Canon CLBR 460ps, CLBP-460PS Service Manual

SERVICE

MANUAL

REVISION 0

OCT. 1998

COPYRIGHT © 1998 CANON INC. CANON CLBP-460PS REVISION 0 OCT. 1998 PRINTED IN JAPAN (IMPRIME AU JAPON)

RY8-1389-000

COPYRIGHT © 1998 CANON INC

Printed in Japan

Imprimé au Japon

Prepared by

PERIPHERAL PRODUCTS QUALITY PLANNING DIV.

PERIPHERAL PRODUCTS TECHNICAL DOCUMENTATION DEPT.

CANON INC.

5-1, Hakusan 7-chome, Toride-City, Ibaraki-Pref. 302-8501, Japan

Use of this manual should be

strictly supervised to avoid

disclosure of confidential

information.

PREFACE

This Service Manual contains basic information required for after-sales service of the laser

beam printer (hereinafter referred to as the “printer”) CLBP-460PS. This information is vital to

the service technician in maintaining the high print quality and performance of the printer.

The paper feeder and duplexing unit, which are prepared for the printer as options, are also

described in this manual.

This manual consists of the following chapters:

Chapter 1: Product information

Features, specifications, operation, and installation

Chapter 2: Operation and Timing

A description of the operating principles and timing sequences of the electrical

and mechanical systems.

Chapter 3: The Mechanical System

Explanation of mechanical operation, disassembly, reassembly, and adjustment

procedures

Chapter 4: Troubleshooting

Maintenance and servicing, reference values and adjustments, troubleshooting

procedures, lubricants, and solvents

Appendix: General timing chart, general circuit diagram, etc.

Information in this manual is subject to change as the product is improved or redesigned.

All relevant information in such cases will be supplied in Service Information Bulletins.

A thorough understanding of this printer, based on information in this Manual and Service

Information Bulletins, is required for maintaining its performance and for locating and repairing the causes of malfunctions.

DTP system

This manual was produced on an Apple PowerMacintosh 9500/200 personal computer and output by an Apple LaserWriter 16/600 PS laser beam printer.

All graphics were produced with Macromedia FreeHand (J), and all documents and page lay-

outs were created with QuarkXPress (E).

The video images were captured with SONY digital video camcorder and MASS microsystems

Quickimage 24 video capture board, and modified with Adobe Photoshop™ (J).

CONTENTS

CHAPTER 1 PRODUCT INFORMATION

I. FEATURES .............................1-1

II. SPECIFICATIONS....................1-3

A. Printer...............................1-3

B. Video Controller ................ 1-5

III. SAFETY INFORMATION .....1-8

A. Laser Safety ...................... 1-8

B. Toner Safety......................1-8

C. Ozone Safety .....................1-8

D. Power Supply Safety..........1-8

IV. PARTS OF THE PRINTER .......1-9

A. External View ....................1-9

B. Cross Sectional View .........1-11

V. INSTALLATION .......................1-13

A. Notes................................. 1-13

B. Choosing a Location..........1-13

C. Unpacking and Installation

.........................................1-15

D. Storing and Handling

Cartridges and ITB Unit.....1-23

VI. MAINTENANCE AND SERVICING BY

THE CUSTOMER ....................1-26

VII. OPERATION............................1-28

A. Control Panel .................... 1-28

B. Control Panel Menu...........1-30

CHAPTER 2 OPERATION AND TIMING

I. BASIC OPERATION.................2-1

A. Functions..........................2-1

B. Basic Sequence of

Operations.........................2-2

C. Power-on Sequence............2-3

II. ENGINE CONTROL SYSTEM....2-4

A. DC Controller PCB.............2-4

B. Fixing Control Circuit ....... 2-14

C. High-voltage Power Supply

Circuit...............................2-20

D. Low-voltage Power Supply

Circuit...............................2-25

E. Video Interface Control .....2-28

F. Other Control....................2-30

III. LASER/SCANNER SYSTEM..... 2-37

A. Laser System.....................2-37

B. Laser Control Circuit.........2-39

C. Scanner System ................2-42

IV. IMAGE FORMATION SYSTEM .2-44

A. Outline..............................2-44

B. Operation .......................... 2-45

C. Print Process.....................2-62

D. Image Stabilization Control

.........................................2-73

V. PICK-UP/FEED SYSTEM.........2-75

A. Outline..............................2-75

B. Paper Pick-up ....................2-77

C. Feed Unit ..........................2-84

D. Fixing and Delivery Unit....2-85

E. Paper Jam Detection .........2-89

VI. VIDEO CONTROL SYSTEM......2-90

A. Video Controller PCB......... 2-90

B. Control Panel .................... 2-93

C. Self Test............................2-94

D. Boot ROM Menu ................2-96

E. Powar Saver.......................2-98

VII. DUPLEXING UNIT ...................2-99

A. Outline..............................2-99

B. Reversing and Duplex

Pick-up Operation .............2-101

C. Paper Jam Detection.........2-106

VIII.PAPER FEEDER......................2-108

A. Outline..............................2-108

B. Pick-up and

Feed Operation.................. 2-109

C. Paper Jam Detection.........2-110

CHAPTER 3 THE MECHANICAL SYSTEM

I. INTRODUCTION......................3-1

A. Outline .............................3-1

B. Removal of the

Toner Cartridge

whit Manual Operation ......3-2

II. EXTERNALS ........................... 3-4

A. Locations ..........................3-4

B. External Covers.................3-5

C. Control Panel ....................3-9

III. MAIN UNITS...........................3-10

A. Laser/Scanner Unit ...........3-10

B. Drum Drive Unit................3-11

C. Rotary Drive Unit..............3-14

D. Multi-purpose

Pick-up Unit ......................3-14

E. Feed Unit .......................... 3-16

F. Fixing Unit ........................3-16

G. Delivery Unit.....................3-17

H. Drum Cartridge

Drawer Unit.......................3-17

I. ITB Unit Drawer Unit.........3-18

J. Developing Rotary.............3-19

IV. MAIN PARTS ..........................3-21

A. Cassette Pick-up Roller ..... 3-21

B. Cassette Feed Roller..........3-21

C. Cassette Separation Roller

.........................................3-21

D. Multi-purpose Tray

Pick-up Roller ...................3-22

E. Separation Pad ..................3-22

F. Secondary Transfer Roller

.........................................3-24

G. Upper Thermoswitch .........3-24

H. Lower Thermoswitch ......... 3-25

I. Upper Thermistor..............3-25

J. Lower Thermistor..............3-26

K. Upper Fixing Heater ..........3-26

L. Lower Fixing Heater ..........3-27

M. Upper Fixing Roller ...........3-28

N. Lower Fixing Roller ...........3-30

O. 90-Fan/60-Fan Air Filter ... 3-32

P. 40-Fan Air Filter ...............3-32

V. SWITCHES/SENSORS.............3-33

A. Locations ..........................3-33

B. ITB Unit Drawer Open

Detection Switch...............3-35

C. Toner Cartridge Door Open

Detection Switch...............3-35

D. Drum Cartridge Drawer Open

Detection Switch...............3-36

E. +24V Interruption Switch1

.........................................3-36

F. +24V Interruption Switch2

.........................................3-37

G. Cassette Paper Size

Detection Switch...............3-37

H. Power Switch.....................3-38

I. Test Print Switch ..............3-38

J. Registration Paper Sensor .3-39

K. Multi-purpose Tray

Last Paper Sensor.............3-39

L. Multi-Purpose Tray

Paper Sensor .....................3-40

M. ITB Home

Position Sensor .................3-40

N. Fixing Unit Pressure

Release Sensor ..................3-41

O. Paper Delivery Sensor .......3-41

P. Cassette Paper Sensor .......3-42

Q. Face-down Tray

Paper Full Sensor ..............3-42

R. Developing Rotary

Home Position Sensor .......3-43

S. Toner Cartridge

Contact Sensor.................. 3-43

T. Toner Level Sensor............3-44

U. Waste Toner Full Sensor....3-44

V. OHT Sensor .......................3-45

W. Density Sensor ..................3-45

VI. SOLENOIDS/CLUTCHES .........3-47

A. Locations ..........................3-47

B. Multi-purpose Tray

Pick-up Solenoid ...............3-48

C. Cassette

Pick-up Solenoid ...............3-48

D. Registration Roller Clutch.3-49

E. ITB Unit Contact Clutch....3-49

F. ITB Cleaning Roller

Press Clutch ......................3-50

G. Secondary Transfer Roller

Press Clutch ......................3-50

VII. MOTORS/FANS ......................3-51

A. Locations ..........................3-51

B. Fixing Motor Unit..............3-52

C. Pick-up Motor.................... 3-52

D. Developing Rotary Motor...3-53

E. Drum Motor.......................3-53

F. Toner Cartridge

Motor Unit ........................3-54

G. 90-Fan............................... 3-54

H. 60-Fan...............................3-55

I. 40-Fan...............................3-56

VIII.ELECTRONIC COMPONENTS ..3-58

A. Locations ..........................3-58

B. DC Controller PCB.............3-59

C. Connector PCB ..................3-60

D. Low-voltage Power

Supply Unit .......................3-60

E. High-voltage

Power Supply Unit.............3-61

F. Developing PCB .................3-61

G. Feed PCB...........................3-62

H. Multi-purpose Tray PCB.....3-62

I. Toner Level

Detection PCBs

[Emitter and Receiver].......3-64

J. Waste Toner Full

Detection PCBs

[Emitter and Receiver].......3-64

K. Cassette Paper Size

Detection PCB ...................3-65

L. Video Controller PCB......... 3-65

IX. DUPLEXING UNIT...................3-66

A. External Covers.................3-66

B. Motors/Solenoids ..............3-69

C. Sensors .............................3-72

D. Electrovic Components .....3-75

X. PAPER FEEDER......................3-77

A. Locations ..........................3-77

CHAPTER 4 TROUBLESHOOTING

I. PREFACE ...............................4-1

A. Malfunction Diagnosis

Flowchart .......................... 4-1

B. Initial Check ..................... 4-4

C. Test Print .......................... 4-6

II. IMAGE DEFECT...................... 4-17

III. PAPER JAMS

TROUBLESHOOTING ..............4-27

IV. PAPER TRANSPORT

TROUBLESHOOTING ..............4-34

V. MALFUNCTION

TROUBLESHOOTING ..............4-36

VI. MALFUNCTION STATUS

TROUBLESHOOTING ..............4-37

VII. MEASUREMENT AND

ADJUSTMENT ........................4-53

A. Mechanical Adjustment ..... 4-53

B. Electrical Adjustment........ 4-54

C. Variable Resistors [VR],

Test Print, Jumpers,

and Switches on PCBs .......4-55

APPENDIX

I. GENERAL TIMING CHART ......A-1

II. GENERAL CIRCUIT DIAGRAM

.........................................A-25

III. LIST OF SIGNALS................... A-29

IV. MESSAGE TABLE ...................A-36

VIII.MAINTENANCE AND

SERVICING.............................4-59

A. Periodic Replacement Parts

.........................................4-59

B. Expected Service Life of

Consumable Parts.............. 4-59

C. Periodic Service ................4-60

D. Cleaning During a Sarvice Visit

.........................................4-60

E. Standard Tools ..................4-64

F. Special Tools.....................4-65

G. List of Lubricants and

Cleaners ............................4-66

IX. SERVICE MODE .....................4-67

A. Outline..............................4-67

B. Mode Description ..............4-73

X. LOCATION OF CONNECTORS .4-78

CHAPTER 1

PRODUCT INFORMATION

I. FEATURES ............................. 1-1

II. SPECIFICATIONS.................... 1-3

III. SAFETY INFORMATION...... 1-8

IV. PARTS OF THE PRINTER ....... 1-9

V. INSTALLATION ....................... 1-13

VI. MAINTENANCE AND

SERVICING BY THE

CUSTOMER ............................ 1-26

VII. OPERATION............................ 1-28

I. FEATURES

1. The smallest and lightest color printer

This printer is the smallest and lightest printer among the Canon color laser beam printers.

2. High resolution and high speed printing

The printer features continuous tone 256-level grayscale/color output at 600 x 600 dpi with

the standard memory configuration of 32MB.

The printer is capable of printing 4 ppm (page per minute) in full color mode and 16 ppm in

mono-color mode (A4 or Letter size).

3. Intermediate transfer belt (ITB)

The printer utilizes an intermediate transfer belt, which forms the toner image by accumulating the four color images required for each full-color print and transferring this image to the

paper. The ITB makes the paper path from the registration area to the fixing area straight,

enabling color printing of various paper types and reducing the likelihood of paper jams.

4. Oilless fixing unit

The printer utilizes toner which contains wax, reducing the likelihood of toner adhesion to the

fixing roller surface and allowing the fixing unit to be oilless.

5. Easy maintenance

The main parts in the printer are structured to simplify maintenance of the printer. The main

parts are as follows.

• ITB unit

• Toner cartridge (Bk, M, C, Y)

• Drum cartridge (photosensitive drum and waist toner case)

• Fixing unit (Fixing unit is not fixed with screws and can be replaced simply by shifting the

• fixing levers.)

• Feed roller, separation roller, and secondary transfer roller

6. Flexible paper handling

The universal cassette (250 sheets of 80g/m2paper) and multi-purpose tray (100 sheets of

80g/m2paper) allow the printer to handle various paper types such as plain paper, OHT, labels,

postcards and envelopes.

With an optional paper feeder (500 sheets of 80g/m2paper) installed in the printer, three way

paper pick-up and large volume printing are made possible.

7. Duplex printing

With an optional duplexing unit installed in the printer, automatic color duplex printing is

made possible.

8. Wide networking

By using the standard equipped Ethernet or optional TokenRing, the printer can support the

following network protocols.

• TCP/IP

• Apple Talk (Ethernet)

• IPX (Novell)

• SMB (Server Message Block)

1 - 1

CHAPTER 1

9. Automatic PDL switching

The printer supports Hewlett-Packard PCL 5C and Adobe PostScript 3TM. The printer can

automatically switch PDL between PCL and PostScript according to the received data.

1 - 2

CHAPTER 1

II. SPECIFICATIONS

A. Printer

1. Printer engine

1) Type Desktop page printer

2) Printing method Electrophotography

3) Printing speed (Note 1) About 4 pages/min (A4, full color)

About 16 pages/min (A4, mono-color)

4) First print time (Note 2) 37 seconds or less (A4, full color)

26 seconds or less (A4, mono-color)

5) Wait time (Note 3) 250 seconds or less

6) Resolution

Horizontal 600 dpi

Vertical 600 dpi

7) Image formation system

Laser Semiconductor laser

Scanning system Rotating six-faced prism mirror

Photosensitive medium OPC

Charging Roller charging

Exposure Laser scanning

Toner Non-magnetic single-component dry toner (Y/M/C), magnetic sin-

gle-component dry toner (Bk)

Development Toner projection development

Toner supply Replaceable Bk toner cartridge

The Bk toner cartridge can print about 9,000 A4- or Letter-size

sheets (if the average print coverage is a 4% image dot ratio with

the print density setting at midpoint.)

Replaceable Y, M, and C toner cartridges

The Y, M, and C toner cartridge can print about 6,000 A4- or

Letter-size sheets (if the average print coverage is a 4% image dot

ratio with the print density setting at midpoint.)

Transfer Primary transfer: Intermediate transfer belt

Secondary transfer: Secondary transfer roller

Separation Curvature

Cleaning The photosensitive drum is cleaned with a rubber blade, and the

intermediate transfer belt is cleaned with the ITB cleaning roller.

Fixing method Heated rollers (Upper heater: 490 W (127 V), 450 W (240 V))

(Lower heater: 490 W (127 V), 450 W (240 V))

8) Paper pick-up Multi-purpose tray

Cassette

Paper feeder (option)

Paper types Plain paper, labels, OHT (recommended by Canon) (Note 4),

envelopes, postcards

Paper size

Multi-purpose tray Plain paper (60-135 g/m

2

Canon recommended paper) from 76.2

mm (width) x 127 mm (length) (minimum) to 216mm (width) x 356

mm (length) (maximum), COM10, Monarch, B5, C5, DL size

envelopes, and papers shown above

Cassette Letter, Legal, Executive, A4, B5, A5 size plain paper (60-105 g/m

2

Canon recommended paper)

1 - 3

CHAPTER 1

Multi-purpose tray capacity

Plain paper:

15 mm stack (About 100 sheets of 75g/m2paper can be stacked.)

Envelope:

12 mm stack (About 15 to 20 COM10 size envelopes can be

stacked.)

Cassette capacity 25 mm stack (About 250 sheets of 75g/m2paper can be stacked.)

Cassette type

Cassette Universal (Can adapt to Letter, Legal, Executive, A4, or A5 size)

9) Paper delivery Face-down/face-up

Face-down tray capacity About 200 sheets of 75g/m2paper

Face-up tray capacity About 50 sheets of 75g/m2paper

10) Duplex printing

Automatic duplex printing

Only plain paper (60-105 g/m2Canon recommended paper) can be

printed on both sides automatically when the duplexing unit

(option) is installed.

Manual duplex printing Not to be used.

11) Operating environment See Fig. 1-5-1 in Section V, Installation.

12) Maximum power consumption

About 1100 W or less (100-127 V, room temperature of 20°C)

About 1100 W or less (220-240 V, room temperature of 20°C)

13) Noise level (Declared noise emissions in accordance with ISO 9296)

Sound power level (1B = 10 dB) 6.8B or less (printing)

5.8B or less (standby)

Sound pressure level 53 dB or less (printing)

(Bystander position) 43 dB or less (standby)

14) Dimensions 500 (width) x 559 (depth) x 394 (height) mm

15) Weight About 48.0 kg (printer-including cassette)

About 1.4 kg (drum cartridge)

About 0.92 kg (Bk toner cartridge)

About 0.77 kg (Y, M, and C toner cartridges)

About 2.0 kg (ITB unit)

16) Power supply 100-127 V (50/60 Hz)

220-240 V (50/60 Hz)

(Voltage tolerance ±10% or less)

17) Options Duplexing unit and paper feeder

Notes: 1. Test print when the rated power supply voltage is input at a room temperature of

20°C

2. Time after the printer receives a PRINT signal from the video controller when it is

ready at an ambient temperature of 20°C until it ends printing and delivering an A4size paper onto the face-down tray.

3. Time from power-ON until the printer completes WAIT period at ambient temperature

of 20°C and the rated AC power source voltage.

4. OHT (OHT T-H1) for CLBP-360PS cannot be used on this printer. As T-H1 is

extremely thin and contains oil, it may cause roller wrapping jams in the fixing unit

if it is used on this printer which utilizes two fixing heaters and produces large

amount of heat.

1 - 4

CHAPTER 1

B. Video Controller

1) CPU 32-bit RISC processor: MIPS R4300 (133MHz)

2) RAM Standard 32MB

Maximum 192MB

3) ROM Flash ROM: 16MB (PCL/PostScript)

4) ROM /RAM DIMM slot 4 (ROM:1, RAM:3)

5) Host interface Standard: IEEE 1284 parallel interface, Ethernet (10/100Base-T,

AUI)

Option: Expansion interface (Token Ring)

6) PDL Standard: PCL 5C, Adobe PostScript Level 3

7) Option HDD HD83 (2.1GB)

8) Resident fonts

PCL fonts: 45 (44 Scalable fonts, 1 Bitmap font)

1 - 5

CHAPTER 1

Albertus Medium (27), Albertus Extra Bold (28), Antique

Olive (19), Antique Olive-Bold (20), Antique Olive-Italic (21),

Arial (29), Arial-Bold (30), Arial-Italic (31), Arial-BoldItalic

(32), CG Omega (5), CG Omega-Bold (6), CG Omega-Italic

(7), CG Omega-BoldItalic (8), CG Times (1), CG Times-Bold

(2), CG Times-Italic (3), CG Times-BoldItalic (4), Clarendon

Condensed (10), Coronet (9), Courier (0), Courier-Bold (39),

Courier-Italic (40), Courier-BoldItalic (41), Garamond

Antiqua (22), Garamond Halbfett (23), Garamond Kursiv

(24), Garamond Kursiv Halbfett (25), Letter Gothic (42),

Letter Gothic-Bold (43), Letter Gothic-Italic (44), Line

Printer (45)Note, Marigold (26), Symbol (37), Times New

(33), Times New-Bold (34), Times New-Italic (35), Times

New-BoldItalic (36), Univers Medium (11), Univers Bold

(12), Univers Italic (13), Univers BoldItalic (14), Univers

Medium Condensed (15), Univers Bold Condensed (16),

Univers Medium Condensed Italic (17), Univers Bold

Condensed Italic (18), Wingdings (38)

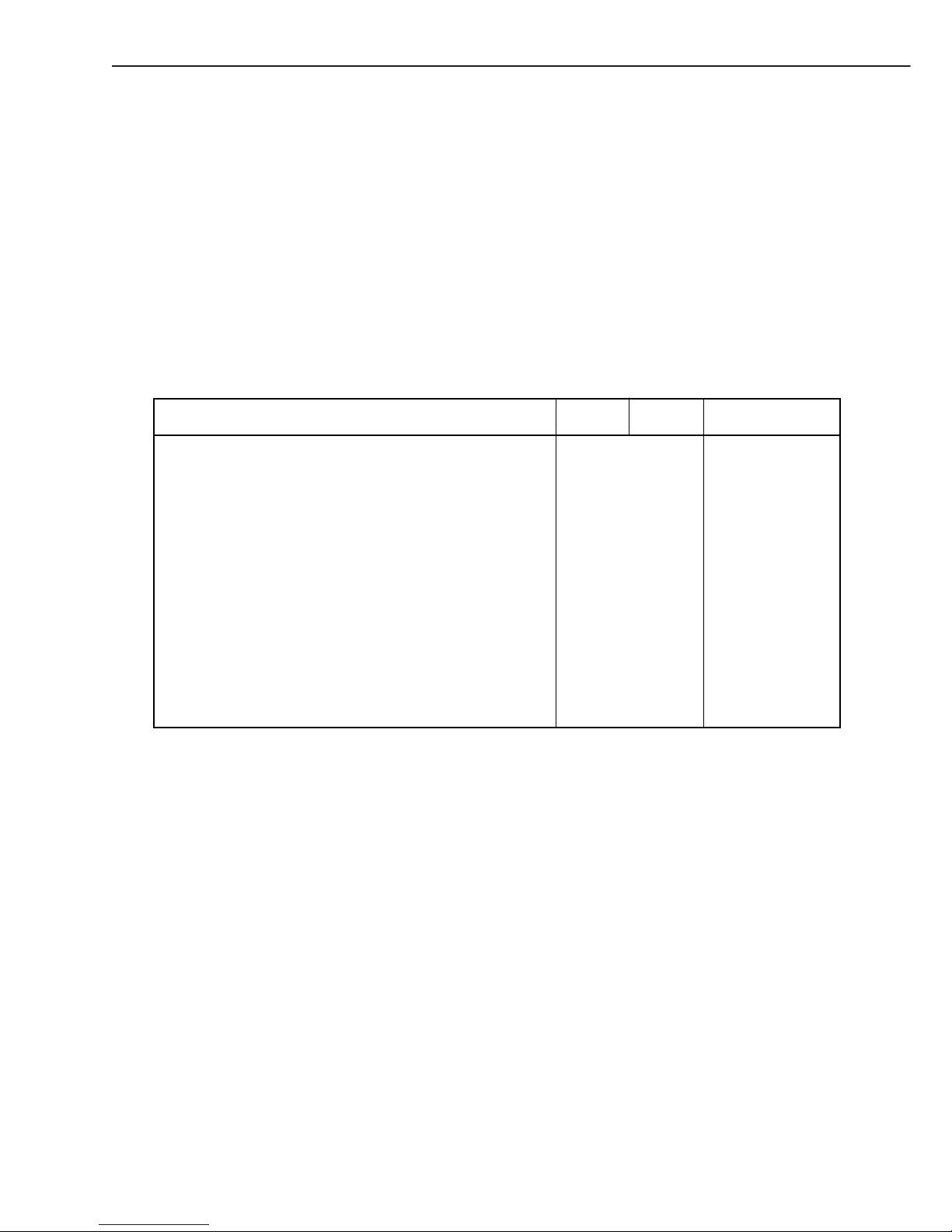

Scalable

Pitch

(CPI)

Size

(Points)

Remarks

It is possible to

print both portrait

and landscape orientations.

Type face

PostScript fonts: 136 (117 Adobe Type 1 fonts, 19 Truetype fonts)

1 - 6

CHAPTER 1

Type face

• Adobe Type 1 PostScript fonts

AlbertusMT, AlbertusMT-Italic, AlbertusMT -Light,

AntiqueOlive-Roman, AntiqueOlive-Bold, AntiqueOliveCompact, AntiqueOlive-Italic, AvantGarde-Book,

AvantGarde-BookOblique, AvantGarde-Demi, AvantGardeDemiOblique, Bodoni, Bodoni-Bold, Bodoni-Italic, BodoniBoldItalic, Bodoni-Poster, Bodoni-PosterCompressed,

Bookman-Demi, Bookman-DemiItalic, Bookman-Light,

Bookman-LightItalic, Carta, Clarendon, Clarendon-Bold,

Clarendon-Light, CooperBlack, CooperBlack-Italic,

Copperplate-ThirtyThreeBC, Copperplate-ThirtyTwoBC,

Coronet, Courier, Courier-Bold, Courier-Oblique, CourierBoldOblique, Eurostile, Eurostile-Bold, EurostileExtendedTow, Eurostile-BoldExtendedTow, GillSans,

GillSans-Bold, GillSans-Italic, GillSans-BoldItalic, GillSansCondensed, GillSans-BoldCondensed, GillSans-Light,

GillSans-LightItalic, GillSans-ExtraBold, Goudy, GoudyBold, Goudy-Italic, Goudy-BoldItalic, Goudy-ExtraBold,

Helvetica, Helvetica-Bold, Helvetica-BoldOblique, HelveticaCondensed, Helvetica-Condensed-Bold, HelveticaCondensed-BoldObl, Helvetica-Condensed-Oblique,

Helvetica-Narrow, Helvetica-Narrow-Bold, Helvetica-NarrowBoldOblique, Helvetica-Narrow-Oblique, Helvetica-Oblique,

JoannaMT, JoannaMT-Bold, JoannaMT -Italic, JoannaMTBoldItalic, LetterGothic, LetterGothic-Bold, LetterGothicBoldSlanted, LetterGothic-Slanted, LubalinGraph-Book,

LubalinGraph-BookOblique, LubalinGraph-Demi,

LubalinGraph-DemiOblique, Marigold, MonaLisa-Recut,

NewCenturySchlbk-Roman, NewCenturySchlbk-Bold,

NewCenturySchlbk-Italic, NewCenturySchlbk-BoldItalic,

Optima, Optima-Bold, Optima-Italic, Optima-BoldItalic,

Oxford, Palatino-Roman, Palatino-Bold,

Palatino-Italic, Palatino-BoldItalic, StempelGaramondRoman, StempelGaramond-Bold, StempelGaramond-Italic,

StempelGaramond-BoldItalic, Symbol, Tekton, TimesRoman, Times-Bold, Times-Italic, Times-BoldItalic, Univers,

Univers-Bold, Univers-BoldExt, Univers-BoldExtObl,

Univers-BoldOblique, Univers-Condensed, UniversCondensedBold, Univers-CondensedBoldOblique, UniversCondensedOblique, Univers-Extended, UniversExtendedObl, Univers-Lighit, Univers-LighitOblique,

Univers-Oblique, ZapfChancery-MediumItalic,

ZapfDingbats.

• TrueType fonts

Apple-Chancery, ArialMT, Arial-BoldMT, Arial-ItalicMT,

Arial-BoldItalicMT, Chicago, Geneva, HoeflerText-Regular,

HoeflerText-Black, HoeflerText-Italic, HoeflerTextBlackItalic, HoeflerText-Ornaments, Monaco, NewYork,

TimesNweRomanPSMT, TimesNweRomanPS-BoldMT,

TimesNweRomanPS-ItalicMT, TimesNweRomanPSBoldItalicMT, Wingdings-Regular.

Scalable

Pitch

(CPI)

Size

(Points)

Remarks

It is possible to

print both portrait

and landscape orientations.

C. Options

1. Duplexing unit

1) Pick-up speed About 4 images (2 sheets) /min.(A4, full color)

About 10 images (5 sheets) /min.(A4, mono-color)

2) Paper types Letter, Legal, Executive, A4, B5 size plain paper (60-105 g/m

2

Canon recommended paper)

3) Dimensions 500 (width) x 708 (depth) x 218 (height) mm

4) Weight About 13.0 kg

5) Power supply 100-127 V (50/60 Hz)

220-240 V (50/60 Hz)

(Voltage tolerance ±10% or less)

DC5V (supplied from the printer)

2. Paper feeder

1) Pick-up speed About 4 pages/min.(A4, full color)

About 16 pages/min (A4, mono-color)

2) Paper types Letter, Legal, Executive, A4, B5, A5 size plain paper (60-105 g/m

2

Canon recommended paper)

3) Dimensions 500 (width) x 559 (depth) x 125 (height) mm

4) Weight About 10.0 kg

5) Power supply DC24V (supplied from the printer)

DC5V (supplied from the printer)

Specifications are subject to change with product improvement.

1 - 7

CHAPTER 1

III. SAFETY INFORMATION

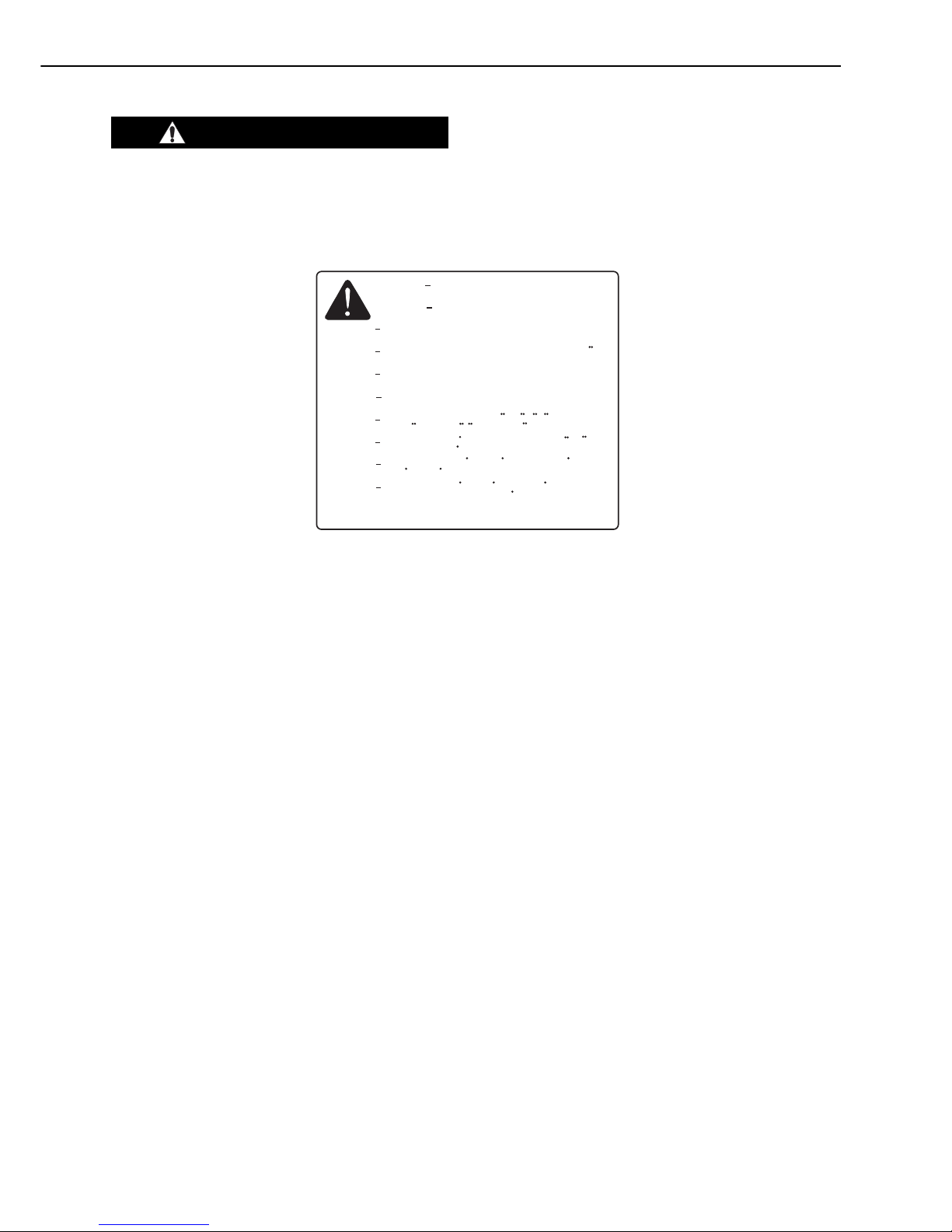

A. Laser Safety

The laser/scanner unit emits invisible laser beam. DO NOT disassemble the unit as the laser

beam, can possibly damage your eyes. The unit cannot be adjusted in the field. The following

label is attached to the cover of the unit:

Fig. 1-3-1

B. Toner Safety

Toner is a harmless substance composed of plastics and a pigment.

If you get toner on your skin or clothes, remove as much as possible with dry tissue and then

wash it with cold water.

If you wash in hot water, the toner gels and becomes hard to remove.

As toner easily decomposes vinyl material, do not let it come into contact with this material.

C. Ozone Safety

An infinitesimal amount of ozone gas (O3) is generated during corona discharge from the charging roller used in this printer. The ozone gas is emitted only when the printer is operating.

The printer meets the ozone emission standard decided by the Underwriters Laboratory (UL)

when it is shipped from the factory.

D. Power Supply Safety

Note that even if the power switch is turned OFF, the current still flows to the primary side of

the power supply unit of the printer.

Unplug the power cable before disassembling and reassembling the printer.

1 - 8

CHAPTER 1

ATTENTION

VORSICHT

ATTENZIONE

PRECAUCION

VARO!

VARNING!

ADVARSEL!

ADVARSE

L

UNSICHTBARE LASERSTRAHLUNG. WENN ABDECKUNG GEOFFNET.

NICHT DEM STRAHL AUSSETZEN.

RAYONNEMENT LASER INVISIBLE EN CAS D'O UVERTURE.

EXPOSITION DANGEREUSE AU FAISCEAU.

INVISIBLE LASER RADIATION WHEN OPEN.

AVOID EXPOSURE TO BEAM.

Invisible laser radiation when open.

AVOID DIRECT EXPOSURE TO BEAM.

RADIAZIONE LASER INVISIOILE IN CASO DI APERTURA.

EVITARE L'ESPOSIZIONE AL FASCIO.

RADIACION LASER INVISIBLE CUANDO SE ABRE.

EVITAR EXPONERSE AL RAYO.

AVATTAESSA OLET ALTTIINA NAKYMATTOMALLE

LASERSATEILYLLE. ALA KATSO SATEESEEN.

OSYNLIG LASERSTRALNING NAR DENNA DEL AR OPPNAD.

BETRAKTA EJ STRALEN.

USYNLIG LASER STRALING. NAR DENNE ER ABEN.

UNDGA BESTRALING.

USYNLIG LASERSTRALING NAR DEKSEL APNES.

UNNGA EKSPONERING FOR

STRALEN.

DANGER

CAUTION

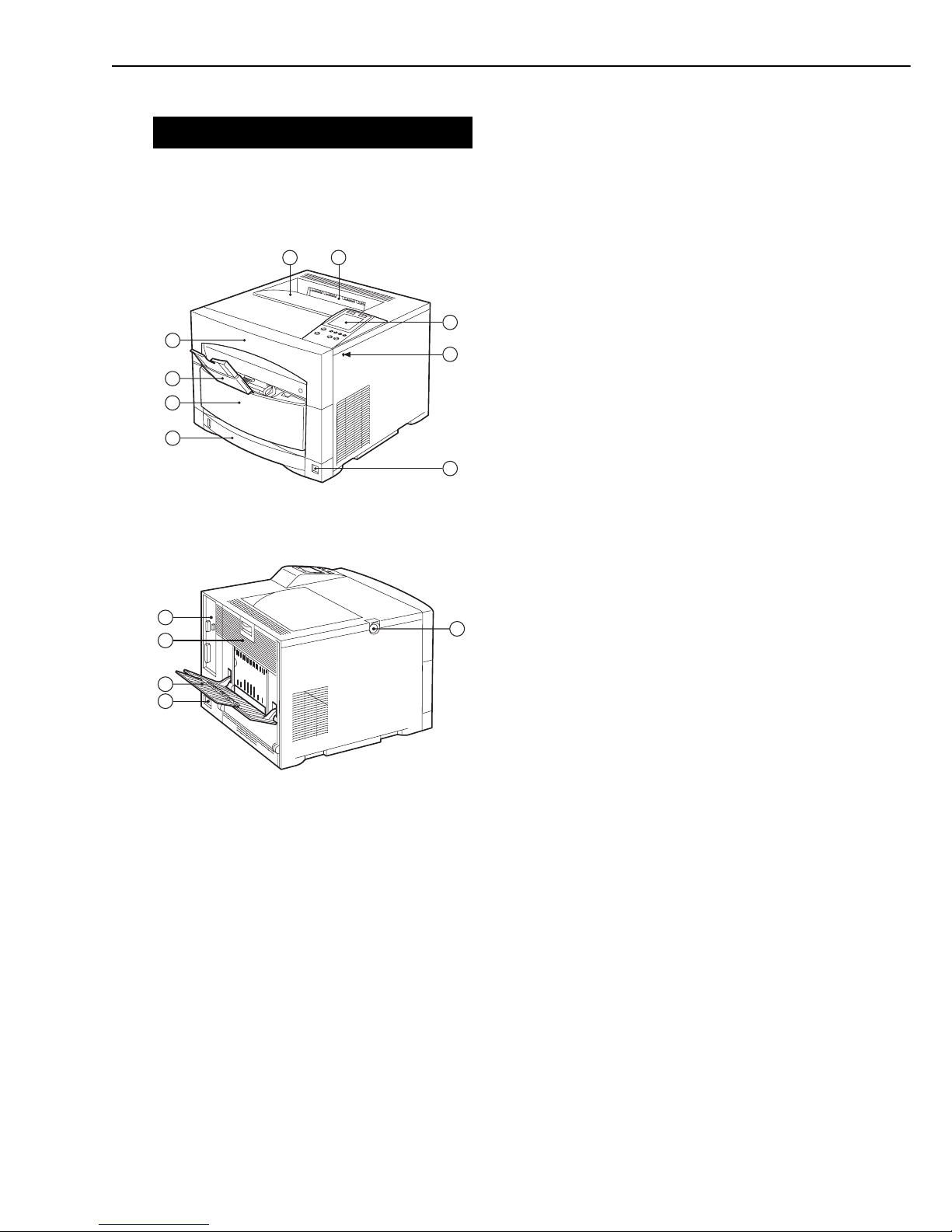

IV. PARTS OF THE PRINTER

A. External View

1. External view of the printer

Fig. 1-4-1

Fig. 1-4-2

1: Top cover

2: Face-down delivery slot

3: Control panel

4: Test print switch

5: Power switch

6: Universal cassette

7: ITB unit drawer

8: Multi-purpose tray

9: Drum cartridge drawer

10: Top cover unlock button

11: Power receptacle

12: Face-up tray

13: Rear cover

14: Video controller unit

1 - 9

CHAPTER 1

14

13

11

12

10

1

4

2

3

5

6

7

8

9

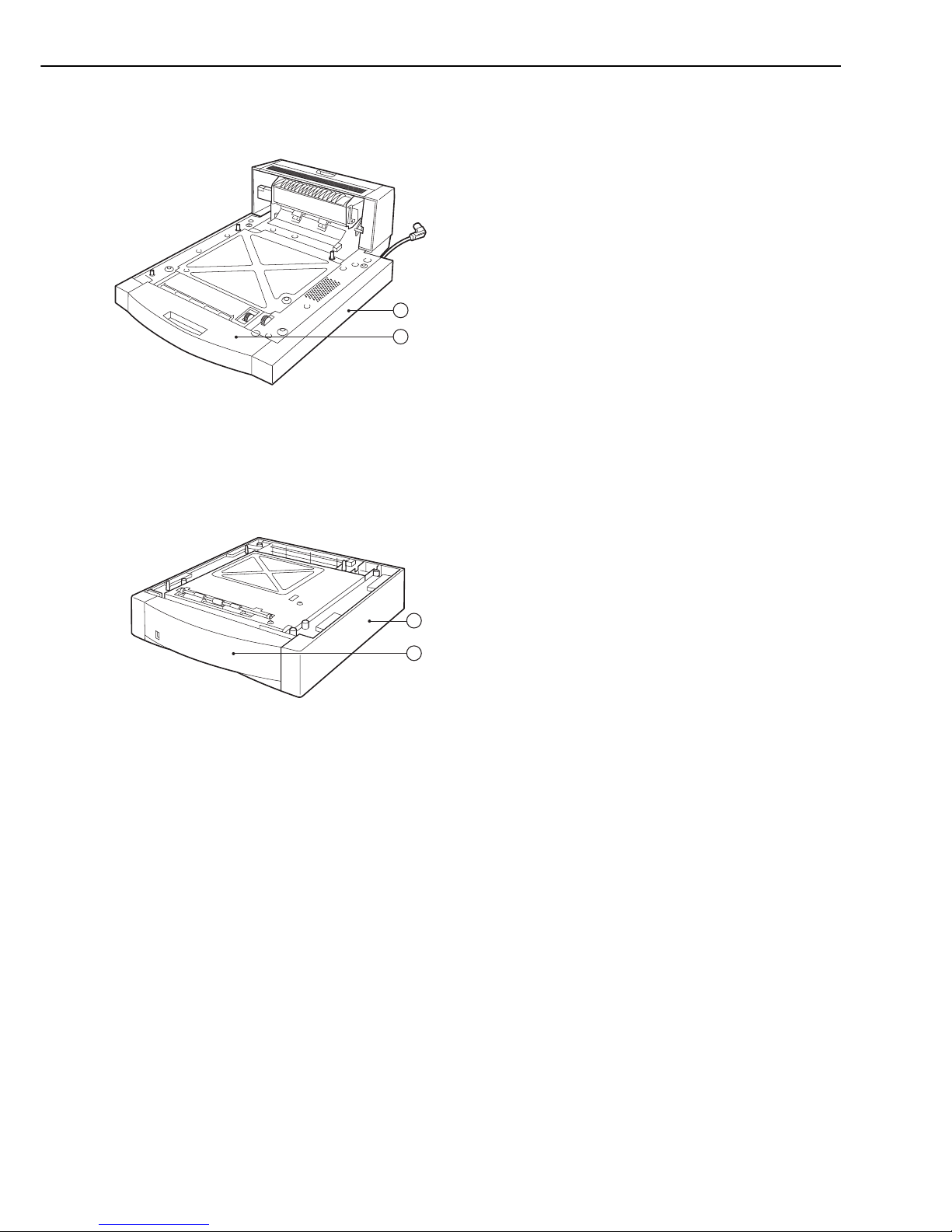

2. External view of the duplexing unit

Fig. 1-4-3

3. External view of the paper feeder

Fig. 1-4-4

15: Duplexing unit

16: Duplex feed unit

17: Paper feeder

18: Paper cassette

1 - 10

CHAPTER 1

15

16

18

17

B. Cross Sectional View

1. Cross sectional view of the printer

Fig. 1-4-5

1 - 11

CHAPTER 1

3 5

1

2

4

6

8

9

11

10

12

13

14

15

16

1819

21

22

23

24

7

17

20

1: Photosensitive drum

2: Primary charging roller

3: Density sensor

4: Laser/scanner unit

5: Drum cartridge

6: Primary transfer roller

7: ITB unit

8: Multi-purpose tray

9: Multi-purpose tray paper pick-up roller

10: Registration roller

11: Feed roller

12: Cassette feed roller

13: Cassette paper pick-up roller

14: Secondary transfer roller

15: ITB cleaning roller

16: Cassette

17: Feed belt unit

18: Upper fixing roller

19: Lower fixing roller

20: Fixing delivery roller

21: Face-up deflector

22: Developing rotary

23: Toner cartridge

24: Face-down delivery roller

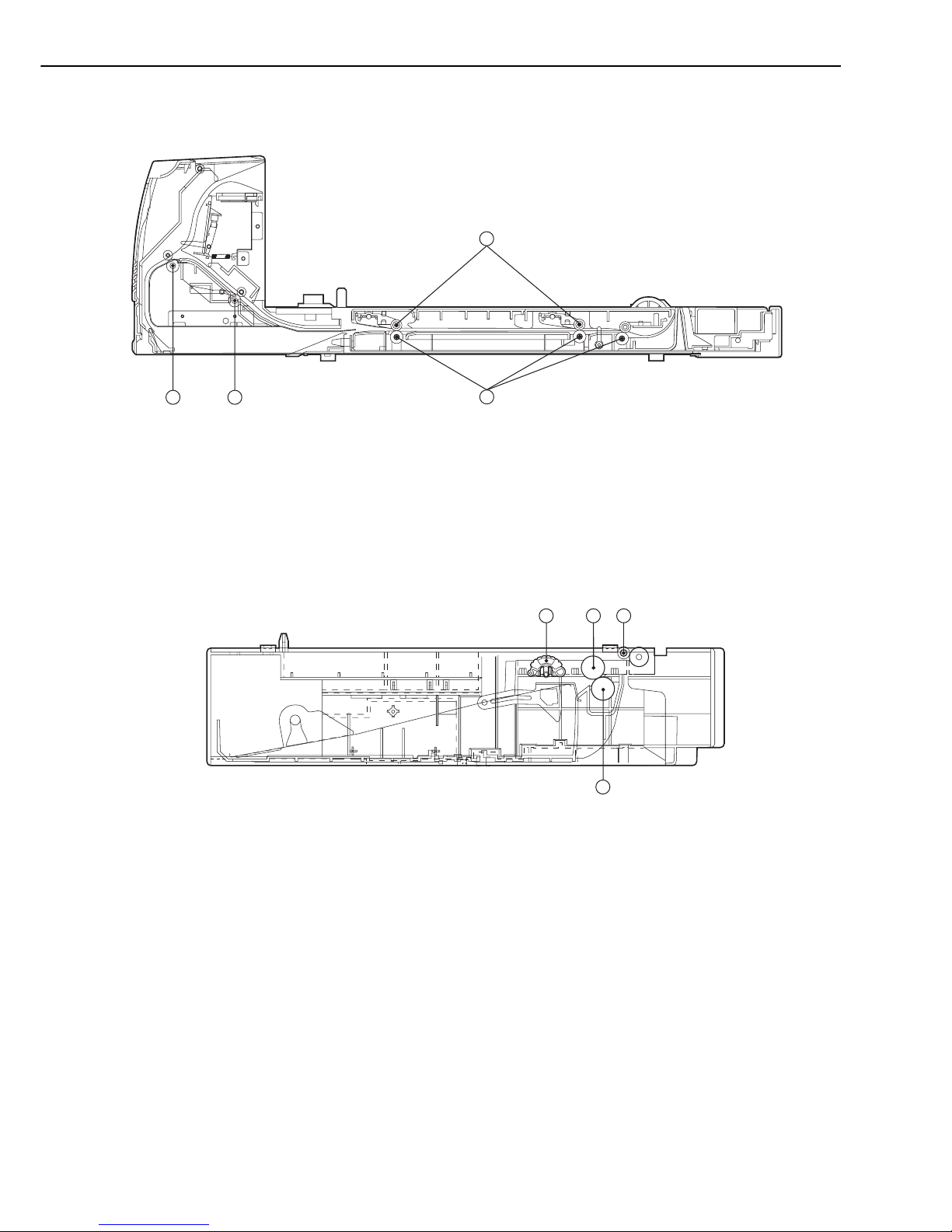

2. Cross sectional view of the duplexing unit

Fig. 1-4-6

3. Cross sectional view of the paper feeder

Fig. 1-4-7

1 - 12

CHAPTER 1

1: Pick-up roller

2: Feed roller 1

3: Feed roller 2

4: Separation roller

1

2

2

3

1 2

3

4

1: Pressure roller

2: Duplex feed roller

3: Reversing roller

V. INSTALLATION

A. Notes

This printer was carefully adjusted and strictly inspected before being packed.

To ensure that it performs as intended, it is very important to install the printer correctly.

The service engineer should have a complete knowledge of the printer, choose a good location,

install the printer according to the proper procedure, and check it out before it is used.

B. Choosing a Location

The following requirements must be met when installing the printer.

The service engineer should inspect the customer’s premises before installing the printer.

1. Power supply

The power supply should meet the following requirements:

• Line voltage (AC): Within ±10% of rated voltage

• Line frequency: Rated frequency

• Grounding: Grounding that meets the safety standard.

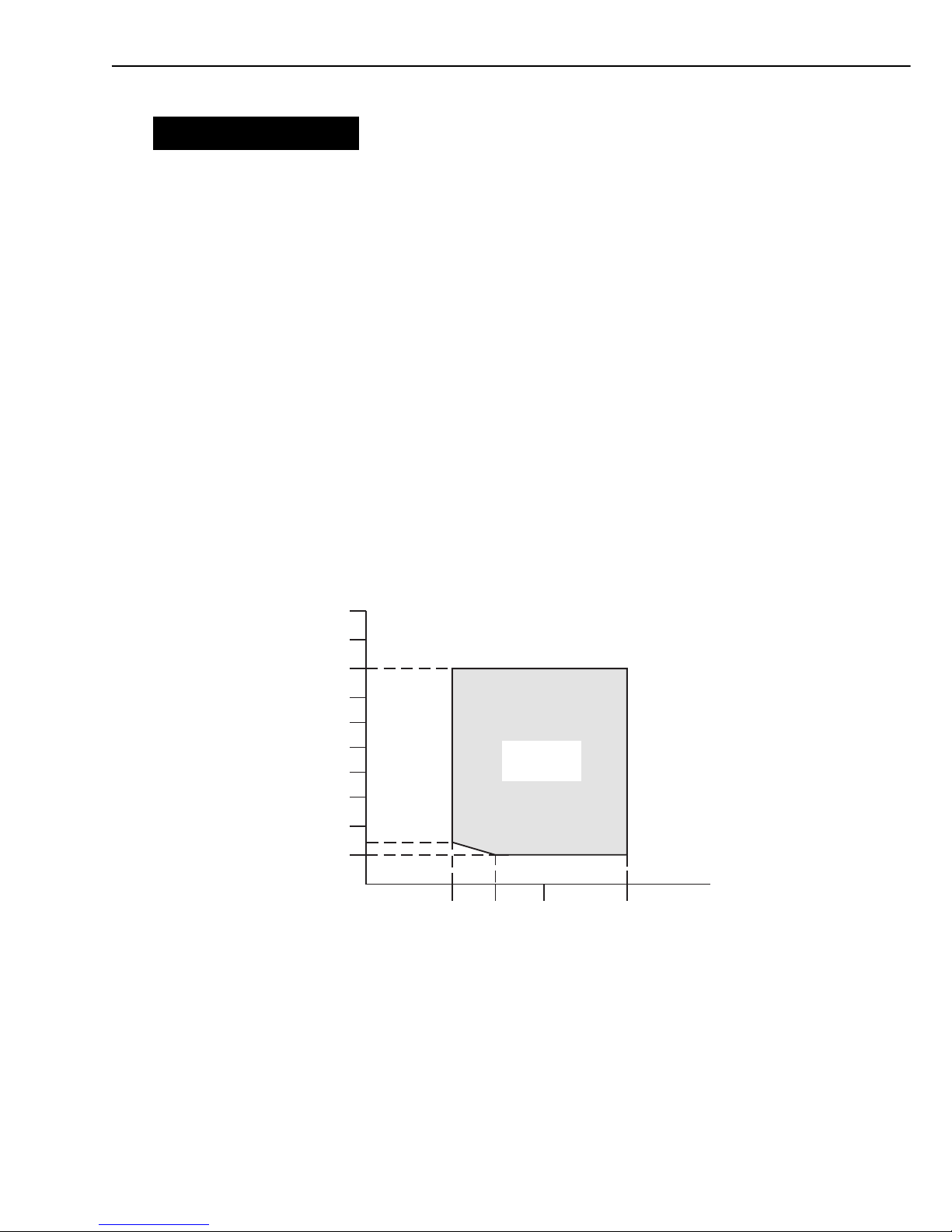

2. Operating conditions

The location should meet the following requirements.

• The printer should be placed on a flat and level surface.

• The temperature and humidity should be within the range shown below.

• The location should be well ventilated.

Fig. 1-5-1

1 - 13

CHAPTER 1

0

30

100

20

40

60

80

0

2010

10

15

14

Humidity (%RH)

Temperature

(˚C)

Operating

environment

Do not install the printer in these places:

• Areas exposed to direct sunlight

If unavoidable, hang heavy curtains to shut out the direct sunlight.

• Areas exposed to the direct wind from the air-conditioning duct.

• Near magnets or equipment that produces a magnetic field

• Areas with vibration

• Dusty areas

• Near flames or water

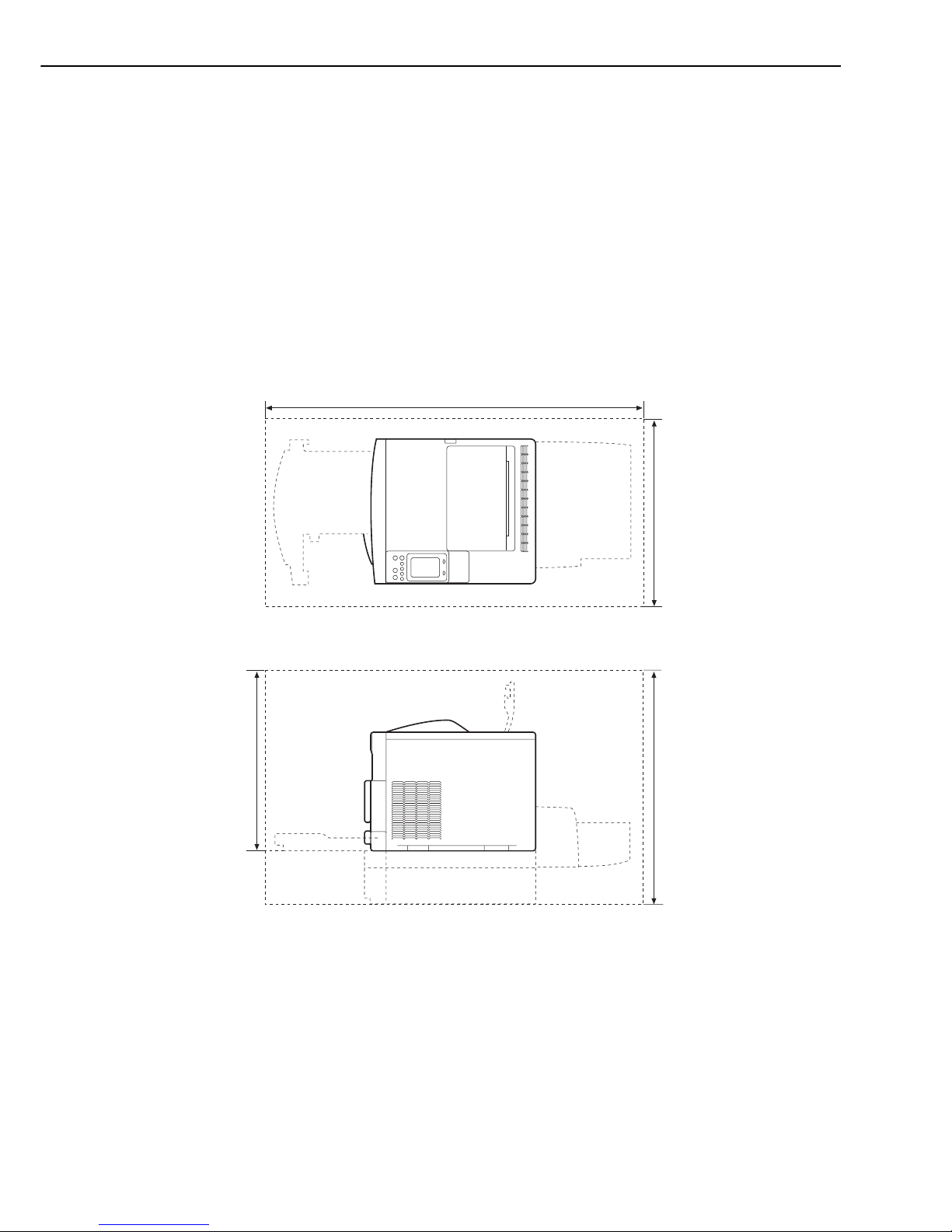

3. Installation space

There must be enough space around the printer to operate it. (See Figure 1-5-2.)

If the printer is to be placed on a desk, be sure that the desk is large enough to accommodate

its feet (rubber pads) and sturdy enough to carry its weight (about 48 kg).

Fig. 1-5-2

1 - 14

CHAPTER 1

820mm

700mm

1560mm

Cassette

Paper feeder

(Option)

538mm

Duplexing unit

(Option)

Duplexing unit

(Option)

C. Unpacking and Installation

If the boxed printer is brought into a warm place from a cold place, condensation will form on

the printer surfaces. This will cause various problems, such as print defects. To stop this happening, leave the printer in its box to acclimatize it to room temperature before unpacking it.

This will take at least an hour.

1. Unpacking

1) Open the packaging.

2) Take out the accessories. Confirm that the power cord (100 to 127V), toner cartridges (total:

4), and drum cartridge are included.

Confirm that the universal cassette and ITB unit are installed in the printer.

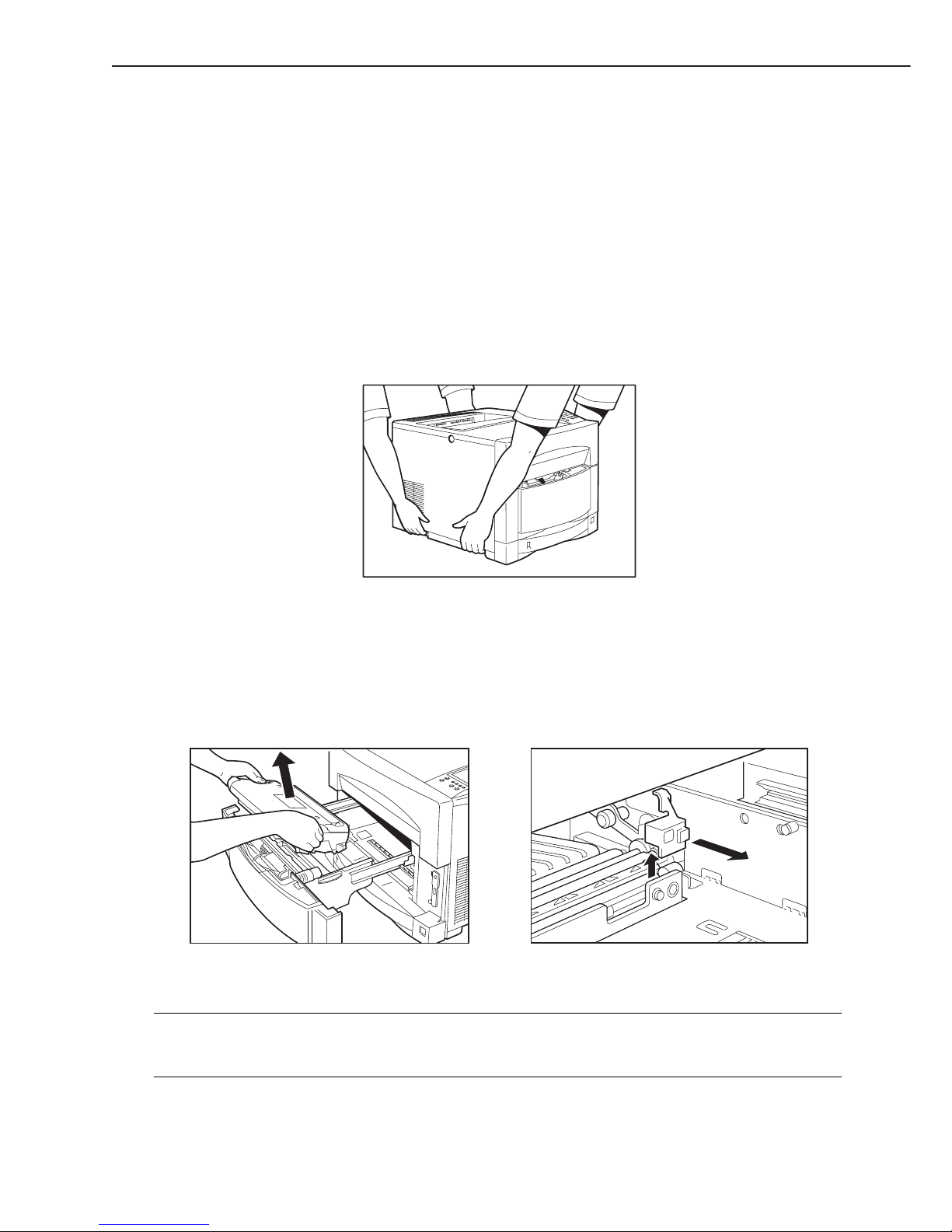

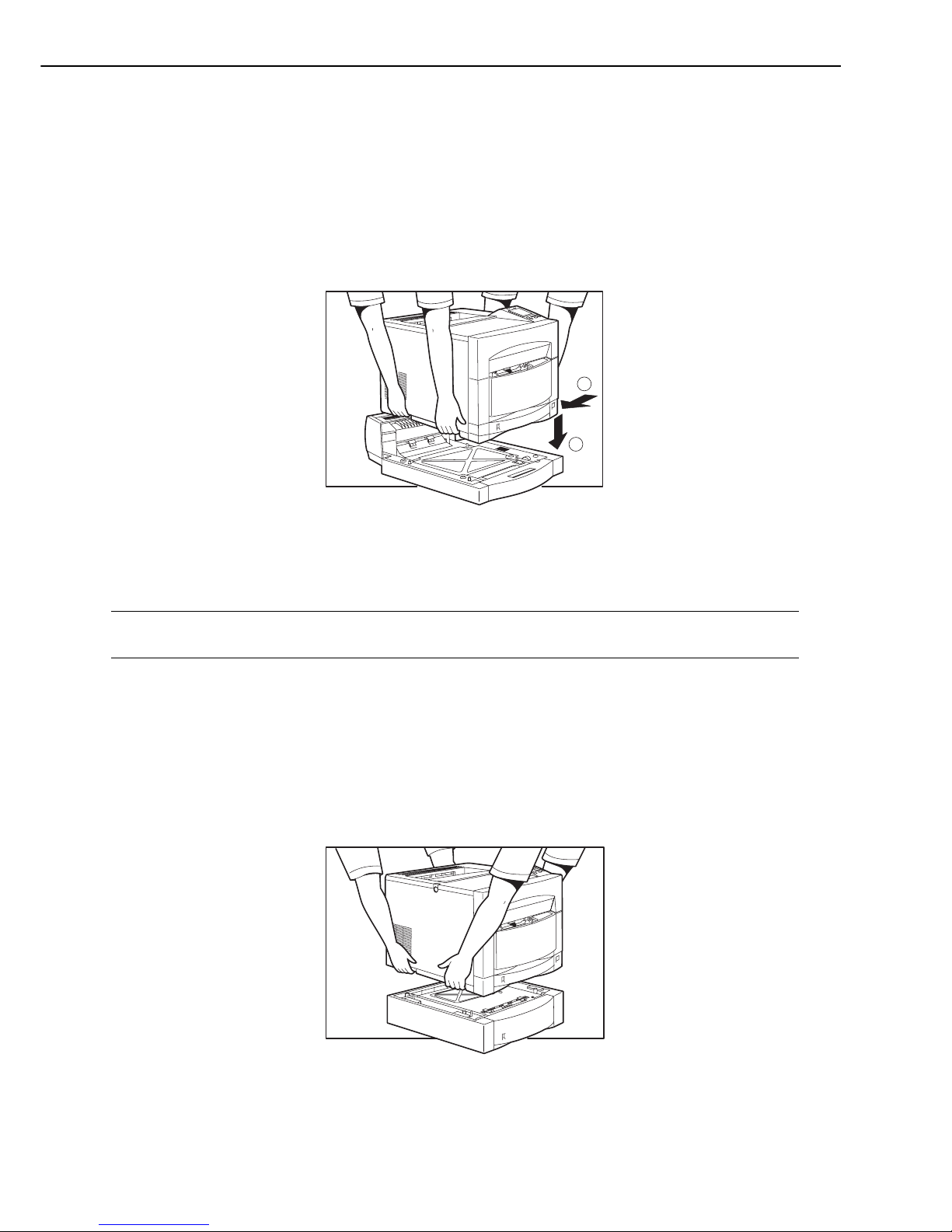

3) Have two persons lift and carry the printer to the installation site. Two persons are required

to move the printer because it weighs about 48 kg.

Fig. 1-5-3

4) Remove the plastic bag from the printer and peel the tape off it. Confirm that the covers

were not damaged or deformed during transport.

5) Remove the universal cassette from the printer and remove the packing material.

6) Open the ITB unit drawer and remove the tape and packing material.

7) Take out the ITB unit and remove the packing material of the secondary transfer roller.

Fig. 1-5-4

Note: When connecting the printer to the computer, make sure to turn them OFF and unplug

the power cord from the power outlet before connecting (disconnecting) the interface in

order to prevent accidents and damages.

1 - 15

CHAPTER 1

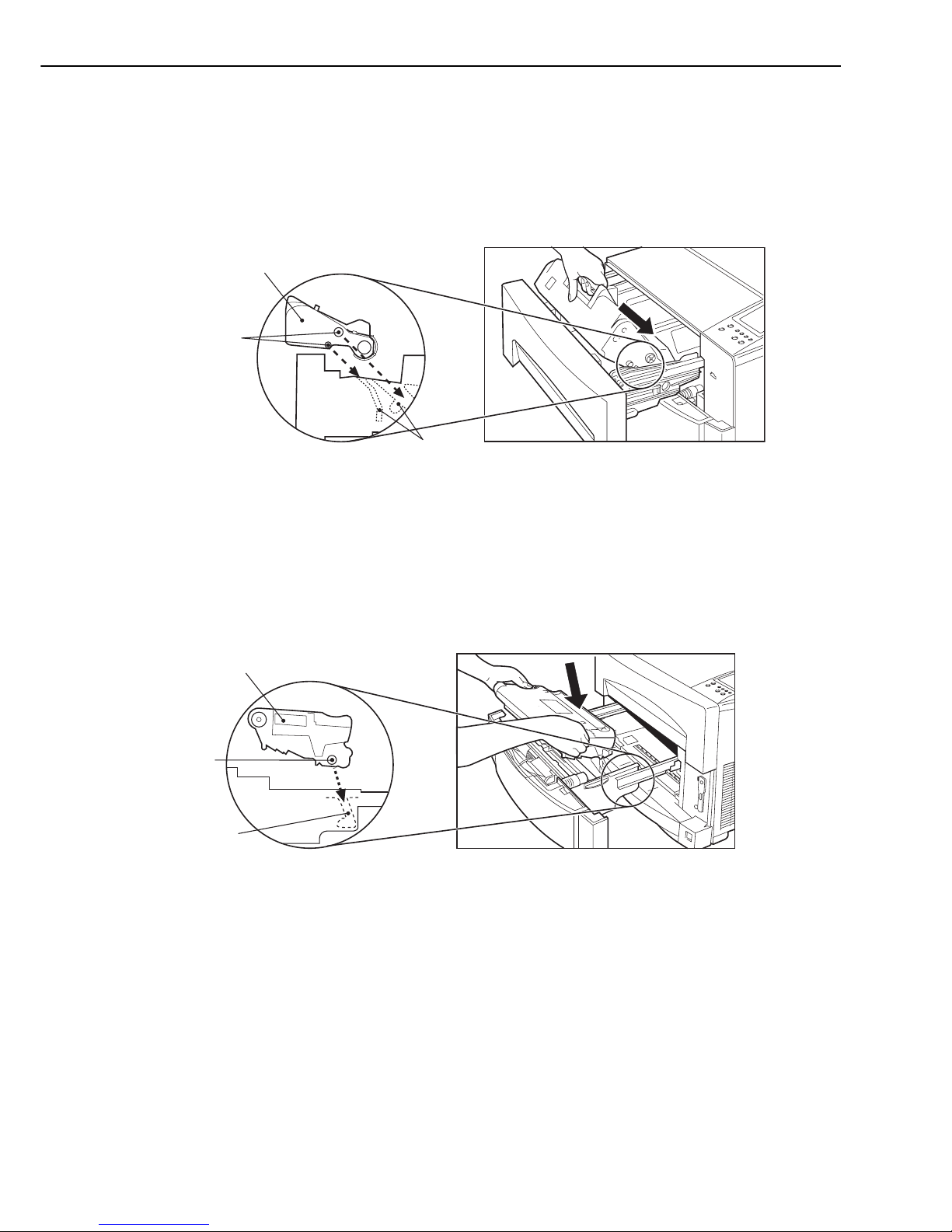

2. Unpacking and installing the drum cartridge

1) Open the drum cartridge drawer.

2) Remove the drum cartridge out of its protection bag.

3) Remove the protective tape from the drum cartridge.

4) Insert the drum cartridge into the printer. Be careful not to damage the photosensitive

drum.

Fig. 1-5-5

5) Close the drum cartridge drawer.

3. Unpacking and installing the ITB unit

1) Open the ITB unit drawer.

2) Insert the ITB unit.

Fig. 1-5-6

3) Close the ITB unit drawer.

4. Unpacking and installing the toner cartridge

This printer can execute the toner cartridge replacement function according to the instruction

from the video controller.

This function detects whether the toner cartridges are installed or not and rotates the developing rotary so that the compartment of the missing toner cartridge comes to the installation slot.

Detection and installation of toner cartridges are conducted in order of Bk, M, C and Y.

1 - 16

CHAPTER 1

Boss

Guide

Drum cartridge

ITB unit

Boss

Guide

Note: Refer to “B. Removal of toner cartridge with manual operation” on page 3-2 when replac-

ing the toner cartridge without using the toner cartridge replacement function.

1) Insert one end of the power cord into the printer and the other end into the outlet. Be sure

to use the supplied power cord.

2) Install the drum cartridge and ITB unit, then turn the printer ON.

Note: The toner cartridge replacement function does not become effective unless the printer is

turned on with the drum cartridge and the ITB unit in it. Install the drum cartridge and

the ITB unit in the printer, then turn it ON.

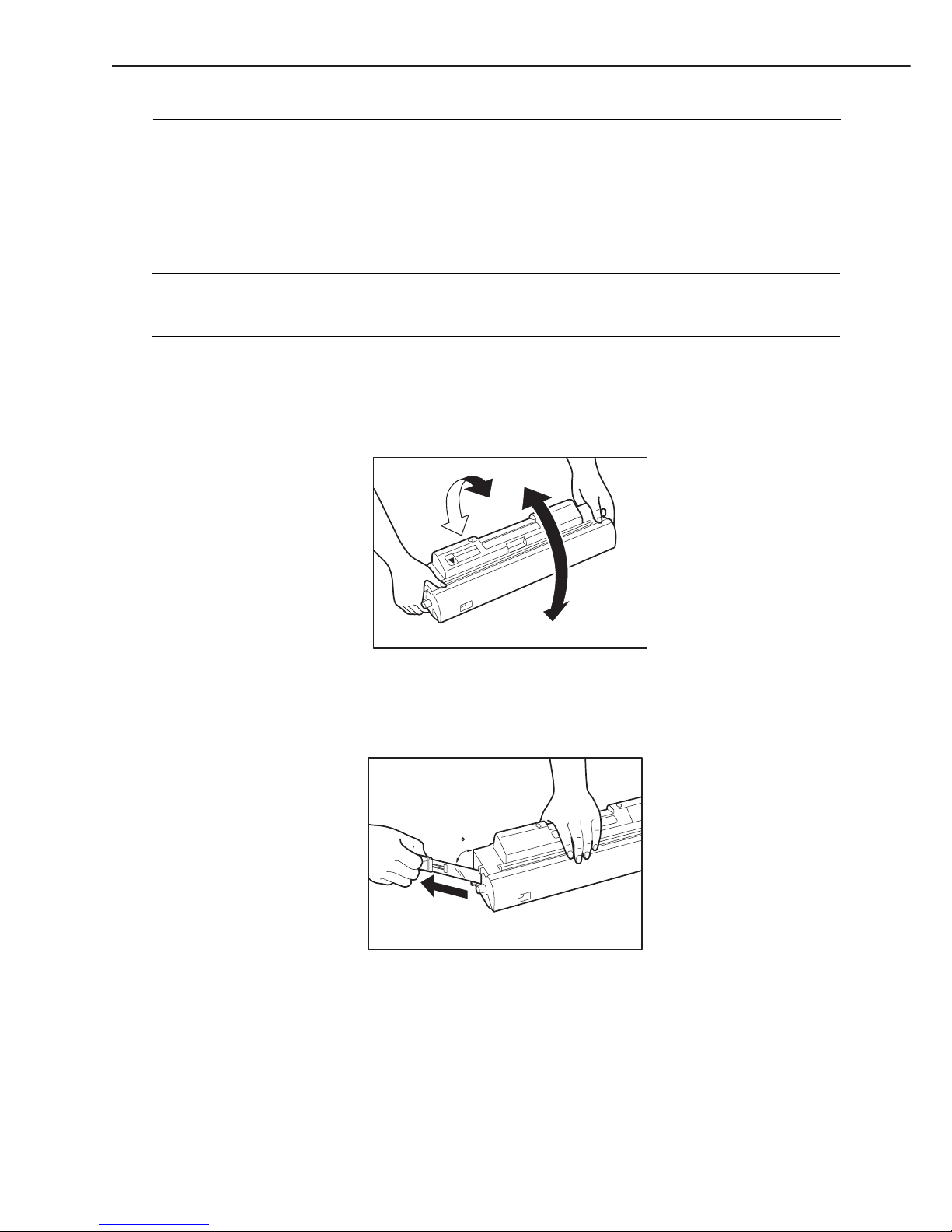

3) Remove the toner cartridge out of its protection bag.

4) Hold the cartridge as shown in Fig. 1-5-7 and slowly rock it up and down five or six times to

distribute toner evenly.

Fig. 1-5-7

5) Place the cartridge on a level surface. Hold down the top of the cartridge with one hand and

pull out the tab with the other hand to remove the sealing tape. (See Fig. 1-5-8)

Fig. 1-5-8

1 - 17

CHAPTER 1

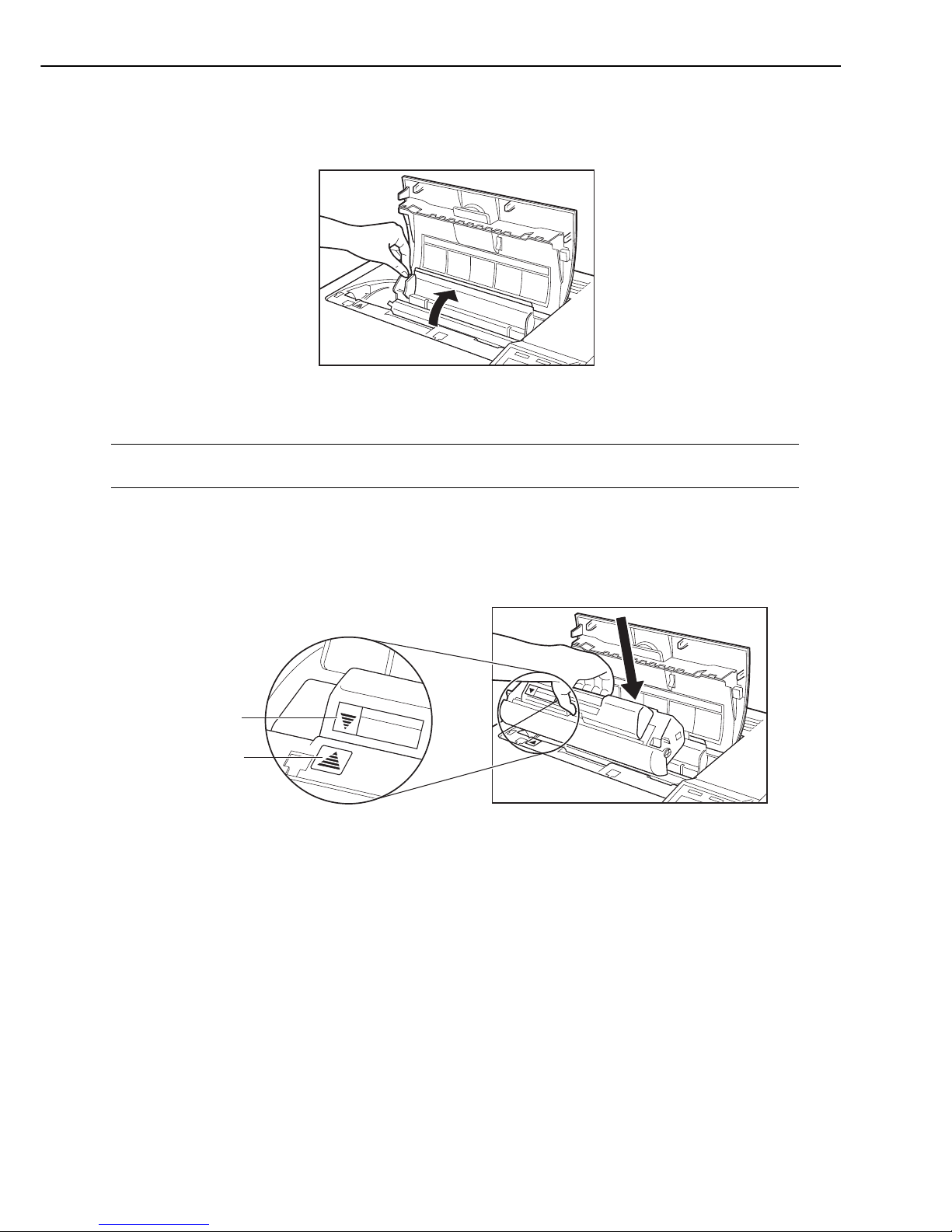

45

6) Push the top cover unlock button and open the top cover.

7) Open the toner cartridge compartment cover.

Fig. 1-5-9

Note: At this point, the compartment of the black toner cartridge is stopped at the installation

slot by the toner cartridge replacement function.

8) Check the marker and choose the toner cartridge with the same color as the marker. (Install

the black toner cartridge first.)

9) Verify that the printer position mark is aligned with the arrow mark on the toner cartridge

and install the cartridge in the printer.

Fig. 1-5-10

1 - 18

CHAPTER 1

Arrow mark

Position mark

TonerCartridge

10) Turn the toner cartridge in the direction of the arrow until it stops.

Fig. 1-5-11

11) Close the toner cartridge compartment cover, then close the top cover.

12) When the top cover is closed, the rotary starts to rotate and stops at the next toner cartridge (Magenta) installation position automatically.

You can also rotate the rotary to the next toner cartridge installation position by pressing the

ROTATE key on the control panel. (Note)

13) Repeat steps 3 to 12 to install the other toner cartridges in the printer.

Note: The ROTATE key is used to removed toner cartridges. However, it is not effective when

the printer is not READY.

1 - 19

CHAPTER 1

5. Unpacking and installing the duplexing unit

1) Unpack the duplexing unit and remove the carton.

2) Take out the accessories.

3) Remove the plastic bag covering the duplexing unit and remove adhesive tapes.

4) Remove the packing materials from the duplexing unit.

5) Place the duplexing unit on a flat surface.

6) Install the printer on the duplexing unit, aligning the duplexing unit positioning dowels with

the printer positioning holes.

Fig. 1-5-12

7) Plug the pig tail of the duplexing unit into the outlet of the printer.

Note: If the printer is ON, turn it OFF and unplug the power cable before installing the duplex-

ing unit.

6. Unpacking and installing the paper feeder

1) Unpack the paper feeder and remove the carton.

2) Remove the tape holding the cassette from the paper feeder.

3) Remove the cassette from the paper feeder. Remove the packing materials.

4) Place the paper feeder on a flat surface.

5) Install the printer on the paper feeder, aligning the paper feeder positioning dowels with the

printer positioning holes.

Fig. 1-5-13

1 - 20

CHAPTER 1

1

2

Loading...

Loading...