Canon Color Bubble Jet BJC-4400 Series, Color Bubble Jet BJC-4300, Color Bubble Jet BJC-4400 Service Reference Manual

™

C olor Bubb le Jet

Printer

BJC-4400

Series

QY8-13P1-000

MAY. 1998

COPYRIGHT 1998 CANON INC. CANON BJC-4400 PRINTED IN JAPAN (IMPRIME AU JAPON)

REVISION 0

SERVICE

REFERENCE MANUAL

Q30-2830-220 120V(CCSI)

Q30-2830-221 120V(CAN)

Q30-2830-222 (UNIVERSAL)

Q30-2830-230,630 220V-240V(EUR)

Q30-2830-231,631 220V-240V(GER)

Q30-2830-232,632 220V-240V(FRN)

Q30-2830-280,680 220V-240V(UK)

Application

This manual has been issued by Canon Inc. for qualified persons to learn technical theory, installation, maintenance, and repair

of products. This manual covers all localities where the products are sold. For this reason, there may be information in this

manual that does not apply to your locality.

Corrections

This manual could include technical inaccuracies or typographical errors due to improvements or changes in the products. When

changes occur in applicable products or in the content of this manual, Canon will release technical information as the need arises.

In the event of major changes in the contents of this manual over a long or short period, Canon will issue a new editions of this

manual.

The following paragraph does not apply to any countries where such pr ovisions ar e inconsistent with local law.

T rademarks

The product names and company names described in this manual are the registered trademarks of the individual companies.

Copyright

This manual is copyrighted with all rights reserved. Under the copyright laws, this manual may not be copied, reproduced or

translated into another language, in whole or in part, without the written consent of Canon Inc., except in the case of internal

business use.

Copyright 1998 by Canon Inc.

CANON INC.

BJ Products Technical Support Dept

16-1, Shimonoge 3-chome, Takatsu-ku, Kawasaki-shi, Kanagawa 213, Japan

This manual was produced on an Apple MacintoshPower Mac 8500/180 personal computer and Apple

LaserWriter16/600PS-J laser beam printer; final pages were printed on Varityper 5300 with 4000-J RIP. All graphics were

produced with MACROMEDIA FREEHAND 5.5J.

All documents and all page layouts were created with QuarkXPress 3.3J.

I.PREFACE

CHAPTER 1: MAJOR CHANGES

This chapter explains the main differences between BJC-4300 and BJC-4400.

CHAPTER 2: SERVICE MANUAL

This chapter explains the main differences between the SERVICE MANUAL of the BJC-4300 and

BJC-4400.

NOTE

· Page No. displayed are those of pages to be replaced for each item.

This manual is based on the following manuals, and only includes differences between BJC-4300 and

BJC-4400.

QY8-1352-000 BJC-4300 SERVICE MANUAL, Rev.0

II.CONTENTS

CHAPTER 1

MAJOR CHANGES

I.MAJOR CHANGES

BJC-4400 contains the following modifications compared to BJC-4300.

1.1 PRODUCT SPECIFICATIONS

1. Faster throughput speed(especially in HS mode)

2. T-shirt Transfer (TR-201) added as media type

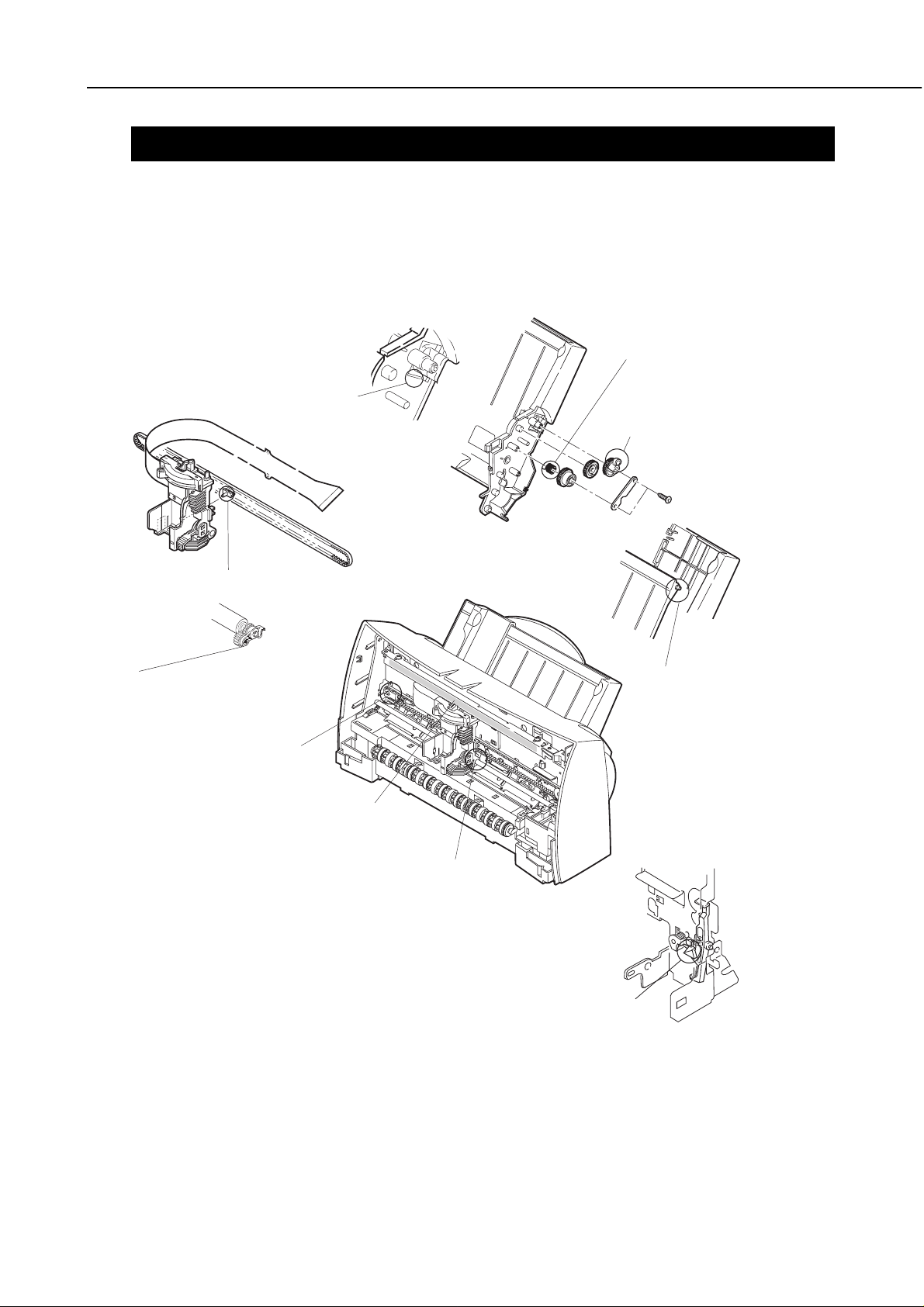

1.2 PRINTER MECHANICAL SYSTEM

1. Countermeasures for quality improvements to the current model were incorporated

Shape changes : Carriage, paper delivery guide, platen and bottom case

Additional changes : Increased area and amount of grease application

1.3 PRINTER ELECTRICAL SYSTEM

1. To improve throughput speed, the carriage motor, the paper feed motor and the motor driver were

modified.

CHAPTER 2

SERVICE MANUAL

Part 2: Product Specifications

BJC-4400

2-1

1. PRODUCT OUTLINE

1.1 Product Outline

This full color bubble jet desktop printer not only realizes high image printing through the implementation

of the PhotoRealism concept, but also higher speed printing compared to previous models.

This printer achieves high image printing by adopting "drop modulation technology" in the color BJ

cartridge and the photo BJ cartridge.

The expanded printing environment has allowed the printer to have banner printing capabilities. The

printer can also be used as a compact color scanner when the scanner cartridge is installed in the carriage.

All the function settings are easily set by the personal computer. The operation is easily performed with the

bidirectional Centronics interface (effective only for the device ID response)

This printer uses a built-in AC adapter. This is a small and light weight personal color printer with high

performance capabilities.

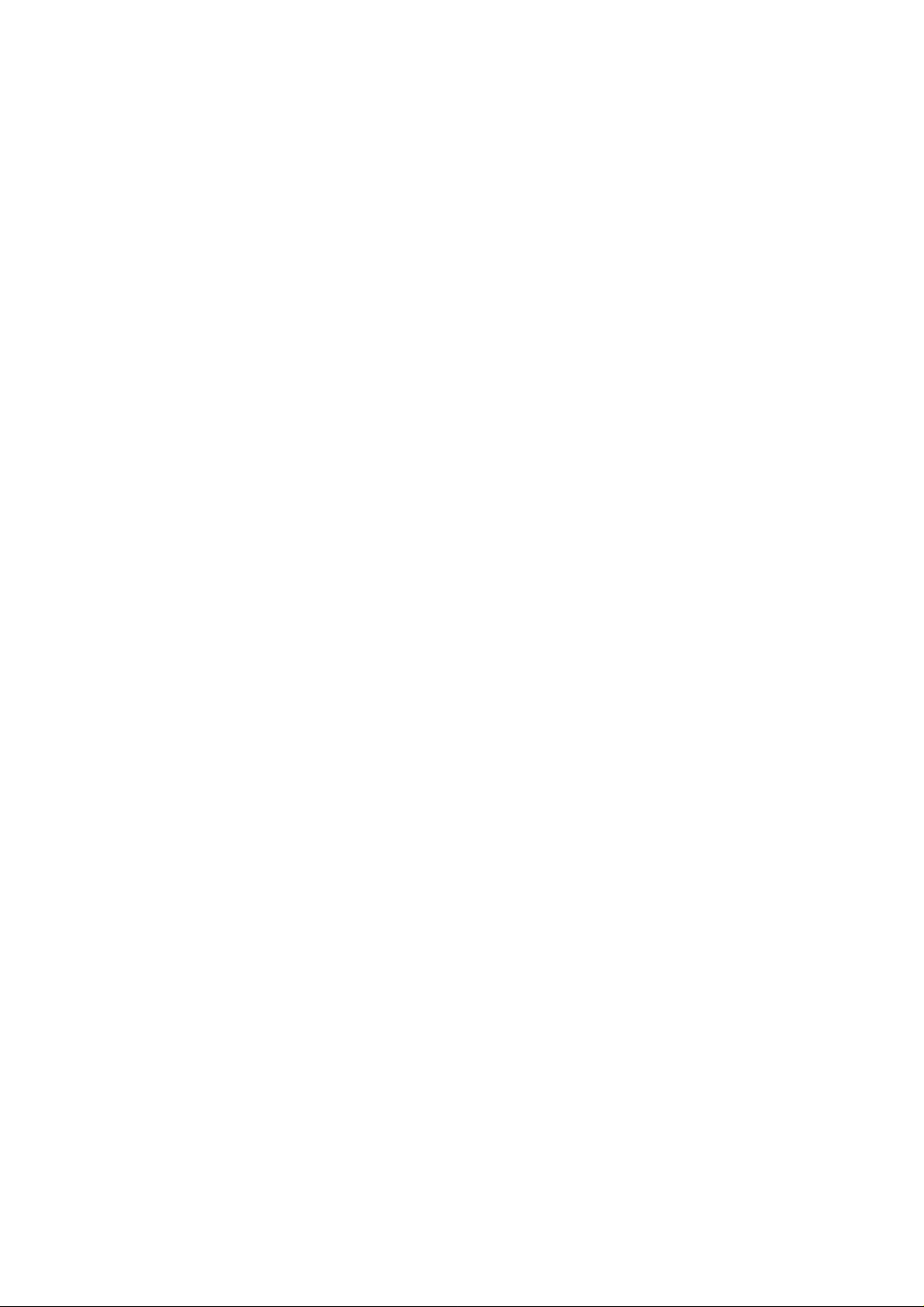

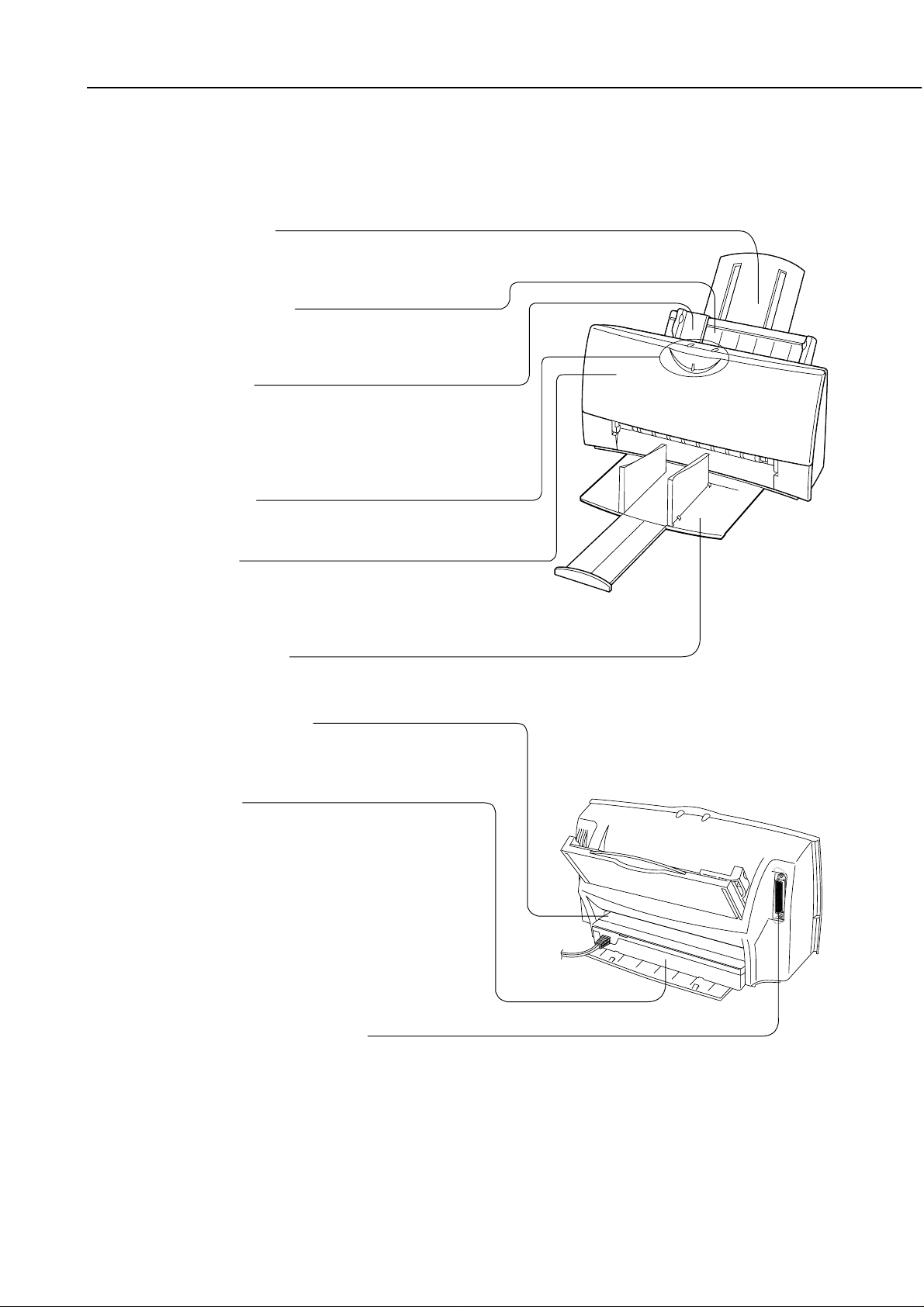

Figure 2-1 Printer Exterior

Paper Guide

Operator Panel

BJ Cartridge Container

Paper Support

Cut Sheet Feeder

Front Cover

Parallel Interface Connector

Paper Output Tray

Paper Output Tray Extension Guide

AC Adapter

Manual Feeding Slot

Part 2: Product Specifications

x 231.6 mm D x 203 mm H

Weight: Approx. 3.5 kg (7.7 lbs) (including color BJ cartridge)

3. Built-in AC adapter employs a high-current capable switching power supply.

4. Automatic power control (auto power on/off)

5. High quality printing of 720 x 360 dpi (in both monochrome and black when using the special printer

driver)

6. Two standard built-in printer control modes

LQ mode (EPSON LQ-2550 emulation)

BJ mode (IBM Proprinter X24E emulation)

[Canon extended mode is supported when using the canon printer driver.]

7. User replaceable BJ cartridge and adopting drop modulation technology color/ photo BJ cartridge .

Color BJ Cartridge Drop modulation technology has been adopted.

(Multi drop) It has separate ink cartridges (Bk) (Y, M, C) and the head with 136 nozzles

in a vertical line; 64 nozzles (Bk) + 24 nozzles x 3 (Y, M, C).

Black BJ Cartridge Contains the black ink and the head with 128 nozzles.

Depending on each sales territory, it is not packed with the printer, but is

available separately.

Photo BJ Cartridge Drop modulation technology has been adopted.

(Multi drop) It has integrated ink cartridges with the head with 136 nozzles in a vertical

line; 64 nozzles (Bk) + 24 nozzles x 3 (Y, M, C).

Black ink cartridge Black ink cartridge for the color BJ cartridge.

Color ink cartridge Tri-color (Y, M, C) ink cartridge for the color BJ cartridge.

(*Previous color and photo BJ cartridges that do not use drop modulation technology may be used,

however the printing quality will be the same as when drop modulation technology is not used.)

8. Device ID compatible to "Plug and Play"

(Responds only to the device ID/status of nibble mode)

9. Banner printing capabilities.

10. Capable of the double paper feeding with the leverless cut sheet feeder and manual feed. (It is possible

to feed paper manually even when the paper has been set on the cut sheet feeder.)

11. Photo quality printing using the Photo kit option and the photo printing special driver.

12. Cartridge container packed with the printer.

13. High quality photo image input using the option color image scanner cartridge.

BJC-4400

1.2 Features

1. Higher speed printing

Black BJ Cartridge : 5.5 PPM (HS mode)

Color BJ Cartridge : 2.2 PPM (HS mode)

2. Compact (desk-top size)

Dimensions: 383 mm W

2-2

Part 2: Product Specifications

2. SPECIFICATIONS

2.1 Printer Specifications

1. Type

Desk-top serial color bubble jet printer

2. Paper feeding method

Auto feeding and manual feeding

3. Cut Sheet Feeder capacity

Plain paper: Maximum 10 mm (approximately 100 pages of 64g/m2paper)

Envelopes: 10 envelopes (Commercial number 10 and DL)

Transparencies: 50 sheets

BPF: 10 sheets

Glossy film/ BJ cloth: One page with the manual feeding

Scanning document: Place between the scanning holder. One page with the ASF.

4. Manual feeding slot capacity

One sheet

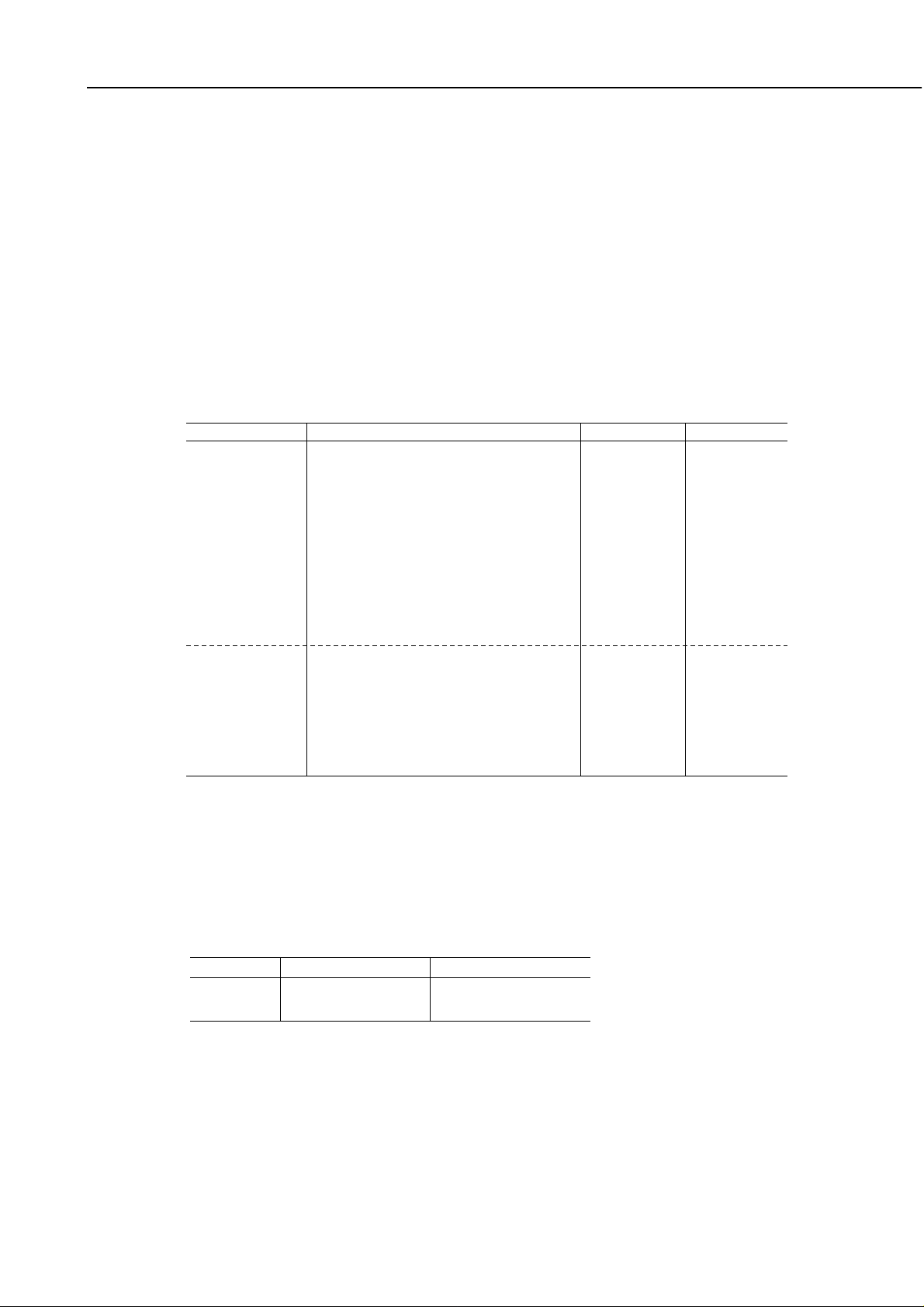

BJC-4400

5. Paper weight

Automatic feed / Manual feeding slot: 64 to 105 g/m2(17 lbs to 28 lbs)

6. Printing speed

Burst

Color BJ Cartridge (Black printing) Black BJ Cartridge (Black printing)

HQ mode 173 cps (10 cpi) 346 cps (10 cpi)

HS mode 271 cps (10 cpi) 542 cps (10 cpi)

7. Printing direction

Unidirectional

(Print direction is automatically changed according to optimum printing directional control.)

8. Printing width

Maximum 8”

9. Line feed speed

90 ms/line (128/360” line)

10. Built-in printing control modes

LQ mode: Epson LQ-2550 emulation

BJ mode: IBM Proprinter X24E emulation

(Canon extended mode is supported when the Canon driver is used.)

11. Line feed pitch (n: programmable)

LQ mode: 1/6”, 1/8”, n/60”, n/72”, n/180”, n/216”, and n/360”

BJ mode: 1/6”, 1/8”, n/180”, and n/360”

2-8

BJC-4400

Part 2: Product Specifications

11. Printing characters

Typefaces: LQ&BJ mode Roman, Gothic, Courier, Prestige, Script, Draft

Pitch: LQ mode 10, 12, 15, 17, 20 cpi, and PS

BJ mode 10, 12, 17 cpi ,and PS

Character matrix: HQ mode 36 (H) x 48 (V) dots

HS mode 18 out of 36 (H) x 48 (V) dots

Character set: LQ mode Italic character set and Graphic character set

and International character set

BJ mode IBM character set 1, 2

and all character set

(code page 437, 850, 852 860, 863 and 865)

12. Number of columns printed

Mode Pitch cpl *

LQ mode 10 cpi 10 cpi 80 cpl

10 cpi doublewide 5 cpi 40 cpl

10 cpi condensed 17 cpi 137 cpl

10 cpi condensed-doublewide 8.5 cpi 68 cpl

12 cpi 12 cpi 96 cpl

12 cpi doublewide 6 cpi 48 cpl

12 cpi condensed 20 cpi 160 cpl

12 cpi condensed-doublewide 10 cpi 80 cpl

15 cpi 15 cpi 120 cpl

15 cpi doublewide 7.5 cpi 60 cpl

Proportional spacing PS Varies

BJ mode 10 cpi 10 cpi 80 cpl

10 cpi doublewide 5 cpi 40 cpl

10 cpi condensed 17 cpi 137 cpl

10 cpi condensed-doublewide 8.5 cpi 68 cpl

12 cpi 12 cpi 96 cpl

12 cpi doublewide 6 cpi 48 cpl

Proportional spacing PS Varies

* cpl: characters per line

13. Bit image

Vertical: 8, 24 and 48 dots

Horizontal: 60, 120, 180, 240, 360 and 720* dpi

* In smoothing mode or when using the Canon driver.

14. Buffer

Receive buffer Download buffer

LQ mode 22 kB 32 kB

BJ mode 22 kB 0 kB

15. Interface

IEEE1284 compatible parallel interface

2-9

Part 2: Product Specifications

✕ 231.6 mm D ✕ 203 mm H

22. Weight

Approximately 3.5 kg (7.7 lbs) (including BJ cartridge)

During operation During storage

Temperature 5°C to 35°C 0°C to 35°C

(41°F to 95°F) (32°F to 95°F)

Humidity 10% to 90%RH 5% to 95%RH

(no condensation) (no condensation)

Voltage/Frequency Power consumption Stand-by status

USA/Canada AC 120V 60 Hz

UK/Australia AC 240V 50 Hz Max. 30 W Max. 4 W

Europe AC 230V 50 Hz

16. BJ cartridge

Color BJ cartridge (Multi Drop)

Type: Color BJ cartridge with replaceable ink cartridges

Print head: 136 nozzles (vertically-lined) Bk (64 nozzles) + Y, M, C (24 nozzles x 3)

Ink colors: Black, cyan, magenta, yellow

Service life:

Approximately 160 pages (in the HQ mode with 1500 character pattern) with a black cartridge

Approximately 90 pages (in the HQ mode) with a color cartridge (7.5% duty per color pattern)

Weight: Approximately 85 g (3.0 oz) (including black and color ink tanks)

Black BJ cartridge

Type: Black BJ cartridge with integrated ink

Print head: 128 nozzles (vertically-lined)

Ink color: Black

Service life: Approximately 700 pages (in the HQ mode); cartridge

Weight: Approximately 85 g (3.0 oz)

Photo BJ cartridge (Multi Drop)

Type: Color BJ cartridge with integrated ink

Print head: 136 nozzles (vertically-lined) Bk (64 nozzles) + Y, M, C (24 nozzles x 3)

Ink colors: Black, cyan, magenta, yellow

Service life: Approximately 25 pages (in the Photo mode); cartridge

Weight: Approximately 74 g (2.8 oz)

BJC-4400

17. Sensor functions

Paper out: Provided

Installation of cartridge: Provided

BJ cartridge/Scanner cartridge identification: Provided

Waste ink amount: Provided

Ink out: None

Paper width: None

18. Acoustic noise level

Approximately 45dB (A)/ HQ 48dB (A)/ HS

(Sound pressure level: According to ISO 9296)

19. Ambient conditions

20. Power source

21. Dimensions

383 mm W

2-10

Part 2: Product Specifications

2.3 Paper Specifications

2.3.1 Paper size

Letter (8.5” ✕ 11”)

Legal (8.5” ✕ 14”)

A5 (148 mm ✕ 210 mm)

A4 (210 mm ✕ 297 mm)

Commercial number 10 envelope (9.5” ✕ 4.1”)

European DL-size (220 mm ✕ 110 mm)

2.3.2 Paper type (Recommended)

Plain paper

Bubble jet paper (Canon LC-301))

Envelope (Commercial number 10 or European DL)

Transparencies (Canon transparency film CF-102)

BPF (Canon back print film BF-102)

Glossy photo paper (Canon glossy paper GP-201)

High gloss paper (Canon high gloss Film HG-101)

Fabric (Fabric sheet FS-101)

Banner (Banner paper)

T-shirt transfer (Canon T-shirt Transfer TR-201)

BJC-4400

2.3.3 Print paper

Media Thickness Lever Paper Feed Flap

Black Color/Photo Method Limit Position

Plain paper Left Center Sheet feeder 10 mm Flat

High resolution paper Center Sheet feeder 10 mm Upright

Envelopes Right Sheet feeder 10 Flat

Transparencies Center Sheet feeder 50 sheets Upright

Back print film Center Sheet feeder 10 sheets Upright

Glossy photo paper Center Sheet feeder 1 sheet Upright

Banner paper Right Sheet feeder 1 sheet Upright

Fabric sheet Right Sheet feeder 1 sheet Upright

High gloss film Center Manual feed slot 1 sheet*1 Upright

T-shirt transfer Right Sheet feeder 1 sheet Flat

2-12

Part 3: Operating Instructions

BJC-4400

3-2

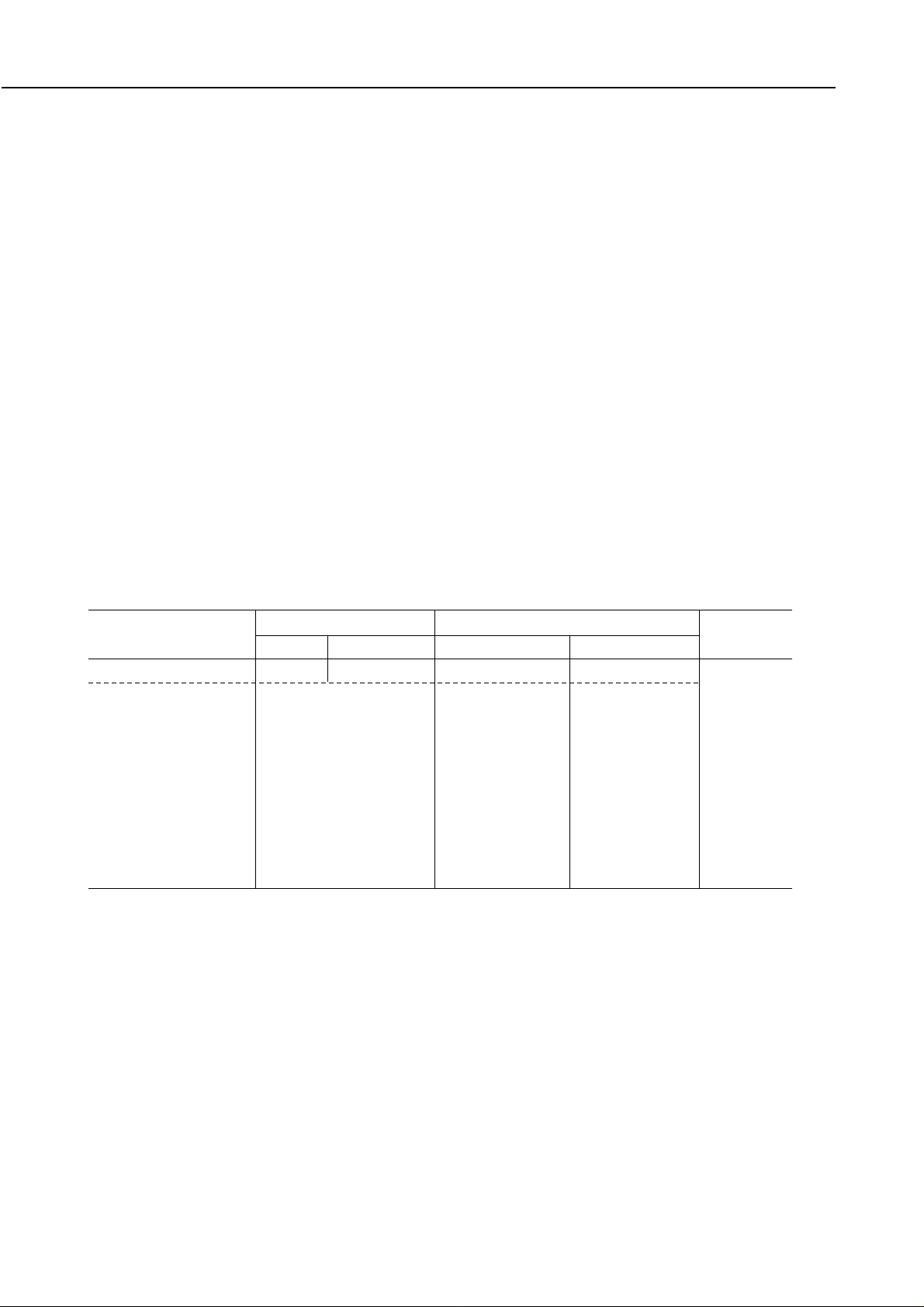

1.2 Printer Dimensions

The printer’s dimensions are shown below. Allow enough space for the printer to be used with ease.

For banner printing leave a space about the size of an A4-size paper in front of the printer. Also allow

enough space at the back of the printer to set the banner paper.

· Do not place the printer in excessive heat or humidity.

· Operate the printer under the following conditions:

Ambient temperature: 5°C to 35°C

Relative humidity: 10% to 90% (no condensation)

· Do not place the printer in direct sunlight.

· Do not place the printer near a device containing a magnet or that generates a magnetic

field.

· Place the printer on a level and stable surface.

· Do not place the printer in areas subject to vibration.

· Keep the printer clean.

· When moving the printer, hold both ends.

Figure 3-2 Printer Dimension

281 mm

268 mm

NOTE

304 mm

383 mm

Part 3: Operating Instructions

Plain paper Left Center Sheet feeder 10 mm Flat

High resolution paper Center Sheet feeder 10 mm Upright

Envelopes Right Sheet feeder 10 envelopes Flat

Transparencies Center Sheet feeder 50 sheets Upright

Back print film Center Sheet feeder 10 sheets Upright

Glossy photo paper Center Sheet feeder 1 sheet Upright

Banner paper Right Sheet feeder 1 sheet Upright

Fabric sheet Right Sheet feeder 1 sheet Upright

High gloss film Center Manual feed slot 1 sheet

*1

Upright

T-shirt Transfer Right Sheet feeder 1 sheet Flat

TABLE 3-1 QUICK REFERENCE FOR SETTING

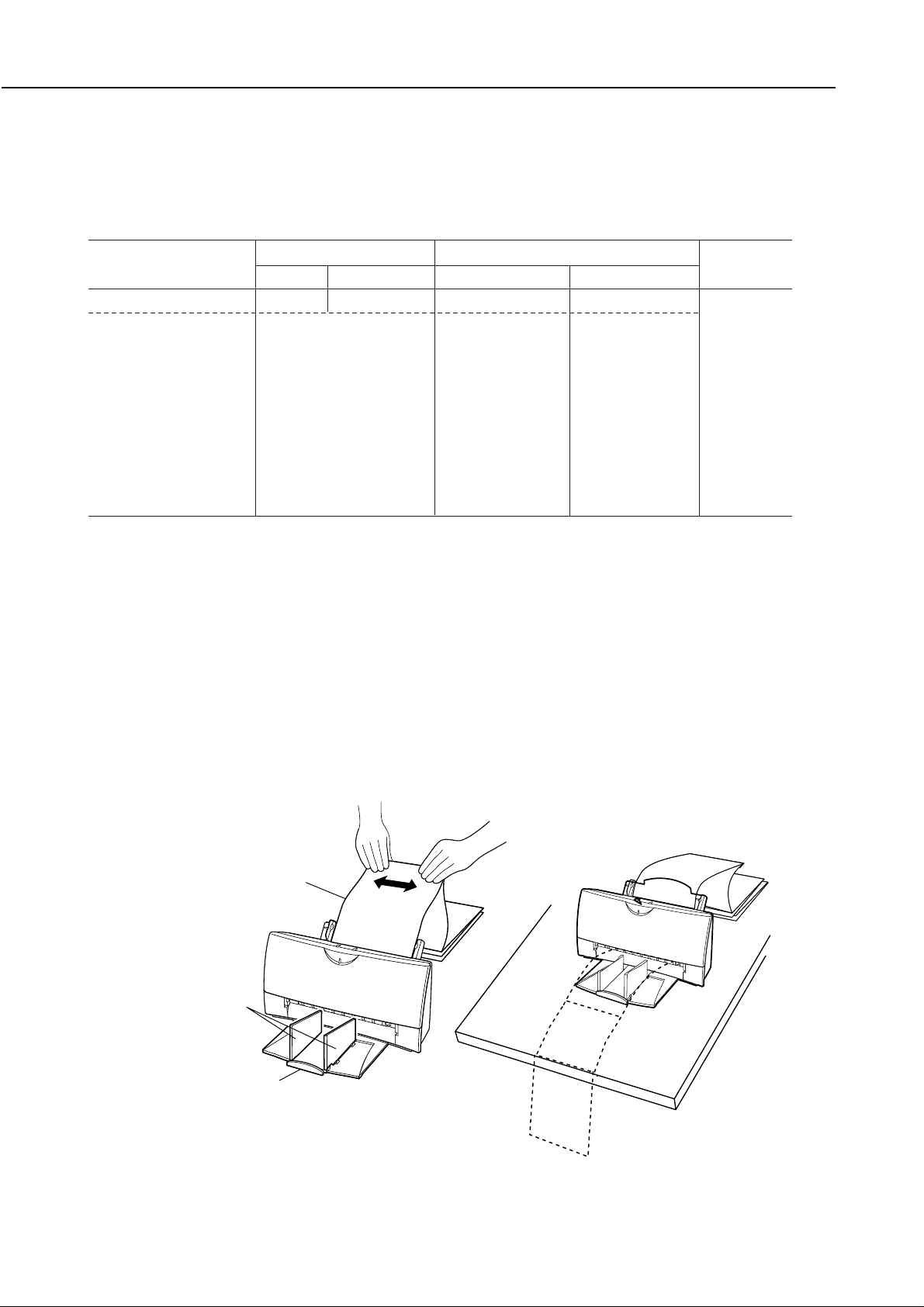

Figure 3-12 Banner Print

1.5 Paper Settings

For optimum printing, the printer has various paper settings to suit various types of paper. Set the paper

selection lever before loading the paper.

Media Thickness Lever Paper Feed Flap

Black Color/Photo Method Limit Position

BJC-4400

*1 Slide one sheet all the way into the manual feeding slot.

1.6 Banner Print

When printing on banner paper, lower the paper support and set the paper delivery flap to the upright

position. To avoid misfeeding, put a light crease between the first and second page and set the first page in

the sheet feeder. Place the rest of the banner paper behind the printer. Do not use the manual feeding slot

to avoid skewing.

Each top margin for banner printing is set at 0mm. However, to avoid printing on the platen, printing will

start 3mm from the initial top margin. Set an extra sheet at the end in case the bottom edge is not printed

on the last page.

Banner printing uses a large amount of ink. To avoid ink shortage, use of a new ink cartridge before

banner printing is recommended.

Banner Paper

Paper Delivery Flap

Output Tray Extention Guide

3-10

Part 3: Operating Instructions

3-11

7 Name of the Parts and Their Functions

The different parts of the printer and their functions are shown below.

BJC-4400

Paper Support

Cut Sheet Feeder

Holds a stack of approximately 100 cut

sheets (64g/cm) for automatic feeding.

Paper Guide

Aligns the cut sheets in the cut sheet feeder

according to the paper size. A maximum

paper width of 241 mm (9.64 in.) can be set.

Autofeeds banner paper and scanning

document.

Control Panel

Front Cover

Paper Output Tray

Manual Feeding Slot

AC Adapter

Parallel Interface Connector

2

See the next page.

Open to install or remove the cartridge, set

the paper thickness lever, or remove the jams

paper.

Pulls out to receive the printed sheets.

Use for feeding media

manually.

Installed on the rear of the

printer, the AC adapter

supplies power from the power

outlet to the printer.

Depending on the location of

purchase, the power cable is

permanently attached to the

AC adapter where as in some

areas the power cable is

detachable.

Connects the printer to the

parallel port on the computer.

Supports the stack of paper loaded in the

cut sheet feeder.

Figure 3-13 Name of the Parts and Their Functions

4-1

BJC-4400

Part 4: Technical Reference

1. OVERVIEW

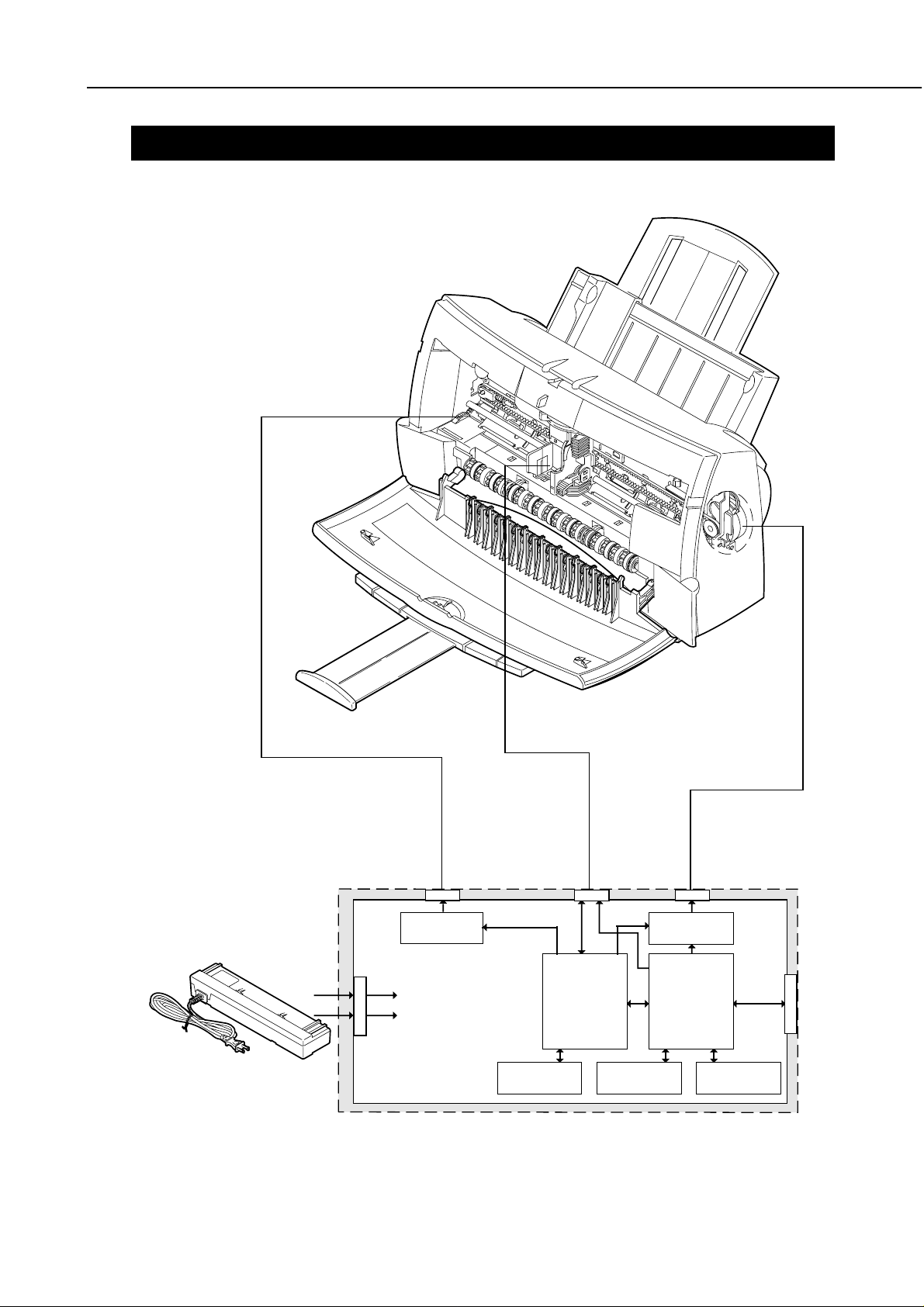

1.1 Printer Diagram

Figure 4-1 Printer Diagram

Paper Feed Motor

Logic Board

VH (+24.0VDC)

J1

Vcc (+5VDC)

J4

Paper Feed

Motor Driver

Carriage

· BJ Cartridge/ Scanner Cartridge

· Home Position Sensor

J5

Carriage Motor

MPU

Control/CG ROM

Carriage Motor

J3

Driver

Printer

Controller

EEPROMDRAM

J2

I/F

The electrical system functions are handled by the logic section or power supply.

The logic section converts the data from the interface into print signals or printer operation signals and

drives the BJ cartridge and motors while monitoring the status of the sensors.

The power supply unit consists of a built in AC adapter which provides DC output to the logic board,

motors and head etc.When DC input power from the AC adapter is being supplied, all of the hardware

components are active except for the following which are inactive: All buttons except the

POWER

button,

and the photo interrupter's sensor.

4-37

BJC-4400

Part 4: Technical Reference

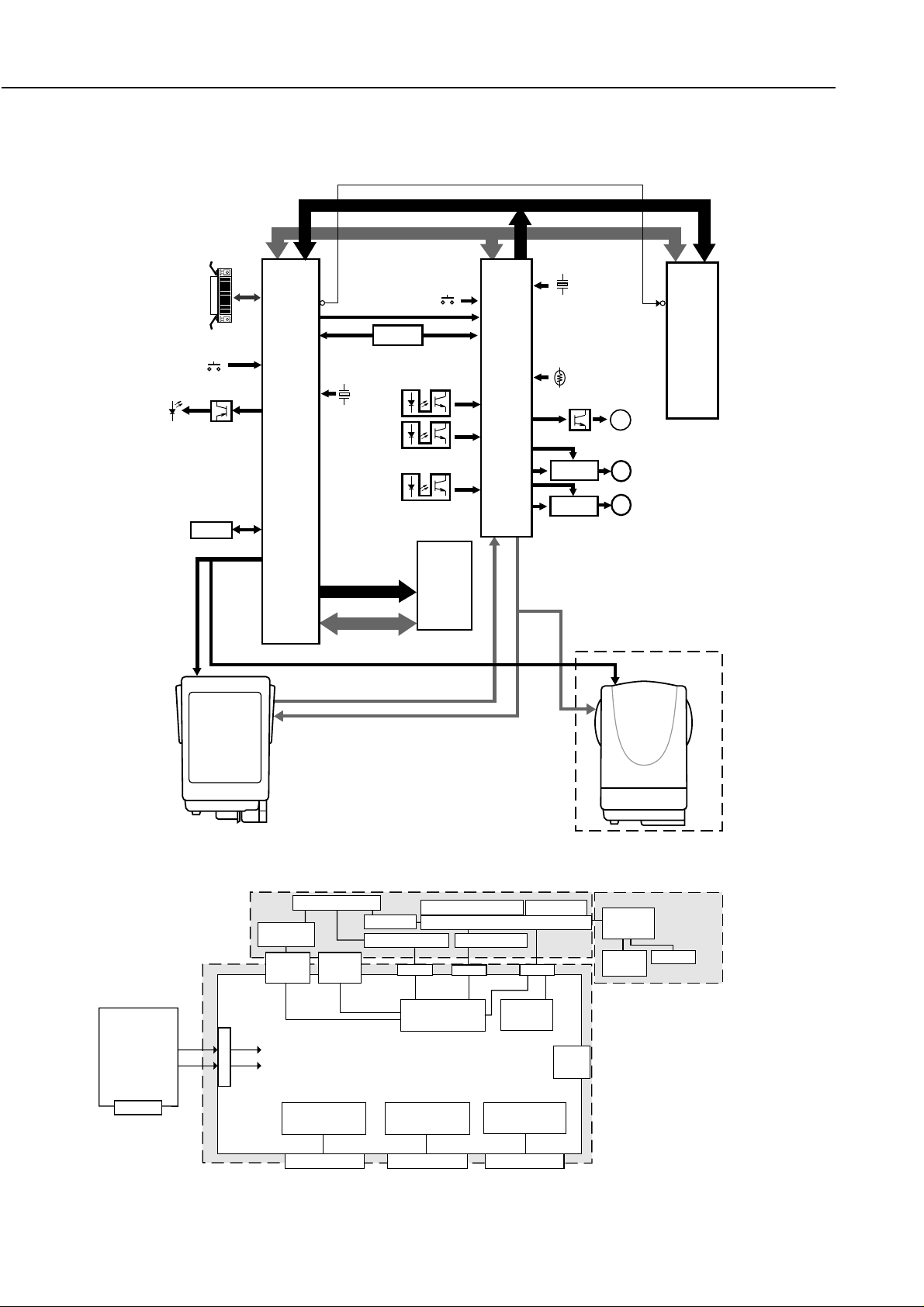

Figure 4-27 Printer Electrical System

4. PRINTER ELECTRICAL SYSTEM

4.1 Overview

Carriage Ribbon Cable

RESUME Switch

DRAM

POWER Switch

Printer Controller

Carriage Motor

J3

J5

Carriage Motor Driver

Pick-up Roller Sensor

AC Adapter

CARTRIDGE Switch

Control/CG ROM

Beeper

J1

J2

J4

MPU

Paper Feed Motor

Paper Feed Motor Driver

Paper End Sensor

Part 4: Technical Reference

Figure 4-28 Logic Board Block Diagram

4.2 Logic Section

4.2.1 Logic section block diagram

BJC-4400

RESUME

CARTRIDGE

ERROR

POWER

HCLOCK

HDATA

HLATCH

BENB1 to 3

HENB0 to 3

ODDENB

EVENENB

Parallel Interface

1 Kbit

EEPROM

MCH0

ID0,1

HRES

BJ Cartridge

Black BJ Cartridge

heater (128 nozzles)

Color BJ Cartridge

heater (136 nozzles)

•

Sub-heater

•

Temperature control

heater

•

Head temperature

sensor

•

Rank resistor

Transistor

SCLOCK

SDATA

SLATCH

COM 0 to 3

C.CHK

C.CHA

A0 to 23

AD0 to 15

CS0

INT 0 to 3

RES

PC2 to 3

PB0

PB1

Printer Controller

PE4 to 7

MA0 to 9

MD0 to 15

VHC,CVDC

Address Bus

A/Data Bus

Reset IC

22.11MHz

DRAM Bus

MA0 to 9

MD0 to 15

A0 to 23

AD0 to 15

POWER Switch

Pickup Roller Sensor

PS2

Paper End Sensor

PS1

Home Position Sensor

DRAM

4-Mbit

A0 to 9

DO 1 to 16

A0 to 15

P87

PB0,PB1

PB4,PB5

RES

P33

P41

P60 to 63

P40

P90 to 93

P35,36

AN1,3

AD16 to 23

AN0

MPU

P71

P72

P73

P94

P95

P42

P66

20MHz

Temp. Sensor

(TH1)

Transistor

Driver IC

Driver IC

HVH

H VDD

CE

Beeper

BZ

PM

Carriage Motor

PM

Paper Feed Motor

Scanner Cartridge

(Option)

•

Scanner controller

•

CCD

•

LEDs (R,G,B)

A0 to 18

D0 to 15

Control/CG ROM

8-Mbit

AC Adapter

AC Inlet

MECHANISM SECTION

Paper Feed Roller

Sheet

Feeder

Pick-up

Roller

Sensor

Paper

End

Sensor

VH (+24.0VDC)

J1

Vcc (+5VDC)

Bi-directional

Interface Control

J2

ELECTRICAL SECTION

Figure 4-29 Printer Block Diagram

Purge Unit

Home Position Sensor

Paper Feed Motor

J4

Mechanism

Control

Logic Board

Indicator Control

Indicators

4-38

Carriage

Carriage Motor

J3

Cartridge

Control

Switch Detection

Control Buttons

BJ Cartridge

J5

Temp.

Sensor

(TH1)

Scanner Cartridge (Option)

Scanner

Controller

LEDs

(R,G,B)

CCD

BJC-4400

Part 4: Technical Reference

4.2.2 Logic section components

1) MPU (IC2)

The MPU contains a 16-bit CPU, 1K-bit RAM, 24-bit address bus port, 16-bit data bus port, stepping

motor controller, interrupter controller, A-D converter, I/O ports, and other components.

Built-in CPU

The 16-bit CPU operates in synchronization with a 20 MHz external clock input.

Address bus

The 24-bit address bus port is connected to an 8 M-bit control/CG ROM and printer controller. The

controller/CG ROM synchronizes with the read signals output by the MPU and the 20 MHz clock

signal. The printer controller then selects the chip.

Data bus

Like the address bus, the 16-bit data bus port is connected to the 8 M-bit control/CG ROM and printer

controller.

Stepping motor controller

The stepping motor controller outputs double 1-2 phase exciter drive signals to both the carriage motor

driver and paper feed motor driver.

The stepping motor controller can switch the the 4-step peak current value of both motor driver.

Interrupt controller

For external interruption, the MPU has ports P80, 81, 84, 85, and 87 to receive the POWER button

on/off switching, data reception, initial interrupt request, receive buffer-full warning, and other signals.

The MPU executes interrupt processing for the respective signals.

A-D converter

The following analog signals are detected after they pass through the built-in A-D converter:

AN0: The printer's internal temperature is detected by the thermistor on the logic board.

AN1: The head temperature is detected by the head temperature sensor in the BJ cartridge.

AN3: The head rank is detected by the rank resistor in the BJ cartridge.

I/O port

The setting status determined by the head ID, paper end sensor, home position sensor, and pick-up

roller sensor are input through the input ports. The buzzer, BJ cartridge detection, head-driving voltage

control, and other signals are output from the output ports.

4-39

2) Printer controller (IC3)

The printer controller contains the interface controller, print head controller, buffer controller, DRAM

controller, EEPROM controller, I/O ports, etc. It operates in synchronization with an external 22.11

MHz external clock input.

Interface controller

The interface controller receives from the computer, 8-bit parallel data which is synchronized with the

data strobe pulse (STROBE) through the BUSY/ACKNLG handshake. It also controls other interface

signals.

The data received through the interface is stored in the DRAM's receive buffer and analyzed by the

MPU.

When the printer initialization signal INIT is input through the interface to the printer controller, the

printer controller outputs a BUSY signal. Also, after INT1 is output to the MPU and print data in the

print buffer is printed, the printer is initialized.

DRAM controller

The DRAM controller is a DRAM-specific bus separated from the MPU bus. It controls the 4 M bit

DRAM's 10-bit address/16-bit data bus and also executes read/write control, RAS/CAS control, and

refresh control.

Buffer controller

The buffer controller automatically writes the received data to the receive buffer on the DRAM,

manages the receive buffer's remaining capacity, automatically reads the print buffer, and clears the data

after it is read.

Print head controller

The print head controller converts the print data read from the DRAM's print buffer from parallel to

serial and sends it to the print head. At the same time, the printed dots are counted for the variable

control of the Heat-enable (H ENB) signal pulse width.

The head-driving signals consist of the block enable signals (B ENB 1, 2, 3), odd/even enable signals

(OddENB/EvenENB), and heat enable signals (H ENB 0, 1, 2, 3). The block enable signals and

odd/even enable signals specify the block for time-shared drive. The heat enable signals control the

eject heater's conduction time.

I/O port

The I/O ports sense the

RESUME

and

CARTRIDGE

buttons' input status. The output ports control

the lighting of the

POWER

and

ERROR

indicators.

Part 4: Technical Reference

4-40

BJC-4400

BJC-4400

Part 4: Technical Reference

3) Control/CG ROM (IC4)

The 8 M-bit control/CG ROM contains the program and bitmap font data for printer control.

4) DRAM (IC7)

Controlled by the printer controller, the 4 M-bit DRAM is used as a receive buffer, download buffer,

print buffer, and working area.

5) Reset IC (IC1)

This IC detects the power voltage when turning on the power or instantaneous power failure.

6) EEPROM (IC6)

Controlled by the printer controller, the 1 K-bit EEPROM (Electrically Erasable and Programmable

ROM) stores various function settings, the total count of printed sheets, and the total waste ink amount.

7) Carriage motor driver (IC12) / Paper feed motor driver (IC13)

The carriage motor driver which is controlled by the MPU drives both the carriage motor and the paper

feed motor which in turn are controlled by an double 1-2 phase exciter with a fixed current bipolar

drive. Upon receiving the switching signal from the MPU, the peak current value can be set

individually into 4 steps for phase A and B. By doing so, it ensures smooth operation of the motors.

10K,1/8W

LF10A

LF11A

LF10B

LF11B

100µ,35W

RA3

C202

0.51,1/4W

R70

0.51,1/4W

R71

+5V

567

8

431

2

N1608Z300T01

FB102

+5V

+5V

C60

0.1µ,25W

C61

FB101

N1608Z300T01

J4

1

A

2

A

3

B

4

B

R72

10K,1/16W

02DZ3.0Z

ZD18

4700p,50V

Paper Feed

R73

360,1/10W

2

1

Motor

Approx.6Ω/

02DZ2.0Z

phase

ZD19

LFVREF

3

Q13

FA1L4M

VM

LFA

LFB

C203

0.1µ,50W

VM-G

Paper Feed

Motor Driver

1

NC

2

VssA

3

Out1

4

NC

5

RsA

6

NC

7

IC13

Out2

8

Out3

9

NC

10

RsB

11

NC

12

Out4

13

VssB

14

NC

28

Vcc

27

INA

26

IOA

25

IIA

24

VsA

23

VrefA

22

LG

21

C/R

20

VrefB

19

VsB

18

IIB

17

IOB

16

INB

15

Vcc

10K,1/8W

CR10A

CR11A

CR10B

CR11B

100µ,35W

RA4

C205

CRA

CRB

+5V

8

3

VM

0.51,1/4W

R74

0.51,1/4W

R75

567

124

C206

0.1µ,50W

VM-G

Carriage Motor

Driver

1

Vcc

NC

2

INA

VssA

3

IOA

Out1

4

IIA

NC

5

VsA

RsA

6

VrefA

NC

IC12

7

LG

Out2

8

C/R

Out3

9

VrefB

NC

10

VsB

RsB

11

12

13

14

IIB

NC

IOB

Out4

INB

VssB

Vcc

NC

+5V

28

27

26

25

24

23

22

21

20

19

18

17

16

15

+5V

C62

R76

0.1µ,25W

02DZ3.0Z

ZD20

C63

J3

1

A

2

A

3

B

4

B

R77

10K,1/16W

360,1/10W

02DZ2.0Z

ZD21

2

CRVREF

3

1

4700p,50V

Q14

FA1L4M

Carriage Motor

Approx.6Ω/

phase

Figure 4-30 Motor-Driving Circuit

4-41

Part 5: Maintenance

BJC-4400

5-3

3. GREASE APPLICATION

Use the special tool to apply grease at the points shown below.

Rubbing Section of Carriage

Hook and Carriage:

About 12 mg (FLOIL G311S)

Rubbing Section of Cam Gear

About 12mg (FLOIL G311S)

Rubbing Section of Clutch

Spring and Clutch Gear:

About 12 mg (FLOIL G311S)

Belt Holder:

About 20mg (FLOIL G311S)

Paper Lifting Plate :

About 6mg (FLOIL G311S)

Idler Roller Shaft Section:

About 6mg (FLOIL G311S)

Rubbing Section of Frame

and Paper Lifting Plate:

About 6 mg (FLOIL G311S)

Both Sides of Carriage Guide Frame:

About 80 to 120 mg (MOLYKOTE PG-641)

Rubbing Section of Carriage and Carriage Shaft:

About 135 to 165 mg (MOLYKOTE PG-641)

Paper Feed Motor Drive

Transmission:

About 6mg (FLOIL G311S)

Figure 5-1 Grease Application Points

Part 5: Maintenance

1 HVG ... GND for head drive voltage VH

2 HVG ... GND for head drive voltage VH

3 HT0 IN Driver signal for temperature control heater

4 HT1 IN Driver signal for temperature control heater

5 HVH OUT Head driver voltage

6 HVH OUT Head driver voltage

7 W-HT OUT Drive signal for temperature control heater

8 INKS1 ... Not used

9 TOP IN Detection signal for rank resistance

10 DIODEA OUT Head temperature sensor (diode) anode

11 ID0 IN Cartridge detection and recognition signal

12 ID1 IN Cartridge detection and recognition signal

13 INKS2 IN/OUT Cartridge detection and recognition signal

14 HVss ... Head's logic drive voltage HVdd GND

15 HENB0(Y) OUT Heat enable

16 Even ENB OUT Even nozzle heat enable

17 HENB1(M) OUT Heat enable

18 HENB3(B) OUT Heat enable

19 Odd ENB OUT Odd nozzle heat enable

20 BENB1 OUT Block enable generation signal

21 BENB2 OUT Decoder output signal

22 BENB3 OUT

23 HVdd OUT IC drive voltage (+5 V)

24 HCLK OUT Print data transfer signal

25 HLATCH OUT Timing signal for print data to latch

26 HRES OUT Latch reset signal

27 HENB2(C) OUT

28 HDATA OUT Printing data

29 DIODEK IN Head temperature sensor (diode) cathode

30 HPO IN Home position sense High/ Low(sense)

31 HPG ... Ground

32 HPA OUT Photo LED drive

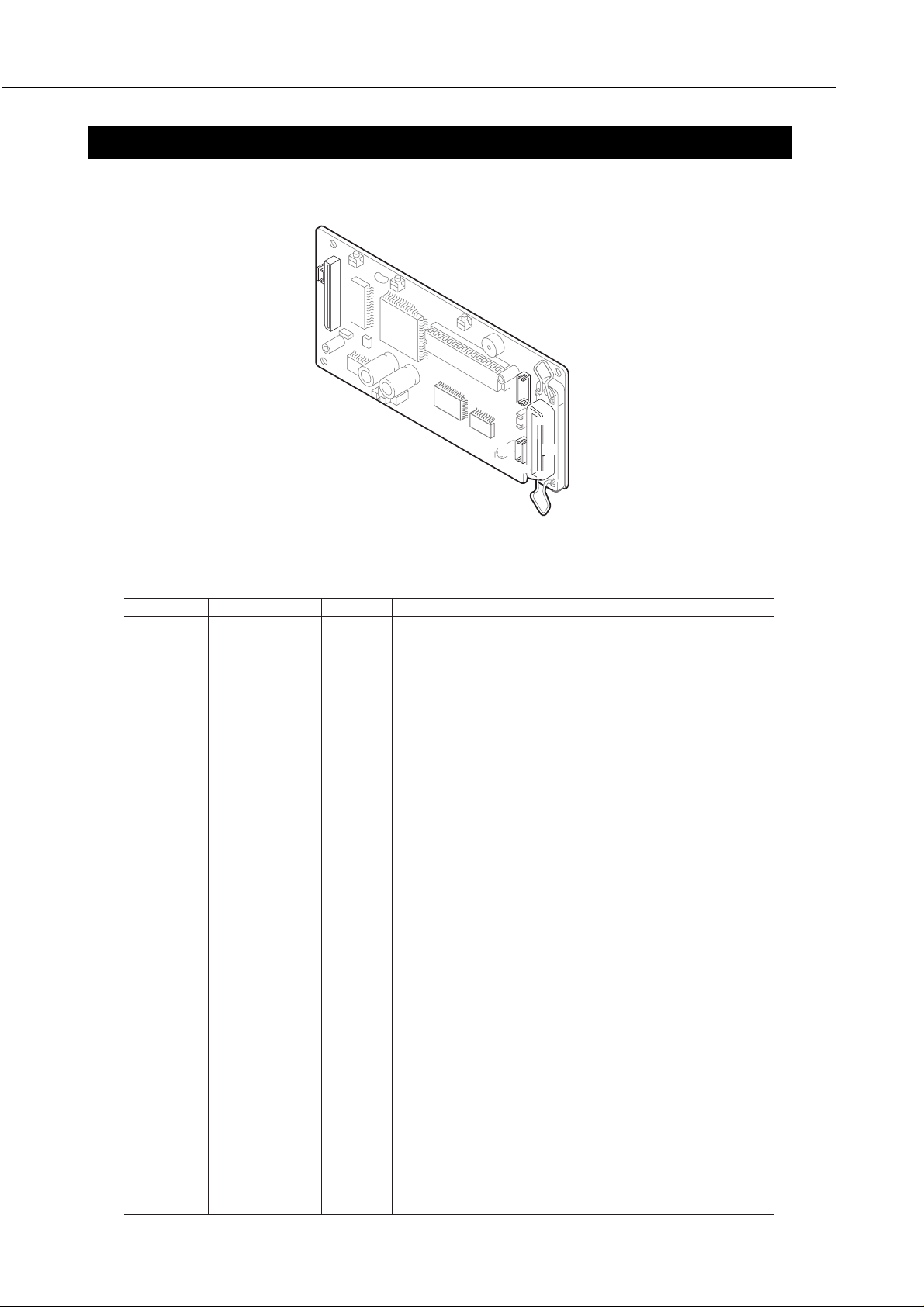

Figure 5-9 Logic Board

7. LOCATION & SIGNAL ASSIGNMENT

7.1 Logic Board

J3

BJC-4400

32

1

31

4

J5

2

1

5

J1

1

1

19

1

J2

J4

J5

5

18

36

J5 (Ribbon cable connector)

Pin No. Signal name IN/OUT Description

5-30

Part 5: Maintenance

BJC-4400

5-31

J3 (Carriage motor connector)

Pin No. Signal name IN/OUT Description

1 CRA OUT Carriage motor phase A

2 CRA OUT Carriage motor phase A

3 CRB OUT Carriage motor phase B

4 CRB OUT Carriage motor phase B

J4 (Paper feed motor connector)

Pin No. Signal name IN/OUT Description

1 LFB OUT Paper feed motor phase B

2 LFA OUT Paper feed motor phase A

3 VM ... Common

4 LFA OUT Paper feed motor phase A

5 LFB OUT Paper feed motor phase B

J1 (DC power connector)

Pin No. Signal name IN/OUT Description

1 Vcc IN +24 VDC

3 GND ... Ground

4 GND ... Ground

5 VH IN +5 VDC

J2 (Interface connector)

Pin No. Signal name IN/OUT Description

1 STROBE IN See Part 2 for details

2 DATA1 IN

3 DATA2 IN

4 DATA3 IN

5 DATA4 IN

6 DATA5 IN

7 DATA6 IN

8 DATA7 IN

9 DATA8 IN

10 ACKNLG OUT

11 BUSY OUT

12 P.E. OUT

13 SELECT OUT

14

AUTO FEED XT

IN

15 N.C ...

16 INIT IN

17 GND ...

18 N.C ...

19 STROBE-RET ...

20 DATA1-RET ...

21 DATA2-RET ...

22 DATA3-RET ...

23 DATA4-RET ...

24 DATA5-RET ...

25 DATA6-RET ...

26 DATA7-RET ...

27 DATA8-RET ...

28 ACKNLG-RET ...

29 BUSY-RET ...

30 P.E.-RET ...

31 INIT IN

32 ERROR OUT

33 GND ...

34 N.C ...

35 +5.0V ...

36 SELEC IIN IN

Part 5: Maintenance

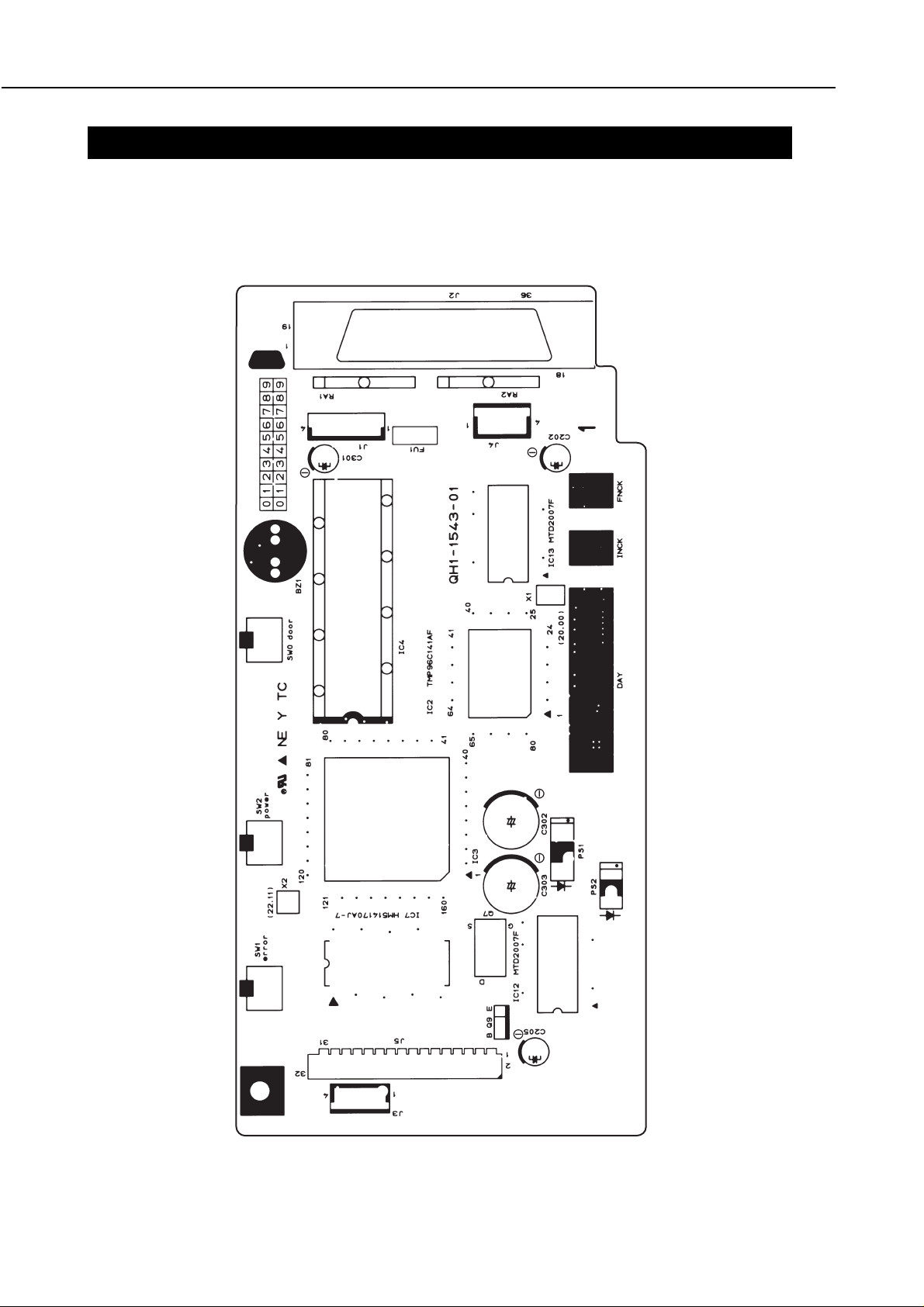

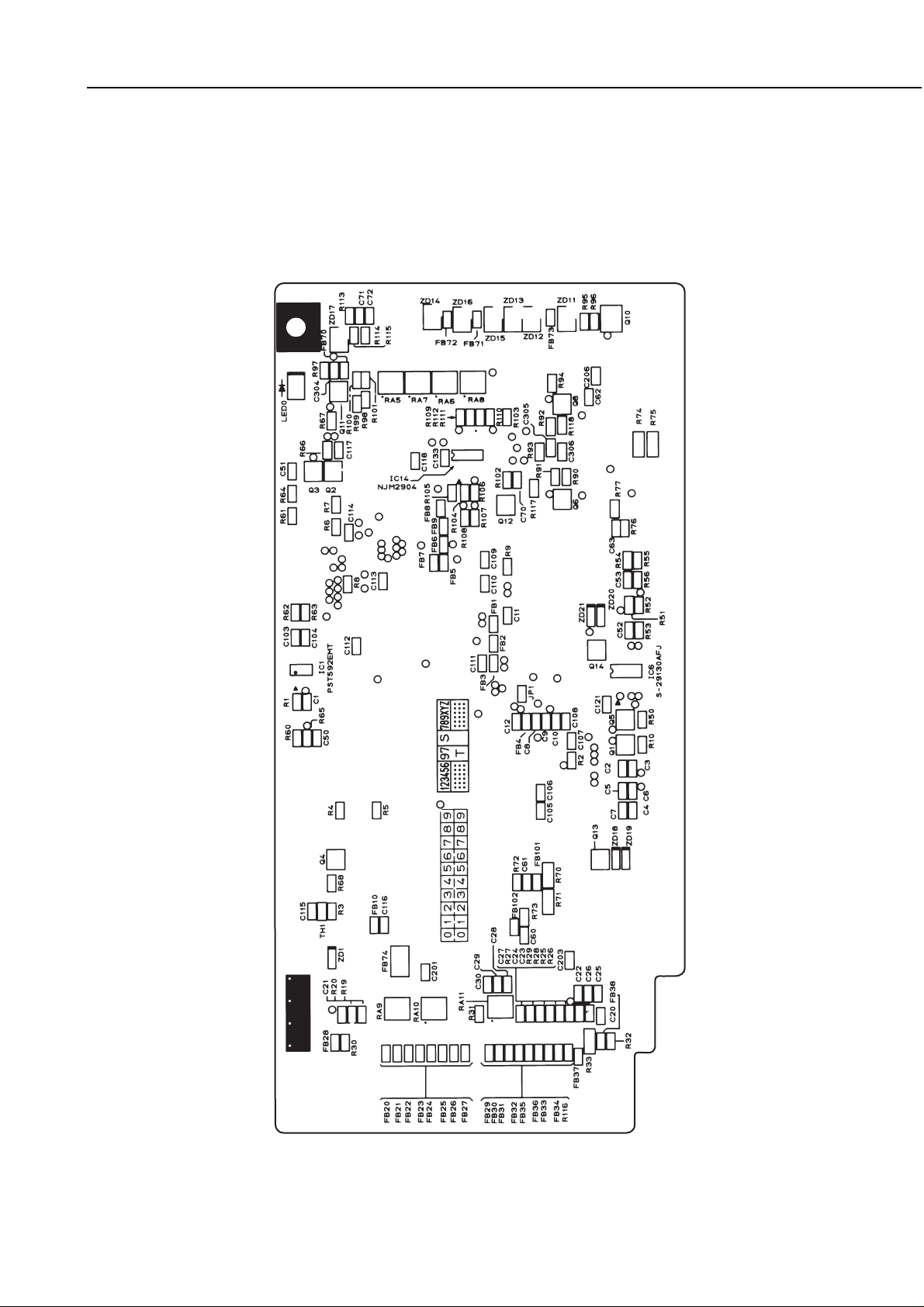

Figure 5-10 Logic Board (Top View)

8. CIRCUIT DIAGRAMS

8.1 Parts Layout

8.1.1 Logic board

BJC-4400

5-32

BJC-4400

Part 5: Maintenance

Figure 5-11 Logic Board (Bottom View)

5-33

Part 5: Maintenance

BJC-4400

5-35

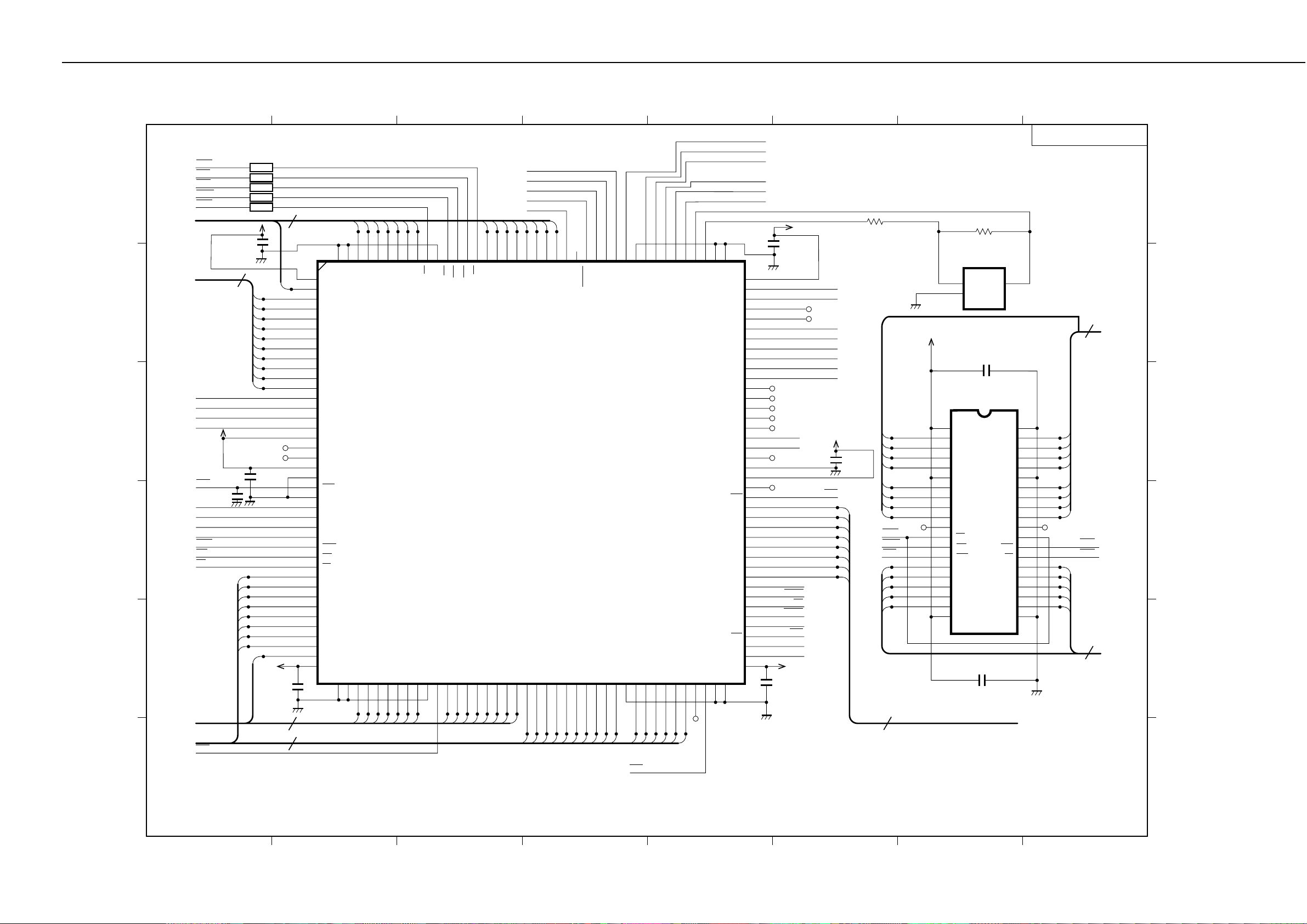

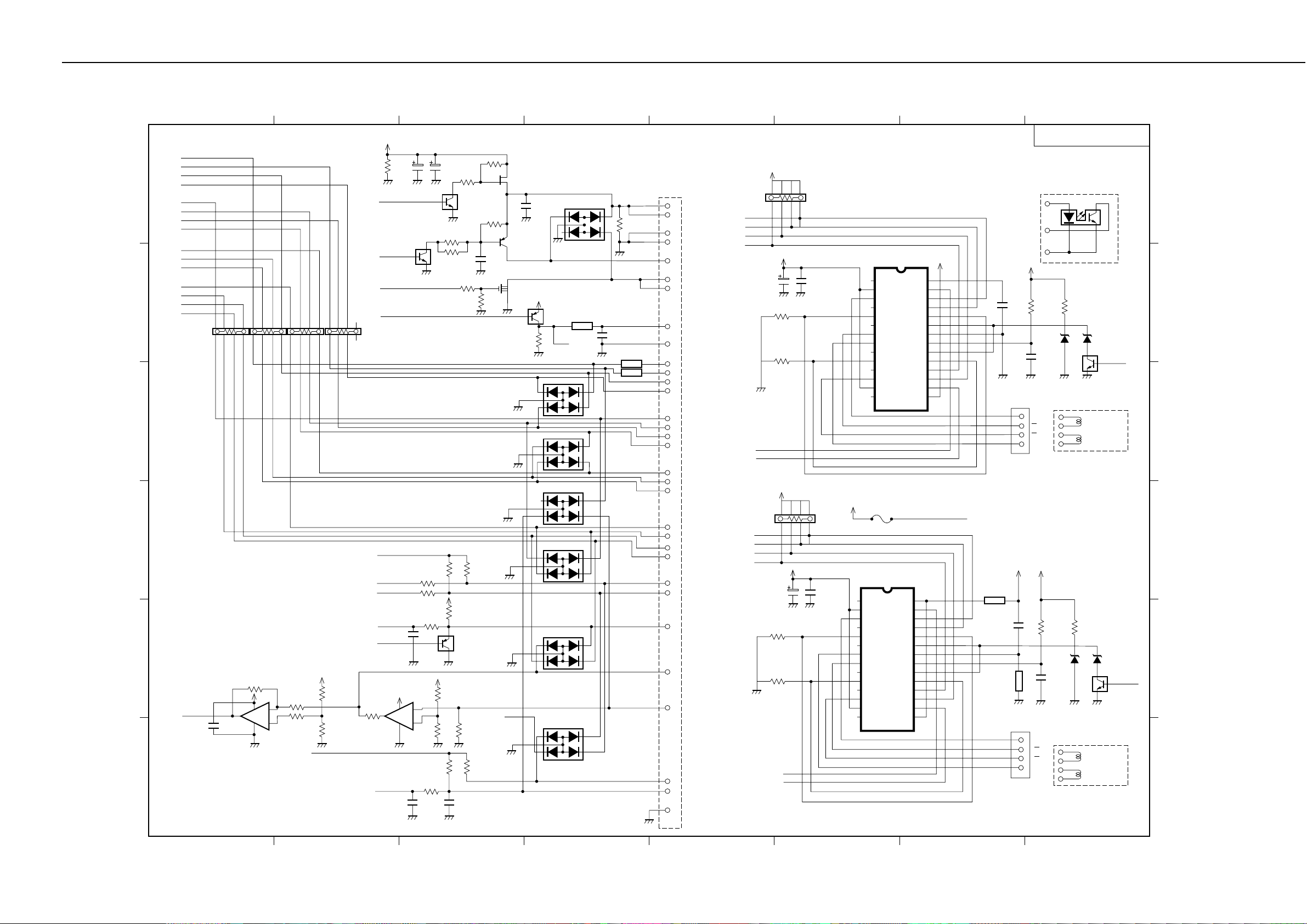

8.2 Circuit Diagrams

87654321

LOGIC BOARD 01

+5V

<03-A8>

<03-B7>

<03-F4>

<03-F4>

<03-F4>

<03-F4>

<05-C8>

<05-B8>

<03-E7>

<03-B7>

<03-D1>

<04-C8>

<03-D4>

<03-D4>

<02-C8>

<02-C8>

<02-C8>

<02-C8>

<04-D1>

<02-C8,

04-B1>

DTH

HRANK

CR10A

CR11A

CR10B

CR11B

IFC

SNC

CVDC

TOPC

CRVREF

BZ

CRA

CRB

INT0

INT2

C2

100p,50V

INT1

INT3

POWER

100p,50V

RES

0.1µ,25V

C10

1000p,50V

C6

C7

+5V

C3

100p,50V

+5V

Temperature

<03-B1>

C5

100p,50V

+5V

C4

100p,50V

10K,1/16W

Sensor

47K,1/16W,0.5%

LF VREF

CP9

CP4

CP5

R2

R3

C9

0.1µ,25V

C107

0.1µ,25V

C108

1000p,50V

1

P60

2

P61

3

P62

4

P63

5

P64

6

P65

7

P66

8

P67

9

P70

10

P71

11

P72

12

P73

13

P80

14

P81

15

P82

16

P83

17

P84

18

P85

19

P86

20

P87

21

NMI

22

WDO

23

RES

24

CLK

TH1

C8

0.01µ,50V

+5V

807978777675747372717069686766

Vss

Vcc

AGND

Vref

AN3

AN2

AN1

AN0

P42

P41

P40

P37

P36

P35

MPU

IC2

TMP96C141AF

QFP-80p

VssX1X2EAP90

252627282930313233343536373839

P91

P92

P93

P94

P95

ALE

Vcc

AD0

AD1

CP6

P34

AD2

2125chip

65

P33

HWR

WR

RD

A23

A22

A21

A20

A19

A18

A17

A16

Vss

AD15

AD14

AD13

AD12

AD11

AD10

AD9

AD8

AD7

AD6

AD5

AD4

AD3

40

JP1

VHC

<03-F7>

PES

<04-B6>

HPS

<03-A7>

ID1

<03-E8>

ID0

<03-E8>

RRS

<04-A6>

HWR

<02-C8>

WR

<02-C8>

RD

<02-C8>

24 A<23..0>

64

FB1

63

62

61

60

59

58

57

56

55

54

53

52

51

50

49

48

47

46

45

44

43

42

41

N1608Z800T01

FB2

N1608Z800T01

FB3

N1608Z800T01

23

22

21

20

19

18

17

16

15

14

13

12

<02-A5>

11

10

9

8

7

6

5

4

Control & CG ROM

(8Mbit)

IC4

DILB42P-8J

19

1

A18

2

18

CS0

10

11

A17

3

8

A7

4

7

A6

5

6

A5

6

5

A4

7

4

A3

8

3

A2

9

2

A1

10

1

A0

11

CE

12

GND

13

OE

14

0

D0

15

8

D8

16

1

D1

17

9

D9

18

2

D2

19

D10

20

3

D3

21

D11

N.C.

A10

A11

A12

A13

A14

A15

A16

BYTE/VPP

GND

D15/A1-1

D14

D13

D12

VDD

R5

0.1608

FB10

20

9

10

11

12

13

14

15

16

17

21

15

7

14

6

13

5

12

4

R4

0.1608

+5V

+5V

42

41

A8

40

A9

39

38

37

36

35

34

33

32

31

30

29

D7

28

27

D6

26

25

D5

24

23

D4

22

<02-A8>

F

F

D

C

N1608Z300T01

0.1µ,25V

<03-C4>

<03-C4>

<03-C4>

<03-C4>

<03-A3>

<03-A3>

C105

LF10A

LF11A

LF10B

LF11B

LFA

LFB

C106

1000p,50V

Oscillator

X1

13

OUT

OUT

GND

CSACv20.00MX040

012

FB4

N1608Z800T01

C115

0.1µ,25V

C116

1000p,50V

B

3

ALE

<02-A8>

C12

33p,50V

16 AD<15..0>

<02-A8>

A

BJC-4400

Part 5: Maintenance

87654321

<02-C1>

<02-C3>

<02-C1>

<02-C3>

<02-C3>

<02-E1>

<02-B1>

<05-D7>

<05-D7>

<05-D8>

<05-D8>

<01-C8,

04-B1>

<01-D8>

<01-C8>

<01-C8>

<01-C8>

<01-E4>

<01-E4>

<01-E4>

MOE

RAS

CAS

MUW

MLW

MD<15..0>

MA<9..0>

RDO

RDI

RCS

SK

C11

RES

0.1µ,25V

INT0

INT1

INT2

INT3

HWR

WR

RD

+5V

C109

0.1µ,25V

10

+5V

23

22

21

20

19

18

17

16

FB5

FB9

FB6

FB8

FB7

9

8

7

6

5

4

3

2

1

0

CP21

CP22

C110

0.1µ,25V

15

+5V

0.1µ,25V

N1608Z301T01

N1608Z301T01

N1608Z301T01

N1608Z301T01

N1608Z301T01

16

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

29

30

31

32

33

34

35

36

37

38

39

40

C111

HDATA

<03-F8>

HCLOCK

<03-F8>

HLATCH

<03-F8>

HRES

<03-F8>

MCH0

<03-F7>

9

1011121314

160

159

158

157

156

Vss

Vss

MD9

Vss

AD14

MD10

AD13

MD11

AD12

Vdd

MD8

MA9

MA8

MA7

MA6

MA5

MA4

MA3

MA2

MA1

MA0

PE4

PE5

PE6

PE7

RXD

TXD

SCLK

Vdd

Vss

RES

TEST

PD0

PD1

PD2

PD3

HWR

WR

RD

A23

A22

A21

A20

A19

A18

A17

A16

AD15

Vdd

Vss

414243444546474849505152535455565758596061626364656667686970717273747576777879

155

MD12

AD11

154

153

MD13

AD10

15

152

MD14

AD9

151

MD15

AD8

LW

Vss

150

Vss

ALE

149

UW

AD7

7654321

148

147

146

145

144

143

OE

CAS

RAS

MD7

MD6

MD5

Printer Controller

AD6

AD5

AD4

AD3

AD2

AD1

142

MD4

AD0A0A1A2A3A4A5A6A7A8A9

141

MD3

IC3

140

MD2

139

MD1

0

138

MD0

137

MCHE0

136

MCHE1

135

HDRES

134

133

132

131

130

129

128

127

126

HCLK

HDATA

Vss

BENB3

Vss

A10

BENB2

BENB1

A11

A12

EVENB

ODENB

A13

A14

HLAT

125

WHEAT

A15

124

X1

CS1

123

X0

CS0

122

121

Vss

FAULT

SELIN

Vss

80

EvenENB

OddENB

W-HEAT

Vss

Vdd

HEN0

HENB3

3 PC3

PC2

PC1

PC0

PB3

PB2

PB1

PB0

PA0

PA1

PA2

PA3

PA4

PE0

PE1

PE2

Vss

Vdd

PE3

STB

IFD0

IFD1

IFD2

IFD3

IFD4

IFD5

IFD6

IFD7

ACK

BUSY

PE

SLCT

AFXT

INIT

Vdd

Vss

BENB3

BENB2

BENB1

120

119

118

117

116

115

114

113

112

111

110

109

108

107

106

105

104

103

102

101

100

99

98

97

96

95

94

93

92

91

90

89

88

87

86

85

84

83

82

81

<03-E7>

<03-E7>

<03-E7>

<03-E8>

<03-E8>

<03-E7>

C114

0.1µ,25V

CP14

CP13

CP12

CP11

CP10

HENB2

HENB3

CP9

CP8

BUSY

SLCT

AFXT

FAULT

SELIN

+5V

C112

0.1µ,25V

+5V

ACK

PE

INIT

HENB1

HENB0

CP16

CP15

INKS2

INKS1

TSW1

TSW0

LED4

LED0

<03-F8>

<03-F8>

<05-D6>

<05-D6>

<05-D6>

<05-D6>

<05-D6>

<05-D6>

<05-D6>

<05-D6>

STB

<03-F8>

<03-F8>

<03-C7>

<03-C7>

<04-C1>

<04-C1>

<04-E5>

<04-E5>

+5V

C113

0.1µ,25V

<05-E6>

<02-F8>

<02-F8>

<02-F8>

R6

47,1/16W

MLW

MUW

RAS

9

0

1

2

3

R7 1M,1/16W

Oscillator

CSTv22.11MX040

1

2

+5V

DRAM(4Mbit)

IC7 UPD424170LE-80L

1

Vcc

2

DO1

3

DO2

4

DO3

5

DO4

6

Vcc

7

DO5

8

DO6

9

DO7

10

CP17

(NC)

DO8

11

NC

12

LW

13

UW

14

RAS

15

A9

16

A0

17

A1

18

A2

19

A3

20

Vcc

X2

OUT

OUT

GND

IC7

C118

1000p,50V

3

C117

1000p,50V

Vss

DO16D

DO15

DO14

DO13

Vss

DO12

DO11

DO10

DO9

NC

NC

CAS

OE

A8

A7

A6

A5

A4

Vss

LOGIC BOARD 02

16

MD<15..0>

40

39

38

37

36

35

34

33

32

31

30

29

28

27

26

25

24

23

22

21

CP18

15

14

13

12

11

10

9

8

8

7

6

5

4

MA<9..0 >

CAS

MOE

10

<02-F8>

<02-F8>

<02-F8>

<02-E8>

F

F

D

C

B

<01-B1>

<01-E1>

<01-A5>

AD<15..0>

A<23..0>

ALE

16

24

141312111098

7654321

0

012345678

9

<01-C4>

1011121314

CS0

CP7

15

8

IFD<7..0>

<05-F6>

A

5-36

BJC-4400

Part 5: Maintenance

87654321

<02-F5>

<02-F5>

<02-F5>

<02-F5>

<02-D3>

<02-D3>

<02-E3>

<02-E3>

<02-F4>

<02-F4>

<02-F4>

<02-F4>

<02-F4>

<01-F4>

<01-F4>

RA8

100,1/8W

<01-F8>

HCLOCK

HDATA

HLATCH

HRES

HENB1

HENB2

HENB3

HENB0

BENB1

BENB2

BENB3

OddENB

EvenENB

ID0

ID1

RA7

100,1/8W

DTH

C133

0.1µ,25W

470K,1/16W

1

NJH2904M

0.5X

R104

IC14

4

8

_

+

0.5X

100,1/16W

R105

2

3

R106

100K,1/16W

0.5X

<05-A7,

04-B8,

04-C8>

+5V

Vsen

<02-A6>

<02-E3>

<02-E3>

<01-E8>

<01-D8>

R107

33K,1/16W

0.5X

R108

12K,1/16W

0.5X

<01-F4>

<01-F4>

<02-F4>

<02-F5>

<01-D8>

RA6

100,1/8W

0.5X

100,1/16W

R109

NJH2904M

VH

R117

10K,1/10W

VHC

W-HEAT

FAIL4H

MCHO

CVDC

100,1/8W

HVdd

INKS1

INKS2

HRANK

TOPC

0.01µ,25W

+5V

7

HPS

2634P

C302

1000K,35W

3

Q8

RA5

220K,1/16W

100,1/16W

100,1/16W

33,1/16W

C70

8

6

_

IC14

5

+

4

7.5K,1/16W

39K,1/16W

10K,1/16W

C71

3

Q6

FAIL4H

2

1

VH-G

100,1/16W

R100

R98

R99

R102

3

Q12

FAIA4M

+5V

R111

0.5X

R114

R113

100µ,50V

R90

C303

1000µ,35W

100K,1/16W

2

1

R92

6.8K,1/10W

R118

6.8K,1/10W

R95

10K,1/16W

220K,1/16W

+5V

R103

510,1/16W

2

1

R110

180K,1/16W

0.5X

R112

1K,1/16W

0.5X

C72

100µ,50V

100K,1/16W

2.7K,1/10W

R96

R101

0.5X

<02-C7>

R115

390,1/16W

R91

25J325Z

2

Q7

3

1

R93

1

3

2

C305

0.1µ,60W

2

Q10

3

25K1772

1

Q11

FP1R4M

47K,1/16W

NNCD6.8G

NNCD6.8G

NNCD6.8G

HVdd

C306

0.1µ,50V

Q9

2581443Q

+5V

3

R97

2

1

2

3

1

2

3

1

2

3

1

2

3

NNCD6.8G

1

2

3

NNCD6.8G

1

2

3

ZD11

1

2

3

NNCD27G

N1608Z121T01

FB870

HVdd

<02-A6>

ZD16

ZD15

ZD14

ZD13

ZD12

ZD17

NNCD6.8G

5

4

5

4

5

4

5

4

5

4

5

4

5

10K,1/10W

R94

4

VH-G

C304

0.1µ,25W

N1608Z121T01

FB71

FB72

N1608Z121T01

HELN325-3(32P)

J5

5

HVH

6

HVH

1

VHG

2

VHG

7

W-HT

3

HT0

4

HT1

HVdd

23

HVss

14

HCLOCK

24

HDATA

28

HLATCH

25

HRES

26

HENB0

15

HENB1

17

HENB2

27

HENB3

18

20

BENB1

21

BENB2

BENB3

22

OddENB

19

16

EvenENB

11

ID0

12

ID1

8

INKS1

INKS2

13

TOP

9

10

DIODEA

DIODEK

29

32

HPA

30

HPO

31

HPG

10K,1/8W

<01-E8>

<01-D8>

<01-D8>

<01-D8>

<01-D8>

<01-D8>

<01-A8>

<01-A8>

<01-A8>

<01-A8>

RA4

CR10A

CR11A

CR10B

CR11B

C205

100µ,35W

CRA

CRB

RA3

10K,1/8W

LF10A

LF11A

LF10B

LF11B

C202

100µ,35W

0.51,1/4W

0.51,1/4W

<01-A8>

<01-A8>

+5V

8

3

VM

0.51,1/4W

R74

0.51,1/4W

R75

+5V

R70

R71

LFA

LFB

VM

567

124

0.1µ,50W

5

678

4

312

C206

VM-G

C203

0.1µ,50W

VM-G

1

2

3

4

5

6

7

8

9

10

11

12

13

14

R12P

MTD2007F

1

NC

2

VssA

3

Out1

4

NC

5

RsA

6

NC

7

Out2

8

Out3

9

NC

10

RsB

11

NC

12

Out4

13

VssB

14

NC

IC12

MTD2007F

NC

VssA

Out1

NC

RsA

NC

Out2

Out3

NC

RsB

NC

Out4

VssB

NC

FU1

IC13

Vcc

INA

IOA

IIA

VsA

VrefA

LG

C/R

VrefB

VsB

IIB

IOB

INB

Vcc

Vcc

INA

IOA

VsA

VrefA

C/R

VrefB

VsB

IOB

INB

Vcc

LOGIC BOARD 03

Home Psition

Sensor

HPA

HPO

C62

0.1µ,25W

J3

HPG

+5V

02DZ3.0Z

C63

1

A

2

A

3

B

4

B

R76

10K,1/16W

ZD20

4700p,50V

R77

360,1/10W

02DZ2.0Z

ZD21

2

CRVREF

3

1

Q14

FA1L4M

Approx.6 Ω/

phase

<01-D8>

+5V

28

27

26

25

IIA

24

23

22

LG

21

20

19

18

IIB

17

16

15

VH

F

F

D

C

+5V

+5V

28

27

26

25

24

23

22

21

20

19

18

17

16

15

N1608Z300T01

FB102

N1608Z300T01

FB101

J4

1

2

3

4

C60

C61

A

A

B

B

0.1µ,25W

02DZ3.0Z

R72

R73

10K,1/16W

ZD18

4700p,50V

Paper Feed

Motor

Approx.6 Ω/

360,1/10W

02DZ2.0Z

ZD19

2

1

Q13

FA1L4M

phase

LFVREF

3

<01-D7>

B

A

5-37

Loading...

Loading...