Canon imagePRESS 1110+, imagePRESS 1125+, imagePRESS 1125P, imagePRESS 1135+, imagePRESS 1135P High Res Brochure

DO C U M E N T FI N I S H I N G

Q U I P M E N T

E

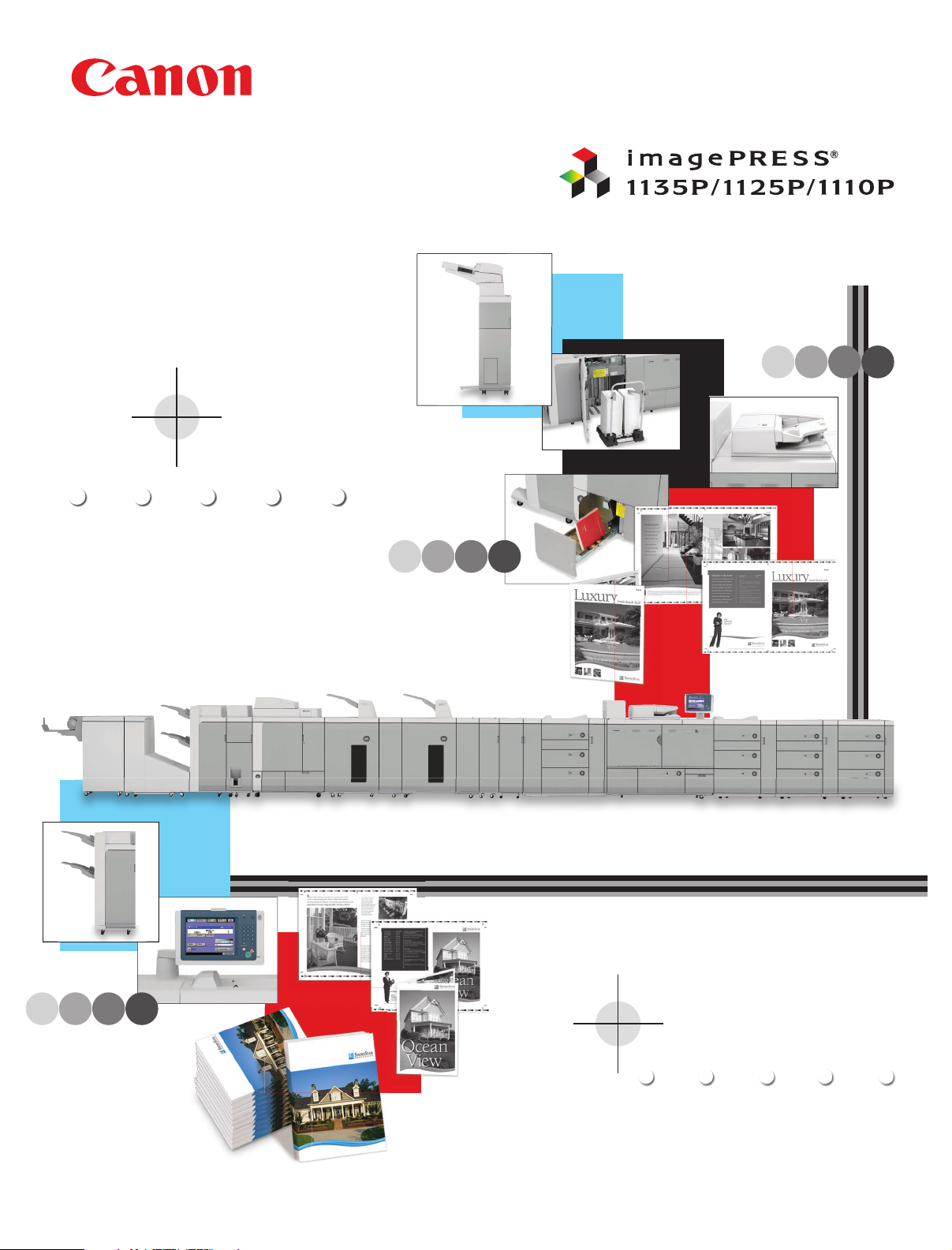

FI NI S H MO R E PR I N T JO B S I N LE S S TI M E

In-line equipment to produce professionally finished

®

documents from your imagePRESS

With a Canon imagePRESS 1135P/1125P/1110P digital press,

you can provide customers with the level of professional

quality they’ve come to expect from offset lithography–not

just on every printed page, but in the overall look of the

finished document.

The imagePRESS 1135P/1125P/1110P digital presses are

fully modular, so they can be configured with the finishing

accessories you need. Their flexibility allows you to select

the right solution for your print environment, regardless of

configuration size.

digital press

AUTOMATICALLY CONVERT PRINTED PAGES INTO

READY-TO-USE PUBLICATIONS AND MAILERS

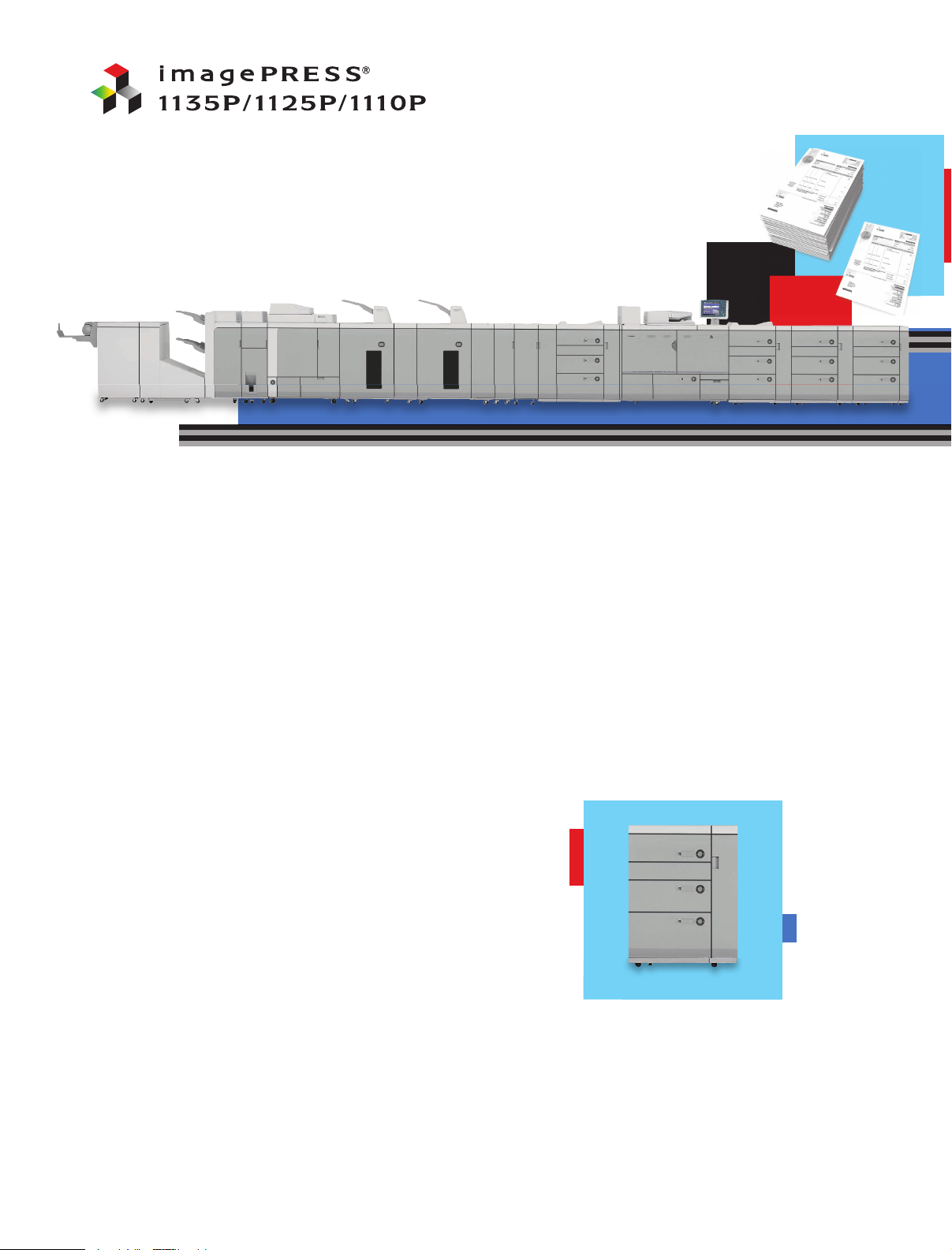

The POD Deck-C1 accessory is designed to maximize

productivity as well as yield greater versatility. Each POD

Deck consists of three drawers that accommodate a total

of 4,000 sheets of paper (14 lb. Bond to 110 lb. Cover), up

to 13" x 19.2". This configuration provides the ability to run

long jobs with fewer interruptions to load paper. In addition,

the extra pick points will allow you to run complex jobs that

require special stocks and colored stocks without the time-

consuming task of having to print and collate. Each POD Deck

comes equipped with air-assist technologies, including suction

feeding, enhanced air-assist, and air separation to ensure

reliable feeding and maximum productivity.

CANON’S SCALABLE, AUTOMATED, IN-LINE FINISHING

EQUIPMENT CAN HELP YOUR BUSINESS:

• Produce higher volumes more cost-effectively

• Turn around a variety of shorter-run jobs more quickly

• Add value to your print jobs

• Respond to changes in the market for printed materials

• Increase profi tability

POD Deck-C1

Another technology in the POD Deck is a heater that auto-

matically turns on when printing on coated stocks. The

heater absorbs any moisture in the deck, which aids in the

feeding of coated stocks too. Each POD Deck also features

an escape tray that diverts double-feeds while the press is

running for maximum productivity. Lastly, the ability to load

paper “on-the-fly” means you never have to stop printing.

Loading...

Loading...