Canon Color Image Reader - L1 Service Manual

654321

Product Outline

Technology

Periodic Servicing

Parts Replacing and Cleaning

Adjustments

Installation

Appendix

REVISION 1

Color Image Reader - L1

Service Manual

b

b

Application

This manual has been issued by Canon Inc. for qualied persons to learn technical theory,

installation, maintenance, and repair of products. This manual covers all localities where the

products are sold. For this reason, there may be informat ion in this manual that does not

apply to your locality.

Corrections

This manual may contain technical inaccuracies or typographical errors due to improvements

or changes in products. When changes occur in applicable products or in the contents of this

manual, Canon will release technical information as the need arises. In the event of major

changes in the contents of this manual over a long or short period, Canon will issue a new

edition of this manual.

The fo ll owi ng pa ragra ph do es not appl y to an y count ries wher e such prov isi on s are

inconsistent with local law.

Trademarks

The product names and company names used in this manual are the registered trademarks

of the individual companies.

Copyright

This manual is copyrighted with all rights reserved. Under the copyright laws, this manual may

not be copied, reproduced or translated into another language, in whole or in part, without the

written consent of Canon Inc.

(C) CANON INC. 2009

Caution

Use of th is ma nu al shou ld be st ri ctly su pe rvised to avoi d disc lo sure of conf id entia l

information.

c

c

Explanation of Symbols

The following symbols are used throughout this Service Manual.

Symbols Explanation Symbols Explanation

Check.

Remove the claw.

Check visually. Insert the claw.

Check the noise. Use the bundled part.

Disconnect the connector.

Push the part.

Connect the connector. Plug the power cable.

Remove the cable/wire

from the cable guide or wire

saddle.

Turn on the power.

Set the cable/wire to the

cable guide or wire saddle.

Remove the screw.

Tighten the screw.

The following rules apply throughout this Service Manual:

1. Each chap ter contains sections explaining the purpose of specific functions and the

relationship between electrical and mechanical systems with reference to the timing of

operation.

In the diagrams,

represents the path of mechanical drive; where a signal name

accompanies the symbol, the arrow indicates the direction of the electric signal.

The expression "turn on the power" means flippin g on the power switch, closi ng the

front door, and closing the delivery unit door, which results in supplying the machine with

power.

2. In the digital circuits, '1' is used to indicate that the voltage level of a given signal is

"High", while '0' is used to i ndicate "Low". (The voltage value, however, differs from

circuit to circuit.) In addition, the asterisk (*) as in "DRMD*" indicates that the DRMD

signal goes on when '0'.

In practically all cases, the internal mechanisms of a microprocessor cannot be checked

in the field. Theref ore, the operations of the microprocessors used in the machin es

are not discussed: they are explained in terms of from sensors to the input of the DC

controller PCB and from the output of the DC controller PCB to the loads.

The desc riptions in this Service Manual are subject to chan ge with out notice for product

improvem ent or other purposes, and majo r changes will be commu nicated in the form of

Service Information bulletins.

All service persons are expected to have a good understanding of the contents of this Service

Manual and all relevant Service Information bulletins and be able to identify and isolate faults

in the machine.

BLANK PAGE

Contents

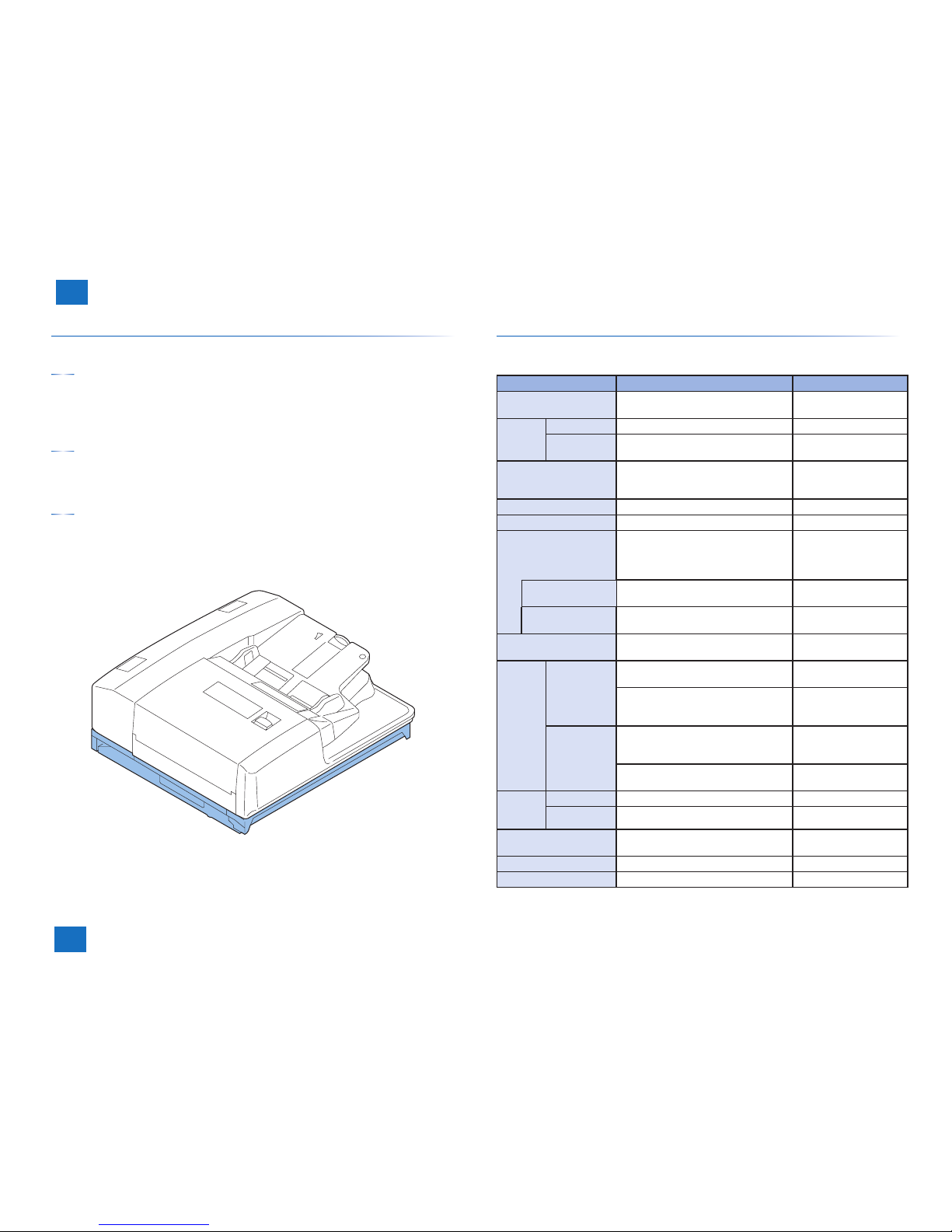

Color Image Reader - L1

1 Product Outline

Characteristic ------------------------------------------------------------------1-1

High speed 2-side scan-at one time (DADF) ------------------------------- 1-1

High capacity pickup tray (DADF) --------------------------------------------- 1-1

Next generation scanner unit (DADF/Reader)------------------------------ 1-1

Specication --------------------------------------------------------------------1-1

Name of each area -----------------------------------------------------------1-2

External view ------------------------------------------------------------------------ 1-2

Sectional view ---------------------------------------------------------------------- 1-2

Option conguration ---------------------------------------------------------- 1-2

2 Technology

Basic conguration -----------------------------------------------------------2-1

Function conguration ------------------------------------------------------------ 2-1

Parts conguration ----------------------------------------------------------------- 2-1

Overview of power circuit -------------------------------------------------------- 2-2

Reader controller PCB ------------------------------------------------------------ 2-2

Scanner unit ------------------------------------------------------------------------- 2-3

Basic sequence -------------------------------------------------------------------- 2-4

Controls --------------------------------------------------------------------------2-6

Scanner drive control ------------------------------------------------------------- 2-6

Original size detection ------------------------------------------------------------ 2-7

Dust detection control ------------------------------------------------------------2-12

Magnication change ------------------------------------------------------------2-16

Image processing ----------------------------------------------------------------- 2-16

Fan -----------------------------------------------------------------------------------2-18

Power unit --------------------------------------------------------------------------2-18

Service work -----------------------------------------------------------------------2-19

3 Periodic Servicing

Periodic Servicing List -------------------------------------------------------3-1

4 Parts Replacing and Cleaning

Parts List ------------------------------------------------------------------------4-1

External Covers -------------------------------------------------------------------- 4-1

Main unit ----------------------------------------------------------------------------- 4-1

Motor ---------------------------------------------------------------------------------- 4-2

Fan ------------------------------------------------------------------------------------ 4-2

Sensor -------------------------------------------------------------------------------- 4-3

PCB ----------------------------------------------------------------------------------- 4-3

Main unit -------------------------------------------------------------------------4-4

Removing the Scanner unit ----------------------------------------------------- 4-4

Periodical/Consumable parts, Spots to Clean -------------------------4-6

Turndown Mirror/Free Curved Mirror Cleaning ----------------------------- 4-6

5 Adjustments

Overview ------------------------------------------------------------------------5-1

Adjustment Method ----------------------------------------------------------- 5-3

Measurement during Reader Controller PCB Replacement and After

RAM Clear --------------------------------------------------------------------------- 5-3

Processing after Scanner Unit Replacement ------------------------------- 5-5

Processing after Copyboard Glass Replacement ------------------------- 5-7

Color Image Reader - L1

6 Installation

Color Image Reader - L1 ----------------------------------------------------6-1

Point to Note About Installation ------------------------------------------------- 6-1

Checking the contents ------------------------------------------------------------ 6-2

Turning Off the Host Machine --------------------------------------------------- 6-3

Installation procedure ------------------------------------------------------------- 6-4

Connection of the equipment --------------------------------------------------6-11

Install the external cover --------------------------------------------------------6-19

Afxing Labels ---------------------------------------------------------------------6-26

Post-installation check -----------------------------------------------------------6-27

Perform the Auto Gradation Adjustment ------------------------------------6-28

Appendix

Service Tools ---------------------------------------------------------------------- I

List of Oils/Solvents -------------------------------------------------------------------I

General Circuit Diagram ------------------------------------------------------- II

General Circuit Diagram (1/1) ----------------------------------------------------- II

1

H11.0

H11.0

Product Outline

Product Outline

1

1

Product Outline

Characteristic

Specifi cation

Name of each area

Option confi guration

■

■

■

■

H11.0

H11.0

1-1

1-1

1

1

Product Outline

Product Outline

Characteristic

High speed 2-side scan-at one time (DADF)

Maximum 200 ipm (2-side, B/W, 300 dpi).

Color scan is also available, maximum 80 ipm (one side/2-side, 300 dpi).

High capacity pickup tray (DADF)

Maximum document loading is 300 sheets (80 g/m2 or lower).

Next generation scanner unit (DADF/Reader)

Adapting CMOS line sensor, allows low power consumption and high-speed trigger.

Exposure to light by white color LED, enables low power consumption, size reducing, and

color balance improvement.

Color aberration-free.

•

•

•

•

•

•

Specifi cation

Following is a specifi cation list of the host machine.

Item Specifi cation/function Remarks

Exposure system High-brightness white LED + refl ection

plate

-

Original

scan

In BOOK mode Scan by movement of scanner unit -

In DADF mode Scan by original stream reading with

scanner unit fi xed

-

Scanning resolution B&W: 600 dpi x 600 dpi

Color: 300 dpi x 300 dpi

600 dpi x 600 dpi *

*: Enabled when the

system upgrade RAM-B1

(optional) is installed

Gradation 256 gradations -

Carriage position detection Scanner unit HP sensor (SR2) -

Magnifi cation change 25% to 400% B&W: scan magnifi cation

change (Sub scanning 2line skipping: 25 to 50%)

Color: degital reproduction

In main scanning

direction

Image processing in main controller PCB -

In sub scanning

direction

Image processing in main controller PCB Some are processed by

the reader controller PCB.

Number of line of CMOS

line censor

4 lines (R, G, B, B/W) -

Original

size detection

In BOOK mode Main scanning direction: detection by

CMOS line censor (scanner unit)

-

Sub scanning direction: detection by refl ection sensor (original size sensor 1 (AB

type) or original si ze sensor2 (Inch type)

-

In DADF mode Main scanning direction: detection by the

original width volume/photointerrupter on

DADF

-

Sub scanning direction: detection by the

photointerrupter on DADF

-

Maximum

original

size

In BOOK mode 297 mm x 431.8 mm -

In DADF mode 304.8 mm x 630 mm -

Dimension 635 x 590 x 72 (W x D x H mm) DADF is not counted for

the height.

Weight Approx. 12 kg -

Option Reader heater For Japan only

Contents of description are subject to change due to product improvement etc.

H11.0

H11.0

1-2

1-2

1

1

Product Outline

Product Outline

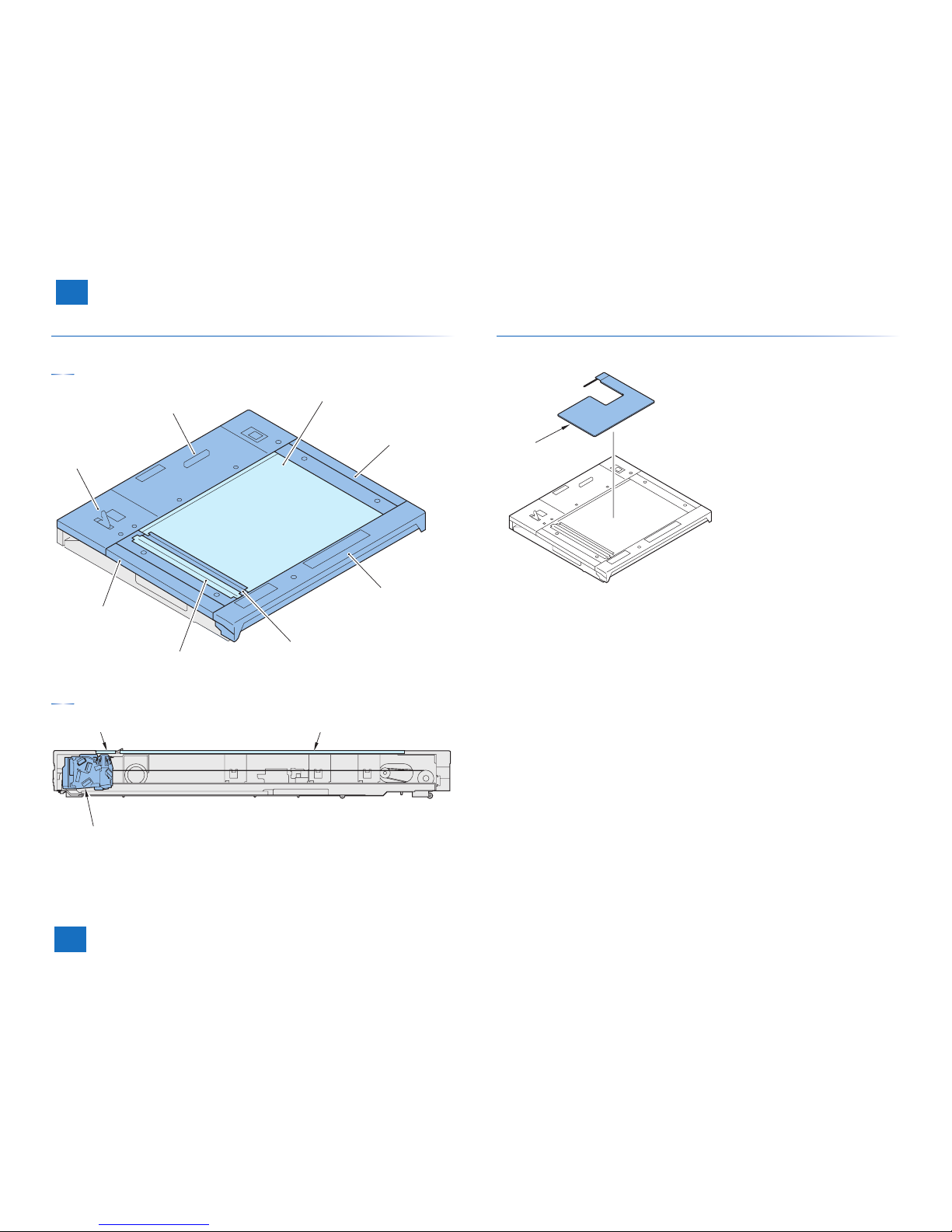

Name of each area

External view

PCB cover

Rear cover

Copyboard glass

Right cover

Front cover

Glass retainer

Stream read glass

Left cover

Sectional view

Stream reading glass

Copyboard glass

Scanner unit

Option confi guration

Followings are the options for the host machine.

Reader heater

BLANK PAGE

2

2

2

Technology

Technology

Technology

Basic confi guration

Controls

■

■

2-1

2-1

2

2

Technology

Technology

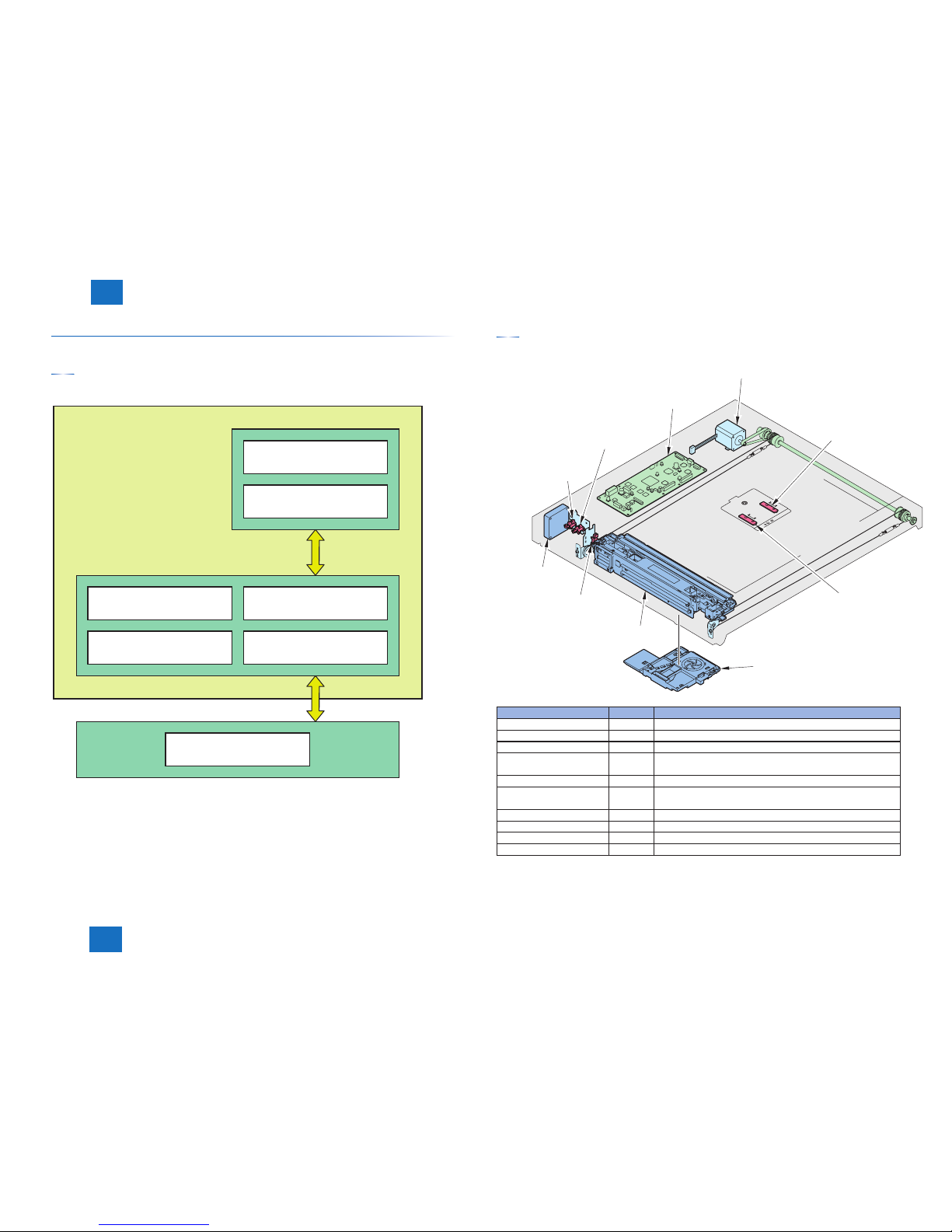

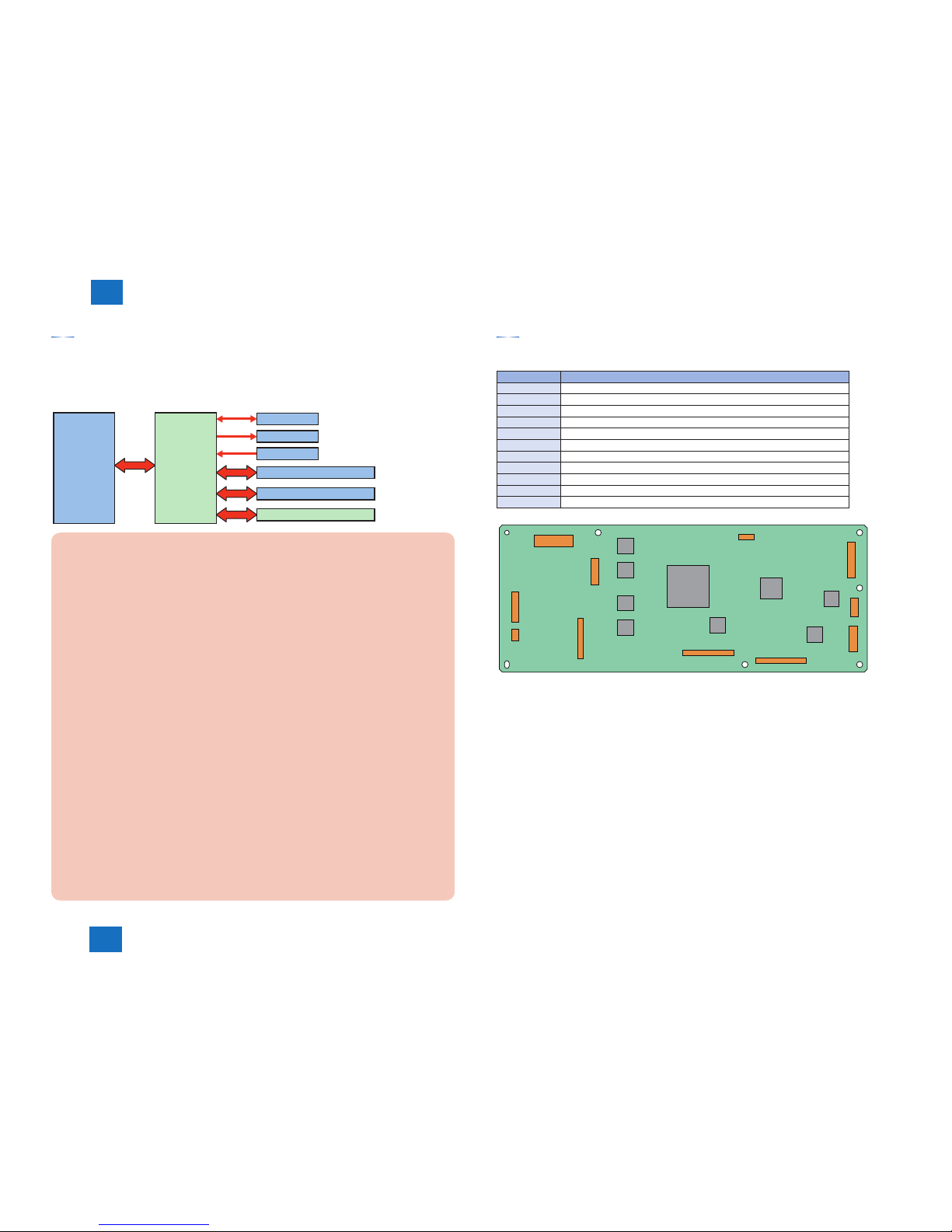

Basic confi guration

Function confi guration

Following is the list of functions.

Original size detection

Image processingDust detection

Scanner drive

Reader controller PCB

A/D conversion

Image scanning

Scanner unitReader unit

Magnification change

Main controller PCB

Parts confi guration

Followings are the positions and names of main confi guration parts.

Original size sensor 2

(CF2)

Original size sensor 1

(CF1)

Scanner unit

cooling fan (FM2)

Scanner unit

DADF

open/closed

sensor 1

(SR1)

Scanner unit

home position sensor

(SR2)

Scanner unit

exhaust fan (FM1)

Reader controller PCB

(PCB1)

Scanner motor (M1)

DADF

open/closed

sensor 2

(SR3)

Component part Symbol Function/specifi cation

Scanner motor M1 2 phase pulse motor: pulse control

Scanner unit exhaust fan FM1 Exhaustion of scanner unit

Scanner unit cooling fan FM2 Cooling of scanner unit

DADF open/closed

sensor 1

SR1 DADF open detection (DADF is detected at 5 degree)

Scanner unit HP sensor SR2 Scanner unit HP detection

DADF open/closed

sensor 2

SR3 DADF open detection (size detection timing is detected

when DADF is open at 25 degree.

Original size sensor 1 CF1 Size detection in sub scanning direction (AB type)

Original size sensor 2 CF2 Size detection in sub scanning direction (INCH type)

Scanner unit --- Image reading, analog image processing

Reader controller PCB PCB1 Control of entire reader, digital image processing

2-2

2-2

2

2

Technology

Technology

Overview of power circuit

Control of the host machine is conducted at the reader controller PCB.

Reader controller PCB also controls the DADF driver PCB and DADF scanner unit.

Following is the relations of each electrical part.

Sensor

Fan

Motor

Host

machine

Reader

controller

PCB

Scanner unit (reader)

Scanner unit (DADF)

DADF driver PCB

Error Code

E270 (Error in the main scanning/sub scanning synchronization signal).

-0001 Sub scanning synchronization signal (VSYNC) is not properly transmitted from CMOS

PCB (front side scanner unit), and this causes image failure or abnormal termination.

-0002 Sub scanning synchronization signal (VSYNC) is not transmitted due to the error in the

main scanning synchronization signal (HSYNC), and this causes image failure or abnormal

termination.

-0101 Sub scanning synchronization signal (VSYNC) is not properly transmitted from CMOS

PCB (back side scanner unit), and this causes image failure or abnormal termination.

E280 (Communication error between reader controller PCB – scanner unit)

- 0001 If the communication is not started within the specifi ed time between reader controller

PCB – front side scanner unit.

- 0101 If the communication is not started within the specifi ed time between reader controller

PCB – back side scanner unit.

E400 (Communication error between reader controller PCB – DADF)

-0001 If reception error occurs during communication between reader controller PCB - DADF

-0002 If reception error occurs during communication between reader controller PCB - DADF

E490 (Error caused by incorrect DADF type)

-0001 If a not-supported DADF type is installed.

E473 (DDI communication error)

-0000 If the reader controller PCB detects communication error between the main controller

PCB and the reader controller PCB.

Reader controller PCB

Following is the function confi guration of reader controller PCB.

Jack No Role

J101 Power supply from the host machine (printer unit)

J103 Connection with DADF open sensor 1/2, scanner unit HP sensor

J104 Connection with fan

J201 Connection with scanner unit on reader

J202 Connection with scanner unit on DADF

J203 Communication with DADF

J204 Connection with PC

J205 Control of scanner motor

J206 Communication with main controller

J207 Connection with original size sensor 1/2

J208 Power supply for DADF

,

,

,

,

,

,

,

+%

,

,

,

,

2-3

2-3

2

2

Technology

Technology

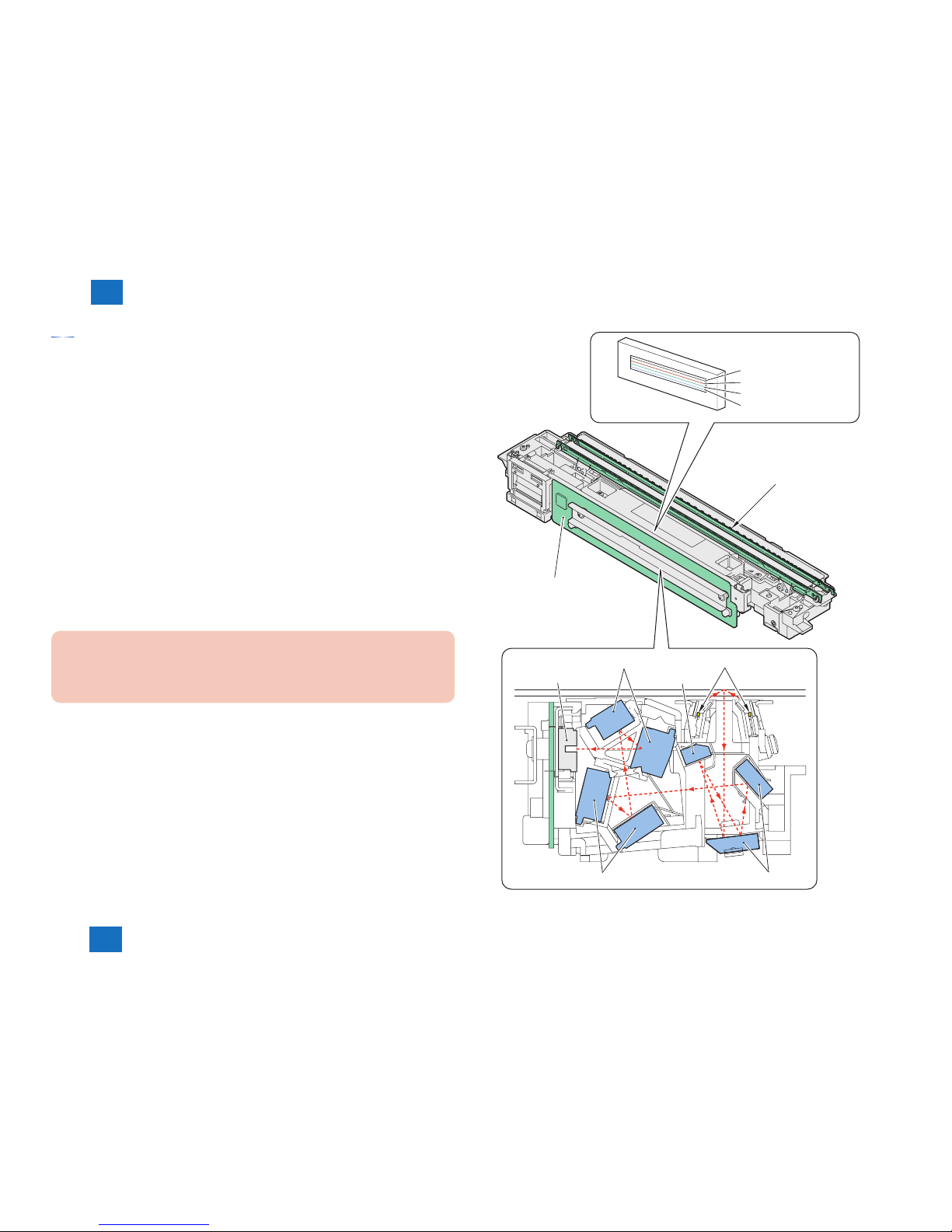

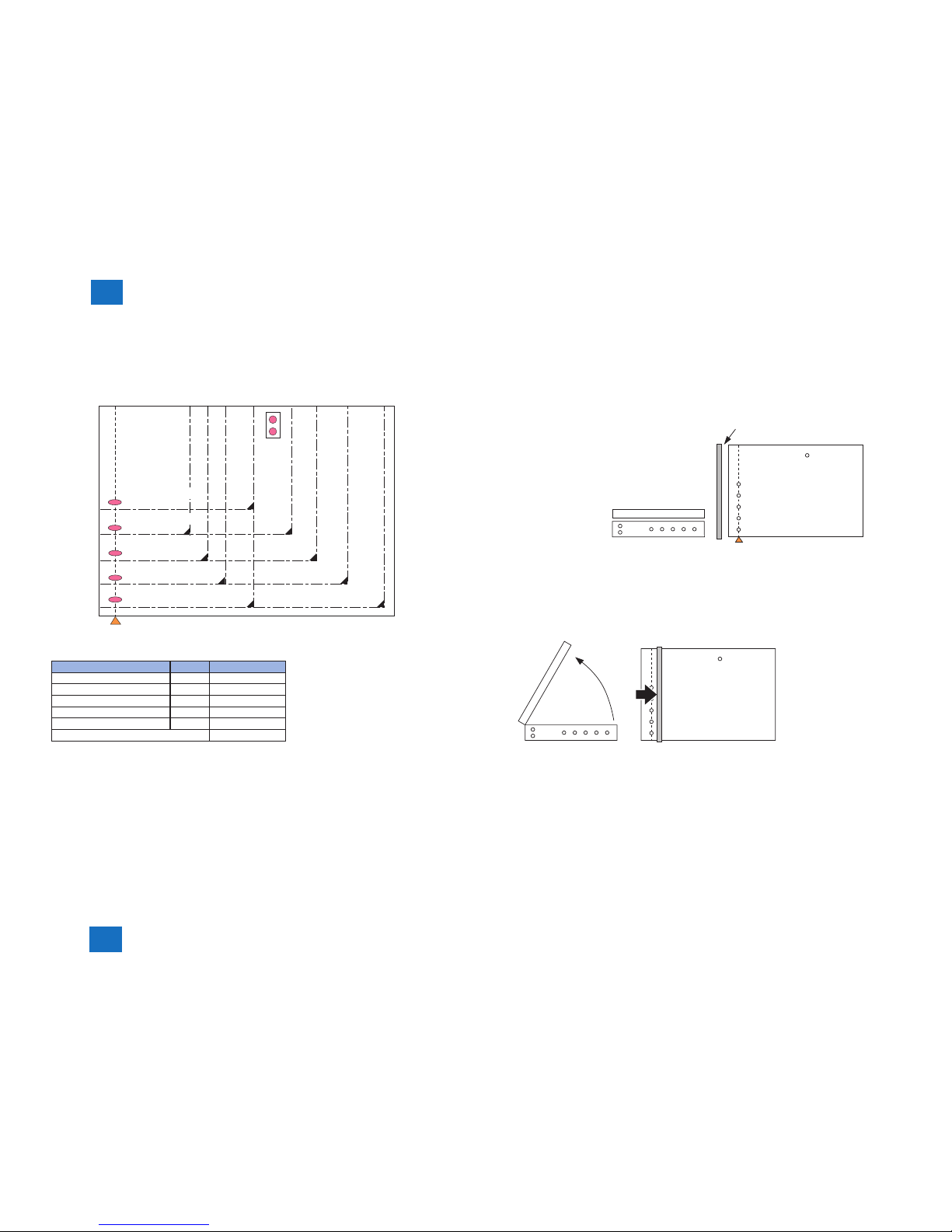

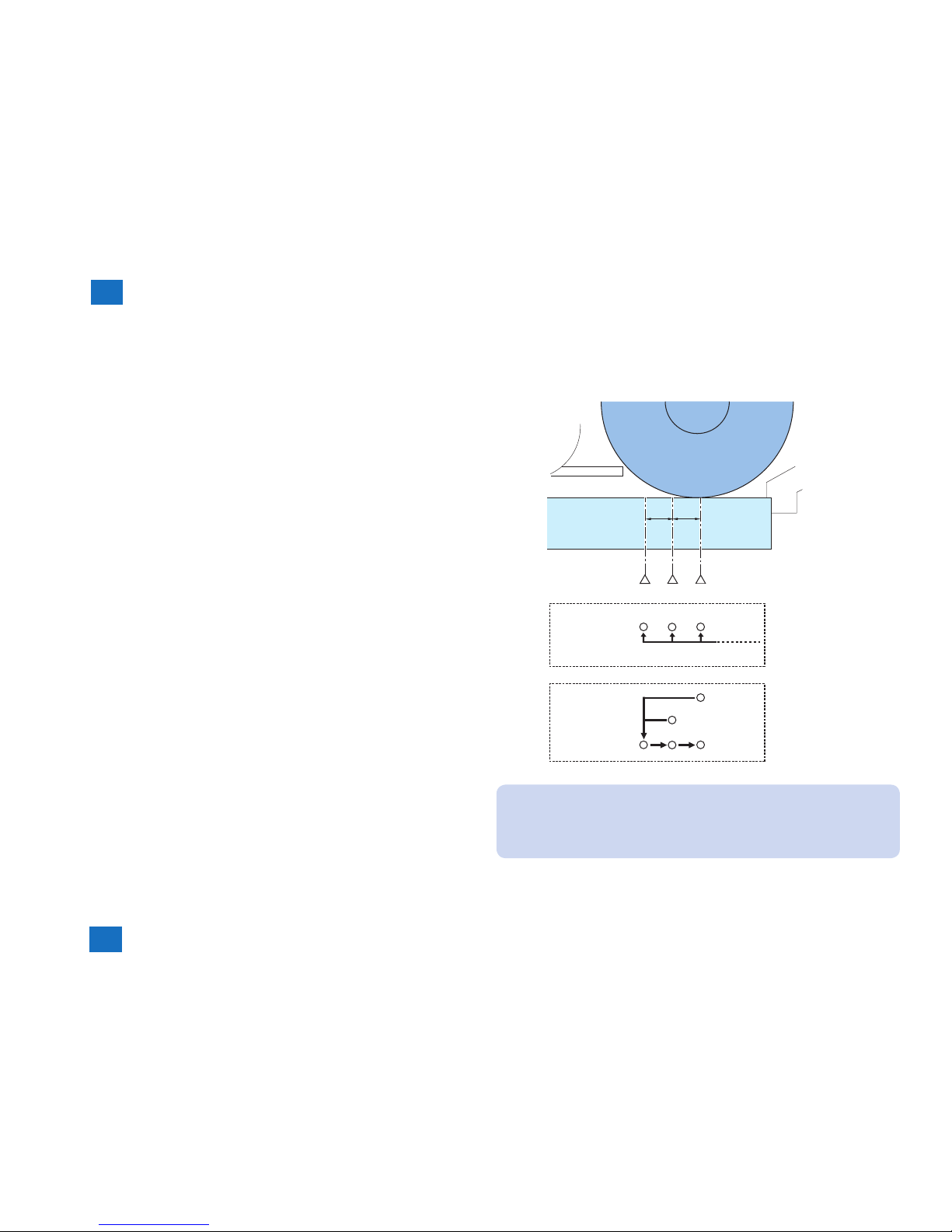

Scanner unit

Original exposure and scanning are performed by the integrated scanner unit of LED, mirror,

lens and CMOS line sensor.

Light emitted from LED is refl ected by the original and reaches the CMOS line sensor through

the 3 folding mirrors and 4 free curvature mirrors.

1. LED lamp unit

On LED lamp unit, the light is generated from the 2 LED lamp PCBs (LED chip: 48 pieces per

PCB).

Generated light is exposed to the original through the refl ection plate.

2. Free curvature mirror

Scanner unit is equipped with the 3 folding mirrors and 4 free curvature mirrors.

Free curvature mirror has symmetric facet in main scanning direction and asymmetric facet in

sub scanning direction against the optical axis.

3. CMOS line sensor

CMOS line sensor scans the image per 1image line.

CMOS line sensor has 4 lines (R, G, B, BW). At B&W scanning, it uses 1 line (B/W) and uses

3 lines (R, G, B) at color scanning.

Error code

E301 (insuffi cient light intensity)

-0001 The light intensity during front side shading is lower than the standard level

-0101 The light intensity during back side shading is lower than the standard level

Free curved mirrors Turndown mirrors

CMOS line sensor

Free curved mirrors

Turndown mirrors

LED (light source)

CMOS PCB

LED lamp unit

CMOS line sensor

Red (R) line

Greeen (G) line

Blue (B) line

Black & white (B / W) line

2-4

2-4

2

2

Technology

Technology

Basic sequence

At power ON

1. HP positioning

2. move to shift

shading start position

3. CMOS-LIVE control *2

gain correction

4. Completion operation

*1: Shifts only if the DADF is open.

*2: Controls by turning on/off the power of the scanner unit and the circuitry

around it for power saving and for protection against overheating.

*3: Shifts only if the DADF is open.

*1

*3

Stop

position

Start

position

Stream

reading

position

Shading

position

Home

position

Shading

start

position

Image

leading

edge

Original

size

detection

position

■

At start key ON (Book mode/1 sheet original)

1. HP positioning

2. move to shift

shading start position

7. Completion operation

6. Original scan

3. move to shift shading

4. fixed shading

- white plate dust detection

- shading correction

5. Start position

move to shift

*1: Executed only if 1 min or more (power off) has passed from the previous session.

*2: Shifts only if the DADF is open.

*3: Shifts only if the DADF is close.

*1

*1

*2

*3

*3

Stop

position

Start

position

Stream

reading

position

Shading

position

Home

position

Shading

start

position

Image

leading

edge

Original

size

detection

position

■

2-5

2-5

2

2

Technology

Technology

At start key ON (DADF mode/1 sheet original)

1. HP positioning

2. move to shift

shading start position

7. Completion operation

6. original stream

reading scan

6. shifts to point of

the stream reading

glass dust detection

3. move to shift shading

4. fixed shading

- white plate dust detection

- shading correction

5. Steam reading position

move to shift

*1: Executed only if 1 min or more (power off) has passed from the previous session.

*2: [Reference] Technology > Controls > Dust detection > Stream reading glass dust detection control

*3: Shifts only if the DADF is open.

*4: Shifts only if the DADF is close.

*1

*1

*3

*2

*4

*4

Stop

position

Stream

reading

position

Shading

position

Home

position

Shading

start

position

Image

leading

edge

Original

size

detection

position

■

2-6

2-6

2

2

Technology

Technology

Controls

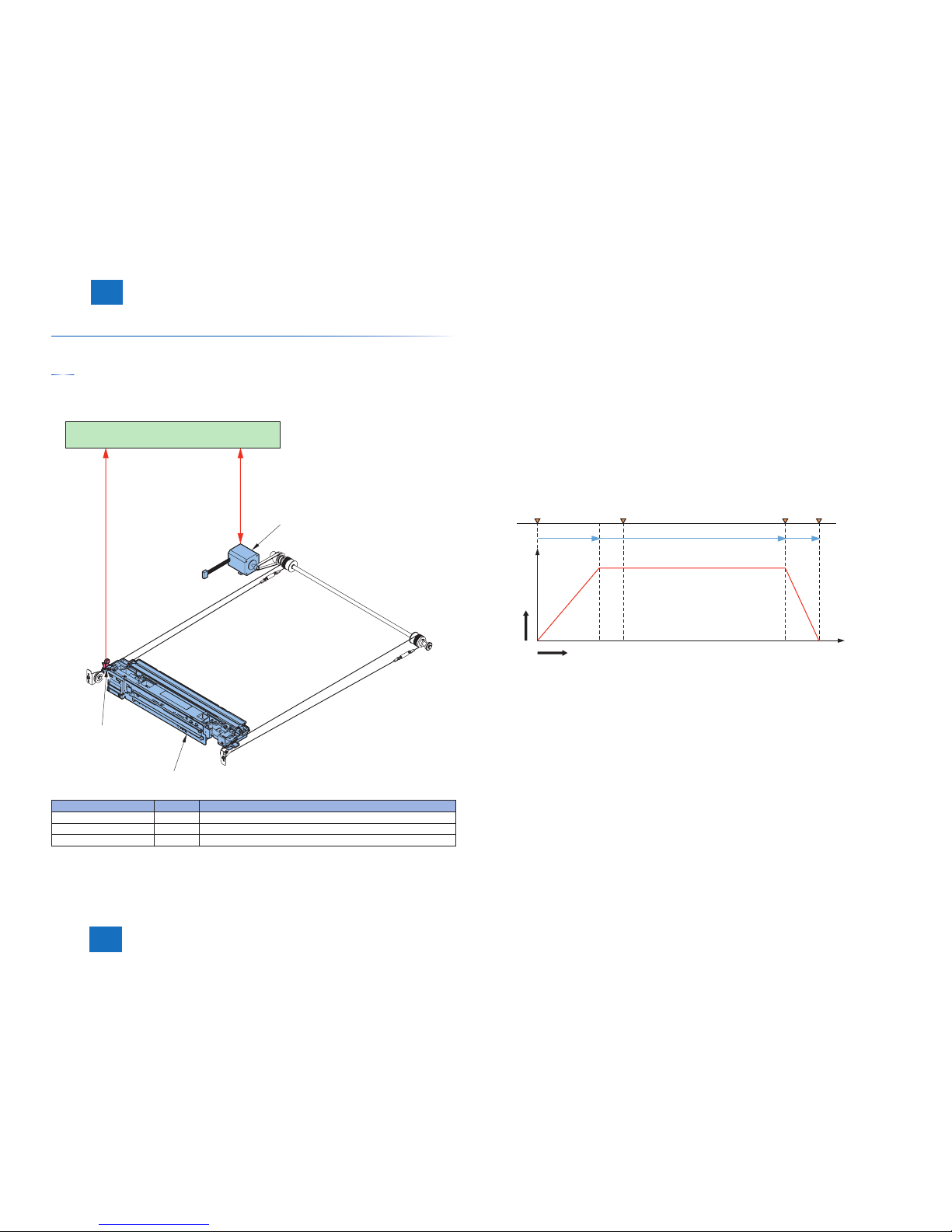

Scanner drive control

Confi guration of drive system

Following is the parts confi guration related with scanner drive system.

ACOM, BCOM

HP

Reader controller PCB

Scanner motor (M1)

Scanner unit

Scanner home position

sensor (SR2)

Component parts Symbol Function

Scanner motor M1 Control of the drive/stop, direction and speed of motor rotation

Scanner unit HP sensor SR2 Scanner unit HP detection

Scanner unit - Image reading, analog image processing

■

Scanner motor control

Following is the control system confi guration related with the scanner motor control.

Motor driver on the reader controller PCB controls the drive/stop, direction and speed of

scanner motor rotation in accordance with the signals from CPU.

1) Backward operation after image scanning

Backward operation after image scanning until shading position of scanner unit is control-

led by 468 mm/sec regardless of color mode.

2) Forward operation at image scanning

At image scanning, the following motor control controls the scanner unit operation.

Start position

Acceleration

Image leading edge

Normal speed

Image trailing edge

Deceleration

Stop

Shift

speed

Shift length

[1] [2] [3] [4]

[1] Acceleration Zone: accelerates to suit the selected mode.

[2] Approac h Zone : moves for speed stabilization.

[3] Image Read Zone: reads the image at a specific speed.

(if black-and-white/SEND mode, twice as fast as in full-color mode.)

[4] Deceleration Zone: past the image trailing edge, immediately decelerates and stops.

■

2-7

2-7

2

2

Technology

Technology

Following shows the scanning speed in each mode.

Function Mode Scan speed

Copy / SEND

B&W 468 mm/sec

Full color 203 mm/sec

Error Code

E202 (error in the scanner home position)

-0001 Error during home position detection operation (outward) of the front scanner unit.

-0002 Error during home position detection operation (homeward) of the front scanner unit.

Service Mode

(Lv.1) COPIER > ADJUST > ADJ-XY> ADJ-X

(Scanner system image leading edge position adjustment)

Enter the value to adjust the position of image leading edge.

Setting range: 1 – 100 (changing the value by 10 moves the position by 1mm)

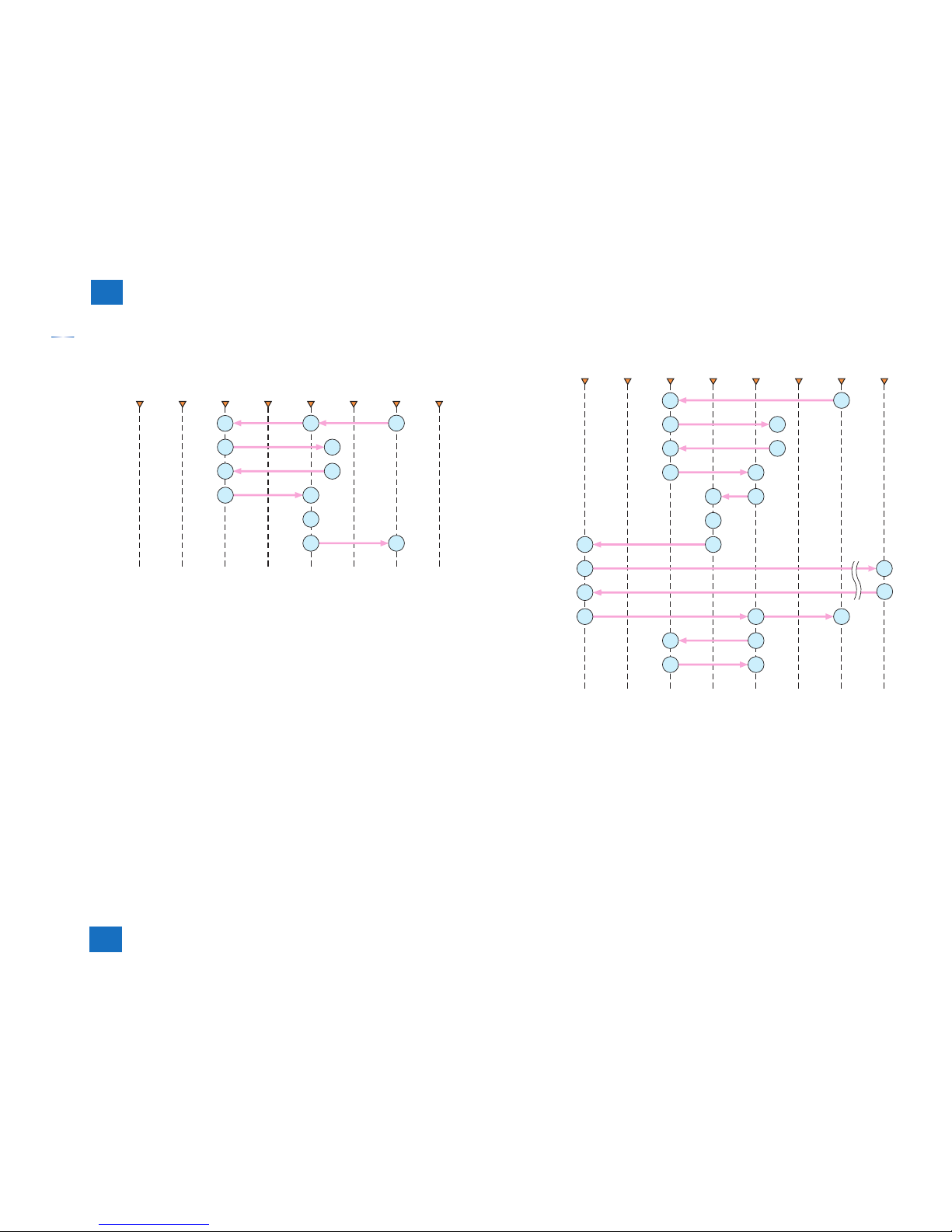

Original size detection

Original size is identifi ed based on the result combinations of refl ection light at the specifi c

point on the refl ection sensor and the scanner unit. To prevent the original from moving when

closing the DADF, there is 2 point original size detection per each size on the scanner unit.

In main scanning direction: scanner unit (AB type: 9 point measurement, Inch type: 6 point

measurement)

In sub scanning direction: refl ection type photo sensor (AB type: 1 point, Inch type: 1 point)

Original size is detected in the following procedure.

1) External light search (in main scanning direction only)

While keeping the LED lamp unit OFF, the CMOS sensor level of each detection point is

measured in main scanning direction.

2) Output level detection of each sensor

While keeping the LED lamp unit ON, CMOS sensor level of each detection point is

measured in main scanning direction.

The machine turns ON the LED of refl ection type photo sensor in sub scanning direction and

measures the sensor output.

Original size is identifi ed by these output combination.

•

•

2-8

2-8

2

2

Technology

Technology

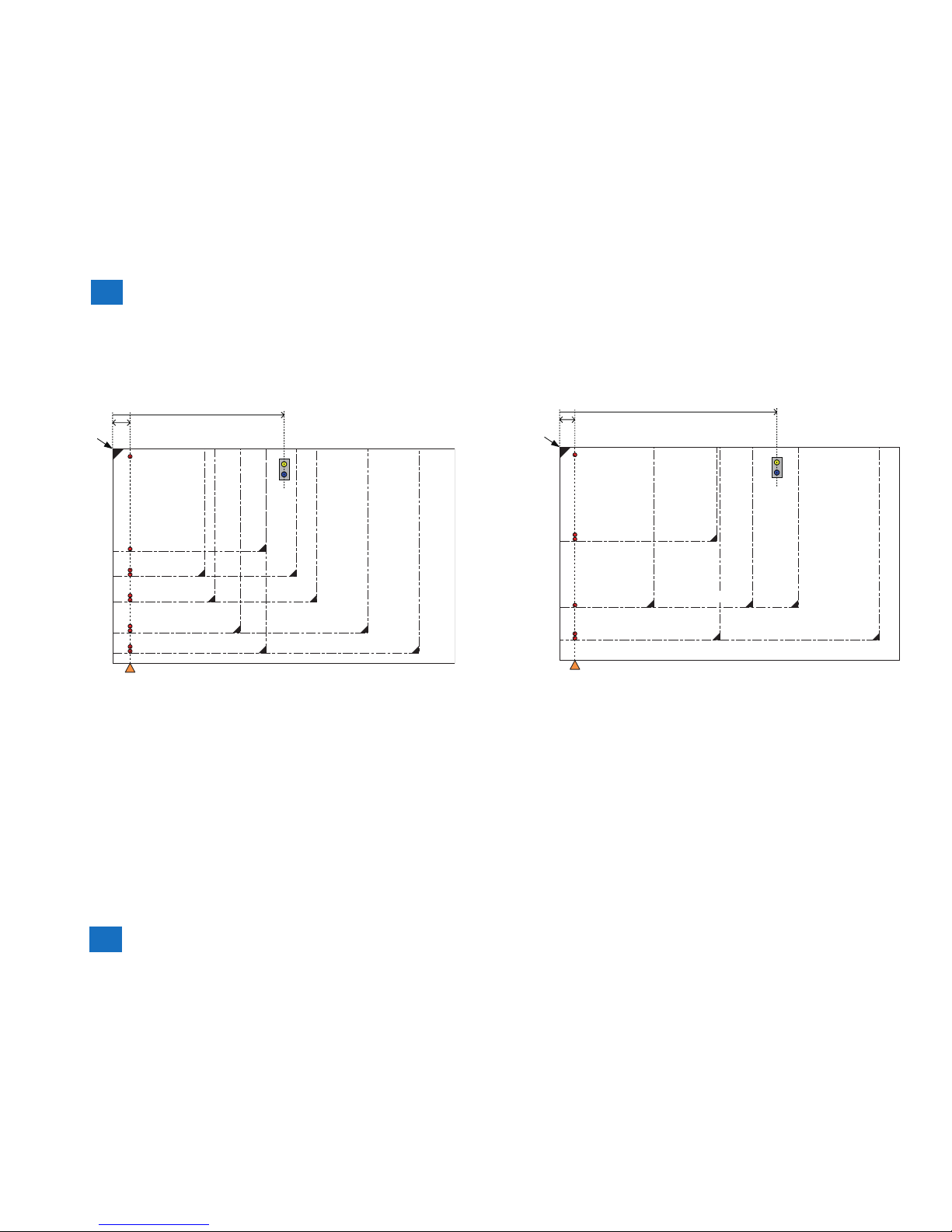

Original size detection position

In main scanning direction, the machine moves the scanner unit to the following position in

reference to the original position and measures the CMOS level of each detection position. In

sub scanning direction, original size is identifi ed by the following sensors.

A5

A5-R

A4-R

A4

A3

B4

B5

B5-R

20 mm

30.0 mm

146.0 mm

169.0 mm

178.0 mm

197.0 mm

206.0 mm

Original

size sensor 1 (CF1)

B6

0 mm239.5 mm

244.0 mm

253.0 mm

284.0 mm

293.0 mm

Original

push-on position

Scanner unit

original detection position

■

STMT-R

LETTER_R

LEGAL

LETTER

LEDGER

Original

push-on position

20 mm

30.0 mm

126.7 mm

135.7 mm

211.9 mm

STMT

0 mm 311 mm

264.0 mm

267.0 mm

Original

size sensor 2 (CF2)

Scanner unit

original detection position

2-9

2-9

2

2

Technology

Technology

Following is the combination of detection result and original size.

A/B: Original presence/absence detection result of 2 points (Refer to [2 point original detec-

tion at each detection position].).

Y: Output level has no change (refer to [Detection operation]).

-: Output level has change (refer to [Detection operation]).

Original size

Scanner unit detection position

Original size sensor 112345

ABABABABAB

A3 YYYYYYYYYY Y

B4 YYYYYYYY - - Y

A4R YYYYYY - - - - Y

A4 YYYYYYYYYY B5 YYYYYYYY - - B5R YYYY - - - - - - Y

A5 YYYYYY - - - - B6 YYYY - - - - - - A5R YY-------- None - - - - - - - - - - -

Original size

Scanner unit detection position

Original size sensor 2123

ABABAB

11” x 17” YYYYYY Y

LGL Y Y Y Y - - Y

LTRR Y Y Y Y - - LTR YYYYYY STMTR Y Y ---- STMT Y Y Y Y - - Absent - - ---- -

To keep the high accuracy detection even though an original moves when the DADF is

closed, this machine has 2 types of controls.

a. 2 point original detection at each detection position

In main scanning direction, the machine determines whether the original is present or not

from the 2 points of CMOS output near the original detection position.

Near 4 mm

Near 13 mm

1A: additional point

of detection

Original size

border line

Original size

border line

1B: conventional point

if detection

Result

Judgment

AB

Y Y Present

Y - Present

- Y Present

- - Absent

* Signal change with DADF Open to Close

Changed: -

Others: Y

The machine uses OR combinations of 2 points for identifi cation.

2-10

2-10

2

2

Technology

Technology

b. Priority on the front original presence

As a result of main scanning direction measurement, if the original absence is detected at

the rear while the original presence is detected at the front, a priority is given to the result of

original presence at the front.

Point of detection 1

Point of detection 2

Point of detection 4

Point of detection 3

Point of detection 5

Scanner unit

original detection position

B5

Original

size

sensor1

Original detection position Result Identifi ed size

1YY

2-Y

3-Y

4YY

5--

Judgment B5

* Signal change with DADF Open to Close

Change: -

Others: Y

Detection operation

Following is the overview of operation for original size detection (AB type).

1) Wait status

Scanner unit: shading position

LED lamp unit: OFF

Original size sensor: OFF

Original detection position

Scanner unit

Original size

sensor 1

Reader unit

DADF

Copyboard

glass

Point of detection 1

Point of detection 2

Point of detection 3

Point of detection 4

Point of detection 5

DADF open/closed sensor 2

DADF open/closed sensor 1

2) DADF opened (The angle of DADF is 25 degree or more).

Scanner unit: It moves to the original detection position (20mm from the original push-on

position)

LED lamp unit: OFF

Original size sensor: OFF

■

2-11

2-11

2

2

Technology

Technology

3) Close DADF (The angle of DADF is from 5 to 25 degree).

3-1) The external light detection operation is performed. Since the area covered by an

original will be blocked from external light, the machine will assume the absence of an

original at points that detect external light. After the DADF sensor 2 detects [Close],

the external light detection operation is started.

In case of the described original size, A3/B4/A4/B5 are excluded from the list of pos-

sible sizes at this point.

original

: external light

25 degrees

3-2) After the external light detection operation, the machine turns ON the LED in the

main scanning direction and the refl ected light is detected by the CMOS line sensor

(5 points). After the fi rst detection, it continues detection by the specifi ed interval (it

completes after 3 sec). The original size sensor 1 starts detection in the sub scanning

direction.

25 degrees

: LED light

4) DADF fully closed (the angle of DADF is 5 degree or less).

The machine monitors the changes of output level of each sensor for 3 sec from when the

DADF open sensor 1 detects the [Close] status. The machine determines the original pres-

ence in the point where the output level has no change.

The machine identifi es the original size from the combination of the level change at 5

points (priority on the front original presence).

5 degrees

5) Wait status (wait for start key)

Scanner unit: shading position

LED lamp unit: OFF

Original size sensor: OFF

2-12

2-12

2

2

Technology

Technology

Dust detection control

Overview

The timing of dust detection is as follows.

[2][1] [2] [2]

[3]

[3]

Start key

ON

Before stream

reading

1st sheet

scanned

2nd sheet

scanned

Between

sheets

After scan Standby

[1] White plate dust detection control

[2] Steam reading glass / Scanning glass dust detection control,

Dust detection correction control (continuous lines)

[3] Dust detection correction control (noncontinuous lines)

Scanner unit

(DADF)

- White plate dust detection

- Stream reading glass dust detection

- Dust detection correction (continuous lines)

- Dust detection correction (noncontinuous lines)

Scanner unit

(Reader)

- White plate dust detection

- Scanning glass dust detection

- Dust detection correction (continuous lines)

- Dust detection correction (noncontinuous lines)

■

White plate dust detection control

In this machine, the fans cool down the inside of the DADF to prevent the overheating at

stream reading operation. As a result, dust in the DADF may stick to the white plate and it

may cause the lines on the image.

To reduce the infl uence from the dust, the white plate dust detection and correction are per-

formed.

(1) White plate dust detection

The machine compares the shading coeffi cient obtained from shift shading and the shading

coeffi cient obtained from fi xed shading to identify the presence/absence of dust and, if any,

identifi es the coordinates and width of the area.

(2) White plate dust correction

If the machine detects the dust as a result of white plate dust detection, it interpolates the

shading coeffi cient of the area using the shading coeffi cient of both sides so as to decrease

the effects of the presence of dust. It executes the shading correction using the shading coef-

fi cient obtained after the interpolation.

When the dust is detected as a result of white plate dust detection, the machine interpolates

the shading coeffi cient of the dust area using the shading coeffi cient of both sides so as to

reduce the effects of the dust. The shading correction is executed after the interpolation.

[Detection Algorithm]

[Correction Algorithm]

Computation of shading

coefficient

(shift shading to

reference area)

Computation of shading

coefficient

(from fixed shading to

shading correction position)

Detection of coordinates of

start of dust and width

Correction of dust area

coefficient using data of both sides

Fixing shading position

Shading correction position

Reference area

(Shading coefficient

White plate

Area

of dust

Comparison

■

2-13

2-13

2

2

Technology

Technology

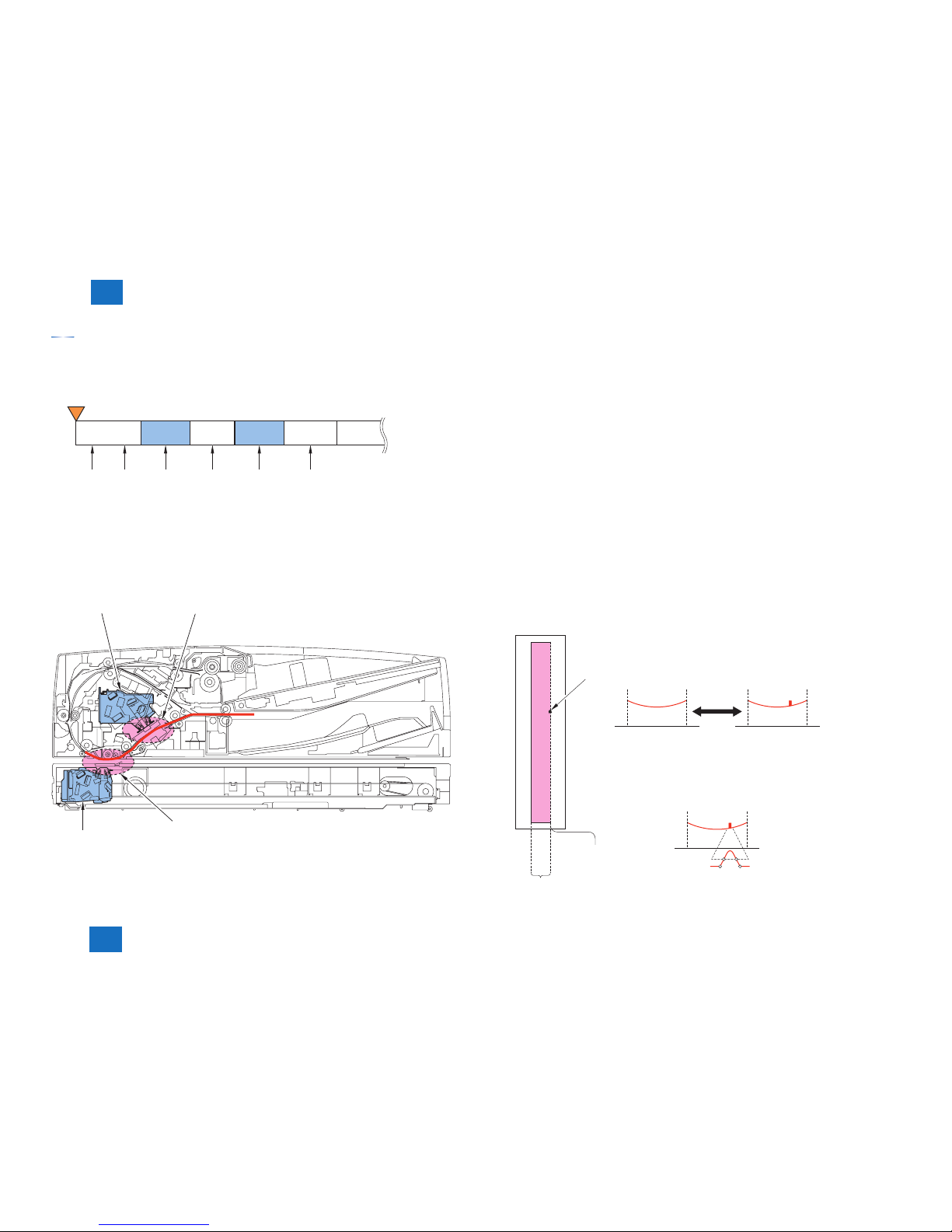

Stream reading glass dust detection control

The machine checks the presence/absent of dust on the stream reading glass and the DADF

platen roller 1. It then changes the point of reading or executes image correction (refer to

[dust detection correction control (continuous lines)]) depending on the result of detection to

avoid the reproduction of dust particles in its output images.

a. At the start of a job

The scanner unit moves to the reading position saved at the detection of the previous job

ends.

After it moves, the dust detection is executed. If the dust is detected, the machine executes

dust correction by making correction on the pixels on both sides of the area where dust is

found.

[1] It moves to the reading position.

b. Between sheets

The dust detection is executed. If the dust is detected, the machine executes dust correction

by making correction on the pixels on both sides of the area where dust is found.

The scanner unit does not move due to the dust detection.

c. At the end of a job

1) The scanner unit moves to the default reading position A.

[2] It moves to the reading position A.

*1: In case that the reading position at the start of a job is one other than A.

2) The dust detection is executed. If there is no dust on the A position, the machine saves

the A as a reading position for a next job and fi nishes the dust detection.

3) If there is a dust on the A position, the machine execute the dust detection on the B

position. If there is no dust on the B position, the machine saves the B as a reading

position for a next job and fi nishes the dust detection.

[3] It moves to the B position.

4) If there is a dust on the B position, the machine executes the dust detection on the C

position. If there also is a dust on the C position, the machine saves the position where

the least dust is found among the A, B or C positions as a reading position for a next job

and then, displays an alarm to perform the cleaning.

[4] It moves to the reading position C.

■

A

0.5 mm 0.5 mm

B

C

*1

*1

At the start

of a job

[1]

At the end

of a job

[3] [4]

[2]

MEMO:

(Lv.1) COPIER > OPTION > IMG-RDR > DFDST-L1

Adjustment of the dust detection level between sheets

(Lv.1) COPIER > OPTION > IMG-RDR > DFDST-L2

Adjustment of the dust detection level at job end

Loading...

Loading...