Canon CLC-1120 Service Information

SERVICE INFORMATION

Issued by Copying Machine Quality Assurance Center, Canon Inc.

MODEL:

COLOR LASER COPIER

1120/1130/1150

Major quality issues Quality upgrade/production efficiency

Field quality problems

Miscellaneous

LOCATION

SUBJECT

Revision of Service Handbook

The captioned technical documentation has been revised to reflect the following:

Reasons

to update the descriptions in the previous documentation covering modification of

functions and correction of typographical mistakes.

The present revision is a full revision. Kindly make arrangements so that the old

document may be replaced with the one being released. Further, please make sure

the old document is properly disposed of.

NO.

: F-04-E00008

DATE

: DEC.2000

FY8-23B4-02Y

Printed in Japan

Imprimé au Japon

COLOR LASER COPIER

1120/1130/1150

REVISION 2

DEC. 2000

COPYRIGHT© 2000 CANON INC. CANON CLC1120/11301150 REV.2 DEC. 2000 PRINTED IN JAPAN (IMPRIME AU JAPON)

FY8-23B4-020

IMPORTANT

THE INFORMATION CONTAINED HEREIN IS PUBLISHED BY CANON, INC., JAPAN, AND IS

FOR REFERENCE USE ONLY. SPECIFICATIONS AND OTHER INFORMATION CONTAINED

HEREIN MAY VARY SLIGHTLY FROM ACTUAL MACHINE VALUES OR THOSE FOUND IN

ADVERTISING AND OTHER PRINTED MATTER.

ANY QUESTIONS REGARDING INFORMATION CONTAINED HEREIN SHOULD BE DIRECTED

TO THE COPIER SERVICE DEPARTMENT OF THE SALES COMPANY.

COPYRIGHT © 2000 CANON INC.

Printed in Japan

Imprimé au Japon

Use of this manual should be

strictly supervised to avoid

disclosure of confidential

information.

Prepared by

OFFICE IMAGING PRODUCTS TECHNICAL SUPPORT DIVISION

CANON INC.

5-1, Hakusan 7-chome, Toride-shi Ibaraki, 302-8501 Japan

COPYRIGHT© 2000 CANON INC. CANON CLC1120/1130/1150 REV.2 DEC. 2000 PRINTED IN JAPAN (IMPRIME AU JAPON)

CONTENTS

CHAPTER 1 MAINTENANCE AND INSPECTION

1

2

A. Scheduled Servicing List ...........................1-1

1. Copier ..................................................1-1

2. Paper Deck..........................................1-3

B. Periodically Replaced Parts.......................1-4

C. Consumables and Durables ......................1-5

1. Copier ..................................................1-5

2. Paper Deck..........................................1-7

D. Image Adjustment Basic Procedure ..........1-9

E. Points to Note for Scheduled Servicing ...1-12

CHAPTER 2 STANDARDS AND ADJUSTMENTS

A. Image Adjustment System.........................2-1

B. Exposure System.......................................2-8

C. Image Formation System...........................2-9

D. Pickup/Feeding System...........................2-14

E. Fixing System .......................................... 2-24

F. Externals/Controls ................................... 2-27

G. Paper Deck ..............................................2-28

H. Electrical System .....................................2-32

CHAPTER 3 ARRANGEMENT AND FUNCTIONS OF

ELECTRICAL PARTS

A. Sensors......................................................3-1

1. CLC1120/1130 ..................................... 3-1

2. CLC1150 .............................................. 3-3

B. Thermistors, Lamps, and Heaters ............. 3-5

C. Clutches .....................................................3-6

1. CLC1120/1130..................................... 3-6

2. CLC1150.............................................. 3-7

D. Solenoids ................................................... 3-8

1. CLC1120/1130..................................... 3-8

2. CLC1150.............................................. 3-9

E. Fans.........................................................3-10

F. Motors ......................................................3-11

G. PCBs........................................................3-13

H. Paper Deck .............................................. 3-15

1. Sensors and Switches ....................... 3-15

2. Motors, Clutches, Solenoids,

and PCBs........................................... 3-16

I. Variable Resistors (VR), Light-Emitting

Diodes (LED), and Check Pins by PCB...3-17

1. DC Driver PCB ..................................3-17

2. CPU PCB...........................................3-18

3. IP main PCB .....................................3-18

4. Analog Processor PCB......................3-19

5. Laser Driver PCB............................... 3-19

6. Lamp Regulator PCB.........................3-20

7. DC Fuse PCB ....................................3-20

8. AC Fuse PCB .................................... 3-21

9. Developing Bias PCB ........................ 3-21

10. HVT-AC PCB ..................................... 3-22

11. Potential Measurement PCB .............3-22

3

4

5

i

CHAPTER 4 SERVICE MODE

A. Outline........................................................ 4-1

1. Starting Service Mode and

Making Selections ...............................4-2

2. Ending Service Mode ..........................4-3

3. Backing Up the RAM ...........................4-3

4. Basic Operation .................................4-12

B. DISPLAY (control display mode) .............4-14

C. I/O (I/O display mode)..............................4-32

CHAPTER 5 SELF DIAGNOSIS

A. Copier ........................................................ 5-1

B. RDF .........................................................5-22

APPENDIX

A. General Timing Chart ............................... A-1

B. Signals and Abbreviations ........................ A-3

1. Signals ................................................ A-3

2. Abbreviations ...................................... A-8

C. General Circuit Diagram ........................... A-9

D. Paper Deck General Circuit Diagram ..... A-13

E. Specifications.......................................... A-15

1. DC-CPU...................................................4-32

2. R-CPU .....................................................4-48

D. ADJUST (adjustment mode) .................... 4-51

E. FUNCTION (operation check mode) .......4-97

F. OPTION (settings mode) ....................... 4-119

G. PG (test print) ........................................4-134

H. COUNTER (counter mode)....................4-136

C. Sorter ....................................................... 5-23

1. Type.................................................. A-15

2. System.............................................. A-15

3. Functions .......................................... A-16

4. Others............................................... A-17

5. Default Ratios ................................... A-17

6. Copying Speed ................................. A-18

7. CLC Paper Deck-E1 ......................... A-19

ii

CHAPTER 1 MAINTENANCE AND INSPECTION

CHAPTER 1 MAINTENANCE AND INSPECTION

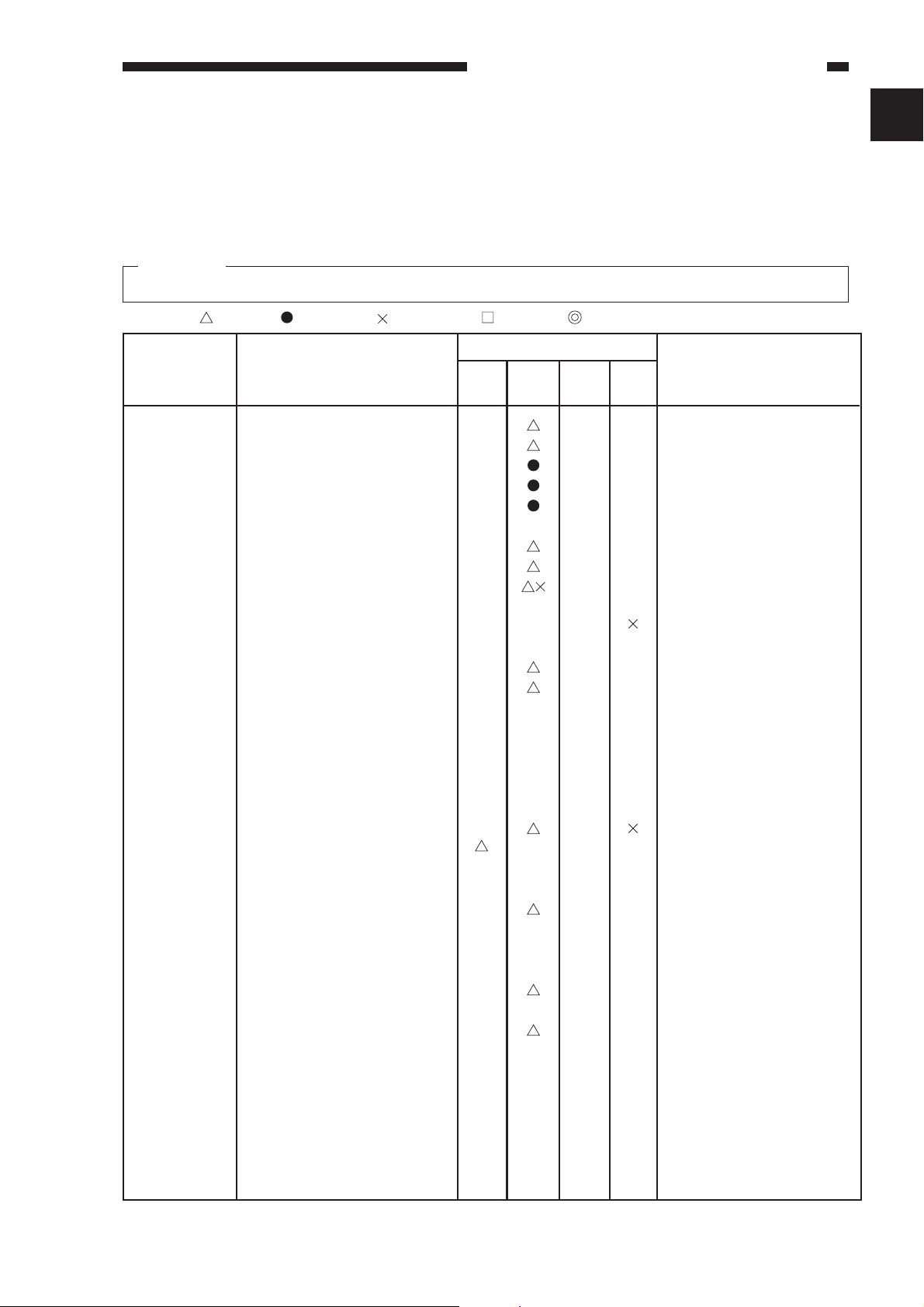

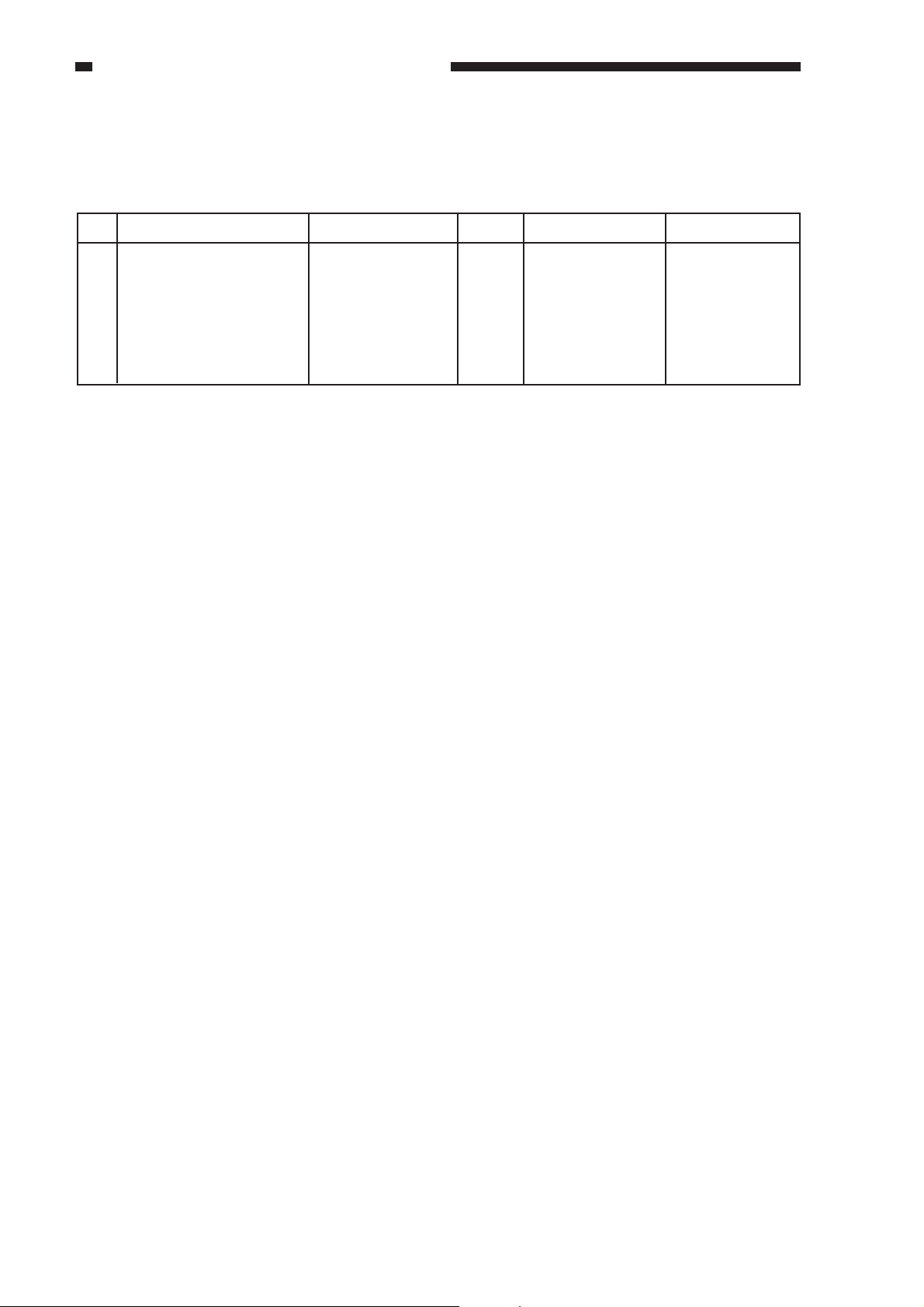

A. Scheduled Servicing List

1. Copier

Caution:

Do not use solvents or oils other than those listed.

Clean Replace Lubricate Adjust Inspect As of December 2000

Intervals

Unit Part

Externals and

controls

Original

exposure

Pickup/

feeding

Copyboard glass

Copyboard cover

Ozone filter

Air filter

Toner filter

Original reflecting cover

No. 1 through No. 3 mirrors,

Scanner rail

Lens

Attraction, registration

spring clutch

Attraction roller

Attraction roller cleaner pan

Registration roller

Pre-registration roller 2

Pre-registration roller 1

Registration path middle guide

Pickup vertical path roller

every

20,000

every

25,000

every

40,000

every

50,000

Use alcohol.

Or, 1 yr.

Or, 1 yr.

Or, 1 yr.

Use blower brush.

After cleaning, apply

silicone oil.

Use lubricant.

Remove unit, and clean.

Remove unit, and clean.

Remove unit, and clean. every 250,000

Remove unit, and clean.

Clean every 250,000

Clean the guide surface. every 250,000

Clean every 250,000

Remarks

1

Transfer drum

Laser exposure

Charging

Transfer drum cleaner

Jam sensor (PS6) metal plate

(resin tape used for No.2

static eliminator mount)

Jam sensor (PS5) metal plate

(polishing roller motor

mounting plate)

Dust-proofing glass

Shielding plate, block

Apply lubricant to the

busihg of the brush.

Clean with lint-free paper;

then, clean with alcohol.

Be sure the part is

completely dry before

mounting.

Do not use water.

For post-cleaning charging

assembly, clean every

20,000 copies.

1-1

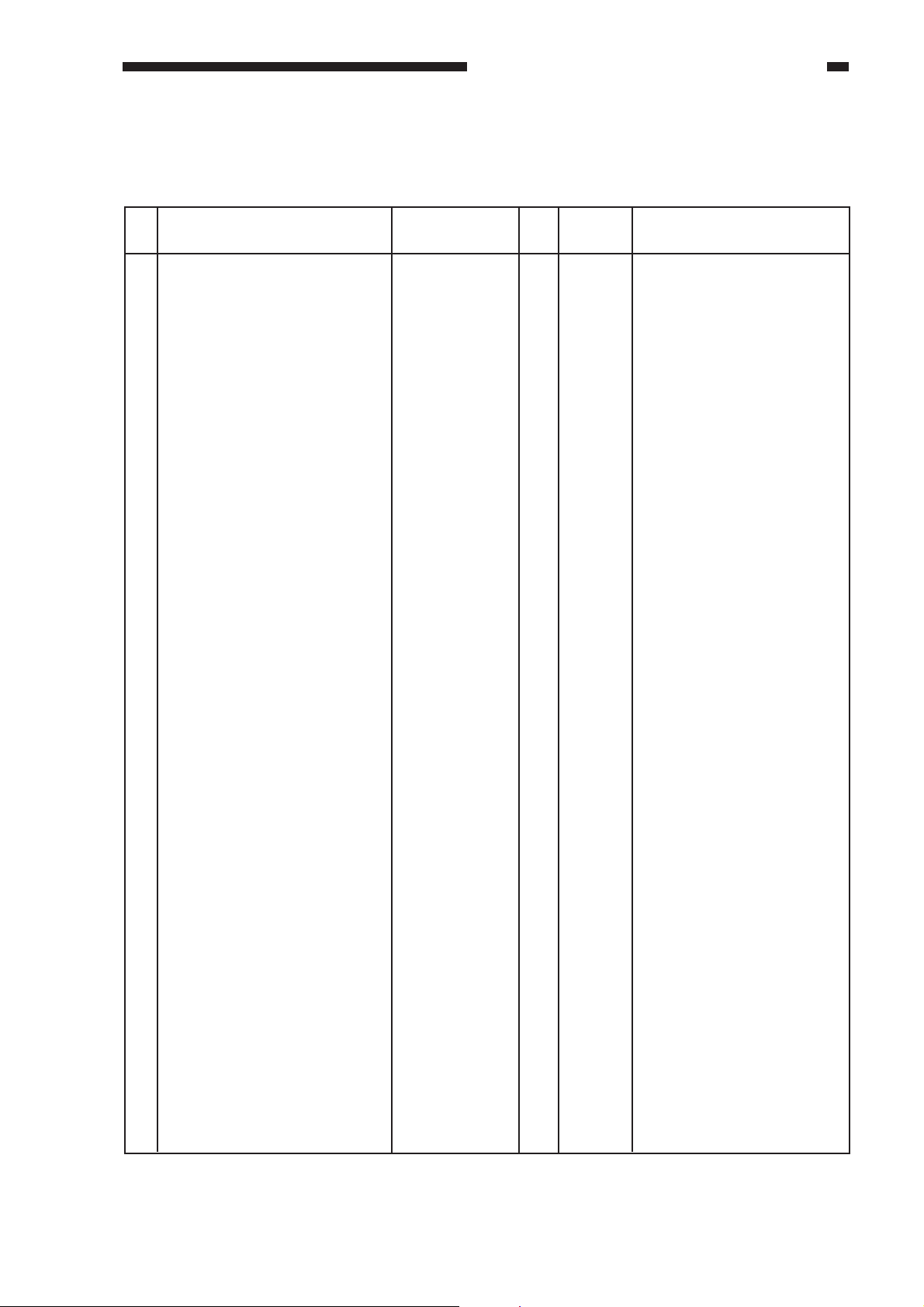

CHAPTER 1 MAINTENANCE AND INSPECTION

Unit Part

Primary charging wire,

Post-cleaning charging wire

Separation, Internal/external

static eliminator charging

wire

Grid plate,

primary charging wire

cleaning pad

every

20,000

Intervals

every

25,000

every

40,000

every

50,000

Remarks

For primary charging

assembly, clean every

20,000 copies in lowhumidity areas; for hightemperature/humidity

areas, clean every 15,000

copies.

In high-temperature/humidity areas, replace

every 15,000 copies.

For high-temperature/humidity areas, replace

every 15,000 copies.

Photosensitive

drum area

Developing

assembly

Fixing

assembly

No. 2 cleaner blade

Black toner concentration

sensor

Pre-cleaner sensor

Pre-exposure lamp filter

Photosensitive drum butting

block

Drum heater slip ring

Photosensitive drum butting

roll

Bias electrode

Fixing inlet guide

Lower roller separation claw

Oil applying blade

Oil applying felt

Thermistor

Fixing oil

(front)

Turn over blade.

See Note .

Clean with cotton wad;

see Note.

Clean when replacing

photosensitive drum.

Clean when replacing

photosensitive drum.

Dry wipe every 150.000

copeis.

Clean when replacing

developer.

Clean each time

developing assembly

(each color) is mounted.

Use solvent.

Use lint-free paper.

Turn over felt.

Dry wipe.

Others

1-2

Waste toner

Hopper toner pan

Leakage breaker

Image adjustment

Remove build up of

toner.

Includes execution of auto

gradation correction.

CHAPTER 1 MAINTENANCE AND INSPECTION

Note:

If you have cleaned the sensor, be sure to execute the following in service mode:

• For the black toner concentration sensor, FUNCTION>INSTALL>INIT-D.

• For pre-cleaning sensor, FUNCTION>SENS-ADJ>CLN-OFST.

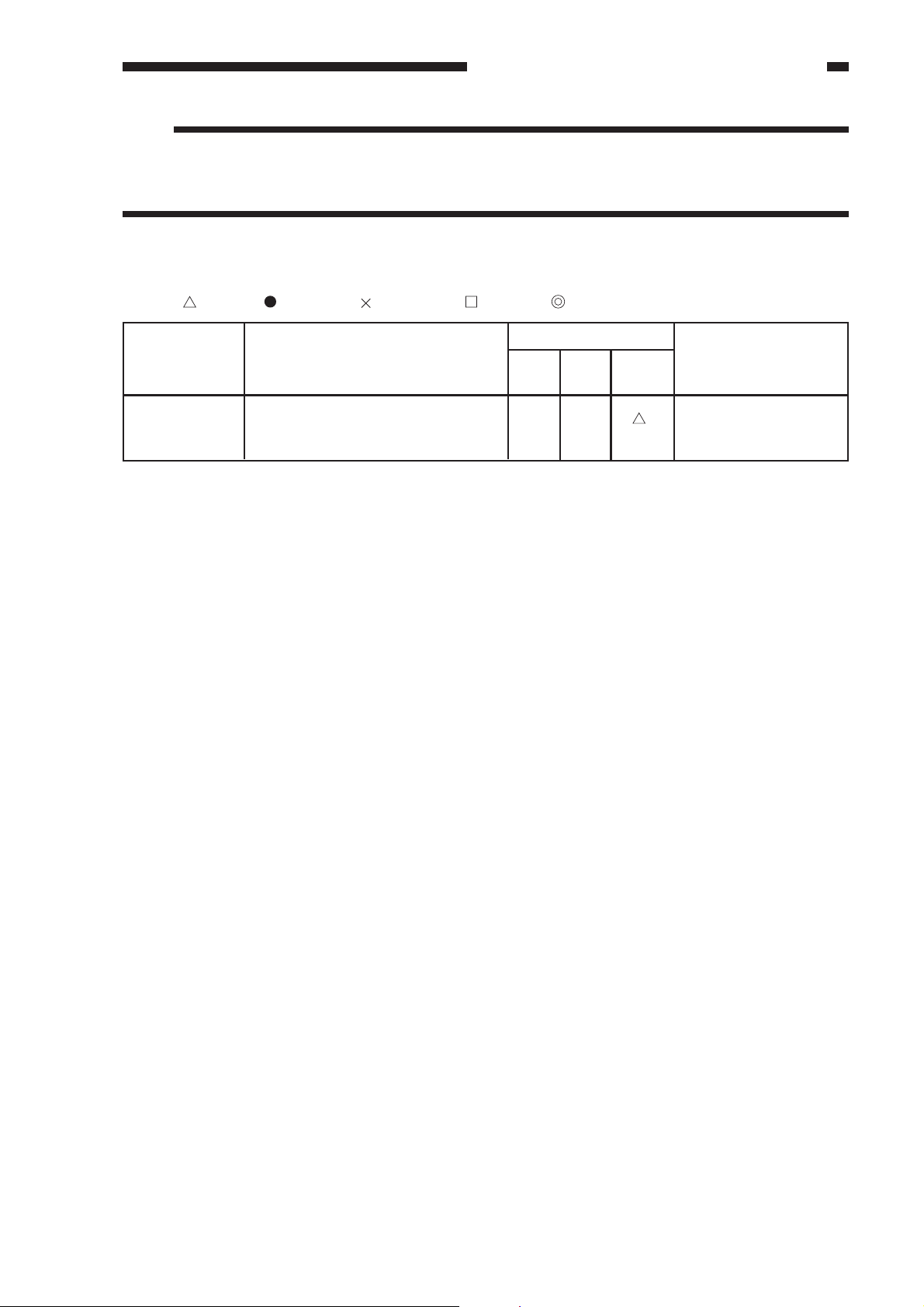

2. Paper Deck

Clean Replace Lubricate Adjust Inspect As of December 2000

Intervals

Unit Part

every

25,000

every

40,000

every

250,000

Remarks

Pickup

assembly

Feed roller, roll

1-3

CHAPTER 1 MAINTENANCE AND INSPECTION

B. Periodically Replaced Parts

As of December 2000

No. Part name Part number Q’ty Life (copies) Remarks

1 Ozone filter (FM2, 5, 6) FB2-4397 3 25,000 Or, 1 yr.

2 Air filter (FM1) FB4-4819 1 25,000 Or, 1 yr.

3 Air filter (FM3) FF5-8405 1 25,000 Or, 1 yr.

4 Air filter (FM14, 15) FB2-0247 2 25,000 Or, 1 yr.

5 Toner filter (FM5, 6) FB4-4442 2 25,000 Or, 1 yr.

6 Ozone filter (FM5) FB4-9641 1 25,000 Or, 1 yr.

1-4

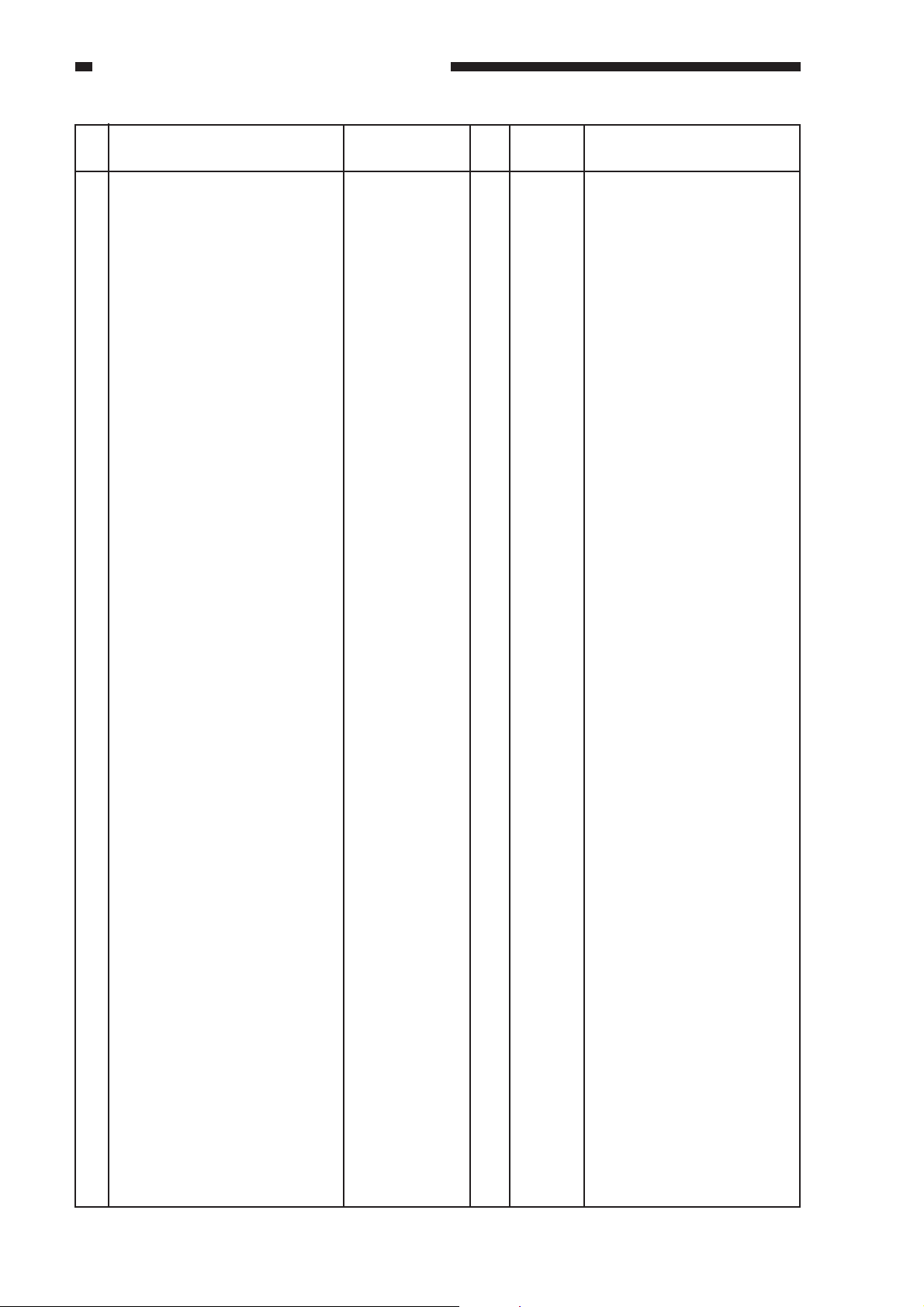

C. Consumables and Durables

CHAPTER 1 MAINTENANCE AND INSPECTION

1. Copier

As of December 2000

No. Part name Part number Q’ty Life Remarks

(copies)

1 Cleaner blade (drum cleaner

assembly)

2 Drum cleaner scoop-up sheet

3 Side seal, front (drum cleaner

assembly)

4 Side seal, rear (drum cleaner

assembly)

5 No. 2 scoop-up sheet (pre-

cleaning sensor)

6 Grid plate (primary charging

assembly)

7 Primary charging assembly

cleaning pad, upper

8 Primary charging assembly

cleaning pad, lower

9 Primary charging wire, 100V

Primary charging wire, 120/

230V

10 Scanning lamp

FB4-4677

FF5-3993

FF5-8392

FF5-8393

FG6-1046

FB4-5117

FF2-3552

FF2-3551

FY3-0030

FY3-0040

FH7-3349

1

20,000

1

20,000

1

20,000

1

20,000

1

20,000

1

20,000

1

20,000

1

20,000

1

20,000

1

20,000

1

25,000

Simultaneously with

photosensitive drum.

Simultaneously with

cleaning blade.

Simultaneously with

cleaning blade.

Simultaneously with

cleaning blade.

Simltaneously with cleaning

blade.

For high temperature/high

humidity, 15,000.

For high temperature/high

humidity, 15,000.

For high temperature/high

humidity, 15,000.

11 Manual feeder pickup roller

12 Manual feeder feed roller

13 Manual feeder separation

roller

14 Attraction roller scraper

15 Waste toner case (6 pc/box)

16 Post-cleaning charging wire

Post-cleaning charging wire

17 Fixing cleaning belt (upper,

lower)

18 Drum cleaner end felt, front

19 Drum cleaner end felt, rear

20 No. 2 cleaning blade

21 Fixing upper roller

22 Oil applying felt

23 Y starter developer

24 M starter developer

25 C starter developer

FF5-4327

FF5-4331

FF2-4710

FF5-8427

FY9-7006

FY3-0030

FY3-0040

FB4-4543

FF5-2246

FF5-2247

FB2-0421

FB4-4484

FF5-9084

F42-3132

F42-3133

F42-3122

F42-3123

F42-3112

F42-3113

2

25,000

1

25,000

1

25,000

1

25,000

1

25,000

1

20,000

1

20,000

1

25,000

1

40,000

1

40,000

2

40,000

1

40,000

1

40,000

1

40,000

1

40,000

1

40,000

1

40,000

1

40,000

1

40,000

Manual feeder counter

reading.

Manual feeder counter

reading.

Manual feeder counter

reading.

By user.

100V

120/230V

Simultaneously with

cleaning blade.

20,000 per edge.

Or, 1 yr.

20,000 per side.

120V UL only.

120V UL only.

120V UL only.

1-5

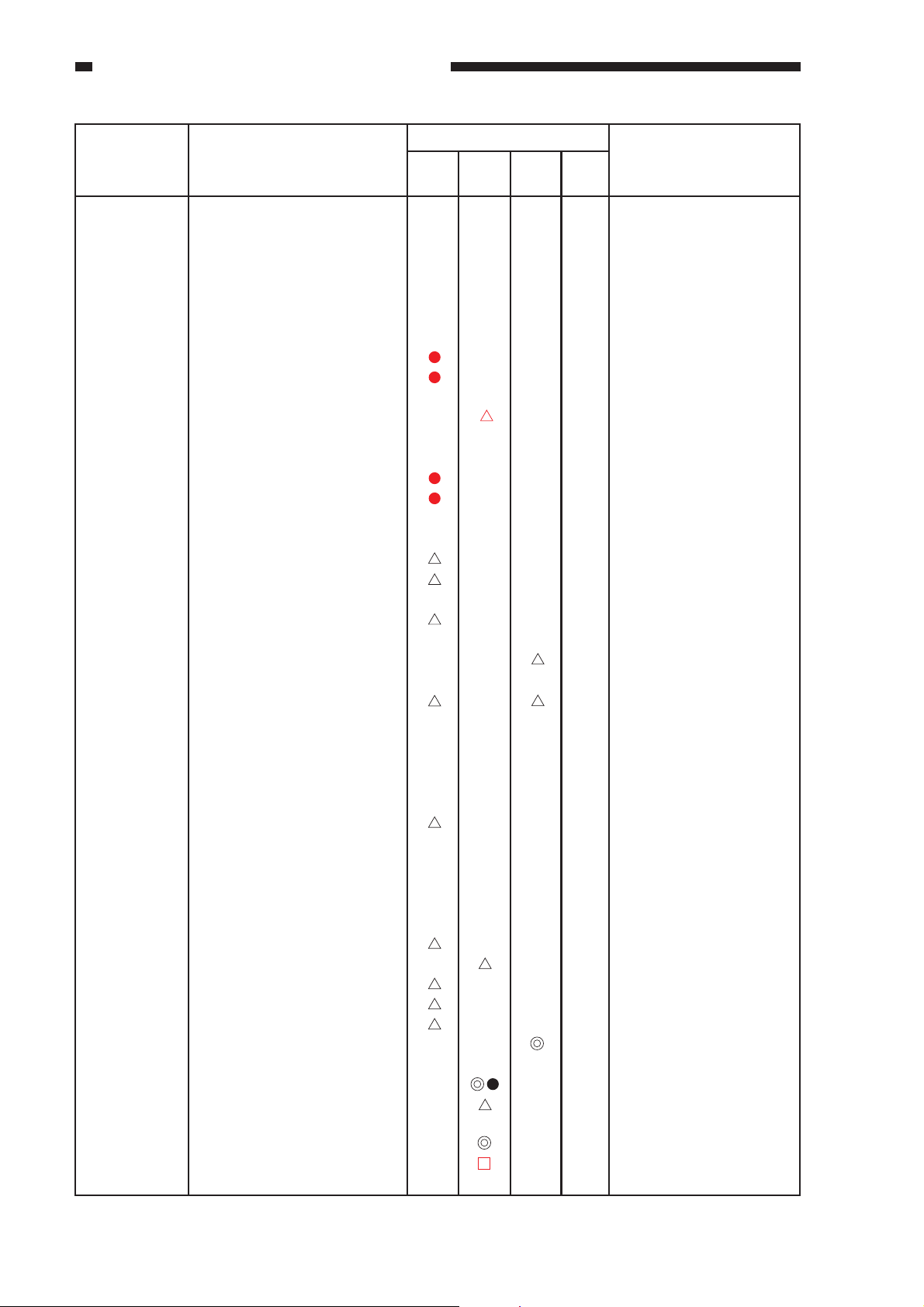

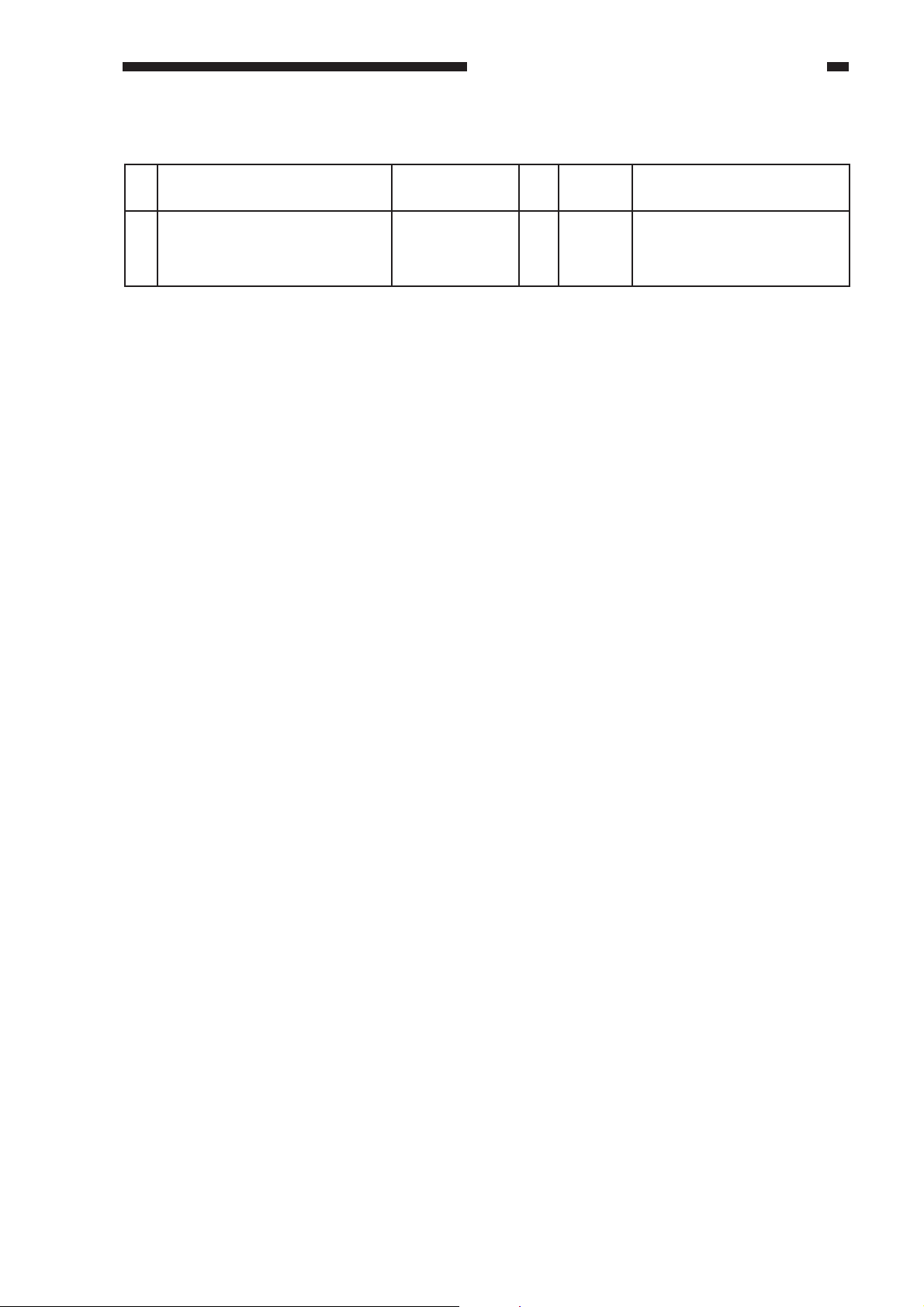

CHAPTER 1 MAINTENANCE AND INSPECTION

No. Part name Part number Q’ty Life Remarks

(copies)

26 Bk starter developer

27 Separation/internal and

external static charging wires

Separation/internal and

external charging wires

28 Attraction brush unit

29 Transfer blade unit

30 Transfer drum cleaner

31 Polishing roller

32 Transfer drum sheet

33 Separation push-up roll

34 Transfer side scraper

35 Fixing lower roller

36 Re-pickup feed roller, front

(re-pickup assembly)

37 Re-pickup feed roller, rear (re-

pickup assembly)

38 Feed roller (re-pickup

assembly)

39 Separation roller (re-pickup

assembly)

40 Feed roller, front (duplexing

unit)

41 Feed roller, rear (duplexing

unit)

42 Oil applying blade

43 Fixing heater, upper

44 Fixing heater, lower

45 Pre-exposure lamp

46 Primary charging assembly

47 Separation charging assembly

48 Internal static eliminator

49 Eternal static eliminator

50 Post-cleaning charging

assembly

51 Insulating bush (fixing

assembly)

52 Pickup roller, front (cassette)

53 Pickup roller, rear (cassette)

54 Separation roller (cassette)

55 Feed roller (cassette)

56 Y developing assembly

57 M developing assembly

58 C developing assembly

59 Bk developing assembly

F42-3102

F42-3103

FY3-0030

FY3-0040

FG6-0798

FG6-0797

FB4-4953

FB4-5111

FB4-4195

FB2-0631

FF5-2070

FB4-4486

FF5-2101

FF5-2102

FF5-2103

FF5-2104

FF5-8366

FF5-8367

FB4-4536

FH7-4617

FH7-4618

FH7-4619

FH7-4611

FH7-4612

FH7-4613

FG5-3181

FG6-0892

FG6-0795

FG6-0796

FG6-0801

FG6-0888

FB4-7807

FF5-7829

FF5-7830

FB2-7777

FF5-7837

FG6-0781

FG6-0782

FG6-0783

FG6-0784

1

1

1

1

1

1

2

1

1

1

2

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

4

1

1

1

1

1

1

1

1

40,000

40,000

50,000

50,000

50,000

50,000

50,000

50,000

50,000

50,000

50,000

50,000

100,000

100,000

100,000

100,000

100,000

100,000

100,000

100,000

100,000

100,000

100,000

100,000

100,000

150,000

150,000

150,000

150,000

150,000

150,000

150,000

250,000

250,000

250,000

250,000

500,000

500,000

500,000

500,000

120V UL only.

100V

120/230V

As a unit.

As a unit.

Simultaneously with transfer

sheet.

Or, 1 yr.

Duplexing counter

reading.

Duplexing counter

reading.

Duplexing counter

reading.

Duplexing counter

reading.

Duplexing counter

reading.

Duplexing counter

reading.

100V

120V

230V

100V

120V

230V

Per cassette holder.

Per cassette holder.

Per cassette holder.

Per cassette holder.

1-6

CHAPTER 1 MAINTENANCE AND INSPECTION

2. Paper Deck

As of December 2000

No. Part name Part number Q’ty Life Remarks

(copies)

1 Paper deck pickup roller

2 Paper deck feeding roller

3 Paper deck separation roller

FB4-2033

FB4-2034

FB2-7777

2

2

1

250,000

250,000

250,000

Actual number of copies.

Actual number of copies.

Actual number of copies.

1-7

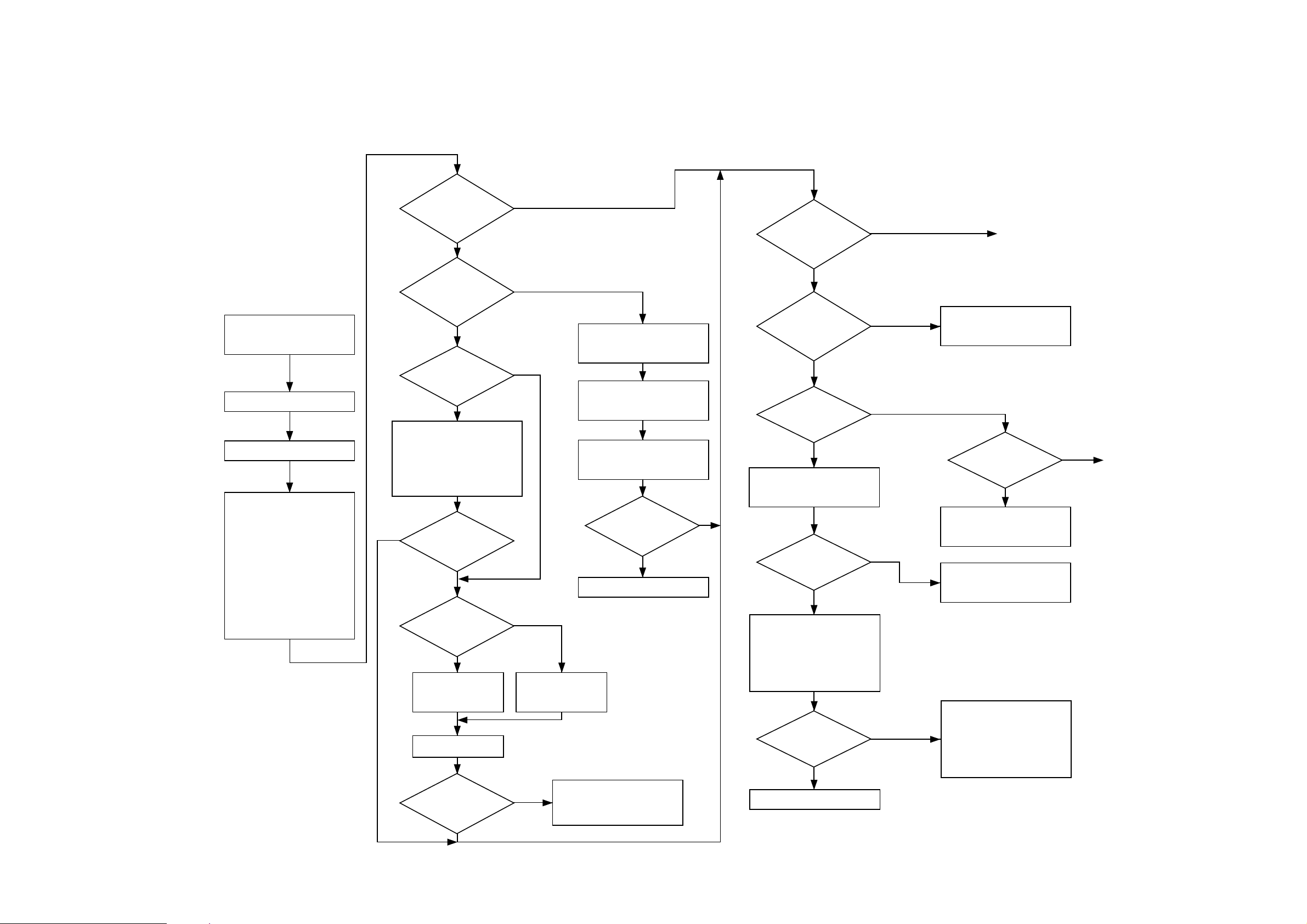

D. Image Adjustment Basic Procedure

Adjusting the Left/Right Density Slope Correcting Difference in Density

Make a copy of

the T est Sheet.

Is the density different

between front

and rear?

YES

NO

Is the darkest

area of the test print

made for a 16-gradation

check too light?

NO

To [A] of next page.

Conditions

· copy density at '5'

· text/photo mode

*If the primary charging

wire is soiled, replace it.

Select OPTION>BODY>PASCAL=0

in service mode.

Check the height of

each charging wire.

Clean the charging wires.*

Make sample copies using TEST in

service mode for the following:

0. normal image using Test Sheet

1. PGTEST=4 using M mono color

2. PGTEST=4 using C mono color

3. PGTEST=4 using Y mono color

4. PGTEST=4 using Bk mono color

5. PGTEST=10

6. PGTEST=5 DENS 48

7. PGTEST=14 photo mode

(TXPH:1)

Is the

density different

between front and rear on

the sample copy made

at PGTYPE=

10 or 5?

YES

Is the difference

in density different from

one color to another?

YES

Check the coating of toner on the

developing cylinder. Check the

developing assembly butting roll

and the photosensitive drum butting

block. Clean them if soiled with toner.

YES

Is the difference in

density gone?

NO

Is the density higher

(darker) at the rear?

YES

Turn the adjusting screw

at the front of the primary

charging assembly

counterclockwise.

Execute test printing at

PGTYPE=10 or 5.

Is the difference in

density gone?

NO

Check to find out if the copyboard

glass is riding over something.

NO

Clean the scanning lamp, reflecting

plate, mirror, standard white plate,

and copyboard glass.

Execute ADJUST>CCD>CCD-ADJ

in service mode.

Check the original scanning lamp.

NO

Turn the adjusting screw

at the front of the primary

charging assembly

clockwise.

1. Check the transfer charging system.

NO

2. Clean the dust-proofing glass.

3. Clean and check the developing

assembly butting roll.

Is the difference in

density gone?

NO

YES

YES

Does the density

become lower (lighter)

gradually in continuous

copying mode?

NO

Is the density low (light)

in all colors?

YES

Execute FUNCTION>DPC>DPC

in service mode.

Is the value of

DISPLAY>DPOT>V00-500,

V00-700 normal?

YES

Open the hopper, and insert the

door switch actuator. Check the

temperature and humidity using

DISPLAY>ANALOG>TEMP,

HUM in service mode.

Are the

temperature and humidity

readings normal?

NO

Check the environment sensor.

YES

NO

NO

YES

Check the high-voltage output of

the internal/external static eliminator.

Is the value

of ADJUST>DENS identical

with the value on

the label?

NO

Enter the data once again, and

make 50 copies.

Check the laser shutter and the

laser system.

Reference (normal values)

V00-500: 430 to 570

V00-700: 600 to 800

1. Check the insulating sheet of the

transfer blade for scratches and

peeling.

2. Check the shaft of the transfer

drum for play.

3. Check the cable inside the transfer

drum.

YES

To [B] of next page.

YES

1-9

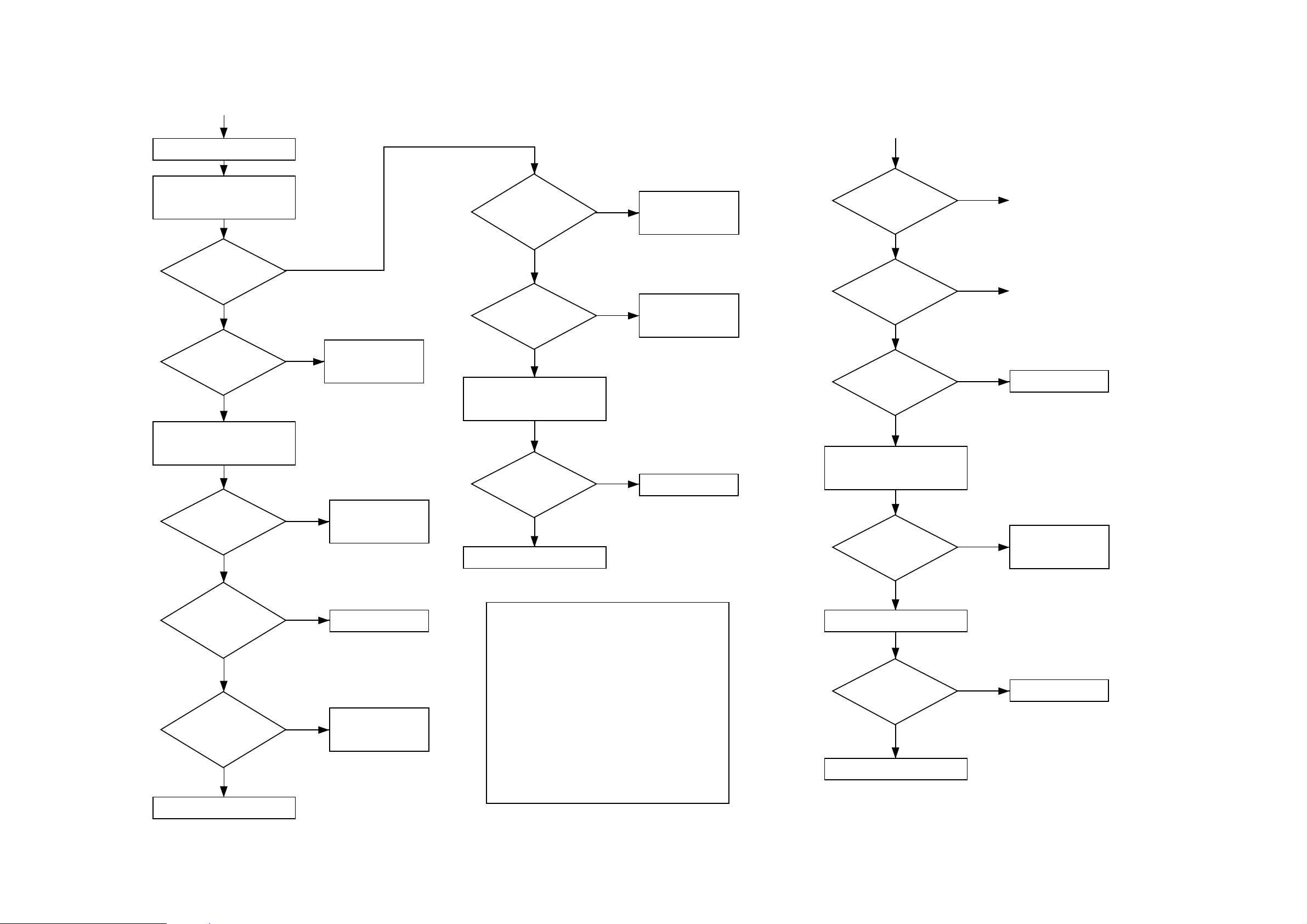

[B]

Check the locked condition of the

developing assembly.

Correcting Fogging

[A]

Check the value of DISPLAY>

DENS>DENS-Y, DENS-M, DENS-C,

DENS-K in service mode.

Is the density of

black normal?

NO

Is the value of

DENS-K -20 or lower?

NO

Compare the density of a test print

made of Bk halftone against one

made at time of installation or

replacement of the developer.

YES

YES

Check the supply of toner

from the hopper.

Is the value of

DENS-Y, DENS-M,

DENS-C the specified

value ± 20?

NO

Is it -20 or lower?

NO

Remove the toner concentration

sensor from inside the developing

assembly.

Is the surface of

the sensor soiled?

YES

YES

YES

Go through the check

items for the developing

assembly.

Check the supply of

toner from the hopper.

Replace the sensor.

Is fogging noted?

YES

Is fogging noted

for all colors?

YES

Is the primary charging

assembly soiled?

NO

Execute FUNCTION>DPC>DPC

in service mode.

NO

NO

YES

To [D] of next page.

To [B].

Clean.*

*Do not clean the grid plate.

Is it more or less the same?

NO

Is the surface of

the black toner concentration

sensor soiled?

NO

Is the test print of Bk

mono halftone uneven?

NO

Replace the Bk developer.

YES

YES

YES

Go through the check

items for the developing

assembly.

Clean the surface of the

sensor.

Replace the

photosensitive drum and

developer (all colors).

NO

Replace the developer.

Check Items for the Developing Assembly

1. Is the mechanism used to lock the developing assembly to

the photosensitive drum normal?

2. Is the position of the developing assembly normal?

3. Are the developing assembly butting roll and butting block

free of dirt?

4. Are the developing bias AC and DC outputs normal?

5. Is the developing cylinder coated with an even layer of toner?

Further, is the coating thick enough?

6. Is the position of the electrode of the developing cylinder

normal?

If a fault is found after making the above checks, perform

cleaning or adjustment as necessary.

If fogging or light density still occurs after making all above

checks (1 through 6), replace the developing assembly.

Is the value of

DISPLAY>DPOT>V00-500,

V00-700 normal>?

YES

Check the developing assembly.

Is there a fault?

NO

Replace the photosensitive drum and

developers (all colors).

NO

YES

Check the laser shutter,

and adjust the laser

power.

Reference (normal value):

V00-500: 430 to 570

V00-700: 600 to 800

Correct the fault.

1-10

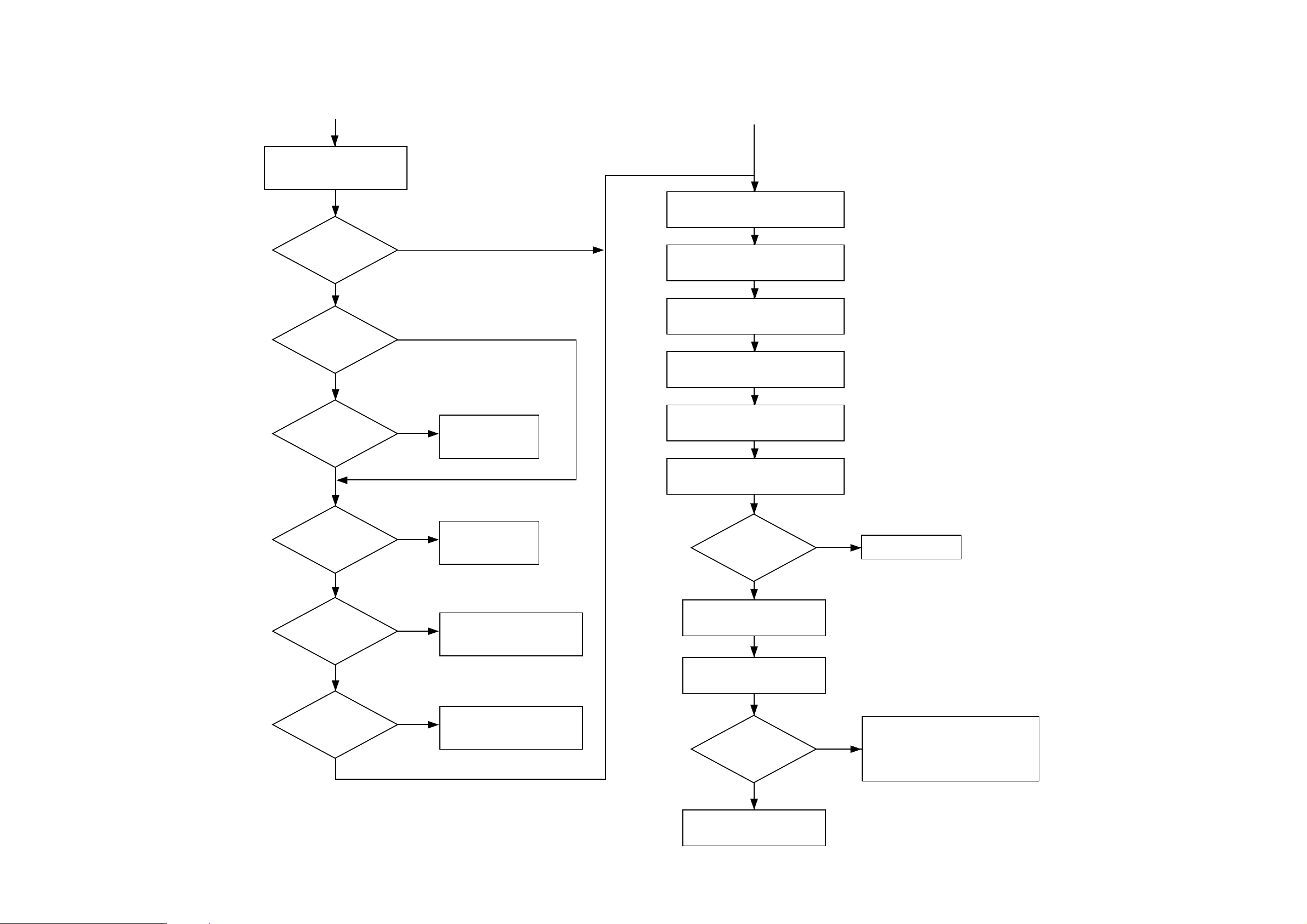

Adjusting Transfer

[D]

Check the locked condition of the

transfer blade in service mode.

Adjusting the Original Exposure System/Color Balance

[C]

Check the positions of the copyboard glass,

standard white plate, original scanning lamp,

reflecting plate, and mirrors, and clean them.

Is a transfer fault noted?

YES

Are there white spots

(transfer fault)?

YES

Is the fault limited to

a specific color?

YES

Are there white spots in

vertical direction?

NO

NO

NO

YES

Check the transfer blade.

Check the transfer blade.

Check to see if the No. 1 mirror/No. 2 mirror

base is not riding over the rail.

Check to find out if the value of

ADJUST>COLOR in service mode is

identical with the value recorded on the label.

Check the contact between the CCD and the

CCD driver PCB.

Set OPTION>BODY>PASCAL in service

mode to ’1’.

Execute ADJUST>CCD>CCD-ADJ in service

mode.

Is the image better?

YES

End.

NO

Are there vertical

lines corresponding to

separation claws?

NO

Make several

test prints. Does the

copy density decrease

(become light)?

YES

YES

NO

Check the output of the separation

charging assembly.

Check the internal/external static

eliminator.

NO

Execute auto gradation correction

in user mode.

Make a copy of the CA1 Test Sheet.

Is the gray scale

(especially light area)

of the copy good?

YES

End.

NO

Make adjustments in ADJUST>COLOR>ADJ-Y,

ADJ-M, ADJ-C, ADJ-K in service mode.

To make copies darker, increase the setting.

To make copies lighter, decrease the setting.

1-11

E. Points to Note for Scheduled Servicing

Optical System

Part Tool and others Work and remarks

Lens, CCD Blower brush Cleaning (Note 1)

Copyboard sheet,

copyboard glass

Standard white plate

Reflecting plate, No. 1

through No. 3 mirrors

Scanner rail Silicone oil Cleaning; then, lubricating

Fixing System

Part Tool and others Work and remarks

Oil applying felt, oil applying

blade

Thermistor

Separation claw

Inlet guide

Alcohol, lint-free paper Cleaning

Blower brush Cleaning

Paper rag Cleaning

Solvent Cleaning

Process System

Part Tool and others Work and remarks

Charging wire, shielding

plate, block

Pre-exposure lamp, filter,

dust-proofing glass,

potential sensor

Pre-cleaning sensor

assembly, No. 2 scoop-up

sheet assembly

Black toner concentration

sensor assembly, No. 2

blade assembly

Developing System

Part Tool and others Work and remarks

Developing assembly

butting roll, butting block

(photosensitive drum)

Developing roll Solvent

Lint-free paper, alcohol Dry wiping; then, cleaning

Lint-free paper, blower

brush

Cotton wad, lint-free

paper

Blower brush

Lint-free paper, blower

brush

Solvent Cleaning at time of replacing

with alcohol

Do NOT use water.

(Note 2)

Cleaning

Use cotton wad to clean the

sensor assembly. (Note 3)

Remove the buildup of toner;

then, dry wipe.

Do NOT use solvent. (Note 4)

the drum.

Cleaning at time of replacing

the developer.

Transfer Drum System

Part Tool and others Work and remarks

Charging wire, shielding

plate, block

Transfer drum cleaner

assembly

Jam sensor (PS6) metal

plate resin tape section

Jam sensor (PS5) metal

plate

Note 1: Take care not to touch the mirror and lens. Take care so that the CCD will not be soiled with dust.

Note 2: Replace the primary charging wire; insert other charging wires after making sure that they are completely dry; further, be sure NOT to clean the grid plate.

Note 3: After mounting, execute FUNCTION>SENS-ADJ>CLN-OFST. Thereafter, record the values of ADJUST>SENS-ADJ>CLN-TH, CLN-TMP on the service label.

Note 4: After mounting, execute FUNCTION>INSTALL>INIT-D.

Lint-free paper, alcohol Dry wiping; then, cleaning

Blower brush Cleaning

Blower brush

Lint-free paper

Blower brush

Lint-free paper

with alcohol.

Do NOT use water. (Note 2)

Dry wiping

Dry wiping

Pickup/Feeding System

Part Tool and others Work and remarks

Attraction roller, attraction

roller cleaner pan

Registration roller,

pre-registration roller 1/2

Pickup vertical path roller Alcohol, lint-free paper Cleaning

Registration path middle

guide

Lint-free paper Cleaning (Remove the unit.)

Alcohol, lint-free paper Cleaning

Alcohol, lint-free paper Clean the guide surface

1-12

CHAPTER 2 STANDARDS AND ADJUSTMENTS

CHAPTER 2 STANDARDS AND ADJUSTMENTS

A. Image Adjustment System

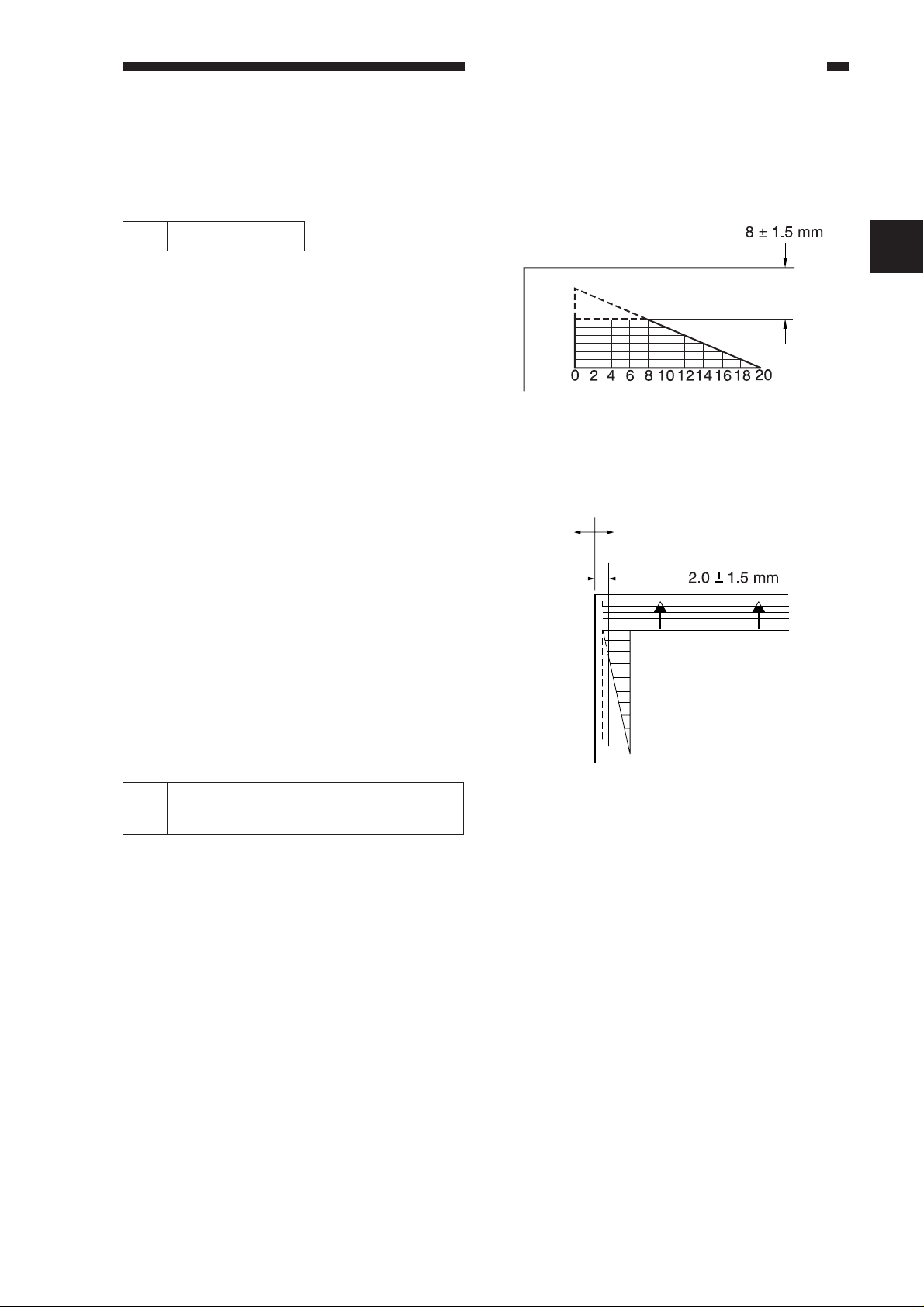

1 Image Margin

The image margin of a copy is normal if it

is as follows when made in Direct with

original detection OFF.

Leading edge: 8/0 ± 1.5 mm (8.0 ± 2.0 mm)

Left/right: 2.0 ± 1.5mm (2.0 ± 1.5 mm)

Trailing edge: 2.5 ± 1.5 mm (4.5 ± 2.0 mm)

The value in parentheses represents

double-sided copying.

Figure 2-1 Leading Edge Image Margin

2

Checking/Adjusting the Image

2

Margin

When making checks and adjustments,

observe the following order:

a. Adjusting the left/right registration

b. Adjusting the attraction position (ATT-T)

c. Adjusting the image margin (RG-XA,

RG-XB)

d. Adjusting the transfer delay (TR-

DELAY)

e. Adjusting the image read start position

(ADJ-XY)

f. Adjust the image trailing edge margin

(TR-END-A, TR-END-B)

Figure 2-2 Left/Right Image Margin

2-1

CHAPTER 2 STANDARDS AND ADJUSTMENTS

A

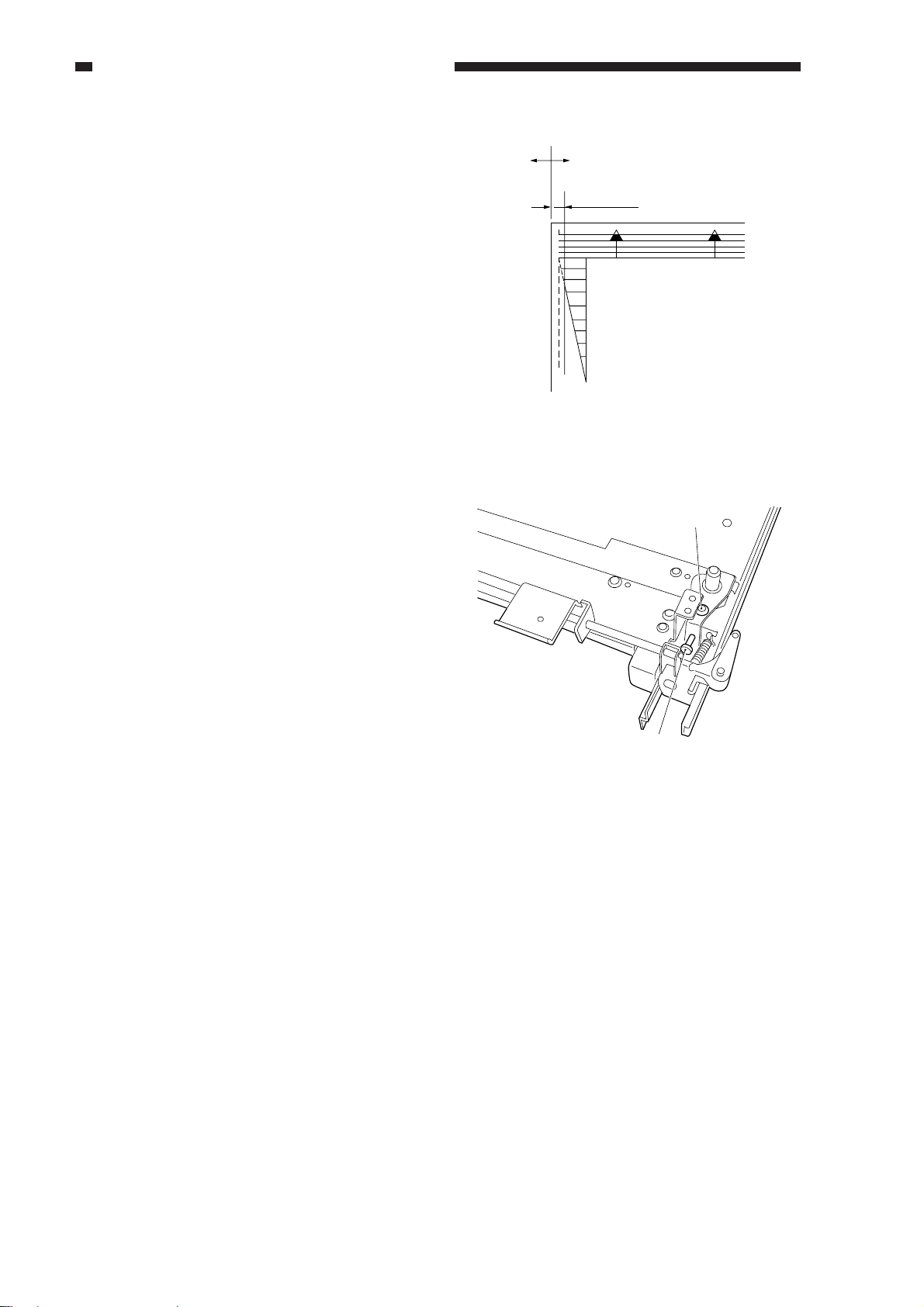

a. Adjusting the Left/Right Registration

1) Make ten copies each from all cassettes,

multifeeder, and duplexing unit, and

check the left/right registration A; it is

correct if as follows:

for cassette: 2.0 ± 1.5 mm

for multifeeder: 2.0 ± 1.5 mm

for duplexing unit: 2.0 ± 1.5 mm

2) If the registration A is not as indicated,

perform the following:

§ For the Cassette

1) Remove the cassette front cover from the

cassette holder you want to adjust.

2) Loosen the left/right screw [1].

3) Turn the adjusting screw [2] to adjust the

position of the horizontal registration

adjusting plate so that the horizontal

registration on an image is 2.0 ± 1.5 mm.

(A full turn causes a shift of about 0.7

mm.)

· To increase the registration along the

front, turn the adjusting screw

counterclockwise.

· To increase the registration along the

rear, turn the adjusting screw

clockwise.

4) After the adjustment, be sure to perform

"registering the paper width basic value."

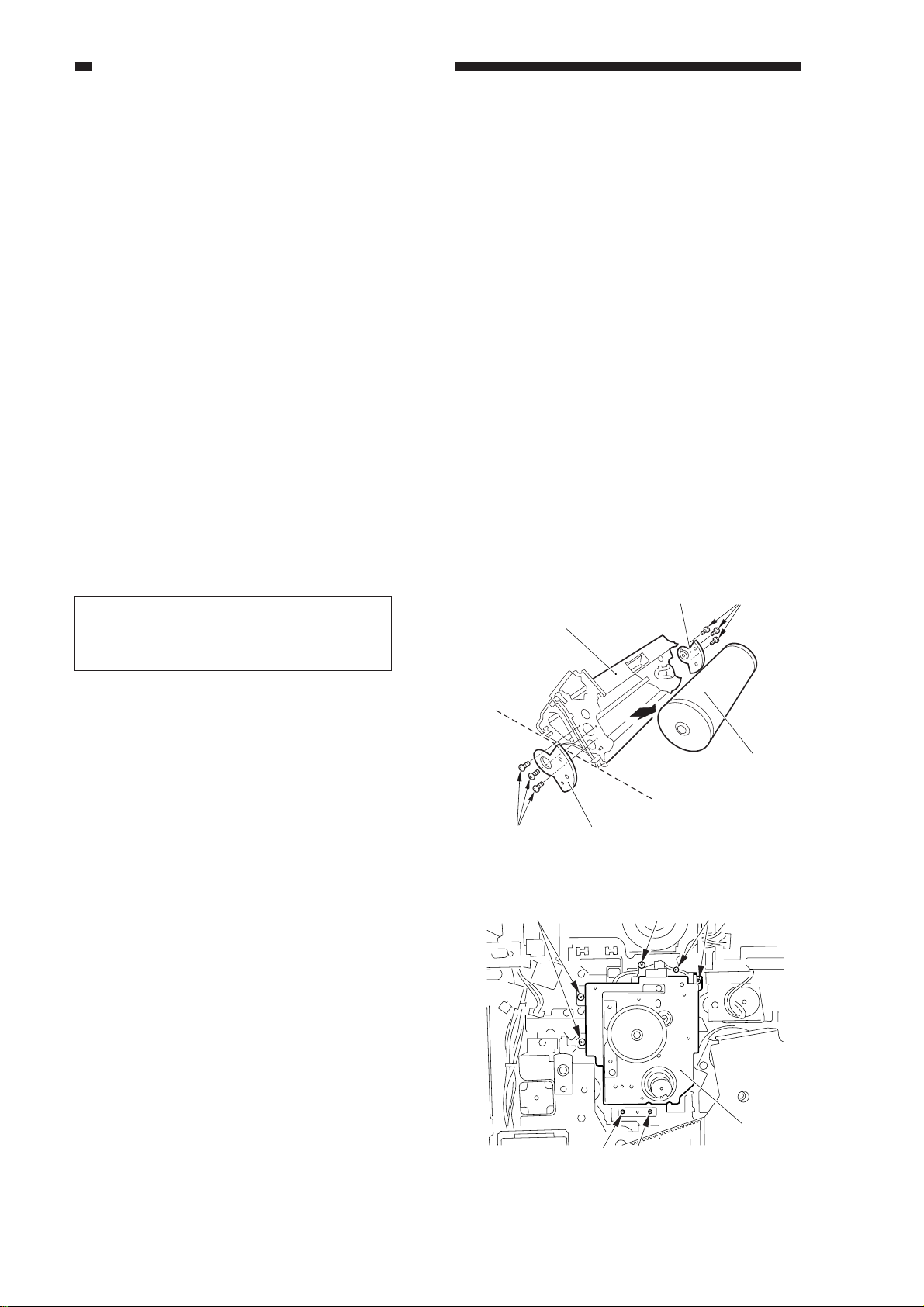

Figure 2-3

[1]

[2]

Figure 2-4

2-2

§ For the Multifeeder

Turn the screw [1] to move the position of

the tray so that the registration is 2.0 ± 1.5

mm in Direct.

CHAPTER 2 STANDARDS AND ADJUSTMENTS

[1]

Figure 2-5

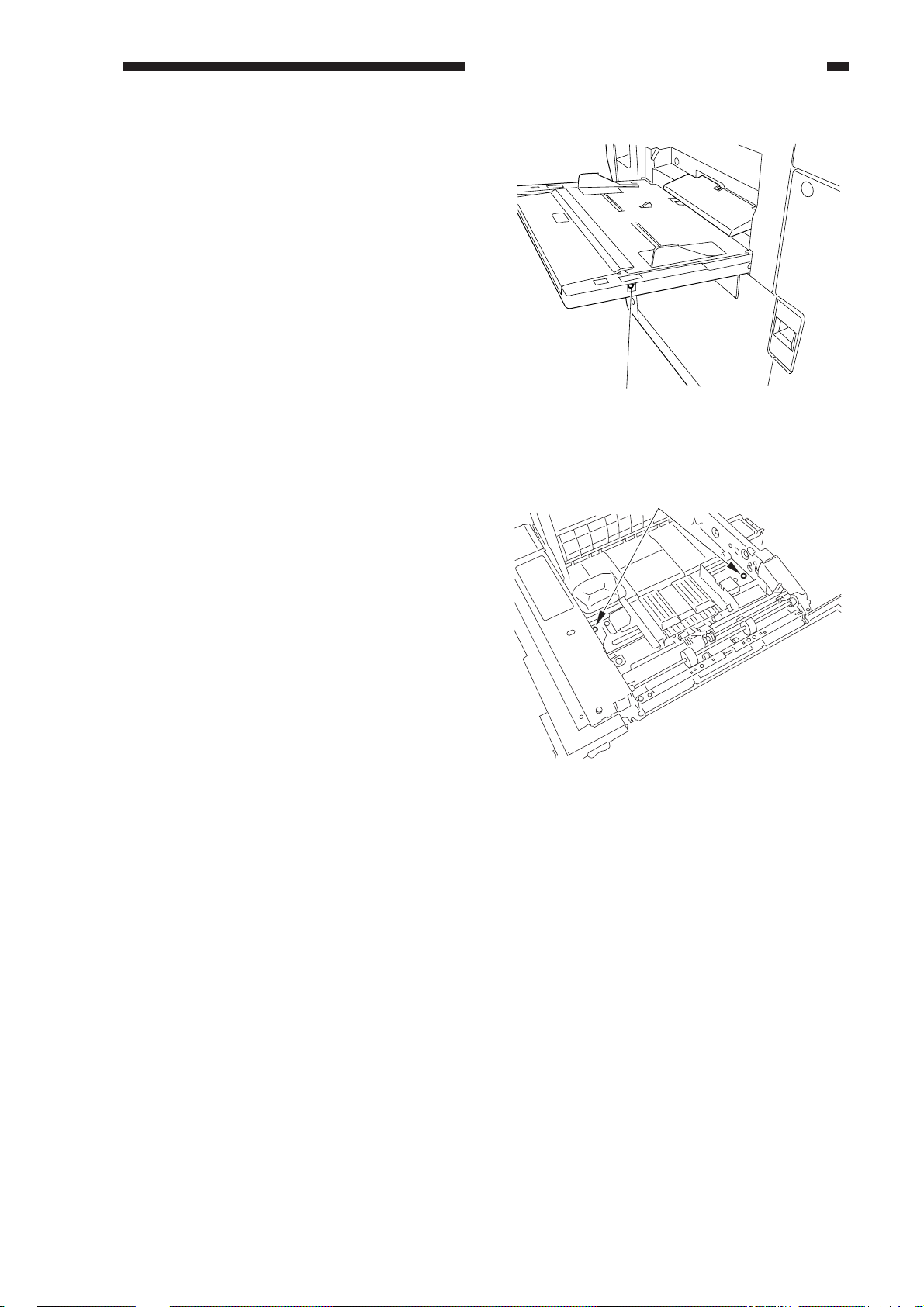

§ For the Duplexing Unit

Loosen the screw [1], and move the

position of the paper jogging guide so that

the registration is 2.0 ± 1.5 mm in Direct.

b. Adjusting the Attraction Position

(ATTRACT)

1) Select A4.

2) Select ADJUST>FEED-ADJ>ATT-

CHK.

3) Set ATT-CHK to '1' (2-sheet retention;

sides B and A), and press OK.

4) Select ATT-ON, and press OK.

• Copy paper will be picked up,

attracted, and stopped.

[1]

Figure 2-6

2-3

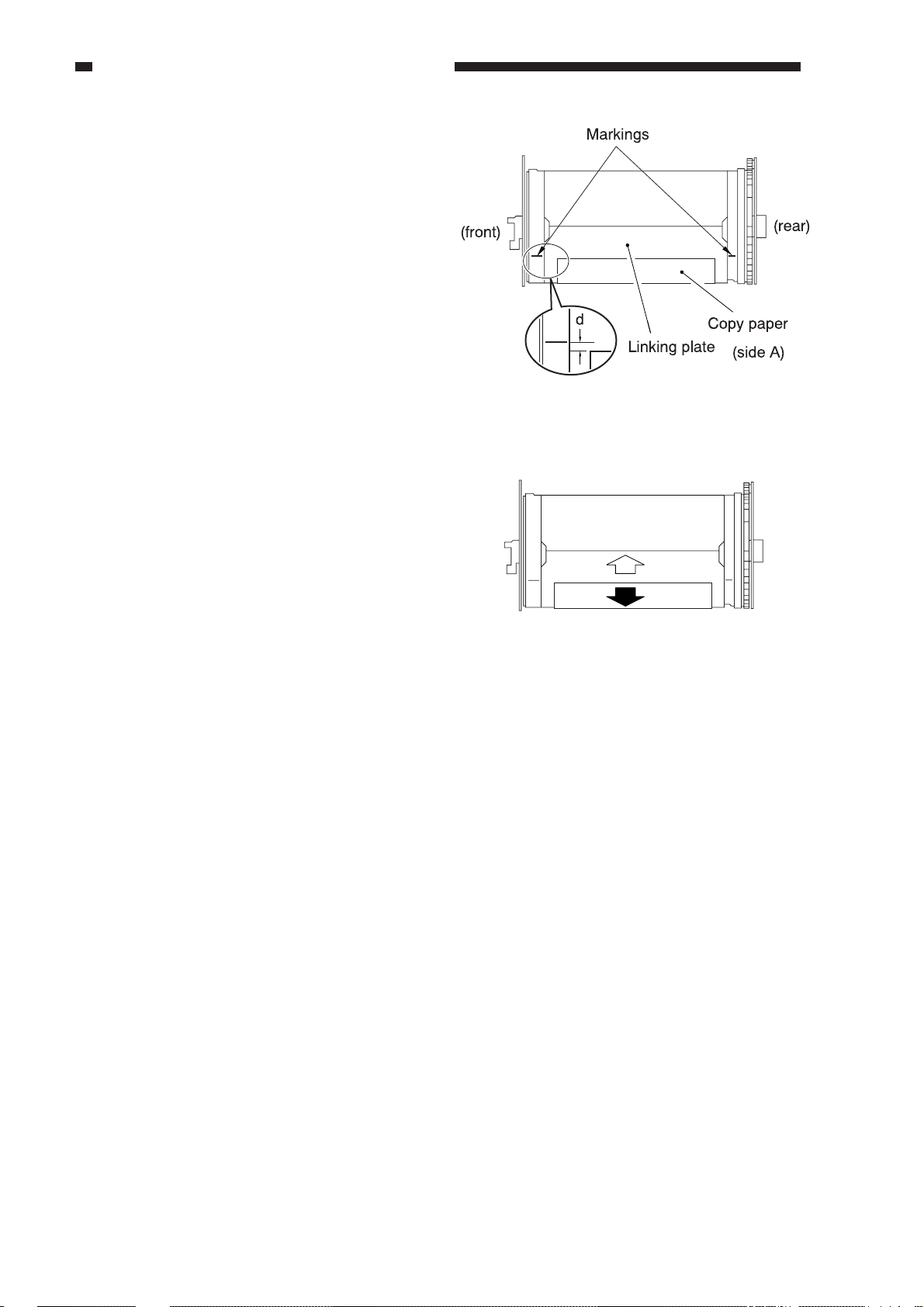

CHAPTER 2 STANDARDS AND ADJUSTMENTS

5) Slide out the transfer frame.

6) Place a ruler and copy paper against the

marking (Figure 2-7) etched to the

transfer drum ring (front, rear), and

measure the position d of the copy paper

in relation to the leading edge of the copy

paper. Perform this for both sides A and

B.

7) Make adjustments so that d is 0 ± 0.5 mm

in service mode (ADJUST>FEED-ADJ).

for side A:ATT-T-A

for side B:ATT-T-B

• Changing ATT-T-A, ATT-T-B to '1'

will shift the point of attraction by

about 0.4 mm.

• A higher setting will delay the start of

attraction (in the direction of the black

arrow) while a lower setting advances

it (in the direction of the white arrow).

8) After adjustment, turn off and then on the

power switch.

• Keep in mind that copies made in

normal mode will be black if you

forget to turn off and then on the

power switch.

(front)

Figure 2-7

(rear)

Figure 2-8

2-4

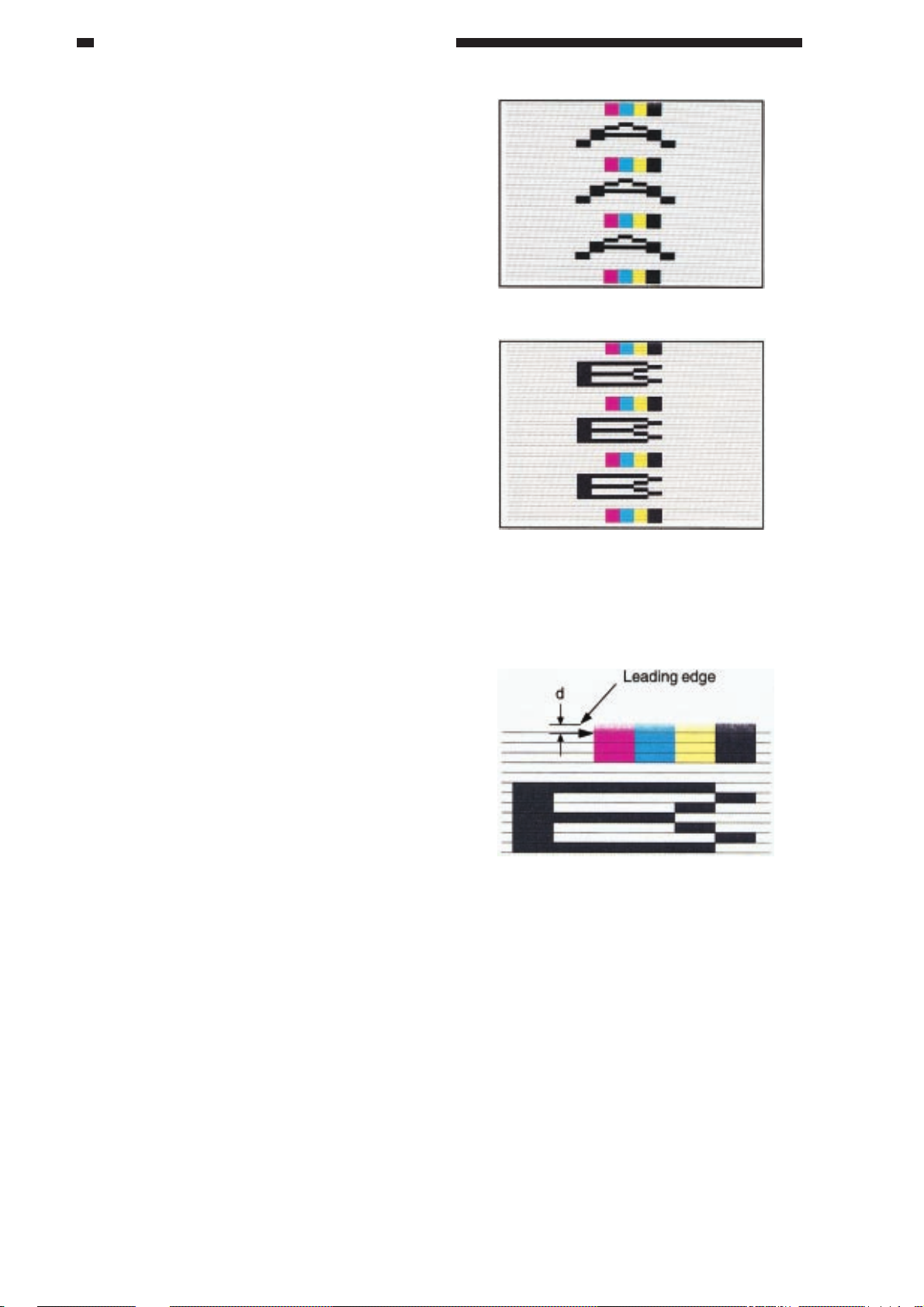

c. Adjusting the Image Leading Edge

Margin (RG-XA, RG-XB)

1) Select ADJUST>FEED-ADJ>RGSTCHK in service mode.

2) Set RGST-CHK to '1' (2-sheet retention;

sides B and A), and press OK.

3) Select RGST-ON, and press OK.

• A total of two prints (one each shown

in the figure) will be generated.

4) Measure the leading edge margin d on the

print. Perform this for both sides A and B.

5) Select the following service modes; then,

make adjustments by changing the

settings so that the leading edge d is 8 ±

0.5 mm.

for side A: ADJUST>FEED-ADJ> RG-

XA

for side B: ADJUST>FEED-ADJ>RG-

XB

• Setting it to '1' will shift the leading

edge margin by about 0.06 mm.

• A higher setting increases the leading

edge margin while a lower setting

decreases it.

CHAPTER 2 STANDARDS AND ADJUSTMENTS

Test print on side A

Test print on side B

Figure 2-9

d

(8.0 ± 0.5 mm)

Figure 2-10

2-5

CHAPTER 2 STANDARDS AND ADJUSTMENTS

d. Adjusting the Transfer Delay (TR-

DELAY)

1) Select FUNCTION>ATTRACT>TR1CHK in service mode.

2) Set TR1-CHK to '1' (2-sheet retention;

both sides B and A), and press OK.

3) Select TR1-ON, and press OK.

• A total of two prints (one each shown

in the figure) will be generated.

Test print on side A

4) Measure the transfer delay d on side B on

the generated print.

5)

Select ADJUST>FEED-ADJ>TR-DLY

-A or B in service mode, and make

adjustments so that the transfer delay is 3

± 0.5 mm.

• Changing the setting to '1' will shift

the transfer delay by about 0.4 mm.

• A higher setting will increase the

transfer delay while a lower setting

will decrease it.

6) Select FUNCTION>ATTRACT>TR2-

CHK in service mode, and set '1' (2-sheet

retention; both sides B and A), and press

OK.

7) Select TR2-ON, and press OK.

8) Check the leading edge margin (8 ± 0.5

mm) on the print.

Test print on side B

Figure 2-11

Figure 2-12

2-6

e. Adjusting the Image Read Start

Position (ADJ-XY)

1) Place the Test Sheet on the copyboard

glass.

2) Select ADJUST>ADJ-XY in service

mode.

3) on the ADJ-XY screen, press the Copy

Start key.

• The appropriate copying mode will

automatically be selected, and a copy

is made with a shift of about 50 mm as

shown in the figure.

4) If part of the image is missing, decrease

the setting of ADJ-X, ADJ-Y in service

mode.

5) If part of the image is outside the image

area, increase the setting of ADJ-X, ADJ-

Y.

6) Press the Copy Start key once again, and

make a check.

7) Press the Reset key.

CHAPTER 2 STANDARDS AND ADJUSTMENTS

ADJ-Y

50

ADJ-X

50

Figure 2-13

f. Adjusting the Image Trailing Edge

Margin (TR-END-A, B; end of transfer

high voltage)

If you have replaced the transfer drum

unit in the field, correct the variation in the end

of the transfer voltage.

1) Select ADJUST>FEED-ADJ>TR-ENDA or B in service mode, and enter '25' (10

mm).

2) Select ADJUST>FEED-ADJ>TR2-ON;

then, press the OK key.

3) Measure the distance X (mm) between the

point at which blurring starts along the

trailing edge of the image on the

generated test print and the trailing edge

of the image.

4) Enter the result of (10 - x)/0.4 as the

adjustment value of TR-END-A or -B.

(Round the result up to a whole number.)

5) Select ADJUST>FEED-ADJ>TR2-ON in

service mode once again; then, press the

OK key.

6) Check to make sure that the image along

the trailing edge of the generated test print

is not blurred.

7)

Record the value of ADJUST>FEEDADJ>TR-END-A or -B on the service

label.

Figure 2-13a

2-7

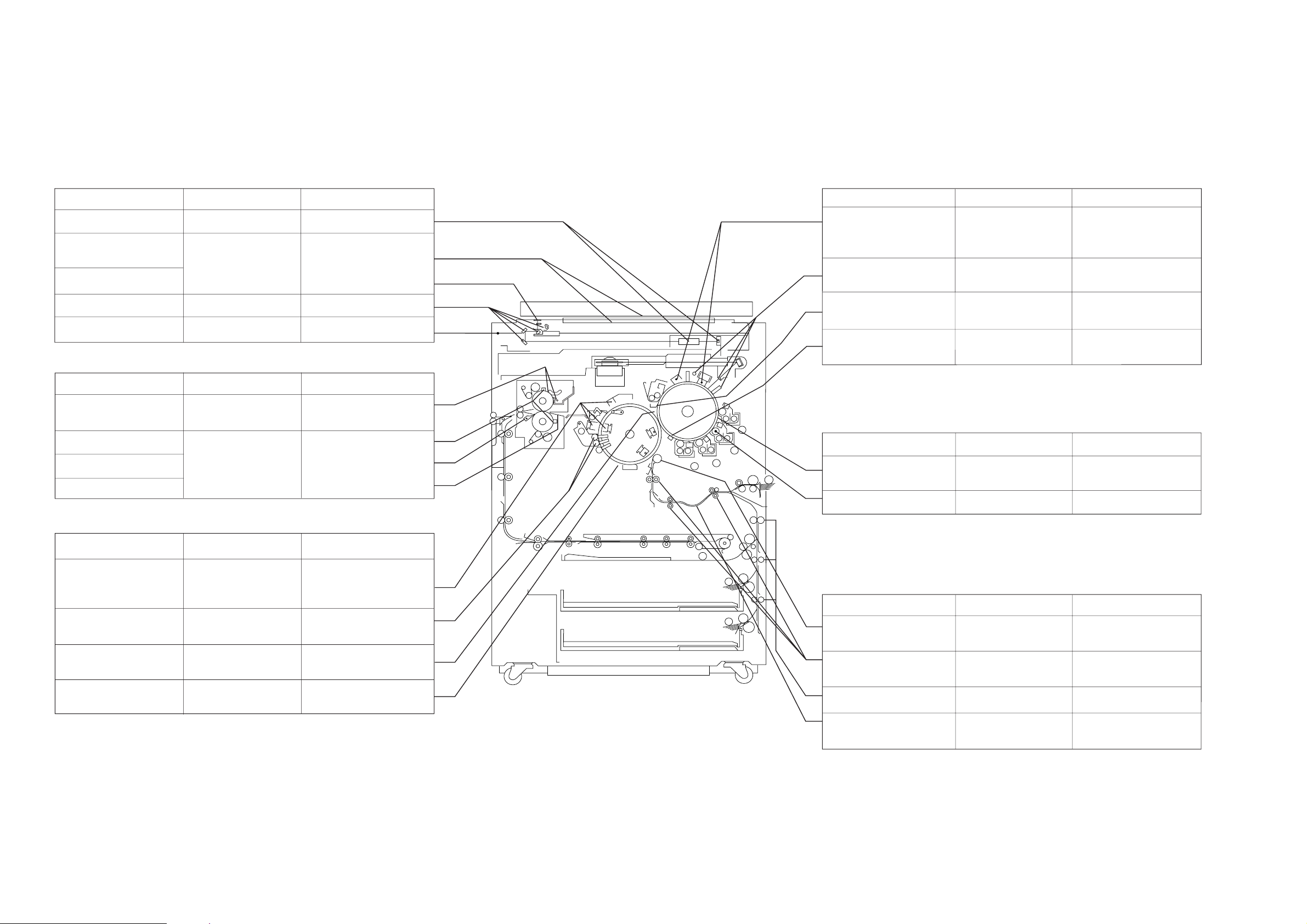

CHAPTER 2 STANDARDS AND ADJUSTMENTS

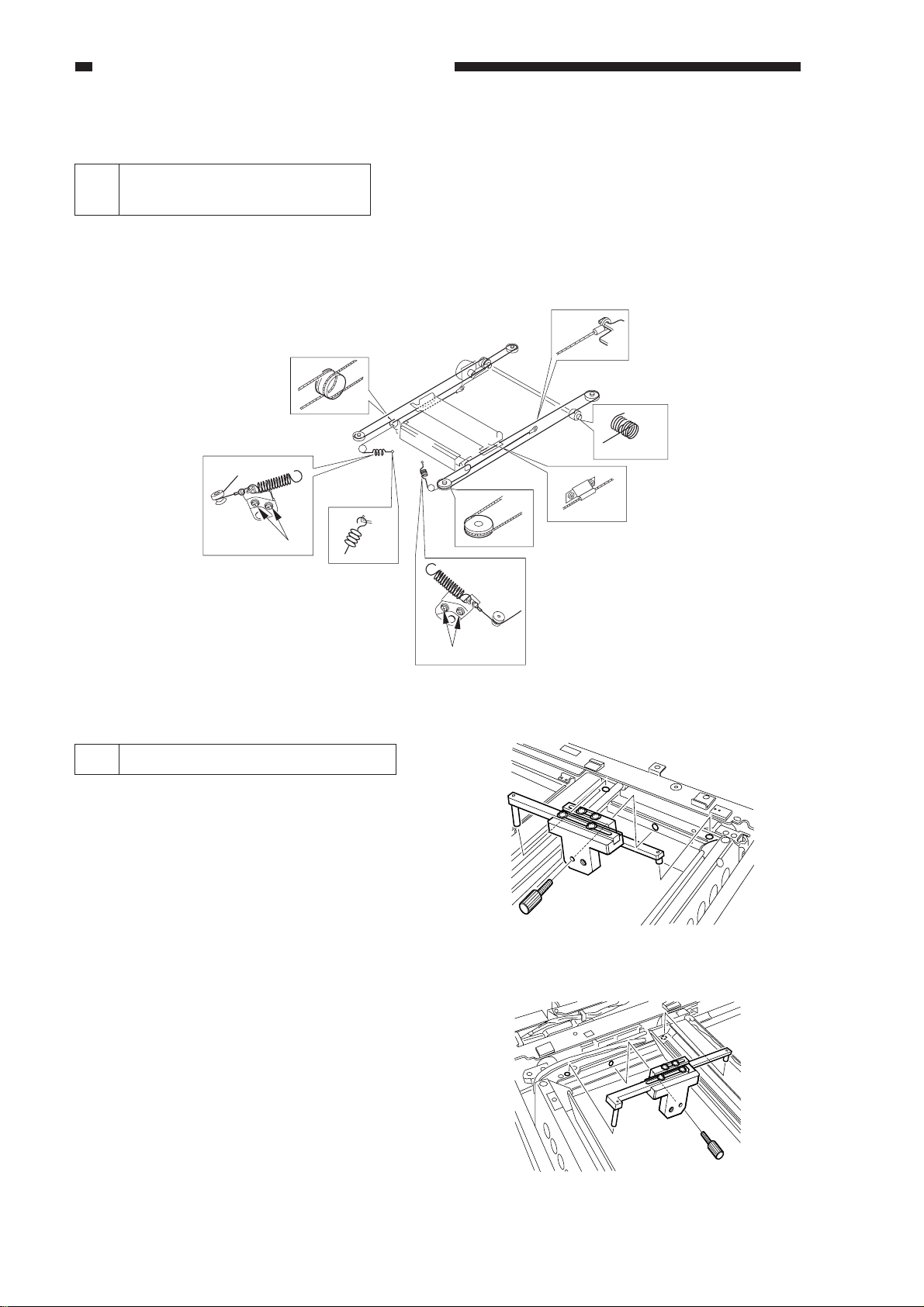

B. Exposure System

Routing the Scanner Drive

1

Cable

Route the scanner drive cable as

indicated; i.e., [1] through [8]. Then, perform

"adjusting the mirror position."

2

8

6

1

3

5, 8

4

Figure 2-14

2 Adjusting the Mirror Position

Be sure to adjust the position of the mirror

when you have routed the scanner drive cable.

1) Extend the arm of the mirror positioning

tool (FY9-3040) fully.

2) Fit the mirror positioning tool between

No. 1 mirror base and No. 2 mirror base.

3) Route the scanner drive cable to the No. 1

mirror mount.

8

Figure 2-15

2-8

Figure 2-16

C. Image Formation System

CHAPTER 2 STANDARDS AND ADJUSTMENTS

Adjusting the Height of

1

Charging Wires

The height (position) of the charging wire

of each charging assembly may be adjusted by

turning the screw found behind the assembly.

A full turn of the screw will shift the charging

wire by about 0.7 mm.

You cannot, however, change the height

of the wire of the internal static eliminator,

external charge eliminator, separation

charging assembly or the post-cleaning

charging assembly.

Points to Note about the

2

Photosensitive Drum

a. The photosensitive drum is vulnerable to

strong light, and exposure to strong light

for an appreciable period of time will lead

to white spots or black bands on copies.

Whenever you have removed the

photosensitive drum from the copier, be

sure to wrap the light-blocking sheet (or

five to six sheets of fresh copy paper)

around it, and keep it in a dark place.

b. If you are installing a new photosensitive

drum, be sure to perform the following:

1) Install the new photosensitive drum.

At this time, be sure to mount it so

that the lot No. label attached inside it

is toward the front of the copier.

2) Mount the primary charging

assembly, pre-cleaning charging

assembly, photosensitive drum

cleaner assembly, and developing

assemblies.

3) Coat the No. 2 blade of the black

toner concentration sensor evenly

with drum cleaner lubricant (TKN-

0480).

4) Coat the blade of the photosensitive

drum cleaner assembly with drum

cleaner lubricant (TKN-0480).

5) Dry wipe the window of the black

toner concentration sensor, and

mount it.

Charging

assembly

Primary

charging

assembly

Separation

charging

assembly

External

charging

assembly

Height of charging wire (mm) Range

10.5

17.0

4 mm (approx.)

17.0

Figure 2-17

2-9

CHAPTER 2 STANDARDS AND ADJUSTMENTS

6) Dry wipe the window of the precleaning sensor, and mount it.

7) Turn on the power switch, and keep

the copier in standby state.

8) Select FUNCTION>INSTALL>

STIR-4 in service mode, and execute

it.

9) Select FUNCTION>SENS-ADJ>

CLN-OFST, and execute it.

10) Record the settings of ADJUST>

SENS-ADJ>CLN-TH, CLN-TMP

on the service label attached behind

the front right cover.

11) Select FUNCTION>INSTALL>

INIT-D in service mode, and execute

it.

c. If the surface of the photosensitive drum

is soiled, wipe it with a flannel cloth

coated with toner. (Do NOT use paper,

lint-free or otherwise.)

Do not use solvent when cleaning it. Do

not touch its surface.

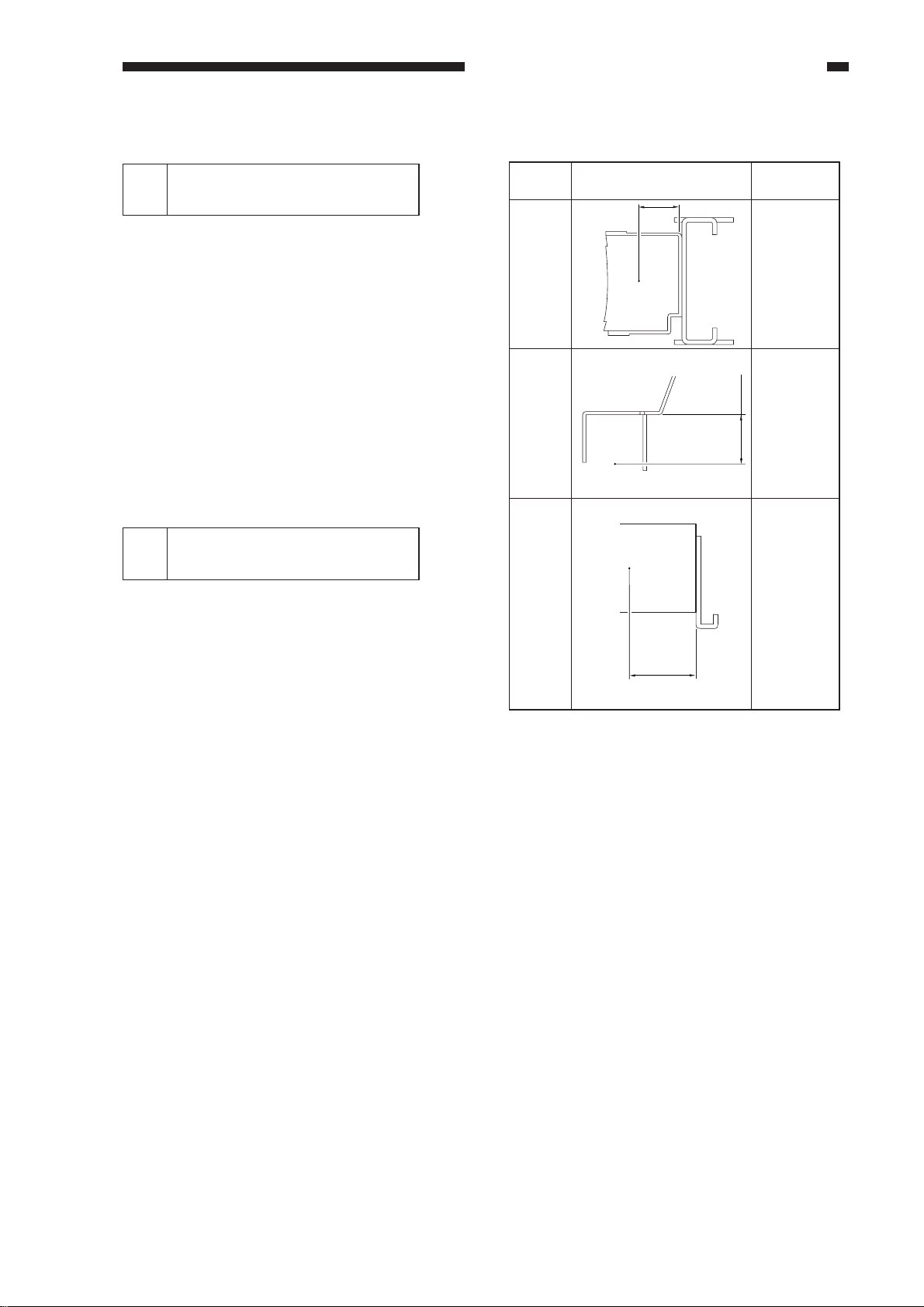

Adjusting the Position of the

3

Photosensitive Drum Fixing

Shaft

Slide the photosensitive drum frame unit

about 5 cm out of the copier, and then slide it

back in. If the movement is not smooth, adjust

the position of the photosensitive drum fixing

shaft using the drum shaft positioning tool

(FY9-3045).

This adjustment, however, need not be

made if the images are free of color

displacement, blurring, and faults at intervals

and, moreover, the discrepancy between the

photosensitive drum fixing shaft and the hole

of the photosensitive drum flange is about 1

mm.

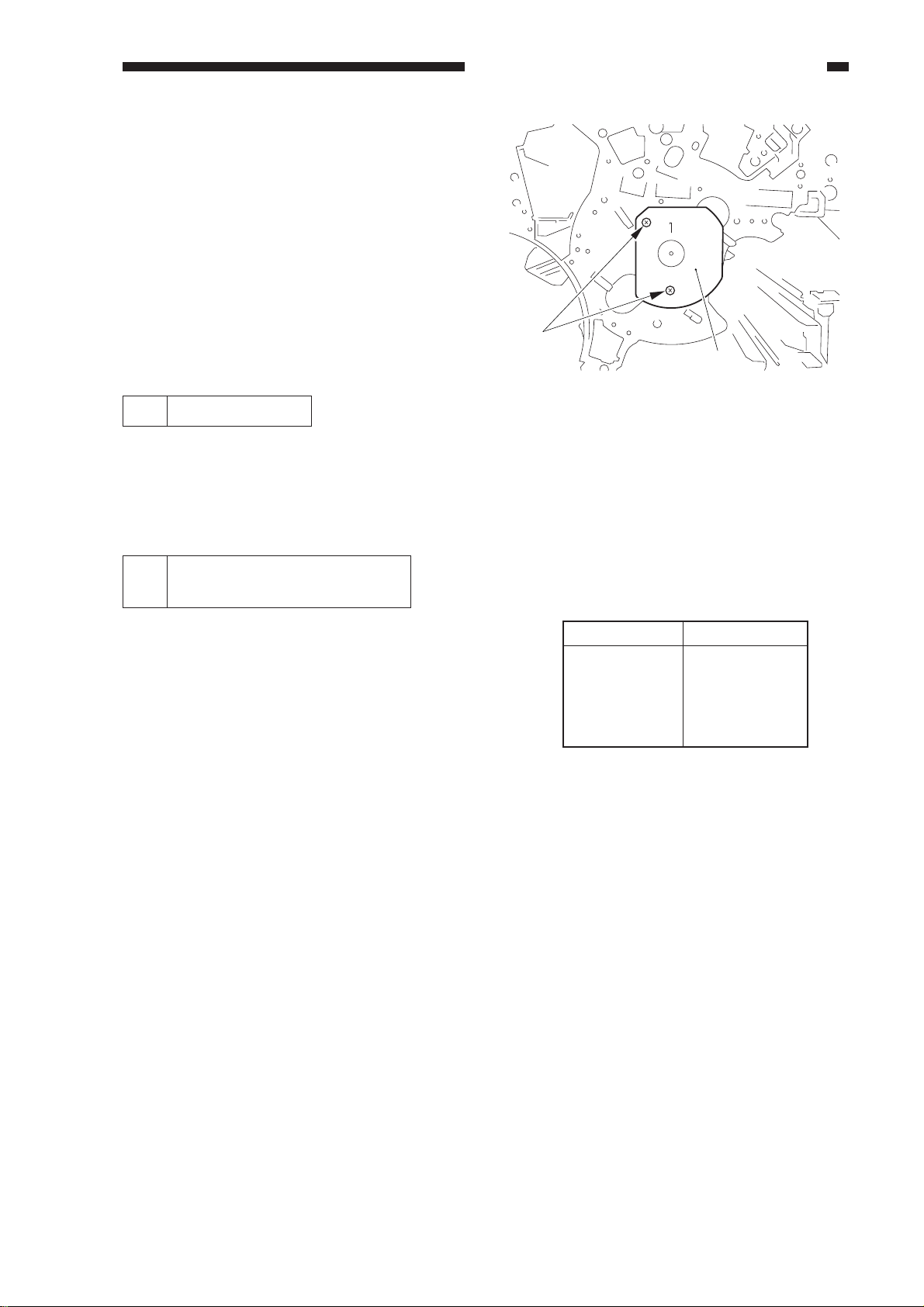

1) Slide out the photosensitive drum unit

from the copier.

2) Remove the six screws [1], and detach the

photosensitive drum butting blocks [2]

(front, back); then, detach the

photosensitive drum [3] from the

photosensitive drum frame unit [4].

3) Slide the photosensitive drum frame unit

into the copier, and secure it in place with

three screws.

4) Secure the drum motor assembly [5] to the

copier temporarily with seven screws [6].

[4]

[1]

[2]

Figure 2-18

[6] [6][6]

[6]

Figure 2-19

[2] [1]

[3]

[5]

[6]

2-10

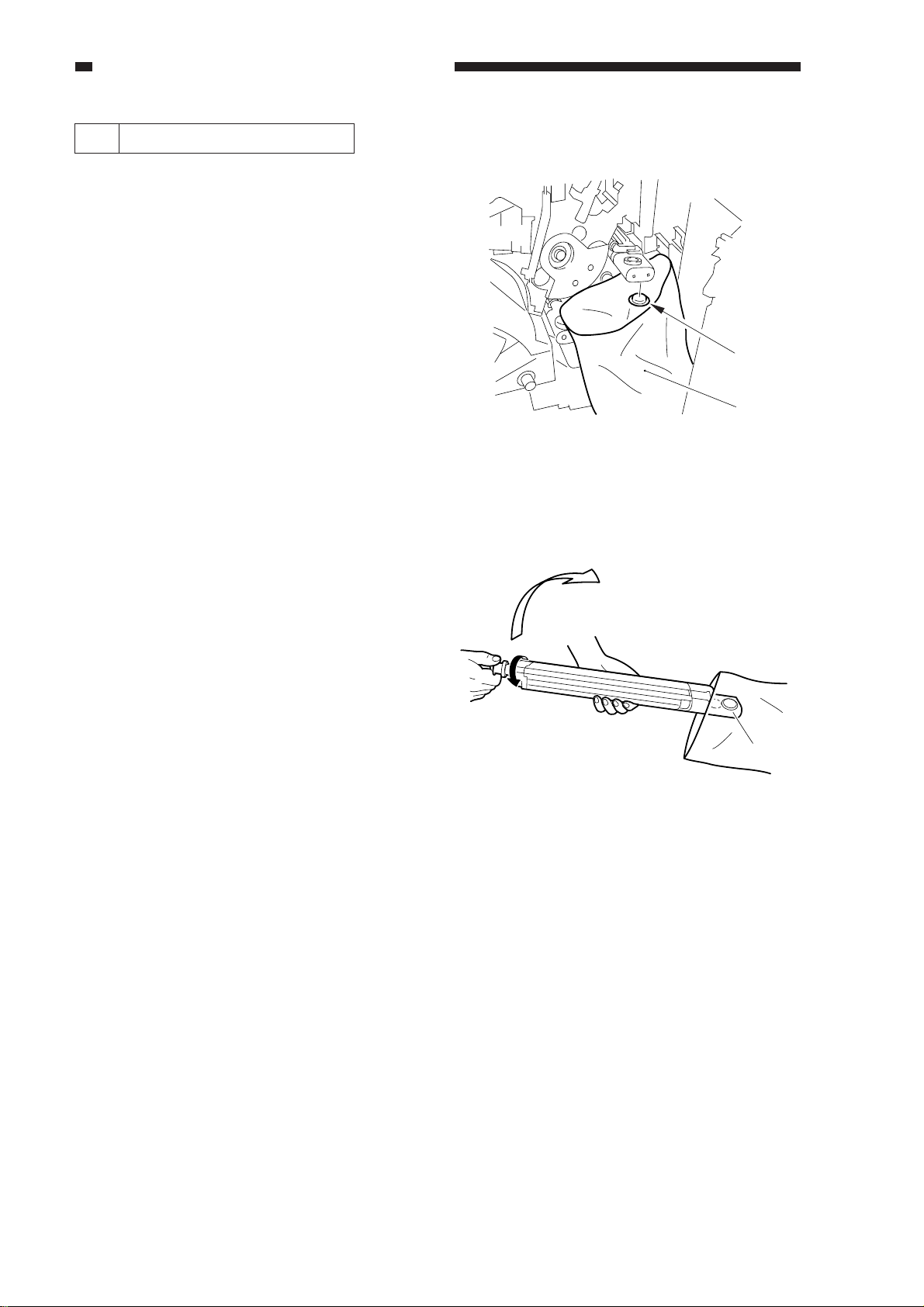

5) Secure the drum shaft positioning tool [7]

in place to the photosensitive drum frame

unit with the two screws [8] removed in

step 2).

6) Secure the drum motor assembly in place

with seven screws.

7) Detach the drum shaft positioning tool,

and slide out the photosensitive drum unit

from the copier; then, mount the unit and

parts removed in step 1).

CHAPTER 2 STANDARDS AND ADJUSTMENTS

[8]

[7]

4 Use of Grease

Do NOT use grease (conducting or

otherwise) to the slip ring for the drum heater.

Adjusting the Developing

5

Assembly S-B Gap

If you have replaced the developing blade,

adjust the S-B gap of each sleeve using the SB gap gauge (FY9-3044).

Developer

Yellow

Cyan

Magenta

Black

Figure 2-20

S-B gap

0.62 mm

0.74 mm

0.74 mm

0.48 mm

Table 2-1

2-11

CHAPTER 2 STANDARDS AND ADJUSTMENTS

6 Replacing the Developer

1) Open the hopper unit fully.

2) An appreciable amount of developer will

fall out in the next step. Keep a plastic bag

[1] as shown.

3) Detach the cap [2] from the discharge

opening found at the front bottom of the

developing assembly whose developer

you want to replace.

4) Select FUNCTION>INSTALL in service

mode.

5) While keeping the plastic bag against the

discharge opening, press RECV-M/C/Y/

K, as appropriate, in service mode.

• When the developer has stopped

pouring, press the Stop key to stop the

operation.

6) Fit the cap back on the discharge opening.

7) Remove the screw, and detach the

developing assembly; then, detach the cap

from the discharge opening.

In the case of the black developing

assembly, disconnect the connector also.

8) While tilting the developing assembly,

turn the gear by hand to discharge all

remaining developer.

At this time, tilt the developing assembly

farther down while turning the gear so that

no toner will remain when it is finally held

upright.

9) Fit the cap to the discharge opening.

10) Mount the developing assembly to the

copier.

11) At the end of the wait period, select

FUNCTION>INSTALL in service mode.

12) Press SPLY-M/C/Y/K, as appropriate.

13) See that the developing assembly is

locked in place, and the screw inside it

rotates (about 10 sec).

[2]

[1]

Figure 2-21

Figure 2-22

2-12

Loading...

Loading...