Cannondale LEFTY MAX 140 Owner's Manual

WARNING

READ THIS SUPPLEMENT AND YOUR

CANNONDALE BICYCLE OWNER’S MANUAL.

Both contain important safety information.

Keep both for future reference.

2010

LEFTY MAX 140

125123.PDF

In this supplement, particularly important information is presented in the following ways:

WARNING

Indicates a hazardous situation which, if not

avoided, could result in death or serious injury.

NOTICE

Indicates special precautions that must be taken to

avoid damage.

TIP

A TIP provides helpful information.

This manual meets EN standards

14764, 14766, and 14781.

Vélo certifié conforme aux exigences du décret

N 95-937 du 24 août 1995 norme NFR030

2010 LEFTY MAX 140

Owner’s Manual Supplement

125123.PDF

EN - 07/09

Please note that the specications and information in this manual are subject to change for product

improvement. For the latest product information, go to http://www.cannondale.com/tech_center/

Replacement Cannondale part numbers are shown

throughout this supplement in BOLD ITALIC text.

CONTENTS

SAFETY INFORMATION ......................................2

INTENDED FORK USE ................................................ 2

FORK DAMAGE ......................................................... 3

SPECIFICATION .................................................4

LEFTY MAX 140 w/ FOX RLC ..................................... 4

LEFTY MAX 140 w/ PBR ........................................... 4

LEFTY WHEEL HUB................................................... 4

FRONT WHEEL ..................................................6

1 1/8” STEERER ADAPTER...................................8

XC3 STEMSTEERER .........................................10

MAINTENANCE SCHEDULE ...............................12

CLEANING ............................................................. 13

FRAME BUMPER ................................................... 13

BOOT INSPECTION ................................................ 14

CLEAN/REOIL AIR FILTER .................................... 15

NEEDLE BEARING RESET....................................... 16

CLEAN/REGREASE TELESCOPE ............................ 18

LEFTY MAX 140 W/ FOX RLC.................................

ADJUSTMENTS ..................................................... 19

SAG/PRELOAD ...................................................... 22

NEEDLE BEARING RESET....................................... 23

SPRING CHANGE ................................................... 24

OIL CHANGE.......................................................... 26

LEFTY MAX 140 W/ PBR ......................................

ADJUSTMENTS ..................................................... 28

RECOMMENDED AIR PRESSURE ........................... 29

NEEDLE BEARING RESET....................................... 30

REPLACEMENT PARTS .....................................31

WARNING

This supplement may include procedures beyond the scope of general mechanical aptitude. Special tools, skills, and knowledge may be

required. Improper mechanical work increases the risk of an accident. Any bicycle accident has risk of serious injury, paralysis or death.

To minimize risk we strongly recommend that owners always have mechanical work done by an authorized Cannondale retailer.

2

SAFETY INFORMATION

INTENDED FORK USE

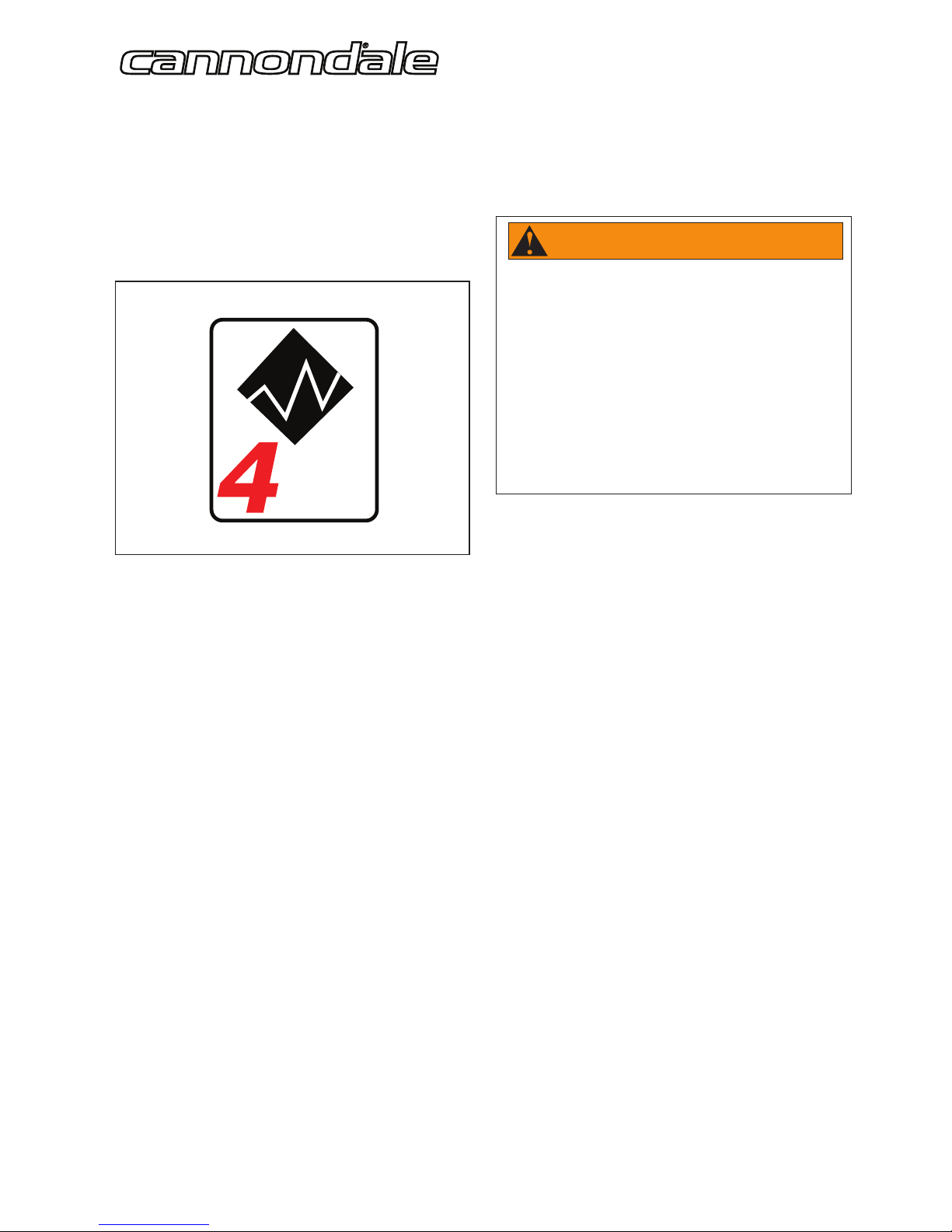

Lefty MAX 140mm forks are intended for use in Condition 4

(All Mountain) riding. The CONDITION 4 symbol is shown next

gure.

For riding on

rough trails

with medium

obstacles

Figure 1.

CONDITION 4

Bikes designed for riding Conditions 1, 2, and 3, plus rough

technical areas, moderately sized obstacles, and small jumps.

Fork is Intended

For trail and uphill riding. All-Mountain bicycles are: (1)

more heavy duty than cross country bikes, but less heavy

duty than Freeride bikes, (2) lighter and more nimble than

Freeride bikes, (3) heavier and have more suspension travel

than a cross country bike, allowing them to be ridden in more

dicult terrain, over larger obstacles and moderate jumps, (4)

intermediate in suspension travel and use components that t

the intermediate intended use, (5) cover a fairly wide range of

intended use, and within this range are models that are more

or less heavy duty. Talk to your retailer about your needs and

these models.

Fork Not Intended

This fork is not intended for use in extreme forms of jumping/

riding such as hardcore mountain, Freeriding, Downhill, North

Shore, Dirt Jumping, Slope-style, Hucking etc.

WARNING

UNDERSTAND YOUR FORK AND ITS INTENDED USE.

USING YOUR FORK THE WRONG WAY IS DANGEROUS.

Industry usage Conditions 1 - 5 are generalized and

evolving. Consult your Cannondale Dealer about how you

intend to use your bike.

Please read your Cannondale Bicycle Owner’s Manual

for more information about Intended Use and

Conditions 1-5.

125123.PDF

3

FORK DAMAGE

WARNING

STOP RIDING A DAMAGED FORK IMMEDIATELY.

The following conditions indicate that serious fork damage is present:

1. Any unusual “klunking” or knocking noises.

2. A change in fork travel.

3. An over-extended, elongated, or compressed boot.

4. Changes from the way the fork had been working

5. Loss of adjustment features, oil leaks, or air leaks.

6. Crash or impact damage (deep scratches, gouges, dents, or bending)

7. Small cracks under the bolt head of upper and lower clamp bolts. This inspection requires the removal of the bolts.

Horizontal cracks above and below the intersection of the upper and lower clamps with the outer tube portion of the

Lefty carbon structure.

Vertical cracks in the outer tube (where the races and needle bearings run). These may show as long, straight lines

perhaps several lines parallel to each other.

Also, please read Inspect For Safety in PART II, Section D. of your Cannondale Bicycle Owner’s Manual.

HAVE ANY DAMAGED FORK INSPECTED AND DAMAGE REPAIRED BY YOUR CANNONDALE DEALER. YOU CAN BE

SEVERELY INJURED, PARALYZED OR KILLED IN AN ACCIDENT IF YOU IGNORE THIS WARNING.

The MAINTENANCE section of this supplement includes information about regular maintenance practices that can keep your fork

in good operating condition.

SERIAL NUMBER

Located on outertube

under the air lter

foam element.

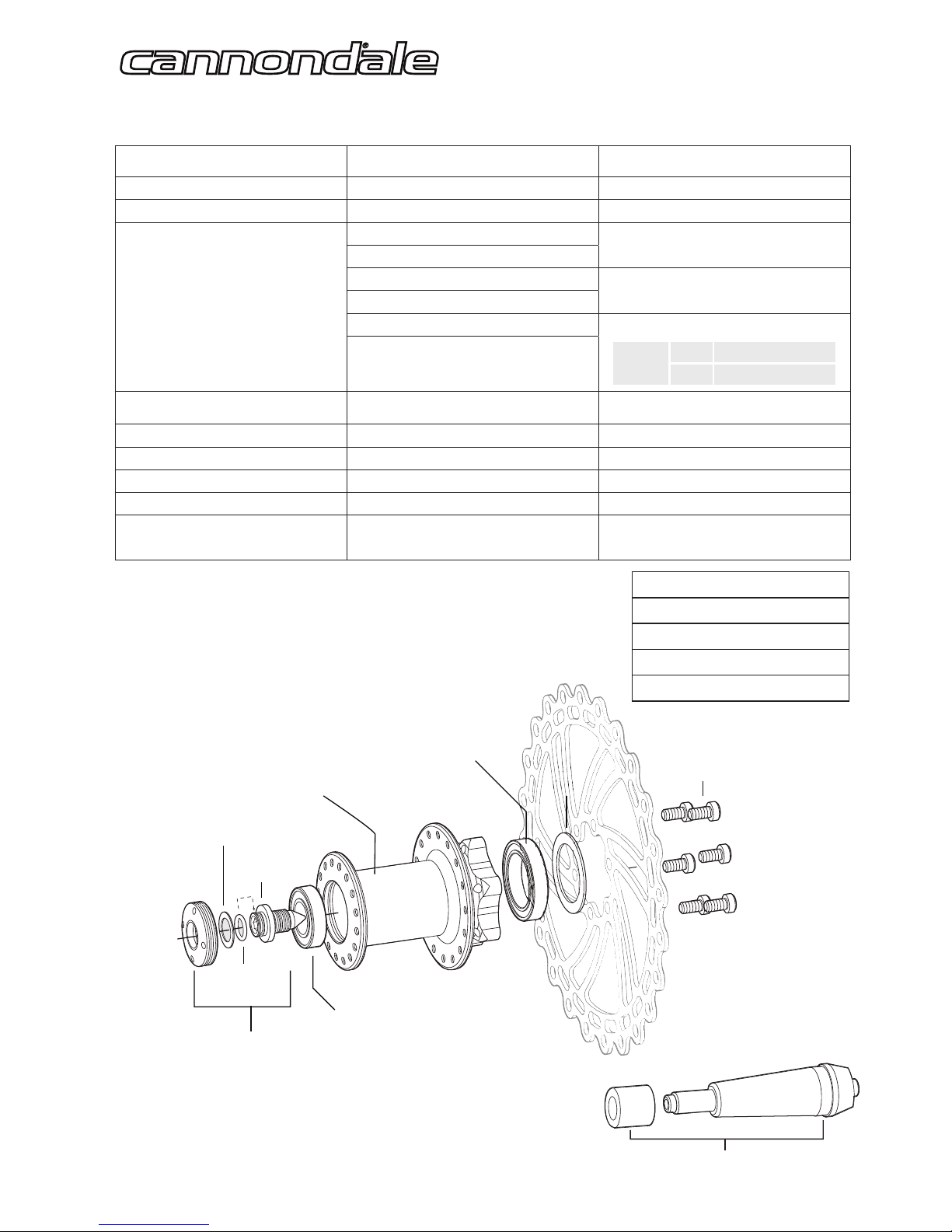

International Standard

BRAKE CALIPER MOUNTS

CALIPER MOUNTING BOLTS

CAP

Park SPA-1

AXLE BOLT

SEAL

INNER BEARING

WHEEL HUB

OUTER BEARING

WASHER

O-RING

NO RIDE

WHEEL TRUING TOOL - QCTL108/

15.0 Nm

DISC ROTOR BOLTS

6.2 Nm, Loctite 262

LEFTY WHEEL HUB

(exploded view)

QC117/

KB61902/

KB61805/

QC118/

QC081/

(24 spk, 6bolt)

QC627/

(32 spk, 6bolt)

WIDTHHT

137.6 mm 4.5”

163.0 mm 5.5”

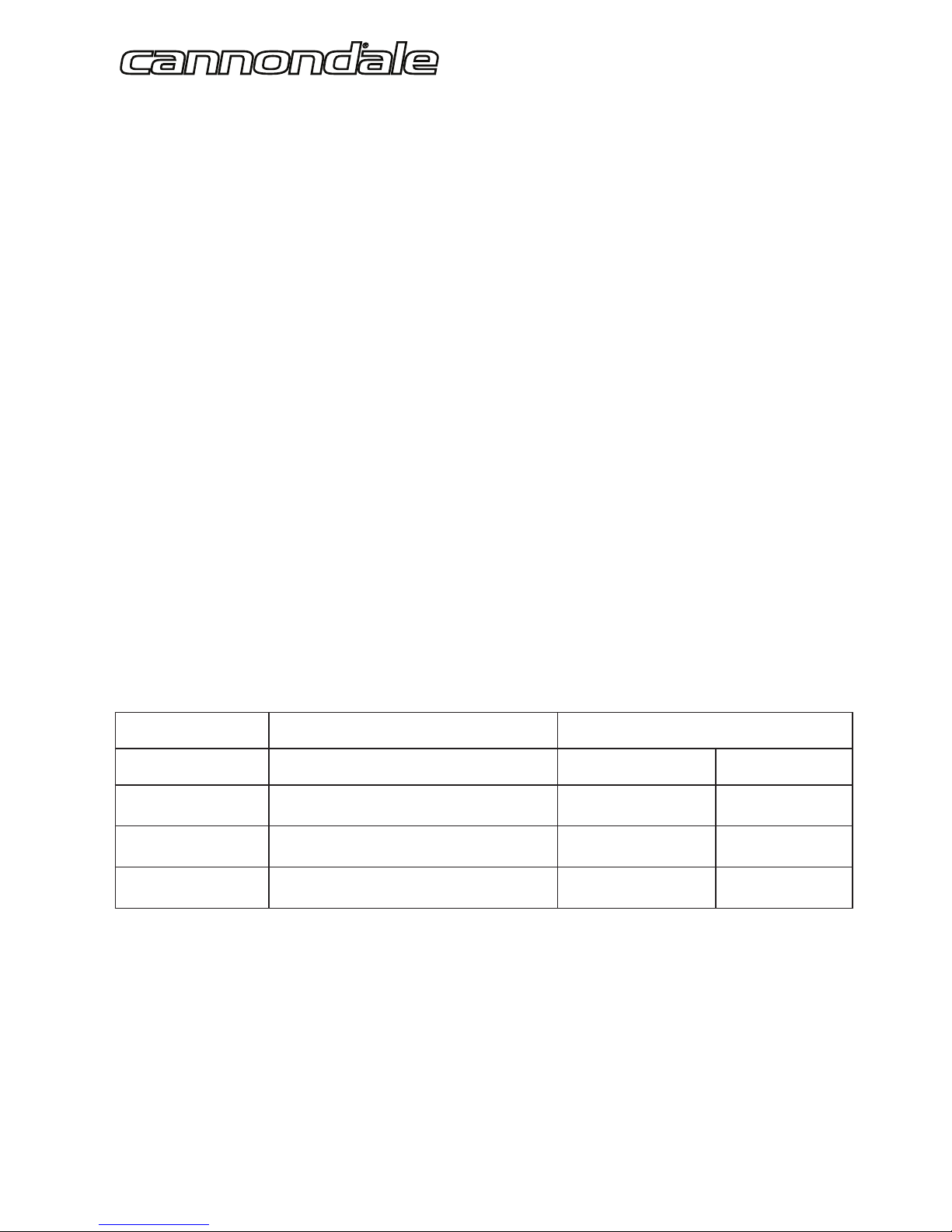

SPECIFICATION

LEFTY MAX 140 w/ FOX RLC LEFTY MAX 140 w/ PBR

TRAVEL 140 mm 140 mm

INTENDED USE CONDITION 4, All Mountain CONDITION 4, All Mountain

ADJUSTMENTS

LOCKOUT

POP-TOP

REBOUND

LOW-SPEED COMPRESSION

REBOUND

BLOW-OFF THRESHOLD

MAIN SPRING AIR PRESSURE

LIMITS:

MIN. 50 psi, 3.4 bar

MAX. 225 psi, 15.5 bar

SPRING PRELOAD

10mm/10 turns MAX.

RECOMMENDED SAG 25-30% 35 - 42 mm 35 - 42 mm

SPRING TYPE/MATERIAL COIL/STEEL SOLO AIR

NEGATIVE SPRING STEEL AIR AUTOMATIC

DAMPER OIL VOLUME 145cc --

DAMPER OIL WEIGHT 10W 5W

TELESCOPE LENGTH

(Needle Bearing Reset)

720 - 730 mm 720 - 730 mm

LEFTY 24 AND 32 SPOKE HUB DIMENSIONS

DISC FLANGE DIAMETER 58MM

NON DISC FLANGE DIAMETER 44.5MM

DISC FLANGE TO CENTER 35MM

NON DISC FLANGE TO CENTER 20MM

125123.PDF

5

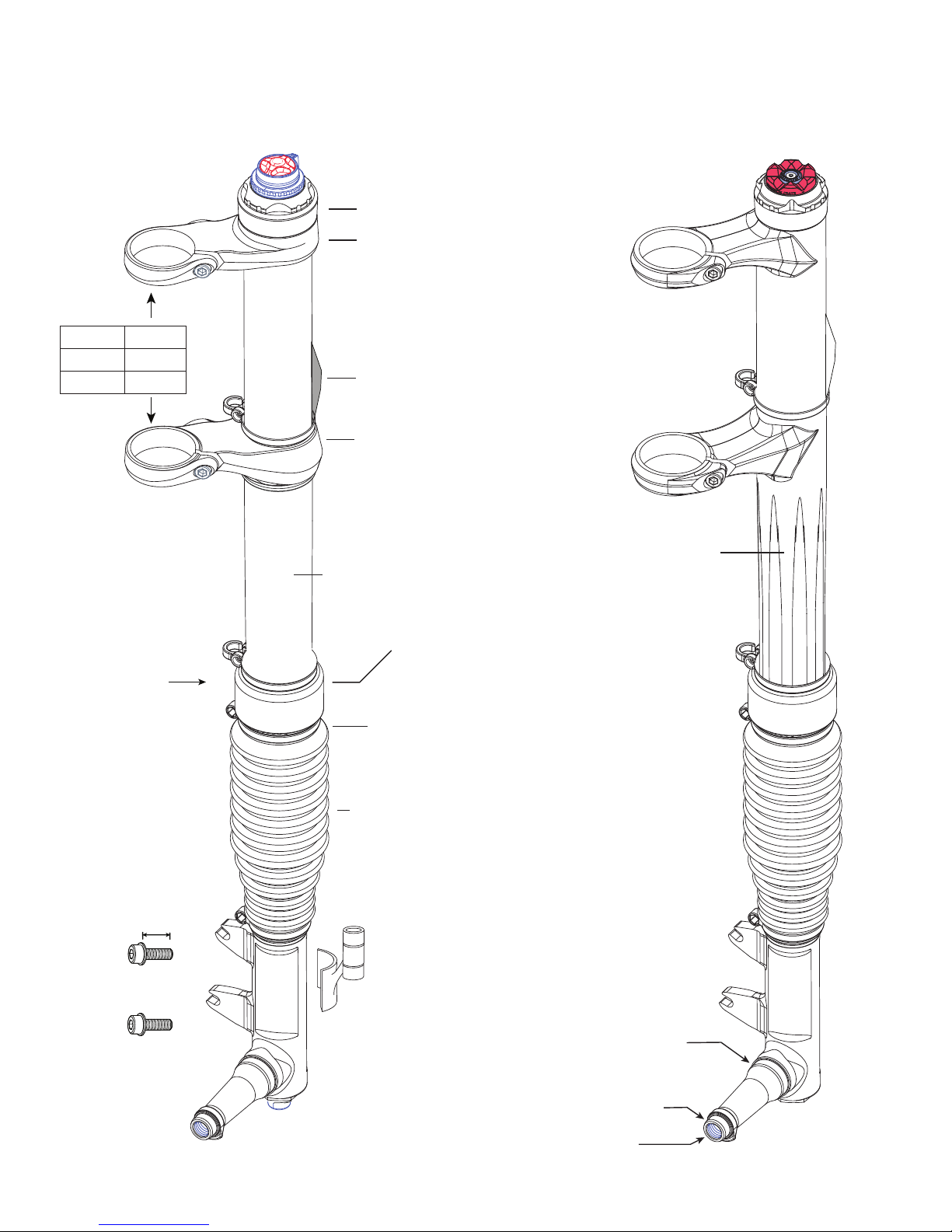

SERIAL NUMBER

Located on outertube

under the air lter

foam element.

CLAMP BOLT

16mm

ONE-PIECE INTEGRATION (O. P.I.)

INNER TUBE/SPINDLE

AIR FILTER ASSEMBLY

HD209/BLK

CARBON

(FOX RLC shown)

OUTER COLLAR

International Standard

BRAKE CALIPER MOUNTS

ADJUSTMENT

PBR - AIR PRESSURE

RLC - BLOW- OFF THRESHOLD

ALLOY

(PBR shown)

9 Nm, 80 In Lbs

CLAMP KIT

HD011/

AXLE BOLT THREADS

OUTER HUB BEARING LAND

INNER HUB BEARING LAND

SENSOR MOUNT

8CM01/BLK

LEFTYBOLTS/

CALIPER MOUNTING BOLTS

UPPER CLAMP

LOWER CLAMP

INTEGRATED 3D FORGED

OUTER TUBE

UPPER /LOWER CLAMPS

CARBON OUTER TUBE

WIDTHHT

137.6 mm 4.5”

163.0 mm 5.5”

BOOT

KF222/

FRAME BUMPER

HD215/

9 Nm, 80 In Lbs

9 Nm, 80 In Lbs

9 Nm, 80 In Lbs

KH057/

Thread repair kit

6

FRONT WHEEL

REMOVAL

1 Loosen the brake caliper mounting bolts.

Tilt the lower caliper bolt out of the boss so the caliper is

up out of the way of the disc. Snug up on the upper bolt

to hold caliper in place.

Take note of brake alignment shims between brake

bosses and the caliper. Be sure to reposition correctly.

2. Turn the hub extraction bolt counter-clockwise (ccw) to

remove the wheel.

NOTICE

■ Make sure the bolt is completely disengaged

before attempting to remove the wheel. Never

try to pull the wheel o forcefully.

■ When the wheel is o, to keep dirt out, cover the

hub opening.

■ Protect spindle from damage when wheel is

removed.

Continue turning the bolt until the wheel can be

removed easily from the spindle.

1

5mm

cw

ccw

125123.PDF

7

INSTALLATION

1. Inspect inside the wheel hub for contamination and

the condition of the hub seal. Take corrective action if

necessary.

Wipe the spindle clean with a dry shop towel and apply a

high-quality bike grease to the spindle bearing lands and

end threads.

2. Slide the wheel straight onto the spindle so, the larger

hub bearing starts to position on it spindle seat. At this

point, the axle bolt threads can correctly engage the

threaded spindle if the wheel is held on straight.

NOTE: Install the front wheel by positioning the bike

horizontally with the spindle facing up. Then place the hub

straight down onto the spindle, and tighten the axle bolt.

3. When the axle bolt threads engage the spindle, turn the

bolt clockwise with nger force slowly to allow the hub

bearings to slide onto the spindle bearing seats.

Once the hub has been drawn onto the hub completely,

use torque wrench to tighten to nal 15.0 N•m (133.0

In•Lbs).

4. Reinstall the brake caliper. Tighten bolts to 78.0 In•Lbf

(9.0 N•m).

5. Spin the wheel to make sure it moves freely. Be sure to

test the brakes for proper operation before riding.

WARNING

DO NOT CONTAMINATE BRAKE CALIPER, PADS, OR

ROTOR WITH GREASE.

WARNING

DO NOT RIDE WITHOUT A PROPERLY MOUNTED,

ADJUSTED, AND FUNCTIONING FRONT BRAKE

SYSTEM.

The Lefty (disc/caliper) acts as an integral secondary

wheel retention system. If the system is missing or

improperly installed, or if the wheel hub axle bolt should

loosen, the front wheel could slide o the spindle end.

When mounting IS compatible brake systems:

Follow brake manufacturer’s instructions when mounting

the brake caliper to the spindle brake bosses. Do not

modify the fork in any way.

PLEASE ASK YOUR CANNONDALE DEALER FOR HELP

WHEN INSTALLING COMPATIBLE FRONT BRAKE

SYSTEMS.

NOTICE

■ LOCATE BRAKE ROTOR BETWEEN THE PADS.

Replace shims that are in use, be sure the shims are

positioned between the caliper (adapter if any) and

inner face of the fork mounts, not under the head of

the caliper bolts.

■ USE ONLY THE LEFTY 16mm CALIPER BOLTS TO

MOUNT THE BRAKE. Longer bolts can result in

contact with the brake rotor causing severe damage.

Check clearance between the bolt tips and rotor after

remounting the caliper. Order replacement bolts Cannondale p/n LEFTYBOLTS/.

■ MAKE SURE THE BRAKE DISC CAN NOT MAKE

CONTACT WITH THE FORK BOOT. A rotating brake

disc can wear through the boot allowing contaminants

into the fork.

8

(A Headset part)

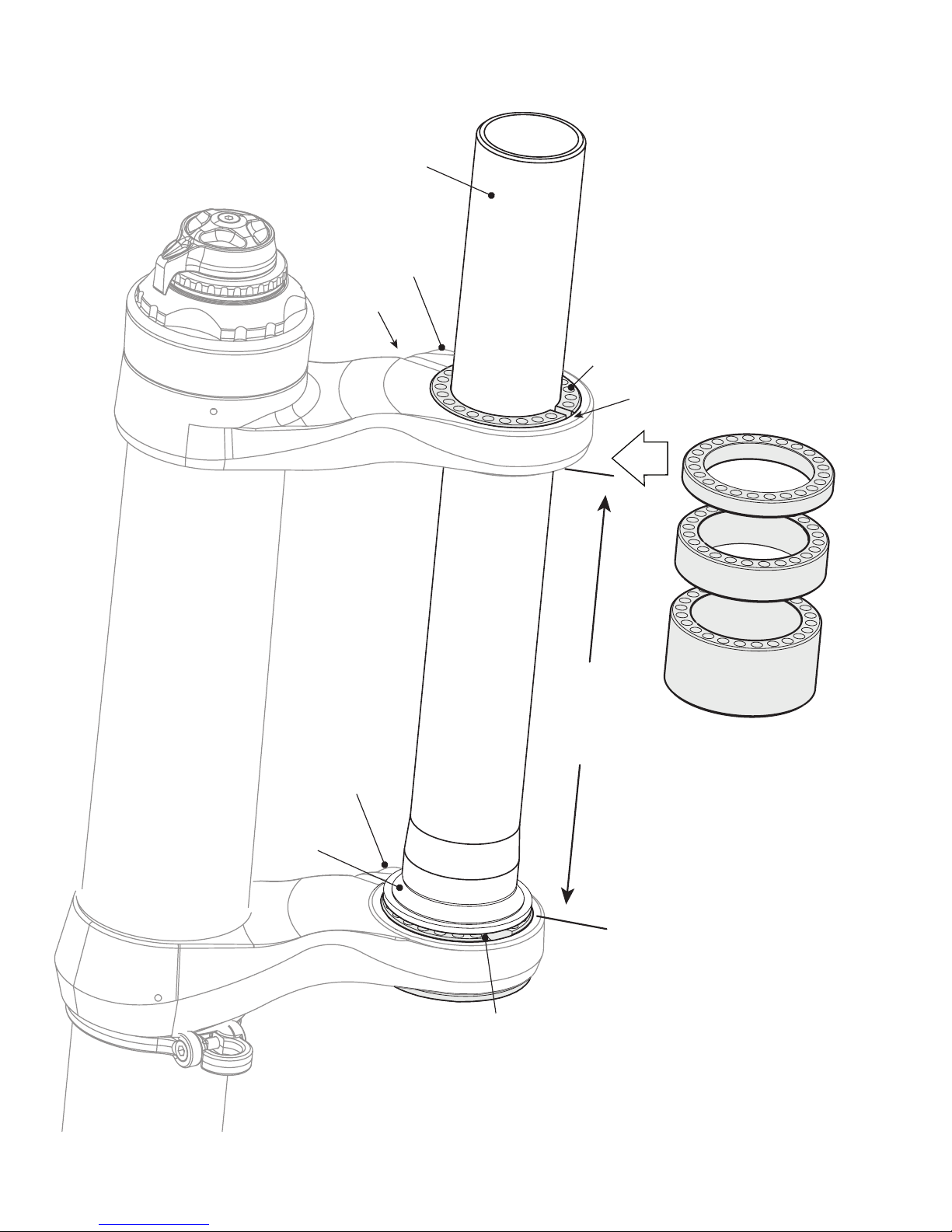

1.125 in STEERER ADAPTER

The 1.125 in steerer adapter assembly enables fork installation into a standard 1.125 head tube. Consult the table on the next

page to determine if the 1.125 steerer adapter system is compatible with the 1.125 head tube before attempting to install the

fork. The adapter system only be installed by a professional bike mechanic.

INSTALLATION POINTS

• When installing the steerer into the headtube with the Lefty, make sure the lower reducer is inserted completely into the

lower clamp.

• Install the upper reducer so that the top is ush with top of upper clamp or raised slightly. Do not install upper reducer with

the top below the below the top of the upper clamp.

• Locate the upper reducer slot 180° opposite the Lefty upper clamp slot.

• Install a combination of adapter kit spacers (5 mm, 10 mm, and 20 mm) to close the gap between the headset top cap and

the upper reducer.

• Install all handlebar stem spacers above the upper reducer.

• Tighten the upper and lower Lefty Clamp bolts AFTER the stem top cap has been installed and preload set. Tighten the Lefty

Clamp bolts to 9 Nm, 80 In Lbs.

MAXIMUM 1.125 HEADTUBE LENGTH (mm)

CANNONDALE KIT 1.125 HEADSET If (A) = 137.7 mm If (A) = 163.0 mm

KH058/ Kit, Steerer,Lefty 1 1/8” w/ Standard Headset 112.3 mm 137.7 mm

KH059/ Kit, Steerer,Lefty 1 1/8” w/ Hiddenset Headset 124.3 mm 149.7 mm

KH060/ Kit, Steerer,Lefty 1 1/8” w/ Zero Stack Headset 127.1 mm 152.5 mm

125123.PDF

9

20 mm

CROWN RACE

(A Headset part)

(A)

CLAMP WIDTH

UPPER REDUCER

Slot

Slot

LOWER REDUCER

1.125 in STEERER

SPACERS

10 mm

5 mm

CLAMP BOLTS

9 Nm, 80 In Lbs

CLAMP BOLT

9 Nm, 80 In Lbs

Loading...

Loading...