Canon Booklet Finisher-D1, Staple Finisher-D1 Service Manual

Staple Finisher-D1 / Booklet Finisher-D1

Product Outline

Technology

Periodic Servicing

Parts Replacing and Cleaning

Adjustment

Troubleshooting

Installation

Appendix

Service Manual Rev. 01

7654321

Application

This manual has been issued by Canon Inc. for qualied persons to learn technical theory,

installation, maintenance, and repair of products. This manual covers all localities where the

products are sold. For this reason, there may be information in this manual that does not

apply to your locality.

Corrections

This manual may contain technical inaccuracies or typographical errors due to improvements

or changes in products. When changes occur in applicable products or in the contents of this

manual, Canon will release technical information as the need arises. In the event of major

changes in the contents of this manual over a long or short period, Canon will issue a new

edition of this manual.

The following paragraph does not apply to any countries where such provisions are

inconsistent with local law.

Trademarks

The product names and company names used in this manual are the registered trademarks

of the individual companies.

Copyright

This manual is copyrighted with all rights reserved. Under the copyright laws, this manual may

not be copied, reproduced or translated into another language, in whole or in part, without the

consent of Canon Inc.

© CANON INC. 2012

Caution

Use of this manual should be strictly supervised to avoid disclosure of condential

information.

Explanation of Symbols

The following symbols are used throughout this Service Manual.

Symbols Explanation Symbols Explanation

Check.

Check visually. Insert the claw.

Remove the claw.

The following rules apply throughout this Service Manual:

1. Each chapter contains sections explaining the purpose of specic functions and the

relationship between electrical and mechanical systems with reference to the timing of

operation.

In the diagrams, represents the path of mechanical drive; where a signal

name accompanies the symbol, the arrow

indicates the direction of the

electric signal.

The expression "turn on the power" means ipping on the power switch, closing the

front door, and closing the delivery unit door, which results in supplying the machine with

power.

Check the noise. Use the bundled part.

Disconnect the connector. Push the part.

Connect the connector. Plug the power cable.

Remove the cable/wire

from the cable guide or wire

saddle.

Set the cable/wire to the

cable guide or wire saddle.

Remove the screw.

Turn on the power.

2. In the digital circuits, '1' is used to indicate that the voltage level of a given signal is

"High", while '0' is used to indicate "Low". (The voltage value, however, differs from

circuit to circuit.) In addition, the asterisk (*) as in "DRMD*" indicates that the DRMD

signal goes on when '0'.

In practically all cases, the internal mechanisms of a microprocessor cannot be checked

in the eld. Therefore, the operations of the microprocessors used in the machines

are not discussed: they are explained in terms of from sensors to the input of the DC

controller PCB and from the output of the DC controller PCB to the loads.

The descriptions in this Service Manual are subject to change without notice for product

improvement or other purposes, and major changes will be communicated in the form of

Service Information bulletins.

All service persons are expected to have a good understanding of the contents of this Service

Manual and all relevant Service Information bulletins and be able to identify and isolate faults

in the machine.

Tighten the screw.

Contents

0

Safety Precautions

Notes Before Servicing ------------------------------------------------------0-2

Points to Note at Cleaning

1

Product Outline

--------------------------------------------------0-2

Product Specications -------------------------------------------------------1-2

Specications ---------------------------------------------------------------------- 1-2

Staple Position ------------------------------------------------------------------------------ 1-3

Names of Parts ----------------------------------------------------------------1-5

External View ----------------------------------------------------------------------- 1-5

Cross Section ----------------------------------------------------------------------- 1-6

2

Technology

Basic Construction ------------------------------------------------------------2-2

Overview ----------------------------------------------------------------------------- 2-2

Electrical Control Unit --------------------------------------------------------2-3

Overview ----------------------------------------------------------------------------- 2-3

Finisher Controller PCB ---------------------------------------------------------- 2-3

Saddle Stitcher Controller PCB ------------------------------------------------ 2-4

Stacking Unit -------------------------------------------------------------------2-5

Overview ----------------------------------------------------------------------------- 2-5

Tray Ascent/Descent Control---------------------------------------------------- 2-6

Auxiliary Tray Lift Control -------------------------------------------------------- 2-7

Tray Paper Surface Detection -------------------------------------------------- 2-8

Feeding Unit --------------------------------------------------------------------2-9

Overview ----------------------------------------------------------------------------- 2-9

Basic Sequence of Operations ------------------------------------------------ 2-11

Horizontal Registration Detection --------------------------------------------- 2-12

Side Registration Correction Operation Shift Operation ----------------2-13

Buffer Operation -------------------------------------------------------------------2-15

Switching Over the Paper Path ------------------------------------------------2-16

Assist Roller Engage Operation ----------------------------------------------- 2-16

Intermediate Process Tray Assembly ----------------------------------2-18

Overview ----------------------------------------------------------------------------2-18

Basic Sequence of Operations ------------------------------------------------ 2-19

Stacking Operation ---------------------------------------------------------------2-20

Shift Operation ---------------------------------------------------------------------2-23

Stapling Operation ---------------------------------------------------------------- 2-24

Delivery Operation ---------------------------------------------------------------- 2-25

Neat Alignment Operation -----------------------------------------------------2-27

Upper Neat Alignment Plate Operation ----------------------------------------------2-27

Upper Return Roller Operation

Lower Neat Alignment Plate Operation

Lower Return Roller Operation

--------------------------------------------------------2-27

----------------------------------------------2-28

--------------------------------------------------------2-28

Saddle Stitcher Unit --------------------------------------------------------2-29

Overview ----------------------------------------------------------------------------2-29

Basic Sequence of Operations ------------------------------------------------ 2-30

Paper Feed Operation -----------------------------------------------------------2-31

Alignment Operation -------------------------------------------------------------2-33

Staple Operation ------------------------------------------------------------------2-34

Paper Folding/Delivery Operations ------------------------------------------2-35

Detecting Jams -------------------------------------------------------------- 2-38

Jam inspection in Finisher ------------------------------------------------------2-38

Stitcher area jam detection -----------------------------------------------------2-40

3

Periodic Servicing

User Maintenance ------------------------------------------------------------3-2

User Maintenance ----------------------------------------------------------------- 3-2

User Maintenance Items (nisher) ----------------------------------------------------- 3-2

User Maintenance Item (saddle)

-------------------------------------------------------- 3-2

Maintenance and Inspection -----------------------------------------------3-3

Periodically Replaced Parts ----------------------------------------------------- 3-3

Periodically Replaced Parts (Finisher) ------------------------------------------------ 3-3

Periodically Replaced Parts (Saddle) ------------------------------------------------- 3-3

Durables ------------------------------------------------------------------------------ 3-3

Durables (Finisher) ------------------------------------------------------------------------- 3-3

Durables (Saddle)

-------------------------------------------------------------------------- 3-3

Periodical Servicing --------------------------------------------------------------- 3-4

Periodical Servicing (Finisher)----------------------------------------------------------- 3-4

Periodical Servicing (Saddle)

4

Parts Replacing and Cleaning

------------------------------------------------------------ 3-4

List of Parts ---------------------------------------------------------------------4-2

List of External/Internal Covers ------------------------------------------------- 4-2

List of Main Unit -------------------------------------------------------------------- 4-3

Stacking Assembly ------------------------------------------------------------------------- 4-3

Feed Assembly

Intermediate Process Tray Assembly

Saddle Stitcher Assembly

------------------------------------------------------------------------------ 4-4

-------------------------------------------------- 4-5

---------------------------------------------------------------- 4-6

List of consumable parts locations -------------------------------------------- 4-7

Finisher Assembly -------------------------------------------------------------------------- 4-7

Saddle Stitcher Assembly

---------------------------------------------------------------- 4-7

Sensors ------------------------------------------------------------------------------- 4-8

Saddle Unit ----------------------------------------------------------------------------------- 4-8

Finisher Unit

---------------------------------------------------------------------------------- 4-9

Motors -------------------------------------------------------------------------------4-10

Saddle Unit ----------------------------------------------------------------------------------4-10

Finisher Unit

--------------------------------------------------------------------------------- 4-11

Solenoids ---------------------------------------------------------------------------4-12

Saddle Unit ----------------------------------------------------------------------------------4-12

Finisher Unit

---------------------------------------------------------------------------------4-13

PCBs ---------------------------------------------------------------------------------4-14

Saddle Unit ----------------------------------------------------------------------------------4-14

Finisher Unit

---------------------------------------------------------------------------------4-15

Switchs ------------------------------------------------------------------------------4-16

Fans ----------------------------------------------------------------------------------4-17

Removing from the connection equipment ---------------------------4-18

Removing from the Host Machine --------------------------------------------4-18

Preparation ----------------------------------------------------------------------------------4-18

Procedure

------------------------------------------------------------------------------------4-18

External/Internal Covers --------------------------------------------------- 4-20

Removing the Rear Cover ------------------------------------------------------4-20

Procedure ------------------------------------------------------------------------------------4-20

Removing the Rear Upper Cover (Right) ----------------------------------- 4-21

Procedure ------------------------------------------------------------------------------------4-21

Removing the Rear Upper Cover (Left) ------------------------------------- 4-21

Preparation ----------------------------------------------------------------------------------4-21

Procedure

------------------------------------------------------------------------------------4-21

Removing the Inner Cover (Upper) -------------------------------------------4-22

Preparation ----------------------------------------------------------------------------------4-22

Procedure

------------------------------------------------------------------------------------4-22

Removing the Inner Cover (Lower) -------------------------------------------4-23

Preparation ----------------------------------------------------------------------------------4-23

Procedure

------------------------------------------------------------------------------------4-23

Electric Control Assembly ------------------------------------------------- 4-24

Removing the Finisher Controller PCB -------------------------------------- 4-24

Preparation ----------------------------------------------------------------------------------4-24

Procedure

------------------------------------------------------------------------------------4-24

Removing the Neat Stack Driver PCB --------------------------------------- 4-24

Preparation ----------------------------------------------------------------------------------4-24

Procedure

------------------------------------------------------------------------------------4-24

Removing the Feed Motor Driver PCB -------------------------------------- 4-25

Preparation ----------------------------------------------------------------------------------4-25

Procedure

------------------------------------------------------------------------------------4-25

Removing the Saddle Stitcher Controller PCB ---------------------------- 4-25

Preparation ----------------------------------------------------------------------------------4-25

Procedure

------------------------------------------------------------------------------------4-25

Stacking Assembly ---------------------------------------------------------- 4-27

Points to Note on handling the Stack Wall Rail ---------------------------4-27

Removing the Stack Wall (Upper) --------------------------------------------4-27

Procedure ------------------------------------------------------------------------------------4-27

Removing the Stack Wall (Lower) --------------------------------------------4-29

Preparation ----------------------------------------------------------------------------------4-29

Procedure

Points to Note on Tray A/B Cable ---------------------------------------------4-31

Position of Tray B at power-on ------------------------------------------------4-31

Removing the Tray A Unit ------------------------------------------------------- 4-32

------------------------------------------------------------------------------------4-29

Preparation ----------------------------------------------------------------------------------4-32

Procedure

------------------------------------------------------------------------------------4-32

Removing the Tray B Unit ------------------------------------------------------4-35

Preparation ----------------------------------------------------------------------------------4-35

Procedure

------------------------------------------------------------------------------------4-35

Adjusting Position of Tray A, B ------------------------------------------------ 4-37

Removing the Tray A/B Lifting Motor ----------------------------------------- 4-37

Feed Assembly -------------------------------------------------------------- 4-39

Removing the Delivery Static Eliminator ------------------------------------4-39

Procedure ------------------------------------------------------------------------------------4-39

Removing the Upper Feed Unit -----------------------------------------------4-40

Preparation ----------------------------------------------------------------------------------4-40

Procedure

Removing the Inlet Feed Motor -----------------------------------------------4-42

Preparation ----------------------------------------------------------------------------------4-42

Procedure

Removing the Paper Trailing Edge Drop Motor ---------------------------4-43

Preparation ----------------------------------------------------------------------------------4-43

Procedure

Removing the Buffer Front Feed Motor -------------------------------------4-43

Preparation ----------------------------------------------------------------------------------4-43

Procedure

Removing the Buffer Motor ----------------------------------------------------- 4-44

Preparation ----------------------------------------------------------------------------------4-44

Procedure

Removing the Puncher Unit ----------------------------------------------------4-46

Preparation ----------------------------------------------------------------------------------4-46

Procedure

Removing the Side Registration Sensor Unit ------------------------------4-47

Preparation ----------------------------------------------------------------------------------4-47

Procedure

Removing the Side Registration Sensor PCB ----------------------------- 4-48

Preparation ----------------------------------------------------------------------------------4-48

Procedure

Removing the Side Registration Shift Unit ---------------------------------4-49

Preparation ----------------------------------------------------------------------------------4-49

Procedure

------------------------------------------------------------------------------------4-40

------------------------------------------------------------------------------------4-42

------------------------------------------------------------------------------------4-43

------------------------------------------------------------------------------------4-43

------------------------------------------------------------------------------------4-44

------------------------------------------------------------------------------------4-46

------------------------------------------------------------------------------------4-47

------------------------------------------------------------------------------------4-48

------------------------------------------------------------------------------------4-49

Removing the Side Registration Shift Motor ------------------------------- 4-53

Preparation ----------------------------------------------------------------------------------4-53

Procedure

------------------------------------------------------------------------------------4-53

Removing the Shift Motor ------------------------------------------------------- 4-54

Preparation ----------------------------------------------------------------------------------4-54

Procedure

------------------------------------------------------------------------------------4-54

Intermediate Process Tray Assembly ----------------------------------4-55

Removing the Stack Delivery Roller Upper Static Eliminator ----------4-55

Procedure ------------------------------------------------------------------------------------4-55

Removing the Neat Paddle (Upper) ------------------------------------------ 4-55

Procedure ------------------------------------------------------------------------------------4-55

Removing the Neat Paddle (Lower) ------------------------------------------ 4-56

Procedure ------------------------------------------------------------------------------------4-56

Removing the Neat Stack Unit (Upper) -------------------------------------4-57

Preparation ----------------------------------------------------------------------------------4-57

Procedure

Removing the Neat Stack Unit (Lower) -------------------------------------4-59

Preparation ----------------------------------------------------------------------------------4-59

Procedure

Removing the Stapler ------------------------------------------------------------ 4-60

Preparation ----------------------------------------------------------------------------------4-60

Procedure

Adjusting Position of Stapler ---------------------------------------------------4-61

Removing the Process Tray Unit ----------------------------------------------4-62

Preparation ----------------------------------------------------------------------------------4-62

Procedure

Removing the Paddle Unit ------------------------------------------------------ 4-65

Preparation ----------------------------------------------------------------------------------4-65

Procedure

Removing the paddle ------------------------------------------------------------4-65

Preparation ----------------------------------------------------------------------------------4-65

Procedure

Removing the Stack Delivery Upper Roller --------------------------------4-66

Preparation ----------------------------------------------------------------------------------4-66

Procedure

Removing the Process Tray (Front) ------------------------------------------ 4-68

Preparation ----------------------------------------------------------------------------------4-68

------------------------------------------------------------------------------------4-57

------------------------------------------------------------------------------------4-59

------------------------------------------------------------------------------------4-60

------------------------------------------------------------------------------------4-62

------------------------------------------------------------------------------------4-65

------------------------------------------------------------------------------------4-65

------------------------------------------------------------------------------------4-66

Procedure ------------------------------------------------------------------------------------4-68

Removing the Process Tray (Rear) ------------------------------------------4-69

Preparation ----------------------------------------------------------------------------------4-69

Procedure

------------------------------------------------------------------------------------4-69

Removing the Feed Belt --------------------------------------------------------4-70

Preparation ----------------------------------------------------------------------------------4-70

Procedure

------------------------------------------------------------------------------------4-70

Removing the Stack Delivery Motor ------------------------------------------4-72

Preparation ----------------------------------------------------------------------------------4-72

Procedure

------------------------------------------------------------------------------------4-72

Removing the Process Tray Plate Unit --------------------------------------4-72

Preparation ----------------------------------------------------------------------------------4-72

Procedure

------------------------------------------------------------------------------------4-72

Removing the Front Alignment Motor ----------------------------------------4-73

Preparation ----------------------------------------------------------------------------------4-73

Procedure

------------------------------------------------------------------------------------4-73

Removing the Rear Alignment Motor ---------------------------------------- 4-75

Preparation ----------------------------------------------------------------------------------4-75

Procedure

------------------------------------------------------------------------------------4-75

Right Angle Adjustment of Alignment Plate---------------------------------4-77

Removing the Process Upper Guide Unit ----------------------------------4-78

Preparation ----------------------------------------------------------------------------------4-78

Procedure

------------------------------------------------------------------------------------4-78

Removing the Belt Controller Unit -------------------------------------------- 4-81

Preparation ----------------------------------------------------------------------------------4-81

Procedure

------------------------------------------------------------------------------------4-81

Removing the Belt Roller -------------------------------------------------------4-85

Preparation ----------------------------------------------------------------------------------4-85

Procedure

------------------------------------------------------------------------------------4-85

Saddle Stitcher Assembly ------------------------------------------------- 4-89

Removing the Saddle Inner Cover (Upper) --------------------------------4-89

Preparation ----------------------------------------------------------------------------------4-89

Procedure

Removing the Saddle Inner Cover (Lower) --------------------------------4-89

Preparation ----------------------------------------------------------------------------------4-89

Procedure

Removing the Saddle Inlet Roller Static Eliminator ----------------------4-90

Preparation ----------------------------------------------------------------------------------4-90

------------------------------------------------------------------------------------4-89

------------------------------------------------------------------------------------4-89

Procedure ------------------------------------------------------------------------------------4-90

Removing the Saddle Intermediate Static Eliminator --------------------4-91

Preparation ----------------------------------------------------------------------------------4-91

Procedure

------------------------------------------------------------------------------------4-91

Removing the Saddle Stapler --------------------------------------------------4-91

Preparation ----------------------------------------------------------------------------------4-91

Procedure

------------------------------------------------------------------------------------4-91

Removing the Feed Guide Lower Static Eliminator ---------------------- 4-92

Preparation ----------------------------------------------------------------------------------4-92

Procedure

------------------------------------------------------------------------------------4-92

Removing the Disengagement Roller ----------------------------------------4-93

Preparation ----------------------------------------------------------------------------------4-93

Procedure

------------------------------------------------------------------------------------4-93

Removing the Thrust Unit -------------------------------------------------------4-95

Preparation ----------------------------------------------------------------------------------4-95

Procedure

------------------------------------------------------------------------------------4-95

Removing the Push-on Plate --------------------------------------------------4-97

Preparation ----------------------------------------------------------------------------------4-97

Procedure

------------------------------------------------------------------------------------4-97

Removing the Positioning Plate Unit -----------------------------------------4-98

Preparation ----------------------------------------------------------------------------------4-98

Procedure

------------------------------------------------------------------------------------4-98

Pulling out the Saddle Unit (service position) ------------------------------4-99

Preparation ----------------------------------------------------------------------------------4-99

Procedure

------------------------------------------------------------------------------------4-99

Removing the Saddle Inlet Static Eliminator ----------------------------- 4-100

Preparation -------------------------------------------------------------------------------- 4-100

Procedure

---------------------------------------------------------------------------------- 4-100

Removing the Saddle Unit ---------------------------------------------------- 4-101

Preparation -------------------------------------------------------------------------------- 4-101

Procedure

---------------------------------------------------------------------------------- 4-101

Removing the Press Unit ----------------------------------------------------- 4-102

Preparation -------------------------------------------------------------------------------- 4-102

Procedure

---------------------------------------------------------------------------------- 4-102

Removing the Press Roller Unit --------------------------------------------- 4-105

Preparation -------------------------------------------------------------------------------- 4-105

Procedure

---------------------------------------------------------------------------------- 4-105

Removing the Fold Roller ----------------------------------------------------- 4-108

Preparation -------------------------------------------------------------------------------- 4-108

Procedure

---------------------------------------------------------------------------------- 4-108

Removing the Alignment Roller Unit --------------------------------------- 4-112

Preparation -------------------------------------------------------------------------------- 4-112

Procedure

---------------------------------------------------------------------------------- 4-112

Removing the Alignment Roller --------------------------------------------- 4-113

Preparation -------------------------------------------------------------------------------- 4-113

Procedure

---------------------------------------------------------------------------------- 4-113

Removing the Saddle Alignment Motor ----------------------------------- 4-113

Preparation -------------------------------------------------------------------------------- 4-113

Procedure

5

Adjustment

---------------------------------------------------------------------------------- 4-113

Basic Adjustment --------------------------------------------------------------5-2

Outline -------------------------------------------------------------------------------- 5-2

Height Adjustment ----------------------------------------------------------------- 5-3

Checking the height ------------------------------------------------------------------------ 5-3

Height adjustment

-------------------------------------------------------------------------- 5-3

Side Registration/Skew Adjustment ------------------------------------------- 5-6

Checking adjustment value -------------------------------------------------------------- 5-6

Side registration adjustment

Skew adjustment

---------------------------------------------------------------------------- 5-8

------------------------------------------------------------- 5-7

Adjusting Sensor Light Intensity -----------------------------------------------5-10

Preparations --------------------------------------------------------------------------------5-10

Procedure

------------------------------------------------------------------------------------ 5-11

Adjustment at Time of Parts Replacement ---------------------------5-12

Outline -------------------------------------------------------------------------------5-12

Adjusting Sensor Light Intensity -----------------------------------------------5-14

Preparations --------------------------------------------------------------------------------5-14

Procedure

Adjusting Position of Tray A, B ------------------------------------------------ 5-16

Adjusting the Alignment Position of the Upper Neat Alignment Plate 5-17

Preparations --------------------------------------------------------------------------------5-17

Procedure

Adjusting the Alignment Position of the Lower Neat Alignment Plate 5-19

Preparations --------------------------------------------------------------------------------5-19

Procedure

------------------------------------------------------------------------------------5-15

------------------------------------------------------------------------------------5-17

------------------------------------------------------------------------------------5-19

Adjusting the Height of Corrugation Roller for Stack Delivery ---------5-22

Preparations --------------------------------------------------------------------------------5-22

Procedure

------------------------------------------------------------------------------------5-22

Right Angle Adjustment of Alignment Plate---------------------------------5-26

Adjusting Alignment Plate Position -------------------------------------------5-27

Preparations --------------------------------------------------------------------------------5-27

Procedure

------------------------------------------------------------------------------------5-27

Adjusting Position of Stapler ---------------------------------------------------5-29

Adjusting Staple Position (1-stapling at the rear) ------------------------- 5-30

Preparations --------------------------------------------------------------------------------5-30

Procedure

------------------------------------------------------------------------------------5-30

Adjusting Staple Position (1-stapling at the front) ------------------------5-33

Preparations --------------------------------------------------------------------------------5-33

Procedure

------------------------------------------------------------------------------------5-33

Adjusting Staple Position (2-stapling positions) ---------------------------5-36

Preparations --------------------------------------------------------------------------------5-36

Procedure

------------------------------------------------------------------------------------5-36

Adjusting Delivery of Staple Stack (lower delivery) ----------------------5-38

Preparations --------------------------------------------------------------------------------5-38

Procedure

------------------------------------------------------------------------------------5-38

Adjusting Delivery of Staple Stack (saddle delivery) ---------------------5-41

Preparations --------------------------------------------------------------------------------5-41

Procedure

------------------------------------------------------------------------------------5-41

Saddle Stitch/Fold Placement Adjustment----------------------------------5-44

Fold placement adjustment -------------------------------------------------------------5-44

Saddle stitch adjustment

-----------------------------------------------------------------5-45

Adjusting Saddle Stitching Position ------------------------------------------5-48

Preparations --------------------------------------------------------------------------------5-48

Procedure

------------------------------------------------------------------------------------5-48

Adjusting Saddle Folding Position --------------------------------------------5-50

Preparations --------------------------------------------------------------------------------5-50

Procedure

------------------------------------------------------------------------------------5-50

Adjusting Position of Saddle Lead Edge Stopper-------------------------5-51

Adjustment After Replacing Finisher Controller PCB --------------------5-53

Bufferless Mode -------------------------------------------------------------------5-54

Preparations --------------------------------------------------------------------------------5-54

Procedure

------------------------------------------------------------------------------------5-54

Adjustment in the Case of Failure in Stacking Performance of Tray

(upper curl) -------------------------------------------------------------------------5-55

Preparations --------------------------------------------------------------------------------5-55

Procedure

------------------------------------------------------------------------------------5-55

Adjustment in the Case of Failure in Stacking Performance of Tray (lower

curl) -----------------------------------------------------------------------------------5-57

Preparations --------------------------------------------------------------------------------5-57

Procedure

------------------------------------------------------------------------------------5-57

Adjustment in the Case of Failure in Stacking Performance of Tray (runon of paper when using thin paper) ------------------------------------------5-59

Preparations --------------------------------------------------------------------------------5-59

Procedure

------------------------------------------------------------------------------------5-59

Adjustment in the Case of Canceling Limit for Tray Stack--------------5-61

Preparations --------------------------------------------------------------------------------5-61

Procedure

------------------------------------------------------------------------------------5-61

Adjusting Alignment for Saddle Stapling ------------------------------------5-63

Auxiliary Adjustment -------------------------------------------------------- 5-66

Outline -------------------------------------------------------------------------------5-66

Adjusting Position of Tray A, B ------------------------------------------------5-68

Adjusting Position of Feed Belt ------------------------------------------------ 5-69

Preparations --------------------------------------------------------------------------------5-69

Procedure

Adjusting Staple Position (1-stapling at the rear) ------------------------- 5-71

Preparations --------------------------------------------------------------------------------5-71

Procedure

Adjusting Staple Position (1-stapling at the front) ------------------------5-74

Preparations --------------------------------------------------------------------------------5-74

Procedure

Adjusting Staple Position (2-stapling positions) ---------------------------5-77

Preparations --------------------------------------------------------------------------------5-77

Procedure

Adjusting Delivery of Staple Stack (lower delivery) ----------------------5-79

Preparations --------------------------------------------------------------------------------5-79

Procedure

Adjusting Delivery of Staple Stack (saddle delivery) ---------------------5-82

Preparations --------------------------------------------------------------------------------5-82

Procedure

------------------------------------------------------------------------------------5-69

------------------------------------------------------------------------------------5-71

------------------------------------------------------------------------------------5-74

------------------------------------------------------------------------------------5-77

------------------------------------------------------------------------------------5-79

------------------------------------------------------------------------------------5-82

Saddle Stitch/Fold Placement Adjustment----------------------------------5-85

Fold placement adjustment -------------------------------------------------------------5-85

Saddle stitch adjustment

-----------------------------------------------------------------5-86

Adjusting Saddle Stitching Position ------------------------------------------5-89

Preparations --------------------------------------------------------------------------------5-89

Procedure

------------------------------------------------------------------------------------5-89

Adjusting Saddle Folding Position --------------------------------------------5-91

Preparations --------------------------------------------------------------------------------5-91

Procedure

------------------------------------------------------------------------------------5-91

Adjusting Position of Saddle Lead Edge Stopper-------------------------5-92

Adjusting Position for Saddle Alignment Width ---------------------------- 5-95

Preparations --------------------------------------------------------------------------------5-95

Procedure

------------------------------------------------------------------------------------5-95

Bufferless Mode -------------------------------------------------------------------5-97

Preparations --------------------------------------------------------------------------------5-97

Procedure

------------------------------------------------------------------------------------5-97

Adjusting Assist Stopper Position ---------------------------------------------5-98

Preparations --------------------------------------------------------------------------------5-98

Procedure

------------------------------------------------------------------------------------5-98

Adjusting Height of Staple Inlet Guide ---------------------------------------5-99

Preparations --------------------------------------------------------------------------------5-99

Procedure

------------------------------------------------------------------------------------5-99

Adjusting Paddle Height ------------------------------------------------------- 5-101

Preparations ------------------------------------------------------------------------------ 5-101

Procedure

---------------------------------------------------------------------------------- 5-101

Adjustment in the Case of Failure in Stacking Performance of Tray

(upper curl) ----------------------------------------------------------------------- 5-103

Preparations ------------------------------------------------------------------------------ 5-103

Procedure

---------------------------------------------------------------------------------- 5-103

Adjustment in the Case of Failure in Stacking Performance of Tray (lower

curl) --------------------------------------------------------------------------------- 5-105

Preparations ------------------------------------------------------------------------------ 5-105

Procedure

---------------------------------------------------------------------------------- 5-105

Adjustment in the Case of Failure in Stacking Performance of Tray (runon of paper when using thin paper) ---------------------------------------- 5-107

Preparations ------------------------------------------------------------------------------ 5-107

Procedure

---------------------------------------------------------------------------------- 5-107

Adjustment in the Case of Canceling Limit for Tray Stack------------5-109

Preparations ------------------------------------------------------------------------------ 5-109

Procedure

---------------------------------------------------------------------------------- 5-109

Adjusting Alignment for Saddle Stapling -----------------------------------5-111

Adjusting Engagement/Disengagement Position of Saddle

Disengagement Roller --------------------------------------------------------- 5-114

Preparations ------------------------------------------------------------------------------ 5-114

Procedure

---------------------------------------------------------------------------------- 5-114

Adjusting Feeding Distance of Saddle Disengagement Roller ------ 5-116

Preparations ------------------------------------------------------------------------------ 5-116

Procedure

---------------------------------------------------------------------------------- 5-116

Adjusting Side Registration of Saddle ------------------------------------- 5-118

Preparations ------------------------------------------------------------------------------ 5-118

Procedure

---------------------------------------------------------------------------------- 5-118

Setting of Pressless Mode ---------------------------------------------------- 5-121

Preparations ------------------------------------------------------------------------------ 5-121

Procedure

---------------------------------------------------------------------------------- 5-121

Adjusting Delivery Angle ------------------------------------------------------ 5-122

Preparations ------------------------------------------------------------------------------ 5-122

Procedure

---------------------------------------------------------------------------------- 5-123

Setting of Tray Speed ---------------------------------------------------------- 5-124

Preparations ------------------------------------------------------------------------------ 5-124

Procedure

---------------------------------------------------------------------------------- 5-124

Changing Lower Delivery Mode --------------------------------------------- 5-126

Preparations ------------------------------------------------------------------------------ 5-126

Procedure

---------------------------------------------------------------------------------- 5-126

Setting of Stop-less Stacking ------------------------------------------------ 5-128

Preparations ------------------------------------------------------------------------------ 5-128

Procedure

---------------------------------------------------------------------------------- 5-128

Adjusting Hole Positions in Feeding Direction --------------------------- 5-129

Upper/Lower Neat Paddle position adjustment ------------------------- 5-130

Preparations ------------------------------------------------------------------------------ 5-130

Procedure

---------------------------------------------------------------------------------- 5-130

Punch skew tolerance adjustment mode --------------------------------- 5-133

Preparations ------------------------------------------------------------------------------ 5-133

Procedure

---------------------------------------------------------------------------------- 5-133

Process Tray alignment operation adjustment mode with A4R/LTRR

size paper ------------------------------------------------------------------------- 5-135

Preparations ------------------------------------------------------------------------------ 5-135

Procedure

---------------------------------------------------------------------------------- 5-135

Side registration position ne adjustment mode (shift amount change) -5-136

Preparations ------------------------------------------------------------------------------ 5-136

Procedure

6

Troubleshooting

---------------------------------------------------------------------------------- 5-137

Upgrading -----------------------------------------------------------------------6-2

Upgrading ---------------------------------------------------------------------------- 6-2

Drive/Sensor check -----------------------------------------------------------6-3

Motor,Solenoid ---------------------------------------------------------------------- 6-3

Sensor -------------------------------------------------------------------------------- 6-6

7

Installation

How to check this Installation Procedure -------------------------------7-2

When Using the Parts included in the package ---------------------------- 7-2

Symbols in the Illustration ------------------------------------------------------- 7-2

Product Name ------------------------------------------------------------------7-2

Checking Before Installation

Checking the Unpacking Space ------------------------------------------------ 7-3

-----------------------------------------------7-3

Checking the Contents ------------------------------------------------------7-4

Unpacking Procedure

Turning OFF the Power Switch

Installation Procedure

Before Installing the Finisher ---------------------------------------------------- 7-8

Connecting with the Host Machine ------------------------------------------- 7-10

Connecting with the Professional Puncher Integration Unit ------------7-15

Connecting with the Paper Folding Unit -------------------------------------7-18

Connecting with the Document Insertion Unit -----------------------------7-21

Connecting Cable ----------------------------------------------------------------- 7-24

Checking Connection ------------------------------------------------------------7-27

--------------------------------------------------------7-5

--------------------------------------------7-7

--------------------------------------------------------7-8

Making Adjustments -------------------------------------------------------- 7-28

Height Adjustment ----------------------------------------------------------------7-28

Checking the height -----------------------------------------------------------------------7-28

Height Adjustment -------------------------------------------------------------------------7-29

Attaching the Labels etc --------------------------------------------------- 7-32

Afxing the Labels ----------------------------------------------------------------7-32

Relocationg the Machine -------------------------------------------------- 7-34

A NOTE on moving the machine ----------------------------------------------7-34

Appendix

Service Tools -------------------------------------------------------------------8-2

Solvents and Oils

List of Signals

List of Signals (nisher) ---------------------------------------------------------- 8-4

List Of Signals (saddle) ----------------------------------------------------------- 8-6

General Circuit Diagram -----------------------------------------------------8-7

-------------------------------------------------------------8-3

------------------------------------------------------------------8-4

Safety Precautions

Notes Before Servicing

■

Points to Note at Cleaning

■

0

Safety Precautions

Safety Precautions > Points to Note at Cleaning

Notes Before Servicing

Caution:

At servicing, be sure to turn off the power source according to the specied steps and

disconnect the power plug.

Caution:

Do not turn off the power switch when downloading is under way.

Turning off the main power switch while downloading is under way can disable the

machine.

Points to Note at Cleaning

0-2

Caution:

When performing cleaning using organic solvent such as alcohol, be sure to check that

the component of solvent is vaporized completely before assembling.

Safety Precautions > Points to Note at Cleaning

Safety Precautions

0

0-2

Product Outline

1

Product Specications

■

Names of Parts

■

Product Outline

1

1

Product Outline > Product Specications > Specications

1-2

Product Specications

Specications

Item Specications

Size:

A3, B4, A4, A4R, B5, B5R,A5R, 13” x 19” (330.2 x 482.6 mm), 12” x 18” (304.8 x

457.2 mm), 11” x 17”, LGL, LTR, LTRR, EXEC, 12 5/8” x 17 11/16”, Postcard,4 on

Paper size/

usable paper

1 Postcard, Custom size (100 x 182 mm to 330.2 x 487.7 mm)

Thickness:

52 to 300 g/m2

Paper types:

Thin paper, Plain paper, Heavy paper, Recycled paper, Color paper, Pre-punched

paper, Bond paper, Transparency, Tab paper, Label paper

Item Specications

Stacking for collate

Tray A

A4, B5, A5R, LTR, EXE, STMTR, 13 x 19, 12 x 18, SRA3, A3, B4, A4R, B5R,

LDR, LGL, LTRR, EXER,Postcard:

1000 sheets (or 147 mm in height)

Tray B

When large volume stack mode is “OFF”:

A4, B5, LTR, EXE, STMTR (feed length: 216 mm or less):

2000 sheets (or 285 mm in length)

13 x 19, 12 x 18, SRA3, A3, B4, A4R, B5R, LDR, LGL, LTRR, EXER (feed

length: 216.1 to 483 mm or less):

1000 sheets (or 147 mm in height)

When large volume stack mode is “ON”:

A4, B5, LTR, EXE, STMTR (feed length: 216 mm or less):

4000 sheets (or 490 mm in height)

13 x 19, 12 x 18, SRA3, A3, B4, A4R, B5R, LDR, LGL, LTRR, EXER (feed

Tray capacity

(Stacking

capacity for 80

g/m2 paper)

length: 216.1 to 483 mm or less):

1500 sheets (or 285 mm in height)

Stacking for stapling

A4, B5, LTR, EXE, STMTR (feed length: 216 mm or less):

3000 sheets (or 423 mm in height) or 200 copies

13 x 19, 12 x 18, SRA3, A3, B4, A4R, B5R, LDR, LGL, LTRR, EXER (feed

length: 216.1 to 483 mm or less):

1500 sheets (or 285 mm in height) or 200 copies(50 copies:more than 120 g/m2

)

Stapling of mixed paper

A4, B5, A5R, LTR, EXE, STMTR (feed length: 216 mm or less):

2000 sheets (or 285 mm in height) or 100 copies

13 x 19, 12 x 18, SRA3, A3, B4, A4R, B5R, LDR, LGL, LTRR, EXER (feed

length: 216.1 to 483 mm or less):

1000 sheets (or 147 mm in height) or 100 copies

Z-fold (only when the Paper Folding Unit-F1 is installed)

Tray A: up to 30 sheets of Z-fold paper per job

Tray B: up to 10 sheets of Z-fold paper per copy, and up to 30 sheets of Z-fold

paper per job

2-fold (only when the Paper Folding Unit-F1 is installed)

Tray A: up to 50 sheets of Z-fold paper per job(LTRR,A4R)

Product Outline > Product Specications > Specications

1

1-2

1

Product Outline > Product Specications > Specications > Staple Position

1-3

Item Specications

When a standard Stamp Cartridge is installed

(The number of sheets that can be stapled may decrease depending on the type

and thickness of the paper.)

A4, B5, A5R, LTR, EXE, STMTR

52 to 80 g/m2 or less: 100 sheets

Over 80 to 81.4 g/m2 or less: 80 sheets

Over 81.4 to 105 g/m2 or less: 60 sheets

Over 105 to 200 g/m2 or less: 20 sheets

Over 200 to 300 g/m2 or less: Cover and back cover only

Stapling

Power Supply 220-240V AC, 50/60Hz, 8A

Maximum

power

consumption

Dimensions

Weight

13 x 19, 12 x 18, SRA3, A3, B4, A4R, B5R, LDR, LGL, LTRR, EXER

52 to 80 g/m2 or less: 50 sheets

Over 80 to 81.4 g/m2 or less: 50 sheets

Over 81.4 to 105 g/m2 or less: 30 sheets

Over 105 to 200 g/m2 or less: 10 sheets

Over 200 to 300 g/m2 or less: Cover and back cover only

Corner stapling:

A3, B4, A4, A4R, B5/LDR, LGL, LTR, LTRR, EXEC

Double stapling:

A3, B4, A4, A4R, B5/LDR, LGL, LTR, LTRR, EXEC,B5R

500W or less

800 mm (1060 mm*) (width) x 792 mm (depth) x 1239 mm (height)

* When the Binding Auxiliary Tray is fully opened

Staple Finisher-Q1: 129 kg

Booklet Finisher-Q1: 181 kg

T-1-1

Staple Position

■

nisher

●

LDR,LTR 72.75±4.0 192.75±4.0 6.0±2.0

A4R 38.25±4.0 158.25±4.0 6.0±2.0

LTR-R,LGL 41.25±4.0 161.25±4.0 6.0±2.0

EXEC 66.25±4.0 186.25±4.0 6.0±2.0

size L1 L2 L3

A3,A4 81.75±4.0 201.75±4.0 6.0±2.0

B4,B5 61.75±4.0 181.75±4.0 6.0±2.0

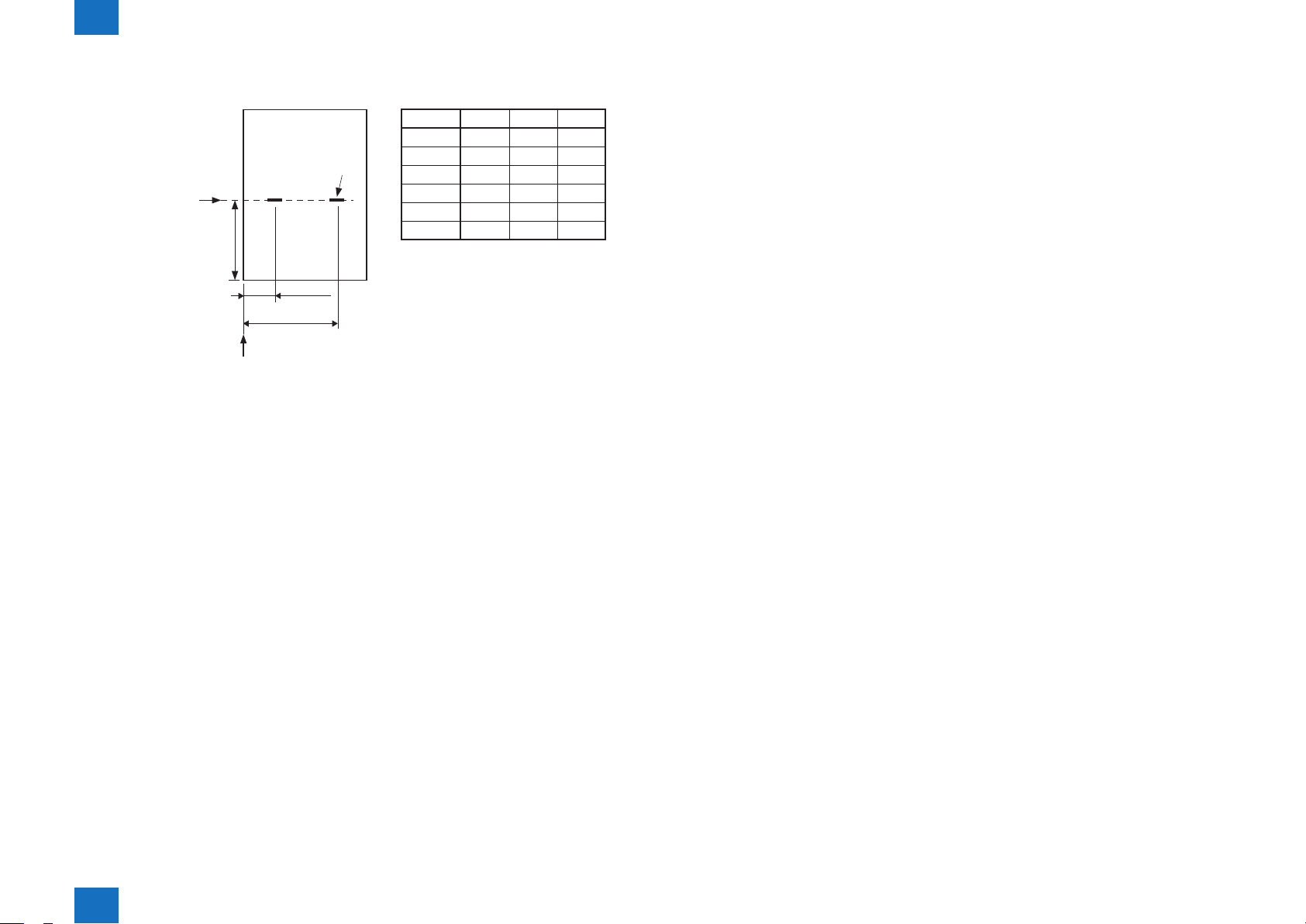

F-1-1

T-1-2

Product Outline > Product Specications > Specications > Staple Position

1

1-3

1

Product Outline > Product Specications > Specications > Staple Position

saddle stitcher

●

1-4

Folding position

Stample position

L3±1.0mm

L1±2.0mm

L2±2.0mm

Stack front edge

Paper Size

A3

B4

A4R

11"x17"

LGL

LTRR

L1

88.5

68.5

45

79.7

48

48

L2

208.5

188.5

165

199.7

168

168

L3

210

182

148.5

216

177.8

139.7

F-1-2

Product Outline > Product Specications > Specications > Staple Position

1

1-4

1

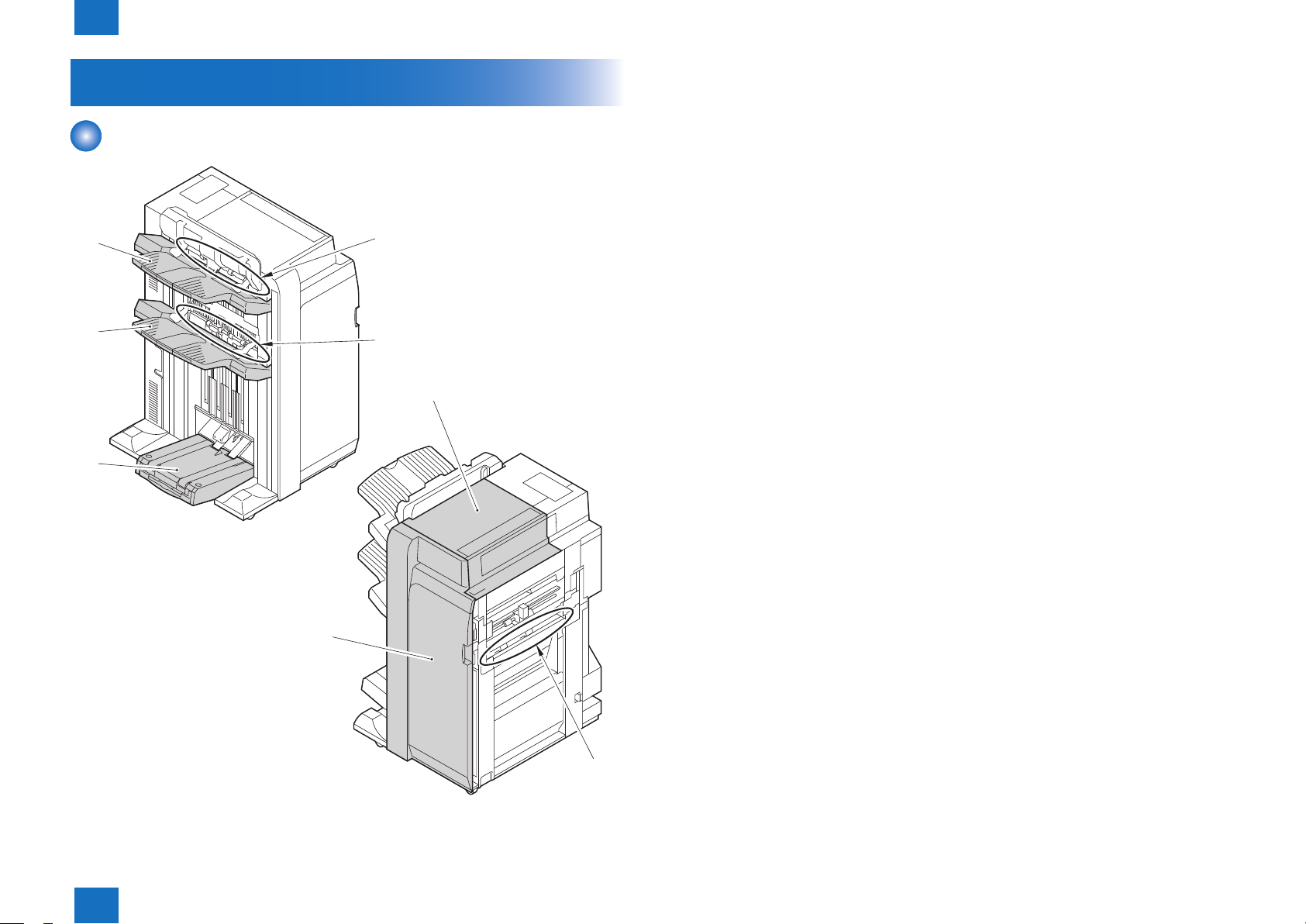

Product Outline > Names of Parts > External View

1-5

Names of Parts

External View

[2]

[1]

[5]

[1] Tray B [5] Saddle delivery belt

[2] Tray A [6] Upper cover

[3] Top delivery outlet [7] Inlet transport unit

[4] Bottom delivery outlet [8] Front cover

[3]

[4]

[6]

Product Outline > Names of Parts > External View

1

[8]

[7]

F-1-3

1-5

1

Product Outline > Names of Parts > Cross Section

Cross Section

1-6

[7] [8]

[6]

[5]

[4]

[3]

[2]

[1]

[31]

[9]

[11] [12][10] [13]

[14]

[15]

[16]

[17]

[18]

[19]

[20]

[21]

[22]

[1] Feed belt [17] Assist roller 1

[2] Sheaf eject roller [18] Inlet delivery roller

[3] Swing guide [19] Saddle inlet delivery roller

[4] Paddle [20] Stapler

[5] Tray B [21] Stitcher

[6] Process feed roller [22] Pull-out roller

[7] Tray A [23] Paper guide plate

[8] Eject roller [24] Fold delivery roller

[9] Buffer roller 2 [25] Adjust roller (upper)

[10] Assist roller 3 [26] Adjust roller (lower)

[11] Buffer roller 3 [27] Sheaf delivery roller

[12] Delivery roller [28] Pre-press roller

[13] Buffer roller 1 [29] Press unit

[14] Assist roller 2 [30] Saddle delivery belt

[15] Shift roller 2 [31] Waste staple case

[16] Shift roller 1

Product Outline > Names of Parts > Cross Section

1

[26]

[23]

[24]

[25][27][28][29][30]

F-1-4

1-6

Technology

2

Basic Construction

■

Electrical Control Unit

■

Stacking Unit

■

Feeding Unit

■

Intermediate Process Tray Assembly

■

Saddle Stitcher Unit

■

Detecting Jams

■

2

Technology

2

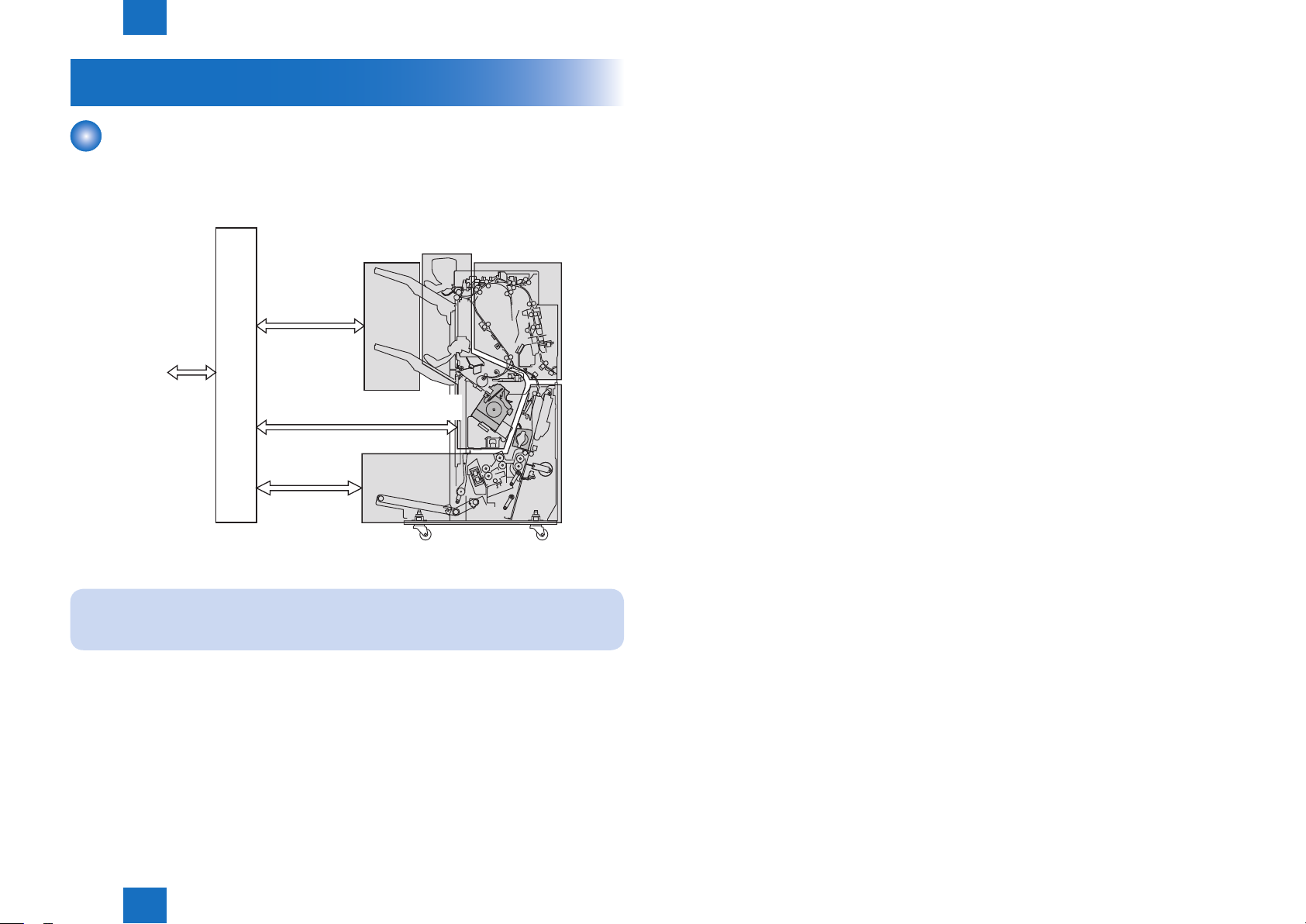

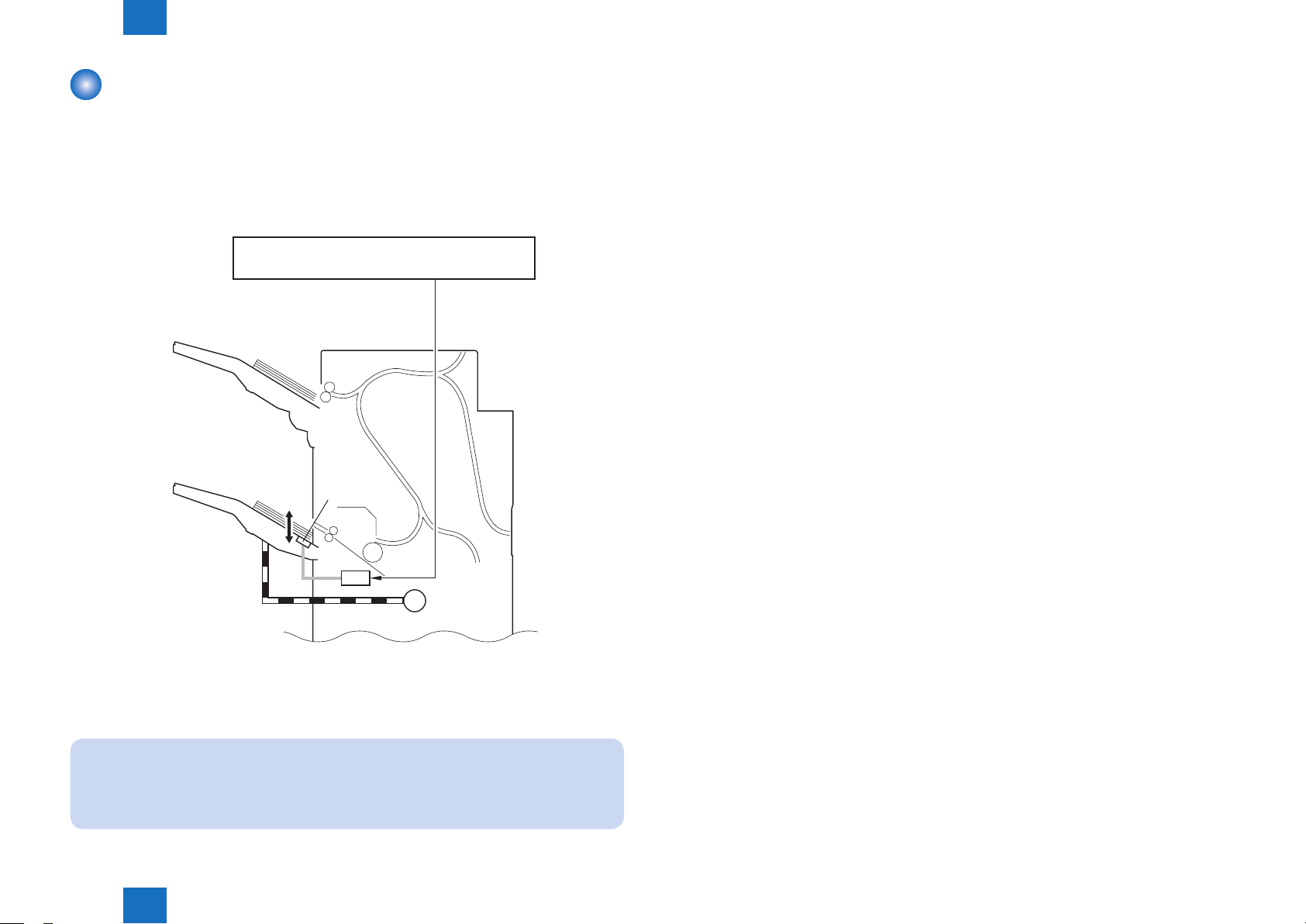

Technology > Basic Construction > Overview

Basic Construction

Overview

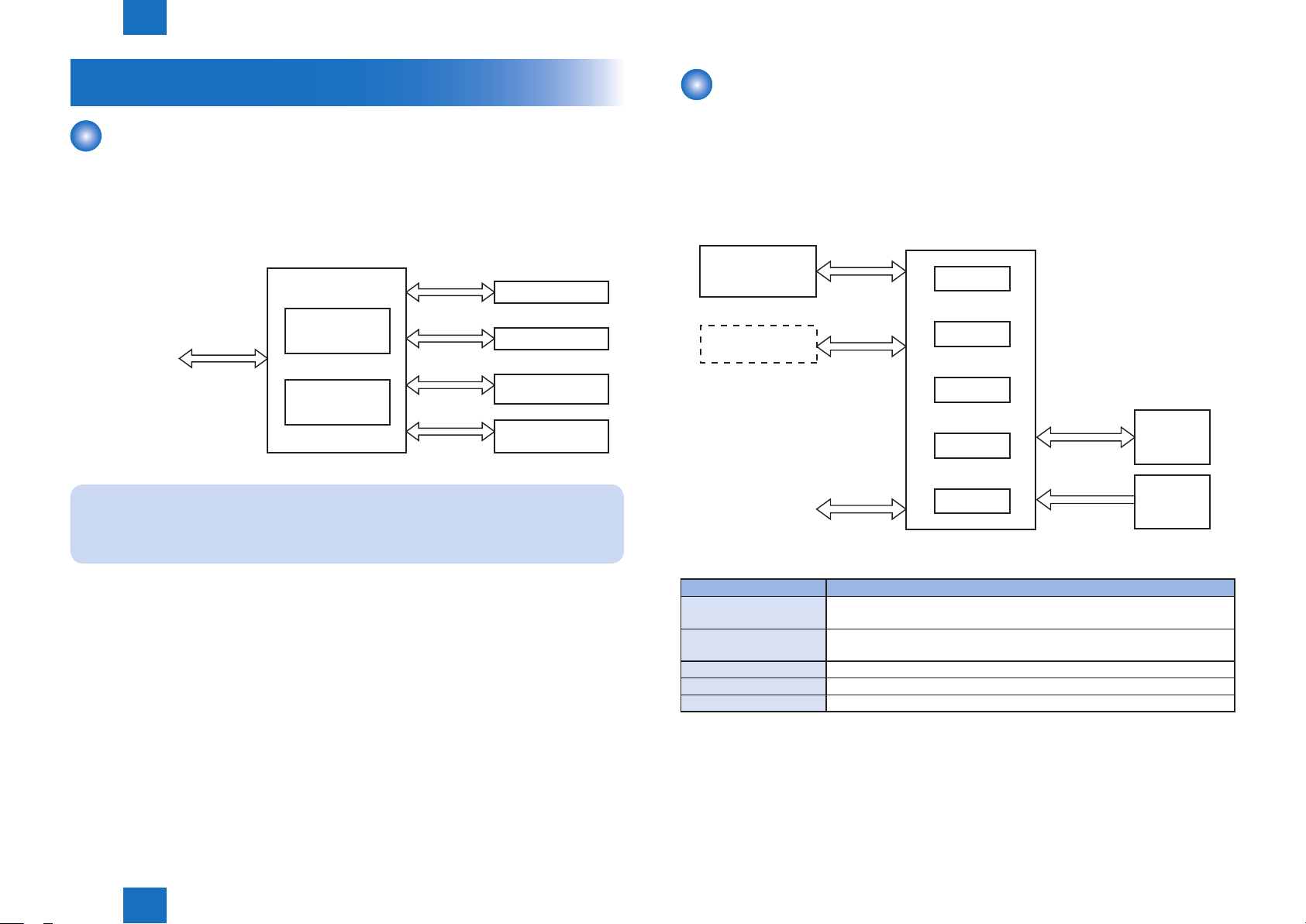

The machine consists of the following 5 blocks: electrical control block, stacking block,

transport block, intermediary tray, and saddle stitcher block.

Electrical control block

Stacking block

To host machine

Intermediary

tray block

Saddle stitcher block

Transport

block

2-2

F-2-1

NOTE:

The descriptions on the saddle stitcher block apply to the Booklet Finisher-Q1 PRO.

Technology > Basic Construction > Overview

2

2-2

2

Technology > Electrical Control Unit > Finisher Controller PCB

2-3

Electrical Control Unit

Overview

The electrical control block governs all the control mechanisms of the machine, i.e., stacking

block, transport block, intermediary tray block, and saddle stitcher block.

The electrical control block consists of 2 entities: nisher controller PCB and saddle stitcher

controller PCB.

Electrical

control block

Finisher

controller PCB

To host machine

Saddle stitcher

controller PCB

NOTE:

The descriptions on the saddle stitcher controller PCB apply to the Booklet Finisher-F1

PRO.

Stacking block

Transport block

Intermediary

tray block

Saddle stitcher

block

F-2-2

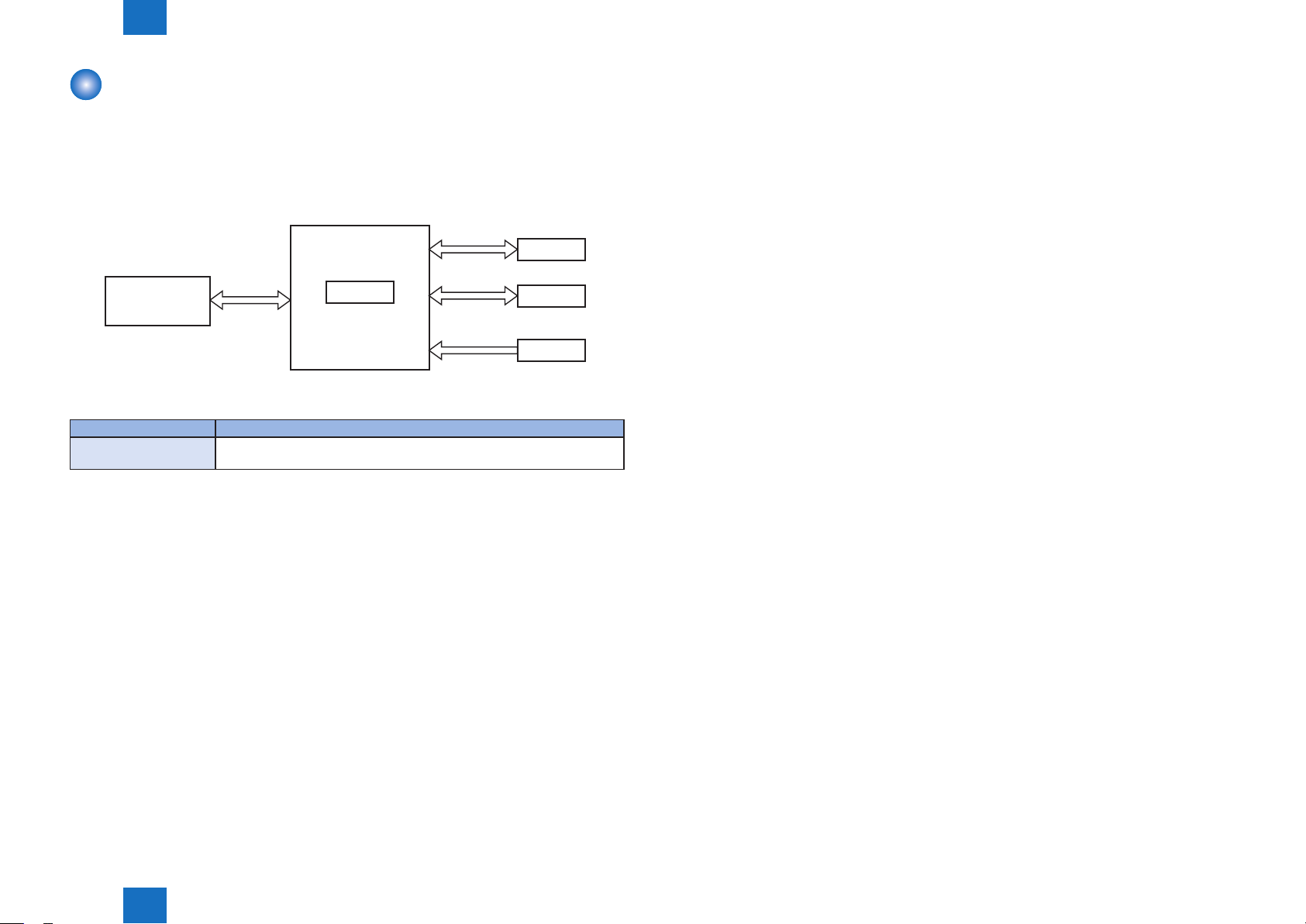

Finisher Controller PCB

The nisher controller PCB drives the various loads (motors, solenoids) of the machine in

response to the commands from the host machine (copier), and indicates the states of the

sensors and switches to the host machine.

It also serves to control the punch unit and the saddle nisher controller PCB.

Finisher

controller PCB

Saddle stitcher

controller PCB

Punch unit

(accessory)

To host machine

The machine uses the following ICs, each possessing specic functions:

IC Description

CPU Controls the communications with the host machine; controls ASIC1/

ASIC2.

ASIC1 Controls the communications with accessories; controls the drive to

various loads.

ASIC2 Controls the drive to various loads.

ROM Stores the rmware used to operate the machine.

EEPROM Stores counter readings and adjustment values.

CPU

ASIC1

ASIC2

ROM

EEPROM

Motor,

Solenoid

Switch,

Sensor

F-2-3

T-2-1

Technology > Electrical Control Unit > Finisher Controller PCB

2

2-3

2

Technology > Electrical Control Unit > Saddle Stitcher Controller PCB

Saddle Stitcher Controller PCB

The saddle stitcher controller PCB drives the machine's various loads (motors, solenoids) in

response to the commands from the nisher controller, and indicates the states of sensors

and switches to the host machine.

Saddle stitcher

controller PCB

Motor

2-4

Finisher

Controller PCB

The machine uses the following major ICs possessing specic functions:

IC Description

ASIC1 Controls the communications with the nisher controller; controls the drive

to various loads.

ASIC1

Solenoid

Sensor

F-2-4

T-2-2

Technology > Electrical Control Unit > Saddle Stitcher Controller PCB

2

2-4

2

Technology > Stacking Unit > Overview

Stacking Unit

Overview

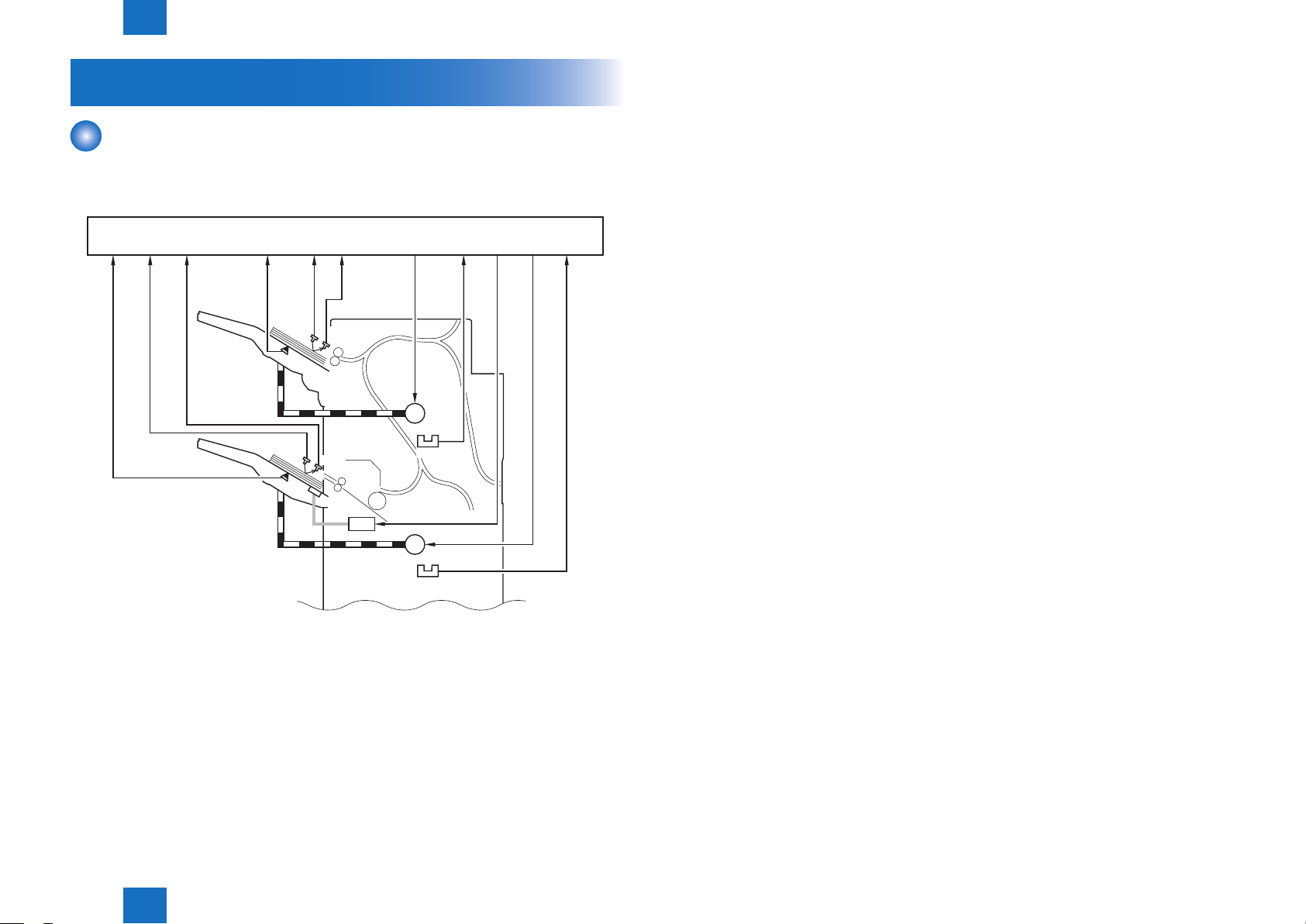

The stacking block moves up and down the 2 delivery trays according to the instructions from

the nisher controller PCB.

Finisher controller PCB

[1] [2] [3] [4] [5] [6] [7] [8] [9]

UN15

Tray A

PS32

UN16

[11][10]

[1] Tray B paper detection signal [7] Tray A lift motor drive single

[2] Tray B paper surface detection light-

emitting signal

[3] Tray B paper surface detection light-

receiving signal

[4] Tray A paper detection signal

[5] Tray A paper surface detection light-

emitting signal

[6] Tray A paper surface detection light-

receiving signal

[8] Tray A lift motor rotation detection

signal

[10] Tray B lift motor drive signal

[11] Tray B lift motor rotation detection

signal

2-5

Tray B

UN17

PS33

UN18

SL9

M22

M23

PS34

PS35

M22 : Tray A lift motor UN15 : Tray A paper side sensor board

(emitter)

M23 : Tray B lift motor UN16 : Train A paper side sensor board

(receiver)

PS32 : Tray A paper sensor UN17 : Tray B paper side sensor board

(emitter)

PS33 : Tray A paper sensor UN18 : Train B paper side sensor board

(receiver)

PS34 : Tray A lift motor rotation sensor

PS35 : Tray B lift motor rotation sensor

F-2-5

Technology > Stacking Unit > Overview

2

2-5

2

Technology > Stacking Unit > Tray Ascent/Descent Control

2-6

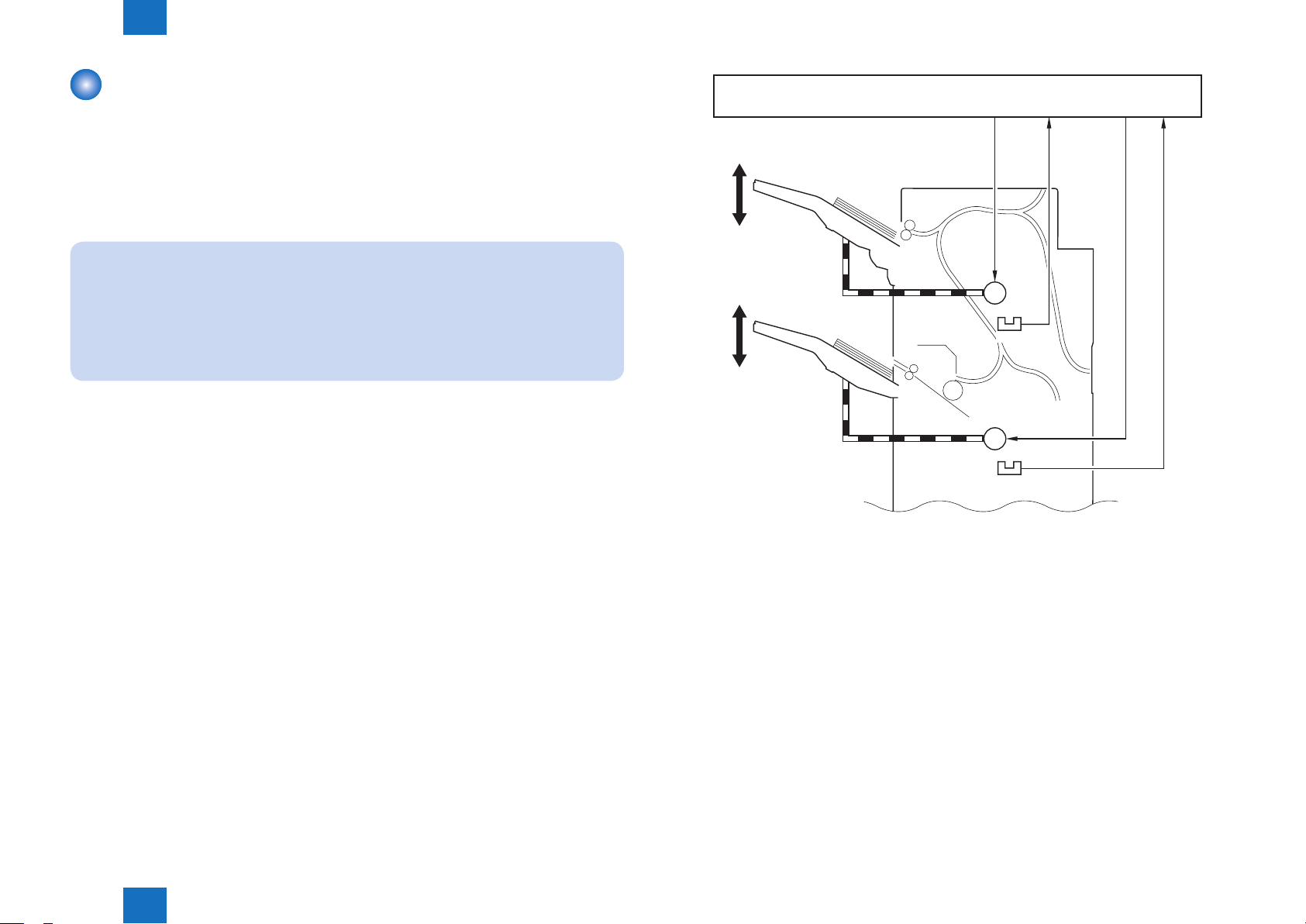

Tray Ascent/Descent Control

The tray A/B is moved up or down by controlling 2 motors (M22, M23) in response to the

instructions from the nisher controller.

The machine uses 2 sensors (PS34, PS35) to check for faults in these motors.

The sensor monitors the rotation of the motors; when any of the following occurs, the nisher

controller PCB will stop the drive to the motor and, at the same time, will communicate the

fact to the host machine:

Related Error Code

• E540 (fault in tray A)

While the tray A motor (M22) is rotating, the tray A lift motor rotation detection signal is

absent for 250 msec or more.

• E542 (fault in tray A)

While the tray B motor (M23) is rotating, the tray B lift motor rotation detection signal is

absent for 250 msec or more.

Finisher controller PCB

[1] [2] [3] [4]

Tray A

M22

PS34

Tray B

M23

PS35

[1] Tray A lift motor drive signal [3] Tray B lift motor drive signal

[2] Tray A lift motor rotation detection

signal

[4] Tray B lift motor rotation detection

signal

F-2-6

Technology > Stacking Unit > Tray Ascent/Descent Control

2

M22 : Tray A lift motor PS34 : Tray A lift motor rotation sensor

M23 : Tray B lift motor PS35 : Tray B lift motor rotation sensor

2-6

2

Technology > Stacking Unit > Auxiliary Tray Lift Control

Auxiliary Tray Lift Control

In response to an increase in the number of folded sheets in the tray, the auxiliary tray is

moved up to prevent a delivery jam associated with the tray B (memo) by making sure that

the lead and trail edges of the stacks deposited in the tray will be even.

The auxiliary tray is moved by operating the solenoid (SL9) according to the instructions from

the nisher controller PCB.

Finisher controller PCB

[1]

Tray A

2-7

Auxiliary tray

Tray B

SL9

M23

F-2-7

[1] Auxiliary tray solenoid drive signal SL9 : Auxiliary tray solenoid

M23 : Tray lift motor

NOTE:

A stack with a folded sheet tends to be higher along its lead edge than its trail edge,

blocking the discharge slot when it contains multiple folded sheets. (A subsequent

sheet will likely hit the preceding sheet, causing a jam.)

Technology > Stacking Unit > Auxiliary Tray Lift Control

2

2-7

2

Technology > Stacking Unit > Tray Paper Surface Detection

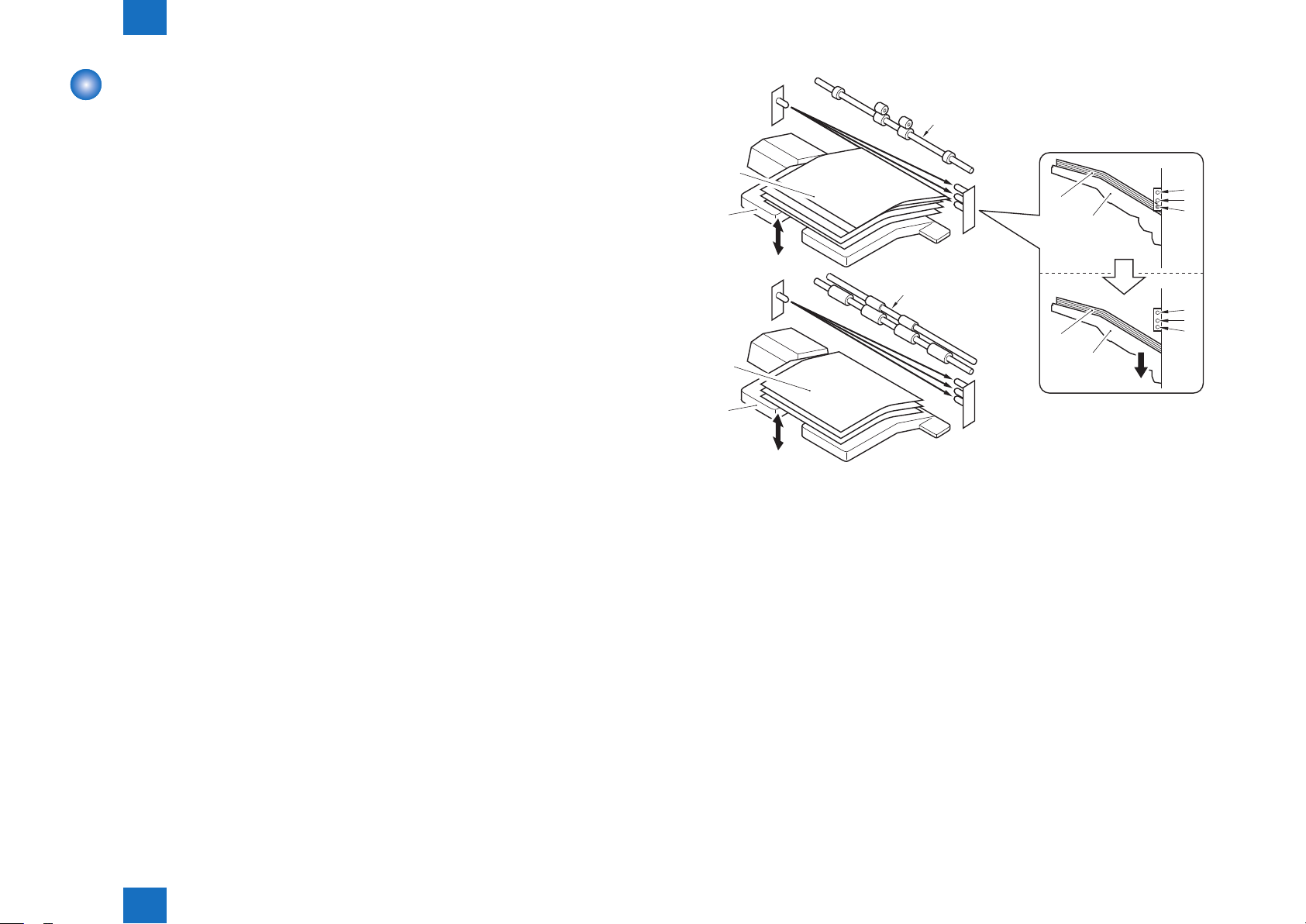

2-8

Tray Paper Surface Detection

The machine is equipped with a mechanism to detect the position of the top of the stack

deposited in its 2 trays.

The trays are each tted with a sensor PCB that consists of a light-emitting segment (UN15,

UN17) and a light-receiving segment (UN16, UN18).

The light-emitting segment is arranged at the rear of the machine, and is a LED. The lightreceiving segment, on the other hand, is found at the front of the machine, and it consists of 3

photosensors.

When the power is turned on or a jam has been removed, the nisher controller PCB checks

the 3 photosensors (light-receiving segment) as soon as the LED (lightemitting segment)

goes on.

As more and more sheets are deposited in the tray, the light reaching the light-receiving

segments will be blocked, causing the nisher controller PCB to move down the tray to keep

the top of the stack at a specic level.

When the tray becomes full of paper (i.e., light blocked, not reaching any of the 3

photosensors), the nisher controller PCB switches over to a different tray for subsequent

delivery. If the newly selected tray is full, it will stop the operation of the machine, and will

indicate the fact to the host machine.

UN15

[4]

[6]

[1]

UN16

[2]

UN17

[5]

[1]

UN18

[3]

[1]

[2]

[1]

[2]

UN16

UN16

[1] Paper [4] Non-sort delivery roller

[2] Tray A [5] Stack delivery roller

[3] Tray B [6] Tray descent movement (sample)

3

2

1

3

2

1

F-2-8

Technology > Stacking Unit > Tray Paper Surface Detection

2

UN15 : Tray A paper surface sensor

(light-emitting)

UN16 : Tray A paper surface sensor

(light-receiving)

UN17 : Tray B paper surface sensor

(light-emitting)

UN18 : Tray B paper surface sensor

(light-receiving)

2-8

2

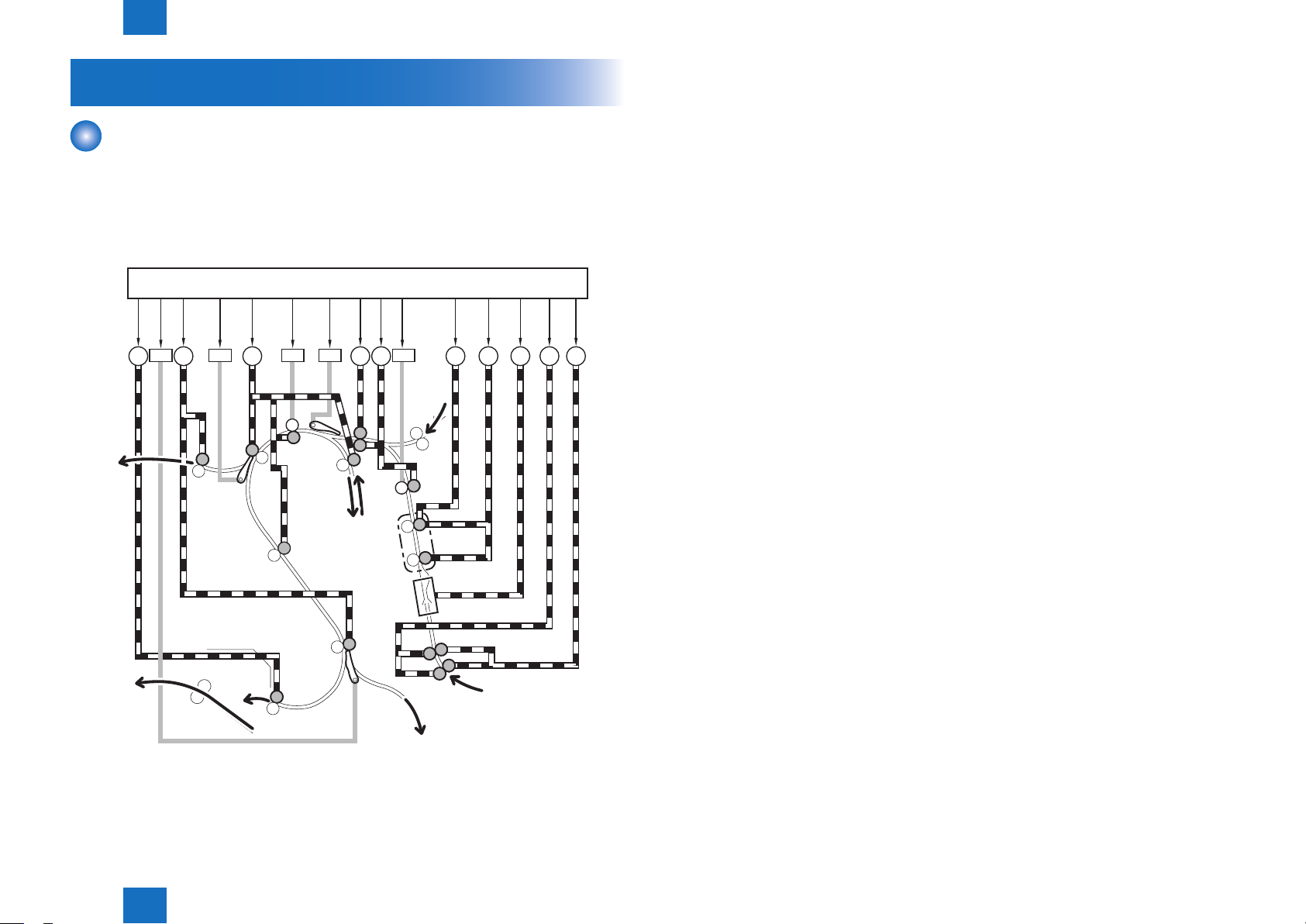

Technology > Feeding Unit > Overview

2-9

Feeding Unit

Overview

The machine's transport block serves to move paper to the stacking block or the saddle

stitcher block according to the instructions from the nisher controller PCB.

It also is used in conjunction with horizontal registration adjustment and alignment operation.

The machine uses 6 sensors to check for jams in the paper path.

Finisher Controller PCB

[1]

[2]

[3]

[4]

[5]

To tray A

[6] [7] [8] [9]

SL2SL3 SL1SL11

M4M5M26 M8 M7 M2

[10]

SL10

M3 M6 M27M1

inserter

From

[11]

[12]

[13]

[14]

[15]

[1] Process feed motor driver signal [9] Buffer front transport motor drive signal

[2] Saddle path switch solenoid drive

signal

[3] Delivery motor drive signal [11] Horizontal registration motor drive

[4] Upper path switch solenoid drive

signal

[5] Buffer motor drive signal [13] Horizontal registration detection unit

[6] Assist Motor Disengagement

Solenoid 2 drive signal

[7] Buffer path switch solenoid [15] Inlet roller disengage motor drive signal

[8] Transport roller shift motor drive

signal

M1 : Inlet transport motor M27 : Inlet motor separation motor

M2 : Shift transport motor SL1 : Buffer path switch solenoid

M3 : Buffer front transport motor SL2 : Upper path switch solenoid

M4 : Buffer motor SL3 : Saddle path switch solenoid

M5 : Delivery motor SL10 Assist Motor Disengagement Solenoid

M6 : Horizontal registration detection unit

shift motor

M7 : Horizontal registration shift motor

M8 : Transport roller shift motor

M26 : Operation feed motor

[10] Assist Motor Disengagement Solenoid

1 drive signal

signal

[12] Shift transport motor drive signal

shift motor drive signal

[14] Inlet transport motor drive signal

1

SL11 Assist Motor Disengagement Solenoid

2

To tray B

Technology > Feeding Unit > Overview

2

Shift Unit

Horizontal

Registration

Detection Unit

To saddle stitcher block

From host machine

F-2-9

2-9

2

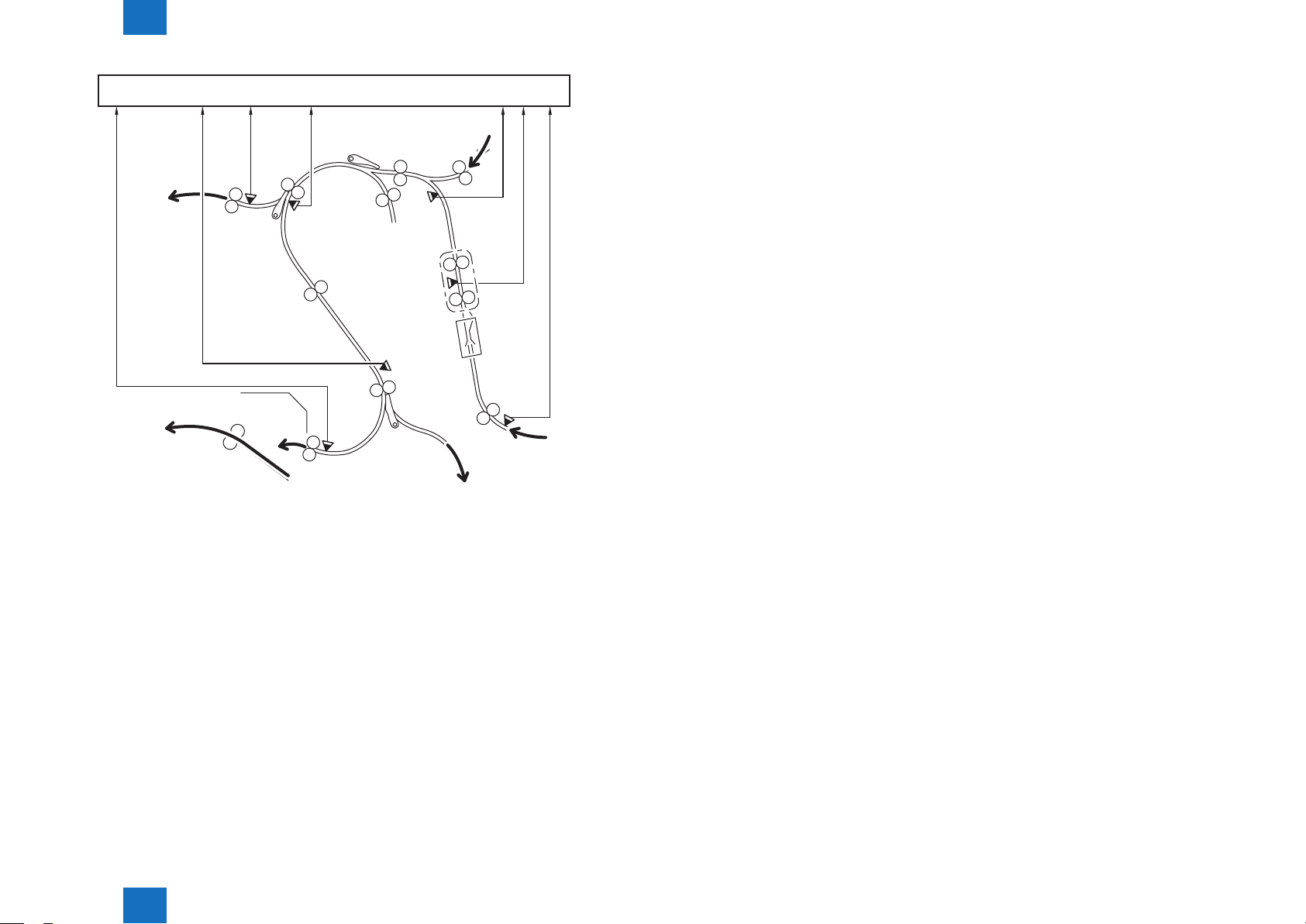

Technology > Feeding Unit > Overview

Finisher controller PCB

2-10

[1] [3][2] [4] [5]

To tray A

To tray B

PS5

UN14

UN22

PS6

From inserter

UN13

PS4

To saddle stitcher unit

[6]

PS3

From host machine

[1] Lower delivery sensor signal [5] Buffer path 1 sensor signal

[2] Lower path sensor signal [6] Shift unit trailing edge sensor

[3] Upper delivery sensor signal

detection signal

[4] Buffer path 2 sensor signal [7] Inlet sensor signal

[7]

F-2-10

PS3 : Inlet sensor UN13 : Buffer path 1 sensor PCB

PS4 : Shift unit trailing edge sensor UN14 : Buffer path 2 sensor PCB

PS5 : Upper delivery sensor UN22 : Lower path sensor PCB

PS6 : Lower delivery sensor

Technology > Feeding Unit > Overview

2

2-10

2

Technology > Feeding Unit > Basic Sequence of Operations

2-11

Basic Sequence of Operations

The transport block uses a sequence of operations that consists of the following 5:

1.HorizontalRegistrationDetection[1]

Detects the position of the paper.

2.HorizontalRegistrationCorrection[2]

Corrects the position of the paper with reference to the result of horizontal registration

detection.

3.Alignment[3]

Switches the position of the stack with reference to the result of horizontal registration

detection. (only in shift mode)

4.BufferOperation[4]

Keeps the sheet stationary inside the transport block; thereafter, joins it with the subsequent

sheet for forward movement.

5.MovementSwitch-Over[5]

Moves the paper to the stacking block or the saddle stitcher block.

6.

The particulars of individual operations are as follows:

[4]

To stacking block

[5]

From inserter

[2]

[3]

[1]

Technology > Feeding Unit > Basic Sequence of Operations

2

To stacking block

From host machine

To saddle stitcher block

F-2-11

2-11

Loading...

Loading...