Canon Staple Finisher-AA1, BookletFinisher-AA1 Service Manual

Revision 4.0

Staple Finisher-AA1/Booklet

Finisher-AA1

Service Manual

1x

1x

Introduction

Introduction

Important Notices

Application

This manual has been issued by Canon Inc. for qualified persons to learn technical theory, installation, maintenance, and repair

of products.

This manual covers all localities where the products are sold. For this reason, there may be information in this manual that does

not apply to your locality.

Corrections

This manual may contain technical inaccuracies or typographical errors due to improvements or changes in products.

When changes occur in applicable products or in the contents of this manual, Canon will release technical information as the

need arises. In the event of major changes in the contents of this manual over a long or short period, Canon will issue a new

edition of this manual.

The following paragraph does not apply to any countries where such provisions are inconsistent with local law.

Trademarks

The product names and company names used in this manual are the registered trademarks of the individual companies.

Copyright

This manual is copyrighted with all rights reserved. Under the copyright laws, this manual may not be copied, reproduced or

translated into another language, in whole or in part, without the consent of Canon Inc.

Copyright CANON INC. 2016

Caution

Use of this manual should be strictly supervised to avoid disclosure of confidential information.

Explanation of Symbols

The following symbols are used throughout this Service Manual.

Symbols Explanation Symbols Explanation

Check.

Remove the claw.

Check visually.

Check a sound. Push the part.

Insert the claw.

1x

1x

1x

1x

1x

1x

1x

1x

Introduction

Symbols Explanation Symbols Explanation

Disconnect the connector. Connect the power cable.

Connect the connector. Disconnect the power cable.

Remove the cable/wire from the

cable guide or wire saddle.

Install the cable/wire to the cable

guide or wire saddle.

Remove the screw.

Install the screw.

Cleaning is needed. Measurement is needed.

The following rules apply throughout this Service Manual:

1. Each chapter contains sections explaining the purpose of specific functions and the relationship between electrical and

mechanical systems with reference to the timing of operation.

In the diagrams, represents the path of mechanical drive; where a signal name accompanies the symbol, the arrow

indicates the direction of the electric signal.

The expression "turn on the power" means flipping on the power switch, closing the front door, and closing the delivery unit

door, which results in supplying the machine with power.

2. In the digital circuits, '1' is used to indicate that the voltage level of a given signal is "High", while '0' is used to indicate "Low".

(The voltage value, however, differs from circuit to circuit.) In addition, the asterisk (*) as in "DRMD*" indicates that the DRMD

signal goes on when '0'.

In practically all cases, the internal mechanisms of a microprocessor cannot be checked in the field. Therefore, the operations

of the microprocessors used in the machines are not discussed: they are explained in terms of from sensors to the input of

the DC controller PCB and from the output of the DC controller PCB to the loads.

The descriptions in this Service Manual are subject to change without notice for product improvement or other purposes, and

major changes will be communicated in the form of Service Information bulletins.

All service persons are expected to have a good understanding of the contents of this Service Manual and all relevant Service

Information bulletins and be able to identify and isolate faults in the machine.

Turn on the power.

Turn off the power.

Loosen the screw.

Tighten the screw.

Contents

Contents

Safety Precautions...............................................................................................1

Notes Before Servicing........................................................................................................................2

Points to Note at Cleaning...................................................................................................................2

Notes On Assembly/Disassembly....................................................................................................... 2

Notes on Assembly/Disassembly........................................................................................................... 2

Points to Note when Tightening a Screw.................................................................................................2

1. Product Overview.............................................................................................4

Features.............................................................................................................................................. 5

Features...............................................................................................................................................5

Specifications...................................................................................................................................... 6

Finisher................................................................................................................................................ 6

Staple Unit............................................................................................................................................8

Staple-Free Binding Unit......................................................................................................................10

Saddle Stitcher Unit (Booklet Finisher)..................................................................................................11

Buffer Pass Unit..................................................................................................................................12

Others................................................................................................................................................ 13

Names of Parts..................................................................................................................................14

External View (Front)...........................................................................................................................14

External View (Rear)........................................................................................................................... 15

External View (Internal)....................................................................................................................... 17

Cross Section..................................................................................................................................... 18

Optional Configuration ......................................................................................................................20

2. Technical Explanation................................................................................... 21

Basic Configuration........................................................................................................................... 22

Component Configuration.................................................................................................................... 22

Overview of the Electrical Circuitry....................................................................................................... 23

Controls.............................................................................................................................................25

Controls..............................................................................................................................................25

Basic Operation.................................................................................................................................26

Outline............................................................................................................................................... 26

Feeding Unit......................................................................................................................................31

Outline............................................................................................................................................... 31

Basic Operation.................................................................................................................................. 32

Feed switch operation......................................................................................................................... 33

Shift Operation....................................................................................................................................34

Buffer Operation..................................................................................................................................37

Stack/Escape Tray Unit.....................................................................................................................40

Outline............................................................................................................................................... 40

Stack Tray Up and Down Movement.....................................................................................................41

Stack Tray Delivery Paper Surface Detection, Paper Full.......................................................................42

Escape Tray Paper Full Detection........................................................................................................ 45

Processing Tray Unit.........................................................................................................................46

i

Contents

Outline............................................................................................................................................... 46

Stacking Operation..............................................................................................................................47

Alignment/Shifting Operation................................................................................................................50

Staple Operation................................................................................................................................. 52

Staple-free Binding Operation.............................................................................................................. 55

Stack Delivery Operation..................................................................................................................... 58

Saddle Stitcher Unit...........................................................................................................................59

Outline ...............................................................................................................................................59

Configuration...................................................................................................................................... 60

Basic Operation.................................................................................................................................. 61

Stacking Operation..............................................................................................................................62

Paper Stack Feed Operation................................................................................................................64

Stitch Operation.................................................................................................................................. 65

Paper Folding/Delivery Operation.........................................................................................................65

Buffer Pass Unit................................................................................................................................ 67

Overview............................................................................................................................................ 67

Fan Operation.....................................................................................................................................67

Jam Detection................................................................................................................................... 69

Outline............................................................................................................................................... 69

Jams.................................................................................................................................................. 70

Power Supply.................................................................................................................................... 73

Power Supply Route............................................................................................................................73

Protection Function............................................................................................................................. 73

Upgrading .........................................................................................................................................74

3. Periodical Service.......................................................................................... 75

Periodic Servicing Tasks...................................................................................................................76

4. Parts Replacement and Cleaning................................................................. 77

Removing this Machine.....................................................................................................................78

Removing the Finisher.........................................................................................................................78

Removing the Buffer Pass Unit............................................................................................................ 78

List of Parts....................................................................................................................................... 80

External / Internal Covers ....................................................................................................................80

Main Units/Parts..................................................................................................................................81

List of Clutches................................................................................................................................... 84

List of Motors...................................................................................................................................... 84

List of Sensors....................................................................................................................................87

List of Switches/ Fans..........................................................................................................................89

List of PCBs........................................................................................................................................91

Other Parts.........................................................................................................................................93

External/Internal Covers....................................................................................................................94

Removing the Rear Cover....................................................................................................................94

Removing the Front Cover...................................................................................................................94

Removing the Lower Front Cover.........................................................................................................94

Removing the Front Inner Cover.......................................................................................................... 95

Main Parts......................................................................................................................................... 96

Removing the Escape Tray..................................................................................................................96

Removing the Stack Tray.....................................................................................................................96

ii

Contents

Removing the Grate-Shaped Lower Guide............................................................................................96

Removing the Swing Unit.....................................................................................................................97

Removing the Processing Tray...........................................................................................................102

Removing the Staple Drive Unit..........................................................................................................103

Removing the Saddle Delivery Tray....................................................................................................104

Removing the Saddle Unit................................................................................................................. 105

Removing the Pushing Unit................................................................................................................106

Removing the Buffer Pass Upper Unit.................................................................................................107

Removing the Static Eliminator (Upper/Lower Escape Delivery Unit).....................................................108

Removing the Stapler Unit................................................................................................................. 108

Removing the Saddle Stitcher Unit..................................................................................................... 109

Removing the Staple-Free Binding Unit.............................................................................................. 109

Removing the Static Eliminator (Stack tray Unit)..................................................................................112

Removing the Static Eliminator (Saddle Delivery Unit)......................................................................... 112

Removing the Paddle Unit................................................................................................................. 113

Removing the Lower Stack Delivery Roller Clutch (CL102).................................................................. 114

Removing the Escape Feed Clutch (CL101)........................................................................................114

Removing the Stack Tray Torque Limiter............................................................................................ 115

PCB.................................................................................................................................................116

Removing the Finisher Controller PCB (PCB101)................................................................................ 116

Removing the Saddle Stitcher Controller PCB (PCB201)..................................................................... 118

Removing the Buffer Pass Controller PCB (PCB201)...........................................................................118

Removing the Buffer Pass Power Supply PCB (PCB203).....................................................................119

Sensor.............................................................................................................................................121

Removing the Delivery Sensor (PS102).............................................................................................. 121

Clutch/ Solenoid.............................................................................................................................. 122

Removing the Paddle Clutch (CL103).................................................................................................122

Motors............................................................................................................................................. 123

Removing the Front Alignment Motor (M107)...................................................................................... 123

Removing the Rear Alignment Motor (M108).......................................................................................123

Removing the Tray Auxiliary Guide Motor (M109)................................................................................124

Removing the Paper End Assist Motor (M113).................................................................................... 124

Removing the Stapler Shift Motor (M114)............................................................................................125

Removing the Staple-Free Binding Motor (M116)................................................................................ 126

Removing the Saddle Paper Pushing Plate/Folding Motor (M204)........................................................ 127

Removing the Saddle Delivery Motor (M207)...................................................................................... 128

Switches .........................................................................................................................................129

Removing the Front Cover Switch (SW101)........................................................................................ 129

Removing the Swing Guide Safety Switch (SW102).............................................................................129

Removing the Manual Staple Switch (SW103).....................................................................................130

Other Parts .....................................................................................................................................131

Pulling Out the Saddle Unit (Service Position)..................................................................................... 131

Removing the Grate-shaped Guide.....................................................................................................131

Removing the Escape Delivery Roller.................................................................................................131

Removing the Return Roller............................................................................................................... 134

Removing the Swing Roller................................................................................................................135

Removing the Folding Roller.............................................................................................................. 136

Removing the pushing plate...............................................................................................................141

iii

Contents

5. Adjustment................................................................................................... 142

Overview......................................................................................................................................... 143

Service Mode....................................................................................................................................143

Basic Adjustment Items..................................................................................................................... 146

Adjustments When Replacing Parts Items...........................................................................................147

Other................................................................................................................................................147

Basic Adjustment.............................................................................................................................148

Overview.......................................................................................................................................... 148

Adjusting the Paper Alignment........................................................................................................... 149

Adjusting the Staple Position..............................................................................................................158

Adjusting the Fold Position ................................................................................................................162

Adjusting the Saddle Stitch ............................................................................................................... 167

Adjustments When Replacing Parts................................................................................................173

Phase Alignment When Installing the Stack Tray Drive Belt................................................................. 173

Phase Alignment When Installing the Swing Unit.................................................................................173

Phase adjustment of paddle unit.........................................................................................................174

Phase Alignment When Installing the Paper Folding Roller.................................................................. 179

Handling Finisher Controller PCB Replacements.................................................................................180

Other............................................................................................................................................... 184

Releasing the Saddle Delivery Tray Stacking Limit.............................................................................. 184

6. Troubleshooting...........................................................................................185

Making Initial Checks...................................................................................................................... 186

List of Initial Check Items................................................................................................................... 186

Processing Tray Area......................................................................................................................187

Adjusting the Alignment and the Staple Position..................................................................................187

Saddle Stitcher Area....................................................................................................................... 188

Fold Placement / Saddle Stitch Adjustment......................................................................................... 188

7. Installation.................................................................................................... 189

How to Utilize This Installation Procedure.......................................................................................190

Illustrations Used in This Procedure....................................................................................................190

Product Name...................................................................................................................................190

Checking Before Installation............................................................................................................191

Checking the Installation Space..........................................................................................................191

Checking the Unpacking Space..........................................................................................................192

Check Items When Turning OFF the Main Power................................................................................ 192

Points to Note on Installation..............................................................................................................193

Installing the Accessories...................................................................................................................194

Unpacking....................................................................................................................................... 195

Unpacking Procedure........................................................................................................................ 195

Checking the Contents....................................................................................................................198

Installation Procedure......................................................................................................................199

Preparing the Host Machine for Installation......................................................................................... 199

Installation of Buffer Pass Unit............................................................................................................202

Preparing The Finisher for Installation.................................................................................................205

Connecting to Host Machine.............................................................................................................. 205

Affixing the Labels...........................................................................................................................208

iv

Contents

Jam Label / Saddle Caution Language Label (Booklet Finisher only).................................................... 208

Tray Setting Labels........................................................................................................................... 208

Making Adjustments........................................................................................................................209

Making Check and Adjustment of the Height....................................................................................... 209

Making Check and Adjustment of the Tilt............................................................................................ 210

Making Checks After Completion of Adjustments.................................................................................212

Making Checks After Completion of Installation Work.................................................................... 213

Disposal Parts Check........................................................................................................................ 213

Operation Check............................................................................................................................... 213

Detaching from the Host Machine...................................................................................................214

Finisher............................................................................................................................................ 214

Buffer Pass Unit................................................................................................................................ 214

APPENDICES....................................................................................................216

Service Tools...................................................................................................................................217

Solvents and Oils.............................................................................................................................. 217

Special Tools.................................................................................................................................... 217

General Circuit Diagram..................................................................................................................218

General Circuit Diagram 1/3...............................................................................................................218

General Circuit Diagram 2/3...............................................................................................................219

General Circuit Diagram 3/3...............................................................................................................220

v

Safety Precautions

Notes Before Servicing......................... 2

Points to Note at Cleaning.................... 2

Notes On Assembly/Disassembly.........2

Safety Precautions

Notes Before Servicing

CAUTION:

At servicing, be sure to turn off the power source according to the specified steps and disconnect the power plug.

CAUTION:

Do not turn off the power switch when downloading is under way. Turning off the main power switch while downloading is

under way can disable the machine.

Points to Note at Cleaning

CAUTION:

When performing cleaning using organic solvent such as alcohol, be sure to check that the component of solvent is

vaporized completely before assembling.

Notes On Assembly/Disassembly

Notes on Assembly/Disassembly

Follow the items below to assemble/disassemble the device.

1. Disconnect the power plug to avoid any potential dangers during assembling/disassembling works.

2. If not specially instructed, reverse the order of disassembly to reinstall.

3. Ensure to use the right screw type (length, diameter, etc.) at the right position when assembling.

4. To keep electric conduction, binding screws with washers are used to attach the grounding wire and the varistor. Ensure to

use the right screw type when assembling.

5. Unless it is specially needed, do not operate the device with some parts removed.

6. Never remove the paint-locked screws when disassembling.

7. During disassembly, reassembly or transportation of the printer, remove the cartridge if required. When the cartridge is out

of the printer, put it in a protective bag even in a short period of time to prevent the adverse effect of light.

8. When you replace the part that the rating plate or the product code label is attached, be sure to remove the rating plate or

the product code label and put it to the new part.

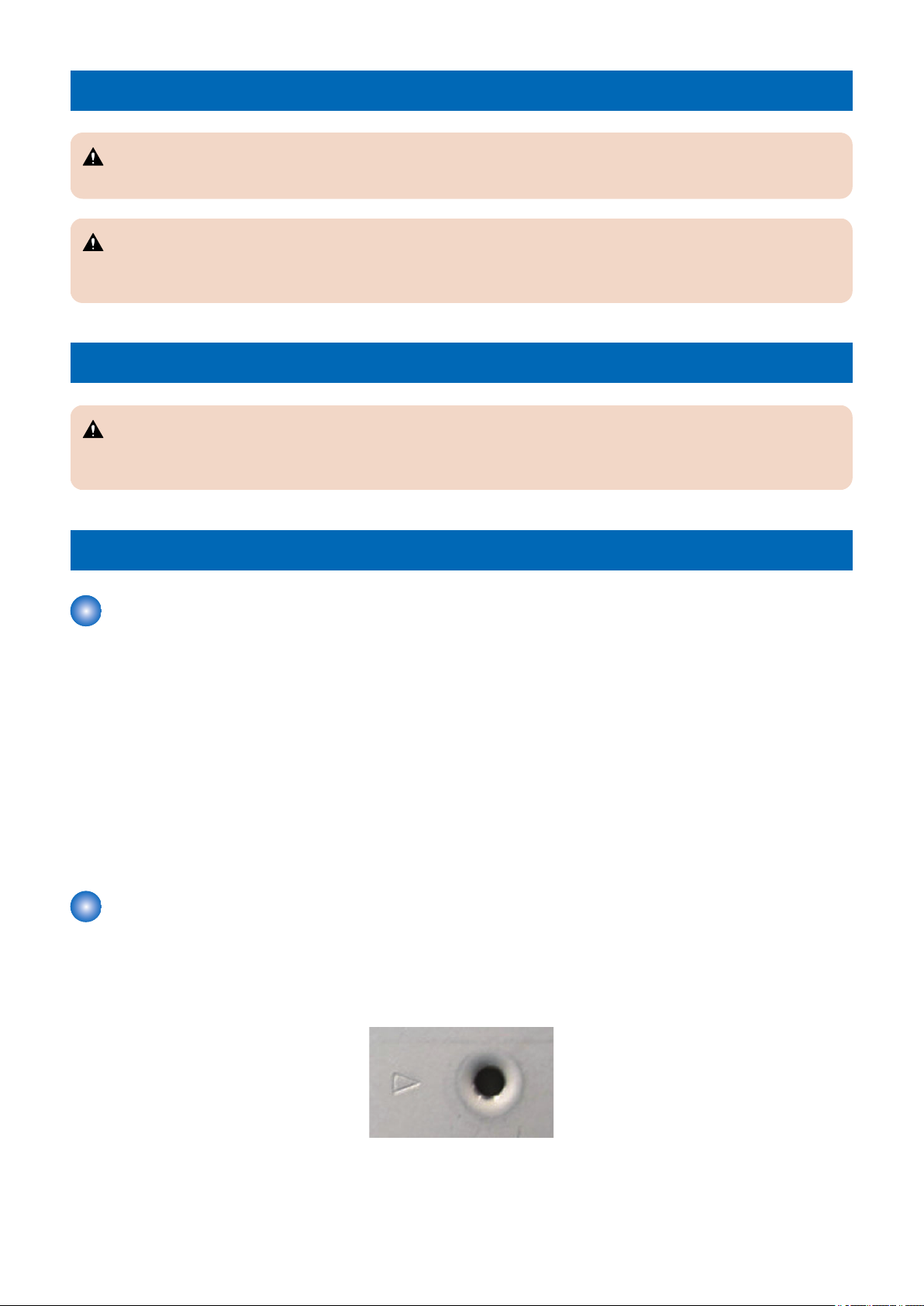

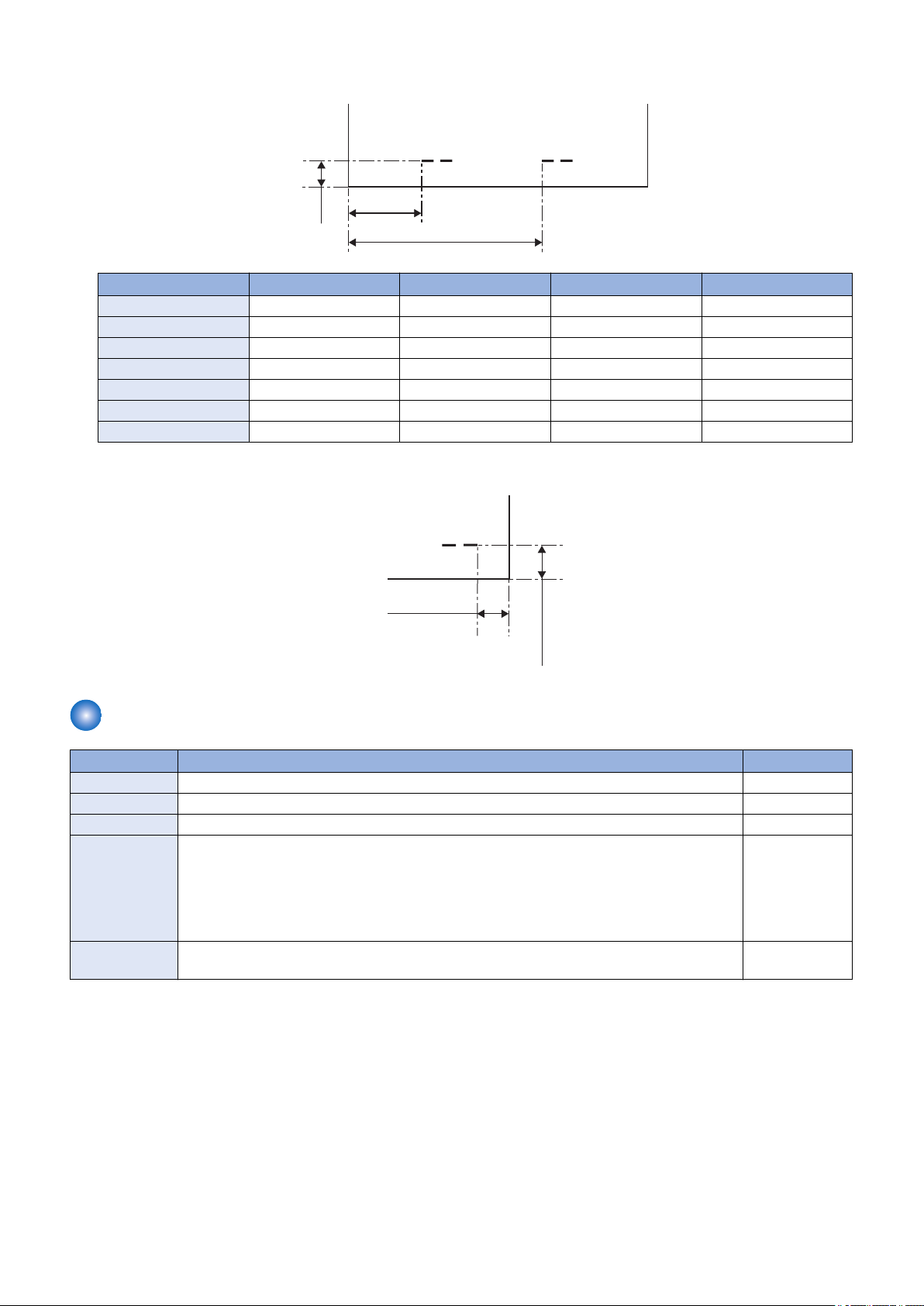

Points to Note when Tightening a Screw

For reduction in weight, thin plates are used in some parts of this machine.

In the case of a screw hole with a triangle mark near it as shown in the figure below, strongly tightening the screw may damage

or deform the screw hole.

In the case of a screw hole with a triangle mark, take care not to apply too much force when tightening the screw.

2

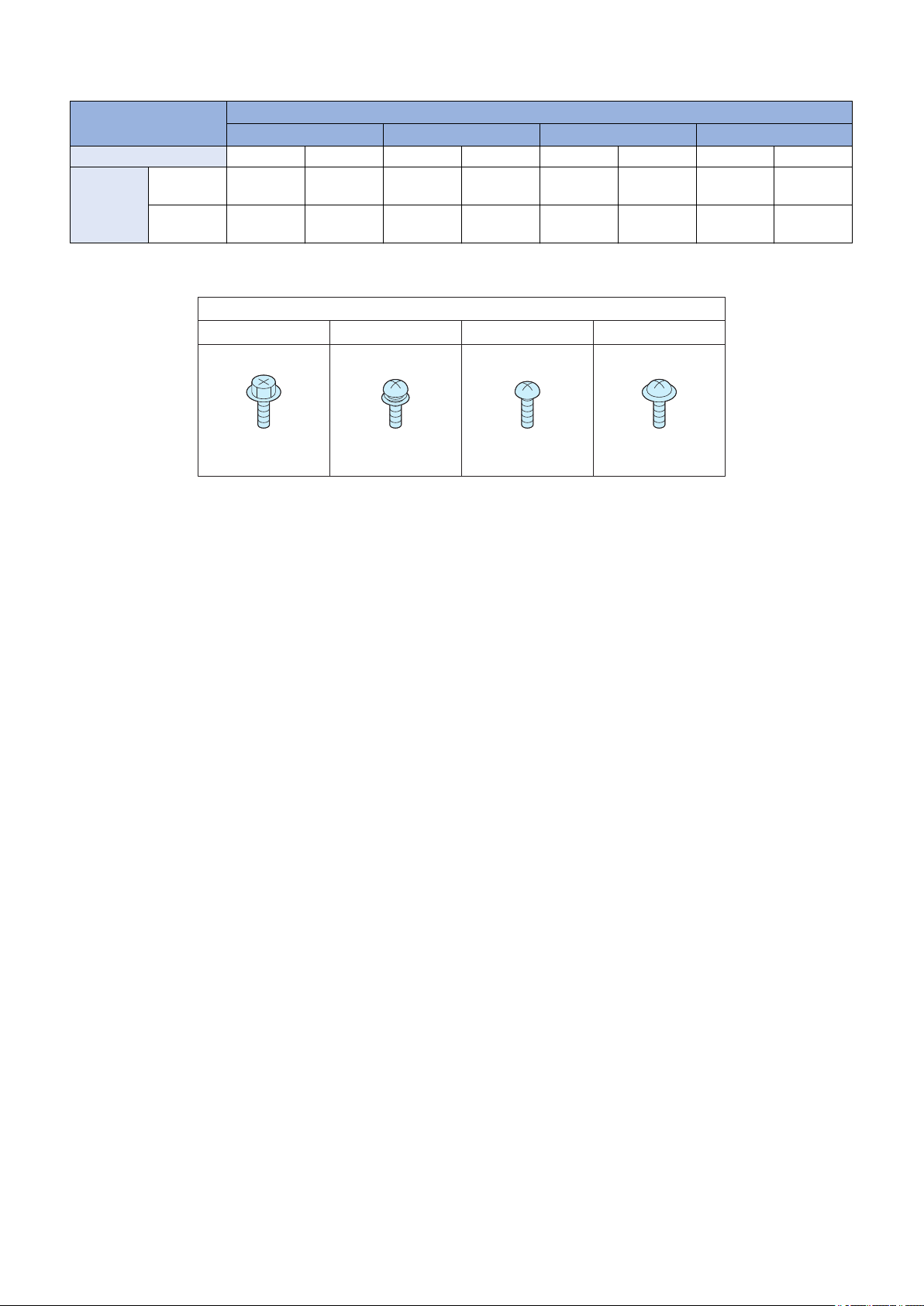

RS tight

Type of Screws

W Sems Binding TP

Safety Precautions

The recommended torque value is shown below as a reference value.

Type of Screws

RS tight W Sems Binding TP

Fastened member Metal Resin Metal Resin Metal Resin Metal Resin

Tightening

torque

(N*m)

* For PCB, refer to the tightening torque value of resin (fastened member).

M4 Approx.

1.6

M3 Approx.

0.8

Approx.

1.6

Approx.

0.8

Approx.

1.6

Approx.

0.6

Approx.

0.8

Approx.

0.6

Approx.

1.6

Approx.

0.6

Approx.

0.8

Approx.

0.6

Approx.

1.6

Approx.

0.6

Approx.

0.8

Approx.

0.6

3

1

Product Overview

Features................................................5

Specifications........................................6

Names of Parts................................... 14

Optional Configuration ....................... 20

1. Product Overview

Features

Features

• The main unit size has been reduced to allow installation in smaller space.

• The optional puncher unit can be installed in the finisher.

• Paper shift mechanism is incorporated into the escape tray delivery area allowing the shift sort stacking in the stack tray and

the upper/lower escape trays.

• Staple, manual staple, and staple-free binding functions are integrated allowing versatile stapling that suit the various

demands.

• Basic performance is substantial. That is the high-capacity stacking function that can stack up to 3,250 sheets (escape tray:

250 sheets, stack tray: 3,000 sheets), the staple function that can staple up to 50 sheets, and booklet binding function that

can stitch up to 20 sheets.

5

1. Product Overview

Specifications

Finisher

Item Specifications Remarks

Stacking method Stack tray: up and down moving type

Escape tray: fixed tray

Stacking orientation

Paper size Feed direction: 139.7 to 457.2 mm

Alignment stacking

size

Paper weight Escape tray 52 to 256 g/m2

Modes Non sort mode [Escape tray/stack tray]

Stacking capacity

(without folding

sheets)

Face up , face down

Cross feed direction: 98.0 to 320.0 mm

Feed direction: 182.0 to 432.0 mm

Cross feed direction: 210.0 to 297.0 mm

Stack tray [Non sort mode]

52 to 300 g/m2

[Shift sort mode/staple mode]

52 to 256 g/m2

[Staple-free binding mode]

52 to 105 g/m2

Feed direction: 139.7 to 457.2 mm

Cross feed direction: 98.0 to 320.0 mm

A3, A4, A4R, A5, A5R, B4, B5, B5R, 11×17, LGL, LTR, LTRR,

STMT, STMTR, EXEC, SRA3, 12"×18", 8K, 16K, 16KR

Shift sort mode [Escape tray]

A3, A4, B4, B5, 11×17, LTR, EXEC, 8K, 16K

[Stack tray]

A3, A4, A4R, B4, B5, 11×17, LGL, LTR, LTRR, EXEC, 8K, 16K

Staple mode [Stack tray]

A3, A4, 11×17, LGL, LTR, LTRR, EXEC, 8K, 16K

Staple-free binding

mode

Processing tray Feed length: 182 mm to 215.9 mm (50 sheets or less)

Escape tray Small size: Height 47 mm ± 3 mm or less (equivalent to 250

[Stack tray]

A3, A4, 11×17, LTR, 8K, 16K

Feed length: More than 215.9 mm to 431.8 mm (30 sheets or

less)

sheets)

Large size: Height 24 mm ± 3 mm or less (equivalent to 125

sheets)

- The stacking capacities are estimates when

converting weight to

number of 81.4 g/m2

sheets.

- The stacking capacities are estimates when

converting weight to

number of 81.4 g/m2

sheets.

- Alignment accuracy

and stacking capacity

for paper weighing 59 g/

m2 or less are not

specified.

6

1. Product Overview

Item Specifications Remarks

Stacking capacity

(without folding

sheets)

Mixed stacking capacity (without

folding sheets)

Stack tray [Non sort/shift sort mode]

- Plain paper

Small size: Height 423 mm or less (equivalent to 3,000 sheets)

(when saddle is used: Height 216 mm or less (equivalent to

1,500 sheets))

Large size: Height 216 mm or less (equivalent to 1,500 sheets)

- Coated paper

Small size: Height 216 mm or less (equivalent to 1,500 sheets)

Large size: Height 108 mm or less (equivalent to 750 sheets)

[Staple mode/staple-free binding mode]

- Plain paper

Small size: Height 423 mm or less, or 200 sets or less (when

saddle is used: Height 216 mm or less)

Large size: Height 216 mm or less, or 100 sets or less

- Coated paper

Small size: Height 216 mm or less, or 100 sets or less

Large size: Height 108 mm or less, or 50 sets or less

Escape tray [Mixed size]

Plain paper combination of A4, B5, and LTR only: Height 47 mm

± 3 mm or less

Combinations of other paper sizes: Height 24 mm ± 3 mm or less

Stack tray [Size mixing]

Plain paper combination of A4, B5, and LTR only : Height

216mm±3mm

Combinations of other paper sizes: Height 108mm ± 3mm

[Stapling mixing]

- Plain paper

Small size: Height 423 mm -/+ 3 mm or less, or 200 sets or less

Large size: Height 216 mm ± 3 mm or less, or 100 sets or less

- Coated paper

Small size: Height 216 mm ± 3 mm or less, or 100 sets or less

Large size: Height 108 mm ± 3mm or less, or 50 sets or less

[Mode mixing]

Plain paper combination of A4, B5, and LTR only: Height 423

mm ± 3 mm

Combinations of other paper sizes: Height 216 mm ± 3 mm or

less

- The stacking capacities are estimates when

converting weight to

number of 81.4 g/m2

sheets.

- The stacking capacity

for paper weighing 59 g/

m2 or less is for up to

the large size height,

and the alignment accuracy for 2-sided print

is not specified.

- Transparency, post

card, label and tracing

paper: 10 sheets or less

- Large size condition is

applied after a sheet of

paper of large size is

delivered.

- The stacking capacities are estimates when

converting weight to

number of 81.4 g/m2

sheets.

- The stacking capacity

for paper weighing 59 g/

m2 or less is for up to

the large size height

- The stacking capacities are estimates when

converting weight to

number of 81.4 g/m2

sheets.

- Stacking capacity is

not guaranteed.

- When the plain paper

and coated paper are

stacked, follows the

specifications of the

coated paper.

- The mixed stacking of

the small size paper

and 432 mm or more

length paper is not possible.

- Stacking on upper/

lower escape tray is not

possible for stapling

mixing and mode mixing.

- Paper size regulations:

Small size (feed length: 220 mm or less): A4, B5, LTR, EXEC, 16K, STMTR, A5R

Large size (feed length: more than 220 mm): A3, A4R, B4, B5R, 11 × 17, LGL, LTRR, 8K

7

1. Product Overview

Staple Unit

Item Specifications Remarks

Stapling method Punching by rotating cam Flat clinch

Stapling paper size Feed direction: 182 mm to 431.8 mm

Cross feed direction: 210 mm to 297 mm

1-point stapling, 2-points stapling

A3, A4, A4R, B4, B5, 11 × 17, LGL, LTR, LTRR, EXEC, 8K, 16K

Stapling capacity Paper Small size Large size - Paper thickness

52 to 90 g/m2 50 sheets 30 sheets

More than 90 to 105 g/m230 sheets 20 sheets

More than 105 to 300

g/m2

Manual stapling Paper thickness: 6.5mm or less (Equivalent to 50 sheets or less, 1-point stapling) - Converting weight to

Staple supply Special staple cartridge (5,000 staples)

Staple detection Available

Initial feed of staple Available

2 sheets 2 sheets

(small size): 11 mm or

less

- Paper thickness

(large size): 5.5 mm or

less

number of 64 g/m2

sheet.

- Paper size regulations:

Small size (feed length: 220 mm or less): A4, B5, LTR, EXEC, 16K , STMTR, A5R

Large size (feed length: more than 220 mm): A3, A4R, B4, B5R, 11 × 17, LGL, LTRR, 8K

8

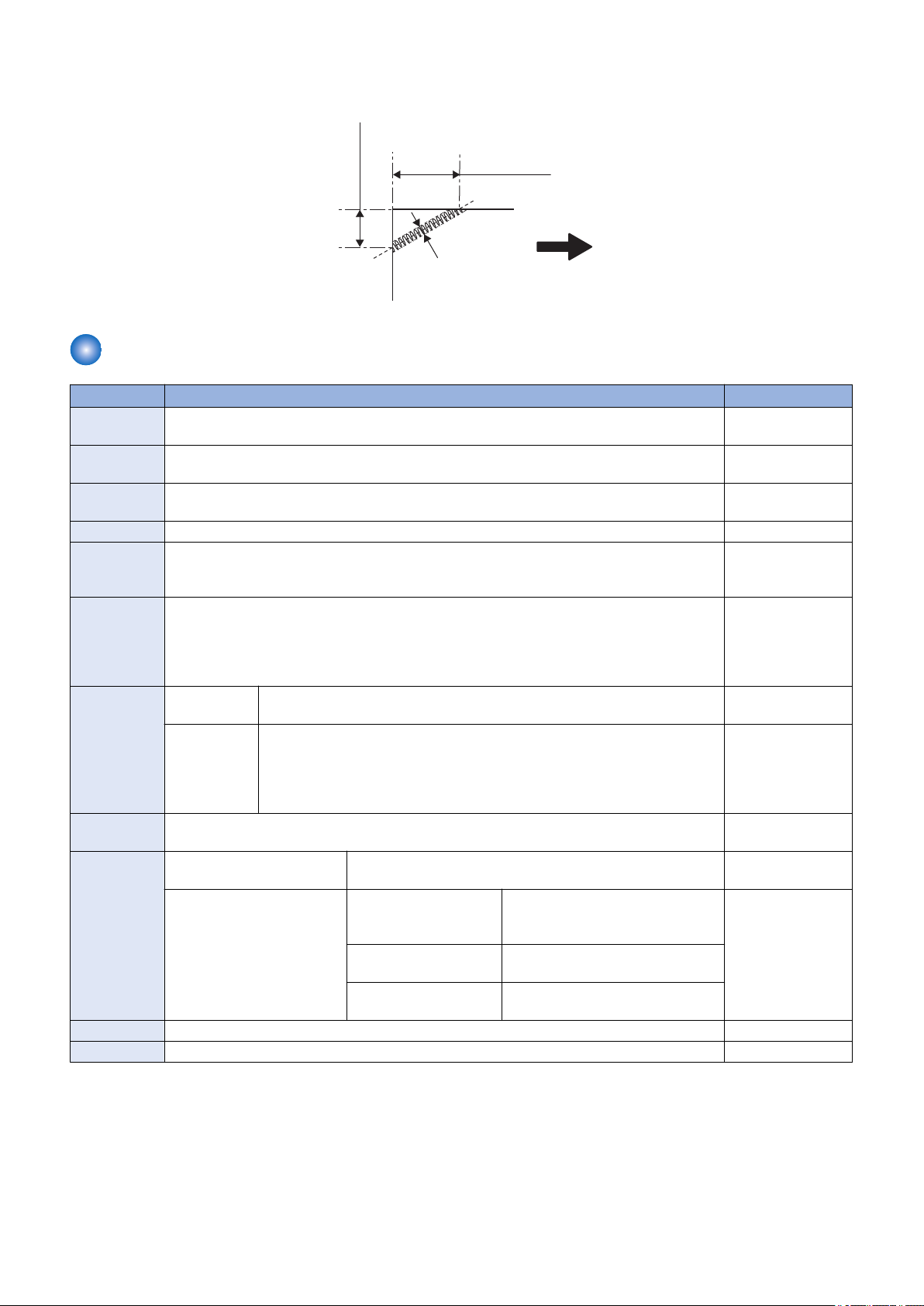

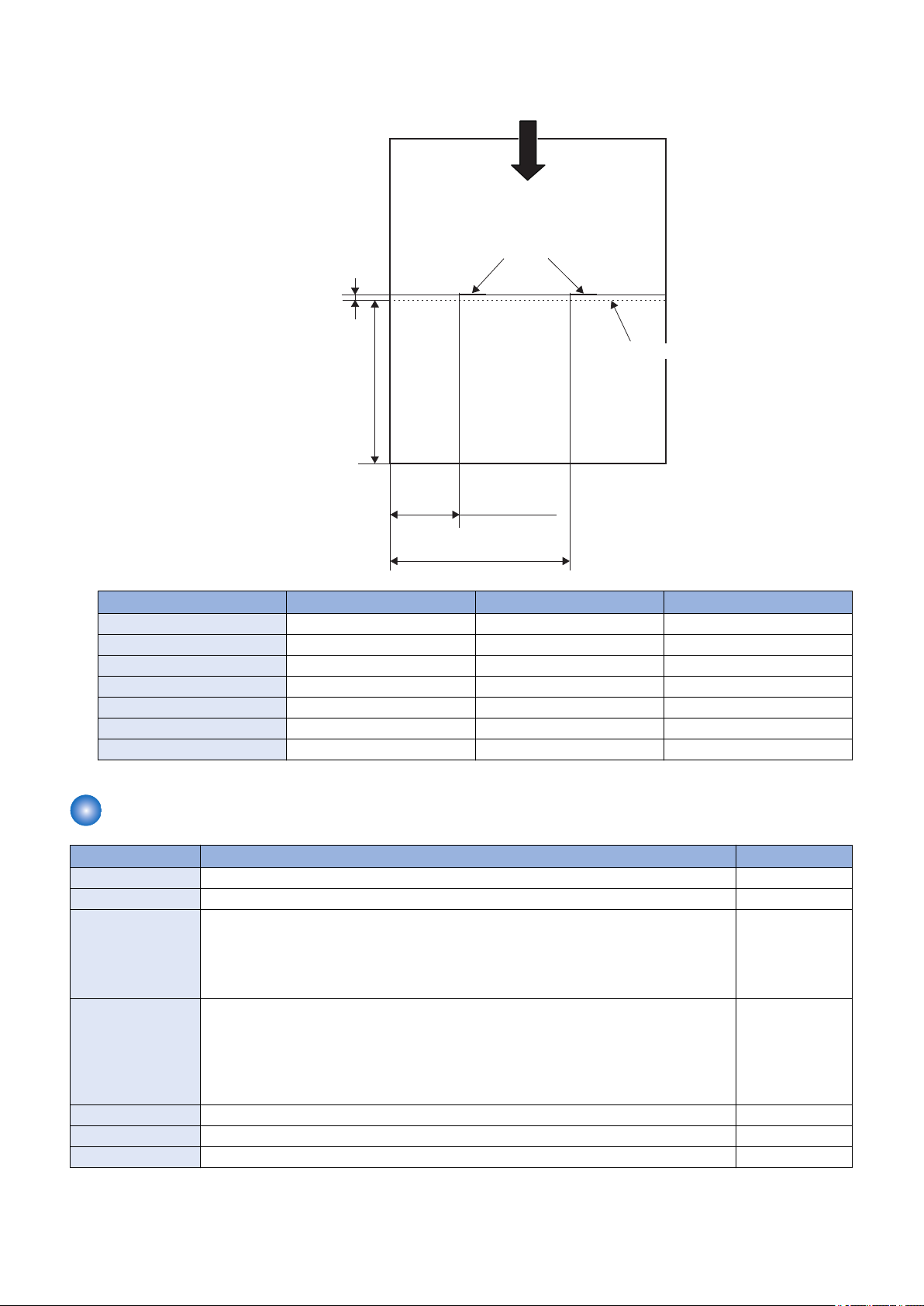

• Staple Position

5.0 ± 2.0 mm

5.0 ± 2.0 mm

4.0 ± 2.0 mm

5.0 ± 2.0 mm

5.0 ± 2.0 mm

5.0 ± 2.0 mm

4.0 ± 2.0 mm

5.0 ± 2.0 mm

- Front 1-point stapling (45 deg): A3, A4, B4, B5, 11×17, LTR, EXEC, 8K, 16 K

- Front 1-point stapling (30 deg): A4R, LGL, LTRR

1. Product Overview

- Rear 1-point stapling (45 deg): A3, A4, B4, B5, 11×17, LTR, EXEC, 8K, 16K

- Rear 1-point stapling (30 deg): A4R, LGL, LTRR

9

L3

L1

L2

5.0 ± 2.0 mm

5.0 ± 2.0 mm

1. Product Overview

- 2-point stapling : A3, A4, A4R, B4, B5, 11×17, LGL, LTR, LTRR, EXEC, 8K, 16K

Paper Size L1 L2 L3 Interval

A3, A4 83 ± 4.0 mm 203 ± 4.0 mm 5.0 ± 2.0 mm 120 mm

B4, B5 63 ± 4.0 mm 183 ± 4.0 mm 5.0 ± 2.0 mm 120 mm

11×17, LTR 74.2 ± 4.0 mm 194.2 ± 4.0 mm 5.0 ± 2.0 mm 120 mm

A4R 39.5 ± 4.0 mm 159.5 ± 4.0 mm 5.0 ± 2.0 mm 120 mm

LTRR, LGL 42.5 ± 4.0 mm 162.5 ± 4.0 mm 5.0 ± 2.0 mm 120 mm

EXEC 68 ± 4.0 mm 188 ± 4.0 mm 5.0 ± 2.0 mm 120 mm

8K, 16K 69.5 ± 4.0 mm 189.5 ± 4.0 mm 5.0 ± 2.0 mm 120 mm

- Manual stapling

Staple-Free Binding Unit

Item Specifications Remarks

Binding method Pressing by rotating cam

Binding position Rear 1-point binding Tooth-shaped

Bindable size A3, A4, 11 × 17, LTR, 8K, 16 K

Binding capacity - 52 to 64 g/m2: 5 sheets or less

- More than 64 to 81.4 g/m2 : 4 sheets or less

- More than 81.4 to 105 g/m2 : 3 sheets or less

Manual staplefree binding

Not available

- Binding a mix of

different widths is

not possible.

- Binding a mix of

same width is

possible.

10

7.8 ± 2.0 mm

13.5 ± 2.0 mm

3.0 mm or less

Delivery direction

1. Product Overview

• Binding position

- Rear 1-point binding (30 deg)

Saddle Stitcher Unit (Booklet Finisher)

Item Specifications Remarks

Stacking orientation

Stapling meth-odVertically separated, semi-flat clinch, stapling at two positions in the middle

Fixed folding stack tray

Folding meth-odRoller pressure 2-fold

Fold position Center folding

Fold position Feed direction: 270 to 457.2 mm

Cross feed direction: 195 to 304.8 mm

A3, B4, A4R, 12X18, 11X17, LGL, LTRR

Paper weight Body page: 52 to 220 g/m2

Cover page: 52 to 256 g/m2

Capacity Without stitch - 52 to 105 g/m2: 1 to 3 sheets

- More than 105 to 256 g/m2: 1 sheet

With stitch - 52 to 81.4 g/m2: 2 to 20 sheets

- More than 81.4 to 105 g/m2: 2 to 10 sheets

- More than 105 to 150 g/m2: 2 to 5 sheets

- More than 150 to 209 g/m2: 2 to 4 sheets

- More than 209 to 220 g/m2: 2 or 3 sheets

Stackable paper

Stacking capacity

Staple supply Special staple cartridge (2,000 staples)

Staple supply Available

Thin, plain, recycled, environmental, heavy, coated paper

Without stitch - 52 to 105 g/m2: 25 sets

- More than 105 to 256 g/m2: 10 sets

With stitch, without cover 52 to 81.4 g/m2 2 to 5 sheets: 25 sets

6 to 10 sheets: 15 sets

11 to 20 sheets: 10 sets

More than 81.4 to 105

g/m2

More than 105 to 220

g/m2

2 to 5 sheets: 25 sets

6 to 10 sheets: 15 sets

10 sets

- Paper weight of the

cover page should

be more than paper

weight of the body

page.

- Includes one cover

page.

- With cover, up to 10

sets.

11

• Staple Position

L2 ± 2.0 mm

L3 ± 1.0 mm

L1 ± 2.0 mm

Stapling position

Feed direction

1.0 mm or less

Folding position

1. Product Overview

Paper Size L1 L2 L3

12"×18" 86.9 mm 206.9 mm 228.6 mm

A3 83 mm 203 mm 210 mm

B4 63 mm 183 mm 182 mm

A4R 39.5 mm 159.5 mm 148.5 mm

11×17 74.2 mm 194.2 mm 215.9 mm

LGL 42.5 mm 162.5 mm 177.8 mm

LTRR 42.5 mm 162.5 mm 139.7 mm

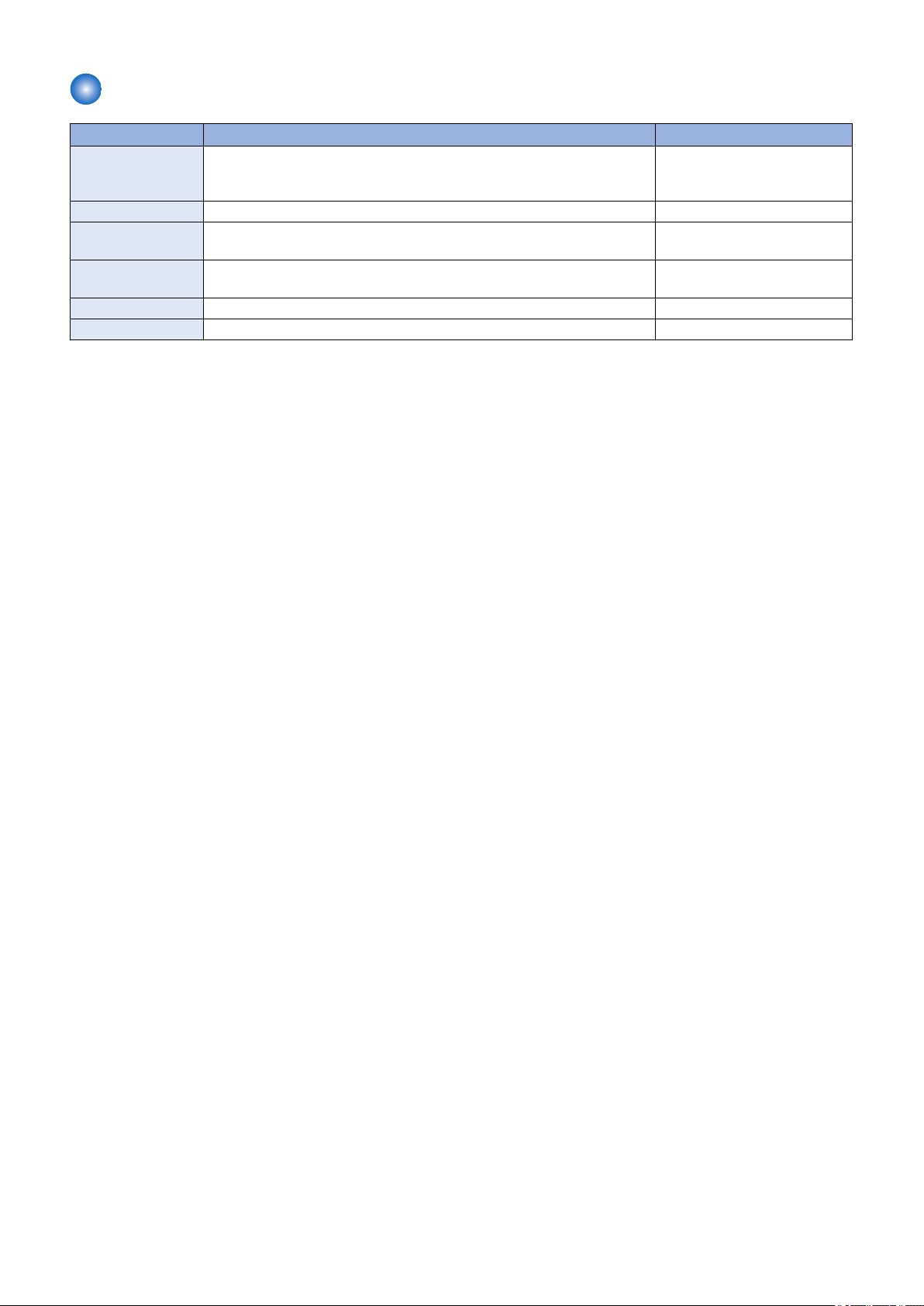

Buffer Pass Unit

Item Description Remarks

Placement Center

Installation Build-in type

Stacking size (Buffer

pass delivery tray)

Stacking capacity

(Buffer pass delivery

tray)

Dimensions W: 480mm × D: 485mm × H: 155mm

Weight Approx 5.4 kg

Power Supply AC100-240V from host machine

Feed direction: 139.7 to 457.0mm

Width direction: 100.0 to 305.0mm

Height 15mm or less (equivalent of 100 sheets) • Transparency,

Long original paper (630mm,

1200mm) is available to fed if jam is

not occurred.

Tracing Paper and

Labels are 20

sheets or less.

• Envelope are 4

sheets or less.

12

Others

Item Specifications Remarks

Paper detection - Escape tray: not available

- Processing tray: available

- Stack tray: not available (near-empty function available)

Control panel Available (manual staple button)

Dimensions 537 mm (637 mm)* (W) × 969 mm (1,016 mm)* (H) × 623 mm (D)

*: When the auxiliary tray is pulled out

Weight - Staple finisher: about 30 kg

- Booklet finisher: about 53kg

Power supply Supplied from the buffer pass unit : DC 24.5V

Power consumption 192W or less (when puncher unit is installed)

1. Product Overview

13

Names of Parts

[1]

[2]

[3]

[4]

[5]

[6]

[7]

[8]

[9]

[10]

[1] [2]

[3]

[4]

[5]

[6]

[7]

[8]

[9]

External View (Front)

■ Staple Finisher

1. Product Overview

No. Part Name No. Part Name

[1] Upper Cover Unit [6] Caster Cover (Front)

[2] Manual Staple Button [7] Caster Cover (Rear)

[3] Front Cover [8] Stack Tray

[4] Manual Staple Paper Inlet (Slit) [9] Escape Tray

[5] Lower Front Cover - -

■ Booklet Finisher

14

No. Part Name No. Part Name

[1]

[2]

[1]

[1] Upper Cover [6] Caster Cover (Front)

[2] Manual Staple Button [7] Caster Cover (Rear)

[3] Front Cover [8] Saddle Delivery Tray

[4] Manual Staple Paper Inlet (Slit) [9] Stack Tray

[5] Lower Front Cover [10] Escape Tray

■ Buffer Pass Unit

1. Product Overview

No. Part Name No. Part Name

[1] Buffer Pass Delivery Tray [2] Buffer Pass Feed Outlet Port

External View (Rear)

■ Staple Finisher

No. Part Name

[1] Rear Cover

15

■ Booklet Finisher

[1]

[1]

No. Part Name

[1] Rear Cover

1. Product Overview

■ Buffer Pass Unit

No. Part Name

[1] Buffer Pass Feed Inlet Port

16

External View (Internal)

[1]

[1]

[2]

■ Staple Finisher

1. Product Overview

No. Part Name

[1] Front Inner Cover

■ Booklet Finisher

No. Part Name No. Part Name

[1] Front Inner Cover [2] Saddle Unit

17

■ Buffer Pass Unit

[1]

[1]

[2]

[4]

[3]

[5]

[6]

[7]

[13]

[12]

[11]

[10]

[9]

[8]

No. Part Name

[1] Buffer Pass Feed Part

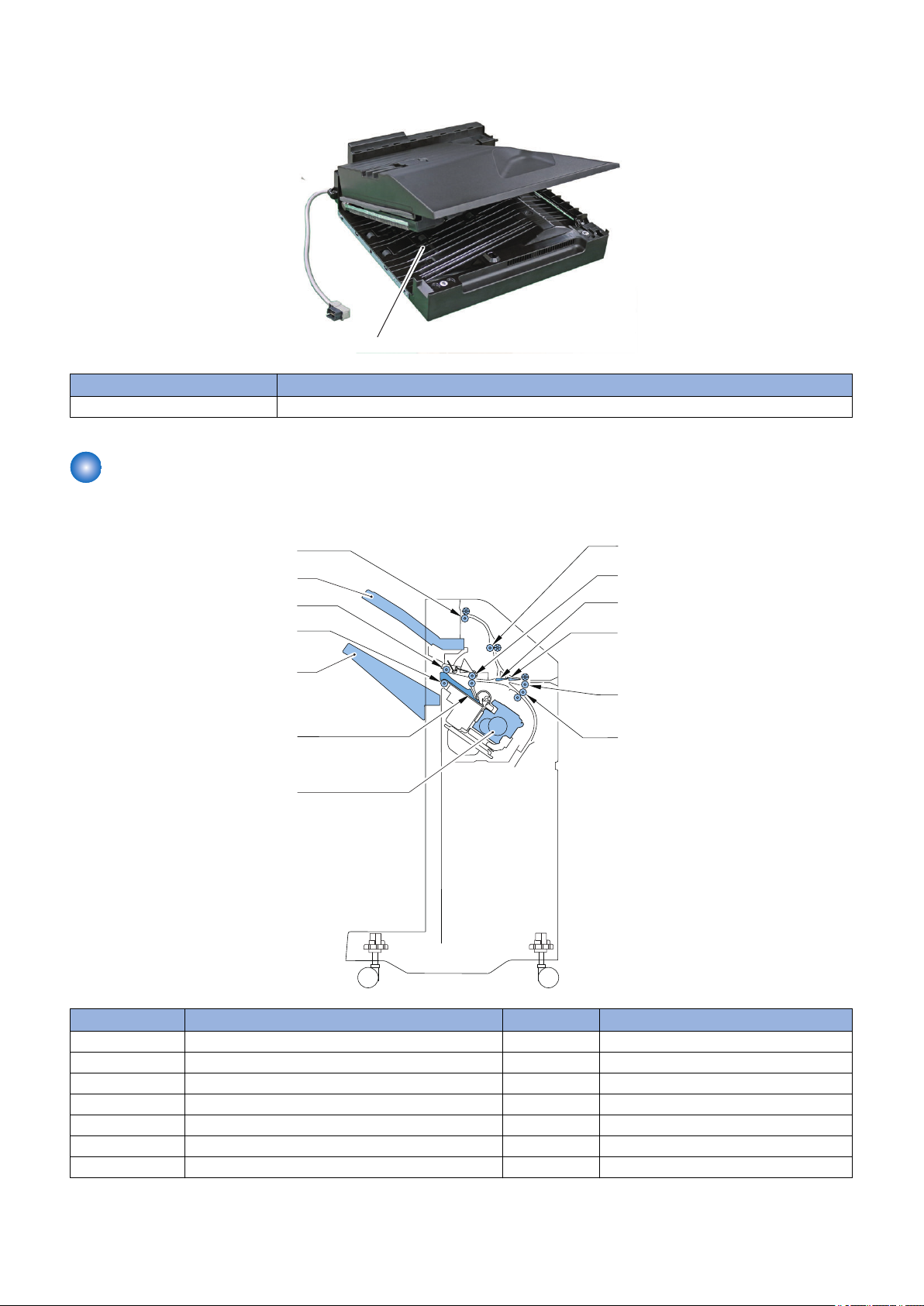

Cross Section

1. Product Overview

■ Staple Finisher

No. Part Name No. Part Name

[1] Escape Delivery Roller [8] Escape Feed Roller 1

[2] Escape Tray [9] Pre-Processing Roller

[3] Upper Stack Delivery Roller [10] Buffer/Saddle Inlet Flapper

[4] Lower Stack Delivery Roller [11] Escape Inlet Flapper

[5] Stack Tray [12] Inlet Roller

[6] Alignment Plate [13] Buffer/Saddle Inlet Roller

[7] Stapler Unit - -

18

■ Booklet Finisher

[1]

[2]

[4]

[3]

[5]

[6]

[7]

[9]

[8]

[10]

[19]

[18]

[17]

[16]

[15]

[14]

[13]

[12]

[11]

[1]

[4]

[3]

[2]

1. Product Overview

No. Part Name No. Part Name

[1] Escape Delivery Roller [11] Escape Feed Roller 1

[2] Escape Tray [12] Pre-Processing Roller

[3] Upper Stack Delivery Roller [13] Buffer/Saddle Inlet Flapper

[4] Lower Stack Delivery Roller [14] Escape Inlet Flapper

[5] Stack Tray [15] Inlet Roller

[6] Alignment Plate [16] Buffer/Saddle Inlet Roller

[7] Stitcher Unit [17] Stapler Unit

[8] Paper Folding Roller [18] Saddle Feed Roller

[9] Saddle Delivery Roller [19] Paper Pushing Plate

[10] Saddle Delivery Tray - -

■ Buffer Pass Unit

No. Part Name No. Part Name

[1] Buffer Pass Feed Roller 1 [3] Buffer Pass Feed Roller 3

[2] Buffer Pass Feed Roller 2 [4] Buffer Pass Feed Roller 4

19

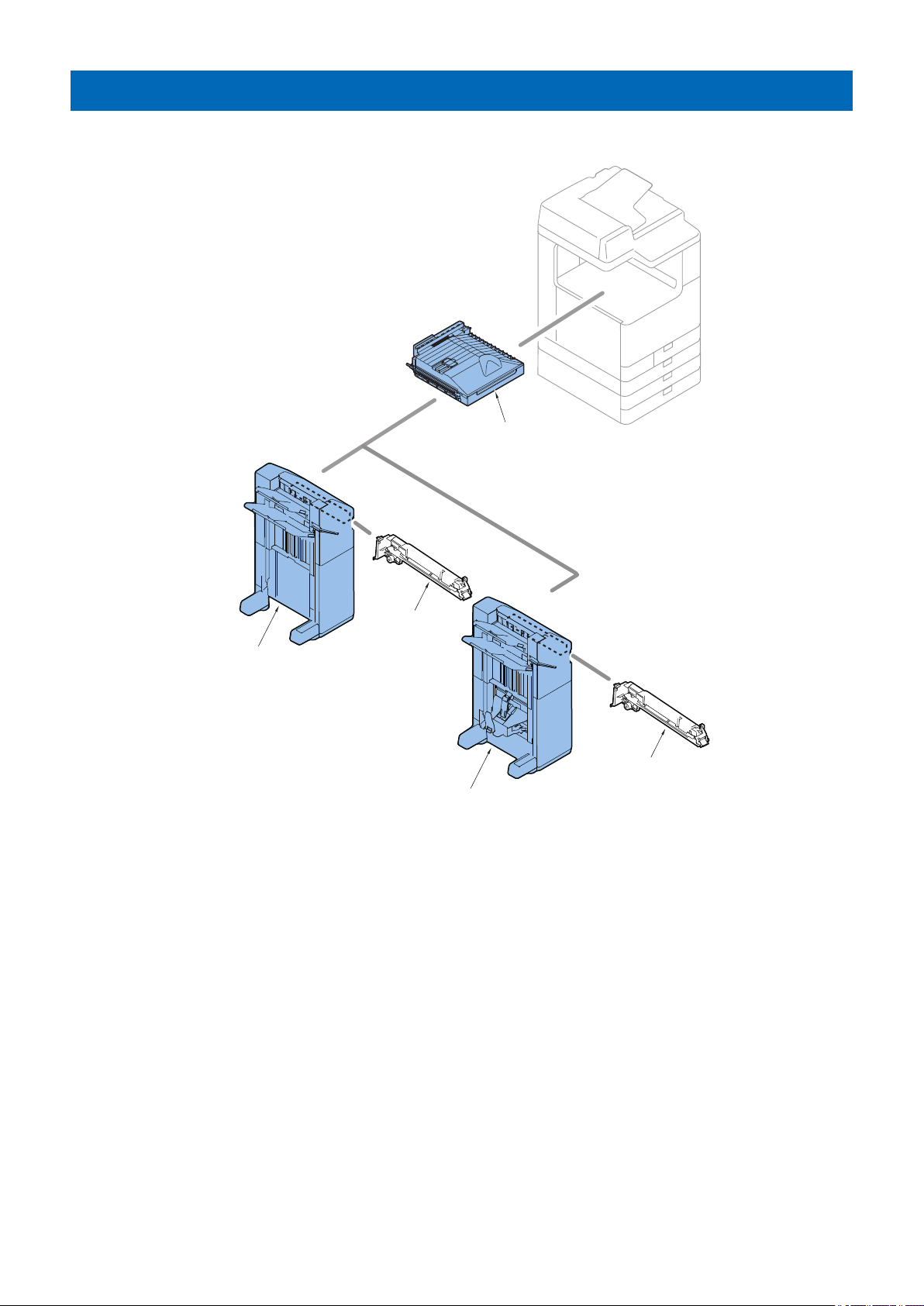

Optional Configuration

Buffer Pass Unit

Puncher Unit

Puncher Unit

Booklet Finisher

Staple Finisher

This equipment can incorporate a puncher unit (option).

1. Product Overview

20

Technical

2

Explanation

Basic Configuration.............................22

Controls...............................................25

Basic Operation...................................26

Feeding Unit........................................31

Stack/Escape Tray Unit.......................40

Processing Tray Unit...........................46

Saddle Stitcher Unit............................ 59

Buffer Pass Unit.................................. 67

Jam Detection..................................... 69

Power Supply......................................73

Upgrading ...........................................74

Tray Unit

Feed Unit

Processing Tray Unit

Buffer Pass Unit

Tray Unit

Feed Unit

Processing Tray Unit

Saddle Stitcher Unit

Buffer Pass Unit

2. Technical Explanation

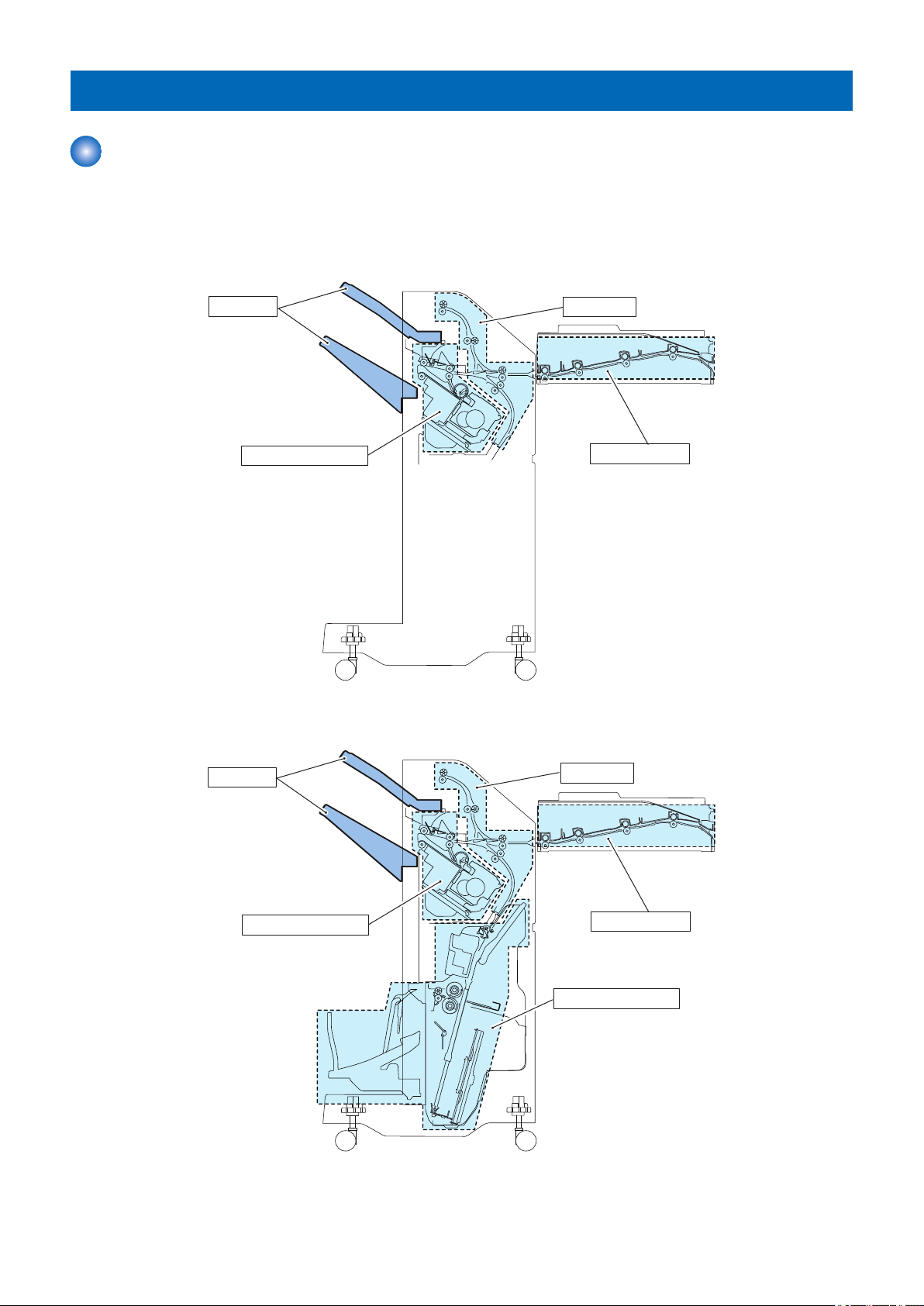

Basic Configuration

Component Configuration

The components of this finisher are organized into 5 major blocks ; Buffer Pass Unit, Feed Unit, Processing Unit, Stack Tray Unit

and Saddle Stitcher Unit.

• Staple Finisher

• Booklet Finisher

22

Loading...

Loading...