Page 1

Electrical/EFI Service Manual

ATV and Motorcycle

P/N : 5002401

August 14, 2002

Page 2

8/14/02

INTRODUCTION

IMPORTANT NOTICE

You must possess si gni ficant mechanical knowledge, skills, and tool s to pe rfo rm mos t o f the

procedures found in this document.

This manual is written for Cannondale Motorsports Dealers and qualified service technicians.

This is not a comprehensive shop safety manual and should no t be used by anyone who is not

familiar with standard safety practices and service techniques. This manual does include

warnings and cautions (see descriptions above) that if ignored, could result in

SEVERE PERSO N AL IN JURY to the service technician or significant damage to the vehicle rendering it unsafe to operate. Anyone operating an “unsafe” vehicle can be SERIOUSLY INJURED

OR KILLED.

We have done our best to ide nti fy si tuat ion s w here warnings or cautions a re nee ded and wil l

continue to do s o i n f ut ure pu bl i c atio ns . Bu t, YOU must always exercise good judgement, and

follow safe shop practices when performing service procedures as described in this manual.

This manual was accurate at the time of publication. Any supplemental information developed

or written after printing may be available on our web site as a “manual supplement.” Service bulletins and technical notes are also published as required. These are also posted on the website.

You may find that the te chnical terms and part names in this manual differ from published parts

catalogs or microfiche.

ABOUT THE MANUAL

All the procedures in this manual are organized in a numbered (step-by-step) easy to read format with accompanying photographs, line art, torque values and specifications. The numbered steps of a few procedures are likely

to be separate pr o c ed ures th em s elv es . Wh en t hi s is th e c as e, t he nu m be re d ste p will include a page reference

number.

COMMENTS?

Send your comments to: Cannondale Corporation, Technical Publications, 2 Corporate Drive, Bedford, PA 15522

Or e-mail: technical.publications@cannondale.com

3

3

Page 3

© 2002 Cannondale Corporation - All Rights Reserved

IMPORTANT MANUAL INFORMATION

CAUTION:

NOTE:

FAILURE TO FOLLOW THE WARNINGS CONTAINED IN THIS MANUAL CAN RESULT IN SERIOUS INJURY

OR DEATH.

Information important to your safety is distinguished in this manual by the following notations: \

The safety alert symbol means......

“ATTENTION! BECOME ALERT! YOUR SAFETY IS

INVOLVED.”

DANGER

WARNING

Indicates that DEATH or severe injury WILL result

instructions are not followed.

Indicates a pote ntial ha zard tha t coul d result in serio us

injury or death.

A CAUTION indic ates that s pecia l pr eca ution s mu st be

taken to avoid damage to the machine.

A NOTE provides helpful information intended to make

maintenance easier or the instructions presented clearer.

if the

Electrical_EFI Service Manual.fm

4

Page 4

8/14/02

CONTENTS

INTRODUCTION - - - - - - - - - - - - - - - - - - - - - - 3

Important Notice - - - - - - - - - - - - - - - - - - 3

About the manual - - - - - - - - - - - - - - - - - 3

Comments? - - - - - - - - - - - - - - - - - - - - 3

IMPORTANT MANUAL INFORMATION- - - - - - - - - - - 4

ENGINE MANAGEMENT SYSTEM (EMS) - - - - - - - - - 6

Engine Control Unit (ECU) - - - - - - - - - - - - - 6

ECU Programming - - - - - - - - - - - - - - - - - 7

Servicing connectors and couplers - - - - - - - - - 9

Barometric pressure sensor - - - - - - - - - - - 10

Throttle position sensor (TPS) - - - - - - - - - - 10

Coolant temperature sensor - - - - - - - - - - - 12

Air temperature sensor - - - - - - - - - - - - - - 12

Crankshaft position sensor - - - - - - - - - - - - 13

Idle Air Control Valve (IACV) - - - - - - - - - - - 14

Ignition coil- - - - - - - - - - - - - - - - - - - - 15

EMS Power Relay - - - - - - - - - - - - - - - - 15

Fuel pump and fuel pressure regulator - - - - - - 17

Cooling Fan (ATV - - - - - - - - - - - - - - - - 20

CANNONDALE DIAGNOSTIC AND MAINTENANCE TOOL

VERSION 2.0 - - - - - - - - - - - - - - - - - - - - - - - 21

General Information - - - - - - - - - - - - - - - 21

Installation - - - - - - - - - - - - - - - - - - - - 21

In the Windows Explorer, double click the SecurityCode

application. Or, you can access this application by clicking

on Security code.exe through the program group. - - 22

Common Problems- - - - - - - - - - - - - - - - 23

Interpreting Error Messages - - - - - - - - - - - 24

Other Messages - - - - - - - - - - - - - - - - - 25

Communication cable - - - - - - - - - - - - - - 27

Cannondale Diag nos tic and M ai nte nan ce tool Main Window - - - - - - - - - - - - - - - - - - - - - - - - 28

ECU Operating code - - - - - - - - - - - - - - - 29

Calibrations - - - - - - - - - - - - - - - - - - - 37

ECU Monitor - - - - - - - - - - - - - - - - - - - 39

Reading Fault Codes- - - - - - - - - - - - - - - 40

Engine Stop Switch (ATV) - - - - - - - - - - - - 59

Clutch Lever Switch (ATV) - - - - - - - - - - - - 59

Key Switch - - - - - - - - - - - - - - - - - - - - 59

Starter Solenoid - - - - - - - - - - - - - - - - - 59

Starter Motor - - - - - - - - - - - - - - - - - - - 60

Fuses - - - - - - - - - - - - - - - - - - - - - - 60

FAULT TROUBLESHOOTING - - - - - - - - - - - - - - 42

Sensor Supply Voltage- - - - - - - - - - - - - - 42

System Voltage - - - - - - - - - - - - - - - - - 43

Fuel Pump - - - - - - - - - - - - - - - - - - - - 44

Ignition Coil - - - - - - - - - - - - - - - - - - - 45

Cooling Fan (ATV Only) - - - - - - - - - - - - - 46

Fuel Injectors - - - - - - - - - - - - - - - - - - 47

Throttle Position Sensor (TPS) - - - - - - - - - - 50

Air temperature Sensor- - - - - - - - - - - - - - 51

Coolant Sensor - - - - - - - - - - - - - - - - - 53

Idle Air Control Valve (IACV) - - - - - - - - - - - 55

Crankshaft Position Sensor- - - - - - - - - - - - 56

COMPONENT TESTING (NON-EFI)- - - - - - - - - - - - 57

Battery- - - - - - - - - - - - - - - - - - - - - - 57

Rectifier /Regulator- - - - - - - - - - - - - - - - 57

Flywheel - - - - - - - - - - - - - - - - - - - - - 58

Start Button (ATV & Motorcycle) - - - - - - - - - 58

Engine Stop Button- - - - - - - - - - - - - - - - 58

5

5

Page 5

© 2002 Cannondale Corporation - All Rights Reserved

ENGINE MANAGEMENT SYSTEM

NOTE :

(EMS)

Engine operation is supported by the management

system consisting of three main types of electrical

components: the ECU, the sensors, and the actuators.

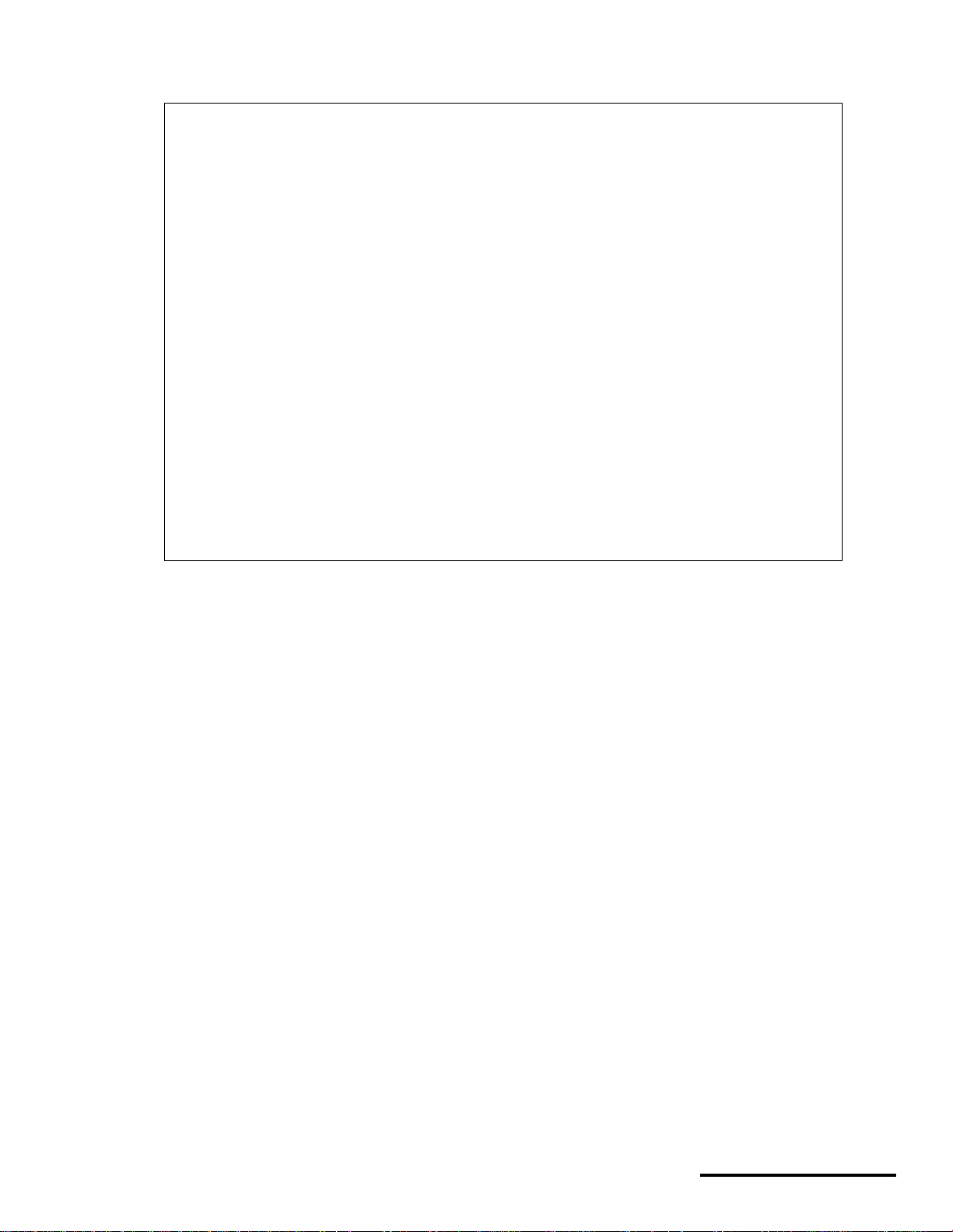

Motorcycle ECUs are located within the subframe.

3

1

• The engine control unit (ECU or ECM) precisely

calculates ignition timing and fuel delivery for al l

engine speeds and loads (based on the

currently installed calibration file and its

mapping). The ECU is an extremely reliable

component and should be the last component

checked in the event there is a problem with the

fuel injection system.

• The sensors of the system collect engine

operating information and transmit it to the

ECU.

• The actuators are devices like the fuel injec tors,

fuel pump, fuel pressure regulator, and spark

plug coil, and relays.

ENGINE CONTROL UNIT (ECU)

The engine control unit or “ECU” is a kind of computer that calculates ignition timing and fuel delivery

for all engine speeds and loads based on its programming. It is s om eti me s r efe r red to as th e “br ai n”

of the fuel injection syste m . Thi s brai n ca lc u la tes fuel

delivery and ignition timing based on information

gathered from ve hi c le sensors (inputs) a nd th e ca l ibration file loaded at the factory.

2

1. ECU

2. Air pressure sensor hose (from airbox and fuel pressure

regulator)

3. Internal barometric (air) pressure sensor.

A TV ECUs are located on the electronics tray under

the cowl.

4

3

1

2

3

The ECU inputs are the air temperature, coolan t,

crankshaft position, throttle position, and barometric

pressure sensors. Information from these sensors

together with the ECU operat ing code ( hex file) an d

engine calibration file (map) are used to control the

system actuators (e.g. fuel pump, ignition coil,

injectors, relays, idle air con trol valve).

In this manual, the engine control unit is referred

to as the “ECU.” It is also sometimes called an

“ECM” or engine control module. Ei ther reference

is OK.

Electrical_EFI Service Manual.fm

1. ECU

2. Air pressure sensor hose (from airbox)

3. Accessories connector

4. EMS power relay

6

Page 6

8/14/02

ECU PROGRAMMING

The ECU is “programmed” with three types of information. the operating code (also known as the “hex”

file, the engine calibr ation file (also kn own as t he

“map”), and the vehicle variables or “calibrations.”

Calibrations are stored in the map file but are specific

to the throttle body and injectors installed on the

vehicle.

of the ATV.

The tool is a combination of a specially developed

Windows- based software program and a data cable

used to connect your PC or pocket PC computer to

your vehicle. With the tool, you can read fault codes,

install engine calibration fil es, set v ehicle rpm , and

monitor engine operating parameters.

Any programmed information can be changed.

using the Cannondale Diagnostic and Maintenance

Tool. Refer to "Cannon dale Diagnostic a nd Maintenance Tool Version 2.0" starting on page 21.

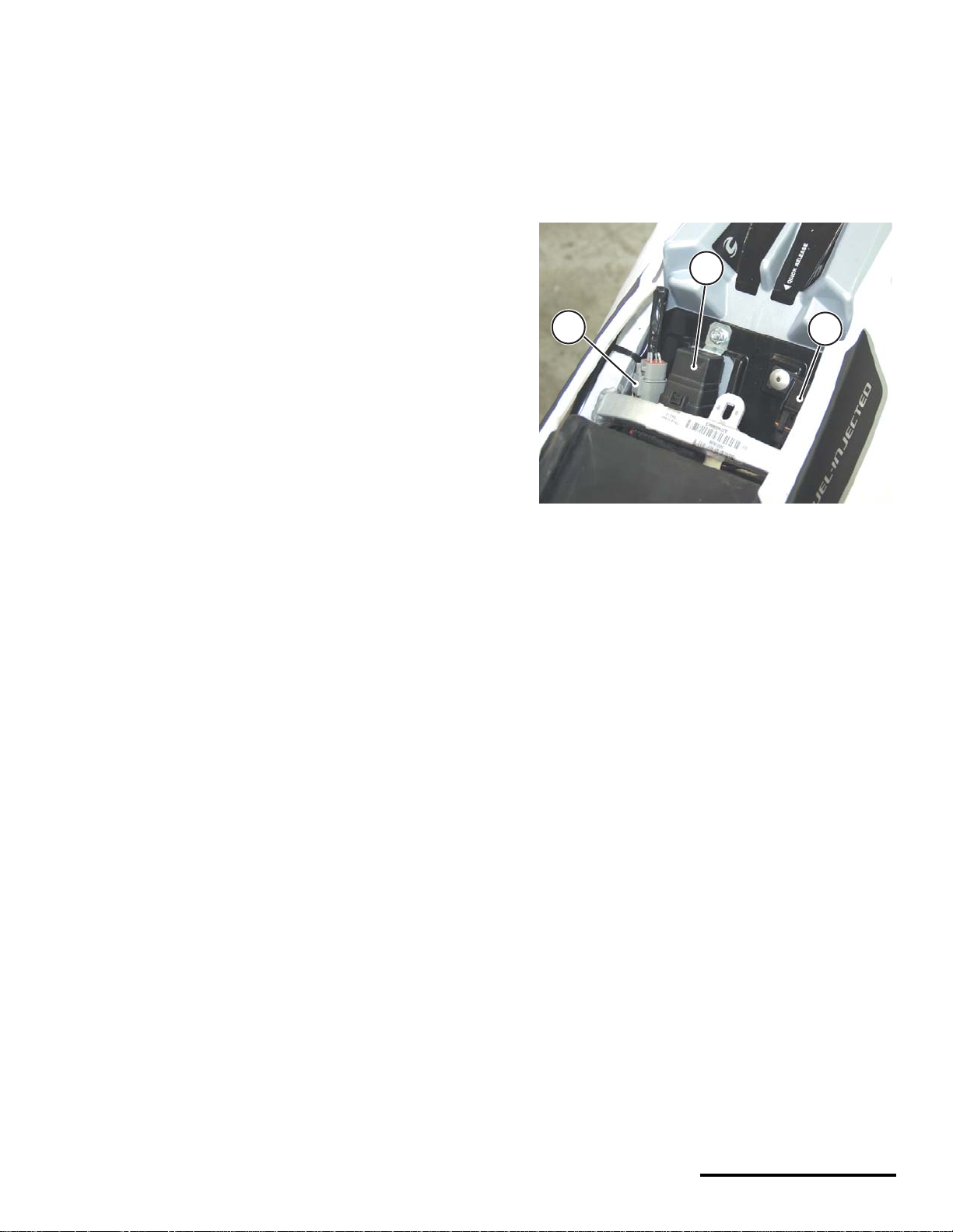

ECU diagnostic connectors

ATVs and motorcycles have a diagnos tic connector to connect the software tool PC to the vehicle.

• On 2001 and 2002 Motorcycles, the diagnostic

connector is located near the ignition coil on the

top of the cylinder head.

• On 2003 motorcycles, the diagnos tic connector

is located near the main fuse under the seat.

• On 2001 - 2003 ATV the diagnostic connector is

located near the radiator shroud on the left side

2

1

1. Diagnostic connector

2. EMS power relay

3. Main fuse

3

Reporting system faults

The ECU is capable of reporting system hardware

malfunctions during operation. It reports current

problems and does not store problem “faults” in

memory.

System faults are read from the ECU using the

Cannondale Diagnostic and Maintenance Tool, a

Windows-based PC pro gram enabling c ommunication between a PC and the vehicle ECU. The ECU

does not store intermittent fau lts; the fa ults repor ted

are occurring at the mom ent when the ECU Fault

Report windo w is s elect ed i n th e s oftwa re to ol. A

special commu nicati on ca ble is neede d to co nnect

the vehicle to a PC. Refer to "Cannondale Diagnostic and Maintenance Tool Version 2.0" starting on

page 21.

This manual provides step-by-step fault diagnostic

testing based on the ac tual fault repor ted by the

software tool. Refer to "Fault Troubleshooting"

starting on page 42.

7

7

Page 7

© 2002 Cannondale Corporation - All Rights Reserved

P1 and P2 Connectors

H

Pin identification (P1 or P2)

MC1000 ECUs have two main harness connector

sockets.

Remove both main harness connectors from the

ECU when performing pin point tests described in

this manual.

Also, if requir ed, be su re t o d iscon nect any oth er

devices; see the specific pin point tests.

• Connector P1 color is bl ack. It connects to the

black ECU socket.

• Connector P2 color is grey. It connects to the

grey ECU socket.

CAUTION:

Allow connector rotating latch to draw the

connector into the ECU socket (coupler) . Do not

press or force the connector; it should slide

into the socket easily.

Check for contamination and pin condition

before reconnecting.

Lubricate the connector seals with a highquality dielectric grease before reinstalling.

Use a commercially available pin gauge when

performing pin point tests. Ordinary tester

probes can spread pins resulting in loose

connections.

Use the following illustration for P1 and P2 pin iden-

tification.

H

G

F

E

D

C

B

A

1

2

3

4

H

G

F

E

D

C

B

A

This photo shows how to identify individual pins in the ECU

harness connectors. Each row is identified by a number 1-4.

Each column is identified by a letter A - H.

Disconnecting the ECU

1. Disconnect the battery.

2. Press in the latch lo cking tab and rotate the latch

in direction (a) until it stops. Pull the connector

from the ECU socket.

1

Electrical_EFI Service Manual.fm

1

a

1. Latch

2. Locking tab

Reconnecting the ECU

1. Make sure the battery is disconnected.

2. Make sure the main fuse is removed.

8

Page 8

8/14/02

3. Align the latch groove and tab on the ECU socket.

Rotate the latch in direction (b) until the latch is

locked by the locking tab. The latch should operate freely with your fingers; do not force it.

2

Cleaning

1. Wipe the connector or coup ler with a clean, lintfree rag and blow off any moisture using

compressed air.

2. Remove corrosion, rust, stains or other foreign

material by using contact cleaner on the terminals.

3. Apply a water-displ acement chemi cal on connec tor seals.

1

1. Latch

2. Tab

SERVICING CONNECTORS AND COUPLERS

Many electrical problems could be caused by faulty

electrical connectors or couplers. Check for the following conditions before beginning any diagnostics:

• wet terminals/pins

• dirty or corroded terminals/pins

4. Apply a light coat of dielectric grease onto the terminals/pins, and properly connect the halves.

Disconnecting

• Release any locking device fir st.

• Do not pull the leads.

Connecting

• Inspect for bent terminals/pins, damaged c able

terminal/pin joints, water, dirt, or corrosion, and

secure wiring. If a terminal or pin is bent,

carefully straighten it with a thin-blade

screwdriver.

• Before joining or connecting, check for dirt or

corrosion

• Push male and female ends together squarely

to avoid incorrectly locating or bending the

terminal pins.

• broken bent cable pins within multi-plug

couplers

• terminal pins backing out of the connector or

coupler

Connector - a single male lead that connects into a

single female lead.

Coupler - multi-pins and usually have some sort of

locking device (e.g., barb, hook, eye) which must be

released before the two halves can be separated.

• Whenever a connector or coupler is

disconnected or checked, be sure to clean it

and apply some dielectric grease before

reconnecting.

• Make sure the two halves connect positi vely.

9

9

Page 9

© 2002 Cannondale Corporation - All Rights Reserved

BAROMETRIC PRESSURE SENSOR

NOTE :

NOTE :

N

The barometric pressur e sensor is housed within

the ECU. Air pressure within the airbox is transferred

to the ECU by a narrow hose. Air pressure information is used to adjust the amount of injected fuel to

match the prevailing conditions. The sensor is not

user serviceable. If no external problems are found

with the hose or the hose routing end points, and a

barometric pressure sensor fault persists, the ECU

will have to be replaced.

When performing tests, start by checking the hose

routing from the ECU to the airbox. The routing

may be interconnected with other devices. Be sure

to check all vacuum/pressure routing hoses for

damage.

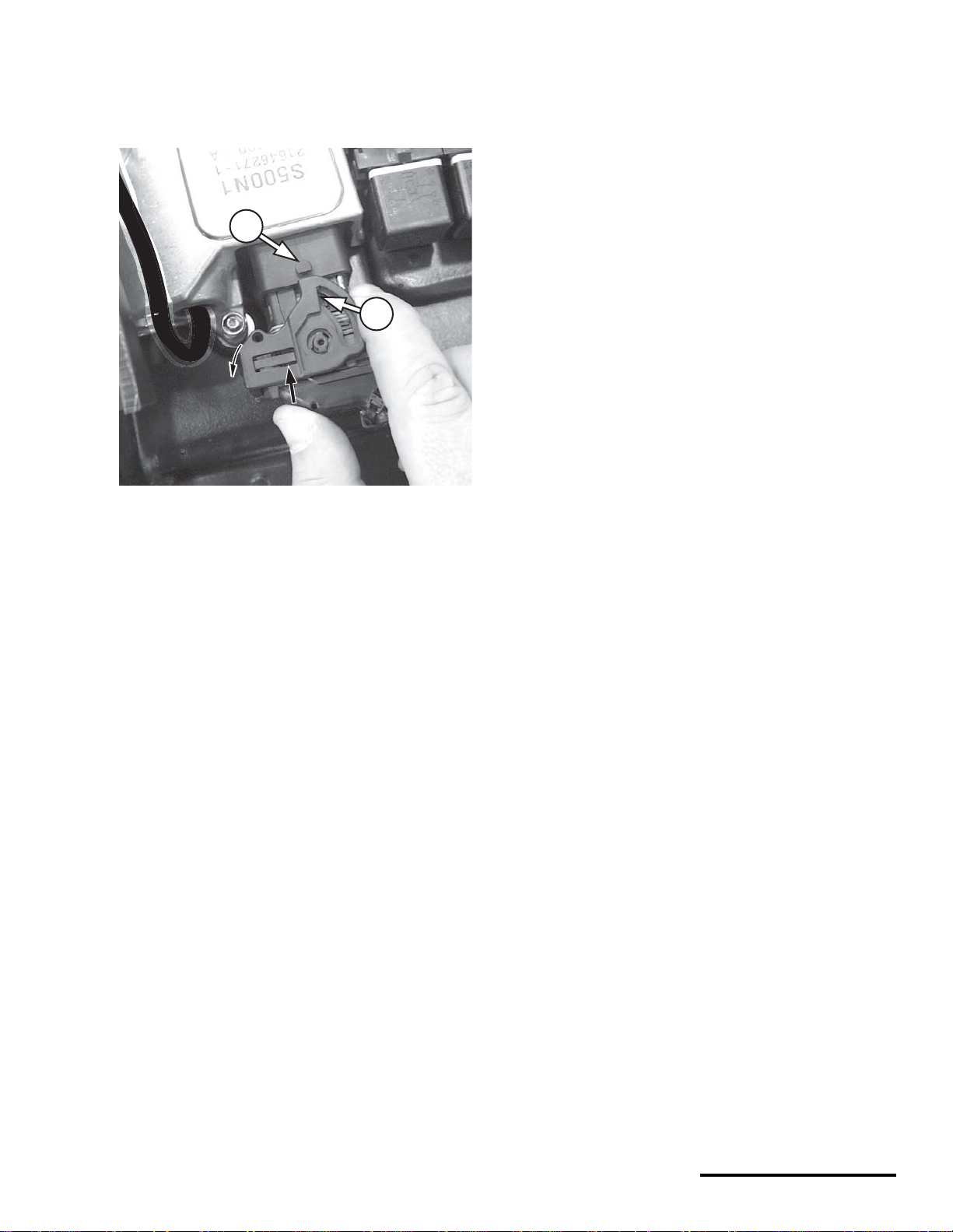

THROTTLE POSITION SENSOR (TPS)

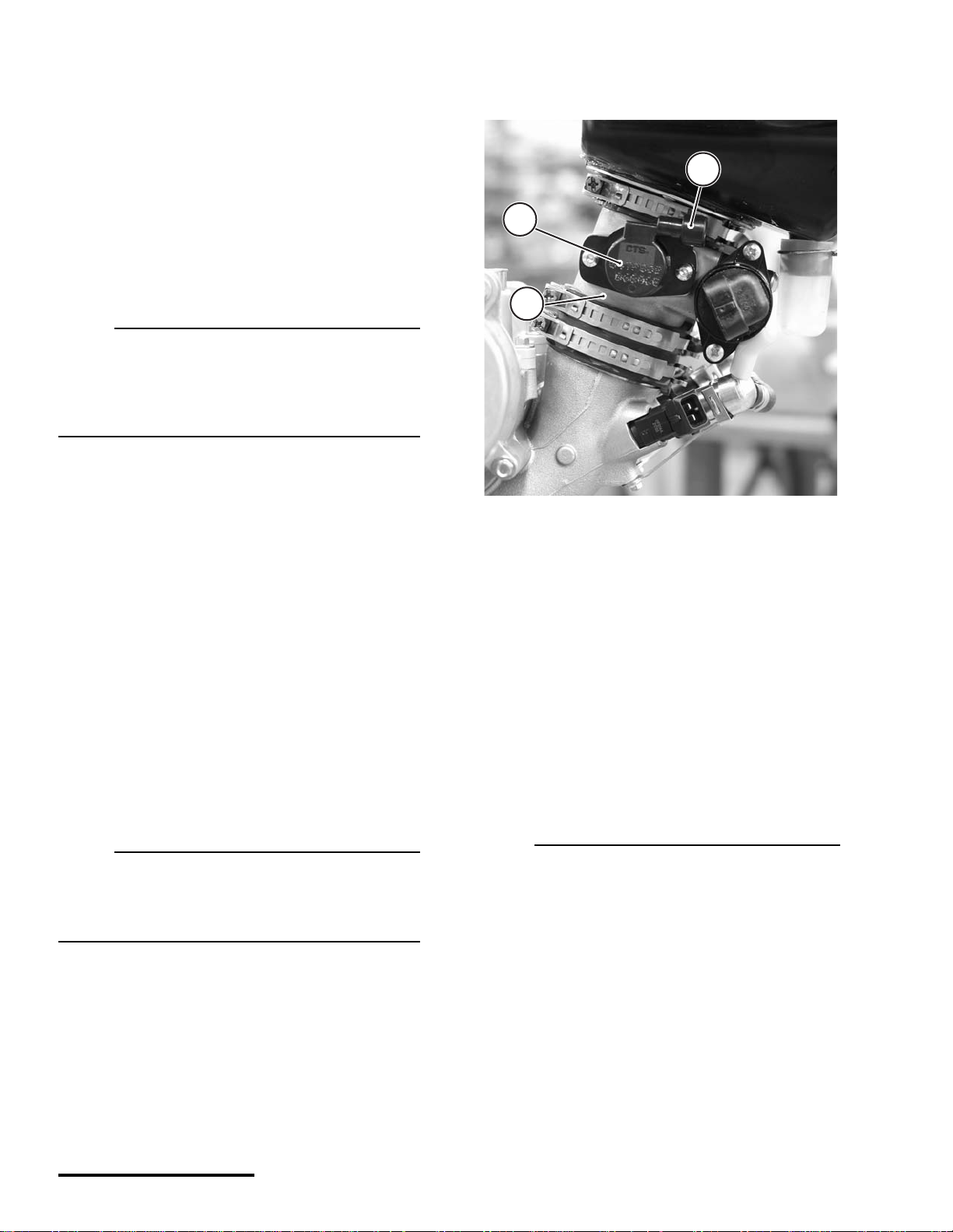

3

1

2

Dynamic Test - ECU Monitor

1. To test, determine the barometric pressure at

elevation in the operating area.

2. Read the reported sens or data with the Cannon-

dale Diagnostic and Maintenance Tool. This value

is reported at the “ Airbox Pressure (k Pa)” field in

the ECU Monitor window. Refer to "ECU Monitor"

starting on page 39.

3. Compare the known value with the one repor ted

by the software tool. If the comparison of the

actual value and the reported value results in a

wide dis pa ri t y, and no ot he r fa u lt s ar e present and

engine trouble remains, consider replacing the

ECU.

When comparing the actual barometric pressure

reading and the one reported through the

software, be sure to convert to equivalent units

(kPa).

1. TPS Sensor

2. Throttle Body

3. Harness connection point

The throttle position sensor (TPS) is a rotary potentiometer attached to the end of the throttle plate shaft

on the right side of the throttle body.

Fueling requirements are calculated by the ECU for

changing throttle positions.

The fully closed and fully open thr ottle positions

(interpreted by the minimum and maximum voltage

read through the sensor) are stored as numeric

values in the ECU.

OTE :

Anytime the throttle body is servic ed or the sensor

is removed or replaced, the min/ma x values must

be re-read into the ECU using the Update

Calibrations window of the tool.

Electrical_EFI Service Manual.fm

Use the Cannondale Diagnostic and Maintenance

Tool.

Refer to "“Throttle Body Leakage” (also called

Throttle Body Offset) (Input range 0 - 100) The

equivalent amount, in percent, of throttle openi ng

10

Page 10

8/14/02

required on a “perfect” throttle body to match the

N

N

air flow of the vehicle's throttle body at the closed

position. Typical values are from 0.0 to 1.0%"

starting on page 37.

The TPS sensor signal informs the ECU of not only

the relative position of the throttle plate, but also the

speed with which it is being opened or clos ed. The

engine load is determined by the TPS and engine

speed (rpm). The voltage output from the TP S

increases proportionately as the throttle is opened.

The sensor contains no user serviceable items.

Dynamic Test - ECU Monitor

1. Use the ECU Monitor windows of the Cannondale

Diagnostic and Maintenance Tool and read the

Throttle position (%) fi eld . T his field is the percent

the throttle plate is open as translated by the

ECU. With the throttle plate completely closed,

this value shoul d read between 2% to 3 %. When

the throttle is fully opened, a normal reading is

97% to 100%. When the idle adjustment is set,

this value should be approximately 3% higher

than the completely closed percent to achieve

rough idle. Fine tuning of the idle adjustment

screw which changes the% percent may be

required

If the Throttle Position (%) field values in the ECU

monitor window are erratic or inconsistent as

described above, the sensor can be tested further

by removing it and reading the resi stance values

with an Ohmmeter.

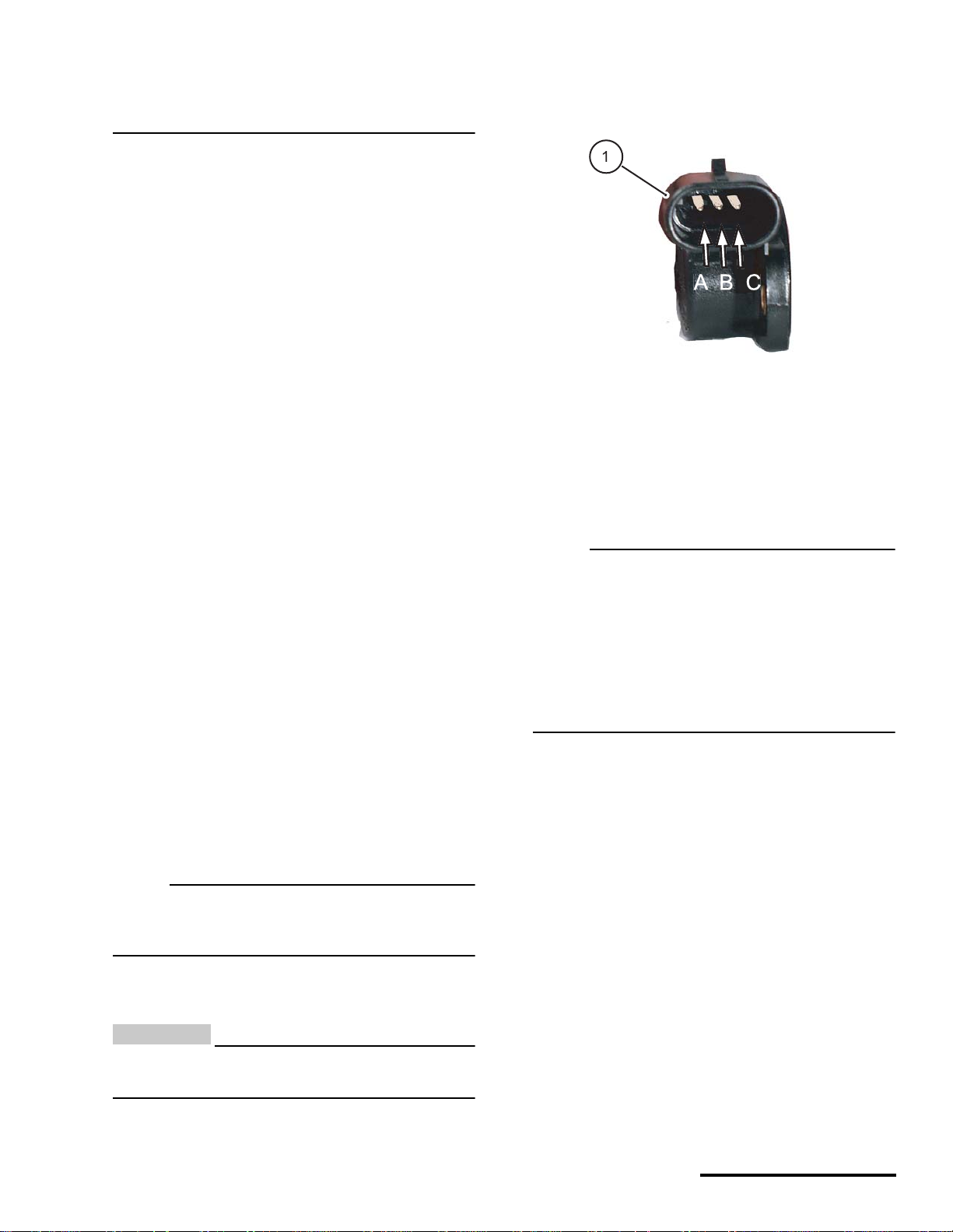

Static Test - Resistance

1. TPS sensor (shown removed)

1. To test the sensor resistance, remove the sensor

harness connector, remove the mounting bolts,

and remove the sensor from the throttle body.

OTE :

Removing the sensor from the throttle pla te shaft

to measure the resistance is not required.

Removing it and inspecting the housing and shaft

socket for damage can be helpful. Remember that

is the sensor is removed, you will have to reset the

sensor min and max values using the software

tool. Refer to "Setting the throttle position sensor

minimum and maximum values" starting on

page 34.

2. Attach a vacuum pump/pressure pump to the

hose end and monitor change. The reading

should increase when increased pressure is

applied. The reading should decrease when vac uum is applied.

OTE :

Be sure to convert the atmospheric pressure units

displayed in the ECU monitor window with units

displayed with the tools.

CAUTION:

Use of high pressure or vacuum when testing

may damage the sensor diaphragm.

11

11

2. Measure resistance across sensor terminals A

and B.

The resistance should be 1200 ± 240 Ohms.

3. Measure the resistance across sensor terminals

A and C.

- slowly rotate the sensor wheel clockwise and

observe variable resistance. Resistance should

increase smoothly from 0 to 1200 ± 240 Ohms.

Page 11

© 2002 Cannondale Corporation - All Rights Reserved

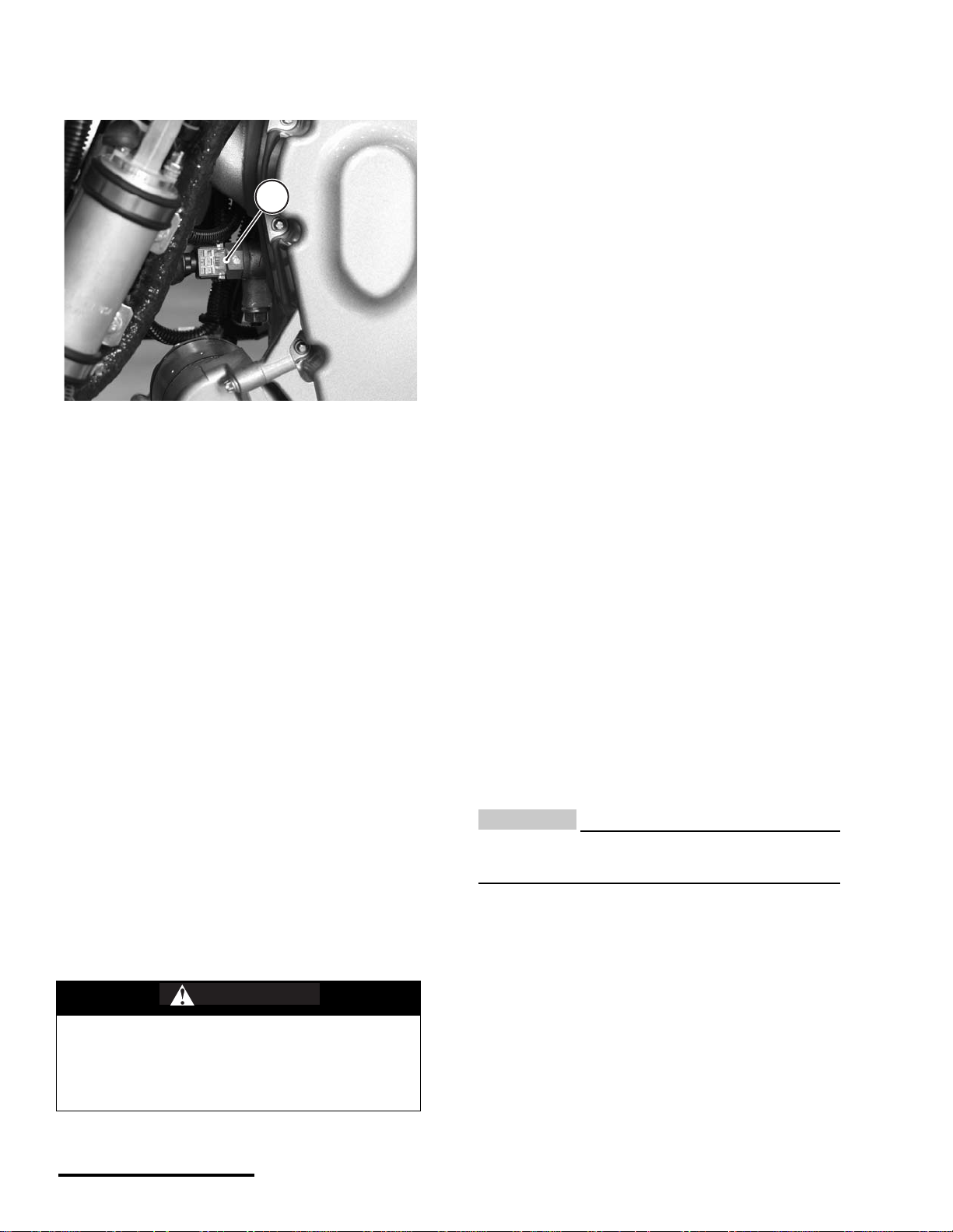

COOLANT TEMPERATURE SENSOR

G

1

1. Coolant temperature sensor (ATV shown)

The coolant temperature sensor is brown in color

and located on the front of the engine cylinder head.

It is an NTC thermistor.

3. Compare the values . If the two va lues do not cor respond closely, the sensor may be damaged. Go

to the next step.

4. Be sure to repl ace the radiator cap a nd start the

engine and allo w to reach operating temperature

(60°C). Observe the Engine Temperature (degC)

field in the ECU Monitor window. If the value does

not increase as the eng ine warms, go to the next

test.

Static Test - Resistance

1. Disconnect the sensor harness connector.

2. Use an Ohmmeter to measure the sensor resistance between terminal s 1 an d 2 . Refe r to " Coo lant Sensor Resistance Range" starting on

page 54. If measured resistance is inconsistent at

the tested temperature r eplace the sensor. If the

sensor is OK, the sensor harness wiring or the

ECU itself may be damaged. Take corrective

action.

The ECU measures the current flow through this

thermistor to groun d and u ses it to det ermin e the

engine coolant temperat ure. The ECU calculates

fueling to optimize engine performance at all tempe ratures. It also calculates hot and cold start fueling

requirements.

The sensor resistance decreases as the temperature increases.

Dynamic Test - ECU Monitor

1. Starting with a completely cool engine, use the

ECU Monitor window of the Cannondale

Diagnostic and Maintenance Tool to read the

Engine Temperature (degC) field in the ECU

Monitor window. Refer to "Using the ECU

Monitor" starting on page 39.

2. Open the radiator cap and tes t the coolant tem-

perature with a thermometer.

WARNIN

Never open the coolant system when the

engine is hot. Coolant is hot and under

high pressure. It can spray out forcefully

and burn or scald you severely.

AIR TEMPERATURE SENSOR

The intake air temperature sensor is attached to the

airbox with the tip mounted inside the airbox.

It is a NTC thermistor and green in color.

Resistance will drop as temperature rises.

The sensor tip is very sens itive to temp erature

change.

CAUTION:

The tip can be damaged easily; use extr a care

when installing or working inside the airbox.

The ECU uses the information from this sensor to

calculate the fuel necessary for a given air temperature.

Dynamic Test - ECU Monitor

1. Use the ECU Monitor window of the Cannon dale

Diagnostic and Maintenance Tool to read the

Engine Temperature (degC) field in the ECU

Monitor window. Refer to "Using the ECU

Monitor" starting on page 39.

Electrical_EFI Service Manual.fm

12

Page 12

8/14/02

2. Compare the value with a reading taken manually

N

in the vicinity of the ai r temperature tip. If the two

values do not corre sp ond clos el y, the sensor may

be damaged.

Static Test - Resistance

1. Remove the sensor from the ai rbox by pl acing an

open-end wrench o n the sen sor body and turni ng

it counter-clockwise until it can be removed.

This senso r de te cts mo ve me nt of a toothed whee l

that is molded into the flywheel and attached to the

right side of the crankshaft. The wheel has a 36-tooth

pattern. The flywheel teet h are ev enly s paced wi th

the exception of one, tri ple -leng th to oth next to one,

triple-length gap. Everytime this tooth/gap passes the

sensor, the ECU interprets i t as b ott om de ad c en te r

(BDC). The EC U u s es t hi s i nf orm ati o n t o de ter m i ne

engine speed and crankshaft p osition i n relation to

the point where fuel is injected and ignition of the air/

fuel mixture occurs.

2. Measure the sensor resistance between terminals

1 and 2. Refer to "Air Temperature Sensor Resistance Range" starting on page 52.

If the measured res istance is inconsistent at the

tested temperature, replace the senso r.

If the measured resistance closely matches the

table values, the sensor is OK, the sensor harness wiring or the ECU it self may be damaged.

Take corrective action.

CRANKSHAFT POSITION SENSOR

1

If the crankshaft position sensor malfunctions, the

engine will not start. If the sensor tip is contaminated

with metallic debris, oils and dirt, or incorrectly

gapped, the engine can run erratically.

If the flywheel is damaged, the sensor may be ok,

but may be reading bad information due to the

resulting change in the ind e xing betwe en th e c ra nkshaft and flywheel teeth. Refer to "Flywheel" starting

on page 58.

OTE :

Metallic debris or other contaminants on the

sensor tip will affect the sensor.

Inspection points

1. Ensure sensor connection to harness is secure.

2. Check sensor gap: 0.5mm-1. 0mm .

a

2

The flywheel cover has been removed for this photo to show the

sensor tip.

1. Crankshaft position sensor

2. Sensor tip

3. Flywheel tooth

4. Gap

SERVICE: Crankshaft position sensor gap

0.02 - 0.03 in (0.5 -1.0 mm)

The crankshaft position sensor is located in the

generator housing.

3. Check for magnetic debris on sensor tip.

4. Check for damaged flywheel teeth.

5. Check flywheel for run-out or play.

6. Check flywheel hub for cracking o r separati on.

Dynamic Test - ECU Monitor

1. Use the ECU monit or window to confirm change

in reported engine rpm.

With the engine off, there should be no reading

displayed at engine rpm field.

Crank the engine over and a reading should be

displayed. If no change is observed, the sensor or

harness circuit is faulty. Take corrective action.

13

13

Page 13

© 2002 Cannondale Corporation - All Rights Reserved

Static Test - Resistance

N

1

1. Disconnect the sensor harness connector.

2. Use an Ohmmeter to mea sure the sensor resistance between terminals 1 and 2.

SERVICE: Crankshaft position sensor

resistance range - 532 TO 588

Ohms

In a cold engi ne, th e val ve ope ns (ar m retr acts)

allowing more air to bypass the throttle plate. As the

engine warms up, th e valv e closes (a rm extend s)

until the bypass channel through the housing is completely shut at 60°C.

Here are some symptoms of a faulty IACV

• Hard starting - the valve arm could be stuck

shut. In this case, the extra air needed for cold

starting conditions is not available. Enough air

may be available to start a warm.

IDLE AIR CONTROL VALVE (IACV)

1. Idle Air Control Valve (IACV)

The Idle Air Control Valve (IACV) is an ECU c on-

trolled valve mounted on the throttle body.

As soon as the ECU is powered up, this valve

begins to move to the correct position (increasing or

decreasing the available air bypass volume needed

for cold start). The ECU co ntrols the valve arm

depending on engine temperature. The valve arm

moves in “steps” that extend or retract the valve arm

inside the bypass housing.

• Engine idles too fast - valve is s tuck open.

• Rough idle - if the valve arm is malfunctio ning

Dynamic Test 1 - ECU Monitor

1. Make sure the engine is completely cool.

2. Use the Cannondale Diagnostic and Maintenance

Tool to read current valve stepped position with

the cool engine.

Read the valve posi tion at IACV Stepper Positio n

field in the ECU Monit or wind ow. Refer to "Usin g

the ECU Monitor" starting on page 39.

OTE :

Make sure the monitor is in “continuous” m ode.

3. Start the engine and allow to it idle normally.

Observe the IACV Stepper Position and Engine

Temperature ( degC ) fie ld s. As the engi ne temperature climbs, the IACV Stepper Position should

increase indi cating that the arm is extending and

the bypass channel in side the housing reducing.

At engine operatin g temperature (60°C) the arm

should be fully extended and the bypass closed.

4. If no change is observed, go to Dynamic Test 2.

The arm travels.024mm per step.

Total travel = 0 to 255 steps

IACV Stepped positions

Fully Open Fully Closed (at 60°C)

175 205

Electrical_EFI Service Manual.fm

Dynamic Test 2 - Confirm arm movement

1. Make sure the vehicle engine is compl etely cool

and press the engine stop button to ensure that

the ECU is powered down.

2. Remove the bypass housing from the throttle

body with the IACV valve attached to it.

14

Page 14

8/14/02

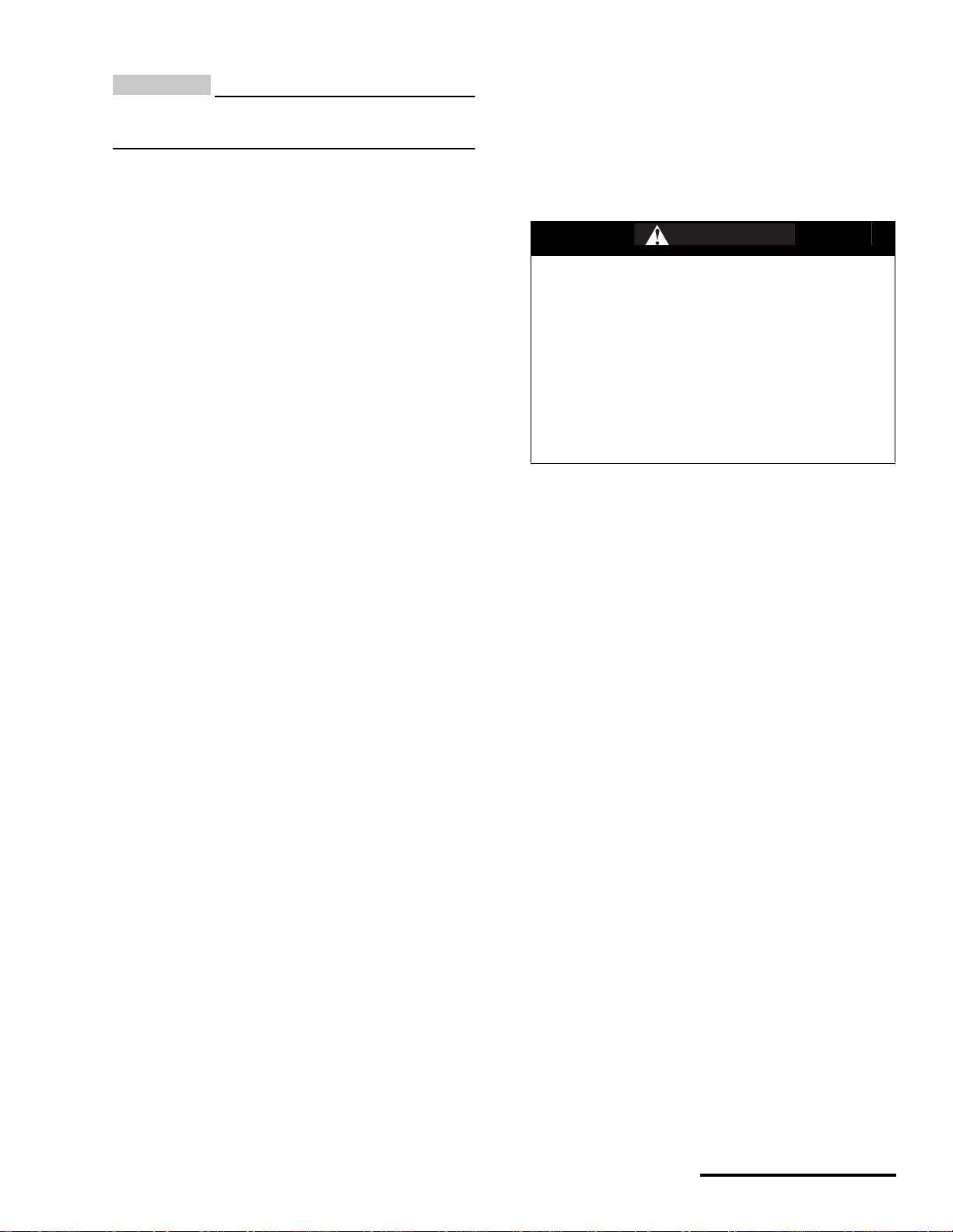

CAUTION:

G

3. Check the co ndi tio n of the tip in sul ator. Make sure

it is not cracked, burned, melted, dried out.

Do not remove the valve from the housing whe n

performing this test.

3. Disconnect the engine coolant sensor.

4. Reconnect the idle air control valve to the harness.

5. Press the engine s tart button quickly without tu rn ing over the engine. The valve should extend fully.

6. Reconnect the coolant sensor and observe movement of the valve arm; the valve should retract

slightly.

If the valve does not mov e, replace it with a new

one.

Static Test - Resistance

1. Remove the valve moun ting screws and remove

the valve from the bypass housing.

2. Inspect the housing pintel seat and valve pintel

end for damage.

4. Make sure the spring is installed with the larger

end facing the coil.

Dynamic Test - Spark Occurrence

WARNIN

An energized ignition coil generates a

high voltage spark capable o f jumping to a

ground point. The following procedure will

create a spark that can ignite any available

fuels. You can be seriously injured or killed

in a resulting fire or explosion.

Make sure the work area and vehicle are

free of any gasoline or flammable liquids

(flooded engine, fuel tank, fuel hoses, solvents).

1. Disconnect the ignition coil from the harness

connector.

2. Remove the retaining clip bolt and coil retainer.

3. Lift the ignition coil out of the cylinder head.

3. Measure resistance across sensor terminals (A)

to (D). The resistance shoul d be 53

4. Measure resistance across sensor terminals (C)

to (B). The resistance should be 53

± 10% Ohms.

± 10% Ohms.

IGNITION COIL

The ignition coil is a “pencil-type” coil located on top

of the spa rk plug within the cylinder head.

The ECU controls when the coil is switched on or

off. The coil is switched on to allow sufficient time for

the coil to charge to a level w here a spark can be

produced at the spark plug. The coil switches off at

ignition, which is timed for good engine performance.

Inspection Points

1. Check the coil body for damage (e.g., burning,

cracks, discoloration (excessive heat).

2. Check the coil termin al pins. Make sure they are

in good condition.

4. Reconnect the harness.

5. Insert a commercially available spark tester into

the end of the coil. Connect the ground lead of the

indicator to the cylinder head.

6. Turn the ignition switch o n and press the engine

start button. If spark is indicated, the coil is OK.

Static Test - Primary Resistance

1. Measure the res istance between t he coil termin al

pins.

EMS POWER RELAY

The EMS power relay supplies the ECU with power

when the vehicle start button is pr essed and will

remain locked when the engine is runn ing. The

relay will hold for up to 2 minutes without the engine

running or turning over, then it will drop power to

ECU.

15

15

Page 15

© 2002 Cannondale Corporation - All Rights Reserved

On motorcycles, if this relay is damaged, the

N

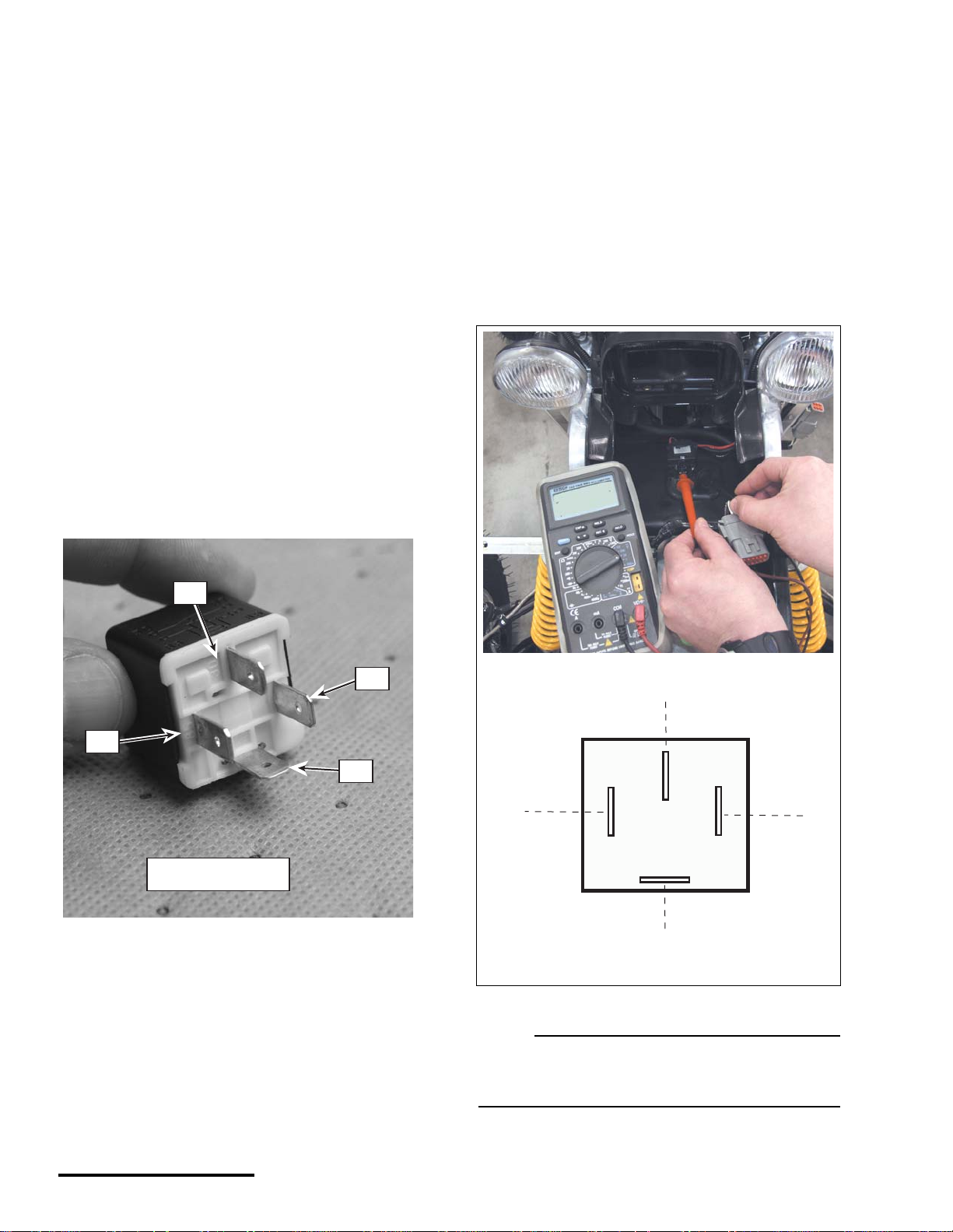

"30"

"85"

"87"

"86"

RELAY - P/N 5000411

engine can start but will shut down when the start

button is released.

number 85. There should be continuity

between terminals 30 and 87. If the re is not,

the relay is damaged; replace it.

On ATVs, if this relay is dam ag e d or r e mo ve d, th e

engine will run, but damage to a harness diode will

result. When the diode fails, the engine will not run.

Dynamic Test

1. Remove the relay from its harness socket.

2. Using an ohmmeter, connect the positive probe

(+) onto terminal number 86 and the negative

(-) probe onto terminal number 85. Check the

resistance. The resistance should be 1500

± 10%

Ohms.

Reverse the meter le ads. If th e readin g is OL (n o

continuity), go to the next step.

If the relay is out of specification, replace the relay

with a new one. If the measured resistance is OK,

go to the next step.

5. Use a voltmeter to verify tha t there is vo ltage

present at the wiring harness socket

corresponding to relay terminal 87. Do not

start the engine. If there is no voltage present,

check the main fuse. Use the vehicle wiring

diagram to check the c ircuit. Take correctiv e

action.

There are no markings on the socket itself;

use the illustration below for identification.

12.5 VDC

3. Using an Ohmmeter, connect the positive

probe (+) onto terminal number 30 and the

negative (-) probe onto terminal number 87.

Check the for continuity. There should be no

continuity. If continuity is observed, the relay

is damaged; replace it. If no continuity is

observed, go to the next step.

4. Connect 12 V (+) battery voltage to the

number 86 terminal and ground terminal

30

85

86

SOCKET

87

OTE :

Wiring diagrams are available on our web site.

http://www.cannondale.com/motorsports/tech/

servman.html

Electrical_EFI Service Manual.fm

16

Page 16

8/14/02

N

OTE :

N

N

N

When the ignition switch is turned “ON,” the

installed relay will make an audible “ clic k.”

FUEL PUMP AND FUEL PRESSURE REGULATOR

The fuel pump and regulator maintain fuel supply

and pressure to the injectors. When the engine management system is first “powered-up,” this pump activates for 3 seconds to pressure the fuel system then

turns off again until the engine starts. When the

engine starts, it resumes pumping, providing pressurized fuel to the injectors. The regulator returns

fuel to the fuel tank.

The fuel pressure regulator maintains the correct

fuel pressure in the fu el rai l ( ho ses an d i nj ect or s ). It

returns fuel to the tank after fuel passes the fuel

injectors. The regulator is connected to the airbox via

a small hose. On ATVs the fuel pressure regulator is

mounted on the main frame on the right side of the

vehicle (front).

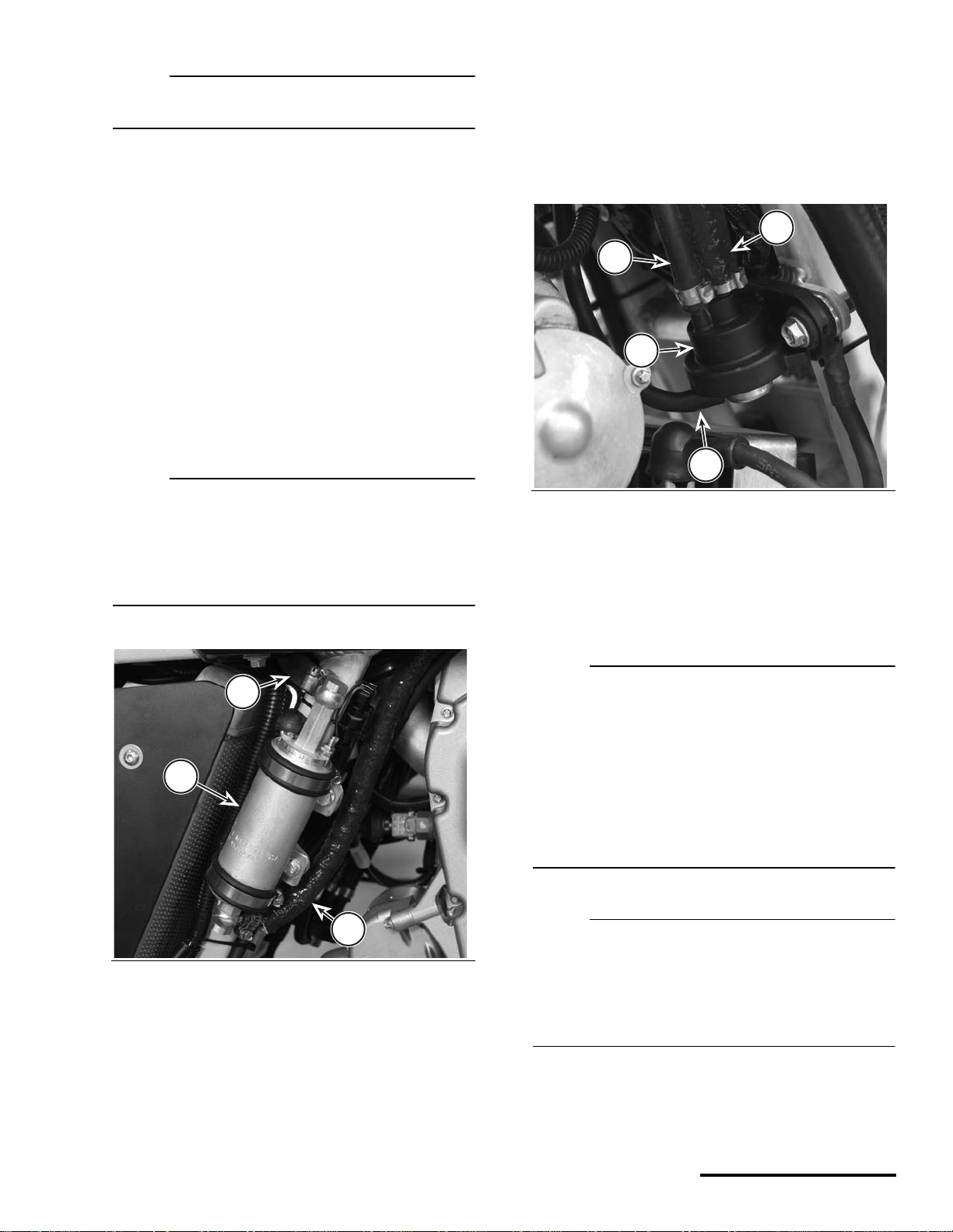

3

2

1

OTE :

The positive (+) pump terminal is always “hot” even with the ignition switch OFF. Thi s terminal is

connected directly to the positive battery voltage

through the main fuse. The pump is acti vated by

ECU switching the negative circuit to ground.

Consult the vehicle wiring diagram for more detail.

3

1

2

1. Fuel pump

2. Fuel inlet (from tank)

3. Fuel outlet (to injectors)

4

Components have been removed for this photo.

1. Fuel pressure regulator housing

2. Fuel hose (from injectors)

3. Fuel hose (return to tank)

4. Air pressure hose (from airbox)

Dynamic Test - Pump and Regulator

OTE :

If you suspect a problem with the fuel pump, first

check to see if it runs at all. Do the following :

Turn the ignition switch “ON” and listen to the

pump, it should make a “whirring” sound for a few

seconds to pressurize the syste m - then the pump

will turn off.

Start the engine and allow the vehicl e to idle. You

should hear a constant whirring” sound - although

it is more difficult to hear.

OTE :

The pump will turn anytime the start button is

pressed on motorcycles, however, the pump

circuit is different is different on ATVs. If the ECU

has not powered down, the pum p will not turn on

unless the clutch lever is pulled in and the start

button is then pressed momentarily.

17

17

1. If the fuel pump does not turn on, check the

following:

Pump wiring terminals. Make sure they are clean

Page 17

© 2002 Cannondale Corporation - All Rights Reserved

and the wiring is in good condition. Make sure the

G

boots are in place.

Check for voltage at the pump when the start

button is pressed. Check for any open or short

circuit conditio ns in the fu el pump ci rcuit. Consul t

the vehicle wiring diagram. Take corrective action

if necessary.

Quick connect fuel fittings - Make sure the O-rings

are in good condition. Damaged O-rings can

result in pressure loss or the introduction of air

into the fuel lines reducing developed fuel

pressure. The fittings have an internal and

external O-ring. Exte rnal O-rings can be chec ked

visually. Fuel flow can be restricted or s top is the

internal O-rings are swollen or damaged.

2. Replace the fuel filter to assure adequate fuel flow

to the pump.

CAUTION:

Do not perform this test with unfiltered fuel;

severe damage can occur to the pump or fuel

injectors.

regulator are OK.

If the fuel pressure reading is low, quickly discon-

nect and reconnect the fuel ta nk return l ine, if the

fuel pressure reading increases when the return

line is disconnected, the regulator is faulty replace

it.

If the fuel pressure does not increase, replace the

pump and regulator.

SERVICE: Fuel pressure

3.0 ±.25 bar

Dynamic Test - Voltage test

1. First, use a multi meter to check for battery

voltage to the pump at the (+) fuel pump terminal.

2. Use an Ohmmeter. Connect the p ositive lead to

main harness connector CN16 pin B. Connect the

negative lead to ground. Have an assistant turn

the ignition switch “ON”. Press the engine start

button and release it.

If there is continu ity, the pum p harness circuit is

OK.

3. Fill fuel tank with the specified fuel as required.

4. Hold a clean rag around the regulator inlet and

loosen the hose clamp to reli ev e any res id ual fuel

system pressure.

5. Install a T-fitting and fuel pressure gauge between

the regulator inlet and hose coming from the

injectors. Make sure the return line attached to

the regulator outlet is con nected to the fuel tank-

tank.

WARNIN

Gasoline is extremely flammable and is

explosive. Handle with extreme care!

When inserting a pressure gauge into the

fuel system, make sure all hose connection are secure. Make sure the fuel tank

outlet and inlet lines are connected properly to the tank.

If there is no continuity, disconnect the ECU and

check for continuity between CN16 pin B and

ECU connector pin P1 H1. There shoul d be cont inuity. Take corrective action and repeat step 2.

If no continuity is present between CN16 pin B

and P1 H1 after the circuit is corrected, replace

the ECU (It is not switching the pump circuit to

ground).

6. Start the engine and read the generated fuel pressure.

If the fuel pressure reading is OK, the pump and

Electrical_EFI Service Manual.fm

18

Page 18

8/14/02

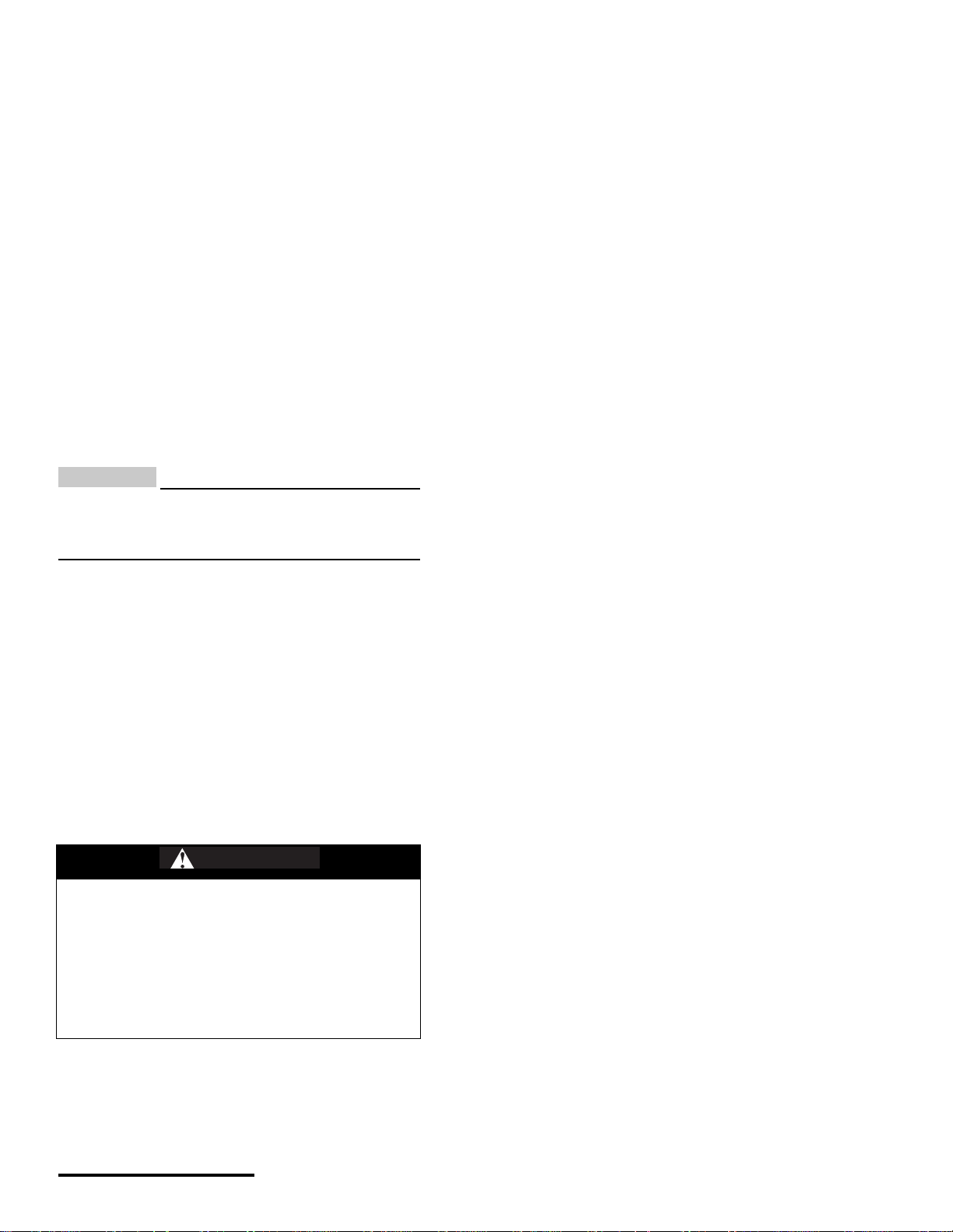

FUEL INJECTORS

N

N

TOP

)

O

G

E

)

CONNECT

O

G

Engine shown removed for clarity.

1. Left fuel injector

2. Right fuel injector

3. Fuel inlet (from fuel pump outlet)

4. Fuel outlet (to pressure regulator)

ATVs and motorcycles utilize a pair of fuel injectors

that operate (inject) simultaneously.

Pressurized fuel flows into the injectors from the

fuel pump. The fuel is delivered into the intake port

when the EC U sends voltage t o the i nj ector internal

solenoid. When th e soleno id actu ates, th e pressurized fuel sprays, through the nozzle.

The fuel injectors are positioned as close as possible to the bac k of the intak e valves. Th e spray

pattern is fixed. The length of time duration that the

injectors stay open is calcul ated b y th e ECU using

the calibration file and data received by the various

sensors.

Dynamic Test - Function

OTE :

The following procedure is based on the

assumption that there is adequate fuel supply and

pressure is available in the fuel rail .

1. Check the injector wiring harness connectors.

Make sure they are secure.

2. Check that the batter y is fully charged. The sen-

sor and actuators of the sys tem depend on accu rate voltage readings to meter the fuel.

3. Check the air filter element. If it is dirty or blocked,

this will severely impede air flow and fuel economy.

4. Check the airbox and throttle body assemblies for

possible air leak s that wo uld resul t in a le aning of

the fuel mixture.

5. Use an automotive stethoscope to determine if

each injector is working properly. You should hear

a steady clicking sound that rises and falls with

the engine speed.

NOZZL

FUEL EXIT

1. Fuel injector (left or right)

-RIN

FUEL ENTRY

-RIN

If you hear nothing, use a commercia lly available

noid light to test for voltage present at the harness

connector.

OTE :

If you do not have a stethoscope, y ou can use a

screwdriver against the injecto r and liste n through

the handle.

Static Test - Resistance

1. Disconnect the in jector, and test the resistan ce of

each injector across the terminals. If the

resistance value is out of specification, replace

the injectors as a pair.

SERVICE: Fuel, fuel injector, resistance

11.75 to 12.75 Ohms

2. Install the injector test light (one at a time) into

19

19

Page 19

© 2002 Cannondale Corporation - All Rights Reserved

each injector harness connector. Crank the

NOTE :

G

engine over. If the light flashes evenly on each

connector, voltage is available at the injectors.

3. If the light fails to flash for either injector, check

the fuel injector wiring circ uit for continuity. Co nsult the vehicle’s wiring diagram.

COOLING FAN (ATV

The positive (+) cooling fan terminal is always “hot,”

- even with the ignition switch OFF. This terminal is

connected directly to the positive battery voltage

through the main fuse.

Dynamic Test - Operate

1. Disconnect the main harne ss connector from the

cooling fan coupler.

WARNIN

Spinning fan blades can cause the fan to

jump on the workbench possibly resulting

in severe injury.

If the fan is removed from the vehic le radiator, be sure to secure the cooling fan to

the work bench. And, position the fan so

that the blades can spin freely when energized. Keep your hand clear of the blades

and wear eye protection.

The ECU switches the negative side of the cooling

fan circuit to ground when engine temperature

reaches the ON point. It breaks the ground contact

when the temperature drops to the OFF point. The

ON and OFF points are determined by the ECU

operating code.

Cooling Fan (ECU switching)

ON OFF

85°C 80°C

Consult the vehicle wiring diagram for circuit

details.

Static Test - Resistance

1. Disconnect the main harness connector from the

cooling fan coupler.

2. Measure the resistance between the two fan

leads. The resistance should be less than 1 Ohm;

if it is go to the next test.

2. Connec t a 12 V (+) battery voltage sour ce to

the red fan lead. Connect the 12V (-) lead to

the black fan lead. If the fan runs, it is OK.

Check to make sure the airflow is correct;

there is a flow direction indicator on the fan

housing. Airflow should be drawn through

the radiator from the front of the vehicle to the

back. Go to the next step.

If the fan does not operate normally (e.g.,

stops and starts, or spins slowly or not at all),

replace the fan.

3. Set the multi meter to VDC or Vdc (20 volt

range).

Connect the positive m eter probe to harness

coupler CN22 pin A.

Connect the negative mete r probe to ground.

Battery voltage should be present.

If battery voltage is not present, check the

main fuse or connections to the ba ttery. If the

main fuse and battery connections are OK,

Check for an open or short circuit in the

cooling fan circuit. Cons ult the vehicle wiring

diagram. Take corrective action.

If it is more than 1 Ohm, replace the fan.

Electrical_EFI Service Manual.fm

If the fan circuit is OK, check the coolant

sensor.

If the coolant sensor is OK, replace the ECU.

20

Page 20

8/14/02

CANNONDALE DIAGNOSTIC AND

MAINTENANCE TOOL VERSION 2.0

This section of the manual describes how to use

the Cannonda le Diagnostic and Maintena nce

software tool.

GENERAL INFORMATION

The Cannondale Diagnostic and Maintenance

Tool, Version 2.0 is a Windows-based software application enabling communication with the vehicle ECU.

Use the tool for:

• Changing the ECU operating code or “hex” fil e.

• Installing a new engine calibration file.

Refer to "Sending a cali bration file or “map” to

the ECU - “Changing a map”" starting on

page 34.

3. Follow the installation screens. When the setup

process is complete, the Cannondale Diagnostic

and Maintenance pro gram group will be installed

and a shortcut to the Cannonda le Diagnostic and

Maintenance tool wi ll be placed on the your desk top.

But, before you can use the software, you’ll need

to complete the a uthorization process by making

a telephone call and typing in an authorization

number.

• Receiving the current engine calibration file

from the vehicle ECU to the PC.

• Set the vehicle throttle body and injector

variables.

• Monitor the (vehicle) ECU operating

parameters.

• Read system faults.

A special in te r face c ab le i s ne ed ed to c on ne c t t he

PC to the vehic le onc e the soft ware i s instal le d and

authorized for use.

INSTALLATION

Installing the software

1. Insert the installation CD into the CD drive of your

computer.

Right click on the Windows START button in the

lower left corner of the screen.

Use Windows Explorer, click on the CD drive

containing the Cannondale Dealer Cal software

CD to view the file contents.

2. Double click on the Setup.exe application.

21

21

Page 21

© 2002 Cannondale Corporation - All Rights Reserved

In the Windows Explorer, double click the SecurityCode application. Or, you can access this application by clicking

on Security code.exe through the program group.

When the DealerCal window displays (see next illustration), call: Optimum Power Technology at 1-800-727-9520

(Monday through Friday, (9 am to 5 pm EST) to obtain the security code needed to activate the software.

Electrical_EFI Service Manual.fm

22

Page 22

8/14/02

Enter the Serial provided by the service r ep i n the

N

DealerCal window. Click Next.

Verifying COM port setup

’Device Manager’ Button.

5. Click the ’+’ next to ’Ports’ to expand the available

ports detail. I f there is a red ’X’ or a yellow ’!’ in

front of the Communications Port, a problem

exists with your Port Driver. Contact your Computer specialist to resolve the proble m. If there is

only a connector icon , note the Communications

Port Name (COM1, COM3, etc.) Run your DealerCal software. Under ’File->Change Port’ change

your Active Port to the above Communications

Port Name. DealerCal will retain this setting.

OTE :

NOTE: If your computer only has a USB

connection, you must purchase a “USB-to-Serial

adaptor” in order to use the DealerCal software.

COMMON PROBLEMS

Under Windows 95/98/2000/NT/ME:

1. Click ’Start’ button and select ’Settings->Control

Panel’.

2. From ’Control Panel’, Double-click ’System’.

3. From ’System Panel’, click ’Device Manager’ or

’Hardware’ tab. If clicking ’Hardware’, click the

’Device Manager’ Button.

4. Click the ’+’ next to ’Ports’ to expand the available

ports detail. I f there is a red ’X’ or a yellow ’!’ in

front of the Communications Port, a problem

exists with your Port Driver. Contact your Computer specialist to resolve the prob lem. If there is

only a connector icon, note the Communications

Port Name (COM1, COM3, etc.) Run your DealerCal software. Under ’File->Change Port’ change

your Active Port to the above Communications

Port Name. DealerCal will retain this setting.

Under Windows XP:

1. Click ’Start’ button and select ’Control Panel’.

2. From ’Control Panel’, Double-click ’Performance

and Maintenance’.

3. From ’Performance and Maintenance’, doubleclick ’System’.

4. From ’System Panel’, click ’Device Manager’ or

’Hardware’ tab. If clicking ’Hardware’, click the

Weak vehicle battery

Before using the software to communicate with the

vehicle, make sure the battery is fully charged. A low

battery can allow the ECU power relay may drop

power to the ECU which will stop any communication

between the PC and ECU.

EMS not powered-up

In order to use the tool, power to the engine management system must be ON. This is required

because the software tool “communicates” with the

ECU. If the engine management circuits are OFF, the

software ca nn ot r e ce i v e or t r an s mi t an y information

to the ECU.

Activating or turning on the engine man agement

system differs between vehicle types (ATV or Motorcycle). But, in both types, if the veh icle ECU s ens es

no activity (no engine start or communications

between the PC and ECU) for two minutes, it will

drop the signal vol tage to the EMS power r elay

shutting down power to i tself. If y ou att emp t to se nd

or receive da ta from th e ECU w hile it is “power eddown”, the “Failed to Unlock System 125” message

will display.

When this happens, the all power to the engine

management system is shut off until the engine start

button is pressed again.

23

23

Page 23

© 2002 Cannondale Corporation - All Rights Reserved

The vehicle’s lighting or starting elec tric al s yst ems

NOTE :

are isolated from the EMS power relay supplying the

ECU. Lighting can remain on if the ECU is powereddown. Or, if insufficient battery voltage is present to

hold the EMS relay on, the starter could turn over the

engine, but because the ECU is powered-down, th e

engine would not start.

Motorcycles

1. Press the ON/OFF button to O N. This will enabl e

the engine management system circuits.

2. Next, quickly press an d release the engine start

button without starting the engine. The green LED

on the interface cable wil l light when the engine

management circuits are powered up.

INTERPRETING ERROR MESSAGES

Failed to Unlock System 125

ATVs

1. Turn the ignition switch to the “ON” posi tion, then

switch the Engine RUN/OFF sw itch to the “RUN”

position.

2. Quickly press and rel ease the green start butto n

without starting the engine. The green LED on the

interface cable will light when the engine management circuits are powered up.

On ATVs, after 2 minutes of inactivity (ECU powerdown), the interface cable block green LED will

not go out. It will remain lit as long as the ATV

ignition is in the “ON” position.

The “Failed to Unlock System 125” message

means that the Ca nn ondale Diagnosti c an d Maintenance Tool was not able to communicate wi th the

vehicle ECU. There can be several causes:

• Check the interface cable at the vehicle harness

connector. Make sure the vehicle connector

pins are not bent or broken inside the

connector. Make sure the cable connector and

vehicle coupler are locked together.

• Check the interface cable attachment to the PC.

Make sure the interface cable is plugged in to

the COM port securely.

• Make sure the right COM port is selected. Refer

to "Verifying COM port setup" starting on

page 23 .

• Make sure the vehicle battery is fully ch arge d.

• Make sure the vehicle engine management

system is powered-up. See page 23.

• Click “OK” and start again.

Electrical_EFI Service Manual.fm

• If the “Failed to Unlock System” message

displays repeatedly, the vehicle ECU or

24

Page 24

8/14/02

interface cable may be damaged.

I/O Error Message

1. You wil l see th is mes s age if th e la st e ngi ne ca libr at ion fil e op ene d wit h the s oft war e i s no lon ger av ai lab le suc h

as: if it was deleted or the CD containing it has been removed from the CD drive.

OTHER MESSAGES

Progress Indicator

Whenever data is bei ng tr an sf er red between the vehicl e ECU and the PC, a progr ess i ndi cato r di sp la ys in the

upper right area of the mai n s c reen . Da ta tran sf er s sh oul d take no mo re tha n 1 mi nut e. If the pr og ress i nd icator

freezes for a long time, close the Cannondale Diagnostic and Maintenance Tool software and try again, Make sure

the cables are connected properly and that the vehicle battery is fully charged.

25

25

Page 25

© 2002 Cannondale Corporation - All Rights Reserved

Retrying Checksum

Data is transferred between the vehicle and PC in small “packets” or chunks. During the transfer process, checks

are performed by the diagnostic tool (software) to en sure th at the data is not damaged during the transfer. Each

small packet is checked during the transfer. If data errors are detected in the packet, the message “Retrying

Checksum...” will display in the progr ess indicator:

Typically, this is due to electrical “nois e” or o ther i nte rfere nc e du ring the pr oc ess. Th e di ag nostic to ol wil l k ee p

trying automatically.

Electrical_EFI Service Manual.fm

26

Page 26

8/14/02

COMMUNICATION CABLE

N

3

Connecting the communication cable

Motorcycles and ATVs have a “diagnostic” connector integrated into the main wiring harness. The

communication cable connects the PC to the vehicle

using the connector.

CAUTION:

Connect the communication cable with the

vehicle engine management system OFF.

On 2001 and 2002 Motorcycle models, the diagnostic connector is located near the ignition coil at

the top of the cylinder head. Vehicle components

must be removed to access the connector.

On 2003 Motorcycles, the diagnostic connector is

located near the main fuse under the seat.

On 2001 - 2003 ATV, the diagnostic connector is

located near the radiator shroud under the front

fender on the left side of the ATV.

1

1. Serial connector (PC)

2. LED

3. Cable

4. Connector (vehicle)

OTE :

Check the diagnostic connector pins for any

bending or damage before connecting to the

vehicle.

27

27

Page 27

© 2002 Cannondale Corporation - All Rights Reserved

CANNONDALE DIAGNOSTIC AND MAINTENANCE TOOL MAIN WINDOW

6

1

3

8

9

1. Numeric Cal ID

2. Description (saved files only - not stored in ECU)

3. Buttons

4. Throttle position sensor min and max values (from vehicle)

5. Throttle Body Leakage (also Throttle Body Offset) (Factory dyno value)

6. Fuel injector flow rate (Factory dyno value)

7. Injector offset (Factory dyno value)

8. Progress indicator

9. Button to access software version information and Cannondale internet files: http://www.cannondale.com/motorsports/tech/maps

Electrical_EFI Service Manual.fm

/

28

Page 28

8/14/02

Engine Calibration File (“Map”)

N

Identification

All Cannondale factory authorized engine calibration files are identified by a N umeric Cal ID code.

The Numeric Cal ID nu mber defines the yea r,

model, and issue sequence of any specific engine

calibratio n fil e. Th e engi ne ca libr ati on N umer ic Cal I D

number is disp l aye d i n th e to p l ef t co rn er of the Can nondale Diagnostic and Maintenance Tool main

YEAR

Reset every 10 years

(ex. 2002)

window whenever a “map” is opened or received

from the vehicle ECU. The co de number al so displays at the Numeric Cal ID field within the main

window.

Cannondale vehicles (ATVs and motorcycles) are

loaded at the factory with a model specific authorized

engine calibration file. This file can also be referred

to as the vehicle “map.”

Engine calibration files have the filename extension

“.ccf”

MODEL CODE

00 - X440s

01 - X440

02 - C440

03 - E440

30 - Cannibal

31 - Speed

32 - Blaze 440

33 - Moto 440

30202.ccf

SEQUENCE NUMBER

Assigned sequentially.

New files are

assigned the next available

number 00-99 for the model.

Always check the website

to verify that a calibration

file is authorized for use

in a particular model.

Filename extension

All Cannondale authorized

engine calibration files will

have the filename extension

".ccf."

OTE :

When a calibration file for a model is update d the SEQ number increases. However, due to continual product

evolution, the updated calibration file for the model may not be authorized for use in vehicles produced

previously. Always consult the Cannondale website for the compatibility of calibration files for a specific

vehicle VIN number.

A database of Cannondale a uthori zed eng ine ca li bration calibrations files is maintained on the Cannondale websi te so tha t service technic ians h ave

ready access to the correct factory authorized calibration files for a particular vehicle VIN.

Go to

http://www.cannondale.com/motorsports/tech/maps/.

If “Untitled” is displayed in the top left corner of the

main window, no calibration file has been opened

(from a saved file) or received from the vehicle ECU.

29

29

ECU OPERATING CODE

The ECU operating code is installed at the factory

before the engine calibration file is loaded.

The operating code also known as the “HEX” file is

like Windows 98 or XP, an “operating system” used in

many PCs. An engine calibration file can be thought

of as a program like Microsoft Excel or Netscape

Navigator, programs which run under Windows.

Page 29

© 2002 Cannondale Corporation - All Rights Reserved

ATV and Motorcycle operating codes are NOT

interchangeable.

The software tool ca n lo ad operating code ver sion

updates to the ECU.

The software does not read back the installed oper-

ating code currently in the ECU.

To install (update) an operating code

CAUTION:

When an operating code is load ed into an ECU

using the software tool, ALL information is

erased from the ECU memory including the

engine calibration file and vehicle variables

(throttle body leakage, fuel injector flow rate,

injector offset). The engine calibration file and

vehicle variables must be reinstalled into the

ECU following the operating code upda te.

2. In the main window click File - Code Download.

Receive the installed engine calibration file

FIRST. As long as nothing goes wrong with the

PC and the information is retained by the

software tool, the information can be sent to the

ECU right after the operating code update is

finished.

WRITE down the engine calibration file ID

number (Numeric Cal ID), the throttle body

leakage, fuel injector flow rate, and injector

offset before continuing.

1. On A TVs turn the ignition switch ON.

On Motorcycles, disconnect the starter solenoid

so that the engine will not turn over when the start

button is held down in a later step.

Electrical_EFI Service Manual.fm

30

Page 30

8/14/02

3. In the ECU Reprogramming Tool window, select

the operating code file to send.

Click Download.

Have an assistant p ress and contin ue to hold the

start button.

The progress indicator will display while the transfer take place.

When the transfer is complete release the start

button. C lick Close.

4. Reinstall the correct engine calibration file. Be

sure to update the v ehicle var iables befo re sending the file to the ECU.

5. On Motorcycles, be sure to reconnect the s tarter

solenoid.

31

31

Page 31

© 2002 Cannondale Corporation - All Rights Reserved

Opening a SAVED Calibration file

NOTE :

NOTE :

A saved calibration file might be one that you have

received via e-mail, downloaded from the our

website, or one that is stored on a diskette or CD.

This button functions the same way as if you click

File - Open in the top right corner of the main

window.

Once “opened,” the file is ready for installation

into the vehicle ECU.

CAUTION:

Before the saved file is sent to the ECU, be sure

to receive the vehicle variable or they will be

lost. Refer to "Receiving a calibration file

FROM THE ECU “Reading a map and

variables”" starting on page 33.

CAUTION:

Check the Numeric Cal ID field in the main

window to make sure the filename selected is

displayed. If not, go back to step 2 and repeat.

To open a saved calibration file,

In version 2.0 of the software, when the program

is launched, the last engine calibration file that

was opened is automatically open in the main

window. This feature is useful for servicing many

unit at once, however, be sure to check the engine

calibration file Numeric Cal ID code in the main

window to make sure that the right file is being

used. If not, complete steps 2 -3.

1. In the main window, click on the “OPEN

Calibration File (saved) button.

Use the Windows explorer to locate (brows e for)

the saved engine calibration file.

Select the file and click OK.

2. The file is now “loaded” to the main window.

Electrical_EFI Service Manual.fm

32

Page 32

8/14/02

Receiving a calibration file FROM THE

N

ECU

“Reading a map and variables”

By receiving the engine calibration file or the

vehicle variables from the ECU, the technical can

determine which specific engine calibration file is in

use by the vehicle and what the vehicle specific

variable are incl uded in the data file: t hrottle min/

max, Throttle body leakage (also known as offset,

fuel injector flow rate, and injector offset).

OTE :

When you “receive” an engine calibration file, a

copy of the file stored in the vehicle ECU is loaded

in the software tool main window. The vehicle

specific variables or “calibration” are also loaded.

No information is removed or deleted from the

vehicle ECU.

You can select to receive all the calibration file

from the vehicle ECU or just the thr ottle body and

injector variables or “calibrations.”

complete” message.

5. Click OK.

The vehicle calibration file has now been

copied to the Cannondale Diagnostic Tool

program. 4-SEND Calibration File (to ECU).

In case of PC failure, it is a good idea, whenever a

file is received from the vehicle ECU to write down

the throttle body and injector variables or

“calibrations.”

To receive

1. Connect the interface cable to the PC and

vehicle.

2. Open the Cannondale Diagnostic Tool software

on your PC.

3. Power-up the ECU.

4. Click the RECEIVE Calibration File (from ECU)

button.

After you click the button, the data transfer will

start. While the data is copied from the ECU to the

PC the progress in dic ato r in the upper right of the

menu will display and the LED on the interface

cable block may appear to flicker. The time

required for the transf er could v ary. It should take

place within 1 minute. When the entire data transfer process is comp let e, y ou wi ll se e the “R ec eive

33

33

Page 33

© 2002 Cannondale Corporation - All Rights Reserved

Sending a calibration file or “map” to

NOTE :

the ECU “Changing a map”

“Sending” a calibration file transfers the engine

calibration file and vehicle variables currently

open in the Cannondale Diagnostic and

Maintenance Tool main window to the vehicle

ECU.

You’ ll want to pay close attention to what engin e

calibration file is actually open before you send

the file to the ECU in the following steps.

Click the OPEN Calibration File (saved) button

to open the Open Calibration File window to

browse for a saved engine calibratio n file on your

PC. Select the filename and click OPEN.

-- or -Select File-> Open.

Sending will over-write the ECU current engine

calibration file and vehicle variabl es.

Vehicle variables (throttle min/max, throttle body

leakage (a.k.a Throttle body leakage), fuel inj ector

flow rate, and injector offset) are over-written only

if the values have been entered through the

Update Calibrations button. If no values are

entered, the vehicle variables stored in the ECU

are used.

If the interface cable is disconnected acc identally

or problems with the PC interrupt the transfer

process, the engine calibration file send process

should be start over from the beginning. Although,

it is possible to quickly reconnect the interface

cable during the transfer process, information can

be lost or damaged.

Do not experiment with calibration files!

Sending unidentified, altered, or third party

calibration files can result in severe damage to

the vehicle or affect the safe operation of the

vehicle. You could be severely injured or killed

in a resulting accident.

Always consult the Cannondale website

(www.cannondale.com) for calibration files

authorized for a specific vehicle identification

number (VIN).

You should now have an engine calibration file

“open” in the CDMT main window. Confirm that

the correct engine calibration file name is displayed in the top l eft corner of the CD MT window

and at the Numeric Cal ID field.

3. Next, make sure the vehicle engi ne management

system is powered-up . When the vehicle is powered-up, the LED on the interface cable block

should be lit.

4. Click the SEND Calibration File (to ECU) button.

If the calibration file open in the main window dif-

fers from the one current ly stor ed in the E CU, the

“Cal version different. Do you wish to procee d?”

prompt will display. Click yes to send the file. Click

cancel to exit.

If you click YES, the fi le that is open in the mai n

window will be sent to the vehicle ECU. It will

over-write the cur rent calibratio n file stored in the

ECU. During this process, the vehicle variables

currently stored in the ECU will be re tained if the

values have not been entered first using the

Update Calibrations button. If values had been

entered, they will over-write the ECU va lues during the send process. When the send has been

completed the vehicle ECU will automatically

power itself down. The LED on the interface cable

block will turn off indicating the ECU power is now

off. The calibration file just sent wi ll rem ain “op en”

in the CDMT window until the program is exited or

another calibration file is opened or received.

1. To send a cal ibra tion fil e to the v ehicle E CU, star t

by connecting the inte rfa ce c ab le to the computer

and vehicle.

2. Open the Cannondale Diagnostic and Maintenance Tool software on your P C. The CDM T program will automatically open the last engine

calibration file that was open using the program.

Electrical_EFI Service Manual.fm

Setting the throttle position sensor minimum and maximum values

The minimum and ma ximum val ues are ca ptured

and recorded into the ECU using the SET Thro ttle

Position button.

34

Page 34

8/14/02

The throttle position sensor minimum and

N

N

maximum values must be set using the CDMT

anytime the throttle body is servi ced (removed,

replaced, installed). It also must be set if the ECU

operating code is updated. Set the throttle po sition

with the engine off. When the values are set using

the tool, the minimum and maximum value actually

read into the software by the technician are checked

against a range. If any read value is out of range, the

software will report it.

are the values of the current engine calibration

file.

Again, make sure the throttle plate is com pletely

closed and click the Read Closed Voltage button.

Yo u should se e a change i n the nume ric value to

the right of the button. The change is the minimum voltage value read from the vehicle TPS

sensor when completely closed. The value can

approach zero, but should be within the typical

range indicated in the window.

OTE :

The “TPS Sensor Closed (volts)” and the “TPS

Sensor open (volts)” are displayed in the CDMT

main screen anytime a engine calibration file is

open or received from the ECU.

1. To set the throttle position, start by making sure

that the idle adjustment screw is backed off

completely. The throttle plate should be

completely shut before you continue.

Double check the throttle bellcrank after backing

the idle adjustment screw off; any slight tension in

the throttle cable can hold the plate open. Confirm

that it is closed all the way by rota ting the throttle

bellcrank with your hand - closing it firmly.

OTE :

When shutting the throttle body plate to set the

minimum value, avoid backing the adjustment

screw out too far that it falls out of the stop plate.

Next, have an assistant hold the throttle lever fully

open. While the lever is held in the “wide open

throttle” position, click the Read WOT Voltage

button. You should see a change in the n umeric

value to the righ t of the button . Tell your assistant

to release the throttle lever.

Now, both values have been read from the vehicle

TPS sensor. Y ou have two options to consider; go

2. Make sure the in ter fac e c abl e is connected to

the computer and vehicle securely.

3. Open the Cannondale Diagnostic and

Maintenance Tool software on your PC.

4. Power-up the vehicle engine management

system.

5. An engine calibration file must be open in the

CDMT main window to continue . Use the OPEN

Calibration File (saved) or use the RECEIVE

Calibration File (from ECU) button to receive the

calibration file that is currently s tored in the vehi cle ECU.

6. Click the SET Throttle Position button. The Cali-

brate Throttle window will display. When the window displays the closed voltage (minimum) and

open voltage (maximum) numeric values shown

35

35

Page 35

© 2002 Cannondale Corporation - All Rights Reserved

to the next step to learn more.

Click this butto

to

senso

u

ds

s

"

y

e

ge

e

d.

read the TP

r minim

voltage.

hese fiel

isplays the value

hat are

ready to accept

he fields initiall

how a value of th

urrently open file.

he values will chan

mmediately after th

ns at the left are

licke

7. If you click the Accept Values button, the values of

the engine calibration file currently stored in the

CDMT will change to the new ones and immediately the Send Calibrations to the ECU prompt will

display.

If you click Cancel , the new values you just read

from the vehicle will b e “forgo tten” and th e val ues

will revert back to the values of the currently open

engine calibration file; and, the CDMT main wi ndow will disp lay.

8. If you click OK, at the S end Calibrations to ECU

prompt, the Select TPS/Inj Calibrations window

will display next. Go to the next step.

If you click Cancel at the Send Calibrations to

ECU prompt, the new values will be updated in

the currently open engine calibration file and

remain until the file is c losed , ano ther ne w eng in e

calibration file ope ned or the values are c hanged

again using the Set Throttle Position button.

The Send Calibrations to the ECU prompt

9. At the Select TPS/Inj Calibr ations window, select

the values to send to th e ECU by clicking in the

check boxes. The val ues displayed in the “From

File” column are the values of the current engine

calibration file open in the CDMT. T he values of

the “From ECU” column are the old values.

Electrical_EFI Service Manual.fm

Click OK to send the val ues to the ECU. Watch

36

Page 36

8/14/02

the progress indicator. When the send is com-

N

plete, the Send complet e pr omp t will dis pl ay, click

OK.

Click Cancel and the “From File” values will not

be sent. They will remain in the currently open

engine calibration file.

CALIBRATIONS

Updating throttle body and fuel injector calibrations

The Select TPS/Inj Calibrations window

10. Power-up the vehicle ECU and click on the

MONITOR ECU Parameters b utto n to dis pla y

the ECU Monitor window.

Find the “Throttle (%) Open value.” Make

sure the ECU parameters display is in the

Continuous mode.

Adjust the idle adju stment screw so that the

“Throttle (%) O pen” value increases by 3 . F o r

example, if the value was 2.3 with the thr ottle

plate fully closed, turn the adjuster until the

value reads 5.3. If you do not open the throttle

plate the engine may no t have enough air to

idle. Opening the thr ottle plate 3% should be

enough to achieve idle.

11. Start the engine and allow to idle normally