Campbell Hausfeld XP5815 Owner’s Manual

Please read and save these instructions. Read carefully before attempting to assemble, install, operate or maintain the product described.

Protect yourself and others by observing all safety information. Failure to ¢omp_ with instructions could result in personal injury and/or prop.

erty damage/Retain instructions for future reference.

Air

Compressors

Description

Air compressor units are intended to

provide compressed air to power pneu-

matic tools, operate spray guns and sup-

ply air for pneumatic valves and actua-

tors. The pumps supplied with these

units have oil lubricated bearings. A

small amount of oil carryover is present

in the compressed air stream.

Applications requiring air free of oil

vapor should have the appropriate filter

insta[led. The air compressor units are to

be mounted per the instructions provid-

ed on a solid floor. Any other use of

these units will void the warranty and

the manufacturer will not be responsi-

ble for problems or damages resulting

from such misuse. Refer to the enclosed

"Replacement Parts Manual" to identify

compressor as single stage or two-stage.

Safety Guidelines

This manual contains information that is

very important to know and understand.

This information isprovided for SAFETY

and to PREVENT EQUIPMENT PROB-

LEMS. To help recognize this informa-

tion, observe the following symbols.

Danger indicates

ardous situation which, ff not avoided,

will result in death or serious injury.

I_WARNINGI Warningindicates

ardous situation which, if not avoided,

could result in death or serious injury.

ardous situation which, ff not avoided,

MAY result in minor or moderate

injury.

I NOTICE I importantinforma-

an imminently haz-

a potentially haz.

Caution indicates a

potentially haz-

Notice indicates

tion, that if not followed, may cause

damage to equipment.

Unpacking

After unpacking the unit, inspect care-

fully for any damage that may have

occurred during transit. Make sure to

tighten fittings, bolts, etc., before

putting unit into service.

I_WARNINGI Donotoperate

during shipping, handling or use.

Damage may result in bursting and

cause injury or property damage.

General Safety

Sincethe air compressor and other

components (material pump, spray

guns, filters, lubricators, hoses,etc.)

used make up a high pressurepump-

ing system,the following safety pre-

cautions must be observed at all times:

included with this

product carefully.

l e a an aI 1

Be thoroughly

familiar with the controls and the

proper use of the equipment.

2. Follow all local electrical and safety

codes as well as the United States

National Electrical Codes (NEC) and

Occupational Safety and Health Act

(OSHA).

3. Only persons well acquainted with

these rules of safe operation should

be allowed to use the compressor.

4. Keep visitors away and NEVER

allow children in the work area.

5. Wear safety glasses and use

hearing protection when operating

the unit.

unit if damaged

Breathable Air Warning

This compressor/pump is NOT

equipped and should NOT be used

"as is" to supply breathing quality

air. For any application of air for

human consumption, you must fit

the air compressor/pump with suit-

able in-line safety and alarm equip-

ment. This additional equipment is

necessary to properly filter and puri-

fy the air to meet minimal specifica-

tions for Grade D breathing as

described in Compressed Gas

Association Commodity

Specification G 7.1 - 1966, OSHA 29

CFR 1910. 134, and/or Canadian

Standards Associations (CSA).

DISCLAIMER OF WARRANTIES

In the event the compressor is used

for the purpose of breathing air

application and proper in-line safety

and alarm equipment is not simulta-

neously used, existing warranties

are void, and the company disclaims

any liability whatsoever for any

loss, personal injury or damage.

6. Do not stand on or use the unit as

a handhold.

7. Before each use, inspect compressed

air system and electrical components

for signs of damage, deterioration,

weakness or leakage. Repair or

replace defective items before using.

8. Check all fasteners at frequent

intervals for proper tightness.

J REMINDER: Keep your dated proof of purchase for warranty purposes! Attach it to this manual or file it for I

© 2003 Call1-800-543-6400 for parts IN254702AV 1/03

Call1-800-544-0350 fortechnicalassistance

safekeeping.

Air Compressors

General Safety (Cont.)

I_WARNINGI

Motors, electrical equip-

ment and controls can

cause electrical arcs that

will ignite a flammable gas or vapor.

Never operate or repair in or near a

flammable gas or vapor. Never store

flammable liquids or gases in the vicini-

ty of the compressor.

Never operate compressor

withoutabeltg.a . This U /

unit canstart automatically _-_

without warning. Personal

injury or property damage could occur

from contact with movingparts.

9. Do not wear Iooseclothing or jewel-

ry that will get caught in the mov-

ing parts of the unit.

Compressor parts may be

hot even if the unit is

stopped.

10. Keep fingers away from a running

compressor; fast moving and hot

parts win cause injury and/or burns.

11. If the equipment should start to

vibrate abnormally, STOP the

engine/motor and check immediate-

ly for the cause. Vibration is gener-

ally an indication of trouble.

12.To reduce fire hazard, keep

engine/motor exterior free of oil,

solvent, or excessive grease.

WARNINGI AnASMecode

setting no higher than the Maximum

Allowable Working Pressure(MAWP)of

the tank MUSThe installed in the air lines

or inthe tank for this compressor.The

ASMEsafety valve must have sufficient

flow and pressureratings to protect the

pressurized components from bursting.

The flow rating can he found in the parts

manual. The safety valve in the intarcool-

er doesnot provide system pro_-tion.

psi for two-stage compressorsand 135

-150 psi for single stage compressors.Do

not operate with pressureswitch or pilot

valvessethigher than 175 psi (two-stage)

or 135- 150 psi (singlestage).

13. Never attempt to adjust ASME safe-

ty valve. Keep safety valve free from

paint and other accumulations.

ty relief valve with a

Maximum operat-

ing pressure is 175

Never attempt to repair or

modify a tank! Welding, |_

drilling or any other mndi- L _ "mE_

fication will weaken the

tank resulting in damage from rupture

or explosion. Always replace worn,

cracked or damaged tanks.

Drain liquid from

I NOTICE I tankdaily.

14. Tanks rust from moisture build-up,

which weakens the tank. Make sure

to drain tank regularly and inspect

periodically for unsafe conditions

suchas rust formation and corrosion.

15. Fast moving air will stir up dust and

debris which may be harmful. Release

air slowlywhen draining moisture or

depressurizing the compressor system.

SPRAYING PRECAUTIONS

IAWARNINGI

Do not spray flammable

materials in vldnity of open

flame or near i_'rtioe

sourcesincludingthe compressor unilL

16. Do not smoke when spraying paint,

insecticides, or other flammable

substances.

17. Use a face mask/respi- FA,,.ah- _

rator when spraying

and spray in a well ven-

tilated area to prevent

health and fire hazards.

18. Do not direct paint or other sprayed

material at the compressor. Locate

compressor asfar away from the spray-

ing area as possibleto minimize over-

spray accumulation on the compressor.

19. When spraying or cleaning with sol-

vents or toxic chemicals, follow the

instructions provided by the chemi-

cal manufacturer.

Installation

IAWARNING]

Disconnect, tag and lock

out power source then

release all pressure from

the system before attempting to

install, service, relocate or perform any

maintenance.

A_--CAUTION] Donotliftormove

unit without appro-

priately rated equipment. Be sure the

unit issecurely attached to lifting

device used. DOnot lift unit by holding

onto tubes or coolers. Do not use unit

to lift other attached equipment.

Never use the

wood shipping

skids for mounting the compressor.

Install and operate unit at least 24"

from any obstructions in a dean, well

ventilated area. The surrounding air

temperature should not exceed 100=F.

This will ensure an unobstructed flow

of air to cool compressor and allow

adequate spacefor maintenance.

Do not locate the

]ACAUTIONI compressoralrlnlet

near steam, paint spray, sandblast areas

or any other source of contamination.

NOTE: If compressor operates in a hot,

moist environment, supply compressor

pump with clean, dry outside air.

Supply air should be piped in from

external sources.

TANK MOUNTING

The tank should be bolted into a flat,

even, concrete floor or on a separate

concrete foundation. Vibration isolators

should be used between thetank leg

and the floor. Model MP345800AJ isola-

tor pads are recommended for horizon-

tal units. Model MP345700AJ isolator

pads are recommended for vertical units.

When using isolator pads, do not draw

bolts tight. Allow the pads to absorb

vibrations. When isolators are used, a

flexible hose or coupling should be

installed between the tank and service

piping.

FAWARNING]

Failure to properly install

the tank can lead to cracks

at the welded jointa and

possible bursting.

PIPING

IAWARNINGI Never use plastic

pressed air. Serious injury or death

could result.

Any tube, pipe or hoseconnectedto the

unit must be able to withstand the tem-

perature generated and retain the pres-

sure. All pressurized components of the

air systemmust have a pressure rating

higher than or equal to the 200 psifor

(PVC) pipe for com-

Cast Iron Series

Installation (Cont.)

two*stage compressorsor 150 psi for sin-

gle stage compressors ASME safety valve

setting. Incorrect selection and installa-

tion of any tube, pipe or hose could result

in bursting and injury. Connect piping sys-

tem to tank using the same size fitting as

the discharge port.

INSTALLING A SHUT-OFF VALVE

A shut-off valve should be installed on

the discharge port of the tank to control

the air flow out of the tank. The valve

should be located between the tank and

the piping system.

(AWARNING] Neverinstalla

between the compressor pump and the

tank. Personal injury and/or equipment

damage may occur.Never use reducers

in discharge piping.

When creating a permanent]y installed

system to distribute compressed air, find

the total length of the system and select

pipe size from the chart. Bury under-

ground lines below the frost line and

avoid pockets where condensation can

gather and freeze.

Apply air pressure to the piping installa-

shut-Off valve

tion and make sure all joints are free

from leaks BEFOREunderground lines

are covered. Before putting the compres-

sorinto service,find and repair all leaks

in the piping, fittings and connections.

MINIMUM PIPE SIZE

FOR COMPRESSED AIR LINE

10 112" I i2" 314" 314"

20 314 3/4 3/4 1

40 314 1 1 1

60 314 1 1 1

100 1 1 1 111,

WIRING

[_WARNING] AIIwiringand

electrical connec-

tions must be performed by a qualified

electrician. Installations must be in

accordance with local and national

codes.

I ,CAUTIONI 3cl_uitingandfire

Overheating, short

damage will result from inadequate

wiring.

Wiring must be installed in accordance

with National Electrical Code and local

codesand standards that have been set

up covering electrical apparatus and

wiring. These should be consulted and

local ordinances observed. Be certain that

adequate wire sizesare used,and that:

1.Service is of adequate ampere rating.

2. The supply line has the same electri-

cal characteristics (voltage, cycles and

phase) as the motor.

3. The linewire isthe propersize and

that no other equipment isoperated

from the same line. The chart gives

minimum recommended Wire sizesfor

compressor installations.

MINIMUM WIRE SIZE

USE 75°C COPPER WIRE

SPL upto22.0 10AWG

5,0

7.5

10,0

15.0

25.0

8AWG 12AWG 14AWG

8AWG 10AWG 12AWG

WA 8AWG 12AWG

WA 6AWG 10AWG

WA 3AWG 8AWG

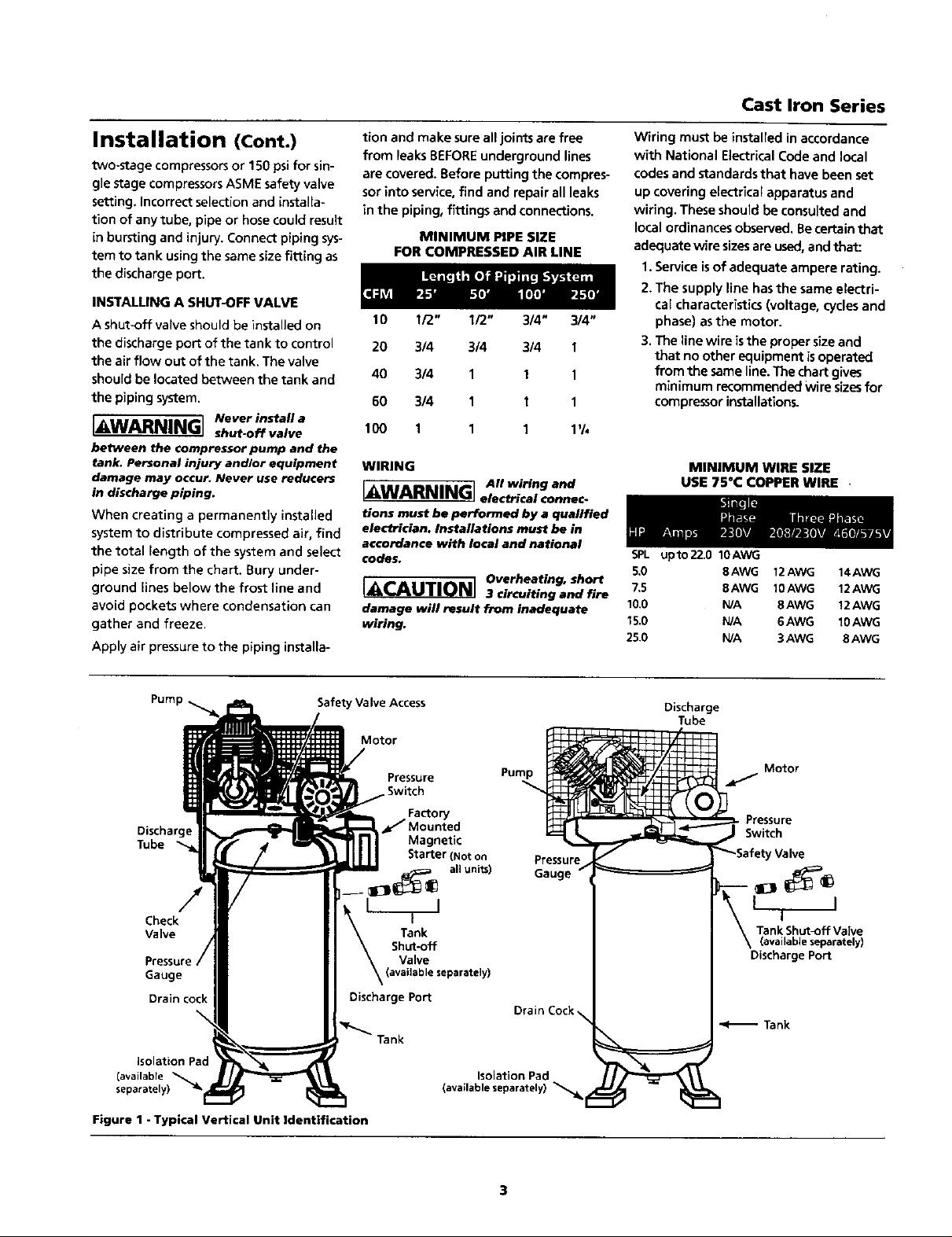

Pump

Discharge

Tube

Safety Valve Access

/

Check

Valve

Gauge

Drain cock

isolation Pad

(available

Figure 1 - Typical Vertical Unit Identification

Motor

Pressure

Switch

Factory

J Mounted

Magnetic

Starter (Not on

__ _]1_ allunits)

Tank

Shut-off

Valve

(available separately)

Discharge Port

Tank

(availableseparately)"_

Pump

Pressure/

Gauge

Drain Cock,

isolation Pad

Discharge

Tube

Motor

Pressure

Switch

Valve

DischargePort

Tank

Loading...

Loading...