Canon W8200 Service Manual

AY3-4306-S02

APR. 2003

COPYRIGHT 2003 CANON INC. CANON W8200 N 0403 0.00-0 PRINTED IN JAPAN (IMPRIME AU JAPON)

REVISION 0

Target Readers

This manual is published by Canon Inc. for qualified persons and contains the necessary

technical information for technical theory, installation, maintenance, and repair of

products. This manual covers all localities where the products are sold. For this reason, it

may contain information that does not apply to your locality.

Revisions

This manual may include technical inaccuracies or typographical errors due to

improvements or changes in the products. When amendments are made to the content of

this manual, Canon will issue technical information as the need arises. In the event of

major alterations to the content of this manual over a long or short period, Canon will

publish a revised version of the manual.

The following paragraph does not apply to any countries where such provisions are

inconsistent with local law.

Trademarks

The product names and company names appearing in this manual are the registered

trademarks or trademarks of the individual companies.

Copyright

This manual is copyrighted and all rights reserved. Under the copyright laws, this

manual may not be copied, reproduced, or translated into other languages, in whole or in

part, without the express written consent of Canon Inc. except in the case of internal

business use.

Copyright 2003 by Canon Inc.

CANON INC.

NB Quality Assurance Div.

16-1, Shimonoge 3-chome, Takatsu-ku, Kawasaki-shi, Kanagawa 213-8512, Japan

This manual was produced on an Apple®Power Macintosh®G3 personal computer and

Canon LASER SHOT LBP-730PS laser beam printer; final pages were printed on Genasett

3100Q.

All logos graphics were produced with MACROMEDIA FREEHAND 7.0J.

All documents and all page layouts were created with QuarkXPress 3.3J.

I. ABOUT THIS MANUAL

This manual is divided into five parts containing the information required for

servicing the W8200 printer.

Part 1: Safety and Precautions

This part contains information on how to service the unit safety. It is very

important, and must be read.

Part 2: Product Specifications

This part outlines the product and its specifications.

Part 3: Operating Instructions

This part explains how to operate the unit properly, how it is installed, and how

to use the service mode.

Part 4: Technical Reference

This part outlines the unit operation giving a technically.

Part 5: Maintenance

This part explains maintenance of the unit. It includes details of disassembly /

assembly, adjustments required when assembling, troubleshooting procedures, and

wiring / circuit diagrams, etc.

This manual does not contain complete information required for

disassembling and assembling the printer. Please also refer to the

separate Parts Catalog.

REF.

I

II. TABLE OF CONTENTS

Page Part 1: SAFETY AND PRECAUTIONS

1- 11.SAFETY PRECAUTIONS

1- 1 1.1 Moving Parts

1- 2 1.2 Ink

1- 2 1.2.1 Ink passages

1- 4 1.2.2 Ink mist

1- 5 1.3 Electrical Parts

1- 6 1.4 Size and Weight of the Printer

1- 72.OTHER PRECAUTIONS

1- 7 2.1 Printhead

1- 7 2.1.1 How to handle the printhead

1- 8 2.1.2 Capping

1- 8 2.1.3 When the printer is not used for a long time

1- 8 2.1.4 Conductivity of ink

1- 9 2.2 Ink Tank

1- 9 2.2.1 Opening the ink tank

1- 9 2.2.2 Handling the ink tank

1-10 2.3 Handling the Printer

1-10 2.3.1 Precautions against static electricity

1-11 2.3.2 Fixing the carriage

1-12 2.3.3 Replacing the waste ink absorber

1-12 2.3.4 Refilling the ink

1-13 3. PRECAUTIONS WHEN SERVICING THE PRINTER

1-13 3.1 Stored Data

1-14 3.2 Firmware Confirmation

1-14 3.3 Precautions Against Static Electricity

1-14 3.4 Precautions for Disassembly/Assembly

1-14 3.5 Self-Diagnostic Feature

1-14 3.6 Disposing of Waste Ink

1-14 3.7 Disposing of Lithium Battery

Part 2: PRODUCT SPECIFICATIONS

2- 11.PRODUCT OVERVIEW

2- 1 1.1 Product Overview

2- 2 1.2 Features

2- 3 1.3 Printhead

2- 3 1.4 Ink Tank

2- 4 1.5 Cutter

2- 4 1.6 Roll Holder

2- 5 1.7 Consumables

2- 5 1.7.1 Printhead

2- 5 1.7.2 Ink tank

2- 5 1.7.3 Cutter blade

2- 62.SPECIFIACATIONS

2- 6 2.1 General Specifications

2-10 2.2 Interface Specifications

2-10 2.2.1 Network

2-11 2.2.2 USB (option)

2-12 2.2.3 IEEE1394 (option)

2-13 2.3 Printer Driver Types

II

Page Part 3: OPERATING INSTRUCTIONS

3- 11.NAMES AND FUNCTIONS OF COMPONENTS

3- 1 1.1 Names and Functions of Components

3- 1 1.1.1 Front

3- 2 1.1.2 Rear

3- 2 1.1.3 Carriage unit

3- 3 1.1.4 Internal part

3- 4 1.1.5 Roll media tray unit

3- 52.PRINTER SETUP

3- 5 2.1 Installation

3- 6 2.1.1 Installation environment

3- 7 2.1.2 Unpacking

3-10 2.1.3 Assembling the stand

3-11 2.1.4 Installing the printer

3-12 2.1.5 Removing packing materials

3-13 2.1.6 Removing the belt stopper

3-14 2.1.7 Connecting the power supply

3-15 2.1.8 Installing the printhead

3-16 2.1.9 Installing the ink tanks

3-17 2.1.10 Language setting

3-18 2.1.11 Loading paper

3-18 2.1.12 Checking and adjusting the print status

3-19 2.1.13 Connecting the interface cable

3-20 3. TRANSPORTING THE PRINTER

3-20 3.1 Transporting the Printer

3-21 3.1.1 Moving the printer on the same floor

3-22 3.1.2 How to transport the printer to a different floor

3-24 3.1.3 Manual capping

3-25 3.2 Reinstalling the Printer

3-25 3.2.1 Installing the printer on the same floor

3-25 3.2.2 Installing the printer on a different floor

3-26 4. OPERATION

3-26 4.1 User Replacements

3-26 4.1.1 Replacing print media

3-26 4.1.2 When to replace roll media

3-27 4.1.3 How to replace roll media

3-30 4.1.4 Loading the cut sheets

3-31 4.1.5 Replacing the printhead

3-33 4.1.6 Replacing the ink tank

3-36 4.1.7 Replacing the cutter blade

3-38 4.2 Operation Panel

3-40 4.3 Change of Printer Status

3-41 4.4 Main Menu

3-41 4.4.1 Main Menu operations

3-42 4.4.2 Map of the main menu

3-46 4.4.3 Contents of main menu

3-53 5. PRINTER SERVICING FUNCTIONS

3-53 5.1 Service Mode

3-53 5.1.1 Service mode operation

3-54 5.1.2 Map of the service mode

3-57 5.1.3 Details of service mode

3-67 5.2 Error Indicators

3-68 5.2.1 Overview of warning and error codes

3-69 5.2.2 Warning and error codes

3-72 5.2.3 Description of warning and error codes

III

Page

3-78 6. PRINTER SPECIAL MODE

3-78 6.1 Controller Replace Mode

3-78 6.2 Download Mode

3-79 7. Printer Service Software

3-79 7.1 Overview of Service Software

3-79 7.1.1 Firmware updating software

3-79 7.1.2 Firmware recovery software

3-79 7.1.3 Service information access software

3-80 7.2 Firmware Updating Software

3-80 7.3 Firmware Recovery Software of the System Controller

3-80 7.3.1 Firmware recovery procedure

3-84 7.4 Service Information Access Software

3-87 7.4.1 Service information access procedure

Part 4: TECHNICAL REFERENCE

4- 11.OVERVIEW

4- 1 1.1 Printer Block Diagram

4- 2 1.2 Print Signal Sequence

4- 5 1.3 Print Driving

4- 5 1.3.1 Print drive control

4- 6 1.3.2 Print drive timing

4- 72.FIRMWARE

4- 7 2.1 Power On/Off

4- 7 2.1.1 Power On

4- 8 2.2 Power Off

4- 8 2.2.1 Power Off sequence

4- 9 2.3 Print Control

4- 9 2.3.1 Print mode

4-11 2.4 Print Position Adjustment

4-11 2.4.1 Print position adjustment

4-11 2.5 Head Management

4-12 2.6 Overheating Protection Control of Printhead

4-12 2.7 Pause between Pages

4-12 2.8 White Raster Skip

4-12 2.9 Sleep Mode

4-13 3. PRINTER MECHANICAL SYSTEM

4-14 3.1 Ink Passage

4-14 3.1.1 Overview of the ink passage

4-16 3.2 Ink Tank Unit

4-16 3.2.1 Structure of ink tank unit

4-18 3.3 Carriage Unit

4-18 3.3.1 Carriage functions

4-19 3.3.2 Structure of carriage

4-22 3.4 Printhead

4-22 3.4.1 Structure of printhead

4-26 3.5 Purge Unit

4-26 3.5.1 Functions of purge unit

4-28 3.5.2 Structure of purge unit

4-31 3.6 Waste Ink Absorber

4-31 3.6.1 Structure of waste ink absorber

4-32 3.7 Air Flow

4-32 3.7.1 Air flow

4-33 3.8 Paper Path

4-33 3.8.1 Overview of paper path

IV

Page

4-37 3.9 Structure of Paper Path

4-37 3.9.1 Structure of roll media tray

4-38 3.9.2 Structure of feed rollers

4-39 3.9.3 Structure of cutter unit

4-40 4. PRINTER ELECTRICAL SYSTEM

4-40 4.1 Overview

4-42 4.2 System Controller

4-42 4.2.1 System controller components

4-45 4.3 Engine Controller

4-45 4.3.1 Engine controller components

4-49 4.4 Carriage Relay PCB

4-49 4.4.1 Carriage relay PCB components

4-50 4.5 Head Relay PCB

4-50 4.5.1 Head relay PCB components

4-51 4.6 Motor Driver

4-51 4.6.1 Motor driver components

4-52 4.7 Power Supply

4-52 4.7.1 Power supply block diagram

4-54 5. DETECTION FUNCTIONS

4-54 5.1 Detection Functions Based on Sensors

4-54 5.1.1 Sensors for covers/roll media tray

4-56 5.1.2 Ink passage system

4-60 5.1.3 Carriage system

4-62 5.1.4 Paper path system

Part 5: MAINTENANCE

5- 11.MAINTENANCE

5- 1 1.1 List of Regular Replacement Parts

5- 1 1.2 List of Consumables

5- 1 1.3 List of Regular Maintenance

5- 22.SERVICE TOOLS

5- 2 2.1 List of Tools

5- 3 2.2 Using the Cover Switch Tool

5- 43.APPLYING THE GREASE

5- 64.SERVICE PARTS

5- 6 4.1 Service Parts

5- 6 4.1.1 Keep all packages with the warning not to turn over.

5- 6 4.1.2 Feed roller

5- 75.DISASSEMBLY/REASSEMBLY

5- 7 5.1 Disassembly/Reassembly

5- 8 5.1.1 Disassembly/assembly flowcharts for major parts

5-10 5.2 Points to Note on Disassembly and Reassembly

5-10 5.2.1 Note on locations prohibited from disassembly

5-11 5.2.2 Manual carriage movement

5-12 5.2.3 Units required for draining the ink

5-13 5.2.4 Outer coversc) Upper rear cover

5-16 5.2.5 Driving unit

5-17 5.2.6 Ink tube unit

5-21 5.2.7 Carriage unit

5-27 5.2.8 Feeder unit

5-30 5.2.9 Purge unit

5-31 5.2.10 Ink tank unit

5-34 5.2.11 Waste ink absorber

5-35 5.2.12 Boards

V

Page

5-36 5.3 Opening the Caps and Moving the Wiper Unit

5-36 5.3.1 Opening the caps and releasing the carriage lock pins

5-37 5.3.2 Moving the wiper unit

5-37 5.4 Opening and Closing the Ink Supply Valve

5-38 5.5 Draining the Ink

5-38 5.5.1 Automatic ink drainage

5-38 5.5.2 Manual ink drainage

5-42 6. ADJUSTMENT AND SETUP

5-42 6.1 Adjustment and Setup Items

5-42 6.1.1 Mistaken insertion of ink tanks prevention mechanism setting

5-42 6.1.2 Adjustment of head holder tilt lever

5-43 6.2 Adjustment and Setup Procedures

5-43 6.2.1 Mistaken insertion of ink tanks prevention mechanism setting

5-44 6.2.2 Adjustment of the head holder tilt lever

5-46 7. TROUBLESHOOTING

5-46 7.1 Outline of Troubleshooting

5-46 7.1.1 Outline

5-46 7.1.2 Notice for Troubleshooting

5-47 7.2 Troubleshooting When Warnings Occur

5-47 7.2.1 x Ink Check (the ink color is indicated by x)

(W01000, W01001, W01002, W01003, W01004, W01005)

5-47 7.2.2 W-Ink Full Soon

(W01006)

5-48 7.2.3 Memory Overflow

(W0100C)

5-48 7.2.4 Feed Limit..

(W0100F)

5-48 7.2.5 Incorrect Media

(W01021)

5-49 7.2.6 W01030/W01031/W01032/W01033/W01034/W01035/W01036/

W01037/W01038/W01039: GARO W0103x (number is indicated by x)

5-50 7.3 Troubleshooting When Errors Occur

5-50 7.3.1 E02000

Roll media end sensor error

5-50 7.3.2 E02005/E0200D/E02016

Feed sensor error

5-51 7.3.3 E0200A/E0200B/E0200C/E0200E/E0200F/E02010/E02017/E02018

Media sensor error

5-52 7.3.4 E02011

Roll media tray set sensor error

5-53 7.3.5 E02015

Cutter error

5-54 7.3.6 E02400/E02401/E02402/E02403

Path mismatch error

5-54 7.3.7 E02500/E02501/E02502/E02503/E02504/E02505

Ink empty error

5-55 7.3.8 E02506/E02507/E02508/E02509/E0250A/E0250B

Ink tank uninstalled error (during ink tank replacement)

5-56 7.3.9 E02520

Ink level unknown error

5-56 7.3.10 E02777

Communication error

5-57 7.3.11 E02800/E02801/E02802/E02803/E02811

Printhead error

VI

Page

5-57 7.3.12 E02804/E02805/E02806/E02807/E02808/E02809/E0280A/

E0280B/E0280C/E0280D/E0280E/E0280F

Ink tank error

5-58 7.3.13 E02812/E02A00/E02A01/E02A02/E02A03

Engine controller internal error

5-58 7.3.14 E02813/ E02814

Head management sensor error

5-59 7.3.15 E02B01

Tray sensor error

5-60 7.3.16 E02B04

Upper cover sensor error

5-60 7.3.17 E02B05

Right cover sensor error

5-61 7.3.18 E02B06

Carriage cover sensor error

5-61 7.3.19 E02D00/E02D01

Sensor error in purge unit

5-62 7.3.20 E02D02

Carriage homeposition error

5-63 7.3.21 E02D03

Feed motor error

5-63 7.3.22 E02D04

Roll media feed motor error

5-64 7.3.23 E02D05

Air flow fan error

5-64 7.3.24 E02D06

Ink supply valve switching error

5-65 7.3.25 E02E01/E02E05

Carriage motor error

5-66 7.3.26 E02E02

Roll media set sensor error

5-67 7.3.27 E02E03

Pinch roller up/down sensor error

5-67 7.3.28 E02E10

IEEE1394 error

5-68 7.3.29 E02F00

System controller internal error

5-69 7.4 Troubleshooting When Service Call Errors Occur

5-69 7.4.1 Printhead error!

(E04000)

5-69 7.4.2 Waste ink full!

(E04001)

5-70 7.4.3 Scale read error!

(E04002)

5-71 7.5 Troubleshooting for Other Problems Indicated on the Display

5-71 7.5.1 Incorrect Value: Check Value

5-71 7.5.2 Offline: Load Roll Media

5-72 7.5.3 Offline: Load Cut Sheet

Offline: Remove Cut Sheet

5-72 7.5.4 Offline: Open Upper Cover

5-73 7.5.5 Offline: Open Tray

5-73 7.5.6 Off line: Open Roll Tray

5-74 7.5.7 Printer Setup: Open Upper Cover

5-74 7.5.8 Printer Setup: Ins. Ink Tank OK

VII

VIII

Page

5-75 7.6 Troubleshooting for Problems Not Indicated on the Display

5-75 7.6.1 Printer does not turn on

5-75 7.6.2 Network is not connected

5-76 7.6.3 Right cover does not open

5-77 7.6.4 Printing problems (ink is full)

5-78 7.6.5 Printing problems (ink is not full)

5-78 7.6.6 Other printing problems

5-80 8. CONNECTOR POSITIONS AND PIN ARRANGEMENT

5-80 8.1 System Controller

5-85 8.2 Engin Controller

5-95 8.3 Carriage Relay PCB

5-100 8.4 Head Relay PCB

5-104 8.5 Motor Driver PCB

5-107 8.6 Power Supply

5-109 9. circuit diagram

5-110 9.1 General Circuit Diagram

5-115 9.2 System Controller

5-130 9.3 Engine Controller

5-145 9.4 Carriage Relay PCB

5-154 9.5 Head Relay PCB

5-157 9.6 Motor Driver

5-160 9.7 Power Supply

IX

III. ILLUSTRATION INDEX

Page Part 1: SAFETY AND PRECAUTIONS

1- 1 Figure 1- 1 Moving Parts of the Printer

1- 3 Figure 1- 2 Ink Passages

1- 4 Figure 1- 3 Ink Mist

1- 5 Figure 1- 4 Electrical Parts

1- 7 Figure 1- 5 Printhead

1- 9 Figure 1- 6 Installing the Ink tank

1-10 Figure 1- 7 Precautions Against Static Electricity

1-11 Figure 1- 8 Capping Position

Part 2: PRODUCT SPECIFICATIONS

2- 1 Figure 2- 1 External View of Printer

2- 3 Figure 2- 2 Printhead

2- 3 Figure 2- 3 Ink Tank

2- 4 Figure 2- 4 Cutter

2- 4 Figure 2- 5 Roll holder

2- 5 Figure 2- 6 Printhead

2- 5 Figure 2- 7 Ink Tank

2- 5 Figure 2- 8 Cutter blade

Part 3: OPERATING INSTRUCTIONS

3- 1 Figure 3- 1 Front View of the Printer

3- 2 Figure 3- 2 Rear View of the Printer

3- 2 Figure 3- 3 Carriage Unit

3- 3 Figure 3- 4 Internal Parts of the Printer

3- 4 Figure 3- 5 Roll Media Tray Unit

3- 5 Figure 3- 6 Required Space when Removing from Box

3- 6 Figure 3- 7 Space Required for Installation

3- 7 Figure 3- 8 Unpacking the Printer

3- 8 Figure 3- 9 Handles the Printer

3- 9 Figure 3- 10 Unpacking the Stand

3- 1 0 Figure 3- 11 Assembling the Stand

3- 11 Figure 3- 12 Installing the Printer

3- 12 Figure 3- 13 Removing Packing Materials

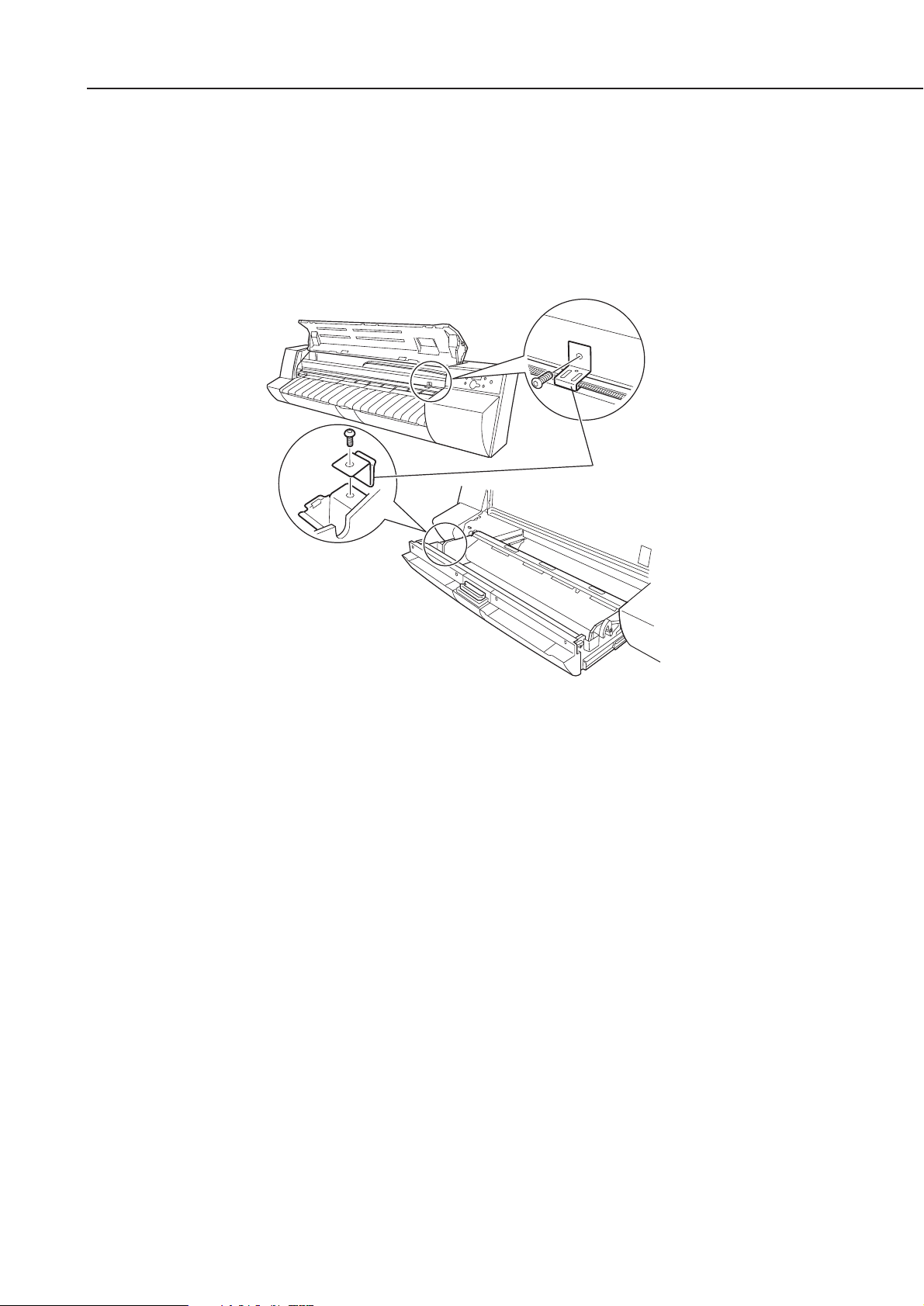

3- 1 3 Figure 3- 14 Removing and Storing the Belt Stopper

3- 1 4 Figure 3- 15 Connenting the Power Supply

3- 15 Figure 3- 16 Installing Printhead

3- 16 Figure 3- 17 Installing an Ink Tank

3- 16 Figure 3- 18 Installing Order of Ink Tanks

3- 1 7 Figure 3- 19 Specifying Language

3- 1 9 Figure 3- 20 Connecting the Interface Cable

3- 24 Figure 3- 21 Position of the Carriage During Manual Capping

3- 2 6 Figure 3- 22 Remaining Roll Media Window

3- 2 7 Figure 3- 23 Loading the Roll Media (1/5)

3- 2 7 Figure 3- 24 Loading the Roll Media (2/5)

3- 2 8 Figure 3- 25 Loading the Roll Media (3/5)

3- 2 8 Figure 3- 26 Loading the Roll Media (4/5)

3- 2 9 Figure 3- 27 Loading the Roll Media (5/5)

3- 29 Figure 3- 28 Cutting the Roll Media

3- 3 0 Figure 3- 29 Loading the Cut Sheet Media

3- 31 Figure 3- 30 Replacing the Printhead (1/2)

Page

3- 32 Figure 3- 31 Replacing the Printhead (2/2)

3- 33 Figure 3- 32 Replacing the Ink Tank (1/2)

3- 34 Figure 3- 33 Replacing the Ink Tank (2/2)

3- 36 Figure 3- 34 Replacing the Cutter Blade

3- 3 8 Figure 3- 35 Operation Panel

3- 4 0 Figure 3- 36 Change of Printer States

3- 40 Figure 3- 37 Correlation Diagram for Each Mode

3- 4 2 Figure 3- 38 Map of the Main Menu (1/3)

3- 4 3 Figure 3- 39 Map of the Main Menu (2/3)

3- 4 4 Figure 3- 40 Map of the Main Menu (3/3)

3- 4 5 Figure 3- 41 Map of the Media Type

3- 4 8 Figure 3- 42 Pattern A (Image)

3- 4 9 Figure 3- 43 Pattern B (Image)

3- 51 Figure 3- 44 Status Print (Image)

3- 52 Figure 3- 45 Nozzle Check Pattern (Image)

3- 52 Figure 3- 46 Viewing the Software Version

3- 5 4 Figure 3- 47 Map of the Service Mode (1/3)

3- 5 5 Figure 3- 48 Map of the Service Mode(2/3)

3- 5 6 Figure 3- 49 Map of the Service Mode(3/3)

3- 5 7 Figure 3- 50 PRINT-INF (Image)

2- 5 8 Figure 3- 51 WARNING

3- 5 8 Figure 3- 52 ERROR

3- 5 9 Figure 3- 53 P-SETTING

3- 5 9 Figure 3- 54 INK CHECK

3- 6 0 Figure 3--55 I/O DISPLAY

3- 61 Figure 3- 56 NOZZLE (Image)

3- 6 2 Figure 3- 57 SCALE (Image)

3- 8 1 Figure 3- 58 com_fut.exe (Startup)

3- 8 1 Figure 3- 59 com_fut.exe (Setup 1)

3- 8 2 Figure 3- 60 com_fut.exe (Setup 2)

3- 8 2 Figure 3- 61 com_fut.exe (Send Image)

3- 8 2 Figure 3- 62 com_fut.exe (Transmission is completed)

3- 8 3 Figure 3- 63 com_fut.exe (Completed Image)

3- 8 4 Figure 3- 64 ssw (Image)

3- 8 5 Figure 3- 65 ssw_head (Image)

3- 8 6 Figure 3- 66 ssw_ink (Image)

3- 87 Figure 3- 67 Service Information Access Software (Startup 1)

3- 87 Figure 3- 68 Service Information Access Software (Startup 2)

3- 88 Figure 3- 69 Service Information Access Software (Setup 1)

3- 88 Figure 3- 70 Service Information Access Software (Setup 2)

3- 89 Figure 3- 71 Service Information Access Software (Code Input)

3- 89 Figure 3- 72 Service Information Access Software (Access Information Image)

Part 4: TECHNICAL REFERENCE

4- 1 Figure 4- 1 Printer Block Diagram

4- 2 Figure 4- 2 Print Signal Sequence

4- 5 Figure 4- 3 Conceptual Diagram of Nozzle Blocks

4- 6 Figure 4- 4 Example of Print Drive Timing (Nozzle Array Bk in Forward Printing)

4- 7 Figure 4- 5 Flow chart after Power On

4- 8 Figure 4- 6 Power Off Flow chart

4- 13 Figure 4- 7 Printer Mechanical System

4- 14 Figure 4- 8 Schematic Diagram of the Ink Passage (for One Color)

4- 16 Figure 4- 9 Ink Tank

4- 1 7 Figure 4- 10 Ink Supply Valve

X

Page

4- 1 9 Figure 4- 11 Carriage Unit (1)

4- 2 0 Figure 4- 12 Carriage Unit (2)

4- 22 Figure 4- 13 Nozzle Configuration

4- 2 3 Figure 4- 14 Nozzle Structure

4- 24 Figure 4- 15 Signal Contact Points

4- 27 Figure 4- 16 Purge Unit

4- 28 Figure 4- 17 Caps

4- 29 Figure 4- 18 Wiping Operation (Image)

4- 3 0 Figure 4- 19 Pumps

4- 3 1 Figure 4- 20 Waste Ink absorber

4- 3 2 Figure 4- 21 Air Flow

4- 3 3 Figure 4- 22 Paper Path

4- 3 4 Figure 4- 23 Roll Media feed Sequence

4- 3 5 Figure 4- 24 Cut Sheet feed Sequence

4- 37 Figure 4- 25 Roll Media Tray

4- 3 8 Figure 4- 26 Manual Feed Tray/Paper Feed Unit

4- 3 9 Figure 4- 27 Cutter Unit

4- 4 1 Figure 4- 28 Printer Electrical Section

4- 42 Figure 4- 29 System Controller

4- 45 Figure 4- 30 Engine Controller

4- 4 9 Figure 4- 31 Carriage Relay PCB

4- 50 Figure 4- 32 Head Relay PCB

4- 5 1 Figure 4- 33 Motor Driver

4- 52 Figure 4- 34 Power Supply Block Diagram

4- 54 Figure 4- 35 Layout of Sensors for Covers/Roll Media Tray

4- 5 6 Figure 4- 36 Layout of Sensors for Ink Passage System

4- 57 Figure 4- 37 Cap Sensor Flag

4- 5 7 Figure 4- 38 Pump Sensor Flag

4- 5 8 Figure 4- 39 Valve Cam Sensor

4- 5 8 Figure 4- 40 Head Management Sensor (Conceptual Representation)

4- 60 Figure 4- 41 Layout of Sensors for Carriage System

4- 6 1 Figure 4- 42 Media Sensor (Image)

4- 6 2 Figure 4- 43 Layout paperpath sensor

Part 5: MAINTENANCE

5- 3 Figure 5- 1 Using the Cover Switch Tool

5- 4 Figure 5- 2 Apply the grease of upper cover

5- 4 Figure 5- 3 Applying the grase of carriage

5- 5 Figure 5- 4 Applying the grease of pinch roller unit

5- 5 Figure 5- 5 Applying the grease of feed roller

5- 6 Figure 5- 6 "Right side up" Sign

5- 8 Figure 5- 7 Disassembly/Assembly Flowcharts for Major Parts

5- 10 Figure 5- 8 Units Needing to be Drained of Ink When the Printer is Disassembled

5- 11 Figure 5- 9 Manual Carriage Movement

5- 12 Figure 5- 10 Units Required for Draining the Ink

5- 13 Figure 5- 11 Opening the Right Cover

5- 13 Figure 5- 12 Rear Right Cover and Rear Left Cover

5- 1 4 Figure 5- 13 Upper Rear Cover

5- 1 4 Figure 5- 14 Upper Cover

5- 15 Figure 5- 15 Paper Release Lever

5- 1 6 Figure 5- 16 Drive Belt (for driving the feed roller)

5- 1 6 Figure 5- 17 Fan Support

5- 17 Figure 5- 18 Joints

5- 18 Figure 5- 19 Prevention of ink leaks

5- 1 9 Figure 5- 20 Cable Mount

XI

Page

5- 19 Figure 5- 21 Ink Tube Unit

5- 21 Figure 5- 22 Prevention of ink leaks

5- 22 Figure 5- 23 Ink Tube Unit

5- 2 2 Figure 5- 24 Carriage Unit

5- 2 3 Figure 5- 25 Belt Stopper

5- 24 Figure 5- 26 Prevention of ink leaks

5- 25 Figure 5- 27 Lock Pin of Head Holder

5- 2 5 Figure 5- 28 Removing the Head Holder

5- 2 6 Figure 5- 29 Checking the Printhead Height Adjustment Lever

5- 2 7 Figure 5- 30 Pinch Roller Unit

5- 2 7 Figure 5- 31 Paper Guide B

5- 2 8 Figure 5- 32 Removing the Head Management Sensor Unit

5- 2 8 Figure 5- 33 Feed Roller

5- 2 9 Figure 5- 34 Cutter Unit

5- 3 0 Figure 5- 35 Removing the Purge Unit

5- 3 1 Figure 5- 36 Opening the Ink Tank Unit

5- 3 2 Figure 5- 37 Joints

5- 3 3 Figure 5- 38 Moving and Securing the Ink Tank Unit

5- 33 Figure 5- 39 Valve Motor Unit

5- 34 Figure 5- 40 Waste Ink Absorber

5- 36 Figure 5- 41 Opening the Caps and Releasing the Carriage Lock Pins

5- 3 7 Figure 5- 42 Opening and Closing the Ink Supply Valve

5- 39 Figure 5- 43 Overview of Manual Ink Drainage (single color)

5- 40 Figure 5- 44 Top View of Ink Tank Unit

5- 4 1 Figure 5- 45 Manual Ink Drainage

5- 43 Figure 5- 46 Mistaken Insertion of Ink Tanks Prevention Mechanism

5- 43 Figure 5- 47 Mistaken Insertion of Ink Tanks Prevention Mechanism

Top View (Image of Restoration to Default Status)

5- 44 Figure 5- 48 Adjusting the Head Holder Tilt Lever

5- 80 Figure 5- 49 System Controller

5- 8 5 Figure 5- 50 Engin Controller

5- 9 5 Figure 5- 51 Carriage Relay PCB

5-100 Figure 5- 52 Head Relay PCB

5-104 Figure 5- 53 Motor Driver PCB

5-107 Figure 5- 5 4 Power Supply

XII

IV. TABLE INDEX

Page Part 1: SAFTEY PRECAUTIONS

1- 6Table 1- 1 TYPICAL HEAVY SERVICE PARTS

Part 4: TECHNICAL REFERENCE

4-10 Table 4- 1 PRINT MODES

4-24 Table 4- 2

SIGNALS AND PIN NUMBERS OF THE SIGNAL CONTACT POINTS

XIII

Part 1

SAFETY AND

PRECAUTIONS

Page

1- 11.SAFETY PRECAUTIONS

1- 1 1.1 Moving Parts

1- 2 1.2 Ink

1- 5 1.3 Electrical Parts

1- 6 1.4 Size and Weight of the Printer

1- 72.OTHER PRECAUTIONS

1- 7 2.1 Printhead

1- 9 2.2 Ink tank

1 -10 2.3 Handling the Printer

1 -13 3. PRECAUTIONS WHEN SERVICING THE PRINTER

1 -13 3.1 Stored Data

1 -14 3.2 Firmware Confirmation

1 -14 3.3 Precautions Against Static Electricity

1 -14 3.4 Precautions for Disassembly/Assembly

1 -14 3.5 Self-Diagnostic Feature

1 -14 3.6 Disposing of Waste Ink

1 -14 3.7 Disposing of Lithium Battery

1-1

W8200

Part 1: Safety and Precautions

1. SAFETY PRECAUTIONS

1.1 Moving Parts

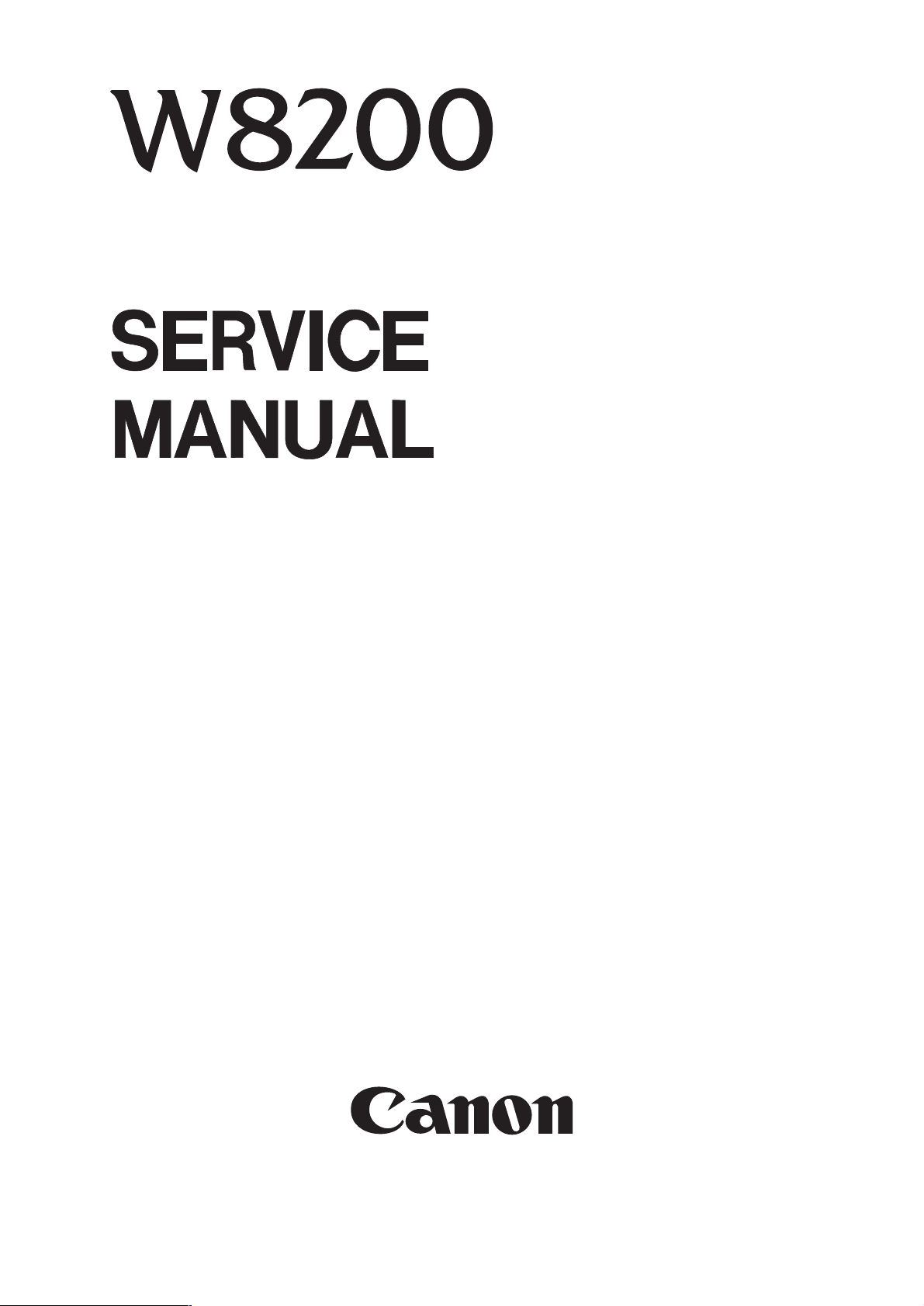

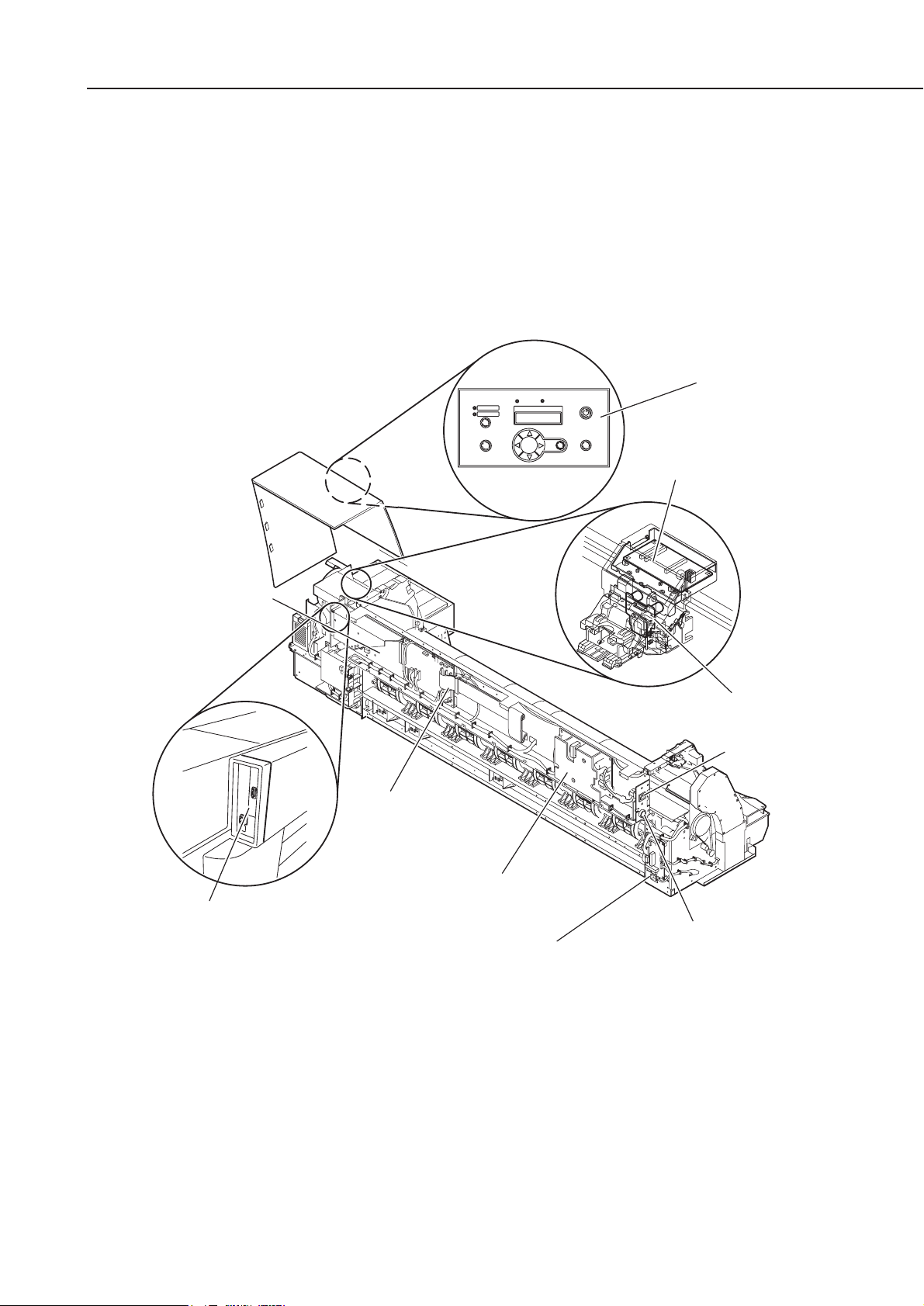

Be careful not to get your hair, clothes, or accessories caught in the moving parts of the

printer.

These include the carriage unit and carriage belt activated by the carriage motor; a

caterpillar unit that interlocks with the carriage and protects the ink tube and flexible

cable and; motor-driven feed roller, purge unit, cutter unit and roll media tray activated

by their own motors.

To prevent accidents, the upper cover of the printer is locked during printing so that it

does not open. If the manual feed tray is opened during printing, the carriage moves to

the right or left to return to the home position, and the carriage motor and feed motor

are immediately stopped. If the upper cover is opened in the online/offline mode, the

carriage motor, feed motor, and other driving power supplies are turned off.

Carriage motor

Feed roller

Pinch roller

Roll media tray

Purge unit

Caterpillar unit

Carriage unit

Carriage belt

Pinch roller drive unit

Feed motor

Roll drive unit

Cutter unit

Figure 1-1 Moving Parts of the Printer

1.2 Ink

1.2.1 Ink passages

Be careful not to touch the ink passages of the printer or to allow ink to stain the

workbench, hands, clothes or the printer under repair.

The ink flows through the ink tank unit, carriage unit, purge unit, maintenance-jet

tray waste ink absorber unit and the ink tubes that relay ink to each unit.

Although the ink is not harmful to the human body, it contains organic

solvents.

Avoid getting the ink in your mouth or eyes.

Flush well with water and see a doctor if contact occurs.

In case of accidental ingestion of a large quantity, call a doctor

immediately.

Black/Photo Cyan/Photo Magenta/Magenta inks

Glycerin 56-81-5, Ethylene glycol 107-21-1,

Diethylene glycol 111-46-6, Isopropyl alcohol 67-63-0

Cyan ink

Glycerin 56-81-5, Ethylene glycol 107-21-1,

Diethylene glycol 111-46-6, Isopropyl alcohol 67-63-0,

Copper compound

Yellow ink

Diethylene glycol 111-46-6, Isopropyl alcohol 67-63-0

Since this ink contains dyes, stains will not come out of clothing.

Part 1: Safety and Precautions

1-2

CAUTION

W8200

1-3

W8200

Part 1: Safety and Precautions

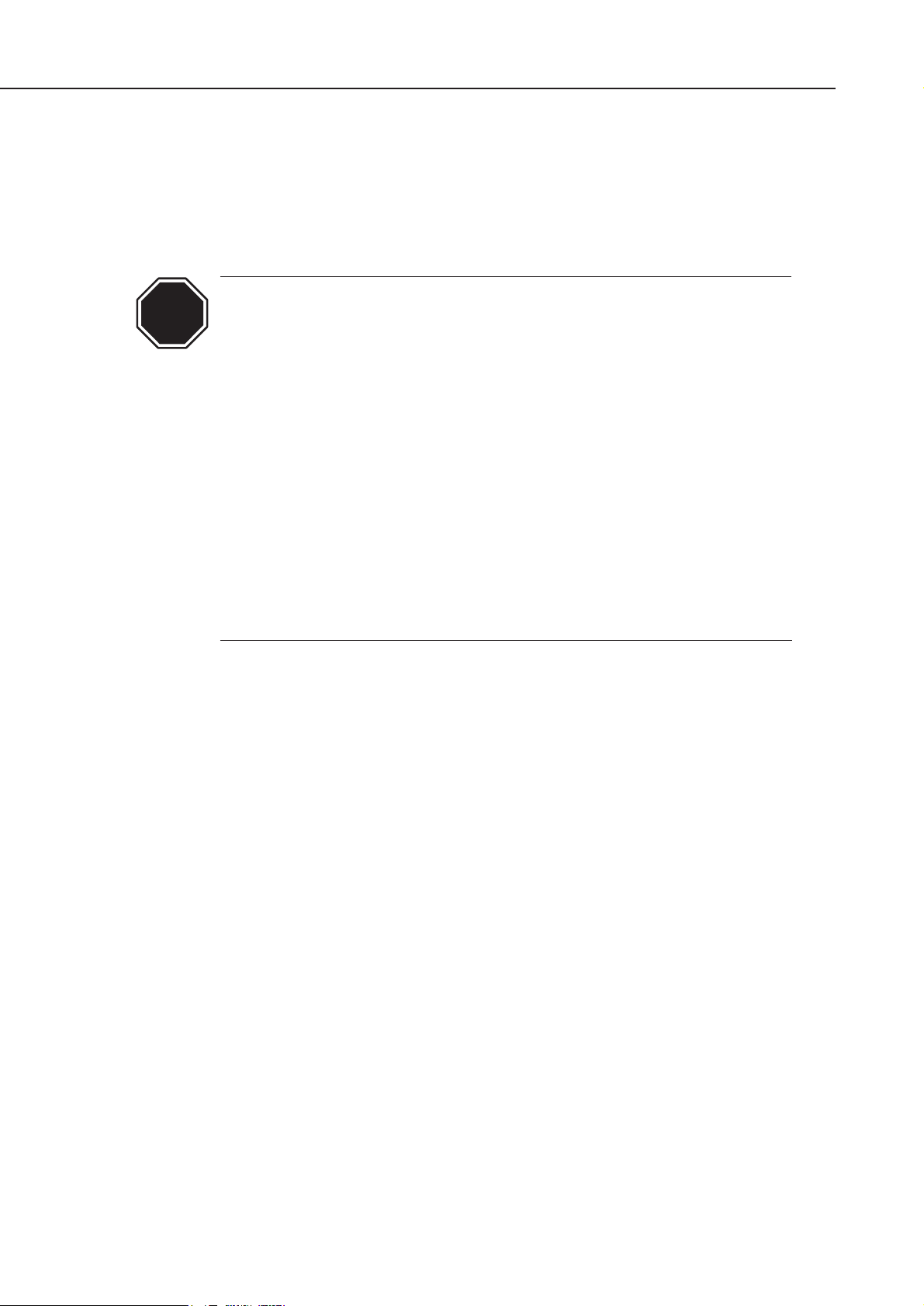

Ink tank unit

Purge unit

Carriage unit

Waste ink absorber

Maintenance-jet tray

Figure 1-2 Ink Passages

Part 1: Safety and Precautions

W8200

1-4

1.2.2 Ink mist

Since the printhead prints by squirting ink onto the media, a minute amount of ink

mist is generated in the printing unit during printing. The ink mist is collected in the

printer by the airflow. However, uncollected ink mist may stain the platen unit,

carriage unit, main rail unit, external unit, or purge unit.

These stains may soil the print media or hands and clothes when servicing the

printer, wipe them off carefully with a soft, well-wrung damp cloth.

Purge unit

Upper cover

Platen unit/Carriage unit/

Main rail unit

Figure 1-3 Ink Mist

1-5

W8200

Part 1: Safety and Precautions

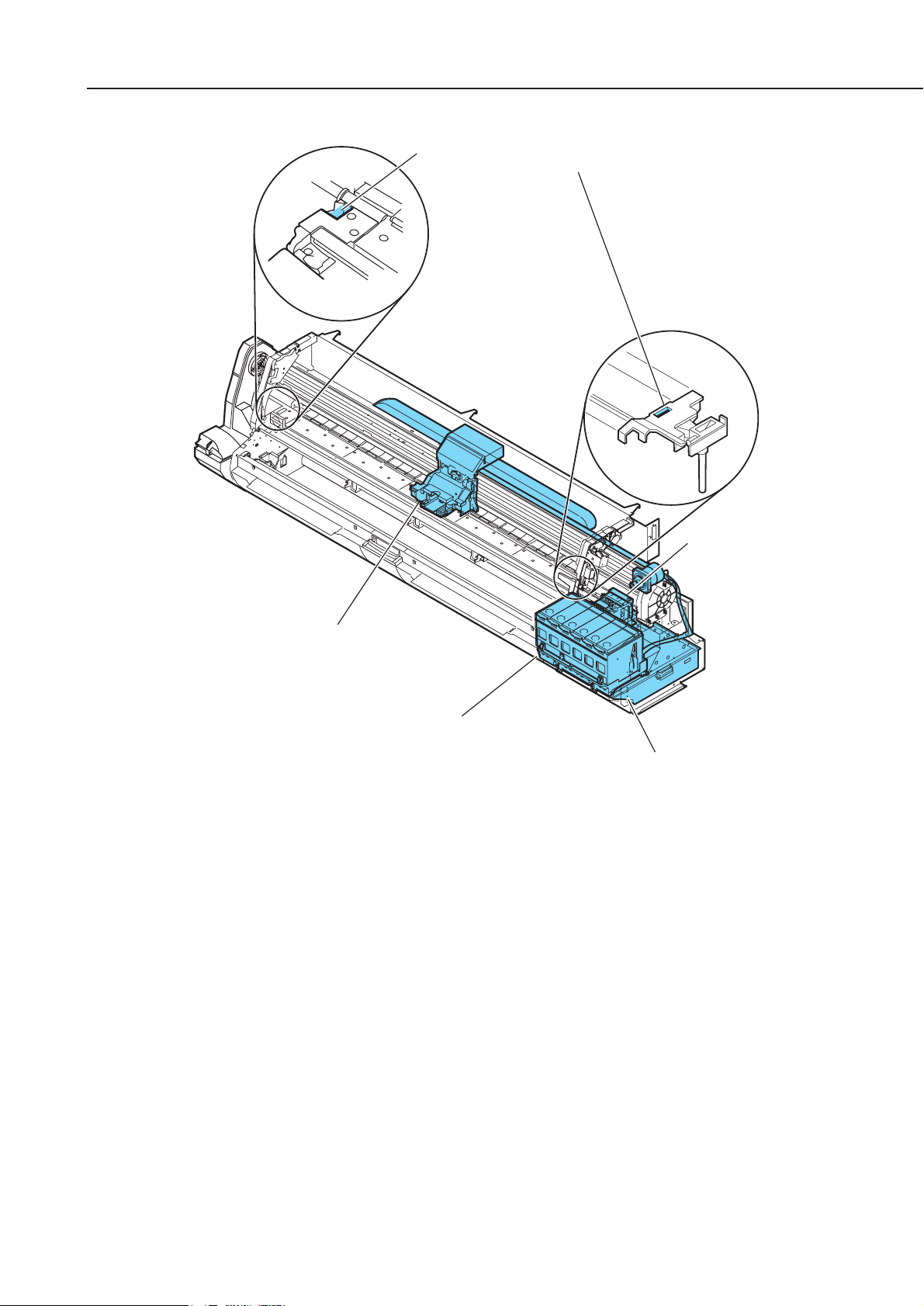

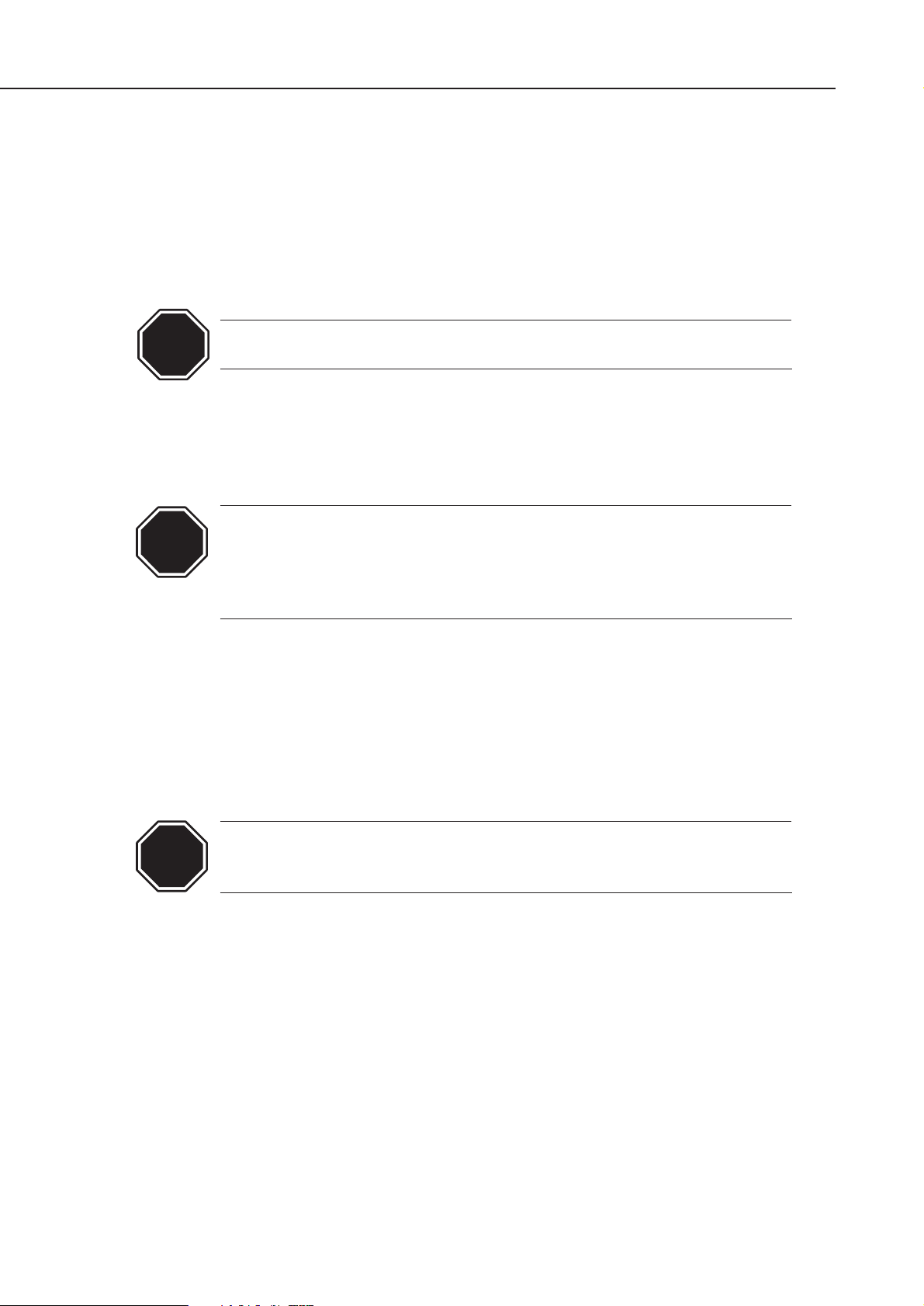

1.3 Electrical Parts

The electrical unit of the printer is activated when connected to the AC power supply.

At the rear of the printer are the system controller, engine controller, power supply,

motor driver PCB, interface connector, and optional connector. The head relay PCB and

carriage relay PCB are incorporated in the carriage unit, and the operation panel is

located on the upper right cover.

When servicing the printer with the cover removed, be extremely careful to avoid

electric shock and shorting contacts.

Figure 1-4 Electrical Parts

System controller

Engine controller

Power supply

Motor driver PCB

AC inlet

Take-up unit connector

Head relay PCB

Carriage relay PCB

Operation panel

Interface connector

Part 1: Safety and Precautions

W8200

1-6

1.4 Size and Weight of the Printer

This printer has service parts which are large and heavy.

Be careful not to get your fingers caught when carrying the printer or setting down the

parts during assembly or disassembly.

The printer stand sticks out of the body in front and behind. Take special care when

carrying large or heavy parts.

TABLE 1-1 TYPICAL HEAVY SERVICE PARTS

Service parts Dimensions of package box: Weight (kg)

width x depth x height (mm)

Roll media tray unit 1311 x 373 x 155 12

1-7

W8200

Part 1: Safety and Precautions

2. OTHER PRECAUTIONS

2.1 Printhead

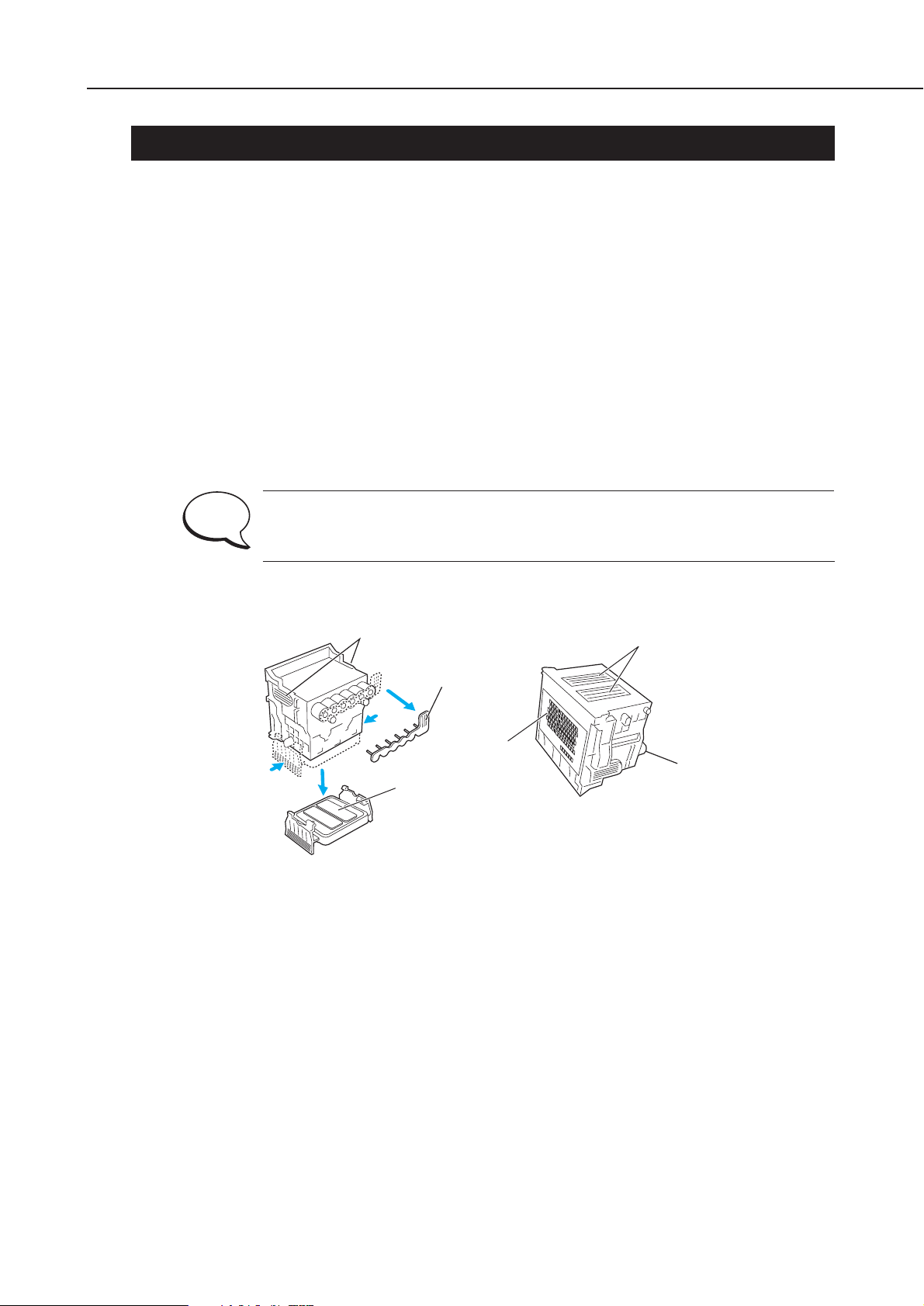

2.1.1 How to handle the printhead

Do not open the printhead package until you are ready to install the head.

When installing the printhead in the printer, hold the knob, and then remove the

protective material and protective cap, in that order. Do not replace the protective cap

once you have removed it from the printhead, since the cap may scratch the nozzles.

To prevent the nozzles from getting clogged with foreign matter or dried ink, install the

printhead immediately after you remove the protective cap. Also make sure to press

down the locking lever of the printhead until you feel a click.

In addition, to prevent clogging of the nozzles, never touch the nozzle unit or ink

supply unit of the printhead, or wipe it with tissue paper or anything else. Also, be

careful not to touch the electrical contact.

Never attempt to disassemble the printhead or to wash it with water.

If the nozzles are clogged or purging operation is poor, white horizontal

lines can appear in the printed output. If the problem is not resolved by

cleaning operations, replace the printhead with a new one.

Figure 1-5 Printhead

Knob

Protective material

Protective cap

Nozzle unit

Electrical contact

Ink port

NOTE

Part 1: Safety and Precautions

W8200

1-8

2.1.2 Capping

The printer will perform the capping operation when printing has finished or during

standby due to errors, in order to protect the printhead and avoid ink leakage.

If the power cord is accidentally unplugged, turn the power button off, reconnect the

power cord, and turn the power button on to confirm that the printer starts up

properly and changes to the “Online” or “Offline” state, then power off the printer

using the power button.

Improper ‘capping’ may cause clogged printhead nozzles due to dried ink

or ink leakage from the printhead.

2.1.3 When the printer is not used for a long time

Keep the printhead installed in the printer even when it is not used for an extended

period of time.

If the printhead is left uninstalled, printing failure may arise from clogged

nozzles due to the depositing of foreign matter or dried ink when it is reinstalled.

Even if the head remains installed, the nozzle may dry out and cause

printing failure if the ink is drained for transport.

2.1.4 Conductivity of ink

The ink used in this printer is electrically conductive. If ink leaks into the mechanical

unit, wipe clean with a soft, well-wrung damp cloth. If ink leaks onto electrical units,

wipe them completely using tissue paper. In particular, if ink penetrates beneath the

IC chips on the logic board and you cannot remove it completely, replace with a new

logic board.

If electrical units are powered on when ink has leaked, the units may be

damaged.

Never connect the power cord when ink has leaked on the electrical units.

CAUTION

CAUTION

CAUTION

1-9

W8200

Part 1: Safety and Precautions

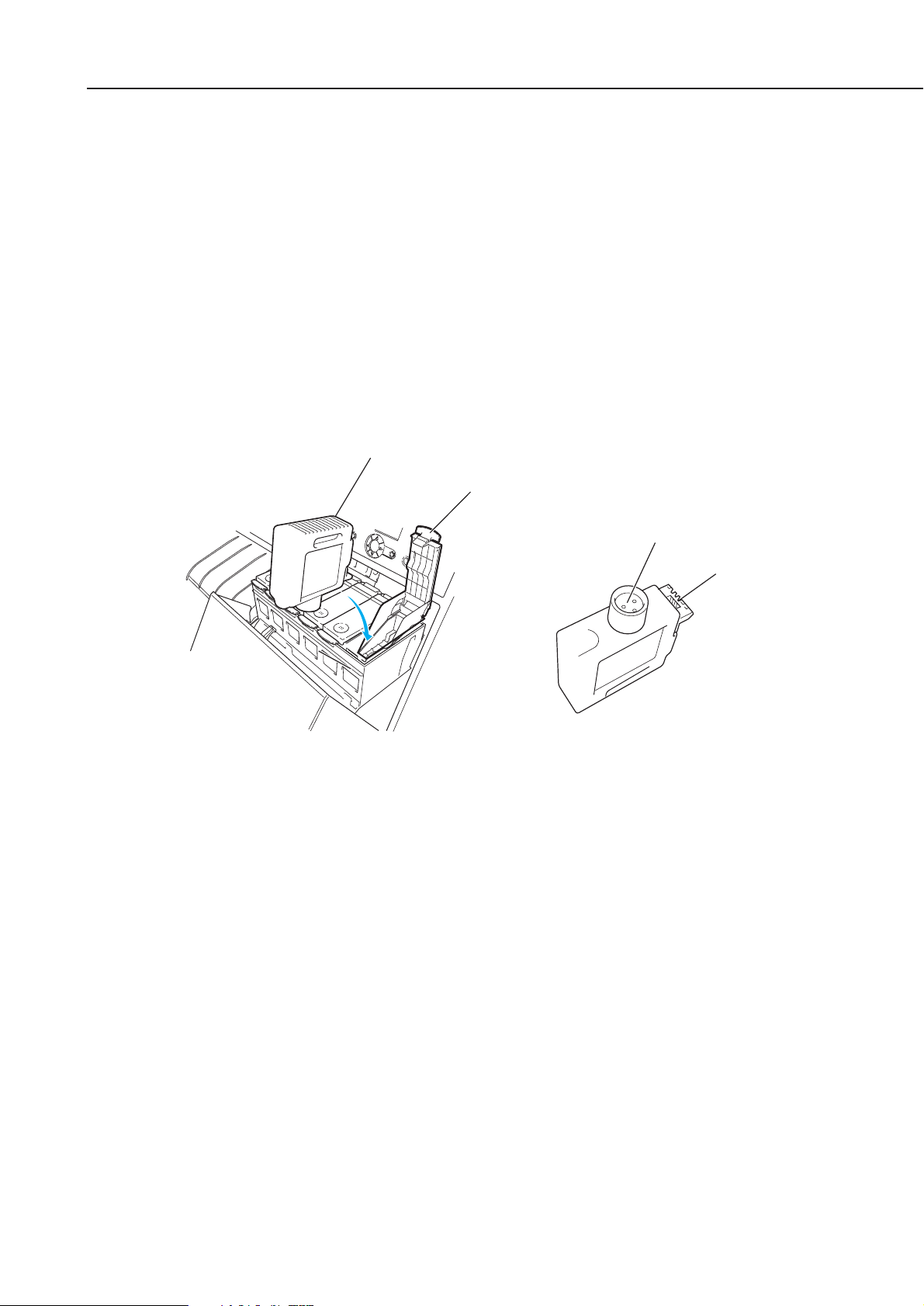

2.2 Ink Tank

2.2.1 Opening the ink tank

Do not open the ink tank until ready to use.

To prevent foreign matter from entering the ink supply unit, install the opened Ink

tank immediately.

2.2.2 Handling the ink tank

To prevent foreign matter from entering the ink flow path and causing ink suction and

printing problems, never touch the ink port or terminal section of the ink tank.

When you press down the ink tank cover, the needle enters the ink supply unit, which

allows ink to flow between the printer and ink tank.

Do not raise or lower the ink tank lever, except when replacing the ink tank.

Figure 1-6 Installing the Ink tank

Ink tank

Ink tank cover

Ink port

Terminal section

Part 1: Safety and Precautions

W8200

1-10

2.3 Handling the Printer

2.3.1 Precautions against static electricity

Certain clothing may generate static electricity, causing an electrical charge to build

up on your body. Such a charge can damage electrical devices.

In particular, never touch the printhead contacts.

Printhead contacts

Carriage unit

Figure 1-7 Precautions Against Static Electricity

1-11

W8200

Part 1: Safety and Precautions

2.3.2 Fixing the carriage

After printing, the carriage caps the printhead and uses the lock arm inside the purge

unit to apply a mechanical lock.

When transporting the printer, use belt stoppers to secure the carriage at the carriage

home position so that the carriage does not become separated from the lock arm. This

will prevent damage and ink leakage during transportation.

Belt stopper

Figure 1-8 Capping Position

Part 1: Safety and Precautions

W8200

1-12

2.3.3 Replacing the waste ink absorber

When the waste ink absorber becomes full, an error occurs to indicate that the tank

must be replaced.

The printer will not operate until the error is canceled.

Be careful that the waste ink does not splash when you remove the waste ink

absorber from the printer.

When the waste ink is full, the air flow fan unit is hold approx. 3.0kg, the

maintenance-jet absorber unit is hold approx. 0.3kg and the waste ink absorber unit

is hold approx. 10.5kg in the printer.

When replacing the waste ink absorber unit in the printer, same time

replacing the air flow fan unit and the maintenance-jet absorber unit.

(Refer to Part 5: 5.2.11 Waste ink absorber unit)

After replacing the waste ink absorber in the printer, be sure to always

clear the counter value of the waste ink absorber using the Service mode.

The counter value of the waste ink absorber is stored in the EEPROM

(IC428) on the engine controller. Therefore, when replacing the engine

controller, be sure to refer to Part 5: 5.2.12 Boards.

2.3.4 Refilling the ink

After removing the ink in the printer according to the automatic or manual ink

draining procedure to disassemble, reassemble, or transport/ship the printer, refill

the ink as soon as possible upon completion of those tasks.

If the ink remaining in the printer after the removal has dried up, the ink deposits on

the surfaces of the components may cause damage or abnormal operation.

CAUTION

3. PRECAUTIONS WHEN SERVICING THE PRINTER

3.1 Stored Data

This printer counts the printing length, number of ink tank replacements, carriage

driving time, number of cleanings, and the cutter usage, and stores this information in

the system controller EEPROM (IC36) and in the engine controller EEPROM (IC428) as

the service mode counter.

The counter holds important information for indicating printer usage status.

You can check the printer information in the counter by printing it in service mode or

displaying it on the display.

Be sure to follow the precautions below when servicing the printer.

1) Repairing or replacing the PCB

Follow the "Each Controller Replacement Procedures" when replacing the system

controller and engine controller.

2) After replacing the carriage unit

The information on the carriage driving time is generated from the carriage unit.

Initialize (clear) the carriage driving time information after replacing the carriage unit.

3) After replacing the purge unit

The information on the number of cleanings is generated from the purge unit. Initialize

(clear) the number of cleanings information after replacing the purge unit.

4) After replacing the waste ink absorber

The information in the waste ink counter is generated from the waste ink absorber.

Initialize (clear) the waste ink counter information after replacing the waste ink

absorber.

You cannot check the counter information once it is initialized (cleared).

Be careful that you do not perform the initialization before checking the

information.

Also, you cannot modify the counter information from the operation panel.

For the "Each Controller Replacement Procedures," see Part 5: 5.2.12

Boards.

1-13

W8200

Part 1: Safety and Precautions

CAUTION

REF.

3.2 Firmware Confirmation

Firmware has been downloaded to each of a System Controller and Engine Controller.

When replacing each board with the one with Service Parts, confirm that each firmware

is the latest version. If it is not the latest version, please update it to the latest version.

For how to upgrade each board, please refer to Part 3: 7. PRINTER SERVICE

SOFTWARE.

3.3 Precautions Against Static Electricity

Certain clothing may generate static electricity, causing an electrical charge to build up

on your body. Such a charge can damage electrical devices.

To prevent this, discharge any static buildup by touching a grounded metal fitting

before you start disassembling the printer.

3.4 Precautions for Disassembly/Assembly

The Parts Catalog describes the disassembly/assembly procedures. See the Parts

Catalog when assembling/disassembling the printer. The precautions for

disassembly/assembly are described in Part 5: 5. DISASSEMBLY/REASSEMBLY.

3.5 Self-Diagnostic Feature

The printer has a diagnostic feature which analyzes printer problems (which may

occur).

The diagnostic results will be displayed on the display and indicated by a light.

For detailed information, see Part 3: 5.2 Error Indicators.

3.6 Disposing of Waste Ink

Dispose of the waste ink according to local regulations.

3.7 Disposing of Lithium Battery

Dispose of the lithium battery according to local regulations.

One lithium battery is installed in the Engine Controller of the printer is

not a replacement part.

Part 1: Safety and Precautions

W8200

1-14

REF.

NOTE

Loading...

Loading...