Canon PC800s, PC900s Service manual

REVISION 0

PC860

F13-8491 TYA00001-

PC880

F13-8291 TZA00001-

PC890

F13-8242 UAA00001-

PC920

F13-8431 TVB00001F13-8441 PUD00001-

PUE00001-

F13-8461 PUH00001-

PC921

F13-8432 TVC00001-

PC940

F13-8436 TVD00001-

PC941

F13-8437 TVE00001-

PC950

F13-8231 TVF00001F13-8241 PUF00001-

PUG00001-

PC960

F13-8434 TVG00001-

PC980

F13-8232 TVH00001-

PC981

F13-8233 TVJ00001-

AUG. 1999

COPYRIGHT © 1999 CANON INC. CANON PC800s/900s REV.0 AUG. 1999 PRINTED IN JAPAN (IMPRIME AU JAPON)

FY8-13GA-000

IMPORTANT

THIS DOCUMENTATION IS PUBLISHED BY CANON INC., JAPAN, TO SERVE AS A SOURCE

OF REFERENCE FOR WORK IN THE FIELD.

SPECIFICATIONS AND OTHER INFORMATION CONTAINED HEREIN MAY VARY SLIGHTLY

FROM ACTUAL MACHINE VALUES OR THOSE FOUND IN ADVERTISING AND OTHER

PRINTED MATTER.

ANY QUESTIONS REGARDING INFORMA TION CONTAINED HEREIN SHOULD BE DIRECTED

TO THE COPIER SERVICE DEPARTMENT OF THE SALES COMPANY.

THIS DOCUMENT ATION IS INTENDED FOR ALL SALES AREAS, AND MA Y CONTAIN INFORMATION NO T APPLICABLE TO CERTAIN AREAS.

COPYRIGHT © 1999 CANON INC.

Printed in Japan

Imprimé au Japon

Use of this manual should be strictly supervised to avoid disclosure of confidential

information.

Prepared by

OFFICE IMAGING PRODUCTS TECHNICAL SUPPORT DIVISION

CANON INC.

5-1, Hakusan 7-chome, Toride-shi, Ibaraki 302-8501 Japan

COPYRIGHT © 1999 CANON INC. CANON PC800s/900s REV.0 AUG. 1999 PRINTED IN JAPAN (IMPRIME AU JAPON)

INTRODUCTION

This service manual has been prepared for the PC800/900 Series machines,

providing basic information used for servicing the machines in the field so as to ensure

their quality and performance.

This service manual consists of the following chapters:

Chapter 1

Chapter 2

Chapter 3

Chapter 4

Chapter 5

Chapter 6

General Description

names of parts, and how originals are reproduced.

Basic Operation

Exposure System

machine's exposure system. It also explains the timing at which exposurerelated mechanisms are operated, and shows how they may be

disassembled/assembled and adjusted.

Image Formation System

machine's image formation system. It also explains the timing at which image

formation-related mechanisms are operated, and shows how they may be

disassembled/assembled and adjusted.

Pick-Up/Feeding System

machine's pickup/feeding system. It also explains the timing at which pickup/

feeding-related mechanisms are operated, and shows how they may be

disassembled/assembled and adjusted.

Fixing System

fixing system. It also explains the timing at which fixing-related mechanisms

are operated, and shows how they may be disassembled/assembled and

adjusted.

discusses the principles of operation used for the machine's

introduces the machine's features, specifications,

explains how copies are made on a step-by-step basis.

discusses the principles of operation used for the

discusses the principles of operation used for the

discusses the principles of operation used for the

Chapter 7

Chapter 8

Chapter 9

Chapter 10

Chapter 11

Appendix contains a general timing chart and general circuit diagrams.

Externals/Auxiliary Mechanisms

for the machine's externals/auxiliary mechanisms. It also explains the timing

at which auxiliary mechanism-related mechanisms are operated, and shows

how they may be disassembled/assembled and adjusted.

ADF

explains the principles of operation of the ADF in view of electrical and

mechanical functions and in relation to their timing of operation. It also shows

how the unit may be disassembled/assembled and adjusted.

Installation

how the machine may be installed using step-by-step instructions.

introduces requirements for the site of installation, and shows

Maintenance and Servicing

consumables/durables and scheduled servicing charts.

Troubleshooting

adjustments, and problem identification (image fault/malfunction).

provides tables of maintenance/inspection, standards/

discusses the principles of operation used

provides tables of periodically replaced parts and

COPYRIGHT © 1999 CANON INC. CANON PC800s/900s REV.0 AUG. 1999 PRINTED IN JAPAN (IMPRIME AU JAPON)

i

The following rules apply throughout this Service Manual:

1. Each chapter contains sections explaining the purpose of specific functions and the

relationship between electrical and mechanical systems with reference to the timing

of operation.

In the diagrams,

accompanies the symbol

represents the path of mechanical drive—where a signal name

, the arrow indicates the direction of the electric signal.

The expression “turn on the power” means flipping on the power switch, closing the

front door, and closing the delivery unit door, which results in supplying the machine

with power.

2. In the digital circuits, ‘1’ is used to indicate that the voltage level of a given signal is

“High,” while ‘0’ is used to indicate “Low.” (The voltage value, however, differs from

circuit to circuit.)

In practically all cases, the internal mechanisms of a microprocessor cannot be checked

in the field. Therefore, the operations of the microprocessors used in the machines

are not discussed: they are explained in terms of from sensors to the input of the DC

controller PCB and from the output of the DC controller PCB to the loads.

The descriptions in this Service Manual are subject to change without notice for

product improvement or other reasons, and major changes will be communicated in the

form of Service Information bulletins.

All service persons are expected to have a good understanding of the contents of this

Service Manual and all relevant Service Information bulletins and be able to identify and

isolate faults in the machine.

ii

COPYRIGHT © 1999 CANON INC. CANON PC800s/900s REV.0 AUG. 1999 PRINTED IN JAPAN (IMPRIME AU JAPON)

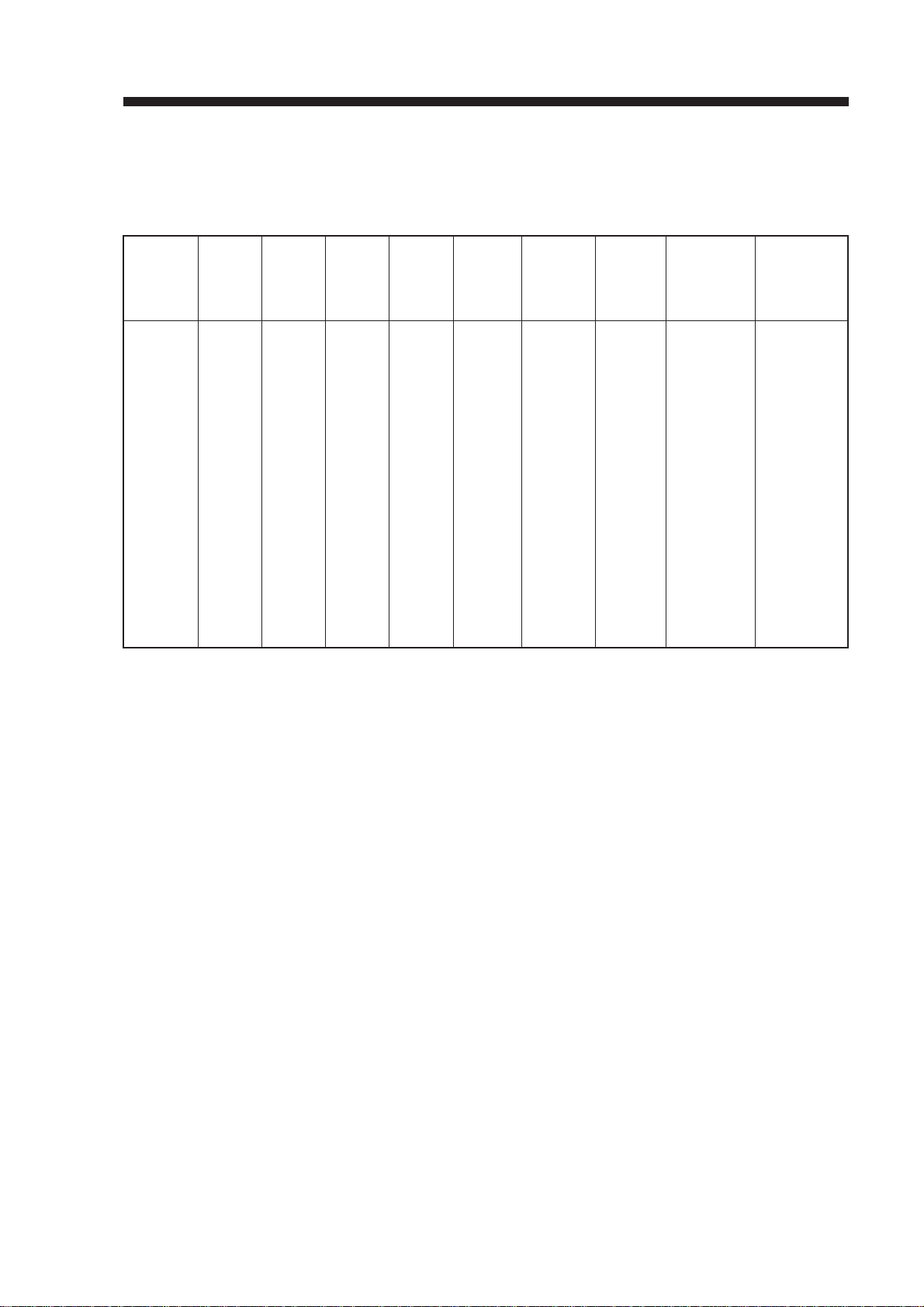

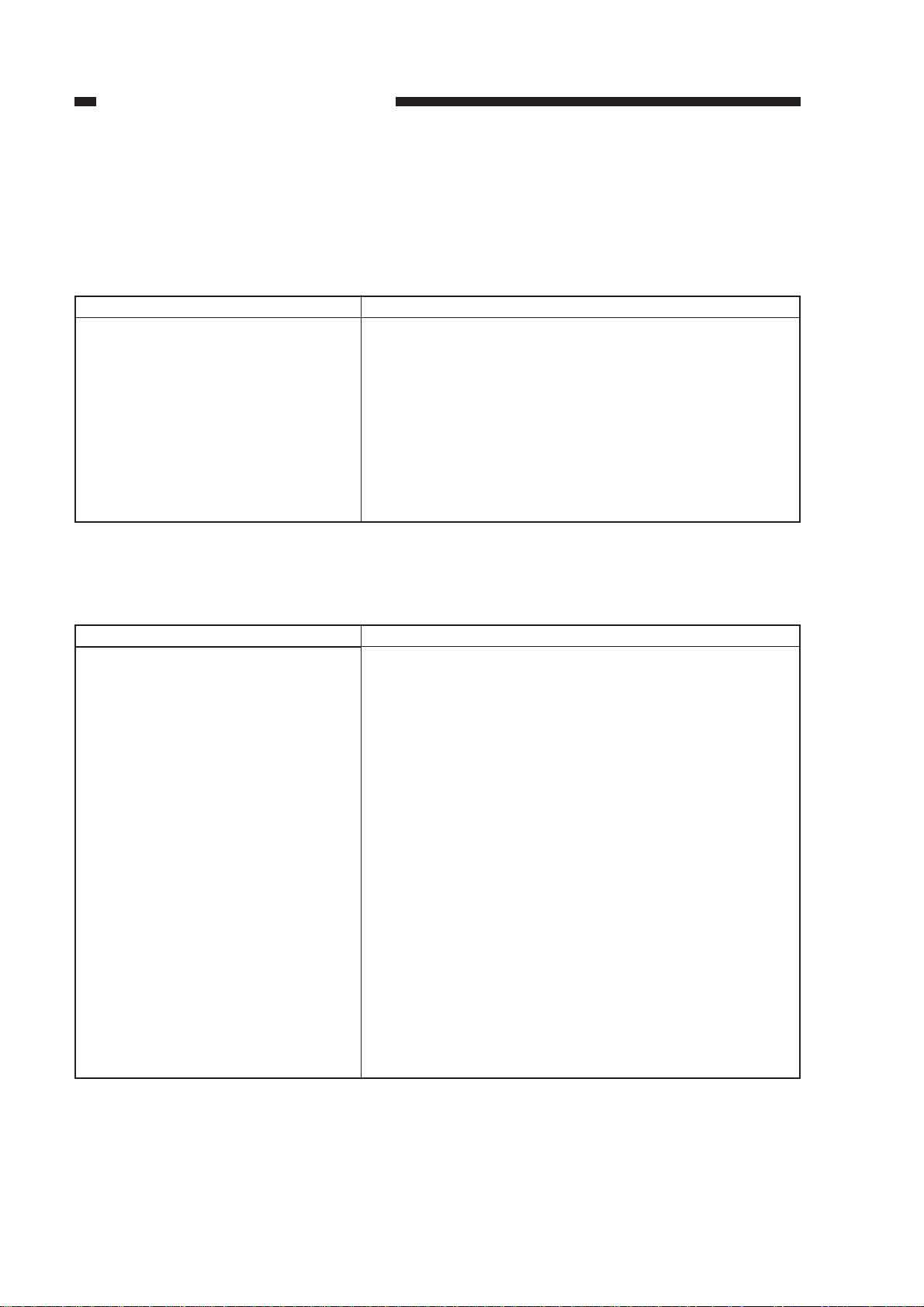

• This service manual covers the models shown in the following table. Be sure to have a

good understanding of the difference from model to model before referring to this

manual.

Model

PC860

PC880

PC890

PC920

PC920

PC920

PC920

PC921

PC940

PC941

PC950

PC950

PC950

PC960

PC980

PC981

Type

code

TYA

TZA

UAA

PUD

PUE

PUH

TVB

TVC

TVD

TVE

PUF

PUG

TVF

TVG

TVH

TVJ

Multi-

feeder

√

√

√

√

√

√

√

√

Single

feeder

√

√

√

√

√

√

√

√

Zoom

√

√

√

√

√

√

√

√

√

√

√

√

√

Default

ratio

2R2E

2R2E

2R2E

2R2E

2R2E

2R2E

3R1E

3R1E

3R1E

3R1E

2R2E

2R2E

3R1E

3R1E

3R1E

3R1E

Density

correction

switch

(SW101)

√

√

√

√

√

√

√

√

The notation “√” indicates that the item in question is available.

ADF

as

standard

√

√

√

√

Cassette

250 sheets

250 sheets

250 sheets

Universal

Universal

Universal

Universal

Universal

Universal

Universal

Universal

Universal

500 sheets

Universal

500 sheets

500 sheets

Copying

speed

(cpm) at

Direct

12

12

12

10

10

10

10

10

13

13

12

12

13

10

13

13

COPYRIGHT © 1999 CANON INC. CANON PC800s/900s REV.0 AUG. 1999 PRINTED IN JAPAN (IMPRIME AU JAPON)

iii

iv

COPYRIGHT © 1999 CANON INC. CANON PC800s/900s REV.0 AUG. 1999 PRINTED IN JAPAN (IMPRIME AU JAPON)

CONTENTS

CHAPTER 1 GENERAL DESCRIPTION

I. FEATURES ..................................1-1

II. SPECIFICATIONS .......................1-2

A. Copier....................................1-2

B. ADF .......................................1-8

III. NAMES OF PARTS................... 1-10

A . External View ..................... 1-10

B. Cross Section..................... 1-13

CHAPTER 2 BASIC OPERATION

I. BASIC OPERATIONS .................. 2-1

A. Functional Construction ........2-1

B. Outline of Electrical

Circuitry .................................2-2

C. Basic Sequence of

Operations.............................2-3

CHAPTER 3 EXPOSURE SYSTEM

IV. USING THE MACHINE ............. 1-15

A. Control Panel...................... 1-15

V. ROUTINE MAINTENANCE

BY THE USER .......................... 1-17

VI. IMAGE FORMATION ................ 1-20

A. Outline................................ 1-20

D. Controlling the Main Motor

(M1) .......................................2-5

E. Inputs to and Outputs from

the DC Controller ..................2-7

I. OPERATIONS ..............................3-1

A. Outline...................................3-1

B. Varying the Reproduction

Ratio......................................3-2

C. Lens Drive System ................3-3

D. Scanner Drive System ..........3-4

II. EXPOSURE SYSTEM .................3-9

A. Controlling the Scanning

Lamp .....................................3-9

III. DISASSEMBLY/ASSEMBLY ..... 3-12

A. Scanner Drive Assembly.... 3-13

B. Lens Drive Assembly ......... 3-31

C. Exposure System ............... 3-37

COPYRIGHT © 1999 CANON INC. CANON PC800s/900s REV.0 AUG. 1999 PRINTED IN JAPAN (IMPRIME AU JAPON)

v

CHAPTER 4 IMAGE FORMATION SYSTEM

I. IMAGE FORMATION SYSTEM ...4-1

A. Outline...................................4-1

B. Timing Chart for the Image

Formation System .................4-3

C. Controlling the Pr imary

Charging Roller Bias .............4-4

D. Controlling the Transfer

Roller Bias.............................4-8

E. Controlling the Developing/

Separation Static Eliminator

Bias .................................... 4-11

CHAPTER 5 PICK-UP/FEEDING SYSTEM

I. PICKUP/FEEDING SYSTEM ....... 5-1

A. Outline................................... 5-1

B. Controlling the Pickup

Roller .....................................5-3

C. Controlling the Movement of

Paper.....................................5-9

D. Detecting Jams .................. 5-12

II. DISASSEMBLY/ASSEMBLY ..... 5-18

F. Measuring the Density of

Originals ............................. 4-16

G. Controlling the Side Blanking

Mechanism......................... 4-21

II. DISASSEMBLY/ASSEMBLY ..... 4-22

A. Cartridge ............................ 4-23

B. Transfer Charging

Assembly............................ 4-25

C. Blank Exposure .................. 4-26

A. Pickup Assembly ................ 5-19

B. Multifeeder Assembly......... 5-28

C. Single-feeder Assembly ..... 5-31

D. Feeding Assembly.............. 5-33

E. Registration Roller

Assembly............................ 5-34

F. Delivery Assembly.............. 5-36

CHAPTER 6 FIXING SYSTEM

I. OPERATIONS ..............................6-1

A. Outline...................................6-1

B. Controlling the Fixing

Temperature ..........................6-3

II. DISASSEMBLY/ASSEMBLY ..... 6-10

A. Fixing Assembly................. 6-11

vi

COPYRIGHT © 1999 CANON INC. CANON PC800s/900s REV.0 AUG. 1999 PRINTED IN JAPAN (IMPRIME AU JAPON)

CHAPTER 7 EXTERNALS/AUXILIARY MECHANISMS

I. FANS............................................7-1

II. POWER SUPPLY SYSTEM.........7-3

A. Outline of the Power Supply

System ..................................7-3

B. Power Supply Circuit.............7-4

C. Detecting an Error on

the Composite Power Supply

PCB .......................................7-6

D. Protecting the Power Supply

Circuit ....................................7-6

CHAPTER 8 ADF

I. ADF ..............................................8-1

A. Outline................................... 8-1

B Basic Construction ................8-2

C. Basic Operations...................8-4

D. Detecting an Original ............8-6

E. Pickup Operation ...................8-8

F. Delivery .............................. 8-12

G. Controlling the Pickup

Motor .................................. 8-14

III. DISASSEMBLY/ASSEMBLY ........7-7

A. External Covers..................... 7-8

B. Control Panel...................... 7-15

C. Copyboard Glass ............... 7-16

D. Main Motor/Main Drive

Assembly............................ 7-17

E. Electrical System ............... 7-21

H. Controlling the Belt Motor .. 8-15

I. Detecting Original Jams..... 8-16

J. Power Supply ..................... 8-17

II. DISASSEMBLY/ASSEMBLY ..... 8-18

A. Removing the ADF............. 8-19

B. External Covers.................. 8-21

C. Drive System...................... 8-23

D. Feeding System ................. 8-26

E. Electrical System ............... 8-33

CHAPTER 9 INSTALLATION

I. SELECTING A SITE ....................9-1

II. UNPACKING AND

INSTALLATION ............................9-2

A. Unpacking and Installation....9-2

CHAPTER 10 MAINTENANCE AND SERVICING

I. PERIODICALLY REPLACED

PARTS....................................... 10-1

II. DURABLES AND

CONSUMABLES ...................... 10-1

III. SCHEDULED SERVICING....... 10-1

IV. STORING AND HANDLING

THE CARTRIDGE..................... 10-2

B. Placing Copy Paper............... 9-9

III. MOVING THE MACHINE.......... 9-12

A. Storing the Cartr idge with the

Packaging Seal Intact ........ 10-2

B. Storing and Handling the

Cartr idge with the Packaging

Seal Removed.................... 10-3

COPYRIGHT © 1999 CANON INC. CANON PC800s/900s REV.0 AUG. 1999 PRINTED IN JAPAN (IMPRIME AU JAPON)

vii

CHAPTER 11 TROUBLESHOOTING

I. MAINTENANCE AND

INSPECTION ............................ 11-3

A. Image Adjustment Basic

Procedure........................... 11-3

B. Points to Note for

Servicing ............................ 11-4

II. STANDARDS AND

ADJUSTMENTS ....................... 11-5

A. Mechanical ......................... 11-5

B. ADF .................................. 11-30

C. Electr ical........................... 11-41

III. TROUBLESHOOTING IMAGE

FAULTS ................................... 11-48

A. Making Initial Checks ....... 11-48

B. Sample Image Faults ....... 11-52

C. Troubleshooting Image

Faults................................ 11-53

IV. TROUBLESHOOTING

MALFUNCTIONS.................... 11-61

A. Troubleshooting

Malfunctions ..................... 11-61

V. TROUBLESHOOTING FEEDING

PROBLEMS ............................ 11-75

A. Copy Paper Jam............... 11-75

B. Faulty Feeding.................. 11-78

VI. ARRANGEMENT AND

FUNCTIONS OF ELECTRICAL

PARTS..................................... 11-79

A. Sensors and Solenoids.... 11-79

B. Switches........................... 11-80

C. Lamp, Heater, Motor, Etc. 11-81

D. PCBs ................................ 11-82

E. ADF .................................. 11-83

F. Variable Resistors (VR) and

Check Pins by PCB.......... 11-84

VII. SELF DIAGNOSIS .................. 11-86

APPENDIX

A. GENERAL TIMING CHART ........ A-1

B. SIGNALS AND

ABBREVIATIONS ....................... A-3

C. GENERAL CIRCUIT

DIAGRAM ................................... A-5

D. DC CONTROLLER CIRCUIT

DIAGRAM ................................... A-7

E. ADF CONTROLLER CIRCUIT

DIAGRAM ................................. A-15

F. COMPOSITE POWER SUPPLY

CIRCUIT DIAGRAM.................. A-19

G. CONTROL PANEL CIRCUIT

DIAGRAM ................................. A-27

H. AE SENSOR CIRCUIT

DIAGRAM ................................. A-29

I. SENSOR CIRCUIT

DIAGRAM ................................. A-30

J. NOISE FILTER CIRCUIT

DIAGRAM ................................. A-31

K. HIGH VOL TAGE CONT A CT

CIRCUIT DIAGRAM.................. A-32

L. BLANK EXPOSURE (front)

CIRCUIT DIAGRAM.................. A-33

M. BLANK EXPOSURE (rear)

CIRCUIT DIAGRAM.................. A-34

N. SPECIAL TOOLS...................... A-35

O. SOLVENTS/OILS...................... A-36

viii

COPYRIGHT © 1999 CANON INC. CANON PC800s/900s REV.0 AUG. 1999 PRINTED IN JAPAN (IMPRIME AU JAPON)

CHAPTER 1

GENERAL DESCRIPTION

This chapter provides specifications of the machine, instructions on how to operate

the machine, and an outline of copying process.

I. FEATURES ..................................1-1

II. SPECIFICATIONS .......................1-2

A. Copier....................................1-2

B. ADF .......................................1-8

III. NAMES OF PARTS................... 1-10

A . External View ..................... 1-10

B. Cross Section..................... 1-13

COPYRIGHT © 1999 CANON INC. CANON PC800s/900s REV.0 AU G. 1999 PRINTED IN JAPAN (IMPRIME AU JAPON)

IV. USING THE MACHINE ............. 1-15

A. Control Panel...................... 1-15

V. ROUTINE MAINTENANCE

BY THE USER .......................... 1-17

VI. IMAGE FORMATION ................ 1-20

A. Outline ................................ 1-20

CHAPTER 1 GENERAL DESCRIPTION

I. FEATURES

1. Personal Copier with a Zoom Function and a Fixed Copyboard

• You can choose either a default enlargement/reduction ratio or any ratio between 70% and

141% in 1% increments.

2. Ecology-Conscious

• The use of a roller charging method has resulted in a considerable reduction of ozone: 0.01

ppm or less on the average, 0.02 ppm or less at maximum (1/100 to 1/1000 compared with

existing Canon machines).

3. SURF Fixing Assembly

• The wait time is 0 sec (at 20°C room temperature), enabling speedy copying work immediately after power-on.

4. Various Paper Sizes

• The paper may be between A4 (LGL) and A5 (STMT) (*Using the universal cassette).

• In manual feed mode, paper may be as large as A4 (LGL) or as small as a business card.

5. All-in-One Cartridge for Simple Maintenance

• The photosensitive drum, toner case, charging roller, developing assembly, and cleaning assembly are constructed as a single entity (cartridge).

The user may expect quality copy images at all times as long as he/she performs simple

replacement/cleaning work.

6. Large Paper Source

• The source of paper may contain as many as 550 sheets of paper (500-sheet cassette +

multifeeder; multifeeder type).

7. Separate top unit

• The machine’s top unit may be opened to make jam removal easy.

8. ADF Type

• Continuous copying is possible with the use of the ADF.

COPYRIGHT © 1999 CANON INC. CANON PC800s/900s REV.0 AUG. 1999 PRINTED IN JAPAN (IMPRIME AU JAPON)

1-1

CHAPTER 1 GENERAL DESCRIPTION

II. SPECIFICATIONS

A. Copier

1. Type

Item

Body

Copyboard

Source of light

Lens

Photosensitive medium

2. Mechanisms

Item

Reproduction

Charging

Exposure

Descriptions

Desk top

Fixed

Halogen lamp (80 V/110 W for 120V-model; 150 V/160 W

for 220/240 V-model)

Fixed focal point lens

OPC drum (24-mm dia.)

Table 1-201

Descriptions

Indirect static reproduction

Roller (direct charging)

Slit (moving light source)

Copy density adjustment

Development

Pickup

Separation

Fixing

Cleaning

Original orientation

Auto or manual

Dry (toner projection)

Cassette (1 pc.)

Single-feeder (single-feeder type)

Multifeeder (multifeeder type)

Curvature separation + static eliminator

Flat heater

Blade

Center reference (copyboard)

Table 1-202

1-2

COPYRIGHT © 1999 CANON INC. CANON PC800s/900s REV.0 AUG. 1999 PRINTED IN JAPAN (IMPRIME AU JAPON)

3. Performance

CHAPTER 1 GENERAL DESCRIPTION

Item

Original type

Maximum original size

Reproduction ratio

Zoom

Wait time

First copy time

Continuous copying

Copy size

Copy paper type

Descriptions

Sheet, book, 3-D object (2kg max.)

A4 (297 × 210 mm)/LGL (216 × 356 mm)

Inch/AB-configuration: 2R2E Inch-configuration: 3R1E

70% to 141% (in 1% increments*1)

0 sec (at 20°C room temperature)

10 sec or less (at 20°C room temperature; Direct, non-AE,

from the cassette)

100 (max.)

A4/LGL (297 × 210 mm/216 × 356 mm max.)

Business card (90 × 55 mm, min.)

Cassette:

2

Plain paper (64 to 80 g/m

B5R), colored paper, recycled paper (64 to 80 g/m

B5R), eco paper (80 g/m

), tracing paper (SM-1, A4R/

2

; A4R)

2

; A4R/

Manual Feeder:

2

Plain paper (52 to 128 g/m

*2

; A4R/B5R), transparency

80

paper, business card (200 g/m

LTRR), recycled paper (64 to 80 g/m

2

per (80 g/m

; A4R), postcard

), tracing paper (SM-1, GNT-

*2,*4

(A4R/LTRR*3), colored

2

or less), label sheet*2 (A4R/

2

*3

; A4R/B5R), eco pa-

Double-Sided/Overlay Copying*5:

2

Plain paper (64 to 128 g/m

(200 g/m

2

or less), recycled paper (64 to 80 g/m2; A4R/

B5R), eco paper (80 g/m

), colored paper, business card

2

; A4R), postcard

*3

Cassette

With claws

Universal cassette (250 sheets of 80 g/m

2

paper; A4/LGL to

A5/STMT)

2

)

2

)

2

)

Multifeeder tray

Copy tray

Non-image width

250-sheet cassette (250 sheets of 80 g/m

500-sheet cassette (500 sheets of 80 g/m

5 mm deep (approx.; 50 sheets of 80 g/m

100 sheets (A4; 80 g/m

2

)

Leading edge: 2.0 ±1.5 mm (Direct; 4.0 mm or less otherwise)

Left/right: 0.0 +2.0, -0.0 mm (0 +4.0, -0.0 mm for LTR)

Auto power-off

Provided (5 min, approx.; fixed)

*6

Table 1-203

COPYRIGHT © 1999 CANON INC. CANON PC800s/900s REV.0 AUG. 1999 PRINTED IN JAPAN (IMPRIME AU JAPON)

1-3

CHAPTER 1 GENERAL DESCRIPTION

*1. Applies only to models with a zoom function.

*2. Applies only to single pickup if the multifeeder is used.

*3. Applies only to vertical feeding.

*4. Upon delivery, be sure to remove each from the copy tray.

*5. Be sure to remove any curling before feeding for a second time.

*6. If stopped because paper ran out during copying operation, 1 hr.

1-4

COPYRIGHT © 1999 CANON INC. CANON PC800s/900s REV.0 AUG. 1999 PRINTED IN JAPAN (IMPRIME AU JAPON)

4. Others

CHAPTER 1 GENERAL DESCRIPTION

Item

Operating condition

Temperature

Humidity

Atmospheric pressure

Power source

Serial number

Maximum power consumption

Noise

Descriptions

7.5°C to 32.5°C/44.5°F to 90.5°F

5% to 85% RH

607.95 to 1013.25 hPa (0.6 to 1 atm)

120 V 60 Hz 220/240 V 50 Hz, 60 Hz

TVBxxxxx PUDxxxxx PUHxxxxx

TVCxxxxx PUExxxxx

TVDxxxxx PUFxxxxx

TVExxxxx PUGxxxxx

TVFxxxxx TYAxxxxx

TVGxxxxx TZAxxxxx

TVHxxxxx UAAxxxxx

TVJxxxxx

0.9 kW or less

Standby: 1.2W (approx.; about 5min; reference only)

Copying: 0.4kWh (approx.; reference only)

Standby: -(sound power level by ISO)

Copying: (sound power level by ISO)

• Single-feeder type: 68 dB or less

• Multifeeder type: 66 dB or less

Ozone

Dimensions (WxDxH)

Weight (including the cassette)

Consumables

*1. 250-sheet cassette type

*2. 500-sheet cassette type

0.01 ppm or less (average; 0.02 ppm or less, max.)

Copyboard Type

484.9 × 448.2 × 297.5 mm

*1

/ 329.0 mm

19.1 in. × 17.6 in × 11.7 in*1/ 13.0 in

*2

*2

ADF Type

*1

484.9 × 448.2 × 358.3 mm

/ 389.8 mm

19.1 in × 17.6 in × 14.1 in*1/ 15.3 in

*2

*2

Copyboard Type

Single-feeder type: 19.3 kg

*1

/ 42.5 lb*1, 20.9 kg*2/ 46.0 lb

Multifeeder type: 19.5 kg*1/ 42.9 lb*1, 21.1 kg*2/ 46.4 lb

ADF Type

Single-feeder type: 23.8 kg

*1

/ 52.4 lb*1, 25.2 kg*2/ 55.4 lb

Multifeeder type: 24.0 kg*1/ 52.8 lb*1, 25.4 kg*2/ 55.9 lb

Copy paper: Keep wrapped, and protect against humidity.

Toner: Avoid direct sunlight, and store at 40°C/104°F, 85%

or less.

Table 1-204

*2

*2

*2

*2

COPYRIGHT © 1999 CANON INC. CANON PC800s/900s REV.0 AUG. 1999 PRINTED IN JAPAN (IMPRIME AU JAPON)

1-5

CHAPTER 1 GENERAL DESCRIPTION

5. Default Ratios

Direct

Reduce I

Reduce II

Reduce III

Reduce IV

Enlarge I

Enlarge II

Item

2R2E (Inch/AB-configuration)

1:1.000

1:0.707

1:0816

1:1.154

1:1.414

Table 1-205

3R1E (Inch-configuration)

1:1.000

1:0.707

1:0.786

1:0.860

1:1.414

1-6

COPYRIGHT © 1999 CANON INC. CANON PC800s/900s REV.0 AUG. 1999 PRINTED IN JAPAN (IMPRIME AU JAPON)

6. Copying Speed

CHAPTER 1 GENERAL DESCRIPTION

Copying speed

at Direct

13

12

10

10

Reproduction ratio

Direct

Reduce I (70.7%)

Reduce II (78.6%)

Reduce IV (86.0%)

Enlarge II (141.4%)

Direct

Reduce I (70.7%)

Reduce III (81.6%)

Enlarge I (115.4%)

Enlarge II (141.4%)

Direct

Reduce I (70.7%)

Reduce III (81.6%)

Enlarge I (115.4%)

Enlarge II (141.4%)

Direct

Reduce I (70.7%)

Reduce II (78.6%)

Reduce III (86.0%)

Enlarge II (141.4%)

Copy size

LTRR

LGL

STMTR

MIN

LGL → LTRR

MARJIN

MAX

A4R

B5R

A5R

A4R → A5R

B5R → A5R

B5R → A4R

A5R→ A4R

A4R

B5R

A5R

A4R → A5R

B5R → A5R

B5R → A4R

A5R → A4R

LTRR

LGL

STMTR

MIN

LGL → LTRR

MARJIN

MAX

Number of copies

*1

( Multifeeder

)

(Copies / min)

13 (9)

11 (8)

13 (9)

13 (9)

13 (9)

13 (9)

10 (9)

12 (9)

12 (9)

12 (9)

12 (9)

12 (9)

12 (9)

10 (9)

10 (9)

10 (9)

10 (9)

10 (9)

10 (9)

10 (9)

10 m(9)

10 (9)

9

10 (9)

10 (9)

10 (9)

10 (9)

9

Table 1-206

*1. The number of copies starting with the pickup operation that follows the delivery of the

19th copy in a continuous copying job. (See p.5-8)

The specifications are subject to change for product improvement.

COPYRIGHT © 1999 CANON INC. CANON PC800s/900s REV.0 AUG. 1999 PRINTED IN JAPAN (IMPRIME AU JAPON)

1-7

CHAPTER 1 GENERAL DESCRIPTION

B. ADF

Item

Original pickup

Original orientation

Original position

Original separation

Original type

Stack

Original processing mode

Original size detection

Mixed original sizes

Descriptions

Auto pickup/delivery

Face-down

Center reference

Top separation

Single-sided (50 to 128 g/m

2

)

A5 (STMT) to A4R (LTRR), LGL

Length: 139.7 to 355.6 mm (feeding direction)

Width: 139.7 to 215.9 mm

30 sheets (80 g/m

2

or less; about 3 mm in height)

Single-sided original to single-sided copy

Yes (in feeding direction)

No

Original detection

Original feeding speed

Communication with host

Dimensions

Weight

Power source

Maximum power consumption

Operating environment

Yes

446 mm/sec

IPC

Width: 474 mm/ 18.7 in.

(659 mm/ 25.9 in. with the tray open)

Depth: 394 mm/ 15.5 in.

Height: 74 mm/ 2.9 in. (216 mm/ 8.5 in. with the tray open)

5 kg/ 11 lb (approx.)

24 VDC and 5 VDC (from the host)

40 W or less

Temperature: same as the host

Humidity: same as the host

Table 1-207

1-8

COPYRIGHT © 1999 CANON INC. CANON PC800s/900s REV.0 AUG. 1999 PRINTED IN JAPAN (IMPRIME AU JAPON)

*1. The following may not be used as an original:

• Sheet with a staple, clip, or glue.

• Sheet with a cut, hole, or tear.

• Sheet with holes for binding.

• Sheet with a carbon back.

• Sheet with a cut-and-paste piece.

• Sheet with curling, bending, or wrinkling.

The specifications are subject to change for product improvement.

CHAPTER 1 GENERAL DESCRIPTION

COPYRIGHT © 1999 CANON INC. CANON PC800s/900s REV.0 AUG. 1999 PRINTED IN JAPAN (IMPRIME AU JAPON)

1-9

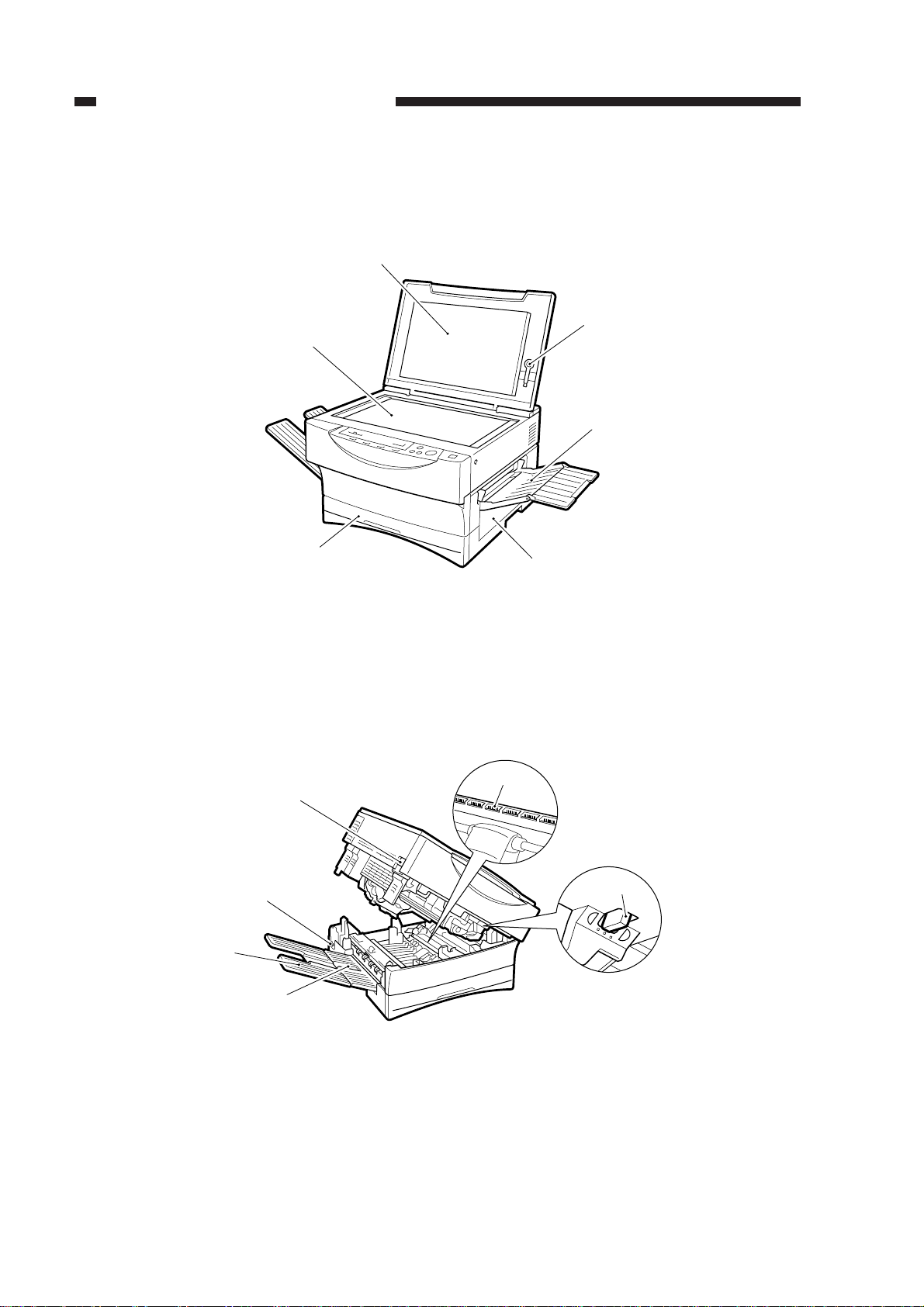

CHAPTER 1 GENERAL DESCRIPTION

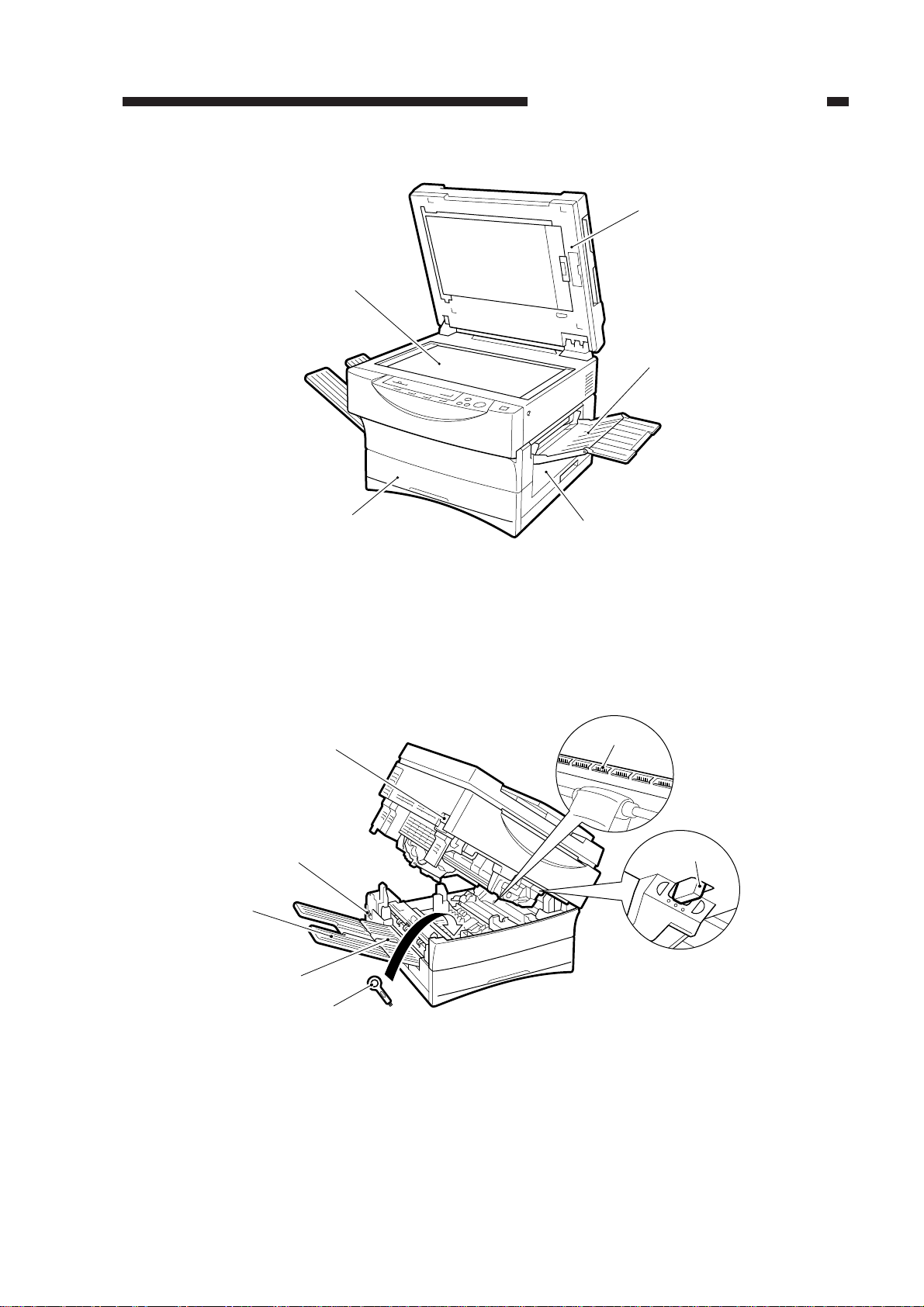

III. NAMES OF PARTS

A. External View

1. Copyboard Type

[1] Copyboard cover

[2] Static eliminator cleaner

[3] Manual feed tray

[6]

[5]

[1]

[2]

[3]

[4]

[4] Right door

[5] Cassette

[6] Copyboard glass

Figure 1-301

[3]

[2]

[1]

[6]

[1] Copy tray

[2] Power cord connector

[3] Open/close lever

[4]

[5]

[4] Static eliminator

[5] Copy density correction switch

[6] Delivery guide plate

Figure 1-302

1-10

COPYRIGHT © 1999 CANON INC. CANON PC800s/900s REV.0 AUG. 1999 PRINTED IN JAPAN (IMPRIME AU JAPON)

2. ADF Type

CHAPTER 1 GENERAL DESCRIPTION

[1]

[5]

[2]

[4]

[1] ADF

[2] Manual feed tray

[3] Right door

[5]

[4]

[3]

[3]

[4] Cassette

[5] Copyboard glass

Figure 1-303

[6]

[7]

[2]

[1]

[1] Static eliminator cleaner

[2] Delivery guide plate

[3] Copy tray

[5] Open/close lever

[6] Static eliminator

[7] Copy density correction switch

[4] Power cord connector

Figure 1-304

COPYRIGHT © 1999 CANON INC. CANON PC800s/900s REV.0 AUG. 1999 PRINTED IN JAPAN (IMPRIME AU JAPON)

1-11

CHAPTER 1 GENERAL DESCRIPTION

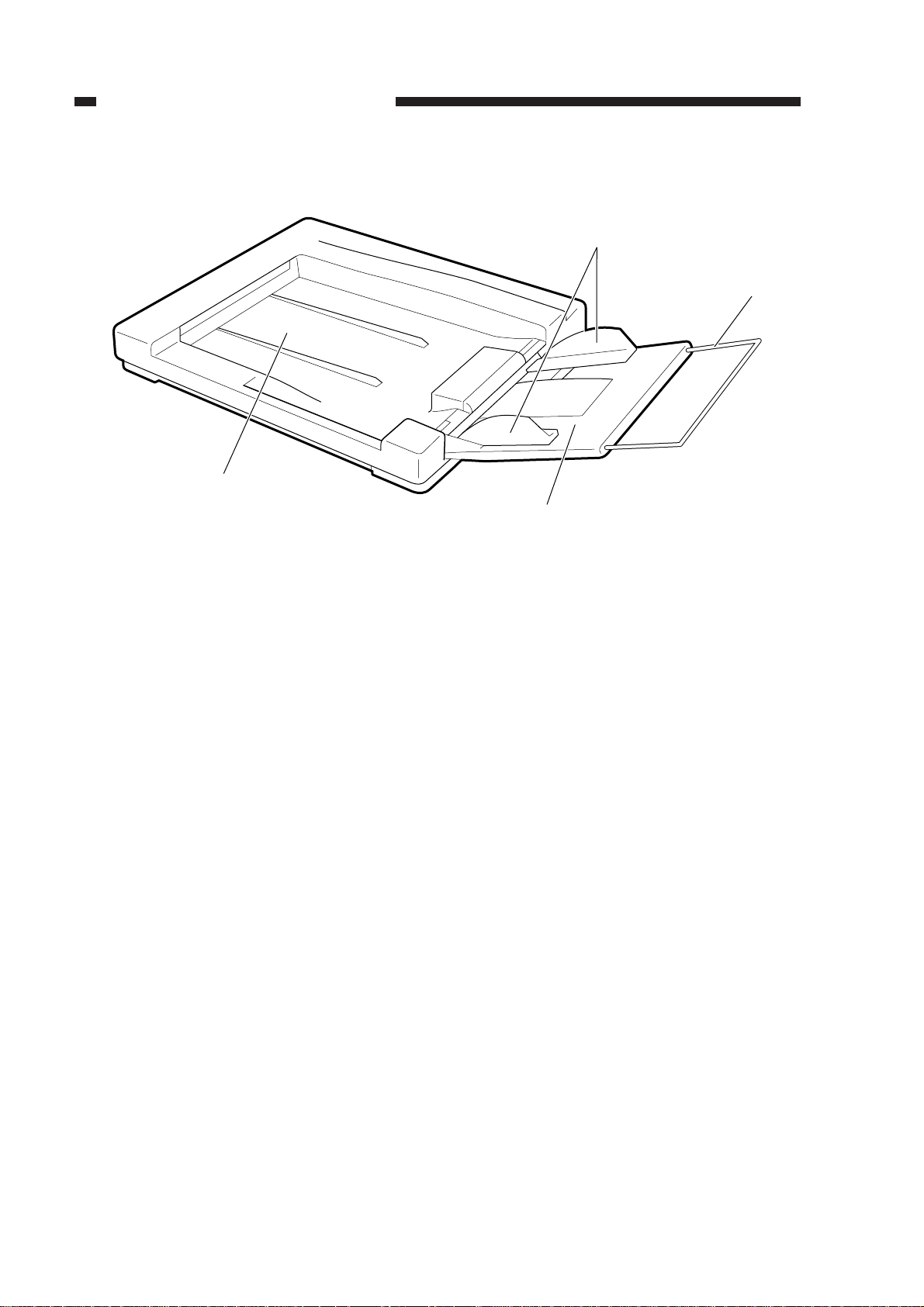

3. ADF

[2]

[3]

[4]

[1]

[1] Original tray

[2] Original delivery tray

[3] Slide guide

[4] Auxiliary tray

Figure 1-305

1-12

COPYRIGHT © 1999 CANON INC. CANON PC800s/900s REV.0 AUG. 1999 PRINTED IN JAPAN (IMPRIME AU JAPON)

B. Cross Section

1. Body

[1]

[2] [3] [4] [5] [6] [7] [8] [9] [10] [11] [12] [13] [14]

CHAPTER 1 GENERAL DESCRIPTION

[28] [27] [26] [25] [24] [23] [22] [21] [20] [19] [18] [17] [29][16] [15]

[1] No. 3 mirror

[2] No. 2 mirror

[3] No. 1 mirror

[4] Scanning lamp

[5] Heat exhaust fan

[6] Copyboard glass

[7] Side blanking lamp

[8] Lens

[9] Primary charging roller

[10] No. 6 mirror

[11] Cartridge

[12] No. 4 mirror

[13] No. 5 mirror

[14] Multifeeder tray

[15] Vertical path roller

[16] Multifeeder pickup roller

[17] Cassette pickup roller

[18] Registration roller

[19] Developing cylinder

[20] Photosensitive drum

Figure 1-306

[21] Transfer roller

[22] Feed belt

[23] Cassette

[24] Fixing upper unit

[25] Fixing lower roller

[26] Cleaning roller

[27] Delivery roller

[28] Copy tray

[29] Single-feeder pickup roller

COPYRIGHT © 1999 CANON INC. CANON PC800s/900s REV.0 AUG. 1999 PRINTED IN JAPAN (IMPRIME AU JAPON)

1-13

CHAPTER 1 GENERAL DESCRIPTION

2. ADF

[6][5][4][3][2][1]

[13] [12]

[1] Delivery roller

[2] Copy tray

[3] Pickup roller 2

[4] Pickup roller 1

[5] Copyboard tray

[6] Auxiliary tray

[7] Guide plate

[11] [9] [8] [7][10]

[8] Separation pad

[9] Registration roller

[10] Feed belt drive roller

[11] Feed belt

[12] Feed belt roller

[13] Feed belt link slave roller

Figure 1-307

1-14

COPYRIGHT © 1999 CANON INC. CANON PC800s/900s REV.0 AUG. 1999 PRINTED IN JAPAN (IMPRIME AU JAPON)

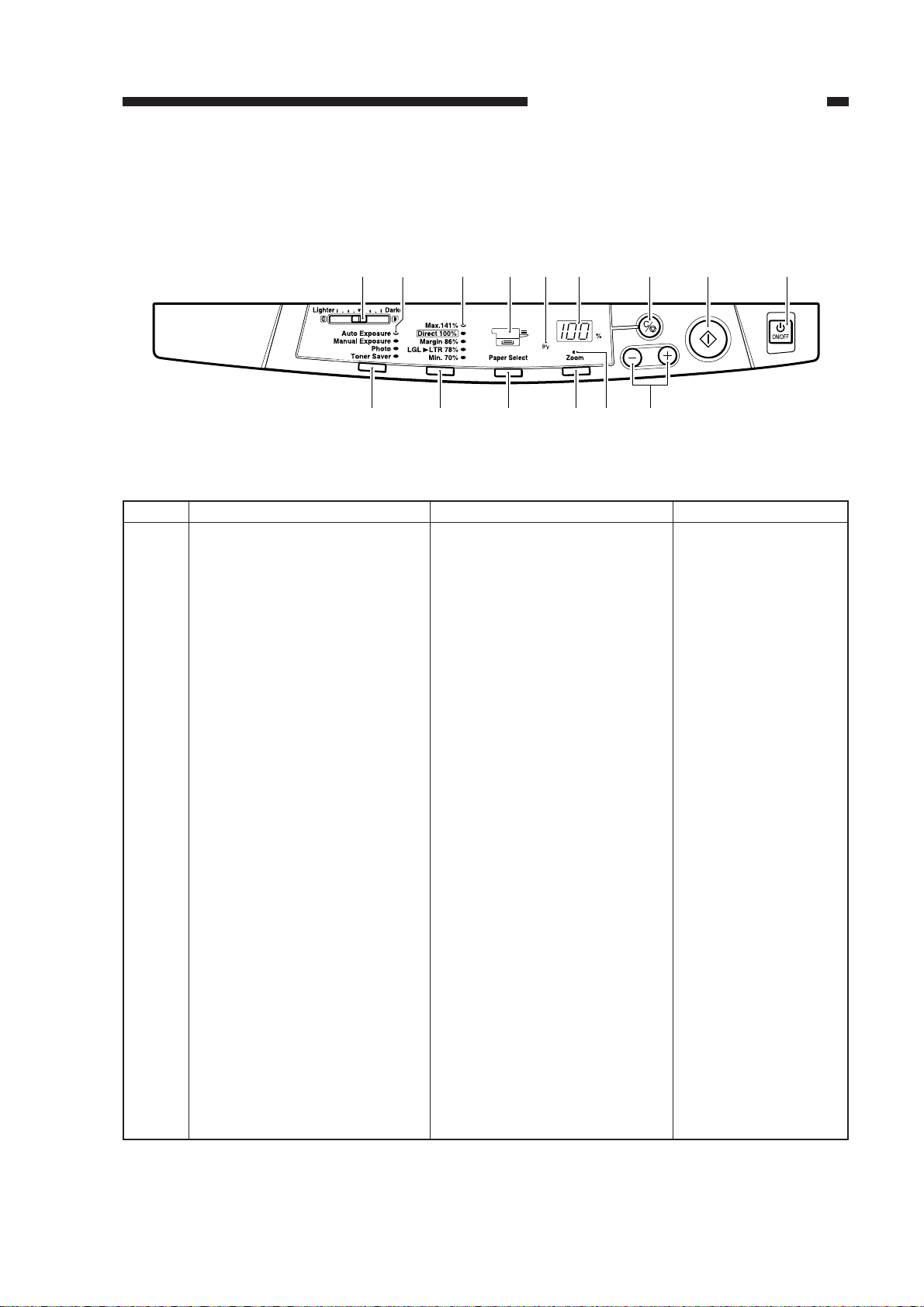

IV. USING THE MACHINE

A. Control Panel

CHAPTER 1 GENERAL DESCRIPTION

No.

1

2

3

4

[15] [14] [12] [10][11][13]

Name

Copy density adjusting lever

Copy density mode indicator

Default ratio indicator

Paper selection indicator

*1

[5][4][3][2]

Figure 1-401

Description

Adjusts the density of copies

manually.

Indicates the selected copy density mode.

Indicates the selected default ratio.

Indicates the selected cassette/

manual feed tray.If there is no

paper loaded, it flashes.

[8] [9][7][6][1]

Remarks

5

Jam indicator

6

Count/ratio indicator

Flashes in response to a jam.

• Indicates the number of copies

or reproduction ratio.

100 (max.; continuous

copying)

• The symbol “%” turns on

when indicating a ratio.

7

Clear/stop key

Stops copying or returns copying mode to standard mode.

Standard Mode

Ratio: 100%

Count: 1

Paper source: cassette

Copy density: auto

8

Copy start key

9

Power switch

COPYRIGHT © 1999 CANON INC. CANON PC800s/900s REV.0 AUG. 1999 PRINTED IN JAPAN (IMPRIME AU JAPON)

Starts copying.

Turns on and off the power.

mode

1-15

CHAPTER 1 GENERAL DESCRIPTION

No.

10

Name

Count/zoom set key

Sets the number of copies or a

Description

zoom ratio.

11

Zoom indicator

*2

Turns on when zoom mode is

selected.

12

13

Zoom key

*2

Paper selection key

*1

Selects/deselects zoom mode.

Selects the cassette/ manual

feed tray.

14

Default ratio key

Selects a default reproduction

ratio.

15

Copy density mode selection

Selects copying density mode.

key

Table 1-401

*1. Applies only to a multifeeder model.

*2. Applies only to a model equipped with a zoom function.

Remarks

May be between 70%

and 141% in 1% increments.

1-16

COPYRIGHT © 1999 CANON INC. CANON PC800s/900s REV.0 AUG. 1999 PRINTED IN JAPAN (IMPRIME AU JAPON)

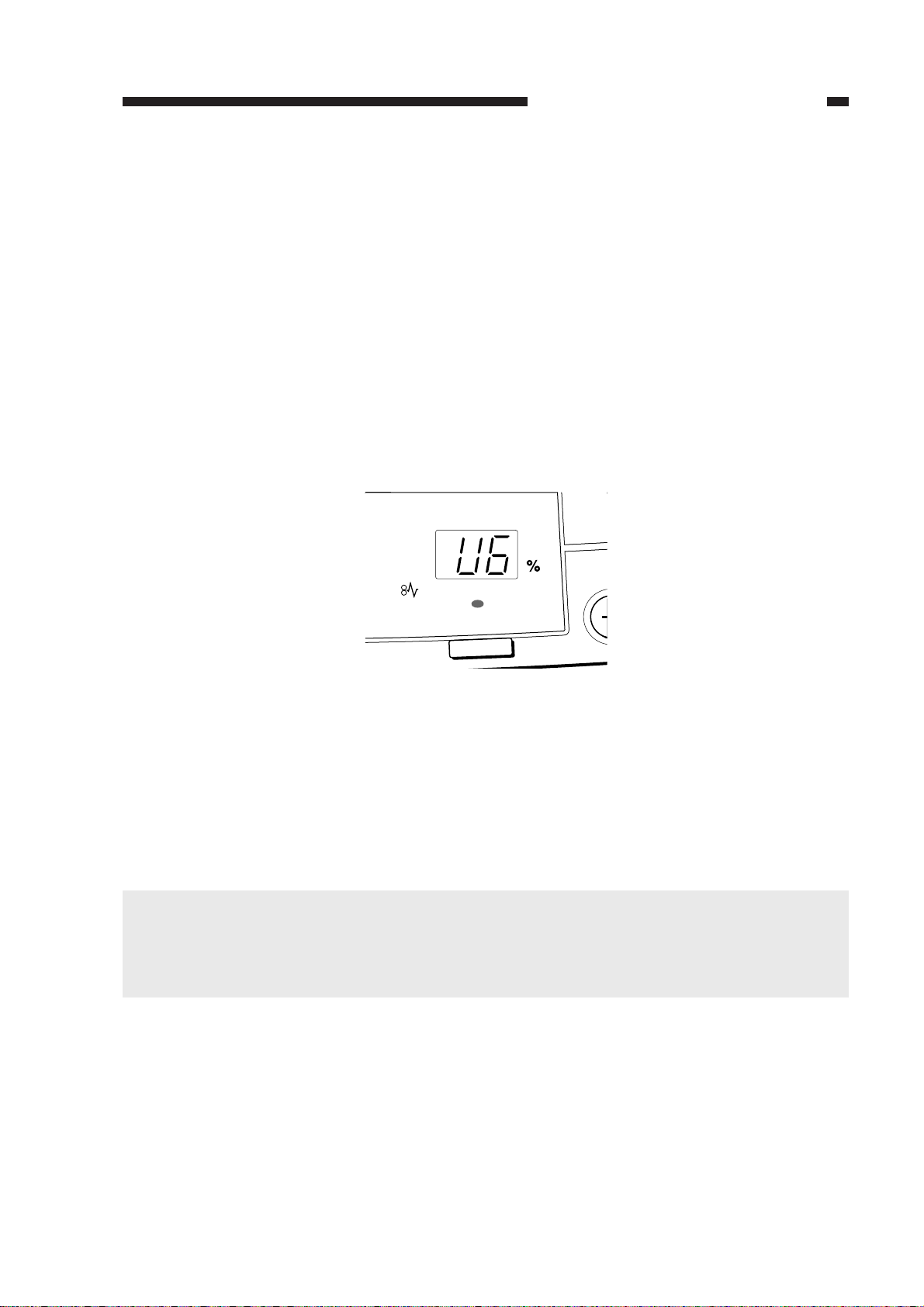

CHAPTER 1 GENERAL DESCRIPTION

V. ROUTINE MAINTENANCE BY THE USER

Instruct the user to clean the following if images tend to be soiled or copy paper tends to jam

often.

1. Soiled Images

a. Copyboard Glass/Copyboard Cover

Clean the cover with a moist cloth (with water or mild detergent solution); then, dry wipe it.

b. Feeding Belt (ADF type)

b.1 Cleaning in Feeder Cleaning Mode

1) Turn on the machine, and hold down the Copy Density Mode Selection key for 4 sec or

more.

• The count/ratio indicator will indicate ‘U6’.

Zoom

Figure 1-501

2) Place about 10 sheets of blank copy paper (A4/LTR) on the original tray of the ADF.

3) Press the Copy Start key.

• Copy paper will be fed from the original tray.

• The indicator flashes ‘U6’ while the feeder is being cleaned.

4) Press the Copy Density Mode Selection key to end the mode.

Caution:

• You cannot start feeder cleaning mode while the machine is making copies or if an error

exists.

• The auto power-off mechanism does not operate while feeder cleaning mode is being

executed.

COPYRIGHT © 1999 CANON INC. CANON PC800s/900s REV.0 AUG. 1999 PRINTED IN JAPAN (IMPRIME AU JAPON)

1-17

CHAPTER 1 GENERAL DESCRIPTION

b.2 Cleaning by Hand

1) Wipe the feed belt with a moist cloth (water or mild detergent solution) in the direction of

the arrow in the figure; then, dry wipe it.

Figure 1-502

2. If Jams Occur Frequently

a. Static Eliminator

1) Remove the static eliminator cleaner from the machine.

Figure 1-503 (Copyboard type)

1-18

COPYRIGHT © 1999 CANON INC. CANON PC800s/900s REV.0 AUG. 1999 PRINTED IN JAPAN (IMPRIME AU JAPON)

Loading...

Loading...