Cannondale Lefty MAX, Lefty Jake Owner's Manual

2:1(560$18$/6833/(0(17

/HIW\0$;/HIW\-DNH

31

READ THIS MANUAL CAREFULLY!

It contains important safety information.

IMPORTANT MANUAL INFORMATION

DANGER

CAUTION :

NOTE:

FAILURE TO FOLLOW THE WARNINGS CONTAINED IN THIS MANUAL CAN RESULT IN SERIOUS INJURY OR DEATH.

Information important to your safety is distinguished in this manual by the following notations:

The safety alert symbol means......

“ATTENTION! BECOME ALERT! YOUR SAFETY IS

INVOLVED.”

Indicates that DEATH or severe injury WILL result if the

instructions are not followed.

WARNING

Indicates a pote ntial haz ard that co uld resu lt in serio us

injury or death.

A CAUTION indicates that special precautions must be

taken to avoid damage to the machine.

A NOTE provides helpful information intended to make

maintenance easier or the instructions presented clearer.

2

CONTENTS

Compression Damping Assembly . . . . 22

website. Go to: http://www.cannondale.com/bikes/

tech/manuals.html

About this Ow ner’s Manual Supp lement 3

Safety Information . . . . . . . . . . . . . . . . . 3

Product Features . . . . . . . . . . . . . . . . . 4

Lefty MAX TPC+ . . . . . . . . . . . . . . . . . . 4

Lefty Jake. . . . . . . . . . . . . . . . . . . . . . . . 4

Fork Pre-Ride Checklist. . . . . . . . . . . . 5

Fork Setup . . . . . . . . . . . . . . . . . . . . . . 6

Cable & Line Routing. . . . . . . . . . . . . . . 6

Front Wheel . . . . . . . . . . . . . . . . . . . . . . 7

Computer Mounting . . . . . . . . . . . . . . . . 9

Tuning. . . . . . . . . . . . . . . . . . . . . . . . . 10

Sag. . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Fork Spring. . . . . . . . . . . . . . . . . . . . . . 11

Spring Kits . . . . . . . . . . . . . . . . . . . . . . 11

Compression Damping. . . . . . . . . . . . . 11

Rebound Damping. . . . . . . . . . . . . . . . 12

Maintenance . . . . . . . . . . . . . . . . . . . . 12

Required Tools. . . . . . . . . . . . . . . . . . . 12

Schedule . . . . . . . . . . . . . . . . . . . . . . . 13

Mechanical Adjustments. . . . . . . . . . 14

Changing the fork oil . . . . . . . . . . . . . . 15

Fork Removal. . . . . . . . . . . . . . . . . . . . 16

Fork installation . . . . . . . . . . . . . . . . . . 16

Changing the fork spring . . . . . . . . . . . 17

Checking needle bearing migration . . . 18

Cleaning . . . . . . . . . . . . . . . . . . . . . . . 19

Illustrations. . . . . . . . . . . . . . . . . . . . . 20

Tire Size / Clearance . . . . . . . . . . . . . . 20

Rebound Damping Assembl y. . . . . . . . 21

ABOUT THIS OWNER’S MANUAL SUPPLEMENT

This manual adds important safety, maintenance,

and proper use information to your Cannondale

Owner’s Manual for Multi-speed Bicycles.

This supplement does not replace your owner’s

manual.

It is important to your safety to read your owner ’s

manual and all the owner’s manual supplements for

your particular bike and components.

You should ha ve recei ved the Cannondal e Owne r’s

Manual for Multi-speed Bicycles all applicable supplements from your dealer when you purchased your

new bike.

If you did not receive an owner ’s manual a nd the

supplements for it, or are not sure what supplements

you should have received with your bike please call

your Cannondale dealer immediately, or call us at

one of the telephone numbers listed on the back

cover of this manual.

Do not ride your new bicycle until you have

received and read the owner’s manual and all

supplements for your particular bicycle.

Keep this supplement with your owner’s manual.

Adobe PDF versions of the Ca nnondal e Owner ’s

Manual for Multi-speed Bicycles and any su pplement can be downloaded free of charge from our

SAFETY INFORMATION

WARNING

POTENTIAL HAZARD

Riding high performance bicycles and suspen sion systems beyond your skills and abilities

WHAT CAN HAPPEN

Advanced bicycle suspension systems can

increase the handling and stability of most

high-performance bicycles.

You could have a bad accident if your skill is

not up to handling an advanced suspension. If

you lack the skills and experience necessary to

travel at higher speeds and maneuver over difficult terrain at the greatly increased performance level, you can travel faster than your

abilities. You can lose control of the bike in

these conditions and crash. Anytime you lose

control of the bike, especially at high speed

and in advanced ter rain, you risk severe injur y

or death in a crash.

HOW TO AVOID THE HAZARD

Ride at reduced speeds.

Learn the performance characteristics of your

bike and suspension components before trying

any downhill or very fast biking.

Ride within your skills and abilities.

T ake a bicycle training course.

3

WARNING

POTENTIAL HAZARD

Riding on a damaged fork

WHAT CAN HAPPEN

If the suspension fork ever begins to...

1. Make “knocking” or “clunking noises

2. Show unexplained increase in travel,

3. Increase in fork extension or travel

4. A sudden loss of lock out ability on

equipped forks.

5. Or, a sudden loss of adjustment features

... continued use can result in a separation of

the fork from the bicycle frame. You can be

severely injured or killed in an accident.

HOW TO AVOID THE HAZARD

If you observe any of the above, DO NOT RIDE.

Take the fork to an Authorized Cannondale

Dealer to have it inspected and serviced.

PRODUCT FEATURES

LEFTY MAX TPC+

• Manitou TPC+ damping with External

Compression and Clicker Rebound Adjustment.

• Internal Pre-load Adjustment

• Titanium Coil Spring

• Golden Spectro Cartridge Fork Fluid 85/150

(2.5W)

• 130 mm of travel with a crown height of 500 mm

• 10mm of negative travel for improved small

bump performance

• International Disc Brake Compatible

• 8" Rotor Compatible Boot

LEFTY JAKE

• Manitou Fluid Flow damping with External

Rebound Adjustment

• Internal Pre-load Adjustment

• Chrome Vanadium Coil Spring

• Golden Spectro Cartridge Fork Fluid 85/150

(2.5W)

• 100 mm of travel with a crown height of 470 mm

• 10mm of negative travel for improved small

bump performance

• International Disc Brake Compatible

• 8" Rotor Compatible Boot

4

FORK PRE-RIDE CHECKLIST

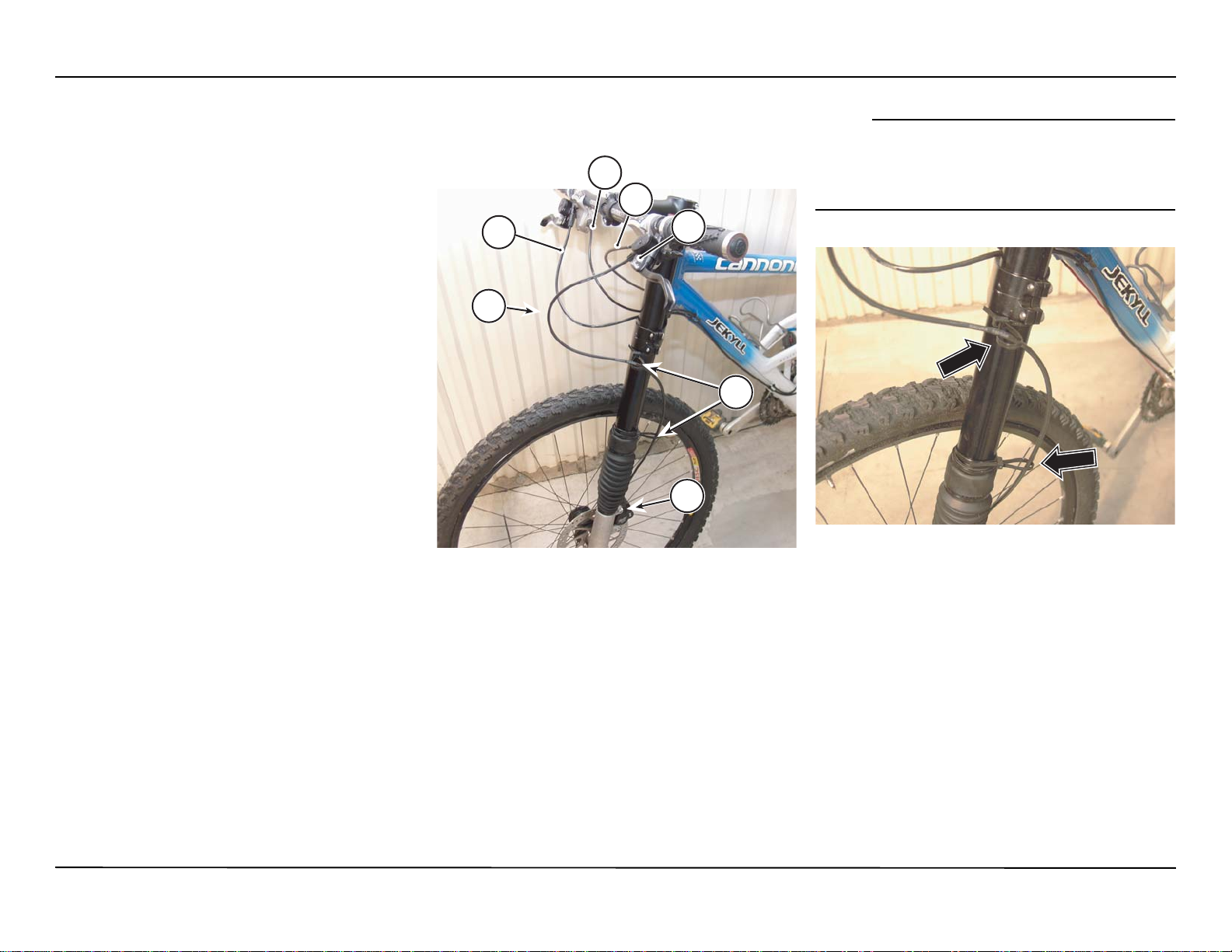

1

2

Your Cann ondale Owner ’s Manu al (Cannondale

Owner’s Manual for Multi-speed Bicycles) includes a

vitally important Pre-ride Inspection Checklist you

MUST follow before every ride.

You must check the following items of your fork

system in addition to the checklist fo und in your

owner’s manual.

Before each ride check the following items:

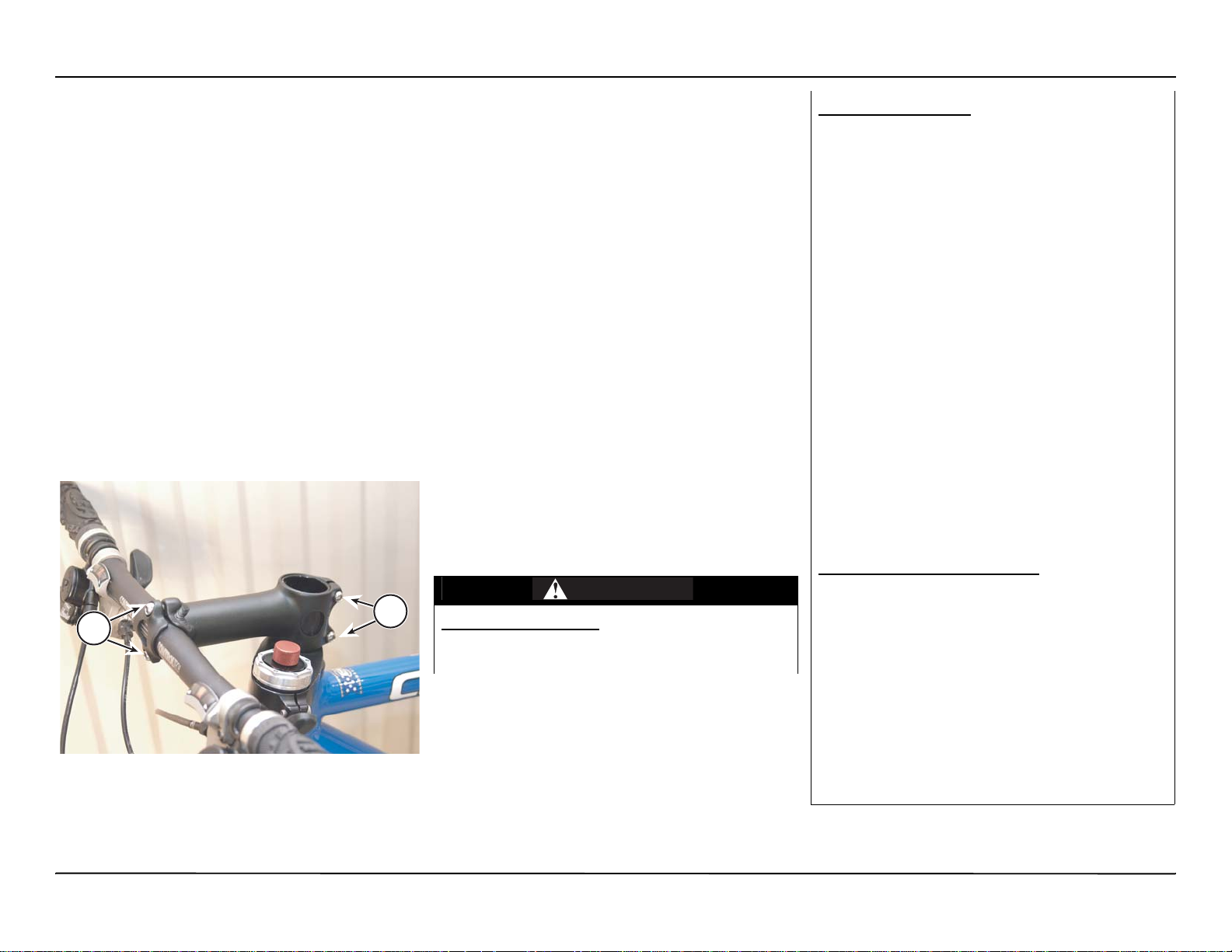

Stem bolts tightness

Make sure that the stem bolts that clamp the stem to

the fork are tight.

TORQUE : Stem bolts - 85.0 lbf•in (9.0 N•m).

1. Stem bolts

2. Handlebar cla mp bo lts

You can check that the stem bolts are tight enough

by standing in front of your bike, holding the front

wheel between your knees, and trying to twist the

handlebars fro m si de to side. The bars s houl d no t

move.

Front wheel attachment

Make sure the fron t whee l is attache d correc tly. Is

the Lefty hub correctly installed and the hub bolt

tightened to the specified torque? Refer to

"Installing the front wheel" starting on page 8.

Check the brakes

Are your brakes func tioning proper ly? With dis c

brakes, the brake pads must be properly installed

and free from grease or oil contamination. A lso,

brake pads must contact the braking surface firmly

with out the brake lever hitting the handlebar.

The Lefty fork must be used with a co mpati ble disc

brake system and it must be fitted correctly; the disc

brake mounted on a Lefty fork acts a secondary

wheel rete ntion device.

WARNING

POTENTIAL HAZARD

(1) Using the wrong disc brake system

(2) Incorrectly fitting/mounting brake discs

WHAT CAN HAPPEN

(1) The disc brake acts a secondary wheel

retention device. An improperly installed rotor

could allow the front wheel to come off of the

axle spindle if the hub axle bolt is loose. A rider

would be at risk of injury or death if the wheel

were to come off of the axle spindle while the

bike is being ridden.

(2) An approved disc brake system is very

important to safely riding the Lefty fork. Cannondale strongly recommend that an Authorized Dealer perform any work to the brakes.

When installing a disc brake to a Lefty fork,

please consult the disc brake fitting instructions that are included with the brakes. Those

instructions are provided for persons who

have a good knowledge of bike specific

mechanical procedures and who are equipped

with the proper tools and equipment. Incorrect

installation or se rvice may reduce br aking performance, and could lead to injury or death. If

you have any doubts about your ability to perform any necessary procedures, contact you

Authorized Dealer.

HOW TO AVOID THE HAZARD

(1) Don’t service the brake system yourself.

Always have your brakes serviced by an

Authorized Cannondale Dealer.

(2) Consult the manufacturer’s disc brake fitting instructions included with the brakes.

Those instructions are provided for persons

who have a good knowledge of bike specific

mechanical procedures and who are equipped

with the proper tools and equipment. If you

have any doubts about your ability to perform

any necessary procedures, contact your

Authorized Cannondale Dealer.

Note also that there is a seal that is held against the

disc side of the Lefty hub by the rotor. Whenever you

5

bolt the brake rotor onto the hub, be sure that the

N

seals rests against the large car tridge beari ng and

that the rotor holds the seal in place. The seal keeps

out water and dirt contamination, and a missing seal

will result in premature bearing wear.

brake line should pass from the lever through the two

cable guides on the outside of the fork leg.

6

5

OTE :

The brake line should not be held tightly in the

cable guides. The guide l oops need to be loos e

enough to allow the brake line to slide freely up

and down.

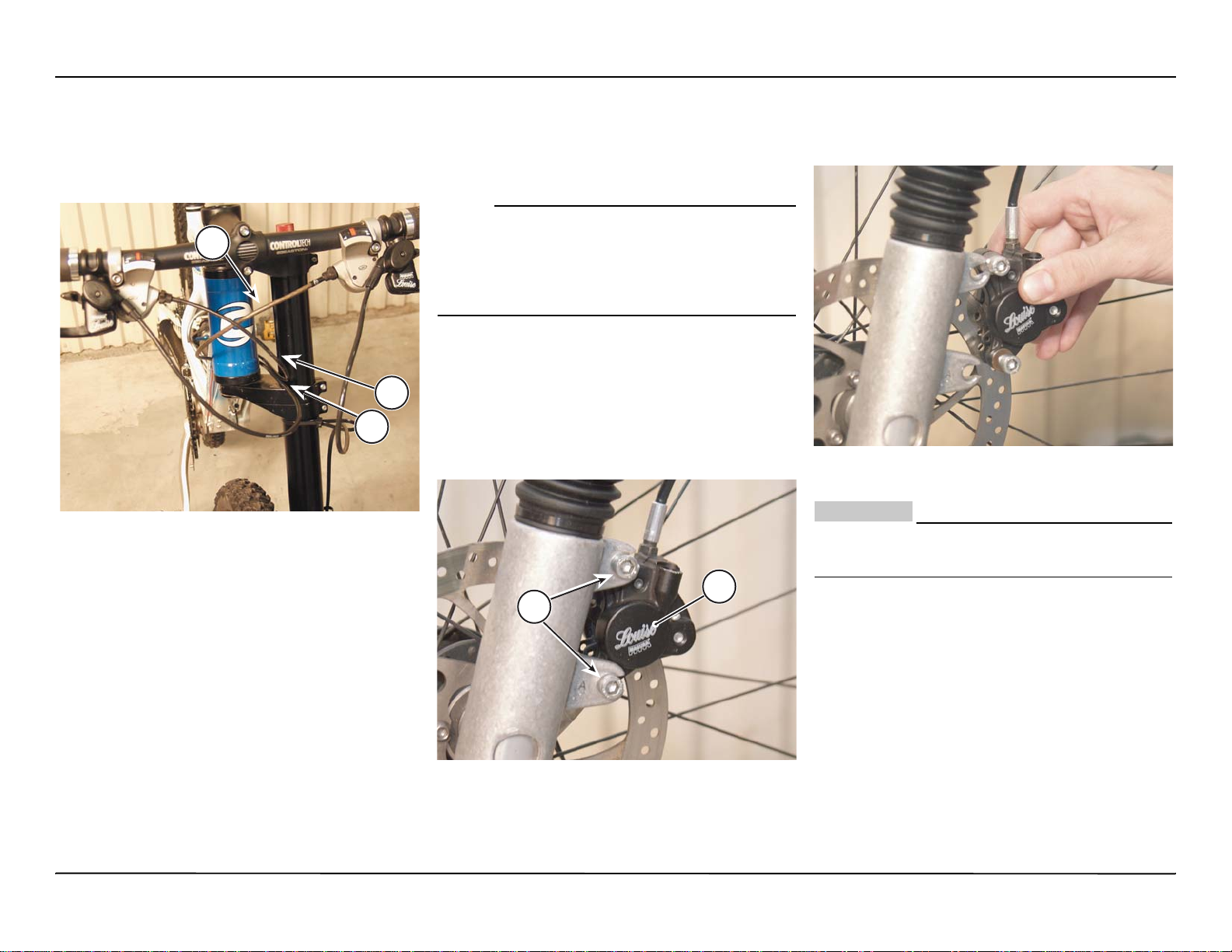

FORK SETUP

CABLE & LINE ROUTING

Front brake line

The front brake line routing shoul d not pass

between the headtube and fork leg. Rather, the

7

1

1. Fr ont br ake line

2. Fr ont brake line guides

3. Fr ont br ake cali per

4. Fr ont br ake leve r

5. Fr ont der a ill eur cabl e

6. Rear derailleur cable

7. Rear brake line

4

2

1

2

3

4

3

6

Rear brake line and rear derailleur cable

N

2

1

3

The rear brake line and rear derailleur cable shoul d

be run between the upper and lower fork clamps,

between the bikes headtube and fork leg.

bolt or beari ng be s ure to r eins tall the ca p with a

small amount of grease on the cap threads.

Remember that the cap is a left-hand thread.

OTE :

It is not necessary to remove the front wheel to

change an inner tube or tire. Simply remove th e

tire from the wheel as you normally would,

making sure to pull the tire off of the non-disc

side of the wheel.

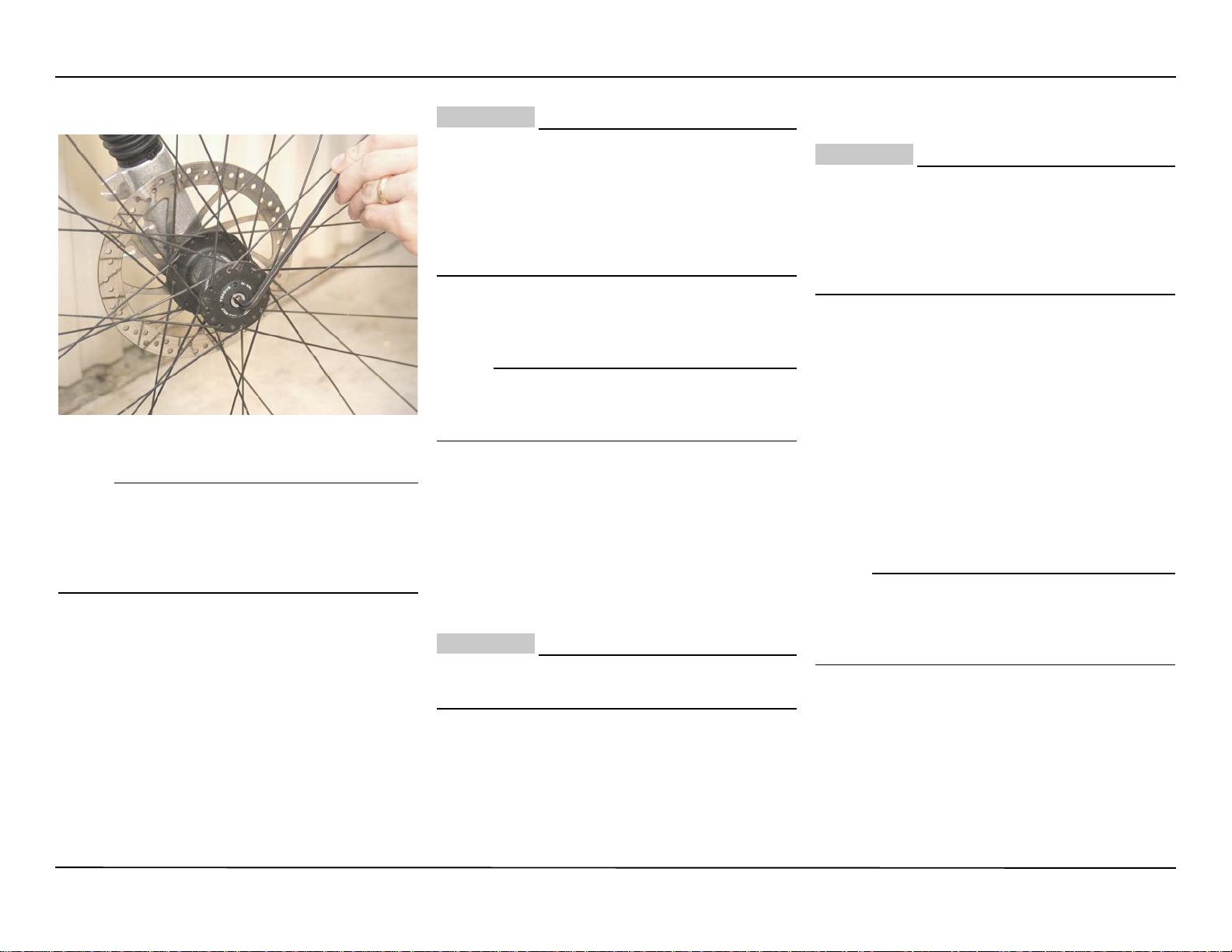

Removing the front wheel

1. Secure the bike upright on a work stand.

2. Loosen (but don’t remove) both disc brake

caliper bolts (5 mm Allen).

from the brake disc (r otor). Take note of any

shims present and be sure to reinstall them

later during reassembly.

1. Rear dera ill eu r cab le

2. Rear brake lin e

3. Front de ra illue r ca ble

Don’t let the caliper hang. Support it carefully

out of the work area.

1

CAUTION :

2

FRONT WHEEL

4. Turn the axle bolt (5 mm Allen) counter-

The Lefty fork front hub uses a self-extracting bolt to

attach the wheel to the Lefty’s axle spindle. The bolt

is held into th e hu b by a cap that is screw ed in to th e

non-disc side of the hub using a pin spanner tool.

The self-extracting bolt and cap combination is very

similar to that used on a crankarm, except, a Lefty

hub cap is reverse threaded. The cap should not be

removed; it is there to hold the axle bolts into the

1. Br ake caliper

2. Bolts

hub. If you do need to remove the cap to replace the

3. Remove the caliper from the mount and away

7

clockwise to loosen it.

NOTE :

N

N

CAUTION :

environments.

The bolt is held in the hub by the self-extracting

cap, and will stay attached to the hub even when

the wheel is removed from the axle spindle.

There is no need to remove that cap from the

hub.

5. Pull the wheel off of the axle spindle.

Take extra measures to protect the L efty axle

spindle from damage when the wheel is

removed. Dents, scratches, or other damage

from a fall or drop to the ground could

severely damage the s pi ndle preventing the

axle bolt from engaging the threads. The fork

could be ruined beyond repair.

Installing the front wheel

OTE :

Remove the front brake caliper from the Lefty

first. The front wheel can not be mounted with

the caliper installed.

1. Apply a light coat of high-quality bike grease to

the inside diameter of the larger cartridge

bearing located in the hub.

2. Apply a thin film of hi gh-quality bike grease to

the axle bolt threads inside the end of the

spindle.

CAUTION :

Take care not to contaminate the brake

caliper, pads, or disc with the grease.

3. Apply a light coat of high-quality bike grease to

the inner spindle axle bolt threads.

CAUTION :

Make sure the spindle (threads and the

spindle shaft) are completely clean before

applying any grease. A dirty spindle or dirt

trapped in grease applied can contribute to

excessive wear of the spindle greatly shorting

its service life.

4. Slide the front wheel onto the axle sp ind le wi th

the disc side of the hub closest to the fork leg.

Be sure to press the wheel straight onto the

spindle; so, the axle bolt th reads will co rrectly

engage with the threads in the spindle.

5. Tighten the front wheel axle bolt (5 mm Allen).

TORQUE : Front wheel axle bolt - 133.0 Lbf•in

(15.0 N•m).

OTE :

It is sometimes easiest to install the front wheel

by positioning the bike horizontally with the

spindle facing up. Then place the hub straight

down onto the spindle, and tighten the axle bolt.

6. Reinstall the brake caliper to the Lefty’s disc

brake mounts. You will first need to slip the

caliper over the brake rotor so that the rotor

runs between the brake pads.

Greasing the threads aids removal if the bolt is

over-tightened accidentally and can prevent

seizure in corrosive or punishing

7. Check to be sure that both brake pads are in

the caliper. Then slide the top caliper bolt into

the upper brake mount, and rota te the bottom

8

Loading...

Loading...