Page 1

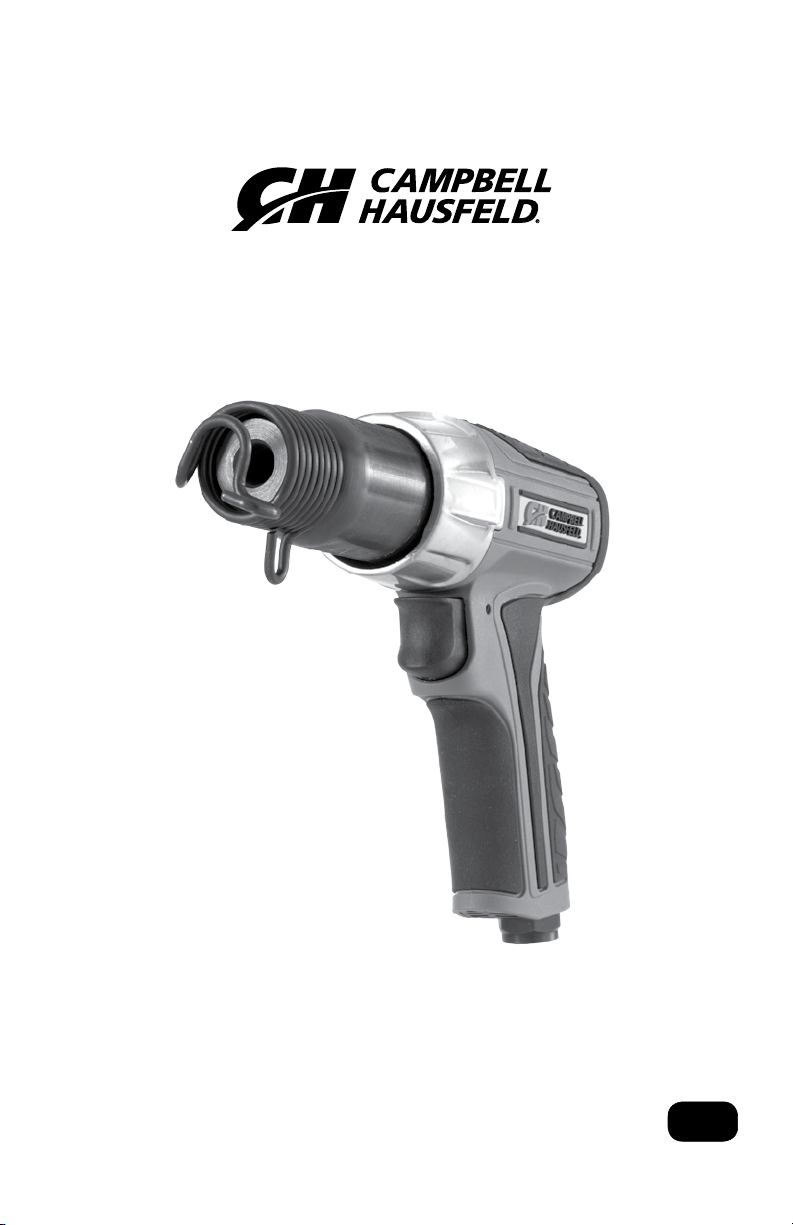

Air Hammer

Operating Instructions

© 2017 Campbell Hausfeld

A Marmon/Berkshire Hathaway Company

Model: XT101000

EN

IN745300 6/17

Page 2

Please read and save these instructions. Read carefully before

attempting to assemble, install, operate or maintain the product

described.

Protect yourself and others by observing all safety information. Failure

to comply with instructions could result in personal injury and/or

property damage! Retain instructions for future reference.

REMINDER: Keep your dated proof of purchase for warranty purposes!

Attach it to this manual or file it for safekeeping.

For parts, product & service information

Model #: ________________________________

Serial #: ________________________________

Purchase Date: __________________________

visit www.campbellhausfeld.com

Campbell Hausfeld

100 Production Drive

Harrison, Ohio 45030

REGISTER YOUR PRODUCT ONLINE NOW! www.campbellhausfeld.com/reg

READ AND FOLLOW ALL INSTRUCTIONS

SAVE THESE INSTRUCTIONS • DO NOT DISCARD

Page 3

BEFORE YOU BEGIN

Description

A medium barrel length of 2-3/4 inches delivers power when output is

critical for cutting through rusted bolts and metal and your other punching,

chipping or scraping jobs. Soft, grippy over-molded contact points on this

air hammer help to absorb tool vibration and reduce fatigue—keeping you

moving to get stuff done on your never-ending project list.

Campbell Hausfeld

The company’s history of creating quality products began in 1836, when

it manufactured horse-drawn wagons and agricultural equipment. Today,

Campbell Hausfeld offers a complete line of air compressors, air tools and

accessories, inflators, nailers and staplers, spray guns, pressure washers, and

more. Finish your projects faster and easier with Campbell Hausfeld – The Air

Power Expert.

UNPACKING

After unpacking the unit, inspect carefully for any damage that may have

occurred during transit. Check for loose, missing or damaged parts. Check

to be sure all supplied accessories are enclosed with the unit. In case of

questions, damaged or missing parts, please visit www.campbellhausfeld.com

for customer assistance.

Do not operate unit if damaged during shipping,

cause injury or property damage.

®

makes it easier for you to finish your projects like a pro.

handling or use. Damage may result in bursting and

Other Parts (Not Provided)

You will need the following items and/or accessories to properly set-up and/or

optimally use your air hammer:

• 3/8 inch (ID) Whip or leader hose to absorb vibration

• 1/4 inch Plug NPT (M)

• 3/8 inch (ID) Air Hose

• 1/4 inch Coupler NPT (F)

o Eliminate coupler confusion with a universal coupler style.

o Quick-connect couplers quickly, easily join hoses to tools.

o If you don’t use a flex plug, consider a swivel coupler to prevent

hose kinks and reduce stress on your air hose.

• 26 Gallon air compressor or larger

• 0.401 Parker Taper chisel bits

• PTFE tape for all fitting connections

• Adjustable wrench for tightening fitting connections

See www.campbellhausfeld.com for additional information on accessories to

support your air tools and pneumatic system.

1

Page 4

BEST PRACTICES

u For best output, maintain pressure at the tool of 90 PSI.

u The longer your air hose the greater the pressure drop from compressor to tool.

If you are using a hose longer than 50 feet, consider upgrading to a 1/2 inch ID air

hose to ensure proper tool pressure.

u Failure to lubricate and maintain your air tools properly will dramatically shorten

their life. Use oil every time you use your air tool to lubricate, clean and inhibit rust

in one step. Campbell Hausfeld sells air tool oil under part number ST1270.

u Due to the excessive vibration created by this tool, a whip hose (aka leader hose) is

recommended. If using a whip hose, do NOT install a coupler set between the tool

and the whip hose.

SPECIFICATIONS

XT101000

Maximum PSI 90

CFM under load 100% duty 3.1 CFM @ 90 PSI

SCFM under load 100% duty 23.9 SCFM @ 90 PSI

Air Compressor Recommendation 26 gallon

Blows Per Minute (BPM) 2,600

Stroke Length 2-3/4 inch

Chisel Shank Diameter 0.401 Parker type

Air Inlet 1/4 inch NPT (F)

Minimum Hose Size 3/8 inch

Housing Material Composite

Tool Weight 2.9 Lbs.

Tool Length 6-7/8 inch

Tool Height 6-3/8 inch

Tool Width 2-1/8 inch

taper shaft

2

Page 5

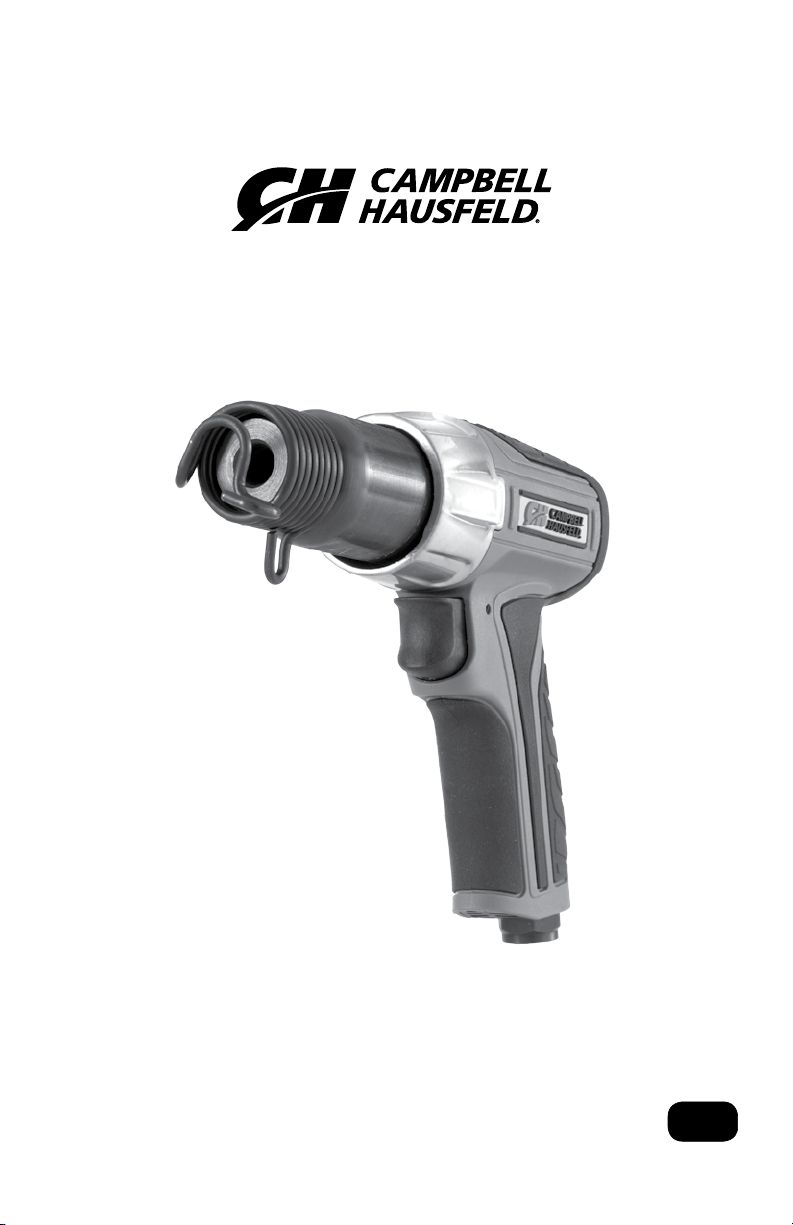

GETTING TO KNOW YOUR UNIT

Threaded Barrel

Spring Retainer

Trigger

Air Inlet

Chisel

SET UP INSTRUCTIONS

* Items shown in Set Up Instructions are not included with this tool.

Exhaust Port

Air Hose

Spring Retainer

Quick

Coupler

Plug

Whip Hose

BEST PRACTICES

u The air compressor used with your air hammer must be able to maintain a

minimum of 90 PSI when the tool is being used. An inadequate air supply can

cause a loss of power and inconsistent tool output/performance.

u A pressure regulator—used at the tool—is helpful to control the operating

pressure of the tool and maintain 90 PSI.

u Use an oiler to provide oil circulation through the tool and a filter to remove liquid

and solid impurities which can rust or “gum up” internal parts of the tool.

u To disconnect a coupler/plug from a system set-up: push the coupler and plug

together before pulling the coupler sleeve back and separating the coupler and

plug.

u Make sure that the chisels used with your pneumatic air hammer are heat-treated

steel for increased durability and longer life.

3

Page 6

LUBRICATION

To protect your tool, lubricate the motor every time--before and after--you

use this tool. You cannot oil the motor too often or put too much oil in the

air inlet.

1. Disconnect the air hammer from air supply and remove the chisel/

hammer bit.

2. Turn the tool upside down.

3. While pulling the trigger, pour approximately a teaspoon of air tool oil

in the air inlet. Campbell Hausfeld makes an air tool oil under model

number ST1270.

4. Connect the tool to the air supply and cover the exhaust port with a

towel. Run the air hammer for about 10 seconds. Oil will spray from the

exhaust port when the tool is triggered.

5. Continue to run until no oil is discharged.

6. Wipe all residual oil from tool before use.

OPERATING INSTRUCTIONS

BEST PRACTICES

u The spring retainer will wear out and should be replaced when worn.

u Never operate air hammer unless it is applied to a work surface. Operating the

tool freely, will cause the chisel bit to break the spring retainer.

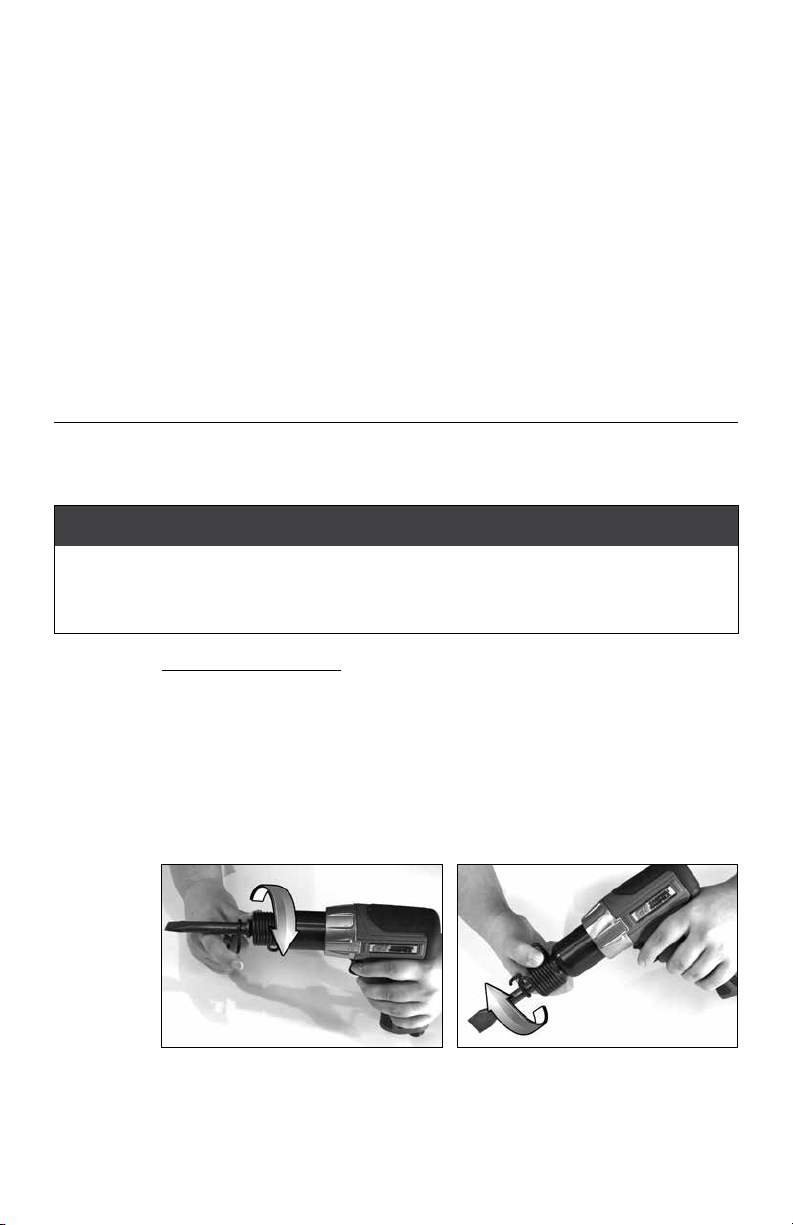

Chisel Bit Installation:

1. Unscrew the spring retainer from the air hammer counter-clockwise.

a. Use the wire tab closest to the hammer base for leverage.

2. Insert chisel bit and feed spring retainer over the bit.

3. Turn spring retainer on to the threaded end in a clockwise direction until

fully seated

a. Use open-end hook to tighten.

4. To change bits, reverse the process.

4

Page 7

STORAGE

Lubricate your air hammer before storing. Follow the lubrication instructions

with an exception to step #4. Only run the air hammer for 2-3 seconds

(instead of 10 seconds) because more oil needs to remain in the air hammer

when storing. Store your tool in a cool dry place.

TECHNICAL SERVICE

For information regarding the operation or repair of this product, please visit

www.campbellhausfeld.com.

SAFETY INSTRUCTIONS

This manual contains information that is very important to know and

understand. This information is provided for SAFETY and to PREVENT

EQUIPMENT PROBLEMS. To help recognize this information, observe the

symbols found on page 8. The Safety Symbols throughout this manual are to

alert you to important safety hazards and precautions.

The DANGER, WARNING, CAUTION, and NOTICE notifications

and instructions in this manual cannot cover all possible condi-

tions and situations that may occur. It must be understood by

the operator that caution is a factor which cannot be built into

this product, but must be supplied by the operator.

With any piece of equipment, new or used, the most important part of its

operation is SAFETY!

Campbell Hausfeld encourages you to familiarize yourself with your new

equipment and stresses safe operation.

The next few pages of this manual are a summary of the main safety aspects

associated with this unit. Be sure to read and understand completely before

operating the machine.

The symbols used throughout the operation and maintenance sections of

this manual call attention to safety procedures.

Important Safety Information

Please read and save these instructions. Read carefully before attempting to

assemble, install, operate or maintain the product described. Protect yourself

and others by observing all safety information. Failure to comply with

instructions could result in personal injury and/or property damage! Retain

instructions for future reference.

This manual contains important safety, operational and maintenance

information. If you have any questions, please visit

www.campbellhausfeld.com for customer assistance.

5

Page 8

SAFETY INSTRUCTIONS (CONTINUED)

California Proposition 65

MANUAL

This product can expose you to chemicals including

lead, which are known to the State of California

to cause cancer and birth defects or other reproductive harm. For more

information go to www.P65Warnings.ca.gov.

Illinois Lead Poisoning Prevention Act

Contains lead. May be harmful if eaten or chewed.

Complies with Federal Standards.

General Safety

This product is a part of a high pressure system and the following safety

precautions must be followed at all times along with any other existing safety

rules.

1. Read all manuals included with this product carefully. Be thoroughly

familiar with the controls and the proper use of the equipment.

2. Only persons well acquainted with these rules of safe operation should

be allowed to use the air tool.

Do not exceed maximum operating pressure of the

air tool (90 PSI). The air tool could explode and result

in death or serious personal injury.

3. Do not exceed any pressure rating of any component in the system.

Maximum operating pressure of 90 PSI is measured at the tool inlet

while the tool is running. The pressure drop between the compressor

and tool needs to be compensated for at the compressor.

4. Disconnect the air tool from air supply before changing tools or

attachments, servicing and during non-operation.

Safety glasses and ear protection must be worn

5. Do not wear loose fitting clothing, scarves, or neck ties. Loose clothing

may become caught in moving parts and result in serious personal injury.

6. Do not wear jewelry when operating any tool. Jewelry may become

caught in moving parts and result in serious personal injury.

7. Do not depress trigger when connecting the air supply hose.

8. Always use attachments designed for use with air powered tools. Do not

use damaged or worn attachments.

9. Never trigger the tool when not applied to a work object. Attachments

must be securely attached. Loose attachments can cause serious injury.

Never carry a tool by the hose or pull hose to move

oil and sharp edges. Replace any hose that is damaged, weak or worn.

10. Protect air lines from damage or puncture.

during operation.

tool or a compressor. Keep hoses away from heat,

6

Page 9

11. Never point an air tool at oneself or any other person. Serious injury

could occur.

12. Check air hoses for weak or worn condition before each use. Make sure

all connections are secure.

Release all pressure from the system before

attempting to install, service, relocate or perform

any maintenance.

13. Keep all nuts, bolts and screws tight and ensure equipment is in safe

working condition.

14. Do not put hands near or under moving parts.

15. Always secure workpiece in a vise or clamp. Do not place hands on the

black cylinder or spring retainer when operating the tool.

The spring retainer must be used to hold the chisel

in place. Personal injury can occur if the chisel is not

secure.

The quick connect retainer or spring retainer must be

used to hold the hammer in place. Personal injury

can occur if the hammer is not secure.

16. Risk of electrical shock: this tool is conductive. Do not hammer into walls

containing live electrical wiring.

Do not misuse this product. Excessive exposure to

vibration, work in awkward positions, and repetitive

work motions can cause injury to hands and arms. Stop using any tool if

discomfort, numbness, tingling, or pain occur, and consult a physician.

This air tool requires lubrication before initial use

and before and after each additional use.

Disconnect air tool from air supply before

lubricating.

Cover exhaust port with a towel before applying air

pressure. Oil will discharge through exhaust port

during first few seconds of operation after an airtool has been lubricated.

Failure to cover exhaust port can result in serious injury.

7

Page 10

SAFETY INSTRUCTIONS (CONTINUED)

Safety Glossary

This manual contains information that is very important to know and

understand. This information is provided for SAFETY and to PREVENT

EQUIPMENT PROBLEMS. To help recognize this information, observe the

following symbols.

Danger indicates an imminently hazardous situation

which, if not avoided, WILL result in death or serious

injury.

Warning indicates a potentially hazardous situation

which, if not avoided, COULD result in death or

serious injury.

Caution indicates a potentially hazardous situation

which, if not avoided, MAY result in minor or

moderate injury.

Notice indicates important information, that if not

followed, may cause damage to equipment.

IMPORTANT or NOTE: Information that requires special attention.

Safety Symbols

The following Safety Symbols appear throughout this manual to alert you to

important safety hazards and precautions.

MANUAL

Wear Eye

and Mask

Protection

Read Manual

First

Risk of

Explosion

Wear Eye

and Hearing

Protection

Risk of

Pressure

Risk of Shock

SAVE THESE INSTRUCTIONS

DO NOT DISCARD

8

Page 11

GENERAL TROUBLESHOOTING GUIDE

SYMPTOM POSSIBLE CAUSE(S) CORRECTIVE ACTION

Tool runs slowly or will

not operate

Moisture blowing out

of tool

Chisel/Hammer is

jammed and will not

move back and forth

* When reassembling the cylinder to the housing, use thread lock on the cylinder threads.

1. Grit or gum in tool 1. Flush tool with Campbell Hausfeld

2. No oil in tool 2. Lubricate tool according to

3. Low air pressure 3. Adjust the compressor regulator to

4. Air hose leaks 4. Tighten and seal hose fittings, if leaks

5. Pressure drops 5. Be sure hose is properly sized. Long

1. Water in tank 1. Drain tank (See air compressor

2. Water in air lines/hoses 2. a. Install a water separator/filter.

1. Chisel/hammer piston and

barrel are dirty or rusty

2. Chisel/hammer piston and

barrel are rusted together

3. Piston is jammed in the

barrel

air tool oil, gum solvent, or an

equal mixture of SAE 10 motor oil

and kerosene. Lubricate tool after

cleaning with Campbell Hausfeld (or

comparable) air tool oil.

lubrication instructions in this

manual.

90 PSI while the tool is running free.

are found.

hoses or tools using large volumes of

air may require a hose with an I.D. of

1/2 inch or larger depending on total

hose length.

manual). Oil tool and run until no

water is evident. Oil tool again and

run 1-2 seconds.

NOTE: Separators work properly

only when air stream is cool.

Locate separator/filter as far as

possible from compressor.

b. Install an air dryer.

c. Anytime water enters tool, tool

should be oiled immediately.

1. a. Heavily oil tool to free up piston.

b. Clean piston and barrel with air

tool oil and remove any burrs on

piston or barrel surfaces. *

c. Replace worn piston and

cylinder.*

d. Anytime water enters tool, tool

should be oiled immediately.

2. Remove piston and de-rust. Replace

piston and cylinder if needed. *

3. Attempt to free jammed piston

using a punch and hammer. It may

be necessary to disassemble barrel

from housing. Clean parts and

reassemble. *

99

Page 12

Reminder: Keep your dated proof of purchase for warranty purposes! Attach it to this manual or file it

for safekeeping.

LIMITED WARRANTY

1. DURATION: From the date of purchase by the original purchaser as follows: Two (2) Years.

2. WHO GIVES THIS WARRANTY (WARRANTOR): Campbell Hausfeld, a Marmon/Berkshire Hathaway

Company, 100 Production Drive, Harrison, Ohio, 45030. Visit www.campbellhausfeld.com.

3. WHO RECEIVES THIS WARRANTY (PURCHASER): The original purchaser (other than for purposes of

resale) of the Campbell Hausfeld product.

4. WHAT PRODUCTS ARE COVERED BY THIS WARRANTY: This Campbell Hausfeld air tool.

5. WHAT IS COVERED UNDER THIS WARRANTY: Substantial defects in material and workmanship which

occur within the duration of the warranty period with the exceptions below.

6. WHAT IS NOT COVERED UNDER THIS WARRANTY:

A. Implied warranties, including those of merchantability and FITNESS FOR A PARTICULAR

PURPOSE ARE LIMITED FROM THE DATE OF ORIGINAL PURCHASE AS STATED IN THE DURATION.

If this product is used for commercial, industrial or rental purposes, the warranty will apply for

ninety (90) days from the date of purchase. Some States do not allow limitation on how long an

implied warranty lasts, so the above limitations may not apply to you.

B. ANY INCIDENTAL, INDIRECT, OR CONSEQUENTIAL LOSS, DAMAGE, OR EXPENSE THAT MAY

RESULT FROM ANY DEFECT, FAILURE, OR MALFUNCTION OF THE CAMPBELL HAUSFELD

PRODUCT. Some States do not allow the exclusion or limitation of incidental or consequential

damages, so the above limitation or exclusion may not apply to you.

C. Any failure that results from an accident, purchaser’s abuse, neglect or failure to operate

products in accordance with instructions provided in the owner’s manual(s) supplied with

product. Accident, purchaser’s abuse, neglect or failure to operate products in accordance with

instructions shall also include the removal or alteration of any safety devices. If such safety

devices are removed or altered, this warranty is void.

D. Normal adjustments which are explained in the owner’s manual(s) provided with the product.

7. RESPONSIBILITIES OF WARRANTOR UNDER THIS WARRANTY: Repair or replace, at Warrantor’s

option, products or components which are defective, have malfunctioned and/or failed to conform

within the duration of the specific warranty period.

8. RESPONSIBILITIES OF PURCHASER UNDER THIS WARRANTY:

A. Provide dated proof of purchase and maintenance records.

B. Visit www.campbellhausfeld.com to obtain your warranty service options. Freight costs must be

borne by the purchaser.

C. Use reasonable care in the operation and maintenance of the products as described in the

owner’s manual(s).

9. WHEN WARRANTOR WILL PERFORM REPAIR OR REPLACEMENT UNDER THIS WARRANTY: Repair

or replacement will be scheduled and serviced according to the normal work flow at the servicing

location, and depending on the availability of replacement parts.

This Limited Warranty applies in the United States, Canada and Mexico only and gives you specific legal

rights. You may also have other rights which vary from state to state or country to country.

10

Page 13

Marteau pneumatique

Instructions d’Utilisation

© 2017 Campbell Hausfeld

A Marmon/Berkshire Hathaway Company

Modèle: XT101000

FR

IN745300 6/17

Page 14

Lire et conserver ces instructions. Il faut les lire attentivement avant

de commencer à assembler, installer, faire fonctionner ou entretenir

l’appareil décrit.

Pour se protéger et protéger autrui, observer toutes les informations sur

la sécurité. Négliger d’appliquer ces instructions peut causer

des blessures et/ou des dommages matériels! Conserver ces instructions

pour consultation ultérieure.

RAPPEL: Conservez votre preuve d’achat datée aux fins de garantie!

Attachez-le à ce manuel ou classez-le pour le garder en sécurité.

Pour de l’information sur les pièces,

produits et services veuillez visiter

N° de modèle : _____________________________

www.campbellhausfeld.com

N° de série : _______________________________

Date d’achat : _____________________________

ENREGISTREZ VOTRE PRODUIT EN LIGNE MAINTENANT !

www.campbellhausfeld.com/reg

LIRE ET SUIVRE TOUTES LES INSTRUCTIONS

CONSERVER CES INSTRUCTIONS • NE PAS JETER

Campbell Hausfeld

100 Production Drive

Harrison, Ohio 45030

Page 15

AVANT DE COMMENCER

Description

Une longueur moyenne de canon de 7 mm (2-3/4 po) délivre l’alimentation

lorsque la puissance de sortie est essentielle pour découper à travers des

boulons et métaux rouillés, ainsi que pour vos autres travaux de poinçonnage,

déchiquetage ou raclage. Les points de contact surmoulés mous et adhérents

situés sur ce marteau pneumatique permettent d’absorber les vibrations de

l’outil et de réduire la fatigue - vous aidant à avancer dans les nombreuses

tâches que vous avez sur votre liste de choses à faire.

CampbellHausfeld

L’histoire de l’entreprise est parsemée de produits de qualités depuis 1836,

alors que furent fabriqués les wagons tirés par les chevaux et les équipements

agraires. Aujourd’hui, Campbell Hausfeld offre une gamme complète de

compresseurs, outils et d’accessoires pneumatiques, pompes de gonflage,

de cloueurs, agrafeuses, pistolets pulvérisateurs, laveuses à pression, et plus.

Terminez vos projets plus rapidement et plus facilement grâce à Campbell

Hausfeld – l’expert de la puissance de l’air.

DÉBALLAGE

Dès que l’appareil est déballé, l’inspecter attentivement pour tout signe de

dommages en transit. Vérifier s’il y a des pièces desserrées, manquantes ou

endommagées. Vérifier pour s’assurer que tous les accessoires fournis sont inclus

avec l’appareil. Pour toutes questions, pièces endommagées ou manquantes,

veuillez visiter www.campbellhausfeld.com pour l’assistance à la clientèle.

Ne pas utiliser un modèle qui a été endommagé

Le dommage peut résulter en explosion et peut causer des blessures ou

dégâts matériels.

®

vous facilite le travail afin de terminer vos projets en pro.

pendant le transport, la manipulation ou l’utilisation.

Autres pièces (non fournies)

Il vous faudra les éléments et/ou accessoires suivants pour correctement mettre

en marche et utiliser de manière optimale votre marteau pneumatique :

• Un tuyau court flexible ou principal de 9,5 mm (3/8 po) afin d’absorber

les vibrations

• Connecteur 6,4 mm (1/4 po) NTP (M)

• Tuyau à air 9,5 mm (3/8 po) (DIA. INT.)

• Raccord 6,4 mm (1/4 po) NPT (F)

o Élimine la confusion par l’utilisation d’un raccord de style universel.

o Les coupleurs à attache rapide raccordent rapidement et facilement

les tuyaux aux outils.

o Si vous n’utilisez pas un connecteur flexible, un raccord pivotant

pourrait être utilisé afin d’éviter l’entortillement et réduire le stress

imposé à votre tuyau d’air.

• Un compresseur d’air de 98,41 litres (26 galons) ou plus

• Bouts de burin Parker Taper 0.401

• Ruban PTFE pour tous les joints des raccords

• Clé ajustable pour serrer les joints des raccords

Voir au www.campbellhausfeld.com pour d’autres informations sur les

accessoires accompagnant vos outils et votre système pneumatique.

Fr1

Page 16

MEILLEURES PRATIQUES

u Pour une meilleure puissance, maintenez la pression à l’outil de 621 kPa.

u Plus votre tuyau à air est long, plus la pression diminuera entre le compresseur et

l’outil. Si vous utilisez un tuyau à air dépassant 15,2m (50 pi), on devrait plutôt

utiliser un tuyau à air de 12,7 mm (1/2 po) de dia. int. pour assurer une pression

appropriée à l’outil.

u À défaut de lubrifier et de correctement entretenir vos outils pneumatiques diminuera

drastiquement leur durée de vie. Utilisez de l’huile chaque fois que vous utilisez votre

outil pour le lubrifier, le nettoyer et éviter la rouille, en une seule étape. Campbell

Hausfeld offre une huile à outils pneumatiques sous le numéro de pièceST1270.

u En raison des vibrations excessives créées par cet outil, il est recommandé d’utiliser

un tuyau court flexible (aussi connu sous le nom de tuyau principal). Si vous

utilisez un tuyau court flexible, N’INSTALLEZ-PAS d’ensemble d’accouplement entre

l’outil et le tuyau court flexible.

CARACTÉRISTIQUES TECHNIQUES

XT101000

kPa maximum 621 kPa

pi³/min (l/min) en charge de service à 100% 87,8 L/min @ 621 kPa

pi³/min standard (l/min) en charge de service à 100% 676,8 L/min @ 621 kPa

Recommandation pour le compresseur d’air 98,41 L

Coups par minutes (CPM) 2600

Longueur de course 6,99 cm (2-3/4 po)

Diamètre de la tige du burin Arbre conique de type

Arrivée d’air 1/4 po NPT (F)

Taille minimum du tuyau 9,5 mm (3/8 po)

Matériau du logement Composite

Poids de l’outil 1,32 kg

Longueur du tuyau 17,46 cm (6-7/8 po.)

Hauteur de l’outil 16,19 cm (6-3/8 po.)

Largeur du tuyau 5,40 cm (2-1/8 po.)

Parker 0.401

Fr2

Page 17

APPRENEZ À CONNAÎTRE VOTRE UNITÉ

Canon tronçonné

Retenue du ressort

Détente

Sortie de l’échappement

INSTRUCTIONS DE MISE EN MARCHE

Coupleur

rapide

Bouchon

Tuyau à air

* Les éléments montrés aux Instructions de mise en marche ne sont pas fournis avec cet outil.

Tuyau flexible court

Retenue du ressort

Arrivée d’air

Burin

MEILLEURES PRATIQUES

u Le compresseur d’air utilisé avec votre marteau pneumatique doit être capable de

maintenir au moins 621 psi lorsque l’outil est en fonction. Un approvisionnement

d’air inadéquat peut causer une perte de puissance et une performance

inconstante de l’outil.

u Un régulateur de pression – utilisé sur l’outil – est utile pour contrôler la pression

de fonctionnement de l’outil et maintenir 621 kPa.

u Utilisez un huileur pour offrir une circulation de l’huile dans l’outil et un filtre pour

retirer les impuretés liquides et solides pouvant causer la rouille ou de l’encrassage.

u Pour débrancher un raccord/embout d’un système: poussez le raccord et l'embout

ensemble avant de tirer le manchon du raccord vers l’arrière et en séparant le

coupleur et l'embout.

u Assurez-vous que les burins qui sont utilisés avec votre marteau pneumatique sont

en acier traité à la chaleur afin de garantir une durabilité accrue et une plus longue

durée de vie.

Fr3

Page 18

LUBRIFICATION

Pour protéger votre outil, lubrifiez le moteur chaque fois –avant et après–

l’avoir utilisé. Vous ne pouvez huiler le moteur trop fréquemment ou placer

trop d’huile dans l’arrivée d’air.

1. Débranchez le marteau pneumatique de l’alimentation d’air et enlevez

le bout du burin/marteau.

2. Tournez l’outil à l’envers.

3. En tirant sur la détente, versez environ une cuillerée à thé d’huile à

outils pneumatiques dans l’arrivée d’air. Campbell Hausfeld offre une

huile à outils pneumatiques sous le numéro de modèleST1270.

4. Connectez l’outil à l’alimentation d’air et couvrez la sortie de

l’échappement avec une serviette. Mettez le marteau pneumatique en

marche pendant 10 secondes. L’huile sera pulvérisée par la sortie de

l’échappement lorsque l’outil sera mis en marche.

5. Continuez tant qu’il y aura de l’huile.

6. Essuyez toute huile résiduelle de l’outil avant de l’utiliser.

MODE D’EMPLOI

MEILLEURES PRATIQUES

u La retenue du ressort s’usera et devrait être remplacée dès qu’elle est usée.

u Ne jamais opérer le marteau pneumatique à moins qu’il ne soit appliqué à une

surface de travail. Laisser fonctionner l’outil librement incitera le bout du burin à

briser la retenue du ressort.

Installation du bout du burin :

1. Dévisser la retenue du ressort du marteau pneumatique dans le sens

anti-horaire.

a. Utiliser l’onglet fileté le plus proche de la base du marteau pour

effectuer un effet de levier.

2. Insérer le bout du burin et placer la retenue du ressort par dessus le bout.

3. Faire tourner la retenue du ressort sur l’extrémité filetée dans le sens

horaire jusqu’à ce qu’elle soit entièrement placée.

a. Utiliser un crochet à extrémité ouverte pour resserrer.

4. Pour changer les bouts, inverser la procédure.

Fr4

Page 19

ENTREPOSAGE

Lubrifier votre marteau pneumatique avant de le ranger. Suivre les directives de

lubrification, sauf pour l’étape 4. Ne faites fonctionner le marteau pneumatique

que pendant 2-3 secondes (au lieu de 10 secondes) parce qu’il doit rester

davantage d’huile dans le marteau pneumatique pendant l’entreposage.

Rangez votre outil dans un endroit frais et sec.

SERVICE TECHNIQUE

Pour de l’information sur le fonctionnement ou la réparation de ce produit,

veuillez visiter le www.campbellhausfeld.com.

INSTRUCTIONS DE SÉCURITÉ

Ce guide contient de l’information très importante que vous devez connaître

et comprendre. Cette information est fournie à des fins de SÉCURITÉ et

dans le but d’ÉVITER DES PROBLÈMES AVEC L’ÉQUIPEMENT. Pour faciliter la

reconnaissance de cette information, observez les symboles se trouvant à la

pageFr8. Les symboles sur la sécurité de ce manuel, visent à vous alerter des

importants dangers à la sécurité et les précautions.

Les symboles DANGER, AVERTISSEMENT, ATTENTION et AVIS

ainsi que les instructions de ce manuel ne peuvent pas couvrir

toutes les conditions et situations qui pourraient se produire.

L’opérateur doit comprendre que le bon sens et des précautions

sont des facteurs qui ne peuvent pas être inclus dans ces

produits, mais doivent être fournis par l’opérateur.

Avec toute pièce d’équipement, neuve ou usée, la plus importante partie de

l’opération est la SÉCURITÉ!

Campbell Hausfeld vous encourage à vous familiariser avec votre nouvel

équipement et insiste sur un fonctionnement sécuritaire.

Les prochaines pages de ce manuel résument les aspects principaux sur la

sécurité liée avec cette unité. Assurez-vous de les lire et les comprendre

entièrement avant d’utiliser cet appareil.

Les symboles utilisés dans les sections de fonctionnement et d’entretien du

présent manuel attirent l’attention sur les procédures de sécurité.

Importantes instructions de sécurité

S’il vous plaît lire et conserver ces instructions. Lire attentivement avant

de monter, installer, utiliser ou de procéder à l’entretien du produit décrit.

Se protéger ainsi que les autres en observant toutes les instructions de

sécurité, sinon, il y a risque de blessure et/ou dégâts matériels! Conserver ces

instructions comme référence.

Ce manuel contient des informations concernant la sécurité, le

fonctionnement et l’entretien. Si vous avez des questions, veuillez visiter

www.campbellhausfeld.com pour l’assistance à la clientèle.

Fr5

Page 20

INSTRUCTIONS DE SÉCURITÉ (SUITE)

Proposition 65 de la Californie

MANUAL

Ce produit peut vous exposer à des produits

chimiques incluant le plomb, connus par l’état de la

Californie comme pouvant causer le cancer, des anomalies congénitales ou

d’autres troubles de la reproduction. Pour plus d’informations, rendez-vous

sur le site www.P65Warnings.ca.gov.

Illinois Lead Poisoning Prevention Act (Loi sur la prévention de

l’empoisonnement au plomb de l’État de l’Illinois)

Contient du plomb. Peut être nocif si ingéré ou

mâché. Respecte les normes fédérales.

Généralités sur la sécurité

Ce produit fait partie d’un système à haute pression et les précautions de

sécurité suivantes doivent être prises en permanence, en même temps que

toute autre règle de sécurité en vigeur.

1. Lire attentivement tous les manuels, y compris celui de ce produit.

Bien se familiariser avec les commandes et l’utilisation correcte de

l’équipement.

2. Seules les personnes bien familiarisées avec ces règles d’utilisation en

toute sécurité doivent être autorisées à se servir de l’outil pneumatique.

Ne pas dépasser la pression maximum de service

de l’outil pneumatique (621 kPa). L’outil

pneumatique risque d’exploser et d’avoir pour résultat des blessures graves,

ou mortelles.

3. Ne pas dépasser la pression nominale de n’importe quelle pièce du

système. La pression de service maximum de 621 kPa est mesurée

à l’arrivée de l’outil pendant que l’outil est en marche. La chute de

pression entre le compresseur et l’outil doit être réglée au compresseur.

4. Débrancher l’outil pneumatique de l’alimentation en air avant de remplacer

des outils ou accessoires, de procéder à l’entretien et de ranger l’outil.

Il est nécessaire de porter des lunettes de protection

5. Ne pas porter de vêtements flottants, d’écharpe ni de cravate. Les

vêtements flottants risquent de se prendre dans les pièces mobiles, ce

qui peut provoquer des blessures graves.

6. Ne pas porter de bijoux lorsqu’on utilise un outil quelconque. Ils risquent

de se prendre dans les pièces mobiles, ce qui peut provoquer des

blessures graves.

7. Ne pas appuyer sur la gâchette lorsque l’on branche le tuyau

d’alimentation en air.

8. Toujours utiliser des accessoires conçus pour les outils pneumatiques. Ne

pas utiliser d’accessoires endommagés ou usés.

9. Ne jamais appuyer sur la gâchette de l’outil tant qu’il n’y ait pas contact

avec une pièce. Les accessoires doivent être bien fixés pour éviter tout

risque de blessure grave.

et un protecteur auditif pendant l’utilisation.

Fr6

Page 21

Ne jamais transporter un outil par le tuyau et ne

jamais l’utiliser pour déplacer l’outil ou le

compresseur. Garder les tuyaux à l’écart de la chaleur, l’huile et les objets

pointus. Remplacer un tuyau usé, faible ou endommagé.

10. Protéger les canalisations d’air contre les dommages ou perforations.

11. Ne jamais diriger un outil pneumatique vers soi-même ni vers une autre

personne afin d’éviter tout risque de blessure grave.

12. Vérifier les tuyaux d’air pour rechercher tout signe de faiblesse ou

d’usure avant chaque utilisation.Veiller à ce que tous les branchements

soient bien serrés.

Dissiper toute la pression du système avant

d’essayer d’installer, réparer, déplacer le produit ou

de procéder à son entretien.

13. Vérifier le serrage des écrous, boulons et vis et s’assurer que

l’équipement soit en bon état de marche.

14. Ne pas se mettre les mains près des pièces mobiles ni en-dessous de

celles-ci.

15. Toujours fixer l’objet de travail dans un étau ou avec une bride. Ne

jamais placer les mains sur le cylindre noir ni sur le dispositif de retenue

de ressort pendant l’opération de l’outil.

Le dispositif de retenue de ressort doit être usé

pour tenir le ciseau dans sa place. Manque de fixer le

ciseau peut résulter en blessure personnelle.

Le dispositif de retenue raccord rapide doit être

utiliser pour fixer le marteau. Manque de bien fixer

le marteau peut résulter en blessure personnelle.

16. Risque de secousse électrique : cet outil est conducteur. Ne pas frapper

sur de parois qui contiennent du câblage sous tension.

Ne pas abuser ce produit. L’exposition excessif à

la vibration, au travail dans les positions d’accès

difficile et le mouvement répététif peuvent causer des blessures aux mains

et aux bras. Arrêter d’utiliser un outil et consulter un médecin si vous avez le

malaise, l’engourdissement, le picotement ou la douleur.

Cet outil pneumatique requiert un graissage avant

d’être utilisé la première fois et après chaque usage.

Débrancher l’outil pneumatique de la source d’air

avant le graissage.

Une fois qu’un outil pneumatique a été graissé, de

l’huile s’écoulera de l’orifice de sortie lors des

quelques premières secondes de fonctionnement. C’est pourquoi cet

orifice doit être recouvert d’un torchon avant d’alimenter en air comprimé.

Manque de couvrir l’orifice de sortie peut résulter en blessure grave.

Fr7

Page 22

INSTRUCTIONS DE SÉCURITÉ (SUITE)

Glossaire sur la sécurité

Ce manuel contient de l’information très importante qui est fournie pour

la SÉCURITÉ et pour ÉVITER LES PROBLÈMES D’ÉQUIPEMENT. Rechercher les

symboles suivants pour cette information.

Danger indique une situation dangereuse imminente

qui MÈNERA à la mort ou à des blessures graves si

elle n’est pas évitée.

Avertissement indique une situation potentiellement

dangereuse qui, si elle n’est pas évitée, POURRAIT

mener à la mort ou à de graves blessures.

Attention indique une situation potentiellement

dangereuse qui, si elle n’est pas évitée, PEUT mener

à des blessures mineures ou modérées.

Avis indique de l’information importante qui

pourrait endommager l’équipement si elle n’est pas

respectée.

IMPORTANT ou REMARQUE: Information qui exige une attention spéciale.

Symboles de sécurité

Les symboles de sécurité suivants apparaissent dans l’ensemble de ce manuel

pour vous aviser des dangers et précautions importants de sécurité.

MANUAL

Lunettes et

masque de

protection

Lire le manuel

d’abord

Risque

d’explosion

Portez une

protection

oculaire et

auditive

Risque de

pression

Risque de

choc

CONSERVER CES INSTRUCTIONS

NE PAS JETER

Fr8

Page 23

GUIDE GÉNÉRAL DE DÉPANNAGE

SYMPTÔME CAUSE(S) POSSIBLE(S) ACTION CORRECTIVE

L’outil fonctionne

lentement ou ne

fonctionne pas

Humidité expulsée de

l’outil

Le ciseau/marteau

est bloqué et ne peut

bouger d’avant à

arrière

* Lors du remontage du cylindre sur le carter, utiliser du frein filet sur le filetage du cylindre.

1. Présence de grenaille ou de

gomme dans l’outil

2. Absence d’huile dans l’outil 2. Lubrifiez l’outil selon les instructions de

3. Pression d’air basse 3. Ajustez le régulateur du compresseur

4. Fuites dans le tuyau d’air 4. Serrer et assurer l’étanchéité des

5. Chute de pression 5. S’assurer que le tuyau soit de la

1. Présence d’eau dans le

réservoir

2. Eau dans les canalisations/

tuyaux

1. Le piston et le cylindre du

ciseau/marteau sont sales ou

rouillés

2. Le piston et le cylindre du

ciseau/marteau sont rouillés

ensemble

3. Le piston est bloqué dans le

cylindre

1. Rincer l’outil avec de l’huile pour

outils pneumatiques Campbell

Hausfeld, du dissolvant de gomme

ou un mélange en proportions égaux

d’huile de moteur SAE 10 et de

kérosène. Lubrifiez l’outil après l’avoir

nettoyé avec de l’huile pour outil à air

Campbell Hausfeld (ou comparable).

lubrification énoncées dans ce manuel.

à 621 kPa pendant que l’outil

fonctionne à vide.

raccords du tuyau en cas de fuites.

bonne taille. Les longs tuyaux ou les

outils exigeant de grands volumes

d’air peuvent nécessiter un tuyau de

diamètre intérieur d’au moins

12,7 mm (1/2 po.), suivant la longueur

totale du tuyau.

1. Vidanger le réservoir. (Voir le manuel

du compresseur.) Huiler l’outil et le

faire tourner jusqu’à ce qu’il semble

ne plus contenir d’eau. Huiler l’outil

de nouveau et le faire tourner

pendant 1-2 seconde(s).

2. a. Monter un séparateur/filtre d’eau.

REMARQUE: Les séparateurs ne

fonctionnent correctement que

lorsque l’air qui les traversent est

frais. Positionner le séparateur/

filtre aussi loin que possible du

compresseur.

b. Monter un sécheur d’air.

c. Graisser l’outil immédiatement si

l’eau entre dans l’outil.

1. a. Bien graisser l’outil afin de libérer

le piston.

b. Nettoyer le piston et le cylindre

avec de l’huile pour outils

pneumatiques et enlever les

ébarbures de la surface du piston

ou du cylindre. *

c. Remplacer le piston et cylindre

usés. *

d. Graisser l’outil immédiatement si

l’eau entre dans l’outil.

2. Enlever le piston et enlever la rouille

du piston. Remplacer le piston et le

cylindre si nécessaire.*

3. Essayer de débloquer le piston à l’aide

d’un pointeau et marteau. Il peut être

nécessaire de démonter le cylindre

du boîtier. Nettoyer les pièces et

remonter. *

Fr9

Page 24

Mémento: Gardez votre preuve datée d’achat à fin de la garantie! Joignez-la à ce manuel ou classez-la

dans un dossier pour plus de sécurité.

GARANTIE LIMITÉE

1. DURÉE: À partir de la date d’achat par l’acheteur original comme suit - Deux (2) ans.

2. GARANTIE ACCORDÉE PAR (GARANT):Campbell Hausfeld, a Marmon/Berkshire Hathaway Company,

100 Production Drive, Harrison, Ohio, 45030. Visitez www.campbellhausfeld.com.

3. BÉNÉFICIAIRE DE CETTE GARANTIE (ACHETEUR): L’acheteur original (sauf en cas de revente) du

produit Campbell Hausfeld.

4. PRODUITS COUVERTS PAR CETTE GARANTIE: Cet outil pneumatique Campbell Hausfeld.

5. COUVERTURE DE LA PRÉSENTE GARANTIE: Défauts importants de matériaux et de main d’oeuvre qui

se produisent durant la période de garantie à l’exception de ce qui est noté plus bas.

6. LA PRÉSENTE GARANTIE NE COUVRE PAS:

A. Les garanties implicites, y compris celles de commercialisabilité et D’ADAPTION À UNE

FONCTION PARTICULIÈRE SONT LIMITÉES À PARTIR DE LA DATE D’ACHAT INITIALE TELLE

QU’INDIQUÉE DANS LA SECTION DURÉE. Si ce produit est utilisé pour une fonction

commerciale, industrielle ou pour la location, la durée de la garantie sera quatre-vingt-dix (90)

jours à compté de la date d’achat. Quelques Provinces (États) n’autorisent pas de limitations de

durée pour les garanties implicites. Les limitations précédentes peuvent donc ne pas s’appliquer.

B. TOUT DOMMAGE, PERTE OU DÉPENSE FORTUIT OU INDIRECT POUVANT RÉSULTER DE TOUT

DÉFAUT, PANNE OU MAUVAIS FONCTIONNEMENT DU PRODUIT CAMPBELL HAUSFELD.

Quelques Provinces (États) n’autorisent pas l’exclusion ni la limitation des dommages fortuits ou

indirects. La limitation ou exclusion précédente peut donc ne pas s’appliquer.

C. Toute panne résultant d’un accident, d’une utilisation abusive, de la négligence ou d’une

utilisation ne respectant pas les instructions données dans le(s) manuel(s) accompagnant le

produit. Un accident, l’utilisation abusive par l’acheteur, la négligence ou le manque de faire

fonctionner les produits selon les instructions comprend aussi l’enlevage ou la modification

de n’importe quel appareil de sûreté. Si ces appareils de sûreté sont enlevés ou modifiés, la

garantie sera annulée.

D. Réglages normaux qui sont expliqués dans le(s) manuel(s) d’utilisation accompagnant le

produit.

7. RESPONSABILITÉS DU GARANT AUX TERMES DE CETTE GARANTIE: Réparer ou remplacer, au choix du

Garant, les produits ou composants défectueux, qui ont connu une défaillance et/ou qui ne sont pas

conformes pendant la durée précise de validité de la garantie.

8. RESPONSABILITÉS DE L’ACHETEUR AUX TERMES DE CETTE GARANTIE:

A. Fournir une preuve d’achat datée et un état d’entretien.

B. Visitez www.campbellhausfeld.com pour obtenir vos options de service sous garantie. Les frais

de transport sont la responsabilité de l’acheteur.

C. Utilisation et entretien du produit avec un soin raisonable, ainsi que le décri(vent)t le(s)

manuel(s) d’utilisation.

9. RÉPARATION OU REMPLACEMENT EFFECTUÉ PAR LE GARANT AUX TERMES DE LA PRÉSENTE

GARANTIE: La réparation ou le remplacement sera prévu et exécuté en fonction de la charge de

travail dans le centre de service et dépendra de la disponabilité des pièces de rechange.

Cette Garantie Limitée s’applique aux É.-U., au Canada et au Mexique seulement et vous donne des droits

juridiques précis. L’acheteur peut également jouir d’autres droits qui varient d’une Province, d’un État ou

d’un Pays à l’autre.

Fr10

Page 25

Martelo pneumático

Instruções de operação

© 2017 Campbell Hausfeld

A Marmon/Berkshire Hathaway Company

Modelo: XT101000

PG

IN745300 6/17

Page 26

Leia e salve estas instruções. Leia atentamente antes de tentar montar,

instalar, operar ou manter o produto descrito.

Proteja-se a você e terceiros observando todas as informações de

segurança. O incumprimento destas instruções pode resultar em lesões

pessoais e/ou danos materiais! Guarde as instruções para referência

futura.

LEMBRETE: Guarde sua prova de compra datada para fins de garantia!

Anexe-a a este manual ou arquivo para sua conservação.

N.º do modelo: _____________________________

N.º de série: _______________________________

Data de compra: ___________________________

REGISTRE SEU PRODUTO ON-LINE AGORA!

www.campbellhausfeld.com/reg

LEIA E SIGA TODAS AS INSTRUÇÕES

GUARDE ESTAS INSTRUÇÕES • NÃO DESCARTE

Para peças, produtos e informações de

serviço,

visite www.campbellhausfeld.com

Campbell Hausfeld

100 Production Drive

Harrison, Ohio 45030

Page 27

ANTES DE COMEÇAR

Descrição

Um comprimento de barril médio de 7 mm (2-3/4 pol.) fornece potência quando a

produção é fundamental para cortar através de parafusos com ferrugem e metal

e outras tarefas de perfuração, aparamento ou raspagem. Pontos de contato

sobremoldados suaves e aderentes neste martelo pneumático pneumático

ajudam a absorver a vibração das ferramentas e a reduzir a fadiga, o que lhe

permite continuar fazendo as tarefas de sua lista de projetos interminável.

Campbell Hausfeld

profissional. A história de criação de produtos de qualidade da empresa começou

em 1836, quando fabricou vagões puxados por cavalos e equipamentos agrícolas.

Hoje, a Campbell Hausfeld oferece uma linha completa de compressores

pneumáticos, ferramentas pneumáticas e acessórios, infladores, pistolas de pregos

e grampeadores, pulverizadores, arruelas de pressão, etc. Conclua seus projetos

mais rápido e mais fácil com Campbell Hausfeld - The Expert Air Power.

DESEMBALAMENTO

Após desembalar a unidade, verifique atentamente se ocorreram danos

durante o transporte. Verifique se existem peças soltas, em falta ou

danificadas. Certifique-se de todos os acessórios fornecidos estão junto

com a unidade. Em caso de dúvida, peças danificadas ou em falta, visite

www.campbellhausfeld.com para obter assistência ao cliente.

Não opere a unidade se estiver danificada durante o

transporte, manuseio ou uso. Os danos podem

resultar em ruptura e causar ferimentos ou danos materiais.

®

faz com que você termine seus projetos como um

Outras peças (não fornecidas)

Você vai precisar dos seguintes itens e/ou acessórios para configurar

corretamente e/ou usar de forma otimizada seu martelo pneumático:

• Mangueira de chicote ou mangueira de chegada de 9,5 mm (3/8 pol.)

(DI) para absorver a vibração

• Conector NPT (M) de 6,4 mm (1/4 pol).

• Mangueira de ar (ID) de 9,5 mm (3/8 pol).

• Acoplador NPT (F) de 6,4 mm (1/4 pol).

o Elimine o acoplador com um estilo de acoplador universal.

o Acopladores de conexão rápida e fácil para juntar mangueiras para

ferramentas.

o Se você não usar um conector flexível, considere um acoplador

giratório para evitar torções da mangueira e reduzir o estresse em

sua mangueira de ar.

• Compressor pneumático de 98,41 L (26 galões) ou mais

• Brocas de formão 0.401 Parker Taper

• Fita PTFE para todas as conexões de montagem

• Chave ajustável para apertar as conexões de encaixe

Consulte www.campbellhausfeld.com para obter informações adicionais sobre

os acessórios para apoiar suas ferramentas pneumáticas e sistema pneumático.

Pg1

Page 28

MELHORES PRÁTICAS

u Para uma melhor produção, mantenha a pressão na ferramenta de 6,2 bar.

u Quanto maior é a sua mangueira de ar, maior é a queda de pressão do compressor

para a ferramenta. Se você estiver usando uma mangueira com mais de 15,24 m

(50 pés), considere a atualização para uma mangueira de ar com 12,7 mm (1/2 pol.)

de Diâm. Int. para garantir pressão da ferramenta adequada.

u A falta de lubrificação e manutenção de suas ferramentas pneumáticas irá reduzir

corretamente de forma drástica a sua vida útil. Use óleo sempre que você usar

sua ferramenta pneumática para lubrificar, limpar e impedir a formação de

ferrugem em uma única etapa. A Campbell Hausfeld vende óleo para ferramentas

pneumáticas sob o número de peça ST1270.

u Devido à vibração excessiva criada por esta ferramenta, recomenda-se usar uma

mangueira de chicote (ou mangueira de chegada). Se usar uma mangueira de chicote.

NÃO instale um conjunto de acoplador entre a ferramenta e a mangueira de chicote.

ESPECIFICAÇÕES

XT101000

Bar máximo 6,2 bar

CFM (l/min.) sob uma carga de trabalho de 100% 87,8 L/min @ 6,2 bar

SCFM (l/min.) sob uma carga de trabalho de 100% 676,8 L/min @ 6,2 bar

Recomendação do compressor pneumático 98,41 L

Golpes por minuto (BPM) 2.600

Duração do curso 6,99 cm (2-3/4 pol.)

Diâmetro da haste de formão Eixo cônico do tipo

Entrada de ar 1/4 pol. NPT (F)

Tamanho mín. da mangueira 9,5 mm (3/8 pol.)

Material da estrutura Composto

Peso da ferramenta 1,32 kg

Comprimento da ferramenta 17,46 cm (6-7/8 pol.)

Altura da ferramenta 16,19 cm (6-3/8 pol.)

Largura da ferramenta 5,40 cm (2-1/8 pol.)

0.401 Parker

Pg2

Page 29

CONHECER SUA UNIDADE

Barril roscado

Retentor de mola

Acionador

Porta de escape

INSTRUÇÕES DE MONTAGEM

Acoplador

de engate

rápido

Conector

Mangueira de ar

* Os itens mostrados nas instruções de montagem não estão incluídos com esta ferramenta.

Mangueira de chicote

Retentor de mola

Entrada de ar

Formão

MELHORES PRÁTICAS

u O compressor pneumático usado com seu martelo pneumático deve ser capaz

de manter um mínimo de 6,2 bar quando a ferramenta está sendo usada.

Um fornecimento de ar insuficiente pode causar uma perda de energia e um

desempenho/vida útil da ferramenta inconsistente.

u Um regulador de pressão — usado na ferramenta — é útil para controlar a pressão

de operação da ferramenta e manter os 6,2 bar.

u Use um lubrificador para proporcionar a circulação de óleo por meio da

ferramenta e um filtro para remoção de impurezas líquidas e sólidas, que podem

oxidar ou colar as partes internas da ferramenta.

u Para desconectar um acoplador/conector a partir da configuração do sistema:

pressione o acoplador e conecte em conjunto antes de puxar a manga do

acoplador para trás e para a separação do acoplador e conector.

u Certifique-se de que os formões usados com seu martelo de ar pneumático sejam

de aço tratado a quente para maior durabilidade e tempo de vida útil.

Pg3

Page 30

LUBRIFICAÇÃO

Para proteger sua ferramenta, lubrifique o motor a cada-- antes e depois-de você usar esta ferramenta. Você não pode lubrificar o motor demasiado

frequentemente ou colocar demasiado o óleo na entrada de ar.

1. Desconecte o martelo pneumático do fornecimento de ar e retire o

formação/broca do martelo.

2. Inverta a ferramenta.

3. Enquanto puxa o acionador, verta aproximadamente uma colher de chá

do óleo da ferramenta pneumática na entrada de ar. A Campbell Hausfeld

produz óleo para ferramentas pneumáticas sob o número de modelo ST1270.

4. Conecte a ferramenta ao fornecimento de ar e proteja a porta de escape

com uma toalha. Coloque o martelo pneumático em funcionamento

durante 10 segundos. O óleo será descarregado da porta de escape

quando a ferramenta for acionada.

5. Continue a funcionar até não existir óleo a ser descarregado.

6. Limpe todo o óleo residual da ferramenta antes de usá-la.

INSTRUÇÕES DE OPERAÇÃO

MELHORES PRÁTICAS

u O retentor de mola ficará desgastado e, nesse momento, deve ser substituído.

u Jamais opere o martelo pneumático, a menos que seja aplicado em uma superfície

de trabalho. Operar a ferramenta livremente fará com que a broca do formão

quebre o retentor de mola.

Instalação das brocas de formão:

1. Desaperte o retentor de mola do martelo pneumático rodando para a

esquerda.

a. Use a lingueta junto da base do martelo para alçamento.

2. Insira a broca de cisel e o retentor de mola sobre a broca.

3. Rode o retentor de mola na direção da extremidade roscada para a

direita até assentar completamente

a. Use um gancho de bocas para apertar.

4. Para mudar de broca, inverta o processo.

Pg4

Page 31

ARMAZENAMENTO

Lubrifique seu martelo pneumático antes de armazená-lo. Siga as instruções de

lubrificação à exceção da etapa n.º 4. Acione o martelo pneumático apenas por 2-3

segundos (em vez de 10 segundos), pois deve permanecer mais óleo no martelo

pneumático ao armazenar. Armazene sua ferramenta em um lugar fresco e seco.

ASSISTÊNCIA TÉCNICA

Para obter informações sobre a operação ou reparação deste produto, visite

www.campbellhausfeld.com.

INSTRUÇÕES DE SEGURANÇA

Este manual contém informações que é muito importante conhecer e

entender. Estas informações são fornecidas para fins de SEGURANÇA e para

EVITAR PROBLEMAS NO EQUIPAMENTO. Para ajudar a reconhecer estas

informações, observe os símbolos encontrados na página 8. Os seguintes

símbolos de segurança aparecem ao longo deste manual para alertar você

sobre perigos e precauções de segurança importantes.

As notificações de PERIGO, ADVERTÊNCIA, PRECAUÇÃO e AVISO

e as instruções neste manual não conseguem abranger todas as

condições e situações possíveis que possam ocorrer. Há que ser

compreendido pelo operador que o cuidado é um fator que não

pode ser incorporado neste produto, mas deve ser fornecido

pelo operador.

Com qualquer peça de equipamento, nova ou usada, a parte mais importante

de sua operação é a SEGURANÇA!

A Campbell Hausfeld encoraja-o a se familiarizar com seu novo equipamento

e salienta a operação segura.

As próximas páginas deste manual são um resumo dos principais aspectos de

segurança associados com esta unidade. Certifique-se de que lê e compreende

completamente estas informações antes de operar a máquina.

Os símbolos usados ao longo das seções de operação e manutenção deste

manual destacam os procedimentos de segurança.

Informações importantes de segurança

Leia e guarde estas instruções. Leia atentamente antes de tentar montar,

instalar, operar ou manter o produto descrito. Proteja-se a você e terceiros

observando todas as informações de segurança. O incumprimento destas

instruções pode resultar em lesões pessoais e/ou danos materiais! Guarde as

instruções para referência futura.

Este manual contém informações importantes de segurança, operação e

manutenção. Se tiver questões, visite www.campbellhausfeld.com para obter

assistência ao cliente.

Pg5

Page 32

INSTRUÇÕES DE SEGURANÇA (CONTINUAÇÃO)

Proposta 65 da Califórnia

MANUAL

Este produto pode expô-lo a produtos químicos,

incluindo chumbo, conhecidos no Estado da

Califórnia por causar câncer, defeitos congênitos ou outros danos genéticos.

Para obter mais informações, acesse www.P65Warnings.ca.gov.

Lei de Prevenção Contra Envenenamento por Chumbo de Illinois

Contém chumbo. Pode ser nocivo se ingerido ou

mastigado. Cumpre as normas federais.

Segurança geral

Este produto é parte de um sistema de alta pressão e as seguintes precauções

de segurança devem ser sempre seguidas, juntamente com quaisquer outras

regras de segurança existentes.

1. Leia todos os manuais incluídos com este produto cuidadosamente.

Esteja totalmente familiarizado com os controles e o uso adequado do

equipamento.

2. Apenas pessoas bem familiarizadas com estas regras de operação segura

devem ser autorizados a usar a ferramenta pneumática.

Não exceda a pressão máxima de operação da

ferramenta pneumática (6,2 bar). A ferramenta

pneumática pode explodir e provocar a morte ou ferimentos graves.

3. Não exceda a classificação de pressão de qualquer componente do sistema.

A pressão máxima de operação de 6,2 bar é medida à entrada da ferramenta

enquanto a ferramenta está em funcionamento. A queda de pressão entre o

compressor e a ferramenta precisa ser compensada no compressor.

4. Desconecte a ferramenta pneumática do fornecimento de ar antes de

mudar de ferramentas ou acessórios, manutenção e durante a inatividade.

Deve usar óculos de segurança e protetores

5. Não use roupas largas, lenços ou gravatas. As roupas soltas podem ficar

presas nas peças móveis e resultar em ferimentos graves.

6. Não use joias ao operar qualquer ferramenta. As joias podem ficar presas

nas peças móveis e resultar em ferimentos graves.

7. Não pressione o acionador ao conectar a mangueira de fornecimento de ar.

8. Use sempre acessórios concebidos para o uso com ferramentas

pneumáticas. Não use acessórios danificados ou desgastados.

9. Nunca acione a ferramenta quando não estiver aplicada em um objeto

de trabalho. Os acessórios devem ser firmemente conectados. Acessórios

soltos podem causar ferimentos graves.

Nunca transporte uma ferramenta pela mangueira

ou um compressor. Mantenha as mangueiras afastadas de calor, óleo e

extremidades afiadas. Substitua qualquer mangueira danificada ou gasta.

auditivos durante a operação.

nem puxe a mangueira para mover a ferramenta

Pg6

Page 33

10. Proteja as linhas de ar contra danos ou punção.

11. Nunca aponte uma ferramenta pneumática em sua direção ou na

direção de qualquer outra pessoa. Podem ocorrer ferimentos graves.

12. Verifique as mangueiras de ar quanto à resistência ou desgaste antes de

cada utilização. Certifique-se de que todas as conexões estão seguras.

Libere toda a pressão do sistema antes de tentar

instalar, manter, mudar ou executar qualquer manutenção.

13. Mantenha todas as porcas, parafusos e pernos apertados e certifique-se

de que o equipamento está em boas condições de segurança.

14. Não coloque as mãos junto ou sob peças móveis.

15. Sempre fixe a peça em um torno ou com um parafuso. Não coloque

as mãos no cilindro preto nem no retentor de mola quando estiver

utilizando a ferramenta.

O retentor de mola deve ser usado para manter

o formação na posição certa. Podem ocorrer lesões

pessoais se o formão não estiver fixo.

O retentor de engate rápido ou o retentor de

mola deve ser usado para manter o martelo na

posição certa. Podem ocorrer lesões pessoais se o martelo não estiver fixo.

16. Risco de choque elétrico: esta ferramenta é condutiva. Não martele em

paredes contendo fiação elétrica ativa.

Não use este produto indevidamente. A exposição

excessiva vibração, trabalho em posições estranhas e

os movimentos de trabalho repetitivos podem causar ferimentos nas mãos e

braços. Pare de usar qualquer ferramenta se ocorrer desconforto, dormência,

sensação de formigamento ou dor e consulte um médico.

Esta ferramenta pneumática precisa de

lubrificação antes do uso inicial e antes e depois de

cada uso adicional.

Desconecte a ferramenta pneumática da fonte

de fornecimento de ar antes de lubrificar.

Cubra a porta de escape com uma toalha antes

de aplicar pressão de ar. Será descarregado óleo da

porta de escape nos primeiros segundos de operação após a lubrificação de

ferramentas pneumáticas. Não cobrir a porta de escape pode resultar em

ferimentos graves.

Pg7

Page 34

INSTRUÇÕES DE SEGURANÇA (CONTINUAÇÃO)

Glossário de segurança

Este manual contém informações que é muito importante conhecer e

entender. Estas informações são fornecidas para fins de SEGURANÇA e para

EVITAR PROBLEMAS NO EQUIPAMENTO. Para ajudar a reconhecer estas

informações, observe os seguintes símbolos.

Perigo indica uma situação iminentemente perigosa

iminente que, se não for evitada, pode resultar em

morte ou ferimentos graves.

Advertência indica uma situação potencialmente

perigosa que, se não for evitada, PODE resultar em

morte ou ferimentos graves.

Precaução indica uma situação potencialmente

perigosa que, se não for evitada, PODE resultar em

ferimentos ligeiros ou moderados.

Aviso indica uma informação importante que,

se não seguida, pode causar danos no equipamento.

IMPORTANTE ou NOTA: Informações que exigem uma atenção especial.

Símbolos de segurança

Os seguintes símbolos de segurança aparecem ao longo deste manual para o

alertar sobre perigos e precauções de segurança importantes.

MANUAL

Use máscara

e proteção

ocular

Leia o manual

primeiro

Risco de

explosão

Use proteção

ocular e

auditiva

Risco de

pressão

Risco de

choque

GUARDE ESTAS INSTRUÇÕES - NÃO DESCARTE

Pg8

Page 35

GUIA GERAL DE SOLUÇÃO DE PROBLEMAS

PROBLEMA CAUSAS POSSÍVEIS AÇÃO CORRETIVA

A ferramenta funciona

de maneira lenta ou

não funciona

Saída de umidade do

interior da ferramenta

Martelete/bedame

estão emperrados e

não avançam nem

volta.

* Ao voltar a colocar o cilindro na estrutura, use um selante para roscas nas roscas do cilindro.

1. Detritos ou resina na

ferramenta

2. A ferramenta está sem óleo 2. Lubrifique a ferramenta de acordo

3. Baixa pressão do ar 3. Ajuste o regulador do compressor

4. Vazamentos da mangueira de ar4. Aperte e vede as conexões da

5. Quedas da pressão 5. Certifique-se de que a mangueira seja

1. Presença de água no tanque 1. Esvazie o tanque. (Consulte o

2. Presença de água nas linhas

de ar/mangueiras

1. Pistão e barril do martelete/

bedame estão sujos ou

enferrujados

2. Pistão e barril do martelete/

bedame enferrujaram juntos

3. O pistão está emperrado no

barril

Pg9

1. Limpe a ferramenta com óleo para

ferramentas pneumáticas Campbell

Hausfeld, solvente de resina ou uma

mistura idêntica de óleo para motor

SAE 10 e querosene. Lubrifique a

ferramenta após a limpeza com óleo

para ferramentas pneumáticas da

Campbell Hausfeld (ou comparável).

com as instruções de lubrificação

neste manual.

para 6,2 bar. Ajuste o regulador do

compressor para 6,2.

mangueira caso sejam encontrados

vazamentos.

do tamanho correto. As mangueiras

longas ou ferramentas que usam

grandes volumes de ar podem

necessitar de uma mangueira com

diâmetro interno de 12,7 mm (1/2

pol.) ou maior, dependendo da

extensão total da mangueira .

manual do compressor pneumático).

Lubrifique a ferramenta e coloque-a

em funcionamento até que não se

identifique mais a presença de água.

Lubrifique a ferramenta novamente e

coloque-a em funcionamento durante

1-2 segundos

2. a. Instale um separador/filtro de

água. NOTA: os separadores

trabalham adequadamente

apenas quando o ar que passa

através do separador está frio.

Coloque o separador/filtro o mais

afastado possível do compressor

b. Instale um secador de ar

c. Sempre que entrar água

na ferramenta, ela deve ser

lubrificada imediatamente.

1. a. Lubrifique bastante a

ferramenta para liberar o pistão

b. Limpe o pistão e o barril com

óleo de ferramenta pneumática

e remova quaisquer rebarbas nas

superfícies das peças*

c. Substitua pistão e cilindros

gastos*

d. Sempre que água entrar na

ferramenta, ela deve receber óleo

imediatamente

2. Remova o pistão e retire a ferrugem.

Substitua o pistão e cilindros se

necessário *

3. Tente liberar o pistão emperrado

usando punção e o martelete. Pode

ser necessário desmontar o barril do

alojamento. Limpe as peças e monte

novamente *

Page 36

Lembrete: Guarde sua prova de compra datada para fins de garantia! Anexe-a a este manual ou arquivo

para guardar.

GARANTIA LIMITADA

1. DURAÇÃO: Desde a data de compra pelo comprador original como se segue: Dois (2) anos.

2. QUEM OFERECE ESTA GARANTIA (RESPONSÁVEL PELA GARANTIA): Campbell Hausfeld, a

Marmon/Berkshire Hathaway Company, 100 Production Drive, Harrison, Ohio, 45030. Visite www.

campbellhausfeld.com.

3. QUEM RECEBE ESTA GARANTIA (RESPONSÁVEL PELA COMPRA): O comprador original (além de para

fins de revenda) do produto da Campbell Hausfeld.

4. QUAL É O PRODUTO ABRANGIDO POR ESTA GARANTIA: Esta ferramenta pneumática da Campbell

Hausfeld.

5. O QUE É ABRANGIDO POR ESTA GARANTIA: Defeitos substanciais no material e fabricação, que

ocorrem ao abrigo do período de garantia, com as seguintes exceções.

6. O QUE NÃO É ABRANGIDO POR ESTA GARANTIA:

A. Garantias implícitas, incluindo de comerciabilidade e ADEQUAÇÃO PARA UMA FINALIDADE

PARTICULAR ESTÃO LIMITADAS A PARTIR DA DATA DE COMPRA ORIGINAL COMO INDICADO

NA DURAÇÃO. Se este produto for usado para fins comerciais, industriais ou de aluguel, a

garantia será aplicada durante noventa (90) dias após a data de compra. Alguns estados não

permitem limitações sobre a duração de uma garantia implícita, logo as limitações acima

podem não se aplicar a você.

B. QUALQUER PERDA, DANO OU DESPESA INCIDENTAL, INDIRETO OU CONSEQUENTE QUE

POSSA RESULTAR DE QUALQUER DEFEITO, FALHA OU MAU FUNCIONAMENTO DO PRODUTO

CAMPBELL HAUSFELD. Alguns estados não permitem a exclusão ou limitações de danos

incidentais ou consequentes, logo a limitação ou exclusão acima pode não se aplicar a você.

C. Qualquer falha que resulte de um acidente, abuso do comprador, negligência ou falha em

operar os produtos de acordo com as instruções fornecidas no(s) manual(is) do proprietário

fornecido(s) com o produto. Os acidentes, abusos do comprador, negligência ou a falha em

operar os produtos de acordo com as instruções também devem incluir a remoção ou alteração

de quaisquer dispositivos de segurança. Se os dispositivos de segurança forem removidos ou

alterados, esta garantia é anulada.

D. Ajustes normais que são explicados no(a) manual(ais) do proprietário fornecido(s) com o

produto.

7. RESPONSABILIDADES DO RESPONSÁVEL PELA GARANTIA AO ABRIGO DESTA GARANTIA: Reparar ou

substituir, a critério do Responsável pela Garantia, os produtos ou componentes com defeito, mau

funcionamento e/ou incumprimento da duração do período de garantia específico.

8. RESPONSIBILIDADES DO COMPRADOR AO ABRIGO DESTA GARANTIA:

A. Fornecer comprovativo de compra com data e registros de manutenção.

B. Visite www.campbellhausfeld.com para obter suas opções do serviço de garantia. Os custos de

transporte devem ser suportados pelo comprador.

C. Tenha um cuidado razoável na operação e manutenção dos produtos conforme descritos no(s)

manual(is) do proprietário.

9. QUANDO O RESPONSÁVEL PELA GARANTIA REALIZARÁ A REPARAÇÃO OU SUBSTITUIÇÃO AO

ABRIGO DESTA GARANTIA: A reparação e a substituição serão agendadas e realizadas de acordo com

o fluxo de trabalho normal na localização de serviço e dependendo da disponibilidade das peças de

substituição.

Esta Garantia Limitada aplica-se apenas aos Estados Unidos da América, Canadá e México e confere

direitos legais específicos. Você também pode ter outros direitos que varia consoante estado ou país.

Pg10

Page 37

Martillo neumático

Manual de Instrucciones

© 2017 Campbell Hausfeld

A Marmon/Berkshire Hathaway Company

Modelo: XT101000

SP

IN745300 6/17

Page 38

Por favor, lea y guarde estas instrucciones. Lealas cuidadosamente antes

de tratar de montar, instalar, operar o dar mantenimiento al producto

aqui descrito.

Protejase usted mismo y a los demas observando toda la informacion de

seguridad. ¡El no cumplir con las instrucciones puede ocasionar daños,

tanto personales como a la propiedad! Guarde estas instrucciones para

referencia en el futuro.

RECORDATORIO: ¡guarde su comprobante de compra con fecha para

fines de la garantía! Adjúntela a este manual o archívela en lugar seguro.

Para ordenar repuestos, información de

productos y servicios visítenos en

Modelo #: ___________________________________

No. de Serie #: ______________________________

Fecha de Compra: ___________________________

www.campbellhausfeld.com

Campbell Hausfeld

100 Production Drive

Harrison, Ohio 45030

¡REGISTRE SU PRODUCTO EN LÍNEA AHORA MISMO!

GUARDE ESTAS INSTRUCCIONES • NO LAS DESECHE

www.campbellhausfeld.com/reg

LEA Y SIGA TODAS LAS INSTRUCCIONES

Page 39

ANTES DE COMENZAR

Descripción

Un cilindro mediano de 7 mm (de 2-3/4 pulgadas) proporciona energía cuando el

rendimiento es crucial para cortar a través de pernos y metal oxidados y para sus

otros trabajos de perforación, desprendimiento o raspado. Los puntos de contacto

suaves y con agarraderas sobremoldeadas de este martillo neumático le ayudan

absorber las vibraciones de la herramienta y reducir la fatiga, manteniéndolo

activo para terminar las tareas de su lista interminable de proyectos.

Campbell Hausfeld

historia de la compañía de crear productos de calidad inició en 1836, cuando

fabricaba carros tirados por caballos y equipos agrícolas. Actualmente,

Campbell Hausfeld ofrece una línea completa de compresores de aire,

herramientas neumáticas y accesorios, infladores, clavadoras y engrapadoras,

pistolas rociadoras, hidrolavadoras y más. Termine sus proyectos con más

rapidez y facilidad con Campbell Hausfeld, los expertos en energía neumática.

DESEMPAQUE

Después de desempacar la unidad, inspecciónela cuidadosamente para

detectar cualquier daño que pueda haber ocurrido durante el envío.

Verifique que no haya piezas sueltas, faltantes ni dañadas. Asegúrese de que

todos los accesorios proporcionados vengan con la unidad. En caso de que

tenga preguntas, o de que haya piezas dañadas o faltantes, por favor visite

www.campbellhausfeld.com para asistencia al cliente.

No debe utilizar la unidad si se ha dañado durante

una explosión y ocasionarle heridas o daños a su propiedad.

®

le facilita terminar sus proyectos como un profesional. La

el envío, manejo o uso. Los daños podrían ocasionar

Otras partes (no incluidas)

Necesitará los siguientes artículos o accesorios para instalar correctamente y

utilizar de manera óptima su martillo neumático:

• Manguera flexible o líder de 9.5 mm (3/8 pulgadas) (ID) para absorber la

vibración

• Tapón NPT de 6,4 mm (1/4 pulg.) (M)

• Manguera de aire de 9,5 mm (3/8 pulg.) (D.I.)

• Acoplador NPT de 6,4 mm (1/4 pulg.) (F)

o Elimine la confusión con los acopladores usando uno de estilo

universal.

o Los acopladores de conexión rápida conectan las mangueras y las

herramientas con facilidad y rapidez.

o Si no utiliza un tapón flexible, considere un acoplador con pivote

para evitar las torceduras y reducir la tensión en su manguera de

aire.

• Compresor de aire de 98.41 litros (26 galones) o más

• Brocas para cincel de forma cónica 0.401 Parker

• Cinta PTFE para todas las conexiones

• Llave ajustable para apretar las conexiones

Consulte www.campbellhausfeld.com para ver más información sobre

accesorios para complementar sus herramientas y sistema neumático.

Sp1

Page 40

MEJORES PRÁCTICAS

u Para un mejor desempeño, mantenga una presión de 6,2 bar en la herramienta.

u Mientras más larga sea su manguera de aire, mayor será la caída de presión entre

el compresor y la herramienta. Si está utilizando una manguera de más de 15,24 m

(50 pies), considere la opción de cambiar a una manguera de aire de 12,7 mm (1/2

pulg.) D.I. para garantizar una presión apropiada en la herramienta.

u De no lubricar y dar mantenimiento de manera apropiada a sus herramientas

neumáticas, reducirá dramáticamente su vida útil. Utilice aceite cada vez que

use su herramienta neumática para lubricar, limpiar e impedir la oxidación en un

solo paso. Campbell Hausfeld vende aceite para herramientas neumáticas con el

número de parte ST1270.

u Debido a la vibración excesiva que produce esta herramienta, se recomienda

una manguera flexible (también conocida como manguera líder). Si utiliza una

manguera flexible, NO instale un juego de acoplamiento entre la herramienta y la

manguera flexible.

ESPECIFICACIONES

XT101000

Presión máxima en bar 6,2 bar

CFM (l/min) con carga al 100% 87,8 L/min @ 6,2 bar

SCFM (l/min) con carga al 100% 676,8 L/min @ 6,2 bar

Compresor de aire recomendado 98,41 L

Golpes por minuto (Blows Per Minute, BPM) 2.600

Longitud de la carrera 6,99 cm

Diámetro del vástago de cincel Eje de forma cónica

Entrada de aire NPT (F) de 1/4 pulg.

Tamaño mínimo de manguera 9,5 mm (3/8 pulg.)

Material de la carcasa Compuesto

Altura de la herramienta 1,32 kg

Longitud de la herramienta 17,46 cm (6-7/8 pulg.)

Peso de la herramienta 16,19 cm (6-3/8 pulg.)

Ancho de la herramienta 5,40 cm (2-1/8 pulg.)

(2-3/4 pulgadas)

de 0,401 tipo Parker

Sp2

Page 41

CONOZCA SU UNIDAD

Cilindro roscado

Retenedor del

resorte

Gatillo

Puerto de escape

Entrada de

aire

INSTRUCCIONES DE CONFIGURACIÓN

Acoplador

rápido

Tapón

Manguera de aire

* Los artículos que se muestran en las instrucciones de instalación no se incluyen con esta herramienta.

Manguera flexible

Retenedor del resorte

Cincel

MEJORES PRÁCTICAS

u El compresor de aire que utilice con su martillo neumático debe ser capaz de

mantener un mínimo de 6,2 bar cuando se utilice la herramienta. Un suministro

inapropiado de aire puede causar una pérdida de potencia y un desempeño

inconsistente de la herramienta.

u Un regulador de presión, que se utiliza en la herramienta, es útil para controlar la

presión de operación de la herramienta y para mantener 6,2 bar.

u Utilice un aplicador de aceite para mantener la circulación de aceite en la