Installation Instructions Model WT2530

Please read and save these instructions. Read carefully before attempting to assemble, install, operate or maintain the product described. Protect yourself and

others by observing all safety information. Failure to comply with instructions could result in personal injury and/or property damage! Retain instructions for

future reference.

Aluminum

BU IL T TO L AS T

Welding Kit

Description

Model WT2530 is an aluminum welding

kit designed for use on all Campbell

Hausfeld wire feed MIG welders (WG

series). This kit includes: PTFE wire liner

(Part Number: WC600210AV) , smoothgroove drive roller (Part Number:

WC500008AV) and four pieces of

0.030" (0.8 mm) aluminum contact tips

(Part Number: WT501800AV). These

parts, when installed in your welder,

allow welding aluminum with greater

success. Along with this kit, you will

need a spool of 0.030" (0.8 mm)

aluminum MIG wire (Part Number:

WE303001AV) and a bottle of 100%

Argon shielding gas (Part Number:

WT601100AV).

PTFE wire liner

The PTFE wire liner reduces the drag on

the soft aluminum welding wire. DO

NOT USE TO WELD STEEL. This liner

should be used for aluminum welding

only to prevent contamination.

1. Verify the welder is OFF and

UNPLUGGED.

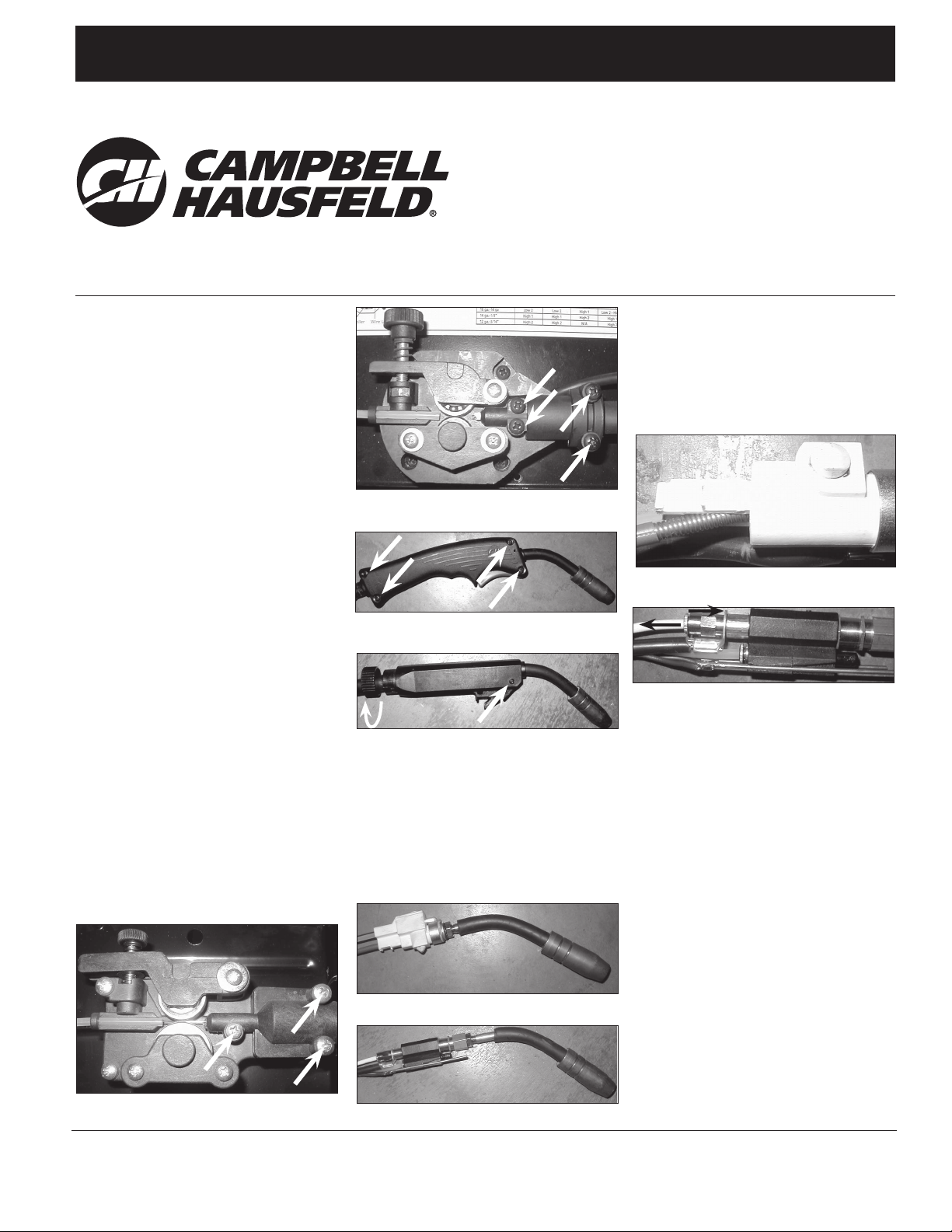

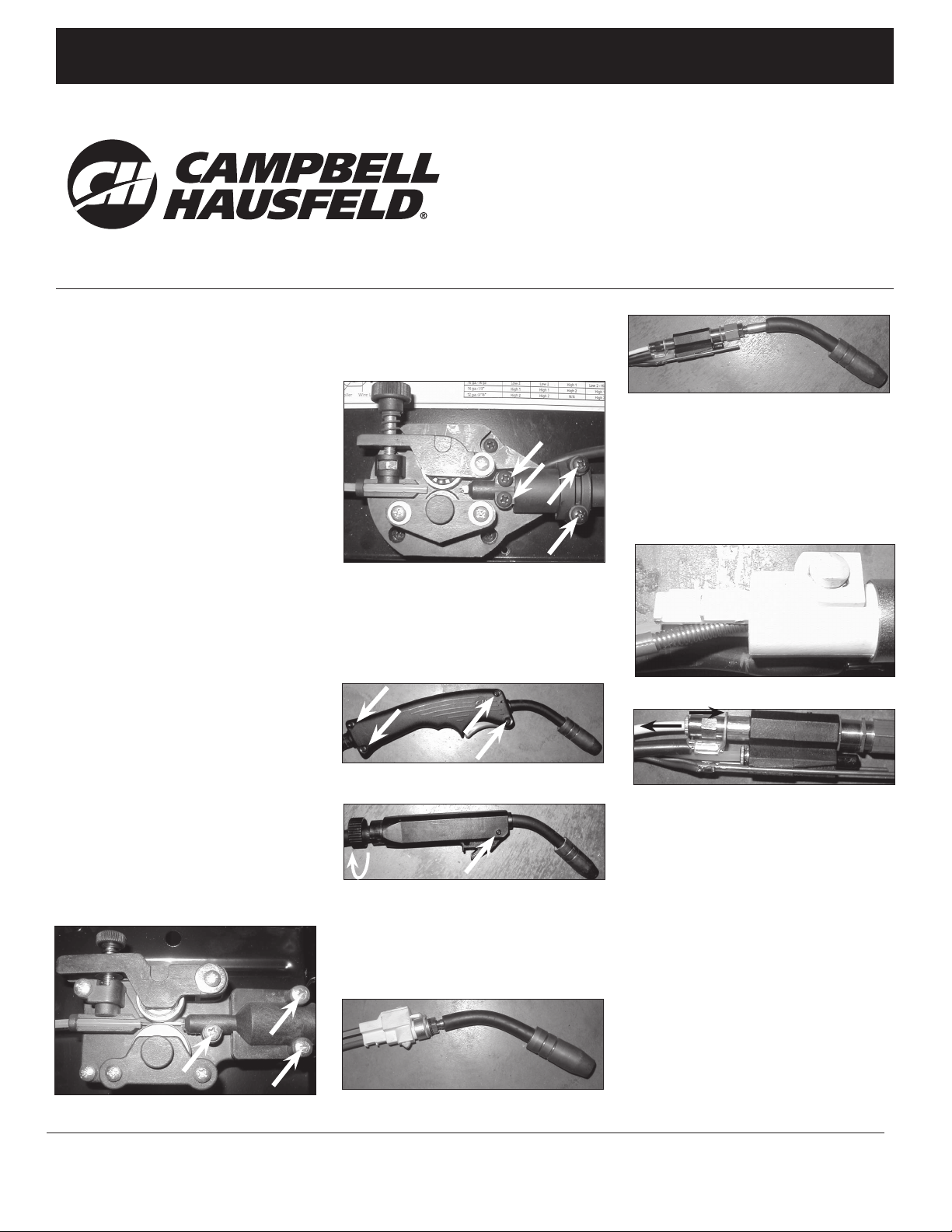

2. Open wire feed door and locate

drive deck. Remove torch cable

cover by removing three screws (see

figure 1a). WG3020: Remove four

screws (see figure 1b).

3. Disassemble torch handle by

Figure 1b – Remove these four screws

Figure 2a – Remove these four screws

Figure 2b – Remove screw and twist nut

removing four screws (see figure

2a). WG3020: Remove one screw

and twist nut (see figure 2b).

4. Remove swan neck/valve assembly

from handle (see figure 3a).

WG3020: (see figure 3b).

5. Remove the existing wire liner from

Swan Neck

Valve

Figure 3a

Swan Neck

the valve. Unlock by pulling up,

then out from the valve (see figure

4a). WG3020: Pull liner from valve

while pressing collar of liner fitting

(see figure 4b).

6. Straighten the torch hose and

Figure 4a

Figure 4b

remove the existing wire liner. Then,

insert the PTFE wire liner into the

torch hose.

7. Push new liner into the valve at an

angle until seated fully and then

push sideways to lock it in position

(see figure 4a). WG3020: Push new

liner into fitting. It locks

automatically.

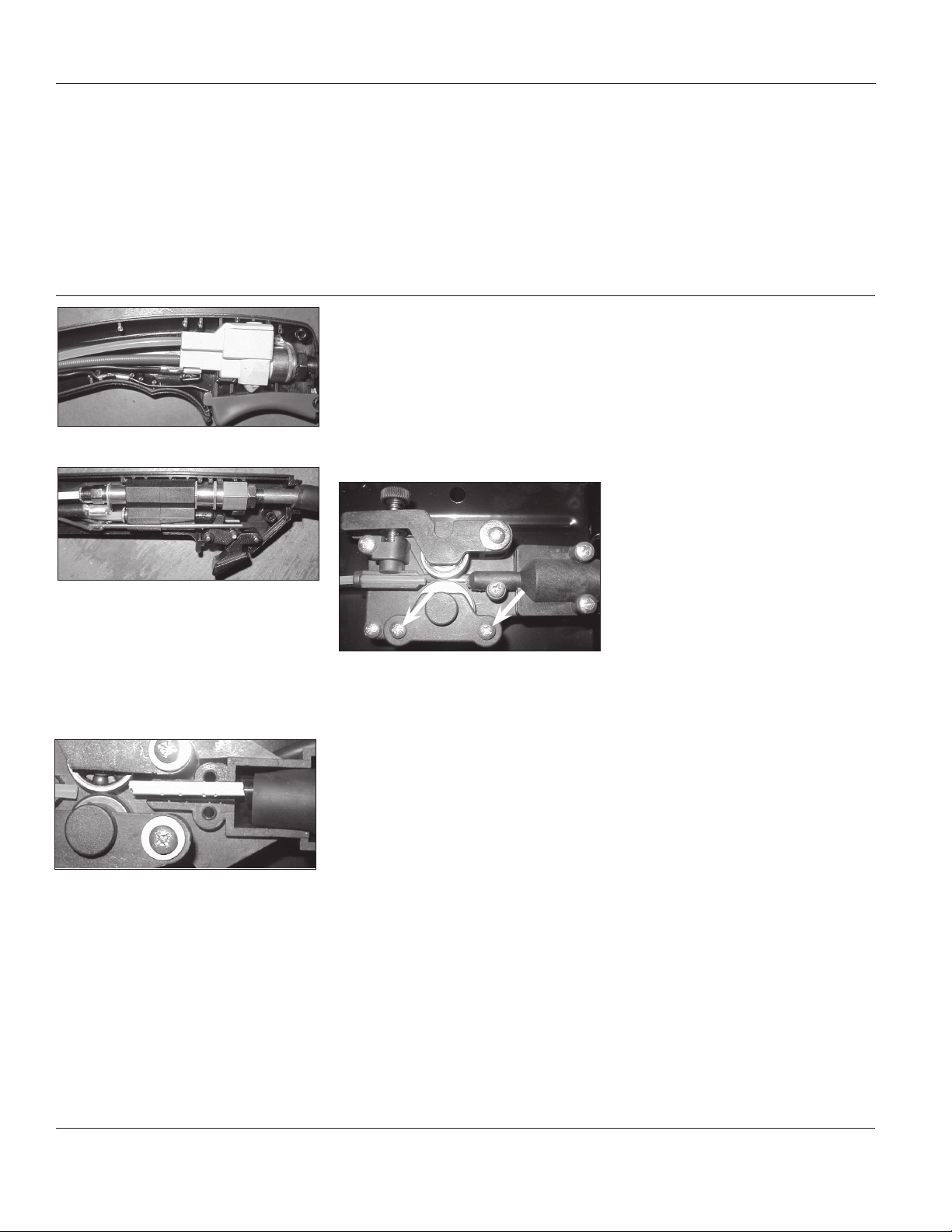

8. Place swan neck/valve assembly into

torch handle, making sure small

black wires are located correctly (see

figure 5a). Reassemble torch handle

with four screws. WG3020: Make

sure trigger is positioned correctly

(see figure 5b).

Figure 1a – Remove these three screws

© 2002 Campbell Hausfeld/Scott Fetzer

Valve

Figure 3b

For parts, manuals, product & service information

visit www.chpower.com

or call 1-800-746-5641

IN971100AV 3/02

Installation Instructions

Aluminum Welding Kit

Figure 5a

Figure 5b

9. Reattach torch cable cover onto

drive deck, making sure wire liner is

aligned with drive roller, but not

touching the roller (see figure 6).

Note: Trim the liner’s length as

needed.

Figure 6

Smooth-Groove Drive Roller

The existing serrated-groove drive roller

will cut notches in the soft aluminum

welding wire. These notches increase

the drag within the wire liner. The

smooth-groove drive roller eliminates

this problem. WG3020: Use the smoothgroove drive roller supplied with your

welder.

1. Verify the welder is OFF and

UNPLUGGED.

2. Open wire feed door and locate

drive deck. Release tension on swing

arm by removing tension screw and

spring.

3. Remove roller cover by removing

two screws (see figure 7).

Figure 7 – Remove these two screws

4. Remove serrated-groove drive roller

and replace with smooth-groove

drive roller. Install drive roller with

"0,8-0,9" stamping facing out. This

aligns the correct groove for 0.030"-

0.035" (0.8-0.9 mm) wire with the

liner.

5. Reinstall roller cover, tension screw

and spring.

Aluminum Contact Tip

The contact tips in this kit have been

designed specifically for welding

aluminum. The hole is slightly oversized

to reduce drag. There is more mass to

handle the extra heat associated with

aluminum welding. And, the tip is

tapered for use with shielding gases.

These tips are to be used with 0.030"

(0.8 mm) aluminum MIG wire.

1. Remove nozzle by turning

counterclockwise.

2. Remove existing contact tip by

turning counterclockwise.

3. Install 0.030" (0.8 mm) aluminum

contact tip.

4. Reinstall nozzle.

Aluminum Welding Help

• Make sure your base metal is very

clean. New aluminum will oxidize

almost immediately. Thin layers of

oxidation are clear and cannot be

seen. Use a stainless steel brush to

clean the weld area and the work

clamp area. Use the stainless steel

brush only on aluminum to prevent

contamination.

• The center of the contact tip must be

clean to transfer the current required

for welding aluminum. Even new

contact tips can benefit from cleaning

with a tip cleaner.

• Since aluminum conducts heat so

well, higher welder output is

required. Also, the wire and travel

speeds need to be faster.

• Work clamp connection must be

thoroughly clean and as close to the

weld area as possible.

• When welding thin material, it is

usually easier to use a "push"

technique rather than a "pull"

technique.

www.chpower.com

2

Instructions de Montage Modèle WT2530

S’il vous plaît lire et conserver ces instructions. Lire attentivement avant de monter, installer, utiliser ou de procéder à l’entretien du produit décrit. Se protéger

ainsi que les autres en observant toutes les instructions de sécurité, sinon, il y a risque de blessure et/ou dégâts matériels! Conserver ces instructions comme

référence.

Kit de Soudure

BU IL T TO L AS T

d’Aluminium

Description

Le modèle WT2530 est un kit de soudure

d'aluminium conçu pour toutes les

soudeuses à l'arc sous la protection de

gaz inerte avec fil électrode fusible à

entraînement du fil électrode Campbell

Hausfeld (série WG). Cette trousse

comprend : Chemise de fil de PTFE (no de

pièce : WC600210AV), rouleau

d’entraînement à rainure lisse (no de

pièce : WC500008AV), quatre pointes de

contact de 0,8 mm (0,030 po)

d’aluminium (no de pièce :

WT501800AV). Ces pièces, installées sur

votre soudeuse, permettent de souder

l'aluminium avec plus de succès. Avec ce

kit, vous aurez besoin d'une bobine de fil

MIG d'aluminium de 0,030 pouce (0,8

mm) (numéro de pièce: WE303001AV) et

d'une bouteille de gaz de protection

d'argon à 100 % (numéro de pièce:

WT601100AV).

Chemise de fil de PTFE

La chemise de fil de PTFE réduit la

traînée sur le fil de soudage d'aluminium

doux. N'UTILISEZ PAS POUR SOUDER

L'ACIER Cette garniture devrait servir

seulement pour la soudure d'aluminium

afin de prévenir la contamination.

1. Vérifiez que l'appareil est hors

tension et DÉBRANCHÉ.

2. Ouvrez la porte d'alimentation du fil

et trouvez le plateau d'alimentation.

Figure 1a – Retirez ces trois vis

Retirez le couvercle du câble du

chalumeau en retirant trois vis (voir

la figure 1a). WG3020: Retirez les

quatre vis (voir la figure 1b).

Figure 1b – Retirez ces quatre vis

3. Démontez la poignée du chalumeau

en retirant les quatre vis (voir la

figure 2a). WG3020: Retirez une vis

et tournez l'écrou (voir la figure 2b).

Figure 2a – Retirez ces quatre vis

Figure 2b – Retirez la vis et tournez l’écrou

4. Retirez le montage du col de cycle/

soupape de la poignée (voir la figure

3a). WG3020: (voir la figure 3b).

Col de cygne

Soupape

Figure 3a

Col de

cygne

Soupape

Figure 3b

5. Retirez la garniture du fil actuelle de

la soupape. Déverrouillez en tirant

vers le haut, puis sortez de la

soupape (voir la figure 4a). WG3020:

Retirez la garniture de la soupape

tout en pressant le collier du raccord

de la garniture (voir la figure 4b).

Figure 4a

Figure 4b

6. Redressez le flexible du chalumeau

et retirez la garniture du fil actuelle.

Puis insérer la nouvelle chemise de fil

de PTFE dans le tuyau du chalumeau.

7. Poussez la nouvelle garniture dans la

soupape de biais jusqu'à ce qu'elle

soit bien installée, puis poussez de

côté pour verrouiller en place (voir la

figure 4a). WG3020: Poussez la

nouvelle garniture dans le raccord.

Elle se verrouille automatiquement.

8. Placez le montage du col de cygne/

soupape dans la poignée du

chalumeau en vous assurant que les

petits fils noirs soient bien placés

(voir la figure 5a). Remontez la

poignée du chalumeau avec quatre

© 2002 Campbell Hausfeld/Scott Fetzer

IN971100AV 3/02

Instructions de Montage

Kit de Soudure d’Aluminium

vis. WG3020: Assurez-vous que la

gâchette soit bien placée (voir la

figure 5b).

Figure 5a

Figure 5b

9. Remontez le couvercle du câble du

chalumeau sur le plateau

d'entraînement en vous assurant

que la garniture du fil soit alignée

avec le dévidoir, mais sans toucher le

rouleau (voir la figure 6).

Remarque: Taillez la longueur de

garniture au besoin.

Figure 6

Dévidoir à rainure lisse

Le dévidoir à rainure dentelée fera des

encoches dans le fil de soudure

d'aluminium mou. Ces encoches

augmentent la traînée de la garniture

du fil. Le dévidoir à rainure lisse élimine

ce problème. WG3020: Utilisez le

dévidoir à rainure lisse fourni avec votre

soudeuse.

1. Vérifiez que l'appareil est hors

tension et DÉBRANCHÉ.

2. Ouvrez la porte d'alimentation du fil

et trouvez le plateau d'alimentation.

Dégagez la tension sur le bras

pivotant en retirant la vis de tension

et le ressort.

3. Retirez le couvercle du rouleau en

retirant deux vis (voir la figure 7).

Figure 7 – Retirez ces deux vis

4. Retirez le dévidoir à rainure

dentelée et remplez-le avec un

dévidoir à rainure lisse. Installez le

dévidoir avec l'estampage "0,8 - 0,9

po" vers l'extérieur. Ceci aligne la

bonne rainure pour le fil 0.030-0.035

pouce (0,8-0,9 mm) avec la

garniture.

5. Réinstallez le dévidoir, la vis de

tension et le ressort.

Tube contact d'aluminium

Les tubes contact dans ce kit ont été

conçus spécifiquement pour la soudure

d'aluminium. Le trou est un peu

surdimensionné pour réduire la traînée.

Il y a plus de masse pour traiter la

chaleur supplémentaire associée à la

soudure d'aluminium. Le tube est effilé

pour l'utiliser avec les gaz de

protection. Ces tubes doivent être

utilisés avec le fil MIG d'aluminium de

0.030 po (0,8 mm).

1. Retirez l'embout en tournant dans

le sens antihoraire.

2. Retirez le tube contact actuel en

tournant dans le sens antihoraire.

3. Installez le tube contact

d'aluminium de 0.030 po (0,8 mm).

4. Réinstallez l'embout.

Aide pour la soudure d'alumini

um

• Assurez-vous que votre base de métal

soit très propre. Le nouvel aluminium

s'oxydera presque immédiatement.

Les minces couches d'oxydation sont

transparentes et ne peuvent pas être

vues. Utilisez une brosse d'acier

inoxydable pour nettoyer la région

de soudure et la région du dispositif

de serrage. Utilisez la brosse d'acier

inoxydable seulement sur l'aluminium

pour éviter la contamination.

• Le centre du tube contact doit être

propre pour transférer le courant

requis pour la soudure d'aluminium.

Même les nouveaux tubes contact

peuvent tirer profit d'un nettoyage

avec un nettoyeur de tube.

• Puisque l'aluminium conduit la

chaleur si bien, il faut une sortie de

soudure plus élevée. De même, la

vitesse de déplacement et du fil doit

être plus rapide.

• La connexion du dispositif de serrage

doit être bien propre et aussi près

que possible de la région de soudure.

• En soudant un matériau mince, il est

normalement plus facile d'utiliser une

technique de "pousser" plutôt

qu'une technique de "tirer".

4 - Fr

Instrucciones para la Instalación Modelo WT2530

Sírvase leer y guardar estas instrucciones.Lea con cuidado antes de tratar de armar, instalar, manejar o darle servicio al producto descrito en este manual. Protéjase

Ud. y a los demás observando todas las reglas de seguridad. El no seguir las instrucciones podría resultar en heridas y/o daños a su propiedad.Guarde este manual

como referencia.

Juego de

BU IL T TO L AS T

Des crip ción

El Mo de lo WT2530 es un jue go de sol dadu ra de alu mi nio di se ña do pa ra usar en

to das las sol da do ras MIG de ali men tación de alam bre de Cam pbell Haus feld

(se rie WG). Este juego incluye: Forro del

alambre en PTFE (No. de Pieza:

WC403621AV), del portabobinas de

ranuras suaves (No. de Pieza:

WC500008AV), y cuatro puntas de

contacto de aluminio de 0,8 mm

(0,030 pulg.) (No. de

Pieza: WT501800AV). Es tas pie zas, cuando se ins ta lan en su sol da do ra, le per miten un éxi to ma yor con la sol da du ra de

alu mi nio. Jun to con es te jue go, ne ce si tará una bo bi na de alam bre MIG de alu minio de 0,8 mm (0,030") (Nú me ro de pieza WE303001AV) y un tan que de gas

pro tec tor de Ar gón 100% (Nú me ro de

pie za: WT601100AV).

Soldadura de

Aluminio

rar la ta pa del ca ble del so ple te (vea

la fi gu ra 1a). WG3020: Qui te cua tro

tor ni llos (vea la fi gu ra 1b).

Figura 1b - Quite estos cuatro tonillos

3. De sar me el man go del so ple te quitan do cua tro tor ni llos (vea la fi gu ra

2a). WG3020: Qui te un tor ni llo y gi re

la tuer ca (vea la fi gu ra 2b).

Cuello de

cisne

Válvula

Figura 3b

del fo rro des de la vál vu la mien tras

pre sio na el cas qui llo del mon ta je del

fo rro (vea la fi gu ra 4b).

Figura 4a

Forro de alambre de PTFE

El forro de alambre de PTFE reduce la

resistencia sobre el alambre suave para

soldadura de aluminio. NO USAR PA RA

SOL DAR ACE RO. Es te fo rro de be usar se

só lo pa ra la sol da du ra de alu mi nio pa ra

evi tar la con ta mi na ción.

1. Ve ri fi que que la sol da do ra es té APA-

GA DA y DE SEN CHU FA DA.

2. Abra la puer ta de ali men ta ción del

alam bre y ubi que la pla ca de con ducción. Qui te los tres tor ni llos pa ra re ti-

Figura 1a - Quite estos tres tornillos

© 2002 Campbell Hausfeld/Scott Fetzer

Figura 2a - Quite estos cuatro tornillos

Figura 2b - Quite el tonillo y gire la tuerca

4. Qui te el en sam bla je de cue llo de cisne /vál vu la del man go (vea la fi gu ra

3a). WG3020: (vea la fi gu ra 3b).

5. Qui te el fo rro del alam bre exis ten te

de la vál vu la. Des tra be ti ran do ha cia

arri ba y lue go ha cia fue ra de la válvu la (vea la fi gu ra 4a). WG3020: Ti re

Cuello de

cisne

Válvula

Figura 3a

Figura 4b

6. En de re ce la man gue ra del so ple te y

qui te el fo rro del alam bre exis ten te.

Luego introduzca el forro de PTFE del

alambre dentro de la manguera del

soplete.

7. Em pu je en án gu lo el fo rro nue vo

den tro de la vál vu la has ta que se

apo ye to tal men te y lue go em pu je

ha cia los la dos pa ra tra bar lo en su

po si ción (vea la fi gu ra 4a). WG3020:

Em pu je el fo rro nue vo en el cas qui llo.

Se tra ba au to má ti ca men te.

8. Co lo que el en sam bla je de cue llo de

cis ne /vál vu la den tro del man go del

so ple te, ase gu rán do se de que los

alam bres ne gros es tén ubi ca dos

co rrec ta men te (vea la fi gu ra 5a).

Vuel va a ar mar el man go del so ple te

con los cua tro tor ni llos. WG3020: Asegú re se de que el ga ti llo es té en la

IN971100AV 3/02

Instrucciones de Instalación

Juego de Soldadura de Aluminio

po si ción ade cua da (vea la fi gu ra 5b).

Figura 5a

Figura 5b

9. Vuel va a co lo car la ta pa del ca ble

del so ple te so bre la pla ca de con ducción, ase gu rán do se de que el fo rro

del alam bre es té ali nea do con la

bo bi na, pe ro sin to car la (vea la fi gura 6). No ta: Cor te el fo rro del lar go

que sea ne ce sa rio.

Figura 6

Guía de ra nu ras sua ves

La guía de ra nu ras se rra das exis ten te

cor ta mues cas en el sua ve alam bre de

sol da du ra de alu mi nio. Es tas ra nu ras

au men tan la re si sten cia den tro del

fo rro del alam bre. La guía de ra nu ras

sua ves eli mi na es te pro ble ma. WG3020:

Use la guía de ra nu ras sua ves que se

pro por cio nó con su sol da do ra.

1. Ve ri fi que que la sol da do ra es té APA-

GA DA y DE SEN CHU FA DA.

2. Abra la puer ta de ali men ta ción del

alam bre y ubi que la pla ca de conduc ción. Li be re la ten sión del bra zo

os ci lan te qui tan do el tor ni llo y re sorte de ten sión.

3. Qui te dos tor ni llos pa ra re ti rar la

ta pa de la guía (vea la fi gu ra 7).

Figura 7 - Quite estos dos tornillos

4. Qui te la guía de ra nu ras se rra das y

reem plá ce la con la de ra nu ras suaves. Ins ta le la guía con el tro que la do

"0,8-0,9" ha cia fue ra. Es to ali nea la

ra nu ra co rrec ta pa ra el alam bre de

0,8-0,9 mm (0,030"-0,035") con el

fo rro.

5. Vuel va a co lo car la ta pa del ro di llo,

el tor ni llo y el re sor te de ten sión.

Pun ta de con tac to de

alu mi nio

Las pun tas de con tac to en es te jue go

fue ron di se ña das es pe cí fi ca men te pa ra

sol dar alu mi nio. El ori fi cio es ape nas

más gran de pa ra re du cir la re sis ten cia.

Es de cir más ma sa pa ra ma ne jar el ca lor

adi cio nal aso cia do con la so la du ra de

alu mi nio. Y la pun ta es ahu sa da pa ra

usar con ga ses de pro tec ción. Es tas puntas son pa ra usar con alam bre MIG de

alu mi nio de 0,8 mm (0,030").

1. Qui te la bo qui lla gi ran do ha cia la

iz quier da.

2. Qui te la pun ta de con tac to exis ten te

gi ran do ha cia la iz quier da.

3. Ins ta le la pun ta de con tac to de alumi nio de 0,8 mm (0,030").

4. Vuel va a co lo car la bo qui lla.

Ayu da pa ra la sol da du ra de alumi nio

• Ase gú re se de que su me tal bá si co

es té bien lim pio. El alu mi nio nue vo se

oxi da ca si de in me dia to. Las del ga das

ca pas de oxi da ción son trans pa ren tes

y no se pue den ver. Use un ce pi llo de

ace ro ino xi da ble pa ra lim piar el área

a sol dar y el área de la gra pa de traba jo. Use el ce pi llo de ace ro ino xi dable so la men te so bre alu mi nio pa ra

evi tar la con ta mi na ción.

• El cen tro de la pun ta de con tac to

de be es tar lim pio pa ra trans fe rir la

co rrien te ne ce sa ria pa ra la sol da du ra

de alu mi nio. In clu so las pun tas de

con tac to nue vas se pue den be ne fi ciar

si se las lim pia con un lim pia dor de

pun tas.

• Co mo el alu mi nio es tan buen con-

duc tor de ca lor, se ne ce si ta un ma yor

ni vel de sa li da de la sol da do ra. También la ve lo ci dad de des pla za mien to

y del alam bre de ben ser ma yo res.

• La co ne xión de la gra pa de tra ba jo

de be es tar to tal men te lim pia y lo más

cer ca na po si ble al área a sol dar.

• Cuan do se suel da ma te rial del ga do,

ge ne ral men te es más sen ci llo usar

una téc ni ca de "em pu je" en lu gar de

una téc ni ca de "ti ra do".

6 - Sp

Notes

Notas

Model WT2530

7

Notes

Notas

Model WT2530

Loading...

Loading...