Canon 5482B002 User Manual

FIRST EDITION

AUG. 2011

COPYRIGHT © CANON ELECTRONICS INC. 2011 CANON DR-M140 FIRST EDITION

MY8-13AR-000

COPYRIGHT © CANON ELECTRONICS INC. 2011

Use of this manual should be

strictly supervised to avoid

disclosure of confidential

information.

PREFACE

This Service Manual describes necessary basic information for field service and maintenance for

maintaining the product quality and functions of this machine.

Contents

Chapter 1: General description

Product specifications, name of parts, operation method

Chapter 2: Functions and operation

Description of operation of machine system and electrical system by function

Chapter 3: Disassembly and reassembly

Disassembly method, reassembly method

Chapter 4: Installation and maintenance

Installation method, maintenance method

Chapter 5: Troubleshooting

Error display and troubleshooting

Appendix: General diagram etc.

Information in this manual is subject to change. Notification of such changes will be given in

Service Information Bulletins.

Thoroughly read the information contained in this Service Manual and the Service Information

Bulletins to gain a correct and deeper understanding of the machine. This is one way of fostering

response for ensuring prolonged quality and function, and for investigating the cause of trouble during

troubleshooting.

COPYRIGHT © CANON ELECTRONICS INC. 2011 CANON DR-M140 FIRST EDITION

Quality Assurance Center

Canon Electronics Inc.

CONTENTS

CHAPTER 1

GENERAL DESCRIPTION

Document Sensor PCB.....................2-20

3.

I. PRODUCT OUTLINE ..............................1-1

1. Features..............................................1-1

2. Main

3. Precautions ......................................... 1-5

NAME OF PARTS.................................... 1-6

II.

1. Name of Parts ..................................... 1-6

III.

USER OPERATION.................................1-7

1. Placing Document

2. Scanning ............................................. 1-8

3. Clearing Paper Jams ........................ 1-10

Specifications.............................1-2

s ............................. 1-7

CHAPTER 2

FUNCTIONS & OPERATION

I. OUTLINE ................................................. 2-1

1. Main Configuration..............................2-1

2. Feed

3. Motor

4. Elec

5. Timing Chart........................................ 2-5

II. READING SYSTEM................................. 2-6

1. Reading Unit .......................................2-6

2. Shading

III. FEED SYSTEM ....................................... 2-8

1. Feeding Mechanism............................ 2-8

2.

IV. CONTROL SYSTEM ............................. 2-13

1. Control Circuits .................................

2. Image Processing ............................. 2-15

. POWER SUPPLY .................................. 2-17

V

1. Power Supply....................................

LAYOUT OF ELECTRICAL COMPONENTS

VI.

1. Layout of Electrical Components ...... 2-18

VII. PARTS LAYOUT ON EACH PCB .......... 2-19

1. Control PCB

2. Operation PCB ..................................2-20

Path ...........................................2-2

Drive .........................................2-3

trical Circuits ................................ 2-4

............................................... 2-7

Feed Error Detection ........................ 2-11

2-13

2-17

.2-18

...................................... 2-19

CHAPTER 3

DISASSEMBLY &

REASSEMBLY

I. EXTERNAL PARTS ................................. 3-1

1. Upper Cover........................................3-1

2. Bottom

3. Document Eject Tray...........................3-3

4. Straight Path Tray

II. BASE UNIT..............................................3-4

1. Control PCB ........................................ 3-4

2. Main

3. Feed

4. Regis

5. S

III. UPPER

1. Sensor PCBs ....................................

2. Ultrasonic Drive PCB ........................3-10

3. Follower

4. U-Turn Unit........................................ 3-12

5. Upper Unit ......................................... 3-13

. READING UNIT ..................................... 3-14

IV

1. Upper Reading Unit ..........................3-14

2. Upper Reading Guide .......................3-15

3. Lower

4. Lower Reading Guide .......................3-16

Cover / Feed Tray

...............................3-3

Motor .......................................... 3-5

Motor.......................................... 3-6

tration Roller (Drive)................... 3-7

traight Eject Roller (Drive).................3-8

UNIT ......................................... 3-10

Roller .................................. 3-1

Reading Unit ..........................3-15

...................3-2

3-10

1

CHAPTER 4

INSTALLATION &

MAINTENANCE

I. INSTALLATION ........................................ 4-1

1. System Requirements.........................4-1

2. Checking the Accessories ................... 4-1

3. Removing the Packing Material.......... 4-2

4. Installing the Software

5. Connecting to a Computer ..................4-3

6. Power On ............................................4-3

.........................4-2

COPYRIGHT © CANON ELECTRONICS INC. 2011 CANON DR-M140 FIRST EDITION

II. PARTS TO BE REPLACED .................... 4-4

1. Periodically Replaced Parts ............... 4-4

2. Consumable Parts .............................. 4-4

3. Major

III. MAINTENANCE ...................................... 4-6

1. User

2. Service

Parts List...................................

Maintenance .............................. 4-6

Maintenance.......................... 4-8

4-5

CHAPTER 5

TROUBLESHOOTING

I. ERROR DISPLAY ................................... 5-1

1. Main Body........................................... 5-1

2. Computer............................................ 5-1

II.

SERVICE MODE..................................... 5-2

1. Outline ................................................ 5-2

2. How to Install

3. How to Start and Finish ...................... 5-7

4. Application

5. Simulation Mode................................. 5-9

A. Main

B. Dcon

C. Get Status.............................................. 5-19

D. Scan Check ........................................... 5-22

Menu............................................... 5-9

1. Regist Adjustment

2. Light Adjustment................................5-11

3. Max Document Size ......................... 5-12

4. Sleep ................................................ 5-13

5. Counter............................................. 5-13

6. Firm Load

Check........................................... 5-16

1. LED................................................... 5-16

2. Sensors and Buttons ........................ 5-16

3. Motor/Feed

Last Error Logs................................. 5-19

1.

2. Check Device ................................... 5-20

3. Serial Number/Other ........................ 5-20

4. Write Setting to Text ......................... 5-21

...................................... 5-6

Information....................... 5-8

.............................. 5-9

......................................... 5-15

Test................................ 5-18

1. Firm Registration .............................. 5-25

2. Firm Load ......................................... 5-27

F

. Analog ................................................... 5-28

1. Analog ..............................................

G. Extended Setting ................................... 5-29

1. Outline

2. Registration Adjustment ................... 5-30

3. Scaling Rate Control......................... 5-32

H. Other

1. Mechani

2.

Recovery of Log Files....................... 5-35

III. TROUBLESHOOTING LIST ................. 5-37

1. Operation Failures ............................ 5-37

2. Image

. OPERATION TROUBLESHOOTING .... 5-38

IV

Power Does Not Come ON .............. 5-38

1.

2. No Scanner is Found........................ 5-39

3. Scanning Does Not Start .................. 5-39

4. Scanner Does Not Feed Properly .... 5-40

5. Scanning Speed is Slow................... 5-41

V. IMAGE TROUBLESHOOTING..............

1. All Blac

2. Too Dark/Too Light............................ 5-43

3.

Streaks in Image............................... 5-44

4. Image Slanted .................................. 5-44

5. Wrong Image Size ............................ 5-45

6. Text Cannot be Seen

7.

Moire in Image.................................. 5-46

IV. AFTER REPLACING PARTS ................ 5-47

.............................................. 5-29

Functions..................................... 5-35

cal Feed Mode .................... 5-35

Failures.................................. 5-37

k/All White/All Streaked ........ 5-43

........................ 5-45

5-28

5-42

APPENDIX

I. GENERAL CIRCUIT DIAGRAM.............. A-1

II. LIST OF SPECIAL EQUIPMENT ............ A-2

an Check ...................................... 5-22

1. Sc

2. Manual Shading ...............................

E. Firm Load.............................................. 5-24

COPYRIGHT © CANON ELECTRONICS INC. 2011 CANON DR-M140 FIRST EDITION

5-24

CHAPTER 1

GENERAL DESCRIPTION

I. PRODUCT OUTLINE.............................. 1-1

I. NAME OF PARTS ................................... 1-6

I

COPYRIGHT © CANON ELECTRONICS INC. 2011 CANON DR-M140 FIRST EDITION

III. USER OPERATION ................................ 1-7

CHAPTER 1 GENERAL DESCRIPTION

I. PRODUCT OUTLINE

1. Features

1) High-speed machine with U-turn path

This is upper and successor model for the DR-2580C.

2) Scanning speed (A4, 200dpi)

B&W, Gray, and Color modes: 40ppm/80ipm

3) Improvement of reliability for the pickup and separation operations

Drive for retard roller is improved.

Outside diameter of feed roller is made larger.

Skew sensor installed.

4) Automatic image processing

Auto-color detection mode

Auto-resolution mode

Full-auto mode

5) Includes easy to user application software

CaptureOnTouch/CapturePerfect

“Windows” is a trademark of Microsoft Corporation in the U.S. and other countries.

Other company names and product names mentioned in this document are registered trademarks or

trademarks of the respective companies.

COPYRIGHT © CANON ELECTRONICS INC. 2011 CANON DR-M140 FIRST EDITION

1-1

CHAPTER 1 GENERAL DESCRIPTION

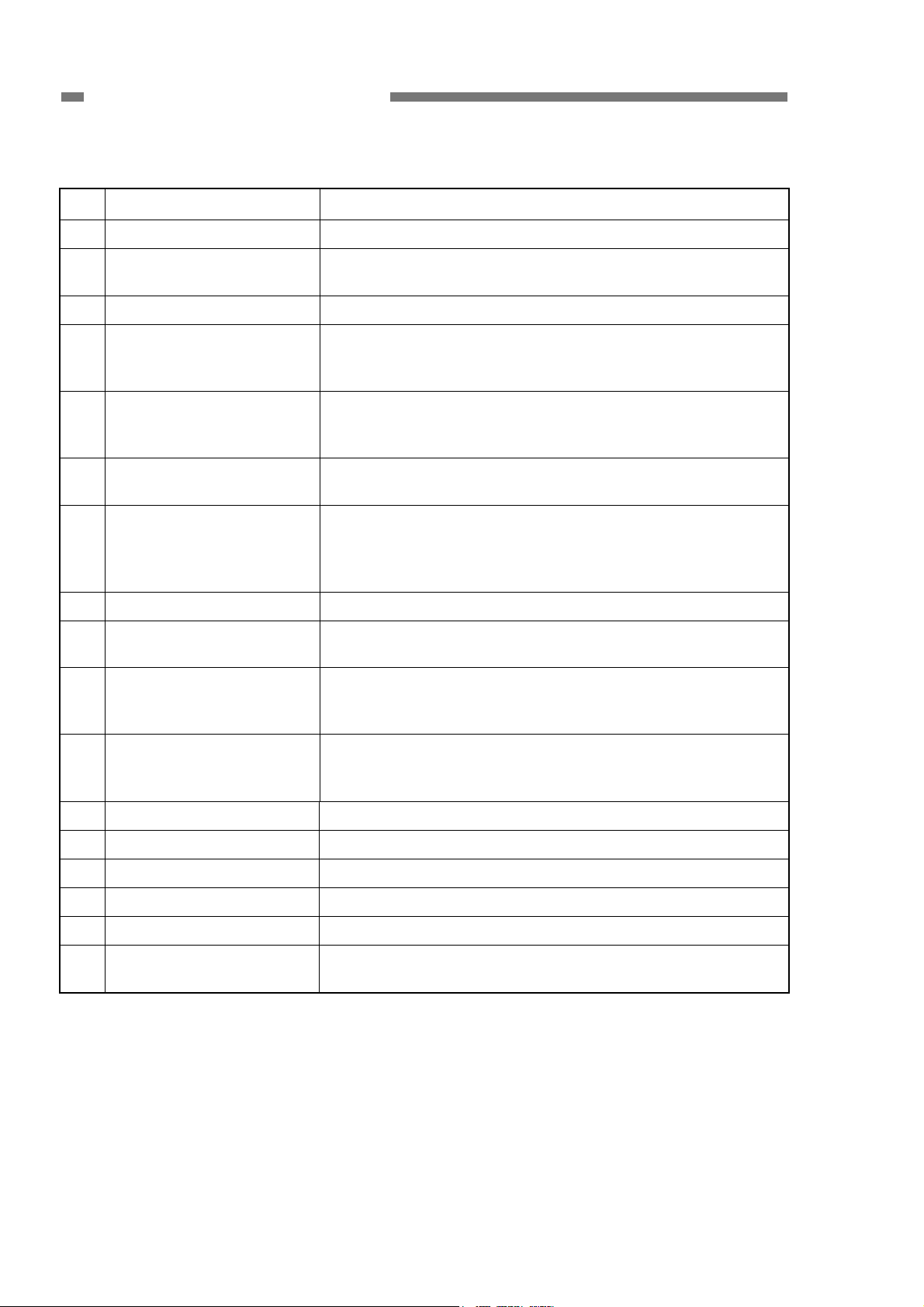

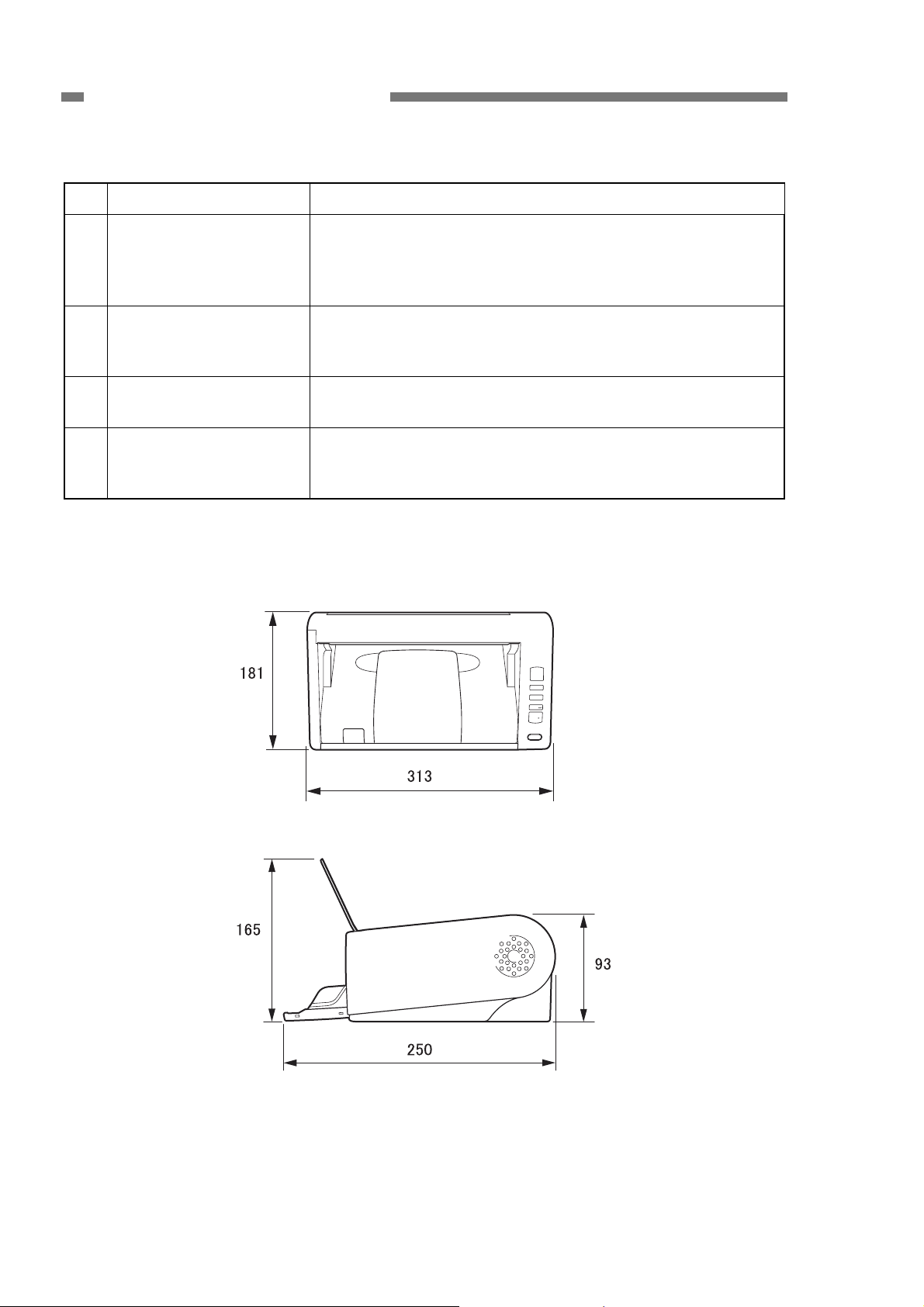

2. Main Specifications

No. Item Specifications

1 Type Desktop type sheet-fed scanner

2 Dimensions

*See details at following.

3 Weight 2.6kg (Main body only)

4 Power supply AC adapter

5 Power consumption 1) Operation: 25W same or less

6 External interface USB 2.0 (Hi-speed)

7 Expected product life

(In-house information only)

8 Installation By user.

9 Option 1) Flatbed scanner: FSU 101

10 Consumable parts

(Commercial goods)

1) Tray closed: 313 (W) x 181 (D) x 93 (H) mm

2) Tray opened: 313 (W) x 250 (D) x 165 (H) mm

1) Input: 100V-240VAC, 50/60Hz

2) Output: 24VDC, 2.0A

2) Sleep mode: 1.9W same or less

3) Power switch OFF: 0.5W same or less

*Hi-speed and Full-speed with USB 3.0 can work.

One of the following two items, whichever comes first.

1) 5 years

2) 1,000,000 sheets (A4)

*Replace parts if necessary.

2) Barcode module (software)

1) Exchange roller kit

*Roller unit and Retard roller

*Replaced by user. Expected life is 200,000 sheets.

11 Bundle software 1) ISIS/TWAIN driver, CapturePerfect 3.1, CaptureOnTouch,

eCopy PDF Pro Office

2) Others depend on Sales region

12 Sensor type, Density 1 line/4 parallel-CMOS contact image sensor, 600dpi

13 Sensor operation mode 600dpi or 300dpi

14 Effective reading width 219mm

15 Light source 3-color (RGB) LED, Single-side illumination

16 Background color White

17 Image data memory 32MB

*Used for the working memory together.

Table 1-101a

1-2

COPYRIGHT © CANON ELECTRONICS INC. 2011 CANON DR-M140 FIRST EDITION

CHAPTER 1 GENERAL DESCRIPTION

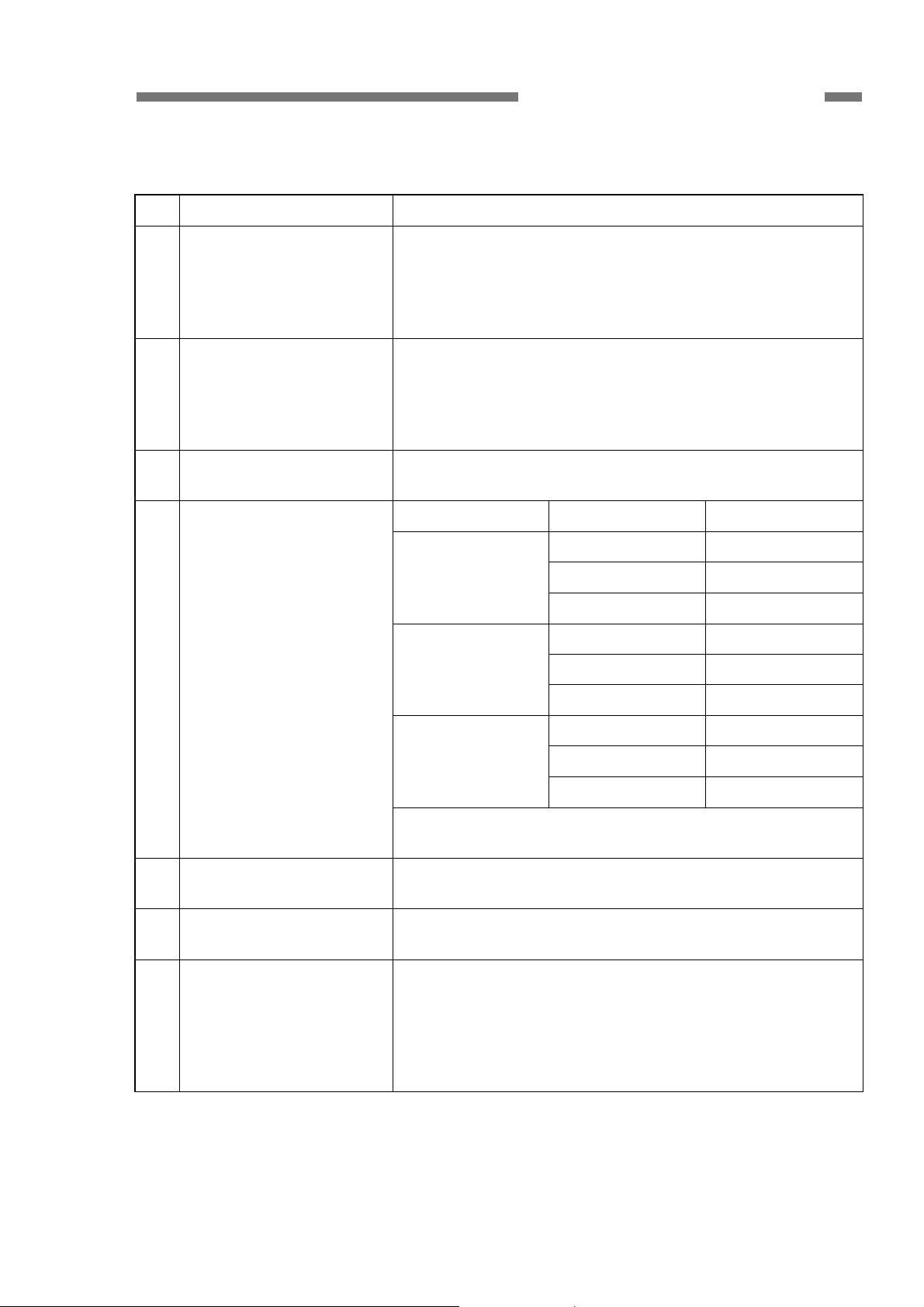

No. Item Specifications

18 Output data to computer 1) Type: 8bit gray or 24bit color

*It has converted always to JPEG compression.

2) Resolution: 600x600dpi, 400x400dpi, 300x300dpi,

Gray→200x200dpi, 150x150dpi

Color→200x400dpi, 150x300dpi

19 Mode setting in driver 1) Binary: B&W, Error diffusion, ATE, ATE-II

*ATE=Advanced Text Enhancement

2) Gray: 8bit

3) Color: 24bit

*Auto-color detection mode can be available.

20 Resolution setting in driver 600x600dpi, 400x400dpi, 300x300dpi, 200x200dpi, 150x150dpi

*Auto-resolution mode can be available.

21 Scanning speed

(A4 size)

Mode Resolution Simplex/Duplex

200dpi 40ppm/80ipm

B&W

(TIFF)

300dpi 40ppm/80ipm

600dpi 20ppm/40ipm

200dpi 40ppm/80ipm

Gray

(JPEG)

300dpi 40ppm/80ipm

600dpi 20ppm/40ipm

200dpi 40ppm/80ipm

Color

(JPEG)

300dpi 40ppm/80ipm

600dpi 12ppm/24ipm

*Using computer for test. The numbers above may differ

depending on the computer, settings and other conditions.

22 Document feed path U-turn path and Straight path

*U-turn is available for document within 0.15mm thickness.

23 Document size 1) Width: 50.8 to 216mm

2) Length: 54 to 356mm

24 Document weight

(Thickness)

1) Normal pickup: 27 to 128g/m2 (0.04 to 0.15mm)

2) None separate/Straight path:

2

27 to 255g/m

(0.04 to 0.30mm)

*Minimum size in normal (52x74mm): 127 to 209g/m

*Maximum size (LGL size: 216x356mm): 52 to 209g/m

*Maximum size (B5 size: 176x250mm): for 27g/m2

Table 1-101b

COPYRIGHT © CANON ELECTRONICS INC. 2011 CANON DR-M140 FIRST EDITION

2

2

1-3

CHAPTER 1 GENERAL DESCRIPTION

No. Item Specifications

25 Special document Post card, Plastic card, Business card, Folio, Long

document and others are available.

*Use straight path for post, plastic & business cards.

*There are some limitations required.

26 Document storage Pickup and Eject (U-turn path):

1) A4 or smaller: 50 sheets max. and 10mm height max.

2) A4 over: 40 sheets max. and 10mm height max.

27 Double feed detection 1) Length detection by registration sensor

2) Double feed detection by ultrasonic sensor

28 Operation/Indication 1) Button: Power, Start, Stop, Job Select, DFR

2) LED: Job No. (7-segment), Power, DFR, Separate

3) Lever: OPEN, Feed selection

Table 1-101c

External dimensions (mm)

1-4

Figure 1-101

COPYRIGHT © CANON ELECTRONICS INC. 2011 CANON DR-M140 FIRST EDITION

CHAPTER 1 GENERAL DESCRIPTION

3. Precautions

This section describes items that

require particular care, for example,

regarding human safety.

These precautions must be observed.

The user should be explained the items that

relate to user safety and instructed to take

appropriate actions.

1) Power OFF in emergency 5) “User Manual”

If such abnormal conditions as

extraordinary noise, smoke, heat and

odor occur, immediately unplug the

power cord.

Be careful not to get clothing (ties, long

hair, etc.) caught in this machine as it

may cause injury. Should this occur,

immediately unplug the power cord.

Do not insert fingers in the feed section

while moving the rollers.

2) Power OFF on disassembling

When disassembling and assembling are

performed, unplug the power cord.

3) Prohibition of modify

This machine must not arbitrarily be

modified or remade. If it is, use may be

forcibly suspended.

To change the specifications or

disassemble and reassemble this

machine, follow the instructions

described in this manual and the service

information.

4) Electromagnetic wave interference

This machine complies with some

standards regarding electromagnetic

wave interference, such as VCCI and

FCC. However, the user may have to

take countermeasures if the machine

causes electromagnetic wave

interference.

Read each “User Manual” thoroughly

prior to use of this machine.

6) Disposal

Follow local regulations when disposing

of the product and parts. This product is

subject to the WEEE Directive in Europe.

COPYRIGHT © CANON ELECTRONICS INC. 2011 CANON DR-M140 FIRST EDITION

1-5

CHAPTER 1 GENERAL DESCRIPTION

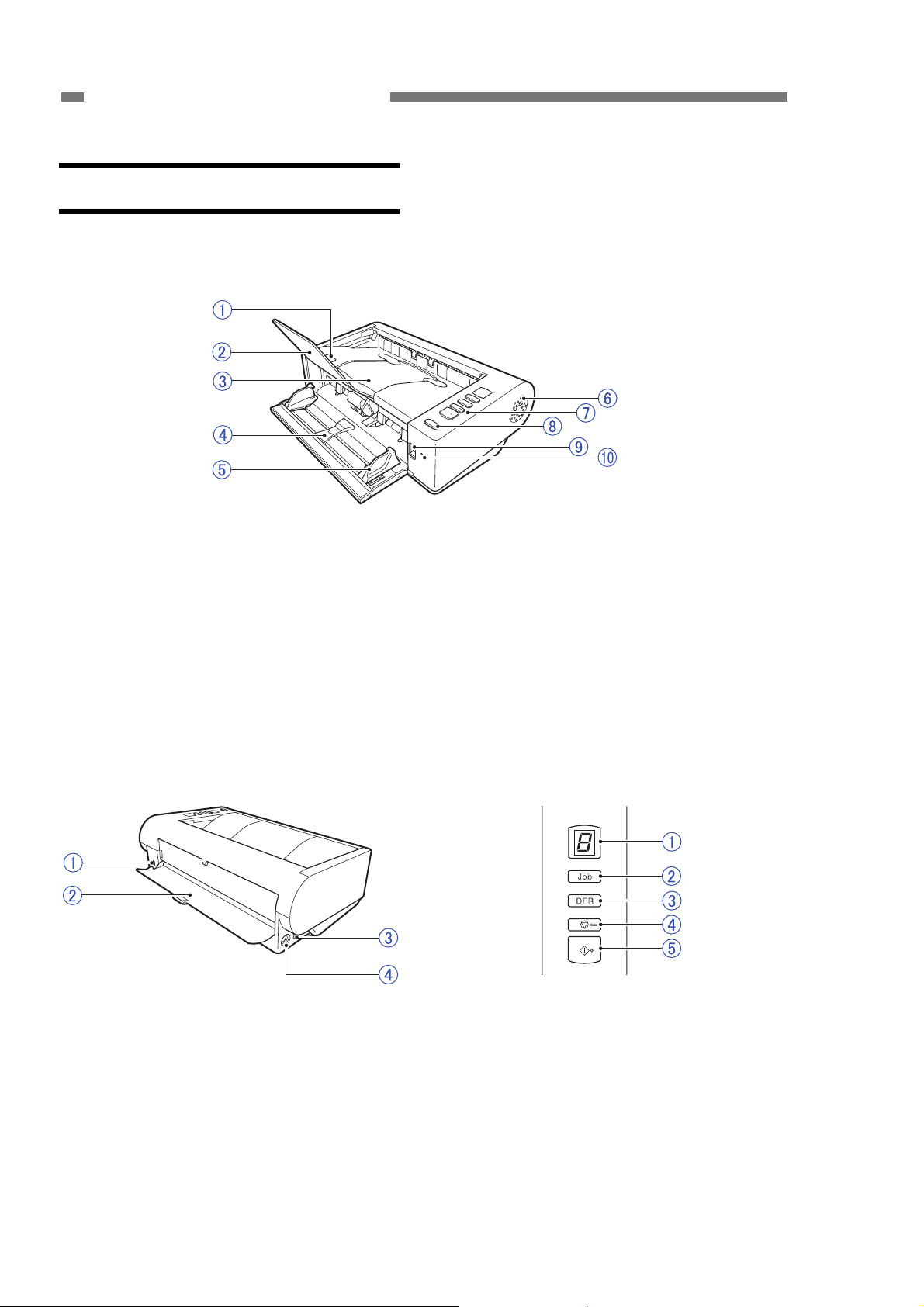

II. NAME OF PARTS

1. Names of Parts

Front View

Figure 1-201

1

OPEN lever

{

2

Document eject extension support

{

3

Document eject tray/Upper unit

{

4

Document feed tray

{

5

Document guides

{

Back View Operating Panel

6

Ventilation holes

{

7

Operating panel

{

8

Power button

{

9

Feed selection lever

{

10

LED indicator (orange)

{

1-6

Figure 1-202 Figure 1-203

1

Kensington slot

{

2

Straight path tray

{

3

USB connector

{

4

Power connector

{

1

Job No. indicator

{

2

Job select button

{

3

DFR (Double Feed Release) button

{

4

Stop button

{

5

Start button

{

COPYRIGHT © CANON ELECTRONICS INC. 2011 CANON DR-M140 FIRST EDITION

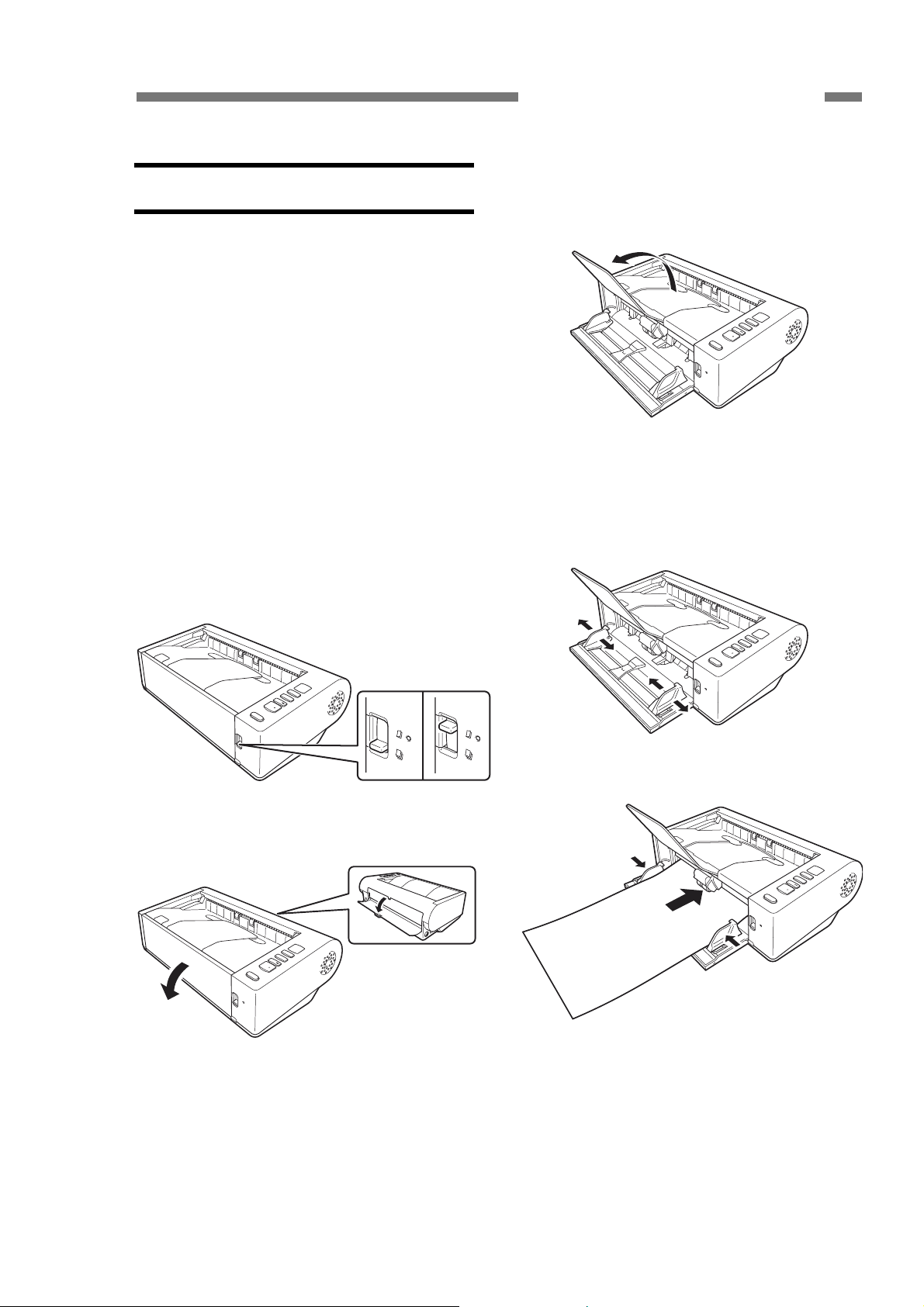

III. USER OPERATION

This section shows how to scan several

sheets of a regular paper document using

the initial settings of CaptureOnTouch. For

details on other operations, refer to the

“User Manual” for this machine.

For installation and maintenance, refer

to “CHAPTER 4 INSTALLATION &

MAINTENANCE”.

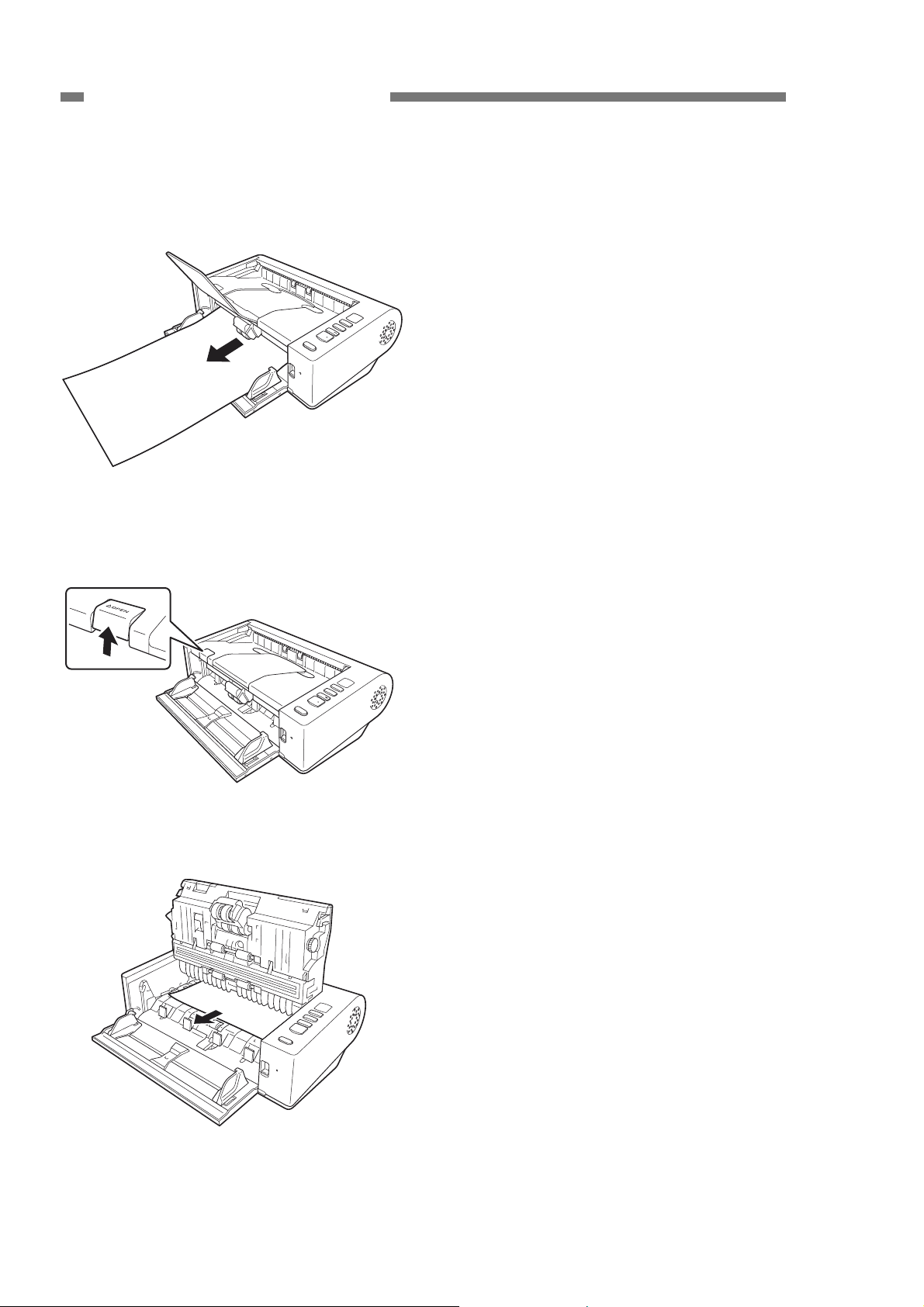

1. Placing Documents

1) Change the feed and eject methods

depending on types of documents. Open

the document feed tray. Furthermore,

open the document eject extension

support if necessary.

CHAPTER 1 GENERAL DESCRIPTION

Figure 1-303

2) Place the document, and adjust the

document guides to fit the document

width.

Figure 1-301

Figure 1-302

Figure 1-304

Figure 1-305

COPYRIGHT © CANON ELECTRONICS INC. 2011 CANON DR-M140 FIRST EDITION

1-7

CHAPTER 1 GENERAL DESCRIPTION

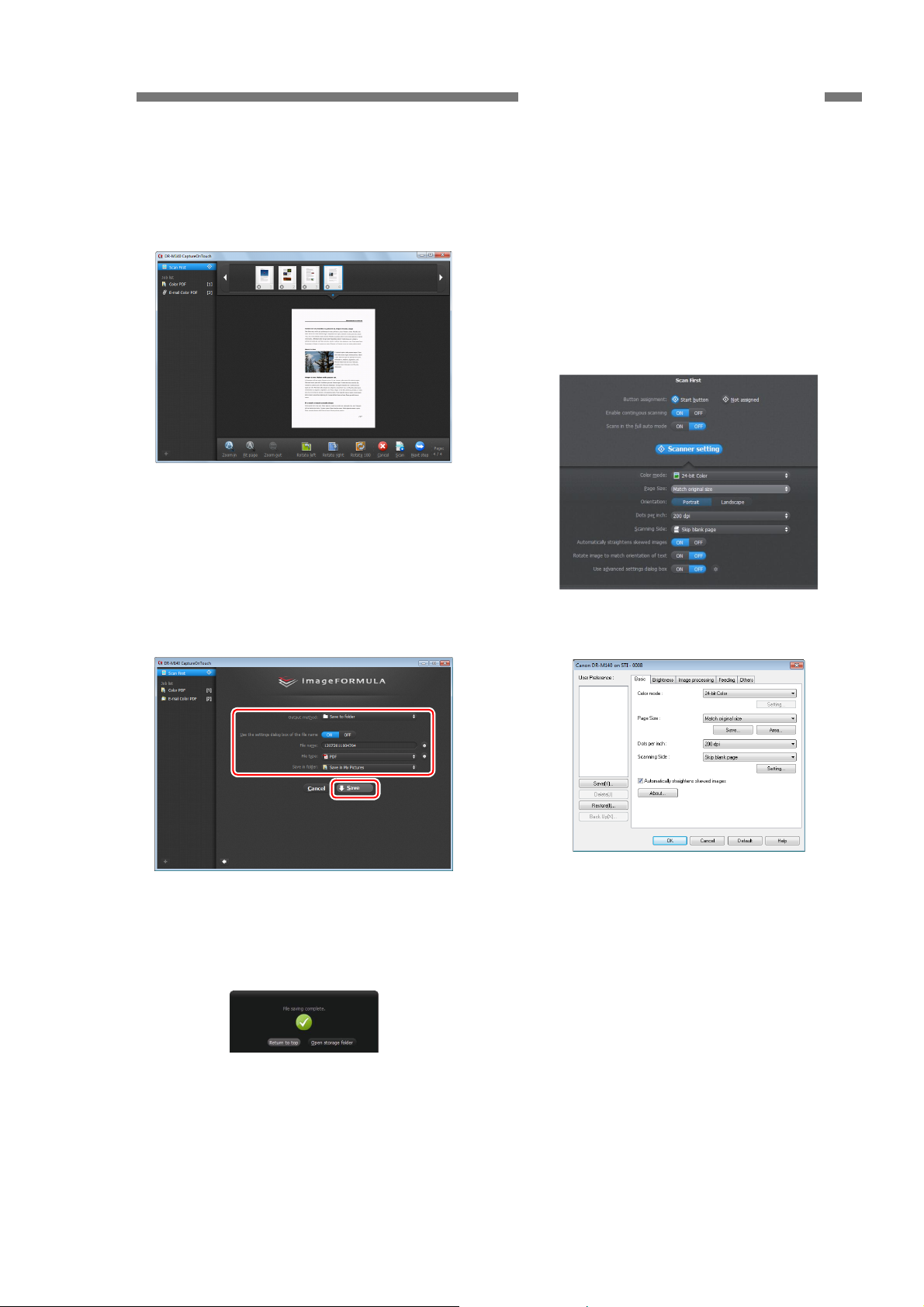

2. Scanning

This section describes how to scan

using [Scan First] in CaptureOnTouch.

Note: CaptureOnTouch is TWAIN

application software.

1) Start CaptureOnTouch.

Double-click the CaptureOnTouch icon in

the task bar to start CaptureOnTouch.

Figure 1-306

2) When the main screen is displayed, click

[Scan First].

Note: Since [Scan First] is enabled by

default, this operation is not required.

compatible

3) Change the [Enable continuous

scanning] and [Scans in the full auto

mode] settings as needed.

Note:

In this example, set [Enable continuous

scanning: ON] and [Scans in the full

auto mode: ON].

Figure 1-308

4) Click the Start button to start the scan.

Figure 1-309

Figure 1-307

1-8

COPYRIGHT © CANON ELECTRONICS INC. 2011 CANON DR-M140 FIRST EDITION

CHAPTER 1 GENERAL DESCRIPTION

5) The scanned image is displayed on the

screen. Once you have finished, click the

[Next step] button.

Figure 1-310

6) The output settings are displayed.

Configure the settings and click the

buttons as needed.

Note: The button names vary depending on

the output method.

Reference: Scanner Settings Screen

You can display the settings on the

screen by setting [Scans in the full auto

mode: OFF] in the step 3. You can then

open the advanced settings dialog box

by setting [Use advanced settings dialog

box: ON] and clicking the button on the

right.

Figure 1-313

Figure 1-311

7) When the output is complete, the finished

screen is displayed.

Figure 1-312

COPYRIGHT © CANON ELECTRONICS INC. 2011 CANON DR-M140 FIRST EDITION

Figure 1-314

1-9

CHAPTER 1 GENERAL DESCRIPTION

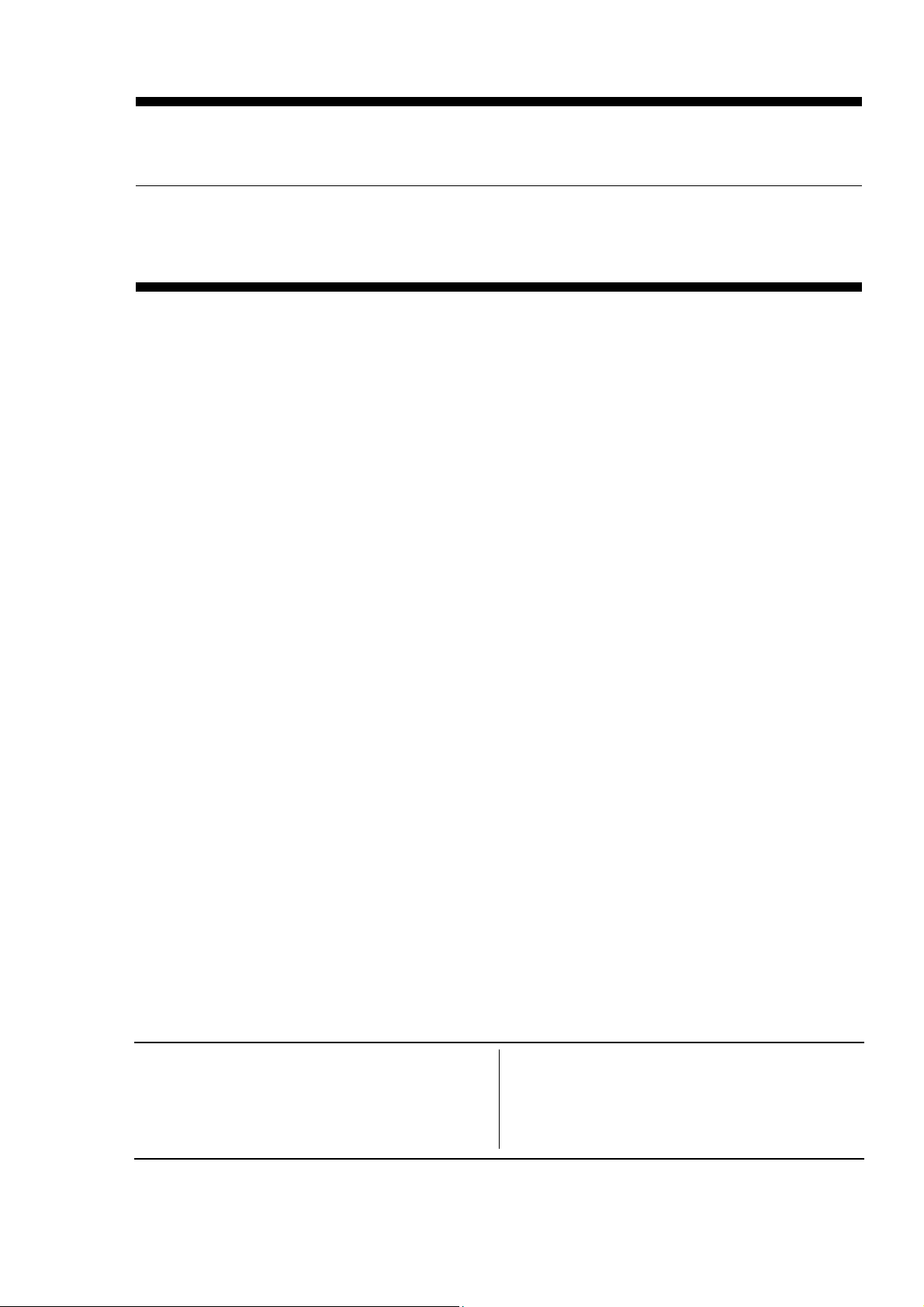

3. Clearing Paper Jams

1) Remove any remaining documents from

the document feed tray.

Figure 1-315

2) Pull up the OPEN lever and open the

upper unit.

Figure 1-316

3) Remove any jammed documents.

Figure 1-317

1-10

COPYRIGHT © CANON ELECTRONICS INC. 2011 CANON DR-M140 FIRST EDITION

CHAPTER 2

FUNCTIONS & OPERATION

I. OUTLINE................................................. 2-1

II. READING SYSTEM ................................ 2-6

III. FEED SYSTEM ....................................... 2-8

V. CONTROL SYSTEM............................. 2-13

I

V. POWER SUPPLY.................................. 2-17

LAYOUT OF ELECTRICAL COMPONENTS

VI.

VII. PARTS LAYOUT ON EACH PCB.......... 2-19

... 2-18

COPYRIGHT © CANON ELECTRONICS INC. 2011 CANON DR-M140 FIRST EDITION

I. OUTLINE

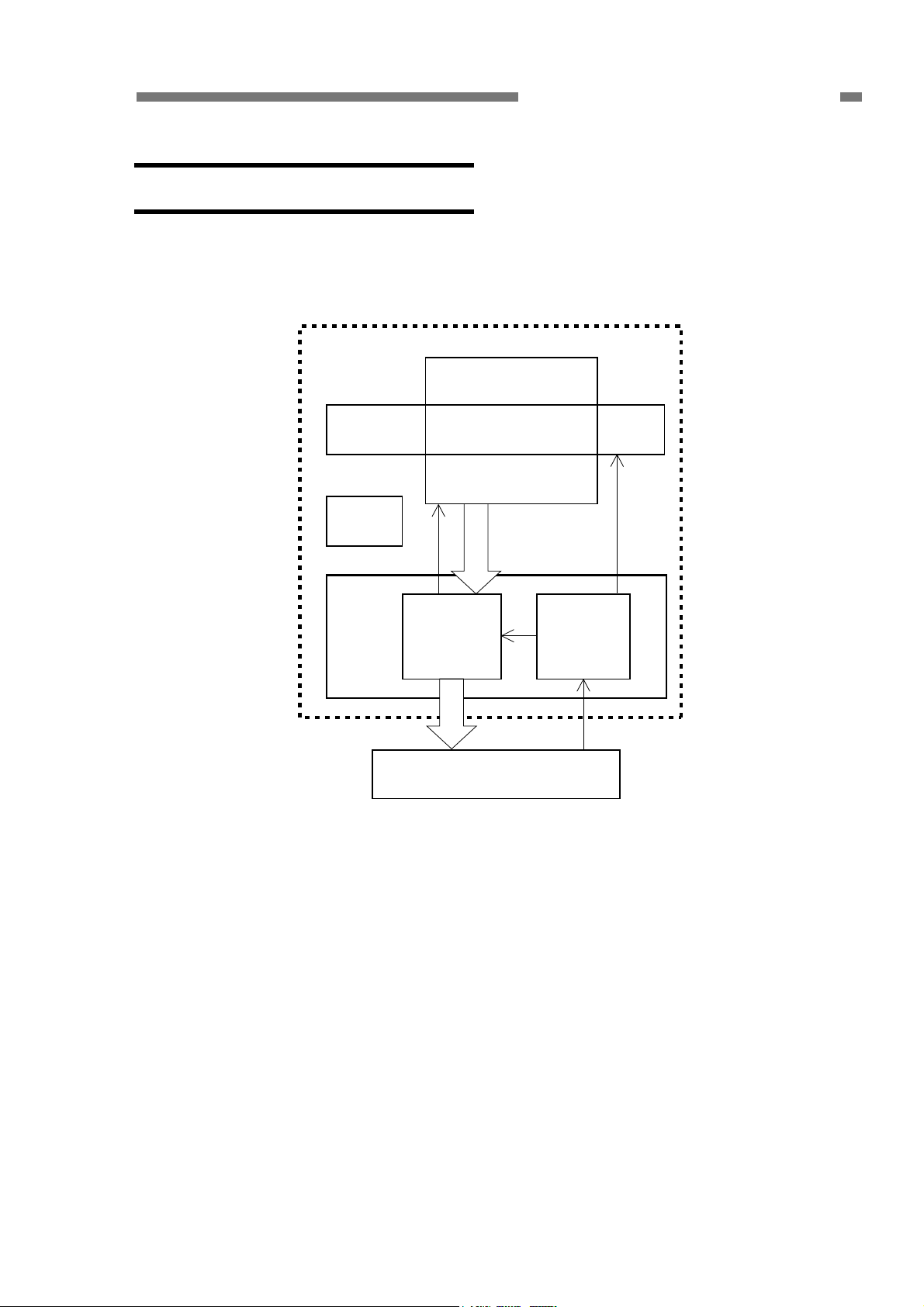

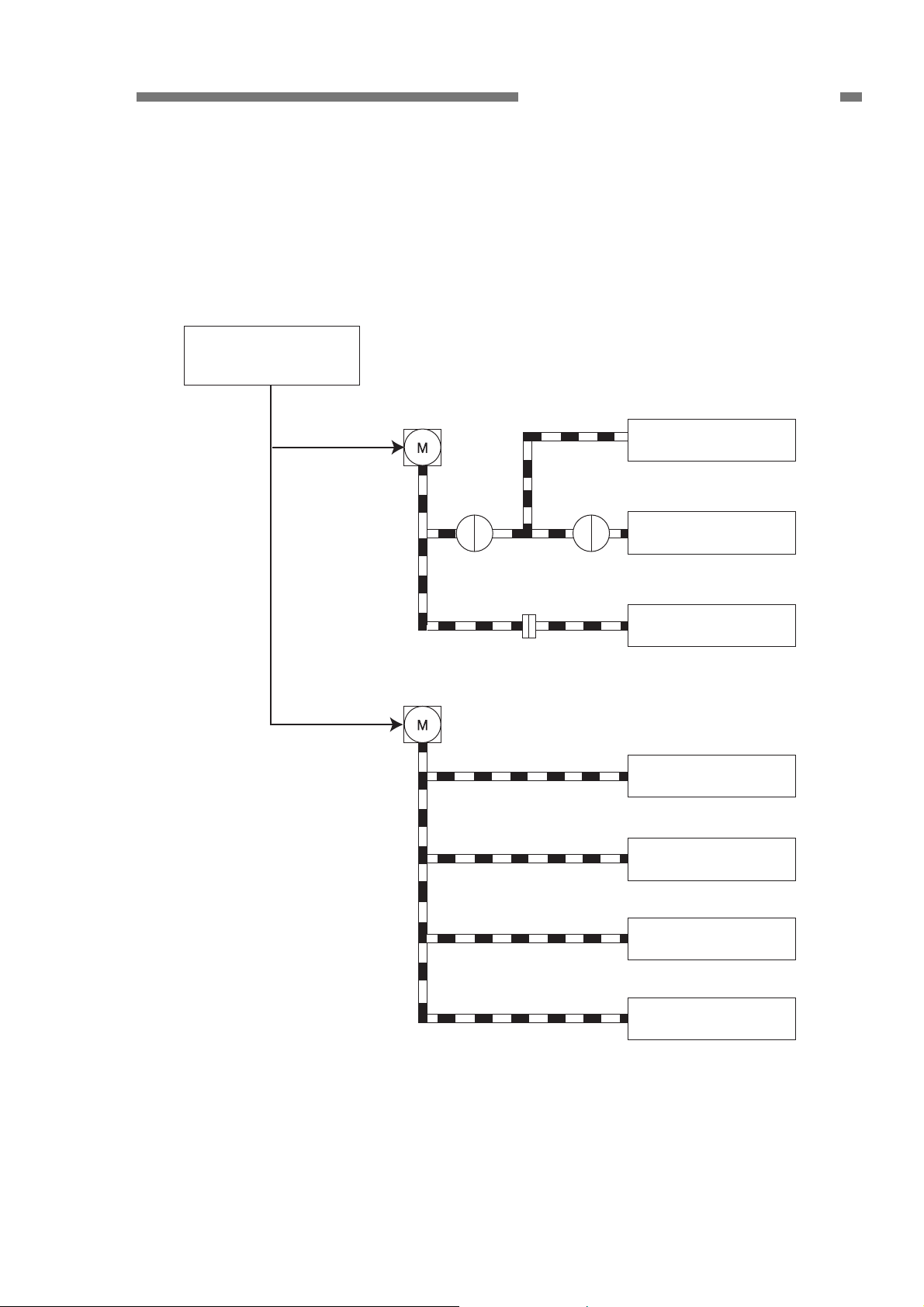

1. Main Configuration

Figure 2-101 shows the main

configuration of this machine.

This machine

Feed

system

Power

supply

section

CHAPTER 2 FUNCTIONS & OPERATION

Reading system

Control

system

1) Reading system

This system reads image data from

image sensors.

2) Feed system

This system performs from document

pickup to document ejection.

3) Control system

This system is comprised of an image

processing section and a feed control

section.

processing

Image

section

Computer

Figure 2-101

Feed

control

section

The image processing section controls

the reading system, and processes the

read image data. The computer also

processes image data.

The feed control section controls the

feed system.

4) Power supply section

This section supplies DC power,

converted from AC power with the AC

adapter, to the control PCB of this

machine.

COPYRIGHT © CANON ELECTRONICS INC. 2011 CANON DR-M140 FIRST EDITION

2-1

CHAPTER 2 FUNCTIONS & OPERATION

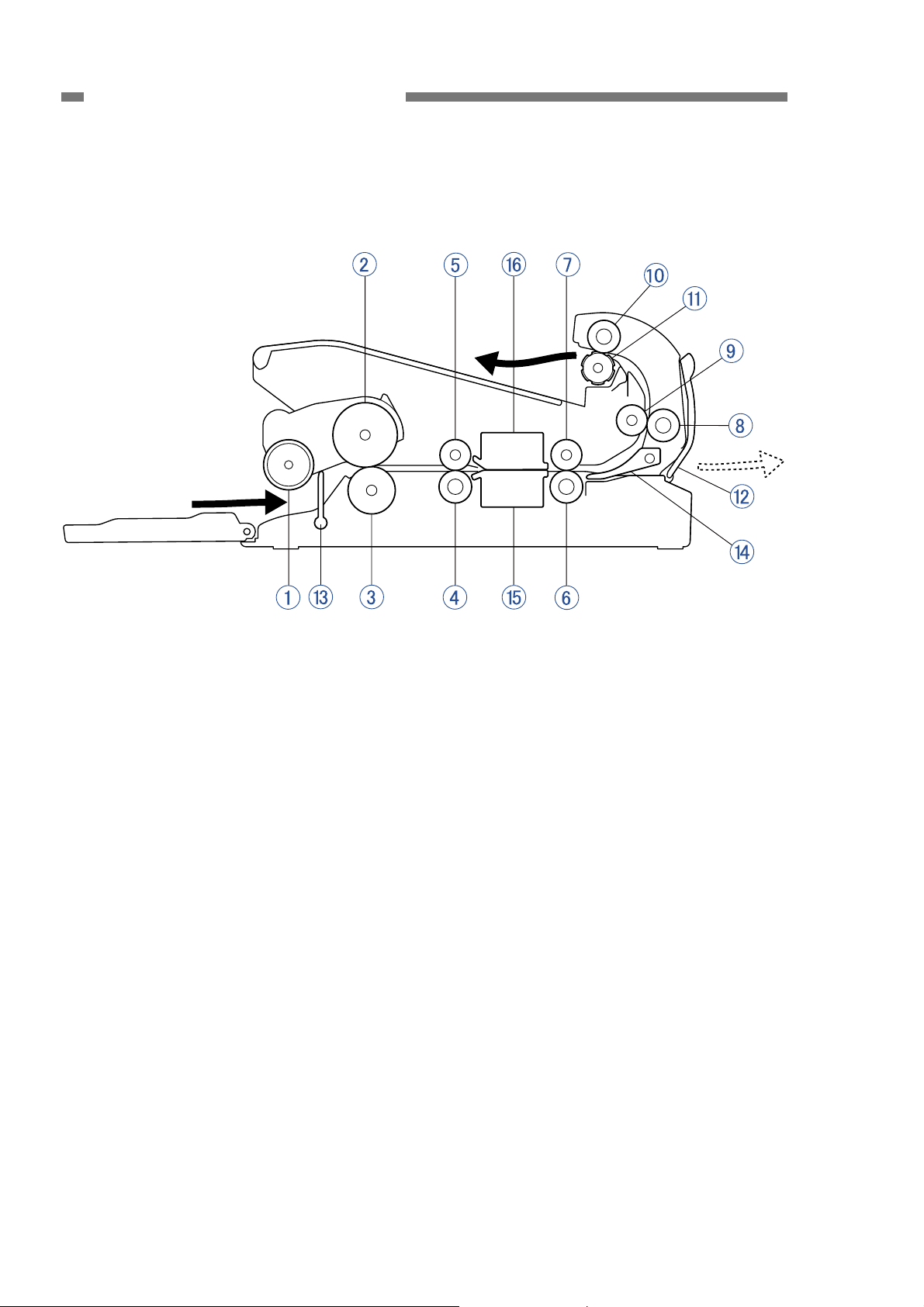

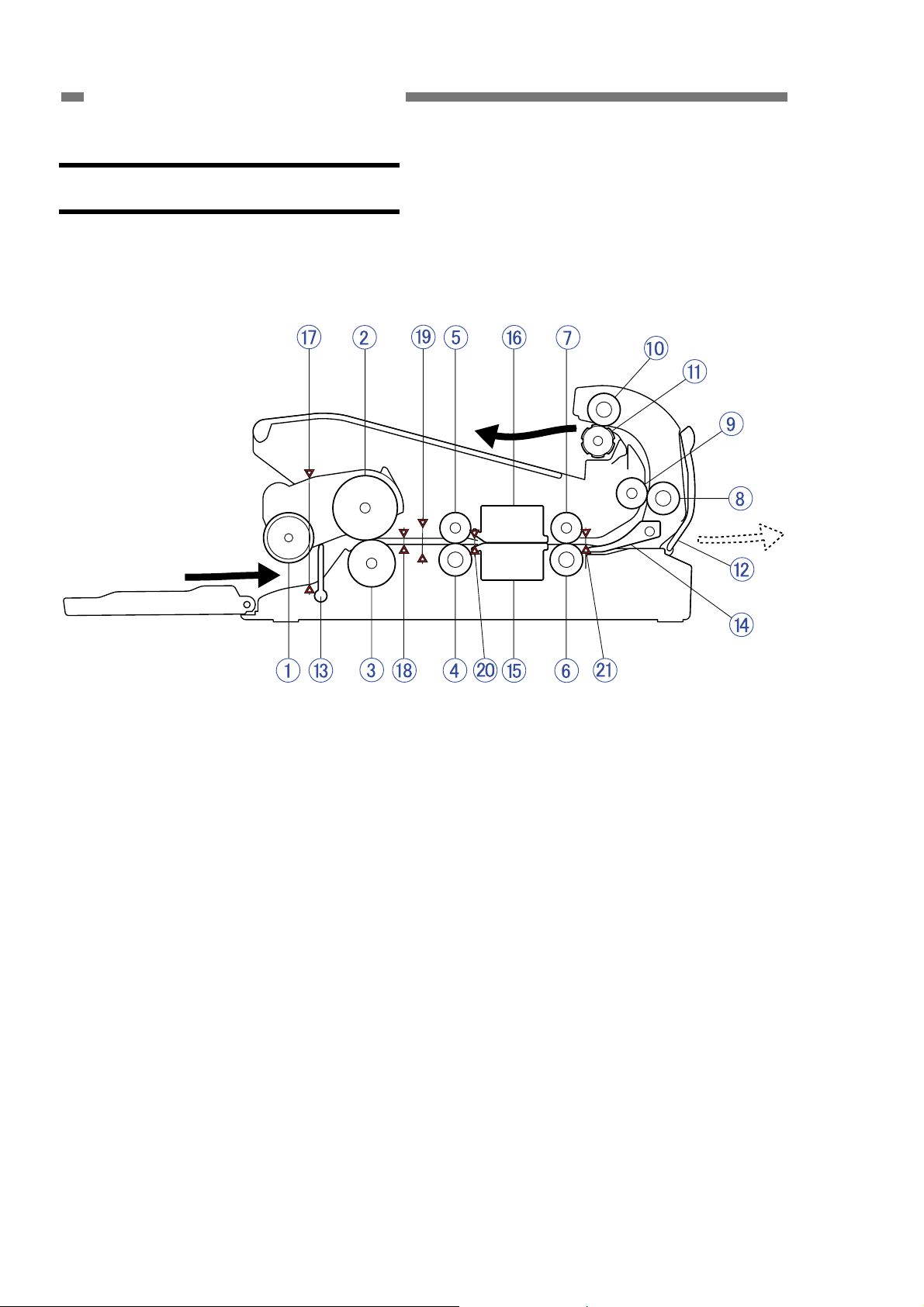

2. Feed Path

A sectional view of the feed path of this

machine is shown below.

Figure 2-102

1

Pickup roller

{

2

Feed roller

{

3

Retard roller

{

4

Registration roller (drive)

{

5

Registration roller (follower)

{

6

Straight eject roller (drive)

{

7

Straight eject roller (follower)

{

8

U-turn roller (drive)

{

9

U-turn roller (follower)

{

10

Eject roller (drive)

{

11

Eject roller (follower)

{

12

Straight path tray

{

13

Stopper

{

14

Flapper

{

15

Reading unit (lower)

{

16

Reading unit (upper)

{

2-2

COPYRIGHT © CANON ELECTRONICS INC. 2011 CANON DR-M140 FIRST EDITION

CHAPTER 2 FUNCTIONS & OPERATION

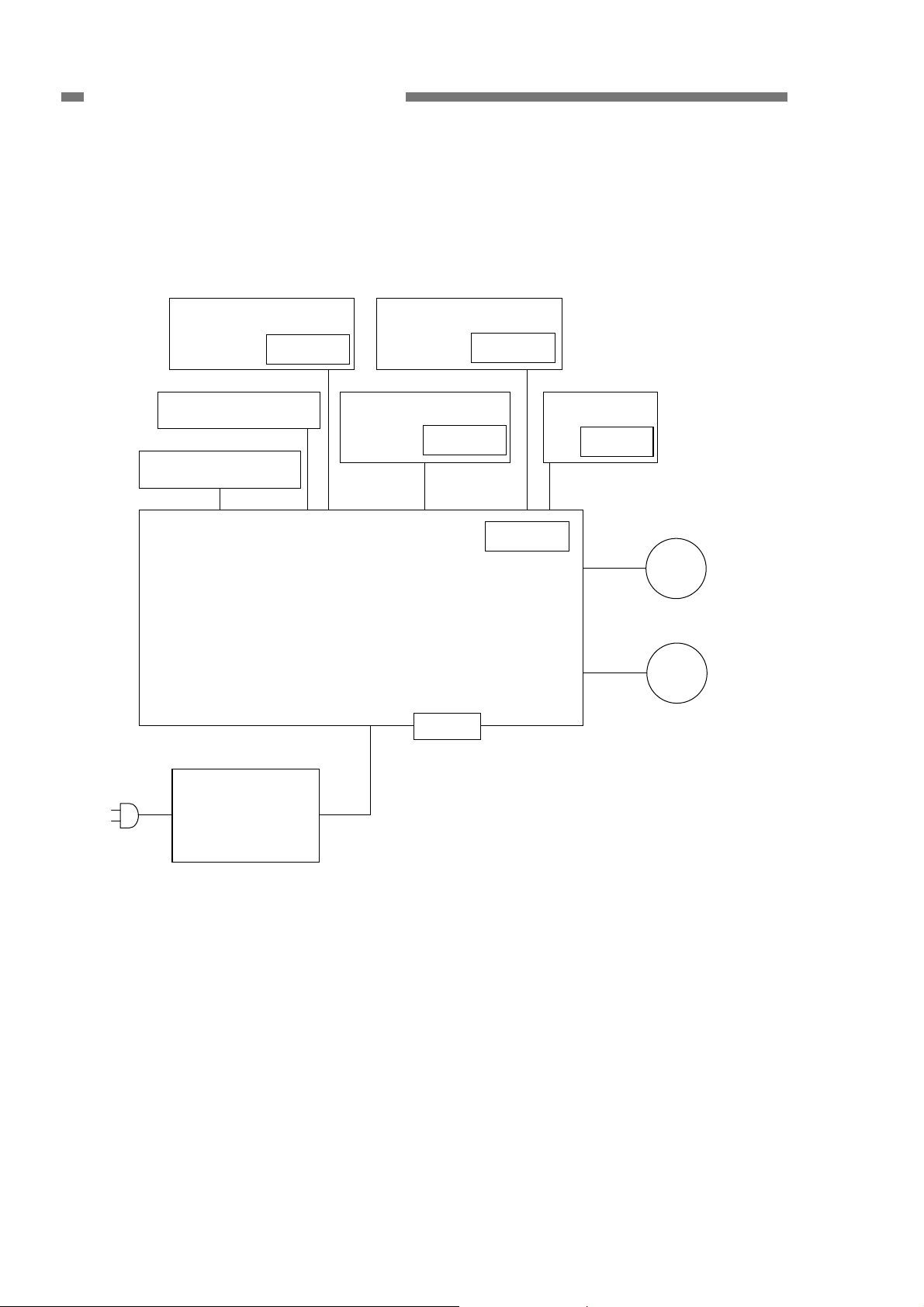

3. Motor Drive

This machine has a feed motor for

picking up documents and a main motor for

feeding documents.

Also, the document stopper of the

pickup section is moved by the feed motor.

Control PCB

Feed motor

Feed selection lever

Pickup roller

Feed roller

One-way clutch

Retard roller

(including torque limiter)

Main motor

Registration roller

Straight eject roller

U-turn roller

Eject roller

Figure 2-103

COPYRIGHT © CANON ELECTRONICS INC. 2011 CANON DR-M140 FIRST EDITION

2-3

CHAPTER 2 FUNCTIONS & OPERATION

4. Electrical Circuits

An overview of the electrical circuits

block diagram of this machine is shown

below.

Skew sensor (R) PCB

Sensor

CIS unit (back)

CIS unit (front)

Control PCB

Ultrasonic sensor

drive PCB

Document sensor

PCB

Sensor

Sensor

Operation PCB

Switch

Main motor

Sensor

AC adapter

Feed motor

USB interface

Figure 2-104

2-4

COPYRIGHT © CANON ELECTRONICS INC. 2011 CANON DR-M140 FIRST EDITION

CHAPTER 2 FUNCTIONS & OPERATION

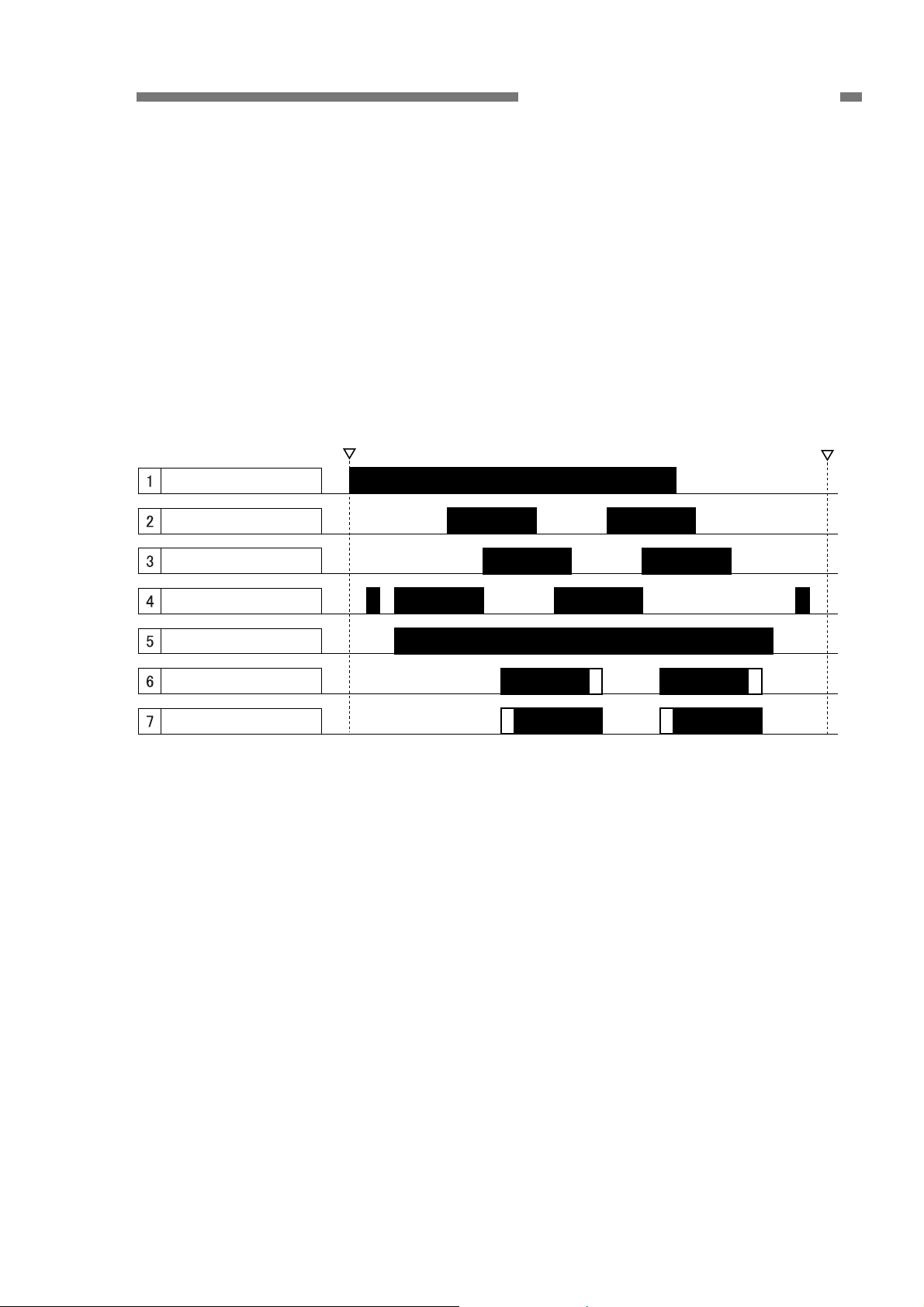

5. Timing Chart

The timing chart when you separately

pickup 2 sheets of document without

temporarily suspending the machine is

shown below.

Once the machine starts scanning, it

activates the feed motor and the main motor

and feeds the document after the initial

operation.

Start

Document sensor

Pre-registration sensor

Post-registration sensor

Feed motor

End

Main motor

Read front surface

Read back surface

Figure 2-105

COPYRIGHT © CANON ELECTRONICS INC. 2011 CANON DR-M140 FIRST EDITION

2-5

CHAPTER 2 FUNCTIONS & OPERATION

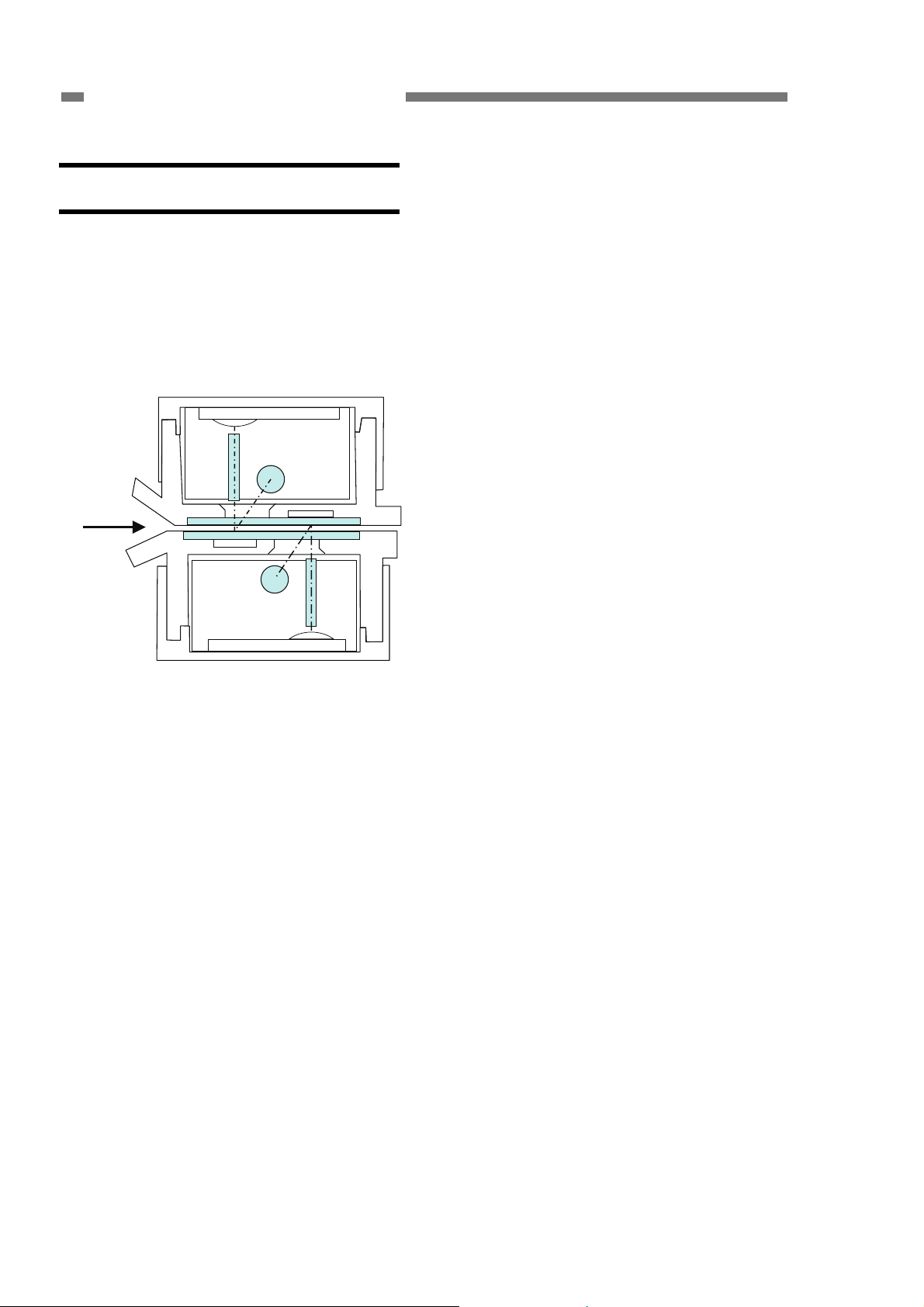

II. READING SYSTEM

1. Reading Unit

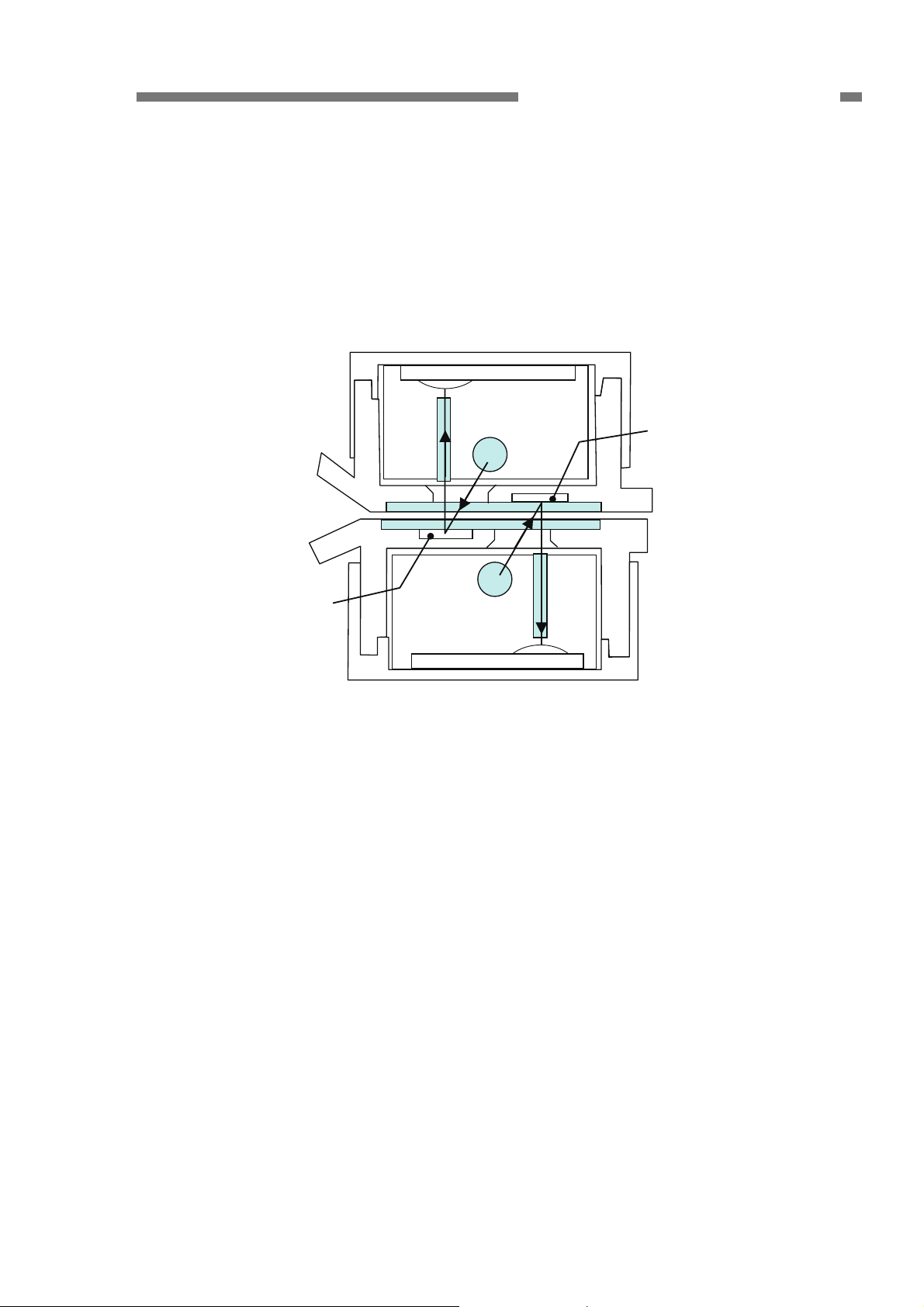

The sectional view of the reading

system is shown below. The upper and

lower reading units have the same

configuration but the different guide shapes.

Upper reading unit

Document

Lower reading unit

Figure 2-201

The upper reading unit reads the front

side of the documents and the lower

reading unit reads the back side of the

documents. This configuration enables the

machine to read both front and back sides

of a document using a single scan.

The read image data are sent to the

image processing section of the control

PCB.

To prevent reading speed from

decreasing, the image data is divided into

four and output in parallel.

The reading unit consists of CIS unit,

guide, and case.

The CIS unit consists of CIS PCB, lens

array, LED (R/G/B), light guide, and case.

The reading glass and white reference

sheet are mounted on the guide.

Photosensitive pixels are mounted on

the CIS PCB with a density of 600 dpi in a

line. The effective reading width is 219mm,

and the number of effective picture

elements is 5184.

A set of three basic color LEDs, red,

green, and blue (RGB), is mounted only on

the one side. This single-side illumination

causes a shadow on a document, which

may effect on the image data quality.

In the binary or grayscale modes, image

data are read with composite light

generated by lighting the RGB LEDs at the

same time. In the color mode, the LED is

successively lit, and reads image data with

each color. As documents are being fed at

regular speed while image data are read,

the reading positions of RGB are shifted

slightly.

In the color dropout mode, only the LED

of a designated color lights. In the color

emphasis mode, the LED of a color other

than a designated color lights.

2-6

COPYRIGHT © CANON ELECTRONICS INC. 2011 CANON DR-M140 FIRST EDITION

CHAPTER 2 FUNCTIONS & OPERATION

2. Shading

This section explains the reading

mechanism of the white reference sheet for

determination of the shading correction

value.

The sectional view of the reading unit is

shown below.

White reference sheet

White reference sheet

Figure 2-202

This machine can read the white

reference data at the document reading

position, unlike other scanners having the

black background color, since its

background color is white. Therefore, there

is neither need to feed the shading sheet

nor to move the internal white reference

sheet or the reading units.

For example, when the lower reading

unit reads the white reference data, the LED

emitted from the lower unit is reflected from

the white reference sheet on the upper unit

to be input to the sensor on the CIS PCB.

Since the white reference sheet is

placed under the reading glass, feeding

document does not cause dirt on it. Note

that executing shading while the reading

glass is dirty can cause poor images such

as white lines occurring in the images.

When this machine is turned ON or

starts scanning, it reads the white reference

data to determine the shading correction

value.

However, the slightly different optical

paths to the light receiving element are used

for the actual document and the white

reference sheet. Therefore this machine

needs fine adjustment of the shading

correction value using the service mode and

the shading sheet. This fine adjustment is

necessary after replacing the reading unit or

after replacing the control PCB recording

the shading correction value.

COPYRIGHT © CANON ELECTRONICS INC. 2011 CANON DR-M140 FIRST EDITION

2-7

CHAPTER 2 FUNCTIONS & OPERATION

III. FEED SYSTEM

1. Feeding Mechanism

The sectional view of the feed system is

shown below.

Figure 2-301

1

Pickup roller

{

2

Feed roller

{

3

Retard roller

{

4

Registration roller (drive)

{

5

Registration roller (follower)

{

6

Straight eject roller (drive)

{

7

Straight eject roller (follower)

{

8

U-turn roller (drive)

{

9

U-turn roller (follower)

{

10

Eject roller (drive)

{

11

Eject roller (follower)

{

12

Straight path tray

{

13

Stopper

{

14

Flapper

{

15

Reading unit (lower)

{

16

Reading unit (upper)

{

17

Document sensor detection point

{

18

Pre-registration/skew sensor detection point

{

19

Ultrasonic sensor detection point

{

20

Post-registration sensor detection point

{

21

Eject sensor detection point

{

2-8

COPYRIGHT © CANON ELECTRONICS INC. 2011 CANON DR-M140 FIRST EDITION

1) Feed path

The feed path in this machine is

horizontal in the reading unit, and has the

two types of straight or U-turn in the eject

section.

When feeding cards, use the straight

path.

2) Drive

The pickup, feed, and retard rollers in the

early stage are driven by the feed motor,

and from the registration roller to the

eject roller in the later stage are driven by

the main motor. The scanning condition

determines each drive speed.

Furthermore, the document stopper is

driven by the feed motor.

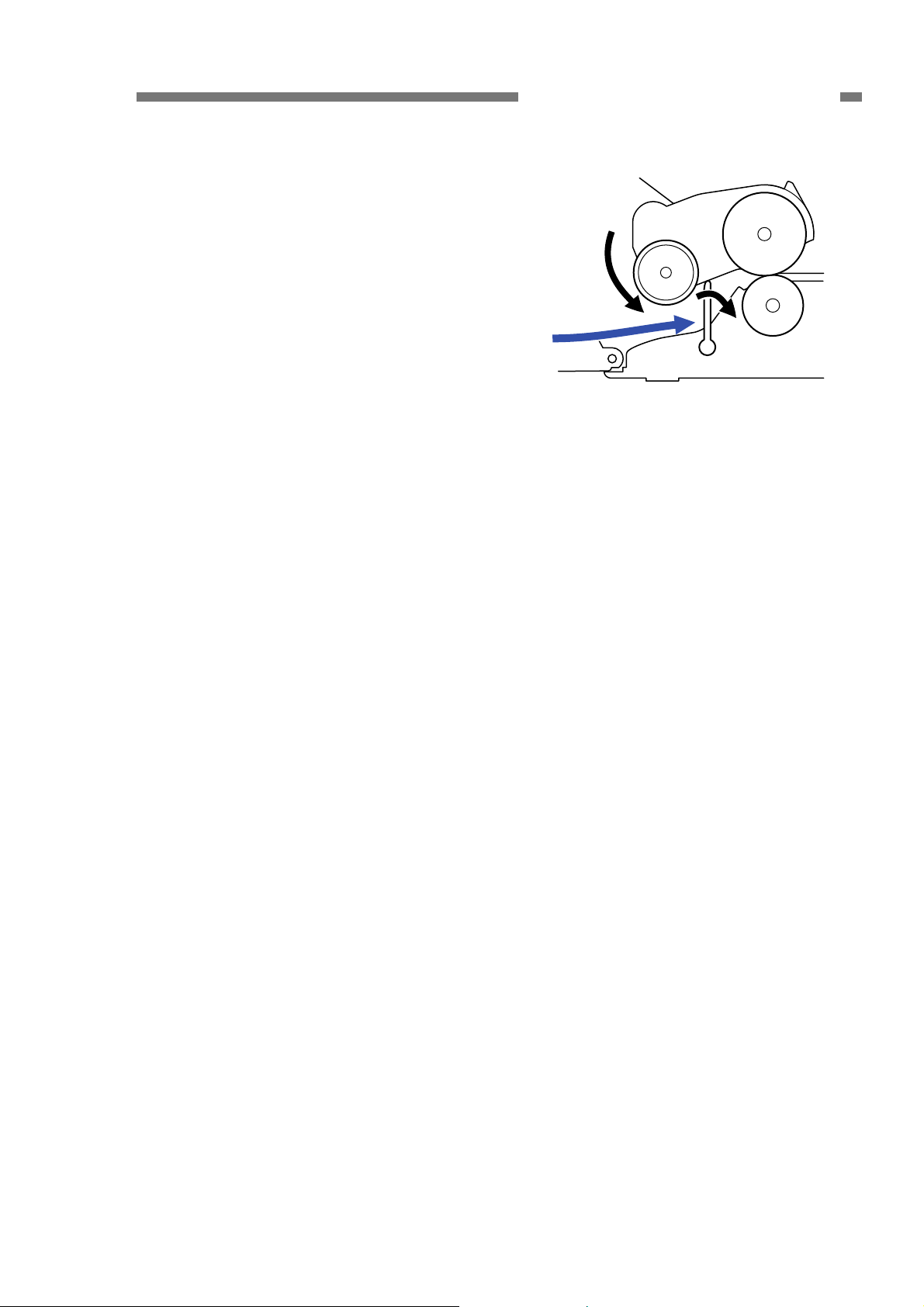

3) Feed

The following figure shows a

cross-sectional diagram of the feed

section before starting the feed. The

document stopper is standing up.

When a document is placed in the inlet,

the leading edge of the document lines

up at the document stopper. Once the

machine starts scanning, the document

is fed after the document stopper is

lowered.

Misfeeds and double feeds have been

reduced by increasing the diameter of

the feed roller and making the retard

roller movable up and down.

CHAPTER 2 FUNCTIONS & OPERATION

Figure 2-302

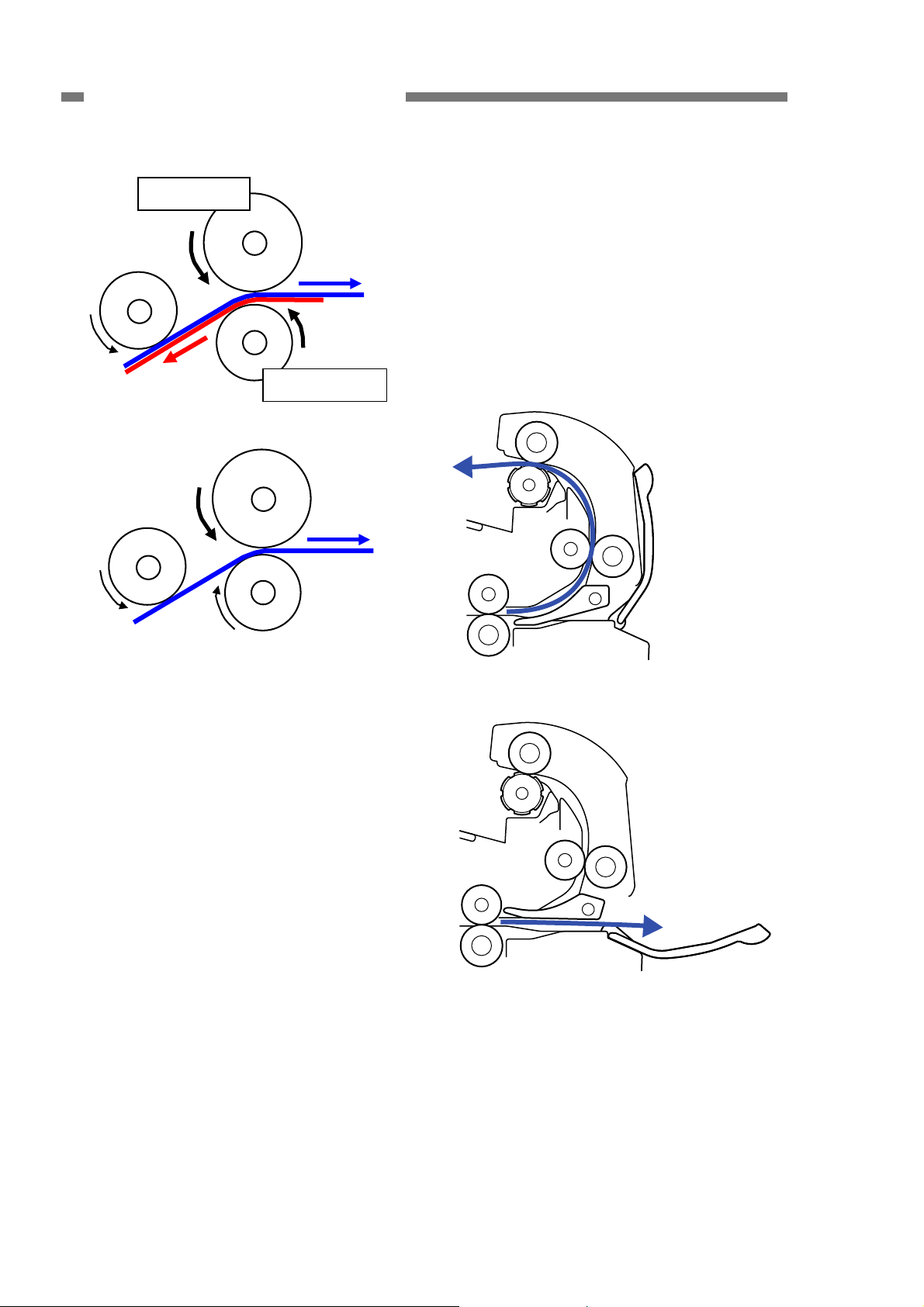

4) Separation

Separation of the documents is

performed by the retard roller.

If the feed selection lever is set to normal

(separate), though the retard roller is

connected to the drive system, since the

torque limiter is built into it, when the

outside pressure on the roller exceeds

the specified value into the feed direction,

the roller begins to rotate in the same

direction.

As shown in Figure 2-303-a, when

overlapped documents enter into the

clearance between the feed roller and

the retard roller, the document in contact

with the feed roller is fed in the direction

entering the scanner and the document

in contact with the retard roller does not

enter the scanner because the retard

roller rotates in the direction to return the

document to the feeder.

As shown in Figure 2-303-b, once a

single document remains, the feed roller

and the document add torque on the

retard roller. When this torque exceeds

the retard roller torque, the retard roller

rotates in the direction pushing the

document into the scanner due to the

torque limiter.

COPYRIGHT © CANON ELECTRONICS INC. 2011 CANON DR-M140 FIRST EDITION

2-9

CHAPTER 2 FUNCTIONS & OPERATION

a.

Feed roller

Retard roller

b.

5) Eject

This machine is equipped with both a

U-turn path and a straight path. The

selection is made by opening or closing

the straight eject tray. This is what

operates the flapper.

The difference is shown in the following

figures.

a. U-turn path

Figure 2-303

However, if the lever is in none separate

feed, the retard roller is allowed to rotate

freely, and the document is fed by the

rotation of the feed roller.

b. Straight path

Figure 2-304

2-10

COPYRIGHT © CANON ELECTRONICS INC. 2011 CANON DR-M140 FIRST EDITION

Loading...

Loading...