Page 1

LEFTY SUPERMAX 2.0

OWNER’S MANUAL SUPPLEMENT

131581

2

Page 2

131581.PDF

About This Supplement

Cannondale Owner’s Manual Supplements provide important model

specific safety, maintenance, and technical information. They are

not replacements for your Cannondale Bicycle Owner’s

Manual.

This supplement may be one of several for your bike. Be sure to

obtain and read all of them.

If you need a manual or supplement, or have a question about your

bike, please contact your Cannondale Dealer immediately, or call us

at one of the telephone numbers listed on the back cover of this

manual.

You can download Adobe Acrobat PDF versions of any Cannondale

Owner’s Manuals or Supplements from our website: www.

cannondale.com/bikes/tech.

• This manual is not a comprehensive safety or service manual

for your bike.

• This manual does not include assembly instructions for your

bike.

• All Cannondale bikes must be completely assembled and

inspected for proper operation by a Cannondale Dealer before

delivery to the owner.

WARNING

This supplement may include procedures beyond the scope of

general mechanical aptitude.

Special tools, skills, and knowledge may be required. Improper

mechanical work increases the risk of an accident. Any bicycle

accident has risk of serious injury, paralysis or death. To

minimize risk we strongly recommend that owners always have

mechanical work done by an authorized Cannondale retailer.

Table of Contents

SAFETY INFORMATION ........................... 2

Intended Use ............................................2

Damage / Inspection ................................2

Disassembly / Modification .....................3

Tire-to-Crown Clearance ..........................3

TECHNICAL INFORMATION .....................4

Supermax 2.0 Structure ...........................4

Wheel Hub ................................................5

Setting Sag ............................................6-7

PBR Lockout ............................................ 8

PBR Rebound .......................................... 8

Wheel Removal ........................................9

Wheel Installation .................................. 10

MAINTENANCE ...................................... 11

Schedule .................................................. 11

Cleaning .................................................. 12

Tightening Torques ................................ 12

Frame Bumper ........................................ 13

Moto Guard ............................................. 13

Brake Line Clamp Positioning ................ 14

Manual Reset ......................................... 15

CANNONDALE LIMITED WARRANTY ......16

REPLACEMENT PARTS .......................17-19

ENNL GEFRITES

Page 3

SAFETY INFORMATION

Damage / Inspection

Intended Use

TR AVEL/

WHEEL SIZE

130 mm / 29’

140 mm / 27.5’

160 mm / 27.5’

Supermax 2.0 ARE NOT INTENDED - For use

in extreme forms of jumping/riding such as hardcore

mountain, Freeriding, Downhill, North Shore, Dirt Jumping,

Hucking etc.

WARNING

UNDERSTAND YOUR LEFTY AND ITS

INTENDED USE. USING YOUR LEFTY THE

WRONG WAY IS DANGEROUS.

Industry usage Conditions 1 - 5 are generalized and evolving.

Consult your Cannondale Dealer about how you intend to

use your bike/fork. Please read your Cannondale Bicycle

Owner’s Manual for more information about Intended Use and

Conditions 1-5.

YOU CAN BE SEVERELY INJURED, PARALYZED

OR KILLED IN AN ACCIDENT IF YOU IGNORE

THIS WARNING.

INTENDED USE

All Mountain,

Overmountain,

ASTM CONDITION 4

WARNING

RIDING WITH DAMAGE IS DANGEROUS.

STOP RIDING IMMEDITE IF DAMAGE IS

PR ESENT.

The following conditions indicate that serious fork damage is

present:

• Any unusual “klunking” or knocking noises.

• Change in travel.

• Changes in normal functions.

• Loss of adjustments features, oil leaks, or air leaks.

• Crash or impact damage (deep scratches, gouges, dents,

or bending)

• Any small cracks under the bolt head of upper and lower

clamp bolts. This inspection requires the removal of the

bolts.

• Horizontal cracks above and below the intersection of the

upper and lower clamps with the outer tube portion of the

Lefty structure.

• Vertical cracks in the outer tube (where the races and

needle bearings run). These may show as long, straight

lines perhaps several lines parallel to each other.

Please read Inspect For Safety in PART II, Section D. of your

Cannondale Bicycle Owner’s Manual.

If your Supermax 2.0 is damaged, do not ride it. Contact your

Cannondale Dealer to arrange service through an authorized

service center.

YOU CAN BE SEVERELY INJURED, PARALYZED

OR KILLED IN AN ACCIDENT IF YOU IGNORE

THIS WARNING.

2 3

Page 4

131581.PDF

Disassembly or Modification

WARNING

DO NOT DISASSEMBLE OR MODIFY YOUR

LEFT Y IN ANY WAY.

Improper service or modification can lead to serious fork

damage or serious personal injury.

• Do not disaassemble the fork.

• Do not attempt modification in any way.

• Do not drill, file, cut or remove material from any

part.

• Do not attempt to repair damage.

• Do not weld, clamp, or bond anything to the fork.

• Do not attempt to remove the damping cartridge or

other internal fork parts.

The MAINTENANCE section of this supplement

includes information about regular owner maintenance

practices that can keep your fork in good operating

condition.

All other service and maintenance procedures must be

completed through an Authorized Headshok Service

Center. Contact your Authorized Cannondale Dealer for

more information.

YOU CAN BE SEVERELY INJURED,

PARALYZED OR KILLED IN AN ACCIDENT

IF YOU IGNORE THIS WARNING.

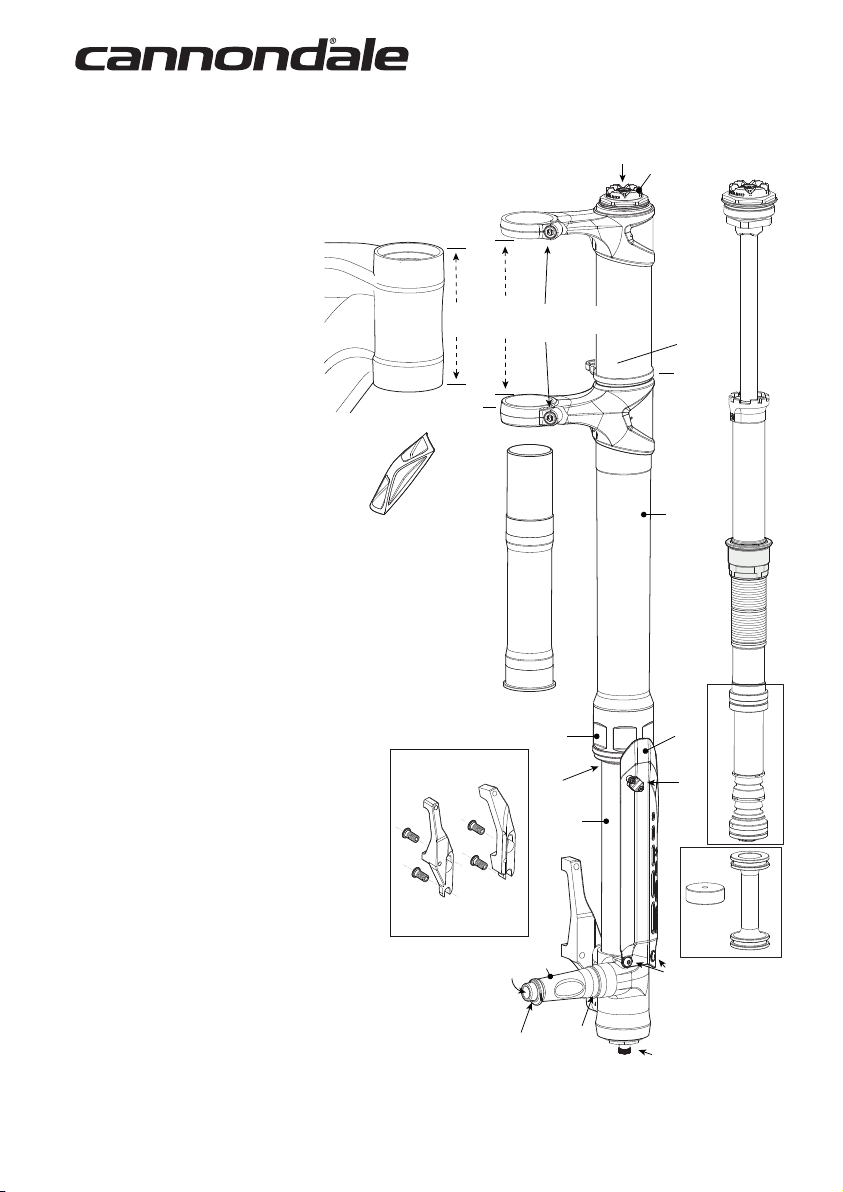

Tire-to-Crown Clearance

WARNING

Modification or installation of damping cartridge/spacers

other than specified; or installing over-sized tires can result in

incorrect tire-to-crown clearance

2

10mm

If tire clearance is less than minimum specified, the rotating tire

could come into contact with the frame causing the wheel to

stop suddenly. This can throw a rider off the bicycle or result in

a loss of control and crash.

CHECK FOR MINIMUM TIRE FORK/

FRAME CLEARANCE (10 mm) WITH ALL

AIR RELEASED FROM LEFTY AND FULLY

COMPRESSED.

Measure between the top of the properly inflated tire (1) and

the bottom of the fork steerer (2).

YOU CAN BE SEVERELY INJURED, PARALYZED

OR KILLED IN AN ACCIDENT IF YOU IGNORE

THIS WARNING.

1

EN

Page 5

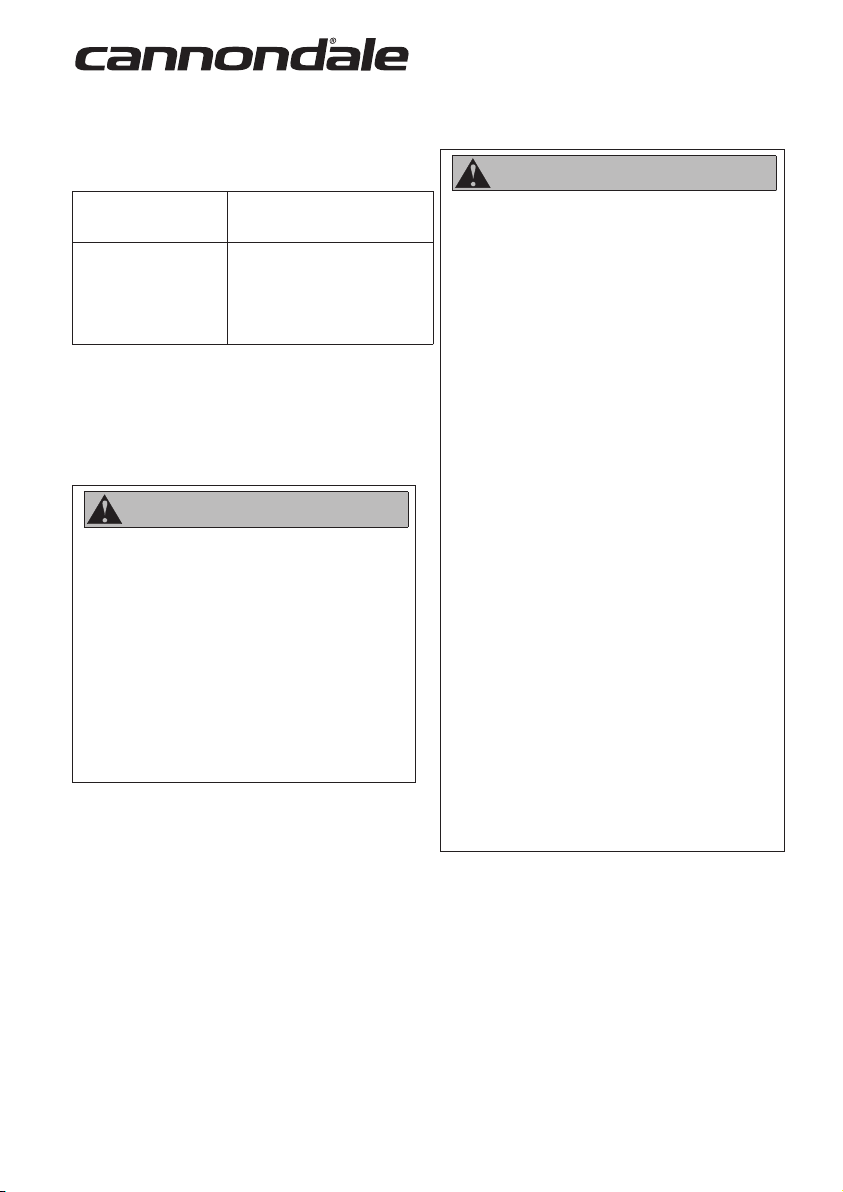

TECHNICAL INFORMATION

Supermax 2.0 Structure

Identifi cation

1. PBR Lockout Button

2. PBR Rebound Dial

3. Bonded Upper Clamp

4. Clamp Bolt

5. Serial Number Location

6. Frame Bumper

7. Carbon / Alloy Outer Tube

8. Brake Housing Guide

9. Bonded Lower Clamp

10. Guard

11. Guard Brake Housing Clamp

12. Lower Collar Assy.

13. Sag O-Ring

14. OPI Inner Tube

15. Guard Mounting Screws

16. Hub Spindle

17. Inner Bearing Land

18. Outer Bearing Land

19. Axle Bolt Threads

20. Schrader Valve

21. Brake Adapter

22. Steerer (1.5 Stems Only)

23. Damping Cartridge (shown removed)

24. SOLO Air Assembly

25. Volume Reducer(s)

1.

2

3

4.

A B

Loctite 242 (blue)

7-9 Nm (62-80 InLbs)

5.

8

9

6.

22

23

7

A

B

C

10

21.

180mm

HYBRID

180mm

SUPERMAX

12.

13.

24.

11

14

Loctite 242 (blue)

9 Nm (80 InLbs)

4

25

16

19

18

17.

15

20

Page 6

131581.PDF

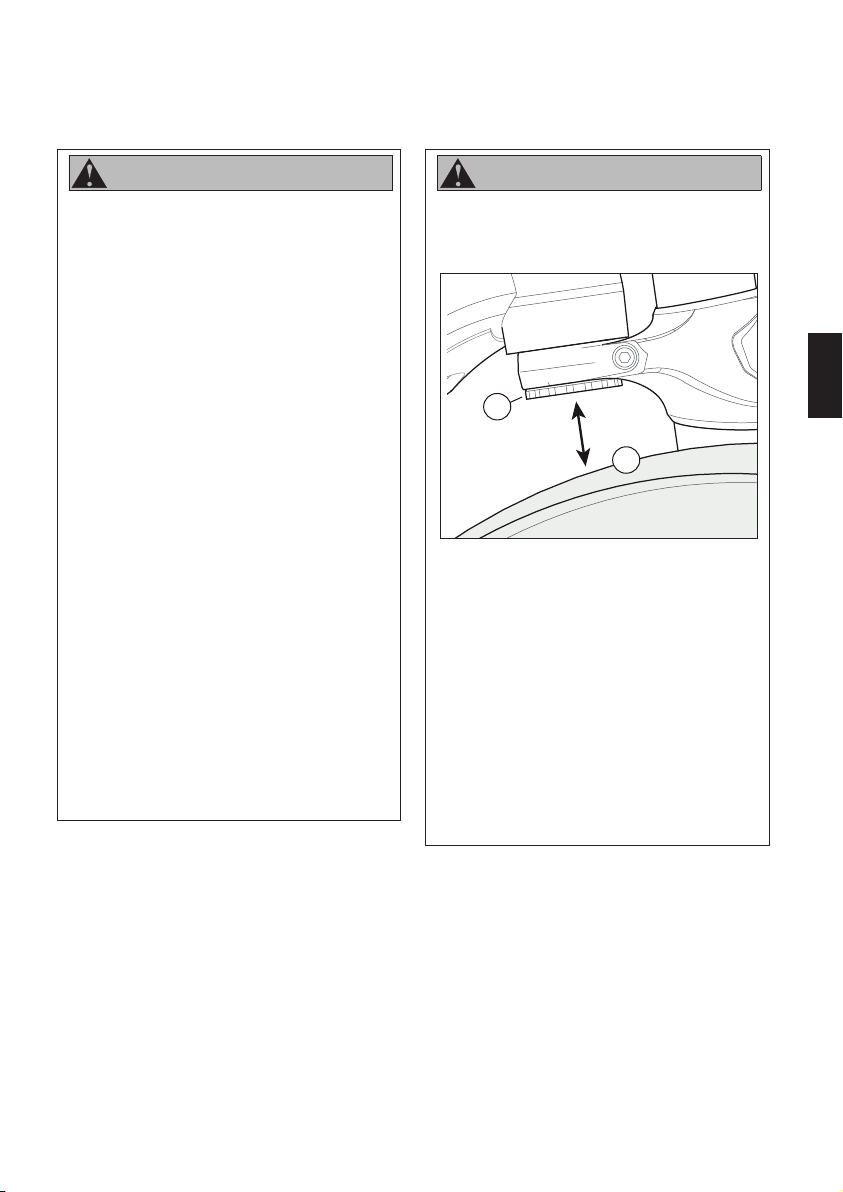

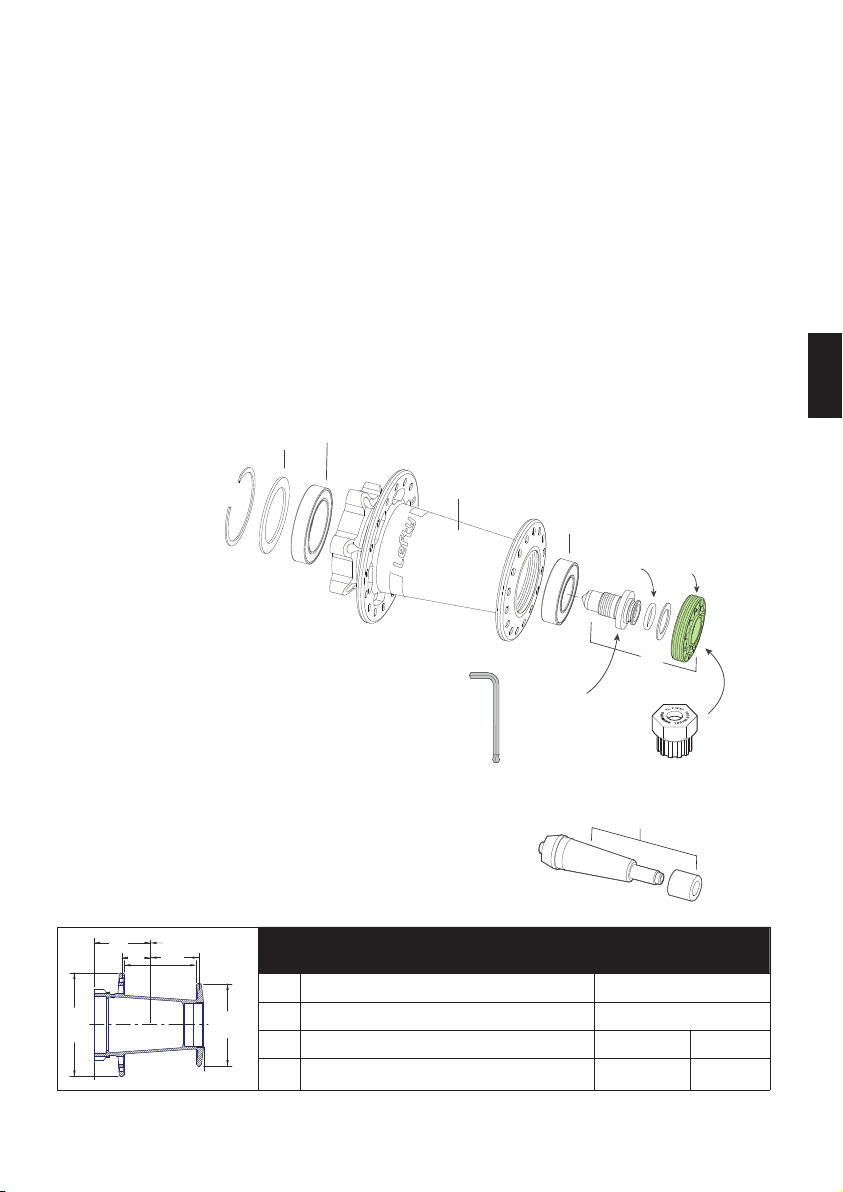

Wheel Hub

■ Either a Supermax 2.0 or LEFTY HYBRID wheel hub may be used with the Supermax 2.0. The wheel hub must be matched with its correct

brake adapter. See item 21 on previous page.

■ The hub cap is a left-hand thread. It retains the axle bolt assembly within the and should only be removed when replacing the bearings

or axle bolts parts, not when removing the wheel.

■ The axle bolt is a right hand (normal) thread. Insert a 5 mm allen key. Turn it clockwise to install a wheel. Turn it counter-clockwise to

remove a wheel.

10.*

1.

Identifi cation

1. Hub Bearing Seal

2. Inner Hub Bearing

3. LEFTY Hub Shell

4. Outer Hub Bearing

5. Axle Bolt Assy.

6. Lefty Hub Wheel Building Tool

7. Axle Bolt

8. Hub Cap (Left-hand thread!)

9. Shimano Tool TL-FW30

10. Ring Clip (*Supermax 2.0 Hub Only)

37 mm

CENTERLINE OF WHEEL

C

D

A

B

KH105/24H KIT,HUB, LEFTY 24H6-BOLT/BLK

KB61805/

QC118/

2.

DIMENSIONS FOR WHEEL BUILDING

KH105/28H KIT,HUB, LEFTY 28H6-BOLT/BLK

KH105/32H KIT,HUB, LEFTY 32H6-BOLT/BLK

KH119/32 KIT,HUB, SUPERMAX 32H6-BOLT/BLK

3.

(Items 1,2,3, and 4)

(Items 10, 1,2,3, and 4)

KB61902/

Light

grease

4.

5 mm

15 Nm (133 InLbs)

6.

7.

QCTL108/

Supermax 2.0

Loctite 242

(blue)

8.

5.

QC117/

9.

Shimano TL-FW30

LEFTY

HYBRID

A Disc Flange Diameter 68.0 mm

B Non Disc Flange Diameter 54.0 mm

C Disc Flange To Center 25.8mm 18.8 mm

D Non Disc Flange To Center 34.6mm 31.6 mm

EN

5

Page 7

SUPERMAX SUPPLEMENT 129975 - UPDATE 03/14

This is an update for your SUPERMAX owner’s manual supplement (p/n 129975). This update

contains specific information for SUPERMAX 160/27.5 and SUPERMAX 140/27.5 to replace/update

in the areas indicated. Please keep it with your owner’s supplement.

Intended Use:

See SUPERMAX supplement page 2.

SUPERMAX 160/27.5 SUPERMAX 140/27.5

ASTM CONDITION 4, All Mountain

Manual Reset:

A

SUPERMAX 160/27.5 SUPERMAX 140/27.5 SUPERMAX 130/29

20mm +/- 3 20mm +/- 3 35mm +/- 3

Recommend Air Spring Pressure:

See page 6.

Setting Sag

Sag is the distance the Supermax 2.0 compresses when the bike is statically loaded with your body weight in your riding

position. Set it according to the Supermax 2.0 travel. Sag is set by changing the air pressure through the Schrader valve at the

bottom of the Supermax 2.0

TOTAL RIDER WEIGHT SUPERMAX 160/ 27.5 SUPERMAX 140/27.5 SUPERMAX 130/29

LBS KG PSI PSI PSI

100 - 109 45 - 49 49 49 55

110 - 119 50 - 54 52 52 60

120 - 129 54 - 59 56 56 64

130 - 139 59 - 63 60 60 66

140 - 149 64 - 68 62 62 70

150 - 159 68 - 72 68 68 74

160 - 169 73 - 77 70 70 78

170 - 179 77 - 81 72 72 80

180 - 189 82 - 86 82 82 83

190 - 199 86 - 90 84 84 87

200 - 209 91 - 95 90 90 90

210 - 219 95 - 99 96 96 93

220 - 229 100 - 104 100 100 95

230 - 239 104 - 108 105 105 97

240 - 249 109 - 113 110 110 100

RECOMMENDED SAG 45-50mm 40-45mm 37-42mm

BIKE TRAVEL 160mm 140mm 130mm

Be aware that conventional pump gages have variations. Therefore, we recommend you to fine tune your set up with the

Recommended Sag.

Supermax 2.0 AIR PRESSURE LIMITS

Minimum: 50 psi, 3.4 bar

Maximum: 225 psi, 15.5 bar

6 7

Page 8

To set sag:

1. Remove the Schrader valve cap (1) at the bottom of the

Supermax 2.0 Attach a bicycle suspension pump to the

Schrader valve (2). See Figure 1.

131581.PDF

2. Set the recommended intial starting air pressure

according to your weight.

3. Slide the sag O-ring (3) against the wiper seal (4). See

Figure 2.

3. Sit on bike in riding position and dismount.

Note: Your riding position affects weight distribution and

therefore sag. For example, in the “Attack” position

(Figure 3). the rider’s weight is distributed equally

front and rear.

4. Measure the sag distance. See Figure 4.

Sag Trouble Shooting

Too much sag add air in small increments

Too little sag reduce air in small increments

Excessive bottom out increasing air pressure

harsh ride or limited

travel

reduce air pressure

NOTICE

A dirty pump or valve end can result in contamination,

damage, and air loss. Make sure pump and valve are

clean before attachment.

2.

4.

3.

50/50

1.

1

EN

2

Attack

3

SAG

4

7

Page 9

PBR Lockout

1.

2.

OPEN POSITION

In the open position, LEFTY travel is active. The red

rebound dial (1) is in the down position. To go to the

locked position, press the blue button (2).

PBR Rebound Dial

LOCKED POSITION

In the locked position, LEFTY travel is locked. The red

rebound dial is up. To go back to the open position, press

the red redound dial down until it clicks.

Rotate dial in the “–” direction (counter-clockwise) to increase rebound speed (faster).

Rotate dial in the “+” direction (clockwise) to decrease rebound speed (slower).

8

Page 10

Wheel Removal

1. If needed, loosen the brake line clamp on the front of the

moto guard so the line can move freely. This will make

handling the brake caliper and attached adapter easier.

2. See Figure 1. Use a 5 mm Allen key to loosen and

back out both brake adapter mounting bolts enough so

that the adapter and attached caliper can slide up and be

removed from the spindle together. It is not necessary to

completely remove the adapter bolts.

131581.PDF

Carefully move the brake caliper out of the way and

protect it from damage.

2. See Figure 3. Insert a 5 mm Allen key into the axle

hub bolt and turn it counter-clockwise.

Continue turning the extraction bolt until the wheel is

disenaged and can be removed easily from the spindle

end.

See Figure 4.

NOTICE

■ Make sure the axle bolt is completely disengaged

before attempting to remove the wheel. Never try

to pull the wheel off forcefully.

■ When the wheel is off, to keep dirt out, cover the

hub opening.

■ Protect spindle from damage when wheel is

removed.

EN

9

Page 11

Wheel Installation

1. Wipe the spindle clean with a dry shop towel. Apply a highquality bike grease to I.D. of the bearings inside the hub.

WARNING

DO NOT CONTAMINATE BRAKE CALIPER,

PADS, OR ROTOR WITH GREASE.

2. Slide the wheel straight onto the spindle. Turn the

axle bolt clockwise to engage the spindle threads. Make sure the

wheel and spindle are supported while tightening the hub bolt.

3. Once the hub has been drawn onto the hub completely, use

torque wrench to tighten to fi nal 15.0 Nm (133.0 InLbs).

Figure 1.

4. Reinstall the brake adapter onto the spindle bosses making sure

that the brake disc locates properly between the pads.

NOTICE

■ LOCATE BRAKE ROTOR BETWEEN THE PADS.

Apply Loctite 242 (blue to the threads and tighten the adapter

mounting bolts to 9 Nm, (78 IN Lbs). See Figure 2.

See

5. Spin the wheel to make sure it moves freely. Be sure to test the

brakes for proper operation before riding.

WARNING

DO NOT RIDE WITHOUT A PROPERLY MOUNTED, ADJUSTED,

AND FUNCTIONING FRONT BRAKE SYSTEM.

The (disc/caliper) acts as an integral secondary wheel retention

system. If the system is missing or improperly installed, or if the

wheel hub axle bolt should loosen, the front wheel could slide

off the spindle end.

Follow brake manufacturer’s instructions when mounting the

brake caliper to the spindle brake bosses. Do not modify the

fork in any way.

PLEASE ASK YOUR CANNONDALE DEALER FOR HELP WHEN

INSTALLING COMPATIBLE FRONT BRAKE SYSTEMS.

10

Page 12

131581.PDF

MAINTENANCE

Schedule

This schedule is intended as a guide only. You must establish a schedule appropriate to your riding style and conditions.

SERVICE ITEM FREQUENCY (NORMAL

RIDING)

Check for damage Pre/Post ride Bike owner

Check for Tightening Torques First Ride / Every 4-5 rides Bike owner

Replace Frame Bumper, Guard As Needed Bike owner

Manual Reset 50 hours Bike owner

Telescope Lubrification 100 hours Dealer

Damper Service:

Air spring/Damping Cartridge Inspection

Full Service (Telescope Rebuild + Damper service) 200 hours Headshok Service Center

RACING - If you race with your Supermax 2.0, you will have to perform the items listed twice as often. (i.e. 50hrs becomes 25hrs)

SCHEDULE PROFESSIONAL FORK SERVICE ANNUALLY (Minimum)

Annually, or when problems are indicated you must have your Supermax 2.0 serviced

through a Cannondale Dealer or an Authorized Headshok Ser vice Center. Disassembly and

inspection by a suspension professional is required to evaluate the internal and external

parts, identif y wear or damage. Damaged par ts must be replaced with new ones and the

work must also include any work described in any technical bulletins or product recalls.

100 hour or every year Dealer

WHO?

WARNING

FREQUENT MAINTENANCE AND INSPECTION IS IMPORTANT TO YOUR SAFETY. YOU

CAN BE SEVERELY INJURED, PARALYZED OR KILLED RIDING ON A BROKEN OR POORLY

MAINTAINED FORK. Ask your Cannondale Dealer to help you develop a complete maintenance program, one that

suits where and how you ride.

EN

Page 13

Cleaning

Clean using only a mild soap and water solution. Clean water and common liquid dish washing soap will work best. Be sure to

cover the adjusters with a clean plastic bag secured with a rubber band or masking tape. Spray off heavy dirt before wiping.

Spray indirectly.

NOTICE

• DO NOT USE A PRESSURE WASHER. Use a low pressure garden hose. Power washing will force contaminants into the

fork promoting corrosion, immediately damaging, or result in accelerated wear.

• DON’T DRY WITH COMPRESSED AIR FOR THE SAME REASON.

Tightening Torques

Correct tightening torque for the fasteners (bolts, screws, nuts) on your bicycle is very important to your safety.the durability

and performance of your bicycle. We urge you to have your Dealer correctly torque all fasteners using a torque wrench. If you

decide to tighten fasteners yourself always use a good torque wrench!

Description Nm In Lbs Loctite™

Upper/Lower Clamp Bolts 7-9 62-80 242 (blue)

Guard Screws 1.0 9 242 (blue)

Wheel Axle Bolt 15 133

Brake Adapter Mouting Bolts 9 80 242 (blue)

12 13

Page 14

Frame Bumper

The bumper cushions the frame from contact with the

Supermax 2.0. Replace it with a new one if it ever becomes

damaged, torn, or missing.

REPLACEMENT: Clean surfaces well. Remove the

backing from the new bumper, position and affi x by pressing

fi rmly against the frame.

IMPORTANT: Be sure to position the bumper so that

when the handlebar is rotated to the left, the bumper

prevents fork contact with the the frame. Frame damage can

result from using the wrong bumper or positioning a bumper

incorrectly. Ask your Cannondale Dealer for help.

HD215/

HD215/

131581.PDF

KH074/

KH074/

EN

Moto Guard

The moto guard protects the inner tube surface from damage.

It also supports the brake line. Check it periodically. Make sure

it is in good condition and attached properly.

NOTICE

Replace guard with a new one if it becomes damaged. It

is a normal wear item.

1. Guard

2. Mounting points

3. Mounting screws

4.

1.

2.

3.

Loctite 242

1.0Nm, (9.0 InLbs)

13

Page 15

SUPERMAX SUPPLEMENT 129975 - UPDATE 03/14

This is an update for your SUPERMAX owner’s manual supplement (p/n 129975). This update

contains specific information for SUPERMAX 160/27.5 and SUPERMAX 140/27.5 to replace/update

in the areas indicated. Please keep it with your owner’s supplement.

Intended Use:

See SUPERMAX supplement page 2.

Manual Reset:

A

SUPERMAX 160/27.5 SUPERMAX 140/27.5 SUPERMAX 130/29

20mm +/- 3 20mm +/- 3 35mm +/- 3

Recommend Air Spring Pressure:

See page 6.

TOTAL RIDER WEIGHT SUPERMAX 160/ 27.5 SUPERMAX 140/27.5 SUPERMAX 130/29

LBS KG PSI PSI PSI

100 - 109 45 - 49 49 49 55

110 - 119 50 - 54 52 52 60

120 - 129 54 - 59 56 56 64

130 - 139 59 - 63 60 60 66

140 - 149 64 - 68 62 62 70

150 - 159 68 - 72 68 68 74

160 - 169 73 - 77 70 70 78

170 - 179 77 - 81 72 72 80

180 - 189 82 - 86 82 82 83

190 - 199 86 - 90 84 84 87

200 - 209 91 - 95 90 90 90

210 - 219 95 - 99 96 96 93

220 - 229 100 - 104 100 100 95

230 - 239 104 - 108 105 105 97

240 - 249 109 - 113 110 110 100

RECOMMENDED SAG 45-50mm 40-45mm 37-42mm

BIKE TRAVEL 160mm 140mm 130mm

Brake Line Clamp Position:

To prevent the guard from contact

with the brake line clamp during

movement, position the clamp

according to the table below.

45mm

CLAMP

Minimum Clamp Height

(from the top of the guard to the lower clamp)

SUPERMAX Travel + 30mm

160/27.5 190mm

140/27.5 170mm

130/29 160mm

43mm

CLAMP

GUARD

14 15

Page 16

SUPERMAX SUPPLEMENT 129975 - UPDATE 03/14

This is an update for your SUPERMAX owner’s manual supplement (p/n 129975). This update

contains specific information for SUPERMAX 160/27.5 and SUPERMAX 140/27.5 to replace/update

in the areas indicated. Please keep it with your owner’s supplement.

Intended Use:

See SUPERMAX supplement page 2.

SUPERMAX 160/27.5 SUPERMAX 140/27.5

ASTM CONDITION 4, All Mountain

Manual Reset

NOTICE:

Do not disaasemble or open for the following procedure.

Perform every 50 hours.

1. With your bike on the fl oor.

Cover the brake rotor with a clean shop towel. Remove the

2.

Schrader valve cap and hold the valve to release all air pressure.

It is normal for a small amount of oil to be expelled with the

escaping air.

3. Hold the valve open while fully compressing the Supermax 2.0

with the the handlebar until it bottoms out. With the air out,

using moderate force, bottom out the Supermax 2.0 fi rmly

several times.

WARNING

Contamination can result in reduced or lost braking

performance.

131581.PDF

EN

4. Now, measure length of exposed inner tube as shown. Repeat

step three until the correct measurement for your

Supermax 2.0 is reached.

5.

When you are fi nished, reset sag.

Manual Reset:

A

SUPERMAX 160/27.5 SUPERMAX 140/27.5 SUPERMAX 130/29

20mm +/- 3 20mm +/- 3 35mm +/- 3

15

A

Measure Fully Compressed

Page 17

CANNONDALE LIMITED WARRANTY

Cannondale Headshok (Supermax 2.0, LEFTY, Fatty, Solo) suspension products are covered under the terms and conditions of

the Cannondale Limited Warranty. It is available on the Policies page of our website at: www.cannondale.com

Be sure to read the exclusions listed in the limited warranty. For example, damage from accidents and improper maintenance

are not covered.

Definitions related to forks:

The fork structure is covered in the FRAMES section of the Cannondale Limited Warranty.

“Fork structure” means certain structural parts of the fork, specifically the fork legs, outer tube, the steerer tube, steerer tube

clamps and the inner tubes with attached dropouts or spindle. Cable clamps, needle bearings, races, and bushings which are

part of the telescopic assembly are normal wear and tear items and ARE NOT covered by the limited lifetime warranty.

The internal fork internal parts are covered by the 1 year (2 years in EU countries) warranty against defects in materials or

workmanship described in the COMPONENTS section of the Cannondale Limited Warranty. “Internal fork parts” are defined

as items such as damping cartridges and their internal parts, seals, o-rings, air cylinders, air pistons, springs, elastomers,

bumpers, bushings, needle bearings, races, and oil. Normal wear and tear on these items is NOT covered by this 1 year (2 in

EU) warranty. Like brake pads on a car, you should expect to have these items professionally replaced or renewed as you use

the fork and they wear.

Fork Warranty Claims

For any warranty claim to be considered, the bicycle/fork must be brought into an Authorized Cannondale Retailer on the

continent on which the bicycle/fork was purchased. The bicycle/fork must be in assembled condition and accompanied by the

original, dated sales receipt for the bicycle/fork.

Dealer Locator at: www.cannondale.com/Dealerlocator

16 17

Page 18

131581.PDF

HD215

REPLACEMENT PARTS - 2015 Supermax 2.0 PBR 130 - 29’

The following replacement part kits are available through a Cannondale Dealer:

KH074

frames L/M/S

frame XL

KH065/

Knobs Only

LEFTYBOLTS

LEFTYBOLTS

Steerer is for

1.5 stems only

and is frame

size specific.

KH118/ _ _ _HT

180mm ADAPTER

LEFTY HYBRID HUB

KH112/

180mm ADAPTER

SUPERMAX HUB

KH111/

HD011/

43mm

w/clamp

KH110/

Solo Air Assembly

is sold separately

Damper

thread

positions

are

frame size

specific.

10 mm

A

B

C

PBR

Damping

Cartridge

KH113/

(color=purple)

Volume

Reducer

42 mm

Solo Air Assembly Kit

Upper

Air Seal

63 mm

KH115/

#112

#112

#119

EN

A

B

C

#212

#212

Loctite 262 (red)

#011

#212

#022

ADAPTER MOUNTING BOLTS

Loctite 242 (blue)

9 Nm (80 InLbs)

Frame

Size

SMALL 97mm 100.2mm KH118/097HT

MEDIUM 109

L

ARGE 122.4mm 125.6mm KH118/122HT B

X-LARGE 134.4mm 137.6mm KH118/134HT B

KH114/

adtube

SI He

Length - (A)

.7mm 112.9mm KH118/109HT

Clamp

Spacing - (B)

Steerer

Kit - (25)

KH047/

Damping

Cartridge Thread

Position

Use only

10mm

volume

reducer

SMALL

MEDIUM

sizes.

Use the

42mm

volume

reducer

for only

LARGE

X-LARGE

KH116/X

Air Piston Only

#009

frame sizes.

A

A

Page 19

REPLACEMENT PARTS - 2015 SUPERMAX 2.0 160 - 27.5

The following replacement part kits are available through a Cannondale Dealer:

KP068/

STEERER CAP

LEFTYBOLTS

5mm

Loctite 242 (blue)

7 Nm (35 InLbs)

Headtube

Length

SUPERMAX 1.5” STEERERS

(Frame size/specific)

KH118/ _HT

KH131/

180mm Adapter

LEFTY SL HUB

KH074

/Frame XL

Frames S/M/L

HD011/

HD215

Damper

thread

positions

are

frame size

specifi c.

FRAME SIZE

SMALL

MEDIUM

KH132/

PBR 160mm

DAMPER ASSY.

27.5”

(color = green)

Solo-Air

assembly

is sold

separately.

A

B

C

LARGE

XLARGE

A

B

C

SOLO-AIR ASSY. KIT

KH133/

Upper

Air Seal

30mm

#013

#114

#114

#212

Loctite 262 (red)

Loctite 262 (red)

KH130/

180mm Adapter

LEFTY SM HUB

ADAPTER MOUNTING BOLTS

Loctite 242 (blue)

9 Nm (80 InLbs)

#022

KH047/

“36-LG”

KH143/

KH129/

Volume

Reducer

none

25 mm

Frame

SI Headtube

Size

Length - (A)

SMALL 97mm 100.2mm KH118/097HT A

MEDIUM 109.7mm 112.9mm KH118/109HT A

LARGE 122.4mm 125.6mm KH118/122HT B

X-LARGE 134.4mm 137.6mm KH118/134HT B

Clamp

Spacing - (B)

KH134/

AIR PISTON ASSY. (only)

Steerer

Kit - (25)

18

#212

#009

Damping

Cartridge Thread

Position

Page 20

131581.PDF

REPLACEMENT PARTS - 2015 SUPERMAX 2.0 140 - 27.5

The following replacement part kits are available through a Cannondale Dealer:

KP068/

STEERER CAP

LEFTYBOLTS

5mm

Loctite 242 (blue)

7 Nm (35 InLbs)

Headtube

Length

SUPERMAX 1.5” STEERERS

(Frame size/specific)

KH118/_HT

KH131/

180mm Adapter

LEFTY SL HUB

KH074/

Frame XL

170mm

HD215/

Frames S/M/L

HD011/

Damper

thread

positions

are

frame size

specifi c.

SMALL

MEDIUM

FRAME SIZE

KH138/

PBR 140mm

DAMPER ASSY.

27.5”

(color = blue)

Solo-Air

assembly

is sold

separately.

A

B

C

LARGE

XLARGE

Upper

Air Seal

53mm

A

B

C

SOLO-AIR ASSY. KIT

KH139/

Loctite 262 (red)

#112

#112

#011

#119

KH130/

180mm Adapter

LEFTY SM HUB

ADAPTER MOUNTING BOLTS

Loctite 242 (blue)

9 Nm (80 InLbs)

#022

KH047/

KH114/

KH110/

#119

42 mm

Clamp

KH116/X

AIR PISTON ASSY. (only)

Steerer

Kit - (25)

Volume

Reducer

10 mm

Frame

SMALL 97mm 100.2mm KH118/097HT A

MEDIUM 109.7mm 112.9mm KH118/109HT A

LARGE 122.4mm 125.6mm KH118/122HT B

X-LARGE 134.4mm 137.6mm KH118/134HT B

#119

SI Headtube

Size

Length - (A)

Spacing - (B)

19

#212

#009

Damping

Cartridge Thread

Position

Page 21

CANNONDALE EUROPE

Cycling Sports Group Europe, B.V.

Hanzepoort 27, 7570 GC, Oldenzaal,

Netherlands

(Voice): +41 61 4879380

(Fax): +31 5415 14240

servicedeskeurope@cyclingsportsgroup.com

CANNONDALE UK

Cycling Sports Group

Vantage Way, The Fulcrum,

Poole, Dorset, BH12 4NU

(Voice): +44 (0)1202 732288

(Fax): +44 (0)1202 723366

sales@cyclingsportsgroup.co.uk

Warning! Read this supplement and your cannondale bicycle owner’s manual.

Both contain important safety information. Keep both for future reference.

WWW.CANNONDALE.COM

© 2014 Cycling Sports Group

131581 (05/14)

20

Loading...

Loading...