SERVICE

MANUAL

imageRUNNER

iR2270/2870/

3570/4570

Multi-PDL

Printer Kit-E1

COPYRIGHT 2004 CANON INC. CANON imageRUNNER Multi-PDL Printer Kit-E1 REV. 0 PRINTED IN U.S.A.

DU7-1133-000

SEPT. 2004

REV. 0

Application

This manual has been issued by Canon Inc. for qualified persons to learn technical theory, installation,

maintenance, and repair of products. This manual covers all localities where the products are sold. For

this reason, there may be information in this manual that does not apply to your locality.

Corrections

This manual may contain technical inaccuracies or typographical errors due to improvements or changes

in products. When changes occur in applicable products or in the contents of this manual, Canon will

release technical information as the need arises. In the event of major changes in the contents of this

manual over a long or short period, Canon will issue a new edition of this manual.

The following paragraph does not apply to any countries where such provisions are inconsistent with

local law.

Trademarks

The product names and company names used in this manual are the registered trademarks of the

individual companies.

Copyright

This manual is copyrighted with all rights reserved. Under the copyright laws, this manual may not be

copied, reproduced or translated into another language, in whole or in part, without the written consent

of Canon Inc.

COPYRIGHT © 2001 CANON INC.

Printed in Japan

Caution

Use of this manual should be strictly supervised to avoid disclosure of confidential information.

Introduction

Symbols Used

This documentation uses the following symbols to indicate special information:

Symbol Description

Indicates an item of a non-specific nature, possibly classified as Note,

Caution, or Warning.

Indicates an item requiring care to avoid electric shocks.

Indicates an item requiring care to avoid combustion (fire).

Indicates an item prohibiting disassembly to avoid electric shocks or

problems.

Indicates an item requiring disconnection of the power plug from the electric

outlet.

Memo

REF.

Indicates an item intended to provide notes assisting the understanding of the

topic in question.

Indicates an item of reference assisting the understanding of the topic in

question.

Provides a description of a service mode.

Provides a description of the nature of an error indication.

Introduction

The following rules apply throughout this Service Manual:

1. Each chapter contains sections explaining the purpose of specific functions and the

relationship between electrical and mechanical systems with reference to the timing of

operation.

In the diagrams, represents the path of mechanical drive; where a signal name

accompanies the symbol, the arrow indicates the direction of the electric

signal.

The expression "turn on the power" means flipping on the power switch, closing the front

door, and closing the delivery unit door, which results in supplying the machine with

power.

2. In the digital circuits, '1'is used to indicate that the voltage level of a given signal is

"High", while '0' is used to indicate "Low".(The voltage value, however, differs from

circuit to circuit.) In addition, the asterisk (*) as in "DRMD*" indicates that the DRMD

signal goes on when '0'.

In practically all cases, the internal mechanisms of a microprocessor cannot be checked

in the field. Therefore, the operations of the microprocessors used in the machines are

not discussed: they are explained in terms of from sensors to the input of the DC

controller PCB and from the output of the DC controller PCB to the loads.

The descriptions in this Service Manual are subject to change without notice for product

improvement or other purposes, and major changes will be communicated in the form of

Service Information bulletins.

All service persons are expected to have a good understanding of the contents of this

Service Manual and all relevant Service Information bulletins and be able to identify and

isolate faults in the machine."

Contents

Contents

Chapter 1 Specifications

1.1 Product composition .................................................................................................. 1-1

1.1.1 Product Composition (USA)............................................................................... 1-1

1.2 Specifications............................................................................................................. 1-2

1.2.1 Specifications ...................................................................................................... 1-2

1.2.2 PCL Printer Driver .............................................................................................. 1-3

1.2.3 PS Printer Driver ................................................................................................. 1-4

Chapter 2 Functions

2.1 New Function............................................................................................................. 2-1

2.1.1 Canon Driver Information Assist Service (DIAS) .............................................. 2-1

2.1.2 FTP Printing........................................................................................................ 2-3

2.1.3 PS-MODE ........................................................................................................... 2-6

2.1.4 Halftone Settings................................................................................................. 2-6

2.1.5 Secured Print Jobs ............................................................................................... 2-7

2.1.6 Up to 50 mm of Gutter...................................................................................... 2-11

2.1.7 Processing on System........................................................................................ 2-13

Chapter 3 Installation

3.1 Points to Note About Installation............................................................................... 3-1

3.1.1 Precaution for installation ................................................................................... 3-1

3.2 Checking components................................................................................................ 3-2

3.2.1 Checking the Contents ........................................................................................ 3-2

3.3 Installation procedure ................................................................................................ 3-4

3.3.1 Installation........................................................................................................... 3-4

Chapter 1

Specifications

Contents

Contents

1.1 Product composition...................................................................................1-1

1.1.1 Product Composition (USA) ...............................................................1-1

1.2 Specifications .............................................................................................1-2

1.2.1 Specifications ...................................................................................... 1-2

1.2.2 PCL Printer Driver ..............................................................................1-3

1.2.3 PS Printer Driver .................................................................................1-4

1.1 Product composition

Chapter 1

1.1.1 Product Composition (USA)

Multi-PDL Printer Kit-E1 USA

[1]

[4]

[1] Boot ROM (type N)..............................................................................1 pc.

[2] User Software CD-ROM Unit (English)..........................................1 pc.

[3] N/W ScanGear CD-ROM (English).................................................1 pc.

[4] Release Note (English)....................................................................1 pc.

[5] N/W Quick Start Guide (English).....................................................1 pc.

[6] User's Manual CD-ROM (English)..................................................1 pc.

[2]

[5]

F-1-1

[3]

[6]

0008-5248

1-1

Chapter 1

1.2 Specifications

1.2.1 Specifications

The main specifications and features of the kit are as shown below.

<Characteristics>

- printing is virtually immediate

- output is close to screen display

T-1-1

Specifications

Data processing

resolution

Effective print area

Supported operating

systems

PCL main scanning direction: 1/6 inch

PS3 main scanning direction: 2.5mm

600 dpi

sub scanning direction: 1/6 inch

sub scanning direction: 2.5mm

Windows 2000 Professional/Server/Advanced

Server

Windows XP Home Edition/Professional

Windows Server 2003 Stadard Edition/Enterprise

Edition

0008-5245

Windows 98/98SE/ME

Windows NT4.0 Workstation/Server

Paper size default papers

1-2

Non-default paper

T-1-2

User-defined paper

PCL minimum 90.53 mm× 131.53 mm

maximum 288.53 mm × 423.53 mm

Chapter 1

PS3

minimum

maximum

94.00 mm × 135.00 mm

292.00 mm × 427.00 mm

Note:

The value in parentheses indicates the area in

mm2.

- The height and width can be specified by 1/10 mm(Except US)or 1/100 inch(US).

- The height must be equal to or greater than width.

1-3

Chapter 1

1.2.2 PCL Printer Driver

FONT HANDLING:

・PCL5e/5c

HP-GL/2 Mode

Texts are handled in the PCL mode, or in the HP-GL/2 mode if:

1. Characters are clipped.

2.Characters are rotated.

Supported typefaces include:

1. Standard

2. Italic

3. Bold

4. Bold Italic

Raster Mode

Use of a device font is determined by the driver setting.

If a device font is used, the Raster Mode will handle data the same as the HP-GL/2

Mode.

If not, the following restrictions will be imposed.

*GDI Raster Fonts unavailable 1 byte fonts such as Courier, MS Sans Serif, MS

Serif, etc.

*GDI Vector Fonts available 1 byte fonts such as Modern, Roman, Script, etc.

*TrueType Fonts available 1 byte fonts such as Arial, Courier New, Symbol, Times

New Roman, etc.

0008-5666

・PCL6

PCL6 controls the texts if:

1.Characters are enlarged or reduced.

2.Characters are rotated.

3.Characters are clipped.

NOTE:

GDI Vector Fonts and TrueType Fonts become available only after added to Windows.

1-4

Chapter 1

1.2.3 PS Printer Driver

Target Printer:

Apple LaserWriter8500 for command

OKI MICROLINE800PS2LT for print quality

Target PDL:

Adobe PostScript Level3 3011

Note. Omit advanced feature of RedBook.

FONT HANDLING:

PS3

PostScript PDL boards support the following font types.

Type 0, 1, 2, 3, 4, 5, 6, 9, 10, 11, 14, 32 and 42

IDFontType 0, 1, 2 and 4

0008-5667

1-5

Chapter 2

Functions

Contents

Contents

2.1 New Function.............................................................................................2-1

2.1.1 Canon Driver Information Assist Service (DIAS) .............................. 2-1

2.1.2 FTP Printing........................................................................................2-3

2.1.3 PS-MODE ...........................................................................................2-6

2.1.4 Halftone Settings.................................................................................2-6

2.1.5 Secured Print Jobs ...............................................................................2-7

2.1.6 Up to 50 mm of Gutter......................................................................2-11

2.1.7 Processing on System........................................................................2-13

2.1 New Function

Chapter 2

2.1.1 Canon Driver Information Assist Service (DIAS)

This is a subset version of the Netspot Suite Service, supporting Driver only: we have

selected Driver's functions (mainly, the functions to acquire Device configuration

information) and redesigned them. The DIAS has the following functions:

- To acquire Device configuration information (acquisition when setting up Printer

Property.)

- To acquire calibration information (acquisition when setting up Printer Property and

printing by the color LBP, Color iR, and etc.)

- To make recognition in department-control printing (communication when setting up

Printer Property or when making a department-control print)

Main structure of DIAS

DIAS (DLL): It is a module loaded on Driver

DIAS (Service): It does a service of installation on printer server when using a shared

printer (resident process)

CBT: It is a module group to control a local port, such as Centronics Cable or USB

H-VDC: It is a module group which are needed for the driver function in DIAS.

Characteristics of DIAS

- Local printer can acquire the configuration information in DIAS (DLL) only.

Local printer means a printer that is "Peer to Peer" connected with Local PC via LPR/IPP/

Centronics Cable/USB and that Spooler (Print queue) appears on the Local PC.

0008-5246

- Shared printer needs to have DIAS (Service) installed on printer server.

The installation of DIAS (Service) must be done via Driver installer.

Shared printer means a printer whose Spooler (Print queue) appears on the printer server

(Remote PC).

- However, in some cases, DIAS (Service) needs to be installed for Local Port connection.

(See "Help" > "Troubleshoot the acquisition of configuration information".

1, WinNT4.0 OS Family (All)/ At the time of Local Port connection (LPT)

2, Win2k Server OS Family (Except Professional)/At the time of Local Port connection

2-1

(LPT/USB) and Terminal Service introduction

3, WinXP Home/Professional Edition/ServerOS 2003 Family (X86:All)/ At the time of

Local Port connection (LPT/USB) and Terminal Service introduction

About the version indication

The same Driver version indication as the one via Netspot Suite Service appears only when

communicating with Device via DIAS (Service) (i.e., when connected through a shared

printer).

Compatibility of DIAS and Netspot Suite Service

DIAS and Netspot Suite Service are compatible and independent. Driver supporting DIAS

does not use Netspot Suite Service even if it is installed.

Cautions when using DIAS

CBT controls all access to Local Port; both DIAS (DLL/Service) and NetSpot Suite Service

use CBT to access Local Port from the same PC.

CBT was installed only on Netspot Suite Service before; it is automatically uninstalled in

response to uninstalling the existing NetSpot Suite Service. Follow the procedures below

when uninstalling the former versions of NetSpot Suite Service v3.40 and when uninstalling

JobMonitor v4.20 and former.

- Reinstall DIAS after the uninstallation is complete. (Reinstallation of DIAS is enabled via

Installer.)

- Update NetSpot Suite Service to the latest version (v3.40 and later).

Former versions of NetSpot Suite Service v3.40

PS Printer Driver v2.10 and former

PCL5e Printer Driver v6.11 and former

PCL5c Printer Driver v6.11 and former

PCL6 Printer Driver v6.11 and former

UFR Printer Driver v1.10 and former

JobMonitor v4.10 and former

About a file name of the CBT module

Following files are installed in the 'c:\Windows\system' folder. (For Windows XP/Windows

Chapter 2

2000/NT/Server2003, this folder name is to be '%SystemRoot%\system32'.)

AuPort.exe

NBCBTNT.dll / NBCBT95.dll

NBPORTNT.exe / NBPORT95.exe

NBLOCALT.dll

nbcbtspt.dat

Method of confirming when CBT is deleted

The following message is displayed.

"Failed to obtain device information Make sure no printer error occurred and printout port

setting is correct."

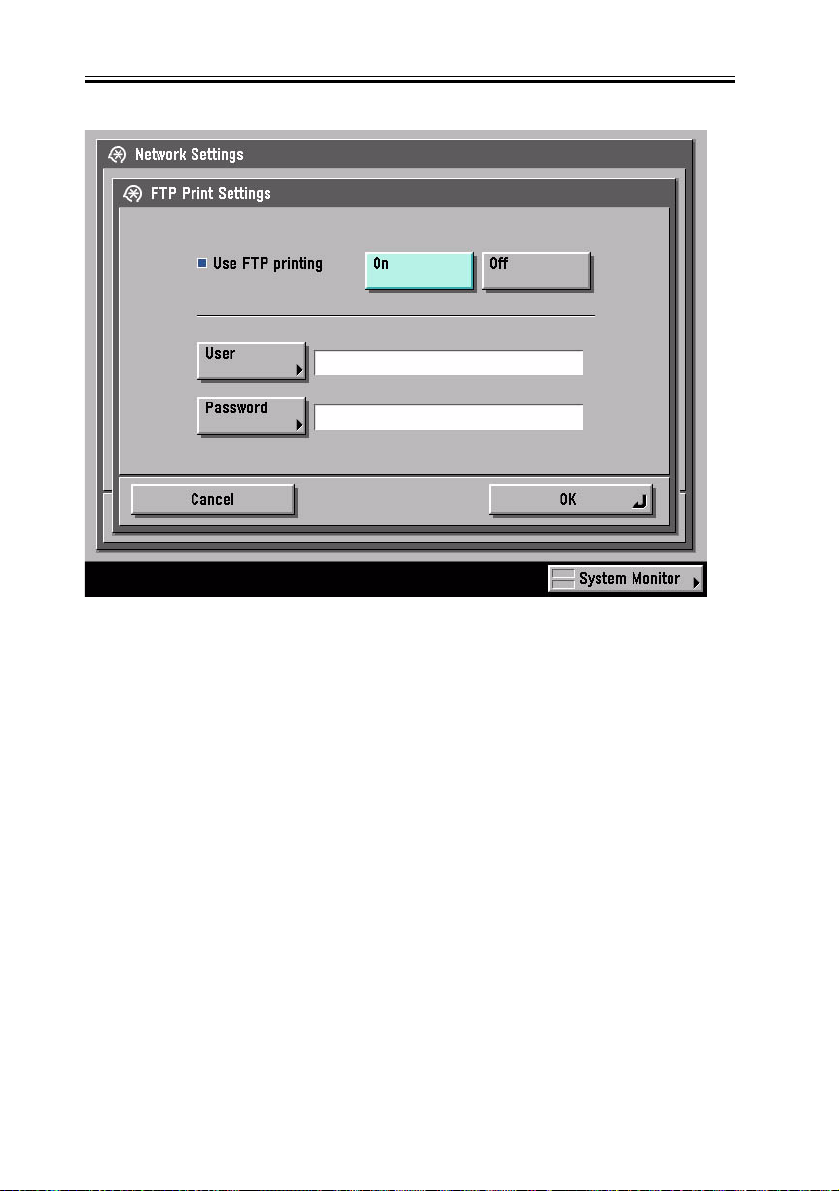

2.1.2 FTP Printing

This device provides a FTP server for receiving print data. The device can accept print jobs

sent in FTP from client PCs. This is called FTP printing, a new feature first employed on

iRC 6800. To use this feature, the FTP Print option must be selected. It is selected by

default. You can access the option by pressing Ad Func, System Settings, Network Settings,

TCP/IP Settings, and FTP Print Settings buttons. In FTP Print Settings screen, only one pair

of a user name and password can be entered for the user who can log in to the FTP server.

No settings are made for both of the fields by default.

0008-5247

2-3

Chapter 2

F-2-1

Commands

The FTP server complies with the RFC 959 -- File Transfer Protocol -- but provides only

printing function. Thus the server does not support other functions required as a RFC 959

compliant server. The commands available for the FTP client are "user," "password," "bin,"

"put," "bye," "hash," and "help." There is no use of other commands since the server does

not provide functions other than printing. The following lists the notes to use the

commands.

- To send print data with the command "put," set the mode to the binary mode using the

command "bin." In the ascii mode, the data cannot be sent with the command "put."

- If the user and password fields are blank, any user with any password can log in. If the

user name "anonymous" is used, any character string can be entered as the password. The

device displays the string in User filed of Log screen.

2-4

- This function is featured mainly to print prn files output from PDL drivers. The device

processes text files and the like as it receives data in LPR (and does not properly print

depending on settings.) The device of PostScript-compatible model can print PDF files,

compatible with PDF V1.3.

The following shows a command specification example, which you will connect the device

of the IP address "172.16.181.131" in FTP with the user name "test" and the password "test"

and print the file "test.prn" in the root directory of the drive C on the client PC.

C:\>ftp 172.16.181.131

Connected to 172.16.181.131.

220 Connection established.

User (172.16.181.131:(none)): test

331 Password required to login.

Password: Note: The password is not displayed.

230 User test logged in.

ftp> bin

200 Type set to IMAGE (binary).

ftp> put c:\test.prn

200 PORT command successful.

150 Opened BINARY data connection for file transfe

226 Transfer complete.

ftp: 15871 bytes sent in 0.00Seconds 15871000.00Kb

ftp> bye

221 Server closing down connection.

C:\>

Number of Connections and Used Ports

The maximum number of concurrent connections is three. If a user attempts to connect to

the FTP server with which three connections have been established, the user cannot log in

and fails in connection. The default port for the FTP server is 21. There is no measure

provided to change the port.

The control port time-out is set to 300 seconds. You need to re-connect to the server if you

Chapter 2

have left the connection for 300 seconds or more after logging in. The data port time-out is

60 minutes. If a data transmission takes more than 60 minutes, the connection is

automatically disconnected.

2.1.3 PS-MODE

Halftone compatibility for iR2200/3300/2800

PS3 Only - Service Mode Level 2

COPIER > OIPTION > USER > PS-MODE

0 = iR4570/3570/2870/2270

1 = iR2200/3300/2800

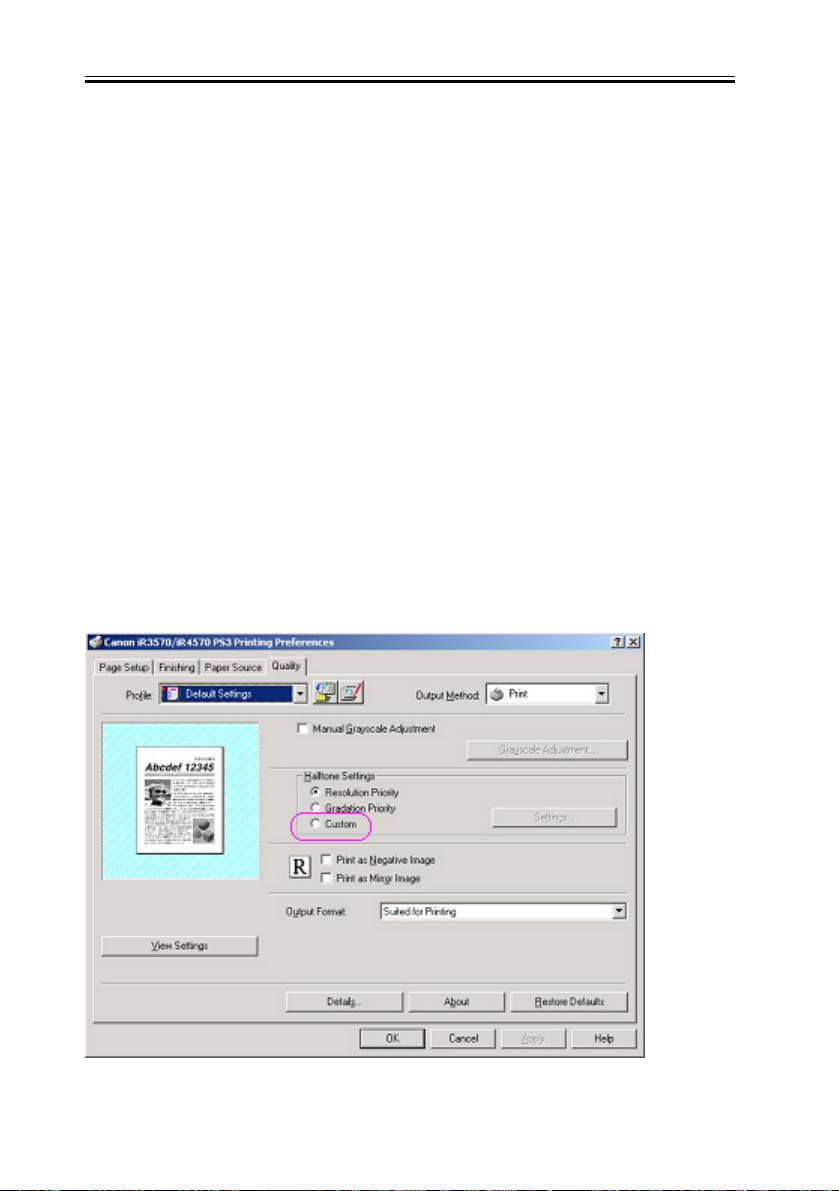

2.1.4 Halftone Settings

Halftone Settings (PS B&W printers)

0008-5388

0008-5390

F-2-2

2-6

Chapter 2

F-2-3

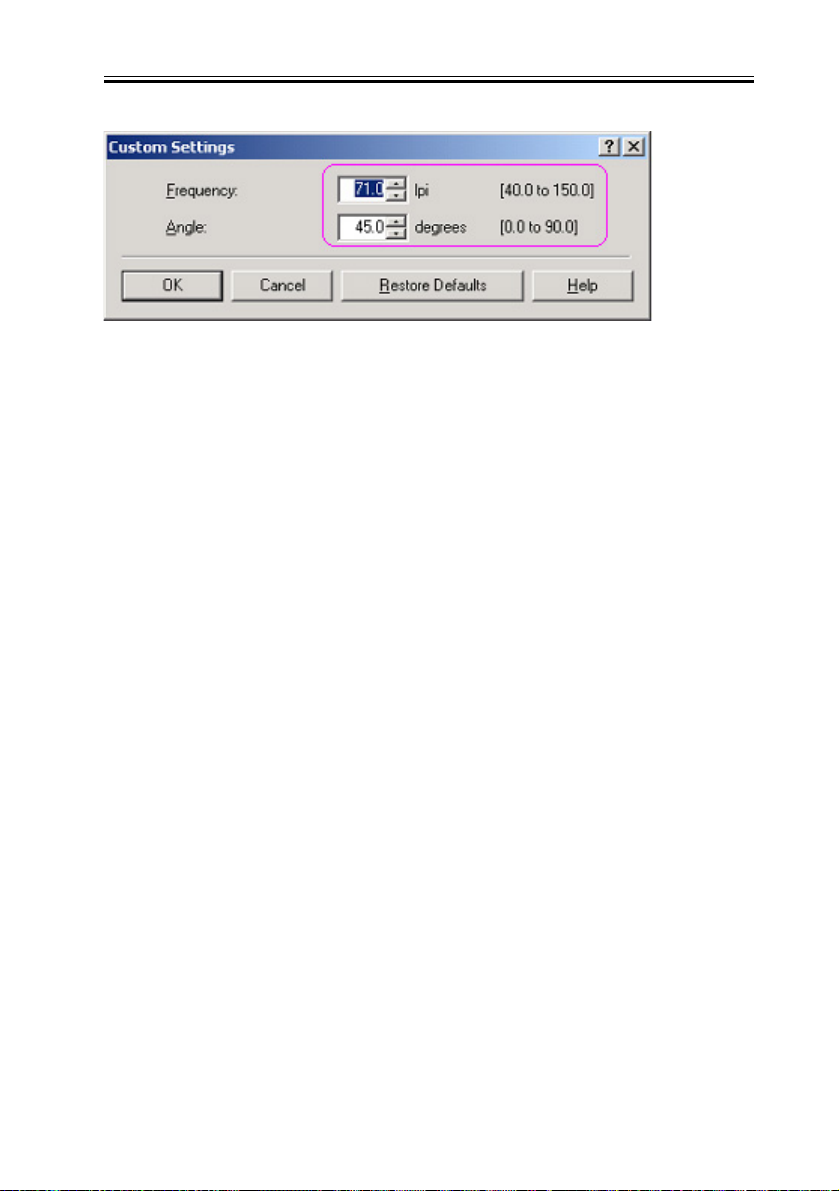

Only for monochrome PS printers, it will be possible to specify the halftone screen

frequency and angle.

For that, in the “Halftone Settings” section in the “Quality” tab, the “Custom” radio button

and the “Settings” buttonwill be provided.

The “Settings” button will be disabled by default and will be enabled by selecting the

“Custom” radio button.

Clicking the “Settings” button will open the “Custom Settings” dialog to set the halftone

screen frequency and angle.

The “Frequency” spin box will default to a value of 71.0 and will accept a value between

40.0 and 150.0.

The “Angle” spin box will default to a value of 45.0 and will accept a value between 0.0

and 90.0.

2.1.5 Secured Print Jobs

Overview:

Secured Print is the function that a password is provided to the PDL print job and it is sent

to the device. Then, it is rasterized on the device side, saved in the image server and output

by entering the password from the device’s panel. This function is used when dealing with

the documents which you do not want other people to see, such as confidential documents.

a) Password is provided.

In order to conduct the Secured Print, the printer driver requires the user to enter the

password from GUI. This password is provided to the print job and it is sent to the device.

This function can be conducted by using CPCA protocol.

0008-5624

2-7

Chapter 2

b) Job execution and pending

PDL print job sent to the device as the Secured Print job is compiled on the job queue like

the normal PDL print job. Then, it is rasterized by PDL interpreter, saved in the image

server as the document image file and becomes pending here. However, all job information,

such as paper supply/output, the number of copies and finishing information remains.

c) Job started by entering the password

If the Secured Print job is pending, the display indicating the pending state appears on the

job status screen of the panel. If you select this job from the panel, you are required to enter

the password. When the password you entered is same as the password provided from the

printer driver, the pending job will be started. When the password is different, the job is

treated as an error, so it is not started and it remains in the pending state. Entering the

password to start the job cannot be executed before the Secured Print job transfers to the

pending state.

d) Output

The started Secured Print job is output to the printer engine with the top priority. This top

priority means that if the jobs can be changed in priority order, the Secured Print job can be

prioritized. This job is proceeded according to all job information specified by the printer

driver, etc., such as paper supply/output, the number of copies and finishing information.

When the processing is completed and all documents are output, the documents and job

information stored in the image server are deleted.

e) Operations for Secured Print jobs

Like other print jobs, Secured Print jobs can be deleted, interrupted, restarted and promoted

by operating from the status screen of the print job. Regarding these operations, the device

side does not distinguish from operations of the normal PDL job. That is, the password entry

is required only when the job is output. If you interrupt or restart the job during outputting,

the password setting and matching are not conducted.

f) Automatically delete of Secured Print Jobs

When Secured Print Job is continuing being suspended for a long time, apparatus deletes a

job automatically.

There are options for automatic job deletion time -- 1, 2, 3, 6, 12, and 24 hours. With a view

of security and memory usage, no option longer than 1 day is available. The elapsed time

starts after all the processes for the PDL data and the rendering for all the image data, for

2-8

which Secured Print is specified, are finished.

g) Specifications and Limitations on Secured Print Jobs

The limitations on Secured Print jobs are listed as follows.

- Once data of a Secured Print job is printed, it is immediately deleted and cannot be printed

any more.

- If the power for the controller is shut down, unprinted data of a Secured Print job is deleted

from the printer.

- All the job information, represented by the paper source and output information,

information of the number of copies, and finishing information, cannot be changed on the

printer.

- If the entire raster information for a Secured Print job cannot be stored in the image server

(hard disk drive) due to insufficient memory, the job results in an error, to be deleted.

- Up to 50 Secured Print jobs of image data being rendered and left unprinted can be stored.

F-2-4

F-2-5

F-2-6

Chapter 2

F-2-7

2.1.6 Up to 50 mm of Gutter

Up to 50 mm of the gutter can be specified. The gutter can be adjusted within a range from

0008-5626

2-11

Chapter 2

-50 mm to 50 mm in 1 mm increments. The local UI and the print driver have the controls

for the gutter settings.

The image is shifted to the width value specified for gutter, making a margin. If the shift

causes the image to overflow from the printable area, the overflowing area is missing from

the print results. The overflowing image will not be reduced to fit into the printable area.

F-2-8

F-2-9

The gutter width range changed to 0-50 mm.

2-12

US: 0.0 to 2.0 inches

UK: 0.0 to 50.0 mm

Chapter 2

2.1.7 Processing on System

Processing after Power Shutdown

If the power is shut down during PDL data processing, all the image data temporarily stored

in the hard disk drive to be printed or stored in Mail Boxes are destroyed and the jobs are

canceled. PDL data stored in the hard disk drive immediately before a power shutdown are

destroyed as the power is shut down. Processing the data of those, therefore, will not resume

when the power is turned on after the shutdown. Jobs interrupted by a power shutdown will

be displayed in the Log list with the End Code “NG (#852).”

0008-5622

2-13

Chapter 3

Parts

Procedure

Replacement

Contents

Contents

3.1 Points to Note About Installation ...............................................................3-1

3.1.1 Precaution for installation ...................................................................3-1

3.2 Checking components ................................................................................3-2

3.2.1 Checking the Contents ........................................................................ 3-2

3.3 Installation procedure.................................................................................3-4

3.3.1 Installation...........................................................................................3-4

3.1 Points to Note About Installation

Chapter 3

3.1.1 Precaution for installation

To install the Kit, you will need a separately available expansion RAM (256 MB) (Except

USA).

0007-7266

3-1

Chapter 3

3.2 Checking components

3.2.1 Checking the Contents

Multi-PDL Printer Kit-E1 USA

[1]

[4]

[1] Boot ROM (type N)..............................................................................1 pc.

[2] User Software CD-ROM Unit (English)..........................................1 pc.

[3] N/W ScanGear CD-ROM (English).................................................1 pc.

[4] Release Note (English)....................................................................1 pc.

[5] N/W Quick Start Guide (English).....................................................1 pc.

[6] User's Manual CD-ROM (English)..................................................1 pc.

Multi-PDL Printer Kit-E1 EUR/OTH

[2]

[5]

F-3-1

[3]

[6]

0007-7268

3-2

Chapter 3

[3]

[6]

[4]

[1]

[2]

[5]

F-3-2

[1] BootROM (type N)............................................................................................1 pc.

[2] User Software CD-ROM Unit (English, French, German, Italian, Spanish).....1 pc.

[3] N/W ScanGear CD-ROM (English, French, German, Italian, Spanish)............1 pc.

[4] Release Note (English, French, German, Italian)...............................................1 pc.

[5] N/W Quick Start Guide (English, French, German, Italian)..............................1 pc.

[6] User's Manual CD-ROM (English, French, German, Italian)............................1 pc.

3-3

Chapter 3

3.3 Installation procedure

3.3.1 Installation

0007-7276

1. Turning Off the Host Machine

Before starting the work, be sure to perform the following on the host machine in strict

order:

1. Hold down on the control panel power switch for 3 sec or more.

2. Go through the instructions indicated on the control panel touch panel (for shutdown

sequence) so that the host machine's main power switch may be turned off.

3. Turn off the main power switch.

4. Disconnect the power cable (from the wall outlet).

[1]

ON/OFF

3-4

[3][2]

F-3-3

[4]

2. Installation

1) Remove the 4 screws [1].

2) Loosen the 2 screws [2].

[1]

[1]

[2]

F-3-4

3) Pull the face cover [1] in upward direction to detach.

Chapter 3

[1]

F-3-5

3-5

Chapter 3

4) Push the locking lever [1] to detach the boot ROM [2].

F-3-6

5) Fit the included boot ROM [1] in place.

F-3-7

6) Attach the face cover using 4 screws.

7) Tighten the 2 screws loosened in step 2).

8) Connect the host machine's power cable (to the wall outlet).

9) Turn on the main power swish.

3. Checking the Installation

Make the following selections, and check the state of the following bits: COPIER >

ACC-STS > PDL-FNC1.

111x xxxx xxxx xxxx (0: OFF; 1: ON)

In the case of the PDL-FNC1, bits 31 through bits 16 are indicated.

Be sure that the following bits are '1': 31, 30, 29.

3-6

SERVICE

MANUAL

imageRUNNER

iR2270/2870/

3570/4570

UFRII

Printer Kit-E3

COPYRIGHT 2004 CANON INC. CANON imageRUNNER UFRII Printer Kit-E3 REV. 0 PRINTED IN U.S.A.

DU7-1133-000

SEPT. 2004

REV. 0

Application

This manual has been issued by Canon Inc. for qualified persons to learn technical theory, installation,

maintenance, and repair of products. This manual covers all localities where the products are sold. For

this reason, there may be information in this manual that does not apply to your locality.

Corrections

This manual may contain technical inaccuracies or typographical errors due to improvements or changes

in products. When changes occur in applicable products or in the contents of this manual, Canon will

release technical information as the need arises. In the event of major changes in the contents of this

manual over a long or short period, Canon will issue a new edition of this manual.

The following paragraph does not apply to any countries where such provisions are inconsistent with

local law.

Trademarks

The product names and company names used in this manual are the registered trademarks of the

individual companies.

Copyright

This manual is copyrighted with all rights reserved. Under the copyright laws, this manual may not be

copied, reproduced or translated into another language, in whole or in part, without the written consent

of Canon Inc.

COPYRIGHT © 2001 CANON INC.

Printed in Japan

Caution

Use of this manual should be strictly supervised to avoid disclosure of confidential information.

Introduction

Symbols Used

This documentation uses the following symbols to indicate special information:

Symbol Description

Indicates an item of a non-specific nature, possibly classified as Note,

Caution, or Warning.

Indicates an item requiring care to avoid electric shocks.

Indicates an item requiring care to avoid combustion (fire).

Indicates an item prohibiting disassembly to avoid electric shocks or

problems.

Indicates an item requiring disconnection of the power plug from the electric

outlet.

Memo

REF.

Indicates an item intended to provide notes assisting the understanding of the

topic in question.

Indicates an item of reference assisting the understanding of the topic in

question.

Provides a description of a service mode.

Provides a description of the nature of an error indication.

Introduction

The following rules apply throughout this Service Manual:

1. Each chapter contains sections explaining the purpose of specific functions and the

relationship between electrical and mechanical systems with reference to the timing of

operation.

In the diagrams, represents the path of mechanical drive; where a signal name

accompanies the symbol, the arrow indicates the direction of the electric

signal.

The expression "turn on the power" means flipping on the power switch, closing the front

door, and closing the delivery unit door, which results in supplying the machine with

power.

2. In the digital circuits, '1'is used to indicate that the voltage level of a given signal is

"High", while '0' is used to indicate "Low".(The voltage value, however, differs from

circuit to circuit.) In addition, the asterisk (*) as in "DRMD*" indicates that the DRMD

signal goes on when '0'.

In practically all cases, the internal mechanisms of a microprocessor cannot be checked

in the field. Therefore, the operations of the microprocessors used in the machines are

not discussed: they are explained in terms of from sensors to the input of the DC

controller PCB and from the output of the DC controller PCB to the loads.

The descriptions in this Service Manual are subject to change without notice for product

improvement or other purposes, and major changes will be communicated in the form of

Service Information bulletins.

All service persons are expected to have a good understanding of the contents of this

Service Manual and all relevant Service Information bulletins and be able to identify and

isolate faults in the machine."

Contents

Contents

Chapter 1 Specifications

1.1 Product composition .................................................................................................. 1-1

1.1.1 Product Composition (USA)............................................................................... 1-1

1.2 Specifications............................................................................................................. 1-2

1.2.1 Specification........................................................................................................ 1-2

1.2.2 UFR II Printer Driver .......................................................................................... 1-3

Chapter 2 Functions

2.1 New Function............................................................................................................. 2-1

2.1.1 Flow of Image Data ............................................................................................ 2-1

2.1.2 Canon Driver Information Assist Service (DIAS) .............................................. 2-1

2.1.3 FTP Printing........................................................................................................ 2-3

2.1.4 Secured Print Jobs ............................................................................................... 2-6

2.1.5 Up to 50 mm of Gutter...................................................................................... 2-10

2.1.6 Load Balancing ................................................................................................. 2-12

2.1.7 Processing on System........................................................................................ 2-13

2.1.8 Sleep Processing ............................................................................................... 2-13

Chapter 3 Installation

3.1 Points to Note About Installation............................................................................... 3-1

3.1.1 Precaution for installation ................................................................................... 3-1

3.2 Checking components................................................................................................ 3-2

3.2.1 Checking the Contents(USA).............................................................................. 3-2

Chapter 1

Specifications

Contents

Contents

1.1 Product composition...................................................................................1-1

1.1.1 Product Composition (USA) ...............................................................1-1

1.2 Specifications .............................................................................................1-2

1.2.1 Specification........................................................................................1-2

1.2.2 UFR II Printer Driver ..........................................................................1-3

1.1 Product composition

Chapter 1

1.1.1 Product Composition (USA)

UFR II Printer Kit-E3

[1]

[4]

[1] BOOT ROM(type P)................................1 pc.

[2] User Software CD-ROM..........................1 pc.

[3] N/W ScanGear CD-ROM.........................1 pc.

[4] Release Note.............................................1 pc.

[5] N/W Quick Start Guide.............................1 pc.

[6] User Manual CD-ROM.............................1 pc.

[2]

[5]

F-1-1

0008-5508

[3]

[6]

1-1

Chapter 1

1.2 Specifications

1.2.1 Specification

0008-5607

The UFR II assigns print processing loads to the print driver and the print controller for

high-speed, low-cost outputs.

Advantages

- While the features are enhanced, the memory usage can be saved supporting both page and

band descriptions.

- Balancing the data processing loads of the driver and controller allows high-speed outputs.

T-1-1

Specification

UFR II

Data processing

600dpi

Effective print main scanning:2.5mm

Supported

operating systems

sub scanning:2.5mm

Windows 2000 Professional/Server/Advanced Server

Windows XP Home Edition/Professional

Windows Server 2003 Standard Edition/Enterprise Edition

Paper size default papaers

The UFR II print driver requires 2.5 mm of the top, bottom, left, and right margins.

1-2

Chapter 1

F-1-2

-Even if Print with Upper Left of Sheet as Starting Point option is selected, marginal areas

of the data for a page are missing in some print results. To solve this problem, adjust the

scaling so that the data fit into the printable area and print the data again.

1.2.2 UFR II Printer Driver

Support Environment (OS/Software)

Windows 2000 Professional/Server

Windows XP Home Edition/Professional

Windows Sever 2003 (32bit edition)

T-1-2

Windows 2000 Professional/Server

CPU Intel Pentium 133MHz or better processor

Memory32MB or larger (Professional) / 128MB or larger (Server)

HDD 850MB or larger (Professional) / 1GB or larger (Server)

0008-5512

1-3

Chapter 1

CPU Intel Pentium 233MHz or better processor

Memory64MB or larger

HDD 1.5GB or larger

CPU Intel Pentium 233MHz or better processor

Memory256MB or larger

HDD 1.5GB or larger

Windows XP Home Edition/Professional Edition

Windows Server 2003 Standard Edition/Enterprise Edition

Font Handling:

Device fonts are not used as the printing uses the UFR II driver.

GDI raster fonts cannot be used – e.g.,

One Byte - Courier, MS Sans Serif, and MS Serif.

Two Byte - FixedSys、System、Small Fonts、Terminal

GDI vector fonts can be used – e.g.,

One Byte - Modern, Roman, and Script.

TureType fonts can be used – e.g.,

One Byte - Arial、Courier New、Symbol、Times New Roman

Note.

Each font becomes usable by the font addition to Windows.

Paper Size:

1-4

T-1-3

Paper Name Paper Size (mm)

Width length

A3 297.0 420.0

A4 210.0 297.0

A5 148.5 210.0

11 x 17 279.4 431.8

LEGAL 215.9 355.6

LETTER 215.9 279.4

STATEMENT 139.7 215.9

EXECUTIVE 184.2 266.7

EXEC 184.2 266.7

COM10 104.7 241.3

MONARCH 98.4 190.5

ISO-C5 162.0 229.0

Chapter 1

ISO-B5 176.0 220.0

Non-default paper:

T-1-4

User-defined paper

UFR II minimum 140.0 mm × 182.0 mm

maximum 297.0 mm × 432.0 mm

- The height must be equal to or greater than width.

Area-Specific Paper Sizes:

In addition to default paper sizes (A4/LTR) and user-defined paper sizes, the printer driver

supports area-specific paper sizes (e.g., Officio), and it handles these area-specific paper

sizes as user-defined paper sizes, requiring the user to register them in advance of use. To

1-5

Chapter 1

do so, see the instructions on registering user-defined paper sizes for individual operating

systems.

When an area-specific paper size is manually set up under [Form to Tray Assignment] of

the driver UI, or if the size obtained by running dynamic configuration happens to be an

area-specific paper size, the driver operates in the corresponding mode. After performing

all associated internal operations, the driver runs a check of area-specific paper sizes stored

as user defined paper sizes, and handles any matching paper as a default paper size (special

paper ID) instead of as a user-defined paper size. Moreover, the driver permits registration

of multiple area-specific paper sizes, treating them as a separate paper group. The driver UI

handles them using specifications designed for LTR paper, permitting the use of finisher

functions, which were previously offered for user-defined paper sizes (except the use of the

middle binding function). Although it will permit all settings, the printer unit may ignore

some of the settings. (The printer driver will simply ignore them, not issuing conflicts.)

T-1-5

Paper size

Govermment Letter

Govermment Legal

Foolscap

Australian Foolscap

Oficio

Folio

Ecuadorian Oficio

Aegentine Oficio

Argentine Letter

Bolivian Oficio

Mexican Oficio

Supported Paper Types:

1-6

Dimensions

Feed

Direction

G_LTR 267.0 203.0

G_LBL

FLSP 330.0 216.0

A_FLSP

OFI 317.0 216.0

FOLIO 330.0 210.0

E_OFI 320.0 220.0

A_OFI 340.0 220.0

A_LTR 220.0 280.0

B_OFI 355.0 216.0

M_OFI 341.0 216.0

330.0 267.0

337.0 206.0

Width

Paper Type Paper Size

Chapter 1

T-1-6

PLAIN

COLOR

A3,B4,A4/A4R,B5,B5R,A5R,11x17,LGL.LTR/

LTRR,STMTR,EXEC,Officio,User-defined paper

RECYCLED

PREPUNCHED

HEAVY

BOND

A3,B4,A4/A4R,B5,B5R,A5R,11x17,LGL.LTR/

LTRR,STMTR,EXEC,User-defined paper

LABELS

Tracing Paper

OHP A4,LTR

ENVELOPE COM10,MONARCH,C5ISO,B5ISO,DL

Finishing:

T-1-7

Finisher Rotate Shift Staple Punch Saddle

None OK N/A N/A N/A N/A

Inner2way Tray OK N/A N/A N/A N/A

Finisher-S1 N/A OK OK OK N/A

Finisher-Q3 N/A OK OK OK N/A

Saddle Finisher-Q4 N/A OK OK OK OK

N/A : not available

1-7

Chapter 2

Functions

Contents

Contents

2.1 New Function.............................................................................................2-1

2.1.1 Flow of Image Data ............................................................................2-1

2.1.2 Canon Driver Information Assist Service (DIAS) .............................. 2-1

2.1.3 FTP Printing........................................................................................2-3

2.1.4 Secured Print Jobs ...............................................................................2-6

2.1.5 Up to 50 mm of Gutter......................................................................2-10

2.1.6 Load Balancing .................................................................................2-12

2.1.7 Processing on System........................................................................2-13

2.1.8 Sleep Processing................................................................................2-13

2.1 New Function

Chapter 2

2.1.1 Flow of Image Data

0008-5592

The following is a diagram showing the flow of image data:

[ PS/PCL Image Data Flow ]

LIPS LX

Driver

PC

Controller

UFR II

interpreter

Work

Memory

DL

Memory

Renderer

Page

Spool

Memory

ENGINE

F-2-1

2.1.2 Canon Driver Information Assist Service (DIAS)

0008-5590

This is a subset version of the Netspot Suite Service, supporting Driver only: we have

selected Driver's functions (mainly, the functions to acquire Device configuration

information) and redesigned them. The DIAS has the following functions:

- To acquire Device configuration information (acquisition when setting up Printer

Property.)

- To acquire calibration information (acquisition when setting up Printer Property and

printing by the color LBP, Color iR, and etc.)

- To make recognition in department-control printing (communication when setting up

Printer Property or when making a department-control print)

Main structure of DIAS

DIAS (DLL): It is a module loaded on Driver

DIAS (Service): It does a service of installation on printer server when using a shared

printer (resident process)

CBT: It is a module group to control a local port, such as Centronics Cable or USB

H-VDC: It is a module group which are needed for the driver function in DIAS.

2-1

Chapter 2

Characteristics of DIAS

- Local printer can acquire the configuration information in DIAS (DLL) only.

Local printer means a printer that is "Peer to Peer" connected with Local PC via LPR/IPP/

Centronics Cable/USB and that Spooler (Print queue) appears on the Local PC.

- Shared printer needs to have DIAS (Service) installed on printer server.

The installation of DIAS (Service) must be done via Driver installer.

Shared printer means a printer whose Spooler (Print queue) appears on the printer server

(Remote PC).

- However, in some cases, DIAS (Service) needs to be installed for Local Port connection.

(See "Help" > "Troubleshoot the acquisition of configuration information".

1, WinNT4.0 OS Family (All)/ At the time of Local Port connection (LPT)

2, Win2k Server OS Family (Except Professional)/At the time of Local Port connection

(LPT/USB) and Terminal Service introduction

3, WinXP Home/Professional Edition/ServerOS 2003 Family (X86:All)/ At the time of

Local Port connection (LPT/USB) and Terminal Service introduction

About the version indication

The same Driver version indication as the one via Netspot Suite Service appears only when

communicating with Device via DIAS (Service) (i.e., when connected through a shared

printer).

Compatibility of DIAS and Netspot Suite Service

DIAS and Netspot Suite Service are compatible and independent. Driver supporting DIAS

does not use Netspot Suite Service even if it is installed.

Cautions when using DIAS

CBT controls all access to Local Port; both DIAS (DLL/Service) and NetSpot Suite Service

use CBT to access Local Port from the same PC.

CBT was installed only on Netspot Suite Service before; it is automatically uninstalled in

response to uninstalling the existing NetSpot Suite Service. Follow the procedures below

when uninstalling the former versions of NetSpot Suite Service v3.40 and when uninstalling

JobMonitor v4.20 and former.

2-2

Chapter 2

- Reinstall DIAS after the uninstallation is complete. (Reinstallation of DIAS is enabled via

Installer.)

- Update NetSpot Suite Service to the latest version (v3.40 and later).

Former versions of NetSpot Suite Service v3.40

PS Printer Driver v2.10 and former

PCL5e Printer Driver v6.11 and former

PCL5c Printer Driver v6.11 and former

PCL6 Printer Driver v6.11 and former

UFR Printer Driver v1.10 and former

JobMonitor v4.10 and former

About a file name of the CBT module

Following files are installed in the 'c:\Windows\system' folder. (For Windows XP/Windows

2000/NT/Server2003, this folder name is to be '%SystemRoot%\system32'.)

AuPort.exe

NBCBTNT.dll / NBCBT95.dll

NBPORTNT.exe / NBPORT95.exe

NBLOCALT.dll

nbcbtspt.dat

Method of confirming when CBT is deleted

The following message is displayed.

"Failed to obtain device information Make sure no printer error occurred and printout port

setting is correct."

2.1.3 FTP Printing

This device provides a FTP server for receiving print data. The device can accept print jobs

sent in FTP from client PCs. This is called FTP printing, a new feature first employed on

iRC 6800. To use this feature, the FTP Print option must be selected. It is selected by

default. You can access the option by pressing Ad Func, System Settings, Network Settings,

TCP/IP Settings, and FTP Print Settings buttons. In FTP Print Settings screen, only one pair

of a user name and password can be entered for the user who can log in to the FTP server.

No settings are made for both of the fields by default.

0008-5591

2-3

Chapter 2

F-2-2

Commands

The FTP server complies with the RFC 959 -- File Transfer Protocol -- but provides only

printing function. Thus the server does not support other functions required as a RFC 959

compliant server. The commands available for the FTP client are "user," "password," "bin,"

"put," "bye," "hash," and "help." There is no use of other commands since the server does

not provide functions other than printing. The following lists the notes to use the

commands.

- To send print data with the command "put," set the mode to the binary mode using the

command "bin." In the ascii mode, the data cannot be sent with the command "put."

- If the user and password fields are blank, any user with any password can log in. If the

user name "anonymous" is used, any character string can be entered as the password. The

device displays the string in User filed of Log screen.

2-4

Chapter 2

- This function is featured mainly to print prn files output from PDL drivers. The device

processes text files and the like as it receives data in LPR (and does not properly print

depending on settings.) The device of PostScript-compatible model can print PDF files,

compatible with PDF V1.3.

The following shows a command specification example, which you will connect the device

of the IP address "172.16.181.131" in FTP with the user name "test" and the password "test"

and print the file "test.prn" in the root directory of the drive C on the client PC.

C:\>ftp 172.16.181.131

Connected to 172.16.181.131.

220 Connection established.

User (172.16.181.131:(none)): test

331 Password required to login.

Password: Note: The password is not displayed.

230 User test logged in.

ftp> bin

200 Type set to IMAGE (binary).

ftp> put c:\test.prn

200 PORT command successful.

150 Opened BINARY data connection for file transfe

226 Transfer complete.

ftp: 15871 bytes sent in 0.00Seconds 15871000.00Kb

ftp> bye

221 Server closing down connection.

C:\>

Number of Connections and Used Ports

The maximum number of concurrent connections is three. If a user attempts to connect to

the FTP server with which three connections have been established, the user cannot log in

and fails in connection. The default port for the FTP server is 21. There is no measure

provided to change the port.

The control port time-out is set to 300 seconds. You need to re-connect to the server if you

2-5

Chapter 2

have left the connection for 300 seconds or more after logging in. The data port time-out is

60 minutes. If a data transmission takes more than 60 minutes, the connection is

automatically disconnected.

2.1.4 Secured Print Jobs

Overview:

Secured Print is the function that a password is provided to the PDL print job and it is sent

to the device. Then, it is rasterized on the device side, saved in the image server and output

by entering the password from the device’s panel. This function is used when dealing with

the documents which you do not want other people to see, such as confidential documents.

a) Password is provided.

In order to conduct the Secured Print, the printer driver requires the user to enter the

password from GUI. This password is provided to the print job and it is sent to the device.

This function can be conducted by using CPCA protocol.

b) Job execution and pending

PDL print job sent to the device as the Secured Print job is compiled on the job queue like

the normal PDL print job. Then, it is rasterized by PDL interpreter, saved in the image

server as the document image file and becomes pending here. However, all job information,

such as paper supply/output, the number of copies and finishing information remains.

c) Job started by entering the password

If the Secured Print job is pending, the display indicating the pending state appears on the

job status screen of the panel. If you select this job from the panel, you are required to enter

the password. When the password you entered is same as the password provided from the

printer driver, the pending job will be started. When the password is different, the job is

treated as an error, so it is not started and it remains in the pending state. Entering the

password to start the job cannot be executed before the Secured Print job transfers to the

pending state.

0008-5624

d) Output

The started Secured Print job is output to the printer engine with the top priority. This top

priority means that if the jobs can be changed in priority order, the Secured Print job can be

prioritized. This job is proceeded according to all job information specified by the printer

2-6

Chapter 2

driver, etc., such as paper supply/output, the number of copies and finishing information.

When the processing is completed and all documents are output, the documents and job

information stored in the image server are deleted.

e) Operations for Secured Print jobs

Like other print jobs, Secured Print jobs can be deleted, interrupted, restarted and promoted

by operating from the status screen of the print job. Regarding these operations, the device

side does not distinguish from operations of the normal PDL job. That is, the password entry

is required only when the job is output. If you interrupt or restart the job during outputting,

the password setting and matching are not conducted.

f) Automatically delete of Secured Print Jobs

When Secured Print Job is continuing being suspended for a long time, apparatus deletes a

job automatically.

There are options for automatic job deletion time -- 1, 2, 3, 6, 12, and 24 hours. With a view

of security and memory usage, no option longer than 1 day is available. The elapsed time

starts after all the processes for the PDL data and the rendering for all the image data, for

which Secured Print is specified, are finished.

g) Specifications and Limitations on Secured Print Jobs

The limitations on Secured Print jobs are listed as follows.

- Once data of a Secured Print job is printed, it is immediately deleted and cannot be printed

any more.

- If the power for the controller is shut down, unprinted data of a Secured Print job is deleted

from the printer.

- All the job information, represented by the paper source and output information,

information of the number of copies, and finishing information, cannot be changed on the

printer.

- If the entire raster information for a Secured Print job cannot be stored in the image server

(hard disk drive) due to insufficient memory, the job results in an error, to be deleted.

2-7

Chapter 2

- Up to 50 Secured Print jobs of image data being rendered and left unprinted can be stored.

F-2-3

2-8

F-2-4

Chapter 2

2-9

Chapter 2

F-2-5

F-2-6

2-10

Chapter 2

2.1.5 Up to 50 mm of Gutter

Up to 50 mm of the gutter can be specified. The gutter can be adjusted within a range from

-50 mm to 50 mm in 1 mm increments. The local UI and the print driver have the controls

for the gutter settings.

The image is shifted to the width value specified for gutter, making a margin. If the shift

causes the image to overflow from the printable area, the overflowing area is missing from

the print results. The overflowing image will not be reduced to fit into the printable area.

F-2-7

0008-5626

F-2-8

2-11

Chapter 2

The gutter width range changed to 0-50 mm.

US: 0.0 to 2.0 inches

UK: 0.0 to 50.0 mm

2.1.6 Load Balancing

0008-5627

The UFR II is designed to balance the loads of the print driver and the controller of the

printer for optimized processing.

The UFR II assigns each processes depending on performances of the print driver and the

OS of the host.

On Windows 2000 and XP, a page can be divided into bands to transfer data to the

controller. In the controller, the data are processed by band all through the processes ending

with the Spool Memory.

Application

GDI

UFR II

driver

Spooler

Load Balance & Band Sort

Load Balance & Band Sort

band mode-

UFR II

IF

<Int erpret>

UFR II

interpreter

<Render> <Compress>

Display List

Band

Memory

Band Spool

Band Spool

Spool Memory

Eng-

ine

F-2-9

On Mac OS X, the print driver transfers data by page and the controller can process them

by band.

2-12

Chapter 2

<Render> <Compress>

Band

Spool Memory

Memory

Eng-

ine

Application

GDI

UFR II

driver

Spooler

page mode-

UFR II

Load Balance

Load Balance

IF

<Interpret >

UFR II

inter-

preter

Displ ay List

F-2-10

2.1.7 Processing on System

0008-5622

Processing after Power Shutdown

If the power is shut down during PDL data processing, all the image data temporarily stored

in the hard disk drive to be printed or stored in Mail Boxes are destroyed and the jobs are

canceled. PDL data stored in the hard disk drive immediately before a power shutdown are

destroyed as the power is shut down. Processing the data of those, therefore, will not resume

when the power is turned on after the shutdown. Jobs interrupted by a power shutdown will

be displayed in the Log list with the End Code “NG (#852).”

2-13

Chapter 2

2.1.8 Sleep Processing

Sleep Processing

The 1 W power consumption mode is employed as Sleep 3 in the printers that supports the

UFR II. Of network interrupts, whereas a traditional printer restores when receiving

packets addressed to it, new printer restores when receiving either of the following packets.

- ARP packets

- Packets addressed to the printer

- Broadcast packets for SNMP search with specific patterns

- SLP multicast packets with specific patterns

- CPCA echo (broadcast) packets with specific patterns

0008-5707

2-14

Chapter 3

Parts

Procedure

Replacement

Contents

Contents

3.1 Points to Note About Installation ...............................................................3-1

3.1.1 Precaution for installation ...................................................................3-1

3.2 Checking components ................................................................................3-2

3.2.1 Checking the Contents(USA)..............................................................3-2

3.1 Points to Note About Installation

Chapter 3

3.1.1 Precaution for installation

If you are installing the Kit to a host machine to which any additional MEAP application

has been installed, you will also need a separately available expansion RAM (256 MB; this

holds true if you are planning to install any additional MEAP application program later).

If a service call associated with E604-0001 occurs when the machine is started up after

installation of the Kit, install the expansion RAM. On the other hand, if you are planning to

use only a MEAP login service, you need not install the expansion RAM.

0008-5601

3-1

Chapter 3

3.2 Checking components

3.2.1 Checking the Contents(USA)

[1]

[4]

[1] BOOT ROM(type P)................................1 pc.

[2] User Software CD-ROM..........................1 pc.

[3] N/W ScanGear CD-ROM.........................1 pc.

[4] Release Note.............................................1 pc.

[5] N/W Quick Start Guide............................1 pc.

[6] User Manual CD-ROM.............................1 pc.

[2]

[5]

F-3-1

0008-5602

[3]

[6]

3-2

Loading...

Loading...