SCANNING BASICS

USEFUL FEATURES

TROUBLESHOOTING

QUICK REFERENCE

DOCUMENT SCANNER

PRECAUTIONS

1

● Make sure that your documents are within the acceptable scanning sizes.

Width: 2.2 – 12 inches (55 – 305 mm)

Length: 2.8 – 17 inches (70 – 432 mm)

Documents up to 39.4 inches (1000 mm) can be scanned in the extra long mode.

Thickness: 0.06 – 0.15 mm (auto feed), 0.05 – 0.3 mm (manual feed)

Weight: 16 – 32 lb. bond (60 – 120 g/m2)

● If there is any wet ink or paste on the document, wait until the ink or paste has thoroughly

dried before scanning the document.

● Always clean the scanning rollers after scanning a document that has pencil writing on it.

● Scanning a double-sided document printed on thin paper may result in an image in which

elements from the opposite page show through. To avoid this, adjust brightness in the

application software.

● If you scan documents with a rough surface, friction between the documents may cause a

feeding error. If this happens, select manual feeding and scan the documents one by one.

● When you scan a batch of NCR documents, make sure they are not stuck together.

Refer to Chapter 4.1 of the DR-6080/9080C Instructions manual for further details on acceptable document types and how

to place documents on the scanner.

■

DOCUMENT TYPES TO AVOID

The Canon DR-6080 and DR-9080C are compact desktop document scanners that

offer rapid scanning, a large document feeding capacity, and reliable paper

feeding. To ensure optimum performance with either unit, please follow the

recommendations below.

To avoid paper jams, damage to documents, and scanner malfunction, do not feed the following types of documents.

Instead, make a copy of the document and scan the copy.

Wrinkled or

creased paper

Curled paper

Torn paper

Paper with clips

or staples

Carbon-backed paper

Coated paper or fax

recording paper

Onion skin or

other thin paper

Paper with binding

holes

SCANNING BASICS

GETTING STARTED

This section explains the basic steps involved in scanning a

document. It assumes that the batch to be scanned contains papers

all of the same size and thickness. When using either the DR-6080 or

the DR-9080C, you should always make sure that the scanner has

been turned ON before turning on the computer connected to it.

STEP

1

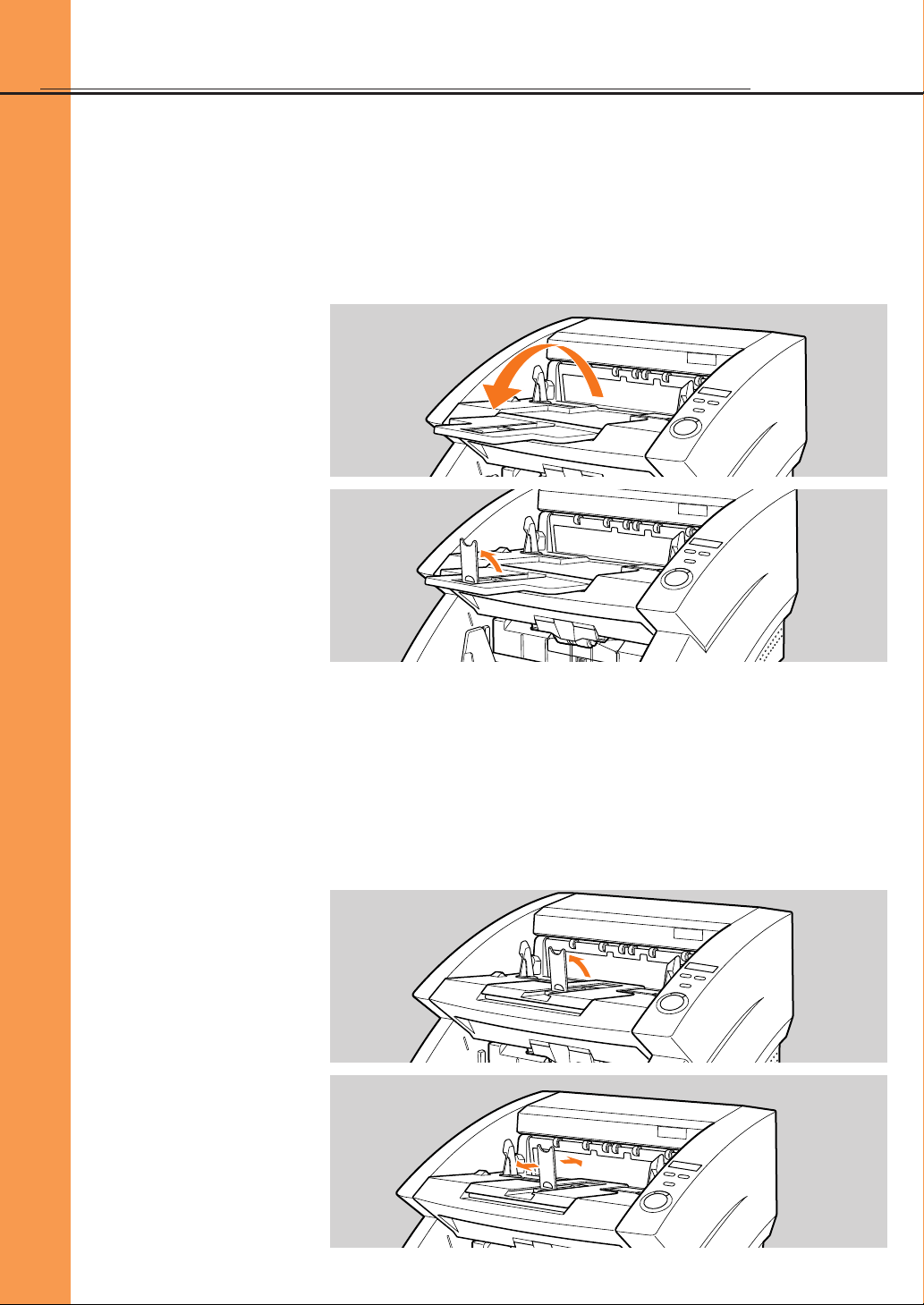

To prepare the DR-6080/9080C for document scanning, first pull out

the document tray extension from the scanner’s lower section (the

document tray). If the document extends beyond the edge of the

document tray, then also open the extension wire.

2

The purpose of this Quick Reference is to provide a

concise overview of the DR-6080/9080C. It is designed

to supplement—not replace—the Instructions manual

included with the scanner. Please review the DR6080/9080C Instructions manual for key information

on safety precautions, installation procedures, and

maintenance guidelines.

▲▲

Document tray extension

1

Extension wire

3

SCANNING BASICS

STEP

2

▲

1

■ Long Documents

If the document you are scanning is long, open the document eject

tray extension. Next, lift up the stopper and adjust its position to match

the length of the document.

■ Short Documents

If the document you are scanning is short, use the stopper without

opening the document eject tray extension. Lift up the stopper and adjust

its position to match the length of the document.

If the document being ejected drifts to the left or right, then adjust the

position of the document eject guides. These are located on either

side of the scanner’s upper tray (the document eject tray).

Document eject

tray extension

Stopper

STEP

3

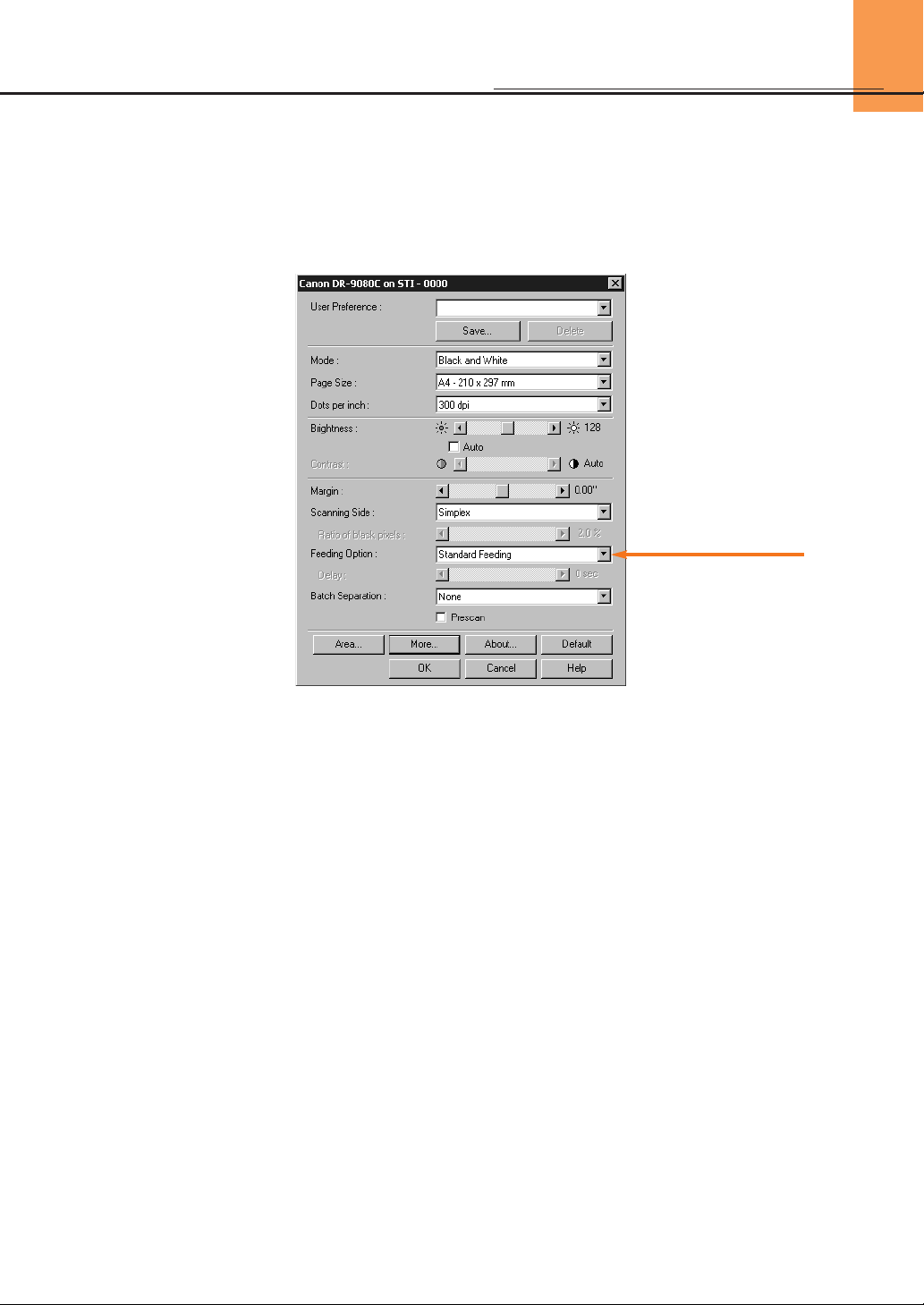

The DR-6080 and the DR-9080C are operated via the bundled

ISIS/TWAIN driver, which is compatible with a wide range of

application software. Use the ISIS/TWAIN driver to select the feeding

option that matches your need.

4

▲

In addition to selecting the feeding option, use the ISIS/TWAIN driver

to make any other scan settings you require.

SCANNING BASICS

1

■ Standard:

Select this mode when you wish to use your application software to start or stop

scanning.

■ Panel:

Select this mode when you need to continuously scan multiple batches of

documents, and the batches differ from one another in the size of the

documents they contain. Scanning starts by pressing the scanner’s built-in Start

key.

■ Automatic:

Select this mode to continuously scan multiple batches of documents that are

all the same size. The scanner will detect documents placed on its Document

Tray and begin scanning automatically.

■ Manual (Bypass Mode):

This mode is intended for documents which cannot be smoothly fed into the

scanner. In this mode, documents are fed into the scanner one page at a time.

Wait until step 5 to select this mode. (See p.7)

Feeding Option

5

STEP

4

Prepare your documents by aligning the batch so that its edges are

even. Then place the batch on the document tray with the documents

face up. The top edge of the batch should be placed against the back

of the document tray.

▲

STEP

5

Adjust the document guides to the width of the documents.

Panel mode: To scan more documents, reload the document tray and press the Start

key. To end scanning, press the Stop key.

▲

STEP

6

Use your application software to instruct scanning to start. In

Standard mode, scanning will begin at this point. In Panel mode, the

Start key will change color from red to green. Press the Start key.

▲

STANDARD FEEDING • PANEL FEEDING

SCANNING BASICS

1

6

SCANNING BASICS

1

STEP

4

Place the first page of the batch face up in the document tray. Adjust

the document guides to the width of the page.

▲

STEP

5

Use your application software to instruct scanning to start.

To scan more documents, simply reload the document tray. Scanning will continue

automatically. To end scanning, press the Stop key.

▲

STEP

6

Prepare your documents by aligning the batch so that its edges are

even. Then place the batch on the document tray with the documents

face up. The top edge of the batch should be placed against the back

of the document tray. Scanning will start automatically when the

sensor on the document tray detects your documents.

▲

AUTOMATIC FEEDING

7

1

STEP

4

Place one page face up on the document tray. Adjust the document

guides to the width of the page.

STEP

5

Select Manual Feeding in

Feeding Option on the

ISIS/TWAIN driver’s settings

screen. Alternatively, press the

Bypass Mode key on the

operation panel. The document

tray will rise.

STEP

6

Use your application software to instruct scanning to start. The page

will now be scanned. To continue scanning, place one page on the

document tray at a time. To end scanning, press the Stop key.

The document tray will stay up as long as the Bypass Mode key is lit. After scanning

has been completed, press the Bypass Mode key to lower the document tray.

MANUAL FEEDING (BYPASS MODE)

SCANNING BASICS

Bypass Mode key

▲▲▲

COUNT ONLY

MODE

In this mode, documents are fed through the scanner and counted,

not scanned. To use this mode, press the Count Only key on the

operation panel. Then place a batch on the document tray and press

the Start key. The number of pages in the batch will appear in the

counter display.

8

▲

PATCH CODE

SHEETS

The scanner can recognize sheets of

paper with patch codes printed on

them. This allows files to be separated

without interrupting the scan. Two patch

code patterns are provided.

▲

DOUBLE FEED

DETECTION

This function automatically detects whether two or more pages have

been fed into the scanner at the same time. An error code is

displayed when a double feed occurs. Two detection methods are

provided: detection by page length and ultrasonic detection. They

can be used separately or together.

▲

STAPLE

DETECTION

Sensors are used to detect feed errors

caused by stapled documents. This

function works with documents that are

larger than A5 (148 x 210 mm) and

stapled in only one corner.

▲

2

USEFUL FEATURES

Count Only key

9

USER

PREFERENCES

To promote ease of use, the bundled ISIS/TWAIN driver offers

registration of up to 100 sets of customized scan settings. After

registration, you can prepare the scanner for a job by simply selecting

a desire setting from a pull-down menu.

▲

PRESCAN

Prescan allows you to scan the first page

of your batch, adjust the brightness and

contrast of the on-screen image to desired

levels, and then continue scanning the

rest of the batch without having to go back

and scan the first page again.

▲

AUTOMATIC

IMAGE ROTATION

You can choose to rotate images by 90, 180, or 270 degrees. Also,

the scanner can be set to recognize how text is oriented by reading

the characters on fed documents. It then automatically rotates images

to their correct position.

▲

MULTISTREAM™

The scanner can produce two images from a single document scan

(for example, a color image for archiving and a binary image for

OCR). Use of this feature requires a compatible software application.

MultiStream is a trademark of Pixel Translations, a division of Captiva Software Corp.

▲

ADVANCED TEXT

ENHANCED

This feature optimizes your scans so that various hard-to-scan

elements (such as text printed on dark color backgrounds, text printed

with light colors, and pencil writing) are clearly legible in the image data.

▲

2

SKEW DETECTION

Skew correction automatically detects if the document is fed at an

angle, and straightens out skewed documents.

▲

USEFUL FEATURES

2000

1996

1997

1998

1999

170

238

189

242

228

QUARTERLY SALES REVIEW

Summary of regional performance profiles

As mentioned in the previous page, the performances of subsidiaries operating in

the three major marketing regions (Asia, Europe, the Americas) have diverged

only slightly over the past five years. These subsidiaries each demonstrate a

different performance profile, and these difference can be accounted for in part by

the contrasting economic conditions prevailing in each region. The Asian

subsidiary has experienced a sustained period of growth during the five-year

period covered in this report. Performances in Europe and the Americas have also

been positive. The European market, in particular, continues to show a constant,

steady growth towards higher overall sales figures. As for the Americas, this

region has also reported healthy growth.

Evaluation of current term sales volume

Early indications for the current term suggest that the trends described in this

report will continue their upward trajectory. Cumulative sales statistics for FY2000

indicated a profit of USD242 million, a figure that exceeded both the initial

estimate and the revised estimate. This was the fifth consecutive fiscal year that

the actual earnings had exceeded both the initial and revised earnings estimates.

The trend began in FY1996,

the first year for which net

earnings figures were

consolidated among the

three regional subsidiaries.

As is visible from the

following graph, the most

significant jump occurred

during FY97 and FY98,

when new systems were

implemented to boost

production capabilities in a

number of key strategic

sub-regions.

Init. Est.

Rev. Est.

Unit: 1 million USD

August 23, 2000

2000

1996

1997

1998

1999

170

238

189

242

228

QUARTERLY SALES REVIEW

Summary of regional performance profiles

As mentioned in the previous page, the performances of subsidiaries operating in

the three major marketing regions (Asia, Europe, the Americas) have diverged

only slightly over the past five years. These subsidiaries each demonstrate a

different performance profile, and these difference can be accounted for in part by

the contrasting economic conditions prevailing in each region. The Asian

subsidiary has experienced a sustained period of growth during the five-year

period covered in this report. Performances in Europe and the Americas have also

been positive. The European market, in particular, continues to show a constant,

steady growth towards higher overall sales figures. As for the Americas, this

region has also reported healthy growth.

Evaluation of current term sales volume

Early indications for the current term suggest that the trends described in this

report will continue their upward trajectory. Cumulative sales statistics for FY2000

indicated a profit of USD242 million, a figure that exceeded both the initial

estimate and the revised estimate. This was the fifth consecutive fiscal year that

the actual earnings had exceeded both the initial and revised earnings estimates.

The trend began in FY1996,

the first year for which net

earnings figures were

consolidated among the

three regional subsidiaries.

As is visible from the

following graph, the most

significant jump occurred

during FY97 and FY98,

when new systems were

implemented to boost

production capabilities in a

number of key strategic

sub-regions.

Init. Est.

Rev. Est.

Unit: 1 million USD

August 23, 2000

QUARTERLY SALES REVIEW

August 23, 2000

2000

1996

1997

1998

1999

Summary of regional performance profiles

As mentioned in the previous page, the performances of subsidiaries operating in

the three major marketing regions (Asia, Europe, the Americas) have diverged

only slightly over the past five years. These subsidiaries each demonstrate a

different performance profile, and these difference can be accounted for in part by

the contrasting economic conditions prevailing in each region. The Asian

subsidiary has experienced a sustained period of growth during the five-year

period covered in this report. Performances in Europe and the Americas have also

been positive. The European market, in particular, continues to show a constant,

steady growth towards higher overall sales figures. As for the Americas, this

region has also reported healthy growth.

Evaluation of current term sales volume

Early indications for the current term suggest that the trends described in this

report will continue their upward trajectory. Cumulative sales statistics for FY2000

indicated a profit of USD242 million, a figure that exceeded both the initial

estimate and the revised estimate. This was the fifth consecutive fiscal year that

the actual earnings had exceeded both the initial and revised earnings estimates.

The trend began in FY1996,

the first year for which net

earnings figures were

consolidated among the

three regional subsidiaries.

As is visible from the

following graph, the most

significant jump occurred

during FY97 and FY98,

when new systems were

implemented to boost

production capabilities in a

number of key strategic

sub-regions.

Init. Est.

Rev. Est.

Unit: 1 million USD

170

238

189

242

228

Original document Text Enhanced OFF Text Enhanced ON

10

2

SKIP BLANK PAGE

Useful for scanning batches that include single- and double-sided

documents, this feature

automatically removes

blank pages from the

image file.

▲

AUTOMATIC PAGE

SIZE DETECTION

This function automatically detects the size/thickness of documents

and adjusts the scanner. It enables you to feed a batch that contains

mixed paper sizes.

▲

COLOR SCANNING

(DR-9080C ONLY)

In addition to binary and grayscale, the DR-9080C provides 24-bit

color scanning of documents.

▲

COLOR DROPOUT

You can instruct the DR-6080 or DR-9080C to remove a specific color

(red, green, or blue) from the image data. This leads to improved

readability for OCR applications.

▲

OPTIONS & CONSUMABLES

▲

■ Imprinter

The imprinter unit is installed inside the scanner, and prints a text

message on the front of the document being scanned. You can set the

text message that is imprinted in the application software.

■ Endorser ED600

The Endorser ED600 unit is installed on top of the scanner, and prints a

eight-digit number on the back of the document being scanned.

■ Hard Counter

A seven-digit counter that is installed inside the upper scanner. It keeps

track of how many pages are fed through the scanner.

■ Barcode Module

Add-on software for the ISIS/TWAIN driver to recognize bar codes. Your

application software must support barcode recognition in order to use this

option.

■ Exchange Roller Kit

Includes pickup rollers, feed rollers, and retard rollers. These must be

changed periodically to maintain scanning quality.

USEFUL FEATURES

TECHNICAL REPORT

INTERDEPARTMENTAL RESOURCE FILE

Shipping & Local Transport: An Overview

Our firm is currently positioned as one of the world's largest provider of

cargo shipping and transport solutions. We have developed service

networks in five continents (60-plus countries), with 210 offices and over

5,000 dedicated professionals ready to serve our customers. We offer an

industry-leading range of ships, containers, specialized cargo options, and

other shipping services. Our diversified range of containers includes dry

freight, flat-rack, reefer, and open containers. Dry freight containers come

in several sizes and designs, with average payloads of 25.3 metric tons.

Flat rack containers are used with heavy cargo that needs special attention

and/or which does not fit into a standard container, e.g., heavy machinery.

Reefer containers, for the transportation of refrigerated cargo, is one of our

Economic and market analysis for future

most highly specialized areas. Standard equipment on this kind of vessel

includes temperature and humidity controls for controlling atmosphere.

development strategies

The last category, open containers, is reserved for over-sized cargo which

does not fit into standard containers. This group is further divided into

The following case study is for interdepartmental knowledge sharing purposes only.

following two types: open-top containers and open-side containers.

Our services were engaged by the Metropolis urban planning department to

conduct market research and analysis in order to identify implementable real

estate development strategies for Metropolis. Our research and analysis was

August 23, 2000

directed toward providing an initial information base and strategic framework for

the formation an ongoing economic development program. We identified: (1)

potential target industries and the comparative advantages these industries

derive from a Metropolis location; and (2) the policies, programs and actions to

enhance the ability of the local economy to respond to the needs of the target

businesses and to encourage beneficial development and redevelopment, while

avoiding marginal development. These included: facilitating the continued

attraction of businesses to the Industrial Park; encouraging retail businesses and

property owners and developers to adapt, redevelop and build new facilities; and

preserving and enhancing the strength downtown Metropolis area.

August 23, 2000

QUARTERLY SALES REVIEW

TECHNICAL REPORT

Summary of regional performance profiles

As mentioned in the previous page, the performances of subsidiaries operating in

the three major marketing regions (Asia, Europe, the Americas) have diverged

only slightly over the past five years. These subsidiaries each demonstrate a

different performance profile, and these difference can be accounted for in part by

the contrasting economic conditions prevailing in each region. The Asian

subsidiary has experienced a sustained period of growth during the five-year

period covered in this report. Performances in Europe and the Americas have also

been positive. The European market, in particular, continues to show a constant,

steady growth towards higher overall sales figures. As for the Americas, this

region has also reported healthy growth.

Evaluation of current term sales volume

Early indications for the current term suggest that the trends described in this

report will continue their upward trajectory. Cumulative sales statistics for FY2000

indicated a profit of USD242 million, a figure that exceeded both the initial

estimate and the revised estimate. This was the fifth consecutive fiscal year that

the actual earnings had

Shipping & Local Transport: An Overview

exceeded both the initial

and revised earnings

Our firm is currently positioned as one of the world's largest provider of

estimates. The trend began

cargo shipping and transport solutions. We have developed service

in FY1996, the first year for

networks in five continents (60-plus countries), with 210 offices and over

which net earnings figures

5,000 dedicated professionals ready to serve our customers. We offer an

were consolidated among

industry-leading range of ships, containers, specialized cargo options, and

the three regional

other shipping services. Our diversified range of containers includes dry

freight, flat-rack, reefer, and open containers. Dry freight containers come

subsidiaries. As is visible

in several sizes and designs, with average payloads of 25.3 metric tons.

from the following graph,

Flat rack containers are used with heavy cargo that needs special attention

the most significant jump

and/or which does not fit into a standard container, e.g., heavy machinery.

occurred during FY97 and

Reefer containers, for the transportation of refrigerated cargo, is one of our

FY98, when new systems

most highly specialized areas. Standard equipment on this kind of vessel

were implemented to boost

includes temperature and humidity controls for controlling atmosphere.

The last category, open containers, is reserved for over-sized cargo which

production capabilities in a

does not fit into standard containers. This group is further divided into the

following two types: open-top containers and open-side containers.

August 23, 2000

August 23, 2000

2000

242

1999

238

1998

228

1997

189

1996

170

Rev. Est.

Init. Est.

Unit: 1 million USD

A

u

g

u

st 2

3

, 2

00

1

INTERDEPARTMENTAL RESOURCE FILE

Economic and market analysis for future

development strategies

The following case study is for interdepartmental knowledge sharing purposes only.

Our services were engaged by the Metropolis urban planning department to

conduct market research and analysis in order to identify implementable real

estate development strategies for Metropolis. Our research and analysis was

directed toward providing an initial information base and strategic framework for

the formation an ongoing economic development program. We identified: (1)

potential target industries and the comparative advantages these industries

derive from a Metropolis location; and (2) the policies, programs and actions to

enhance the ability of the local economy to respond to the needs of the target

businesses and to encourage beneficial development and redevelopment, while

avoiding marginal development. These included: facilitating the continued

attraction of businesses to the Industrial Park; encouraging retail businesses and

property owners and developers to adapt, redevelop and build new facilities; and

preserving and enhancing the strength downtown Metropolis area.

August 23, 2000

This blank page gets omitted from the image file.

11

3

STEP

1

Remove documents from the scanner’s upper and lower trays, and

remove any extra parts attached to the upper tray. Close the

document eject tray extension if it is open.

Paper may have jammed if scanning stops midway or “PXX” appears

on the counter display. Follow the procedure below to remove

jammed paper from inside the scanner. When finished, check your

PC monitor to see which document was last scanned before

continuing to scan.

▲

STEP

2

Press the open/close button to open the upper scanner. Lift the upper

scanner gently until it stops and locks in the open position.

▲

STEP

3

Remove the jammed paper from inside the scanner.

▲

STEP

4

Carefully close the upper scanner. Do not force the upper

scanner down. Doing so might damage the scanner. Once the

upper scanner is near its original position, press down firmly on both

sides until you hear the upper scanner click into place.

▲

PAPER JAMS IN THE PAPER FEED UNIT

TROUBLESHOOTING

12

3

STEP

1

Remove documents from the scanner’s upper and lower trays, and

remove any extra parts attached to the upper tray. Close the

document eject tray extension if it is open.

If a document is jammed in the scanner’s paper exit section, the

upper scanner only needs to be lifted up slightly for you to remove the

document.

▲

STEP

2

Press the open/close button to open the upper scanner. Lift the upper

scanner slightly.

▲

STEP

3

Remove the jammed paper from the paper exit section.

▲

STEP

4

Press the upper scanner down firmly on both sides to close it. If you

press the upper scanner down only on one side, the opposite side will

not fully close. Make sure that you hear the upper scanner click into

place.

▲

PAPER JAMS IN THE PAPER EXIT SECTION

TROUBLESHOOTING

13

3

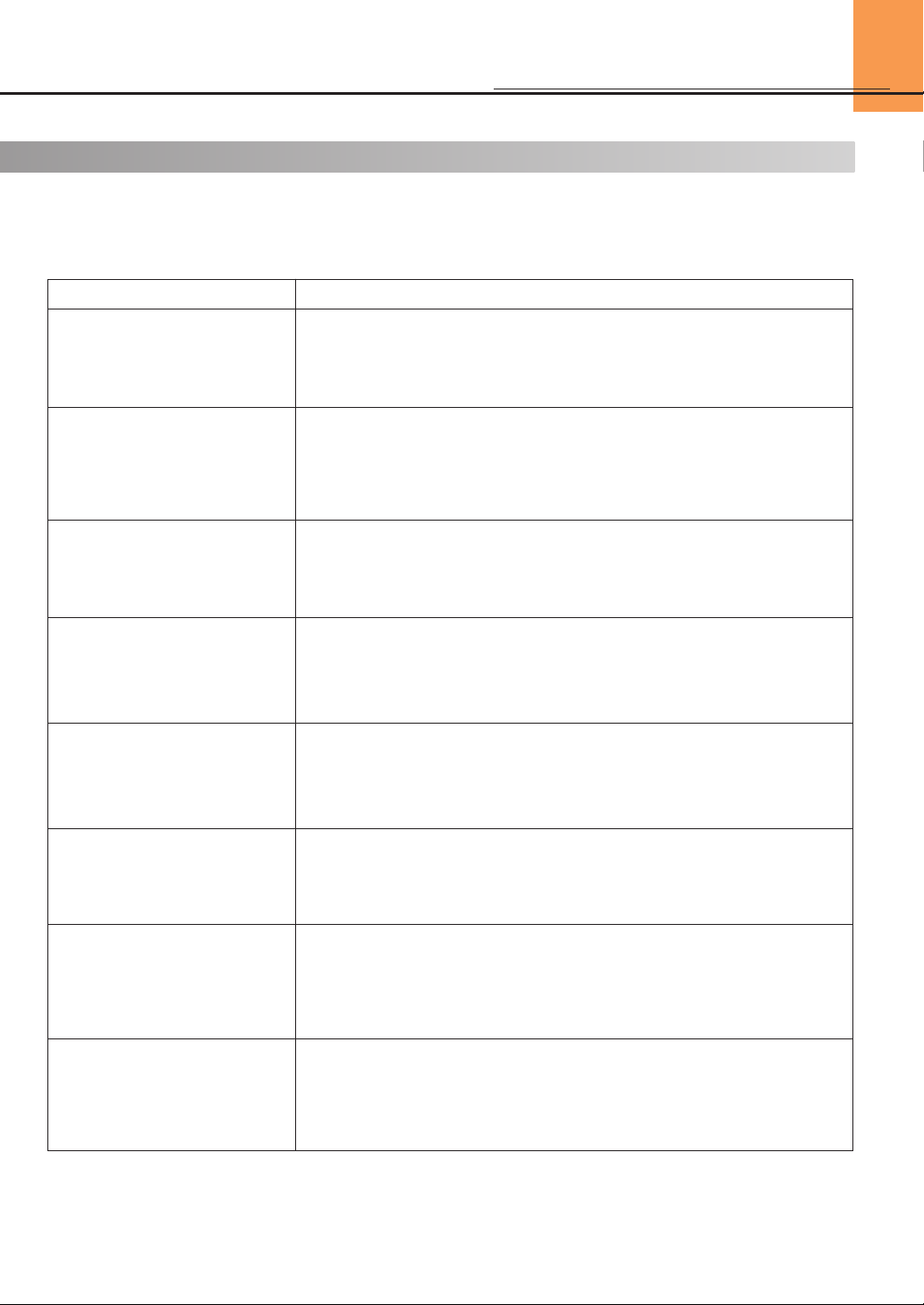

ERROR CODES

TROUBLESHOOTING

Error codes appear on the operation panel’s counter display when a

scanner malfunction occurs.

Error Code Cause and Solution

The document does not feed correctly.

Press the Stop key to reset the counter. Place the document back on

the document tray and scan the document again.

A01

C01

C04

C06

The upper scanner is open.

Close the upper scanner.

The Endorser ED600 cover is open (with the optional

Endorser ED600 installed).

Close the Endorser ED600 cover.

The imprinter cover and Endorser ED600 cover are open

(with the optional imprinter and Endorser ED600 installed).

Close the imprinter cover and Endorser ED600 cover.

C02

The imprinter cover is open (with the optional imprinter

installed).

Close the imprinter cover.

C03

The upper scanner and imprinter cover are open (with the

optional imprinter installed).

Close the upper scanner and imprinter cover.

C05

The upper scanner and Endorser ED600 cover are open (with

the optional Endorser ED600 installed).

Close the upper scanner and Endorser ED600 cover.

C07

The upper scanner, imprinter cover, and Endorser ED600

cover are open (with the optional imprinter and Endorser

ED600 installed).

Close all covers.

d02

Double feed detected by document length.

Check the document against the scanned image, and scan the

document again.

d04

Double feed detected by ultrasonic.

Check the document against the scanned image, and scan the

document again.

14

3

A complete list of error codes and solutions to other types of

scanner trouble can be found in Chapter 6 of the Instructions

manual (“Troubleshooting”).

TROUBLESHOOTING

Error Code Cause and Solution

Double feed detected by document length and ultrasonic.

Check the document against the scanned image, and scan the

document again.

d06

Exx

J01

J02

Scanner internal error

Service call error. The scanner must be repaired by a service

engineer. Turn OFF the power, contact your service representative,

and notify them of the error code.

Staple detected, document transfer stopped.

Open the upper scanner and remove the document. Check to see if

the document was scanned correctly, and scan the document again.

Staple detected, document feed stopped.

Open the upper scanner and remove the document. Check to see if

the document was scanned correctly, and scan the document again.

J18

Detected a skewed document, document feed stopped.

Open the upper scanner and remove the document. Check to see if

the document was scanned correctly, and scan the document again.

P00

Document detected in the scanner when the power was

turned ON or the upper scanner was open.

Remove the document that was left in the scanner. (See p.11)

P02

Detected a document that is longer than the document that

is set.

Open the scanner and remove the document. Check to see if the

document was scanned correctly, and scan the document again.

P03

Detected a document that is shorter than the document that

is set.

Open the scanner and remove the document. Check to see if the

document was scanned correctly, and scan the document again.

CANON Customer Service Centers

© CANON ELECTRONICS INC. 2003 PRINTED IN JAPANPUB.CE-CE-305 0104AB0.2

*CE-CE-305*

Loading...

Loading...