Page 1

Please read and save these instructions. Read carefully before attempting to assemble, install, operate or maintain the product described.

Protect yourself and others by observing all safety information. Failure to comply with instructions could result in personal injury and/or

property damage! Retain instructions for future reference.

IN971800AV 4/03

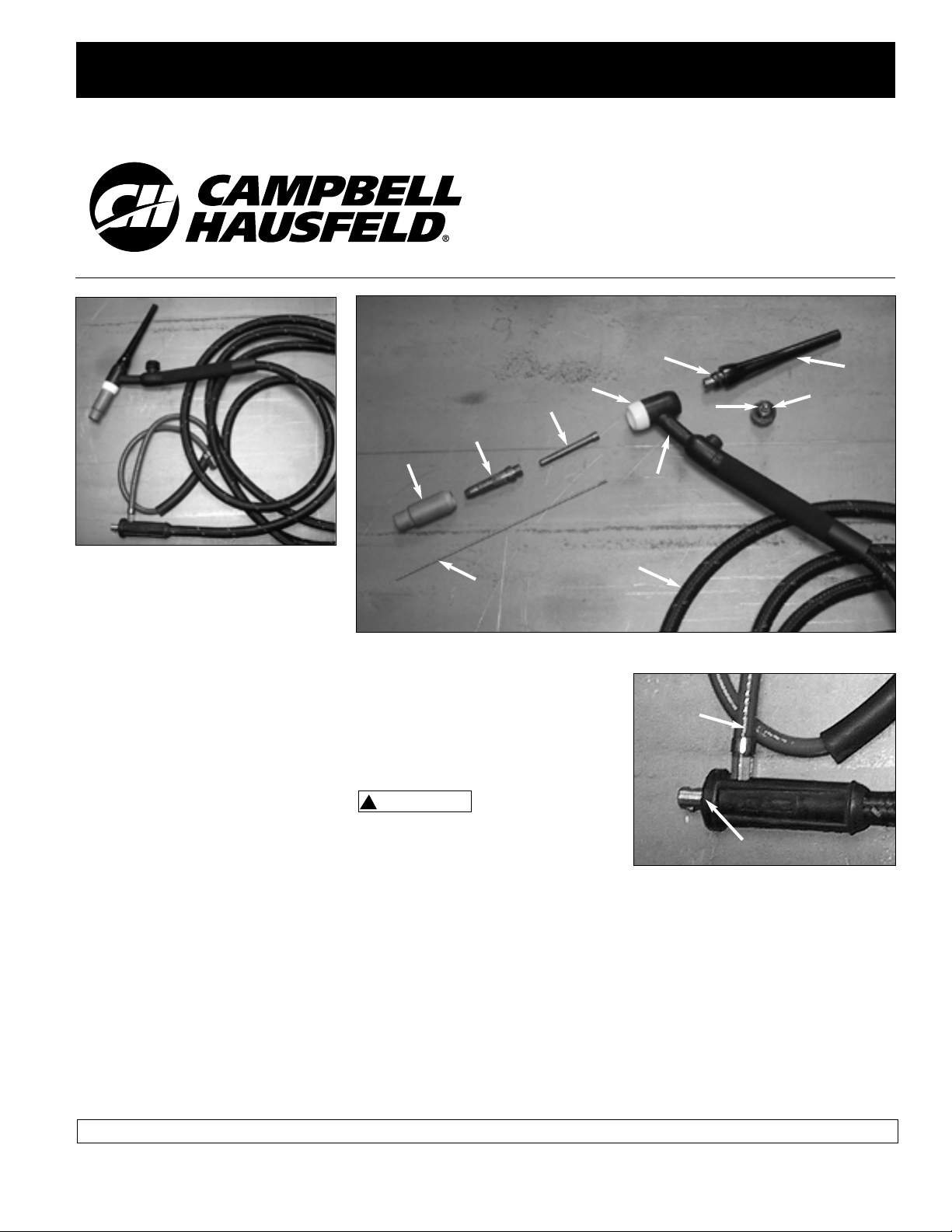

Operating Instructions Model WT6100

TIG Torch

Description

The WT6100 TIG torch allows you to

convert your Arcitech 110 inverter

technology welder to a TIG (GTAW)

welder. TIG stands for Tungsten Inert

Gas. GTAW is Gas Tungsten Arc

Welding. TIG is also commonly call

Heliarc

®

welding, but Heliarc®is a brand

name of the Linde Company, not a

process. Heliarc

®

comes from Helium

Arc Welding, as helium is an inert gas

used to keep impurities from the weld.

Today most TIG welding is done with

100% Argon shielding gas.

TIG welding gives the most beautiful

and clean welds with the most

precision and control. It is the best

process for welding dissimilar size items

together. The drawback to TIG welding

is that it takes a high skill level, and it is

slow.

TIG welding is often used in welding

Aluminum, however welding

Aluminum with TIG requires an AC

high frequency power source. The

Campbell Hausfeld Arcitech 110 has DC

only output, so it can not weld

Aluminum with the TIG process.

Unpacking

When unpacking, inspect carefully for

any damage that may have occurred

during transit. Make sure any loose

fittings and screws, etc. are tightened

before putting unit into service.

The electrode

holder is "live"

(has current potential) when machine is

turned on.

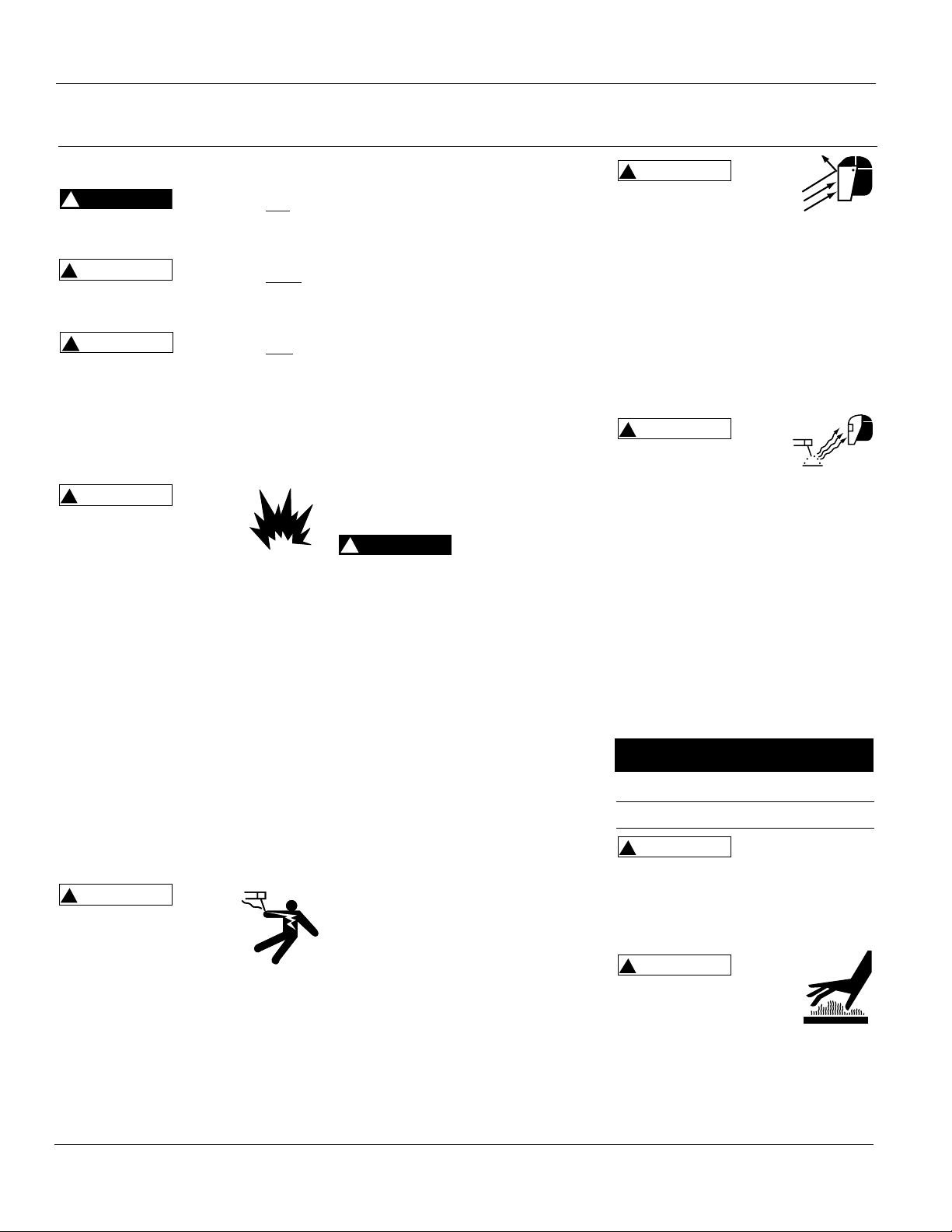

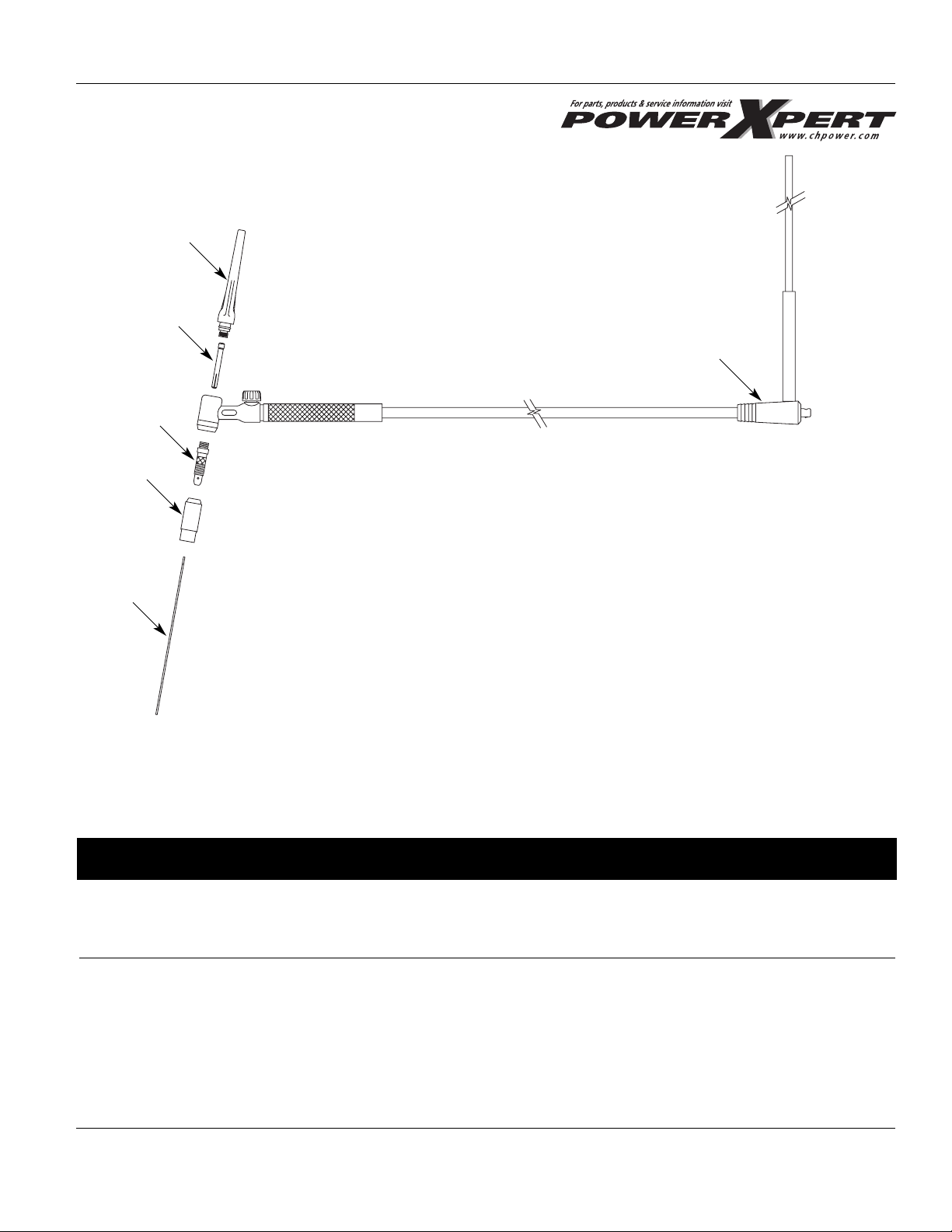

Components of the WT6100

TIG Torch:

1. 2% Thoriated Tungsten Electrode -

1/16” (1.6 mm)

2. Nozzle #7 use with 1/16” (1.6 mm)

electrode

3. Collet Body - match to electrode size

(1.6 mm)

4. Collet - matched to electrode size

(1.6 mm)

5. Insulator

6. Torch Head

7. Gas Valve

8. O-rings (for gas valve and back cap)

9. Back Cup

10. 12.5’ Torch hose

11. Dinse plug power connector

(connect to negative (-) output on

welder)

12. Gas connector (connect to gas

regulator on 100% Argon tank)

For parts, manuals, product & service information

visit www.chpower.com

or call 800-746-5641

Figure 1 - Welder Components and

Controls

© 2003 Campbell Hausfeld/Scott Fetzer

Figure 2

1

2

3

4

5

6

7

8

8

9

10

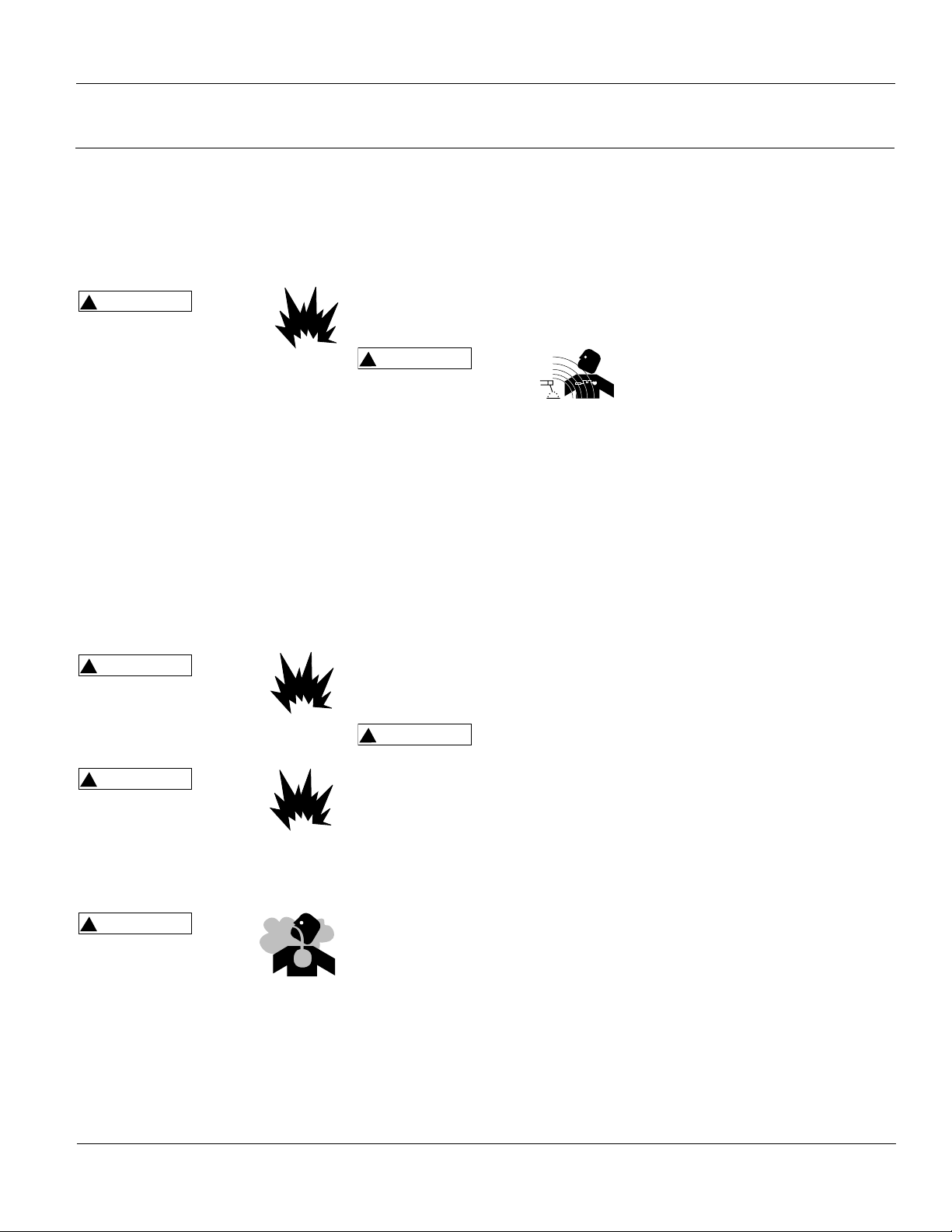

Figure 3

11

12

REMINDER: Keep your dated proof of purchase for warranty purposes! Attach it to this manual or file it for safekeeping.

BUILT TO LAST

!

WARNING

Page 2

2

Operating Instructions

GTAW Arc Welding Torch

General Safety

Danger means a

hazard that will

cause death or serious injury if the

warning is ignored.

Warning means a

hazard that could

cause death or serious injury if the

warning is ignored.

Caution means a

hazard that may

cause minor or moderate injury if the

warning is ignored. It also may mean a

hazard that will only cause damage to

property.

Note: Note means any additional

information pertaining to the product

or its proper usage.

Always

keep a

fire extinguisher accessible

while performing arc

welding operations.

● Before starting or servicing any

electric arc welder, read and

understand all instructions. Failure

to follow safety precautions or

instructions can cause equipment

damage and or serious personal

injury or death. For additional

safety information, obtain a copy of

ANSI Standard Z49.1 - Safety in

Welding and Cutting. This

publication may be ordered from

the American Welding Society, 550

NW. LeJune Rd., Miami, FL 33135.

● All installation, maintenance, repair

and operation of this equipment

should be performed by qualified

persons only in accordance with

national, state, and local codes.

Im-

proper

use of electric arc welders

can cause electric shock,

injury, and death! Take all

precautions described in

this manual to reduce the possibility of

electric shock.

● Verify that all components of the

arc welder are clean and in good

condition prior to operating the

welder. Be sure that the insulation

on all cables, electrode holders, and

power cords is not damaged.

Always repair or replace damaged

components before operating the

welder. Always keep welder panels,

shields, etc. in place when operating

the welder.

● Always wear dry protective clothing

and welding gloves, and insulated

footwear.

● Always operate the welder in a

clean, dry, well ventilated area. Do

not operate the welder in humid,

wet, rainy, or poorly ventilated

areas.

● Be sure that the work piece is

properly supported and grounded

prior to beginning any electric arc

welding operation.

● Coiled welding cable should be

spread out before use to avoid

overheating and damage to

insulation.

Never immerse the

electrode or torch

in water. If the welder becomes wet for

any reason, be absolutely certain that

it is completely clean and dry prior to

attempting use!

● Always shut the equipment off and

unplug the power prior to moving

the unit.

● Always attach the ground lead first.

● Verify that the work piece is

securely grounded.

● Always shut off electric arc welding

equipment when not in use and

remove the electrode from the

holder.

● Never allow any part of the body to

touch the electrode and ground or

grounded work piece at the same

time.

● Awkward welding conditions and

positions can be electrically

hazardous. When crouching,

kneeling or at elevations, be sure to

insulate all conductive parts, wear

appropriate protective clothing, and

take precautions to prevent injury

from falls.

● Never attempt to use this

equipment at current settings or

duty cycles higher than those

specified on the equipment labels.

● Never use an electric arc welder to

thaw frozen pipes.

Flying

sparks

and hot metal can cause

injury. As welds cool, slag

can be thrown off. Take all precautions

described in this manual to reduce the

possibility of injury from flying sparks

and hot metal.

● Wear ANSI approved face shield or

safety glasses with side shield

protection when chipping or

grinding metal parts.

● Wear ear plugs when welding

overhead to prevent spatter or slag

from falling into ears.

Electric

arc

welding operations

produce intense light and

heat and ultraviolet (UV) rays. This

intense light and UV rays can cause

injury to eyes and skin. Take all

precautions described in this manual to

reduce the possibility of injury to eyes

and skin.

● All persons operating this

equipment or in the area while

equipment is in use must wear

protective welding gear including:

welding helmet or shield with

proper shade as specified in the

following chart, flame resistant

clothing, leather welding gloves,

and full foot protection.

Current Filter

e

Up To 160 Amps 10

160 To 250 Amps 12

Never look at arc

welding operations

without eye protection as described

above. Never use a shade filter lens

that is cracked, broken, or rated below

number 10. Warn others in the area not

to look at the arc.

Electric

arc

welding operations cause

sparks and heat metal to

temperatures that can cause

severe burns! Use protective gloves

and clothing when performing any

metal working operation. Take all

precautions described in this manual to

reduce the possibility of skin and

clothing burns.

www.chpower.com

Current Filter

(Amps) Shade

!

DANGER

!

WARNING

!

CAUTION

!

WARNING

!

WARNING

!

DANGER

!

WARNING

!

WARNING

!

WARNING

!

WARNING

Page 3

Safe Handling of Compressed Gases

in Cylinders

CGA Pamphlet P-1, from Compressed

Gas Association, 1235 Jefferson Davis

Highway, Suite 501, Arlington, VA

22202

Code for Safety in Welding and

Cutting

CSA Standard W117.2, from Canadian

Standards Association, Standards Sales,

178 Rexdale Boulevard, Rexdale,

Ontario, Canada M9W 1R3

Cutting And Welding Processes

NFPA Standard 51B, from National Fire

Protection Association, Batterymarch

Park, Quincy, MA 02269

Safe Practices For Occupational And

Educational Eye And Face Protection

ANSI Standard Z87.1, from American

National Standards Institute, 1430

Broadway, New York, NY 10018

Refer to the Material Safety Data Sheets

and the manufacturers instructions for

metals, electrodes, coatings and

cleaners.

Installation

LOCATION

Selecting the proper location can

significantly increase performance,

reliability and life of the arc welder.

● For best results locate the welder in

an environment that is clean and dry.

Avoid locations exposed to high

temperature, high humidity, dust

and corrosive fumes. High humidity

causes moisture condensation on

electrical components. Moisture can

contribute to corrosion and short

electrical components. Dust and dirt

in the welder retain moisture and

increase wear of moving parts.

● Place the welder in an area that

provides at least twelve inches (305

mm.) of ventilation space at both the

front and rear of the unit. Keep all

obstructions away from this

ventilation space.

● Store electrodes and filler metal in a

clean, dry location with low

humidity.

● The welder control panel contains

information regarding proper input

● Make sure that all persons in the

welding area are protected from

heat, sparks, and ultraviolet rays.

Use additional face shields and

flame resistant barriers as needed.

● Never touch work pieces until

completely cooled.

Heat and

sparks

produced during electric arc

welding and other metal

working operations can

ignite flammable and explosive

materials! Take all precautions

described in this manual to reduce the

possibility of flames and explosions.

● Remove all flammable materials

within 35 feet (10.7 meters) of

welding arc. If removal is not

possible, tightly cover flammable

materials with fire proof covers.

● Do not operate any electric arc

welder in areas where flammable or

explosive vapors may be present.

Take precautions to be sure that

flying sparks and heat do not cause

flames in hidden areas, cracks,

behind bulkheads, etc.

Fire

hazard!

Do not weld on containers or

pipes that contain or have

contained flammable

materials or gaseous or liquid

combustibles.

Arc

welding

closed cylinders or

containers such as tanks or

drums can cause explosion if

not properly vented! Verify that any

cylinder or container to be welded has

an adequate ventilation hole, so that

expanding gases can be released.

Do not

breathe

fumes that are produced by

the arc welding operation.

These fumes are

dangerous. If the welding area cannot

be adequately ventilated, be sure to

use an air-supplied respirator.

● Keep the head and face out of the

welding fumes.

● Do not perform electric arc welding

operations on metals that are

galvanized or cadmium plated, or

Model WT6100

contain zinc, mercury, or beryllium

without completing the following

precautions:

a. Remove the coating from the

base metal.

b. Make sure that the welding area

is well ventilated.

c. Use an air-supplied respirator.

Extremely toxic fumes are created

when these metals are heated.

The

electromagnetic field that is

generated during arc

welding may interfere with the

operation of various electrical and

electronic devices such as cardiac

pacemakers. Persons using such devices

should consult with their physician

prior to performing any electric arc

welding operations.

● Route the electrode and work

cables together and secure with

tape when possible.

● Never wrap arc welder cables

around the body.

● Always position the electrode and

ground leads so that they are on

the same side of the body.

● Exposure to electromagnetic fields

during welding may have other

health effects which are not known.

Always be sure

that the welding

area is secure and free of hazards

(sparks, flames, glowing metal or slag)

prior to leaving. Be sure that

equipment is turned off and electrode

is removed. Be sure that cables are

loosely coiled and out of the way. Be

sure that all metal and slag has cooled.

ADDITIONAL SAFETY STANDARDS

ANSI Standard Z49.1 from American

Welding Society, 550 N.W. LeJune Rd.

Miami, FL 33126

Safety and Health Standards

OSHA 29 CFR 1910, from

Superintendent of Documents, U.S.

Government Printing Office,

Washington, D.C. 20402

National Electrical Code

NFPA Standard 70, from National Fire

Protection Association, Batterymarch

Park, Quincy, MA 02269

www.chpower.com

3

!

WARNING

!

WARNING

!

WARNING

!

WARNING

!

WARNING

!

WARNING

Page 4

100% Argon shielding gas is connected

to the torch at a regulated rate of 15 30 cubic feet per hour (cfh.) If you have

too little gas, you will see porosity of

your weld. Too much flow is just a

waste of gas.

Filler metal is applied to the TIG weld

by hand feeding as is done with oxyacetylene (flame power) welding. The

filler metal must match the material

you are welding. For welding mild

steel, use an un-coated steel rod such

as Welco W-1200, AWS A5.2-69, class

RG60, or E70S-6 MIG wire. The

diameter of the filler metal is based on

the thickness of the material being

welded (See chart).

Tungsten Electrodes come in a variety

of compositions and sizes. Since the

Arcitech 110 welder with WT6100 torch

is a DC TIG welder, you should use only

2% Thoriated tungsten electrodes.

These electrodes have a red

identification mark. The diameter of

the electrode is determined by the

thickness of the material being welded.

(See chart).

THE COLLET AND COLLET BODY SIZE

MUST MATCH THE DIAMETER OF

THE TUNGSTEN ELECTRODE.

Before installing the Tungsten

Electrode you must grind a point on

the welding end of the electrode. A

point of 15 - 30 degrees is desired. It is

important to grind the point with

grinding marks running lengthwise as

opposed to running the direction of

the diameter.

4

Operating Instructions

GTAW Arc Welding Torch

voltage and amperage. Follow the

specifications on the welder front

panel.

● The receptacle used for the welder

must be properly grounded and the

welder must be the only load on the

power supply circuit.

The Components of TIG

Welding (not included with

your WT6100 TIG torch) are:

1. A constant current power supply

such as the Arcitech 110 inverter

technology arc welder.

2. A bottle of 100% Argon Shielding

gas

3. An Argon regulator with proper

connections from the regulator to

the TIG torch.

4. Filler metal

5. Proper safety equipment such as a

welding helmet and gloves.

Set Up:

Torch connection to power supply - The

WT6100 torch comes with a quick

connect Dinse plug that is plugged in

to the NEGATIVE (-) receptacle on the

power supply.

The Work clamp is plugged in to the

POSITIVE (+) receptacle of the power

supply.

A beginning heat output amp setting is

selected based on the thickness of the

steel to be welded (See chart below).

www.chpower.com

Install the Tungsten Electrode in the

torch by hand tightening the collet

body first, and then the back cap.

Install the electrode so that the pointed

end sticks out past the nozzle about

3/16”.

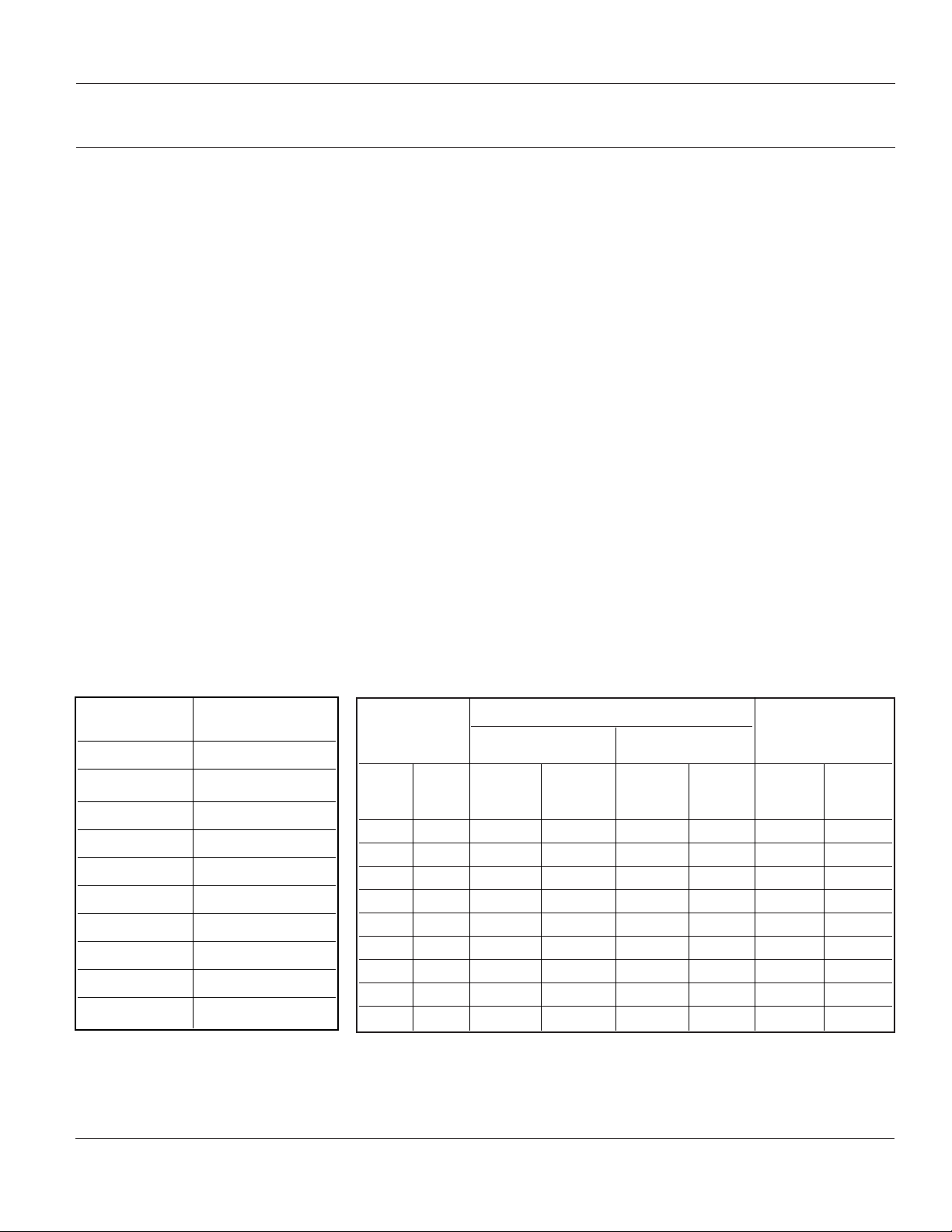

Steel Thickness Tungsten Electrode Diameter Filler Wire Diameter DC Amp

Inches Inches Millimeters Inches Millimeters Setting

.020" - .040" .020" 0.5 1/16" 1.6 2 - 20

.040" - 1/16" .040" 1 1/16" 1.6 10 - 75

1/16" - 1/8" 1/16" 1.6 1/16" 1.6 60 - 150

1/8" - 3/16" 5/64" 2 3/32" 2.4 100 - 200

3/16" - 1/4" 3/32" 2.4 1/8" 3.2 170 - 250

TIG Consumable Selection Chart

Figure 4 - Tungsten should stick out

3/16”

Figure 5- Install Back Cap

Page 5

Electrode Direct Current (amps) Alternating Current

Diameter Electrode Negative Electrode Positive (amps)

Polarity Polarity

Tungsten Tungsten Tungsten

(in) (mm) Pure with Pure with Pure with

Tungsten Oxides Tungsten Oxides Tungsten Oxides

0.02 0.5 2-20 2-20 N/A N/A 2-15 2-15

0.04 1.0 10-75 10-75 N/A N/A 15-55 15-70

1/16 1.6 40-130 60-150 10-20 10-20 45-90 60-125

5/64 2.0 75-180 100-200 15-25 15-25 65-125 85-160

3/32 2.4 130-230 170-250 17-30 17-30 80-140 120-210

1/8 3.2 160-310 225-330 20-35 20-35 150-190 150-250

5/32 4.0 275-450 350-480 35-50 35-50 180-260 240-350

3/16 5.0 400-625 500-675 50-70 50-70 240-350 330-460

1/4 6.3 550-875 650-950 65-100 65-100 300-450 430-575

Striking an arc:

Turn on the welder and the gas valves

on the gas bottle, regulator, and torch.

Rest the torch nozzle on the base

metal to be welded without the

Tungsten electrode touching the base

metal.

Rotate the torch so that the Tungsten

electrode lightly touches the base

metal and immediately lift off or rotate

off as the arc ignites.

Keep the Tungsten 1/8” - 3/16” from

the work piece while maintaining the

arc.

As the metal gets hot, it becomes a

shiny orange molten puddle. Dip the

filler metal rod in the puddle to add

filler metal.

Model WT6100

5

Pre-TIG Welding tips:

TIG welding is much harder to master

than other welding processes.

Experience welding with an OxyAcetylene (flame power) torch will help

greatly with learning TIG welding.

CLEAN the area to be welded.

Cleanliness is imperative. You can’t get

the base metal too clean. There is no

flux to float off impurities with the TIG

process.

Cut filler metal rods to shorter lengths

for easier control. Usually TIG filler

metal comes in 36” lengths. It is much

easier to handle if it is 18” or 12”. Clean

the filler metal with alcohol and a clean

white cloth. Dirt and dust contaminate

a weld.

TIG welding gives off less light than

other arc welding processes, but you

must still use a #10 minimum shade

welding lens to protect your eyes.

Get yourself into a comfortable

position to weld. Seated with your arms

supported by a welding table or by the

work-piece.

Tips while TIG welding:

Always let the filler metal rod be

melted by the molten puddle. NOT

by the torch.

Never touch the hot Tungsten

electrode to the molten puddle. The

molten steel will be wicked up by the

Tungsten, contaminating the electrode.

When you contaminate the Tungsten

with steel, stop welding and re-grind

the point of the electrode, removing

the steel contamination.

When you burn a hole through the

base metal, stop welding and let the

weld cool before re-starting the arc.

Before making an important TIG weld,

practice on a test piece. TIG welding is

an art, and practice improves quality.

There is a lot of self-satisfaction to

mastering this welding process and

seeing that perfect weld.

www.chpower.com

Identifcation

Color

Oxide

Green None

Blue 0.4% ThO

2

Yellow 1.0% ThO

2

Red 2.0% ThO

2

Violet 3.0% ThO

2

Orange 4.0% ThO

2

Brown 0.3% ZrO

2

White 0.8% ZrO

2

Black 1.0% LaO

2

Grey 2.0% CeO

2

TIG Electrode Identification Recommended TIG Parameters for Optional Electrodes

Page 6

6

www.chpower.com

Operating Instructions

AC or Alternating Current - electric

current that reverses direction periodically.

Sixty cycle current travels in both directions

sixty times per second.

Arc Length - the distance from the end

of the electrode to the point where the arc

makes contact with the work surface.

Base Metal - the material to be welded.

Butt Joint - a joint between two

members aligned approximately in the

same plane.

Crater - a pool, or pocket, that is formed

as the arc comes in contact with the base

metal.

DC or Direct Current - electric current

which flows only in one direction. The

polarity (+ or -) determines which direction

the current is flowing.

DC Reverse Polarity - occurs when the

electrode holder is connected to the

positive pole of the welding machine.

Reverse Polarity directs more heat into

melting the electrode rather then the work

piece. It is used on thinner material.

DC Straight Polarity - occurs when the

electrode holder is connected to the

negative pole of the welding machine.

With straight polarity more heat is directed

to the work piece for better penetration

on thicker material.

Electrode - a coated metal wire having

approximately the same composition as

the material being welded.

Fillet Weld - approximately a triangle in

cross-section, joining two surfaces at right

angles to each other in a lap, T or corner

joint.

Flux - a coating, when heated, that

produces a shielding gas around the

welding area. This gas protects the parent

and filler metals from impurities in the air.

Flux Cored Arc Welding (FCAW) also called Gasless, is a welding process

used with a wire-feed welding machine.

The weld wire is tubular with flux material

contained inside for shielding.

Gas Metal Arc Welding (GMAW) also called MIG, is a welding process used

with a wire feed welding machine. The

wire is solid and an inert gas is used for

shielding.

Gas Tungsten Arc Welding (GTAW)

- also called TIG, is a welding process used

with welding equipment with a high

frequency generator. The arc is created

between a non-consumable tungsten

electrode and the work piece. Filler metal

may or may not be used.

Lap Joint - a joint between two

overlapping members in parallel planes.

MIG - see Gas Metal Arc Welding.

Open Circuit Voltage (OCV) - the

voltage between the electrode and the

ground clamp of the welding machine

when no current is flowing (not welding).

The OCV determines how quickly the arc is

struck.

Overlap - occurs when the amperage is

set too low. In this instance, the molten

metal falls from the electrode without

actually fusing into the base metal.

Porosity - gas pockets, or cavities,

formed during weld solidification. They

weaken the weld.

Penetration - the depth into the work

piece that has been heat effected by the

arc during the welding process. A good

weld achieves 100% penetration meaning

that the entire thickness of the work piece

has been heated and resolidified. The heat

effected area should be easily seen on the

opposite side of the weld.

Shielded Metal Arc Welding

(SMAW) - also called Stick, is a welding

process with uses a consumable electrode

to support the arc. Shielding is achieved by

the melting of the flux coating on the

electrode.

Slag - a layer of flux soot that protects

the weld from oxides and other

contaminants while the weld is solidifying

(cooling). Slag should be removed after

weld has cooled.

Spatter - metal particles thrown from the

weld which cool and harden on the work

surface. Spatter can be minimized by using

a spatter resistant spray on the work piece

before welding.

Stick - see Shielded Metal Arc Welding.

Tack Weld - weld made to hold parts in

proper alignment until final welds are

made.

TIG - see Gas Tungsten Arc Welding.

Travel Angle - the angle of the

electrode in the line of welding. It varies

from 5º to 45º depending on welding

conditions.

T Joint - made by placing the edge of

one piece of metal on the surface of the

other piece at approximately a 90º angle.

Undercut - a condition that results when

welding amperage is too high. The

excessive amperage leaves a groove in the

base metal along both sides of the bead

which reduces the strength of the weld.

Weld Pool or Puddle - a volume of

molten metal in a weld prior to its

solidification as weld metal.

Weld Bead - a narrow layer or layers of

metal deposited on the base metal as the

electrode melts. Weld bead width is

typically twice the diameter of the

electrode.

Work Angle - the angle of the electrode

from horizontal, measured at right angles

to the line of welding.

Welding Terms

Page 7

WP17FV

7

www.chpower.com

WT6100

For Replacement Parts, Call 1-800-746-5641

Replacement Parts List

Please provide following information: Address parts correspondence to:

- Model number The Campbell Group

- Serial number (if any) Attn: Parts Department

- Part description and number as shown in parts list 100 Production Drive

Harrison, OH 45030 U.S.A.

1 1.6 mm 2% Thoriated tungsten electrode - (10 per package) WC250033AV 1

2 7/16” ID Ceramic nozzle #7 WC250123AV 1

3 1.6 mm Collet body WC250103AV 1

4 1.6 mm Collet WC250113AV 1

5 Back cup WC250130AV 1

6 Dinse connector with gas port WC250131AV 1

Ref. No Description Part Number Qty.

1

2

3

4

5

6

WP17FV

Page 8

8

www.chpower.com

1. Duration: The manufacturer warrants that it will repair, at no charge for parts or labor, Welding Torch, or Cables, proven

defective in material or workmanship, during the following time period(s) after date of original retail purchase:

90 Days: The TIG Welding Torch

2. Who Gives This Warranty (Warrantor):

Campbell Hausfeld

The Scott Fetzer Company

100 Production Drive

Harrison, OH 45030

Telephone: (513)-367-4811

3. Who Receives This Warranty (Purchaser): The original purchaser of the Campbell Hausfeld product.

4. What is covered under this warranty: Defects in material and workmanship which occur within the duration of the

warranty period. This warranty extends to the TIG Welding Torch only.

5. What is not covered under this warranty:

A. Implied warranties, including those of merchantability and FITNESS FOR A PARTICULAR PURPOSE ARE LIMITED IN

DURATION TO THIS EXPRESS WARRANTY. After this period, all risks of loss, from whatever reason, shall be on the

purchaser. Some states do not allow limitations on how long an implied warranty lasts, so above limitations may not apply

to you.

B. ANY INCIDENTAL, INDIRECT, OR CONSEQUENTIAL LOSS, DAMAGE, OR EXPENSE THAT MAY RESULT FROM ANY DEFECT

FAILURE OR MALFUNCTION OF THE CAMPBELL HAUSFELD PRODUCT. Some states do not allow limitations on how long an

implied warranty lasts, so above limitations may not apply to you.

C. This warranty does not apply to any accessory items included with the product which are subject to wear from usage; the

repair or replacement of these items shall be at the expense of the owner. These TIG items include but are not limited to;

Tungsten, Collet, Collet Body, Ceramic Nozzles. In addition, this warranty does not extend to any damage caused by the

untimely replacement or maintenance of any of the previously listed CONSUMABLE parts.

D. Any failure that results from accident, purchaser’s abuse, neglect or failure to operate products in accordance with

instructions provided in the owner’s manual(s) supplied with the product.

E. Pre-delivery service, i.e. assembly and adjustment.

7. Responsibilities of Warrantor under this warranty: Repair or replace, at Warrantor’s option, products or components

which have failed within duration of the warranty period.

8. Responsibilities of purchaser under this warranty:

A. Deliver or ship the Campbell Hausfeld product or component to Campbell Hausfeld. Freight costs, if any, must be borne by

the purchaser.

B. Use reasonable care in the operation and maintenance of the products as described in the owner’s manual(s).

9. When Warrantor will perform repair or replacement under this warranty: Repair or replacement will be scheduled

and serviced according to the normal work flow at the servicing location, and depending on the availability of replacement

parts.

This Limited Warranty gives you specific legal rights and you may also have other rights which vary from state to state.

Limited Warranty

Page 9

MÉMENTO: Gardez votre preuve datée d'achat à fin de la garantie!

Joignez-la à ce manuel ou classez-la dans un dossier pour plus de sécurité.

S’il vous plaît lire et conserver ces instructions. Lire attentivement avant de monter, installer, utiliser ou de procéder à l’entretien du produit

décrit. Se protéger ainsi que les autres en observant toutes les instructions de sécurité, sinon, il y a risque de blessure et/ou dégâts matériels!

Conserver ces instructions comme référence.

Instructions D’Utilisation Modèle WT6100

Chalumeau TIG

Description

Le chalumeau TIGWT6100 vous permet

de convertir votre soudeur à technologie

de convertisseur Arcitech 110 en soudeur

TIG (GTAW). TIG est « l'arc sous gaz

inerte avec électrode de tungstène »

(Tungsten Inert Gas). GTAW est le «

soudage à l'électrode de tungstène »

TIG s'appelle aussi couramment la

soudure Heliarc

®

, mais Heliarc®est un

nom de marque de la société Linde,

non pas une procédure. Le terme

Heliarc

®

découle de Soudure à l'arc

d'hélium, puisque l'hélium est un gaz

inerte utilisé pour garder les impuretés

loin de la soudure. La plupart de la

soudure TIG d'aujourd'hui se fait au

gaz de protection d'argon à 100 %.

La soudure TIG donne les plus belles et

les plus propres soudures avec le plus

de précision et de contrôle. C'est le

meilleur processus pour souder

ensemble les articles de tailles

différentes. Le désavantage de la

soudure TIG est qu'il faut un niveau

élevé de technique et elle est lente.

La soudure TIG est souvent utilisée pour

souder l'aluminium, mais cette soudure

sous TIG exige une source d'alimentation

en c.a. à haute fréquence. Le modèle

Arcitech 110 Campbell Hausfeld a

seulement une sortie de c.c. donc cela

ne peut pas souder d'aluminium avec

la procédure TIG.

Déballage

Lors du déballage, l’examiner

soigneusement pour rechercher toute

trace de dommage susceptible de s’être

produit en cours de transport. S’assurer

que tous raccords, vis, etc. sont serrés

avant de mettre ce produit en service.

Le porte-

électrode

est “électrisé” (porte une charge électrique)

quand le modèle est en marche (ON).

Composants du chalumeau

TIG WT6100 :

1. Électrode en tungstène thorié

2 % - 1/16 po (1,6 mm)

2. Embout no 7 utilisé avec électrode

de 1/16 po (1,6 mm)

3. Corps de la pince-barre - agencer à

la taille de l'électrode (1,6 mm)

4. Mandrin - agencer à la taille de

l'électrode (1,6 mm)

5. Isolateur

6. Tête de chalumeau

7. Soupape à gaz

8. Joints toriques (pour la soupape à

gaz et le capuchon de retour).

9. Coupelle de retour

10. Tuyau de chalumeau de 12,5 pi

(3,81 m)

11. Fiche de connexion dinse (se

connecte à la sortie négative (-) sur

le soudeur)

12. Connecteur de gaz (se connecte au

régulateur de gaz sur le réservoir

Argon à 100 %)

IN971800AV 4/03

© 2003 Campbell Hausfeld/Scott Fetzer

Figure 1 - Contrôles et composants de

soudure

Figure 2

1

2

3

4

5

6

7

8

8

9

10

Figure 3

11

12

BUILT TO LAST

!

AVERTISSEMENT

Page 10

10 - Fr

Instructions d’Utilisation

Généralités Sur La Sécurité

Danger

indique:

Ne pas suivre cet avertissement causera la

perte de vie ou blessures graves.

Avertisse-

ment

indique: Ne pas suivre cet avertissement

peut causer la perte de vie ou blessures

graves.

Attention

indique:

Ne pas suivre cet avertissement peut causer

des blessures (légères ou moyennes) ou

dommage matériel.

Remarque: Remarque indique:

Information additionnelle concernant

le produit ou son utilisation.

Toujours avoir un extincteur

d’incendie disponible pendant le

soudage à l’arc.

● Lire et comprendre toutes

instructions avant de démarrer un

soudeur à l’arc ou de procéder à son

entretien. Ne pas suivre les

précautions et instructions de

sécurité peut mener à des blessures

graves, perte de vie ou dommage

matériel. Pour plus d’information

concernant la sécurité, obtenir la

publication ANSI Standard Z49.1 Safety in Welding and Cutting.

Cette publication est disponible à

l’American Welding Society, 550

NW. LeJune Rd., Miami, FL 33135.

● Toute installation, entretien,

réparation et utilisation de cet

équipement doivent être effectués

par des personnes qualifiées

conformément aux codes

nationaux, provinciaux et locaux.

La mauvaise utilisation des

soudeurs à l’arc peut mener à

des chocs électriques, blessures,

et perte de vie ! Suivre toutes les

précautions indiquées dans ce manuel afin

de réduire le risque de choc électrique.

● S’assurer que toutes les pièces du

soudeur à l’arc sont propres et en

bon état avant d’utiliser le soudeur.

S’assurer que l’isolation sur tous les

câbles, porte-électrodes et cordons

d’alimentation n’est pas

endommagée. Toujours réparer ou

remplacer les pièces détachées qui

sont endommagées avant d’utiliser le

soudeur. Toujours maintenir les

panneaux et couvercles de soudage

en place pendant l’uilisation du

soudeur.

● Toujours porter des vêtements

protecteurs et gants de soudage secs,

et des chaussures isolantes.

● Toujours utiliser le soudeur dans un

endroit propre, sec et bien ventilé.

Ne jamais utiliser de soudeur dans un

endroit humide, trempé, pluvieux,

ou mal-ventilé.

● S’assurer que l’objet sur lequel vous

travaillez est bien fixé et mis à la

terre correctement avant de

commencer votre soudage

électrique à l’arc.

● Le câble de soudage roulé devrait

être déroulé avant l’utilisation afin

d’éviter le surchauffage et les

dommages à l’isolation.

Ne jamais immerger l'électrode ou le

chalumeau dans l'eau. Si le soudeur devient

trempé, il est nécessaire qu’il soit

complètement sec et propre avant

l’utilisation !

● Toujours mettre l’équipement hors

circuit et le débrancher avant de le

déplacer.

● Toujours brancher d’abord le

conducteur de terre.

● Vérifier que l’objet sur lequel vous

travaillez soit mis à la terre

correctement.

● Toujours mettre l’équipement de

soudage électrique à l’arc hors

circuit s’il n’est pas utilisé et enlever

l’électrode du porte-électrode.

● Ne jamais permettre que votre corps

touche l’électrode et le contact à la

terre, ou l’objet sur lequel vous

travaillez en même temps.

● Les conditions et positions de

soudage difficiles peuvent poser des

risques électriques. Si vous êtres

accroupis, à genoux ou surélevé,

s’assurer que toutes les pièces

conductrices sont isolées. Porter des

vêtements protecteurs convenables

et prendre des précautions contre

les chutes.

● Ne jamais essayer d’utiliser cet

équipement aux réglages de

courant ou facteurs d’utilisation

plus hauts que ceux indiqués sur les

étiquettes de l’équipement.

● Ne jamais utiliser de soudeur

électrique à arc pour dégeler les

tuyaux congelés.

Les étincelles volantes et le

métal chaud peuvent causer des

blessures. La scorie peut s’échapper quand

les soudures refroidissent. Prendre toutes

les précautions indiquées dans ce manuel

pour réduire la possibilité de blessure par

les étincelles volantes et le métal chaud.

● Porter un masque de soudure

approuvé par ANSI ou des lunettes

protectrices avec écrans protecteurs

latéraux pendant le burinage ou

l’ébarbage des pièces en métal.

● Utiliser des protège-tympans pour le

soudage aérien afin d’éviter que la

scorie ou la bavure tombe dans les

oreilles.

Le soudage électrique à l’arc

produit une lumière intense, de

la chaleur et des rayons

ultraviolets (UV). Cette lumière intense et

ces rayons UV peuvent causer des blessures

aux yeux et à la peau. Prendre toutes les

précautions indiquées dans ce manuel afin

de réduire la possibilité de blessure aux

yeux et à la peau.

● Toutes les personnes qui utilisent

cet équipement ou qui sont sur

place pendant l’utilisation de

l’équipement doivent porter des

vêtements de soudage protecteurs y

compris: masque ou casque de

soudeur ou écran avec filtre indiqué

sur le tableau suivant, vêtements

incombustibles, gants de soudeur en

cuir, et protection complète pour les

pieds.

Ne jamais

observer le

soudage sans protection pour les yeux

indiqué ci-dessus. Ne jamais utiliser de

lentille filtrante fendue, cassée, ou classifiée

Chalumeau de soudure à l’arc GTAW

Courant Lentille

(Amps) Filtrante

Jusqu’à 160 Amps 10

160 À 250 Amps 12

!

DANGER

!

AVERTISSEMENT

!

ATTENTION

!

AVERTISSEMENT

!

AVERTISSEMENT

!

DANGER

!

AVERTISSEMENT

!

AVERTISSEMENT

!

AVERTISSEMENT

Page 11

11 - Fr

moins que 10. Avertir les autres personnes

sur place de ne pas regarder l’arc.

Le soudage électrique à l’arc

produit des étincelles et chauffe

le métal à des températures qui

peuvent causer des brûlures graves !

Utiliser des gants et des vêtements

protecteurs pendant tout travail de métal.

Prendre toutes les précautions indiquées

dans ce manuel afin de réduire la possibilité

de brûlures de peau ou de vêtements.

● S’assurer que toutes les personnes à

l’endroit du soudage sont protégés

contre la chaleur, les étincelles et les

rayons ultraviolets. Utiliser des

masques additionnels et des écrans

coupe-feu au besoin.

● Ne jamais toucher les objets de travail

avant qu’ils ne refroidissent

complètement.

La chaleur et les étincelles

produites pendant le soudage

électrique à l’arc et autres

travaux de métal peuvent allumer les

matériaux inflammables et explosifs!

Prendre toutes les précautions indiquées

dans ce manuel afin de réduire la possibilité

de flammes et d’explosions.

● Enlever tous les matériaux

inflammables à moins de 35 pieds

(10,7 mètres) de l’arc de soudage. Si

ceci n’est pas possible, couvrir les

matériaux inflammables avec des

couvertures incombustibles.

● Ne pas utiliser de soudeur électrique

à l’arc dans les endroits qui

contiennent des vapeurs

inflammables ou explosifs.

● Prendre des précautions pour

s’assurer que les étincelles volantes

et la chaleur ne produisent pas de

flammes dans des endroits cachés,

fentes, derrière les

cloisons, etc.

Risque d’incendie! Ne pas

souder les récipients ou tuyaux

qui contiennent ou ont contenu des

matériaux inflammables ou combustibles

gazeux ou liquides.

Le soudage à l’arc des cylindres

ou récipients fermés tels que les réservoirs

ou bidons peuvent causer une explosion

s’ils ne sont pas bien ventilés ! Vérifier qu’il

y a un trou de ventilation suffisant dans

tout cylindre ou récipient pour permettre la

ventilation des gaz en expansion.

Ne pas inspirer les vapeurs

produites par le soudage à l’arc.

Ces vapeurs sont dangereuses.

Utiliser un respirateur si l’endroit de

soudage n’est pas bien ventilé.

● Tenir la tête et le visage hors des

vapeurs de soudage.

● Ne pas faire de soudage électrique à

l’arc sur les métaux qui sont

galvanisés ou plaqués en cadmium,

ou qui contiennent du zinc, du

mercure, ou du beryllium sans suivre

les précautions suivantes :

a. Enlever l’enduit du métal

commun.

b. S’assurer que l’endroit de

soudage est bien ventilé.

c. Utiliser un respirateur à air fourni.

Des vapeurs extrêmement toxiques

sont produites pendant le chauffage

de ces métaux.

Le champ électro-magnétique

produit pendant le soudage à

l’arc peut causer de

l’interférence avec le fonctionnement de

plusieurs appareils électriques tels que les

pacemakers cardiaques. Toutes les

personnes qui utilisent ces appareils

doivent consulter leur médecin avant tout

soudage électrique à l’arc.

● Acheminer l’électrode et les câbles

ensemble et les fixer avec du ruban

adhésif si possible.

● Ne jamais enrouler les câbles de

soudage à l’arc autour du corps.

● Toujours placer l’électrode et les

conducteurs de terre afin qu’ils

soient sur le même côté du corps.

● L’exposition aux champs électromagnétiques peut provoquer

d’autres réactions inconnues en

matière de santé.

Toujours laisser l’endroit de soudage sûr et

sans risques (étincelles, flammes, métal

chauffé au rouge ou scorie). S’assurer que

l’équipement est hors circuit et que

l’électrode est enlevée. S’assurer que les

câbles sont roulés (sans serrer) et hors du

chemin. S’assurer que tout métal et scorie

sont refroidis.

NORMES DE SÉCURITÉ ADDITIONNELLES

Norme ANSI Z49.1 de l’ American

Welding Society, 550 N.W. LeJune Rd.

Miami, FL 33126

Safety and Health Standards

(Normes de Sécurité et de Santé)

OSHA 29 CFR 1910, du Superintendent

of Documents, U.S. Government

Printing Office, Washington, D.C. 20402

National Electrical Code (Code

Électrique National)

Norme NFPA 70, du National Fire

Protection Association, Batterymarch

Park, Quincy, MA 02269

Safe Handling of Compressed Gases in

Cylinders (Manipulation Sûr des Gaz

Comprimés en Cylindres)

CGA Pamphlet P-1, du Compressed Gas

Association, 1235 Jefferson Davis

Highway, Suite 501, Arlington, VA 22202

Code for Safety in Welding and Cutting

(Code de Sécurité pour le Soudage et le

Coupage)

Norme CSA W117.2, de l’Association

canadienne de normalisation,

Standards Sales, 178 Rexdale Boulevard,

Rexdale, Ontario, Canada M9W 1R3

Cutting And Welding Processes

(Procédés de Coupage et de Soudage)

Norme NFPA 51B, du National Fire

Protection Association, Batterymarch

Park, Quicy, MA 02269

Safe Practices For Occupational And

Educational Eye And Face Protection

(Règlements Professionnels et

D’Éducation de Sécurité pour la

Protection des Yeux et du Visage)

Norme ANSI Z87.1, de l’American

National Standards Institute, 1430

Broadway, New York, NY 10018

Se référer aux Material Safety Data

Sheets (fiches de sécurité) et aux

instructions du fabricant pour les

métaux, électrodes, enduits et produits

pour le nettoyage.

Installation

EMPLACEMENT

Le choix d’un bon endroit peut

améliorer le rendement, le

Modèle WT6100

!

AVERTISSEMENT

!

AVERTISSEMENT

!

AVERTISSEMENT

!

AVERTISSEMENT

!

AVERTISSEMENT

!

AVERTISSEMENT

!

AVERTISSEMENT

Page 12

fonctionnement et la durée de vie utile

du soudeur à l’arc.

● Pour un meilleur résultat, placer le

soudeur dans un endroit propre et

sec. Éviter les endroits qui sont

exposés aux températures hautes, à

une humidité élevée, à la poussière

et aux vapeurs corrosives.

L’humidité élevée produit de la

condensation sur les pièces

électriques. L’humidité peut

contribuer à la corrosion et causer

un court-circuit dans les pièces

électriques. La poussière et la sâleté

dans le soudeur conservent

l’humidité et augmentent l’usure

des pièces mobiles.

● Choisir un endroit pour le soudeur

qui fournit au moins douze po (305

mm) d’espace de ventilation en avant

et en arrière du modèle. Ne pas

obstruer cet espace de ventilation.

● Ranger les électrodes et le métal de

remplissage dans un endroit propre

et sec à faible humidité.

● Le panneau de contrôle du soudeur

contient de l’information sur la

bonne tension et le bon ampérage.

Suivre les spécifications sur le

panneau avant du soudeur.

● La prise de courant utilisée pour le

soudeur doit être mise à la terre

correctement et le soudeur doit

être le seul appareil de charge sur le

circuit.

Les composants de soudure

TIG (non inclus avec votre

chalumeau TIG WT6100) sont :

1. Une alimentation de courant

constante telle que la technologie

de convertisseur du soudeur à l'arc

Arcitech 110.

2. Une bonbonne de gaz de

protection d'argon à 100 %

3. Un régulateur d'argon à bonnes

connexions du régulateur au

chalumeau TIG.

4. Métal de remplissage

5. Équipe de sécurité approprié comme

des gants et un casque de soudure.

Installation :

Connexion du chalumeau à

l'alimentation de courant - Le

chalumeau WT6100 est fourni avec

une fiche de connexion rapide dinse

brochée dans une prise NÉGATIVED (-)

sur l'alimentation de courant.

La pince de travail est branchée dans

une fiche POSITIVE (+) d'alimentation

de courant.

Un réglage de début de sortie

d'ampères thermique est choisie selon

l'épaisseur d'acier à souder (voir le

tableau plus bas).

Le gaz de protection d'argon à 100 %

est raccordé au chalumeau à une

vitesse régulée de 15 à 30 pieds cubes

par heure (p

3

/h). Si vous avez trop peu

de gaz, vous verrez de la porosité sur

votre soudure. Trop de débit est une

perte de gaz.

Le métal de remplissage s'applique à la

soudure TIG manuelle tout comme

pour la soudure oxyacéthylénique

(puissance de la flamme). Le métal de

remplissage doit être assorti au métal

que vous soudez. Pour souder l'acier

doux, utilisez un baguette d'acier non

revêtue comme un fil MIG E70S-6,

Welco W-1200, AWS A5.2-69, catégorie

RG60. Le diamètre du métal de

remplissage s'appuie sur l'épaisseur du

matériau à souder (voir le tableau).

Les électrodes de tungstène sont

fournies en une gamme de

compositions et de tailles. Puisque le

soudeur Arcitech 110 à chalumeau

WT6100 est un soudeur TIG à c.c., vous

devriez utiliser seulement des

électrodes de tungstène thorié à 2 %.

Ces électrodes ont une marque

d'identification rouge. Le diamètre de

l'électrode est déterminé par

l'épaisseur du matériau à souder (voir

le tableau).

LA TAILLE DE LA PINCE-BARRE ET

DU CORPS DE LA PINCE-BARRE

DOIVENT ÊTRE ASSORTIS AU

DIAMÈTRE DE L'ÉLECTRODE DE

TUNGSTÈNE.

Avant d'installer l'électrode de

tungstène, vous devez rectifier une

pointe de l'extrémité de soudure de

l'électrode. Une pointe de 15 à 30

degrés est préférable. Il est important

de rectifier la pointe avec des marques

de meule le long de la longueur plutôt

qu'en direction du diamètre.

Installez l'électrode de tungstène dans

le chalumeau en resserrant à la main

d'abord le corps du pince-barre et

ensuite le capuchon de retour. Installez

l'électrode pour que l'extrémité

pointue sorte de l'embout, soit environ

3/16 po.

Conseils de soudure pré-TIG:

La soudure TIG est beaucoup plus

difficile à maîtriser que toute autre

procédure de soudure. Une expérience

de soudure avec un chalumeau

d'oxyacétylénique (puissance de

flamme) aidera beaucoup à apprendre

la soudure TIG.

NETTOYEZ l'endroit à souder. Il est

impératif que l’endroit soit propre. Il

12 - Fr

Chalumeau de soudure à l’arc GTAW

Instructions D’Utilisation

Épaisseur d’acier Diamètre d’électrode de tungstène Diamètre de fil de remplissage Amp c.c.

Pouces Pouces Millimètres Pouces Millimètres Réglage

.020" - .040" .020" 0.5 1/16" 1.6 2 - 20

.040" - 1/16" .040" 1 1/16" 1.6 10 - 75

1/16" - 1/8" 1/16" 1.6 1/16" 1.6 60 - 150

1/8" - 3/16" 5/64" 2 3/32" 2.4 100 - 200

3/16" - 1/4" 3/32" 2.4 1/8" 3.2 170 - 250

Tableau de sélection de biens consommables TIG

Page 13

13 - Fr

Modèle WT6100

est impossible d'avoir un métal de base

trop propre. Il n'y a aucun flux pour

enlever par flottement avec la

procédure TIG.

Couper les tiges de métal de remplissage

pour avoir des longueurs plus courtes

pour faciliter le contrôle. Le métal de

remplissage TIG est normalement fourni

en longueurs de 36 po (91,44 cm). Il est

plus facile de manipuler le métal s'il est

de 18 (45,7 cm) ou 12 po (30,48 cm).

Nettoyer le métal de remplissage avec

de l'alcool et un chiffon blanc propre.

La poussière et la saleté contaminent

une soudure.

La soudure TIG produit moins de

lumière que d'autres processus de

soudure à l'arc, mais vous devez quand

même utiliser une lentille de soudure

minimum #10 pour protéger vos yeux.

Choisir une position confortable pour la

soudure, assis, les bras supportés par

une table de soudure ou par la pièce de

travail.

Amorçage d’arc :

Mettre le soudeur en marche et les

soupapes de gaz sur la bonbonne de

gaz, le régulateur et le chalumeau.

Reposer l'embout du chalumeau sur le

métal de base à souder sans que

l'électrode de tungstène ne touche le

métal de base.

Tourner le chalumeau pour que

l'électrode de tungstène touche

délicatement le métal de base et retirer

immédiatement ou tourner pour

couper lorsque l'arc s'allume.

Garder le tungstène de 1/8 à 3/16 po

(0,31 à 0,47 cm) de la pièce de travail

Figure 4 - Tungstène doit sortir de

3/16 po

Figure 5- Installaton de coupelle de

retour

Identifcation

couleur

Oxyde

Vert None

Bleu 0.4% ThO

2

Jaune 1.0% ThO

2

Rouge 2.0% ThO

2

Violet 3.0% ThO

2

Orange 4.0% ThO

2

Brun 0.3% ZrO

2

Blanc 0.8% ZrO

2

Noir 1.0% LaO

2

Grus 2.0% CeO

2

Identification de l'électrode TIG

Paramètres TIG recommandés pour les électrodes optionnelles.

Diamètre Courant direct (amps) Courant alternatif

d’électrode Électrode Négative Électrode positive (amps)

Polarité Polarité

Tungstène Tungstène Tungstène

(in) (mm) Pure avec Pure avec Pure avec

Tungstène Oxydes Tungstène Oxydes Tungstène Oxydes

0.02 0.5 2-20 2-20 N/D N/D 2-15 2-15

0.04 1.0 10-75 10-75 N/D N/D 15-55 15-70

1/16 1.6 40-130 60-150 10-20 10-20 45-90 60-125

5/64 2.0 75-180 100-200 15-25 15-25 65-125 85-160

3/32 2.4 130-230 170-250 17-30 17-30 80-140 120-210

1/8 3.2 160-310 225-330 20-35 20-35 150-190 150-250

5/32 4.0 275-450 350-480 35-50 35-50 180-260 240-350

3/16 5.0 400-625 500-675 50-70 50-70 240-350 330-460

1/4 6.3 550-875 650-950 65-100 65-100 300-450 430-575

tout en maintenant l'arc.

Au fur et à mesure où le métal devient

chaud, il se transforme en flaque de

fusion orange brillant. Tremper la tige

de métal de remplissage dans la flaque

pour ajouter le métal de remplissage.

filler metal.

Conseils de soudure TIG :

Toujours laisser la baguette de

métal de remplissage à faire fondre

par la flaque de fusion. NON par le

chalumeau.

Ne jamais toucher l'électrode de

tungstène chaude sur la flaque de

fusion. L'acier en fusion sera saisi par

le tungstène ce qui contaminera

l'électrode.

Lorsque vous contaminez le tungstène

avec l'acier, cesser de souder et rectifier

la pointe de l'électrode en retirant la

contamination de l'acier.

Lorsque vous brûlez un trou par le

métal de base, cesser de souder et

laisser la soudure refroidir avant de

relancer l'arc.

Avant toute soudure TIG importante,

pratiquer sur une pièce d'essai. La

soudure TIG est un art et la pratique

améliore la qualité. Il y a beaucoup

d'autosatisfaction dans la maîtrise de

cette procédure de soudure et dans la

vue d'une soudure parfaite.

Page 14

14 - Fr

Instructions D’Utilisation

Courant Alternatif ou c.a. - courant

électrique qui change de direction

périodiquement. Le courant à soixante

cycles voyage dans les deux directions

soixante fois par seconde.

Longueur de L’Arc - La distance du

bout de l’électrode jusqu’au point où l’arc

contacte la surface de travail.

Métal Commun - le matériel qui doit

être soudé.

Joint en Bout - un joint entre deux

pièces qui sont alignées

approximativement dans le même plan.

Cratère - une flaque ou poche qui est

produite quand l’arc contacte le métal.

Courant Continu ou c.c. - courant

électrique d’une direction seulement. La

polarité (+ ou -) détermine la direction du

courant.

Polarité Inversée c.c. - quand le porteélectrode est branché au pôle positif du

soudeur. La Polarité Inversée dirige plus de

chaleur dans l’électrode plutôt que sur

l’objet de travail pour l’utilisation sur les

matériaux plus minces.

Polarité Ordinaire c.c. - quand le

porte-électrode est branché au pôle

négatif du soudeur. Plus de chaleur est

dirigé vers l’objet de travail pour meilleur

pénétration des matériaux épais.

Électrode - un fil en métal enrobé ayant

approximativement la même composition

du matériel qui doit être soudé.

Soudure en Cordon - dimension

approx. d’un triangle, profil en travers, qui

uni les deux surfaces à angles droits en

soudure à recouvrement, en T ou en coin.

Flux - un enduit qui produit un gaz

protecteur autour de l’endroit de soudage.

Ce gaz protège les métaux contre les

polluants dans l’air.

Soudure À L’Arc Fourré de Flux - ou

Sans-gaz est une méthode de soudage

utilisée avec un soudeur à alimentation en

fil. Le fil de soudage est tubulaire avec du

flux à l’intérieur pour protection.

Soudure À L’arc au chalumeau - est

une méthode utilisée avec un soudeur à

alimentation en fil. Le fil est solide et un

gaz inerte est utilisé pour protection.

Soudure À L’Arc Tungstène au

chalumeau - est une méthode de

soudage utilisée avec de l’équipement de

soudage qui a une génératrice à haute

fréquence. L’arc est crée entre un

électrode tungstène non-usable et l’objet

de travail. Du bouche-pores peut être

utilisé.

Soudure à Recouvrement - un joint

entre deux pièces en chevauchement.

MIG - voir « soudage à l'arc sous gaz avec

fil plein ».

Tension au Repos - la tension entre

l’électrode et le collier de mise à la terre du

soudeur quand il n’y a pas de flux de

courant (pas de soudage). Ceci détermine

la vitesse auquelle l’arc est amorcé.

Chevauchement - se produit quand

l’ampérage est trops basse. En ce cas, le

métal fondu tombe de l’électrode sans se

fusant dans le métal commun.

Porosité - des soufflures, ou creux

formés pendant la solidification de la

soudure qui affaiblissent la soudure.

Pénétration -la profondeur que la

chaleur affecte l’objet pendant la soudure.

Une soudure de haute qualité est celle qui

atteint une pénétration de 100%. C’est à

dire que l’objet de travail en entier a été

chauffé et solidifié à nouveau. Les endroits

affectés par la chaleur devraient être

visibles sur le sens inverse de la soudure.

Soudure À L’Arc Au Métal Enrobé -

est une méthode de soudage qui utilise

une électrode usable pour soutenir un arc.

L’enduit de flux fondu sur l’électrode

fournit la protection.

Scorie - une couche d’encrassement de

flux qui protège la soudure des oxydes et

autres polluants pendant le

refroidissement de la soudure. Enlever la

scorie après que la soudure s’est refroidie.

Bavure - particules métalliques volantes

qui se refroidissent sur la surface de travail.

La bavure peut être diminuée si vous

utilisez un agent vaporisateur qui résiste la

bavure sur l’objet de travail avant de

souder.

Baguette - voir « soudage à l'arc avec

électrode enrobée »

Point de Soudure - une soudure

utilisée pour tenir les pièces en alignement

jusqu’à ce que les soudures actuelles sont

faites.

TIG - voir « soudage à l'électrode de

tungstène ».

L’Angle de Déplacement - l’angle de

l’électrode dans la ligne de soudure.Ceci

est variable, de 5º à 45º selon les

conditions.

Joint en T - placer le bord d’un morceau

de métal sur l’autre à un angle de 90º.

Caniveau - une condition résultant d’un

ampérage trops haut qui produit une

rainure dans le métal commun le long des

deux côtés du cordon de soudure et sert à

afaiblir la soudure.

Flaque de Soudure - un volume de

métal fondu dans une soudure avant son

soldification.

Cordon de Soudage - une couche(s)

étroite de métal placé sur le métal

commun pendant que l’électrode fond. Le

cordon de soudage est typiquement deux

fois le diamètre de l’électrode.

Angle de Travail - l’angle de l’électrode

à angle droit de la ligne de soudure.

electrode.

Lexique De Termes De Soudage

Page 15

15 - Fr

WP17FV

WT6100

Pour Pièces de Rechange, appeler 1-800-746-5641

Liste de Pièces de Rechange

S’il vous plaît fournir l’information suivante:

Correspondence:

- Numéro du modèle

The Campbell Group

- Numéro de série (si présent)

Attn: Parts Department

-

Description de la pièce et son numéro sur la liste de pièces 100 Production Drive

Harrison, OH 45030 U.S.A.

1 1,6 mm 2 % électrode de tungstène thorié - (10 par paquet) WC250033AV 1

2 11,1 mm (7/16 po) DI de l'embout de céramique no 7 WC250123AV 1

3 1,6 mm corps de pince-barre WC250103AV 1

4 Mandrin 1.6 mm WC250113AV 1

5 Coupelle de retour WC250130AV 1

6 Fiche de connexion dinse avec port de gaz WC250131AV 1

Node

Ref. Description Numéro de Pièce Qté.

1

2

3

4

5

6

WP17FV

Page 16

16 - Fr

Instructions D’Utilisation

1. Durée : Le fabricant garantit la réparation sans frais pour les pièces ou la main d’oeuvre du chalumeau de soudure ou des

câblesqui s’avèrent défectueux au niveau des matériaux ou de la fabrication durant la période suivante après la date

d’achat au détail original :

90 jours: le chalumeau de soudure TIG

2. Garantie Accordée Par (Garant) :

Campbell Hausfeld

The Scott Fetzer Company

100 Production Drive

Harrison, OH 45030

Telephone: (513)-367-4811

3. Bénéficiaire De Cette Garantie (Acheteur) : L’acheteur initial du produit Campbell Hausfeld .

4. Couverture De La Présente Garantie : Défauts de matière et de fabrication qui se révèlent pendant la période de

validité de la garantie. Cette garantie ne couvre que le chalumeau TIG.

5. La Présente Garantie Ne Couvre Pas :

A. Les garanties implicites, y compris celles de commercialisabilité et D’ADAPTION À UNE FONCTION PARTICULIÈRE SONT

LIMITÉES EN DURÉE À CETTE GARANTIE. Après cette durée, tout risques de perte, quoi que ce soit, devient la

responsabilité de l’acheteur. Certaines Provinces n’autorisent pas de limitations de durée pour les garanties implicites. Les

limitations précédentes peuvent donc ne pas s’appliquer.

B. TOUT DOMMAGE, PERTE OU DÉPENSE FORTUIT OU INDIRECT POUVANT RÉSULTER DE TOUT DÉFAUT, PANNE OU

MAUVAIS FONCTIONNEMENT DU PRODUIT CAMPBELL HAUSFELD. Certaines Provinces n’autorisent pas l’exclusion ni la

limitation des dommages fortuits ou indirects. La limitation ou exclusion précédente peut donc ne pas s’appliquer.

C. Les accessoires qui sont compris avec le produit et qui sont soumis à l’usure par l’usage normal; la réparation ou le

remplacement de ces objets sont la responsabilité de l’acheteur. Ces pièces TIG comprennent, mais ne sont pas limités à;

Tungstène, pince-barre, corps de pince-barre, embouts de céramique. Additionnellement, cette garantie ne comprend pas

le dommage causé par le remplacement ou entretien prématuré des pièces USABLES précédentes.

D. Toute panne résultant d’un accident, d’une utilisation abusive, de la négligence ou d’une utilisation ne respectant pas les

instructions données dans le(s) manuel(s) accompagnant le produit.

E. Service avant livraison, i.e. montage et ajustement.

7. Responsabilités Du Garant Aux Termes De Cette Garantie : Réparation ou remplacement, au choix du Garant, des

produits ou pièces qui se sont révélés défectueux pendant la durée de validité de la garantie.

8. Responsibilités De L’Acheteur Aux Termes De Cette Garantie :

A. Livraison ou expédition du produit ou pièce Campbell Hausfeld à Campbell Hausfeld. Taux de frais , si applicable, sont la

responsabilité de l’acheteur.

B. Utilisation et entretien du produit avec un soin raisonable, ainsi que le décri(vent)t le(s) mnuel(s) d’utilisation.

9. Réparation ou Remplacement Effectué Par Le Garant Aux Termes De La Présente Garantie : La réparation ou le

remplacement sera prévu et exécuté en fonction de la charge de travail dans le centre d’entretien et dépendra de la

disponibilité des pièces de rechange.

Cette garantie limitée confère des droits précis. L’acheteur peut également jouir d’autres droits qui varient d’une Province à

l’autre.

Garantie Limitée

Page 17

RECORDATORIO: ¡Guarde su comprobante de compra con fecha para fines de la garantía!

Adjúntela a este manual o archívela en lugar seguro.

Sírvase leer y guardar estas instrucciones.Lea con cuidado antes de tratar de armar, instalar, manejar o darle servicio al producto descrito en

este manual. Protéjase Ud. y a los demás observando todas las reglas de seguridad. El no seguir las instrucciones podría resultar en heridas y/o

daños a su propiedad.Guarde este manual como referencia.

IN971800AV 4/03

Manual de instrucciones Modelo WT6100

Soplete TIG

Descripción

El soplete TIG WT6100 le permite

convertir su soldadora Arcitech 110 de

tecnología de inversión a una

soldadora TIG (GTAW). TIG (por su sigla

en inglés) significa gas inerte de

tungsteno. GTAW (por su sigla en

inglés) significa soldadora de arco con

gas tungsteno. TIG también se

denomina comúnmente soldadura

Heliarc

®

, pero Heliarc®es un nombre de

marca de Linde Company, no es un

proceso. Heliarc

®

deriva de soldadura

de arco con helio, pues el helio es un

gas inerte que se utiliza para evitar las

impurezas en la soldadura.

Actualmente la mayoría de las

soldaduras TIG se realizan con gas de

protección argón al 100%.

La soldadura TIG ofrece una de las

soldaduras más hermosas y limpias con

la mayor precisión y control. Es el mejor

proceso para soldar entre sí artículos de

tamaños diferentes. El inconveniente

de la soldadura TIG es que requiere un

alto nivel de experiencia y es lenta.

Frecuentemente la soldadura TIG

utiliza aluminio para soldar, sin

embargo, la soldadura de aluminio con

TIG requiere una fuente de energía de

CA de alta frecuencia. La soldadora

Campbell Hausfeld Arcitech 110 tiene

salida sólo para CC, por lo tanto no

puede soldar con aluminio usando el

proceso TIG.

Para desempacar

Al desempacar este producto, revíselo

con cuidado para cerciorarse de que

esté en perfecto estado. Igualmente,

cerciórese de apretar todos los pernos,

tuercas y conexiones antes de usarlo.

La pinza

que

sostiene el electrodo tiene “tensión”

(podría conducir electricidad) mientras la

máquina está encendida.

Componentes del soplete

TIG WT6100:

1. Electrodo de tungsteno toriado al

2% - 1,6 mm (1/16")

2. Boquilla Nº7 para usar con el

electrodo de 1,6 mm (1/16")

3. Cuerpo de la boquilla - corresponde

con el tamaño del electrodo (1,6mm)

4. Casquillo - corresponde con el

tamaño del electrodo (1,6 mm)

5. Aislante

6. Cabeza del soplete

7. Válvula de gas

8. Anillos en O (para la válvula de gas

y el capuchón trasero)

Figura 1 - Componentes y controles de la

soldadora

© 2003 Campbell Hausfeld/Scott Fetzer

Figura 2

1

2

3

4

5

6

7

8

8

9

10

Figura 3

11

12

BUILT TO LAST

!

ADVERTENCIA

Page 18

9. Capuchón trasero

10. Manguera del soplete de 31,7 cm

(12,5 pies)

11. Conector de energía con enchufe

Dinse (se conecta a la salida negativa

(-) en la soldadora)

12. Conector de gas (se conecta al

regulador de gas en el tanque de

argón al 100%)

Informaciones Generales de

Seguridad

Esto le

indica una

situación que le ocasionará heridas graves o

la muerte si ignora lo advertido.

Esto le

indica una

situación que podría ocasionarle heridas

graves o la muerte si ignora lo advertido.

Esto le

indica una

situación que puede ocasionarle heridas si

ignora lo advertido. También le puede

indicar una situación que ocasionaría daños

a su propiedad sólamente.

Nota: le indica cualquier otra

información adicional en relación al

producto o su uso adecuado.

Siempre mantenga un

extingidor de incendio accesible

cuando esté soldando con arcos eléctricos.

● Antes de encender o darle servicio a

las soldadoras eléctricas de arco,

debe leer y comprender todas las

instrucciones. El no seguir las

advertencias o instrucciones que le

damos en este manual le podría

ocasionar daños al equipo, y/o

heridas graves e inclusive la muerte.

Para recibir mayor información,

solicite una copia del estándard

Z49.1 de la ANSI Titulado Seguridad al soldar y cortar. Esta

publicación la puede ordenar (en

inglés) a la American Welding

Society, 550 NW. LeJune Rd., Miami,

FL 33135.

● La instalación, mantenimiento,

reparación y operación de esta

soldadora debe ser hecho por una

persona calificada según los códigos

nacionales, estatales y locales.

!El uso inadecuado de

soldadoras eléctricas de arco

podría ocasionarle

electrocutamiento, heridas y la muerte!

Siguiendo nuestras advertencias reduciría

las posibilidades de electrocutamiento.

● Cerciórese de que todos los

componentes de la soldadora de

arco estén limpios y en buen estado

antes de utilizarla. Cerciórese de que

los aislantes en todos los cables,

pinzas para sostener electrodos y

cordones eléctricos no estén

dañados. Siempre repare o

reemplace las piezas dañadas antes

de utilizar la soldadora. Siempre

mantenga todas las tapas de la

soldadora en su lugar mientras la

esté utilizando.

● Siempre use ropa adecuada y que

esté seca, guantes para soldadores y

zapatos aislantes.

● Use la soldadora sólo en áreas

limpias, secas y bien ventiladas. No

la use en áreas húmedas, mojadas, a

la intenperie o que no estén bien

ventiladas.

● Antes de comenzar a soldar

cerciórese de que la pieza esté bien

fija y conectada a tierra.

● Debe desenrollar el cable para

soldar para evitar que se sobrecaliente y se le dañe el forro aislante.

Nunca

sumerja el

electrodo ni el soplete en agua. Si la

soldadora se moja por cualquier motivo,

¡cerciórese de que esté completamente seca

antes de tratar de usarla!

● Antes de tratar de tratar de moverla

a otro sitio siempre apáguela y

desconéctela.

● La conexión a tierra debe hacerse de

último.

● Cerciórese de que la conexión a

tierra esté bien hecha.

● Siempre apague la soldadora y

sáquele el electrodo cuando no esté

trabajando.

● Nunca toque el electrodo y la tierra

o pieza conectada a tierra al mismo

tiempo.

● Las posiciones poco comunes le

pueden ocasionar peligro de

electrocutamiento. Al estar en

cuclillas, arrodillado o en alturas,

cerciórese de aislar todas las piezas

que puedan conducir electricidad,

use ropa adecuada par soldar y

tome precauciones para no caerse.

● Nunca trate de usar este equipo con

corrientes eléctricas o ciclajes

diferentes a los especificados en las

etiquetas.

● Nunca use una soldadora eléctrica

para descongelar tuberías que se

hayan congelado.

Las chispas y el metal caliente le

pueden ocasionar heridas.

Cuando la pieza que soldó se enfrie la

escoria podría despegarse. Tome todas las

precauciones descritas en este manual para

reducir las posibilidades de que sufra

heridas por estas razones.

● Sólo use máscaras aprobadas por la

organización norteamericana ANSI o

anteojos de seguridad con

protección lateral al tratar de cortar

o esmerilar piezas de metal.

● Si va a soldar piezas que estén por

encima de usted debe protegerse los

oidos para evitar que le caigan

residuos adentro.

Al soldar con arcos eléctricos

se producen luces intensas,

calor y rayos ultravioletas.

Estos le podrían ocasionar

heridas en la vista y la piel. Tome todas las

medidas de precaución descritas en este

manual para reducir las posibilidades de

heridas en la vista o la piel.

● Todos los operadores o personas

que se encuentren en el área de

trabajo mientras estén usando el

equipo deben usar la vestimenta

adecuada incluyendo: máscara de

soldador con los niveles de

oscuridad especificados en la tabla a

continuación, ropa resistente al

fuego, guantes de cuero para soldar

y zapatos de protección.

18 - Sp

Manual de instrucciones

Soplete de soldadura por arco GTAW

!

PELIGRO

!

ADVERTENCIA

!

PRECAUCION

!

ADVERTENCIA

!

ADVERTENCIA

!

PELIGRO

!

ADVERTENCIA

!

ADVERTENCIA

Page 19

Hasta 160 Amps 10

de 160 a 250 Amps 12

Nunca

mire

hacia el área donde esté soldando sin

protegerse la vista tal como se ha descrito

anteriormente. Nunca use lentes oscuros

que estén partidos, rotos o de un número

menor a 10. Debe advertirle a otras personas

en el área que no deben mirar el arco.

Al soldar con arcos eléctricos

puede causar chispas y calentar

el metal a temperaturas que le

podrían ocasionar quemaduras graves! Use

guantes y ropa de protección para hacer

este tipo de trabajo. Tome todas las

medidas de precaución descritas en este

manual para reducir las posibilida-des de

quemarse la piel o la ropa.

● Cerciórese de que todas la personas

que se encuentren en el área de

trabajo estén protegidas contra el

calor, las chispas, y los rayos

ultravioletas. Igualmente debe

utilizar protecciones adicionales

cuando sea necesario.

● Nunca toque las piezas que ha

soldado hasta que éstas se hayan

enfriado.

El calor y las chis-pas producidas

al soldar con arcos eléctricos y

otros trabajos con metales

podrían encender materiales inflamables o

explosivos! Tome todas las medidas de

precaución descritas en este manual para

reducir las posibilidades de llamas o

explosiones.

● Mueva todos los materiales

inflamables que se encuentren en

un radio de 35 pies (10,7 metros) del

arco de soldadura. Si no lo puede

hacer, deberá cubrirlos con algún

material que los aisle del fuego.

● No use una soldadora eléctrica de

arco en áreas donde pueda haber

vapores inflmables o explosivos.

● Tome todas las precauciones

necesarias para evitar que las

chispas y el calor ocasionen llamas

en áreas poco accesibles, ranuras,

detrás de divisiones, etc.

Peligro de in-cendio! Nunca

debe soldar envases o tuberías

que contengan o hayan contenido

materiales inflamables o combustibles

gaseosos o líquidos.

Al soldar con arcos eléctricos

cilindros cerrados o tambores

podría ocasionar explosioones si no están

bien ventilados ! Cerciórese de que

cualquier cilindro o envase que vaya a

soldar tenga un orificio de ventilación para

que los gases puedan liberarse.

No debe respirar los gases

emitidos al soldar con arcos

eléctricos. Estos son peligrosos. Si no

puede ventilar bien el área de trabajo,

deberá usar un respirador.

● Mantenga la cabeza y la cara

alejada de los gases emitidos.

● No debe soldar con arcos eléctricos

metales galvanizados o con capa de

cadio, o aquellos que contengan

zinc, mercurio o berilio sin tomar

las siguientes precauciones:

a. Quitarle la capa al metal.

b. Cerciorarse de que el área de

trabajo esté bien ventilada.