Canon Booklet Trimmer-A1 Service Manual

BOOKLET

TRIMMER-A1

REVISION 0

FEB. 2002

COPYRIGHT

©

2002 CANON INC. 2000 CANON BOOKLET TRIMMER-A1 REV.0 FEB. 2002 PRINTED IN U.S.A. (IMPRIME AU U.S.A.)

FY8-13HG-000

Application

This manual has been issued by Canon Inc. for qualified persons to learn technical

theory, installation, maintenance, and repair of products. This manual covers all

localities where the products are sold. For this reason, there may be information in this

manual that does not apply to your locality.

Corrections

This manual may contain technical inaccuracies or typographical errors due to

improvements or changes in products. When changes occur in applicable products or in

the contents of this manual, Canon will release technical information as the need arises.

In the event of major changes in the contents of this manual over a long or short period,

Canon will issue a new edition of this manual.

The following paragraph does not apply to any countries where such provisions are

inconsistent with local law.

Trademarks

The product names and company names used in this manual are the registered

trademarks of the individual companies.

Copyright

This manual is copyrighted with all rights reserved. Under the copyright laws, this

manual may not be copied, reproduced or translated into another language, in whole or

in part, without the written consent of Canon Inc.

COPYRIGHT © 2002 CANON INC.

Printed in U.S.A.

Imprimé au U.S.A.

Caution

Use of this manual should be strictly supervised to avoid disclosure of confidential information.

COPYRIGHT© 2002 CANON INC. 2000 CANON BOOKLET TRIMMER-A1 REV.0 FEB. 2002

INTRODUCTION

1 Symbols Used

This documentation uses the following symbols to indicate special information:

Symbol Description

Indicates an item of a non-specific nature, possibly classified as Note, Caution,

or Warning.

Indicates an item requiring care to avoid electric shocks.

Indicates an item requiring care to avoid combustion (fire).

Indicates an item prohibiting disassembly to avoid electric shocks or problems.

Indicates an item requiring disconnection of the power plug from the electric

outlet.

Indicates an item intended to provide notes assisting the understanding of the

Memo

topic in question.

Indicates an item of reference assisting the understanding of the topic in ques-

REF.

tion.

Provides a description of a service mode.

Provides a description of the nature of an error indication.

Refers to the Copier Basics Series for a better understanding of the contents.

COPYRIGHT© 2002 CANON INC. 2000 CANON BOOKLET TRIMMER-A1 REV.0 FEB. 2002

i

INTRODUCTION

2 Outline of the Manual

This Service Manual provides basic facts and figures about the BOOKLET TRIMMERA1 needed to service the machine in the field, ensuring product quality and machine functions.

This Service Manual consists of the following chapters:

Chapter 1 General Description: features, specifications, parts names, op-

eration mode, machine operation, basic

construction

Chapter 2 Basic Operations: basic operation, mechanism control

Chapter 3 Mechanical Systems: disassembly/assembly, adjustment

Chapter 4 Maintenance and Inspection: periodically replaced parts, periodically

cleaned parts, periodically inspected parts

Chapter 5 Troubleshooting: PCBs software upgrading, error code, jam

code

Chapter 6 Appendix: general circuit diagram, timing chart

User Mode

Service Mode

This Service manual does not contain instructions on the installation of the machine. For

installation, refer to the Installation Procedure that comes with the machine.

ii

COPYRIGHT© 2002 CANON INC. 2000 CANON BOOKLET TRIMMER-A1 REV.0 FEB. 2002

INTRODUCTION

The following rules apply throughout this Service Manual:

1. Each chapter contains sections explaining the purpose of specific functions and the

relationship between electrical and mechanical systems with reference to the timing

of operation.

In the diagrams,

accompanies the symbol

represents the path of mechanical drive; where a signal name

, the arrow indicates the direction of the electric signal.

The expression “turn on the power” means flipping on the power switch, closing the

front door, and closing the delivery unit door, which results in supplying the machine

with power.

2. In the digital circuits, ‘1’ is used to indicate that the voltage level of a given signal is

“High,” while ‘0’ is used to indicate “Low.” (The voltage value, however, differs from

circuit to circuit.) In addition, the asterisk (*) as in “DRMD*” indicates that the

DRMD signal goes on when ‘0’.

In practically all cases, the internal mechanisms of a microprocessor cannot be

checked in the field. Therefore, the operations of the microprocessors used in the machines are not discussed: they are explained in terms of from sensors to the input of

the DC controller PCB and from the output of the DC controller PCB to the loads.

The descriptions in this Service Manual are subject to change without notice for

product improvement or other purposes, and major changes will be communicated in

the form of Service Information bulletins.

All service persons are expected to have a good understanding of the contents of this

Service Manual and all relevant Service Information bulletins and be able to identify

and isolate faults in the machine.

COPYRIGHT© 2002 CANON INC. 2000 CANON BOOKLET TRIMMER-A1 REV.0 FEB. 2002

iii

CONTENTS

Contents

CHAPTER 1 GENERAL DESCRIPTION

1 Features and Functions ....................... 1-1

2 Specifications ...................................... 1-2

3 Names of Parts .................................... 1-3

3.1 External View ............................. 1-3

3.2 Cross Section ............................. 1-5

4 Oparation Mode .................................. 1-6

4.1 Outline ....................................... 1-6

4.2 Particulars .................................. 1-6

4.3 Making Selections ..................... 1-6

4.4 Others ......................................... 1-6

5 Using the machine .............................. 1-7

5.1 Control Panel ............................. 1-7

CHAPTER 2 BASIC OPERATIONS

1 Basic Operation .................................. 2-1

1.1 Outline ....................................... 2-1

1.1.1 Feeding the Booklet............. 2-1

1.1.2 Feeding to the Cutting Position

(trim mode only) .................. 2-2

1.1.3 Booklet Press

(trim mode only) .................. 2-3

1.1.4 Cutting (trim mode only)..... 2-4

1.1.5 Releasing the Pressing/

Releasing the Stopper

(trim mode only) .................. 2-5

1.1.6 Paper exiting

(trim mode only) .................. 2-6

2 Controlling the Parts ........................... 2-8

2.1 Controlling the Feeding

Assembly ................................... 2-8

2.1.1 Construction ........................ 2-8

2.1.2 Mechanisms ......................... 2-9

2.1.3 Controlling the Feeding

Assembly ........................... 2-10

2.2 Controlling the Pressing

Assembly ................................. 2-13

2.2.1 Construction ...................... 2-13

2.2.2 Mechanisms ....................... 2-15

5.2 Removing a Jam ......................... 1-8

5.2.1 Correcting the Overstacking

Error ................................... 1-13

5.2.2 Collecting and Disposing of

Waste Paper ....................... 1-15

6 Basic Construction ............................ 1-16

6.1 Functional Construction .......... 1-16

6.2 Outline of the Electrical

Circuitry ................................... 1-17

6.3 Wiring Between Options.......... 1-18

6.4 Trimmer Power Supply ............ 1-19

2.2.3 Shifting and Releasing the

Stopper ............................... 2-15

2.2.4 Controlling the Pressing of

the Booklet ......................... 2-17

2.2.5 Controlling the Stopper/

Press ................................... 2-18

2.3 Controlling the Trimmer

Assembly ................................. 2-21

2.3.1 Construction ...................... 2-21

2.3.2 Mechanisms ....................... 2-23

2.3.3 Controlling the Trimming

Operation ........................... 2-23

2.3.4 Removing

the Waste Paper .................. 2-24

2.3.5 Controlling the Trimmer .... 2-24

2.3.6 Removing

the Waste Paper .................. 2-26

2.4 Stacker Assembly ..................... 2-28

2.4.1 Construction ...................... 2-28

2.4.2 Mechanisms ....................... 2-29

2.4.3 Delivery ............................. 2-30

2.4.4 Upright Stacking................ 2-32

2.4.5 Controlling the Delivery/

Stacking Operation ............ 2-34

iv

COPYRIGHT© 2002 CANON INC. 2000 CANON BOOKLET TRIMMER-A1 REV.0 FEB. 2002

CHAPTER 3 MECHANICAL SYSTEMS

0 Before Disassembling the Machine .... 3-1

0.1 Removing the Power Cord ......... 3-1

0.2 Checking the Operation After

Re-assembly ............................... 3-1

1 External Covers .................................. 3-2

1.1 Removing the Front Cover ........ 3-2

1.2 Removing the Upper Cover ....... 3-2

1.3 Removing the Rear Cover .......... 3-3

1.4 Removing the Right Front

Cover 2 ....................................... 3-4

2 Feeding Assembly + Cutter

Assembly ............................................ 3-5

2.1 Removing the Fan Motor Unit

(M108) ....................................... 3-5

2.2 Removing the Feeding Belt from

the Upper Feeding Assembly ..... 3-6

2.3 Removing the Feeding Belt from

the Lower Feeding Assembly .... 3-8

2.4 Removing the sensors at the Lower

Feeding Assembly: Waste Bin Full

Sensor (PS109), and Inlet Sensor

(PS101) .................................... 3-10

2.5 Removing the Cutter Blade

(upper, lower) ........................... 3-11

3 Control Panel .................................... 3-14

3.1 Removing the Trimmer ROM ... 3-14

3.2 Removing the Control Panel ..... 3-15

3.3 Removing the Trimmer DC

Controller PCB ........................ 3-16

4 Stacker Assembly.............................. 3-17

4.1 Removing the Stacker

Assembly ................................. 3-17

4.2 Removing the Pusher Motor and

the Pusher Sensor (PS112) ...... 3-19

4.3 Removing the Vertical Feeding

Roller Rubber ........................... 3-22

4.4 Removing the Stacker Cover Sensor

(PS114) and the Stacker Cover

Switch (MS3, MS4) ................. 3-23

5 Press Assembly ................................. 3-25

5.1 Removing the Upper Press

Assembly ................................. 3-25

5.2 Removing the Upper Press

Assembly Feeding Belt ............ 3-26

COPYRIGHT© 2002 CANON INC. 2000 CANON BOOKLET TRIMMER-A1 REV.0 FEB. 2002

5.3 Removing the Lower Press

Assembly ................................. 3-26

5.3.1 Parallelism Adjustment between

the Folding Face and the

Trimming Face................... 3-29

5.4 Removing the Stopper Motor

(M103) ..................................... 3-30

5.5 Removing the Stopper Release

Motor (M104) .......................... 3-30

5.6 Removing the Feed Sensor

(PS102), Stopper HP Sensor

(PS103), and Stopper Release

HP Sensor (SP104) .................. 3-31

5.7 Removing the Lower Press

Assembly Feeding Belt ............ 3-31

5.8 Removing the Press Motor

(M105) ..................................... 3-32

5.9 Removing the Cutter Motor

(M102) ..................................... 3-33

5.10 Removing the Cutter HP Sensor

(PS106) .................................... 3-35

6 Units at the Rear ............................... 3-36

6.1 Removing the Holder Motor

(M106) ..................................... 3-36

6.2 Removing the Holder Sensor

Unit (Holder upper limit sensor

PS110, Holder lower limit sensor

PS111) ...................................... 3-37

6.2.1 Holder Upper Limit

Sensor Adjustment ............. 3-38

6.2.2 Holder Lower Limit

Sensor Adjustment ............. 3-39

6.3 Removing the Feeding Motor

(M101) ..................................... 3-40

6.4 Removing the Waste Paper Bin

Sensor (PS107) ........................ 3-40

6.5 Removing the Trimmer Drive

PCB .......................................... 3-41

6.6 Removing the Power Supply

Circuit Unit .............................. 3-41

6.7 Removing the Current

Breaker ..................................... 3-42

6.8 Removing the Sensor (press

assembly bottom plate) ............ 3-43

CONTENTS

v

CONTENTS

CHAPTER 4 MAINTENANCE AND INSPECTION

1 Maintenance and Inspection ............... 4-1

1.1 Tools Needed ............................. 4-1

1.2 Periodically Replaced Parts ....... 4-1

1.3 Periodically Cleaned/Inspected

Parts............................................ 4-1

CHAPTER 5 TROUBLESHOOTING

1 Making Adjustments When Replacing

Mechanical/Electrical Parts ................ 5-1

1.1 Trimmer DC Controller PCB ..... 5-1

1.2 Trimmer Drive PCB ................... 5-1

1.3 Lower Press Assembly ............... 5-2

1.4 Holder Upper Limit Sensor and the

Holder Lower Limit Sensor ....... 5-2

1.5 Belt Tension of

the Holder Plate ......................... 5-2

2 Upgrading the Software ...................... 5-3

3 Error Code .......................................... 5-4

4 Jam Code .......................................... 5-12

APPENDIX

USER MODE

1 Construction of User Mode ................ U-1

1.1 Overview ................................... U-1

1.2 Starting User Mode and

Making Selections .................... U-3

1.2.1 Trimmer Control Panel ....... U-3

1.3 Ending User Mode .................... U-4

1.4 Basic Operation ......................... U-4

1.4.1 Trimmer Control Panel

(in user mode) ..................... U-4

1.5 Others ........................................ U-4

1.5.1 Backing Up the Data .......... U-4

2 Details of Items .................................. U-5

2.1 Trim Width Adjustment ............ U-5

2.1.1 Operating from the Host

Machine Control Panel

(operation mode in 'System';

see the descriptions of service

mode items) ........................ U-5

2.1.2 Operating from the Trimmer

Control Panel (operation mode

in 'Local'; see descriptions on

service mode items) ............ U-6

2.1.3 Adjusting the Trim Width ... U-7

2.2 Changing the Display

Language ................................... U-8

vi

COPYRIGHT© 2002 CANON INC. 2000 CANON BOOKLET TRIMMER-A1 REV.0 FEB. 2002

SERVICE MODE

1 Construction of Service Mode ............ S-1

1.1 Outline ....................................... S-1

1.2 Starting Service Mode and

Making Selections ..................... S-2

1.3 Ending Service Mode ................ S-2

1.4 Basic Operation .......................... S-3

1.4.1 Trimmer Control Panel

(in service mode) ................. S-3

1.5 Others .........................................S-3

CONTENTS

1.5.1 Backing Up Data ................. S-3

2 Details of Items ................................... S-4

2.1 Version Indication ......................S-4

2.2 Trim Counter .............................. S-5

2.3 Operation Mode ......................... S-6

2.4 Selecting Factory Setting for

Trim Width .................................S-7

2.5 Motor Test ................................ S-10

2.6 I/O Port Display .......................S-12

COPYRIGHT© 2002 CANON INC. 2000 CANON BOOKLET TRIMMER-A1 REV.0 FEB. 2002

vii

CHAPTER 1

GENERAL DESCRIPTION

COPYRIGHT© 2002 CANON INC. 2000 CANON BOOKLET TRIMMER-A1 REV.0 FEB. 2002

CHAPTER 1 GENERAL DESCRIPTION

1 Features and Functions

The trimmer is equipped with mechanisms to receive a booklet prepared by its host saddle

finisher, trim to smooth its edge, and deposit the result in a stack.

Edge being

trimmed

F01-100-01

COPYRIGHT© 2002 CANON INC. 2000 CANON BOOKLET TRIMMER-A1 REV.0 FEB. 2002

After trimming

1-1

CHAPTER 1 GENERAL DESCRIPTION

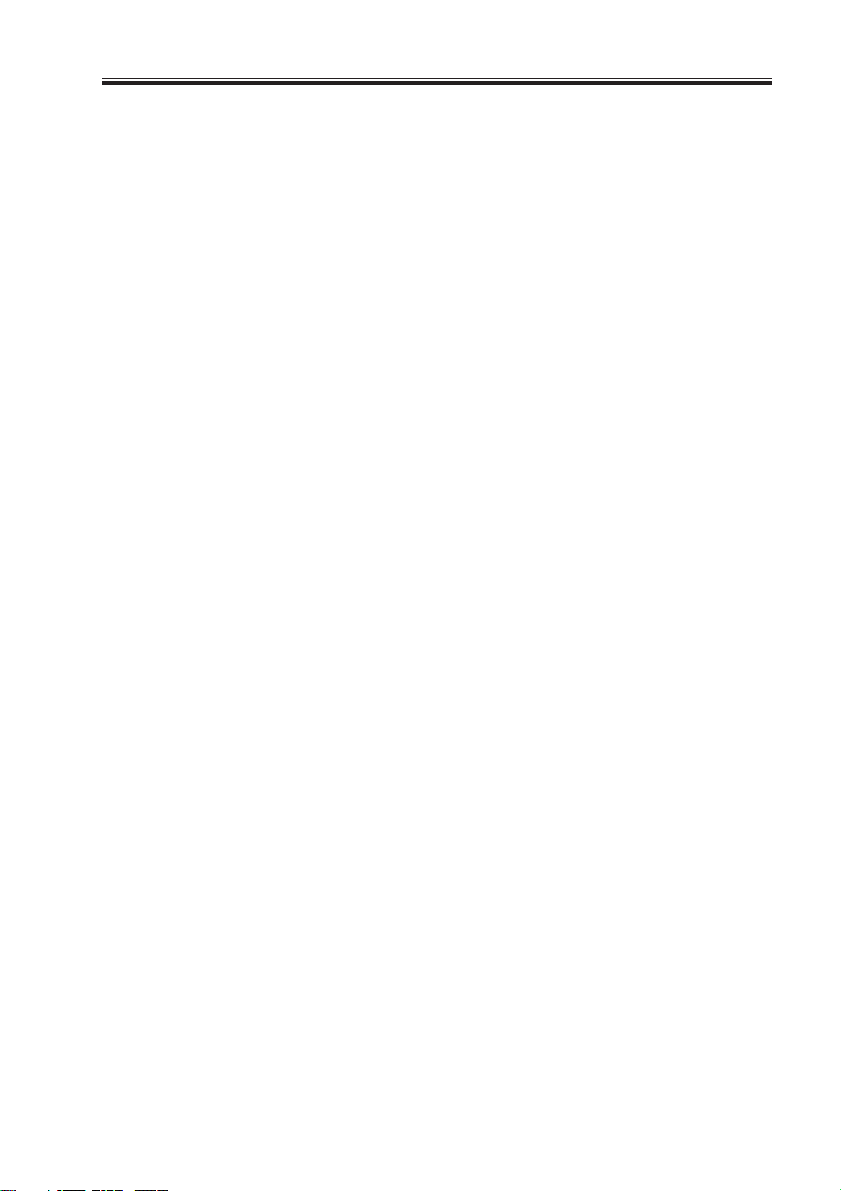

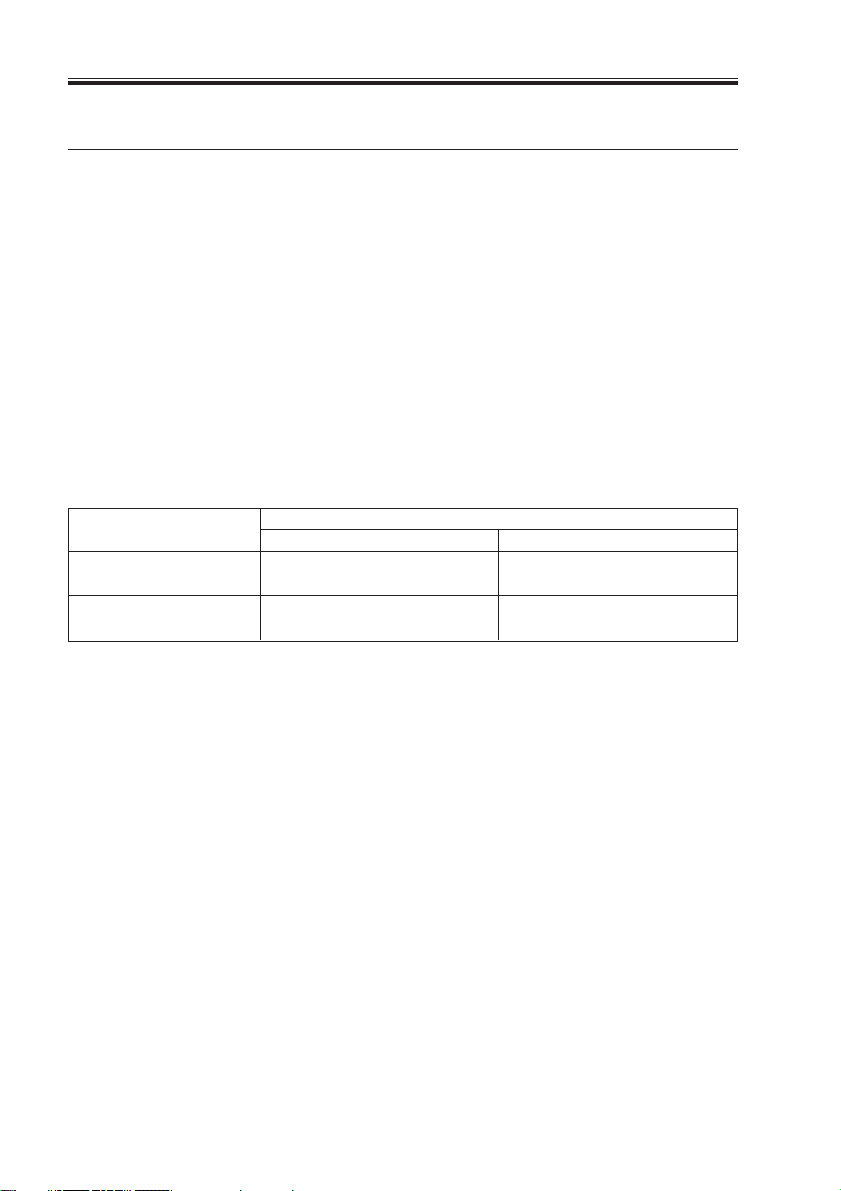

2 Specifications

Item Description Remarks

Type w/ stacking mechanism; reciprocating upper

blade; edge trimming device

Number of sheets 30 sheets

to trim (14 sheets of 80 g paper + cover of 200 g paper)

Stack size 200 mm (equivalent of 2,000 sheets of 80 g

paper; 5-fold 100 booklets; 10-fold 50 booklets)

Paper size A3/B4/A4R, Ledger/LetterR

Trimming time 3 sec (approx.)

Trimming 6.3 sec (approx.)

operation time

Minimum trimming 2 mm or more

thickness

Cutter life 500,000 operations or more

Waste paper case 500 sheets (approx.)

capacity

Allowable curling 10 mm max.

(measurement taken of a stack of

5 delivered sheets)

Curl

Sheets

Degree of parallel See the table below.

in relation to folded Degree of parallel = |A-B|

end

Cover

Absent

Present 2 to 15 1.5 mm or less

Operating Temperature: 10°C to 30°C Same as host device

environment Humidity: 10% to 80% RH Same as host device

Size 1321 × 562 × 629 1165 mm

(W × H × D) mm (width of external assembly)

Power supply 100 to 230 V; 50, 60 Hz

Maximum power 300 W (approx.)

consumption

Weight 68 kg (approx.)

Number of Degree of

sheets bound parallel

2 to 5 1.0 mm or less

6 or 15 1.5 mm or less

Fold

A

B

T01-200-01

1-2

COPYRIGHT© 2002 CANON INC. 2000 CANON BOOKLET TRIMMER-A1 REV.0 FEB. 2002

Trimmed

edge

3 Names of Parts

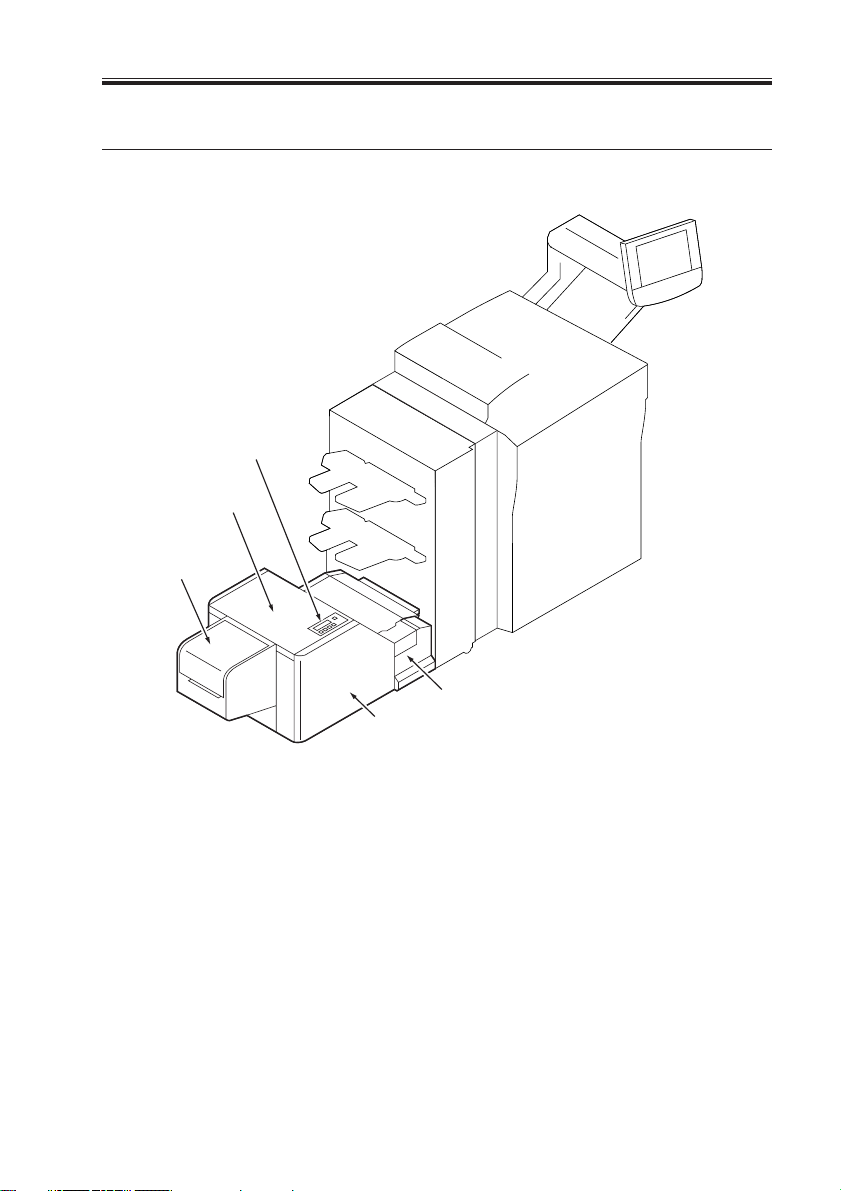

3.1 External View

[1]

[2]

[3]

CHAPTER 1 GENERAL DESCRIPTION

[5]

[4]

[1] Control panel

[2] Trimmer

[3] Stacker cover

F01-301-01

COPYRIGHT© 2002 CANON INC. 2000 CANON BOOKLET TRIMMER-A1 REV.0 FEB. 2002

[4] Front cover

[5] Rigth front cover

1-3

CHAPTER 1 GENERAL DESCRIPTION

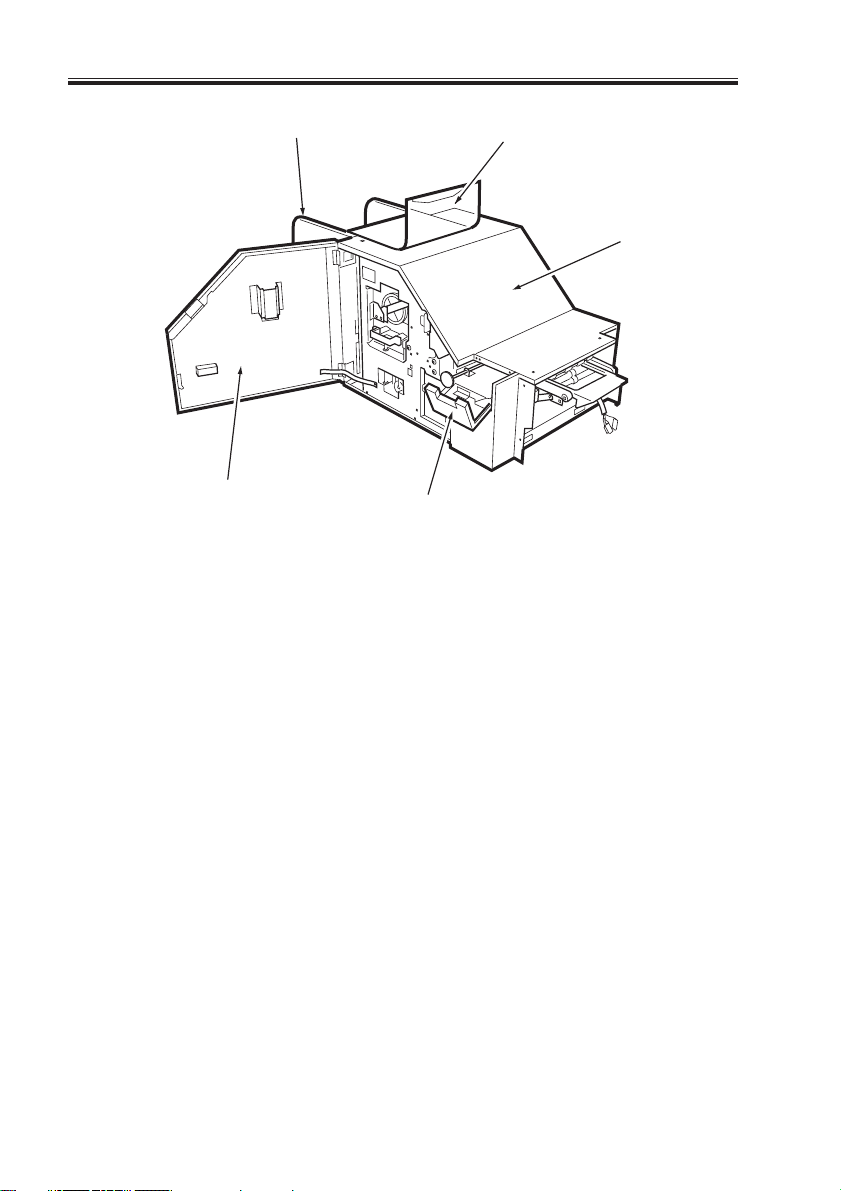

[1] Stacker cover

[2] Stacker unit

[3] Front cover

[3]

[2]

[1]

[5]

[4]

[4] Right front cover

[5] Top plate

F01-301-02

1-4

COPYRIGHT© 2002 CANON INC. 2000 CANON BOOKLET TRIMMER-A1 REV.0 FEB. 2002

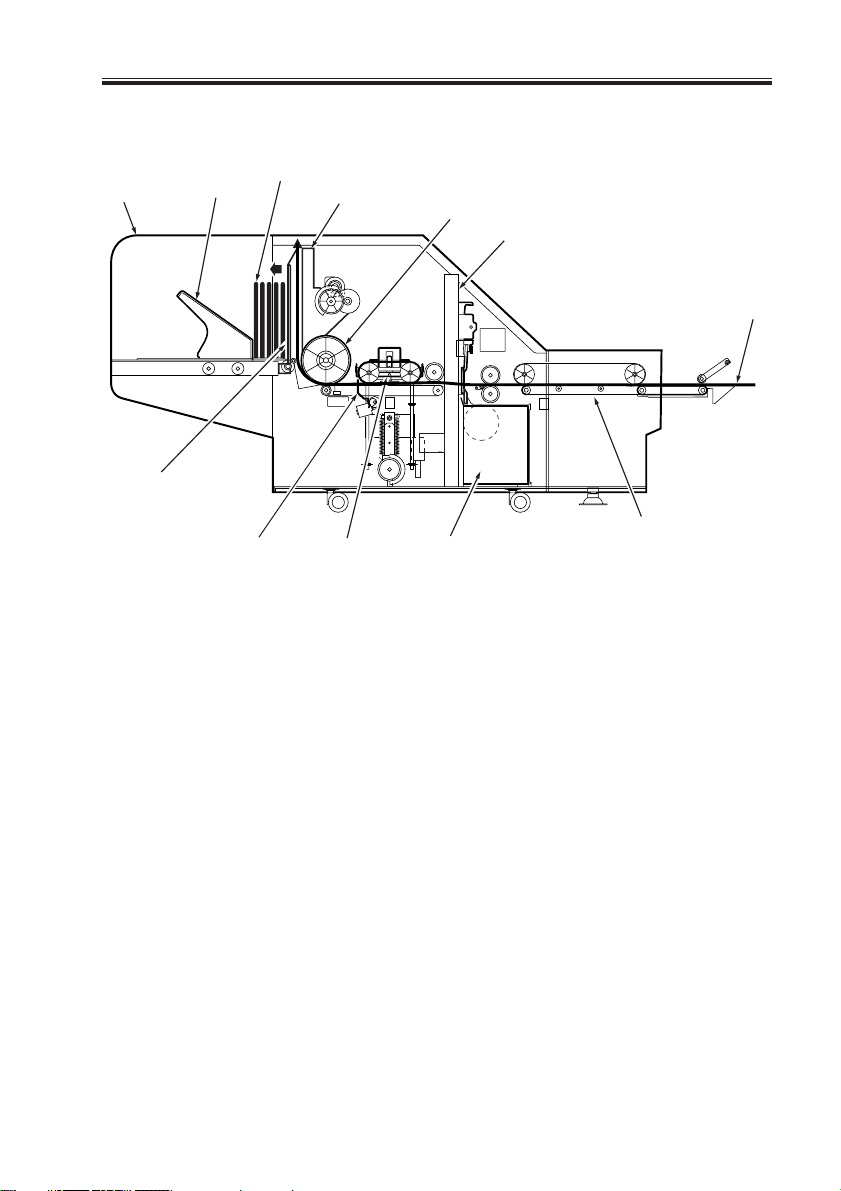

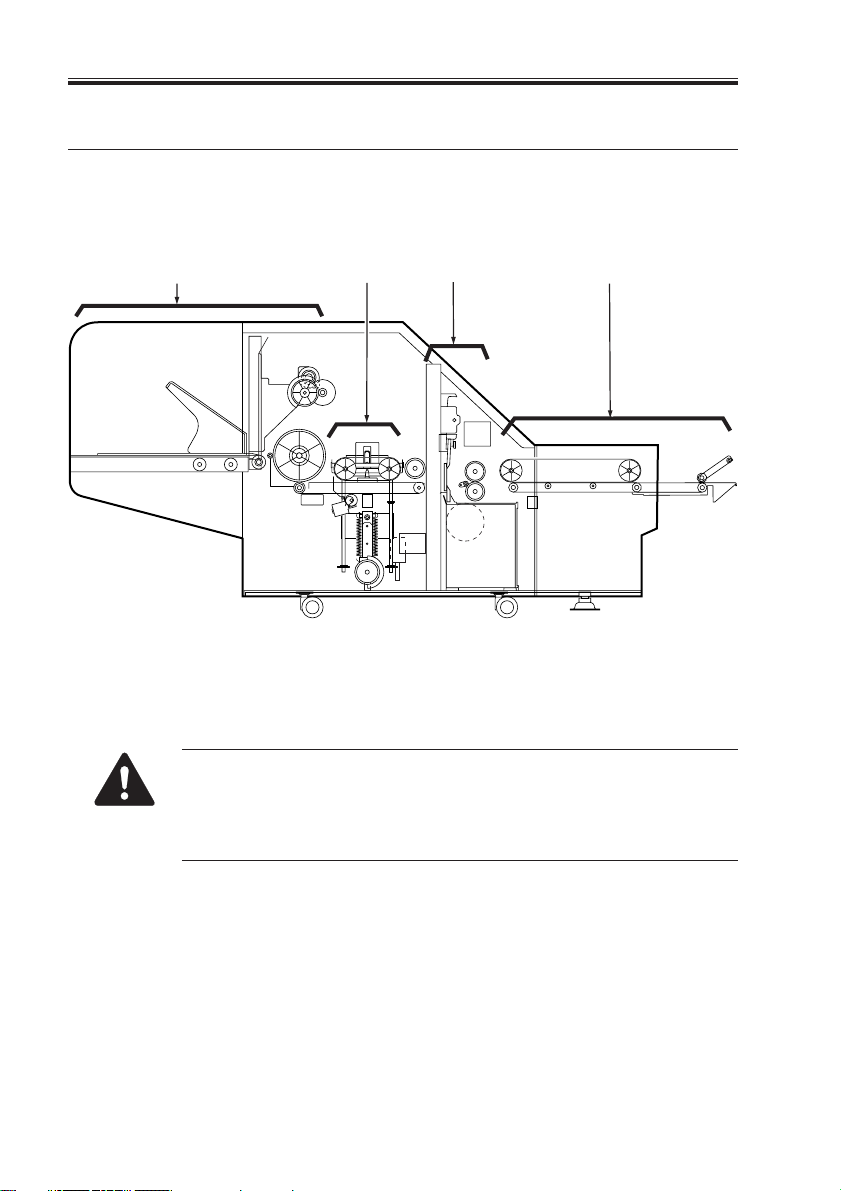

3.2 Cross Section

CHAPTER 1 GENERAL DESCRIPTION

[6]

[5]

[7]

[4]

[8] [9] [10]

[1] Cutter unit

[2] Vertical feeding roller

[3] Pusher unit

[4] Delivered booklets

[5] Delivery tray

[6] Stacker

[3]

[2]

[1]

[12]

[11]

[7] Holder assembly

[8] Stopper assembly

[9] Pressing assembly

[10] Waste paper box

[11] Entrance feeding assembly

[12] Paper path

F01-302-01

COPYRIGHT© 2002 CANON INC. 2000 CANON BOOKLET TRIMMER-A1 REV.0 FEB. 2002

1-5

CHAPTER 1 GENERAL DESCRIPTION

4 Oparation Mode

4.1 Outline

The machine offers 2 operation modes listed below:

Operation Modes

"SYSTEM" mode (Default): Use it to enable/disable trimming, and to adjust the trim-

ming width (These settings are done in the host copier's

control panel).

"LOCAL mode": Use it to enable/disable trimming, and to adjust trimming

width (Theae settings are done in the trimmer's control

panel).

4.2 Particulars

Depending on the selected operation mode, differences exist in relation to the following

items:

Operation mode

"LOCAL" "SYSTEM"

Enabling trimming Possible from trimmer's control Possible from host copier's control

panel panel

Adjusting trimming width Possible from trimmer's control Possible from host copier's control

panel panel

T01-402-01

4.3 Making Selections

Selections can be made in service mode. (See the descriptions for service mode.)

4.4 Others

• The language used in the trimmer's control panel can be changed only from the

trimmer's control panel.

• The language used in the trimmer's control panel is independent of the language used in

its host copier's language (i.e., there is no correlation between the two sets of specifications).

• When the machine is operating in "LOCAL" mode, the commands for "trimming" or

"trimming width adjustment" from the host copier or the driver will not be recognized,

and the operations will be as specified in the trimmer's control panel.

1-6

COPYRIGHT© 2002 CANON INC. 2000 CANON BOOKLET TRIMMER-A1 REV.0 FEB. 2002

5 Using the machine

5.1 Control Panel

CHAPTER 1 GENERAL DESCRIPTION

[1] [2] [3]

Trim

ON/OFF

No. Key operation

1 LCD

2 Trim lamp

3 Trim ON/OFF key

4 Menu key

5 -/< key

6 +/> key

7 Enter key

8 Error lamp

Menu Enter

-/< +/>

[6][5][4]

F01-501-01

Description

Indicates the state of the machine or to

bring up settings screens (e.g., Menu).

LED ON: Trim/ON

LED OFF: Trim/OFF

To be pressed to enable/disable the trim

function.

To be pressed to set/release the menu.

To be pressed when selecting a mode or

changing the cut width.

To be pressed when selecting a mode or

changing the cut width.

TO be pressed to store the settings made.

LED flashing: paper jam, cover open,

stack full, waste paper

box full/not set

fault (service error)

T01-501-01

Error

[8][7]

Remarks

20 characters × 2 lines

Only when LOCAL Mode

A press while setting a mode

will invalidate the settings being made.

The changes made will be in

opposite sequence to the use of

the +/> key.

The changes made will be in

opposite sequence to the use of

the -/< key.

COPYRIGHT© 2002 CANON INC. 2000 CANON BOOKLET TRIMMER-A1 REV.0 FEB. 2002

1-7

CHAPTER 1 GENERAL DESCRIPTION

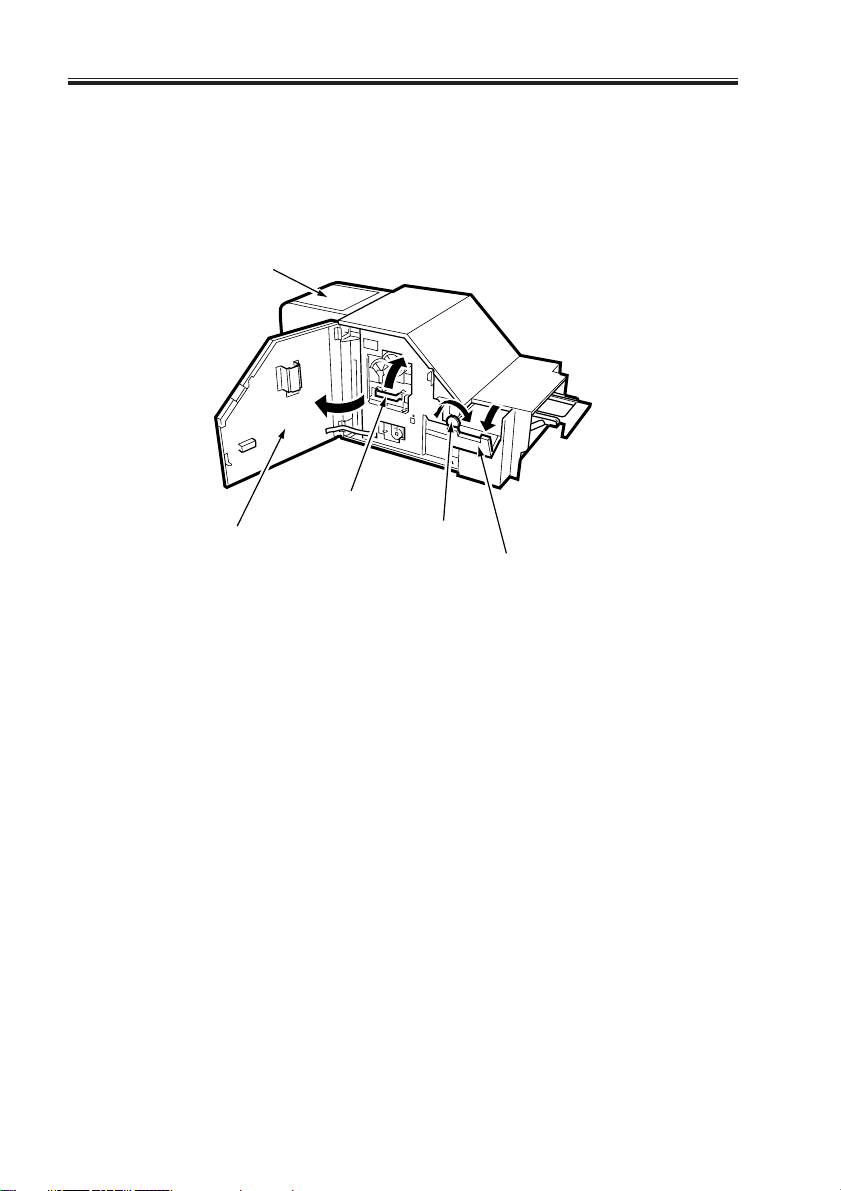

5.2 Removing a Jam

If a booklet jams at the entrance to the feeding assembly, open the front cover and the

right front cover; then, turn the jam releasing knob to remove the jam.

If a booklet jams in the press assembly, open the front cover and keep the press assembly

releasing lever up to remove it.

[5]

[2]

[1]

[3]

[4]

[1] Front cover

[2] Press assembly releasing knob

[3] Jam removal releasing lever

1-8

COPYRIGHT© 2002 CANON INC. 2000 CANON BOOKLET TRIMMER-A1 REV.0 FEB. 2002

[4] Right front cover

[5] Stacker cover

F01-502-01

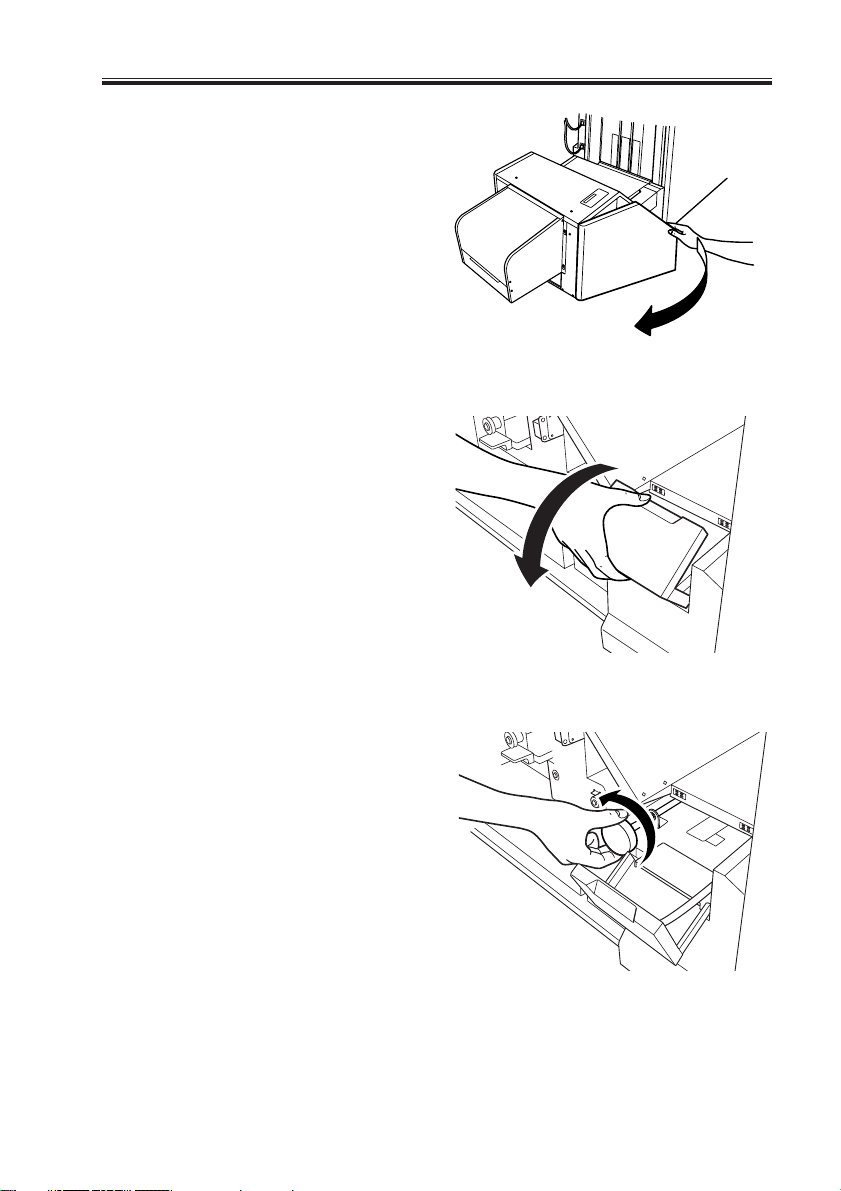

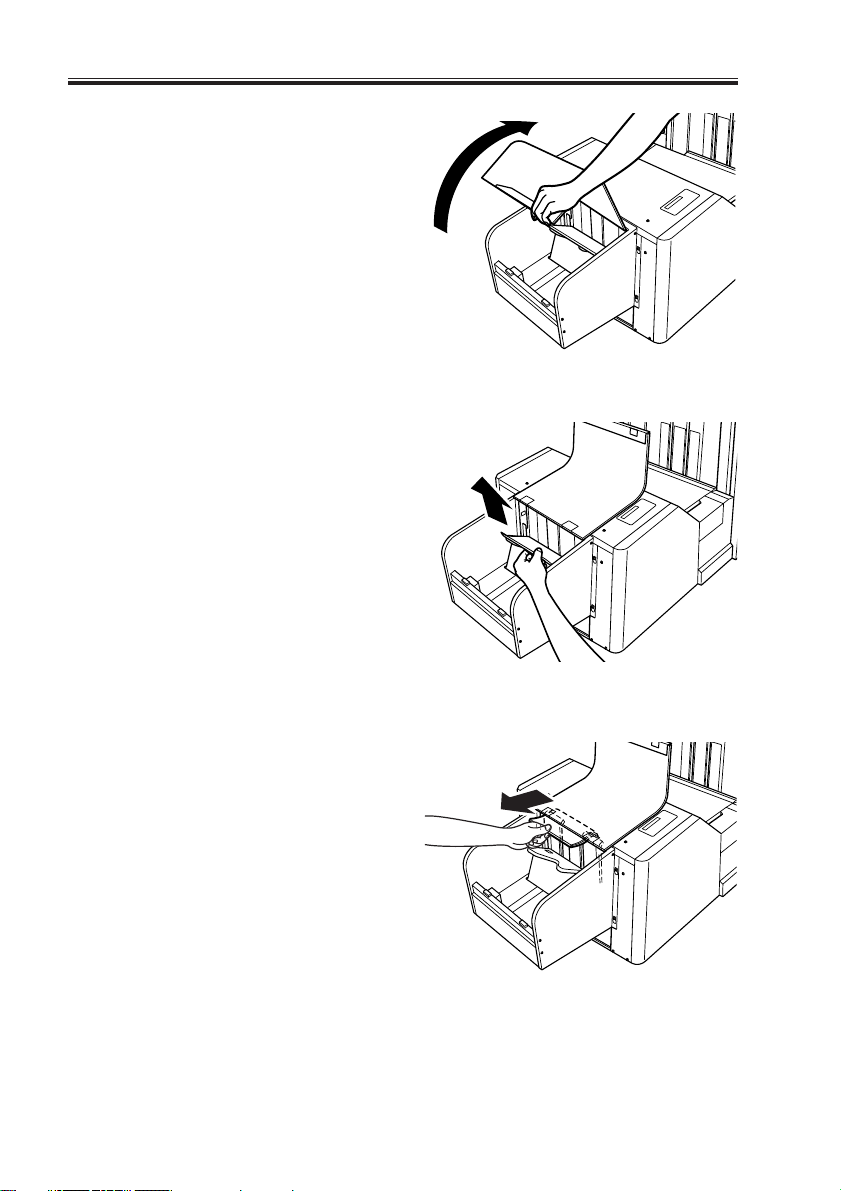

1) Open the front cover.

2) Open the right front cover.

CHAPTER 1 GENERAL DESCRIPTION

F01-502-02

3) Turn the knob of the feeding assembly

counter clockwise.

COPYRIGHT© 2002 CANON INC. 2000 CANON BOOKLET TRIMMER-A1 REV.0 FEB. 2002

F01-502-03

F01-502-04

1-9

CHAPTER 1 GENERAL DESCRIPTION

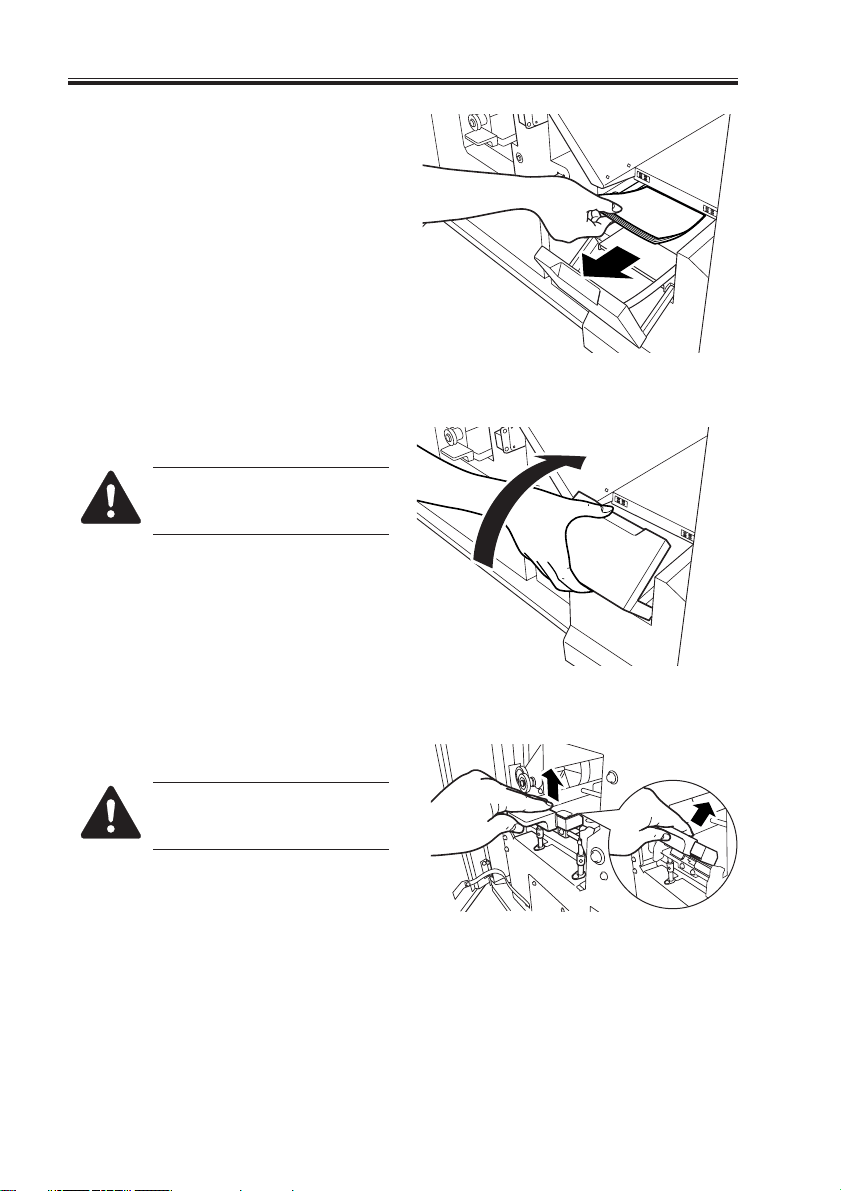

4) Remove the paper jam.

5) Close the right cover.

When closing the cover, be sure

to take care so as not to trap

your fingers.

F01-502-05

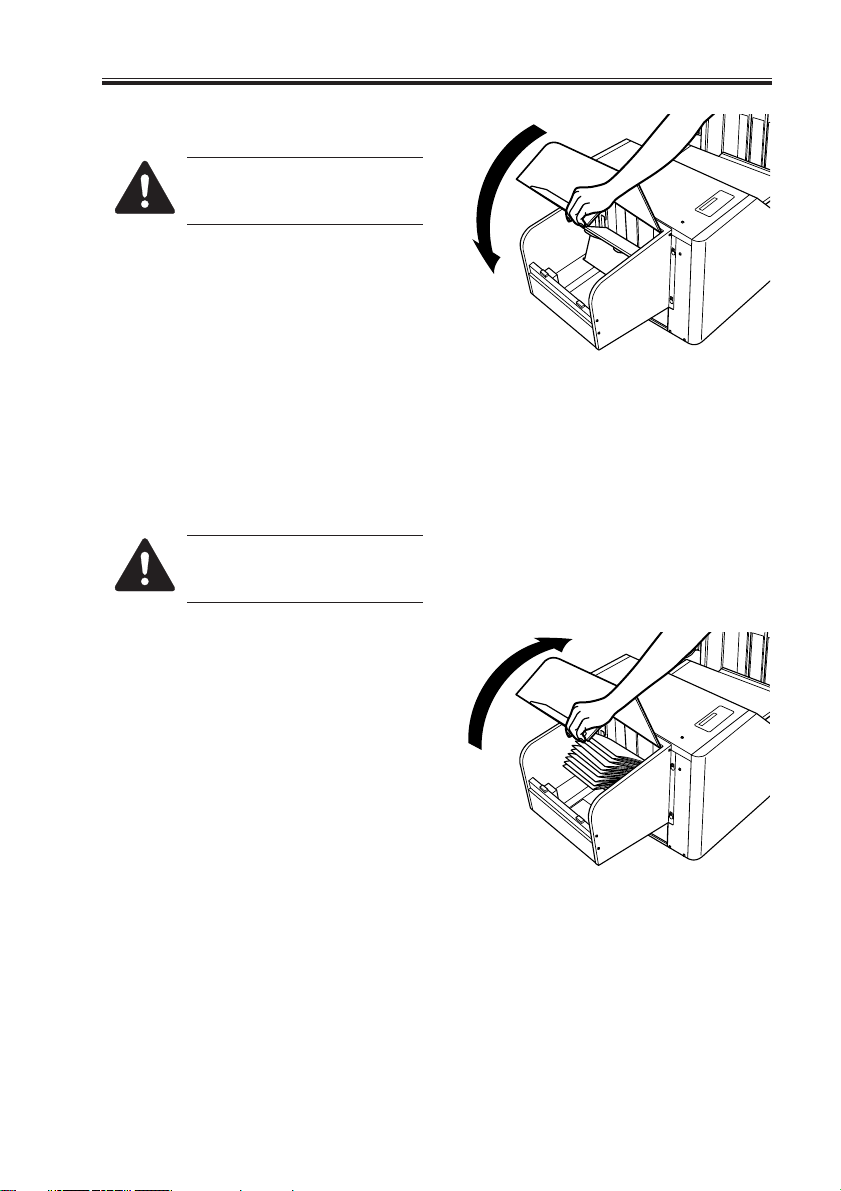

6) Lift the releasing lever.

When lifting the lever, be sure

to take care so as not to trap

your fingers.

1-10

F01-502-06

F01-502-07

COPYRIGHT© 2002 CANON INC. 2000 CANON BOOKLET TRIMMER-A1 REV.0 FEB. 2002

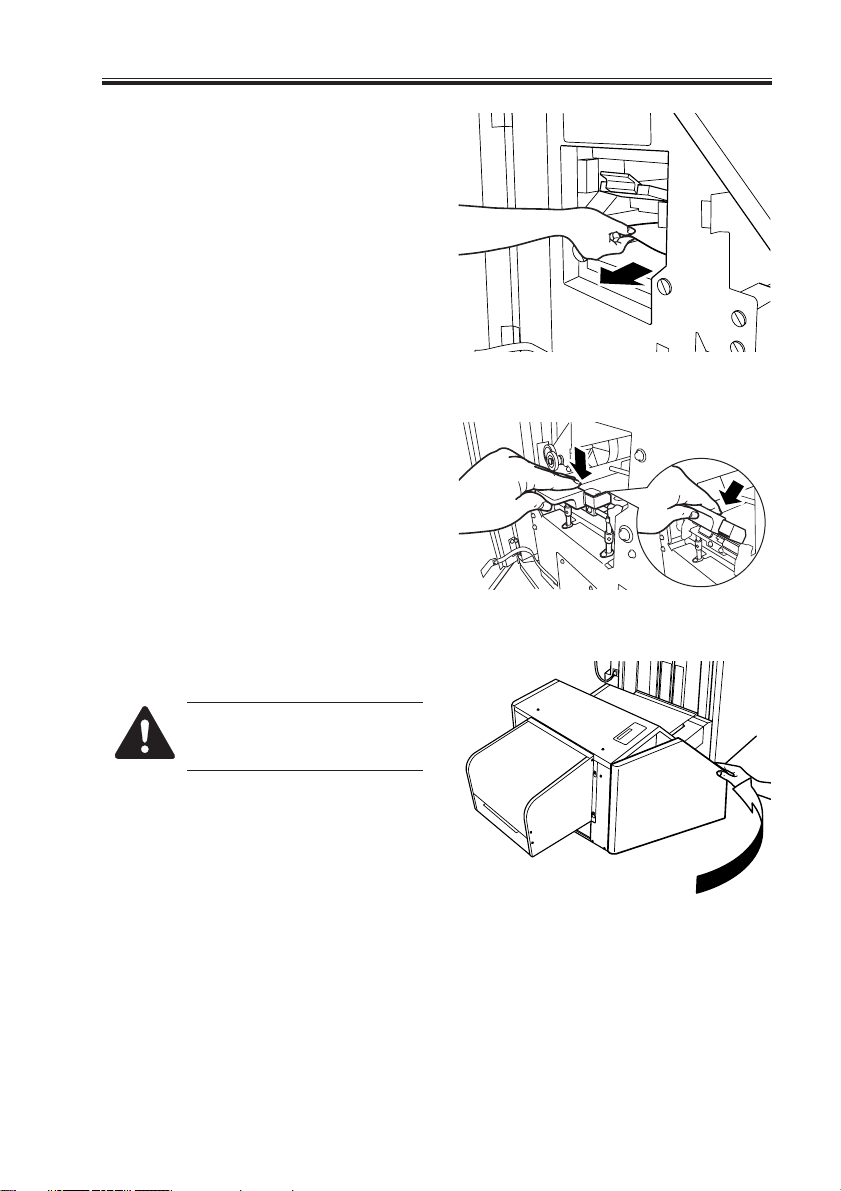

7) Remove the paper jam.

8) Shift the releasing lever back into its

initial position.

CHAPTER 1 GENERAL DESCRIPTION

F01-502-08

F01-502-09

9) Close the front cover.

When closing the cover, be sure

to take care so as not to trap

your fingers.

COPYRIGHT© 2002 CANON INC. 2000 CANON BOOKLET TRIMMER-A1 REV.0 FEB. 2002

F01-502-10

1-11

CHAPTER 1 GENERAL DESCRIPTION

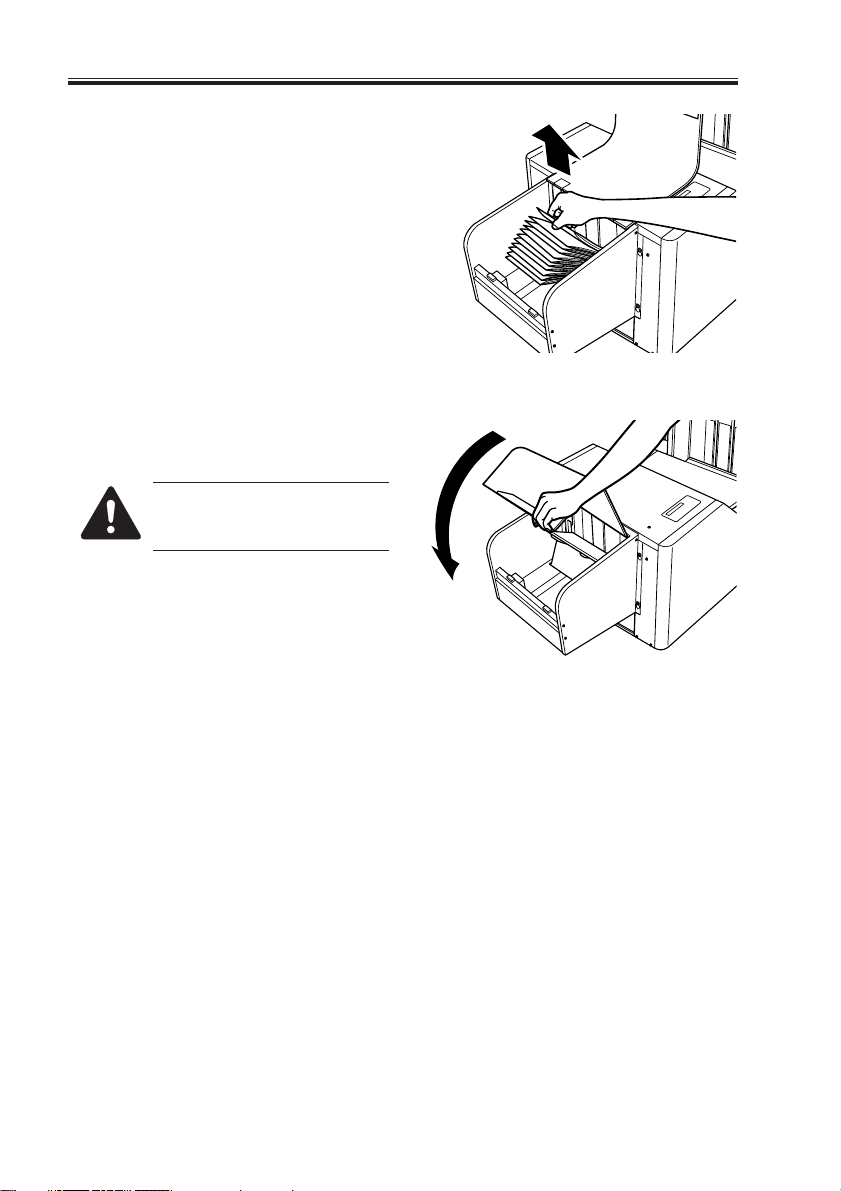

10) Open the stacker cover.

11) Remove the paper from the stacker assembly.

F01-502-11

12) Remove the paper jam from the rear of

the stacker assembly.

1-12

COPYRIGHT© 2002 CANON INC. 2000 CANON BOOKLET TRIMMER-A1 REV.0 FEB. 2002

F01-502-12

F01-502-13

13) Close the stacker cover.

When closing the cover, be sure

to take care so as not to trap

your fingers.

5.2.1 Correcting the Overstacking Error

When the stacker tray overflows with

printouts, the machine will stop its operation. Remove the printouts as follows:

Do not impose a load of 10 kg

or more on the stacker assembly.

1) Open the stacker cover.

CHAPTER 1 GENERAL DESCRIPTION

F01-502-14

COPYRIGHT© 2002 CANON INC. 2000 CANON BOOKLET TRIMMER-A1 REV.0 FEB. 2002

F01-502-15

1-13

CHAPTER 1 GENERAL DESCRIPTION

2) Remove all paper from the stacker assembly.

3) Close the stacker cover. (The job will

resume automatically.)

When closing the cover, be sure

to take care not to trap your fingers.

F01-502-16

1-14

F01-502-17

COPYRIGHT© 2002 CANON INC. 2000 CANON BOOKLET TRIMMER-A1 REV.0 FEB. 2002

CHAPTER 1 GENERAL DESCRIPTION

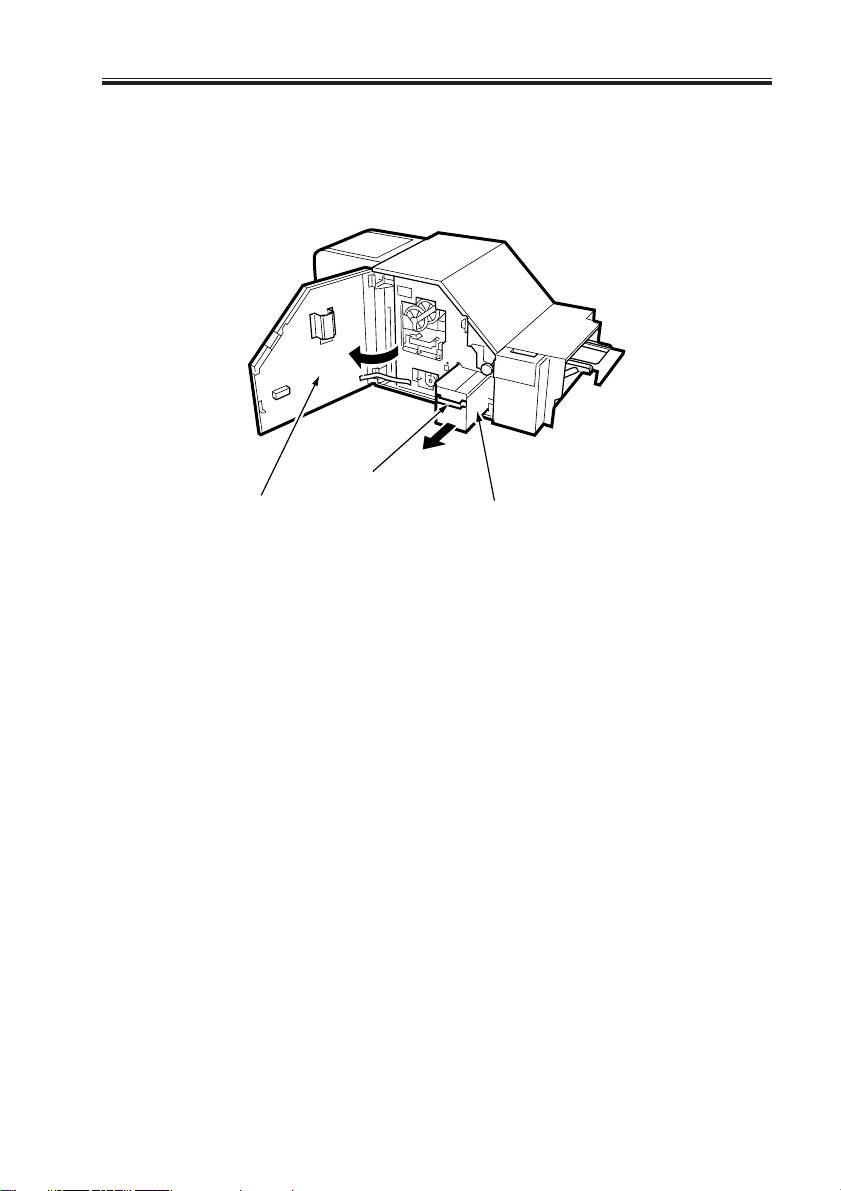

5.2.2 Collecting and Disposing of Waste Paper

The waste paper from cutting operation is collected in a waste paper box. To dispose of

the paper, open the front cover, shift the waste paper box lever, and draw out the waste paper

box.

[2]

[1]

[3]

[1] Front cover

[3] Waste paper box

[2] Waste paper box handle

F01-502-18

COPYRIGHT© 2002 CANON INC. 2000 CANON BOOKLET TRIMMER-A1 REV.0 FEB. 2002

1-15

CHAPTER 1 GENERAL DESCRIPTION

6 Basic Construction

6.1 Functional Construction

As shown in the following diagram, the machine consists of the feeding section, cutter

section, pressing section and stacker section.

[1]

[1] Stacker section

[2] Pressing section

The trim process (i.e. paper feeding process) differs by the trim Designation

Modes; Designating method of the trim designation modes are different between the trim operation modes; in LOCAL mode to be designated in the

trimmer's control panel, in SYSTEM mode to be designated in its host

copier's control panel.

[2] [3]

[3] Cutter section

[4] Feeding section

F01-601-01

[4]

1-16

COPYRIGHT© 2002 CANON INC. 2000 CANON BOOKLET TRIMMER-A1 REV.0 FEB. 2002

CHAPTER 1 GENERAL DESCRIPTION

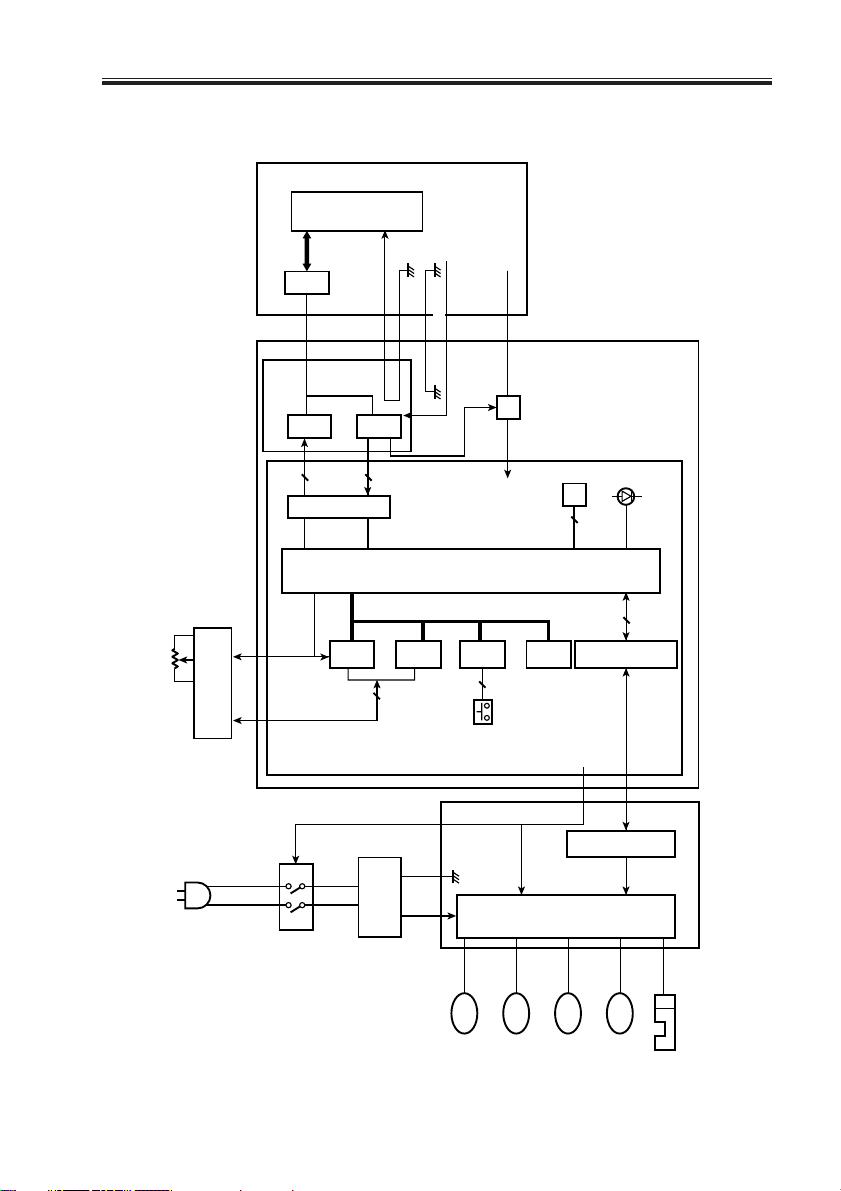

6.2 Outline of the Electrical Circuitry

CPU

LCD

5VF

circuit

Serial

I/O.EXP

8

Interface circuit

RS

Eclk,R/W,

controller

Serial I/O.EXP

Trimmer connection

Serial

I/O.EXP

7

LCD

WR I/F

detection

LCD

RD I/F

D7~D0

Saddle finisher

5VF

Powe r

ON/OFF

Trimmer CPU

Key IN

I/F

5

24V

5Vtrm

DC-DC converter

EPROM

(1Mbit)

4

EEPROM

38

Interface circuit

5Vtrm

Interface circuit

Trimmer control

panel and

controller PCB

Error indicator LED

5Vtrm circuit

unit

Power supply

Motor driver

sensor I/F circuit

24Vtrm

PM

1 pc.

6 pc.

Motor

Motor

DCBM

F01-602-01

COPYRIGHT© 2002 CANON INC. 2000 CANON BOOKLET TRIMMER-A1 REV.0 FEB. 2002

Motor

Fan

1 pc.

DCBLM

motor

1 pc.

Trimmer driver PCB

15 pc.

Sensor

1-17

CHAPTER 1 GENERAL DESCRIPTION

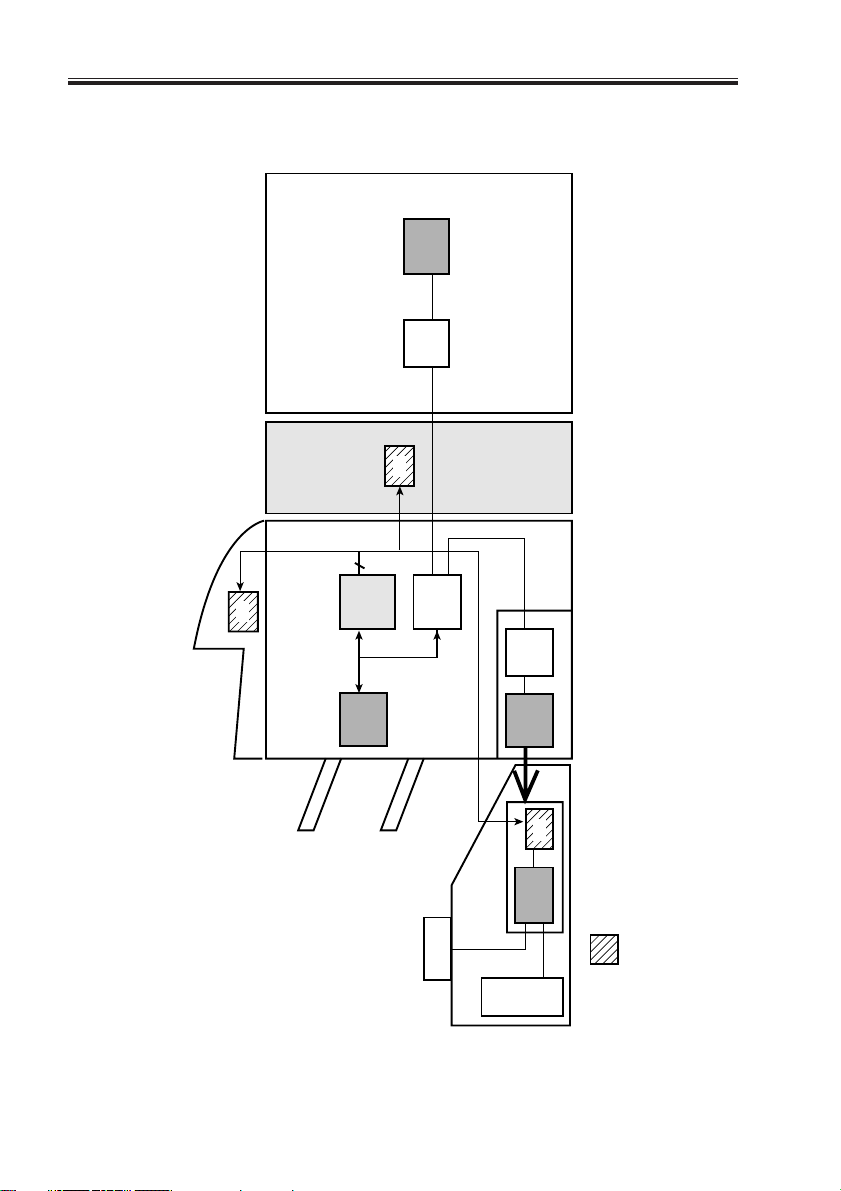

6.3 Wiring Between Options

CPU

Printer

IPC

Inserter

1 pc.

4

Serial I/O

CPU bus

controller

CPU

1 pc.

Trimmer

IPC

Display

Z-folding

IPC

CPU

2 pc.

CPU

Trimmer controller

Driver PCB

Saddle finisher

Serial-to-parallel IC

1-18

F01-603-01

COPYRIGHT© 2002 CANON INC. 2000 CANON BOOKLET TRIMMER-A1 REV.0 FEB. 2002

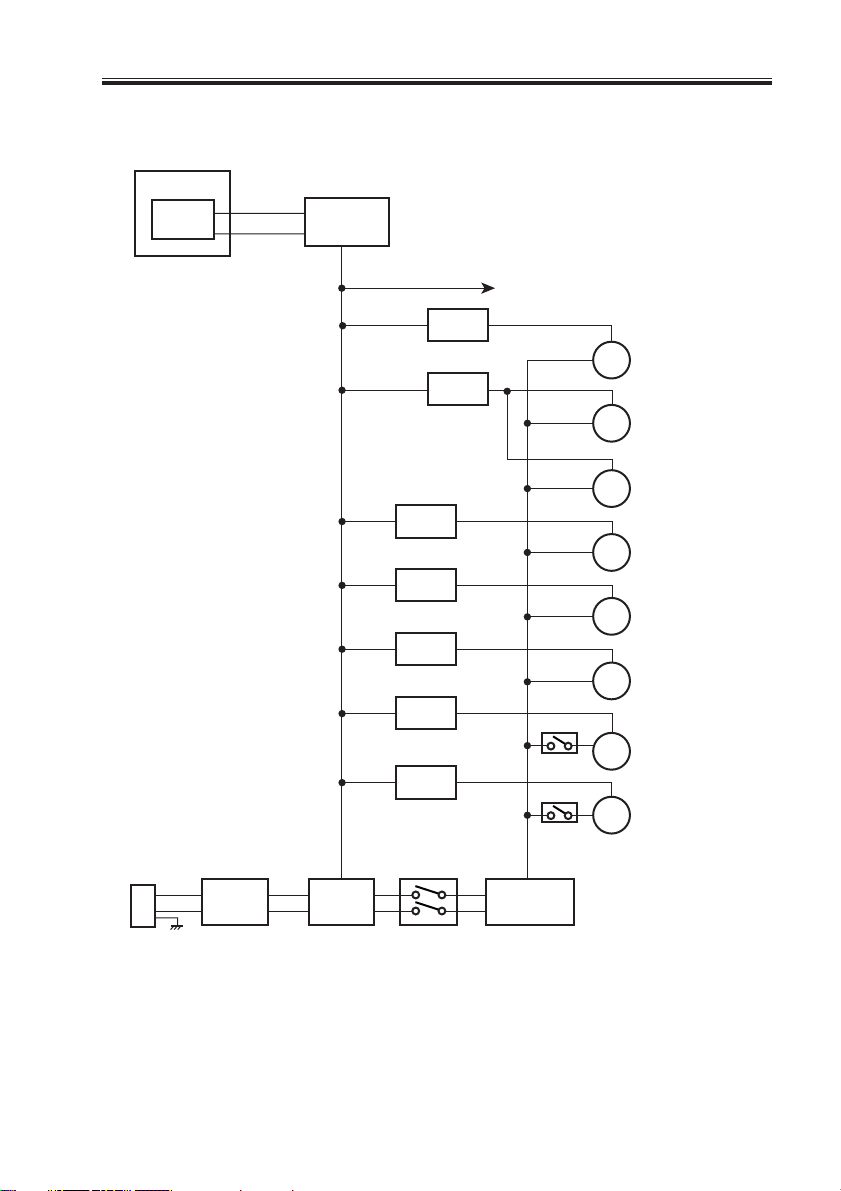

6.4 Trimmer Power Supply

Finisher

Powe r

supply

+24VL

+5R

Regulator

circuit

+5V

Driver

Driver

Driver

Driver

CHAPTER 1 GENERAL DESCRIPTION

Sensors

Driver

M101

Driver

Feeding motor

M102

Cutter motor

M108

Waste paper removal

fan motor

M103

Stopper motor

M104

Stopper release

motor

M105

Press motor

Stacker cover

Driver

switch

Stacker cover

switch

+24VP

DC power

supply

Power plug

Circuit

breaker

Relay

Front cover

switch

F01-604-01

COPYRIGHT© 2002 CANON INC. 2000 CANON BOOKLET TRIMMER-A1 REV.0 FEB. 2002

M106

Holder motor

M107

Pusher motor

1-19

CHAPTER 2

BASIC OPERATIONS

COPYRIGHT© 2002 CANON INC. 2000 CANON BOOKLET TRIMMER-A1 REV.0 FEB. 2002

Loading...

Loading...