Page 1

FR NOTICE D'EMPLOI ET D'INSTALLATION

DES TABLES DE CUISSON

GB INSTRUCTION FOR THE INSTALLATION AND

OPERATION OF HOBS

IT ISTRUZIONI D'USO E DI INSTALLAZIONE

PIANO DI COTTURA

~~~

PA 640/2

PLA 640

PLA 631

PSA 6 4 0 / 2

PLAS 6 4 0

93785779

PLDA 640

PLDAS 64 0

1

Page 2

CONTENTS

Unpacking the appliance.....................................................................21

Recommendations ..............................................................................21

Presentation of the hob.......................................................................22

• INSTALLATION

Safety instructions ..............................................................................23

Modification of the factory gas setting :

* Fitting of the correct jets.............................................................24

* Adjusting of the air ring.............................................................. 25

Fitting the hob..............................................................................26/27

Gas connection...................................................................................28

Electrical connection...........................................................................28

After final installation of the hob (if modification of the gas setting) :

Adjusting of the lower flame on the gas burners..................................30

• USING THE APPLIANCE

The different gas burners ....................................................................31

Igniting and setting the burner ............................................................32

The hot plate......................................................................................33

Cooking with the electrical hot plate...................................................34

General maintenance .................................................................... 35-36

• TECHNICAL DATA... .........................................................37

20

Page 3

UNPACKING THE APPLIANCE

Inside the appliance, you will find :

• a plastic bag containing :

- the new jets for the gas modification, if required,

- the fixing brackets with screws to install the hob in the worktop,

- for some models, a tapered connector with seal, is a compulsory requirement

for hobs in certain countries,

and,

• a spanner to change the jets if the factory gas setting does not correspond to your

installation requirements.

RECOMMENDATIONS

PLEASE READ THE FOLLOWING CAREFULLY IN ORDER TO GET THE BEST FROM

YOUR APPLIANCE.

Please keep the operating and installation instructions in a safe place for future reference.

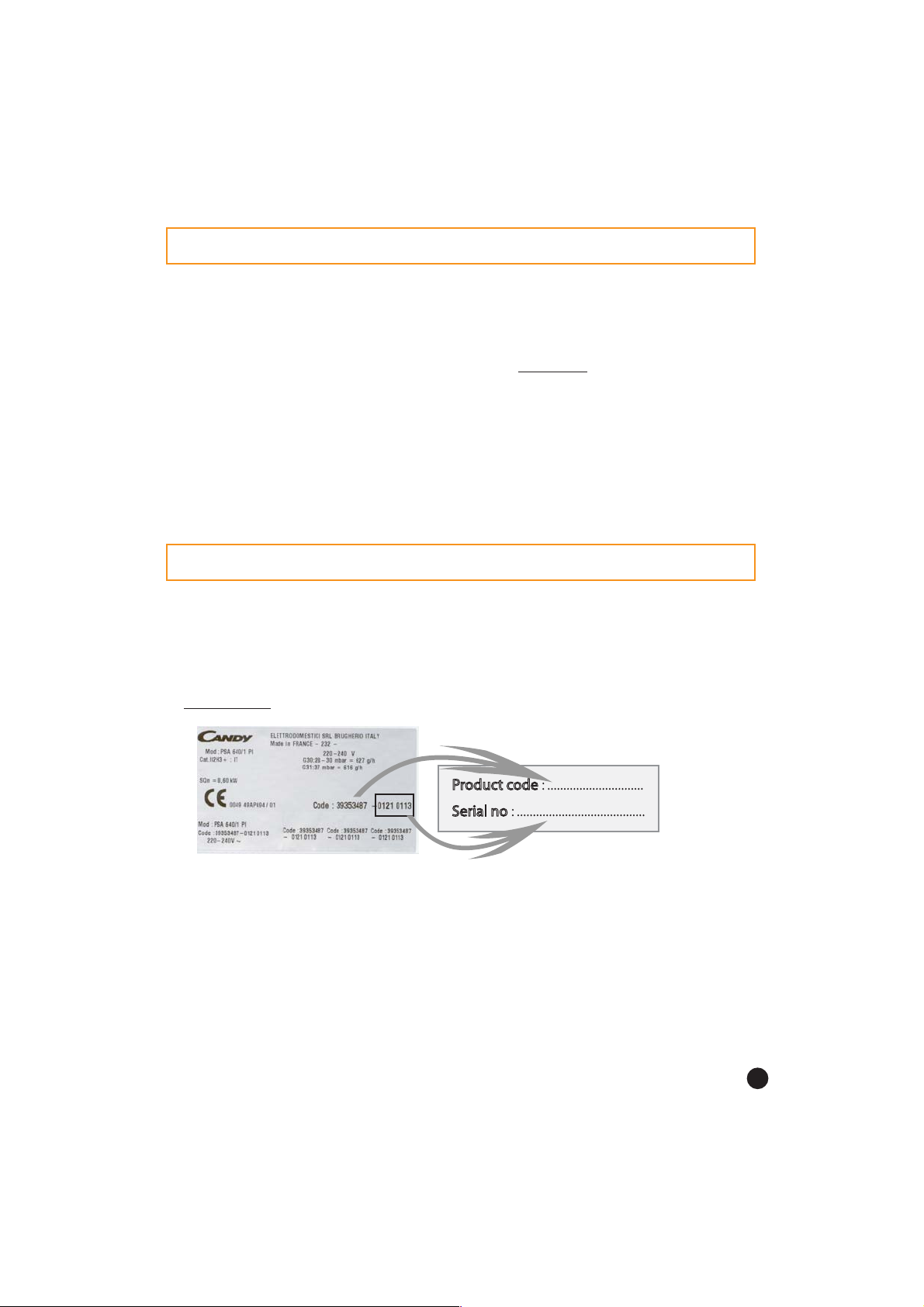

Before fixing the hob, note the serial number of the appliance just in case you may require

future repairs from after sales service organisation.

. Rating plate (located under the lower casing of the hob)

• All accessible parts of the hob become hot while it is in operation. Always, keep

children away from it.

• The hob should be given a quick clean after each use, to avoid the accumulation of

spillages and grease, which if not removed, will harden and could cause the production of

smoke and unpleasant smells.

• When cooking with fats or oils, never leave gas burner unattended. Overheated fats or

oils can quickly catch fire.

21

Page 4

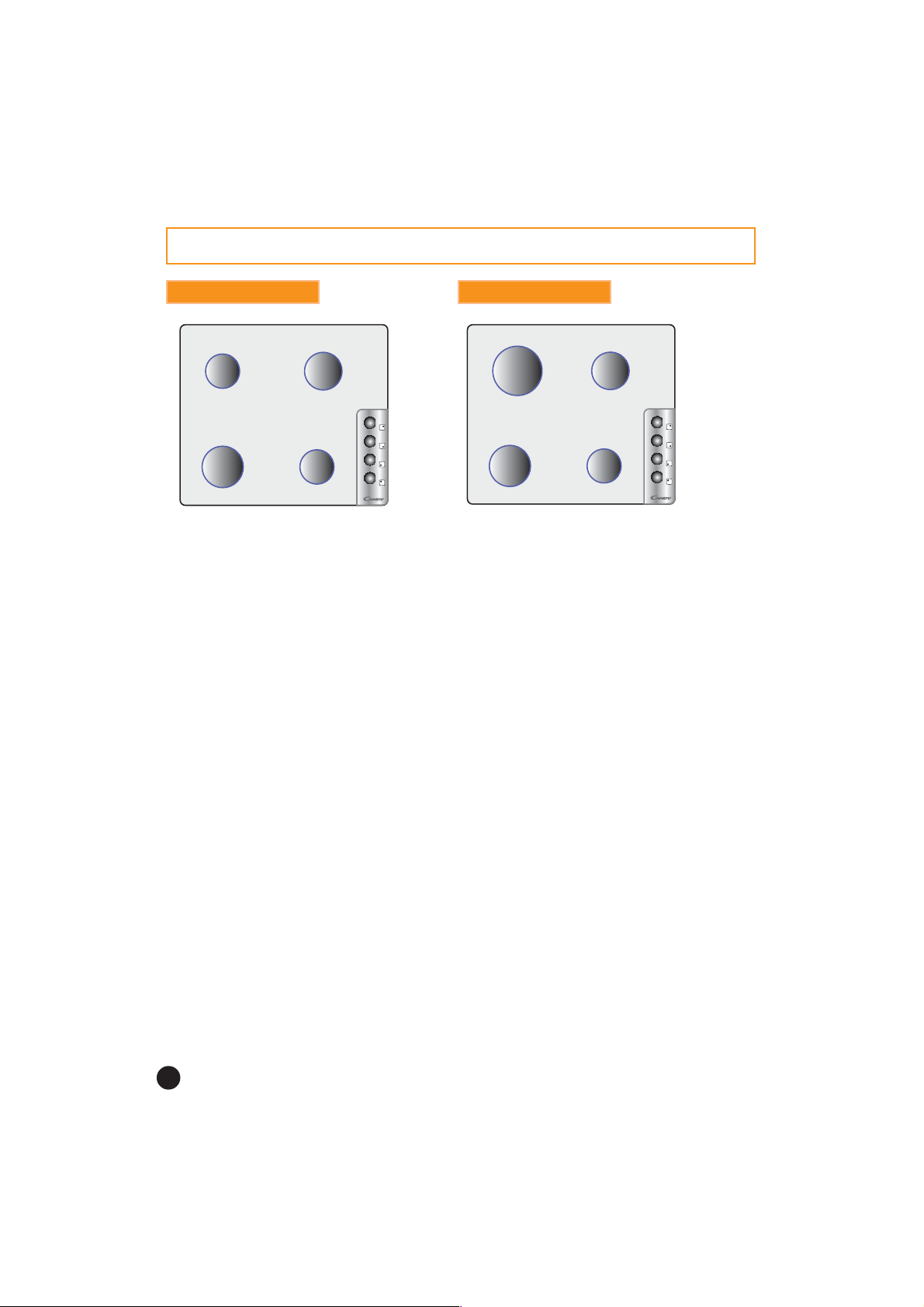

PRESENTATION

ALL GAS HOB

MIXED HOB

TOUT GAZ

p

l

a

t

t

e

o

2

,

5

t

s

1

a

f

,

4

-

i

5

m

k

e

W

S

t

s

3

a

f

,

2

y

k

r

W

e

V

or

D

g

o

n

i

u

r

b

e

l

t

s

k

a

W

F

t

1

s

,

a

4

f

5

-

i

k

m

W

e

S

PA 640/2 F : 4 gas burners, and cast-iron pan supports.

PLA 640 : 4 gas burners, and enamelled pan supports.

PLAS 640 : 4 gas burners, safety device, and cast-iron or chrome

pan supports according to colour.

PLA 631 : 3 gas burners +1 hot plate 2000 W, and enamelled

pan supports.

H

2

W

0

0

0

3

,

2

t

k

s

W

a

F

,

5

2

t

k

s

a

F

t

s

1

a

f

,

4

-

i

5

m

e

S

W

k

W

22

PSA 640/2 : 4 gas burners, safety device and enamelled pan supports.

PSA 640/2 F : 4 gas burners, safety device, and cast-iron pan supports.

PLDA 640 : 4 gas burners with 1 double ring, and enamelled pan supports.

PLDAS 640 : 4 gas burners, safety device, with 1 double ring, and enamelled

pan supports.

Overall dimensions :

Width : 59 cm Depth : 51 cm Height : 3 cm

Building-in dimensions - (see chapter "Installation")

Width : 56 cm Depth : 48 cm

Page 5

INSTALLATION

Installing a domestic appliance can be a complicated operation which if not

carried out correctly, can seriously affect consumer safety.

It is for this reason that the task should be undertaken by a professionally

qualified person who will carry it out in accordance with the technical regulations

in force.

In the event that this advice is ignored and the installation is carried out by an

unqualified person, CANDY declines all responsibility for any technical failure

of the product whether or not it results in damage to goods or injury to

individuals.

Before installing the hob :

make sure that the appliance is compatible with the gas supply source.

The hob is pre-set in the factory to work with the type of gas shown on the packing

and the plate attached to it.

Natural gas G 20-20 mbar / G 25-25 mbar : mains gas

if necessary, adapt the hob for use with another type of gas : if the hob

must be used with another type of gas than the gas pre-set in the factory, it is necessary

to adapt the hob gas burners (page 24/25).

The procedure for adaptation consists of :

. fitting the correct jets to ensure nominal delivery,

. adjusting the appearance of the flame by regulating the air ring according to the

data given in the table.

For installation :

built-in hob (page 26/27).

make the gas connection according to the type of gas to be used : based on

the gas to be used, choose the appropriate gas connection (page 28).

Warning : certain countries request the setting of a tapered connector. Follow the

special instructions in page 28.

make the hob electrical connection according to the instructions (page

29).

adjusting the minimum flame of the taps : if necessary, adjust the minimum

flame of the taps by turning the by-pass screw (page 30).

All modification concerning the hob gas setting must be indicated on the rating plate

of the hob.

23

Page 6

INSTALLATION: "GAS CONNECTION"

• CHANGING THE GAS TYPE : the calorific power output and gas pressure will

vary according to the gas supply. Burner setting must be carried out once the gas and

electrical installation is complete.

When changing gas type, you must follow the procedure below :

. fit the correct jets,

. adjust the appearance of the flame by regulating the air ring.

. adjust the minimum flame on the taps (see page 30).

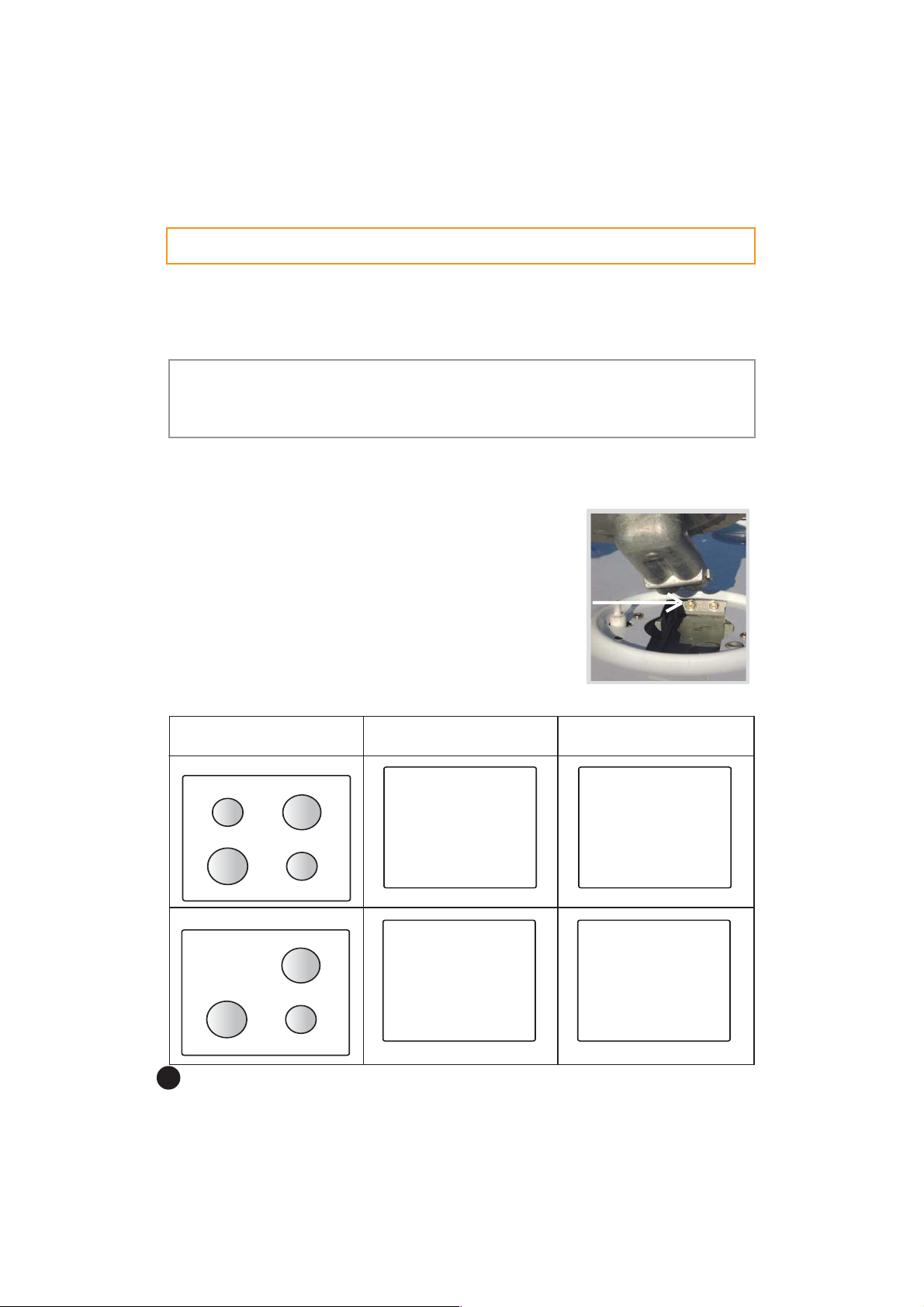

• CHANGING THE JETS :

Each jet is designated by size. A special spanner supplied with the appliance is designed to

hold the jets securely during the set up operation.

To gain access to the jets :

. remove the pan supports,

. remove the burner cap and body,

. using the spanner supplied with the appliance, unscrew

the jet,

. fit the correct jet for the type of gas to be used,

. secure the het tightly,

. replace the burner body, cap and the pan support.

Example : Fast or Double ring gas burner 3,2 kW

Burner

body

Jet

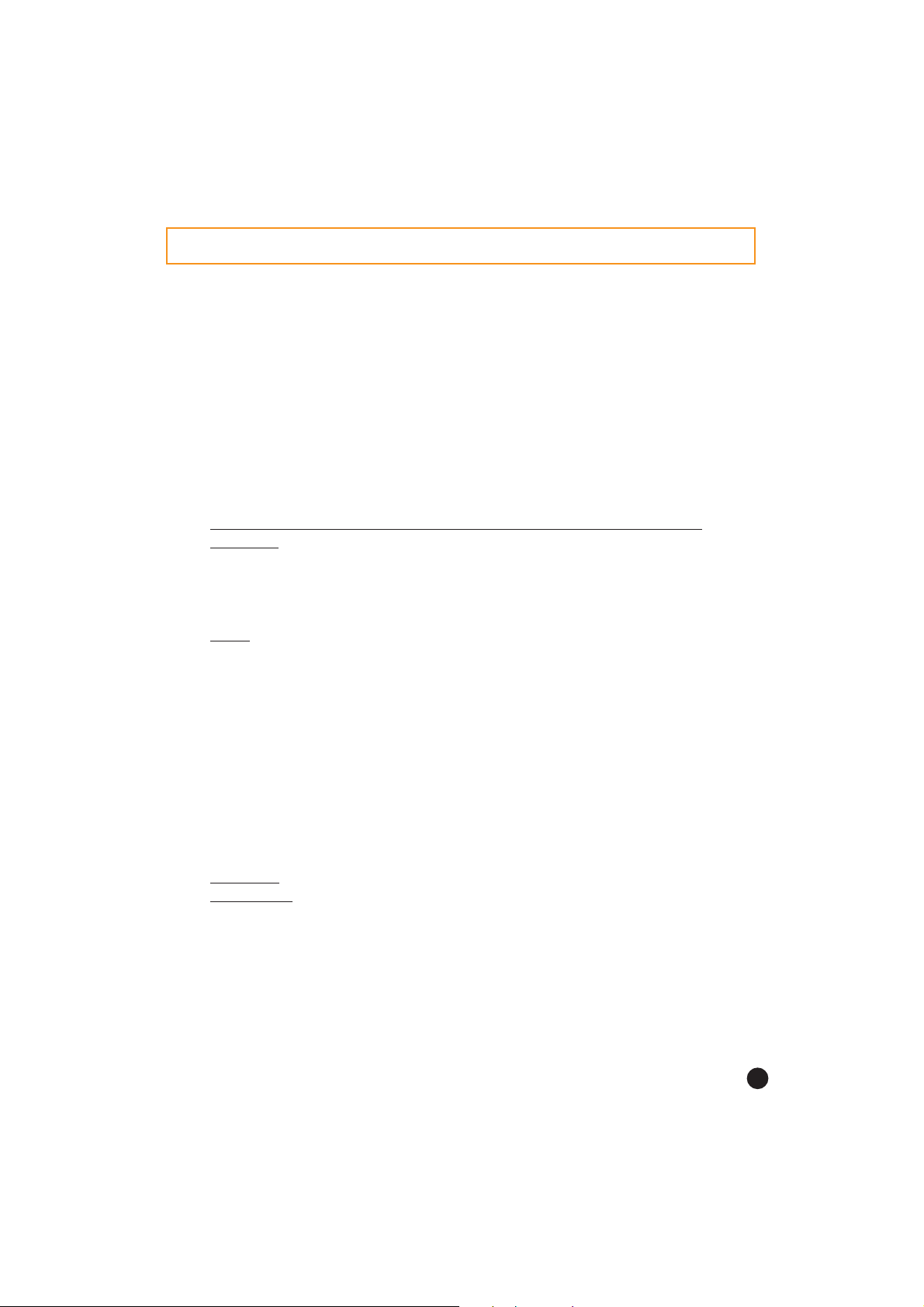

4 gas burners

1,45 kW 2,5 kW

Semi-

fast

3,2 kW

Fast

or

Double ring

3 gas burners + 1 hot plate

3,2 kW

Fast

24

Fast

1,45 kW

2,5 kW

Fast

1,45 kW

Semi-

fast

Semi-

Fast

G20-20 mbar / G25-25 mbar

Jet

96

Jets

94 x 2

Jets

94 x 2

Jet

122

Jet

96

Jet

122

Jet

96

G30 28-30 mbar

G31 37 mbar

Jet

61

Jets

65 x 2

Jets

65 x 2

Jet

80

Jet

61

Jet

80

Jet

61

Page 7

INSTALLATION: "GAS CONNECTION"

• SETTING THE APPEARANCE OF THE FLAME

1. Regulating the air ring on the hob burners : the setting is important as it ensures the

correct combustion and enables the burners to work at maximum efficiency. The table

refers to the value "X" in mm ; it may be necessary to regulate this by plus or minus 1 mm

to obtain a perfect flame.

2. To gain access to the air rings on the hob burners: remove the pan support, the burner

cap and body of the relevant burner. The air ring is located at the lengthening of the burner

unit which is fixed by a screw (see drawing).

If necessary : . unscrew the screw that holds the air flow adjuster,

. set the correct distance according to the air adjuster protrudes,

. secure the screw when the operation is completed.

Semi-fast burner 1,45 kW

or Fast burner 2,5 kW

Screw

Quota "X" in mm of the air ring according to the gas setting

PA - PSA 640/2

Fast

PLA - PLAS 640

Semi-fast Fast

Fast

Semi-fast Fast

PLA 631

Fast

PLDA 640

PLDAS 640

Semi-fast

Semi-fast

Quota

X

Air ring

G20-20 mbar

G25-25 mbar

6 10

14 6

6 10

Fast burner 3,2 kW and

Fast double ring 3,2 kW

Quota

X

Air

ring

Screw

G30 28-30 mbar G31 37 mbar

00

00

00

7 9

14 7

7 9

Double

ring

Semi-fast

15 6

00

15 7

25

Page 8

INSTALLATION: "BUILDING-IN"

BUILDING-IN : both the unit into which the hob will be fitted and any adjacent kitchen

furniture must be made from heat resistant material and fixed with heat resistant adhesive.

If, when installing the hob, the lower part of the casing is adjacent to an area normally

accessible when handling or cleaning, fit a partition 1 cm below the base of the casing with

a 10x10 cm opening at the rear right-hand corner, to avoid any risk of burning or damage.

There should also be a 5 cm gap between the appliance and all adjacent vertical surfaces.

A foam adhesive is supplied with the hob. Stick this seal under the edge of the body as near

as possible to the outer edge of the hob. Press round the edges of the hob, so that the seal

flattens out and ensures an air tight seal.

Warning : at the rear of the appliance, take care not to block the air inlets necessary for

combustion to take place.

FITTING THE SEAL

• Top view of the seal

• Cross section of the hob

seal

26

6 mm

SEAL

Worktop level

- Take care not to block the air inlets

necessary for combustion to take place -

Page 9

INSTALLATION: "BUILDING-IN"

The body of the hob is fitted with 4 location holes to take the fixing brackets that secure the

hob in the unit. Place the 4 fixing brackets in such a way that the hob is placed perfectly in

the support unit.

Location for fixing brackets

Fixing

bracket

Building-in according to TYPE X

(Norm CEI 335-2-6)

Opening

10x10 cm

27

Page 10

INSTALLATION: "GAS CONNECTION"

The hob can be built-in ; it is type "X" for built-in hob (in compliance with electrical

regulations EN 60.335.2.6) ; in class 3 (in compliance with gas norm EN 30.1.1) ;

adjoining furniture should not be higher than the level of the hob.

This appliance is not connected to an evacuation device for the products of combustion. It

must be installed and connected in compliance with the norms in force in the country of

installation. Particular attention should be given to the availability of ventilation. The turnover of air necessary for combustion is a minimum of 2 m3/h per kW of power.

Gas connection should be carried out in compliance with the norms in force in the

country of installation. A stop tap, a regulator valve or a release valve for propane gas,

should be fitted to the gas supply pipe. Use only taps, regulator valves, connectors and

flexible hoses with the official mark of approval of the country of installation.

Built-in appliance

Butane Rigid - Flexible pipe with mechanical connectors (1) Propane Rigid - Flexible pipe with mechanical connectors (1) Natural Rigid - Flexible pipe with mechanical connectors (1) -

(1) on condition that the hose is accessible along the whole of its length and it should be

located so it cannot be reached by naked flame or affected by combustion gases. Neither

should it be near hot parts of the hob nor anywhere where hot spillages could affect it.

2 POSSIBLE MEANS OF CONNECTION* :

• CONNECTION BY RIGID PIPE

Connect directly to the threaded end of the inlet pipe.

• CONNECTION BY FLEXIBLE PIPE WITH MECHANICAL CONNECTOR

Screw the nuts of the flexible pipe directly on to the inlet pipe at one end and the gas

supply stop tap at the other.

We recommend this type of connection.

* A tapered connector is supplied in the bag to fit certain models of hobs made for specific

markets. It must only be used in countries where it is compulsory (for example : Great

Britain, Netherlands, Germany).

28

Page 11

INSTALLATION: "ELECTRICAL CONNECTION"

The mains electricity supply connected to the appliance should comply with the norms in

force in the country of installation.

Connection to the mains electricity supply should be through a socket with an earth terminal,

or through an intermediary switching device with a gap between contacts of at least 3 mm.

The power supply unit must be protected by appropriate fuses and use cables of a large

enough cross section to provide a normal supply to the appliance.

The hob is fitted with a power supply cable* which allow it to be connected only to a power

supply of 230 V between phases, or between phase and neutral.

• Connect to a 10/16 Amp socket. Before connecting, it is compulsory

to check :

. the power supply voltage shown on the electricity meter,

. the adjustment of the circuit breaker, and

. the fuse rating 10A.

Note : the socket must be reachable for any eventual repair. Take care of its location

at the time you install the hob.

Warning : before proceeding with the connection, check the continuity of the

earthing of the power supply unit.

We cannot be held responsible for any accident which has resulting from the use

of an appliance which is not connected to earth, or whose earthing is defective.

* The eventual replacement of the supplying cord must be carried on by the After Sales

Service or by an agreed engineer, with a cord whose characteristics must be similar to the

original one :

. Gas hob : cord type H05 V2V2-F, 3 G 0,75 section,

. Mixed hob : cord type H05 V2V2-F, 3 G 1,5 section.

29

Page 12

INSTALLATION: "REGULATING THE FLAME"

• SETTING THE IDLE FLAME

If you have changed the type of gas, it is important to verify the flame stability at the

minimum regulation.

"Gaining access to the by-pass screw"

To gain access to hob burner by-pass screws, remove the knobs from the control panel.

By-pass screw of the hob burner

!

Never loosen

the others screws !

REGULATING THE MINIMUM FLAME ON THE HOB BURNER

a) Natural gas :

. simply loosen the screw.

. switch on the burner and turn the knob to minimum.

. Turn the by-pass screw until a low flame is visible. Turn the control knob from

minimum to maximum position to check that it is satisfactory.

b) Butane-propane gas :

The by-pass screw should be screwed fully home, without being locked.

30

Page 13

THE GAS BURNER

THE VERY FAST or VERY FAST "DOUBLE RING" BURNER has a power rating

of 3,2 kW :

Use the large burner for bringing to the boil, for cooking large quantities, and generally for

all foods requiring rapid cooking.

THE FAST BURNER has a power rating of 2,5 kW :

It is ideal for stewing, sauces and slow cooking.

THE SEMI-FAST BURNER has a power rating of 1,45 kW :

Use this small burner for small pans.

For a proper use of the burners, choose pans which match the dimensions given below :

* Very fast Ø 18 cm and more

* Very fast double crown Ø 18 cm and more

* Fast Ø from 16 to 18 cm

* Semi-fast Ø 12 cm

On models fitted with cast iron pan supports, we

supply a reduction pan support to use pans with

dimensions of less than Ø 12 cm, on the rear left

burner.

SOME TIPS ....

• Pans with curved, ridged or warped bottoms are not recommended.

• Avoid boiling food too intensely. Food is not cooked any more quickly this way. In fact,

it is subjected to severe agitation, which may cause the food to lose some of its flavour.

• To save gas, make sure that the flames do not overlap the bottom of the pan.

• Do not use the gas burner with an empty pan.

RECOMMENDATIONS : when the burners are not in service, the general gas

supply tap should always be turned off.

31

Page 14

THE GAS BURNER

Each burner is contolled by a tap with progressive settings allowing :

* a wider choice of settings from the maximum position to the lowest and most precise one,

* easier flame regulation according to the pan diameter,

* no risk of cutting off the flame or switching off when the flame is turned down quickly.

Each burner is fitted with automatic ignition. The ignition can be made with one hand, while

you have the pan in the other hand.

USE :

• Turn on the gas tap,

• A symbol next to each control knob indicates which burner is lit.

Hob with automatic ignition integrated on the knob :

• Press and turn the knob until position"High flame" keeping it pressed to produce

sparks which in turn ignite the burner.

Hob with safety device on the burner and automatic ignition integrated on the

knob :

The thermocouple fast safety is a device allowing the automatic cut-out of the gas

supplying on the burner, in case the flame dies out accidentally.

• Press and turn the knob to position "High flame" keeping it pressed to produce

sparks which in turn ignite the burner. Keep the pressure on the control knob a few

seconds to permit the releasing of the safety device.

32

• Set the flame according to your cooking requirements.

Intermediate positions are available between the "High flame" and "Low flame"

settings on the control knob.

• To turn the flame out, turn the control knob back to stop position.

Please note :

. If there is a power cut, the burner can be ignited by pressing in and turning the knob

to position "High flame" and holding a naked flame to the burner.

Page 15

THE HOT PLATE

THE SPEED PROTECTED HOT PLATE fitted to the mixed hob is located at the

rear left.

This is a cast-iron hot plate, controlled by a 7 position switch.

An internal thermostat cuts off part of the power supply if there is any abnormal heating.

(if, for example, a hot plate is working without a pan on it).

BEFORE USING THE ELECTRICAL HOT PLATE :

• Before using the electric hot plate for the first time, let it heat up for a few minutes,

without a pan, at maximum temperature to let the protective coating harden.

HOW TO USE :

• For best results, it is advisable to start on the maximum heat and then turn back

to an intermediate temperature taking into account the type and volume of the food.

• An indicator light comes on to show that the hot plate is operating.

• To switch off, turn the knob back to the starting point " ".

THE DIFFERENT TEMPERATURE SETTINGS :

Below are a few examples which are given as guidelines. When you become more

familiar with the appliance, you will be able to choose settings to suit your own

personal tastes and requirements.

1wolyreV

2woL

3yletaredoM

4muideM

5hgiH

6hgihyreV

snoitisoP

...gniyrf,spohc,skaetS

.....spitemoS

....etalocohcdnarettubtlem,tohhsidapeekoT

...sggedehcaop,gniddupecir,swets,secuas,gnikoocwolS

....retawgniliob,tiurf,sdoofnezorf,snaeB

....hsif,seperc,atsap,selbategevhserf,selppademaetS

....skaets,settelemo,gnikoocesnetnieroM

33

Page 16

Cooking with the electrical hot plate

To get the best results from your appliance it is important to observe the following :

• Use thick, flat-bottomed cooking vessel :

a completely flat bottom prevents the overheating of some points which cause food to stick.

Thick metal allows for good heat distribution.

• Make sure that the bottoms of pan are dry :

this will prevent things from sticking to the hot plate because of moisture.

• Use pans with a diameter large enough to completely cover the hot plate,

otherwise some of the energy will be wasted and if there are any spillages the hot plate will

quickly become stained and difficult to maintain (rust, etc.).

• Never leave a hot plate switched on without a pan on it : it could become deformed,

which would reduce its efficiency.

• When cooking with fat or oil, never leave the hob unattented, very hot fats and

oils can quickly catch fire.

• When the hot plate is hot, avoid any contact with materials made of plastic or aluminium

foil.

Caution :

the heating surfaces clearly get hot while operating, so make sure that small

children are kept well away from the hob.

34

Page 17

CLEANING

Before all cleaning or dismantling operation, it is imperative to :

. disconnect the hob to the mains supply,

. let all parts of the hob cool down.

Never use :

harsh abrasives, scouring pads or sharp object to clean the hob.

• GENERAL MAINTENANCE

THE HOB

. Enamelled steel hob : simply clean the enamelled hob with soapy water when the hob is

cold, rinse and wipe with a clean dry cloth. If you clean the enamelled hob when it is hot,

you may tarnish it.

. Stainless steel : clean with soapy water, rinse and dry. You can use a special product to

clean stainless steel which is available in stores.

THE KNOBS - For thorough cleaning, the control knobs can be removed by pulling them

upwards.

Clean with soapy water, rinse and dry well before replacing.

THE GAS BURNERS

For cleaning, it is recommended to remove all greasy or burnt deposits with ammonia

based products or usual cleaning products.

• The burner cap : it is simply placed on the burner.

Remove the pan support, the burner cap and clean it with a slightly soapy sponge. Rinse

and dry.

The enamelled steel burner cap : do not immerse it in cold water when it is hot, this will

prevent the enamel cracking as a result of thermal shock.

• The burner body : regular cleaning will maintain the appliance original appearance.

Clean with a soapy sponge, rinse and dry. If the holes become clogged, brush the caps using

soapy water and dry with a clean cloth.

When re-assembling the burners, make sure that the burner caps and the burners

themselves are dry and after, seat them correctly.

Be careful not to let any water get into the burners.

35

Page 18

CLEANING

THE PAN SUPPORT

Depending on the model, the pan supports are made of chrome steel, enamelled steel or

cast-iron.

They are simply placed on the hob. Lift them up to remove them.

For the maintenance of the pan support, never use harsh abrasives, scouring pads or sharp

objects as this will cause irreparable damage to the enamel.

When the pan support is cold, simply clean with soapy water, rinse and dry with a clean

cloth.

Chromed grids and burners

Chromed grids and burners have the tendency to dark with the use.

This is a normal and inevitable phenomenon, but it doesn’t jeopardize absolutely the

functionnality of the hob.

In option, enamelled grids and burners are available from our after sales service centre.

THE HOT PLATE

Heat it for a while if necessary, to burn the deposits. After switching off and cooling down

of the plate, wipe it with an absorbing paper. In any cases, it is important to protect the hot

plate from humidity.

Do not use abrasive products.

To maintain and preserve the appearance, rub a drop of neutral oil, such as sewing machine

oil into the surface of the hot plate.

The hot plate should always be dry, or slightly greasy, if it is not to be used for some time.

Remove any rust using emery paper followed by a suitable commercially available

product for the maintenance of soil hotplates.

36

Page 19

TECHNICAL DATA

renrubtsaF

tfeltnorf

Wk2,3Wk54,1Wk5,2Wk54,1

rabm02-02G

rabm52-52G

rabm03-8203G

rabm7313G

136ALP136ALP

136ALP136ALP

136ALP

Wk2,3

rabm02-02G

rabm52-52G

rabm03-8203G

tsaf-imeS

renrub

tfelraer

046SADLP-ADLP/046SALP-ALP/2/046ASP-AP046SADLP-ADLP/046SALP-ALP/2/046ASP-AP

046SADLP-ADLP/046SALP-ALP/2/046ASP-AP046SADLP-ADLP/046SALP-ALP/2/046ASP-AP

046SADLP-ADLP/046SALP-ALP/2/046ASP-AP

h/l918

h/l379

h/g726

h/g616

etalptoH

W0002

h/l186

h/l908

h/g125

renrubtsaF

thgirraer

Wk5,2Wk54,1

renruftsaf-imeS

thgirtnorf

rabm7313G

In order to improve the quality of the products, CANDY may carry out modifications linked

to technical improvements.

Appliance meeting with the standard CEE 89/336, 73/23 and 90/396.

h/g215

37

Loading...

Loading...