)

Default operation: Running =>22 connected to 24

24 RO2B

25 RO3C

26 RO3A

27 RO3B

Relay output 3 (P 1403)

Default operation: Fault (-1) =>25 connected to 27

(Fault => 25 connected to 26)

Parameters Changed Relative to HVAC Default

Parameter Value

9902

APPLIC MACRO 8 (INT TIMER) 1609 START ENABLE 25 (DI5)

EXT1 COMMANDS 11 (TIMER1) 3207 SUPERV 3 PARAM 0103 (OUTPUT FREQ)

1001

1002

EXT2 COMMANDS 11 (TIMER1) 3601 TIMERS ENABLE 1 (DI1)

1201

CONST SPEED SEL 0 (NOT SEL) 3622 BOOST SEL 3 (DI3)

RELAY OUTPUT 17 (STARTED) 3626 TIMER 1 SRC 23 (B+P3+P2+P1)

1401

1601

RUN ENABLE 2 (DI2)

Parameter Value

Start-Up

Page 45

ACH550 User’s Manual 45

Internal Timer with Constant Speeds / PRV

This macro configures for applications such as a timed powered roof ventilator

(PRV) which alternates between two constant speeds (constant speed 1 and 2)

based on a built-in timer.

Momentarily activating digital input 3 (DI3) provides a b oost fu nction which operates

the motor. See group 36, Timer Functions, for more information on setting up timers.

X1

1SCR

+

2AI1

3AGND

410V

5AI2

6AGND

mA

7AO1

mA

8AO2

9AGND

10 24V

11 GND

12 DCOM1

13 DI1

14 DI2

15 DI3

16 DI4

17 DI5

18 DI6

Signal cable shield (screen)

External reference 0(2)…10 V or 0(4)…20 mA

Analog input circuit common

Reference voltage 10 VDC

Not configured

Analog input circuit common

Output frequency: 0(4)…20 mA

Output current: 0(4)…20 mA

ON

J1

ON

Analog output circuit common

Auxiliary voltage output +24 VDC

Common for DI return signals.

Digital input common for all

Timer enable: Activate to start/stop drive from timer

Run permissive: Deactivate to stop drive (P 1601)

Timer override: Activate to start drive

Safety interlock 1: Deactivate to stop drive (P 1608)

Safety interlock 2: Deactivate to stop drive (P 1609)

Not configured

Jumper Settings

AI1: 0(2)

AI2: 0(4)

…10 V

…20 mA

19 RO1C

20 RO1A

Relay output 1 (P 1401)

Default operation: Started =>19 connecte d to 21

21 RO1B

22 RO2C

23 RO2A

Relay output 2 (P 1402)

Default operation: Running =>22 connected to 24

24 RO2B

25 RO3C

26 RO3A

27 RO3B

Relay output 3 (P 1403)

Default operation: Fault (-1) =>25 connected to 27

(Fault => 25 connected to 26)

Parameters Changed Relative to HVAC Default

Parameter Value

Parameter Value

9902 APPLIC MACRO 9 (INT TIMER CS) 3416 SIGNAL 3 MIN -200.0%

1002

EXT2 COMMANDS 0 (NOT SEL) 3417 SIGNAL 3 MAX 200.0%

1103

REF1 SEL 0 (KEYPAD) 3419 OUTPUT 3 DSP UNIT 4 (%)

REF3 SEL 2 (AI2) 3420 OUTPUT 3 MIN -200.0%

1106

1201

CONST SPEED SEL 15 (TIMER1) 3421 OUTPUT 3 MAX 200.0%

1301

MINIMUM AI10.0% 3622 BOOST SEL 3 (DI3)

RELAY OUTPUT 17 (STARTED) 4001 GAIN 1.0

1401

1601

RUN ENABLE 2 (DI2) 4002 INTEGRATION TIME 60.0 s

1609

START ENABLE 25 (DI5) 4101 GAIN 1.0

SUPERV 3 PARAM 0103 (OUTPUT FREQ) 4102 INTEGRATION TIME 60.0 s

3207

3415

SIGNAL 3 PARAM 0105 (TORQUE) 4110 SETPOINT SEL 1 (AI1)

Start-Up

Page 46

46 ACH550 User’s Manual

Floating Point

This application macro is for applications where speed reference needs to be

controlled through digital inputs (DI5 & DI6). By activating digital input 5, the speed

reference increases, by activating digital input 6, the speed reference decreases. If

both digital inputs are active or inactive, the reference does not change.

Note! When constant speed 1 is activated using digital input 3 (DI3), the reference

speed is the value of parameter 1202. The value remains as the reference speed

when digital input 3 is deactivated.

X1

1SCR

2AI1

3AGND

410V

5AI2

6AGND

mA

mA

7AO1

8AO2

9AGND

10 24V

11 GND

12 DCOM1

13 DI1

14 DI2

15 DI3

16 DI4

17 DI5

18 DI6

19 RO1C

20 RO1A

Signal cable shield (screen)

Not configured

Analog input circuit common

Reference voltage 10 VDC

Not configured

Analog input circuit common

Output frequency: 0(4)…20 mA

Output current: 0(4)…20 mA

ON

J1

ON

Analog output circuit common

Auxiliary voltage output +24 VDC

Common for DI return signals.

Digital input common for all

Start/Stop: Activate to start drive

Run permissive: Deactivate to stop drive (P 1601)

Constant (Preset) speed 1 (P 1202)

1

Safety interlock 1: Deactivate to stop drive (P 1608)

Reference up: Activate to increase reference

Reference down: Activate to decrease reference

Relay output 1 (P 1401)

Default operation: Started =>19 connecte d to 21

Jumper Settings

AI1: 0(2)

AI2: 0(4)

…10 V

…20 mA

21 RO1B

22 RO2C

23 RO2A

Relay output 2 (P 1402)

Default operation: Running =>22 connected to 24

24 RO2B

25 RO3C

26 RO3A

27 RO3B

Relay output 3 (P 1403)

Default operation: Fault (-1) =>25 connected to 27

(Fault => 25 connected to 26)

Start-Up

Parameters Changed Relative to HVAC Default

Parameter Value Parameter Value

9902 APPLIC MACRO 10 (FLOATINGPNT) 3416 SIGNAL 3 MIN -200.0%

1103

REF1 SEL 7 (DI5U, 6D) 3417 SIGNAL 3 MAX 200.0%

1401

RELAY OUTPUT 17 (STARTED) 3419 OUTPUT 3 DSP UNIT 4 (%)

1601

RUN ENABLE 2 (DI2) 3420 OUTPUT 3 MIN -200.0%

3207

SUPERV 3 PARAM 0103 (OUTPUT FREQ) 3421 OUTPUT 3 MAX 200.0%

3415

SIGNAL 3 PARAM 0105 (TORQUE)

Page 47

ACH550 User’s Manual 47

Dual Setpoint with PID

This macro configures for dual setpoint PID applications, where activating digital

input 3 (DI3) changes the process PID controller’s setpoint to another value. When

using direct speed reference in AUTO mode or process PID, see "General

Considerations" on page 35. Set process PID setpoints (internal to the drive) using

parameters 4011 (

X1

+

+

mA

mA

SET1) and 4111 (SET2).

1SCR

2AI1

3AGND

410V

5AI2

6AGND

7AO1

8AO2

9AGND

10 24V

11 GND

12 DCOM1

13 DI1

14 DI2

15 DI3

16 DI4

17 DI5

18 DI6

Signal cable shield (screen)