Page 1

CD999i / CD999IS

Condenser Dryer

INSTRUCTION MANUAL

:

Made in United Kingdom

WWW.CAMPOMATIC.COM

Page 2

INSTALLATION

Position the tumble dryer so that the plug remains accessible after installation. Do not block the vent at

the front or base of the dryer, as this will impair the working of the machine. This appliance must not be

installed behind a lockable door, a sliding door or a door with hinges on the opposite side to that of the

tumble dryer.

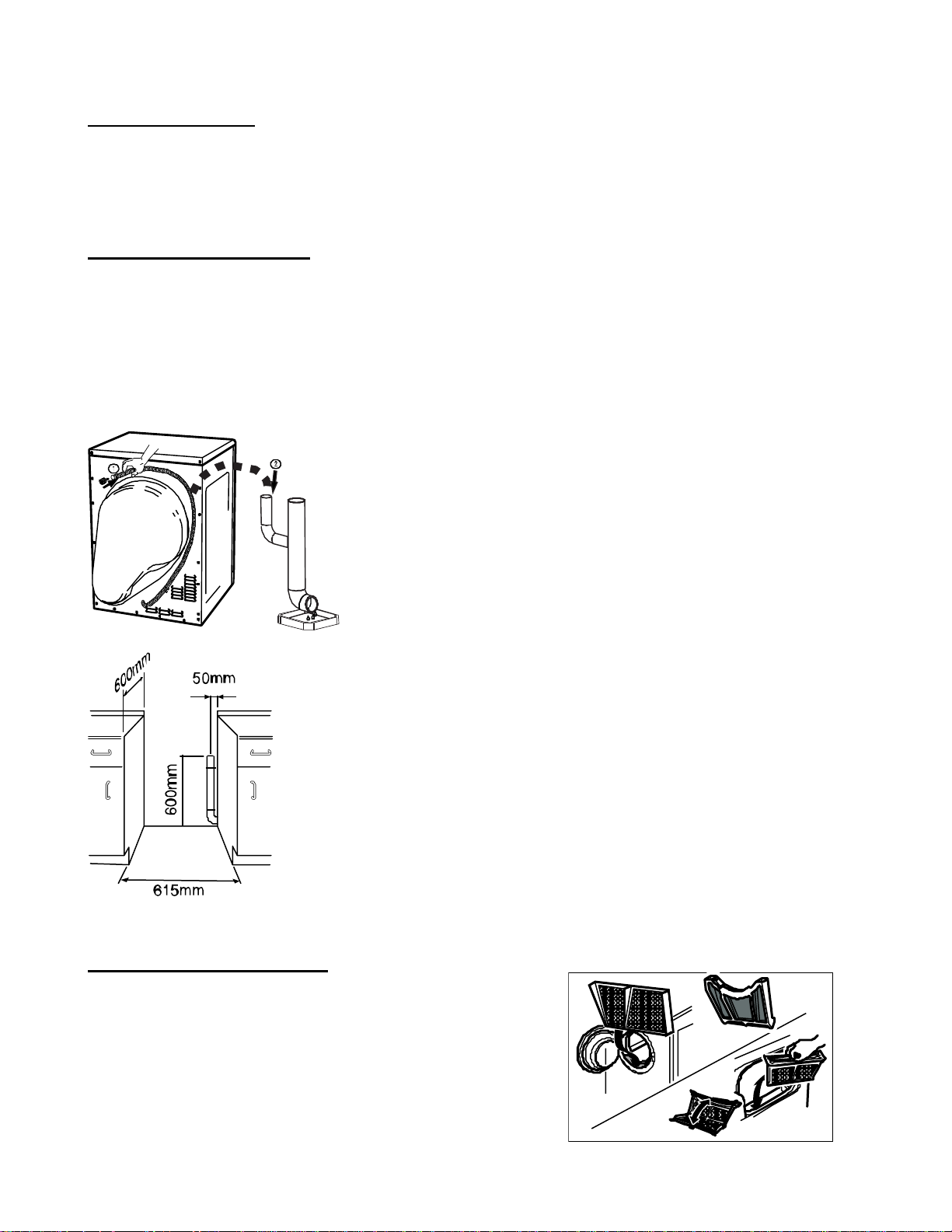

DRAINAGE OPTIONS

Your new tumble dryer is fitted with an internal drain pump, which gives you the option of being able to

drain condensed water to its water bottle, or to your household waste pipe. Connecting your dryer to a

household waste pipe will mean you will not need to periodically empty the water bottle. As supplied, the

drier will drain the water to its bottle. If you wish to convert the dryer so that its water is diverted to a

household waste pipe, follow the simple instructions below:1/ Pull the drain hose from the valve at the top of the unit.

2/ Fit the drain hose into your household waste pipe, ensuring a gap between the end of the hose and any

water in the waste pipe.

To return your drier back to taking the condensed water to the water

bottle, simply fit the drain hose back to the valve at the top of your

drier.

If the drain hose is not long enough to reach your waste pipe, a

drain extension kit can obtained from your retailer (part number

4213 089 8778).

The illustration shows the minimum space required by the dryer and the

position of the waste-pipe within this space and behind the dryer. If a trap

is fitted it must not obstruct the air inlet at the back of the dryer. The

waste pipe can be positioned on either side of the dryer.

If the waste pipe is used by the dryer and a washing machine then its

diameter must be large enough to contain both hoses - 1.5" bore (38mm)

minimum.

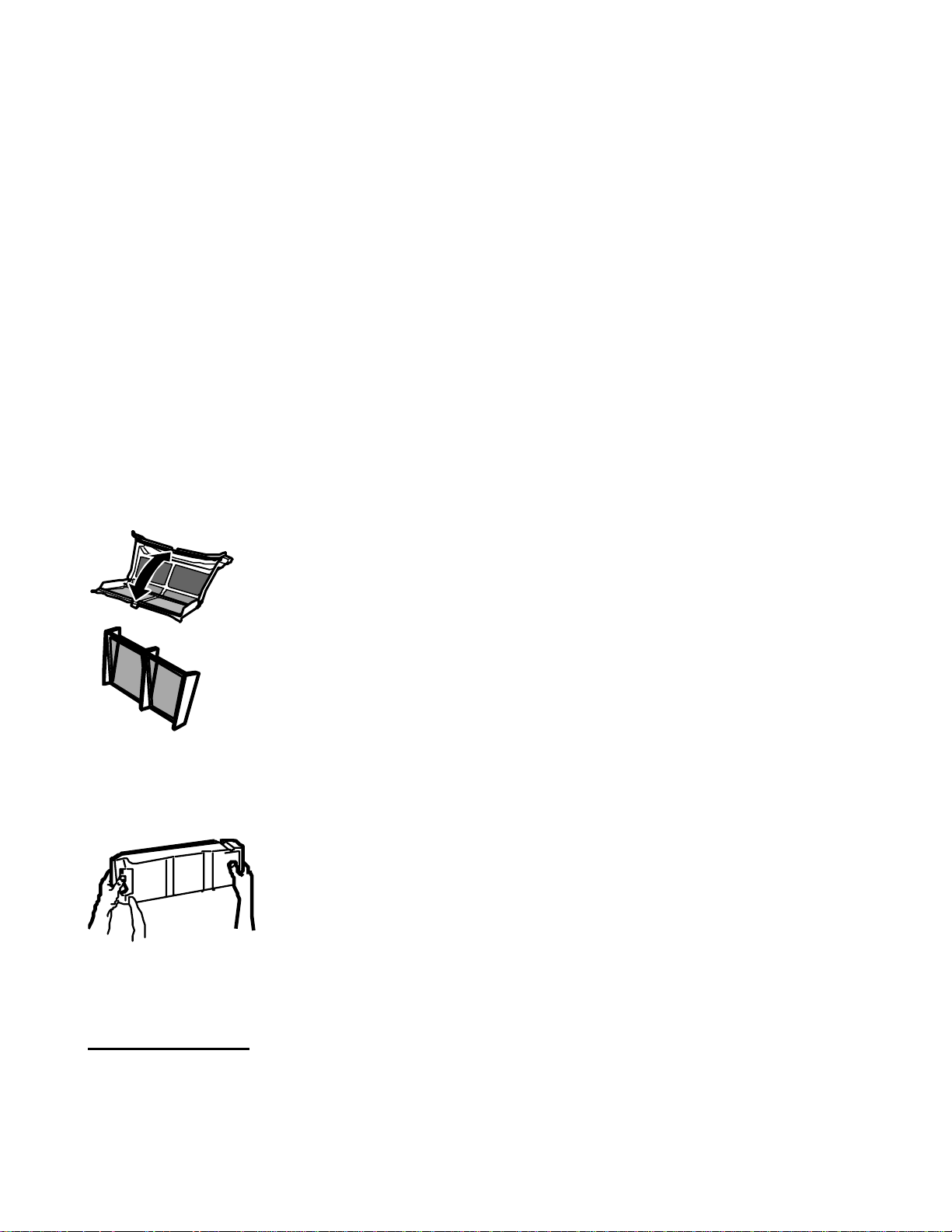

FINAL INSTALLATION

Push the filter into its operating position as shown in

the diagram. If you wish to change the side on which

your door opens, see the instructions on the back

page. Remove any dust by wiping the drum and door

with a damp cloth. Any initial smell of burning will

be caused by dust on the heater and will quickly

disappear.

Page 3

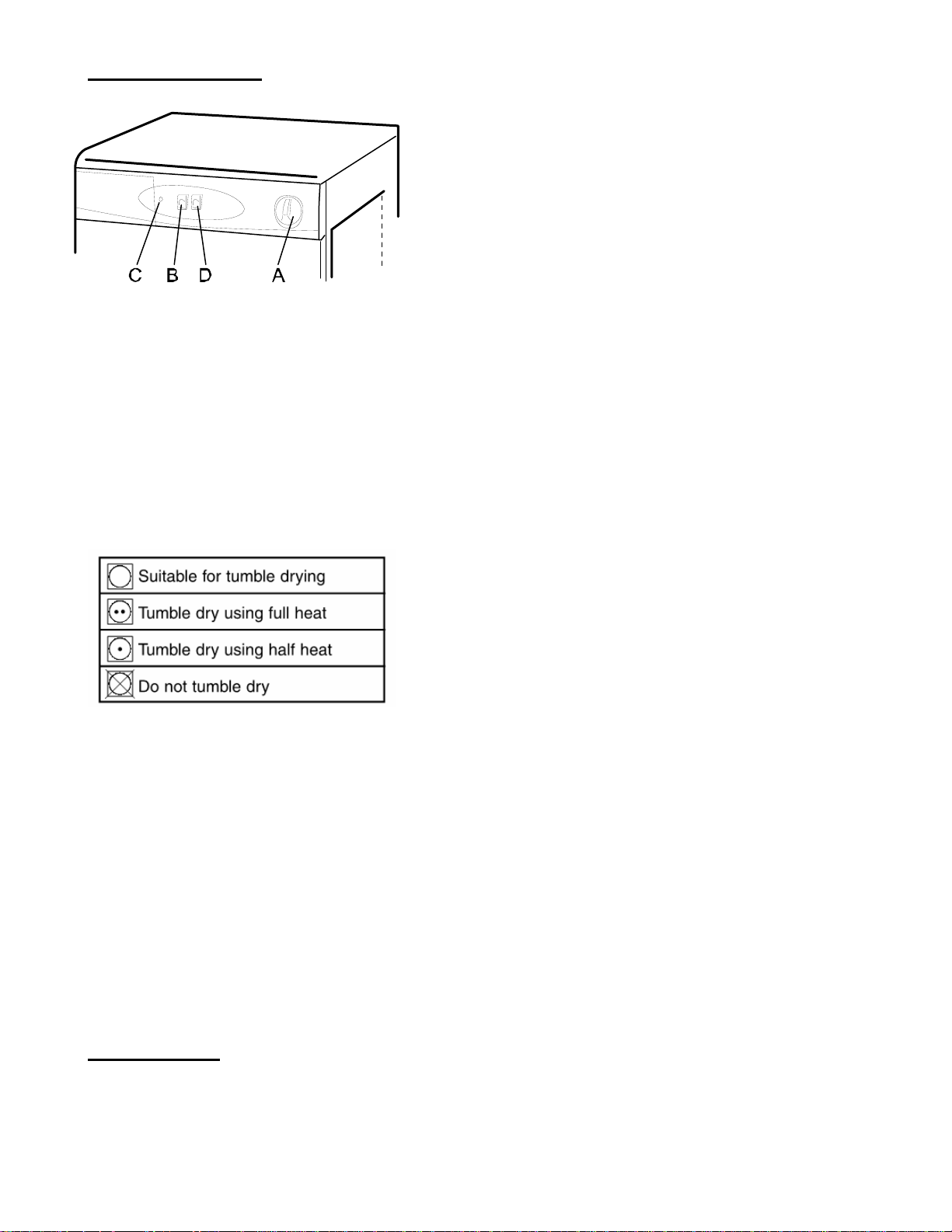

THE CONTROLS

A. THE TIMER

Select the required drying time based on the recommendations on the control panel.

B. HEAT SWITCH Select the required heat setting based on the recommendations on the control

panel.

C. BOTTLE FULL NEON This will light when the bottle needs emptying or when it is

incorrectly inserted.

D. START BUTTON Press Start button after closing the door and selecting the required drying time.

PREPARATION

Check care labels inside the garments.

CARE LABELS YOU MAY FIND ON YOUR FABRICS

Do not tumble dry woollen or wool mixture articles unless the article is labelled as being suitable .This

should avoid shrinkage.

Place delicate articles e.g.tights, scarves, inside a pillowcase.

To avoid the need to iron easycare polyester/cotton items it is .better to only dry small loads (i.e. half fill

drum) It is better to dry small and large articles together.

Fabric softeners, or similar products, should be used as specified by the Fabric Softener instructions. Do

not overload the dryer or dry large bulky items such as duvets or sleeping bags as it is important that the

airflow through the dryer is not obstructed.

Items that have been soiled with substances such as cooking oil, acetone, alcohol, petrol, kerosene, spot

removers, turpentine, waxes and wax removers should be washed in hot water with an extra amount of

detergent before being dried in the tumble dryer.

Items such as foam rubber (latex foam), shower caps, waterproof textiles, rubber backed articles and

clothes or pillows fitted with foam rubber pads should not be dried in the tumble dryer.

OPERATION

Open the door.

Load clothes loosely into the drum.

Load sheets first, starting with one corner.

Close the door.

Page 4

Dry your hands.

Check that the timer is in the ‘0’position.

Plug in the machine.

Select correct heat position, (see programme chart on control panel for recommendations).

Set the timer to the required time setting (see programme chart on control panel for recommendations).

Press the start button if fitted.

The drum will begin rotating. Reversing drum models will stop periodically to rotate in the reverse

direction for a short time.

Should the clothes become dry before the cycle has finished, or if an excessive programme time has been

selected, the drum will continue to rotate while the thermostat will automatically regulate the heater to

reduce the risk of over drying.

If the door is opened during a cycle the dryer will stop. To restart, close the door and press the start button

(if fitted).When drying large items such as sheets, we suggest you periodically stop the dryer to

redistribute the load.

There is an automatic 12 minute cool down period at the end of every cycle, during which the heater is

switched off. This helps to minimize creasing, and must always be used fully to avoid the risk of fire.

NEVER SWITCH THE DRYER OFF AND LEAVE A HOT LOAD IN THE DRUM. RISK OF

FIRE.

ALWAYS CLEAN THE FILTER AFTER EACH USE. Failure to do so could cause the safety cut-out

to operate.

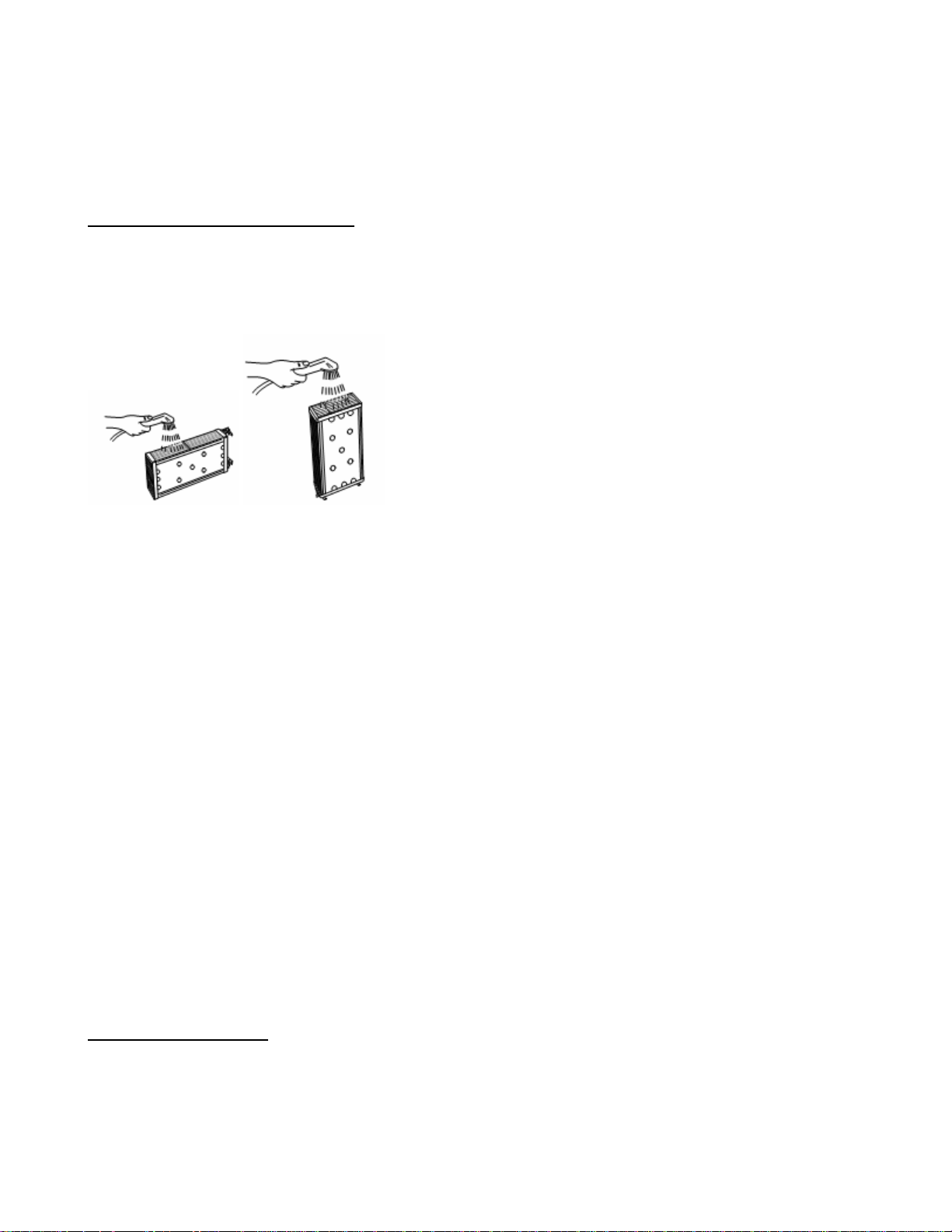

- Pull the filter upwards and away from the appliance.

- Remove any threads or fluff by hand or with a soft brush.

- Slide the filter back.

ALWAYS EMPTY THE WATER BOTTLE

THE CONDENSER

The condenser and ducting should be cleaned monthly or more frequently if the dryer is in constant use.

See “CLEANING THE CONDENSER” below.

NOTE: The condenser will discolour through use.

REMOVING THE CONDENSER

- Wash the filter occasionally in detergent solution using a soft brush to

remove small particles.

- If your filter becomes damaged, replace it to ensure no damage is caused to

the dryer.

- Open the door, pull out and empty the bottle.

- Replace the bottle ensuring that it is pushed all the way in - if it is not, the

dryer will not operate.

- If the dryer is connected to a drain there is no need to empty the bottle but it

must be correctly fitted to the machine.

Page 5

–Firmly pull the condenser out.

RE-INSTALLING THE CONDENSER

–Carefully push the condenser back into the machine, until it is pushed fully home and a “click” is heard.

IMPORTANT:

–Ensure all lint and fluff is removed from around the grille seal before closing or water may leak.

- The dryer may leak if the condenser is not correctly re-installed.

CLEANING THE CONDENSER

CAUTION: For maximum efficiency, the plates are made from very thin aluminum and are easily

damaged. Do not try to poke anything between the plates or use a hard object or tool for cleaning. At all

times, handle the condenser carefully and avoid crushing the plates.

–Remove the condenser (see above).

–Flush the fluff from between the plates under running water and carefully shake off excess water.

Whilst the condenser is removed, clean as much fluff as

possible from inside the ducting by reaching a hand into the

machine. In particular, keep the passage from the fan clear (on

the right hand side of the condenser duct).

After cleaning, re-install the condenser (see above).

ANY PROBLEMS

If the clothes are not dry after normal drying time:

–Check that you used the correct heat setting.

–Check that you have not set the timer within a cool down period.

–Check that the lint filter has been cleaned. A blocked filter will restrict the airflow.

–Check that the condenser unit and associated duct work are clean. If blocked, these will restrict the

airflow.

–Check that your dryer is heating - below the door to the left side, should feel warm to the touch after the

first 10-15 minutes of its programme.

Failure to heat may indicate the safety cut-out has operated. To reset, simply press the red button at the

rear of the machine. If it has operated then a sharp “click” will be heard.

This cut-out only operates if the airflow is severely restricted so make sure the filter is clean and that all

other restrictions are removed before re-starting.

If the cut-out continues to operate after checking the above points, you should contact your service agent.

Check that the machine has the correct weight load in the drum before stating the appliance.

If your machine does not work check the following before calling a service engineer:-

- Check that there is a supply of electricity.

- Check that the door has been properly closed and the machine is switched on (start button pressed, if

fitted).

- Check that the water bottle has been withdrawn from, and–replaced into the machine. The bottle full

warning light should be off.

- Check the fuse in the moulded plug.

OPTIONAL EXTRAS

Stacking Kit.

This enables the dryer to be stacked on top of another similar flat topped appliance. Only stack kit 0312004-01000 should be used. Any other stack kit may affect performance.

The above item can be purchased as an accessory for your tumble dryer from your supplier.

Page 6

TECHNICAL DATA

OVERALL DIMENSIONS:

Height:85 cm

Width:59.5 cm

Depth:58 cm

MAXIMUM DRY WEIGHT LOADS:

7kg Dry Weight

8kg Wet Weight

(For minimum creasing 2kg)

Delicates 2kg

For electrical ratings see plate on back of dryer.

For Model No. see serial plate inside door (needed when requesting service).

Room temperature range 5˚C to 30˚C. (Drying performance decreases as room temperature falls).

Your washing machine should have a spin speed of not less than 1000rpm for maximum efficiency.

IMPORTANT USER INFORMATION

–This tumble dryer is intended for NORMAL DOMESTIC USE ONLY.

–Please note it is not recommended that the dryer is placed directly next to ovens or cookers as the

performance of the dryer may be affected.

–A carpet must not obstruct the ventilation openings in the base of the dryer.

–Do not stack the tumble dryer on top of other appliances without the correct stacking kit.

–Any electrical work required to install the appliance should be carried out by a qualified person.

–It is important to clean the lint filter after each drying cycle and the condenser every month or the

restrictions to airflow will extend drying times and could cause the safety cut-out to trip.

–Under no circumstances should anything other than the recommended articles be placed in the tumble

dryer.

–The tumble dryer should be serviced by an appointed service organisation and only genuine parts used.

–It is dangerous to alter or modify the product in any way other than fitting authorized accessories.

–We recommend that the appliance is unplugged each time after use.It should always be disconnected

from the electricity supply or long periods (i.e.weekends,if it is to be left unattended f

holidays etc.)

–The rear of the dryer gets quite hot during use. Position the dryer so that the back is not accessible while

in operation, but ensure that the sides have a space available to allow airflow.

–The special mains cable and plug assembly must only be replaced with a genuine part from the

manufacturer or our appointed service agent.

It is important to clean fluff from the window of the dryer and around the door seal after each drying

cycle. Failure to do so could result in water leaking.

This appliance is not intended for use by persons (including children) with reduced physical, sensory or

mental capabilities, or lack of experience and knowledge, unless they have been given supervision or

instruction concerning use of the appliance by a person responsible for their safety.

Children should be supervised to ensure they do not play with the appliance.

Fabric softeners , or similar products, should be used as specified by the fabric softener instructions.

WARNING: Never stop a tumble dryer before the end of a drying cycle unless all items are quickly

removed and spread out so that heat is dissipated.

Remove all objects from pockets such as lighters and matches.

DO NOT use a two-way adaptor, or extension lead. The dryer must be connected to its own socket.

DO NOT block the air inlets at the front, base, rear and side of your dryer.

DO NOT allow fluff to accumulate around the tumble dryer. Risk of fire

DO NOT exceed the recommended maximum load.

DO NOT dry unwashed items in the tumble dryer

Page 7

DO NOT place articles in the dryer if anything other than a water solution has been used in the cleaning

process.

DO NOT attempt to dry dripping wet articles.

DO NOT use the tumble dryer if you suspect that it is damaged in any way. Under no circumstances

should you attempt to repair the appliance yourself. Repairs carried out by inexperienced persons may

cause serious injury. Consult your local appointed service engineer and insist on genuine spare parts.

THIS APPLIANCE MUST BE EARTHED

This appliance is marked according to the European Directive 2002/96/EC

on Waste Electrical and Electronic Equipment (WEEE).

This guideline is the frame of a European wide validity of return and

Recycling on Waste Electrical and Electronic Equipment.

This label, positioned on the rear of your dryer, indicates the surface is hot when in operation - avoid

touching.

CAUTION

HOT SURFACE

Page 8

REVERSING THE DOOR OPENING

Page 9

ΏΎΒϟ ϩΎΠΗ ήϴϴϐΗ ΕΎϤϴϠόΗ

Page 10

ΓήϴτΧ ΕΎΑΎλ· ΙϭΪΣ ϰϟ· ΓήΒΧ ϢϬϳΪϟ βϴϟ ιΎΨη ΔτγϮΑ.ΔϴϠλϷ έΎϴϐϟ ϊτϗ ήϴϏ ϞΒϘΗ ϻϭ ΪϤΘόϤϟ ϲϠΤϤϟ ΔϧΎϴμϟ αΪϨϬϣ ήθΘγ.

ίΎϬΠϟ άϫ ξϳέ΄Η ΐΠϳ

άϫίΎϬΠϟϞϤΤϳΔϣϼϋΎ˱ϘϓϭϪϴΟϮΘϠϟϲΑϭέϭϷ

2002/96/ECΔϴϧϭήΘϜϟϹϭ ΔϴΎΑήϬϜϟ ΕΪόϤϟ ΕΎϳΎϔϨΑ ϖϠόΘϤϟ)WEEE.(

ωΎΟήΘγϼϟ ΔϴΑϭέϭϷ ΔϴΣϼμϟΎΑ ιΎΨϟ έΎσϹ Ϯϫ ϞϴϟΪϟ άϫ

ΔϴϧϭήΘϜϟϹϭ ΔϴΎΑήϬϜϟ ΕΪόϤϟ ΕΎϳΎϔϧ ήϳϭΪΗ ΓΩΎϋ·ϭ

ϻβΑϼϤϟ ϒϔΠϣ ϝϮΣ ϢϛήΘϳ ήΑϮϟ ϙήΘΗ.ϖϳήΣ ΙϭΪΣ ήτΧ ϰϟ· ϚϟΫ ϱΩΆϳ ΪϘϓ

ϻϪΑ ϰλϮϤϟ ϞϤΤϠϟ ϰμϗϷ ΪΤϟ ίϭΎΠΘΗ.

ϻ ϒϴϔΠΘΑ ϢϘΗβΑϼϤϟ ϒϔΠϣ ϲϓ ΔϟϮδϐϤϟ ήϴϏ ΩϮϤϟ.

ϻϒϴψϨΘϟ ΔϴϠϤϋ ϲϓ ˯ΎϤϟ ϝϮϠΤϣ ήϴϏ ήΧ ˯ϲη ϱ ϡΪΨΘγ ϝΎΣ ϲϓ ϒϔΠϤϟ ϲϓ ΩϮϤϟ ϊπΗ.

ϻ˯ΎϤϟ ΎϬϨϣ ήτϘΘϳ ϲΘϟ ΩϮϤϟ ϒϴϔΠΗ ϝϭΎΤΗ.

ϻΔϘϳήσ Δϳ΄Α ϪϔϠΗ ϲϓ ϚθΗ ΖϨϛ Ϋ· βΑϼϤϟ ϒϔΠϣ ϡΪΨΘδΗ.ϝΎΣ ϱ΄Α ϚδϔϨΑ ίΎϬΠϟ Ρϼλ· ϝϭΎΤΗ ϻ.ΡϼλϹ ΕΎϴϠϤϋ ˯ήΟ· ϱΩΆϳ Ϊϗ

ϴΒϨΗϪ

ϦΧΎγ τγ

ϞϴϐθΘϟ ˯ΎϨΛ ϦΧΎγ τδϟ ϥ ϰϟ· ˬϒϔΠϤϟ Ϧϣ ϲϔϠΨϟ ˯ΰΠϟ ϰϠϋ ΩϮΟϮϤϟ ˬϖμϠϤϟ άϫ ήϴθϳ–ϪδϤϟ ΐϨΠΘϓ.

Page 11

Χ ΕΎϘΤϠϣΔϳέΎϴΘ

ιήΘϤϟ ΐϴϛήΘϟ ΕϭΩ ΔϋϮϤΠϣ.

˳ϮΘδϣ τγ ϱΫ ϪΑΎθϣ ήΧ ίΎϬΟ ϰϠϋ ιήΘϣ ϞϜθΑ ϒϔΠϤϟ ΐϴϛήΗ Ϧϣ ΔϋϮϤΠϤϟ ϩάϫ Ϧ˷ϜϤΗ.ΐϴϛήΘϟ ΕϭΩ ΔϋϮϤΠϣ ϡΪΨΘγ ΐΠϳ

0312-004-01000ςϘϓ.˯ΩϷ ϰϠϋ ϯήΧ ΐϴϛήΗ ΕϭΩ ΔϋϮϤΠϣ ϱ ήΛΆΗ Ϊϗ.

ϟ ϖΤϠϤϛ ϩϼϋ ΓέϮϛάϤϟ ήμϨόϟ ˯ήη ϦϜϤϳϚϳΪϟ ΩέϮϤϟ Ϧϣ ϒϔΠϤϠ.

ΔϴϨϔϟ ΕΎϧΎϴΒϟ

ΔϴϠϜϟ ΩΎόΑϷ

ωΎϔΗέϻ :85Ϣγ

νήόϟ :59.5Ϣγ

ϖϤόϟ :58Ϣγ

ϒϴϔΠΘϟ ϥίϭϷ ϰμϗϷ ΪΤϟ:

ΔϔϴϔΨϟ βΑϼϤϟ2ϢΠϛ

ˬΔϴΎΑήϬϜϟ ΕΎϔϴϨμΘϠϟ ΔΒδϨϟΎΑϒϔΠϤϠϟ ϲϔϠΨϟ ˯ΰΠϟ ϰϠϋ ΓΩϮΟϮϤϟ ΔΣϮϠϟ ήψϧ.

ΏΎΒϟ ϞΧΩ ΔϴϤϗήϟ ΔΣϮϠϟ ήψϧ ίήτϟ Ϣϗέ ΔϓήόϤϟ)ΔϣΪΧ ΐϠσ ΪϨϋ ΔΑϮϠτϣ.(

Ϧϣ Δϓήϐϟ ΓέήΣ ΔΟέΩ ΡϭήΘΗ5ϰϟ· ΔϳϮΌϣ ΕΎΟέΩ30ΔϳϮΌϣ ΔΟέΩ)Δϓήϐϟ ΓέήΣ ΔΟέΩ ΖπϔΨϧ ΎϤϠϛ ϒϴϔΠΘϟ ˯Ω ϞϘϳ.(

δϐϟ ϥέϭΩ Δϋήγ ϞϘΗ ϻ ϥ ΐΠϳϦϋ ΔϟΎ1000Γ˯Ύϔϛ ϰμϗ ϖϴϘΤΘϟ ΔϘϴϗΪϟ ϲϓ ΓέϭΩ.

ΔϣΎϬϟ ϡΪΨΘδϤϟ ΕΎϣϮϠόϣ

ϥΎϣϷ ϒϗϮΗ Γΰϴϣ ϞϴϐθΗ ϲϓ ΐΒδΘΗ Ϊϗϭ ϒϴϔΠΘϟ.

ΔϠϳϮσ)ϱΕϼτόϟΦϟ ˬΕίΎΟϷ ϝϼΧ ϪϣΪΨΘγ ϡΪϋ ϝΎΣ ϲϓ ˬΔϴϋϮΒγϷ(

˯ϮϬϟ ϖϓΪΘΑ ΡΎϤδϠϟ ΐϧϮΠϟ ϰϠϋ ΔΣΎδϣ ήϓϮΗ Ϧϣ Ϊϛ΄Η ϦϜϟϭ ˬϞϴϐθΘϟ.

ϒϴϔΠΗ ΓέϭΩ Ϟϛ ΪόΑ ΏΎΒϟ ΓΩΪγ ϝϮΣϭ ϒϔΠϤϟ ΓάϓΎϧ Ϧϣ ήΑϮϟ ϒϴψϨΗ ϢϬϤϟ Ϧϣ.˯ΎϤϠϟ ΏήδΗ ΙϭΪΣ ϰϟ· ϚϟάΑ ϡΎϴϘϟ ϡΪϋ ϱΩΆϳ Ϊϗ.

ιΎΨηϷ ΔτγϮΑ ϡΪΨΘγϼϟ κμΨϣ ήϴϏ ίΎϬΠϟ άϫ)ϝΎϔσϷ ϢϬϴϓ ΎϤΑ (ΔϴδΤϟ ΕέΪϘϟ ϱϭΫ ϭ ΔλΎΨϟ ΕΎΟΎϴΘΣϻ ϱϭΫΔϴϠϘόϟ ϭ

ϝϭΆδϣ κΨη ΔτγϮΑ ίΎϬΠϟ ϡΪΨΘγΎΑ ΔϘϠόΘϤϟ ΕΎϤϴϠόΘϠϟ ϭ ϑήηϺϟ ϮόπΨϳ Ϣϟ Ύϣ ˬΔϓήόϤϟϭ ΓήΒΨϟ ϰϟ· ϥϭήϘΘϔϳ Ϧϳάϟ ϭ ΔπϔΨϨϤϟ

ϢϬΘϣϼγ ϥΎϤπϟ.

ίΎϬΠϟΎΑ ϢϬΜΒϋ ϡΪϋ ϥΎϤπϟ ϑήηϺϟ ϝΎϔσϷ ϊπΨϳ ϥ ΐΠϳ.

ˬΔϠΛΎϤϤϟ ΕΎΠΘϨϤϟ ϭ ˬΔθϤϗϷ ϢϴόϨΗ ΩϮϣ ϡΪΨΘγ ΐΠϳΔθϤϗϷ ϢόϨϤΑ ΔλΎΨϟ ΕΎϤϴϠόΘϟ ΔτγϮΑ ΩΪΤϣ Ϯϫ ΎϤϛ.

ήϳάΤΗ:ΪϳΪΒΗ ϢΘϳ ΚϴΤΑ ΎϬόϳίϮΗϭ Ύ˱όϳήγ ήλΎϨόϟ ΔϓΎϛ Δϟί· ϢΘΗ Ϣϟ Ύϣ ϒϴϔΠΘϟ ΓέϭΩ ˯ΎϬΘϧ ϞΒϗ Ύ˱ϘϠτϣ βΑϼϤϟ ϒϔΠϣ ϑΎϘϳΈΑ ϢϘΗ ϻ

ΓέήΤϟ.

ΏΎϘΜϟϭ ΕΎΣΪϘϟ ϞΜϣ ΏϮϴΠϟ Ϧϣ ΕΎϘϠόΘϤϟ ΔϓΎϛ ΔϟίΈΑ Ϣϗ.

-Δϟϵ ϞϴϐθΗ Ϧϣϭ ϴΤλ ϞϜθΑ ΏΎΒϟ ϕϼϏ· Ϧϣ ϖϘΤΗ)ϪΑ ˱ΰϬΠϣ ϒϔΠϤϟ ϥΎϛ Ϋ· ˬϞϴϐθΘϟ ˯ΪΑ έί ϰϠϋ ςϐπϟ ϢΗ.(

-ΎϬΗΩΎϋ· ΖϤΗϭ Δϟϵ Ϧϣ ΎϬΟήΧ· ϢΗ ϩΎϴϤϟ ΔΟΎΟί ϥ Ϧϣ ϖϘΤΗ.΄ϔτϣ ΔΟΎΟΰϟ ˯ϼΘϣ ήϳάΤΗ ΡΎΒμϣ ϥϮϜϳ ϥ ΐΠϳ.

-βΒϘϤϟ ϲϓ ΩϮΟϮϤϟ ήϬμϤϟ Ϧϣ ϖϘΤΗ.

ϦτϘϟ7ΔϓΎΠϟ ΓέΪϘϟ ϢΠϛ /8ΓέΪϘϟ ϢΠϛϝ

)ΪϴόΠΘϟ ϞϴϠϘΘϟ2ϢΠϛ(

-Ϊόϣ ϒϔΠϤϟ άϫςϘϓ ϲϟΰϨϤϟ ϡΪΨΘγϼϟ.

-ϚϟάΑ ϒϔΠϤϟ ˯Ω ήΛ΄Θϳ Ϊϗ ΚϴΣ ΪϗϮϤϟ ϭ ϥήϓϷ έϮΠΑ ΓήηΎΒϣ ϒϔΠϤϟ ϊοϭ ϦδΤΘδ˵ϳ ϻ Ϫϧ ΔψΣϼϣ ϰΟήϳ.

-ϟ ΕΎΤΘϓ ΔϴοέϷ ΕΎηϭήϔϤϟ ϕϮόΗ ϻ ϥ ΐΠϳϒϔΠϤϟ Ϟϔγ ΓΩϮΟϮϤϟ ΔϳϮϬΘ.

-ΔΤϴΤμϟ ΐϴϛήΘϟ ΕϭΩ ΔϋϮϤΠϣ ϡΪΨΘγ ϥϭΩ ϯήΧ ΓΰϬΟ ϕϮϓ βΑϼϤϟ ϒϔΠϣ ΐϴϛήΘΑ ϢϘΗ ϻ.

-ίΎϬΠϟ ΐϴϛήΘϟ ΔΑϮϠτϣ ΔϴΎΑήϬϛ ϝΎϤϋ ϱ΄Α ϞϫΆϣ κΨη ϡϮϘϳ ϥ ΐΠϳ.

-δϓ ϻ·ϭ ήϬη Ϟϛ ϒΜϜϤϟ ϒϴψϨΗϭ ϒϴϔΠΗ ΓέϭΩ Ϟϛ ΪόΑ ΔϟΎδϨϟ ΓΎϔμϣ ϒϴψϨΗ ϢϬϤϟ ϦϣΕΎϗϭ ΔϟΎσ· ϰϟ· ˯ϮϬϟ ϖϓΪΗ ϖϮϋ ϱΩΆΘ

-ϑϭήχ Δϳ ΖΤΗ βΑϼϤϟ ϒϔΠϣ ϲϓ ΎϬΑ ϰλϮϤϟ ήϴϏ ΩϮϣ ϊοϭ ϡΪϋ ΐΠϳ.

-ςϘϓ ΔϴϠλϷ έΎϴϐϟ ϊτϗ ϡΪΨΘγ ΐΠϳ ΎϤϛ ΓΪϤΘόϣ ΔϧΎϴλ ΔδγΆϣ ΔτγϮΑ βΑϼϤϟ ϒϔΠϣ ΔϧΎϴλ ΐΠϳ.

-ήϴϴϐΗ ήτΨϟ ϦϣΓΪϤΘόϤϟ ΕΎϘΤϠϤϟ ΐϴϛήΗ ϑϼΨΑ ΔϘϳήσ Δϳ΄Α ΞΘϨϤϟ ϞϳΪόΗ ϭ.

-ϡΪΨΘγϻ ΪόΑ Γήϣ Ϟϛ ϲϓ ˯ΎΑήϬϜϟ Ϧϋ ίΎϬΠϟ ϞμϔΑ ϲλϮϳ.ΐΠϳϭϪϠμϓΎ˱ϤΩϦϣέΪμϣ˯ΎΑήϬϜϟΔϟΎΣ ϲϓϡΪϋϪϣΪΨΘγΕήΘϔϟ

-ΰΠϟ νήόΘϳϡΪΨΘγϻ ϝϼΧ ΔϧϮΨδϠϟ ϒϔΠϤϟ Ϧϣ ϲϔϠΨϟ ˯.˯ΎϨΛ βϤϠϟ Ύ˱οήόϣ ϲϔϠΨϟ ˯ΰΠϟ ϥϮϜϳ ϻ ΚϴΤΑ ϊοϭ ϲϓ ϒϔΠϤϟ ϊο

-ϨμϤϟ Δϛήθϟ Ϧϣ ΔϴϠλϷ ˯ΰΟϷΎΑ ςϘϓ βΑΎϘϤϟ ΔϋϮϤΠϣϭ ιΎΨϟ ˯ΎΑήϬϜϟ ϞΑΎϛ ϝΪΒΘγ ΐΠϳΪϤΘόϤϟ ΔϣΪΨϟ Ϟϴϛϭ Ϧϣ ϭ Δό.

ϻϳΎϬϣ ϡΪΨΘδΗΪϳΪϤΗ ϚϠγ ϭ ϲΎϨΛ Ί.ϪΑ ιΎΨϟ βΑΎϘϟΎΑ ϒϔΠϤϟ ϞϴλϮΗ ΐΠϳ.

ϻϒϔΠϤϠϟ ϲΒϧΎΠϟϭ ϲϔϠΨϟϭ ϲϣΎϣϷ ˯ΰΠϟ ϲϓ ΓΩϮΟϮϤϟ ˯ϮϬϟ ϞΧΪϣ ΪδΑ ϢϘΗ.

Page 12

ϩΎϴϤϟ ΔΟΎΟί ώϳήϔΘΑ Ύ˱ϤΩ Ϣϗ

-ΎϬϐϳήϔΘΑ Ϣϗϭ ΝέΎΨϠϟ ΔΟΎΟΰϟ ΐΤγϭ ΏΎΒϟ Θϓ.

-ϴΤμϟ ϞϜθϟΎΑ ΎϬόοϭ Ϧϣ Ϊϛ΄Θϟ ϊϣ ΔΟΎΟΰϟ Ϊϋ–ˬϴΤλ ϞϜθΑ ΎϬόοϭ ϢΘϳ Ϣϟ Ϋ·

ϔΠϤϟ ϞϤόϳ ϦϠϓϒ.

-ΐΠϳ ϦϜϟϭ ΔΟΎΟήϟ ώϳήϔΘϟ ΔΟΎΣ ϙΎϨϫ ϥϮϜΗ Ϧϟ ϑήμϤΑ ϒϔΠϤϟ ϞϴλϮΗ ϝΎΣ ϲϓ

Δϟϵ ϲϓ ϴΤλ ϞϜθΑ ΎϬΒϴϛήΗ.

ϒΜϜϤϟ

ΖΑΎΛ ϞϜθΑ ϒϔΠϤϟ ϡΪΨΘγ ϡΪϋ ϝΎΣ ϲϓ έήϜΘϣ ϞϜθΑ ϭ Ύ˱ϳήϬη ΏϮΒϧϷϭ ϒΜϜϤϟ ϒϴψϨΗΐΠϳ.ήψϧ"ϒΜϜϤϟ ϒϴψϨΗ"ϩΎϧΩ.

ψΣϼϣΔ:ϡΪΨΘγϻ ϝϼΧ ϒΜϜϤϟ ϥϮϟ ήϴϐΘϴγ.

ϒΜϜϤϟ Δϟί·

-ΝέΎΨϠϟ ϒΜϜϤϟ ΐΤγ.

ϒΜϜϤϟ ΐϴϛήΗ ΓΩΎϋ·

-ΕϮλ Ϥδ˵ϳϭ Ύ˱ϣΎϤΗ ϪόοϮϣ ϲϓ ήϘΘδϳ ϰΘΣ ˬΔϟϵ ϲϓ ΔϳΎϨόΑ ϒΜϜϤϟ ΐϴϛήΗ Ϊϋ"ΔϘτϘσ."

ϡΎϫ:

-ΪϘϓ ϻ·ϭ ϕϼϏϹ ϞΒϗ ΔϜΒθϟ ΓΩΪγ ϝϮΣ Ϧϣ ΔϟΎδϨϟϭ ήΑϮϟ ΔϓΎϛ Δϟί· Ϧϣ Ϊϛ΄ΗϩΎϴϤϠϟ ΏήδΗ ΙΪΤϳ.

-ϴΤλ ϞϜθΑ ϒΜϜϤϟ ΐϴϛήΗ ΓΩΎϋ· ϡΪϋ ϝΎΣ ϲϓ ϒϔΠϤϠϟ ΏήδΗ ΙΪΤϳ Ϊϗ

ϒΜϜϤϟ ϒϴψϨΗ

ϪϴΒϨΗ:ϒϠΘϠϟ ϪοήόΗ ϞϬδϳ ϱάϟϭ ϖϴϗήϟ ϡϮϴϧϮϤϟϷ Ϧϣ Ύϔμϟ ϊϴϨμΗ ϢΗ ˬΓ˯Ύϔϛ ϰμϗ ϖϴϘΤΘϟ.ϦϴΑ ˯ϲη ϱ ϡΎΤϗ· ϝϭΎΤΗ ϻ Ϛϟάϟ

ϋ ϲϓ ΔΒϠλ ΓΩ ϭ ΐϠλ ˯ϲη ϡΪΨΘγ ϭ ΎϔμϟϒϴψϨΘϟ ΔϴϠϤ.Ύϔμϟ ϢτΤΗ ΐϨΠΗϭ ΔϳΎϨόΑ ϒΜϜϤϟ ϊϣ Ύ˱ϤΩ ϞϣΎόΗ.

-ϒΜϜϤϟ ΔϟίΈΑ Ϣϗ)ϩϼϋ ήψϧ.(

-Ϊΰϟ ˯ΎϤϟ Ϧϣ ΔϳΎϨόΑ κϠΨΗϭ ˳έΎΟ ˯Ύϣ ΖΤΗ Ύϔμϟ ϦϴΑ ΩϮΟϮϤϟ ήΑϮϟ ϒτη.

ΐϴΑΎϧϷ ϞΧΩ Ϧϣ ήΑϮϟ Ϧϣ ϦϜϤϣ έΪϗ ήΒϛ ϒϴψϨΘΑ Ϣϗ ˬϒΜϜϤϟ Δϟί· ΪϨϋϦϋ

ϖϳήσΔϟϵ ϞΧΩ ϦϳΪϴϟ ΪΣ ϝΎΧΩ·.Ϧϣ ήϤϤϟ ΔϓΎψϧ ϰϠϋ φϓΎΣ ˬιΎΧ ϞϜθΑ

ΔΣϭήϤϟ)ϮΟϮϤϟϒΜϜϤϟ ΏϮΒϧ Ϧϣ ϦϤϳϷ ΐϧΎΠϟ ϰϠϋ ΓΩ.(

ϒΜϜϤϟ ΐϴϛήΗ Ϊϋ ˬϒϴψϨΘϟ ΪόΑ)ϩϼϋ ήψϧ.(

ϞϛΎθϣ Δϳ ΙϭΪΣ ϝΎΣ ϲϓ

ϱΩΎόϟ ϒϴϔΠΘϟ Ζϗϭ ΪόΑ βΑϼϤϟ ϒΠΗ Ϣϟ Ϋ·:

-γ Ϧϣ ϖϘΤΗϴΤμϟ ΓέήΤϟ ΩΪϋ· ϡΪΨΘ.

-ΪϳήΒΗ ΓήΘϓ ϦϤο ΖϗΆϤϟ ϦϴϴόΗ ϡΪϋ Ϧϣ ϖϘΤΗ.

-Δϔϴψϧ ΔϟΎδϨϟ ΓΎϔμϣ ϥ Ϧϣ ϖϘΤΗ.˯ϮϬϟ ϖϓΪΗ ΔϗΎϋ· ϰϟ· ΓΎϔμϤϟ ΩΪδϧ ϱΩΆϴγ.

-ϥΎϔϴψϧ ϥήΘϘϤϟ ΏϮΒϧϷϭ ϒΜϜϤϟ ΓΪΣϭ ϥ Ϧϣ ϖϘΤΗ.˯ϮϬϟ ϖϓΪΗ ΔϗΎϋ· ϰϟ· ϚϟΫ ϱΩΆϴγ ˬΩΪδϧ ΙϭΪΣ ϝΎΣ ϲϓ.

-ΤΗϦϴΨδΘϟΎΑ ϡϮϘϳ ϒϔΠϤϟ ϥ Ϧϣ ϖϘ–ΓΪϤϟ ΞϣΎϧήΒϟ ϞϴϐθΗ ΪόΑ βϤϠϟ ΪϨϋ ήδϳϷ ΐϧΎΠϟ ϰϟ· ΏΎΒϟ Ϟϔγ ˯ϑΪΑ ήόθΗ ϥ ΐΠϳ10-

15ΔϘϴϗΩ

ϥΎϣϷ ϒϗϮΗ ΡΎΘϔϣ ϞϴϐθΗ ϢΗ Ϫϧ ϰϟ· ϦϴΨδΘϟ ϡΪϋ ήϴθϳ Ϊϗ.Δϟϵ Ϧϣ ϲϔϠΨϟ ˯ΰΠϟ ϲϓ ΩϮΟϮϤϟ ήϤΣϷ έΰϟ ϰϠϋ ςϐο ˬϦϴϴόΘϟ ΓΩΎϋϹ.

Ϋ·ωΎϤγ ϢΘϴδϓ ϞϴϐθΘϟ ϢΗ "ΔϘτϘσ ΕϮλ "ϱϮϗ.

ϞϴϐθΘϟ ΓΩΎϋ· ϞΒϗ ϯήΧϷ ϖϮόϟ ΔϓΎϛ Δϟί· Ϧϣϭ Δϔϴψϧ ΓΎϔμϤϟ ϥ Ϧϣ Ϊϛ΄Θϓ ˬΓΪθΑ ˯ϮϬϟ ϖϓΪΗ ΔϗΎϋ· ϝΎΣ ϲϓ ςϘϓ ϥΎϣϷ ϒϗϮΗ ϞϤόϳ.

ϞϴϛϮΑ ϝΎμΗϻ ΐΠϴϓ ˬϩϼϋ ΓέϮϛάϤϟ ρΎϘϨϟ Ϧϣ ϖϘΤΘϟ ΪόΑ ϞϤόϟ ϲϓ ϥΎϣϷ ϒϗϮΗ ήϤΘγ Ϋ·ϚϳΪϟ ΔϣΪΨϟ.

ϪϠϴϐθΗ ˯ΪΑ ϞΒϗ ΔϧϮτγϷ ϞΧΩ ϴΤμϟ ϥίϮϟ ΩϮΟϭ Ϧϣ ϖϘΤΗ.

ΔϧΎϴλ αΪϨϬϤΑ ϝΎμΗϻ ϞΒϗ ϲϠϳ ΎϤϣ ϖϘΤΘϓ Δϟϵ ϞϤόΗ Ϣϟ Ϋ·:-

-˯ΎΑήϬϜϟΎΑ ΩΪϣ· ΩϮΟϭ Ϧϣ ϖϘΤΗ.

Page 13

ϡΪΨΘγ ΐΠϳΔθϤϗϷ ϢόϨϤΑ ΔλΎΨϟ ΕΎϤϴϠόΘϟ ΔτγϮΑ ΩΪΤϣ Ϯϫ ΎϤϛ ˬΔϠΛΎϤϤϟ ΕΎΠΘϨϤϟ ϭ ˬΔθϤϗϷ ϢϴόϨΗ ΩϮϣ.ϒϔΠϤϟ ϞϴϤΤΘΑ ϢϘΗ ϻ

ϒϔΠϤϟ ϝϼΧ ˯ϮϬϟ ϖϓΪΗ ΔϗΎϋ· ϡΪϋ ϢϬϤϟ Ϧϣ Ϫϧ ΚϴΣ ϡϮϨϟ αΎϴϛϭ ΕΎϓΎΤϠϟ ϞΜϣ ΓήϴΒϛ ΔϤΨο ΩϮϣ ϒϴϔΠΗ ϭ Ϊί ϞϜθΑ.

ϤΑ ΖΨτϠΗ ϲΘϟ ΩϮϤϟ ϞδϏ ΐΠϳΔϨϴΘϨΑήΘϟ Ζϳίϭ ϊϘΒϟ Δϟί· ΩϮϣϭ ϦϴγϭήϴϜϟϭ ϦϳΰϨΒϟϭ ϞΤϜϟϭ ϥϮΘϴγϷϭ ϡΎότϟ Ζϳί ϞΜϣ ΩϮ

βΑϼϤϟ ϒϔΠϣ ϲϓ ΎϬϔϴϔΠΗ ϞΒϗ ϒψϨϤϟ Ϧϣ ΓήϴΒϛ ΔϴϤϛ ϡΪΨΘγΎΑ ϦΧΎγ ˯Ύϣ ϲϓ ϊϤθϟ Δϟί· ΩϮϣϭ ωϮϤθϟϭ.

ϲΠϨϔγϷ ρΎτϤϟ ϞΜϣ ΩϮϣ ϒϴϔΠΗ ϡΪϋ ΐΠϳ)βϜΗϼϟ ΓϮϏέ (ϤΤΘγϻ ΕΎόΒϗϭρΎτϤϟΎΑ ΔϤϋΪϤϟ ΩϮϤϟϭ ˯ΎϤϠϟ ΔϣϭΎϘϤϟ ΔΠδϧϷϭ ϡΎ

βΑϼϤϟ ϒϔΠϣ ϲϓ ϲΠϨϔγϷ ρΎτϤϟΎΑ ΔϨτΒϤϟ ΪΎγϮϟ ϭ ΔθϤϗϷϭ.

ϞϴϐθΘϟ

ΏΎΒϟ Θϓ.

ΔϧϮτγϷ ϞΧΩ ΎϬτϐο ϥϭΩ βΑϼϤϟ ϊο.

ΓΪΣϭ Δϳϭί Ϧϣ ΔϳΪΑ ˬ˱ϻϭ Ε˯ϼϤϟ ϊο.

ΏΎΒϟ ϖϠϏ.

ϚϳΪϳ ϒϔΟ.

ϰϠϋ ΖϗΆϤϟ ϥ Ϧϣ ϖϘΤΗϊοϮϟ"0."

˯ΎΑήϬϜϟΎΑ Δϟϵ ϞϴλϮΘΑ Ϣϗ.

ˬϴΤμϟ ϦϴΨδΘϟ ϊοϭ ΩΪΣ)ΕΎϴλϮΘϟ ΔϓήόϤϟ ϢϜΤΘϟ ΔΣϮϟ ϰϠϋ ΩϮΟϮϤϟ ΞϣΎϧήΒϟ ςτΨϣ ήψϧ.(

ΏϮϠτϤϟ ΖϗϮϟ ΩΪϋ· ϰϠϋ ΖϗΆϤϟ ϦϴϴόΘΑ Ϣϗ)ΕΎϴλϮΘϟ ΔϓήόϤϟ ϢϜΤΘϟ ΔΣϮϟ ϰϠϋ ΩϮΟϮϤϟ ΞϣΎϧήΒϟ ςτΨϣ ήψϧ.(

ϞϴϐθΘϟ ˯ΪΑ έί ϰϠϋ ςϐο.

ΒΘγϥέϭΪϟ ϲϓ ΔϧϮτγϷ Ϊ.Γήϴμϗ ΓήΘϔϟ ϲδϜϋ ϩΎΠΗ ϲϓ ϥέϭΪϠϟ ϱέϭΩ ϞϜθΑ ΔϴδϜόϟ ΔϧϮτγϷ ίήσ ϒϗϮΘΘγ.

Ύ˱ϴΎϘϠΗ ΓέήΤϟ ϢψϨϣ ϡϮϘϴγ ΎϤϨϴΑ ϥέϭΪϟ ϲϓ ΔϧϮτγϷ ήϤΘδΘδϓ ˬΞϣΎϧήΒϠϟ Ϊί Ζϗϭ ΪϳΪΤΗ ϢΗ Ϋ· ϭ ˬΓέϭΪϟ ˯ΎϬΘϧ ϞΒϗ βΑϼϤϟ ΖϔΟ Ϋ·

ήτΧ ϞϴϠϘΘϟ ϥΎΨδϟ ϢϴψϨΘΑΪΰϟ ϒϴϔΠΘϟ.

ϒϔΠϤϟ ϒϗϮΘϴδϓ ϒϴϔΠΗ ΓέϭΩ ϝϼΧ ΏΎΒϟ Θϓ ϢΗ Ϋ·.ϞϴϐθΘϟ ˯ΪΑ έί ϰϠϋ ςϐοϭ ΏΎΒϟ ϖϠϏ ˬϞϴϐθΘϟ ΓΩΎϋϹ.˯ΎϴηϷ ϒϴϔΠΗ ΪϨϋ

ϞϤΤϟ ϊϳίϮΗ ΓΩΎϋϹ ϱέϭΩ ϞϜθΑ ϒϔΠϤϟ ϑΎϘϳΈΑ ϲλϮϧ ˬΕ˯ϼϤϟ ϞΜϣ ΓήϴΒϜϟ.

ώϠΒΗ ΔϴΎϘϠΗ ΪϳήΒΗ ΓήΘϓ ΪΟϮΗ12ϛ ΔϳΎϬϧ ϲϓ ΔϘϴϗΩϥΎΨδϟ ϞϴϐθΗ ϑΎϘϳ· ΎϬϟϼΧ ϢΘϳ ˬΓέϭΩ Ϟ.ΐΠϳϭ ˬΔθϤϗϷ ΪόΠΗ ϞϴϠϘΗ ϰϠϋ άϫ ΪϋΎδϳϭ

ϖϳήΣ ΙϭΪΣ ήτΧ ΐϨΠΘϟ ϞϣΎϛ ϞϜθΑ Ύ˱ϤΩ ΎϬϣΪΨΘγ.

ΔϧϮτγϷ ϞΧΩ ήϴΒϛ ϞϤΣ ϙήΗϭ ϒϔΠϤϟ ϞϴϐθΗ ϑΎϘϳΈΑ ˱ΪΑ ϢϘΗ ϻ.ϖϳήΣ ΙϭΪΣ ήτΨϟ νήόΘϟ ϰϟ· ϚϟΫ ϱΩΆϳ ΪϘϓ.

ϟ ϒϴψϨΗ ϰϠϋ Ύ˱ϤΩ ιήΣϡΪΨΘγ Ϟϛ ΪόΑ ΓΎϔμϤ.ϥΎϣϷ ϒϗϮΗ ΡΎΘϔϣ ϞϴϐθΗ ϰϟ· ϚϟάΑ ϡΎϴϘϟ ϡΪϋ ϱΩΆϳ Ϊϗ.

-ίΎϬΠϟ Ϧϣ ΎϬΟήΧ ϢΛ ϰϠϋϷ ΓΎϔμϤϟ ΐΤγ.

-ΔϨϴϟ ΓΎηήϔΑ ϭ ϙΪϴΑ ήΑϭ ϭ ρϮϴΧ Δϳ ΔϟίΈΑ Ϣϗ.

-ΓΎϔμϤϟ ΐϴϛήΗ Ϊϋ.

-ϝϮϠΤϤΑ ΓήΘϓ Ϟϛ ΓΎϔμϤϟ ϞδϏΓήϴϐμϟ ΕΎΌϳΰΠϟ ΔϟίϹ ΔϨϴϟ ΓΎηήϓ ϡΪΨΘγΎΑ ϒψϨϣ.

-έήο ϱϷ ϒϴϔΠΘϟ Δϟ νήόΗ ϡΪϋ ϥΎϤπϟ ΎϬϟΪΒΘγΎϓ ˬΓΎϔμϤϟ ΖϔϠΗ Ϋ·.

Page 14

ϲΎϬϨϟ ΐϴϛήΘϟ

Ϣγήϟ ϲϓ οϮϣ Ϯϫ ΎϤϛ ΎϬϠϴϐθΗ ϊοϭ ϲϓ ΓΎϔμϤϟ ϊϓΩ.ΖϨϛ Ϋ·

ΕΎϤϴϠόΘϟ ήψϧ ˬϩϮΤϧ ΏΎΒϟ Θϔϳ ϱάϟ ΐϧΎΠϟ ήϴϴϐΗ ϲϓ ΐϏήΗ

ΓήϴΧϷ ΔΤϔμϟ ϰϠϋ ΓΩϮΟϮϤϟ.δϣ ϖϳήσ Ϧϋ ΔΑήΗ ϱ ΔϟίΈΑ Ϣϗ

Α ΏΎΒϟϭ ΔϧϮτγϷΔΒσέ εΎϤϗ ΔότϘ.ϰϠϋ ΔΑήΗ ΩϮΟϭ ϱΩΆϴγ

Ύ˱όϳήγ ϲϔΘΨΗ ϢΛ ΔϳΪΒϟ ϲϓ ϖϳήΣ ΔΤέ έϮϬχ ϰϟ· ϥΎΨδϟ.

ϢϜΤΘϟ ήλΎϨϋ

ϲϟϵ ϒϴϔΠΘϠϟ ΐγΎϨϣ

ϞϣΎϜϟ ϦϴΨδΘϟΎΑ ϒϔΠ˵ϳ

ςγϮΘϤϟ ϦϴΨδΘϟΎΑ ϒϔΠ˵ϳ

Ύ˱ϴϟ ϒϔΠ˵ϳ ϻ

.ΖϗΆϤϟ:ϢϜΤΘϟ ΔΣϮϟ ϰϠϋ ΓΩϮΟϮϤϟ ΕΎϴλϮΘϠϟ Ύ˱Ϙϓϭ ΏϮϠτϤϟ ϒϴϔΠΘϟ Ζϗϭ ΩΪΣ.

Ώ .ϊϔΗήϣ ΓέήΤϟ έί/ξϔΨϨϣ:ΔϔϴϔΨϟϭ ΔϴϋΎϨμϟ ΔθϤϗϸϟ ΔπϔΨϨϤϟ ΓέήΤϟϭ ΔϴϧΎΘϜϟϭ ΔϴϨτϘϟ ΔθϤϗϸϟ ΔόϔΗήϤϟ ΓέήΤϟ.

Ν .ΔΟΎΟΰϟ ˯ϼΘϣ ΡΎΒμϣ:ϴΤμϟ ϊοϮϠϟ ΎϬΗΩΎϋ· ϡΪϋ ϝΎΣ ϲϓ ϭ ˯ΎϤϟ ΔΟΎΟί ˯ϼΘϣ ϝΎΣ ϲϓ Δϟϵ ϒϗϮΘΘγϭ ΡΎΒμϤϟ άϫ ˯ϲπϴγ

ϡΎΗ ϞϜθΑ.

Ω .ϞϴϐθΘϟ ˯ΪΑ έί:θΘϟ ˯ΪΑ έί ϰϠϋ ςϐοΏϮϠτϤϟ ϒϴϔΠΘϟ Ζϗϭ ΪϳΪΤΗϭ ΏΎΒϟ ϕϼϏ· ΪόΑ Ϟϴϐ.

˰ϫ .ϩΎϴϤϟ ΔΟΎΟί:)ϞϔγϷ ΐΤδϟ ΏΎΑ Ϟϔγ:(ΓέϭΩ Ϟϛ ΪόΑ ΎϬϐϳήϔΗ ΐΠϳ)ϒϳήμΗ ϡϮσήΧ ΕϭΩ ΔϋϮϤΠϣ ΐϴϛήΗ ϝΎΣ ϲϓ ˯ΎϨΜΘγΎΑ.(

ήϴπΤΘϟ

βΑϼϤϟ ϞΧΩ ΓΩϮΟϮϤϟ ΔϳΎϨόϟ ΕΎϘμϠϣ κΤϓ.

ϤϗϷ ϰϠϋ ΎϫΪΠΗ Ϊϗ ϲΘϟ ΔϳΎϨόϟ ΕΎϘμϠϣΔθ

ϒϴϔΠΘϠϟ ΔϤϼϣ ΎϬϧ ϰϟ· ήϴθϳ ΓΩΎϤϟ ϰϠϋ ϖμϠϣ ΪΟϮϳ Ϣϟ Ύϣ ϑϮμϟΎΑ ΔΟϭΰϤϤϟ ϭ ϑϮμϟ Ϧϣ ΔϋϮϨμϤϟ ΩϮϤϟ ϒϴϔΠΘΑ ϢϘΗ ϻ .ΪϘϓ

ϼϟ ΎϬοήόΗ ΐϨΠΗ ϰϟ· ϚϟΫ ϱΩΆϳεΎϤϜϧ.

ΓΩΎγϭ βϴϛ ϞΧΩ ΕΎΣΎηϮϟϭ ΔϘϴπϟ βΑϼϤϟ ϞΜϣ ˬΔϔϴϔΨϟ ΩϮϤϟ ϊο.

ήΘδϴϟϮΒϟ Ϧϣ ΔϋϮϨμϤϟ ΩϮϤϟ ϲϜϟ ΔΟΎΤϟ ΐϨΠΘϟ/ςϘϓ Γήϴϐλ ΕΎϴϤϛ ϒϴϔΠΗ Ϟπϔϳ ΎϬΑ ΔϳΎϨόϟ ϞϬδϳ ϲΘϟ ϦτϘϟ)ϒμϧ ˯Ϟϣ ϢΘϳ ϱ

ςϘϓ ΔϧϮτγϷ .(Ύ˱όϣ ΓήϴΒϜϟϭ Γήϴϐμϟ ΩϮϤϟ ϒϴϔΠΗ Ϟπϔϳ.

Page 15

Ύ˱ΣΎΘϣ ˯ΎΑήϬϜϟ ϞϴλϮΗ βΒϘϣ Ϟψϳ ΚϴΤΑ ϊοϭ ϲϓ βΑϼϤϟ ϒϔΠϣ ϊοΐϴϛήΘϟ ΪόΑ.ΓΪϋΎϗ ϭ ΔϬΟϭ ϲϓ ΓΩϮΟϮϤϟ ΔΤΘϔϟ ΪδΗ ϻ

ήΗ ΓΩΎϋΈΑ Ϣϗ ˬϩΎϴϤϟ ΔΟΎΟί ϰϟ· ϯήΧ Γήϣ ΔϔΜϜϤϟ ϩΎϴϤϟ ΐΤδΑ ϒϔΠϤϟ ϡϮϘϳ ϲϛΐϴϛ

ϒϔΠϤϟ ϰϠϋ ΩϮΟϮϤϟ ϡΎϤμϟ ϲϓ ϒϳήμΘϟ ϡϮσήΧ.

ϦϜϤϴϓ ˬϑήμϟ ΏϮΒϧ ϰϟ· ϝϮλϮϠϟ ˳ϑΎϛ ήϴϏ ϒϳήμΘϟ ϡϮσήΧ ϝϮσ ϥΎϛ Ϋ·

ϚϳΪϟ ΔΰΠΘϟ ϊΎΑ Ϧϣ ϒϳήμΘϠϟ ΪϳΪϤΗ ΕϭΩ ΔϋϮϤΠϣ ϰϠϋ ϝϮμΤϟ)˯ΰΠϟ Ϣϗέ4213

ΕΎϤϴϠόΘϟ ήϗ

ΐϴϛήΘϟ

Δϟϵ ϞϤόΑ έήοϹ ϰϟ· ϚϟΫ ϱΩΆϴγ ΚϴΣ ˬϒϔΠϤϟ.ϞλΎϔϤΑ ΏΎΑ ϭ ϖϟΰϨϣ ΏΎΑ ϭ ϖϠϐϠϟ ϞΑΎϗ ΏΎΑ ϒϠΧ ίΎϬΠϟ άϫ ΐϴϛήΗ ϡΪϋ ΐΠϳ

βΑϼϤϟ ϒϔΠϣ ΏΎΒϟ ϞΑΎϘϤϟ ΐϧΎΠϟ ϰϠϋ.

ϒϳήμΘϟ ΕέΎϴΧ

ΔΨπϤΑ ΰϬΠϣ ΪϳΪΠϟ βΑϼϤϟ ϒϔΠϣΖϴΑΎϧ ϰϟ· ϭ ϪΑ ΔλΎΨϟ ˯ΎϤϟ ΔΟΎΟί ϰϟ· ΔϔΜϜϤϟ ϩΎϴϤϟ ϒϳήμΗ ΔϴϧΎϜϣ· ϴΘϳ ΎϤϣ ˬΔϴϠΧΩ ϑήλ

ΔϴϟΰϨϤϟ ϑήμϟ.ϱέϭΩ ˳ϞϜθΑ ˯ΎϤϟ ΔΟΎΟί ώϳήϔΗ ϰϟ· ΝΎΘΤΗ Ϧϟ ΔϴϟΰϨϤϟ ϑήμϟ ΐϴΑΎϧ΄Α ϒϔΠϤϟ ϞϴλϮΗ ΪϨϋ.Ωϭΰϣ ϒϔΠϤϟ ϥϷϭ

ΎϬϴϟ· ϩΎϴϤϟ ϒϳήμΘΑ ϡϮϘϴδϓ ΔΟΎΟΰϟΎΑ.ΒϏήϟ ΔϟΎΣ ϲϓϊΒΗ ˬΔϴϟΰϨϣ ϑήλ ΏϮΒϧ ϰϟ· ϪϫΎϴϣ ϞϳϮΤΗ ϢΘϳ ΚϴΤΑ ϒϔΠϤϟ ϞϳϮΤΗ ϲϓ Δ

ΔϴϟΎΘϟ ΔτϴδΒϟ ΕΎϤϴϠόΘϟ:-

1 /ίΎϬΠϟ ϰϠϋ ϲϓ ϡΎϤμϟ Ϧϣ ϒϳήμΘϟ ϡϮσήΧ ΐΤγ.

2 /ΏϮΒϧ ϲϓ ϩΎϴϣ ϱϭ ϡϮσήΨϟ ϑήσ ϦϴΑ ΔϓΎδϣ ΩϮΟϭ Ϧϣ Ϊϛ΄Θϟ ϊϣ ˬϚϳΪϟ ϲϟΰϨϤϟ ϑήμϟ ΏϮΒϧ ϲϓ ϑήμϟ ϡϮσήΧ ΐϛέ

ϒϳήμΘϟ.

0898778.(

ϦϴΑ ΔΑϮϠτϤϟ ΔϓΎδϤϠϟ ϰϧΩϷ ΪΤϟ ϲΤϴοϮΘϟ Ϣγήϟ οϮϳΏϮΒϧ ϊοϭϭ ϒϔΠϤϟ

ϒϔΠϤϟ ϒϠΧϭ ΔΣΎδϤϟ ϩάϫ ϦϤο ϑήμϟ.ϕϮόϳ ϻ ΐΠϳ βΒΤϣ ΐϴϛήΗ ϝΎΣ ϲϓ

ϒϔΠϤϟ ϒϠΧ ΩϮΟϮϤϟ ˯ϮϬϟ άϔϨϣ.ϯΪΣ· ϰϠϋ ϑήμϟ ΏϮΒϧ ϊοϭ ϦϜϤϤϟ Ϧϣϭ

ϒϔΠϤϟ ϲΒϧΎΟ.

Ύϫήτϗ ϥϮϜϳ ϥ ΐΠϳ ˬΔϴϟ ΔϟΎδϏϭ ϒϔΠϤϟ ΔτγϮΑ ϑήμϟ ΏϮΒϧ ϡΪΨΘγ ϝΎΣ ϲϓ

θϴϟ ϲϔϜϳ ΎϤΑ ˱ήϴΒϛϦϴϣϮσήΨϟ ϞϤ-ήτϘϠϟ ϰϧΩϷ ΪΤϟ ϥϮϜϳ ΚϴΣ1.5ΔλϮΑ)38

ϣ

Page 16

CD999i / CD999IS

Campoma c S.R.L. Via Configliachi 5/B . 35031, Abano Terme (Padova), ITALIA

WWW.CAMPOMATIC.COM

Loading...

Loading...