Page 1

HOBS 60 cm

USER INSTRUCTIONS

GB

Page 2

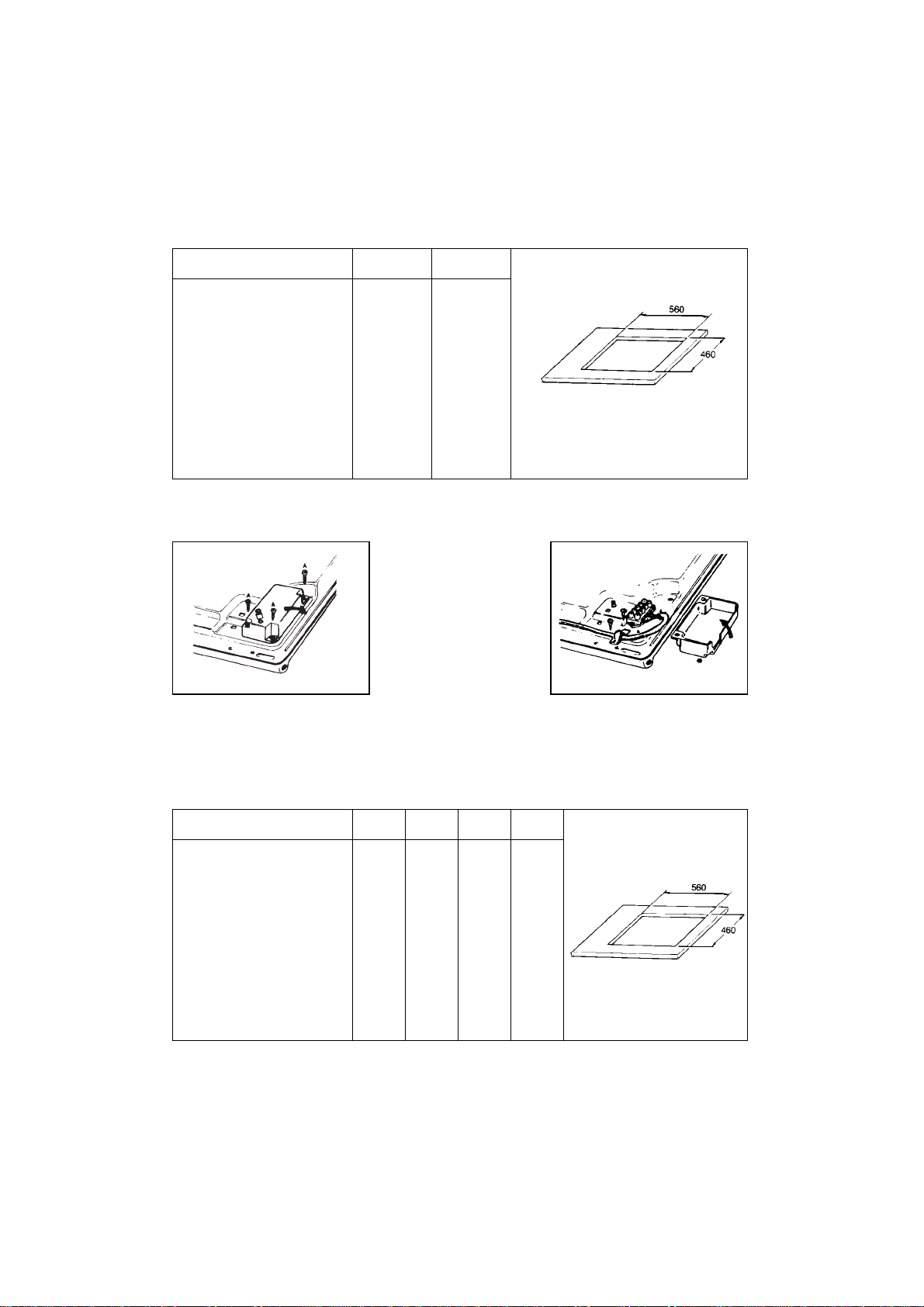

TECHNICAL CHARACTERISTICS

Cooking hobs 60x50

Gas

Electric

Burners 4 gas –

– 4 elec.

Reference type P4 01 PE 03

Supply Voltage/Frequency (V/Hz) 240/50 240/50

Installed electric power (W) – 6000

Gas burner power:

Medium burner kW 1,45 (x 3) –

Large burner kW 2,9 –

Power of gas installed:

- G20/20 mbar (kW)* 7,45

- G30/28-30 mbar (g/h) 542

Electric ignition yes –

Product size mm. 585x500 585x500

Degree protection – Type Y

Class 3

Fig. 1

Fig. 4 Fig. 4 bis

* Manufacturer setting GB cat. II2H3+

TECHNICAL CHARACTERISTICS

FOR AUSTRALIA

Cooking hobs 60x50

Burners 4 gas 4 gas 3 gas 3 gas

– – 1electric 1 electric

Reference type P401 P402 P301 P302

Supply Voltage/Frequency (V/Hz) 230/50 230/50 230/50 230/50

Installed electric power (W) – – 1400 1400

Semi rapid burner 3 3 2 2

Rapid burner 1 1 1 1

Power of gas installed: (MJ/H)

- Natural gas 1,13 kPa* 28 28 22,1 22,1

- LPG gas 2,75 kPa 25,2 25,2 19,7 19,7

Electric ignition yes yes yes yes

Gas safety device – yes – yes

Product size mm. 585x500 585x500 585x500 585x500

Degree protection – – Type Y Type Y

Class 3 3 3 3

Fig. 1

* Manufacturer setting

Page 3

2

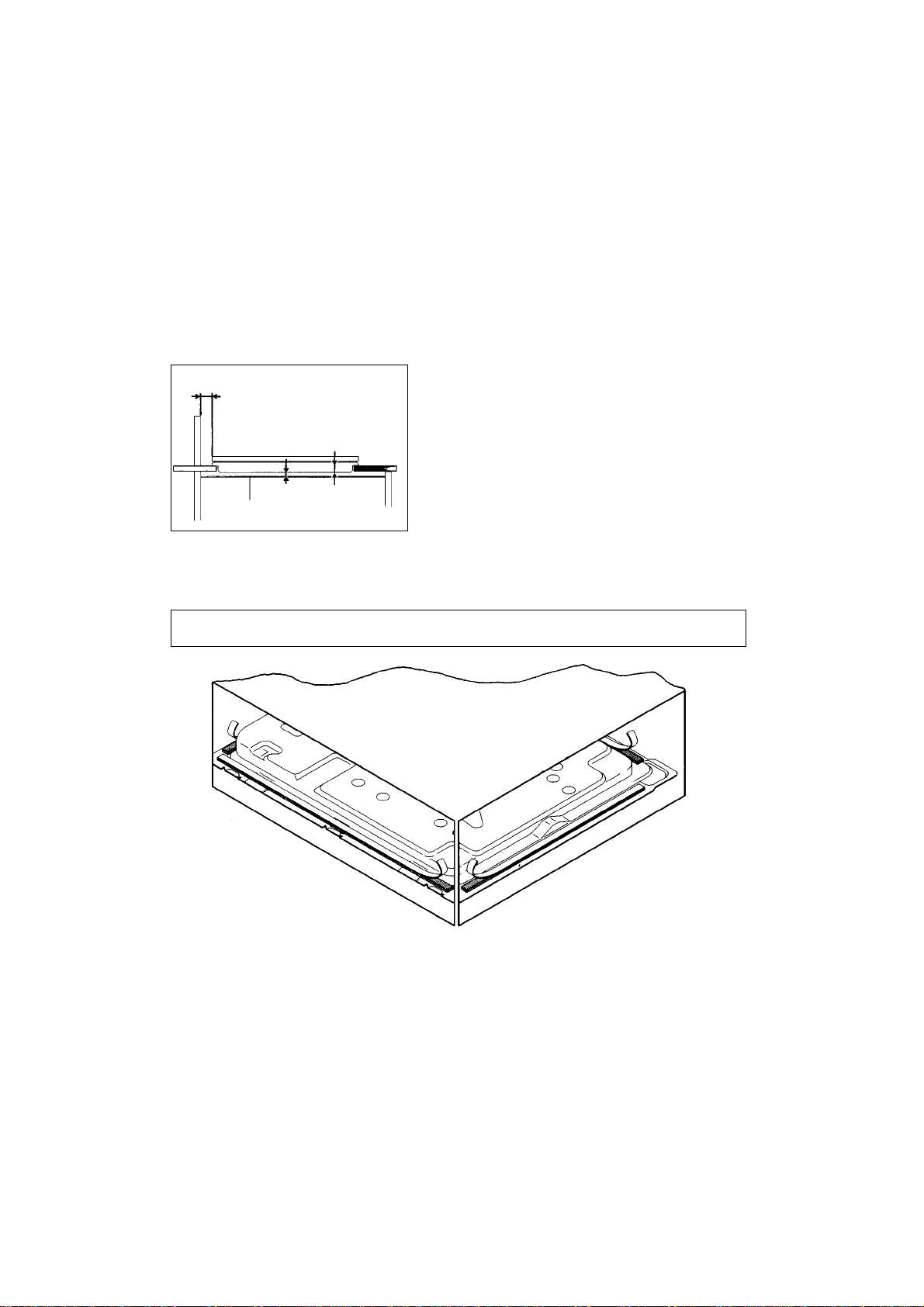

VERY IMPORTANT - APPL YING THE SEALANT

Important - The diagram below shows how the sealant should be applied.

INSTALLATION

The Purchaser is responsible for the installation of the hob. The Manufacturer does not

accept any responsibility for any damage or loss resulting from incorrect installation,

and as such this will not covered by the Manufacturer’s Guarantee.

The hob may be installed in any worktop which is heat resistant to a temperature of

100° C, and has a thickness of 25 - 40 mm. The dimensions of the insert to be cut

out of the worktop are in shown in Fig. 1.

If the Hob is fitted next to a cabinet on either side,

the distance between the Hob and the cabinet

must be at least 30 mm (see Fig. 2); while the

distance between the hob and the rear wall must

be at least 40 mm.

If below the hob there is an accessible space,

there must be a partition panel in insulating material (wood or similar) providing a space of at least

10 mm below the Hob (see Fig. 2).

The Hob unit is fitted by attaching the Fixing

Clamps supplied, using the holes at the base of

the unit.

Fig. 2

Partition panel

30 mm

min.

30 mm

10 mm

This appliance has been designed for non-prof essional,i.e. domestic, use.

Appropriate checks and tests have ensured that, even in the most extreme conditions,

the temperatures reached are within acceptable limits

. The Hob is thermally insula-

ted (in line with Regulation EN) and may be installed: next to panels higher than

the

worktop, for type «Y», or next to panels not higher than the worktop for type

«X.».

See technical characteristics table «Degree of protection».

Page 4

3

Instructions for the installer

The following information is intended for qualified and competant persons only who will

ensure that your appliance is installed correctly. All current legislation concerning the

installation of Gas appliances must be observed by the installer*

* For the U.K. only - By law, the gas installation/commissioning must be carried out

by a «Corgi», registered installer .

This appliance must be installed in accordance with applicable regulations and should

only be used in well-ventilated locations. Before using this appliance carefully study the

instruction book.

Suitable location

A gas-powered cooking appliance produces heat and humidity in the area in which it is

installed. For

this reason you should ensure good ventilation either

by keeping all natural air passages open or by installing an extractor hood with an exhaust flue. Intensive

and prolonged use of the appliance may require extra ventilation, such the opening of

a window or an increase in speed of the electric fan,

if you have one.

If a hood cannot be installed, an electric fan should be fitted to an outside wall or window as long there are air vents in the area.

The electric fan should be able to carry out a complete change of air in the kitchen 3-5

times every hour. The installer should follow the relavant national standards.

Electrical connection (4 electric plates)

In the installation of this appliance a DOUBLE POLE SWITCH must be incorporated into the electrical connection.

The electric hob should always be connected to the 30 amp supply by a qualified electrician.

To substitute the power supply cord, unscrew the 3 screws marked “A” to remove the

cover. In this instance it must be connected to the mains supply via the appropriately

rated cable/flex. Connect the supply cord to the terminal block and to the earth terminal

(Fig. 4).

Fasten the cord by means the 2 screws marked “B” and reset the cover (Fig. 4 bis).

Before connecting the appliance check the efficiency of the earth circuit. Earthing of

the appliance is required by law. The manufacturer declines any responsibility should

this safety measure not be observed. Connection to the electrical supply should be

made by 4.00 mm

2

flex 85° C BS 6007 and connected through the cooker junction unit

to the cooker control unit.

To connect the cable remove the protection cover and insert the cable through the cable chock and fasten it. Effect the connection according to the diagram shown on the

label fixed to the side of terminal board, taking care to connect the earth wire to the

treaded pin near the terminal board.

Always seek the advice of a qualified electrician regarding installation.

Electrical connection

Warning - this appliance must be earthed

This appliance is designed for domestic use only. Connection to the mains supply must

be made by a competant electrician, ensuring that all current regulations concerning

such installations are observed.

Page 5

4

The appliance must only be connected to a suitably rated spur point, a 3 pin 13 amp

plug/socket is not suitable. Adouble pole switch must be provided and the circuit must

have appropriate fuse protection. Further details of the power requirement of the individual product will be found in the users’ instruction and on the appliance rating plate.

In the case of built-in product you are advised, should you wish to use a longer cable

than the one supplied, that a suitably rated heat resistant type must be used.

(Rubber

insulated cable type H05RR-F, H05VV-F, H05V2V2-F must be used. The cables

should be 1,5 mm

2

section for products with electrically heated elements, and 0,75

mm

2

for others products. Also, the maximum external diameter of the cable should

not be greater than 7 mm.)

The wiring must be connected to the mains supply as follows:

CONNECT TO SPUR TERMINAL

Green & Yellow Wire Earth Connection

Blue Wire Neutral Connection

Brown Wire Live Connection

Note: We do not advocate the use of earth leakage devices with electric cooking

appliances installed to spur points because of the .tnuisance trippingn which may occur.

You are again reminded that the appliance must be correctly earthed, the manufacturer declines any responsibility for any event occurring as a result of incorrect

electrical installation.

Installation of electrical connections

Declaration of compliance: This equipment, in the parts intended to come into contact with food, complies with the regulations laid down in EEC directives 89/109.

This appliance complies with directive 89/336/EEC, 73/23/EEC, 90/396/EEC and

the following changes.

Page 6

5

The labels on the Hob indicate the types of gas that can be used.

It is possible to use other types of gas after carrying out simple modifications.

Warning: If gas can be smelt in the vicinity of this appliance turn off the gas supply to

the appliance and call the engineer directly.

Do not search for a leak with a naked flame.

Adapting the hob to different types of gas

To adapt the Hob for use with different types of gas, carry out the following instructions:

— remove the grids and burners

— insert the hexagonal spanner (supplied) into the burner support (Fig. 5)

— unscrew the injector and replace it with one suitable for the gas to be used (see

Table below)

— regulate minimum flame and flame combustion (see nexts chapters).

Gas connection(see page 11)

Hexagonal spanner

Fig. 5

Table of Gas Consumption 1 W = 0,860 kcal/h

GAS

TYPE

METHANE

MGAS

G 20

BUTANE

GAS

G 30

PROPANE

GAS

G 31

Ø INJECTORS

1/100 mm.

093

127

61

84

61

84

NOMINAL THERMAL

POWER

kW kcal/h

1,55 1.290

2,95 2.537

1,55 1.290

2,95 2.537

1,55 1.290

2,95 2.537

kW kcal/h

0,38 327

0,65 559

0,38 327

0,65 559

0,38 327

0,65 559

Norm. Min. Max.

20 17 25

28/30 20 35

37 25 45

CAPACITY

143 l/h

281 l/h

109 g/h

215 g/h

107 g/h

211 g/h

REDUCED THERMAL

POWER

PRESSURE

m bar

BURNER

MEDIUM

LARGE

MEDIUM

LARGE

MEDIUM

LARGE

Rapid

Semi rapid

Total NHGC

141 10,3

110 5,9

28

81 8,7

65 5,5

25,2

5 mm 4 mm

7 mm 2 mm

LPGMJ/HInjector size

LPG gas

Reg. 2,75 kPa

Natural gas

Reg. 1,13 kPa

MJ/HInjector size

Burner

NG

Quota «X» depending

on type of gas

Cooking hobs 60x50 for Australia

Page 7

Regulating the minimum flame

After lighting the burners, turn the control knob to the minimum setting and then remove the knob (this can easily be removed by apply a gentle pressure).

Using a small «Terminal» type screwdriver the regulating screw can be adjusted as in

Fig. 8. Turning the screw clockwise reduces the gas flow, whilst turning it anticlockwise

increases the flow – Use this adjustment to obtain a flame of approximately 3 to 4 mm

in length and then replace the control knob.

If GPL (cylinder) gas is being used, turn the screw clockwise right to the end of the

travel of the by-pass.

Screws regulating

(for differend models)

6

REGULATING THE BURNERS

Flame Combustion

For maximum efficiency from the burners, the correct combustion of the flame is necessary.

A good flame must be well aligned and without yellow tips (Fig. 7/B). If there is insufficient

air the flame will be uneven with yellow tips (Fig. 7/A). If there is too much air, the flame

will be very short and bright (Fig. 7/C). In these cases the combustion must be adjusted by

re-fitting the carburation tube to the Venturi (where there is insufficient air) or removing the

carburation tube (in the case of too much air). To position the carburation tube, the fixing

screws must be loosened, and retightened when the satisfactory combustion is obtained.

Standard regulation values are stated in fig. 6 and following table.

Fig. 6 Fig. 7

Type of

burner

Medium

Large

Quota «X» depending on type of gas

Butane G 30 Propane G 31 Methane G 20

5 mm 7 mm 2 mm

2 mm 5 mm 4 mm

BURNER CAP

BURNER

AIR REGULATION

SCREW

FIXING

SCREW

Fig. 8

Page 8

7

POWER OUTPUT - ELECTRIC HOTPLATES

Setting

0 OFF

1 VERY LOW Warming dishes & melting butter and chocolate

2 LOW Simmering, sauces, stews, milk puddings, poached eggs

3 MODERATE Vegetables, frozen foods, boiling water

4 MEDIUM Fresh Vegetables, pasta, fish, pancakes.

5 HIGH Omelettes, steaks

6 VERY HIGH Chops

INSTRUCTIONS FOR USE

Using the gas Burner

If the burners have not been used for a couple of days, wait for a few seconds before

lighting the burner, this will allow any air present in the pipes to escape.

To ignite the burners on hobs without electric ignition, place a lighted taper close to

the burner, press in and turn the control knob anti-clockwise.

For those hobs with electric ignition, simply turn the control knob to the ignition or maximum position and press the button marked ★. The spark is fired only when the button

is released. If the burner does not ignite first time, try again.

As a safety device, some models automatically cut off the gas supply if the flame is

accidently extinguished. In this case, push and rotate the control knob and keep it held

down for approx 5-6 seconds.

The burner will then remain lit.

ATTENTION: When cleaning the hob, take care to replace the burners correctly,

this will ensure that the ignition point is not blocked.

Use of electric hotplates

For the best use of the electric hotplates and to minimise energy consumption, the

following recommendations should be noted.

A neon indicator light adjacent to the control knob will glow when the electric plate is

in use.

PRESSURE ADJUSTMENT (for Australia only)

First turn the gas off to the appliance. Remove the sealing screw from the regulators

test point at the rear of the appliance and fit the hose of the Manometer to it.

Turn the gas on and light the Wok Burner and one Medium Burner at maximum setting. Check the pressure and adjust at the regulator if necessary to the settings in the

table below or on the Data plate.

For Propane Gas adjust at the regulator on the cylinder - Turn regulator adjusting

screw clockwise increases pressure whilst anti-clockwise decreases pressure. Refit

the test point sealing screw when finished.

Page 9

8

Fig. 7

YES NO NO NO NO

GENERAL ADVICE

For the best results, the flat-bottomed pans should match the gas burner size as follows:

— Medium from 12 - 20 cm.

— Large from 20 - 26 cm.

For smaller containers a reducer stand (supplied with some models) should be used

and the gas burner should be regulated so that the flame does not overlap the base

of the pan. The reducer stand is for use with the medium burner. Vessels with concave

or convex base should not be used.

WARNING:If a burner is accidentally extinguehed, turn the knob to the off position and do not attempt to re-ignite if for at least 1 minute.

To protect the glass lid from damage and in the interests of safety, the burners/plates

must be turned off and the burner/pan support/plate area must be cool before closing

the lid down.

Only pans which have smooth flat bases should be used on the electric hotplates. The

size of the pan should be as close as possible to the diameter of the hotplate, and never smaller (see Fig. 9). The base of the pan should be dry and spillages should be

avoided. Empty pans should not be left on the plates, nor should the plates left switched

on without a pan.

Page 10

9

MAINTENANCE AND CLEANING

Important Advice

Before cleaning the Hob, ensure the appliance has cooled down. S

witch off the

electricity supply.

When cleaning the enamelled, varnished or chrome sections, use warm soapy water

or a non caustic detergent. For stainless steel use an appropriate cleaning solution.

Hotplates should only be cleaned with a cotton cloth coated with vaseline or seed oil.

Never use abrasives, corrosive detergents, bleaching agents or acids. Avoid any acid

or alkaline substances (lemon, juice, vinegar etc.) on the enamelled, varnisched or stainless steel sections.

The burners can be cleaned with soapy water. To restore their original shine, use a

household stainless steel cleaner. After cleaning, dry the burners and replace.

It is important the Burners are replaced correctly.

This appliance must only be used for the purpose for which it is intended, domestic

cooking, and any other use will be considered improper and could therefore be danger

ous. The Manufacturer will not be responisble for any damage or loss resulting from

improper use.

Lubricating the gas taps

If a gas tap becomes stiff, it should be dismantled, cleaned carefully with petrol and

smeared with a drop of special heat resistant grease.

The following operations should be carried but:

— disconnect the electrical power supply, close the gas supply tap from the mains or

cylinder.

— Remove the hob top plate by removing the corner screws and those under the

burners.

— Remove the two screws holding down the head flange.

— Remove the head flange and the retaining spring on the knob shaft.

— Remove the gas regulation cone, clean it with petrol and smear it with some heat

resistant grease, taking care not to obstruct any holes through which gas must pass.

— Re-assemble all the parts, making sure that the spring and the rotating axis of the

cone fitted to the knob shaft are correctly seated.

Aftercare

Before calling out a Service Engineer please check the following:

— that the plug is correctly inserted and fused;

— that the gas supply is not faulty.

If the fault cannot be identified:

switch off the appliance — do not tamper with it — call the Aftercare Service Centre.

The Manufacturer will not be responsible for any inaccuracy resulting from printing or transcript errors contained in this brochure. We reserve the right to carry out modifications to products as required, including

the interests of consumption, without prejiudice to the characteristics relating to safety or function.

Page 11

10

NOTES

Page 12

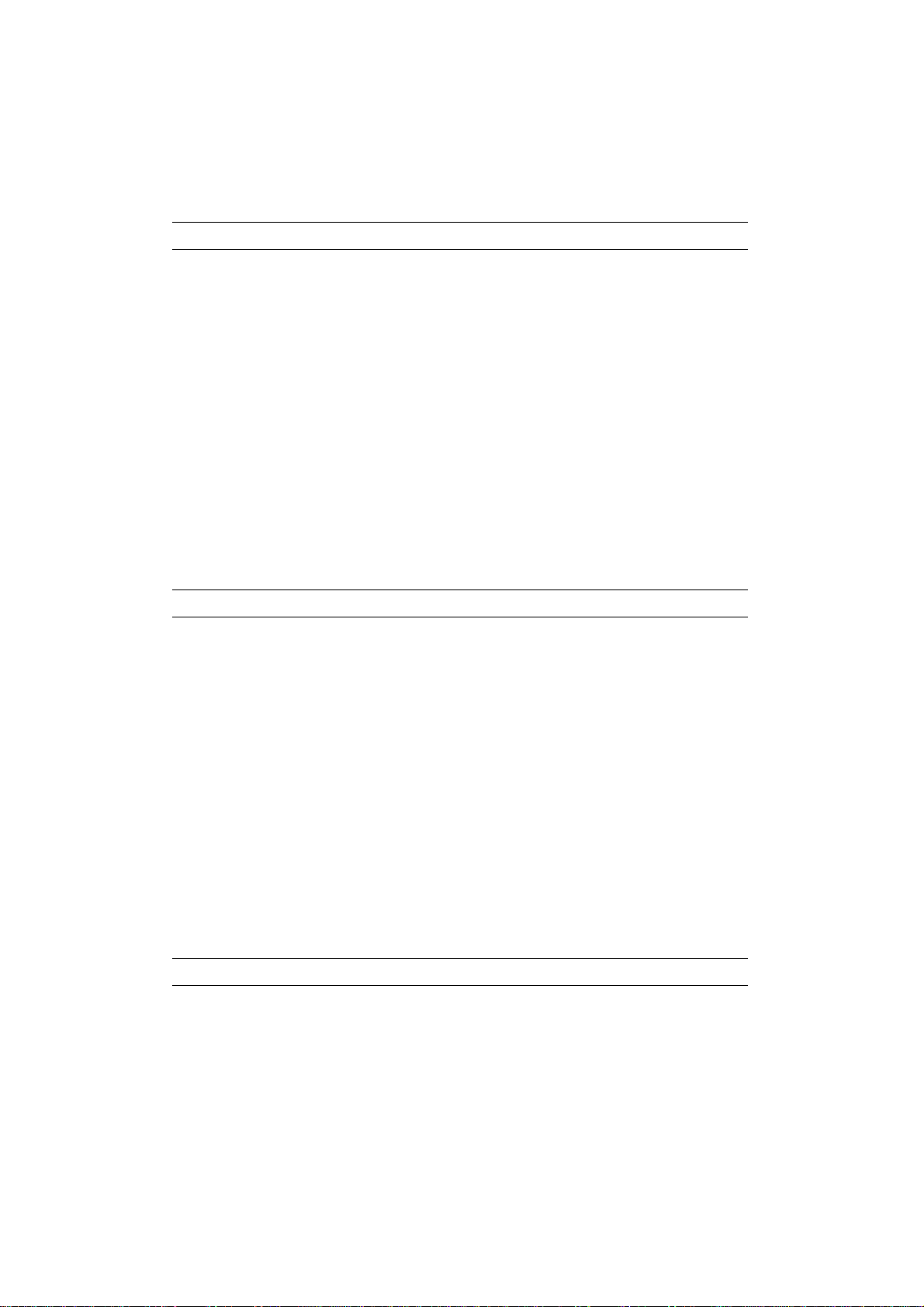

INSTRUCTIONS FOR ASSEMBLY OF THE HOB

TO THE GAS SUPPLY PIPES

These instructions are for Fitters qualified for installation of equipment in line with the

relevant national standard. All work must be carried out with the electricity supply disconnected.

ASSEMBLY PROCEDURE

2 Spanners, sizes 17 and 23 mm are required.

1/2” GAS

A) As illustrated, assemble parts in sequence:

A) fixed pipe

B) washer

C) Elbow fitting with

tapered thred

connection

2) Tighten the joints

with the Spanners,

remembering to twist

the pipes into position

before tightening.

3) Attach fitting C to

mains supply using

rigid copper pipe.

VERY IMPORTANT

For ease of installation and to avoid gas leaks, it is recommended to connect the pipes as follows:

First connect the pipe to the Hob

and then

Connect the pipe to the gas supply.

In this sequence is not followed, there is a danger that gas will be trapped

in the pipe.

AFTER INSTALLATION, CHECK THE TIGHTNESS OF ALL JOINTS USING

A SOAPY SOLUTION

11

Grafica R.B. - 07/00 - Cod. 9259761.6C

Loading...

Loading...