Canon Color Laser Copier 1100_1180 Service Manual

SERVICE INFORMATION

Issued by Copying Machine Quality Assurance Center, Canon Inc.

MODEL:

COLOR LASER COPIER

1100/1120/1130/1140/1150/1160/1180

Major quality issues Quality upgrade/production efficiency

Field quality problems

Miscellaneous

LOCATION

SUBJECT

Revision of Service Manual

The captioned technical documentation has been revised to reflect the following:

Reasons

to update the descriptions in the previous documentation covering modification of

functions and correction of typographical mistakes.

The present revision is a full revision. Kindly make arrangements so that the old

document may be replaced with the one being released. Further, please make sure

the old document is properly disposed of.

NO.

: F-04-E00007

DATE

: FEB.2002

FY8-13G3-03Y

Download Free Service Manual at http://printer1.blogspot.com

Printed in Japan

Imprimé au Japon

COLOR LASER COPIER

1100/1120/1130/1140/1150/

1160/1180

REVISION 3

FEB. 2002

COPYRIGHT © 2002 CANON INC. CANON CLC1100/1130/1150/1160/1180 REV.3 FEB. 2002 PRINTED IN JAPAN (IMPRIME AU JAPON)

Download Free Service Manual at http://printer1.blogspot.com

FY8-13G3-030

IMPORTANT

THIS DOCUMENT ATION IS PUBLISHED BY CANON INC., JAPAN, TO SERVE AS A SOURCE

OF REFERENCE FOR WORK IN THE FIELD.

SPECIFICATIONS AND OTHER INFORMATION CONTAINED HEREIN MAY VARY SLIGHTLY

FROM ACTUAL MACHINE VALUES OR THOSE FOUND IN ADVERTISING AND OTHER

PRINTED MA TTER.

ANY QUESTIONS REGARDING INFORMA TION CONT AINED HEREIN SHOULD BE DIRECTED

TO THE COPIER SERVICE DEPARTMENT OF THE SALES COMP ANY.

THIS DOCUMENT A TION IS INTENDED FOR ALL SALES AREAS, AND MAY CONT AIN INFORMA TION NOT APPLICABLE TO CER T AIN AREAS.

COPYRIGHT © 2002 CANON INC.

Printed in Japan

Imprimé au Japon

Use of this manual should be strictly supervised to avoid disclosure of confidential

information.

Prepared by

OFFICE IMAGING PRODUCTS TECHNICAL SUPPOR T DIVISION

CANON INC.

5-1, Hakusan 7-chome, Toride, Ibaraki, 302-8501 Japan

COPYRIGHT © 2002 CANON INC. CANON CLC1100/1130/1150/1160/1180 REV.3 FEB. 2002 PRINTED IN JAPAN (IMPRIME AU JAPON)

Download Free Service Manual at http://printer1.blogspot.com

INTRODUCTION

This Service Manual contains basic data and figures on the plain paper CLC1100/

1120/1130/1140/1150/1160/1180 needed to service the machine in the field. The copier

is designed to enable fully automated copying work, and may be configured with the

following options:

1. RDF-E2/E3

2. Stapler Sorter-F1

3. Film Projector-D1

4. CLC Paper Deck-E1

For the RDF-E2/E3, Stapler Sorter-F1, and Film Projector-D1, see their respective

Service Manuals for details. This Service Manual covers the copier itself, and consists of

the following chapters:

This manual omits descriptions on technologies used in common with existing

machines. Refer to the Copier Basic Series as necessary for additional information.

Chapter 1

Chapter 2

Chapter 3

Chapter 4

Chapter 5

Chapter 6

General Description

shows how to operate the printer unit, and explains how copies are made.

Basic Operation

Exposure System

mechanical/electrical operations of the copier’s exposure system. It also

explains the timing at which the various units involved are operated, and

shows how they may be disassembled/assembled and adjusted.

Image Processing System

the mechanical/electrical operations of the copier’s image processing

system. It also explains the timing at which the various units involved are

operated, and shows how they may be disassembled/assembled and

adjusted.

Laser Exposure System

mechanical/electrical operations of the copier’s laser exposure system. It

also explains the timing at which the various units involved are operated,

and shows how they may be disassembled/assembled and adjusted.

Image Formation System

formed. It also explains the timing at which the various units involved in

image formation are operated, and shows how they may be disassembled/

assembled and adjusted.

introduces the copier’s features and specifications,

provides outlines of the steps used to generate copies.

discusses the principles of operation used for the

discusses the principles of operation used for

discusses the principles of operation used for the

discusses the principles of how images are

Chapter 7

Chapter 8

COPYRIGHT © 2002 CANON INC. CANON CLC1100/1130/1150/1160/1180 REV.3 FEB. 2002 PRINTED IN JAPAN (IMPRIME AU JAPON)

Pick-Up/Feeding System

picks up and moves paper inside it. It also explains the timing at which the

various units involved are operated, and shows how they may be

disassembled/assembled and adjusted.

Fixing System

images to paper. It also explains the timing at which the various units

involved are operated, and shows how they may be disassembled/

assembled and adjusted.

discusses the principles of how the printer unit fuses toner

discusses the principles of how the printer unit

i

Download Free Service Manual at http://printer1.blogspot.com

Chapter 9

Chapter 10

Externals/Auxiliary Mechanisms

explains the principles used for the copier’s various control mechanisms in

view of the functions of electrical and mechanical units and in relation to

their timing of operation. It also shows how these units may be

disassembled/assembled and adjusted.

Paper Deck

operations between pickup and delivery performed by the paper deck. It

also explains the timing at which the various units involved are operated,

and shows how they may be disassembled/assembled and adjusted.

discusses the principles of operation used for the series of

shows the copier’s external parts, and

Chapter 11

Chapter 12

Chapter 13

Appendix contains a general timing chart and general circuit diagrams.

The following rules apply throughout this Service Manual:

1. Each chapter contains sections explaining the purpose of specific functions

2. In the digital circuits, ‘1’ is used to indicate that the voltage level of a given

Installation

how the printer unit may be installed using step-by-step instructions.

Maintenance and Servicing

and consumables/durables and scheduled servicing charts.

Troubleshooting

adjustments, and problem identification (image fault/malfunction).

and the relationship between electrical and mechanical systems with

reference to the timing of operation.

In the diagrams,

signal name accompanies the symbol

of the electric signal.

The expression “turn on the power” means flipping on the power switch,

closing the front cover, and closing the delivery unit cover, which results in

supplying the machine with power.

signal is “High,” while ‘0’ is used to indicate “Low.” (The voltage value,

however, differs from circuit to circuit.) In addition, the asterisk (*) as in

“DRMD*” indicates that the DRMD signal goes on when ‘0’.

In practically all cases, the internal mechanisms of a microprocessor cannot

be checked in the field. Therefore, the operations of the microprocessors used

in the machines are not discussed: they are explained in terms of from sensors

to the input of the DC controller PCB and from the output of the DC controller

PCB to the loads.

introduces requirements for the site of installation, and shows

provides tables of periodically replaced parts

provides tables of maintenance/inspection, standards/

represents the path of mechanical drive where a

, the arrow indicates the direction

The descriptions in this Service Manual are subject to change without notice for

product improvement or other purposes, and major changes will be communicated in the

form of Service Information bulletins.

All service persons are expected to have a good understanding of the contents of this

Service Manual and all relevant Service Information bulletins and be able to identify and

isolate faults in the machine.

ii

COPYRIGHT © 2002 CANON INC. CANON CLC1100/1130/1150/1160/1180 REV.1 FEB. 2002 PRINTED IN JAPAN (IMPRIME AU JAPON)

Download Free Service Manual at http://printer1.blogspot.com

This manual is compiled in such a way so that a fuller understanding of the machine

may be acquired by using it side by side with the Copier Basic Series. By way of providing

a reference to the document, this manual uses the following convention:

EX:

Part 2>Chapter 3>2.1 “Shading Correction”

The Copier Basic Series represents an accumulation of Canon’s copier technologies

used in common in existing machines, and descriptions in the document are intended to

supplement the contents of Service Manuals. The Copier Basic Series consists of the

following four parts:

Part 1:Basics

Part 2:Copiers

Part 3:Accessories

Part 4:Controllers

COPYRIGHT © 2002 CANON INC. CANON CLC1100/1130/1150/1160/1180 REV.1 FEB. 2002 PRINTED IN JAPAN (IMPRIME AU JAPON)

iiiii-a

Download Free Service Manual at http://printer1.blogspot.com

Download Free Service Manual at http://printer1.blogspot.com

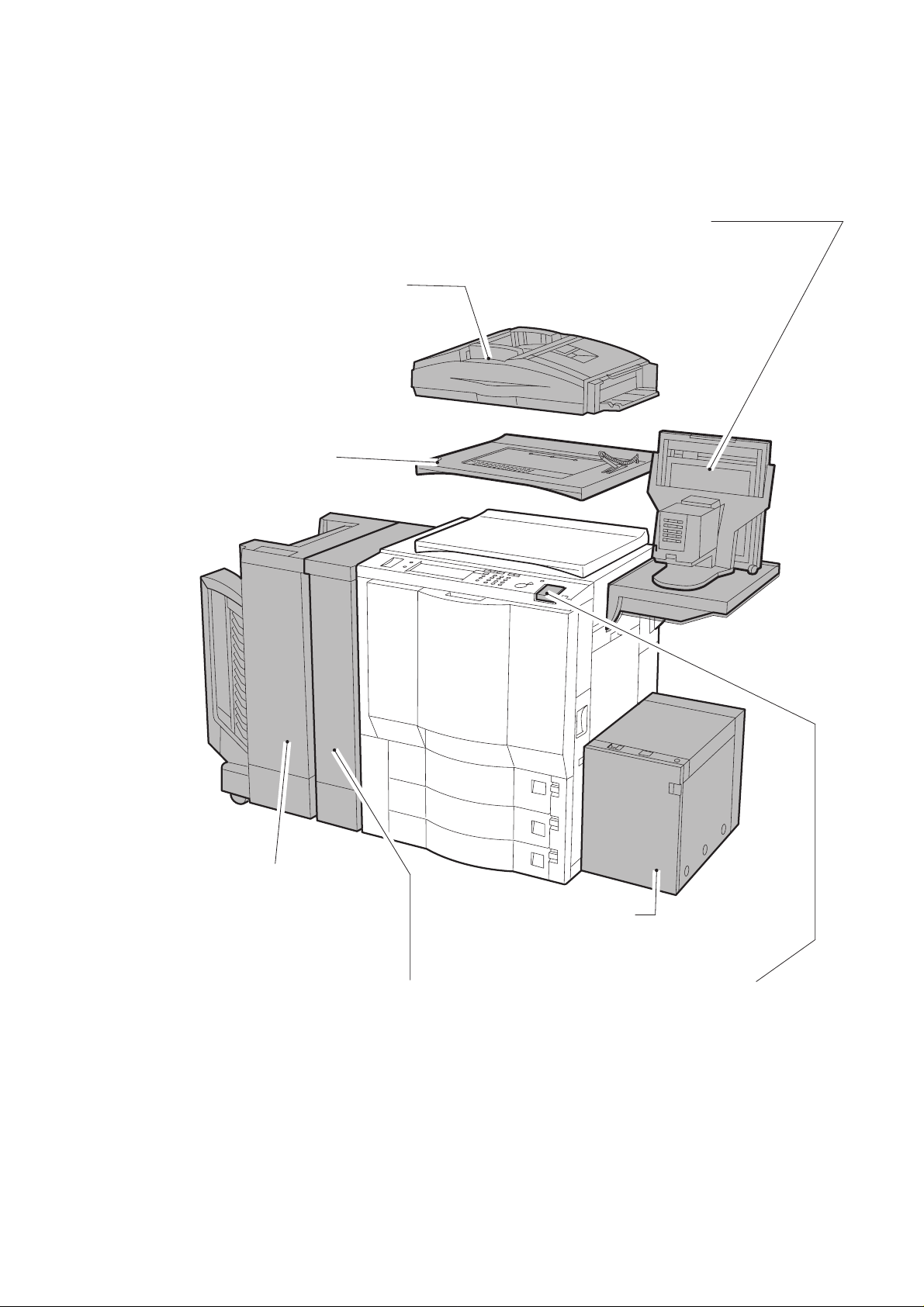

System Configuration

The CLC1100/1120/1130/1150 may be configured as follows to make up a system (the shaded

areas indicate options):

CLC Film Projector-D1

*

Projects 35mm negative or

RDF-E2/E3

Feeds a large number of originals

automatically for continuous

positive film, large-size negative

film, or transparencies for making

color copies.

copying. Accepts double-sided

originals.

Editor-F1

Enables selecting areas and

colors using a point pen.

Stapler Sorter-F1

Sorts or groups copies.

Staples sorted copies.

CLC Paper Deck-E1

Accommodates as many as 2500 sheets of

paper (A4/B5/LTR).

CLC Buffer Path Unit 1

Limits curling of copied paper.

Control Card-V

Enables control of copying

work by group.

The figures above represents the CLC1150; however, the CLC1100/1120/1130 may be

configure in the same way.

: CLC Film Projector D1 is not available for CLC1100.

*

CLC1100/1120 :2-cassette model

CLC1130 :3-cassette model

CLC1150 :2-cassette model with a duplexing unit.

v

COPYRIGHT © 2002 CANON INC. CANON CLC1100/1130/1150/1160/1180 REV.1 FEB. 2002 PRINTED IN JAPAN (IMPRIME AU JAPON)

iii

Download Free Service Manual at http://printer1.blogspot.com

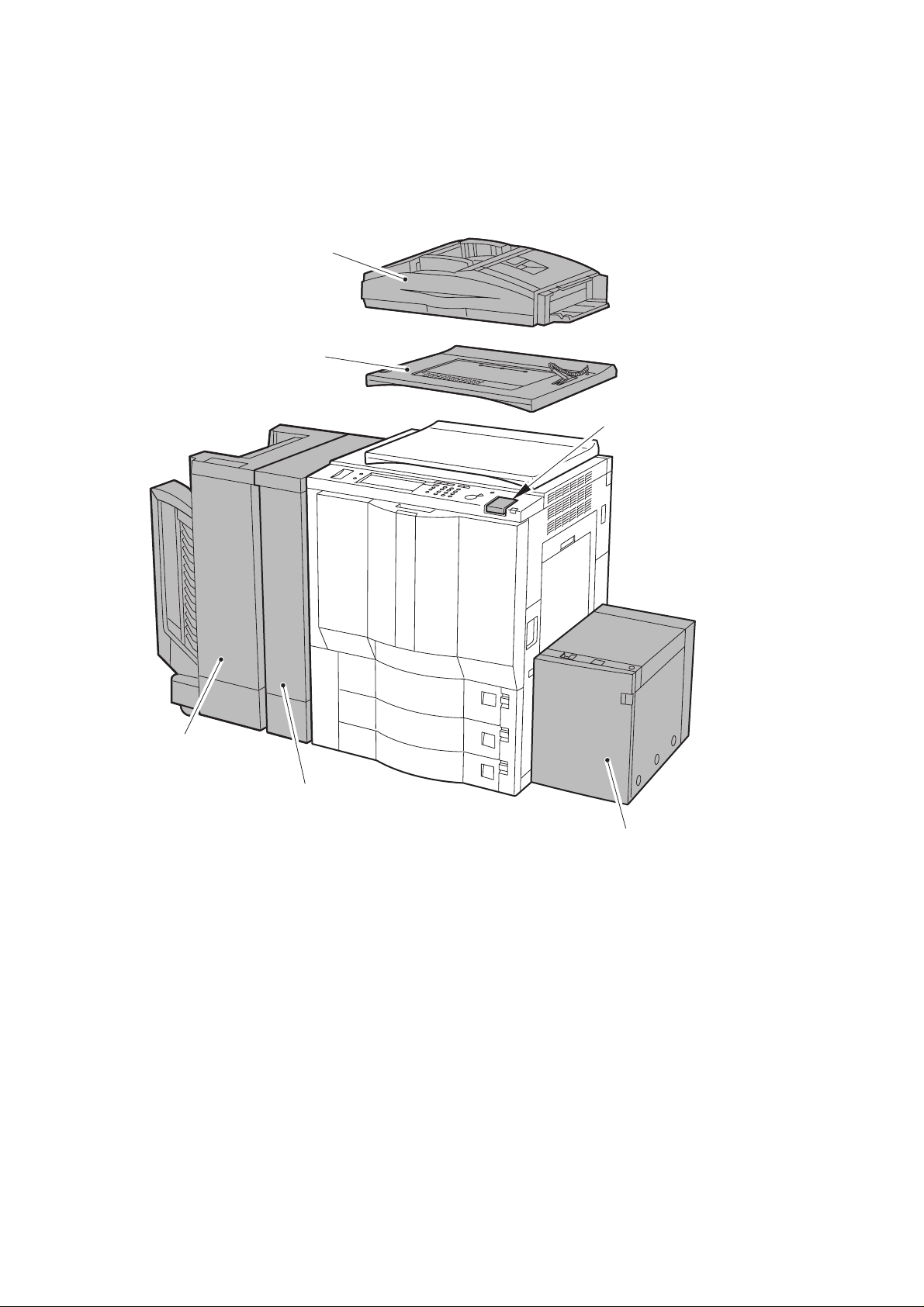

The CLC1140/1160/1180 may be configured as follows to make up a system (the shaded areas

indicate options):

RDF-E2/E3

Feeds a large number of originals

automatically for continuous

copying. Accepts double-sided

originals.

Editor-F1

Enables selecting areas and

colors using a point pen.

Control Card-V

Enables control of

copying work by group.

Stapler Sorter-F1

Sorts or groups copies.

Staples sorted copies.

CLC Buffer Path Unit 1

Limits curling of copied

paper.

CLC1140 :2-cassette model

CLC1160 :3-cassette model

CLC1180 :2-cassette model with a duplexing unit.

CLC Paper Deck-E1

Accommodates as many as 2500

sheets of paper (A4/B5/LTR).

viiv

COPYRIGHT © 2002 CANON INC. CANON CLC1100/1130/1150/1160/1180 REV.0 FEB. 2002 PRINTED IN JAPAN (IMPRIME AU JAPON)

Download Free Service Manual at http://printer1.blogspot.com

CONTENTS

CHAPTER 1 GENERAL DESCRIPTION

I. FEATURES..................................1-1

II. SPECIFICATIONS.......................1-2

A. Type..................................1-2

B. System .............................1-2

C. Functions.......................... 1-3

D. Others .............................. 1-4

E. Default Ratios...................1-4

F. Copying Speed ................ 1-5

G. CLC Paper Deck-E1.........1-6

III. NAMES OF PARTS ....................1-7

A. External View .........................1-7

B. Cross Section.........................1-9

IV. USING THE COPIER............... 1-12

A. Control Panel ...................... 1-12

B. Extended Functions ............ 1-13

CHAPTER 2 BASIC OPERATION

C. User Mode........................... 1-14

V. DAILY MAINTENANCE BY

THE USER ............................... 1-16

VI. SAFETY ................................... 1-17

A. Safety of Laser Light ........... 1-17

B. CDRH Regulations.............. 1-18

C. Handling the Laser

Assembly............................. 1-19

D . Safety of Toner .................... 1-21

VII. IMAGE FORMATION................ 1-22

A. Outline................................. 1-22

B. Auxiliary Process ................ 1-24

1. Post-Cleaning

Charging........................ 1-24

I. OUTLINE OF OPERATIONS ......2-1

A. Functional Construction ......... 2-1

B. Electrical Circuitry .................. 2-2

1. Outline.............................. 2-2

2. CPU PCB .........................2-2

3. Control Panel ...................2-2

II. BASIC SEQUENCE OF

OPERATIONS .............................2-4

A. At Power-On...........................2-4

B. Basic Sequence of

Operations (copying) ..............2-6

C. Generating the Image

Leading Edge Signal..............2-7

COPYRIGHT © 2002 CANON INC. CANON CLC1100/1130/1150/1160/1180 REV.1 JAN. 2000 PRINTED IN JAPAN (IMPRIME AU JAPON)

III. CONTROLLING ELECTRICAL

1. Outline ..............................2-7

2. Controlling Side A and

Side B............................... 2-8

MECHANISMS......................... 2-10

A. Controlling the Main Motor

(M4)..................................... 2-10

1. Outline........................... 2-10

B. Controlling the Drum Motor

(M2)..................................... 2-12

1. Outline........................... 2-12

C. Inputs to and Outputs from

the Major PCBs ....................2-14

v

Download Free Service Manual at http://printer1.blogspot.com

CHAPTER 3 EXPOSURE SYSTEM

I. OPERATION................................3-1

A. Outline....................................3-1

B. Basic Sequence of

Operations.............................. 3-2

1. Sequence of

Operations ........................3-2

2. Scanner Home Position

Sensor and Operation......3-3

II. SCANNER DRIVE SYSTEM .......3-4

A. Controlling the Scanner

Motor ...................................... 3-4

1. Outline..............................3-4

2. Operations........................ 3-5

B. Changing the Reproduction

Ratio....................................... 3-5

III. CONTROLLING THE INTENSITY

OF THE SCANNING LAMP ........3-6

A. Outline....................................3-6

B. Operations..............................3-7

1. Turning On/Off the

Scanning Lamp................3-7

2. Detecting the Activation

of the Scanning Lamp......3-7

3. Detecting an Error in the

Activation of the

Scanning Lamp ................3-7

4. Controlling the Intensity

of the Scanning Lamp......3-7

IV. DISASSEMBLY/ASSEMBLY .......3-8

A. Original Exposure System .....3-9

1. Removing the Scanning

Lamp ................................3-9

2. Orienting the Scanning

Lamp ................................3-9

3. Removing the Standard

White Plate.................... 3-10

4. Mounting the Standard

White Plate.................... 3-10

B. Scanner Drive Assembly ..... 3-11

1. Removing the Scanner

Drive Motor.................... 3-11

2. Adjusting the Tension of the

Belt When Mounting the

Scanner Drive Motor ..... 3-11

3. Routing the Scanner

Cable............................. 3-11

CHAPTER 4 IMAGE PROCESSING SYSTEM

I. OUTLINE.....................................4-1

II. CCD/CCD DRIVE........................ 4-2

A. Controlling the CCD ...............4-2

B. CCD Driver Circuit..................4-2

III. ANALOG IMAGE

PROCESSING ............................4-3

IV. DIGITAL IMAGE

PROCESSING ............................4-4

A. Outline....................................4-4

B. Shading Correction ................4-6

a. Shading Correction .......... 4-6

C. 3-Line CCD Position

Matching Circuit......................4-7

D. Sensor Color Correction

Circuit .....................................4-7

E. Original Position Detection

Circuit .....................................4-8

F. Black Detection Circuit and

Edge/Line Width

Detection Circuit.....................4-9

G. Chromatic Space Correction

Circuit .................................. 4-10

H. Direct Mapping Circuit......... 4-10

I. Logarithmic Correction and

BGR-to-YMC Conversion.... 4-11

a. Logarithmic Correction.. 4-11

b. BGR-to-YMC Conversion4-11

J. Toner Color Correction

Circuit .................................. 4-12

K. Coloring/Contour

Processing .......................... 4-12

L. Density Processing ............. 4-13

M. Enlargement/Reduction,

Shift, and Edit Processing... 4-13

N. Sharpness/Filter

Processing .......................... 4-14

O. Anti-Counterfeit

Mechanism.......................... 4-14

1. Counterfeit Tracing

Mechanism.................... 4-14

vi

COPYRIGHT © 2002 CANON INC. CANON CLC1100/1130/1150/1160/1180 REV.0 MAR. 1999 PRINTED IN JAPAN (IMPRIME AU JAPON)

Download Free Service Manual at http://printer1.blogspot.com

2. Bank Note Detection

Mechanism.................... 4-14

P. CMYBk/RGB Integration ..... 4-15

Q. T exture Processing.............. 4-15

R. Color Conversion ................ 4-15

V. DISASSEMBLY/ASSEMBLY .... 4-16

A. Electrical Parts.................... 4-17

CHAPTER 5 LASER EXPOSURE SYSTEM

1. Removing the CCD

Unit................................ 4-17

2. Removing the Analog

Processor PCB ............. 4-18

3. Removing the Image

Processor PCB (IP-MAIN,

IP-ED, IF, IP-ECO) ........ 4-19

I. OPERATIONS .............................5-1

A. Functions................................5-1

B. Sequence of Operations

(laser exposure system).........5-2

II. GENERA TING THE BD

SIGNAL .......................................5-3

III. LASER DRIVER CIRCUIT ..........5-4

A. Controlling the Laser

System ...................................5-4

B. Controlling the Temperature

of the Laser Unit.....................5-5

IV. LASER SCANNER MOTOR .......5-6

CHAPTER 6 IMAGE FORMATION SYSTEM

I. IMAGE FORMATION SYSTEM...6-1

A. Outline....................................6-1

B. Controlling the C Sensor........6-3

C. Sequence of Operations

(image formation system) .......6-7

I I . IMAGE ST ABILIZA TION ...............6-8

A. Outline ....................................6-8

B. Controlling the Surface

Potential of the Drum ............6-10

1. Outline ............................6-10

2. Measuring the Surface

Potential of the Drum .... 6-10

3. Measuring the Dark Area

Potential Attenuation..... 6-11

4. Controlling the Environment

Contrast Potential.......... 6-11

5. Setting the Grid Bias and

the Developing Bias ...... 6-12

V. DISASSEMBLY/ASSEMBLY .......5-7

A. Electrical Parts.......................5-8

1. Removing the Original

Scanner Motor

Dirver PCB .......................5-8

2. Removing the Laser

Scanner Unit ....................5-8

3. Removing the Laser

Controller PCB/Laser

Driver PCB .................... 5-10

4. Adjusting Laser Power .. 5-11

5. Adjusting the Laser ....... 5-13

6. Sequence of Operations

(initial drum surface

potential control timing). 6-13

7. Auto Gradation Correction

in User Mode ..................6-14

8. Checking the LED Activation

for the Potential

Measurement Circuit..... 6-14

III. CONTROLLING THE CHARGING

MECHANISM ........................... 6-17

A. Controlling the Primary

Charging Mechanism and

the Grid Bias ....................... 6-17

1. Operation ...................... 6-17

2. Protection Circuit........... 6-17

B. Controlling the

Developing Bias .................. 6-18

1. Operation ...................... 6-18

2. When Controlling the M

Developing Bias ............ 6-19

COPYRIGHT © 2002 CANON INC. CANON CLC1100/1130/1150/1160/1180 REV.0 MAR. 1999 PRINTED IN JAPAN (IMPRIME AU JAPON)

vii

Download Free Service Manual at http://printer1.blogspot.com

C. Controlling the Attraction

Charging Mechanism and

Transfer Charging Current... 6-20

1. Operations..................... 6-20

D. Controlling the Separation

Charging Current ................ 6-21

1. Operation ...................... 6-21

E. Controlling the External/Internal

Static Eliminating Current ... 6-23

1. Operation ...................... 6-23

F. Controlling the Post-Cleaning

Charging Current ................ 6-24

1. Operations ..................... 6-24

G. Controlling the Temperature of

the Photosensitive Drum..... 6-25

1. Control........................... 6-25

2. Controlling the Power

Using the Environment

Switch SW6................... 6-25

H. Controlling the Primary

Charging Wire Cleaning

Mechanism.......................... 6-27

1. Operations..................... 6-27

2. Conditions for

Operation ...................... 6-27

IV. DEVELOPING

ASSEMBLIES .......................... 6-28

A. Outline................................. 6-28

B. Locking the Developing

Assembly............................. 6-29

C. Controlling the Concentration

of Color Toner...................... 6-31

1. Outline........................... 6-31

2. Measuring the

Concentration of Color

Toner on the Developing

Cylinder Assembly ........ 6-32

3. Controlling the Color

Toner Concentration

Measurement Mechanism

of the Photosensitive

Drum ............................. 6-33

4. Sequence of

Measurement ................ 6-34

D. Controlling the Concentration of

Black T oner.......................... 6-35

1. Outline........................... 6-35

2. Controlling the Supply of

Black T oner.................... 6-35

3. Measuring the Concentration

of Black Toner

(patch detection) ........... 6-36

4. Detecting Dirt on the

Window ......................... 6-38

5. Sequence of Operations

(measurement).............. 6-39

6. Error Code (E020)

Related to Control of Toner

Concentration................ 6-40

E. New Gradation Correction Con-

trol (patch detection; CLC1140/

1160/1180)........................ 6-46a

1. Outline......................... 6-46a

2. New Gradation Correction

Control

(patch detection) ......... 6-46a

3. Timing of

Measurement ...............6-46c

4. Error Code Related to New

Gradation Correction Control

(E020) ......................... 6-46d

F. Supplying T oner .................. 6-47

V. PHOTOSENSITIVE DRUM

CLEANER ASSEMBLY ............ 6-48

A. Outline................................. 6-48

B. Controlling the Reciprocating

Mechanism of the Cleaning

Blade ................................... 6-49

C. Controlling the Collection of

Waste Toner ........................ 6-49

1. Checking the Waste

Toner Case (full)............ 6-49

2. Detecting a Waste Toner

Feedscrew Lock

Condition....................... 6-50

VI. DISASSEMBL Y/ASSEMBL Y .... 6-51

A. Photosensitive Drum

Assembly............................. 6-52

1. Construction.................. 6-52

2. Removing the

Photosensitive Drum..... 6-52

3. When Replacing the

Photosensitive Drum..... 6-56

4. Cleaning the

Photosensitive Drum..... 6-58

5. Removing the Drum

Heater ........................... 6-59

6. Removing the Drum

Heater Brush................. 6-60

B. Pre-Exposure Lamp ............ 6-60

1. Removing the

Pre-Exposure

Lamp Unit...................... 6-60

C. Charging Assembly ............. 6-61

1. Outline........................... 6-61

2. Removing the Primary

Charging Assembly....... 6-61

3. Removing the Grid

Plate .............................. 6-61

viii

COPYRIGHT © 2002 CANON INC. CANON CLC1100/1130/1150/1160/1180 REV.2 FEB. 2002 PRINTED IN JAPAN (IMPRIME AU JAPON)

Download Free Service Manual at http://printer1.blogspot.com

4. Replacing the Wire

Cleaning Pad of the

Primary Charging

Assembly ....................... 6-62

5. Removing the Post-Cleaning

Charging Assembly....... 6-63

6. Adjusting the Height of the

Charging Wire ............... 6-63

D . Developing Assemblies....... 6-64

1. Construction of the Y/M/C

Developing Assembly.... 6-64

2. Construction of the Bk

Developing Assembly.... 6-64

3. Removing the Developing

Assembly....................... 6-64

4. Removing the ATR Sensor

of the Y/M/C Developing

Assembly....................... 6-65

5. Removing the

Developing Cylinder...... 6-66

6. Adjusting the S-B Gap .. 6-70

7. Replacing the

Developer...................... 6-70

E. Hoppe Assembly................. 6-73

1. Opening the Hopper ..... 6-73

2. Removing the Hopper

Unit................................ 6-73

3. Removing the Hopper

Motor ............................. 6-74

4. Removing the Toner

Supply Clutch................ 6-75

F . Photosensitive Drum

Cleaner Assembly.................6-77

1. Removing the

Photosensitive Drum

Cleaner Unit .................. 6-77

2. Replacing the

Photosensitive Drum

Cleaner Blade ............... 6-78

3. Replacing the

Photosensitive Drum

Cleaner Scoop-Up

Sheet............................. 6-79

4. Removing the

Photosensitive Drum

Cleaner End Seal and

Felt ................................ 6-79

G. Pre-Cleaning Sensor

Assembly No. 2 Scoop-Up

Sheet Assembly .................. 6-80

1. Replacing the No. 2

Scoop-Up Sheet

Assembly....................... 6-80

2. Points to Note When

Handling the Pre-Cleaning

Sensor Assembly .......... 6-80

H. Black T oner Concentration

Sensor Assembly ................ 6-81

1. Removing the Black Toner

Concentration Sensor ... 6-81

2. Removing the No. 2

Blade ........................... 6-81b

3. Removing the Gradation

Sensor (CLC1140/1160/

1180 only) ..................... 6-82

I. Cleaner Blade

Reciprocating Motor.......... 6-82a

1. Removing the

Reciprocating Motor

Assembly..................... 6-82a

J. Waste Toner Feeding

Assembly........................... 6-82a

1. Removing the Waste Toner

Feedscrew Assembly .. 6-82a

K. Developing Drive

Assembly............................. 6-84

1. Removing the Developing

Drive Assembly and the

Developing Assembly

Rail ................................ 6-84

CHAPTER 7 PICK-UP / FEEDING SYSTEM

I. OPERATIONS .............................7-1

A. Outline....................................7-1

B. Arrangement of Rollers

and Sensors...........................7-2

1. CLC1150/1180.................7-2

2. CLC1130/1160.................7-3

COPYRIGHT © 2002 CANON INC. CANON CLC1100/1130/1150/1160/1180 REV.2 FEB. 2002 PRINTED IN JAPAN (IMPRIME AU JAPON)

Download Free Service Manual at http://printer1.blogspot.com

II. PICKUP ASSEMBLY...................7-5

A. Pickup from the Cassette.......7-5

1. Outline..............................7-5

B. Lifter Movement .....................7-9

1. Outline..............................7-9

2. Detecting the Presence/

Absence of Paper ......... 7-10

ix

3. Detecting the Level of

Paper............................. 7-10

C. Detecting the Paper Size

Inside the Cassette ............. 7-11

1. Fixed-Size Type

Cassette........................ 7-11

2. Universal Type

Cassette........................ 7-11

3. Paper Sizes and

Cassettes ...................... 7-12

4. Paper Width Basic

Value ............................. 7-13

5. Sequence of Operations

(pickup from the

cassette)........................ 7-14

D. Pickup from the

Multifeeder .......................... 7-15

1. Operations..................... 7-15

2. Detecting the Size of

Paper............................. 7-16

3. Movement of the Lifter .. 7-17

4. Sequence of

Operations ..................... 7-18

E. Picking Up

Transp arencies.................... 7-19

III. DUPLEXING UNIT

(CLC1150/1180 ONLY) ............ 7-21

A. Outline ................................. 7-21

1. Basic Construction........ 7-21

2. Arrangement of Rollers

and Sensors.................. 7-23

B. Stacking Paper .................... 7-24

C. Movement of the Paper

Jogging Guide Plate ........... 7-25

1. Operations ..................... 7-25

D. Sequence of Operations

(1st side of a

double-sided copy).............. 7-27

E. Re-Pickup from the

Duplexing Unit..................... 7-28

1. Operations..................... 7-28

2. Sequence of

Operations ..................... 7-29

IV. CONTROLLING THE

REGISTRA TION/ATTRACTION

MECHANISM ........................... 7-30

A. Outline................................. 7-30

B. Locking and Unlocking the

Registration Roller .............. 7-31

C. Controlling the Attraction

Mechanism.......................... 7-32

D. Sequence of Operations

(registration/attraction) ........ 7-33

V. TRANSFER DRUM .................. 7-34

A. Outline................................. 7-34

B. Controlling the Locking

Cam Inside the Transfer

Drum ................................... 7-36

C. Controlling Separation ........ 7-39

1. Outline........................... 7-39

2. Separating Paper .......... 7-40

D. Cleaning the Separation

Drum Sheet......................... 7-41

1. Outline........................... 7-41

2. External Brush .............. 7-42

3. Polishing Roller ............. 7-42

E. Sequence of Operations

(transfer drum) .................... 7-44

VI. DETECTING JAMS.................. 7-45

A. Outline................................. 7-45

B. Sequence of Operations

(jam detection) .................... 7-47

VII. DISASSEMBLY/ASSEMBLY

(PICK-UP ASSEMBLY) ............ 7-48

A. Pickup Assembly................. 7-49

1. Construction.................. 7-49

2. Removing the Cassette

Pickup Assembly/

Duplexing Pickup

Assembly....................... 7-49

3. Removing the Pickup

Roller............................. 7-51

4. Removing the Cassette

Pickup Assembly Feed

Roller/Separation

Roller............................. 7-51

5. Adjusting the Pressure of

the Separation Roller .... 7-53

6. Position of the Cassette

Pickup Assembly and

Pickup Roller Solenoid

(SL7, SL8, SL9) ............ 7-55

7. Adjusting the Left/Right

Registration of the

Cassette........................ 7-55

8. Removing the Duplexing

Unit Feed Roller ............ 7-56

9. Removing the Duplex

Unit Separation Roller... 7-56

10. Removing the Duplexing

Unit Pickup Roller ......... 7-57

B. Multifeeder .......................... 7-60

1. Removing the Multifeeder

Assembly....................... 7-60

2. Removing the Pickup

Roller, Feed Roller, and

Separation Roller .......... 7-60

3. Left/Right Registration .. 7-63

x

COPYRIGHT © 2002 CANON INC. CANON CLC1100/1130/1150/1160/1180 REV.1 FEB. 2002 PRINTED IN JAPAN (IMPRIME AU JAPON)

Download Free Service Manual at http://printer1.blogspot.com

4. Attaching the Timing Belt

for the Multifeeder

Assembly....................... 7-63

5. Position of the Multifeeder

Pickup Solenoid ............ 7-63

C. Duplexing Unit..................... 7-64

1. Removing the

Duplexing ...................... 7-64

2. Removing the Feed

Roller............................. 7-64

3. Remove the Duplexing

Feed Assembly ............. 7-65

4. Adjusting the Left/Right

Registration of the

Duplexing Unit............... 7-68

5. Adjusting the Position of the

Paper Jogging Guide

Sensor (PS40) .............. 7-69

6. Assembling the Paper

Jogging Guide Plate

Drive Assembly ............. 7-70

7. Position of the Stopper

Plate Solenoid............... 7-70

8. Position of the Duplexing

Paper Feed Roller

Solenoid ........................ 7-70

9. Position of the Stacking

Guide Solenoid ............. 7-71

D. Pickup Motor Drive

Assembly............................. 7-72

1. Removing the Cassette

Pickup Drive Assembly/RePickup Drive Assembly . 7-72

2. Removing the Duplexing

Motor ............................. 7-72

VIII. DISASSEMBLY/ASSEMBLY

(TRANSFER ASSEMBLY/

DELIVERY ASSEMBLY) .......... 7-73

A. Removing the Transfer

Drum Assembly/Transfer

Drum Frame ........................ 7-74

1. Removing the T ransfer

Drum ............................. 7-74

2. Points to Note When

Handling the Transfer

Drum ............................. 7-75

3. Removing the T ransfer

Drum Frame .................. 7-76

B. No. 1 Feeding Assembly ..... 7-77

1. Construction.................. 7-77

2. Removing the Horizontal

Path Assembly .............. 7-77

3. Removing the Attraction

Roller Unit ..................... 7-78

4. Removing the Scraper

of the Attraction Roller .. 7-79

5. Removing the Attraction

Roller............................. 7-80

6. Replacing the Attraction

Roller Unit Spring Clutch

Assembly....................... 7-80

7. Removing the Registration

Roller............................. 7-81

8. Replacing the Registration

Roller Releasing Spring

Clutch Assembly ........... 7-85

C. Transfer Cleaner Unit .......... 7-86

1. Removing the T ransfer

Cleaner Unit .................. 7-86

2. Removing the T ransfer

Cleaner Brush............... 7-86

3. Removing the Scraper

(upper, lower) of the

Transfer Cleaner Unit .... 7-86

4. Removing the T ransfer

Drum Cleaner Assembly

Filter .............................. 7-87

5. Applying Lubricant to the

Transfer Drum Cleaner.. 7-87

D . Transfer Drum Assembly ..... 7-88

1. Construction.................. 7-88

2. Removing the T ransfer

Drum Sheet................... 7-89

3. Attaching the T ransfer

Drum Sheet................... 7-90

4. Removing the Attraction

Brush............................. 7-93

5. Remove the Transfer

Blade ............................. 7-93

6. Removing the External

Static Eliminator ............ 7-93

7. Removing the Internal

Static Eliminator ............ 7-94

8. Removing the Separation

Changing Assembly ...... 7-94

9. Removing the Polishing

Roller............................. 7-94

10. Removing the Polishing

Roller Unit ..................... 7-95

11. Removing the Separation

Push-Up Solenoid......... 7-97

12. Remove the Brush

Motor (M11)................... 7-98

13. Removing the Transfer

Cleaner Push-On

Brush Unit ..................... 7-99

14. Removing the Separation

Push-Up Roll............... 7-100

COPYRIGHT © 2002 CANON INC. CANON CLC1100/1130/1150/1160/1180 REV.2 FEB. 2002 PRINTED IN JAPAN (IMPRIME AU JAPON)

xi

Download Free Service Manual at http://printer1.blogspot.com

E. Transfer Drum Locking Motor

Assembly (PM5)................ 7-100

F. Transfer Drum Cleaner Locking

Motor Assembly (PM6) ..... 7-101

1. Removing the T ransfer

Drum Cleaner Locking

Motor Assembly .......... 7-101

G. Delivery Assembly

(CLC1100/1120/1130/

1140/1160 only) ................ 7-101

1. Removing the Delivery As-

sembly......................... 7-101

CHAPTER 8 FIXING SYSTEM

H. Duplexing Delivery Assembly

(CLC1150/1180 only)........ 7-102

1. Removing the Duplexing

Delivery Assembly ...... 7-102

2. Position of the Delivery

Assembly Paper

Deflecting Plate Drive

Solenoid (SL10) .......... 7-102

I. OPERATIONS .............................8-1

A. Outline....................................8-1

B. Sequence of Operations

(fixing system)........................8-3

II. FIXING DRIVE SYSTEM ............8-4

A. Controlling the Speed of the

Fixing Roller ...........................8-4

B. Taking Up the Fixing

Cleaning Belt..........................8-6

C. Fixing Oil Applying

Mechanism.............................8-7

III. CONTROLLING THE FIXING

TEMPERATURE .........................8-9

A. Controlling the Temperature

of the Fixing Roller .................8-9

B. Protective Functions ........... 8-11

IV. DISASSEMBLY/ASSEMBLY .... 8-13

A. Fixing Assembly.................. 8-14

1. Removing the Fixing

Assembly....................... 8-14

2. Opening the Fixing

Upper Roller Unit .......... 8-14

3. Removing the Fixing

Upper Heater ................ 8-15

4. Removing the Fixing

Upper Roller.................. 8-15

5. Removing the Fixing

Lower Heater................. 8-16

6. Removing the Fixing

Lower Roller .................. 8-17

7. Difference among Fixing

Rollers (upper/lower,

front/rear) ...................... 8-18

8. Removing the Fixing Upper

Thermistor..................... 8-19

9. Removing the Fixing

Lower Thermistor............8-19

10. Removing the Fixing

Thermal Switch (lower) . 8-20

11. Removing the Fixing

Thermal Switch (upper) 8-20

12. Adjusting the Fixing

Nip................................. 8-20

B. Fixing Cleaner Assembly .... 8-21

1. Removing the Fixing

Upper Cleaning Belt...... 8-21

2. Mounting the Fixing

Upper Cleaning Belt...... 8-22

3. Removing the Fixing

Lower Cleaning Belt...... 8-23

4. Mounting the Fixing

Lower Cleaning Belt...... 8-24

C. Oil Applying Assembly/

Removing Assembly ........... 8-25

1. Removing the Oil

Applying Felt ................. 8-25

2. Removing the Oil Fixing

Blade ............................. 8-26

D. Internal Delivery Assembly . 8-26

1. Removing the Fixing

Separation Claw............ 8-26

E. Drive Assembly ................... 8-27

1. Removing the Fixing

Motor (M5)..................... 8-27

2. Points to Note When

Replacing the Oil

Pump............................. 8-27

3. Adjusting the Fixing

Upper/Lower

Solenoid ........................ 8-27

xii

COPYRIGHT © 2002 CANON INC. CANON CLC1100/1130/1150/1160/1180 REV.1 FEB. 2002 PRINTED IN JAPAN (IMPRIME AU JAPON)

Download Free Service Manual at http://printer1.blogspot.com

CHAPTER 9 EXTERNALS / AUXILIARY MECHANISMS

I. CONTROL PANEL...................... 9-1

A. Outline....................................9-1

II. DOWNLOADING.........................9-2

A. Outline....................................9-2

B. Registering Firmware.......... 9-2d

C. Making Connections ........... 9-2g

D. Downloading the Firmware ...9-2j

E. Uploading Backup Data ........9-2l

F. Downloading Backup

Data..................................... 9-2n

G. Work at the End of a Job .... 9-2p

III. COUNTERS ................................9-3

A. Outline....................................9-3

IV. FANS...........................................9-4

A. Outline....................................9-4

B. Operations..............................9-6

1. 2-Speed Rotation

Control..............................9-6

2. Sequence of

Operations ........................9-6

V. POWER SUPPLY........................9-7

A. Supplying Power ....................9-7

1. Outline..............................9-7

2. Distribution of Power

among Switches...............9-8

B. Rated Outputs of the DC

Power Supply PCB.............. 9-10

C. Protection System............... 9-11

D. Backup Battery.................... 9-13

VI. EDITOR.................................... 9-14

A. Outline................................. 9-14

B. Operations ........................... 9-14

C. Zero-Adjustment of Input

Coordinates......................... 9-16

VII. DISASSEMBLY/ASSEMBLY .... 9-17

A. Covers ................................. 9-18

1. External Covers ............ 9-18

2. Right Upper Cover ........ 9-18

3. Left Inside Cover........... 9-19

4. Transfer Drum Frame

Cover............................. 9-19

5. Fixing Assembly

Cover............................. 9-19

6. Transfer Drum Frame

Right Cover ................... 9-20

7. Removing the

Copyboard Glass............9-20

8. Removing the Upper

Cover............................. 9-21

B. Control Panel ...................... 9-22

1. Removing the Control

Panel ............................. 9-22

2. Removing the Control

Panel PCB..................... 9-22

3. Removing the LCD

PCB............................... 9-22

4. Removing the Numeric

Keypad PCB.................. 9-23

C. Editor................................... 9-24

1. Removing the Editor

Controller PCB .............. 9-24

2. Removing the Editor

Mirror............................. 9-25

D. Flywheel .............................. 9-26

1. Removing the

Flywheel........................ 9-26

2. Points to Note When

Handling the Flywheel .. 9-26

E. Fans .................................... 9-27

1. Outline........................... 9-27

F. Drive System Belt Layout.... 9-28

G. Drum Motor Assembly ........ 9-28

1. Removing the Drum

Motor (M2)..................... 9-28

2. Mounting the Drum

Motor Assembly ..............9-30

H . Main Motor (M4) Drive

Assembly............................. 9-32

1. Removing the Main

Motor (M4)..................... 9-32

I. CPU PCB ............................ 9-33

1. Removing the CPU

PCB............................... 9-33

2. Replacing the CPU

PCB............................... 9-33

3. Replacing the Flash

Memory on the CPU

PCB............................... 9-33

J. HVT PCB............................. 9-35

1. Removing the HVT

PCB............................... 9-35

K. Developing Bias PCB.......... 9-35

1. Removing the

Developing Bias PCB.....9-35

COPYRIGHT © 2002 CANON INC. CANON CLC1100/1130/1150/1160/1180 REV.2 FEB. 2002 PRINTED IN JAPAN (IMPRIME AU JAPON)

xiii

Download Free Service Manual at http://printer1.blogspot.com

CHAPTER 10 PAPER DECK

I. PAPER DECK.......................... 10-1

A. Inputs to and Outputs

from the Deck Driver ........... 10-1

B. Pickup ................................. 10-4

1. Outline........................... 10-4

2. Pickup Operations......... 10-4

3. Sequence of Operations

(pickup) ......................... 10-6

C. Detecting Paper in the Deck 10-7

1. Detecting the Presence/

Absence of Paper ......... 10-7

2. Switching the Deck

Paper Size..................... 10-8

3. Detecting the Level of

Paper in the Deck.......... 10-8

D. Deck Lifter ........................... 10-9

1. Lifter Movement ............ 10-9

2. Paper Level Indicator on

the Deck Front Cover .. 10-11

E. Opening/Closing the Deck

(compartment)................... 10-12

1. Deck Opening/Closing

Movement ................... 10-12

2. Sequence of Operations

(deck opening/closing

movement) .................. 10-13

F. Controlling the Deck

Motors ............................... 10-14

1 Controlling the Deck Pickup

Motor (PM101) ............ 10-14

2. Controlling the Deck

Lifter Motor (M101) ...... 10-15

II. DETECTING JAMS................ 10-17

A. Outline............................... 10-17

III. DISASSEMBLY/ASSEMBLY .. 10-19

A. External Covers ................ 10-20

1. Removing the Front

Cover........................... 10-20

2. Removing the Rear

Cover........................... 10-22

3. Removing the Right

Cover........................... 10-22

4. Removing the Upper

Cover........................... 10-22

B. Paper Deck - Related

Work.................................. 10-23

1. Removing the Deck

from the Copier ........... 10-23

2. Removing the

Compartment .............. 10-25

3. Changing the Deck

Paper Size................... 10-26

4. Adjusting the Deck

Registration................. 10-27

5. Adjusting the Position

of the Roll.................... 10-27

C. Drive System..................... 10-28

1. Removing the Deck Pickup

Clutch (CL102)............ 10-28

2. Removing the Deck Pickup

Motor Assembly .......... 10-28

3. Removing the Deck Lifter

Motor (M101) .............. 10-29

4. Removing the Lifter Cable

(front of the deck)........ 10-30

5. Removing the Lifter Cable

(deck rear)................... 10-31

6. Routing the Lifter

Cable........................... 10-33

D. Feeding System ................ 10-34

1. Removing the Deck

Pickup Unit .................. 10-34

2. Removing the Deck

Pickup Roller............... 10-34

3. Orientation of the Deck

Pickup Roller............... 10-35

4. Removing the Deck

Pickup/Feed Roller...... 10-36

5. Orientation of the Deck

Pickup/Feed Roller...... 10-36

6. Removing the Deck

Separation Roller ........ 10-36

7. Adjusting the Deck

Separation Roller

Pressure...................... 10-37

8. Position of the Deck Pickup

Solenoid (SL101) ........ 10-38

E. Electrical System .............. 10-38

1. Removing the Deck

Driver PCB .................. 10-38

2. Removing the Deck

Open Switch PCB ....... 10-39

xiv

COPYRIGHT © 2002 CANON INC. CANON CLC1100/1130/1150/1160/1180 REV.1 JAN. 2000 PRINTED IN JAPAN (IMPRIME AU JAPON)

Download Free Service Manual at http://printer1.blogspot.com

CHAPTER 11 INSTALLATION

I. SELECTING THE SITE............ 11-1

II. INSTALLATION......................... 11-4

A. Unpacking ........................... 11-4

B. Removing the Fixing Materials

and Mounting the Waste Toner

Collection Case................... 11-7

C. Supplying Fixing Oil ............ 11-9

D. Mounting the Drum Cleaner

and Setting the Environment

Switch................................ 11-11

E. Supplying Toner ................ 11-15

F. Supplying the Starter

Developer .......................... 11-19

G. Checking the Images and

Operations......................... 11-23

H. Changing the Cassette

Paper Size......................... 11-25

III. RELOCA TING THE COPIER . 11-28

IV. MOUNTING THE DOCUMENT

HOLDER ................................ 11-30

V. INSTALLING THE CONTROL

CARD UNIT-V......................... 11-31

1. Mounting the Control

Card Unit..................... 11-31

VI. INST ALLING THE COPY DA TA

CONTROLLER-A1 ................. 11-33

1. Setting the Board ........ 11-33

2. Installing to the

Copier.......................... 11-34

3. Checking Operations .. 11- 36

4. Removing from the

Copier.......................... 11-36

VII. INSTALLING THE REMOTE

DIAGNOSTIC DEVICE II ....... 11-37

1. Installing to the

Copier.......................... 11-37

VIII. INSTALLING THE CASSETTE

HEATER ................................. 11-46

CHAPTER 12 MAINTENANCE AND SERVICING

I. PERIODICALLY REPLACED

PARTS ..................................... 12-1

II. CONSUMABLES AND

DURABLES.............................. 12-2

A. Copier.................................. 12-2

B. Paper Deck.......................... 12-4

CHAPTER 13 TROUBLESHOOTING

I. MAINTENANCE AND

INSPECTION ........................... 13-3

A. Image Adjustment Basic

Procedure............................ 13-3

B. Points to Note for Scheduled

Servicing ............................. 13-6

II. ST ANDARDS AND

ADJUSTMENTS....................... 13-7

A. Image Adjustment

System .............................. 13-7a

III. SCHEDULED SERVICING

CHART ..................................... 12-5

IV. SCHEDULED SERVICING

LIST.......................................... 12-7

A. Copier.................................. 12-7

B. Paper Deck.......................... 12-8

B. Exposure System.............. 13-14

C. Image Formation System.. 13-15

D. Pickup/Feeding System .... 13-20

E. Fixing System ................... 13-28

F. Externals/Controls ............ 13-31

G. Paper Deck........................ 13-32

H. Electrical System .............. 13-36

III. TROUBLESHOOTING

FAUL TY IMAGES ................... 13-51

A. Making Initial Checks ........ 13-51

COPYRIGHT © 2002 CANON INC. CANON CLC1100/1130/1150/1160/1180 REV.2 FEB. 2002 PRINTED IN JAPAN (IMPRIME AU JAPON)

xv

Download Free Service Manual at http://printer1.blogspot.com

1. Environment of the

Site .............................. 13-51

2. Checking the Originals

against Symptoms ...... 13-51

3. Checking the Copyboard

Cover, Copyboard Glass,

and Standard White

Plate ............................ 13-51

4. Checking the Charging

Assemblies.................. 13-51

5. Checking the Developing

Assembly..................... 13-51

6. Checking the Paper..... 13-52

7. Checking Periodically

Replaced Parts ........... 13-52

8. Others ......................... 13-52

B. Standard Images............... 13-53

C. Test Print ........................... 13-56

1. Selecting a Test Print

Pattern......................... 13-56

2. Horizontal Stripe Test Print

(PG>TYPE=10, 16)..... 13-57

3. 256-Color Test Print

(PG>TYPE=2)............. 13-58

4. 256-Gradation Test Print

(PG>TYPE=3)............. 13-59

5. 16-Gradation Test Print

(PG>TYPE=4)............. 13-60

6. Halftone Test Print

(PG>TYPE=5)............. 13-61

7. Grid Test Print

(PG>TYPE=6)............. 13-63

8. YMCBk 64-Gradation Test

Print (PG>TYPE=12) .. 13-64

9. BGR 64-Gradation Test

Print (PG>TYPE=13) .. 13-65

10. Full-Color 16-Gradation

(YMCBk) Test Pint

(PG>TYPE=14)........... 13-66

11. Full-Color Light Area/16Gradation (YMCBk) Test

Print (PG>TYPE=15) .. 13-67

12. Full Color Block Pattern

(with γ correction;

PG>TYPE=80)

(CLC1140/1160/1180

only) .......................... 13-67a

13. Full Color Block Pattern

(without γ correction;

PG>TYPE=81)

(CLC1140/1160/1180

only) .......................... 13-67b

D . Troubleshooting Image

Problems ........................... 13-68

IV. TROUBLESHOOTING

MALFUNCTIONS................... 13-97

A. Troubleshooting

Malfunctions...................... 13-97

V. TROUBLESHOOTING

FEEDING FAUL TS............... 13-150

A. Paper Jams ..................... 13-150

B. Feeding Faults................. 13-160

VI. ARRANGEMENT OF

ELECTRICAL PARTS .......... 13-161

A. Sensors........................... 13-161

1. CLC1100/1120/1130/

1140/1160 ................. 13-161

2. CLC1150/1180.......... 13-163

B. Thermistors, Lamps,

and Heaters .................... 13-165

C. Clutches .......................... 13-166

1. CLC1100/1120/1130/

1140/1160 ................. 13-166

2. CLC1150/1180.......... 13-167

D. Solenoids ........................ 13-168

1. CLC1100/1120/1130/

1140/1160 ................. 13-168

2. CLC1150/1180.......... 13-169

E. Fans ................................ 13-170

F. Motors ............................. 13-171

G. PCBs ............................... 13-173

H. Paper Deck...................... 13-175

1. Sensors and

Switches.................... 13-175

2. Motors, Clutches,

Solenoids, and

PCBs ......................... 13-176

I. Variable Resistors (VR),

Light-Emitting Diodes (LED),

and Check Pins by PCB.. 13-177

1. DC Driver PCB.......... 13-177

2. CPU PCB .................. 13-178

3. IP main PCB ............ 13-178

4. Analog Processor

PCB........................... 13-179

5. Laser Driver PCB ...... 13-179

6. Lamp Regulator

PCB........................... 13-180

7. DC Fuse PCB ........... 13-180

8. AC Fuse PCB............ 13-181

9. Developing Bias

PCB........................... 13-181

10. HVT-AC PCB............. 13-182

11. Potential Measurement

PCB........................... 13-182

VII. SERVICE MODE.................. 13-183

A. Outline............................. 13-183

xvi

COPYRIGHT © 2002 CANON INC. CANON CLC1100/1130/1150/1160/1180 REV.2 FEB. 2002 PRINTED IN JAPAN (IMPRIME AU JAPON)

Download Free Service Manual at http://printer1.blogspot.com

1. Starting Service Mode and

Making Selections..... 13-184

2. Ending Service

Mode ......................... 13-185

3. Backing Up the

RAM .......................... 13-185

4. Basic Operation ........ 13-194

B. DISPLAY

(control display mode)..... 13-196

C. I/O (I/O display mode) ..... 13-215

1. DC-CPU .................... 13-216

2. R-CPU....................... 13-232

APPENDIX

D. ADJUST

(adjustment mode) .......... 13-235

E. FUNCTION

(operation check mode) .. 13-282

F. OPTION (settings mode) 13-305

G. PG (test print).................. 13-321

H. COUNTER

(counter mode)................ 13-323

VIII. SELF DIAGNOSIS ............... 13-329

A. Copier.............................. 13-329

B. RDF................................. 13-350

C. Sorter .............................. 13-351

A. GENERAL TIMING

CHART ....................................... A-1

B. SIGNALS AND

ABBREVIATIONS....................... A-3

C. GENERAL CIRCUIT

DIAGRAM................................... A-9

D. PAPER DECK GENERAL

CIRCUIT DIAGRAM................. A-13

E. SPECIAL TOOLS..................... A-15

F. SOLVENTS AND OILS ............ A-17

COPYRIGHT © 2002 CANON INC. CANON CLC1100/1130/1150/1160/1180 REV.2 FEB. 2002 PRINTED IN JAPAN (IMPRIME AU JAPON)

xvii

Download Free Service Manual at http://printer1.blogspot.com

Download Free Service Manual at http://printer1.blogspot.com

CHAPTER 1

GENERAL DESCRIPTION

This chapter shows the copiers specifications, and provides an outline of how to operate the

copier and how copies are generated.

I. FEATURES .................................. 1-1

II. SPECIFICATIONS ....................... 1-2

A. Type .................................. 1-2

B. System ............................. 1-2

C. Functions .......................... 1-3

D. Others .............................. 1-4

E. Default Ratios...................1-4

F. Copying Speed ................ 1-5

G. CLC Paper Deck-E1.........1-6

III. NAMES OF PARTS ....................1-7

A. External View .........................1-7

B. Cross Section.........................1-9

IV. USING THE COPIER............... 1-12

A. Control Panel ...................... 1-12

COPYRIGHT © 2002 CANON INC. CANON CLC1100/1130/1150/1160/1180 REV.1 JAN. 2000 PRINTED IN JAPAN (IMPRIME AU JAPON)

B. Extended Functions ............ 1-13

C. User Mode........................... 1-14

V. DAILY MAINTENANCE BY

THE USER ............................... 1-16

VI. SAFETY ................................... 1-17

A. Safety of Laser Light ........... 1-17

B. CDRH Regulations.............. 1-18

C. Handling the Laser

Assembly............................. 1-19

D . Safety of Toner .................... 1-21

VII. IMAGE FORMATION................ 1-22

A. Outline................................. 1-22

B. Auxiliary Process ................ 1-24

Download Free Service Manual at http://printer1.blogspot.com

Download Free Service Manual at http://printer1.blogspot.com

CHAPTER 1 GENERAL DESCRIPITON

I. FEATURES

1. High Image Quality

The copier uses micro-diameter toner and a limited amount of silicone oil, ensuring a thin layer

of toner on transparencies. It allows changing the hues of magenta toner and, together with the use

of a direct mapping method, enables a wider range of color reproduction.

2. High Productivity

The copier turns out as many as 11 copies per minute in full color, or 42 mono-color copies. It

takes as little as 18.1 sec (Except for CLC1100) or 21.0 sec (CLC1100) to generate the first full-

color copy* and 9.6 sec to generate the first mono-color copy*.

*No pre-scanning.

3. High Stability

The copier uses a new method to control the concentration of toner, promising stable

production of high-quality copies.

The newly adopted gradation correction control mechanism ensures stability of operation

(CLC1140/1160/1180 only).

4. Varied Transfer Materials

2

The copier allows the use of paper from as thin as 64 g/m

to as thick as 209 g/m2.

5. Large Source of Paper

The addition of options will equip the copier with a paper source ready to provide as many as

4400 sheets.

3 Cassettes (standard): 550 sheets x 3 cassettes (CLC1130/1160 only; for CLC1100/1120/

1140/1150/1180, 550 sheets x 2 cassettes)

Multifeeder: 250 sheets

CLC Paper Deck-E1*: 2500 sheets

*Option

COPYRIGHT © 2002 CANON INC. CANON CLC1100/1130/1150/1160/1180 REV.2 FEB. 2002 PRINTED IN JAPAN (IMPRIME AU JAPON)

1-1

Download Free Service Manual at http://printer1.blogspot.com

CHAPTER 1 GENERAL DESCRIPITON

II. SPECIFICATIONS

A. Type

Item Specifications

Body Console (reader and printer constructed as one)

Copyboard Fixed

Light source Halogen lamp

Lens Arranged in an array

Image reader Photocell (BRG line CCD; fixed, mirror scanning)

Photosensitive medium OPC drum (180-mm dia.)

Table 1-201

B. System

Item Specifications

Copying Laser beam indirect photostatic transfer

Charging Corona

Exposure Slit, laser beam

Contrast adjustment Automatic

Development Dry toner projection

Toner supply Manual (345 g/bottle)

Pickup Cassette x 2 (CLC1100/1120/1140/1150/1180), cassette x 3

(CLC1130/1160), multifeeder tray, duplexing unit (CLC1150/

1180)

Attraction Pre-transfer static attraction

Transfer Blade transfer

Separation Separation claw, separation pushup roll (separation

charging assembly as auxiliary mechanism)

Cleaning Cleaning blade

Fixing Heat roller

Upper: 540 W (100/120 V), 700 W (230 V)

Lower: 500 W (common for all models)

Note: The CLC1120/1140 is available only as a non-Japanese model.

Table 1-202

1-2

COPYRIGHT © 2002 CANON INC. CANON CLC1100/1130/1150/1160/1180 REV.1 FEB. 2002 PRINTED IN JAPAN (IMPRIME AU JAPON)

Download Free Service Manual at http://printer1.blogspot.com

CHAPTER 1 GENERAL DESCRIPITON

C. Functions

Item Specifications

Resolution Reader: 400 x 400 dpi

Printer: 800-equivalent x 400 dpi

Gradation 256 gradations

Original type Sheet, book, 3-D object (2 kg max.)

Maximum original size A3 (297 x 420 mm) / 279.4 x 431.8 mm (11 x 17)

Copy size AB: 6R5E (Japanese)

Inch/A: 5R4E (North or Central America)

AB/Inch: 6R5E (Asia, Oceania, South America)

Zoom 25% to 400% (in 1% increments)

Wait time 8 min 30 sec or less (at 20ºC) ; 120V

8 min or less (at 20ºC) ; 230V

First copy time (w/o pre-scanning)

Continuous copying 1 to 100 sheets

Copying speed See Table 1-206.

Copy size Cassette: B5 (257 x 182 mm)/LTR to A3 (297 x 420

Paper type Cassette: Plain paper (64 to 105 g/m

Cassette

Multifeeder 250 sheets (81.4 g/m2)

Duplexing unit 50 sheets (105 g/m

Copy tray 100 sheets 981.4 g/m

Image margin Leading edge: 8.0 ± 1.5 mm (8.0 ± 2.0 mm)

Auto clear Yes, 2-min standard (may be changed between 0 and 9 min)

Auto power-off Yes , 1-hr standard (may be changed between 0 and 24hr)

Power Save mode Yes , (Saving level may be either -10%, -25%, -50%, or

CLC1100: Less than 21.0 sec (full color ; no pre-

scanning)

Except for CLC1100: Less than 18.1 sec (full color ; no pre-

scanning)

Less than 9.6 sec (mono color ; no pre-scanning)

mm)/279.4 x 431.8 mm (11 x 17)

Multifeeder: B5 (257 x 182 mm) to A3 (297 x 420 mm)/

279.4 x 431.8 mm (11 x 17) + extra length

size (12 x 18)

2

), transparency

(A4/LTR)

2

Multifeeder: Plain paper (64 to 209 g/m

), transparency

(A4/LTR)

Auto double-sided: Plain paper only (90 to 105 g/m

Multifeeder double-sided: Plain paper only (90 to 209 g/m

No claw, front loading, 60 mm deep (about 550 sheets of 81.4 g/m2)

2

)

2

)

Trailing edge: 2.5 ± 1.5 mm (4.5 ± 2.0 mm)

Left/right: 2.0 ± 1.5 mm (2.0 ± 1.5 mm)

Parentheses represent double-sided copying.

non-recovery)

2

)

2

)

Table 1-203

COPYRIGHT © 2002 CANON INC. CANON CLC1100/1130/1150/1160/1180 REV.3 FEB. 2002 PRINTED IN JAPAN (IMPRIME AU JAPON)

1-3

Download Free Service Manual at http://printer1.blogspot.com

CHAPTER 1 GENERAL DESCRIPITON

Item Specifications

Options RDF-E2 (only CLC1120/1130/1150), RDF-E3, RDF-E2

CLC1100 Series Power Supply Kit

Stapler Sorter-F1/F2

CLC Buffer Pass Unit 1

CLC Paper Deck-E1

Document Tray-C1 (CLC1100/1120/1130/1150)

Document Tray-H1 (CLC1140/1160/1180)

CLC Film Projector-D1 (only CLC1120/1130/1150)

Editor-F1, CLC Editor-F1 Separating kit

CLC IP-ED Board-B1 (hereafter, IP-ED Board)

CLC Interface Board-D1 (hereafter, IP-IF Board)

Cassette Heater Kit-15, Cassette Heater Kit-16

Control Card-V

Copy Data Controller-A1

NE Controller-A1

Remote Diagnostic Device II

Table 1-203

1-3a

COPYRIGHT © 2002 CANON INC. CANON CLC1100/1130/1150/1160/1180 REV.0 FEB. 2002 PRINTED IN JAPAN (IMPRIME AU JAPON)

Download Free Service Manual at http://printer1.blogspot.com

CHAPTER 1 GENERAL DESCRIPITON

D. Others

Item Specifications

Operating environment Temperature: 15º to 30ºC / 59 to 86 ºF

Humidity: 5% to 80%

Atmospheric pressure: 810 to 1013 hPa (0.8 to 1.0 atm)

Power supply 100V / 50, 60Hz 120V / 60Hz, 230V / 50Hz

Serial No. CLC1100: MAP ***** MHR ***** QST***** MPU *****

QSU ***** QER ***** RER ***** SDQ *****

TEC ***** USD *****

CLC1120: NNE ***** NND ***** PNJ *****

RNC ***** MPY *****

CLC1130: LNC ***** PNM ***** QND ***** QEE*****

RNE ***** SNC ***** SDH ***** TNC *****

TDR ***** UNC ***** UHF ***** PNR *****

PSK *****

CLC1150: LNB ***** NNC ***** PNB *****

QNB ***** QDF ***** RNB ***** SNB *****

SDE ***** TNB ***** TDQ *****UNB *****

UHE ***** PNH ***** PSJ***** MPX *****

CLC1140: MQW ***** RSY ***** MRM *****

CLC1160: MJT ***** RSW ***** QFJ *****

RFN ***** SEF ***** TEQ ***** UJQ *****

CLC1180: MJU ***** RSX ***** MQX ***** RSZ *****

QFK ***** RFM ***** SEG ***** TER *****

UJR ***** MRL *****

Maximum power consumption 1.5 kW or less

Copying: 719 Wh or less (reference only)

Standby: 338 Wh or less (reference only)

Noise Copying: 73 dB (sound power level)

Standby: 59 dB (sound power level)

Ozone 0.02 ppm or less (average; 0.05 ppm max.)

Dimensions Width: 768 mm / 30.2 in

Depth: 773 mm / 30.5 in (CLC1100/1120/1130/1150)

774 mm / 30.5 in (CLC1140/1160/1180)

Height: 1000 mm / 39.4 in

Weight 291.5 kg / 642.5 lb (approx.; CLC1150)

277.5 kg / 611.6 lb (approx.; CLC1130)

272.5 kg / 600.6 lb (approx.; CLC1100/1120)

291.6 kg / 642.7 lb (CLC1180)

277.6 kg / 611.8 lb (CLC1160)

272.6 kg / 600.8 lb (CLC1140)

Consumables Paper: Keep wrapped, and protect against moisture.

Toner: Protect against direct sunlight, and keep

under 40ºC, 85%.

1-4

Table 1-204

COPYRIGHT © 2002 CANON INC. CANON CLC1100/1130/1150/1160/1180 REV.3 FEB. 2002 PRINTED IN JAPAN (IMPRIME AU JAPON)

Download Free Service Manual at http://printer1.blogspot.com

Loading...

Loading...