Page 1

SERVICE

MANUAL

iPF710

COPYRIGHT ©2007 CANON INC. CANON imagePROGRAF 710 REV. 0 PRINTED IN U.S.A.

OCTOBER 2007

REV. 0

DU7-1244-000

Page 2

Application

This manual has been issued by Canon Inc. for qualified persons to learn technical theory, installation,

maintenance, and repair of products. This manual covers all localities where the products are sold. For this reason,

there may be information in this manual that does not apply to your locality.

Corrections

This manual may contain technical inaccuracies or typographical errors due to improvements or changes in

products. When changes occur in applicable products or in the contents of this manual, Canon will release technical

information as the need arises. In the event of major changes in the contents of this manual over a long or short

period, Canon will issue a new edition of this manual.

The following paragraph does not apply to any countries where such provisions are inconsistent with local law.

Trademarks

The product names and company names used in this manual are the registered trademarks of the individual

companies.

Copyright

This manual is copyrighted with all rights reserved. Under the copyright laws, this manual may not be copied,

reproduced or translated into another language, in whole or in part, without the written consent of Canon Inc.

COPYRIGHT © 2001 CANON INC.

Printed in Japan

Caution

Use of this manual should be strictly supervised to avoid disclosure of confidential information.

Page 3

Symbols Used

This documentation uses the following symbols to indicate special information:

Symbol Description

Indicates an item of a non-specific nature, possibly classified as Note, Caution, or

Warning.

Indicates an item requiring care to avoid electric shocks.

Indicates an item requiring care to avoid combustion (fire).

Indicates an item prohibiting disassembly to avoid electric shocks or problems.

Indicates an item requiring disconnection of the power plug from the electric outlet.

Indicates an item intended to provide notes assisting the understanding of the topic in

Memo

question.

Introduction

REF.

Indicates an item of reference assisting the understanding of the topic in question.

Provides a description of a service mode.

Provides a description of the nature of an error indication.

Page 4

Introduction

The following rules apply throughout this Service Manual:

1. Each chapter contains sections explaining the purpose of specific functions and the relationship between electrical and mechanical systems with reference to the timing of operation.

In the diagrams, represents the path of mechanical drive; where a signal name accompanies the

symbol, the arrow indicates the direction of the electric signal.

The expression "turn on the power" means flipping on the power switch, closing the front door, and closing

the delivery unit door, which results in supplying the machine with power.

2. In the digital circuits, '1'is used to indicate that the voltage level of a given signal is "High", while '0' is used

to indicate "Low".(The voltage value, however, differs from circuit to circuit.) In addition, the asterisk (*) as

in "DRMD*" indicates that the DRMD signal goes on when '0'.

In practically all cases, the internal mechanisms of a microprocessor cannot be checked in the field.

Therefore, the operations of the microprocessors used in the machines are not discussed: they are explained

in terms of from sensors to the input of the DC controller PCB and from the output of the DC controller PCB

to the loads.

The descriptions in this Service Manual are subject to change without notice for product improvement or other

purposes, and major changes will be communicated in the form of Service Information bulletins.

All service persons are expected to have a good understanding of the contents of this Service Manual and all

relevant Service Information bulletins and be able to identify and isolate faults in the machine."

Page 5

Contents

Contents

Chapter 1 PRODUCT DESCRIPTION

1.1 Product Overview .............................................................................................. 1-1

1.1.1 Product Overview....................................................................................................... 1-1

1.2 Features.............................................................................................................. 1-2

1.2.1 Features....................................................................................................................... 1-2

1.2.2 Printhead ..................................................................................................................... 1-2

1.2.3 Ink Tank....................................................................................................................... 1-3

1.2.4 Cutter unit.................................................................................................................... 1-3

1.2.5 Roll Holder................................................................................................................... 1-3

1.2.6 Stand............................................................................................................................ 1-4

1.2.7 IEEE1394 (FireWire) Board...................................................................................... 1-5

1.2.8 Consumables.............................................................................................................. 1-5

1.3 Product Specifications ...................................................................................... 1-7

1.3.1 Product Specifications............................................................................................... 1-7

1.4 Detailed Specifications ................................................................................... 1-10

1.4.1 Print Speed and Direction....................................................................................... 1-10

1.4.2 Interface specifications............................................................................................ 1-17

1.5 Names and Functions of Components ........................................................ 1-18

1.5.1 Front ........................................................................................................................... 1-18

1.5.2 Rear............................................................................................................................ 1-19

1.5.3 Carriage..................................................................................................................... 1-20

1.6 Basic Operation ............................................................................................... 1-21

1.6.1 Operation Panel ....................................................................................................... 1-21

1.6.2 Main Menu................................................................................................................. 1-22

1.7 Safety and Precautions .................................................................................. 1-40

1.7.1 Safety Precautions ...................................................................................................1-40

1.7.1.1 Moving Parts ....................................................................................................................... 1-40

1.7.1.2 Adhesion of Ink ................................................................................................................... 1-41

1.7.1.3 Electric Parts ....................................................................................................................... 1-42

1.7.2 Other Precautions ....................................................................................................1-44

1.7.2.1 Printhead.............................................................................................................................. 1-44

1.7.2.2 Ink Tank ............................................................................................................................... 1-45

1.7.2.3 Handling the Printer ........................................................................................................... 1-46

1.7.3 Precautions When Servicing Printer .....................................................................1-48

1.7.3.1 Notes on the Data Stored in the Printer .......................................................................... 1-48

1.7.3.2 Confirming the Firmware Version .................................................................................... 1-48

Page 6

Contents

1.7.3.3 Precautions against Static Electricity.............................................................................. 1-48

1.7.3.4 Precautions for Disassembly/Reassembly..................................................................... 1-49

1.7.3.5 Self-diagnostic Feature ..................................................................................................... 1-49

1.7.3.6 Disposing of the Lithium Battery...................................................................................... 1-49

Chapter 2 TECHNICAL REFERENCE

2.1 Basic Operation Outline.................................................................................... 2-1

2.1.1 Printer Diagram ......................................................................................................... 2-1

2.1.2 Print Signal Sequence.............................................................................................. 2-2

2.1.3 Print Driving................................................................................................................ 2-3

2.2 Firmware ............................................................................................................. 2-6

2.2.1 Operation Sequence at Power-on .......................................................................... 2-6

2.2.2 Operation Sequence at Power-off .......................................................................... 2-7

2.2.3 Print Control ............................................................................................................... 2-8

2.2.4 Print Position Adjustment Function ...................................................................... 2-14

2.2.5 Head Management ................................................................................................. 2-14

2.2.6 Printhead Overheating Protection Control .......................................................... 2-14

2.2.7 Pause between Pages ........................................................................................... 2-15

2.2.8 White Raster Skip ................................................................................................... 2-15

2.2.9 Sleep Mode .............................................................................................................. 2-15

2.3 Printer Mechanical System............................................................................. 2-16

2.3.1 Outline ....................................................................................................................... 2-16

2.3.1.1 Outline.................................................................................................................................. 2-16

2.3.2 Ink Passage ............................................................................................................. 2-17

2.3.2.1 Ink Passage ........................................................................................................................ 2-17

2.3.2.2 Ink Tank Unit....................................................................................................................... 2-19

2.3.2.3 Carriage Unit....................................................................................................................... 2-22

2.3.2.4 Printhead ............................................................................................................................. 2-25

2.3.2.5 Purge Unit ........................................................................................................................... 2-26

2.3.2.6 Maintenance Cartridge...................................................................................................... 2-32

2.3.2.7 Air Flow................................................................................................................................ 2-33

2.3.3 Paper Path ............................................................................................................... 2-33

2.3.3.1 Outline.................................................................................................................................. 2-33

2.3.3.2 Paper Path .......................................................................................................................... 2-35

2.3.3.3 Cutter Unit ........................................................................................................................... 2-36

2.4 Printer Electrical System................................................................................. 2-37

2.4.1 Outline ....................................................................................................................... 2-37

2.4.1.1 Overview.............................................................................................................................. 2-37

2.4.2 Main Controller ........................................................................................................ 2-39

2.4.2.1 Main controller components ............................................................................................. 2-39

2.4.3 Carriage Relay PCB ............................................................................................... 2-41

2.4.3.1 Carriage relay PCB components ..................................................................................... 2-41

2.4.4 Head Relay PCB ..................................................................................................... 2-41

Page 7

Contents

2.4.4.1 Head relay PCB components ........................................................................................... 2-41

2.4.5 Maintenance Cartridge Relay PCB .......................................................................2-42

2.4.5.1 Maintenance cartridge relay PCB components ............................................................. 2-42

2.4.6 Power Supply ............................................................................................................2-42

2.4.6.1 Power supply block diagram............................................................................................. 2-42

2.5 Detection Functions with Sensors ................................................................ 2-43

2.5.1 Sensors for covers................................................................................................... 2-43

2.5.2 Ink passage system................................................................................................. 2-44

2.5.3 Carriage system ....................................................................................................... 2-47

2.5.4 Paper path system................................................................................................... 2-49

Chapter 3 INSTALLATION

3.1 Transporting the Printer ................................................................................... 3-1

3.1.1 Transporting the Printer ............................................................................................3-1

3.1.1.1 Transporting the Printer....................................................................................................... 3-1

3.1.2 Reinstalling the Printer ..............................................................................................3-4

3.1.2.1 Reinstalling the Printer ........................................................................................................ 3-4

Chapter 4 DISASSEMBLY/REASSEMBLY

4.1 Service Parts...................................................................................................... 4-1

4.1.1 Service Parts............................................................................................................... 4-1

4.2 Disassembly/Reassembly................................................................................ 4-1

4.2.1 Disassembly/Reassembly......................................................................................... 4-1

4.3 Points to Note on Disassembly and Reassembly ........................................ 4-3

4.3.1 Note on locations prohibited from disassembly .................................................... 4-3

4.3.2 Moving the carriage manually .................................................................................. 4-3

4.3.3 Units requiring draining of ink................................................................................... 4-3

4.3.4 External Covers.......................................................................................................... 4-4

4.3.5 Waste Ink Box........................................................................................................... 4-11

4.3.6 Driving Unit................................................................................................................ 4-12

4.3.7 Ink Tube Unit............................................................................................................. 4-13

4.3.8 Carriage Unit............................................................................................................. 4-16

4.3.9 Feeder Unit ............................................................................................................... 4-21

4.3.10 Purge Unit ............................................................................................................... 4-22

4.3.11 Ink Tank Unit........................................................................................................... 4-23

4.3.12 Head Management Sensor................................................................................... 4-25

4.3.13 Multi Sensor............................................................................................................ 4-26

4.3.14 PCBs ........................................................................................................................ 4-27

4.3.15 Opening the Cap/Moving the Wiper Unit............................................................ 4-28

4.3.16 Opening/Closing the Ink Supply Valve ............................................................... 4-29

Page 8

Contents

4.3.17 Draining the Ink ..................................................................................................... 4-30

4.4 Applying the Grease ........................................................................................ 4-31

4.4.1 Applying the Grease ............................................................................................... 4-31

4.5 Adjustment and Setup Items.......................................................................... 4-33

4.5.1 Adjustment Item List ............................................................................................... 4-33

4.5.2 Procedure after Replacing the Feed Roller or Feed Roller Encoder .............. 4-33

4.5.3 Procedure after Replacing the Carriage Unit or Multi Sensor.......................... 4-33

4.5.4 Procedure after Replacing the Head Management Sensor ............................. 4-34

Chapter 5 MAINTENANCE

5.1 Periodic Replacement Parts............................................................................. 5-1

5.1.1 Periodic Replacement Parts .................................................................................... 5-1

5.2 Consumable Parts ............................................................................................. 5-1

5.2.1 Consumable Parts..................................................................................................... 5-1

5.3 Periodic Maintenance........................................................................................ 5-2

5.3.1 Periodic Maintenance ............................................................................................... 5-2

Chapter 6 TROUBLESHOOTING

6.1 Troubleshooting ................................................................................................. 6-1

6.1.1 Outline ......................................................................................................................... 6-1

6.1.1.1 Outline of Troubleshooting ................................................................................................. 6-1

6.2 Location of Connectors and Pin Arrangement.............................................. 6-2

6.2.1 Main controller PCB .................................................................................................. 6-2

6.2.2 Carriage relay PCB ................................................................................................. 6-12

6.2.3 Head relay PCB....................................................................................................... 6-19

6.3 Version Up ........................................................................................................ 6-24

6.3.1 Firmware Update Tool ............................................................................................ 6-24

6.4 Service Tools.................................................................................................... 6-25

6.4.1 Tool List .................................................................................................................... 6-25

6.4.2 Using the Cover Switch Tool ................................................................................. 6-26

Chapter 7 SERVICE MODE

7.1 Service Mode...................................................................................................... 7-1

7.1.1 Service Mode Operation .......................................................................................... 7-1

7.1.2 Map of the Service Mode ......................................................................................... 7-2

7.1.3 Details of Service Mode ......................................................................................... 7-10

7.1.4 Sample Printout ....................................................................................................... 7-27

7.2 Special Mode.................................................................................................... 7-32

7.2.1 Special Modes for Servicing .................................................................................. 7-32

Page 9

Contents

Chapter 8 ERROR CODE

8.1 Outline................................................................................................................. 8-1

8.1.1 Outline.......................................................................................................................... 8-1

8.2 Warning Table ................................................................................................... 8-2

8.2.1 Warnings ..................................................................................................................... 8-2

8.3 Error Table ......................................................................................................... 8-3

8.3.1 Error Code List ........................................................................................................... 8-3

8.4 Sevice Call Table .............................................................................................. 8-6

8.4.1 Service call errors ...................................................................................................... 8-6

Page 10

Chapter 1 PRODUCT DESCRIPTION

Page 11

Contents

Contents

1.1 Product Overview .............................................................................................. 1-1

1.1.1 Product Overview....................................................................................................... 1-1

1.2 Features.............................................................................................................. 1-2

1.2.1 Features....................................................................................................................... 1-2

1.2.2 Printhead ..................................................................................................................... 1-2

1.2.3 Ink Tank....................................................................................................................... 1-3

1.2.4 Cutter unit.................................................................................................................... 1-3

1.2.5 Roll Holder................................................................................................................... 1-3

1.2.6 Stand............................................................................................................................ 1-4

1.2.7 IEEE1394 (FireWire) Board...................................................................................... 1-5

1.2.8 Consumables.............................................................................................................. 1-5

1.3 Product Specifications ...................................................................................... 1-7

1.3.1 Product Specifications............................................................................................... 1-7

1.4 Detailed Specifications ................................................................................... 1-10

1.4.1 Print Speed and Direction....................................................................................... 1-10

1.4.2 Interface specifications............................................................................................ 1-17

1.5 Names and Functions of Components ........................................................ 1-18

1.5.1 Front ........................................................................................................................... 1-18

1.5.2 Rear............................................................................................................................ 1-19

1.5.3 Carriage..................................................................................................................... 1-20

1.6 Basic Operation ............................................................................................... 1-21

1.6.1 Operation Panel ....................................................................................................... 1-21

1.6.2 Main Menu................................................................................................................. 1-22

1.7 Safety and Precautions .................................................................................. 1-40

1.7.1 Safety Precautions ...................................................................................................1-40

1.7.1.1 Moving Parts ....................................................................................................................... 1-40

1.7.1.2 Adhesion of Ink ................................................................................................................... 1-41

1.7.1.3 Electric Parts ....................................................................................................................... 1-42

1.7.2 Other Precautions ....................................................................................................1-44

1.7.2.1 Printhead.............................................................................................................................. 1-44

1.7.2.2 Ink Tank ............................................................................................................................... 1-45

1.7.2.3 Handling the Printer ........................................................................................................... 1-46

1.7.3 Precautions When Servicing Printer .....................................................................1-48

1.7.3.1 Notes on the Data Stored in the Printer .......................................................................... 1-48

1.7.3.2 Confirming the Firmware Version .................................................................................... 1-48

1.7.3.3 Precautions against Static Electricity .............................................................................. 1-48

1.7.3.4 Precautions for Disassembly/Reassembly ..................................................................... 1-49

1.7.3.5 Self-diagnostic Feature ..................................................................................................... 1-49

1.7.3.6 Disposing of the Lithium Battery...................................................................................... 1-49

Page 12

Chapter 1

1.1 Product Overview

1.1.1 Product Overview

This printer is a large-format printer that prints in a maximum width of 36 inches with high-speed photographic

picture quality.

This printer is a desktop product that delivers its output on roll media or cut sheets.

0012-6185

[2]

[3]

[1]

[5]

[6]

[4]

[11] [12] [13] [14] [15]

F-1-1

T-1-1

[7]

[8]

[9]

[1] Top Cover [9] USB Port

[2] Upper Left Cover [10] Power Supply Connector

[3] Stand (option) [11] Roll Holder Set

[4] Output Stacker (included with stand) [12] Printhead

[5] Operation Panel [13] Ink Tank

[6] Ink Tank Cover [14] Power Cord

[7] Expansion Board Slot [15] Cleaner Brush

[8] Ethernet Connector

[10]

1-1

Page 13

Chapter 1

1.2 Features

1.2.1 Features

-Rear loading of roll media, making for compact, lightweight device geometry.

-Borderless four-side printing support (roll media) removes laborious cutting work, easing the job of creating

posters to a significant degree.

-High resolutions of 2400 x 1200 dpi maximum, coupled with the exceptionally light-fast, water-proof and

ozone-proof five-color pigment inks of Y, M, C, BK and MBK, deliver high-quality photographic picture

quality.

-High-speed printing under bidirectional print control.

-Ink supply through tubing to a completely independent printhead and large-capacity ink tanks.

-Ready for roll media and cut media.

-Roll media pass in widths between 254 and 914.4 mm and in lengths up to 18 m.

-The cutter unit that mounts on the carriage allows paper to be cut automatically.

-Cut media are fed and ejected and ink tanks replaced all in an easy-to-access front panel operation.

-USB2.0 high-speed interface and 10Base-T/100Base-TX in standard support of a TCP/IP network, plus

optional support of IEEE1394.

1.2.2 Printhead

The printhead that mounts on the carriage is an integrated six-color disposable printhead.

It has 5,120 nozzles for MBK and 2,560 nozzles for each additional color arranged in a zigzag pattern.

If print quality remains unimproved even after a specified cleaning operation, replace the printhead.

Replacement about one year after the date of initial unpacking is also recommended.

0012-6186

0013-2741

1-2

F-1-2

Page 14

Chapter 1

1.2.3 Ink Tank

Ink tanks are disposable.

An ink tank should be replaced when an ink tank replacement prompt message appears or when six months

expire after the date of initial unpacking, whichever occurs earlier.

To install ink tanks, open the right cover of the printer. Ink tanks are furnished with a notch for preventing

incorrect installation, which will allow the tanks to be installed at the position marked in the right color and

nowhere else.

Ink tanks are available in the four dye ink colors of black, cyan, magenta and yellow and the pigment ink color

of mat black.

F-1-3

0013-0607

1.2.4 Cutter unit

The cutter unit that mounts on the carriage is disposable.

Replace the cutter unit when it gets dull.

0013-5146

F-1-4

1.2.5 Roll Holder

The printer comes with a roll holder for 2-inch paper tube and 3-inch paper tube attachment.

The roll holder clamps the paper tubes of roll media with an outside diameter of 150 mm or less from inside.

F-1-5

0017-4103

1-3

Page 15

Chapter 1

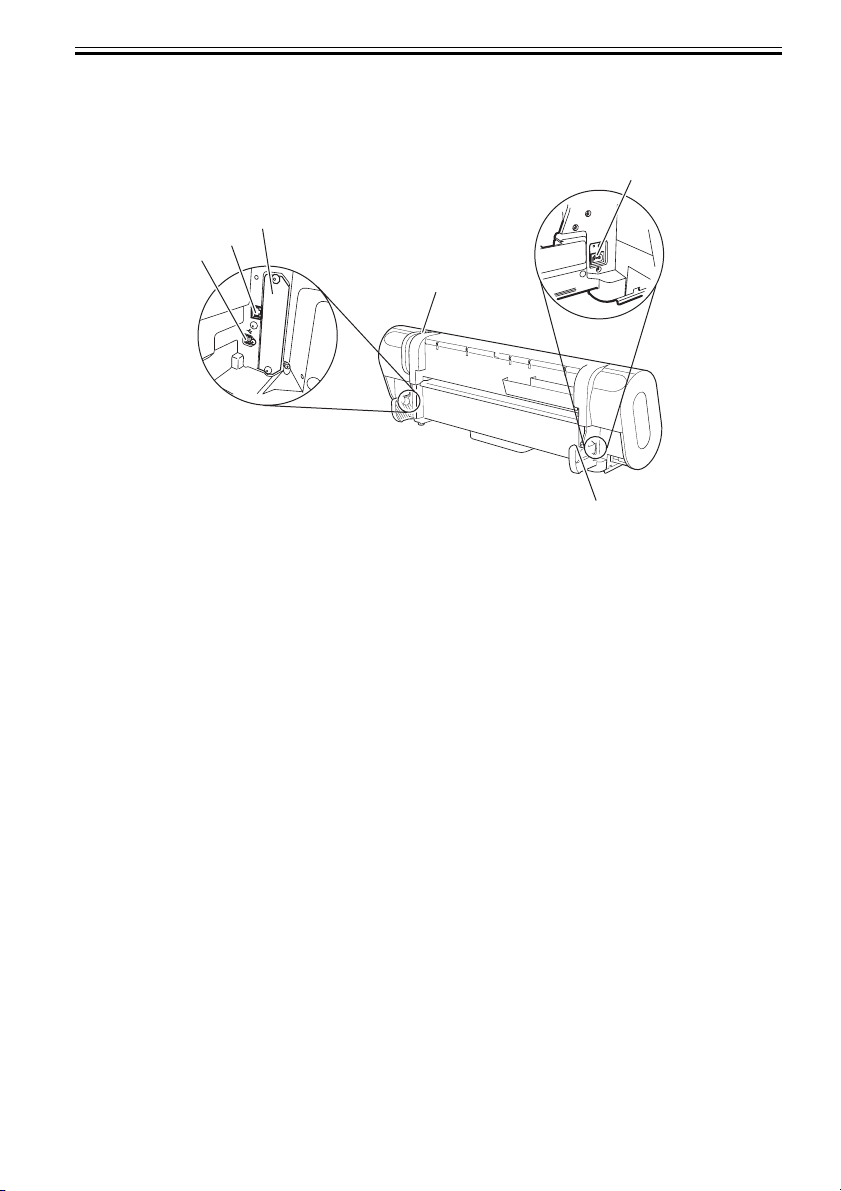

1.2.6 Stand

It is a stand that puts the printer. Equipped with casters so that the printer can be easily moved. The output

stacker included with stand can use by the two ways of the regular position or extended position.

F-1-6

MEMO:

- Use the output stacker in the regular position [A]. However, for the specified media, it can also be used in the

extended position [B]. The media can be removed more easily when the output stacker is in the extended

position.

- The output stacker can accommodate one sheet. Remove each sheet before printing if you are printing a series

of documents.

0016-4115

1-4

[A]

[B]

F-1-7

Page 16

1.2.7 IEEE1394 (FireWire) Board

IEEE1394 (FireWire) expansion board (option)

An interface board that provides an additional IEEE1394 (FireWire) port.

F-1-8

1.2.8 Consumables

a. Printhead

The expendable printhead is the same as the one that comes with the printer.

Chapter 1

0016-8123

0013-2743

F-1-9

b. Ink Tanks

The expendable ink tanks are available in five colors: mat black, black, cyan, magenta and yellow. They are

the same the same as the ones that come with the printer. Usable for six months after unpacking.

The ink tank that can be used with this printer is labeled "A".

F-1-10

1-5

Page 17

Chapter 1

c. Maintenance cartridge

The expendable maintenance cartridge is the same as the one that comes with the printer.

The maintenance cartridge is furnished with a shaft cleaner.

F-1-11

1-6

Page 18

1.3 Product Specifications

1.3.1 Product Specifications

Type Bubble-jet printer (desktop type)

Feeding system Roll media: Manual (Rear loading)

Cut media: Paper tray (Front loading)

Feeding capacity Roll media: 1 roll (up to 150mm in outside diameter)/Inner

diameter of paper tube: 2 or 3 inches

Cut media: 1 sheet

Delivery method Delivers the media with its printed side up in the forward

direction.

Sheet delivery capability 1 sheet (collected in a output stacker)

Cutter [CT-05] Auto-cutter with replaceable cartridges

Type of media Plain Paper, Plain Paper(High Quality), Plain Paper(High

Grade), All Plain Paper_Conserve MBK, Coated Paper,

Heavyweight Coated Paper, Premium Matte Paper, Glossy

Photo Paper, Semi-Glossy Photo Paper, Recycled Coated

Paper, Extra Heavyweight Coated Paper, Heavyweight Glossy

Photo Paper 2, Heavywght SemiGlos Photo Paper 2, Satin

Photographic Paper 190gsm, Synthetic Paper, Adhesive

Synthetic Paper, Proofing Paper, Colored Coated Paper, CAD

Tracing Paper, CAD Translucent Matte Film, CAD Clear Film,

Newsprint for Proofing1, Newsprint for Proofing2, Economy

Bond Paper, Universal Bond Paper, Premium Coated Paper,

Matte Coated Paper 90gsm, Glossy Photographic Paper

190gsm, Glossy Photographic Paper 240gsm, Satin

Photographic Paper 240gsm, HW Glossy Photo Paper, HW

Satin Photo Paper, Premium RC Photo Luster, Commercial

Proofing Paper, Commercial RC Proofing 210gsm,

Commercial RC Proofing 270gsm

Supported thickness 0.07mm to 0.8mm

Media size (Roll media) Width: 254mm to 914.4mm

Length: 203.2mm to 18m (Roll media up to 150 mm in outside

diameter)

Media size (Cut sheet) Width: 203.2mm to 917mm

Length: 203.2mm to 1600mm

Chapter 1

0017-4110

1-7

Page 19

Chapter 1

Printable area (Roll media) Bordered printing: Internal area, excluding 3mm top, bottom,

Printable area (Cut sheet) Internal area, excluding a 3mm top margin, 23mm bottom

Printing recommendation

area (Roll media)

Printing recommendation

area (Cut sheet)

Margins (Roll media) Roll media: 3mm for top, bottom and left and right margins

Margins (Cut sheet) 3mm top margin, 23mm bottom margin and 3mm left and right

Memory 256MB

Firmware Flash ROM (update from USB or Ethernet, IEEE1394)

Emulation Not available.

Interface USB2.0, Ethernet, IEEE1394 (option)

and left and right margins.

Borderless printing: Internal area, excluding 0mm top, bottom,

and left and right margins.

* The printable area may vary with each type of paper media

used.

Width of media allowing borderless printing:

36"(914mm), A0(841mm), B1(728mm), 24"(610mm),

A1(594mm), B2(515mm), 16"(407mm), 14"(356mm),

10"(524mm)

Media type allowing borderless printing:

Heavyweight Coated Paper, Premium Matte Paper, Glossy

Photo Paper, Semi-Glossy Photo Paper, Extra Heavyweight

Coated Paper, Heavyweight Glossy Photo Paper 2, Heavywght

SemiGlos Photo Paper 2, Satin Photographic Paper 190gsm,

Premium Coated Paper, Glossy Photographic Paper 190gsm,

Glossy Photographic Paper 240gsm, Satin Photographic Paper

240gsm, HW Glossy Photo Paper, HW Satin Photo Paper,

Premium RC Photo Luster

margin and 3mm left and right margins.

*1 Borderless printing does not support cut media as yet.

*2 The printable area may vary with each type of paper media

used.

Internal area, excluding a 20mm top margin, 5mm bottom

margin, and 5mm left and right margins.

Internal area, excluding a 20mm top margin, 23mm bottom

margin, and 5mm left and right margins.

Borderless roll media: 0mm for top, bottom and left and right

margins

margins

* Borderless printing does not support cut media as yet.

Increase of memory: none

- Printer description language

GARO (Graphic Arts language with Raster Operation), HPGL/2, HP RTL

1-8

Page 20

Chapter 1

Operation panel LCD (160 X 128 dots), 12 keys, 5 LEDs

Printhead/Ink Tank type Printhead and separate ink tanks

Printhead [PF-03] Number nozzles: 2560 nozzles per color

Ink tank [PFI-102] MBK, BK, C, M, Y

Detection functions (Cover

system)

Detection functions (Ink

passage system)

Detection functions

(Carriage system)

Detection functions (Paper

path system)

Operating noise Sound pressure level: 54dB (A) or less, operating; 35dB or less,

Operating environment Temperature: 15 to 30 degrees centigrade

Print quality guaranteed

environment

Power supply 100-240VAC (50/60Hz)

Power consumption

(Maximum)

Power consumption When idle in energy save mode (sleep mode)

Printer unit dimensions

(WxDxH)

Weight Approx. 64kg (including the stand)

- Panel language

English

- Message language

English, German, French, Italian, Spanish, Chinese, Korean,

Russianand and Japanese

Capacity: 130ml per color (Ink tanks supplied with the printer

contain 90ml of each color.)

Head cap position sensor: Yes/ Cover open/closed sensor: Yes

Ink tank sensor: Yes/Remaining ink level sensor: Yes/

Maintenance cartridge sensor: Yes/Used ink tank full sensor:

Yes/Printhead sensor: Yes

Paper slip sensor: Yes/Carriage position sensor: Yes/Carriage

home position sensor: Yes/Carriage cover open/closed sensor:

Yes/Carriage temperature sensor: Yes

Paper sensor: Yes/Leading and trailing paper end sensors: Yes/

Paper width sensor: Yes/Slant sensor: Yes/Paper release lever

position sensor: Yes/Roll media bottom sensor: Yes/

Remaining roll media sensor: Yes/Feed roller rotation sensor:

Yes

idle

Acoustic power level: 6.8 Bels

Humidity: 10% to 80% without dew condensation

Temperature: 15 to 30 degrees centigrade

Humidity: 10% to 80%RH

140W or less

100-120V: 5W or less (When IEEE1394 board installed, 10W

or less)

220-240V: 6W or less (When IEEE1394 board installed, 11W

or less)

When switched off (idle):

1W or less

1507mm(width) x 871mm(depth) x 1094mm(height)

(including the stand)

1-9

Page 21

Chapter 1

1.4 Detailed Specifications

1.4.1 Print Speed and Direction

Media Type Print Priority

Plain

Paper/

Recycled

Paper

Plain Paper Office Document Standard 1/2 Bi-directional 1200x1200 BK

Line Document/

Text

Image Draft 1 Bi-directional 1200x1200 BK

Plain Paper

(High Quality)

Plain Paper

(High Grade)

All Plain

Paper_Conser

ve MBK

Office Document Standard 1/2 Bi-directional 1200x1200 BK

Line Document/

Text

Image Draft 1 Bi-directional 1200x1200 BK

Office Document Standard 1/2 Bi-directional 1200x1200 BK

Line Document/

Text

Image Draft 1 Bi-directional 1200x1200 BK

Office Document Standard 1/2 Bi-directional 1200x1200 BK

Line Document/

Text

Image Draft 1 Bi-directional 1200x1200 BK

T-1-2

Print

Quality

Draft 1 Bi-directional 1200x1200 BK

Standard 1 Bi-directional 1200x1200 BK

High 2 Single-directional 1200x1200 BK

Standard 2 Bi-directional 1200x1200 BK

High 4 Bi-directional 1200x1200 BK

Draft 1 Bi-directional 1200x1200 BK

Standard 1 Bi-directional 1200x1200 BK

High 2 Single-directional 1200x1200 BK

Standard 2 Bi-directional 1200x1200 BK

High 4 Bi-directional 1200x1200 BK

Draft 1 Bi-directional 1200x1200 BK

Standard 1 Bi-directional 1200x1200 BK

High 2 Single-directional 1200x1200 BK

Standard 2 Bi-directional 1200x1200 BK

High 4 Bi-directional 1200x1200 BK

Draft 1 Bi-directional 1200x1200 BK

Standard 1 Bi-directional 1200x1200 BK

High 2 Single-directional 1200x1200 BK

Standard 2 Bi-directional 1200x1200 BK

High 4 Bi-directional 1200x1200 BK

Print-

Printing Direction

Pass

1 Bi-directional 1200x1200 BK

2 Single-directional 1200x1200 BK

1 Bi-directional 1200x1200 BK

2 Single-directional 1200x1200 BK

1 Bi-directional 1200x1200 BK

2 Single-directional 1200x1200 BK

1 Bi-directional 1200x1200 BK

2 Single-directional 1200x1200 BK

Print

Resolution

(dpi)

BK ink

0017-4241

Used

1-10

Page 22

Chapter 1

Media Type Print Priority

Plain

Paper/

Economy

Bond Paper

Recycled

Paper

Universal

Bond Paper

Standard

Paper 1569B

80g

Standard

Paper 1570B

90g

Print

Quality

Office Document Standard 1/2 Bi-directional 1200x1200 MBK

Line Document/

Text

Image Draft 1 Bi-directional 1200x1200 MBK

Office Document Standard 1/2 Bi-directional 1200x1200 MBK

Line Document/

Text

Image Draft 1 Bi-directional 1200x1200 MBK

Office Document Standard 1/2 Bi-directional 1200x1200 MBK

Line Document/

Text

Image Draft 1 Bi-directional 1200x1200 MBK

Office Document Standard 1/2 Bi-directional 1200x1200 MBK

Line Document/

Text

Image Draft 1 Bi-directional 1200x1200 MBK

Draft 1 Bi-directional 1200x1200 MBK

Standard 1 Bi-directional 1200x1200 MBK

High 2 Single-directional 1200x1200 MBK

Standard 2 Bi-directional 1200x1200 MBK

High 4 Bi-directional 1200x1200 MBK

Draft 1 Bi-directional 1200x1200 MBK

Standard 1 Bi-directional 1200x1200 MBK

High 2 Single-directional 1200x1200 MBK

Standard 2 Bi-directional 1200x1200 MBK

High 4 Bi-directional 1200x1200 MBK

Draft 1 Bi-directional 1200x1200 MBK

Standard 1 Bi-directional 1200x1200 MBK

High 2 Single-directional 1200x1200 MBK

Standard 2 Bi-directional 1200x1200 MBK

High 4 Bi-directional 1200x1200 MBK

Draft 1 Bi-directional 1200x1200 MBK

Standard 1 Bi-directional 1200x1200 MBK

High 2 Single-directional 1200x1200 MBK

Standard 2 Bi-directional 1200x1200 MBK

High 4 Bi-directional 1200x1200 MBK

Print-

Printing Direction

Pass

1 Bi-directional 1200x1200 MBK

2 Single-directional 1200x1200 MBK

1 Bi-directional 1200x1200 MBK

2 Single-directional 1200x1200 MBK

1 Bi-directional 1200x1200 MBK

2 Single-directional 1200x1200 MBK

1 Bi-directional 1200x1200 MBK

2 Single-directional 1200x1200 MBK

Print

Resolution

(dpi)

Used

BK ink

1-11

Page 23

Chapter 1

Media Type Print Priority

Coated

Paper

Coated Paper Line Document/

Heavyweight

Coated Paper

Extra

Heavyweight

Coated Paper

Recycled

Coated Paper

Premium

Matte Paper

Colored

Coated Paper

Print

Quality

Text

Image Standard 4 Bi-directional 1200x1200 MBK

Line Document/

Text

Image Standard 4 Bi-directional 1200x1200 MBK

Line Document/

Text

Image Standard 4 Bi-directional 1200x1200 MBK

Line Document/

Text

Image Standard 4 Bi-directional 1200x1200 MBK

Line Document/

Text

Image Standard 6 Bi-directional 1200x1200 MBK

Image Standard 4 Bi-directional 1200x1200 BK

Draft 1 Bi-directional 1200x1200 MBK

Standard 2 Bi-directional 1200x1200 MBK

High 4 Bi-directional 1200x1200 MBK

High 8 Bi-directional 2400x1200 MBK

Highest 12 Bi-directional 2400x1200 MBK

Draft 1 Bi-directional 1200x1200 MBK

Standard 2 Bi-directional 1200x1200 MBK

High 4 Bi-directional 1200x1200 MBK

High 8 Bi-directional 2400x1200 MBK

Highest 12 Bi-directional 2400x1200 MBK

Draft 1 Bi-directional 1200x1200 MBK

Standard 2 Bi-directional 1200x1200 MBK

High 4 Bi-directional 1200x1200 MBK

High 8 Bi-directional 2400x1200 MBK

Highest 12 Bi-directional 2400x1200 MBK

Draft 1 Bi-directional 1200x1200 MBK

Standard 2 Bi-directional 1200x1200 MBK

High 4 Bi-directional 1200x1200 MBK

High 8 Bi-directional 2400x1200 MBK

Highest 12 Bi-directional 2400x1200 MBK

Draft 1 Bi-directional 1200x1200 MBK

Standard 2 Bi-directional 1200x1200 MBK

High 4 Bi-directional 1200x1200 MBK

High 8 Bi-directional 2400x1200 MBK

Highest 16 Bi-directional 2400x1200 MBK

High 8 Bi-directional 1200x1200 BK

Print-

Printing Direction

Pass

1 Bi-directional 1200x1200 MBK

4 Bi-directional 1200x1200 MBK

1 Bi-directional 1200x1200 MBK

4 Bi-directional 1200x1200 MBK

1 Bi-directional 1200x1200 MBK

4 Bi-directional 1200x1200 MBK

1 Bi-directional 1200x1200 MBK

4 Bi-directional 1200x1200 MBK

1 Bi-directional 1200x1200 MBK

4 Bi-directional 1200x1200 MBK

Print

Resolution

(dpi)

Used

BK ink

1-12

Page 24

Chapter 1

Media Type Print Priority

Coated

Paper

Premium

Coated Paper

LightWeight

Coated Paper

J80270 90g

High

Resolution

Barrier Paper

180g

Matt Coated

Paper 9171

120g

Extra Matt

Coated Paper

7215 180g

Print

Quality

Line Document/

Text

Image Standard 4 Bi-directional 1200x1200 BK

Line Document/

Text

Image Standard 4 Bi-directional 1200x1200 BK

Line Document/

Text

Image Standard 4 Bi-directional 1200x1200 BK

Line Document/

Text

Image Standard 4 Bi-directional 1200x1200 BK

Line Document/

Text

Image Standard 4 Bi-directional 1200x1200 BK

Draft 1 Bi-directional 1200x1200 BK

Standard 2 Bi-directional 1200x1200 BK

High 4 Bi-directional 1200x1200 BK

High 8 Bi-directional 2400x1200 BK

Highest 12 Bi-directional 2400x1200 BK

Draft 1 Bi-directional 1200x1200 BK

Standard 2 Bi-directional 1200x1200 BK

High 4 Bi-directional 1200x1200 BK

High 8 Bi-directional 2400x1200 BK

Highest 12 Bi-directional 2400x1200 BK

Draft 1 Bi-directional 1200x1200 BK

Standard 2 Bi-directional 1200x1200 BK

High 4 Bi-directional 1200x1200 BK

High 8 Bi-directional 2400x1200 BK

Highest 12 Bi-directional 2400x1200 BK

Draft 1 Bi-directional 1200x1200 BK

Standard 2 Bi-directional 1200x1200 BK

High 4 Bi-directional 1200x1200 BK

High 8 Bi-directional 2400x1200 BK

Highest 12 Bi-directional 2400x1200 BK

Draft 1 Bi-directional 1200x1200 BK

Standard 2 Bi-directional 1200x1200 BK

High 4 Bi-directional 1200x1200 BK

High 8 Bi-directional 2400x1200 BK

Highest 12 Bi-directional 2400x1200 BK

Print-

Printing Direction

Pass

1 Bi-directional 1200x1200 BK

4 Bi-directional 1200x1200 BK

1 Bi-directional 1200x1200 BK

4 Bi-directional 1200x1200 BK

1 Bi-directional 1200x1200 BK

4 Bi-directional 1200x1200 BK

1 Bi-directional 1200x1200 BK

4 Bi-directional 1200x1200 BK

1 Bi-directional 1200x1200 BK

4 Bi-directional 1200x1200 BK

Print

Resolution

(dpi)

Used

BK ink

1-13

Page 25

Chapter 1

Media Type Print Priority

Coated

Paper

Photo

Paper

Opaque Paper

White 120g

Matt Coated

Paper 140g

Photo

Realistic Paper

210g

LightWeight

Coated Paper

Glossy Photo

Paper

Semi-Glossy

Photo Paper

Heavyweight

Glossy Photo

Paper 2

Heavywght

SemiGlos

Photo Paper 2

Print

Quality

Line Document/

Text

Image Standard 4 Bi-directional 1200x1200 BK

Line Document/

Text

Image Standard 4 Bi-directional 1200x1200 BK

Line Document/

Text

Image Standard 4 Bi-directional 1200x1200 BK

Line Document/

Text

Image Standard 4 Bi-directional 1200x1200 BK

Image Standard 6 Bi-directional 1200x1200 MBK

Image Standard 6 Bi-directional 1200x1200 MBK

Image Standard 6 Bi-directional 1200x1200 MBK

Image Standard 6 Bi-directional 1200x1200 MBK

Draft 1 Bi-directional 1200x1200 BK

Standard 2 Bi-directional 1200x1200 BK

High 4 Bi-directional 1200x1200 BK

High 8 Bi-directional 2400x1200 BK

Highest 12 Bi-directional 2400x1200 BK

Draft 1 Bi-directional 1200x1200 BK

Standard 2 Bi-directional 1200x1200 BK

High 4 Bi-directional 1200x1200 BK

High 8 Bi-directional 2400x1200 BK

Highest 12 Bi-directional 2400x1200 BK

Draft 1 Bi-directional 1200x1200 BK

Standard 2 Bi-directional 1200x1200 BK

High 4 Bi-directional 1200x1200 BK

High 8 Bi-directional 2400x1200 BK

Highest 12 Bi-directional 2400x1200 BK

Draft 1 Bi-directional 1200x1200 BK

Standard 2 Bi-directional 1200x1200 BK

High 4 Bi-directional 1200x1200 BK

High 8 Bi-directional 2400x1200 BK

Highest 12 Bi-directional 2400x1200 BK

High 8 Bi-directional 2400x1200 MBK

Highest 16 Bi-directional 2400x1200 MBK

High 8 Bi-directional 2400x1200 MBK

Highest 16 Bi-directional 2400x1200 MBK

High 8 Bi-directional 2400x1200 MBK

Highest 16 Bi-directional 2400x1200 MBK

High 8 Bi-directional 2400x1200 MBK

Highest 16 Bi-directional 2400x1200 MBK

Print-

Printing Direction

Pass

1 Bi-directional 1200x1200 BK

4 Bi-directional 1200x1200 BK

1 Bi-directional 1200x1200 BK

4 Bi-directional 1200x1200 BK

1 Bi-directional 1200x1200 BK

4 Bi-directional 1200x1200 BK

1 Bi-directional 1200x1200 BK

4 Bi-directional 1200x1200 BK

Print

Resolution

(dpi)

Used

BK ink

1-14

Page 26

Chapter 1

Media Type Print Priority

Photo

Paper

Proofing

Paper

Synthetic

Paper

Satin

Photographic

Paper 190gsm

Premium RC

Photo Luster ,

10 mil

Instant Dry

Papers Glossy

200g

Instant Dry

Papers Satin

200g

Photo Paper

High Glossy

250g

Photo Paper

Semi Matt

250g

Photo Paper

Satin 240g

Photo Paper

Pearl 260g

Proofing Paper Image Standard 6 Bi-directional 1200x1200 MBK

Professional

Proof and

Photo Glossy

195g

Professional

Proof and

Photo

Semiglossy

195g

Professional

Proof and

Photo

Semigloss

255g

Synthetic

Paper

Adhesive

Synthetic

Paper

Print

Quality

Image Standard 6 Bi-directional 1200x1200 MBK

High 8 Bi-directional 2400x1200 MBK

Highest 16 Bi-directional 2400x1200 MBK

Image Standard 6 Bi-directional 1200x1200 BK

High 8 Bi-directional 2400x1200 BK

Highest 16 Bi-directional 2400x1200 BK

Image Standard 6 Bi-directional 1200x1200 BK

High 8 Bi-directional 2400x1200 BK

Highest 16 Bi-directional 2400x1200 BK

Image Standard 6 Bi-directional 1200x1200 BK

High 8 Bi-directional 2400x1200 BK

Highest 16 Bi-directional 2400x1200 BK

Image Standard 6 Bi-directional 1200x1200 BK

High 8 Bi-directional 2400x1200 BK

Highest 16 Bi-directional 2400x1200 BK

Image Standard 6 Bi-directional 1200x1200 BK

High 8 Bi-directional 2400x1200 BK

Highest 16 Bi-directional 2400x1200 BK

Image Standard 6 Bi-directional 1200x1200 BK

High 8 Bi-directional 2400x1200 BK

Highest 16 Bi-directional 2400x1200 BK

Image Standard 6 Bi-directional 1200x1200 BK

High 8 Bi-directional 2400x1200 BK

Highest 16 Bi-directional 2400x1200 BK

High 8 Bi-directional 2400x1200 MBK

Highest 16 Bi-directional 2400x1200 MBK

Image Standard 6 Bi-directional 1200x1200 BK

High 8 Bi-directional 2400x1200 BK

Highest 16 Bi-directional 2400x1200 BK

Image Standard 6 Bi-directional 1200x1200 BK

High 8 Bi-directional 2400x1200 BK

Highest 16 Bi-directional 2400x1200 BK

Image Standard 6 Bi-directional 1200x1200 BK

High 8 Bi-directional 2400x1200 BK

Highest 16 Bi-directional 2400x1200 BK

Image Standard 6 Bi-directional 1200x1200 MBK

High 8 Bi-directional 2400x1200 MBK

Highest 16 Bi-directional 2400x1200 MBK

Image Standard 6 Bi-directional 1200x1200 MBK

High 8 Bi-directional 2400x1200 MBK

Highest 16 Bi-directional 2400x1200 MBK

Print-

Pass

Printing Direction

Print

Resolution

(dpi)

Used

BK ink

1-15

Page 27

Chapter 1

Media Type Print Priority

Adhesive

Matt Paper

CAD CAD Tracing

Special Special 1 Image Standard 6 Bi-directional 1200x1200 MBK

High

Resolution

Graphic Paper

Self ADH

Paper

CAD

Translucent

Matte Film

CAD

Translucent

Matte Film

Special 2 Image Standard 6 Bi-directional 1200x1200 MBK

Special 3 Image Standard 6 Bi-directional 1200x1200 MBK

Special 4 Image Standard 6 Bi-directional 1200x1200 MBK

Special 5 Image Standard 6 Bi-directional 1200x1200 MBK

Image Standard 6 Bi-directional 1200x1200 BK

Line Document/

Text

Line Document/

Text

Line Document/

Text

Print

Quality

High 8 Bi-directional 2400x1200 BK

Highest 16 Bi-directional 2400x1200 BK

Draft 1 Bi-directional 1200x1200 BK

Standard 2 Bi-directional 1200x1200 BK

High 4 Bi-directional 1200x1200 BK

Draft 1 Bi-directional 1200x1200 BK

Standard 2 Bi-directional 1200x1200 BK

High 4 Bi-directional 1200x1200 BK

Standard 2 Bi-directional 1200x1200 MBK

High 4 Bi-directional 1200x1200 MBK

Highest 8 Bi-directional 1200x1200 MBK

High 8 Bi-directional 2400x1200 MBK

Highest 16 Bi-directional 2400x1200 MBK

High 8 Bi-directional 2400x1200 MBK

Highest 16 Bi-directional 2400x1200 MBK

High 8 Bi-directional 2400x1200 MBK

Highest 16 Bi-directional 2400x1200 MBK

High 8 Bi-directional 2400x1200 MBK

Highest 16 Bi-directional 2400x1200 MBK

High 8 Bi-directional 2400x1200 MBK

Highest 16 Bi-directional 2400x1200 MBK

Print-

Printing Direction

Pass

1 Bi-directional 1200x1200 BK

4 Bi-directional 1200x1200 BK

1 Bi-directional 1200x1200 BK

4 Bi-directional 1200x1200 BK

4 Bi-directional 1200x1200 MBK

8 Bi-directional 1200x1200 MBK

Print

Resolution

(dpi)

Used

BK ink

1-16

Page 28

1.4.2 Interface specifications

a. [USB] (Standard)

(1) Interface Type

USB 2.0, full speed (12 Mbits/sec), high Speed (480 Mbits/sec)

(2) Methods of data transfer

Controlled transfer

Bulk transfer

(3) Signal level

Compliant with the USB standard.

(4) Interface cable

Twisted-pair shielded cable, 5.0 m or shorter

Compliant with the USB standard.

Wire AWG No.28, data line pair (AWG: American Wire Gauge)

AWG No.20 to No.28, distribution line pair

(5) Interface connector

Printer side: USB standard, Series B receptacle

Cable side: USB standard, Series B plug

b. [Network] (Standard)

(1) Interface Type

IEEE802.3-compliant interface

(2) Data transfer method

10Base-T/100Base-TX

(3) Signal level

Input: Threshold.

10Base-T: Max +585mV, min +300mV

100Base-TX: Turn-on +1000mV diff pk-pk, turn-off +200mV diff pk-pk

Output:

10Base-T: +2.2V - + 2.8V

100Base-TX: +0.95V - +1.05V

(4) Interface cable

Category 5 (UTP or FTP) cable, 100 m or shorter

Compliant with the ANSI/EIA/TIA-568A or ANSI/EIA/TIA-568B standard.

(5) Interface connector

Printer side: IEEE802.3 and ANSI X3.263-compliant, ISO/IEC60603-7 standard

Chapter 1

0013-4625

c. [IEEE1394] (option)

(1) Interface Type

IEEE1394-1995, P1394a (Version 2.0)-compliant interface

(2) Method of data transfer

Asynchronous transfer

(3) Signal levels

Input:

Differential input voltage: +173mV - +260mV during S100 arbitration

+142mV - +260mV, receiving data

+171mV - +262mV during S200 arbitration

+132mV - +260mV, receiving data

+168mV - +265mV during S400 arbitration

+118mV - +260mV, receiving data

1-17

Page 29

Chapter 1

Output :

Differential output voltage: +172mV - +265mV

(4) Interface cable

Twisted-pair shielded cable, 4.5 mm or shorter.

Compliant with the IEEE1394-1995 or (Version 2.0) standard

(5) Interface connector

Printer side: IEEE1394-compliant, 6-pin connector (socket)

Cable side: IEEE1394-compliant, 6-pin connector (plug)

Cable side: Compliant with the ANSI/EIA/TIA-568A or ANSI/EIA/TIA-568B standard, Type RJ-45.

1.5 Names and Functions of Components

1.5.1 Front

[2]

[1]

[3]

[4]

[5]

[6]

0012-6202

1-18

[7]

[8]

F-1-12

[1] Top cover

Open this cover when installing the printhead, load media and clear jams inside the printer.

[2] Eject guide

Supports ejected media to keep it from floating up.

[3] Maintenance cartridge

Blots excess inks.

[4] Maintenance cartridge cover

Open this cover to replace the maintenance cartridge.

[5] Operation panel

Operate the printer or check its status from this panel.

[6] Ink tank cover

Open this cover to replace ink tanks.

[7] Stand (option)

It is a stand that puts the printer.

[8] Output stacker (included with stand)

It is a stacker made of the cloth that stacks the ejected media.

Page 30

1.5.2 Rear

Chapter 1

0013-4638

[2]

[4]

[5]

[6]

[1]

[3]

F-1-13

[1] Release lever

Releases the paper retainer. Press this lever rearward to load paper or clean the interiors of the

printer.

[2] Power connector

Connect the power cord to this connector.

[3] Roller holder slot

Set the roll holder in this guide slot.

[4] Expansion PCB slot

Mount an IEEE1394 (Fire Wire) expansion PCB on his slot.

[5] USB port

Connect the USB cable to this port. Ready for the USB2.0 hi-speed mode.

[6] Ethernet connector

Connect the Ethernet cable to this connector.

1-19

Page 31

Chapter 1

1.5.3 Carriage

[3]

[2]

0013-4655

[1]

[6]

[7]

F-1-14

[1] Carriage cover

Protects the carriage.

[2] Printhead fixer cover

Clamps the printhead.

[3] Printhead

A key component that houses nozzles.

[4] Shaft cleaner

Keeps the carriage shaft clean.

[5] Printhead fixer lever

Locks the printhead fixer cover.

[6] Slant adjustment lever

Fine-adjusts slants in ruled lines during printing.

[7] Cutter unit

A curved cutting edge that cuts paper automatically. It is tucked inside when cutting is not

performed.

[4]

[5]

1-20

Page 32

Chapter 1

OK

Menu

1.6 Basic Operation

1.6.1 Operation Panel

The functions of the keys and meanings of LED indications on the operation panel are described below.

0012-6207

[3] [2]

[4]

Online

Data

Message

[5]

[a]

[6]

[1] Display

Displays the printer menu, status or messages.

[2] Data lamp (green)

"Blinking" The printer is receiving or processing a print job when it is printing.

The printer has suspended a print job or is receiving firmware data when it is not printing.

"Off" No print job is available.

[3] Message lamp (orange)

"Lit continuously" A warning message is on display.

"Blinking" An error message is on display.

"Off" The printer is normal or is powered off.

[4] Online key

Switches the printer between two alternative modes: online and offline.

"Lit continuously" The printer is in online mode. Lights green.

"Off" The printer is in offline mode.

[5] Menu key

Displays a printer main menu.

[6] Paper source selector

[a] Roll media lamp (green)

"Lit continuously" Roll media have been selected as a paper source.

"Off" Cut media have been selected as a paper source.

[b] Cut media lamp (green)

"Lit continuously" Cut media have been selected as a paper source.

"Off" Roll media have been selected as a paper source.

[7] Paper source selector key

Toggles a paper source between roll and cut media each time the key is pressed.

[8] Color labels

[b]

[7] [8]

[1]

F-1-15

[9] [10]

[14]

Infomation

Cleaning

(3 Sec.)

Eject

[11]

Powe r

Stop

Colors and names of ink tanks associated with the remaining ink levels appearing on the display.

[9] Keys

[Menu mode]

[13]

[12]

1-21

Page 33

Chapter 1

" key" Displays the previous action or setting.

" key" Displays the next action or setting.

" key" Opens the menu one level above.

" key" Opens the menu one level lower.

[Offline mode]

" key" Feeds roll media manually in the direction opposite to the direction in which paper is

ejected.

" key" Feeds roll media manually.

[10] OK key

Sets or runs a selected action or value when the printer is in menu mode.

[11] eject key

Executing menu and ejects paper.

[12] Stop key

Quits a processing job.

[13] Power key

Switches the power to the printer on and off.

[14] Information key

Displays a printer submenu. Information about the inks and paper displays each time this key is

pressed.

Hold this key for 3 seconds to clean the printhead.

1.6.2 Main Menu

The printer has a Main menu which includes a menu related to maintenance such as adjustment of ink ejection

position of each nozzle and head cleaning, a menu related to printing settings such as auto cutting and ink drying

time, and a menu related to parameters such as a message language.

1. Main menu operations

a) How to enter the Main menu

To enter the Main menu, press the [Menu] button on the operation panel.

b) How to exit the Main menu

To exit the Main menu, press the [Online] button.

c) Buttons used with the Main menu

- Selecting menus and parameters: [ ] or [ ] button

- Going to the next lower-level menu: [ ] button

- Going to the next higher-level menu: [ ] button

- Determining a selected menu or parameter: [OK] button

2. Main Menu

The structure of the main menu is as follows. Values at right indicated by an asterisk "*" are the defaults.

0017-5615

T-1-3

First Level Second Level Third Level Fourth Level Fifth Level

[Media Menu] [Roll Media

Type](*1)

[HW Glossy Photo](*5)

[HW SemiGl

Photo](*5)

[Syn. Paper](*5)

[Adh. Syn. Paper](*5)

[Proofing Paper](*5)

[News Proof 1](*5)

[News Proof 2](*5)

[News Proof 3](*5)

[Colored Coated](*5)

1-22

Page 34

Chapter 1

First Level Second Level Third Level Fourth Level Fifth Level

[CAD Trace Paper](*5)

[CAD Matte Film](*5)

[CAD Clear Film](*5)

Special # Here, the

number is 1 to 5(*5)

[Chk Remain.Roll] [Off]*

[On]

[Roll Length

Set](*2)

[Paper Details] (The paper type is

displayed here.)

(*5)

[### m]

[### feet](*9)

[Roll DryingTime] [Off]

[30 sec.]

[1 min.]

[3 min.]

[5 min.]

[10 min.]

[30 min.]

[60 min.]

[Scan Wait Time] [Off]

[1 sec.]

[3 sec.]

[5 sec.]

[7 sec.]

[9 sec.]

[Feed Priority] [Automatic]*

[Band Joint]

[Print Length]

[Adjust Length] -0.70 to 0.70

[Head Height] [Automatic]*

[Highest]

[High]

[Standard]

[Low]

[Lowest]

T-1-4

First Level Second Level Third Level Fourth Level Fifth Level

[Paper Details] (The paper type is

displayed here.) (*5)

[Skew Check Lv.] [Standard]*

[Loose]

[Off]

[VacuumStrngth] [Automatic]

[Strongest]

1-23

Page 35

Chapter 1

First Level Second Level Third Level Fourth Level Fifth Level

[Strong]

[Standard]

[Weakest]

[Width Detection] [Off]

[On]*

[NearEnd

RollMrgn]

[Cut Speed] [Fast]

[Trim Edge First] [Automatic]

[Cutting Mode] [Automatic]

[Bordless Margin] [Automatic]

[CutDustReduct.] [Off]

[NearEnd Sht Mrgn] [3mm]

[Return Defaults] [No]

[GL2 Settings] [GL2 Replot] [No]

[Yes]

[GL2 BufferClear] [No]

[Yes]

[Color Mode] [Color]*

[Monochrome]

[Print Quality] [Draft]

[Standard]*

[High]

[Input Resolution] [600dpi]*

[300dpi]

[Media Source] [Roll Paper]*

[Cassette]

[Manual]

[Conserve Paper] [Off]

[On]*

[3mm]

[20mm]

[Standard]

[Slow]

[Off]

[On]

[Eject]

[Manual]

[Fixed]

[On]

[20mm]

[Yes]

1-24

Page 36

T-1-5

First Level Second Level Third Level Fourth Level Fifth Level

[GL2 Settings] [End Point Shape] [Software]*

[Rounded]

[Smoothing] [Software]*

[Smooth]

[Line Width] [1dot]

[2dot]

[3dot]

[4dot]*

[5dot]

[6dot]

[7dot]

[Adjust Printer] [Auto Head Adj.] [Standard Adj.] [No]

[Yes]

[Advanced Adj.] [No]

[Yes]

[Auto Print] [Off]

[On]*

[Manual Head Adj] [No]

[Yes]

[Auto Band Adj.] [Standard Adj.] [No]

[Yes]

[Advanced Adj.] [No]

[Yes]

[Manual Band Adj] [No]

[Yes]

[Adjust Length](*3) [No]

[Yes]

[Adjust Head Skew] [No]

[Yes]

[Interface Setup] [EOP Timer] [10 sec.]

[30 sec.]

[1 min.]

[2 min.]

[5 min.]

[10 min.]*

[30 min.]

[60 min.]

[TCP/IP] [IP Mode] [Automatic]

[Manual]*

[Protocol](*4) [DHCP] [On]

Chapter 1

1-25

Page 37

Chapter 1

First Level Second Level Third Level Fourth Level Fifth Level

[Off]*

[BOOTP] [On]

[Off]*

[RARP] [On]

[Off]*

T-1-6

First Level Second Level Third Level Fourth Level Fifth Level

[Interface Setup] [TCP/IP] [IP Setting] [IP Address] 0.0.0.0* to

255.255.255.255

[Subnet Mask] 0.0.0.0* to

255.255.255.255

[Default G/W] 0.0.0.0* to

[NetWare] [NetWare] [On]

[Off]*

[Frame Type](*6) [Auto Detect]

[Ethernet 2]

[Ethernet 802.2]*

[Ethernet 802.3]

[Ethernet SNAP]

[Print Service](*6) [BinderyPServer]

[RPrinter]

[NDSPServer]*

[NPrinter]

[AppleTalk] [On]

[Off]*

[Ethernet Driver] [Auto Detect] [On]*

[Off]

[Comm.Mode](*7) [Half Duplex]*

[Full Duplex]

[Ethernet Type](*7) [10 Base-T]*

[100 Base-TX]

[Spanning Tree] [Not Use]*

[Use]

[MAC Address]

[Ext.Interface] [No]

[IEEE1394]

[Init. Settings] [No]

[Yes]

[Maintenance] [Maint. cart.] [No]

[Yes]

255.255.255.255

1-26

Page 38

First Level Second Level Third Level Fourth Level Fifth Level

[Replace P.head] [No]

[Yes]

[Repl. S. Cleaner] [No]

[Yes]

[Change Cutter] [No]*

[Yes]

[Move Printer] [No]

[Yes]

[System Setup] Warning] [Buzzer] [Off]

[On]*

[Detect Mismatch] [Pause]

[Warning]*

[None]

T-1-7

First Level Second Level Third Level Fourth Level Fifth Level

[System Setup] [Keep Media Size] [Off]*

[On]

[Paper Size Basis] [Sht Selection 1] [ISO A3+]*

[13"x19"(Super B)]

[Sht Selection 2] [ISO B1]*

[28"x40"(ANSI F)]

[Noz. Check Freq.] [Off]

[1 page]

[10 pages]

[Automatic]*

[Sleep Timer] [5 min.]*

[10 min.]

[15 min.]

[20 min.]

[30 min.]

[40 min.]

[50 min.]

[60 min.]

[240 min.]

[Length Unit] [meter]*

[feet/inch]

[Time Zone] [0: London (GMT)]

[+1: Paris, Rome]

[+2: Athens, Cairo]

[+3: Moscow]

Chapter 1

1-27

Page 39

Chapter 1

First Level Second Level Third Level Fourth Level Fifth Level

[+4: Eerenan, Baku]

[+5: Islamabad]

[+6: Dacca]

[+7: Bangkok]

[+8: Hong Kong]

[+9: Tokyo, Seoul]

[+10: Canberra]

[+11: NewCaledonia]

[+12: Wellington]

[-12: Eniwetok]

[-11: Midway is]

[-10: Hawaii (AHST)]

[-9: Alaska (AKST)]

[-8: Oregon (PST)]

[-7: Arizona (MST)]

[-6: Texas (CST)]

[-5: NewYork (EST)]

T-1-8

First Level Second Level Third Level Fourth Level Fifth Level

[System Setup] [Time Zone] [-4: Santiago]

[-3: Buenos Aires]

[-2: ]

[-1: Cape Verde]

[Date Format] [yyyy/mm/dd]*

[dd/mm/yyyy]

[mm/dd/yyyy]

[Date & Time] [Date] [yyyy/mm/dd](*8)

[Time] [hh:mm]

[Language] [Japanese]*

[Francais]

[Italiano]

[Deutsch]

[Espanol]

[Pyccknn]

[Chinese]

[Korea]

[Engulish]

[Contrast Adj.] -4 to 4

[Reset PaprSetngs] [No]

[Yes]

1-28

Page 40

First Level Second Level Third Level Fourth Level Fifth Level

[Test Print] [Status Print] [No]

[Yes]

[Media Details] [No]

[Yes]

[Print Job Log] [No]

[Yes]

[Menu Map] [No]

[Yes]

[Nozzle Check] [No]

[Yes]

[Information]] [System Info]

[Error Log] [########-####]

[Job Log] (Choose from

information about the

latest three print jobs.)

[Document Name]

[User Name]

[Page Count]

[Job Status]

[Print Start Time] [yyyy/mm/dd

hh:mm]

[Print End Time] [yyyy/mm/dd

hh:mm]

[Print Time] [xxx sec.]

[Print Size] [xxxxxxxxsq.mm]

[Media Type]

[Interface]

[Ink Consumed] [xx.x ml]

Chapter 1

*1: Displayed if a roll is loaded.

*2: Displayed if Chk Remain.Roll is On.

*3: Displayed if IP Mode is Automatic.

*4: Displayed if IP Mode is Automatic.

*5: For information on the types of paper the printer supports, refer to the Media Guide. The media type setting

in the printer driver and related software (as well as on the Control Panel is updated when you install Media

Configuration Tool from the User Software CD-ROM or if you change paper information by using Media

Configuration Tool.

*6: Available only if NetWare is On.

*7: Available only if Auto Detect is Off.

*8: Follows the setting in Date Format.

*9: Not displayed if a roll or a sheet has been fed.

3. Main menu during printing

The structure of the main menu during printing is as follows.

1-29

Page 41

Chapter 1

T-1-9

First Level Second Level Third Level Fourth Level Fifth Level

[Menu Durng Prtng] [Head Cleaning] [Head Cleaning A]

[Head Cleaning B]

[Fine Band Adj.] -5 to 5

[Information] [System Info]

[Error Log] [########-####]

[Job Log] (Choose from

information about the

latest three print jobs.)

[Document Name]

[User Name]

[Page Count]

[Job Status]

[Print Start Time]

[Print End Time]

[Print Time]

[Print Size]

[Media Type]

[Interface]

[Ink Consumed]

1-30

Page 42

Chapter 1

4. Main Menu Settings

Main menu items are described in the following tables.

T-1-10

Setting Item Description, Instructions

[Paper Cut] Displayed if a roll is loaded.

[Rep. Ink Tank] When exchanging the ink tank, choose Yes and follow the instructions on the

[Head Cleaning] Specify Printhead cleaning options.

[Media Menu] Specify the type and size of paper.

[Paper Details] Specify detailed paper-related settings, including the ink drying time and

[GL2 Settings] Make settings for making prints using GL2.

[Adjust Printer] Adjust the Printhead alignment or amount of feed by printing a test pattern.

[Interface Setup] Configure the network settings.

[Maintenance] Replace the Printhead , prepare to transfer the printer, and clean the Pick Up

[System Setup] Specify the printer system settings, including the date format and display

[Test Print] Choose Status Print to print information about the printer.

Choose Yes to cut the roll at the current position. The paper will be fed, if

necessary, so that the sheet is at least 10 cm (39.4 in.)long after the cut. The paper

will not be cut if there is not enough paper left to feed the paper this much.

screen.

Choose Head Cleaning A if printing is faint, oddly colored, or contains foreign

substances.

Choose Head Cleaning B if no ink is printed at all, or if printing is not improved

by Head Cleaning A .

borderless printing options.

Roller .

language.

Choose Media Details to print the paper settings as specified in Med.Detail Set. .

Choose Print Job Log to print a record of print jobs, including the paper type and

size, amount of ink used, and so on.

Choose Menu Map to print a list of the main menu options.

Choose Nozzle Check to print a test pattern for checking the nozzles.

If you have selected a leading edge margin of 20 mm in Nr End Sht Mrgn in the

printer menu, the test print sheet may not be printed completely.

[Information] Displays the information about the printer and history of print jobs.

1-31

Page 43

Chapter 1

[Paper Settings]

T-1-11

Setting Item Description, Instructions

[Cas Paper Type] Choose the type of paper in the Cassette .

[Roll Media Type] Choose the type of roll.

[Chk Remain.Roll] Choose On to print a barcode at the end of a roll before you remove it. The printed