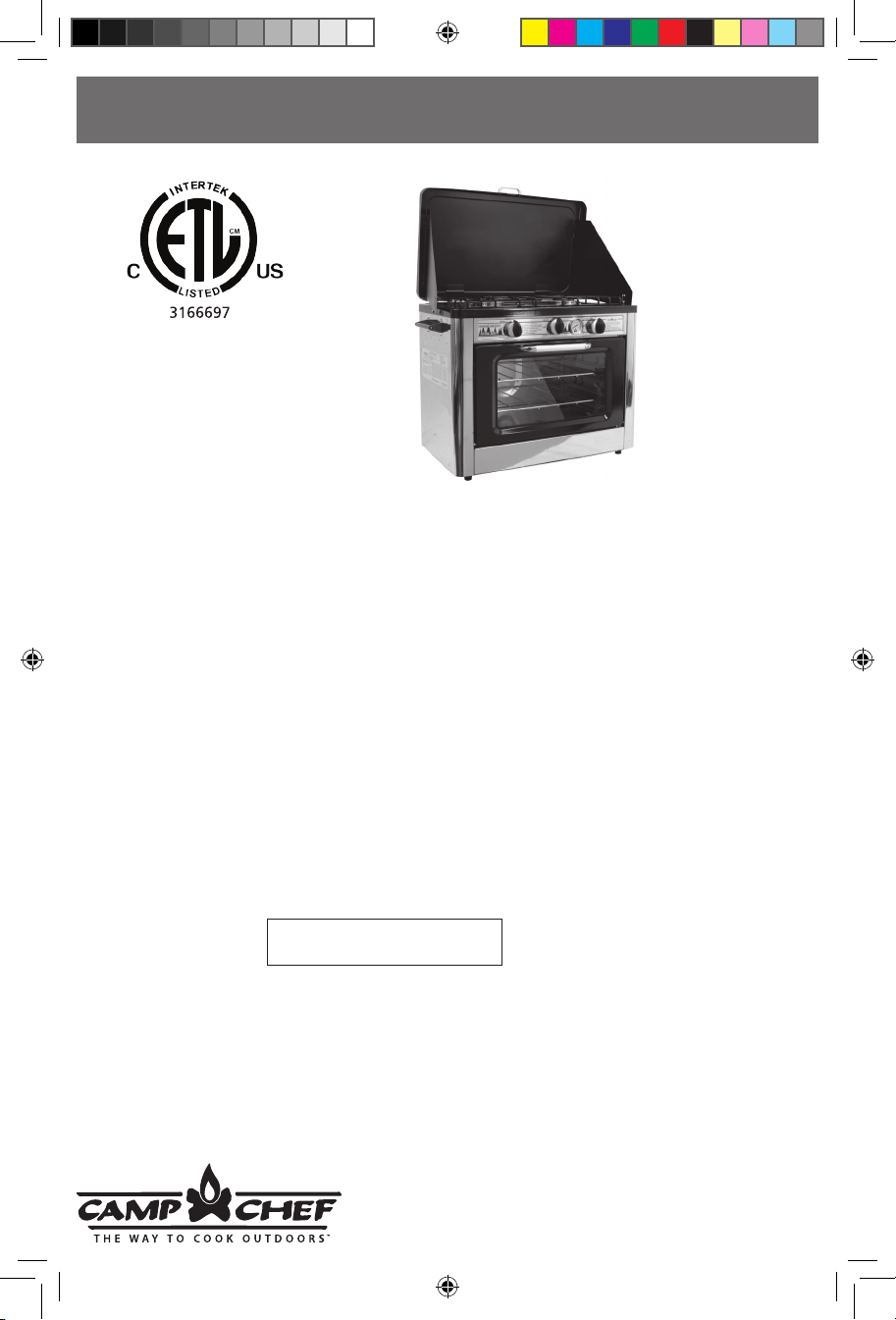

Page 1

OUTDOOR CAMP OVEN CARE,

USE AND SAFETY INSTRUCTIONS

PORTABLE GAS

CAMP STOVE

Conforms to ANSI STD Z21.72b-2002

Certified to CSA STD 11.2b-2002

To installer or person assembling this appliance: Leave this manual

with this appliance for future reference.

To consumer: Keep this manual for future reference. This

instruction manual contains important information necessary for

the proper assembly and safe use of this product.

Read and follow all warnings and instructions before assembling

and using the appliance.

Follow all warnings and instructions when using the appliance.

DO NOT DISCARD THIS INSTRUCTION MANUAL.

Fill in model number found on the product.

Model Number:

C-OVEN 2

For outdoor use only.

3985 N. 75 W., Hyde Park UT 84318

1.800.650.2433 or 1.435.752.3922

0312-Coven-TriBook.indd 1 3/22/12 4:29 PM

Page 2

FOR YOUR SAFETY

If you smell gas:

1. Do not attempt to light the appliance.

2. Extinguish any open ame.

3. Disconnect from fuel supply.

FOR YOUR SAFETY

Do not store or use gasoline or other liquids with ammable

vapors in the vicinity of this or any other appliance.

CARBON MONOXIDE HAZARD

This appliance can produce carbon monoxide which has no odor.

Using it in an enclosed space can kill you.

Never use this appliance in an enclosed space such as a camper,

tent, car or home.

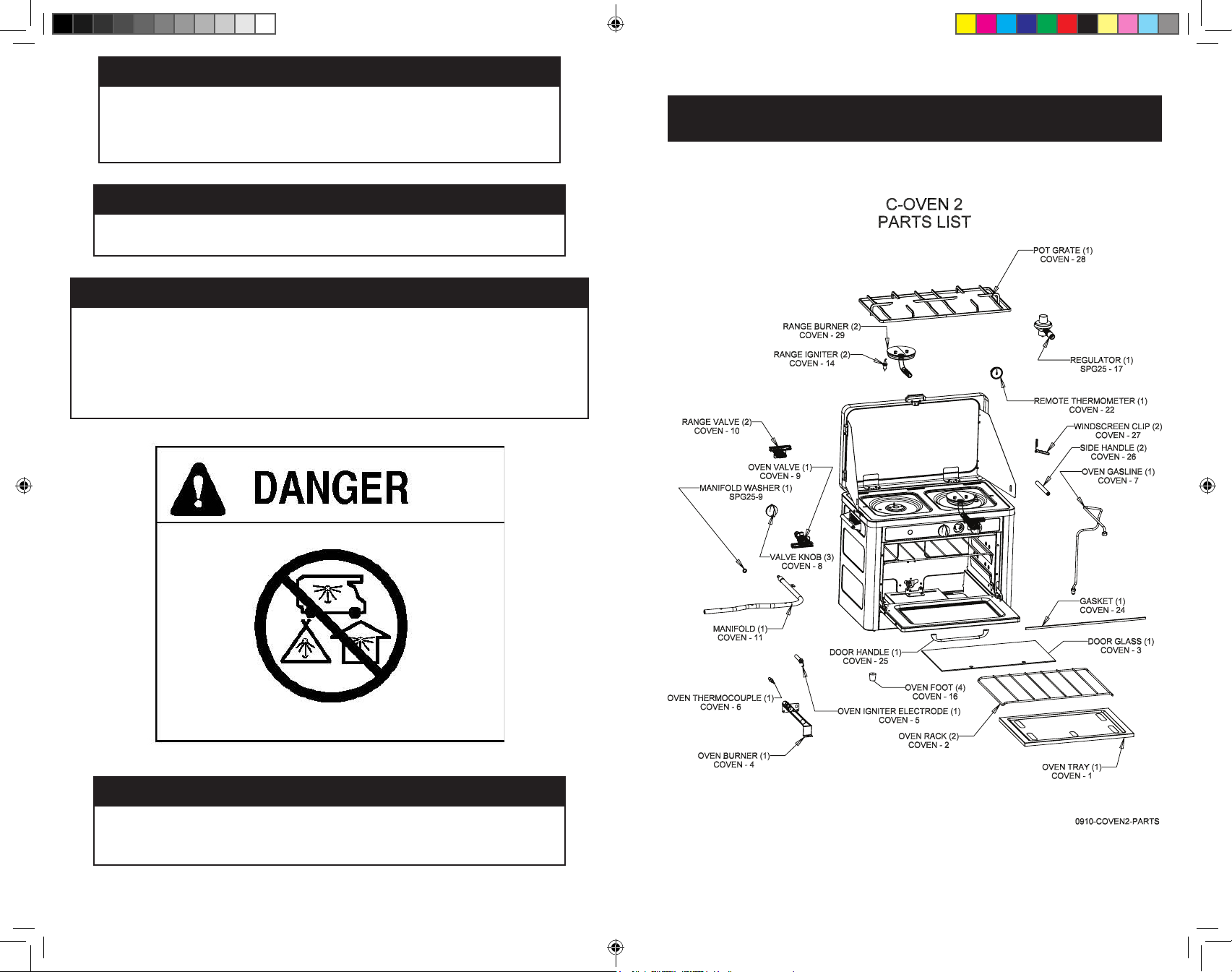

PARTS LIST

WARNING

This product contains chemicals known to the State of California to cause cancer and birth defects or other reproductive harm.

0312-Coven-TriBook.indd 2-3 3/22/12 4:29 PM

Page 3

1. DO NOT leave this appliance unattended while in use. The user must

remain in the immediate area of

the product and have a clear view

of the product at all times during

operation.

2. Keep children and pets away from

burner at all times.

3. The use of alcohol, prescription or

non-prescription drugs may impair

your ability to properly assemble or

safely operate this appliance.

4. For OUTDOOR use only. Do

NOT use in a building, garage

or any other enclosed area. Do

NOT use in or on recreational

vehicles or boats. NEVER use this

appliance as a heater.

5. Do not operate appliance under

ANY overhead construction.

Keep a minimum clearance of

1 foot (0.3 m) from the sides,

front and back of appliance to

ANY construction. Keep the area

clear of all combustible material

and flammable liquids, including

wood, dry plants and grass, brush,

paper, and canvas. Never use this

appliance within 25 ft. (7.5 m) of

any flammable liquid.

6. Use ONLY on a level, stable

surface.

7. Keep the fuel supply hose away

from any heated surfaces.

8. To prevent accidental fires, before

using the appliance ensure that the

hose is not damaged and all joints

and connections are not leaking

by turning on the cylinder valve,

leave the burner valve closed, and

apply a soapy solution to the joints

and connections. If a continuous

hissing sound is heard, or if the

soapy solution bubbles, there is a

leak. Do not use the appliance if

there is a leak. Replace the faulty

parts.

9. Extinguish all open flames before

connecting the gas supply to the

appliance and before checking for

leaks.

10. When cooking with oil or grease, a

thermometer MUST be used.

11. NEVER allow oil or grease

temperature to get hotter than

400ºF (200ºC). If the temperature

exceeds 400ºF (200ºC) or if oil

begins to smoke, IMMEDIATELY

turn burner off.

12. When cooking with oil or grease,

fire extinguishing materials shall

be r eadil y accessible. In the event of

an oil or grease fire do NOT

attempt to extinguish with water.

Use a Type BC dry chemical fire

extinguisher or smother fire with

dirt, sand or baking soda.

13. NEVER overfill the cooking pot

with oil, grease or water.

14. When frying with oil or grease, all

food products MUST be completely

thawed and towel dried to remove

excess water. Failure to completely

thaw and dry food may cause oil

or grease to overflow. Follow

or grease to overflow. Follow

instructions in this manual for

frying foods.

15. When frying, slowly submerse food

products into the oil or grease. Do

NOT drop.

16. DO NOT place an empty

cooking vessel on burner while

in operation. Use caution

when placing anything in the

cooking vessel while burner is in

operation.

17. In the event of rain, hail, sleet

or other forms of precipitation,

while cooking with oil or

grease, IMMEDIATELY turn off

burner(s) and gas supply, then

cover cooking vessel. Do NOT

attempt to move the appliance or

the cooking vessel.

18. Avoid bumping or impact with

the appliance to prevent spillage or

splashing of hot cooking liquid.

19. Do NOT move the appliance when

in use. Allow unit to cool to 115°F

(45°C) before moving or storing.

20. This appliance will be hot during

and after use. Use insulated oven

mitts or gloves for protection

from hot surfaces or splatter from

cooking liquids.

21. In case there is a fire, call the

local fire department or dial

911. Stay clear from flames.

Do not attempt to extinguish an

oil or grease fire with water.

22. Use only accessories, such as

cooking vessels recommended

by the manufacturer, to allow

safe and proper performance

of the product. Never use

a cooking vessel larger than

the capacity and diameter

recommended by the

manufacturer.

23. This product is not intended for

commercial use.

24. The Max Pot Diameter is 10”.

25. Do not obstruct the ow of com-

bustion and ventilation air.

NOTE: This appliance is set to use 16.4 oz. disposable

propane cylinders. Use only cylinders marked propane.

Disposable propane cylinders must be disconnected from

the stove when it is in storage.

Refillable Bulk LP-Gas Tanks with a maximum capacity

of 20 pounds may also be used with an optional bulk

tank adapter hose. (Bulk tank adapter hose may not be

included) Refillable propane gas cylinders must be turned

off at the LP-Gas supply cylinder when the stove is not

in use.

The LP-gas cylinder(s) used with this stove must be

constructed and marked in accordance with the

specifications for LP-gas cylinders of the U.S. Department

of Transportation or Transport Canada, CAN/CSA B339.

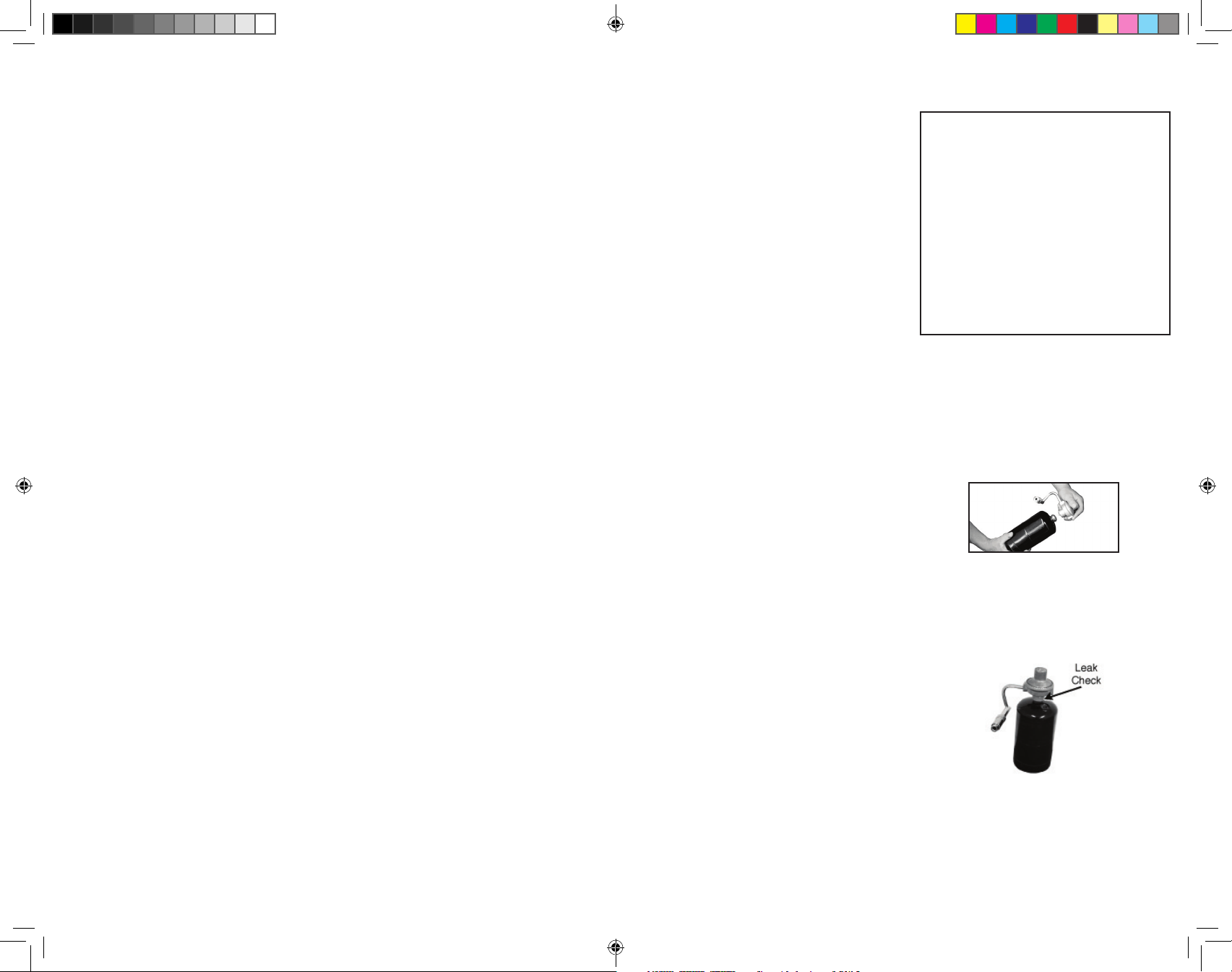

Setup Using Disposable Bottle

1. Make sure burner valves are off.

2. Remove plastic cap from top of

propane cylinder. Save cap for use

in storing. Screw propane cylinder

into regulator. Be careful not to cross

thread. Hand Tighten only.

3. Check the connection between the

cylinder and the regulator with

soapy water. Bubbles indicate a leak.

Check that the connection is not

cross-threaded and that it is tight.

Perform another leak check. If there

is still a leak, remove the cylinder

and contact the manufacturer for

service or repair.

0312-Coven-TriBook.indd 4-5 3/22/12 4:29 PM

Page 4

4. The regulator uses a threaded fitting

to attach to the stove. It is necessary

to hold the stove to make sure the

fitting is seated. Align the regulator

to the fuel tube on the rear of the

stove and push on. Screw on the

outer threaded sleeve in a clockwise

direction until tight.

5. Never operate stove with propane

cylinder in an inverted position.

Dismantling Disposable

Propane Cylinder

1. Turn all valves to the off position and

make sure all flames are extinguished.

2. Remove the bottle from the regulator

by turning counter-clockwise.

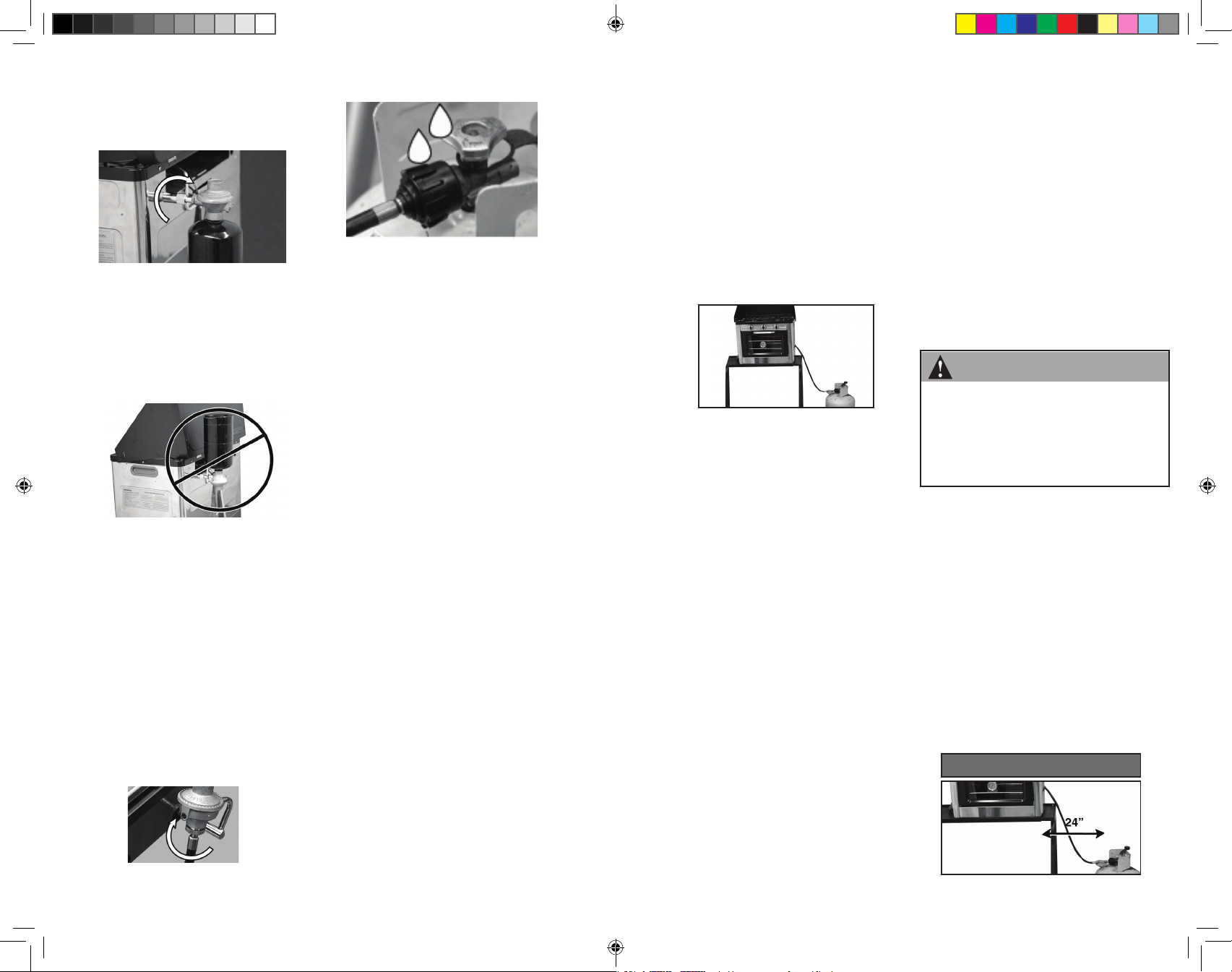

Setup Using Hose And

Refillable Cylinder

1. Make sure burner valves are off.

2. Attach hose to regulator & regula-

tor to stove (as shown).

LEAK CHECK REGULATOR & HOSE

3. Attach hose to cylinder.

4. Open cylinder valve.

5. Perform leak check on hose to

regulator, and hose to cylinder

connections with soapy water.

Bubbles indicate a leak. Check that

the connection is not cross-threaded

and that it is tight. Perform another

leak check. If there is still a leak,

remove the cylinder and contact the

manufacturer for service and repair.

6. Turn off fuel at the cylinder and

disconnect both ends of the hose

when not in use.

Dismantling Hose And

Refillable Cylinder

1. Before dismantling high pressure

hose, be sure gas pressure in hose is

eliminated.

2. Ignite stove and turn off gas valve on

cylinder.

3. Allow flame to self-extinguish.

4. When flame is out, close valves on

the appliance.

5. Remove hose.

• Use appliance only with LP (propane)

gas and the regulator/valve assembly

supplied.

• Installation must conform with

local codes, or in their absence with

National Fuel Gas Code, NFPA 54/

ANSI Z223.1. Handling and storage

of LP cylinders must conform to LP

Gas Code NFPA/ANSI 58. Appliance

is not for use in or on recreational

vehicle and/or boats.

• Do not modify this appliance.

Modifications will result in a

safety hazard. Questions regarding

certification in other areas may be

addressed to 1-435-752-3922.

• Apartment Dwellers: Check

with management to learn the

requirements and fire codes for using

an LP Gas appliance at an apartment.

If allowed, use outside on the ground

floor with a 10 foot clearance from

walls or rails.

• Before opening LP tank valve, check

the coupling nut for tightness. When

appliance is not in use, turn off

control knob and LP tank valve on

supply cylinder.

• Never use LP tank if visibly rusted,

damaged, or out of date.

• If you notice grease or other hot

material dripping from appliance

onto valve, hose or regulator, turn

off gas supply at once. Determine

the cause, correct, clean and inspect

valve, hose and regulator before

continuing. Perform a leak test.

• The regulator may make a humming

or whistling noise during operation.

This will not affect the safety or use

of appliance.

• Clean and inspect the hose before

each use of the appliance. If there

is evidence of abrasion, wear, cuts

or leaks, the hose must be replaced

prior to the appliance being put into

operation. See product tag for hose &

regulator information.

• Do not block holes in bottom or sides

of appliance.

• Never operate appliance with LP

tanks out of correct position specified

in Assembly Instructions.

WARNING

Combustion by-products

produced when using this

product contain chemicals

known to the State of California

to cause cancer, birth defects, or

other reproductive harm.

• Always close LP tank valve and

remove coupling nut before moving

LP tank form specified operating

position.

• NEVER store a spare LP tank under

or near appliance or in enclosed areas.

NEVER fill the cylinder beyond 80%

full. An overfilled spare LP tank is

hazardous due to possible gas released

from the safety relief valve. Failure

to follow these instructions exactly

could cause a fire resulting in death

or serious injury.

Warning: Hose is a trip hazard

0312-Coven-TriBook.indd 6-7 3/22/12 4:29 PM

Page 5

• If you see, smell, or hear escaping

gas, immediately get away from the

LP tank/appliance and call your fire

department.

• All spare LP tanks must have safety

caps installed on the LP tank outlet

LP Tank Removal, Transport

and Storage

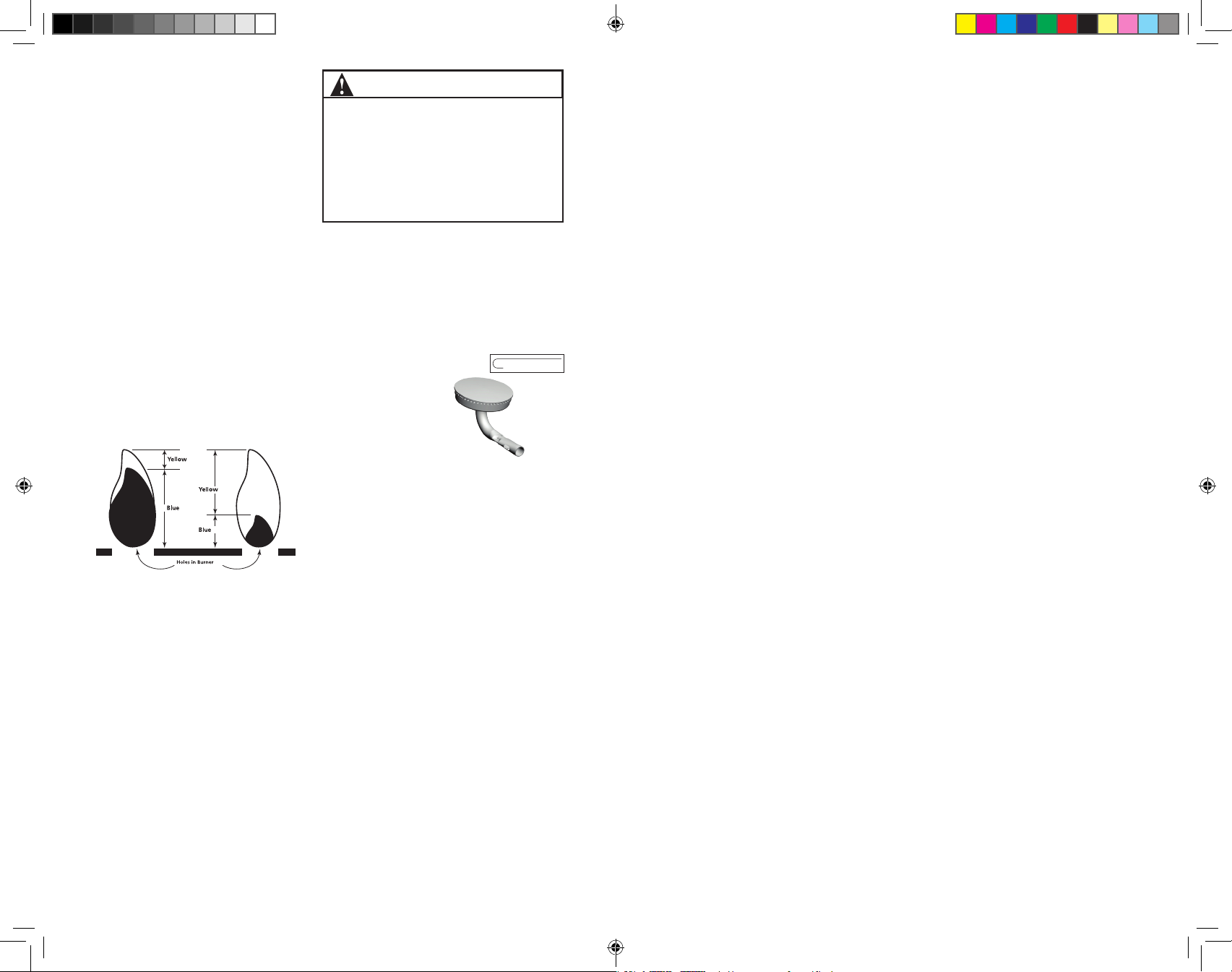

• Turn OFF all control knobs and

LP tank valve. Turn coupling nut

counterclockwise by hand only – do

not use tools to disconnect. Install

safety cap onto LP tank valve. Always

use cap and strap supplied with valve.

Failure to use safety cap as directed

may result

in serious

personal

injury and/

or property

damage.

safety cap

• A disconnected LP tank in storage or

being transported must have a safety

cap installed (as shown). Refillable

LP-Gas cylinders must be stored

outdoors in a well ventilated space,

out of the reach of children, and must

not be stored in a building, garage or

any other enclosed area. Never leave

an LP tank inside a vehicle, which

may become overheated by the sun.

• Do not store LP tanks in an area

where children play.

• Storage of an appliance indoors is

permissible only if the cylinder is

disconnected and removed from the

appliance.

• When the refillable LP-gas supply

cylinder is not disconnected from the

stove, the stove and cylinder must be

stored outdoors, in a well ventilated

space, out of the reach of children,

and must not be stored in a building,

garage or any other enclosed areas.

LP Tank

The LP tank used with your

appliance must meet the following

requirements:

• Purchase LP tanks only with these

required measurements: 12” (30.5cm)

(diameter) x 18” (45.7cm) (tall) with

20 lb. (9 kg.) capacity maximum.

• Be constructed and marked in

accordance with specifications for

LP tank of the U.S. Department

of Transportation (DOT) or the

National Standard of Canada, CAN/

CSA-B339, Cylinders, Spheres and

Tubes for the Transportation of

Dangerous Goods.

• The refillable propane cylinder used

with this appliance must include a

collar to protect the cylinder valve.

LP tank valve must

have:

• Type 1 outlet

compatible with

regulator or

appliance.

OPD Hand Wheel

• Safety relief valve.

• UL listed Overfill Protection Device

(OPD). This OPD safety feature is

identified by a unique triangular hand

wheel. Use only tanks equipped with

this type of valve. LP tank must be

arranged for vapor withdrawal.

LP (Liquefied Petroleum Gas)

• LP gas is non-toxic, odorless and

colorless when produced. For Your

Safety, LP gas has been given an odor

(similar to rotten cabbage) so that it

can be smelled.

• LP gas is highly flammable and may

ignite unexpectedly when mixed

with air.

LP Tank Filling

• Use only licensed and experienced

dealers.

• LP dealer must purge tanks before

filling.

• Dealer should NEVER fill LP tank

more than 80% of LP tank volume.

Volume of propane in tanks will vary

by temperature.

• A frosty regulator indicates gas

overfill. Immediately close LP tank

valve and call local LP gas dealer for

assistance.

• Do not release liquid propane (LP)

gas into the atmosphere. This is a

hazardous practice.

• To remove gas from LP tank, contact

an LP dealer or call a local fire

department for assistance. Check

the telephone directory under “Gas

companies” for nearest certified LP

dealers.

LP Tank Exchange

• Many retailers that sell appliances

offer you the option of replacing your

empty LP tanks through an exchange

service. Use only those reputable

exchange companies that inspect,

precision fill, test and certify their

cylinders. Exchange your tank only

for an OPD safety feature-equipped

tank as described in the “LP Tank”

section of this manual.

• Always keep new and exchanged

LP tanks in upright position during

use, transit or storage.

• Leak test new and exchanged

LP tanks BEFORE connecting to

appliance.

LP Tank Leak Test

For your Safety

• Leak test must be repeated each time

LP tank is exchanged or refilled.

• Do not smoke during leak test.

• Do not use an open flame to check

for gas leaks.

• Appliance must be leak checked

outdoors in well-ventilated area, away

from ignition sources such as gas

fired or electrical appliances. During

leak test, keep appliance away from

open flames or sparks.

Use a clean paintbrush and 50/50

soap and water solution. Use

mild soap and water. Do not use

household cleaning agents.

Damage to gas train components

can result. Brush soapy solution onto

all weld seams and entire valve area.

WARNING

If “growing” bubbles appear, do

not use or move the LP tank.

Contact an LP gas supplier or your

fire department.

0312-Coven-TriBook.indd 8-9 3/22/12 4:29 PM

Page 6

Connecting Regulator To The

LP Tank

Only use the pressure regulator &

hose supplied with this appliance. See

assembly instructions or appliance

name tag for regulator model

number.

1. Place LP tank

on a secure,

level, and stable

surface.

2. Turn control knob

to the OFF position.

3. Turn LP tank OFF by turning hand

wheel clockwise to a full stop.

4. Remove the protective cap from

LP tank valve. Always use cap and

strap supplied with valve.

Do not use a POL

transport plug

(plastic part with

external threads)!

It will defeat the

safety feature of

the valve.

(B) Nipple has to

be centered into

the LP tank valve

(C) Hold coupling

nut and regulator

as shown for

proper connection

to LP tank valve

5. Hold regulator, insert nipple (B)

into LP tank valve. Hand tighten

coupling nut, holding regulator in

a straight line (C) with LP tank

valve so as not to cross thread the

connection.

6. Turn the coupling nut clockwise

to tighten to a full solid stop. The

regulator will seal on the back-check

feature in LP tank valve, resulting in

some resistance. An additional onehalf to three quarters turn is required

to complete connection. Tighten by

hand only – do not use tools.

NOTE: If you cannot complete

connection, disconnect regulator and

repeat steps 5 and 6. If you are still

unable to complete the connection,

do not use this regulator!

• Do not insert any foreign objects into

the valve outlet. You may damage

the valve and cause a leak. Leaking

propane may result in explosion, fire,

severe personal injury, or death.

• Never attempt to attach this appliance

to the self-contained LP gas system of

a camper or trailer or motor home.

Leak Testing Valves, Hoses and

Regulator

1. Turn all control knob(s) to OFF.

2. Be sure regulator is tightly connected

to LP tank.

3. Completely open LP tank valve

by turning hand wheel counter

clockwise. If you hear a rushing

sound, turn gas off immediately.

There is a major leak at the connection.

Correct before proceeding.

4. Brush soapy

solution onto

indicated

connections

shown at right.

5. If “growing” bubbles appear,

there is a leak. Close LP tank

valve immediately and retighten

connections. If leaks cannot be

stopped, do not try to repair. Call

for replacement parts. Order new

parts by giving the serial number,

model number and name of items

needed to the Service Center at

1-435-752-3922.

6. Always close LP tank valve after

performing tank leak test by turning

hand wheel clockwise.

WARNING

• Do not use appliance until leak

checked.

• If you cannot stop a gas leak,

immediately close LP tank valve

and call LP gas supplier or your

fire department!

Setup Instructions:

• Setup the oven on a level surface.

• Open the lid and attach the

windscreens to the side of the oven

as shown.

• Make sure the pot grate is installed

properly with the wire ends fitting

into the holes on the top of the oven

to prevent the rack from moving (See

Picture)

Lighting Stove Instructions:

Do not lean over the Oven while

lighting.

1. Remove all appliances from the

burner to create a free flow or air.

2. Open lid - Do not attempt to light

the stove with the lid closed.

3. Fully open LP bottle valve if using a

bulk tank.

4. Turn control valve slowly to the High

position. Cooker will ignite. Adjust

controls to desired temperature.

5. If ignition does not occur in 5

seconds, turn the burner control(s)

off, wait 5 minutes, and repeat

lighting procedure. If built-in ignitor

will not light follow the preceding

steps and hold a lit long igniter

or match next to the burner when

opening the control valve.

Lighting Oven Instructions:

Do not lean over the Oven while

lighting.

1. Remove all appliances from the oven

to create a free flow of air.

2. Open Oven Door. Do not attempt to

light the oven with the door closed.

3. Remove the bottom oven tray to

reveal the burner.

4. Push the gas valve handle in and

turn slowly to the high position. The

Oven Burner will ignite. (If lighting

with a match, light match and place

it over the burner. Slowly turn on

the valve Do not stand with head or

arms over the burner.)

5. Keep handle depressed for 10

seconds.

6. If the burner does not stay lit repeat

the process.

7. Re-install the bottom oven tray over

the burner.

8. Adjust the controls to the desired

position.

9. If ignition does not occur in 5 seconds,

turn the burner control(s) off, wait

0312-Coven-TriBook.indd 10-11 3/22/12 4:29 PM

Page 7

5 minutes, and repeat the lighting

procedure. If built-in ignitor will

not light follow the preceding steps

and hold a lit long igniter to match

next to the burner when opening the

control valve.

If the flame is accidentally

extinguished, turn the appliance

valves OFF and WAIT 5 minutes

before attempting to ignite.

Burner Flame Check

• Light burner; rotate knob(s) from

HIGH to LOW. You should see

a smaller flame in LOW position

than seen on HIGH. Always check

flame prior to each use. A good flame

should be blue with minimal yellow

tip. Some yellow tips on flames are

acceptable as long as no carbon or

soot deposits appear.

Turning LP Cooker Off

• Turn all knobs to OFF position.

Turn LP tank OFF by turning handwheel clockwise to a full stop.

Hose Check

• Before each use, check to

see if hoses are cut or worn. Replace

damaged hose assembly before using

appliance. Use only valve/ hose /

regulator specified by manufacturer.

See product sheet for hose & regulator

information.

Cleaning The Burner

NOTE: Spiders and small insects can

spin webs and build nests inside the

CAUTION

All cleaning and maintenance

should only be done when the

appliance is cool and with the fuel

supply turned off at the LP cylinder.

DO NOT clean any part in a selfcleaning oven. The extreme heat

will damage the finish.

burner. This especially occurs in late

summer and fall before frost when

spiders are most active. These nests

can obstruct gas flow and cause a fire

in and around the burner and orifice.

Such a fire can cause operator injury

and serious

damage to the

appliance. To

help prevent a

blockage and

ensure full heat

output, clean and

inspect burner

tube often (once or twice a month).

NOTE: Water or air pressure will not

normally clear a spider web.

Steps for cleaning the Burner:

1. Remove burner assembly from

burner.

2. Look inside the burner tube for

nests, webs, or mud.

3. To remove the above obstructions,

use an accessory flexible venturi

brush or bend a small hook on one

end of a long flexible wire or use an

air hose.

4. Inspect and clean the burner

if needed.

5. When assembling the burner back to

the stove, the proper location of the

burner with respect to the orifice is

important. The burner tube must be

located over the brass orifice fitting.

Cleaning and Maintenance

Correct care and maintenance will keep

your appliance operating smoothly.

Clean regularly as determined by the

amount of use. NOTE: Clean the

entire appliance each year and tighten

all hardware on a regular basis (1-2

times a year or more depending on

usage). Cleaning should be done where

detergents won’t harm patio, lawn, or

the like. Keep appliance area clear

and free from combustible materials,

gasoline and other flammable vapors

and liquids. Keep the ventilation

opening(s) of the cylinder enclosure

free and clear from debris.

Suggested Cleaning Materials

• Mild dish washing liquid

detergent

• Wire brush

• Nylon cleaning pad

• Hot water

• Paper clip

• Soft brass bristled brush

Component Cleaning:

• Burner should be wiped clean. Hot

soapy water and a soft bristle brush

can be used to clean the burner

surfaces. Clean clogged gas port holes

with an opened paper clip. Replace

corroded or damaged burners that

would emit excess gas.

• COOKING SURFACES, POTS

AND PANS: Clean the cooking

surface with soapy water and a nylon

cleaning pad.

• After appliance has cooled, wipe

areas where paint and finish have

burned off to minimize rusting.

Using a thermometer

Prior to lighting, position

thermometer clip so that at least 1/2”

of thermometer tip is submerged

in oil. Reposition thermometer

as necessary to cook. Continue to

use thermometer until burner is turned

off.

If Frying:

• Follow instructions provided by the

• When cooking with oil or grease, a

• Introduction of water from any source

• Be sure thermometer is in good

• Do not over fill the pot with cooking

appliance manufacturer.

thermometer must be used.

into the cooking oil or grease may

cause overflow and severe burns from

hot oil and water splatter. When frying

with oil and grease, all food products

MUST be completely thawed and

towel dried to remove water before

being immersed in the fryer.

working condition. To check the

thermometer, insert it into a pot

of boiling water and ensuring that

it registers approximately 212°F

± 20°F (100°C ± 10°C). If it does

not function properly, obtain a

replacement thermometer specified

by the manufacturer before using the

appliance.

liquid. Never fill appliance more than

half full of cooking liquid or past

the maximum fill line (a permanent

marking on fryer).

• If cooking liquid has spilled

and ignited, do not attempt to

extinguish with water. Immediately

turn gas supply OFF at the supply

cylinder and:

• Extinguish flames using a BC type

fire extinguisher as recommended

by the fryer manufacturer; or

smother flames with dirt or sand.

• In case there is a fire, call the

local fire department or dial 911.

0312-Coven-TriBook.indd 12-13 3/22/12 4:29 PM

Page 8

• To avoid accidental burns from

burner flame or hot cooking liquid,

turn the burner off before inserting

or removing food from the fryer.

• When removing food from the

fryer, be sure to avoid burns from

hot cooking liquid drippings.

LIMITED WARRANTY

INSTRUCTIONS D’ENTRETIEN, D’UTILISATION ET DE

SÉCURITÉ RELATIVES AU FOUR DE CAMP DE PLEIN AIR

SURMONTÉ D’UN RÉCHAUD À 2 BRÛLEURS

To activate warranty, register on-line at: www.CampChef.com

The manufacturer warrants stove components (except paint and finish) to be free from

defect in materials and workmanship for 1 year from the date of purchase. All accessories

(included with stove or purchased separately) are warranted from defect in materials and

workmanship for 90 days from the original purchasing date. Within these periods, the

manufacturer will replace or repair defective parts deemed unusable from its original intent

by making available the parts thereof FOB Logan, UT 84321

Product paint and finish is not warranted. The exterior finish of the product will wear down

over time.

Clean the unit after each use to maintain the finish and prolong the life of your product. Wipe

away all grease and ashes. Keep metal products free of moisture, salts, acids and harsh fluctuations

in temperatures.

Warranty does not cover normal wear of parts or damage caused by misuse, abuse,

overheating and alteration. Repairs or alterations made by anyone other than Camp Chef

are not covered in this Warranty. Manufacturer will not be held liable for any losses due

to neglectful operation. Furthermore, this Warranty does not cover damaged caused by

natural disasters such as earthquakes, hurricanes, tornadoes, floods, lightning, fires, etc.

Upon the expiration of this warranty all such liability will terminate. No other warranties

are expressed or implied.

Keep all original sales receipts. Proof of purchase is required to obtain Warranty

services. Prior written approval and a Return Authorization Number must be obtained

and accepted for repair or replacement only. Returns must be shipped prepaid.

Collect shipment or shipments without a Return Authorization Number will not

be accepted.

To obtain Warranty services call 1.800.650.2433.

*Warranty applies to the contiguous US states only.

Fours de camp au gaz

de type portatif

ANSI Z21.72b-2002

CSA 11.2b-2002

• À l’intention de l’installateur ou de la personne qui

assemble l’appareil: Conserver cette notice avec l’appareil

pour référence ultérieure.

• À l’attention du consommateur: Conserver cette notice

pour référence ultérieure. Cette notice contient des

reseignements importants permettant un assemblage

adéquat et à une utilisation sécuritaire de l’appareil.

Lire et suivre toutes les mises en garde et toutes

les instructions avant l’assemblage et l’utilisation de

l’appareil.

Suivre toutes les mises en garde et toutes les instructions

lors de l’utilisation de l’appareil.

NE PAS JETER CETTE NOTICE D’UTILISATION.

Inscrire le numéro de modèle indiqué sur le produit.

Numéro de modèle:

C-OVEN 2

Pour usage en plein air uniquement.

3985 N. 75 W., Hyde Park UT 84318

1.800.650.2433 or 1.435.752.3922

0312-Coven-TriBook.indd 14-15 3/22/12 4:29 PM

Page 9

POUR VOTRE SÉCURITÉ

Que faire si vous sentez une odeur de gaz:

1. Ne pas tenter d’allumer d’appareils.

2. Éteindre toute amme.

3. Couper l’alimentation en gaz á la source.

POUR VOTRE SÉCURITÉ

Ne pas entreposer ni utiliser d’essence ni d’autres vapeurs ou

liquides inammables á proximité de cet appareil ou de tout

autre appareil.

MONOXYDE DE CARBONE

Cet appareil peut produire du monoxyde de carbone, un gaz

iniodore.

L’utilisation de cet appareil dans des aspaces clos peut en-

traîner la mort.

Ne jamais utiliser cet appareil dans un epace clos comme un

véhicule de camping, une tente, une automobile ou une maison.

ROBINET DU RECHAUD

RONDELLE DU MANIFOLD

BRÛLEUR DU RÉCHAUD

ALLUME-GAZ DU RÉCHAUD

ROBINET DU FOUR

PARTS LIST

GRILLE PORTE-PLATS

DETENDEUR

THERMOMETRE

CLIP PARE-BRISE

POIGNÉE LATÉRALE

CONDUITE DE

GAZ DU FOUR

BOUTON DU ROBINET

JOINT

VITRE DE LA PORTE

AVERTISSEMENT

Ce produit contient des produits chimiques connus de l’Etat

THERMOCOUPLE DU FOUR

BROLEUR DU FOUR

POIGNEE DU PORTE

PIED DU FOUR

ELECTRODE DE L’ALLUME-GAZ

GRILLE DU FOUR

PLATEAU DU FOUR

de Californie pour causer le cancer et les malformations

congénitales ou autres anomalies de la reproduction.

0312-Coven-TriBook.indd 16-17 3/22/12 4:29 PM

Page 10

1. NE PAS laisser l’appareil sans

surveillance lorsqu’il sert.

L’utilisateur doit rester à proximité

du produit de façon à pouvoir bien

le voir en tout temps pendant son

utilisation.

2. En tout temps, tenir les enfants et

les animaux domestiques à l’écart

du brûleur.

3. La consommation d’alcool, ou de

médicaments obtenus ou non sur

ordonnance, risque de diminuer

la faculté du consommateur de

monter correctement l’appareil ou

de l’utiliser en toute sécurité.

4. Pour usage EN PLEIN AIR

uniquement. NE PAS utiliser

dans un bâtiment, un garage ou

tout autre endroit clos. NE PAS

utiliser sur des véhicules récréatifs

ou des bateaux de plaisance. NE

JAMAIS utiliser cet appareil en

tant qu’appareil de chauffage.

5. Ne pas faire fonctionner l’appareil

sous une structure surplombante.

Maintenir un dégagement minimal

de 30 cm (1 pied) sur les côtés, le

devant et l’arrière de l’appareil par

rapport à TOUTE construction.

Garder la zone entourant l’appareil

libre de matériaux combustibles et

de fluides inflammables, y compris

le bois, les plantes sèches et l’herbe,

les broussailles, le papier et la

toile. Ne jamais utiliser le présent

appareil à moins de 7,5 m (25 pi)

de tout liquide inflammable.

6. Utiliser UNIQUEMENT une

surface de niveau, stable.

7. Garder le tuyau d’alimentation

en carburant éloigné des surfaces

chauffées.

8. Pour éviter les feux accidentels,

s’assurer, avant d’utiliser l’appareil,

que le tuyau n’est pas endommagé et

qu’il n’y a pas de fuite au niveau des

joints et connexions, en procédant

comme suit: ouvrir le robinet de

la bouteille, laisser la valve du

brûleur fermée et appliquer une

solution savonneuse sur les joints

et les connexions. Si l’on entend

un sifflement ou si le savon fait des

bulles, c’est qu’il y a fuite. Dans

ce cas, ne pas utiliser l’appareil.

Remplacer les pièces défectueuses.

9. Éteindre les flammes nues avant de

connecter l’alimentation en gaz à

l’appareil et de confirmer l’absence

de fuites.

10. On DOIT utiliser un hermomètre

si l’on cuisine avec de l’huile ou de

la graisse.

11. Ne jamais laisser la température

de l’huile ou de la graisse dépasser

200ºC (400 ºF). Si la température

est supérieure à 200 ºC (400 ºF)

ou que l’huile dégage de la fumée,

éteindre IMMÉDIATEMENT le

brûleur.

12. Si l’on cuisine à l’huile ou en

se servant de graisse, s’assurer

qu’un équipement d’extinction

d’incendie est à portée de main. En

cas de feu d’huile ou de graisse, NE

PAS essayer d’éteindre les flammes

à l’eau. Utiliser un extincteur à

poudre BC ou étouffer le feu au

moyen de terre, de sable ou de

bicarbonate de soude.

13. NE JAMAIS trop remplir le

chaudron de cuisson d’huile,

de graisse ou d’eau. Suivre les

instructions de la présente notice

pour déterminer les niveaux

convenables d’huile, de graisse

ou d’eau.

14. Si l’on fait de la friture à l’huile

ou en se servant de graisse, tous

les produits alimentaires doivent

être complètement décongelés

et épongés sur une serviette

pour éliminer l’excédent d’eau.

L’huile ou la graisse peuvent

déborder si les aliments ne sont

pas complètement décongelés et

épongés. Suivre les instructions

de la présente notice, concernant

la friture.

15. Pour frire des aliments, les

immerger lentement dans l’huile

ou la graisse. NE PAS les déposer

abruptement dans le récipient.

16. NE PAS placer de récipient de

cuisson vide sur un brûleur

allumé. Faire preuve de prudence

lorsque l’on place un aliment

dans le récipient de cuisson sur

un brûleur allumé.

17. En cas de pluie pendant la cuisson

à l’huile ou à la graisse, éteindre

IMMÉDIATEMENT le(s)

brûleur(s) et couper l’alimentation

en gaz, puis couvrir le récipient

de cuisson. NE PAS essayer de

déplacer l’appareil ou le récipient

de cuisson.

18. Éviter à l’appareil tout choc ou

impact qui risquerait de faire

déverser ou gicler le liquide de

cuisson chaud.

19. NE PAS déplacer l’appareil lors de

son utilisation. Laisser l’appareil

refroidir à 45 °C (115 °F) avant de

le déplacer ou de le ranger.

20. L’appareil est chaud durant et

après l’utilisation. Utiliser des

gants de cuisinier isolants pour

se protéger des surfaces chaudes

ou des éclaboussures de liquide

de cuisson.

21. En cas d’incendie, appeler les

pompiers ou composer le 911.

Rester à l’écart des flammes. Ne

pas tenter d’éteindre un feu d’huile

ou de graisse au moyen d’eau.

22. Pour assurer la bonne performance

du produit en toute sécurité, utiliser

uniquementdes accessoires,

notammentdes récipients de

cuisson, recommandés par

le fabricant. Ne jamais utiliser

de récipient de cuisson dont

la capacité et le diamètre sont

supérieurs à ceux recommandés

par le fabricant.

23. Ce produit n’est pas destiné à un

usage commercial. 24. Le diamètre

maximum des récipients de

cuisson est de 25 cm (10 po).

24. Le diamètre maximum des

récipients de cuisson est de 25 cm

(10 po).

25. Ne pas gêner le flux de combustion

et l’air de ventilation.

NOTE : Le présent appareil est conçu pour utiliser des

bouteilles de propane jetables de 465 g (16,4 oz). Utiliser

uniquement des bouteilles portant la mention « propane ».

Les bouteilles de propane jetables doivent être débranchées

du four pendant l’entreposage.

Des réservoirs en vrac de GPL rechargeables d’une capacité

maximale de 9 kg (20 livres) peuvent également être utilisés

avec un adaptateur pour réservoir en vrac supplémentaire.

(L’adaptateur pour réservoir en vrac peut ne pas être inclus).

Les bouteilles de gaz propane rechargeables doivent être

fermées au niveau de la bouteille de GPL lorsque le four

n’est pas utilisé.

La/les bouteille(s) de gaz GPL utilisée(s) avec le présent

four doit/doivent être fabriquée(s) et porter les marquages

conformément aux spécifications relatives aux bouteilles de

gaz GPL du Ministère des transports des États-Unis ou à la

norme CAN/CSA B339 de Transport Canada.

0312-Coven-TriBook.indd 18-19 3/22/12 4:29 PM

Page 11

Assemblage avec une bouteille

jetable

1. S’assurer que les boutons de réglage

des brûleurs sont fermés.

2. Enlever le bouchon en plastique

au-dessus de la bouteille de

propane. Garder le bouchon pour

l’utiliser pendant l’entreposage.

Visser la bouteille de propane dans

le détendeur. Faire attention de ne

pas fausser le filetage. Serrer à la

main uniquement.

3. Vérifier le raccordement entre

la bouteille et le détendeur avec

de l’eau savonneuse. Des bulles

indiquent une fuite. Vérifier que

le filetage du raccordement n’est

pas faussé et que le raccordement

est serré. Vérifier une deuxième

fois la présence de fuites. Si une

fuite subsiste, enlever la bouteille et

contacter le fabricant en vue d’un

entretien ou d’une réparation.

4. Le détendeur utilise un

raccordement fileté qui s’attache

au four. Il est nécessaire de

tenir le four pour s’assurer que

le raccordement est positionné

correctement. Aligner le détendeur

sur le tuyau d’alimentation à

l’arrière du four et les pousser l’un

contre l’autre. Visser le manchon

fileté extérieur dans le sens des

aiguilles d’une montré jusqu’à ce

qu’il soit serré.

5. Ne jamais faire fonctionner le four

avec une bouteille au propane dans

une position inversée.

Démontage Disponible

Cylindre de Propane

1. Tourner toutes les valves au de la

position et assurer-vous que toutes

les flammes sont éteintes.

2. Enlever la bouteille du régulateur

en tournant en sens inverse des

aiguilles d’une montre.

Assemblage avec un adaptateur et

une bouteille rechargeable

1. S’assurer que les boutons de réglage

des brûleurs sont fermés.

VÉRIFIER LA

PRÉSENCE DE

FUITES AU

NIVEAU DU DÉTENDEUR ET DE

L’ADAPTATEUR.

2. Attacher

l’adaptateur au

détendeur et

le détendeur

au four (tel

qu’illustré).

3. Attacher l’adaptateur à la bouteille.

4. Ouvrir le robinet de la bouteille.

5. Vérifier qu’il n’y a pas de fuites au

niveau des raccordements entre

l’adaptateur et le détendeur, et entre

l’adaptateur et la bouteille avec

de l’eau savonneuse. Des bulles

indiquent une fuite. Vérifier que

le filetage du raccordement n’est

pas faussé et que le raccordement

est serré. Vérifier une deuxième

fois la présence de fuites. Si une

fuite subsiste, enlever la bouteille et

contacter le fabricant en vue d’un

entretien ou d’une réparation.

6. Fermer l’arrivée de gaz au niveau

de la bouteille et débrancher les

deux extrémités de l’adaptateur

lorsque le four n’est pas utilisé.

Démontage de l’adaptateur et de la

bouteille rechargeable

1. Avant le démontage de l’adaptateur

sous haute pression, s’assurer que

la pression du gaz dans l’adaptateur

est éliminée.

2. Allumer le four et fermer le robinet

d’arrivée du gaz de la bouteille.

3. Laisser la flamme s’éteindre d’ellemême.

4. Quand la flamme est éteinte,

fermer les boutons de réglage de

l’appareil.

5. Enlever l’adaptateur.

• Utiliser l’appareil uniquement avec

du gaz propane (GPL) et l’ensemble

régulateur/robinet fourni.

• L’installation doit être conforme

aux codes en vigueur ou à la norme

NFPA 54/ANSI Z223.1 du National

Fuel Gas Code. La manutention et

l’entreposage des bouteilles de gaz

propane doivent être conformes à la

norme NFPA/ANSI 58 du « LP Gas

Code ». Ne pas utiliser cet appareil

à bord d’un bateau de plaisance ou

d’un véhicule récréatif.

• Ne pas modifier cet appareil. Toute

modification présente des risques

en matière de sécurité. Pour toute

question concernant l’homologation

dans d’autres régions, composer le

1-435-752-3922.

• Pour les personnes résidant en

appartement: Consulter le gérant de

l’immeuble en ce qui concerne les

exigences et le code des incendies

particuliers à l’utilisation d’un

appareil au gaz propane dans les

immeuble à appartements. Si cela

est permis, utiliser l’appareil en plein

air à même le sol à une distance de 3

m (10 pi) des cloisons ou des mains

courantes. Ne pas utiliser l’appareil

au-dessus d’un appartement, sur un

balcon de condo ou une terrasse, ou

sous ceux-ci.

• Avant d’ouvrir le robinet de la

bouteille de gaz, vérifier que l’écrou

de raccordement est serré. Lorsque

l’appareil ne sert pas, fermer le

bouton de réglage et le robinet de la

bouteille de gaz.

• Ne jamais utiliser la bouteille de gaz

0312-Coven-TriBook.indd 20-21 3/22/12 4:29 PM

Page 12

si elle est rouillée, endommagée ou

périmée.

• Si de la graisse ou une autre

substance chaude s’écoule de

l’appareil sur le robinet, le tuyau ou

le détendeur, couper immédiatement

l’alimentation en gaz. En déterminer

la cause, corriger la situation, et

nettoyer et inspecter le robinet,

le tuyau et le détendeur, avant de

continuer. Effectuer un contrôle

d’étanchéité.

• Il est possible que le détendeur

bourdonne ou siffle pendant le

fonctionnement. Cela n’entrave

en rien la sécurité ou le bon

fonctionnement de l’appareil.

• Nettoyer et inspecter le tuyau avant

chaque utilisation de l’appareil. En

cas d’éraflures, d’usure, de coupures

ou de fuites, remplacer le tuyau

avant d’utiliser l’appareil. Se reporter

à la fiche technique au sujet des

informations relatives au tuyau et au

détendeur.

• Ne pas bloquer les trous situés sur le

bas ou les côtés de l’appareil.

• Ne jamais faire fonctionner

l’appareil si la bouteille de gaz n’est

pas correctement positionnée,

conformément aux instructions de

montage.

• Fermer toujours le robinet de la

bouteille de gaz et retirer l’écrou de

raccordement, avant de repositionner

la bouteille.

• Ne jamais faire fonctionner

l’appareil si la bouteille de gaz n’est

pas correctement positionnée,

conformément aux instructions de

montage.

• Fermer toujours le robinet de la

AVERTISSEMENT

Les sous-produits de combustion

découlant de l’utilisation de cet appareil

contiennent des produits chimiques

considérés par l’État de Californie

comme pouvant causer le cancer ou

des malformations congénitales ou

encore avoir d’autres effets nocifs sur

l’appareil reproducteur.

bouteille de gaz et retirer l’écrou de

raccordement, avant de repositionner

la bouteille.

• Ne jamais ranger une bouteille de

gaz de rechange sous l’appareil ou à

proximité, ou dans un endroit clos.

NE JAMAIS remplir la bouteille

au-delà de 80 % de sa capacité. Le

remplissage excessif de la bouteille

de rechange présente un risque en

cas de décharge de gaz à partir de la

soupape de sûreté. Si ces instructions

ne sont pas suivies à la lettre, un

incendie pouvant entraîner le décès

ou des blessures graves risque de se

produire.

• Si l’on voit, sent ou entend du gaz

s’échapper, s’éloigner immédiatement

de la bouteille de gaz ou de l’appareil

et appeler les pompiers.

Warning: Hose is a trip hazard

• La bouteille à gaz de rechange doit

comporter un bouchon de sécurité

pour protéger son robinet.

Retrait, transport et entreposage

de la bouteille de gaz

• FERMER tous les boutons de réglage

et le robinet de la bouteille de gaz.

Tourner l’écrou de raccordement

à la main, dans le sens contraire

des aiguilles d’une montre; ne pas

utiliser d’outil pour le déconnecter.

Poser le bouchon de sécurité sur

le robinet de la bouteille de gaz.

Utiliser toujours le bouchon et le

collet fournis avec le robinet. Si le

bouchon de sécurité n’est pas utilisé

conformément aux instructions,

cela peut entraîner des blessures

graves ou des dommages matériels.

• La bouteille de gaz doit être munie

d’un bouchon de sécurité (tel

qu’illustré)

lorsqu’elle est

entreposée ou

transportée.

Ne pas

safety cap

entreposer de bouteille de gaz dans

un endroit clos tel qu’un garage,

une véranda, un patio couvert ou

autre bâtiment. Ne jamais laisser

de bouteille de gaz à l’intérieur

d’un véhicule car celle-ci pourrait

surchauffer sous l’effet du soleil.

• Ne pas entreposer de bouteille de

gaz dans une aire de jeux pour

enfants.

• L’appareil ne peut être rangé à

l’intérieur que si la bouteille est

déconnectée et retirée de l’appareil.

• Lorsque la bouteille de GPL

rechargeable est toujours raccordée

au four, le four et la bouteille doivent

être entreposés en plein air, dans un

espace bien ventilé, hors de la portée

des enfants et ne peuvent pas être

entreposés dans un bâtiment, un

garage ou tout autre endroit clos.

Bouteille de gaz

La bouteille de gaz utilisée avec

l’appareil doit répondre aux exigences

suivantes:

• N’acheter que des bouteilles

possédant les dimensions suivantes

: 30,5 cm (12 po) de diamètre x 45,7

cm (18 po) de hauteur, et d’une

capacité maximale de 9 kg (20 lb).

• Être fabriquées et marquées

conformément aux spécifications

relatives aux bouteilles de gaz

du Département des Transports

américain (DOT) ou de la Norme

nationale du Canada CAN/CSAB339-96 intitulée Bouteilles et tubes

pour le transport des marchandises

dangereuses,

• La bouteille de gaz utilisée avec

cet appareil doit être munie d’un

collet pour protéger le robinet de la

bouteille.

Le robinet de la bouteille de gaz doit

comporter ce qui suit:

• Une prise de type 1 compatible avec

le détendeur ou l’appareil.

• Soupape de sûreté.

• Un dispositif anti-débordement

homologué UL.

Ce dispositif

antidébordement

est identifié

par un volant

OPD Hand Wheel

de manoeuvre

triangulaire. Utiliser uniquement

les bouteilles munies de ce type de

robinet. La bouteille de gaz doit

permettre l’évacuation des vapeurs.

0312-Coven-TriBook.indd 22-23 3/22/12 4:29 PM

Page 13

GPL (Gaz de pétrole liquéfié)

• Lorsqu’il est produit, le GPL est non

toxique, inodore et incolore. On lui

a donné une odeur (semblable à celle

du chou pourri) pour permettre de

le détecter.

• Le GPL est un gaz très inflammable

qui peut s’enflammer inopinément

lorsqu’il se mélange à l’air.

Remplissage de la bouteille de GPL

• N’avoir recours qu’aux services de

vendeurs autorisés et expérimentés.

• La bouteille de GPL doit être vidée

par le vendeur avant le remplissage.

• Le vendeur ne doit JAMAIS remplir

la bouteille de GPL à plus de 80% de

sa capacité. Le volume de propane

contenu dans la bouteille varie selon

la température.

• Un détendeur qui devient givré

est une indication d’un trop-plein

de gaz. Fermer immédiatement

le robinet de la bouteilleet

communiquer avec le négociant en

gaz local pour obtenir de l’aide.

• Ne jamais laisser échapper de gaz

de propane liquide (GPL) dans l’air.

Cela pourrait être dangereux.

• Pour vider le réservoir de GPL,

communiquer avec un négociant

en gaz ou le service des pompiers

de la localité pour obtenir de l’aide.

Les négociants en gaz certifiés les

plus près sont répertoriés sous la

rubrique « gaz – compagnies » dans

l’annuaire téléphonique.

Échange de bouteille de GPL

• On peut choisir de faire remplacer

le réservoir vide par l’intermédiaire

d’un service d’échange. N’avoir

recours qu’aux entreprises

d’échange reconnues qui inspectent,

remplissent avec précision, testent

et certifient leurs bouteilles.

S’assurer d’échanger la bouteille

contre une bouteille munie d’un

dispositif antidébordement, comme

décrit dans la section traitant de la

bouteille de GPL.

• S’assurer que la bouteille est toujours

debout pendant l’utilisation, le

transport ou l’entreposage.

• Vérifier s’il y a des fuites dans la

bouteille de GPL, AVANT de la

raccorder à l’appareil.

Test d’étanchéité Sécurité

• La détection de fuites doit être

répétée chaque fois que l’on

remplace ou que l’on fait remplir

la bouteille.

• Ne pas fumer lorsque l’on effectue

le test d’étanchéité.

• Ne pas tenter de détecter la

présence d’une fuite de gaz au

moyen d’une flamme nue.

• La tentative de détection doit être

effectuée à l’extérieur, dans une

zone bien aérée, loin des sources

d’allumage, comme les appareils

électriques ou les appareils

alimentés au gaz. Pendant

la vérification, s’assurer que

l’appareil n’est pas à proximité de

flammes nues ou d’étincelles.

WARNING

Si des bulles se mettent à gonfler,

ne pas utiliser la bouteille de GPL et

ne pas la déplacer. Communiquer

avec un fournisseur de GPL ou

avec le service des pompiers de la

localité.

Connexion du détendeur à la

bouteille de GPL

Utiliser uniquement le détendeur et le

tuyau fournis avec cet appareil. Voir

les instructions de montage ou la

plaque signalétique de l’appareil pour

le numéro de modèle du détendeur.

1. Placer la bouteille de

GPL sur une surface

de niveau sûre et

stable.

2. S’assurer que

le bouton de

commande est à la position « OFF

» (ARRÊT).

3. Tourner le volant de manoeuvre de

la bouteille vers la droite jusqu’à ce

que le robinet soit complètement

fermé.

4. Enlever le

capuchon

protecteur

du robinet de

la bouteille.

Utiliser

toujours le

bouchon et le

collet fournis avec le robinet. Ne

pas utiliser de bouchon de transport

POL (pièce en plastique avec filetage

externe)! Il rendra inopérant le

dispositif de sécurité du robinet.

5. Tenir le détendeur et insérer la

bague (B) dans le robinet de la

bouteille. Serrer manuellement

l’écrou de raccordement en tenant

le détendeur en ligne droite (C) par

rapport au robinet de la bouteille,

afin de ne pas fausser le filetage du

raccord.

(B) La bague doit

être centrée dans

le robinet de la

bouteille de GPL

(C) Maintenir

l’écrou de

raccordement et

le détendeur, tel

qu’indiqué, pour

assurer un bon

raccordement

au robinet de la

bouteille de GPL

6. Tourner l’écrou de raccordement

vers la droite jusqu’à ce qu’il soit

bien serré. Le détendeur se scelle

sur le dispositif anti-retour du

robinet de la bouteille de GPL, ce qui

occasionne une certaine résistance.

Effectuer entre un demi et trois

quarts de tour supplémentaires

pour compléter le raccordement. Ne

serrer que manuellement – n’utiliser

aucun outil.

REMARQUE: Si l’on ne peut pas

compléter le raccordement, débrancher

le détendeur et répéter les étapes 5 et 6.

Si l’on ne peut toujours pas compléter

le raccordement, ne pas utiliser ce

détendeur!

• N’insérer aucun objet dans le robinet,

au risque de l’endommager et de

provoquer une fuite. Une fuite de

propane peut entraîner une explosion,

un incendie, des blessures corporelles

graves ou même la mort.

• Ne jamais tenter de raccorder cet

appareil au système autonome GPL

d’une camionnette de camping, d’une

roulotte ou d’une autocaravane.

0312-Coven-TriBook.indd 24-25 3/22/12 4:29 PM

Page 14

Test d’étanchéité sur les robinets, les

tuyaux et le détendeur

1. Mettre le(s) bouton(s) de commande

de l’appareil à la position « OFF »

(ARRÊT).

2. S’assurer que le détendeur est bien

relié à la bouteille de GPL.

3. Ouvrir complètement le robinet

de la bouteille en tournant le

volant vers la gauche. Si un bruit

de chute se fait entendre, fermer

immédiatement le robinet du gaz,

car il y a fuite importante au niveau

du raccordement. Corriger cette

fuite avant d’utiliser l’appareil.

4. Étendre la

solution

savonneuse

sur les

raccordements

montrés sur

l’illustration à droite.

5. Il y a présence de fuite si des bulles

desavon se mettent à gonfler.

Fermer immédiatement le robinet

de la bouteille de GPL et resserrer

les raccordements. Si l’on ne peut

arrêter la fuite, ne pas tenter de

réparer l’appareil. Communiquer

avec le centre de services au 1-435752-3922 aux États- Unis pour

commander des pièces de rechange,

en mentionnant le numéro de série,

le numéro de modèle et le nom des

pièces requises.

6. Toujours fermer le robinet de la

bouteille après avoir effectué le test

d’étanchéité, en tournant le volant

vers la droite.

AVERTISSEMENT

• Ne pas utiliser l’appareil avant

de s’assurer qu’il ne comporte

pas de fuite.

• Si on ne peut colmater la fuite

de gaz, fermer immédiatement

le robinet de la bouteille de

gaz et communiquer avec un

fournisseur de GPL ou avec le

service des pompiers!

Instructions d’assemblage

• Assembler le four sur une surface de

niveau.

• Ouvrir le couvercle et attacher les

écrans pare-vent autour du four

comme illustré.

• S’assurer que la grille porte-plats

est installée correctement, les fils

des extrémités s’encastrant dans les

trous sur le dessus du four pour

empêcher la grille de bouger (voir

illustration).

Allumer le réchaud avecune

allumette:

Ne pas se pencher sur le réchaud au

propane pendant l’allumage.

1. Retirer tous les récipients du brûleur,

de manière à ne pas restreindre le

débit d’air.

2. Mettre la valve de réglage du

détendeur en position « OFF »

(ARRÊT).

3. Ouvrir complètement la soupape de

la bouteille de gaz.

4. Frotter une allumette et la placer

audessus du brûleur. Ouvrir

lentement la valve de réglage du

détendeur. Ne pas mettre la tête ou

les bras au-dessus du réchaud.

5. Si l’allumage ne se produit pas

dans les cinq secondes, fermer le(s)

bouton(s) de réglage du brûleur,

attendre cinq minutes et répéter la

procédure d’allumage.

Allumage à l’aide de l’allumeur

rotatif:

Ne pas se pencher sur le réchaud au

propane au moment de l’allumage.

1. Retirer tous les récipients la porte,

de manière à ne pas restreindre le

débit d’air.

2. Ouvrir le couvercle – ne pas

essayer d’allumer le réchaud avec le

couvercle fermé.

3. Ouvrir le robinet de la bouteille de

GPL à fond si un réservoir en vrac

est utilisé.

4. Tourner le bouton de réglage

lentement jusqu’à la position haute

(high). Le four va s’allumer. Régler les

boutons à la température désirée.

2. Ouvrir la porte du four. Ne pas

essayer d’allumer le four avec la

porte fermée.

3. Enlever le plateau inférieur du four

pour voir le brûleur.

4. Enfoncer le bouton de réglage du

four et le tourner lentement vers la

position haute (high). Le brûleur du

four s’allumera. (Pour allumer avec

une allumette, frotter l’allumette

et la placer au-dessus du brûleur.

Tourner lentement le bouton de

réglage du four. Ne pas laisser la tête

ou les bras au-dessus du brûleur.

5. Maintenir le bouton enfoncé

pendant 10 secondes.

6. Si le brûleur ne reste pas allumé,

répéter la procédure.

7. Replacer le plateau inférieur du four

au-dessus du brûleur.

8. Régler les boutons de réglage jusque

la position désirée.

9. Si l’allumage ne se produit pas dans

les 5 secondes, fermer le(s) bouton(s)

du/des brûleurs, attendre 5 minutes,

et recommencer les procédures

d’allumage. Si l’allume-gaz intégré

ne fonctionne pas, suivre les étapes

de la procédure ci-dessus et tenir une

allumette ou un allume-gaz à long

bec allumé à proximité du brûleur en

ouvrant le bouton de réglage.

Le séchage de la peinture et des pièces

dégage une odeur seulement lors de la

première utilisation.

Si la flamme s’éteint accidentellement,

fermer les robinets de l’appareil et

attendre 5 minutes avant d’essayer de

le rallumer.

Vérification des flammes du brûleur

• Allumer le brûleur; tourner le(s)

bouton(s) de la position HIGH à

LOW. La position LOW devrait

produire une plus petite flamme que

la position HIGH. Toujours vérifier

la flamme avant chaque utilisation.

Une bonne flamme devrait être

bleue avec des pointes légèrement

jaunes. Des pointes jaunes sur les

Jaune

Jaune

bleu

bleu

trous du brûleur

0312-Coven-TriBook.indd 26-27 3/22/12 4:29 PM

Page 15

flammes sont acceptables tant

qu’aucun dépôt de carbone ou de

suie n’apparaît pas.

Éteindre le réchaud au propane

• Mettre tous les boutons en position

« OFF » (ARRÊT). Tourner le volant

de manoeuvre de la bouteille vers la

droite jusqu’à ce que le robinet soit

complètement fermé.

Vérification du tuyau

• Avant chaque utilisation, vérifier si

le tuyau est percé ou usé. Remplacer

tout tuyau endommagé avant

d’utiliser l’appareil. N’utiliser que

la valve, le tuyau et le détendeur

spécifiés par le fabricant. Se reporter

à la fiche technique au sujet des

informations relatives au tuyau et

au détendeur.

Nettoyage du brûleur

REMARQUE: Des araignées ou des

insectes peuvent tisser leur toile ou

faire leur nid dans le brûleur. Cela se

produit particulièrement à la fin de l’été

et à l’automne, avant le gel, lorsque les

araignées sont le plus actives. Ces nids

risquent d’obstruer le débit de gaz et de

provoquer un incendie dans le brûleur

et l’orifice ou autour de ceux-ci. Un

tel incendie peut blesser l’utilisateur

et causer des

dommages

importants à

l’appareil. Pour

éviter tout

blocage et assurer

un rendement de

chaleur maximal, nettoyer et inspecter

souvent le tube du brûleur (une ou

deux fois par mois).

MISE EN GARDE

N’effectuer le nettoyage et la

maintenance que lorsque l’appareil

est froid et que l’alimentation en gaz

est coupée au niveau de la bouteille

de gaz. NE nettoyer aucune des

pièces situées à l’intérieur d’un four

autonettoyant. La chaleur extrême

endommagea la finition.

REMARQUE: L’eau ou de l’air sous

pression ne suffit pas normalement à

éliminer les toiles d’araignée.

Procédure de nettoyage du brûleur :

1. Enlever l’ensemble du brûleur de

l’appareil.

2. Vérifier qu’il n’y a pas de nids,

de toiles d’araignée ou de boue à

l’intérieur du tube du brûleur.

3. Pour supprimer ce genre

d’obstruction, utiliser une brosse

venturi flexible, courber un long

fil flexible pour faire un crochet ou

utiliser un tuyau d’air.

4. Inspecter le brûleur et le nettoyer

au besoin.

5. Lors du réassemblage du brûleur

à l’appareil, il est important de

respecter l’emplacement correct

du brûleur par rapport à l’orifice.

Le tube du brûleur doit être

situé au-dessus de l’orifice du

raccordement en laiton.

Nettoyage et entretien

Pour assurer le bon fonctionnement

de l’appareil, effectuer correctement

son entretien et sa maintenance.

Le nettoyer de façon régulière

en fonction du degré d’utilisation.

REMARQUE: Nettoyer l’appareil tout

entier une fois l’an et serrer toutes

les pièces de quincaillerie sur une

base régulière (une à deux fois l’an

ou davantage, selon l’utilisation).

Effectuer le nettoyage de façon à

ne pas endommager la terrasse, la

pelouse, etc. avec des détergents.

Produits de nettoyage suggérés

• Détergent liquide pour vaisselle

doux

• Brosse métallique

• Tampon à récurer en nylon

• Eau chaude

• Trombone

• Brosse à soies souples en laiton

Nettoyage des éléments:

• Le brûleur devrait être frotté

jusqu’à ce qu’il soit propre. De

l’eau savonneuse très chaude et une

brosse à poils doux peuvent être

utilisées pour nettoyer les surfaces

du brûleur. Dégager les trous

d’arrivée du gaz bouchés à l’aide d’un

trombone ouvert. Remplacer les

brûleurs corrodés ou endommagés

susceptibles de dégager une quantité

de gaz excessive.

• SURFACES DE CUISSON,

CHAUDRONS ET CASSEROLES:

Nettoyer la surface de cuisson à

l’eau savonneuse et au moyen d’un

tampon à récupérer en nylon.

• Une fois l’appareil refroidi, essuyer

les endroits où la peinture et la

finition sont brûlées, pour minimiser

les risques de rouille.

Utiliser un thermomètre

Avant d’allumer le brûleur, utiliser

un thermomètre et positionner sa

fixation de telle sorte qu’au moins

la moitié du thermomètre soit

plongée dans l’huile. Repositionner

le thermomètre au besoin au cours

de la cuisson. Continuer à utiliser le

thermomètre jusqu’à ce que le brûleur

soit éteint.

Friture:

• Suivre les instructions fournies par

le fabricant de l’appareil.

• On doit utiliser un thermomètre si

l’on cuisine à l’huile ou à la graisse.

• Le fait d’ajouter de l’eau à l’huile

ou à la graisse pendant la cuisson

peut causer un débordement et

provoquer des brûlures graves dues

aux éclaboussures d’huile et d’eau

chaudes. Si l’on fait de la friture

à l’huile ou à la graisse, tous les

produits alimentaires DOIVENT

être complètement décongelés et

épongés pour éliminer l’excédent

d’eau avant de les immerger dans la

friteuse.

• S’assurer que le thermomètre est en

bon état de fonctionnement. Pour

vérifier le thermomètre, le placer

dans un chaudron d’eau bouillante

et s’assurer qu’il indique bien 100

°C ± 10 °C (212 °F ± 20 °F). S’il

ne fonctionne pas correctement, se

procurer un thermomètre de rechange

recommandé par le fabricant, avant

d’utiliser l’appareil.

• Éviter de trop remplir le chaudron

de liquide de cuisson. Ne jamais

remplir le récipient de liquide de

cuisson au-delà de la moitié de sa

capacité ou de la ligne de remplissage

maximal (indiquée par une marque

permanente sur la friteuse).

• Si le liquide de cuisson se déverse

ou prend feu, ne pas essayer de

l’éteindre en servant d’eau. Couper

immédiatement l’alimentation en gaz

au niveau de la bouteille et:

0312-Coven-TriBook.indd 28-29 3/22/12 4:29 PM

Page 16

• éteindre les flammes à l’aide d’un

extincteur à poudre BC, tel que

recommandé par le fabricant de la

friteuse; ou

• étouffer les flammes au moyen de

terre ou de sable.

• En cas d’incendie, appeler les pompiers

ou composer le 911.

• Pour prévenir les brûlures accidentelles

provoquées par les flammes du

brûleur ou le liquide de cuisson

chaud, éteindre le brûleur avant de

mettre des aliments dans la friteuse

ou de les en retirer.

• Lors du retrait des aliments de la

friteuse, éviter de se brûler avec les

gouttes de liquide de cuisson chaud.

HORNO DE CAMPAR AL AIGRE LIBRE – 2

QUEMADORES GAMA DE HORNO CUIDADO, USO Y

INSTRUCIONES DE SEGURIDAD.

GARANTIE LIMITÉE

Pour activer la garantie, remplir le formulaire d’inscription ci-joint et l’expédier par

courrier à Camp Chef, PO Box 4057, Logan, UT 84323 États-Unis, ou s’inscrire en ligne

à: CampChef.com

Le fabricant garantit que les composants du réchaud (à l’exception de la peinture de la

finition) sont exempts de défauts de matériaux ou de fabrication pendant un an à partir de

la date d’achat. Tous les accessoires (compris avec le réchaud ou achetés séparément) sont

garantis contre tout défaut de matériaux ou de fabrication pendant 90 jours à partir de la

date d’achat initiale. Durant ces périodes, le fabricant s’engage à remplacer ou réparer les

pièces défectueuses considérées comme étant inutilisables par rapport à l’usage auquel elles

étaient initialement destinées et à les fournir FOB Logan, UT 84321 États-Unis.

La peinture et la finition du produit ne sont pas garanties. La finition extérieure du produit

s’use avec le temps. Retoucher au besoin l’extérieur avec de la peinture à pulvériser

résistant aux températures élevées. Ne pas peindre les surfaces intérieures.

Nettoyer l’appareil après chaque utilisation afin d’en préserver la finition et d’en prolonger

la durée de vie. Essuyer les traces de graisse et de cendres. Protéger les produits métalliques

contre l’humidité, les sels, les acides et les fortes fluctuations de température.

La garantie ne couvre pas l’usure normale des pièces ou les dommages causés par une

mauvaise utilisation, les abus, la surchauffe et les modifications. Toute réparation ou

modification effectuée par quiconque autre que Camp Chef n’est pas couverte par la présente

garantie. Le fabricant ne saurait être tenu responsable de toute perte due à une utilisation

entachée de négligence. De plus, la présente garantie ne s’étend pas aux dommages causés

par des catastrophes naturelles telles que tremblements de terre, ouragans, tornades,

inondations, foudre, incendie, etc.

La responsabilité du fabricant prend fin à l’expiration de la garantie. Il n’existe aucune autre

garantie expresse ou implicite.

Conserver toutes les factures d’origine. Une preuve d’achat est requise pour toute

réclamation en vertu de la garantie. Obtenir au préalable une autorisation écrite et un numéro

d’autorisation de retour de marchandise. Les articles retournés sont acceptés uniquement en

vue d’une réparation ou d’un remplacement. Expédier tout retour port payé. Les envois en

port dû sans numéro d’autorisation de retour de marchandise ne sont pas acceptés.

PORTABLE GAS

ESTUFA DE CAMPAMENTO

ANSI Z21.72b-2002

CSA 11.2b-2002

• Para el instalador o la persona quien arma este

aparato: Deje este manual con este aparato para futura

referencia.

• Al consumidor: Guarde este manual para futura

referencia.

Este manual de instrucciones contiene información

importante necesaria para el montaje apropiado y uso

seguro de este producto.

Lea y siga todas las advertencias e instrucciones antes de

armar y usar este aparato.

Siga todas las advertencias e instrucciones cuando use el

aparato.

NO DESECHE ESTE MANUAL DE INSTRUCCIONES.

Llene el número de modelo encontrado en este producto.

Número de modelo:

C-OVEN 2

Pour obtenir des services sous garantie, appeler le 1.800.650.2433.

*La garantie s’applique aux états américains contigus uniquement.

0312-Coven-TriBook.indd 30-31 3/22/12 4:29 PM

Sólo para uso externo.

3985 N. 75 W., Hyde Park UT 84318

1.800.650.2433 or 1.435.752.3922

Page 17

PARA SU SEGURIDAD

Si usted huele gas:

1. No intente encender el aparato.

2. Extinga cualquier llama directa.

3. Desconecte el suministrador de combustible.

PARA SU SEGURIDAD

No almacene ni use gasolina u otros liquidos que contengan

vapores inamables cerca de este ni con ningún otro aparato.

RIESGO DE MONOXIDO DE CARBONO

• Este aparato puede producir monóxido de carbono el cual no

tiene olor.

• Usarlo en un área cerrada puede causarle la muerte.

• Nunca use este aparato en un área cerrada como son las

caravanas, tiendas de campaña, autos ni dentro de la casa.

PELIGRO

PARTS LIST

ADVERTENCIA

Este producto contiene un componente

químico que se conoce en el setado de

California como cáusante de Cåancer.

0312-Coven-TriBook.indd 32-33 3/22/12 4:29 PM

Page 18

1. No DEJE este aparato desatendido

mientras está en uso. El usuario

debe quedarse en el área inmediata

al producto y tener una visión clara

del producto en todo momento

durante la operación.

2. Mantenga a los niños o mascotas

lejos del quemador durante todo el

tiempo.

3. El uso de alcohol, las medicinas

con prescripción o sin prescripción,

pueden afectar su capacidad de

armar apropiadamente u operar de

manera segura este aparato.

4. Sólo para uso EXTERNO. No USE

en un edificio, garaje, o cualquier

otra área cerrada. NO use en o

sobre vehículos recreativos o botes.

NUNCA use este aparato como un

calentador.

5. No opere el aparato bajo NINGUNA

construcción sobrecalentada.

Mantenga un margen mínimo de 1

PIE (0.3m) desde los lados, frente y

detrás del aparato a CUALQUIER

construcción. Nunca use este aparato

de 25 piez(7.5m) de cualquiere

liquido flamable.

6. Use solamente en un nivel estable. 7.

Mantenga la manguera del dispensador

del combustible lejos de superficies

calientes.

8. Para prevenir incendios accidentales,

antes de usar el aparato asegúrese

que la manguera no se dañe y

que todas las juntas y conexiones

estén libres de fugas prendiendo la

válvula del cilindro, deje la válvula

del quemador cerrada, y aplique

solución cubierta de jabón a las

juntas y conexiones. Si se escucha un

sonido de crujido continuo, o si la

solución cubierta de jabón burbujea,

hay una fuga. No use el aparato si

hay una fuga. Reemplace las partes

defectuosas.

9. Apague toda llama abierta antes

de conectar el suministro de gas

al aparato y antes de revisar si hay

fugas.

10. Cuando cocine con aceite o grasa,

se DEBE usar un termómetro.

11. Nunca permita que la temperatura

del aceite o grasa llegue a calentarse

más de 400ºF o 200ºC. Si la temperatura excede de 400ºF (200ºC), o

si el aceite empieza a tener humo,

INMEDIATAMENTE apague el

quemador.

12. Cuando cocine con aceite o grasa,

los materiales para apagar incendios

deberían estar fácilmente accesibles.

En el caso de que el aceite o la

grasa se incendien NO intente

apagar con agua. Use un extintor de

incendio tipo BC de polvo químico

o apague el fuego con tierra, arena,

bicarbonato de soda.

13. NUNCA sobrellene la olla con aceite,

grasa o agua. Siga las instrucciones

en este manual para establecer los

niveles apropiados de aceite, grasa

o agua.

14. Cuando fría con aceite o grasa,

todos los productos alimenticios

DEBEN descongelarse completamente o secarse con toallas para

quitar el exceso de agua. Si no

descongela y no seca completamente

los alimentos puede causar que se

derrame aceite o grasa. Siga las

instrucciones en este manual para

comidas fritas.

15. Cuando fría, sumerja lentamente

los productos alimenticios en el

aceite o gas. NO los lance.

16. NO ponga un recipiente de cocina

vacío sobre el quemador mientras

está en operación. Use cautela

cuando ponga algo en el recipiente

de cocina mientras el quemador

está en operación.

17. En el caso de lluvia mientras esta

cocinando con aceite o grasa,

INMEDIATAMENTE apague

el quemador(es) y el suministro

de gas, luego cubra el recipiente

de cocina. NO intente mover el

aparato o el recipiente de cocina.

18. Evite la abolladura o impacto con

el aparato para prevenir vertido o

salpicadura de líquido de cocina

caliente.

19. NO quite el aparato cuando está en

uso. Permita que la unidad se enfríe

a 115°F (45°C) antes de quitar o

almacenar.

20. Este aparato estará caliente durante

y después del uso. Use mitones

o guantes de horno térmicamente

aislados para protección de

superficies calientes o salpicaduras

de líquidos de cocina.