Page 1

REMINDER: Keep your dated proof of purchase for warranty purposes!

Attach it to this manual or file it for safekeeping.

Description

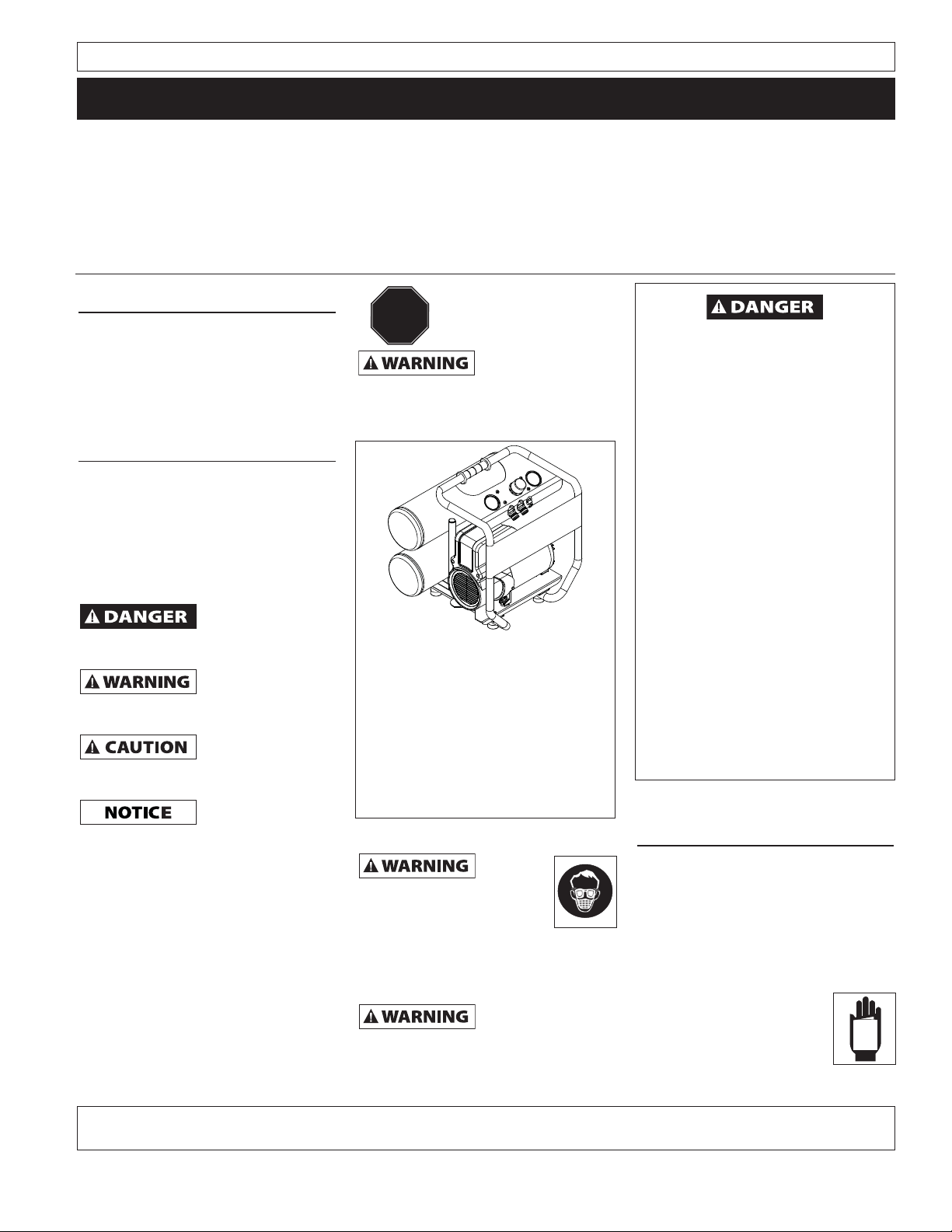

Oilless compressors are designed for a

variety of home tasks. These compressors

can power smaller pneumatic tools, but

work ideally for brad nailers, finishing

nailers and staplers. These units

operate without oil.

Safety Guidelines

This manual contains information that

is very important to know and

understand. This information is

provided for SAFETY and to PREVENT

EQUIPMENT PROBLEMS. To help

recognize this information, observe the

following symbols.

Danger indicates an

imminently

hazardous situation which, if not avoided,

will result in death or serious injury.

Warning indicates

a potentially

hazardous situation which, if not avoided,

COULD result in death or serious injury.

Caution indicates a

potentially

hazardous situation which, if not avoided,

MAY result in minor or moderate injury.

Notice indicates

important

information, that if not followed, may

cause damage to equipment.

Unpacking

After unpacking the unit, inspect

carefully for any damage that may have

occurred during transit. Make sure to

tighten fittings, bolts, etc., before putting

unit into service. In case of questions,

damaged or missing parts, please call the

nearest Maxus Authorized Service Center.

Have the serial number, model number

and parts list (with missing parts circled

before calling).

Please read and save these instructions. Read carefully before attempting to assemble, install, operate or maintain the product described.

Protect yourself and others by observing all safety information. Failure to comply with instructions could result in personal injury and/or

property damage! Retain instructions for future reference.

Operating Instructions WX8019

DO NOT RETURN THE

PRODUCT TO THE

RETAILER!

Do not operate

unit if damaged

during shipping, handling or use.

Damage may result in bursting and

cause injury or property damage.

IN626100AV 4/09

Breathable Air Warning

This compressor/pump is NOT

equipped and should NOT be used

“as is” to supply breathing

quality air. For any application of

air for human consumption, you

must fit the air compressor/pump

with suitable in-line safety and

alarm equipment. This additional

equipment is necessary to

properly filter and purify the air

to meet minimal specifications

for Grade D breathing as

described in Compressed Gas

Association Commodity

Specification G 7.1 - 1966, OSHA

29 CFR 1910. 134, and/or Canadian

Standards Associations (CSA).

DISCLAIMER OF WARRANTIES

IN THE EVENT THE COMPRESSOR IS

USED FOR THE PURPOSE OF

BREATHING AIR APPLICATION AND

PROPER IN-LINE SAFETY AND ALARM

EQUIPMENT IS NOT SIMULTANEOUSLY

USED, EXISTING WARRANTIES ARE

VOID, AND THE MANUFACTURER

DISCLAIMS ANY LIABILITY

WHATSOEVER FOR ANY LOSS,

PERSONAL INJURY OR DAMAGE.

Oilless Compressors

See Warranty on page 6 for important information about commercial use of this product.

© 2009

Record the Model and Serial numbers

(located on the compressor) and the

date of purchase in the spaces below.

Model No. ________________________

Serial No. ________________________

Date of purchase __________________

Retain these numbers for future

reference.

CALIFORNIA PROPOSITION 65

You can

create dust when you cut,

sand, drill or grind materials

such as wood, paint, metal,

concrete, cement, or other

masonry. This dust often contains

chemicals known to cause cancer, birth

defects, or other reproductive harm.

Wear protective gear.

This product or its

power cord

contains lead, a chemical known to the

State of California to cause cancer and

birth defects or other reproductive

harm. Wash hands after handling.

General Safety

Information

OPERATIONAL SAFETY

Since the air compressor and other

components (material pump, spray

guns, filters, lubricators, hoses, etc.)

used, make up a high pressure pumping

system, the following safety precautions

must be observed at all times:

1. Read all manuals included

with this product carefully.

Be thoroughly familiar

with the controls and the

proper use of the equipment.

STOP!

MANUAL

Page 2

Installation

LOCATION

The tank must sit level or slope slightly

towards the drain valve to allow the

tank to drain properly. It is extremely

important to install the compressor in a

clean, well ventilated area where the

surrounding air temperature will not

be more than 40°C (104°F).

A minimum clearance of 0.1 meters

(4 inches) between the compressor and

a wall is required because objects could

obstruct air flow.

Do not locate the

compressor air inlet

near steam, paint spray, sandblast areas

or any other source of contamination.

This debris will damage the motor.

ELECTRICAL INSTALLATION

All wiring and

electrical

connections should be performed by a

qualified electrician. Installation must

be in accordance with local codes and

national electrical codes.

GROUNDING INSTRUCTIONS

1. This product is for use on a nominal

240 volt circuit and has a grounding

plug that looks like the plug

illustrated in Figure 1. Make sure the

product is connected to an outlet

having the same configuration as the

plug. This product must be grounded.

In the event of an electrical short

circuit, grounding reduces risk of

electrical shock by providing an escape

wire for electric current. This product

is equipped with a cord having a

grounding wire with an appropriate

grounding plug. Cord must be

plugged into an outlet that is properly

installed and grounded in accordance

with all local codes and ordinances.

Improper

use of grounding plug can

result in a possible risk of

electrical shock!

2. Follow all local electrical and safety

codes, as well as in the U.S.A.,

National Electrical Codes (NEC) and

Occupational Safety and Health Act

(OSHA).

3. Only persons well acquainted with

these rules of safe operation should

be allowed to use the compressor.

4. Keep visitors away and NEVER allow

children in the work area.

5. Wear safety glasses and

use hearing protection

when operating the pump

or unit.

6. Do not stand on or use the pump or

unit as a handhold.

7. Before each use, inspect compressed

air system and electrical components

for signs of damage, deterioration,

weakness or leakage. Repair or

replace defective items before using.

8. Check all fasteners at frequent

intervals for proper tightness.

Motors,

electrical equipment and

controls can cause electrical

arcs that will ignite a

flammable gas or vapor.

Never operate or repair in or near a

flammable gas or vapor. Never store

flammable liquids or gases in the

vicinity of the compressor.

Compressor parts may be

hot even if the unit is

stopped.

9. Keep fingers away from a running

compressor; fast moving and hot

parts will cause injury and/or burns.

10. If the equipment should start to

abnormally vibrate, STOP the

engine/motor and check

immediately for the cause.

Vibration is generally a warning of

trouble.

11. To reduce fire hazard, keep

engine/motor exterior free of oil,

solvent, or excessive grease.

2

Oilless Compressors

Never remove or

attempt to adjust

safety valve. Keep safety valve free

from paint and other accumulations.

Never

attempt

to repair or modify a tank!

Welding, drilling or any other

modification will weaken the

tank resulting in damage

from rupture or explosion. Always

replace worn or damaged tanks.

Drain liquid from

tank daily.

12. Tanks rust from moisture build-up,

which weakens the tank. Make sure

to drain tank daily and inspect

periodically for unsafe conditions

such as rust formation and

corrosion.

13. Fast moving air will stir up dust and

debris which may be harmful.

Release air slowly when draining

moisture or depressurizing the

compressor system.

SPRAYING PRECAUTIONS

Do not

spray flammable materials in

vicinity of open flame or near

ignition sources including the

compressor unit.

14. Do not smoke when spraying paint,

insecticides, or other flammable

substances.

15. Use a face mask /

respirator when spraying

and spray in a well

ventilated area to prevent

health and fire hazards.

16. Do not direct paint or other sprayed

material at the compressor. Locate

compressor as far away from the

spraying area as possible to

minimize overspray accumulation

on the compressor.

17. When spraying or cleaning with

solvents or toxic chemicals, follow

the instructions provided by the

chemical manufacturer.

Grounded

Outlet

Grounded Pin

Figure 1

General Safety

Information (cont.)

Page 3

WX8019

3

Glossary of Terms

Pressure Switch - Auto/Off Switch - In

the AUTO position, the compressor

shuts off automatically when tank

pressure reaches the maximum preset

pressure. In the OFF position, the

compressor will not operate. This

switch should be in the OFF position

when connecting or disconnecting the

power cord from the electrical outlet or

when changing air tools.

Regulator - The regulator controls the

amount of air pressure released at the

hose outlet.

ASME Safety Valve - This valve

automatically releases air if the tank

pressure exceeds the preset maximum.

Discharge Tube - This tube carries

compressed air from the pump to the

check valve. This tube becomes very hot

during use. To avoid the risk of severe

burns, never touch the discharge tube.

Check Valve - One-way valve that

allows air to enter the tank, but

prevents air in the tank from flowing

back into the compressor pump.

Tank Drain - This valve is located on

the bottom of the tank. Use this valve

to drain moisture from the tank daily

to reduce the risk of corrosion.

Do not use a

grounding adapter

with this product!

2. If repair or replacement of cord or

plug is necessary, do not connect

grounding wire to either flat blade

terminal. The wire with insulation

having an external surface that is

green (with or without yellow

stripes) is the grounding wire.

Never connect

green (or green

and yellow) wire to a live terminal.

3. Check with a qualified electrician or

serviceman if grounding instructions

are not completely understood, or if

in doubt as to whether product is

properly grounded. Do not modify

plug provided; if it will not fit outlet,

have proper outlet installed by a

qualified electrician.

WIRING

1. Local electrical wiring codes differ

from area to area. Source wiring,

plug and protector must be rated for

at least the amperage and voltage

indicated on motor nameplate, and

meet all electrical codes for this

minimum.

2. Use a slow blow fuse or a circuit

breaker.

Figure 2

MOISTURE IN COMPRESSED AIR

Moisture in compressed air will form

into droplets as it comes from an air

compressor pump. When humidity

is high or when a compressor is in

continuous use for an extended

period of time, this moisture will

collect in the tank. When using a

paint sprayer, this water will be

carried from the tank through the

hose, and out of the gun as droplets

mixed with the spray material.

IMPORTANT: This condensation

will cause water spots in a paint

job, especially when spraying other

than water based paints. A filter in

the air line (MP3105), located as

near to the gun as possible, will

help eliminate this moisture.

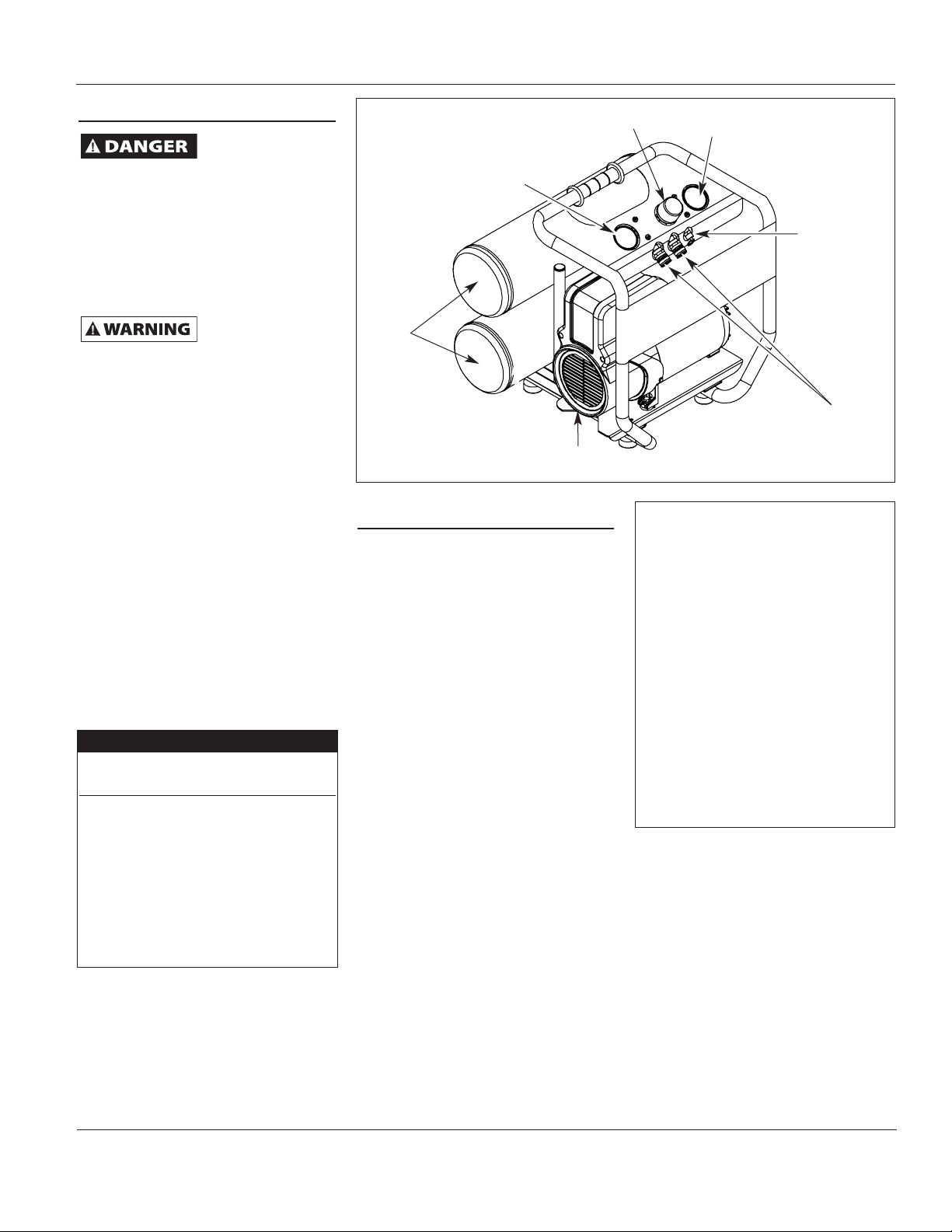

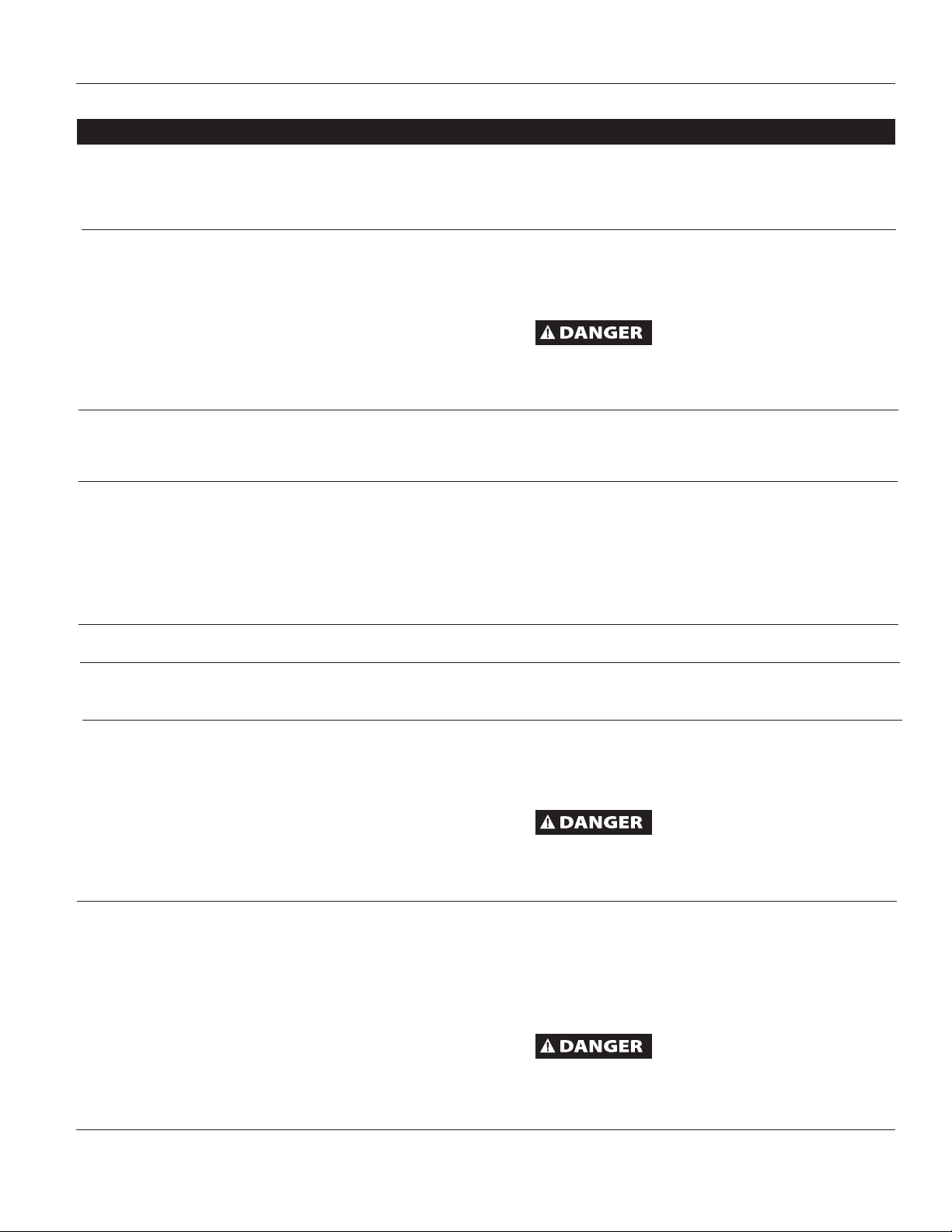

Regulator

Pump Shroud

Quick connect

coupler

Outlet Pressure

Gauge

Tank Pressure

Gauge

Tank

Safety

Valve

Reduce tank pressure below 10 psi by

pulling the safety valve, then drain

moisture from tank. Drain daily to

avoid tank corrosion.

LUBRICATION

This is an oilless product and does not

require lubrication to operate.

Installation (cont.)

25 ft. 50 ft. 100 ft.

14 12 10

Use of an extension cord may cause

excess heat to motor. This could lead

to tripped breaker (at electrical

panel) or tripped thermal overload

(on compressor motor). If this occurs,

eliminate extension cord and plug

compressor directly into electrical

outlet. Avoid using extension cords;

use longer air hose(s) instead.

Minimum Gauge of Extension Cord

Page 4

Maintenance

Disconnect power source

then release all pressure

from the system before

attempting to install, service,

relocate or perform any maintenance.

The compressor should be checked

often for any visible problems and the

following maintenance procedures

should be performed each time the

compressor is used.

1. Pull ring on safety valve and allow it

to snap back to normal position.

Safety valve must

be replaced if it

cannot be actuated or it leaks air after

ring is released.

2. With compressor shut off and

pressure released: Drain moisture

from tank by opening drain valve

underneath tank (See Figure 4).

3. Turn power OFF and clean dust and

dirt from motor, tank, and air lines.

IMPORTANT: Unit should be located

as far from spraying area as hose will

allow to prevent over-spray from

clogging intake port.

Operation

ASME SAFETY VALVE

Do not remove or

attempt to adjust

the safety valve!

This valve should be

checked under

pressure occasionally

by pulling the ring by

hand. If air leaks after

ring has been

released, or valve is stuck and cannot

be actuated by ring, it MUST be

replaced.

REGULATOR KNOB

1. This knob controls air pressure to an

air operated tool, or paint spray gun.

2. Turning knob clockwise increases air

pressure at outlet.

3. Turning counterclockwise will lower

air pressure at outlet.

4. Fully counterclockwise will shut off

flow of air completely.

OUTLET PRESSURE GAUGE

1. This gauge shows at-a-glance, air

pressure at outlet. Air pressure is

measured in bar [1 bar is equal to

14.5 pounds per square inch (psi)].

2. Be sure this gauge reads ZERO

before changing air tools or

disconnecting hose from outlet.

TANK PRESSURE GAUGE

Gauge shows pressure in tank

indicating compressor is building

pressure properly.

4

Figure 4

THERMAL OVERLOAD PROTECTOR

This compressor is

equipped with an

automatic reset thermal overload

protector which will shut off motor if it

becomes overheated.

If thermal overload protector shuts

motor OFF frequently look for the

following causes.

1. Low voltage.

2. Wrong gauge wire or length of

extension cord.

3. Clogged air filter.

4. Lack of proper ventilation.

The motor must be

allowed to cool

down before start-up is possible. The

motor will automatically restart without

warning if left plugged into electrical

outlet, if the motor is turned on.

STORAGE

1. When not in use, store hose and

compressor in a cool, dry place.

2. Drain tank of moisture

3. Disconnect hose and hang open ends

down to allow any moisture to drain.

Drain

Valve

Oilless Compressors

Figure 3

Page 5

WX8019

5

Troubleshooting Chart

Symptom Possible Cause(s) Corrective Action

1. No electrical power

2. Breaker open

3. Pressure switch bad

4. Motor over worked

5. Tank pressure above cut-in

1. Incorrect size fuse, circuit overloaded

2. Extension cord usage - wrong gauge wire

and/or too long.

3. Worn check valve

4. Defective unloader valve (on pressure

switch)

5. Defective motor capacitor(s)

6. Defective motor

1. Loose connections (fittings, tubing, etc.)

2. Open tank drain valve

1. Excessive air usage

2. Clogged intake filter

3. Open tank drain valve

4. Air leaks in piping (on machine or in

outside system)

5. Piston ring worn

6. Broken valve (in pump)

1. Excessive water in tank

2. High humidity

1. Defective pressure switch

2. Excessive air usage

1. Circuit overloaded

2. Extension cord usage - wrong gauge wire

and/or too long.

3. Loose electrical connections

4. Worn check valve

5. Defective unloader valve (on pressure

switch)

6. Defective motor capacitor(s)

7. Defective motor

1 Lack of proper ventilation / room

temperature too high

2. Clogged intake filter

3. Circuit overloaded

4. Extension cord usage - wrong gauge wire

and/or too long.

5. Worn check valve

6. Defective unloader valve (on pressure

switch)

7. Defective motor

1. Plugged in? Switch on? Check fuse/breaker

2. Reset, determine cause of problem

3. Replace

4. Turn off, let cool, turn on.

5. Bleed tank pressure down to cut-in.

1. Check for proper fuse, use time-delay fuse. Disconnect

other electrical appliances from circuit or operate

compressor on its own branch circuit

2. Remove extension cord or refer to Extension Cord Chart on

page 3

3. Replace check valve

Do not disassemble check valve

with air in tank; bleed tank

4. Replace unloader valve.

5. Replace capacitor(s)

6. Replace motor

1. Check all connections with soap and water solution.

Tighten; or remove and apply pipe dope or pipe tape to the

threads, then reassemble.

2. Close tank drain valve

1. Decrease air usage; compressor not large enough for air

requirement

2. Clean or replace filter

3. Close tank drain valve

4. Check all connections with soap and water solution.

Tighten; or remove and apply pipe dope or pipe tape to the

threads, then reassemble.

5. Replace piston and cylinder.

6. Replace valve

1. Drain tank

2. Move to area of less humidity; use air line filter

1. Replace switch

2. Decrease air usage; compressor not large enough for air

requirement

1. Disconnect other electrical appliances from circuit or

operate compressor on its own branch circuit

2. Remove extension cord or refer to Extension Cord Chart on

page 3

3. Check all electrical connections

4. Replace check valve

Do not disassemble check valve

with air in tank; bleed tank

5. Replace unloader valve

6. Replace capacitor(s)

7.Replace motor

1. Move compressor to well ventilated area

2. Clean or replace filter

3. Check for proper fuse, use time-delay fuse. Disconnect

other electrical appliances from circuit or operate

compressor on its own branch circuit

4. Remove extension cord or refer to Extension Cord Chart on

page 3

5. Replace check valve

Do not disassemble check valve

with air in tank; bleed tank

6. Replace unloader valve.

7. Replace motor

Compressor will not run

Fuses blow/circuit breaker

trips repeatedly

Tank pressure drops when

compressor shuts off

Air output lower than

normal/low discharge

pressure

Excessive moisture in

discharge air

Compressor runs

continuously

Motor hums but cannot

run or runs slowly

Thermal overload

protector cuts out

repeatedly

Page 6

6

WX8019

Limited Warranty

1. DURATION: From the date of purchase by the original purchaser as follows: three years or five years, depending on the model.

2. WHO GIVES THIS WARRANTY (WARRANTOR):

Maxus, 100 Production Drive, Harrison, Ohio, 45030

3. WHO RECEIVES THIS WARRANTY (PURCHASER): The original purchaser (other than for purposes of resale) of the Maxus product.

4. WHAT PRODUCTS ARE COVERED BY THIS WARRANTY: Any Maxus air compressor, air tool or supplementary air accessory supplied or

manufactured by Warrantor.

5. WHAT IS COVERED UNDER THIS WARRANTY: Defects due to material and workmanship with the exceptions noted below.

6. WHAT IS NOT COVERED UNDER THIS WARRANTY:

A. Implied warranties, including those of merchantability and FITNESS FOR A PARTICULAR PURPOSE ARE LIMITED FROM THE DATE OF

ORIGINAL PURCHASE AS STATED IN THE DURATION. If this product is used for commercial, industrial or rental purposes, the warranty

will apply for ninety (90) days from the date of purchase. Four cylinder single-stage and two-stage products are not limited to a ninety

(90) day warranty when used in commercial or industrial applications. Some States do not allow limitations on how long an implied

warranty lasts, so the above limitations may not apply to you.

B. ANY INCIDENTAL, INDIRECT, OR CONSEQUENTIAL LOSS, DAMAGE, OR EXPENSE THAT MAY RESULT FROM ANY DEFECT, FAILURE, OR

MALFUNCTION OF THE PRODUCT. Some States do not allow the exclusion or limitations of incidental or consequential damages, so the

above limitation or exclusion may not apply to you.

C. Any failure that results from an accident, purchaser’s abuse, neglect or failure to operate products in accordance with instructions

provided in the owner’s manual(s) supplied with product.

D. Pre-delivery service, i.e. assembly, oil or lubricants, and adjustment.

E. Normal adjustments or expendable items which are explained in the owner’s manual(s) provided with the product including but not

limited to belts and pressure switch.

F. Items or service that are normally required to maintain the product, i.e. lubricants, filters and gaskets, etc.

G. Gasoline engines and components are expressly excluded from coverage under this limited warranty. The Purchaser must comply with

the warranty given by the engine manufacturer which is supplied with the product.

H. Additional items not covered under this warranty:

1. All Compressors

a. Any component damaged in shipment or any failure caused by installing or operating unit under conditions not in accordance

with installation and operation guidelines.

b. Pump or valve failure caused by rain, excessive humidity or corrosive environments.

c. Cosmetic defects that do not interfere with compressor functionality.

d. Rusted tanks, including but not limited to rust due to improper drainage.

e. Electric motors and check valves after the first year of ownership.

f. Drain cocks.

g. Damage due to improper wiring.

h. Other items not listed but considered general wear parts.

2. Lubricated Compressors

a. Pump wear or valve damage caused by using oil not specified.

b. Pump wear or valve damage caused by any oil contamination or by failure to follow proper oil maintenance guidelines.

3. Belt Drive / Direct Drive / Gas Driven Compressors

a. Belts.

b. Ring wear from inadequate filter maintenance.

c. Manually adjusted load/unload and throttle control devices.

7. RESPONSIBILITIES OF WARRANTOR UNDER THIS WARRANTY: Repair or replace, at Warrantor’s option, products or components which are

defective, have malfunctioned and/or failed to conform within duration of the warranty period.

8. RESPONSIBILITIES OF PURCHASER UNDER THIS WARRANTY:

A. Provide maintenance records to make warranty claim.

B. Portable products or components must be delivered or shipped to the nearest Maxus Authorized Service Center. Freight costs, if any,

must be borne by the purchaser.

C. Use reasonable care in the operation and maintenance of the products as described in the owner’s manual(s).

9. WHEN WARRANTOR WILL PERFORM REPAIR OR REPLACEMENT UNDER THIS WARRANTY:

A. Repair or replacement will be scheduled and serviced according to the normal work flow at the servicing location, and depending on

the availability of replacement parts.

B. If the purchaser does not receive satisfactory results from the Authorized Service Center, the purchaser should contact the Maxus

Product Service Department (see paragraph 2).

Limited Warranty applies in the U.S. and Canada only and gives you specific legal rights. You may also have other rights which vary from

State to State or country to country.

Oilless Compressors

Page 7

MÉMENTO : Gardez votre preuve datée d’achat à fin de la garantie !

Joignez-la à ce manuel ou classez-la dans un dossier pour plus de sécurité.

Description

Les compresseurs sans huile sont conçus

pour une variété de projets domestiques.

Ces compresseurs peuvent actionner de

petits outils pneumatiques, mais ils

travaillent spécialement bien avec les

cloueuses de pointes de vitrier, couleuses

de finissage et les agrafeuses. Ces

modèles fonctionnent sans huile.

Directives de Sécurité

Ce manuel contient de l’information très

importante qui est fournie pour la

SÉCURITÉ et pour ÉVITER LES PROBLÈMES

D’ÉQUIPEMENT. Rechercher les symboles

suivants pour cette information.

Danger indique

une situation

hasardeuse imminente qui RÉSULTERA

en perte de vie ou blessures graves.

Avertissement

indique une

situation hasardeuse potentielle qui

PEUT résulter en perte de vie ou

blessures graves.

Attention indique

une situation

hasardeuse potentielle qui PEUT

résulter en blessures.

Avis indique de

l’information

importante pour éviter le dommage

de l’équipement.

Déballage

Lors du déballage de ce produit,

l’examiner soigneusement pour

rechercher toute trace de dommage

susceptible de s’être produit en cours

de transport. Veiller à serrer tout

raccord, boulon, etc., avant de mettre

ce produit en service. En cas de

dommage ou de parties manquantes,

S.V.P. composer le 1-888-MAXUS4U

pour demander conseil ou appeler un

Centre De Service Autorisé Maxus.

Prière d’avoir le numéro de série,

numéro de modèle et liste de parties

(avec les parties manquantes

encerclées) avant d’appeler.

S’il vous plaît lire et conserver ces instructions. Lire attentivement avant de monter, installer, utiliser ou de procéder à l’entretien du produit

décrit. Se protéger ainsi que les autres en observant toutes les instructions de sécurité, sinon, il y a risque de blessure et/ou dégâts matériels !

Conserver ces instructions comme référence.

Instructions D’Utilisation WX8019

NE PAS RENVOYER LE

PRODUIT AU

MARCHAND!

Ne pas utiliser un

modèle qui a été

endommagé pendant le transport, la

manipulation ou l’utilisation. Le

dommage peut résulter en explosion et

peut causer des blessures ou dégâts

matériels.

IN626100AV 4/09

Avertissement D’Air

Respirable

Ce compresseur/pompe n’est pas

équipé pour et ne devrait pas être

utilisé “comme soi” pour fournir de

l’air respirable. En cas d’applications

d’air pour la consommation

humaine, le compresseur

d’air/pompe doit être équipé avec de

l’équipement de sécurité en

canalisation et d’alarme. Cet

équipement additionnel est

nécessaire pour filtrer et purifier l’air

afin d’atteindre les spécifications

minimales pour la respiration Grade

D décrites dans le Compressed Gas

Association Commodity

Specification G 7.1 - 1966, OSHA 29

CFR 1910. 134, et/ou Canadian

Standards Associations (CSA).

DÉNÉGATION DES GARANTIES

SI LE COMPRESSEUR EST UTILISÉ

POUR LES APPLICATIONS D’AIR

RESPIRABLE ET L’ÉQUIPEMENT DE

SÉCURITÉ EN CANALISATION ET

D’ALARME N’EST PAS UTILISÉ

SIMULTANÉMENT, LES GARANTIES

EN EXISTANCE SERONT ANNULÉES,

ET LE FABRICANT NIE TOUTE

RESPONSABILITÉ POUR N’IMPORTE

QUELLE PERTE, BLESSURE OU

DOMMAGE.

Compresseur Sans Huile

Voir la Garantie à la page 12 pour de l’information importante sur l’utilisation commercial de ce produit.

© 2009

Enregistrer les numeros de Modele et

de Serie (Situes sur le compresseur) et

la date d’achat dans l’espace cidessous.

No. de Modèle _____________________

No. de Série _____________________

Date d’Achat _____________________

Garder ces numéros pour référence.

7Fr

PROPOSITION 65 CALIFORNIE

Vous pouvez créer de la

poussière en coupant,

ponçant, perçant ou meulant

les matériaux tels que le bois,

la peinture, le métal, le béton, le

ciment ou autre maçonnerie. Cette

poussière contient souvent des

produits chimiques reconnus pour

causer le cancer, les déformations

congénitales ou autres problèmes de la

reproduction. Portez de l’équipement

de protection.

Ce produit ou son

cordon contient

du plomb, un produit chimique qui

de l’avis de l’État de Californie peut

causer le cancer et des anomalies

congénitales ou d’autres problèmes

pour la reproduction. Se laver les mains

après toute manipulation.

Généralités sur la

Sécurité

SÉCURITÉ DE FONCTIONNEMENT

Puisque le compresseur d’air et les

autres pièces détachées (pompe,

pistolets, filtres, graisseurs, tuyaux, etc.)

font partie d’un système de haute

pression, il est nécessaire de suivre les

précautions suivantes:

ARRÊT!

Page 8

17. Suivre les instructions du fabriquant

pendant la pulvérisation ou le

nettoyage avec des solvants ou

produits chimiques toxiques.

Installation

ENDROIT

Le réservoir doit être nivelé ou incliné

un peu vers le robinet de vidange afin

de permettre le vidange correct.

Il est très important d’installer le

compresseur dans un endroit propre

et bien ventilé où la température

n’excédera pas 40˚ C (104˚ F).

Laisser un espace libre de 10,16 cm

(minimum) entre le compresseur et le

mur car les objets peuvent obstruer la

circulation d’air.

Ne pas situer la

prise d’air du

compresseur près de la vapeur, un jet

pulvérisé de peinture, endroits de

décapage au sable ou autre sources de

contamination. Le débris

endommagera le moteur.

INSTALLATION ÉLECTRIQUE

Seul un électri-cien

qualifié doit

effectuer l’installa-tion électrique et

raccordements électriques. Respecter

toutes les codes locals et nationales de

l’électricité.

INSTRUCTIONS DE MISE À LA TERRE

1. Ce produit est conçu pour

l’utilisation d’un circuit de 120 volts

et a une fiche de mise à la terre

comme celle indiquée sur la Figure 1.

Assurer que le modèle est branché à

une prise de courant qui a la même

configuration que la fiche. Ce

produit doit être mis à la terre. Dans

l’évenement d’un court-circuit, la

mise à la terre diminue le risque de

secousse électrique en fournissant un

fil d’échappement pour le courant

électrique. Ce produit est équipé

avec un cordon qui a un fil de terre

avec une fiiche de terre. Le cordon

doit être branché dans une prise de

courant qui a été installée et mise à

la terre correctement en respectant

tous les codes et règlements locaux.

1. Lire attentivement tous

manuels compris avec ce

produit. Se familiariser

avec ce produit, ses

commandes et son

utilisation.

2. Suivre tous les codes de sécurité

locaux ainsi que les National

Electrical Codes (NEC) and

Occupational Safety and Health Act

(OSHA) des É.-U.

3. Seules les personnes bien

familiarisées avec ces règles

d’utilisation doivent être autorisées

à se servir du compresseur.

4. Garder les visiteurs à l’écart de/et

NE JAMAIS permettre les enfants

dans l’endroit de travail.

5. Utiliser des lunettes de

sécurité et la protection

auditive pendant

l’utilisation du modèle.

6. Ne pas se tenir debout sur/ni utiliser

le modèle comme une prise.

7. Inspecter le système d’air comprimé

et pièces détachées électriques pour

toute indication de dommage,

détérioration, faiblesse ou fuites

avant chaque utilisation. Réparer

ou remplacer toutes pièces

défectueuses avant l’utilisation.

8. Inspecter le degré de serrage de toutes

attaches par intervalles régulières.

Ne jamais

essayer

de réparer ou de modifier un

réservoir! Le soudage, perçage

ou autre modifications

peuvent affaiblir le réservoir

et peuvent résulter en dommage de

rupture ou d’explosion. Toujours

remplacer un réservoir usé, fendu ou

endommagé.

Les

pièces du

compresseur peuvent être

chaudes, même si le modèle

est hors circuit.

9. Garder les doigts à l’écart du

compresseur; les pièces mobiles et

chaudes peuvent causer des

blessures et/ou des brûlures.

10. Si l’équipement vibre

anormalement, ARRÊTER le moteur

et l’inspecter immédiatement. La

vibration est généralement une

indication d’un problème.

8Fr

Oilless Compressors

11. Pour réduire le risque d’incendie,

garder l’extérieur du moteur libre

d’huile, de solvant ou de graisse

excessive.

Ne jamais enlever

ou essayer

d’ajuster la soupape de sûreté. Tenir la

soupape de sûreté libre de peinture et

d’autres accumulations.

Ne

jamais essayer de réparer ou

de modifier un réservoir! Le

soudage, perçage ou autre

modifications peuvent affaiblir le

réservoir et peuvent résulter en

dommage de rupture ou d’explosion.

Toujours remplacer un réservoir usé,

fendu ou endommagé.

Purger le réservoir

quotidiennement.

12. L’accumulation d’humidité cause la

rouille qui peut affaiblir le réservoir.

Assurez vous de drainer le réservoir

chaque jour et de contrôler

périodiquement pour découvrir de

conditions de danger comme la

formation d’oxydation et la

corrosion.

13. L’air mouvante peut agiter la

poussière et le débris qui peut être

dangereux. Lâcher l’air lentement

en purgeant l’humidité ou pendant

la dépressurisation du système du

compresseur.

PRÉCAUTIONS DE PULVÉRISATION

Ne pas

pulvériser les matériaux

inflammables dans un

endroit de flamme ouverte ni

près d’une source d’ignition

y compris le compresseur.

14. Ne pas fumer pendant la pulvérisation

de la peinture, d’insecticides ou autres

matières inflammables.

15. Utiliser un masque /

respirateur pendant la

pulvérisation et pulvériser

dans un endroit bien

ventilé pour éviter le

risque de blessures et d’incendie.

16. Ne pas diriger la peinture ou autre

matériel pulvérisé vers le

compresseur. Situer le compresseur

aussi loin que possible de l’endroit

de pulvérisation pour réduire

l’accumulation de surpulvérisation

sur le compresseur.

Grounded

Outlet

Grounded Pin

Figure 1

Généralités sur la

Sécurité (suite)

MANUAL

Page 9

WX8019

9Fr

Glossaire des termes

Manostat - Interrupteur Auto/Off.

Dans la position AUTO, le compresseur

se coupe automatiquement quand la

pression du réservoir arrive à la

pression maximale réglée d’avance.

Dans la position OFF, le compresseur

ne fonctionnera pas. Cet interrupteur

devrait être dans la position OFF

pendant le branchement ou le

débranchement du cordon

d’alimentation de la prise de courant

ou pendant le changement d’outils

pneumatiques.

Régulateur - Le régulateur sert à

régler la pression d’air à la sortie du

tuyau.

Soupape de Sûreté ASME - Cette

soupape laisse échapper l’air si la

pression du réservoir dépasse la

pression maximum réglée d’avance.

Tuyau de Décharge - Ce tuyau

transporte l’air comprimé de la pompe

au clapet. Ce tuyau devient très chaud

pendant l’utilisation. Pour éviter le

risque des brûlures sévères, ne jamais

toucher le tuyau de décharge.

Clapet - Une soupape à sens unique

qui permet l’arrivée d’air dans le

réservoir mais ne permet pas que l’air

se recule dans la pompe.

Installation (Suite)

L’usage

incorrect d’une fiche mise à

la terre peut résulter en

secousse électrique!

Ne pas utiliser un

adaptateur de

mise à la terre avec ce produit!

2. Si la réparation ou le remplacement

du cordon ou de la fiche est

nécessaire, ne pas connecter le fil de

terre à ni une ni l’autre borne plate.

Le fil avec l’isolation qui a une

surface externe verte (avec ou sans

rayures) est le fil de terre.

Ne jamais brancher

le fil vert (ou vert et

jaune) à une borne électrisée.

3. Si vous ne comprenez pas les

instructions pour la mise à la terre ou

si vous n’êtes pas certains si le

produit est mis à la terre

correctement, vérifier avec un

électricien ou une personne qualifiée.

Ne pas modifier la fiche fournie; si la

fiche n’est pas la bonne taille pour la

prise de courant, contacter un

électricien qualifié pour l’installation

d’une nouvelle prise de courant.

INSTALLATION DE FILS

1. Les codes électriques d’installation

de fils sont variables d’un endroit à

l’autre. Les fils d’alimentation, fiche

et protecteurs doivent être classifiés

pour au moins l’ampérage et la

tension indiqués sur la plaque

indicatrice du moteur et doivent

répondre aux codes électriques pour

ce minimum.

2. Utiliser une fusée à retardement ou

un disjoncteur.

L’HUMIDITÉ DANS L’AIR

COMPRIMÉ

L’humidité dans l’air comprimé forme

des goutelettes en arrivant de la

pompe du compresseur. Si l’humidité

est élevée ou si le compresseur est

utilisé continuellement, cette

humidité s’accumulera dans le

réservoir. En utilisant un pistolet à

peinture, cette eau sera transportée

hors du réservoir par moyen du tuyau

en forme de goutelettes mélangées

avec le matériel utilisé.

IMPORTANT: Cette condensation

peut avoir comme résultat des

taches d’eau sur votre travail de

peinture, surtout en pulvérisant

la peinture qui n’est pas de base

d’eau. Pendant la décapage au

sable, cette eau servira à tenir le

sable ensemble et à causer une

obstruction dans le pistolet.

Vidange du réservoir - Cette soupape

est située sur la base du réservoir. Utiliser

cette soupape pour purger l’humidité du

réservoir quotidiennement afin de

réduire le risque de corrosion.

Réduire la pression d’air du réservoir à

69 kPa (10 lb/po

2

) en tirant la soupape

de sécurité, puis retirer l’humidité du

réservoir. Vidanger chaque jour pour

éviter la corrosion du réservoir.

LUBRIFICATION

Ce produit est “sans-huile” et n’exige

pas d’huile pour fonctionner.

Figure 2

Réservoir

Régulateur

Couvercle de la pompe

Raccord

universel

Manomètre

du Réservoir

Manomètre de Sortie

Soupape de

Sûreté

7,5 m 15 m 30 m

14 12 10

Utiliser une rallonge pourrait mener

à une chaleur excessive au moteur.

Ceci?pourrait mener au

déclenchement du disjoncteur (au

panneau électrique) ou au

déclenchement du protecteur de

surcharge thermique (sur le moteur

du compresseur). Si ceci se produit,

éliminer la rallonge et brancher le

compresseur directement dans la

prise de courant. Éviter d'utiliser des

rallonges, utiliser plutôt un(des)

tuyau(x) à air plus long(s).

Calibre minimum de la rallonge

Page 10

Entretien

Débrancher de la source de

puissance et ensuite dissiper

toute la pression du système

avant d’essayer d’installer, de

réparer, de déplacer ou de procéder à

l’entretien.

Inspecter le compresseur souvant et

suivre les procédés d’entretien suivants

pendant chaque utilisation du

compresseur.

1. Tirer sur l’anneau de la soupape de

sûreté et la laisser revenir à sa

position normale.

S’il y a une fuite

après que la

soupape soit lâchée ou si la soupape ne

fonctionne pas, elle devrait être

remplacée.

2. Avec le compresseur hors circuit et la

pression dissipée, purger l’humidité

du réservoir en ouvrant le robinet de

purge sous le réservoir. (Figure 4)

3. Tourner le bouton (de puissance) OFF

et nettoyer la poussière et la saleté du

moteur, réservoir, et canalisations d’air.

IMPORTANT: Situer l’unité aussi loin

de l’endroit de pulvérisation que

possible afin d’empêcher que l’orifice

d’entrée devienne obstrué par la

surpulvérisation.

Fonctionnement

SOUPAPE DE SÛRETÉ ASME

Ne jamais enlever

ou essayer

d’ajuster la soupape de sûreté!

Inspecter cette

soupape de temps à

temps en tirant sur la

bague avec la main.

S’il y a une fuite une

fois que la bague est

relâchée ou si la bague est prise, la

soupape DOIT être remplacée.

BOUTON DU RÉGULATEUR

1. Ce bouton règle la pression à un

outil pneumatique ou à un pistolet

pulvérisateur.

2. La pression d’air à la sortie est

augmentée en tournant le bouton

à la droite.

3. La pression d’air à la sortie est

réduite en tournant le bouton à la

gauche.

4. Pour couper le débit d’air, tourner

complètement à la gauche.

MANOMÈTRE RÉGLÉ DE SORTIE

D’AIR

1. Ce manomètre indique la pression

d’air de sortie. La pression d’air est

mesurée en kPa.

2. Assurer que le manomètre est à

ZERO avant de changer les outils

pneumatiques ou avant de

débrancher le tuyau de la sortie.

MANOMÈTRE DU RÉSERVOIR

Le manomètre indique la pression dans

le réservoir ce qui indique que le

compresseur fonctionne bien.

10 Fr

PROTECTEUR DE SURCHARGE

THERMIQUE

Ce compres-seur

est équipé avec un

protecteur de surcharge thermique de

rajustement automatique qui sert à

couper le moteur s’il devient

surchauffé.

Si le protecteur de surcharge thermique

coupe le moteur (OFF) à maintes

reprises, vérifier pour les causes

suivants.

1. Tension basse.

2. Calibre de fil ou taille de cordon

prolongateur incorrect.

3. Filtre d’air obstrué.

4. Ventilation insuffisante.

Le moteur doit se

refroidir avant le

démarrage si possible. Le moteur se

relancera sans avis si branché dans une

prise de courant et s’il est en marche

(ON)

ENTREPOSAGE

1. Si hors d’usage, entreposer le tuyau

et le compresseur dans un endroit

frais et sec.

2. Purger l’humidité du réservoir.

3. Débracheer le tuyau et l’accrocher

avec les bouts ouverts face en bas

afin de faire égoutter l’humidité.

Oilless Compressors

Figure 4

Soupape

de vidange

Figure 3

Page 11

11 Fr

WX8019

Guide De Dépannage

Symptôme Cause(s) Possible(s) Mesures Correctives

1. Manque de puissance électrique

2. Disjoncteur déclenché

3. Manostat en panne

4. Le moteur a travaillé excessivement.

5. La pression du réservoir se trouve

au-dessus de la limite de coupure

1. Taille de fusible incorrect, surcharge

2. Utilisation de rallonge - Calibre inadéquat

de la rallonge et/ou rallonge trop longue.

3. Soupape de retenue usée

4. Soupape de décharge défectueuse (sur le

manostat)

5. Condensateur(s) de moteur défectueux

6. Moteur défectueux

1. Raccordements dégagés (raccords, tuyaux,

etc.)

2. Ouvrir le robinet de vidange du réservoir

1. Utilisation d’air excessive

2. Filtre d’entré obstrué

3. Ouvrir le robinet de vidange du réservoir

4. Fuites d’air dans la tuyauterie (sur le

modèle ou dans le système extérieur)

5. Anneau de piston usé

6. Soupape brisée (dans la pompe)

1. Eau excessive dans le réservoir

2. Humidité élevée

1. Manostat défectueux

2. Utilisation d’air excessive

1. Surcharge de circuit

2. Utilisation de rallonge - Calibre inadéquat

de la rallonge et/ou rallonge trop longue.

3. Connexions électriques dégagées

4. Soupape de retenue usée

5. Soupape de décharge défectueuse (sur le

manostat)

6. Condensateur(s) de moteur défectueux

7. Moteur défectueux

1. Manque de ventilation adéquate/

température ambiante trop élevée.

2. Filtre d’air obstrué

3. Surcharge de circuit

4. Utilisation de rallonge - Calibre inadéquat

de la rallonge et/ou rallonge trop longue.

5. Soupape de retenue usée

6. Soupape de décharge défectueuse (sur le

manostat)

7. Moteur défectueux

1. Modèle branché? L’interrupteur est-il sur la position ON?

Vérifier le fusible/disjoncteur

2. Rajuster et trouver la source du problème

3. Remplacer

4. Éteindre l’unité, laisser refroidir, mettre en marche.

5. Purger la pression du réservoir jusqu’à la limite de coupure.

1. Vérifier le type de fusible, utiliser un fusible à retardement.

Débrancher les autres appareils électriques du circuit ou faire

fonctionner le compresseur sur un circuit unique.

2. Retirer la rallonge ou se reporter au Tableau de Rallonges,

page 9 Fr.

3. Remplacer la soupape de retenue

Ne pas démonter le clapet s’il y a

de l’air dans le réservoir; vidanger

le réservoir

4. Remplacer la soupape de décharge.

5. Remplacer le condensateur(s).

6. Remplacer le moteur

1. Vérifier tous les raccordements avec de l’eau savonneuse.

Resserrer; ou retirer et appliquer aux filets un produit

scellant ou de ruban pour filets, puis remonter.

2. Fermer le robinet de vidange du réservoir

1. Réduire l’utilisation d’air; le compresseur n’est pas assez

large pour la demande d’air

2. Nettoyer ou remplacer le filtre

3. Fermer le robinet de vidange du réservoir

4. Vérifier tous les raccordements avec de l’eau savonneuse.

Resserrer; ou retirer et appliquer aux filets un produit

scellant ou de ruban pour filets, puis remonter.

5. Remplacer

6. Remplacer la soupape

1. Purger le réservoir

2. Déplacer à un endroit moins humide; utiliser un filtre en

canalisation d’air

1. Remplacer le manostat

2. Réduire l’utilisation d’air; le compresseur n’est pas assez

large pour la demande d’air

1. Débrancher les autres appareils électriques du circuit ou

faire fonctionner le compresseur sur un circuit réservé.

2. Retirer la rallonge ou se reporter au Tableau de Rallonges,

page 9 Fr

3. Vérifier tous les connexions électriques

4. Remplacer la soupape de retenue

Ne pas démonter le clapet s’il y a

de l’air dans le réservoir; vidanger

le réservoir

5. Remplacer la soupape de décharge.

6. Remplacer le condensateur(s).

7. Remplacer le moteur

1. Déplacer le moteur dans un endroit bien ventilé

2. Nettoyer ou remplacer

3. Vérifier le type de fusible, utiliser un fusible à retardement.

Débrancher les autres appareils électriques du circuit ou

faire fonctionner le compresseur sur un circuit réservé.

4. Retirer la rallonge ou se reporter au Tableau de Rallonges,

page 9 Fr.

5. Remplacer la soupape de retenue

Ne pas démonter le clapet s’il y a

de l’air dans le réservoir; vidanger

le réservoir

6. Remplacer la soupape de décharge.

7. Remplacer le moteur

Le compresseur ne

fonctionne pas

Fusibles sautés/le

disjoncteur se déclenche à

maintes reprises

Perte de pression dans le

réservoir à air quand le

compresseur se coupe

Débit d’air plus bas que

normal/pression de

décharge basse

Humidité excessive dans

l’air de débit

Le compresseur fonctionne

continuellement

Le moteur ronron mais ne

peut pas fonctionner ou

fonctionne lentement

Le protecteur de surcharge

thermique se déclenche à

maintes reprises

Page 12

12 Fr

Garantie Limitée

1. DURÉE: À partir de la date d’achat par l’acheteur original comme suit: trois ans ou cinq ans, selon le modèle.

2. GARANTIE ACCORDÉE PAR (GARANT): Maxus, 100 Production Drive, Harrison, Ohio, 45030

3. BÉNÉFICIAIRE DE CETTE GARANTIE (ACHETEUR): L’acheteur original (sauf en cas de revente) du produit Maxus.

4. PRODUITS COUVERTS PAR CETTE GARANTIE: N’importe quel compresseur d’air, outil pneumatique ou accessoire pneumatique

supplémentaire Maxus qui est fourni par ou fabriqué par le Garant.

5. COUVERTURE DE LA PRÉSENTE GARANTIE: Défauts de matière et de fabrication avec les exceptions indiquées ci-dessous.

6. LA PRÉSENTE GARANTIE NE COUVRE PAS:

A. Les garanties implicites, y compris celles de commercialisabilité et D’ADAPTION À UNE FONCTION PARTICULIÈRE SONT LIMITÉES À

PARTIR DE LA DATE D’ACHAT INITIALE TELLE QU’INDIQUÉE DANS LA SECTION DURÉE. Si ce ompresseur d’air est utilisé pour une

fonction commerciale ou pour la location, la durée de la garantie sera quatre-vingt-dix (90) jours à compté de la date d’achat. Les

produits à quatre cylindres d’un ou de deux étages ne sont pas limités à une garantie de quatre-vingt-dix (90) jours si utilisés dans les

applications commerciaux ou industrielles. Quelques Provinces (États) n’autorisent pas de limitations de durée pour les garanties

implicites. Les limitations précédentes peuvent donc ne pas s’appliquer.

B. TOUT DOMMAGE, PERTE OU DÉPENSE FORTUIT OU INDIRECT POUVANT RÉSULTER DE TOUT DÉFAUT, PANNE OU MAUVAIS

FONCTIONNEMENT DU PRODUIT. Quelques Provinces (États) n’autorisent pas l’exclusion ni la limitation des dommages fortuits ou

indirects. La limitation ou l’exclusion précédente peut ne donc pas s’appliquer.

C. Toute panne résultant d’un accident, d’une utilisation abusive, de la négligence ou d’une utilisation ne respectant pas les instructions

données dans le(s) manuel(s) accompagnant le produit.

D. Service avant livraison; le montage, l’huile ou la graisse et les réglages par exemples.

E. Réglages normaux ou articles qui ne sont pas indispensables qui sont expliqués dans le(s) manuel(s) d’utilisation accompagnant le

produit, y compris, mais pas limités aux courroies et au manostat.

F. Articles ou services qui sont exigés pour l’entretien du produit; graisses, filtres et joints d’étanchéités par exemples.

G. Les moteurs à essence et les pièces détachées sont expressément exclus de cette garantie limitée. L’acheteur doit observer la garantie

du fabricant de moteur qui est fournie avec le produit.

H. Articles supplémentaires qui ne sont pas couverts sous cette garantie:

1. Tous les Compresseurs

a. Toutes pièces détachées endommagées pendant l’expédition ou n’importe quelle panne causée par un montage ou

fonctionnement du modèle sous des conditions qui ne conforment pas aux directives de montage et de fonctionnement.

b. La panne de la pompe ou de la soupape causée par la pluie, l’humidité excessive ou un environnement corrosif.

c. Les défauts de forme qui n’ont pas d’effet sur le fonctionnement du compresseur

d. Les réservoirs rouillés, y compris mais pas limités à la rouille causé par le vidange incorrect.

e. Les moteurs électriques et clapets après la première année de possession.

f. Robinets de vidange.

g. Condensateurs de moteur.

h. Autres articles pas inscrits, mais considérés pièces à usure générale.

2. Compresseurs Graissés

a. Usure de la pompe ou dommage aux soupapes causé par l’utilisation d’huile non-spécifiée.

b. Usure de la pompe ou dommage aux soupapes causé par toute contamination d’huile ou par le manque de suivre les directives

d’entretien d’huile.

3. Commande par Courroie / Commande Directe / Compresseurs à Essence

a. Courroies

b. Usure de bagues causée par l’entretien de filtre insuffisant

c. Appareils manuels de chargement/déchargement et appareils de commande d’obturateur.

7. RESPONSABILITÉS DU GARANT AUX TERMES DE CETTE GARANTIE: Réparation ou remplacement, au choix du Garant, des produits ou

pièces qui se sont révélés défectueux ou qui ne se sont pas conformés pendant la durée de validité de la garantie.

8. RESPONSABILITÉS DE L’ACHETEUR AUX TERMES DE CETTE GARANTIE:

A. Fournissez les fiches d’entretien pour faire reclamation de la garantie.

B. Les produits portatifs ou pièces détachees doivent être livrés au Centre de Service Autorisé Maxus le plus près.

C. Utilisation et entretien du produit avec un soin raisonable, ainsi que le décri(vent)t le(s) manuel(s) d’utilisation.

9. RÉPARATION OU REMPLACEMENT EFFECTUÉ PAR LE GARANT AUX TERMES DE LA PRÉSENTE GARANTIE:

A. La réparation ou le remplacement sera prévu et exécuté en fonction de la charge de travail dans le centre de

service et dépendra de la disponabilité des pièces de rechange.

B. Si l’acheteur n’est pas satisfait des services du Centre De Service Autorisé, l’acheteur devrait contacter le

Département De Service Maxus (se référer au paragraph 2).

Garantie Limitée est valide dans les É.-U. et au Canada seulement et vous donne des droits judiciaires spécifiques. Vous pouvez égalmement

jouir d’autres droits qui varient d’un État à l’autre ou d’un pays à l’autre.

WX8019

Compresseur Sans Huile

Page 13

NÃO DEVOLVA

O PRODUTO

À LOJA !

Não opere o

compressor que

tenha sido danificado durante o envio,

manuseio ou utilização. O dano pode

ocasionar explosão e causar ferimentos

ou danos à propriedade.

Descrição

Os compressores sem óleo são

projetados para uma variedade de

aplicações domésticas. Esses

compressores podem acionar pequenas

ferramentas pneumáticas, mas são

ideais para máquinas de pregar pregos,

máquinas de pregar pregos de

acabamento e grampeadores.

Essas unidades funcionam sem óleo.

Normas de Segurança

Esse manual contém informações muito

importantes de serem conhecidas e

compreendidas. Essas informações são

fornecidas para SEGURANÇA e para

EVITAR PROBLEMAS COM O

EQUIPAMENTO. Para ajudar a

reconhecer essas informações, observe

os seguintes símbolos.

Perigo indica uma

situação de perigo

iminente que, se não evitada, resulta

em morte ou lesão grave.

Advertência indica

uma situação

potencialmente perigosa que, se não

evitada, pode resultar em morte ou

lesão grave.

Atenção indica

uma situação

potencialmente perigosa que, se não

evitada, pode resultar em lesão menor

ou moderada.

Aviso indica

informação

importante que, se não for seguida,

pode causar dano ao equipamento.

Remoção da Embalagem

Após desembalar a unidade, inspecione

cuidadosamente por qualquer dano que

possa ter ocorrido durante o transporte.

Assegure de apertar acessórios,

parafusos, etc, antes de colocar a

unidade em funcionamento. Em caso de

dúvidas, defeito ou ausência de peças,

por favor, ligue para o Centro de Serviço

Autorizado Maxus mais próximo.

Tenha em mãos o número de série,

número do modelo e lista de peças

(contendo as peças ausentes assinaladas

antes de ligar).

Por favor, leia e guarde essas instruções. Leia com atenção antes de tentar montar, instalar, utilizar ou fazer manutenção no produto descrito.

Proteja a si mesmo e outras pessoas observando todas as informações de segurança, caso contrário podem ocorrer lesões pessoais e/ou danos

materiais! Guarde essas instruções para futuras consultas.

Instruções de Utilização WX8019

IN626100AV 4/09

Advertência sobre

Ar Respirável

Este compressor /bomba não está

equipado e não deve ser usado

para suprimento de ar com

qualidade respirável. Antes de

utilizá-lo para esse fim, deverá ser

instalado no compressor um

sistema de segurança e alarme

incorporado à linha. Este

equipamento suplementar é

necessário para uma filtragem

e purificação adequada do ar para

atender às especificações mínimas

do Grau D de ar respirável,

descrito na especificação

G 7.1 – 1996 da Associação de Ar

Comprimido. Também deverá

atender ao artigo 29 CFR 1910.

134 da organização norteamericana OSHA e/ou Associação

Canadense de Normas (Canadian

Standards Association - CSA).

DESOBRIGAÇÃO DE GARANTIAS

NO CASO DO COMPRESSOR SER

USADO PARA FORNECER AR

RESPIRÁVEL SEM A INSTALAÇÃO

NA LINHA DE AR DO

EQUIPAMENTO DE SEGURANÇA E

ALARME, TODAS AS GARANTIAS

SE ANULAM E O FABRICANTE NÃO

SE RESPONSABILIZA POR DANOS,

FERIMENTOS OU LESÕES PESSOAIS.

Compressores sem óleo

Veja a Garantia na página 18 para informações importantes sobre o uso comercial deste produto.

© 2009

13 Pg

LEMBRETE: Guarde o seu comprovante de compra datado para fins de garantia do produto!

Anexe-o junto desse manual ou arquivo para melhor proteção.

Registre os Número do Modelo e Série

(localizados no compressor) e a data

da compra nos espaços abaixo.

No do Modelo ______________________

No de Série ________________________

Data da compra ____________________

Mantenha esses números guardados

para consultas futuras.

PROPOSIÇÃO 65 DA CALIFÓRNIA

As

atividades de cortar, lixar, furar

ou triturar materiais como

madeira, tinta, metal, concreto,

cimento ou outro tipo de alvenaria geram

pó. Esse pó freqüentemente contém

substâncias químicas conhecidas por

causarem câncer, defeitos congênitos ou

outras lesões ao sistema reprodutor. Use

equipamentos de proteção.

Esse produto ou o

seu cabo de

alimentação contém chumbo, um

produto químico conhecido no Estado

da Califórnia por causar câncer e

defeitos congênitos ou outras lesões

ao sistema reprodutor. Lave as mãos

após o manuseio.

Informações Gerais

de Segurança

SEGURANÇA DURANTE A OPERAÇÃO

Como o compressor e outros

componentes (bomba de material,

pistolas pulverizadoras, filtros,

lubrificadores, mangueiras, etc)

usados fazem parte de um sistema

de bombeamento de alta pressão,

as seguintes precauções de segurança

devem ser observadas durante todo

o tempo:

PARE!

Page 14

Instalação

LOCALIZAÇÃO

O tanque deve estar nivelado ou um

pouco inclinado para o lado da válvula

de drenagem de modo que se possa

drenar todo o tanque de maneira

apropriada.

É extremamente importante instalar

o compressor numa área limpa, bem

ventilada e com temperatura ambiente

inferior a 40º C (104º F).

É necessário um espaço mínimo

de 0,1 metro (4 polegadas) entre

o compressor e a parede para que

nenhum objeto obstrua o fluxo de ar.

Não instale

a entrada de ar do

compressor próximo de áreas com

vapor, tinta, jato de areia ou qualquer

fonte de contaminação. Os resíduos

podem causar danos ao motor.

INSTALAÇÃO ELÉTRICA

Toda a fiação e

conexões elétricas

deverão ser feitas por um eletricista. A

instalação deve estar de acordo com as

normas nacionais de instalações

elétricas.

INSTRUÇÕES DE ATERRAMENTO

1. Este produto foi projetado para uso

com tensão de 240 volts e possui um

conector com aterramento como

mostrado na figura 1. Certifique-se

de que o compressor esteja

conectado a uma saída com a mesma

configuração do conector.

Este produto deve ser aterrado. Em

caso de curto circuito, o aterramento

reduz o risco de choque elétrico por

oferecer um cabo elétrico para

desvio da corrente. Este produto está

equipado com um cabo contendo um

fio de aterramento com seu

respectivo conector apropriado.

Este fio deverá ser conectado a uma

tomada que esteja corretamente

instalada e aterrada de acordo com

todas as normas e códigos locais.

Compressores sem óleo

1. Leia cuidadosamente os

manuais incluídos com

este produto. Familiarizese com os controles e uso

correto do equipamento.

2. Siga todas as recomendações de

segurança do trabalho e eletricidade

estabelecidas em seu país, como por

exemplo as normas NEC (National

Electrical Codes) e OSHA (Occupational

Safety and Health Act) dos EUA.

3. O compressor deve ser operado

somente por pessoas com

conhecimento dessas recomendações

de segurança.

4. Mantenha os visitantes à distância

e NUNCA permita a presença de

crianças na área de trabalho.

5. Use óculos de segurança

e protetor auricular

enquanto estiver operando

a bomba ou a unidade.

6. Não pise sobre o compressor ou

o utilize como apoio de mão.

7. Antes de cada uso, faça uma

inspeção do sistema de ar

comprimido e dos componentes

elétricos verificando se existem

danos, deterioração, desgaste ou

vazamentos. Conserte ou substitua

as peças defeituosas antes de usar

o equipamento.

8. Verifique todas as conexões

frequentemente para apertá-las

quando necessário.

Motores,

equipamentos elétricos e

controles podem gerar arcos

elétricos capazes de

ocasionar ignição de gases

ou vapores inflamáveis. Nunca opere

ou faça reparos em locais próximos de

gases ou vapores inflamáveis. Nunca

armazene líquidos ou gases inflamáveis

nas proximidades do compressor.

Algumas

partes do compressor podem

estar quentes mesmo quando

este estiver desligado.

9. Mantenha os dedos longe do

compressor em operação; peças

móveis ou partes quentes poderão

causar queimaduras e/ou lesões.

10. Se o equipamento apresentar

vibração fora do normal, PARE o

motor e verifique imediatamente a

causa. A vibração geralmente é um

aviso de que algo não está correto.

11. Para reduzir o risco de incêndio,

mantenha a parte exterior do

motor limpa e sem óleo, solvente

ou excesso de graxa.

Nunca remova ou

tente ajustar a

válvula de segurança. Mantenha a

válvula de segurança livre de tinta ou

acúmulo de sujeira.

Nunca

tente

fazer conserto ou modificação

no tanque! Soldas,

perfurações ou outras

modificações diminuem a resistência do

tanque podendo causar ruptura ou

explosão do tanque. Os tanques

danificados ou gastos devem ser sempre

substituídos.

Drene o líquido do

tanque diariamente.

12. Os tanques enferrujam com o

acúmulo de umidade e isso diminui

a resistência do tanque. Faça a

drenagem do tanque diariamente

e faça inspeções periódicas

procurando por ferrugem ou

pontos de corrosão.

13. O ar em rápido movimento levanta

o pó e resíduos que podem ser

prejudiciais. Libere o ar lentamente

enquanto estiver drenando a

umidade ou despressurizando

o sistema do compressor.

PRECAUÇÕES DURANTE

A PULVERIZAÇÃO

Não

pulverize materiais

inflamáveis nas proximidades

de uma chama ou próximo de

dispositivos de ignição

incluindo-se a unidade do compressor.

14. Não fume durante a pulverização

de tintas, inseticidas ou outras

substâncias inflamáveis.

15. Use uma máscara facial /

respirador enquanto

estiver pulverizando e

utilize o pulverizador

numa área ventilada para

prevenir danos à saúde e perigo de

incêndio.

16. Não pulverize tinta ou outro material

diretamente sobre o compressor.

Coloque o compressor num local que

seja afastado da área de trabalho

para minimizar o acúmulo de

resíduos sobre o compressor.

17. Quando for pulverizar ou realizar

limpeza com solventes ou

substâncias tóxicas, siga as

instruções fornecidas pelo

fabricante destas substâncias.

14 Pg

Tomada com

aterramento

Pino de aterramento

Figura 1

Informações Gerais de

Segurança (Continua)

MANUEL

Page 15

Instalação (Cont.)

O uso

incorreto do conector com

aterramento pode causar o

possível risco de choque

elétrico!

Não utilize um

adaptador de

aterramento com este produto.

2. Caso seja necessário o reparo ou a

substituição do fio ou do conector,

não conecte o fio de aterramento

a um nenhum dos terminais planos.

O fio com isolamento na cor verde

(com ou sem listras amarelas) é o fio

de aterramento.

Nunca conecte o

fio verde (ou verde

e amarelo) a um terminal de tensão.

3. Consulte um eletricista caso não

tenha compreendido bem as

instruções ou se tiver dúvidas se

o equipamento está aterrado

corretamente. Não modifique o

conector fornecido; se não conseguir

adaptá-lo à tomada, chame um

eletricista e providencie a instalação

de uma tomada apropriada.

INSTALAÇÃO ELÉTRICA

1. As normas de instalações elétricas

são diferentes para cada região.

A fiação, conectores e proteções

devem ser selecionados de acordo

com as especificações de amperagem

e voltagem indicadas na placa do

motor atendendo às especificações

mínimas.

2. Use um fusível de ação lenta ou um

disjuntor.

Glossário de termos

Pressostato - Interruptor

Auto/Desligado – Na posição AUTO

o compressor desliga automaticamente

quando a pressão no tanque atinge

o valor máximo pré-estabelecido.

Na posição DESLIGADO, o compressor

não opera. O interruptor deve estar

na posição DESLIGADO quando for

conectar ou desconectar o

equipamento da tomada ou durante

a troca das ferramentas pneumáticas.

Regulador - O regulador controla a

pressão do ar liberado na mangueira.

Válvula de segurança ASME - Esta

válvula libera o ar automaticamente se

a pressão no tanque ultrapassar o valor

máximo pré-estabelecido.

Tubo de descarga - Este tudo

transporta o ar comprimido desde a

bomba até a válvula de retenção. Este

tubo se aquece muito durante o uso do

compressor. Para evitar queimadura,

nunca toque o tubo de descarga.

Válvula de retenção – Válvula de

fluxo unidirecional que somente

permite a passagem de ar que entra no

tanque e evita o retorno de ar para a

bomba do compressor.

Dreno do tanque – Esta válvula se

localiza no fundo do tanque. Serve

para drenar a umidade condensada no

tanque diariamente, reduzindo o risco

de corrosão.

Reduza a pressão no tanque abaixo de

0,69 bar puxando a válvula de

segurança e a seguir drene a umidade

do tanque. Faça a drenagem

diariamente para evitar corrosão do

tanque.

LUBRIFICAÇÃO

Este é um compressor sem óleo e não

necessita de lubrificação para operar.

15 Pg

WX8019

UMIDADE NO AR COMPRIMIDO

A umidade no ar comprimido

forma gotículas de água que saem

com o ar da bomba do compressor.

Quando a umidade é alta ou

quando o compressor está em uso

contínuo por longos períodos,

a umidade é coletada no tanque.

Ao utilizar um pulverizador de

tinta, a água será transportada

desde o tanque até a mangueira

e sai através da pistola de pintura

como gotículas misturadas ao

material pulverizado.

IMPORTANTE: Esta condensação

causará manchas na superfície

pintada, especialmente quando se

utilizam tintas que não sejam à

base de água. Um filtro na linha

de ar (MP3105), localizado o mais

próximo possível da pistola ajuda

a eliminar esta umidade.

Tanque

Manômetro do tanque

Regulador

Cobertura da bomba

Manômetro

de saída

Acoplador

universal

Válvula de

segurança

Figura 2

7,5 m 15 m 30 m

14 12 10

A utilização de uma extensão pode

ocasionar o sobreaquecimento do

motor. Isto, por sua vez, pode

desarmar um disjuntor (no painel

elétrico) ou pode causar sobrecarga

térmica (no motor do compressor).

Se isto ocorrer, elimine a extensão

e ligue o compressor diretamente

na tomada. Evite usar extensões.

Em vez disso, utilize mangueira(s)

de ar de maior comprimento.

Espessura Mínima da Extensão

Page 16

Operação

VÁLVULA DE SEGURANÇA ASME

Não remova ou

tente ajustar a

válvula de segurança.

Esta válvula às vezes

deve ser inspecionada

sob pressão puxandose o anel com a mão.

Se ocorrer vazamento

de ar após ter soltado

o anel, ou a válvula

estiver emperrada e não puder ser

utilizada com o anel, então ela deverá

ser substituída.

BOTÃO DO REGULADOR

1. Este botão controla a pressão do ar

para uma ferramenta pneumática ou

pistola de pulverização.

2. Gire o botão no sentido horário para

aumentar a pressão de ar na saída.

3. Gire o botão no sentido anti-horário

para diminuir a pressão do ar na

saída.

4. Gire completamente o botão no

sentido anti-horário para cessar

completamente o fluxo de ar.

MANÔMETRO DA SAÍDA

1. Este manômetro permite verificar

a pressão de saída. A pressão é

medida em bar [1 bar equivale

a 14.5 libras/polegada

2

(psi)].

2. Certifique-se de que o manômetro

esteja no ZERO antes de trocar as

ferramentas pneumáticas ou

desconectar a mangueira.

MANÔMETRO DO TANQUE

Este manômetro mostra a pressão no

tanque e indica se compressor mantém

a pressão do sistema.

Manutenção

Desligue

a energia elétrica e então

libere toda a pressão do

sistema antes de fazer

alguma instalação, reparo,

movimentação ou qualquer outra

manutenção.

O compressor deve ser inspecionado

regularmente para verificar se existem

problemas visíveis. Os seguintes

procedimentos de manutenção devem

ser realizados a cada uso do

compressor.

1. Puxe o anel da válvula de segurança

e deixe voltar para a posição normal.

A válvula de segurança deve ser

substituída se ela não puder ser

utilizada ou se ocorrer vazamento

de ar após o anel ser solto.

2. Com o compressor desligado e toda a

pressão liberada, drene a umidade

do tanque abrindo a válvula de

drenagem localizada na parte

inferior do tanque (veja figura 4).

3. Desligue o compressor e limpe a

sujeira do motor, do tanque e das

linhas de ar. IMPORTANTE:

O compressor deve estar localizado

o mais longe possível da área de

trabalho, de acordo com o tamanho

da mangueira, para prevenir

entupimento do filtro.

PROTETOR TÉRMICO

Este compressor está

equipado com um

dispositivo automático de proteção contra

sobrecarga térmica, que desliga o motor se

o mesmo estiver sobreaquecido.

Se o dispositivo de proteção contra

sobrecarga térmica DESLIGAR o motor

com frequência, verifique se as

seguintes ocorrências estão causando

esse desligamento.

1. Baixa voltagem.

2. Fiação com espessura errada

ou extensão com comprimento

inadequado.

3. Filtro de ar obstruído.

4. Falta de ventilação adequada.

Deve-se aguardar

o resfriamento do

motor antes que seja possível dar a partida

no mesmo. O motor voltará a funcionar

automaticamente sem aviso se for deixado

ligado na corrente elétrica, se estiver na

posição “ligado”.

Após o resfriamento do compressor por

30 minutos, reinicie o protetor térmico

manualmente apertando o botão

mostrado na figura 5.

ARMAZENAMENTO

1. Quando não estiver em uso,

mantenha a mangueira e o

compressor em local fresco e seco.

2. Drene a umidade do tanque

3. Desconecte a mangueira e deixe-a

pendurada com as extremidades para

baixo para permitir o escoamento da

água.

16 Pg

Compressores sem óleo

Figura 4

Válvula de

drenagem

Figura 3

Page 17

17 Pg

WX8019

Tabela da solução de problemas

Problema Possíveis causas Ação corretiva

1. Não há fornecimento de energia elétrica

2. O disjuntor está desarmado

3. Interruptor de pressão defeituoso

4. O motor está sobrecarregado

5. Pressão do tanque acima do valor de corte

1. Fusível fora de especificação, circuito

sobrecarregado

2. Utilização de extensão – espessura de fio

inadequada e/ou excesso de comprimento.

3. Válvula de retenção com desgaste excessivo

4. Válvula de descarga (no interruptor de

pressão) defeituosa

5. Capacitor(es) do motor defeituoso(s)

6. Motor defeituoso

1. Ferragens soltas (conexões, tubulações, etc.)

2. Válvula de drenagem do tanque aberta

1. Uso excessivo de ar

2. Filtro de entrada obstruído

3. Válvula de drenagem de tanque aberta

4. Vazamentos de ar na tubulação (na máquina

ou no sistema externo)

5. Anel do pistão desgastado

6. Válvula quebrada (na bomba)

1. Excesso de água no tanque

2. Índices elevados de umidade

1. Interruptor de pressão defeituoso

2. Uso excessivo de ar

1. Circuito sobrecarregado

2. Utilização de extensão – fio fora de

especificação (espessura insuficiente) e/ou

comprimento excessivo.

3. Conexões elétricas soltas

4. Válvula de retenção excessivamente desgastada

5. Válvula de descarga (no interruptor

de pressão) defeituosa

6. Capacitor(es) do motor defeituoso(s)

7. Motor defeituoso

1. Ventilação inadequada/temperatura

ambiente excessiva

2. Filtro de entrada obstruído

3. Circuito sobrecarregado

4. Utilização de extensão – fio fora de

especificação (espessura insuficiente)

e/ou comprimento excessivo.

5. Válvula de retenção excessivamente desgastada

6. Válvula de descarga (no interruptor

de pressão) defeituosa

7. Motor defeituoso

1. O equipamento está ligado na tomada? O interruptor está na

posição “ligado”? Verificou o fusível/disjuntor?

2. Rearme, determine a causa do problema

3. Substitua

4. Desligue, espere esfriar, ligue novamente.

5. Faça a sangria da pressão do tanque até atingir o valor de corte.

1. Verifique se o fusível correto está sendo usado, utilize fusível