Canon CLC5000 Service Manual

CLC5000

REVISION 0

JAN.2001

COPYRIGHT© 2001 CANON INC. 2000 2000 20000 CANON CLC5000 REV.0 JAN. 2001 PRINTED IN JAPAN (IMPRIME AU JAPON)

FY8-13GZ-000

Application

This manual has been issued by Canon Inc. for qualified persons to learn technical

theory, installation, maintenance, and repair of products. This manual covers all

localities where the products are sold. For this reason, there may be information in this

manual that does not apply to your locality.

Corrections

This manual may contain technical inaccuracies or typographical errors due to

improvements or changes in products. When changes occur in applicable products or in

the contents of this manual, Canon will release technical information as the need arises.

In the event of major changes in the contents of this manual over a long or short period,

Canon will issue a new edition of this manual.

The following paragraph does not apply to any countries where such provisions are

inconsistent with local law.

Trademarks

The product names and company names used in this manual are the registered

trademarks of the individual companies.

Copyright

This manual is copyrighted with all rights reserved. Under the copyright laws, this

manual may not be copied, reproduced or translated into another language, in whole or

in part, without the written consent of Canon Inc.

COPYRIGHT © 2001 CANON INC.

Printed in Japan

Imprimé au Japon

Caution

Use of this manual should be strictly supervised to avoid disclosure of confidential information.

COPYRIGHT© 2001 CANON INC. 2000 2000 2000 CANON CLC5000 REV.0 JAN. 2001 PRINTED IN JAPAN (IMPRIME AU JAPON)

INTRODUCTION

1 Symbols Used

This documentation uses the following symbols to indicate special information:

Symbol Description

Indicates an item of a non-specific nature, possibly classified as Note, Caution,

or W arning.

Indicates an item requiring care to avoid electric shocks.

Indicates an item requiring care to avoid combustion (fire).

Indicates an item prohibiting disassembly to avoid electric shocks or problems.

Indicates an item requiring disconnection of the power plug from the electric

outlet.

Indicates an item intended to provide notes assisting the understanding of the

Memo

topic in question.

REF.

COPYRIGHT

©

Indicates an item of reference assisting the understanding of the topic in question.

Provides a description of a service mode.

Provides a description of the nature of an error indication.

Refers to the Copier Basics Series for a better understanding of the contents.

2001 CANON INC. 2000 2000 2000 2000 CANON CLC5000 REV.0 JAN. 2001

i

INTRODUCTION

2 Outline of the Manual

This Service Manual contains basic facts and figures needed to service the machine, Paper

Deck-J1/K1, Buffer Pass Unit-B1, conducted to ensure a high level of performance and expected functions.

The following accessories come with separate service manuals or service informations;

refer to them for details:

1. RDF-E3

2. Stapler Sorter-F2

3. Film Projector-E1

4. Editor-F1

5. ED Board-C1

6. Interface Board-E1

7. Preview Monitor Board

* Refer to CLC1000 series service manual.

This Service Manual is organized as follows;

<Main body & Accessory>

Chapter 1 General Description: Features, specifications, how to operate

Chapter 2 New Functions: Principle operations of each unit;

timing of operations; how to disassemble and assemble

(special information from CLC1000 series only)

If necessary, refer CLC1000 series service manual.

Chapter 3 Installation: Requirements on the site of installation, installation pro-

cedure

Chapter 4 Maintenance And Inspection:Periodically replaced parts table, consumables and

durables table, scheduled servicing chart, scheduled servicing table

Chapter 5 Troubleshooting: Basic procedure for image adjustment, standards/adjust-

ments, troubleshooting image faults, troubleshooting mal-

functions

Appendix: General timing chart, general circuit diagrams

<Service Mode>

<Error Codes>

ii

COPYRIGHT

©

2001 CANON INC. 2000 2000 2000 2000 CANON CLC5000 REV.0 JAN. 2001

INTRODUCTION

The descriptions in this Service Manual are based on he following rules:

1. In each chapter, the uses of the function in question and its relationship to electrical and

mechanical systems are discussed and the timing of operation of its associated parts is

explained by means of outlines and diagrams.

In the diagrams, the symbol

represents a mechanical path, while the symbol

with a name next to it indicates the flow of an electric signal.

The expression “turn on the power” means turning on the power switch, closing the

front cover, and closing the delivery cover so that the machine will be supplied with

power.

2. In circuit diagrams (digital), a signal whose level is High is expressed as being ‘1’,

while a single whose level is Low is expressed as being ‘0’; the level of voltage, however, varies from circuit to circuit.

The machine uses CPUs, whose internal mechanisms cannot be checked in the field,

and, therefore, are not explained. In addition, the machine’s PCBs are not intended for

repairs at the user’s and, therefore, are explained by means of block diagrams: two types

are used, i.e., between sensors and inputs of PCBs equipped with a control or drive

function and between outputs equipped with a control or drive function and loads; in addition, functional block diagrams are used at times.

Changes made to the machine for product improvement are communicated in the form of

a Service Information bulletin as needed. All service persons are expected to go through all

service documentation including the bulletins and be equipped to respond to the needs of

the field (as by being able to identify possible causes of problems).

COPYRIGHT

©

2001 CANON INC. 2000 2000 2000 2000 CANON CLC5000 REV.0 JAN. 2001

iii

INTRODUCTION

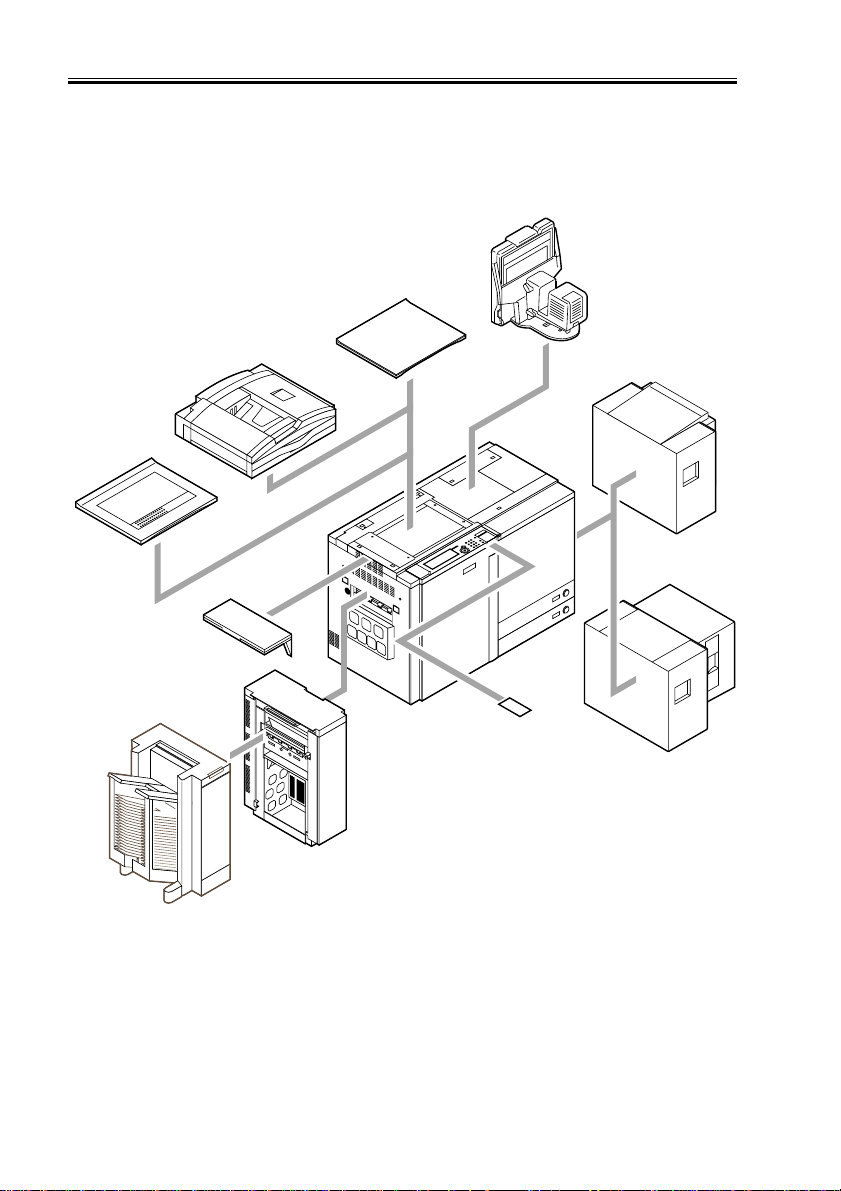

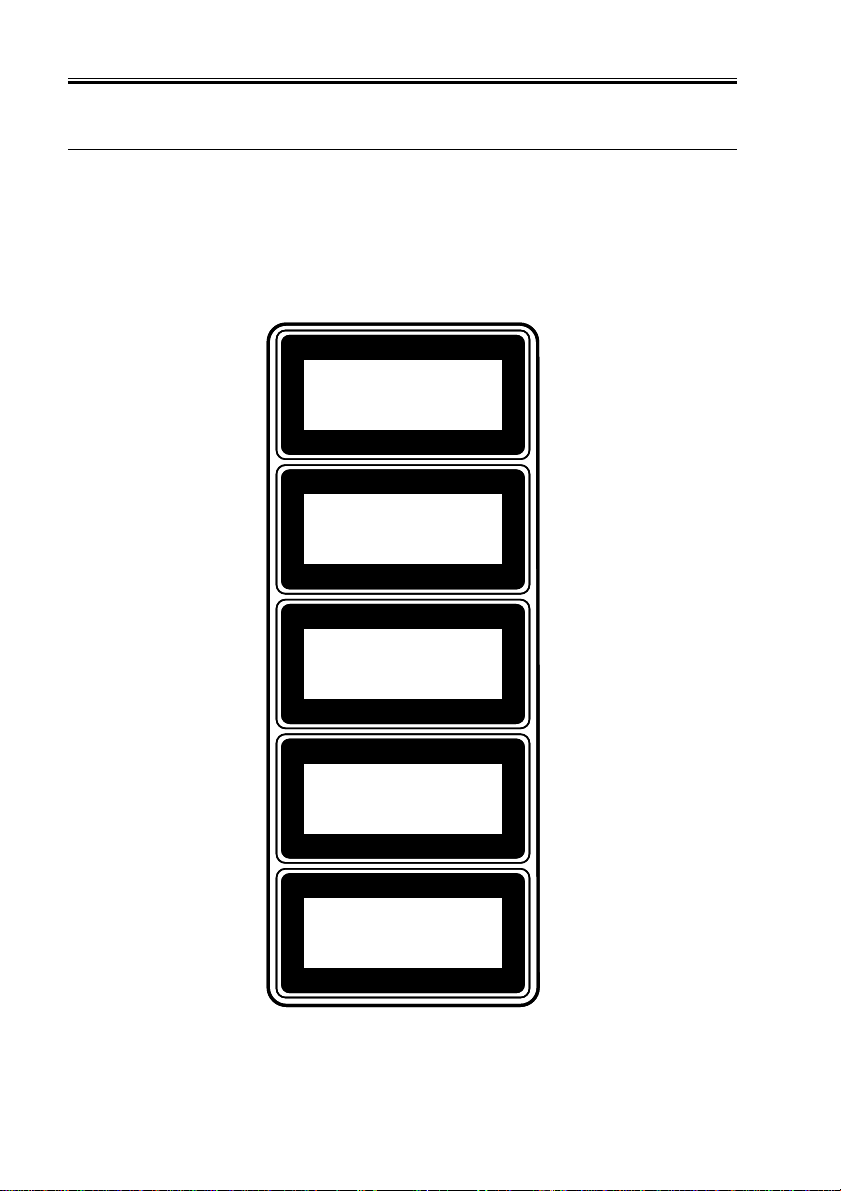

System Configuration

CLC5000 may be configured as follows:

*

Standard

Film projector-E1

Copyboard cover*

Editor-F1

Original tray*

Stapler sorter-F2

RDF-E3

Paper deck-J1

Main body

Control card-V

Paper deck-K1

Buffer pass unit-B1

Accessary boards as follows:

• ED board-C1

• Interface board-E1

• Preview monitor board

iv

COPYRIGHT

©

2001 CANON INC. 2000 2000 2000 2000 CANON CLC5000 REV.0 JAN. 2001

Main Body &

Accessory

COPYRIGHT © 2001 CANON INC. 2000 2000 20000 CANON CLC5000 REV.0 JAN. 2001

Contents

CHAPTER 1 GENERAL DESCRIPTION

1 Specifications...................................... 1-1

1.1 Type............................................ 1-1

1.2 Functions.................................... 1-2

1.3 Others ......................................... 1-4

1.3.1 Copier .................................. 1-4

1.4 Default Ratios ............................ 1-6

1.5 Copying Speed ........................... 1-7

2 Safety .................................................. 1-8

2.1 Safety of Laser Light ................. 1-8

2.2 CDRH Ordinance.......................1-9

2.3 Handling Parts Associated with the

Laser Unit ................................ 1-10

CHAPTER 2 NEW FUNCTIONS

3 Names of Parts .................................. 1-12

3.1 External Vi ew........................... 1-12

3.2 Cross Section ...........................1-14

4 Control Panel .................................... 1-16

4.1 Control Panel ........................... 1-16

4.1.1 Instructions to the User ...... 1-17

4.2 List of User Modes .................. 1-19

5 Routine Maintenance by the User .... 1-20

5.1 Cleaning the Outside................ 1-20

5.2 Checking the Leakage Breaker 1-20

CONTENTS

1 Exposure System ................................ 2-1

1.1 Outline of the Original Exposure

System........................................2-1

1.2 Comparison of Exposure

Systems ...................................... 2-2

1.3 Basic Sequence of Operations

(exposure system) ...................... 2-3

1.3.1 Scanner Home Position Sensor

and Operations ..................... 2-3

1.3.2 Sequence of Operations.......2-4

1.4 Scanner Motor ........................... 2-5

1.4.1 Outline ................................. 2-5

1.4.2 Operations............................ 2-5

1.5 Controlling the Intensity of the

Scanning Lamp .......................... 2-6

1.5.1 Outline ................................. 2-6

1.5.2 Operations............................ 2-6

1.6 Disassembly/Assembly .............. 2-8

1.6.1 Removing the Scanner

Motor ................................... 2-9

1.6.2 Removing the Lens Base Cover/

CCD Cover/CCD Unit....... 2-10

1.6.3 Removing the Scanner

Cover ................................. 2-11

COPYRIGHT

©

2001 CANON INC. 2000 2000 2000 2000 CANON CLC5000 REV.0 JAN. 2001

2 Image Processing System ................. 2-12

2.1 Outline of the Image Processing

System...................................... 2-12

2.2 Differences in the Image

Processing System ................... 2-13

2.3 Functional Blocks .................... 2-14

2.4 IP Memory Board ....................2-15

2.5 Direct Mapping ........................ 2-15

3 Laser System..................................... 2-16

3.1 Outline of the Laser System .... 2-16

3.2 Differences in the Laser

System...................................... 2-16

3.3 Image Formation Using 800

Lines......................................... 2-17

3.4 Image Position Correction

Sequence in Standby................2-18

3.4.1 Outline ............................... 2-18

3.4.2 Timing of Operation .......... 2-18

3.5 Disassembly/Assembly ............ 2-19

3.5.1 Preparing for Laser

Unit-Related W ork............. 2-20

3.5.2 Removing the Laser Unit

Motor ................................. 2-23

vii

CONTENTS

3.5.3 Removing the C Image Position

Correction Mirror Unit ......2-25

3.5.4 Mounting the C Image Position

Correction Mirror Unit ......2-26

3.5.5 Removing the C Slant

Correction Motor ............... 2-27

3.5.6 Removing the C Ratio

Correction Motor ............... 2-28

3.5.7 Shifting the scanner Unit...2-29

4 Image Formation System .................. 2-34

4.1 Outline of the Image Formation

System......................................2-34

4.2 Differences in the Image Formation

System......................................2-35

4.3 Auto Gradation Correction

(PASCAL) ................................ 2-37

4.3.1 Outline ............................... 2-37

4.3.2 Operations

(full correction)..................2-37

4.3.3 Operations

(quick correction) .............. 2-42

4.4 Transfer Unit............................2-44

4.4.1 Outline ............................... 2-44

4.4.2 Cleaning Mechanism for

the Transfer Belt ................2-45

4.5 Disassembly/Assembly ............ 2-49

4.5.1 Charging System ............... 2-50

4.5.2 Process Unit System .......... 2-54

4.5.3 Transfer Belt Unit .............. 2-66

4.5.4 Transfer Belt Base ............. 2-82

5 Pickup/Feed System ......................... 2-86

5.1 Outline of the Pickup/

Feed System ............................. 2-86

5.2 Differences in the Pickup/

Feed System ............................. 2-87

5.3 Cassette Pickup Assembly ....... 2-90

5.3.1 Outline ............................... 2-90

5.3.2 Cassette Lifter Operation... 2-92

5.3.3 Sequence of Operations

(pickup).............................. 2-93

5.4 Multifeeder Pickup Assembly.. 2-94

5.4.1 Operations.......................... 2-94

5.4.2 Sequence of Operations

(multifeeder pickup) .......... 2-95

5.4.3 Releasing the Registration

Roller .................................2-96

viii

COPYRIGHT

©

2001 CANON INC. 2000 2000 2000 2000 CANON CLC5000 REV.0 JAN. 2001

5.5 Duplex Unit.............................. 2-97

5.5.1 Outline ............................... 2-97

5.5.2 Feeding in Duplex Mode ... 2-98

5.5.3 Sequence of Operations in

Duplex Mode (1st side) ... 2-100

5.5.4 Pickup from the Duplex

Unit .................................. 2-101

5.6 Detecting Jams ....................... 2-103

5.6.1 Outline ............................. 2-103

5.6.2 Sequence of Jam

Detection.......................... 2-103

5.7 Disassembly/Assembly .......... 2-104

5.7.1 Removing the Multifeeder

Assembly .........................2-105

5.7.2 Removing the Cassette Pickup

Assembly .........................2-106

5.7.3 Removing the Re-Pickup

Assembly .........................2-108

5.7.4 Removing the Re-Pickup

Motor ............................... 2-109

5.7.5 Removing the Re-Pickup Unit

Clutch .............................. 2-110

5.7.6 Removing the Re-Pickup

Shutter Solenoid .............. 2-111

5.7.7 Removing the Duplex Unit

Feed roller........................2-112

5.7.8 Removing the Pre-Fixing

Feeding Assembly ........... 2-112

5.7.9 Removing the Pre-Duplex

Feeding Unit .................... 2-113

5.7.10 Delivery/Reversing

Assembly .........................2-116

6 Fixing System ................................. 2-120

6.1 Outline of the Fixing System.2-120

6.2 Outline of the Fixing System.2-121

6.3 Outline of the Fixing/Delivery

Assembly ............................... 2-123

6.4 Controlling the Fixing Roller

Temperature ........................... 2-124

6.5 Controlling the Fixing Oil

Temperature ........................... 2-126

6.6 Protective Mechanisms .......... 2-127

6.6.1 Detecting Overheating

(software).........................2-127

CONTENTS

6.6.2 Detecting Overheating

(hardware)........................ 2-127

6.6.3 Detecting an Open Circuit

in the Thermistor ............. 2-128

6.6.4 Detecting a Fault in the

Triac.................................2-128

6.6.5 Detecting Overheating of

Fixing Oil (software) ....... 2-128

6.6.6 Detecting Overheating of

Fixing Oil (hardware) ...... 2-128

6.6.7 Detecting Low Temperature of

Oil (software)................... 2-129

6.6.8 Detecting Low Temperature of

Oil (hardware).................. 2-129

6.6.9 Operation of the Thermal

Switch .............................. 2-129

6.7 Controlling the Fixing Speed. 2-130

6.8 Timing Chart

(fixing/delivery assembly) ..... 2-131

6.8.1 Basic Sequence of

Operations........................ 2-131

6.8.2 Changing the Fixing

Speed ............................... 2-132

6.9 Driving the Fixing Cleaning

Web ........................................ 2-133

6.10 Disassembly/Assembly .......... 2-134

6.10.1 Fixing Assembly .............. 2-135

6.10.2 Upper Fixing Cleaner

Assembly .........................2-141

6.10.3 Lower Fixing Cleaning

Assembly .........................2-143

6.10.4 Fixing Oil Applying Unit 2-144

7 Externals and Controls ................... 2-150

7.1 Outline of the Externals and

Controls.................................. 2-150

7.2 Differences in the Externals and

Controls.................................. 2-150

7.3 Fans ........................................ 2-151

7.3.1 Arrangement of the Fans . 2-151

7.3.2 Types of Fans ................... 2-152

7.3.3 Sequence of Operations... 2-153

7.4 Power Supply......................... 2-154

7.5 Download............................... 2-157

7.6 Disassembly/Assembly .......... 2-158

7.6.1 Fans and Filters................ 2-159

7.6.2 Switches........................... 2-169

7.6.3 PCBs ................................ 2-169

7.6.4 Drive System ................... 2-184

8 Paper Deck-J1/K1 ...........................2-197

8.1 Outline ................................... 2-197

8.2 Differences in the Paper

Deck-J1/K1 ............................ 2-197

8.3 Outline of Operations ............ 2-198

8.3.1 Outline ............................. 2-198

8.3.2 Pickup Operations ...........2-199

8.3.3 Sequence of Operations

(pickup from paper deck) 2-200

8.4 Disassembly/Assembly .......... 2-201

8.4.1 Removing the Pickup

Roller ...............................2-202

8.4.2 Removing the Pickup/Feed

roller ................................ 2-203

8.4.3 Removing the Separation

Roller ...............................2-205

8.4.4 Removing the deck

sensor ............................... 2-206

9 Buffer Pass Unit-B1........................ 2-207

9.1 Outline ................................... 2-207

9.1.1 Outline of the Electrical

Circuitry...........................2-208

9.1.2 Inputs to and Outputs from the

Buffer Pass Driver PCB ... 2-209

9.2 Differences in the Buffer Path

Unit ........................................ 2-211

9.3 Feeding Operations ................ 2-212

9.3.1 Outline ............................. 2-212

9.3.2 Controlling the Feeding

Speed ............................... 2-216

9.3.3 Controlling the Buffer Pass

Motor ............................... 2-217

9.4 Removing Curling ................. 2-219

9.4.1 Outline ............................. 2-219

9.4.2 Operations........................ 2-221

9.5 Detecting Jams ....................... 2-224

9.5.1 Outline ............................. 2-224

9.5.2 Delay Jam ........................ 2-225

9.5.3 Stationary Jam ................. 2-226

9.6 Power Supply......................... 2-227

COPYRIGHT

©

2001 CANON INC. 2000 2000 2000 2000 CANON CLC5000 REV.0 JAN. 2001

ix

CONTENTS

9.6.1Outline ................................... 2-227

9.7 Disassembly/Assembly .......... 2-228

9.7.1 External Covers ............... 2-229

9.7.2 Feeding System ............... 2-230

9.7.3 PCBs ................................ 2-244

9.7.4 Fans and Motors .............. 2-245

9.7.5 Sensors............................. 2-249

9.7.6 Solenoids ......................... 2-253

CHAPTER 3 INSTALLATION

1 Selecting the Site ................................ 3-1

2 Points to Note for Installation and Relo-

cation .................................................. 3-4

2.1 Base Plate and Installation/

Relocation Work ........................ 3-4

3 Installation .......................................... 3-5

3.1 Unpacking .................................. 3-5

3.2 Removing the Fixings, Supplying

Fixing Oil, and Changing the Voltage Rating (240V North American

Model)........................................ 3-7

3.3 Supplying Toner.......................3-14

3.4 Supplying Starter ..................... 3-22

3.5 Checking Images and

Operations ................................ 3-26

4 Relocating the Machine .................... 3-27

5 Installing the Original Tray .............. 3-29

6 Installing the Control Card V ...........3-30

7 Installing the DA Unit-A1 ................ 3-34

8 Using the Crane Transport kit........... 3-38

8.1 Items to Prepare .......................3-38

8.2 Procedure .................................3-39

8.2.1 Preventing Deformation of

Externals ............................ 3-39

8.2.2 Mounting the Belt Retaining

Members ............................ 3-40

8.2.3 Mounting the Developing Bias

Assembly Protection

Member.............................. 3-41

CHAPTER 4 MAINTENANCE AND SERVICING

1 Periodically Replaced Parts ................ 4-1

2 Consumables and Durables ................ 4-4

2.1 Copier......................................... 4-4

2.1.1 By the Copier’s Hard

Counter ................................ 4-4

2.1.2 By the Soft Counter in Service

Mode (COUNTER) ............. 4-6

x

COPYRIGHT

©

2001 CANON INC. 2000 2000 2000 2000 CANON CLC5000 REV.0 JAN. 2001

2.2 Buffer Pass Unit-B1...................4-6

2.3 Paper Deck-K1/J1 ...................... 4-6

3 Scheduled Servicing Procedure .......... 4-7

4 Scheduled Maintenance Chart ............ 4-8

4.1 Copier......................................... 4-8

4.2 Buffer Pass Unit - B1............... 4-12

4.3 Paper Deck - J1/K1 .................. 4-12

CONTENTS

CHAPTER 5 TROUBLESHOOTING IMAGE FAULTS/

MALFUNCTIONS

1 Guide to Table ..................................... 5-1

1.1 Image Adjustment Basic

Procedure ................................... 5-3

1.2 Points of the Scheduled

Servicing .................................... 5-5

2 Standards and Adjustments ................. 5- 7

2.1 Image-Related Parts ................... 5-7

2.1.1 Non-Image W idth ................ 5-7

2.1.2 Image Margin ...................... 5-8

2.1.3 Checking and Adjusting the

Non-Image Width and

Margin ................................. 5-9

2.1.4 Image Positioning Correction

........................................... 5-16

2.2 Original Illuminating System .. 5-17

2.2.1 When Replacing the Scanning

Lamp, Standard White Plate,

Lamp Regulator, Reflecting

Lamp Cover, Reader Controller

PCB, Flash memory on Reader

Controller PCB, or Analog Pro-

cessor PCB CCD Unit .......5-17

2.2.2 Routing the Scanner Cable 5-17

2.3 Photosensitive Drum-Related

Parts.......................................... 5-21

2.3.1 Removing the Photosensitive

Drum .................................. 5-21

2.3.2 Points to Note When Installing

the Photosensitive Drum.... 5-22

2.3.3 Points to Note When Fitting the

Drum Drive Belt ................ 5-23

2.4 Charging Assembly-Related

Parts.......................................... 5-23

2.4.1 Adjusting the Height of the

Charging W ire.................... 5-23

2.4.2 Points to Note When Handling

the Primary Grid Plate and the

Primary Charging Wire......5-24

2.5 Developing Assembly-Related

Parts.......................................... 5-24

2.5.1 Replacing the Developer.... 5-24

2.5.2 When Replacing the Develop-

ing Assembly (CMYK)......5-28

2.5.3 When Replacing the

Photosensitive Drum .......... 5-29

2.5.4 When Supplying the Hopper

with Toner .......................... 5-30

2.6 Transfer Belt Unit .................... 5-31

2.6.1 Points to Note When Replacing

the Transfer Belt ................5-31

2.6.2 Initializing the Transfer Belt

Swing Control Data ........... 5-32

2.6.3 Adjusting the Tension on the

Drive Belt of the Transfer Belt

Motor ................................. 5-32

2.6.4 Adjusting the Position of the

Transfer Belt-Related

Solenoid ............................. 5-33

2.7 When Replacing the Pick-Up/

Feeding-Related Parts .............. 5-34

2.7.1 Registering the Cassette/

Multifeeder Paper Width Basic

Setting (under ‘FUNC’)..... 5-34

2.7.2 Orientation of the Cassette

Pickup Roller ..................... 5-36

2.7.3 Orientation of the Cassette

Feed Roller ........................ 5-37

2.7.4 Orientation of the Cassette

Separation Roller ............... 5-37

2.7.5 Adding the Pressure of the

Cassette Separation Roller.5-37

2.7.6 Orientation of the Paper Deck

Pick-Up Roller ................... 5-38

2.7.7 Orientation of the Paper Deck

Pick-Up/Feeding Roller.....5-38

2.7.8 Orientation of the Paper Deck

Separation Roller ............... 5-38

2.7.9 Adjusting the Position of the

Paper Deck Pick-Up Roller

Releasing Solenoid

(SL8001)............................5-39

COPYRIGHT

©

2001 CANON INC. 2000 2000 2000 2000 CANON CLC5000 REV.0 JAN. 2001

xi

CONTENTS

2.7.10 Adjusting the Pressure of the

Paper Deck Separation/Feeding

Roller .................................5-39

2.7.11 Positioning the Cassette Pickup

Roller Releasing Solenoid

(SL9, SL10) ....................... 5-39

2.7.12 Adjusting the Pressure of the

Multifeeder Separation

Roller .................................5-40

2.7.13 Adjusting the Position of the

Multifeeder Pick-Up Roller

Releasing Solenoid

(SL5) .................................. 5-40

2.7.14 Adjusting the Position of the

Delivery Paper Deflecting Plate

Solenoid (SL14) ................ 5-40

2.7.15 Adjusting the Position of the

Duplexing Unit Paper Deflecting Plate Solenoid

(SL11)................................5-41

2.7.16 Adjusting the Position of the

Duplexing Unit Stacking

Assembly Paper Guide

Plate ...................................5-41

2.7.17 Adjusting the Position of the

Duplexing Unit Feeding Roller

Solenoid (SL13) ................ 5-42

2.7.18 Attaching the Timing Belt for

the Duplexing Unit Stacking

Assembly Paper Guide

Plate ...................................5-42

2.7.19 Adjusting the Position of the

Separation Claw Solenoid

(SL15)................................5-43

2.7.20 Adjusting the Position of the

Upper Fixing Web Take-Up

Solenoid (SL3) .................. 5-43

2.7.21 When Replacing the

Registration Roller Unit .... 5-43

2.7.22 Correcting Skew

Movement(slope of the

registration roller unit)....... 5-44

2.8 Laser Exposure System............ 5-45

2.8.1 When Replacing the Laser

Unit .................................... 5-45

2.8.2 When Replacing the Video Con-

troller PCB.........................5-45

2.8.3 When Replacing the BD

Unit .................................... 5-45

2.8.4 Adjusting the Laser Power 5-45

2.8.5 Adjusting the Laser

Intensity ............................. 5-49

2.8.6 Laser Focus Adjustment ....5-50

2.9 Fixing Assembly-Related Parts 5-52

2.9.1 Points to Note When Replacing

the Fixing Heater ............... 5-52

2.9.2 Adjusting the Nip (fixing pres-

sure adjusting nut) .............5-52

2.9.3 Adjusting the Mounting Position of the External Paper

Delivery Unit ..................... 5-53

2.10 Electrical .................................. 5-54

2.10.1 When Replacing Major

Parts ................................... 5-54

2.10.2 Checking the Environment

Measurement PCB .............5-58

2.10.3 Checking the High Voltage

Control System .................. 5-60

2.10.4 Checking the

Photointerrupters ............... 5-61

3 Troubleshooting Image Problems..... 5-66

3.1 Initial Checks ........................... 5-66

3.1.1 Checking the Site of

Installation ......................... 5-66

3.1.2 Checking the Originals......5-66

3.1.3 Checking the Copyboard Cover,

Copyboard Glass, and

Standard White Plate ......... 5-66

3.1.4 Checking the Charging

Assemblies.........................5-66

3.1.5 Checking the Developing

Assembly ........................... 5-66

3.1.6 Checking the Paper............ 5-66

3.1.7 Checking the Periodically

Replaced Parts ................... 5-67

3.1.8 Others ................................ 5-67

3.2 Standard Image ........................5-67

3.2.1 Gray Scale.......................... 5-67

3.2.2 Color Patches..................... 5-67

3.2.3 Photo.................................. 5-67

xii

COPYRIGHT

©

2001 CANON INC. 2000 2000 2000 2000 CANON CLC5000 REV.0 JAN. 2001

CONTENTS

3.2.4 3-Color Gradation Scale....5-67

3.2.5 Halftone Band.................... 5-68

3.2.6 Fogging.............................. 5-68

3.3 Test Prints ................................ 5-70

3.3.1 Selecting a Test Pattern ...... 5-70

3.3.2 256-Color Test Print

(PGTYPE=02) ................... 5-72

3.3.3 256-Gradation Test Print

(PGTYPE=03) ................... 5-73

3.3.4 17-Gradation Test Print

(PGTYPE=04) ................... 5-74

3.3.5 Halftone Test Print

(PGTYPE=05) ................... 5-75

3.3.6 Grid Test Print

(PGTYPE=06) ................... 5-77

3.3.7 Image Position Correction

Pattern (PGTYPE=07).......5-78

3.3.8 Horizontal Stripe (FF acti v ation)

T est Print (PGTYPE=10)......5-79

3.3.9 Full Color 17-Gradation

(YMCBk+RGB+gray) T est

Print (PGTYPE=14) .......... 5-80

3.4 Troubleshooting Image Faults . 5-81

3.4.1 The image is too light

(all colors).......................... 5-81

3.4.2 The image is too light

(specific color). .................. 5-81

3.4.3 The copy has uneven density

(vertical)............................. 5-81

3.4.4 The copy has uneven density

(horizontal). ....................... 5-83

3.4.5 The copy has fogging. ....... 5-84

3.4.6 The copy has vertical

streaks/vertical lines. ......... 5-84

3.4.7 The copy has white streaks/

white lines (vertical). ......... 5-87

3.4.8 The copy has horizontal streaks/

horizontal fogging. ............ 5-89

3.4.9 The copy has white spots

(horizontal). ....................... 5-91

3.4.10 The copy has white spots. ..5-92

3.4.11 The copy has white spots

(trailing center). ................. 5-93

3.4.12 The copy has white spots

(meandering)...................... 5-94

3.4.13 The copy has a soiled image or

soiled back. ........................ 5-94

3.4.14 The copy has poor fixing. .. 5-96

3.4.15 The copy has bleeding toner

(during fixing). .................. 5-97

3.4.16 The copy is blank. ............. 5-98

3.4.17 The copy is solid black. ..... 5-99

3.4.18 The copy has color

displacement. ................... 5-101

3.4.19 The copy has image blur ..5-102

3.4.20 Adjust the Image

Leading ............................ 5-103

4 Troubleshooting..............................5-104

4.1 Troubleshooting Malfunctions5-104

4.1.1 E000/E004 .......................5-104

4.1.2 E005................................. 5-109

4.1.3 E006................................. 5-109

4.1.4 E008................................. 5-110

4.1.5 E012................................. 5-111

4.1.6 E013................................. 5-112

4.1.7 E014................................. 5-114

4.1.8 E015................................. 5-114

4.1.9 E017................................. 5-115

4.1.10 E018 ................................. 5-115

4.1.11 E020 ................................. 5-116

4.1.12 E023 ................................. 5-120

4.1.13 E030 ................................. 5-120

4.1.14 E040 ................................. 5-121

4.1.15 E041 ................................. 5-123

4.1.16 E044 ................................. 5-124

4.1.17 E050 ................................. 5-125

4.1.18 E061 ................................. 5-125

4.1.19 E062 ................................. 5-127

4.1.20 E072 ................................. 5-128

4.1.21 E073 ................................. 5-128

4.1.22 E074 ................................. 5-129

4.1.23 E075 ................................. 5-130

4.1.24 E076 ................................. 5-135

4.1.25 E077 ................................. 5-135

4.1.26 E100 ................................. 5-136

4.1.27 E110 ................................. 5-138

4.1.28 E194 ................................. 5-138

4.1.29 E220 ................................. 5-141

4.1.30 E226 ................................. 5-141

4.1.31 E249 ................................. 5-141

COPYRIGHT

©

2001 CANON INC. 2000 2000 2000 2000 CANON CLC5000 REV.0 JAN. 2001

xiii

CONTENTS

4.1.32 E350 ................................. 5-142

4.1.33 E351 ................................. 5-142

4.1.34 E517 ................................. 5-143

4.1.35 E620 ................................. 5-144

4.1.36 E700 ................................. 5-144

4.1.37 E718 ................................. 5-145

4.1.38 E800 ................................. 5-146

4.1.39 E804 ................................. 5-146

4.1.40 E805 ................................. 5-146

4.1.41 E807 ................................. 5-147

4.1.42 E822 ................................. 5-148

4.1.43 E824 ................................. 5-148

4.1.44 E826 ................................. 5-149

4.1.45 AC power is absent. ......... 5-149

4.1.46 DC power is absent. ......... 5-151

4.1.47 The scanner fails to move

forward/in reverse............ 5-152

4.1.48 The scanning lamp fails to

turn ON. ........................... 5-153

4.1.49 The lifter fails to move up

(pick-up from the

cassette). .......................... 5-154

4.1.50 Pick-up fails (cassette 1)..5-155

4.1.51 Pick-up fails (cassette 2)..5-156

4.1.52 The multifeeder fails to

pick up paper. .................. 5-157

4.1.53 The registration roller fails to

rotate. ............................... 5-157

4.1.54 Retention fails..................5-158

4.1.55 The pre-exposure lamp fails to

turn ON. ........................... 5-159

4.1.56 The fixing heater fails to turn

ON. .................................. 5-159

4.1.57 The drum heater fails to

rotate. ............................... 5-161

4.1.58 The counter fails to operate. 5-162

4.1.59 The cassette heater fails to

operate. ............................ 5-163

4.1.60 Abnormal noise is heard. . 5-164

5 Troubleshooting Feeding Problems 5-165

5.1 Jams ....................................... 5-165

5.1.1 Pick-Up Assembly ...........5-167

5.1.2 Pick-up Feeding Assembly . 5-168

5.1.3 Transfer Unit Assembly... 5-169

5.1.4 Separation/Pre-Fixing

Feeding Assembly ........... 5-169

xiv

COPYRIGHT

©

2001 CANON INC. 2000 2000 2000 2000 CANON CLC5000 REV.0 JAN. 2001

5.1.5 Fixing/Deli very Assembly5-170

5.1.6 Deliv ery V ertical Path, Duplexing

Reversing Assembly , and Pre-du-

plex Feeding Assembly....... 5-171

5.1.7 Duplex feeding Assembly/

Duplex Assembly............. 5-172

5.2 Feeding Faults........................ 5-173

5.2.1 Double Feeding ...............5-173

5.2.2 Wrinkles .......................... 5-173

6 Arrangement and Functions of

Electrical Parts ................................ 5-174

6.1 Sensors ................................... 5-174

6.2 “Lamps, Switches, Thermistors,

and Heaters”...........................5-178

6.3 Clutches ................................. 5-182

6.4 Solenoids................................ 5-183

6.5 Fans ........................................ 5-184

6.6 Motors....................................5-186

6.7 PCBs ...................................... 5-188

6.8 Variable Resistors (VR), LightEmitting Diodes (LED), and Check

Pins by PCB ........................... 5-190

6.8.1 DC Controller PCB ......... 5-191

6.8.2 Video Controller PCB...... 5-192

6.8.3 Reader Control PCB ........5-193

6.8.4 Image Processor PCB ...... 5-194

6.8.5 IP Memory PCB .............. 5-195

6.8.7 Transfer Belt Motor

Driver PCB ...................... 5-196

6.8.6 Analog Processor PCB .... 5-196

6.8.8 Laser Driver PCB ............ 5-197

6.8.9 Lamp Regulator PCB ......5-199

6.8.10 Enviroment Sensor PCB..5-200

6.8.11 HVT1 ............................... 5-201

6.8.12 HVT2 ............................... 5-202

6.8.13 HVT4 ............................... 5-204

6.8.14 HVT5 ............................... 5-204

6.8.15 ED board A1....................5-205

6.8.16 Interface board B1 ........... 5-206

6.8.17 Preview monitor board .... 5-207

6.9 Paper Deck-K1....................... 5-208

6.10 Paper Deck-J1.........................5-209

6.11 Buffer pass unit C1 .................5-210

7 Upgrading (download) .................... 5-212

7.1 Items to Prepare .....................5-212

7.2 Preparing for the Work........... 5-212

7.3 Making Connections .............. 5-212

7.4 Downloading.......................... 5-214

7.5 After the Work .......................5-215

APPENDIX

CONTENTS

1 General Timing Chart ........................ A-1

2 General Circuit Diagram.................... A-3

3 Paper Deck J1/K1

General Timing Chart ........................ A-7

2 Buffer Pass Unit

General Circuit Diagram.................... A-8

5 Special Tools ...................................... A-9

6 Solvents and Oils ............................. A-12

COPYRIGHT

©

2001 CANON INC. 2000 2000 2000 2000 CANON CLC5000 REV.0 JAN. 2001

xv

CHAPTER 1

GENERAL DESCRIPTION

COPYRIGHT

©

2001 CANON INC. 2000 2000 2000 2000 CANON CLC5000 REV.0 JAN. 2001

CHAPTER 1 GENERAL DESCRIPTION

1 Specifications

1.1 Type

Body Console

Copyboard Fixed

Light source Halogen lamp

Lens Fixed lens array

Image reading Photocell (BGR 3-line CCD); scanning by mirror with CCD

fixed in place

Photosensitive medium OPC drum (60-mm dia.); 4 pc.

Reproduction Indirect statophotographic

Charging Corona

Exposure Laser beam

Contrast adjustment Auto

Development Toner projection (CMYK)

Toner supply Manual (YMC, 750 g; K, 6450 g)

Paper source Special front cassette (2 pc.), paper deck, multifeeder

Attraction Static electricity (simultaneously with cyan transfer)

Transfer Blade (transfer belt)

Separation Static electricity

Photosensitive drum cleaning Blade

Fixing Heat roller (upper, 800 W; lower, 600 W)

COPYRIGHT

©

T01-101-01

2001 CANON INC. 2000 2000 2000 2000 CANON CLC5000 REV.0 JAN. 2001

1-1

CHAPTER 1 GENERAL DESCRIPTION

1.2 Functions

Type of original Sheets, 3-D object (2 kg max.)

Maximum size of original A3 (297 x 420 mm)/11 x 17 (279 x 432 mm)

Reproduction ratio Direct (±0.5%); default enlargement/reduction (±1.0%; see

auto ratio selection, zoom

Wait time (20ºC) 9 min or less

First copy time (A4/LTR) 12 sec or less (A4/LTR)

Continuous copying 999 copies max.

Copying speed See T01-105-01.

Copy size Cassette Maximum: A3 (297 x 420 mm)/11 x 17 (279 x 432 mm)

Multifeeder Maximum: A3 extra length (305 x 457 mm)

Paper deck A4 (210 x 297mm), LTR (216 x 279 mm), 11 x 17 (279 x 432 mm),

Type of Cassette Plain paper (80 to 105 g/m2), transparency (special),

copy paper thin paper (64 to 79 g/m2)

Multifeeder Thin paper (64 to 79 g/m2), plain paper (80 to 163 g/m2),

Paper deck Plain paper (80 to 105 g/m2), transparency (special), thin paper

(64 to 79 g/m2)

Double-sided Plain paper (105 g/m2; auto double-sided and manual

copy double-sided)

Cassette w/o claw, center reference, 550 sheets (of 105 g/m2 paper; approx.)

Multifeeder 250 sheets (of 81.4 g/m2 paper; approx.)

Paper deck Stack height Paper Deck-J1 205 mm (2000 sheets of

Delivery tray 250 sheets (of 81.4 g/m2 paper; approx.)

Image margin Single-sided Double-sided

Non-image width Single-sided Double-sided

Reading resolution 400 dpi

(main scanning direction)

Reading resolution 400 dpi

(main scanning direction)

Table 1-201); zoom, 25% to 400% (±1.0%, in 1% increments);

Minimum: A5 (148 x 210 mm)/STMT (216 x 139.5 mm)

Minimum: Postcard (A6 non-default)

A3 extra-length (305 x 457 mm), 12 x 18 (305 x 457 mm),

B5 (182 x 257 mm), A3 (297 x 420 mm), B4 (257 x 364 mm)

thick paper (106 to 163 g/m2; including cast coated paper and

special postcard), extra-thick paper (164 to 253 g; including

cast coated paper and postcard), special paper 1/2,

transparency (special)

Paper Deck-K1 410 mm (4000 sheets of

Leading edge: 2.5±1.5 mm Leading edge: 2.5±2.0 mm

Left/right: 2.0±1.5 mm Left/right: 2.0±1.5 mm

Trailing edge: 2.5±1.5 mm Trailing edge: 2.5±2.0 mm

Leading edge: 2.5±1.5 mm Leading edge: 2.5±2.0 mm

(in full image, 0.5±0.5 mm)

Let/right: 2.0±1.5 mm Left/right: 2.0±1.5 mm

(in full image, 0±1.0 mm) (in full image, 0±1.0 mm)

81.4 g/m2 paper)

81.4 g/m2)

(in full in full image, 0.5±0.5 mm)

1-2

COPYRIGHT

©

T01-102-01

2001 CANON INC. 2000 2000 2000 2000 CANON CLC5000 REV.0 JAN. 2001

CHAPTER 1 GENERAL DESCRIPTION

Density adjustment Manual (9 steps), color AE, BE

Color mode ACS, black, full color

Color adjustment Color balance, registration, hue, chroma, density area

Original mode Text/print photo, text/film photo, text, print photo, film photo,

map, second copy

Original detection Size, position

Cassette selection Auto paper selection, auto cassette selection

Page separation Page separation, free division, enlargement separation,

reduced page composition (requires RDF), double-sided

separation (requires RDF)

Auto double-sided Single-sided to double-sided, double-sided to double-sided

(requires RDF), double-sided to single-sided (requires RDF),

page separation double-sided

Bind margin Yes (right/left bind, bind width, back only)

Frame erase Original, book, sheet

Shift Center shift, corner shift, free shift

Transparency interleaf Yes

One-touch adjustment Yes

Interrupt Yes

ID mode Yes

Auto start Yes

Auto clear Yes

(2 min standard; may be changed or disabled in user mode)

Auto power-off Yes (2 hr standard; may be changed or disabled in user mode)

Pre-heat Yes

Area selection/Non-rectangle Yes (requires ED Board-C1)

area selection

Marker selection No

Synthesis Yes (requires ED Board-C1)

Image create Yes (some functions require ED Board-C1)

Color create Use (some functions require ED Board-C1)

User mode Settings selection Yes

Standard mode change Registration/initialization

Mode memory 9 modes: full set, 3; no area, 6

Timer Auto clear time, auto power-off time

Density correction Yes

Auto gradation correction Yes

Background level adjustment Yes

Text/photo level Text/photo separation level (7 steps)

Zoom fine tuning Yes

Cleaning Yes

Transparency cassette selection Yes

Thin paper cassette selection Use

COPYRIGHT

©

T01-102-02

2001 CANON INC. 2000 2000 2000 2000 CANON CLC5000 REV.0 JAN. 2001

1-3

CHAPTER 1 GENERAL DESCRIPTION

1.3 Others

1.3.1 Copier

Operating environment Temperature: 15 to 27.5ºC

Humidity: 25% to 75%

Atm pressure: 810.6 hPa to 1013.3 hPa (0.8 to 1.0 atm)

Power supply Serial No.

200V LQZxxxxx

208/240V NSXxxxxx (UL)

230V PRXxxxxx (ITA)

230V SCZxxxxx (FRN)

Power supply (rated voltage ±10%) 230V TDLxxxxx (GER)

230V UHBxxxxx (AMS)

230V PRMxxxxx (general)

230V QEBxxxxx (UK)

230V PDQxxxxx (CA)

Power consumption 3 KW or less (during copying, A4, full-color continuous)

0.62 KW (during standby; reference only)

Noise 77 dB (during copying) ISO sound power level

71 dB (during standby) (1 m from machine)

Ozone 0.02 ppm or less 0.05 ppm

(upon installation) (100,000 copies or 1 yr)

Consumables Paper Keep wrapped to protect against humidity.

Toner Avoid direct sunlight, and keep it at 40ºC or lower.

Fixing oil Avoid direct sunlight.

Dimensions See F01-103-01.

Weight 490.0 kg (body only)

3.7 kg (copyboard)

4.9 kg (editor)

28.5 kg (A4 paper deck)

39.4 kg (A3 paper deck)

1-4

COPYRIGHT

©

T01-103-01

2001 CANON INC. 2000 2000 2000 2000 CANON CLC5000 REV.0 JAN. 2001

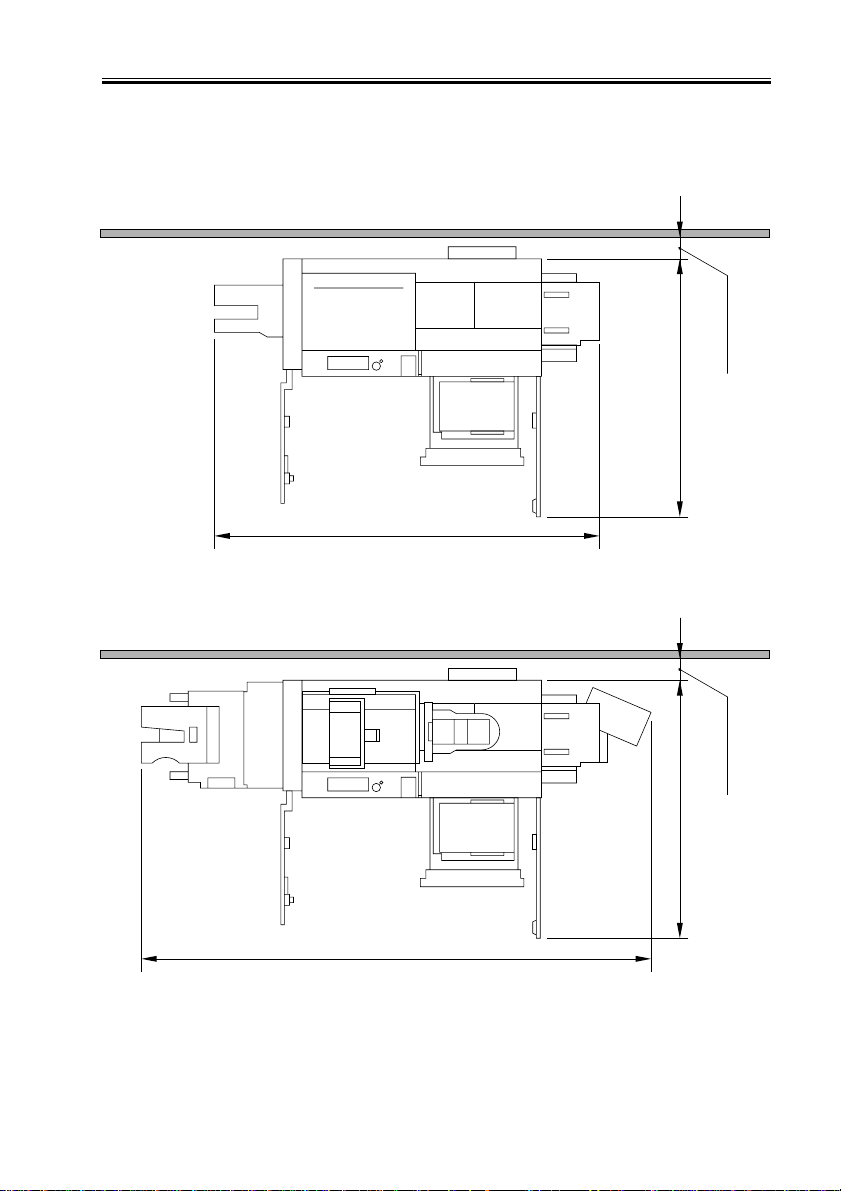

Dimensions

• Without Options

2106mm

• With Paper Deck-J1, Feeder, Stapler Sorter,

Buffer Path Unit, and Projector

CHAPTER 1 GENERAL DESCRIPTION

100 mm min.100 mm min.

COPYRIGHT

©

3052mm

F01-103-01

2001 CANON INC. 2000 2000 2000 2000 CANON CLC5000 REV.0 JAN. 2001

1565mm 1565mm

1-5

CHAPTER 1 GENERAL DESCRIPTION

1.4 Default Ratios

Site Reduction Ratio Enlargement Ratio

B4 to A3

— 0.250 B5R to A4R 1.153

B5 to A4

A3 to A5 0.500 A4R to B4 1.223

A5 to B5

Japan A3 to B5 0.611 A4R to B4 1.414

6R5E B5R to B4

A3 to A4R 0.707 A5 to A3 2.000

B4 to B5R

B4 to A4R 0.815 — 4.000

A3 to B4 0.865 —

A4R to B5R

— 0.250 LGL to 11x17 1.214

— 0.500 — 1.294

North America

5R4E

Europe

3R3E A3 to A5 0.500 A5 to A3 2.000

Others A3 to A4R 0.707 A4R to A3 1.414

5R5E B4 to B5R B5R to B4

11x17 to LTRR 0.647 LTRR to 11x17 2.000

11x17 to LGL 0.733 MINIT to LTRR 4.000

LGL to LTRR 0.786 —

— 0.250 A4R to A3 1.414

A3 to A4R 0.707 — 4.000

— 0.250 B4 to A3 1.153

B5R to A4R

B5 to A4

A3 to A5 0.500 A4R to B4 1.223

A5 to B5

B4 to A4R 0.815 A5 to A3 2.000

A3 to B4 0.865 4.000

A4R to B5R

1-6

COPYRIGHT

©

T01-104-01

2001 CANON INC. 2000 2000 2000 2000 CANON CLC5000 REV.0 JAN. 2001

CHAPTER 1 GENERAL DESCRIPTION

1.5 Copying Speed

Source Side Medium Copying speed

A4/LTR A3/11x17 4R/B4

Cassette 1st Plain paper 50 25 30

Transparency 9 — 8

Paper deck 1st Plain paper 50 25 30 (B4)

Duplex unit 2nd Plain paper 2 0 10 10

Multifeeder 1st Plain paper 35 18 22

2nd Thick paper 16 11 12

Extra-thick paper 13 8 9

Transparency 9 7 8

T01-105-01

The above specifications are subject to change for product improvement.

COPYRIGHT

©

2001 CANON INC. 2000 2000 2000 2000 CANON CLC5000 REV.0 JAN. 2001

1-7

CHAPTER 1 GENERAL DESCRIPTION

2 Safety

2.1 Safety of Laser Light

Laser light can be harmful to the human body. The machine’s laser unit is sealed in a protective housing and external covers to prevent escape of laser light to the outside of the machine, protecting the individuals around the machine from the harmful effects of laser light

as long as the machine is used in normal ways.

CLASS 1

CLASS 1

LASER PRODUCT

LASER PRODUCT

APPAREIL

APPAREIL

A RAYONNEMENT

A RAYONNEMENT

LASER DE CLASSE 1

LASER DE CLASSE 1

1-8

LASER KLASSE 1

LASER KLASSE 1

PRODUCTO LASER DE CLASE 1

PRODUCTO LASER DE CLASE 1

APPARECCHIO LASER DI CLASSE 1

APPARECCHIO LASER DI CLASSE 1

IN ACCORDO CON LA NORMA

IN ACCORDO CON LA NORMA

CEI 76-2

CEI 76-2

F01-201-01

COPYRIGHT

©

2001 CANON INC. 2000 2000 2000 2000 CANON CLC5000 REV.0 JAN. 2001

CHAPTER 1 GENERAL DESCRIPTION

2.2 CDRH Ordinance

The Center for Devices and Radiological Health of the US Food and Drug Administration

put into effect an ordinance to govern laser products on August 2, 1976.

The ordinance applied to laser products produced on August 1, 1976, and the sale of laser

products is banned in the US without certification under the ordinance.

The following is the label indicating compliance under the CDRH ordinance, and it must

be attached to all laser products sold in the US.

F01-202-01

A different description may be used for a different product.

COPYRIGHT

©

2001 CANON INC. 2000 2000 2000 2000 CANON CLC5000 REV.0 JAN. 2001

1-9

CHAPTER 1 GENERAL DESCRIPTION

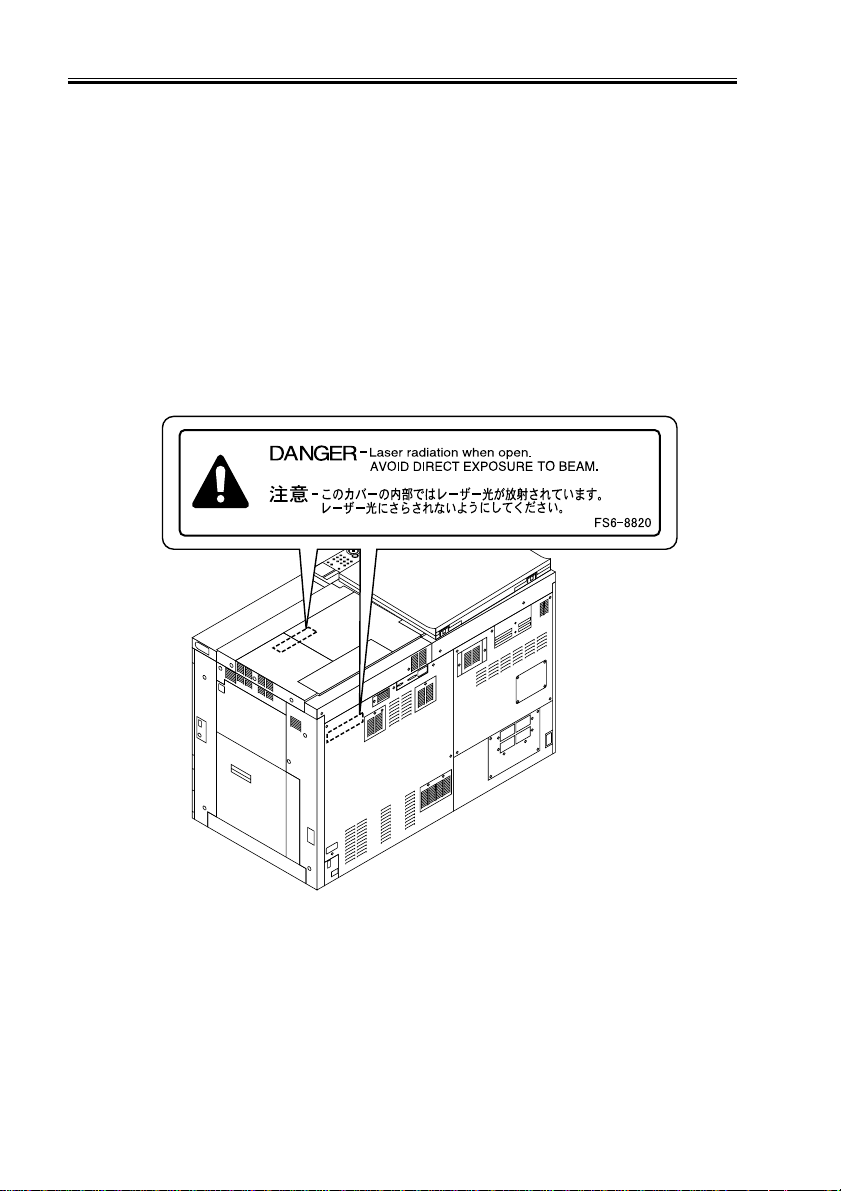

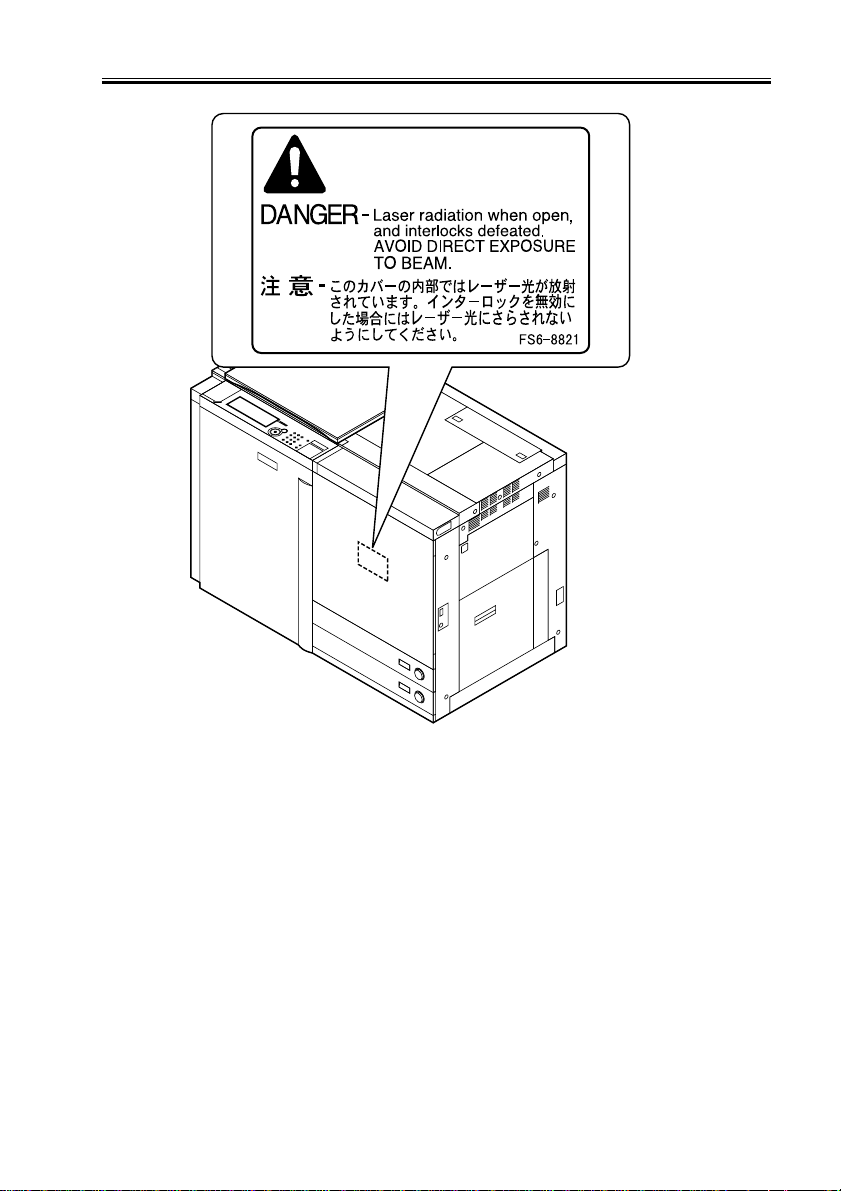

2.3 Handling Parts Associated with the Laser Unit

Do not introduce a screwdriver or the like (i.e., with a high degree of reflectance) into the

laser path when servicing the areas around the laser unit.

Also, remove watches, rings, and the like to prevent laser light from reflecting to your

eyes.

Extra attention is called for when servicing the inside of covers to which the following

label is attached.

The machine is equipped with a shutter to cut off the path of laser light. The shutter operates in conjunction with the hopper assembly, and remains open as long as the hopper is set

in the machine, closing when the hopper assembly is slid to the front.

It is even more important to heed the foregoing points when the hopper assembly is inside

the machine or when a shutter opening tool is fitted (after sliding out the hopper assembly).

1-10

COPYRIGHT

©

F01-203-01

2001 CANON INC. 2000 2000 2000 2000 CANON CLC5000 REV.0 JAN. 2001

CHAPTER 1 GENERAL DESCRIPTION

COPYRIGHT

©

F01-203-02

2001 CANON INC. 2000 2000 2000 2000 CANON CLC5000 REV.0 JAN. 2001

1-11

CHAPTER 1 GENERAL DESCRIPTION

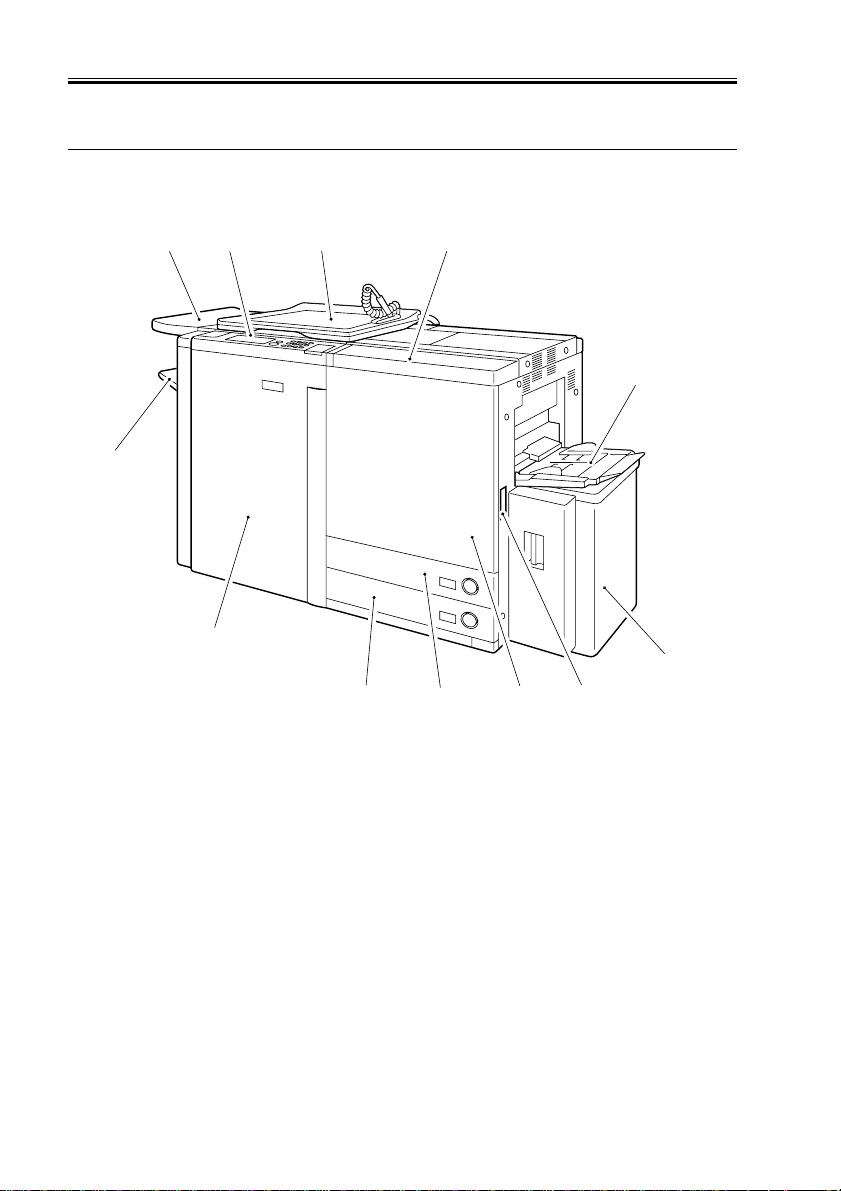

3 Names of Par ts

3.1 External View

[1] [2] [3] [4]

[12]

[11]

[5]

[6]

[7][8][9][10]

[1] Copyboard [7] Control key/power switch

[2] Control panel [8] Right front cover

[3] Editor (accessor y) [9] Cassette 1

[4] Hopper lid (toner supply mouth) [10] Cassette 2

[5] Multifeeder assembly [11] Left front cover

[6] Paper deck (accessory) [12] Delivery tray

F01-301-01

1-12

COPYRIGHT

©

2001 CANON INC. 2000 2000 2000 2000 CANON CLC5000 REV.0 JAN. 2001

CHAPTER 1 GENERAL DESCRIPTION

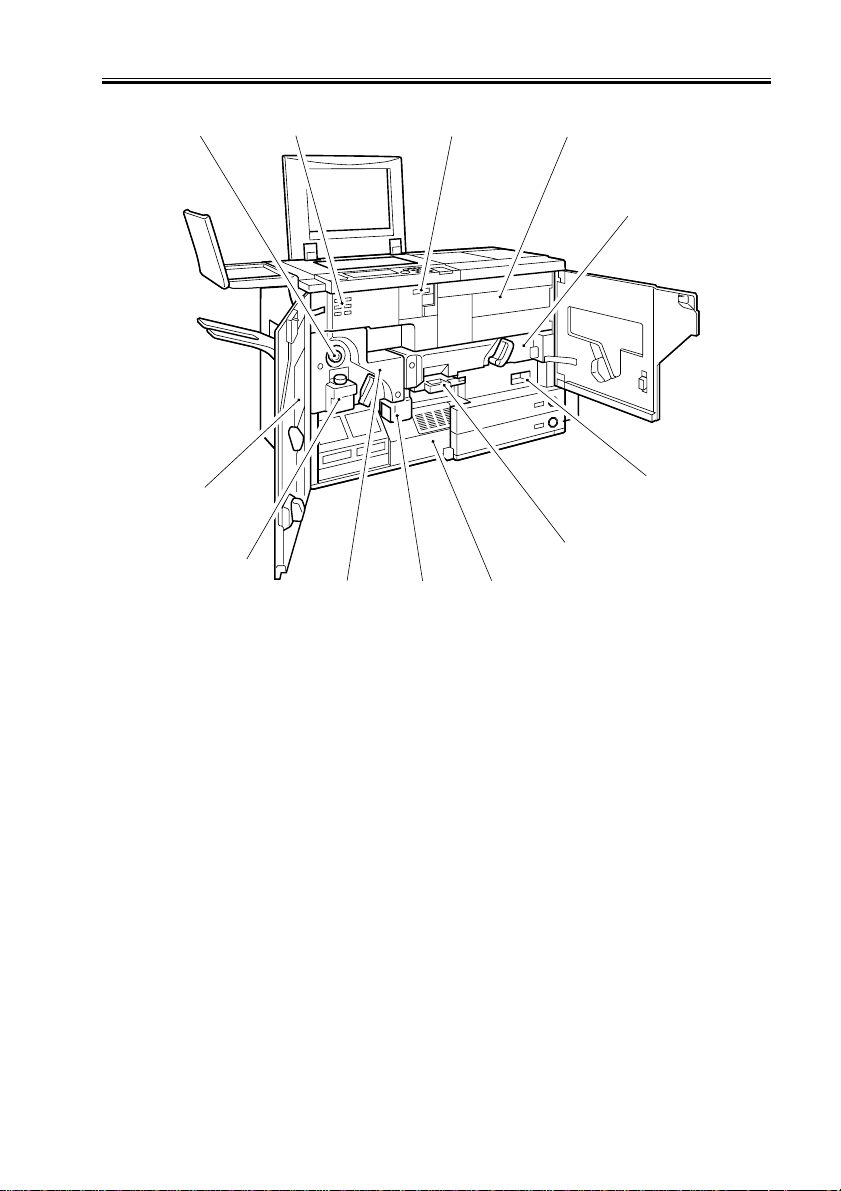

[1] [2] [3] [4]

[5]

[11]

[10]

[9]

[8]

[7]

[12]

[6]

[1] Fixing assembly knob [7] Duplex front feedingassembly

[2] Counter [8] Waste toner box (for transfer belt)

[3] Front cover switch [9] Fixing/delivery/reversal unit

[4] Hopper assembly [10] Fixing oil bottle

[5] Transfer unit [11] Ser vice book case

[6] Duplex unit [12] Waste toner box (for process unit)

F01-301-02

COPYRIGHT

©

2001 CANON INC. 2000 2000 2000 2000 CANON CLC5000 REV.0 JAN. 2001

1-13

Loading...

Loading...