Page 1

See Warranty on page 16 for important information about commercial use of this product.

Operating Instructions and Parts Manual GN5060, GN6575

Please read and save these instructions. Read carefully before attempting to assemble, install, operate or maintain the product described.

Protect yourself and others by observing all safety information. Failure to comply with instructions could result in personal injury and/or

property damage! Retain instructions for future reference.

N

A

C

R

E

U

S

S

A

Y

T

I

L

A

Need

U

Q

Assistance?

Generator

Call Us First!

1-800-803-1436

Table of Contents

Description . . . . . . . . . . . . . . . . . . . . . .1

Unpacking . . . . . . . . . . . . . . . . . . . . . . .1

Specifications. . . . . . . . . . . . . . . . . . . . .1

Safety Guidelines . . . . . . . . . . . . . . . . .2

General Safety Information . . . . . . 2 - 3

Glossary of Terms . . . . . . . . . . . . . . . . .3

Pre-operation . . . . . . . . . . . . . . . . . 3 - 4

Operation . . . . . . . . . . . . . . . . . . . . 5 - 6

Maintenance . . . . . . . . . . . . . . . . . . . . .6

Storage . . . . . . . . . . . . . . . . . . . . . . . . .6

Troubleshooting Chart . . . . . . . . . . . . .7

Service Record . . . . . . . . . . . . . . . . . . . .8

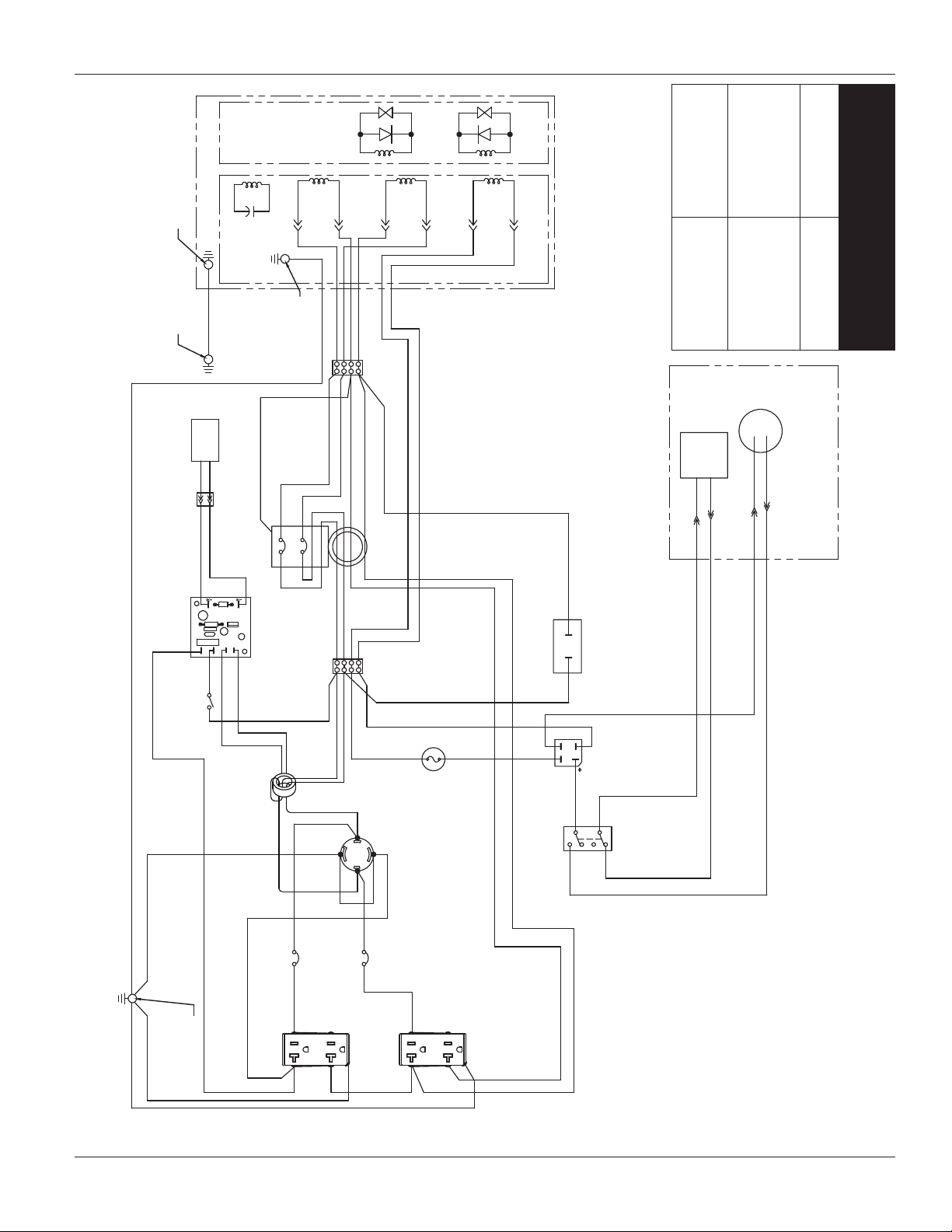

Wiring Diagram. . . . . . . . . . . . . . . . . . .9

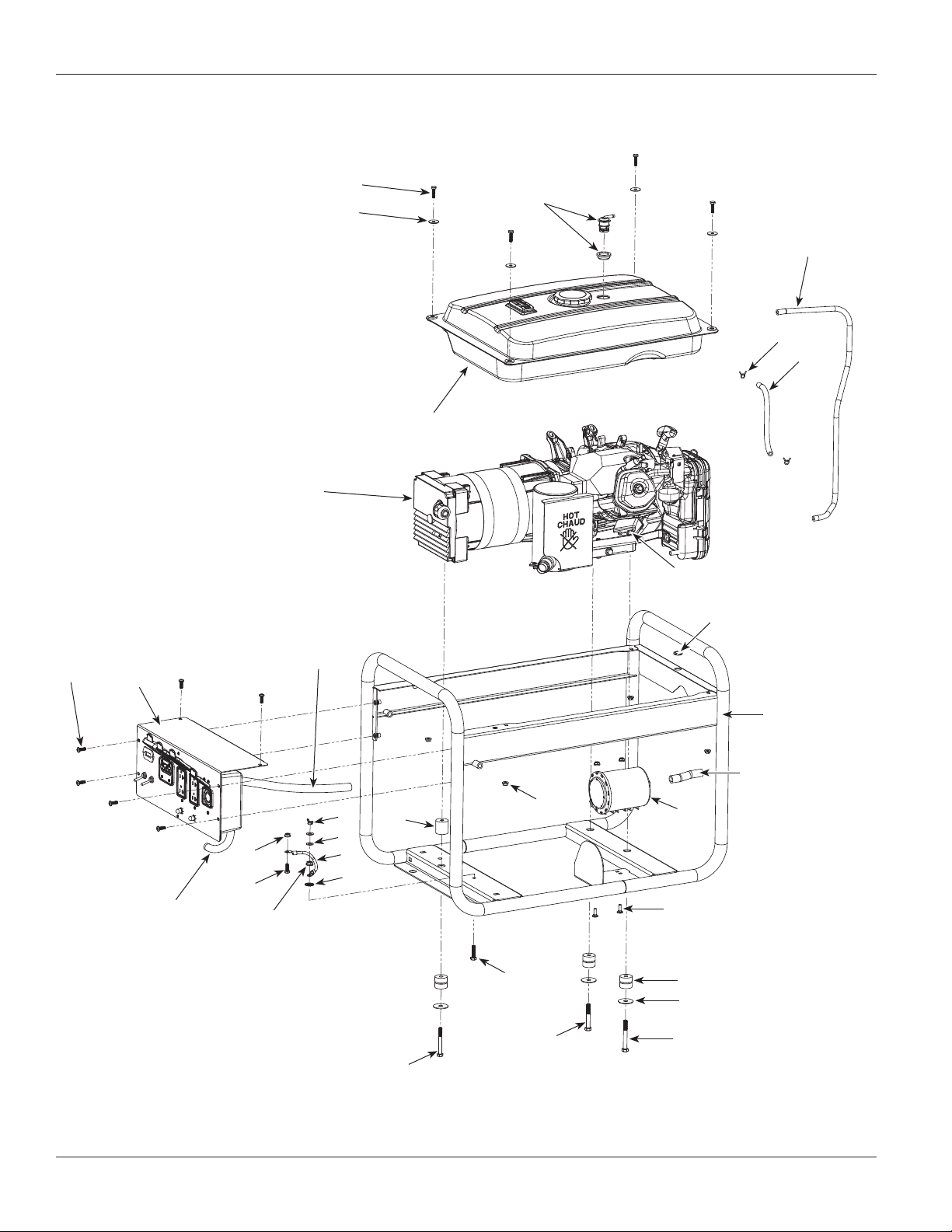

Generator Assembly . . . . . . . . . . 10 - 11

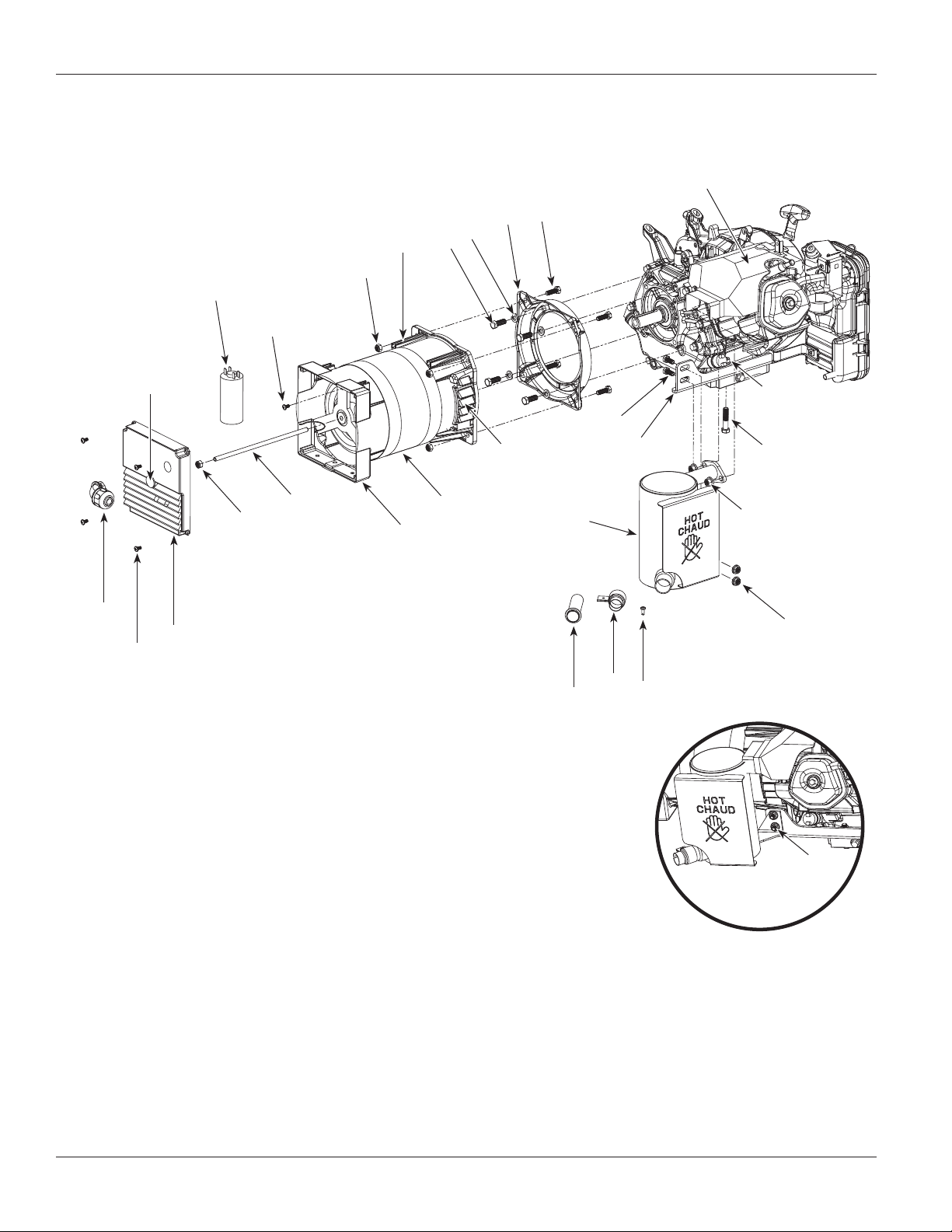

Alternator Assembly . . . . . . . . . . 12 - 13

Control Panel Assembly . . . . . . . 14 - 15

Warranty . . . . . . . . . . . . . . . . . . . . . . .16

P

R

O

G

R

A

M

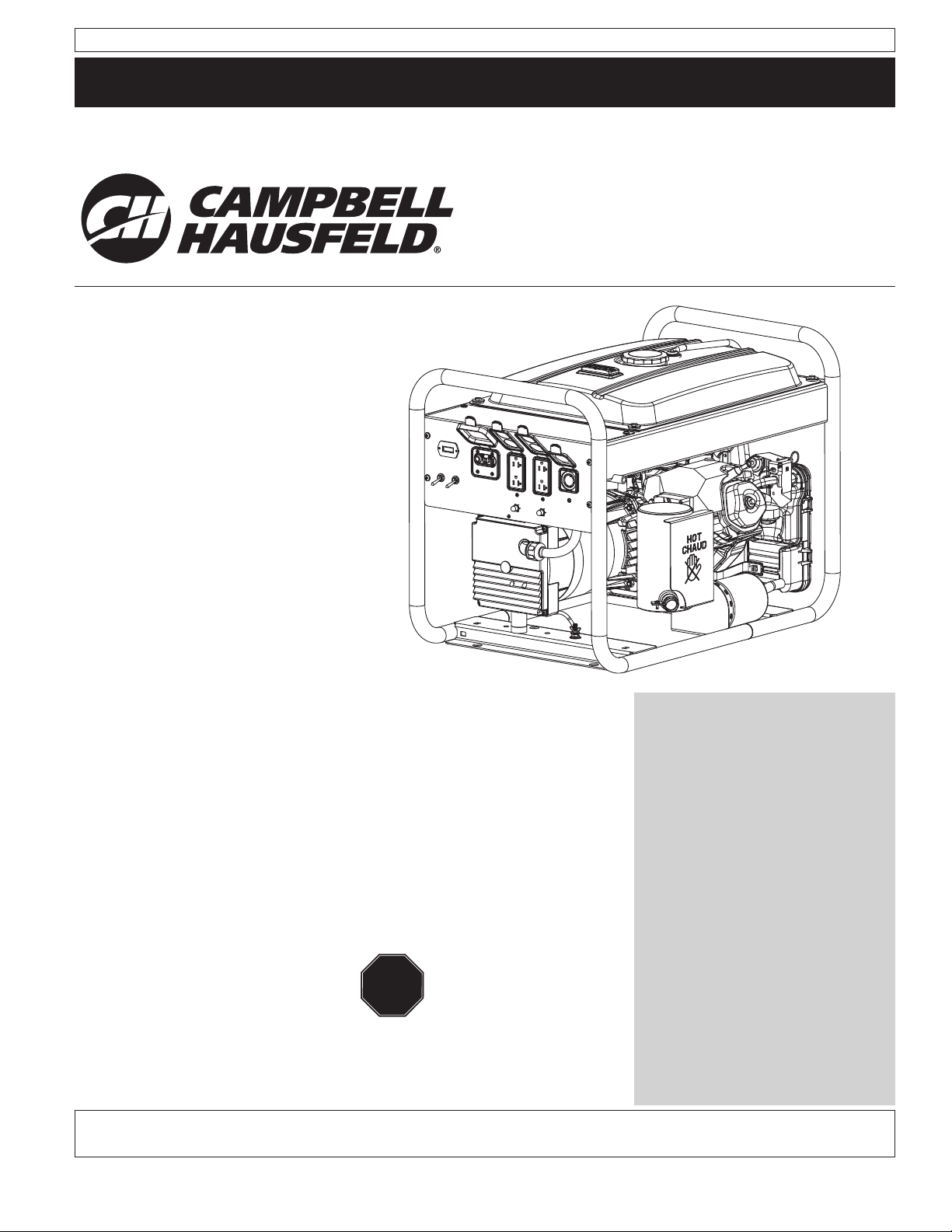

Description

These Campbell Hausfeld generators are

powered by gasoline engines. Each unit

is equipped with 120V and 230V outlets

which provide continuous smooth

power for the task at hand. These

outlets are protected by GFCI (Ground

Fault Circuit Interrupters) and thermal

circuit breakers.

READ & FOLLOW ALL INSTRUCTIONS

SAVE THESE INSTRUCTIONS

DO NOT DISCARD

REMINDER: Keep your dated proof of purchase for warranty purposes!

Attach it to this manual or file it for safekeeping.

© 2012 Campbell Hausfeld/Scott Fetzer

Unpacking

When unpacking unit, inspect carefully

for any damage that may have occurred

during transit. Make sure any loose

fittings, bolts, etc., are tightened before

putting unit into service. In case of

questions, damaged or missing parts,

please call 1-800-803-1436 for customer

assistance. Have the serial number, model

number, and parts list (with missing parts

circled) before calling.

DO NOT RETURN

STOP!

For parts, product & service information

visit www.chpower.com or call 1-800-803-1436

THE PRODUCT TO

THE RETAILER!

Specifications

Model GN5060

Engine . . . . . . . . . . . Honda GX270

Valve Type . . . . . . . . . . . . . . .OHV

Engine Size / Type. . . . . . 270cc / 4 Stroke

Start Type. . . . . . . . . . Manual Recoil

Alternator Type . . . . . 2 Pole, Brushless

Phase / Frequency. . . . . . . . 1 PH / 60 Hz

Alternator Rating . . . . . . . . . 5.2 KVA

Fuel Tank Cap . . . . 6 Gallons [22.7 Liter]

Model GN6575

Engine . . . . . . . . . . . Honda GX390

Valve Type . . . . . . . . . . . . . . .OHV

Engine Size / Type. . . . . . 390cc / 4 Stroke

Start Type. . . . . . . . . . Manual Recoil

Alternator Type . . . . . 2 Pole, Brushless

Phase / Frequency. . . . . . . . 1 PH / 60 Hz

Alternator Rating . . . . . . . . . 6.8 KVA

Fuel Tank Cap . . . . 6 Gallons [22.7 Liter]

IN954800AV 3/12

Page 2

Operating Instructions and Parts Manual

Safety Guidelines

This manual contains information

that is very important to know and

understand. This information is

provided for SAFETY and to PREVENT

EQUIPMENT PROBLEMS. To help

recognize this information, observe the

following symbols.

Danger indicates

hazardous situation which, if not

avoided, WILL result in death or serious

injury.

Warning indicates

hazardous situation which, if not

avoided, COULD result in death or

serious injury.

Caution indicates

hazardous situation which, if not

avoided, MAY result in minor or

moderate injury.

Notice indicates

information, that if not followed, may

cause damage to equipment.

NOTE: Information that requires special

attention.

General Safety Information

CALIFORNIA PROPOSITION 65

The engine exhaust

contains chemicals known to the State

of California to cause cancer, birth

defects, or other reproductive harm.

You can

dust when you cut, sand, drill

or grind materials such as

wood, paint, metal, concrete,

cement, or other masonry. This dust

often contains chemicals known to

cause cancer, birth defects, or other

reproductive harm. Wear protective

gear.

EMISSIONS

Engines that are

with U.S. EPA emission regulations for

SORE (Small Off Road Equipment), are

certifi ed to operate on regular unleaded

gasoline, and may include the following

emission control systems: (EM) Engine

Modifi cations and (TWC) Three-Way

Catalyst (if so equipped).

Using a generator

YOU IN MINUTES. Generator exhaust

contains carbon monoxide. This is a

poison you cannot see or smell.

www.chpower.com

an imminently

a potentially

a potentially

important

from this product

create

certifi ed to comply

indoors CAN KILL

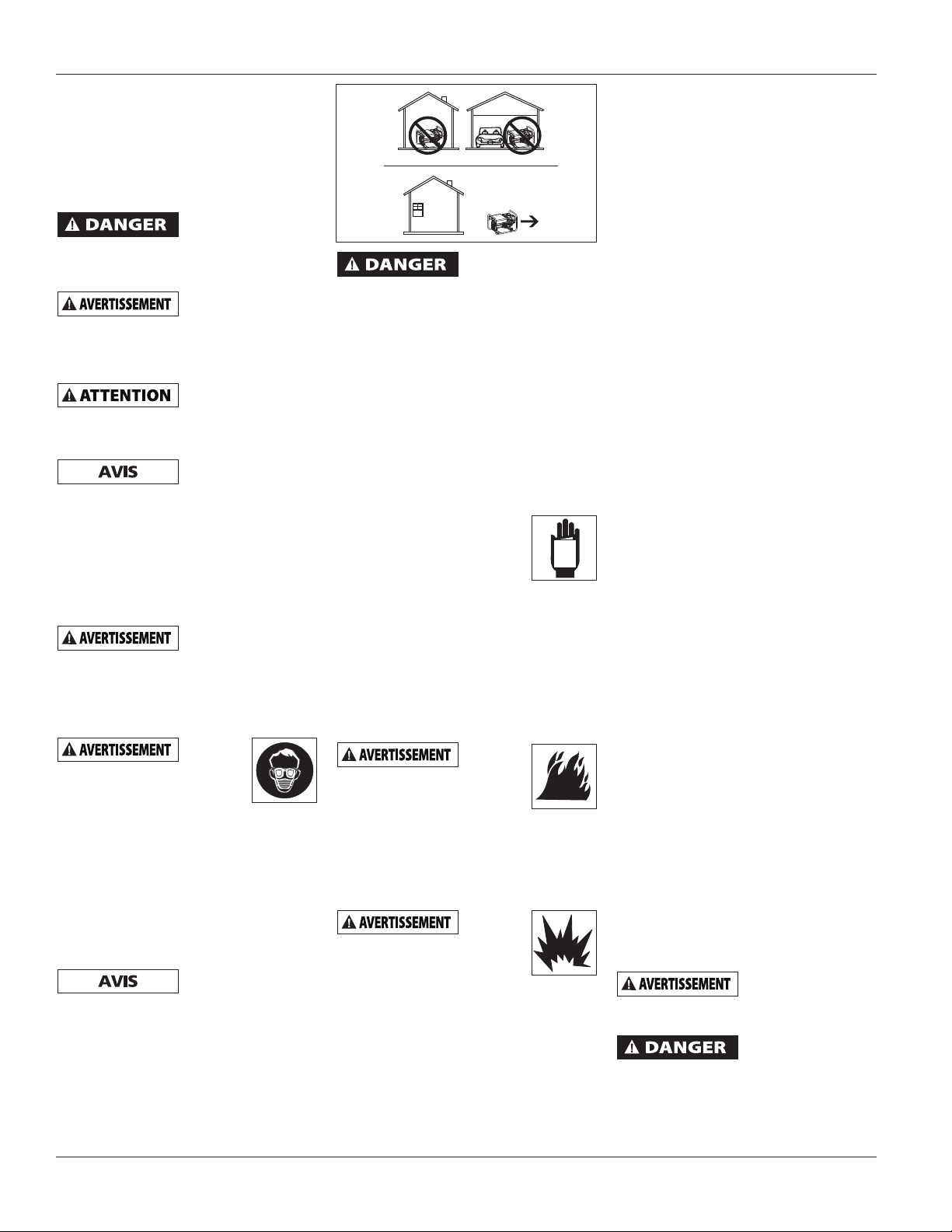

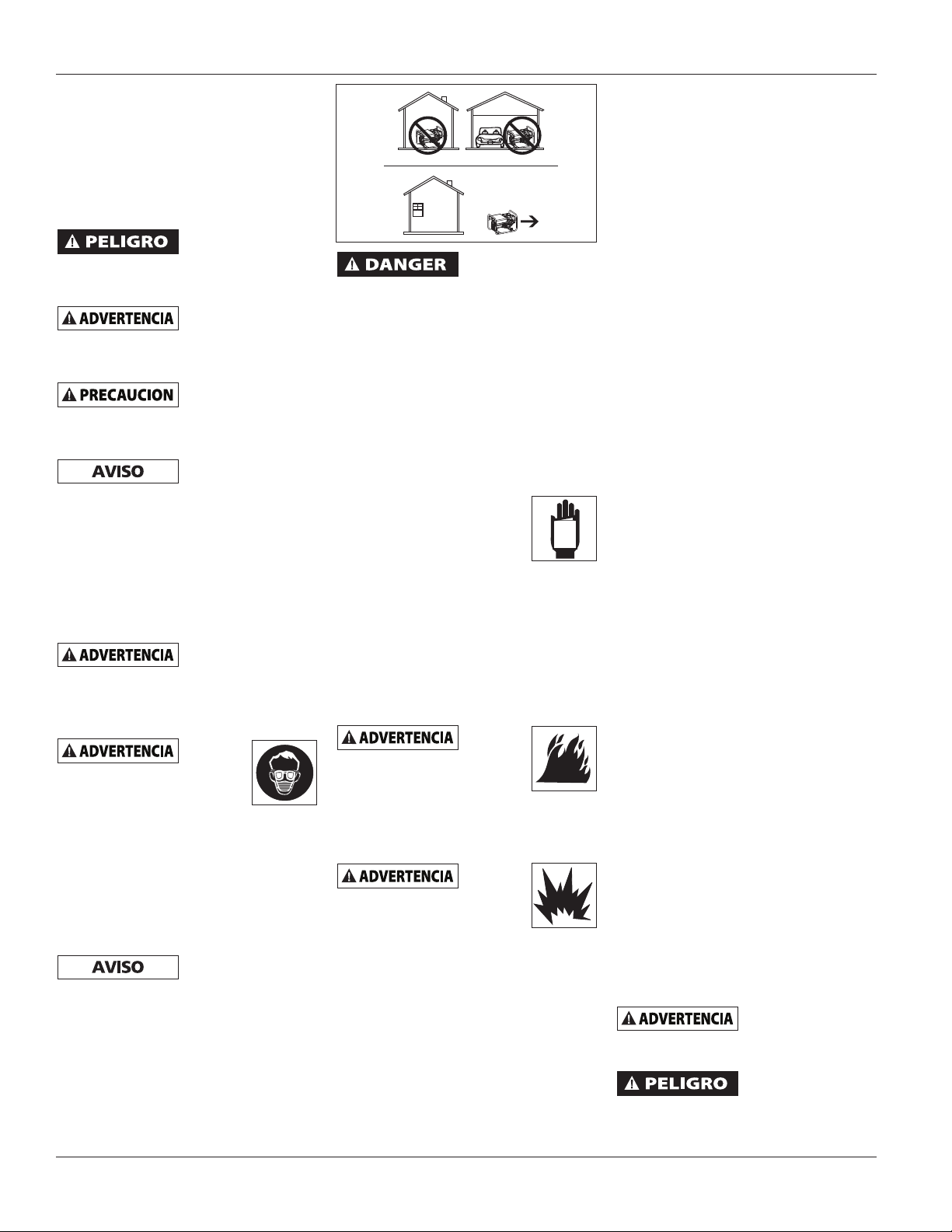

• NEVER use inside a house or

garage, EVEN IF doors and windows

are open.

• Only use OUTSIDE and far away

from windows, doors and vents.

GENERAL SAFETY

• Before starting or

servicing any generator,

read and understand all

instructions. Failure to

follow safety precautions

or instructions can cause equipment

damage and / or serious personal

injury or death. Engine instructions

for these units are contained in

a separate manual. Retain all

manuals for future reference.

FUEL AND

ARE EXTREMELY FLAMMABLE!

Allow engine to cool at

least two (2) minutes before

refueling. Do not use gasoline / ethanol

blends with greater than 15% ethanol.

Never

this generator in an explosive

or flammable atmosphere or

poorly ventilated area.

• Never use this generator for

any application other than that

specified by the manufacturer.

Never operate this generator under

conditions not approved by the

manufacturer. Never attempt to

modify this generator to perform

in any manner not intended by the

manufacturer.

• For maintenance and repairs,

use only products and parts

recommended by the manufacturer.

• Be sure that the generator is

properly grounded to an external

ground path prior to operation.

Refer to the section entitled

"Grounding Instructions" for

proper grounding procedures.

• Be sure that the generator is

operated only by persons who

have read and understand these

instructions.

VAPORS

operate

2

MANUAL

• Be sure that the generator is placed

on a flat level surface prior to and

during operation. The generator

must not slide or shift during

operation.

• Keep all persons away from the

generator during operation.

• Do not allow persons wearing

loose clothing or jewelry to start

or operate the generator. Loose

clothing or jewelry may become

entangled in moving components,

causing equipment damage and or

personal injury.

• Keep all persons away from parts

that move or become hot during

operation.

• Be sure all powered devices are

shut off prior to connecting them

to the generator.

• Keep the generator clean and well

maintained at all times.

• Be sure that all tools and appliances

are in good repair and are properly

grounded. Use devices that have

three prong power cords. If an

extension cord is used, be sure

that it has three prongs for proper

grounding.

Do not operate this

generator on wet

surfaces or in the rain.

Shut off the engine

and disconnect the

spark plug wire before performing any

service or maintenance to the unit.

• Use only unleaded fuel. Do not

refill the fuel tank while the engine

is running. Use precautions to

prevent fuel spillage during refills.

Be sure the fuel tank cap is securely

in place before starting the engine.

Clean up any spilled fuel before

starting the engine. Allow engine

to cool for at least two minutes

before refueling. Do not add fuel

while smoking or if unit is near

any sparks or open flames. Do not

overfill tank - allow room for fuel

to expand. Always keep nozzle in

contact with tank during fueling.

• This generator may be used for

emergency stand-by service. In

such cases, a manual transfer

switch must be installed between

the electric utilities meter and the

electrical distribution box. This

switch should be installed by a

licensed electrician.

Page 3

GN5060, GN6575

General Safety Information

(Continued)

Never mix oil with

gasoline for this

engine. This is a four cycle engine

designed to run on pure gasoline. Oil

is used for engine lubrication purposes

only.

HOT

SURFACES! Hot surfaces

will severely burn flesh. Do

not touch engine, muffler,

and alternator until the unit has fully

cooled.

Always

keep a

fire extinguisher accessible

while operating unit.

• All installation, maintenance, repair

and operation of this equipment

should be performed by qualified

persons only in accordance with

national, state, and local codes.

Improper

use of

electric generators can cause

electric shock, injury, and

death! Take all precautions

described in this manual to reduce the

possibility of electric shock.

• Verify that all components of

the generator are clean and in

good condition prior to operating

the generator. Be sure that the

insulation on all cables and power

cords is not damaged. Always repair

or replace damaged components

before operating the generator.

Always keep panels, shields, etc.

in place when operating the

generator.

• Always wear dry protective

clothing, gloves, and insulated

footwear.

• Always operate the generator in a

clean, dry, well ventilated area. Do

not operate the generator in wet,

rainy, or poorly ventilated areas.

• Never use the generator as a work

surface.

If the generator

becomes wet for

any reason, be absolutely certain that

it is completely clean and dry prior to

attempting use!

• Always shut the equipment off

prior to moving the unit.

ADDITIONAL SAFETY STANDARDS

Safety and Health Standards

OSHA 29 CFR 1910, from

Superintendent of Documents,

U.S. Government Printing Office,

Washington, D.C. 20402

National Electrical Code

NFPA Standard 70, from National Fire

Protection Association, Batterymarch

Park, Quincy, MA 02269

Glossary of Terms

CC (Cubic Centimeter) - measure of

the engine's cylinder volume above the

piston when measured with the piston

fully retracted by the crankshaft.

Four Stroke Engine - an internal

combustion engine in which the piston

completes four separate strokes; intake,

compression, power, and exhaust during

two separate revolutions of the engine's

crankshaft.

RPM - Revolutions per Minute. Typically

this is for measuring engine crankshaft

or alternator rotor speed.

EPA - United States Environmental

Protection Agency.

CARB or ARB - California

Environmental Protection Agency Air

Resources Board.

NEC - National Electrical Code

UL - Underwriters Laboratories

CSA - Canadian Standards Association

NEMA - National Electrical

Manufacturers Association

Alternator - an electromechanical

device that converts mechanical energy

to electrical energy in the form of

alternating current.

Hertz (Hz) - a unit of frequency of

alternating current measured in cycles

per second.

Brushless - an alternator that creates

a magnetic field in the rotor that

induces electrical current in stationary

conductors which are wound as coils.

By contrast, brush type generators

commute electrical current from the

rotor to the stator through carbon

spring loaded brushes that make

electrical contact through commutator

bars.

AC (Alternating Current) - an

electrical current that reverses its

direction periodically or at a frequency.

DC (Direct Current) - an electrical

current that moves in one direction

therefore having a polarity.

Volt (V) - a measurement unit of work

needed to move an electric charge.

Ampere (A) or (I) - a unit to define the

rate of flow of electrical current.

Watt (W) - a unit of electrical power

calculated by W = V x I or

W = volts x amps.

Kilowatt (KW) - a unit of watt

measurement equal to W/1000. For

example: 5000W = 5KW.

Power Factor (PF) - the ratio of the

real power flowing to the load to the

apparent power in the circuit.

Kilo Volt-Ampere (KVA) - the unit

used for the apparent power in an

electrical circuit. KVA = KW/PF.

GFCI (Ground Fault Circuit

Interrupter) - a circuit breaker that

opens when leakage current is detected.

Thermal Circuit Breaker (CB) - a

circuit breaker that opens when current

exceeds the circuit breaker's current

limit.

Pre-Operation

LOCATION

Selecting the proper location can

significantly increase performance,

reliability and life of the generator.

For best results locate the generator in

an environment that is clean and dry.

Dust and dirt in the unit retain moisture

and increase wear of moving parts.

INSTRUCTIONS

Check engine oil level. Oil is NOT mixed

with the gasoline, however adequate

oil supply is necessary for proper

engine lubrication. Refer to the Engine

Manual for SAE, API and fill quantity

specifications. Unit is shipped without

oil in engine.

3

www.chpower.com

Page 4

Operating Instructions and Parts Manual

Pre-Operation (Continued)

GROUNDING

1. Use the ground terminal and

wing nut on the generator frame

to connect the unit to a suitable

ground source. Securely fasten

the end terminal of the ground

wire to the ground terminal on

the generators frame. Tighten the

washer and wing nut on top of the

ground wire end terminal.

2. The ground wire should be made

of #8 gauge wire. Do not use wire

with a higher gauge number.

Higher gauge numbers indicate

thinner wire, which may not

provide an adequate ground path.

3. The other end of the ground wire

must be securely fastened to an

approved ground source.

The following are ground sources

approved by the National Electric

Code. Other ground sources may be

acceptable. Refer to the National

Electric Code and local regulations for

further ground source information. If

not sure of regulations or procedures,

obtain assistance from a qualified

(licensed or certified) electrical

technician.

a. An underground water pipe at

least ten feet in length

b. A non-corrosive underground

pipe at least eight feet in length

and 3/4 inch diameter

c. A steel or iron underground rod

at least eight feet in length and

5/8 inch diameter

d. A non-ferrous rod at least

eight feet in length, 1/2 inch

in diameter, and approved for

grounding purposes

Any rod or pipe used for grounding

must be driven to eight feet deep or

buried in the deepest possible trench.

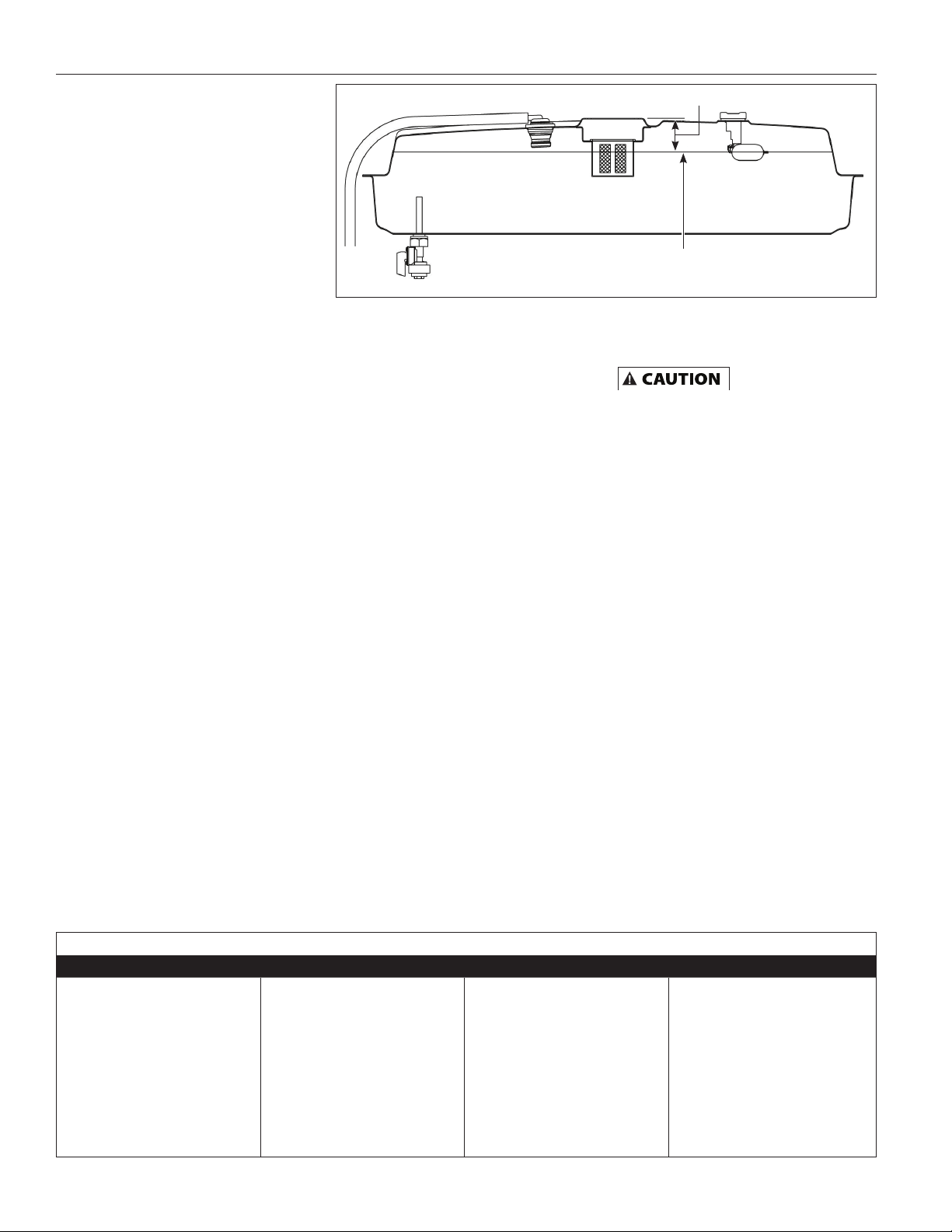

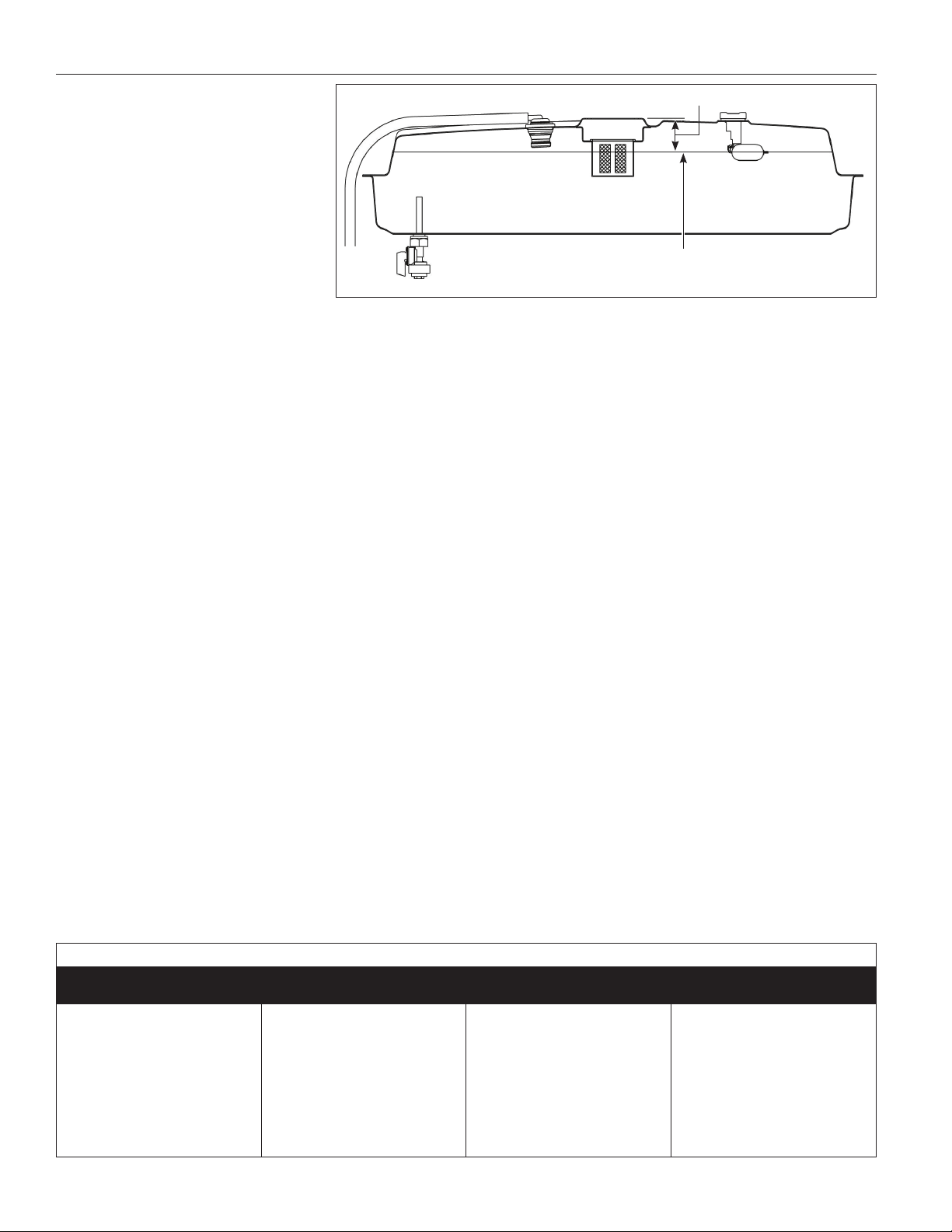

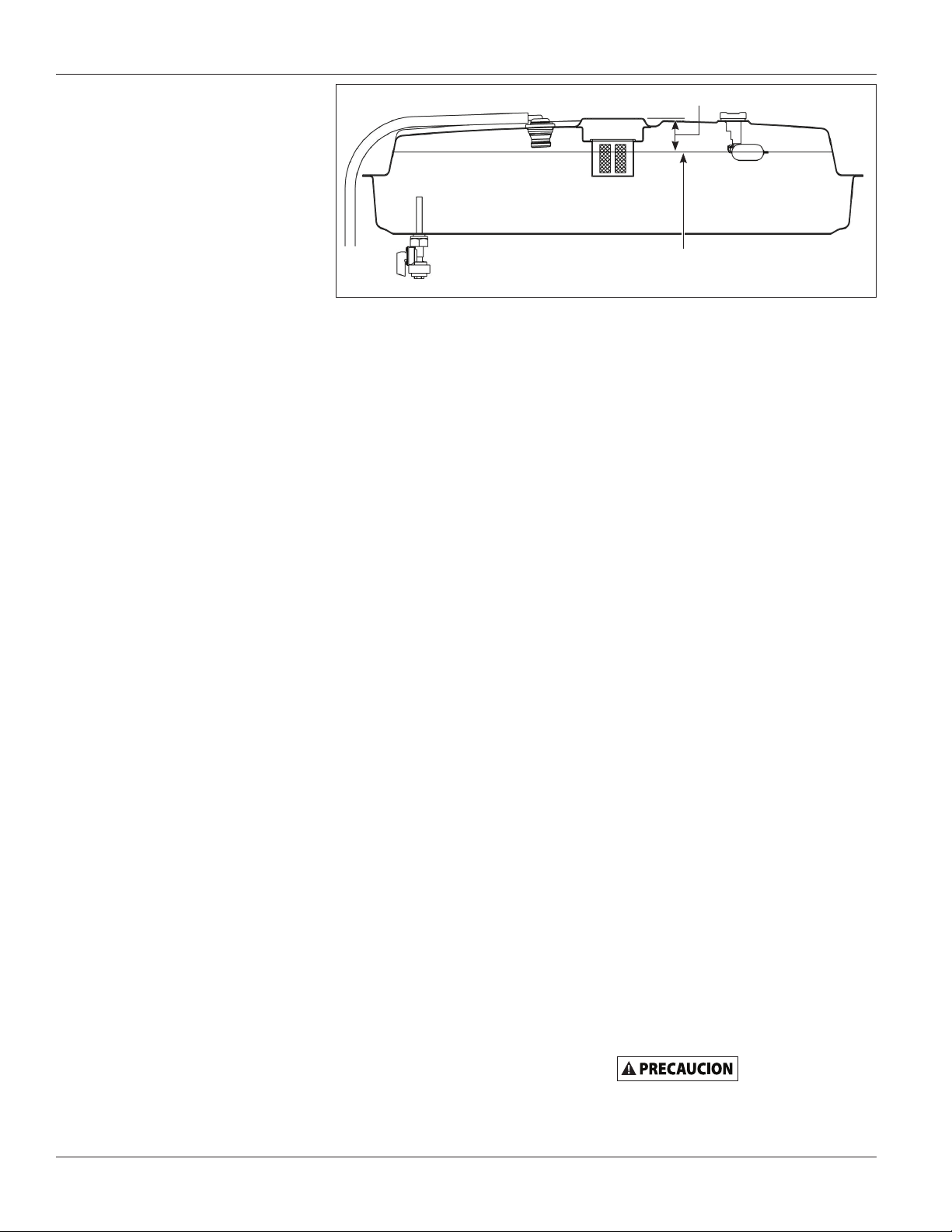

Figure 1

FUELING AND REFUELING

(SEE FIGURE 1)

1. Shut-off engine and wait 2 minutes

before filling fuel tank.

2. Remove fuel cap and fill fuel tank

to bottom of metal filler neck;

about 1-3/8 inch [3.5 cm or 35 mm]

from top of filler neck opening.

3. Do not overfill fuel tank. Overfilling

may damage roll-over valve and

carbon canister.

4. Reinstall fuel cap; make sure to

rotate cap clockwise unit it stops.

STARTING

1. Remove all electrical loads from the

generators.

2. Rotate fuel petcock valve lever,

located on underside of fuel tank,

to the vertical position to open

valve.

3. Flip engine toggle switch (on

control panel) to the ON position.

4. The engine is equipped with an

automatic choke. However, the

choke mechanism has a manual

override feature for extreme cold

weather starting. For extreme cold

weather starting, pull choke wire;

after engine warms, push choke in

to it's normal operating position.

5. Pull the starter rope with a brisk,

smooth motion.

1-3/8 inch [3.5 cm or 35 mm]

Gasoline Fill Level

6. After each start up, allow the

engine to run for 2-3 minutes with

no load.

Engine speed is

preset to provide

proper output voltage. Never attempt

to modify or adjust engine speed or

output voltage.

ENGINE BREAK-IN

After initial start-up, the engine

should be broken in according to the

manufacturer's instructions. Refer to the

engine manual for the proper break-in

procedure.

SHUT-OFF

1. Shut off and remove all electrical

load devices from the generator.

2. Allow the engine to run for 2-3

minutes with no electrical loads.

3. Flip the engine toggle switch (on

control panel) to the OFF position.

4. Verify that the generator has

completely stopped.

5. Rotate fuel petcock valve lever,

located on underside of fuel tank,

to the horizontal position to close

valve.

6. Allow the unit to cool before

installing any covers.

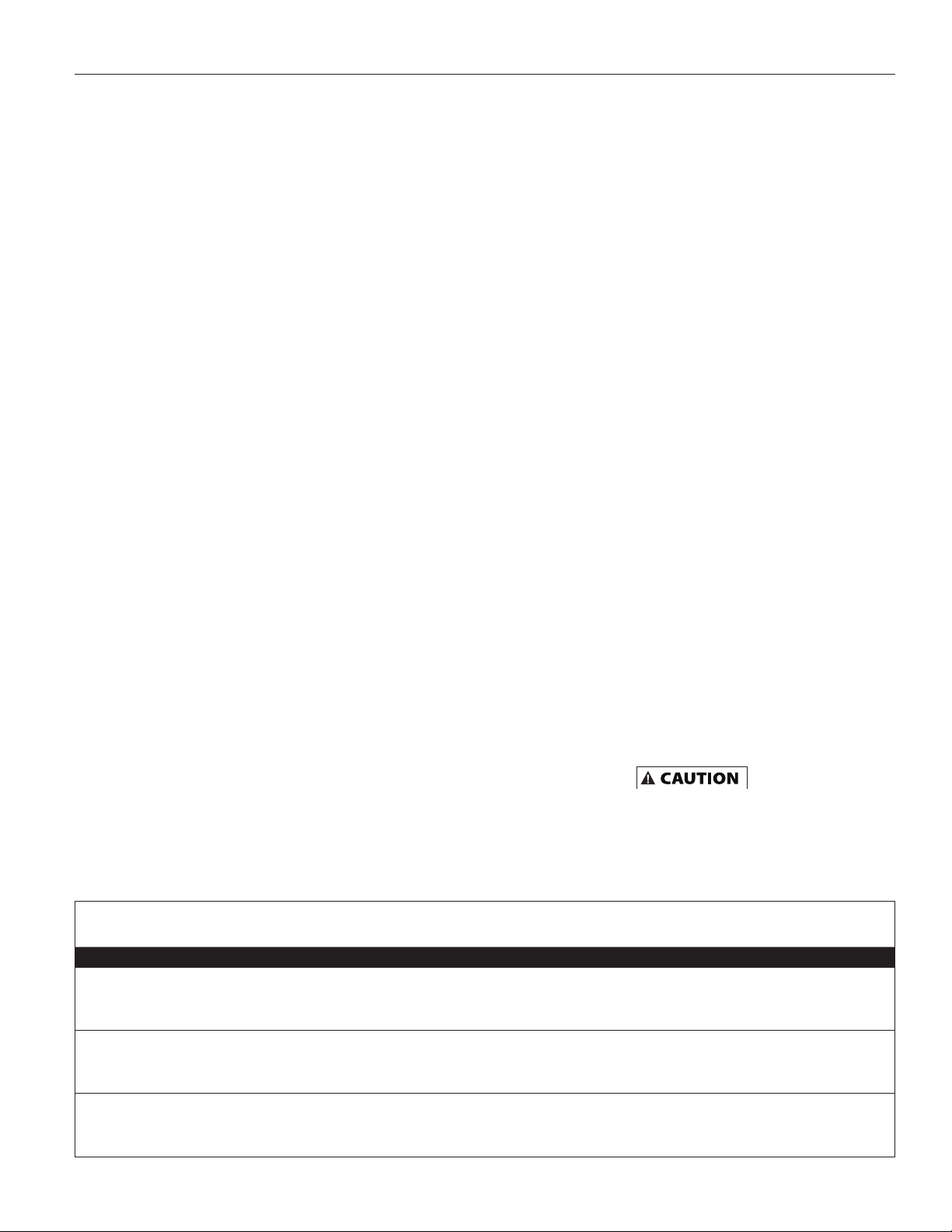

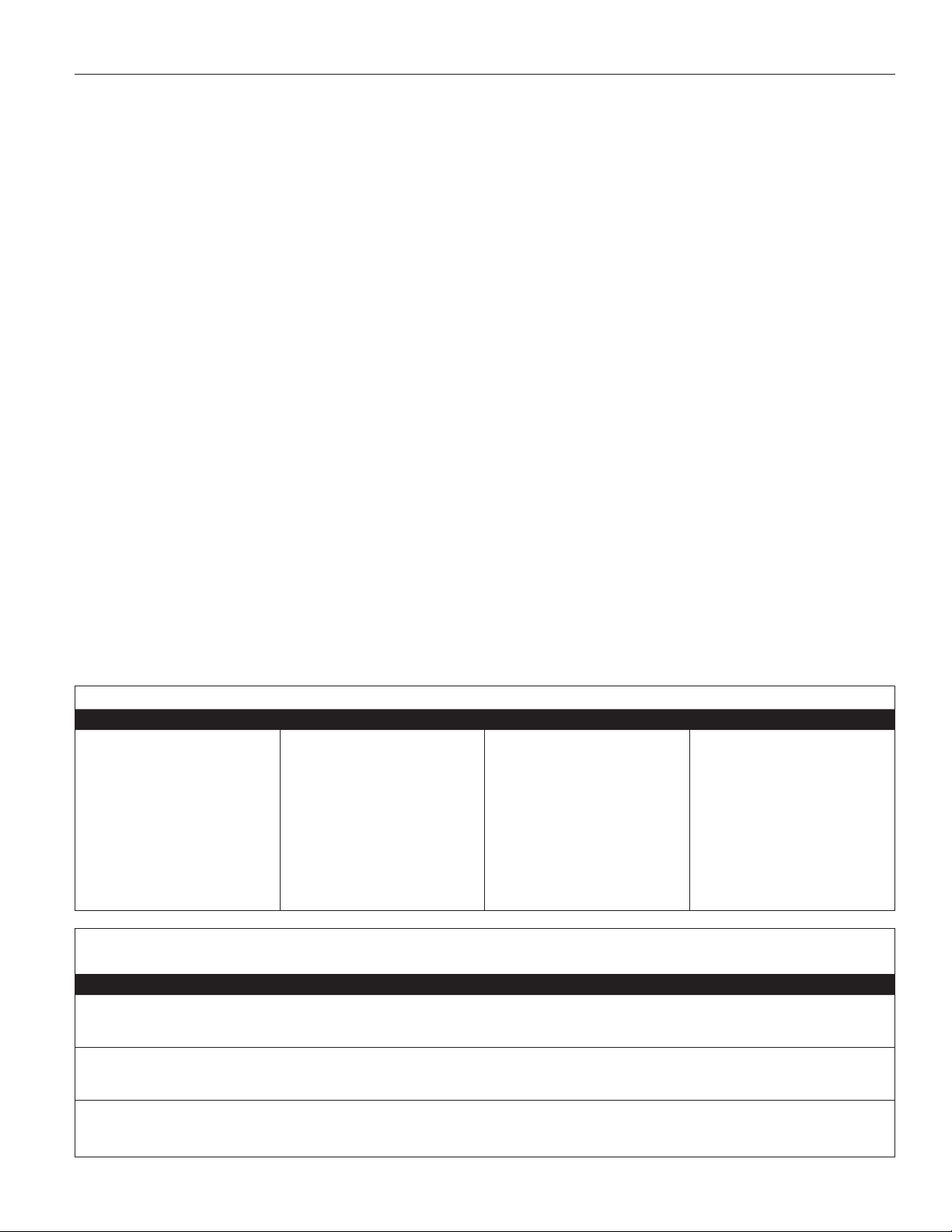

TABLE 1 - ESTIMATED POWER USAGE (WATTS)

LOAD DEVICE WATTS LOAD DEVICE WATTS LOAD DEVICE WATTS LOAD DEVICE WATTS

Air conditioner 2000-3000 Electric drill

(large)

Automatic

washer

Brooder 100+ Freezer 300-500 Skillet 1200 Water pump 1000-3000

Clothes dryer 5000-10,000 Hot plate 330-1100 Space heater 600-4800 Water heater 1000-5000

Coffee maker 400-700 Iron 500-1500 Sump pump 400-3000 Small hand saw 1000-2000

Electric drill

(small)

www.chpower.com

150-1500 Fan 40-200 Refrigerator 190-2000 Vacuum cleaner 200-300

225-1000 Light bulb AS RATED Television 200-500 Large hand saw 1500-2500

500-1000 Radio 50-200 Toaster 900-1700

4

Page 5

GN5060, GN6575

Pre-Operation (Continued)

AUTO-IDLE CONTROL (IF EQUIPPED)

Some units have an auto-idle control

that idles the engine when there is no

demand required of the generator.

The control panel has an idle control

toggle switch to enable or disable this

function.

1. Idle Control Switch - ON enables

the auto-idle feature and the

engine will automatically idle when

not under load.

2. Idle Control Switch - OFF disables

the auto-idle feature and the

engine will run at full throttle.

LOW OIL SHUTDOWN

A low oil shutdown switch is provided

to protect the engine and generator

on most extended run models. When

engine oil level drops too low for

proper engine operation, the low oil

shutdown switch causes the engine

to shut off. If oil level is low when

attempting to start the generator

engine, the low oil level shutdown

switch prevents the engine from

starting. If engine does not start, check

oil level.

NOTE: It is important to keep the

generator unit on a level surface. The

oil level shutdown switch can prevent

the engine from starting even if oil level

is sufficient, when the generators unit is

placed on an uneven surface.

Operation

LOAD DEVICES

1. All load devices and extension cords

should use three prong terminals.

Refer to Table 2 for extension cord

and cable size requirements.

2. Allow the engine to run for 2-3

minutes before applying any

electrical loads.

3. The 120 volt receptacles are rated

for 20 amps and may be used in any

combination of 120 volt loads and

also with 240 volt loads through

the 240 volt receptacles.

The 240 volt receptacles, found

on some generators, are rated for

20 amps and may be used in any

combination of 240 volt loads and

also with 120 volt loads through

the 120 volt receptacles.

The 120/240 volt twist lock

receptacle is rated for 20 amps and

may be used in any combination of

120 volt and 240 volt loads.

4. Individual receptacles should not

be loaded beyond the amperage

rating.

5. Total combined load through

any combination of receptacle

must not exceed the rated load

limits of the generator. Refer to

the identification plate on the

generators for amp and wattage

specifications.

6. Always shut off and remove loads

before starting or shutting off the

generator engine.

7. When plugging multiple electrical

load devices into the generator

receptacles, be sure to connect and

activate the highest power draw

item first. Allow the generator

engine to stabilize, then connect

and activate the next highest power

draw device. The smallest power

draw device should be connected to

the receptacle and activated last.

NOTE: Power draw can be calculated

by multiplying volts and amps. The

resulting number is wattage.

Never exceed the posted maximum

wattage for the generator or any

individual receptacle. Refer to owner's

manuals and product tags to determine

the wattage of all electrical load

devices.

If actual watt ratings are not available,

the Power Usage Chart, see Table 1, may

be used as a general guideline.

Remember that devices which generate

heat during operation such as heaters,

incandescent light bulbs, motors and

hair dryers have a higher power draw

than devices which generate little heat

during operation such as florescent

bulbs, radios, and clocks.

Long power cords and extension cords

also draw additional power. Keep cords

at minimum possible length.

Refer to Table 2 for maximum limits for

lengths of extension cords.

8. Circuit protection is provided by a

circuit breaker. The circuit breaker

opens when the generator load

exceeds its maximum capacity

or a short circuit occurs. If the

circuit breaker opens, perform the

following procedures to correct the

problem:

a. Shut off and disconnect all

electrical loads.

b. Attempt to determine the cause

of the electrical problem overloading or short circuit.

c. Do not use any devices that have

short circuits. Avoid overloading

the generator.

d. Press the circuit breaker

pushbutton to reset the circuit

breaker.

Repeated cycling of

the circuit

breaker indicates a problem and

may cause damage to the generator

or load devices. Do not operate the

generatoreated cycling of the circuit

breaker occurs.

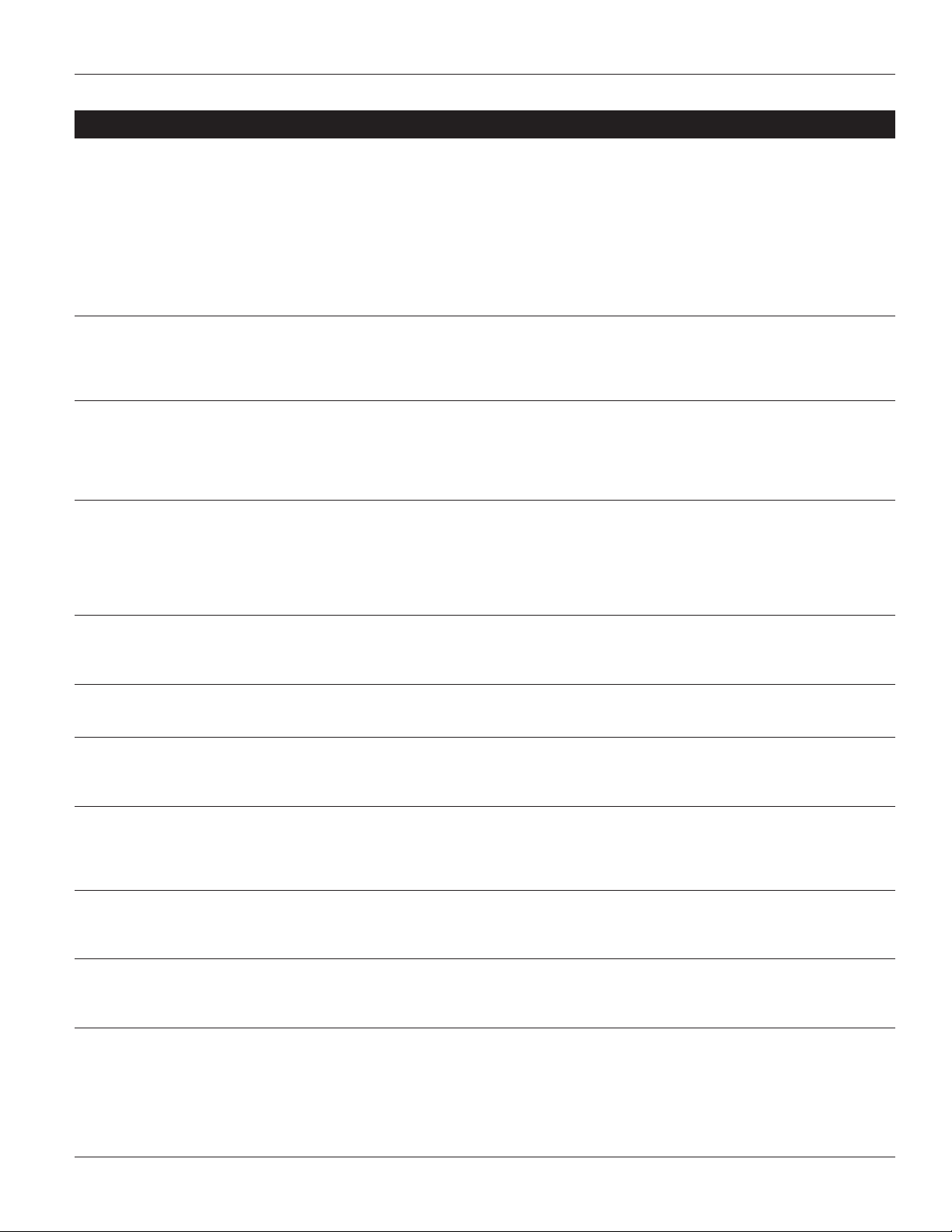

TABLE 2 - EXTENSION CORDS

Maximum Recommended Lengths (in feet)

Amps Watts 120 V Watts 240 V #8 Wire #10 Wire #12 Wire #14 Wire #16 Wire

2.5 300 600 1000 600 375 250

5 600 1200 500 300 200 125

7.5 900 1800 350 200 125 100

10 1200 2400 250 150 100 50

15 1800 3600 150 100 65

20 2400 4800 175 125 75 50

25 3000 6000 150 100 60

30 3600 7200 125 65

40 4800 9600 90

www.chpower.com

5

Page 6

Operating Instructions and Parts Manual

Operation (Continued)

INSTALLATION FOR STAND-BY USE

Precautions must be taken to prevent

electrical back feeding into utility

systems. This requires isolation of

the electrical system. To isolate the

electrical system, perform the following

procedures:

1. Turn off the main electrical system

switch prior to connecting the

generator.

2. In accordance with national and

local standards, a double throw

transfer switch must be installed in

the system.

Always shut off

main power prior to

temporary connection of the generator

to a building electrical system.

Installation of the

generator as a

backup electrical source must be

performed by a qualified (licensed or

certified) electrical technician.

Maintenance

INFREQUENT USAGE

If the generator is used infrequently,

starting difficulty may occur. To help

prevent this, the generators should be

run for approximately 30 minutes per

week.

STORAGE

If the generator is not to be used for

extended periods of time, the following

pre-storage procedures should be

performed:

1. Make sure engine oil is filled to the

proper level.

2. Drain all fuel from the tank, lines,

carburetor and fuel valve.

3. Remove the spark plug, and pour

approximately one teaspoon of oil

into the spark plug hole.

4. Pull the starter cord several times

to spread the oil throughout the

cylinder.

5. Slowly pull the starter cord, until

resistance is felt. This indicates that

the piston is moving upward on the

compression cycle, and the intake

and exhaust valves are closed. (The

piston pushes a small amount of

air from the spark plug hole on

compression.)

6. Use of fuel stabilizers or antigumming agents in the fuel system

can help prevent the build up of

gum and varnish.

Whenever the generator is stored, be

sure that the fuel shut-off valve is in the

closed position.

Refer to the engine manual that

accompanies this unit for instructions

regarding maintenance of engine

components.

Never tamper with

engine speed

settings. Any governor adjustments

should be made by qualified personnel

only.

www.chpower.com

6

Page 7

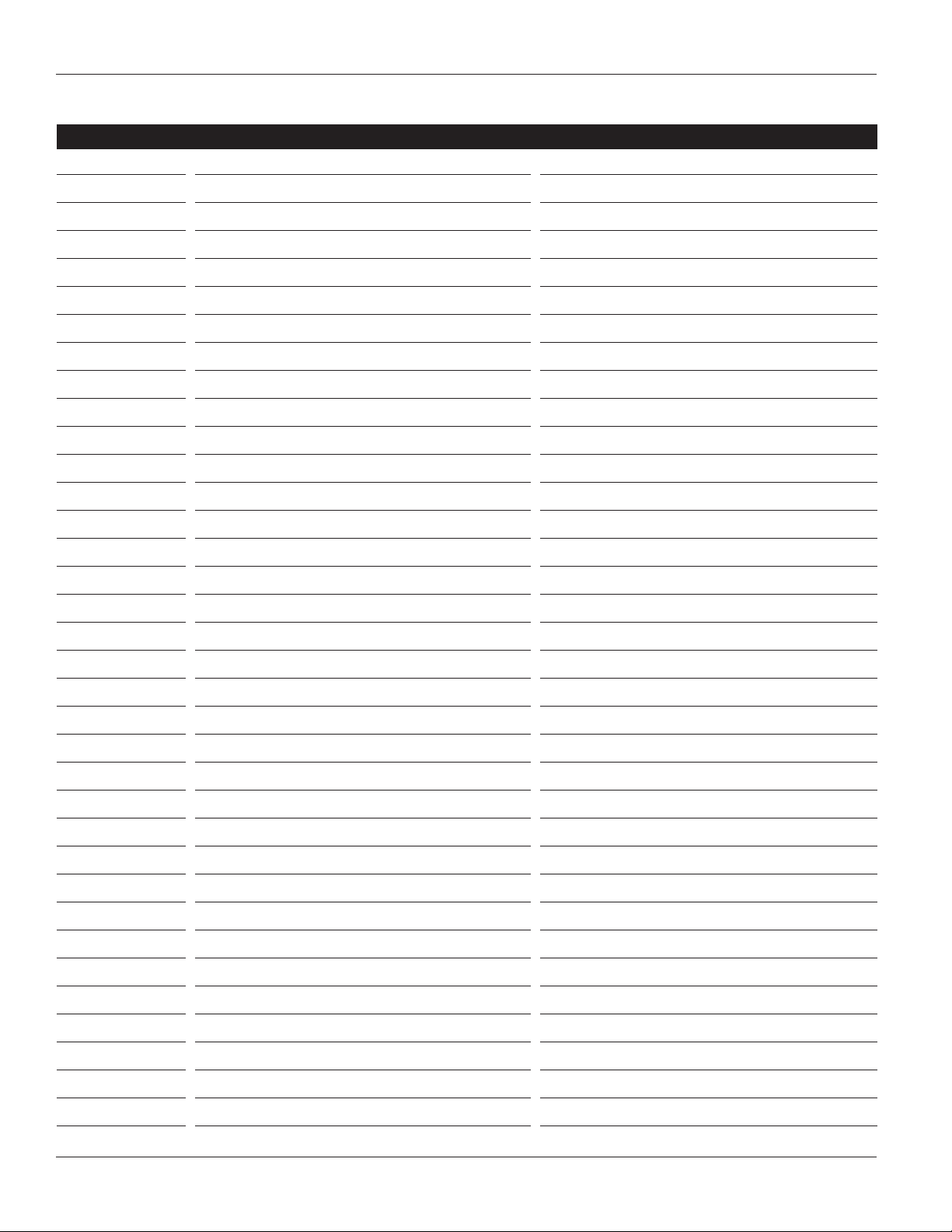

Troubleshooting Chart

Symptom Possible Cause(s) Corrective Action

Engine will not

start

Engine runs

but there is no

electrical output

Generator runs

but does not

support all

electrical devices

connected.

No output

voltage

Low output

voltage with no

load

High output

voltage with no

load

Low output

voltage under

load

Erratic output

voltage

Noisy operation 1. Loose generator or engine bolt

Auto-Idle does

not work

★ These diagnostic and repair procedures should be performed by an authorized service center.

1. Run switch is set to "OFF".

2. Fuel valve is turned to "CLOSE".

3. Choke is open.

4. Fuel tank is empty.

5. Engine is filled with

contaminated or old gas

6. Spark plug is dirty.

7. Spark plug is broken.

8. Unit is not on level surface.

9. Oil is low.

1. Main or secondary circuit

breaker(s) are tripped.

2. Bad connecting of wires / cables.

3. Bad electrical device connected

to generator.

1. Generator is overloaded

2. Short in one of the connected

devices.

3. Air cleaner is dirty.

1. Engine speed is too slow

2. Open, shorted, or incorrect

wiring

3. Faulty capacitor

4. Open or shorted field windings

5. Open diodes

6. Circuit breaker tripped

1. Engine speed is too slow

2. Open diodes

3. Faulty capacitor

4. Open or shorted fi eld windings

1. Faulty capacitor

2. Engine speed is too fast

1. Open diode

2. Engine speed too slow at full

load

3. Excessive load applied

1. Unbalanced engine

2. Dirty, corroded, or loose wiring

connection

3. Unstable load applied

2. Short circuit in generator field or

load

3. Faulty bearing

1. Damaged or disconnect wire in

idle control circuit.

2. Failed idle control circuit board.

3. Failed current sensing coil.

1. Set run switch to "ON".

2. Turn fuel valve to "OPEN" position.

3. Close the choke.

4. Add gas.

5. Change the gas in the engine.

6. Clean spark plug.

7. Replace spark plug.

8. Move unit to a level surface to prevent low oil shutdown from

triggering.

9. Add or replace oil.

1. Reset main or secondary circuit breaker(s).

2. If you are using an extension cord, try a different one.

3. Try connecting a different device.

1. Turn off all electrical devices. Unplug all electrical devices. Turn

off generator. Wait several minutes. Restart generator. Try

connecting fewer electrical loads to the generator.

2. Try disconnecting any faulty or short-circuited electrical loads.

3. Clean or replace air cleaner.

1. Adjust engine speed. ★

2. Referring to the wiring diagram, clean and reconnect all

wiring. ★

3. Replace capacitor. ★

4. Test winding resistance, replace field winding if necessary. ★

5. Test diodes, replace if necessary. ★

6. Reset circuit breaker.

1. Adjust engine speed. ★

2. Test diodes, replace if necessary. ★

3. Replace capacitor. ★

4. Test winding resistance, replace field winding if necessary. ★

1. Replace capacitor. ★

2. Adjust engine speed. ★

1. Test diodes, replace if necessary. ★

2. Adjust engine speed. ★

3. Reduce the applied load.

1. Refer to engine manual.

2. Referring to the wiring diagram, clean and reconnect all

wiring. ★

3. Remove all loads, then apply each one individually to

determine which one is causing erratic function.

1. Tighten all mountings.

2. Test winding resistance, replace fi eld winding if necessary.

Test load devices for shorts. Replace defective load device.

3. Replace bearing.

1. Repair or replace wiring.

2. Replace idle control board.

3. Replace current sensing coil.

GN5060, GN6575

★

7

www.chpower.com

Page 8

Operating Instructions and Parts Manual

Service Record

Date Maintenance performed Repair components required

www.chpower.com

8

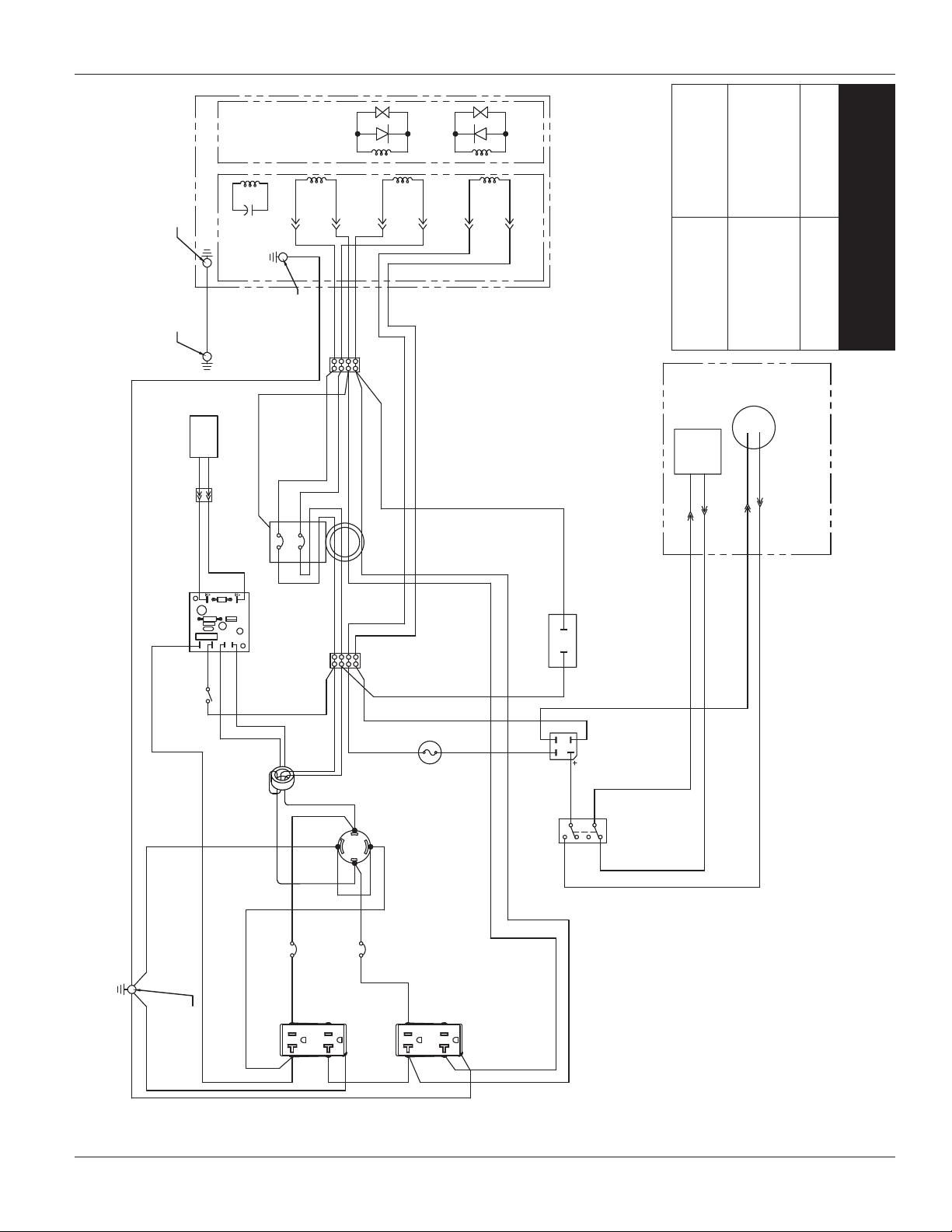

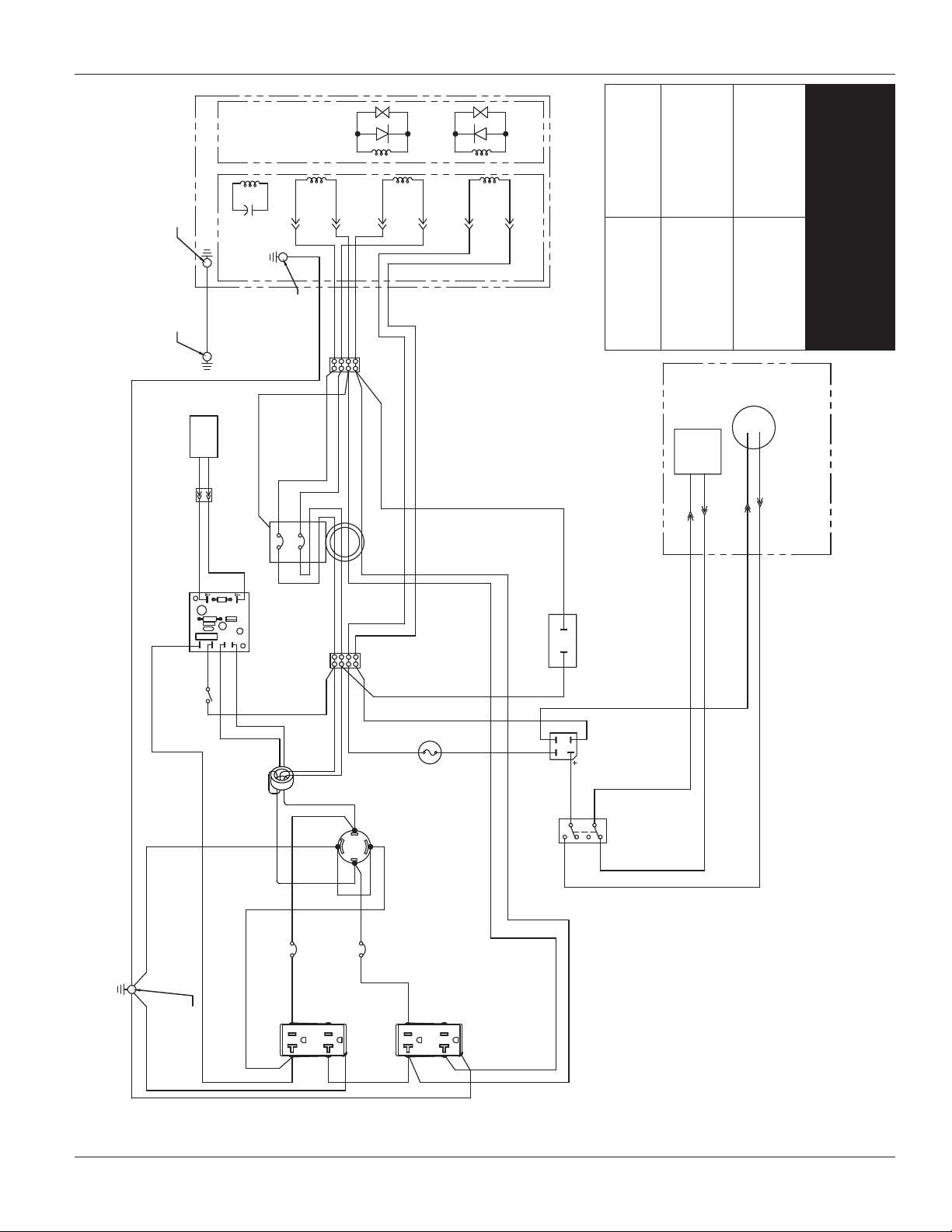

Page 9

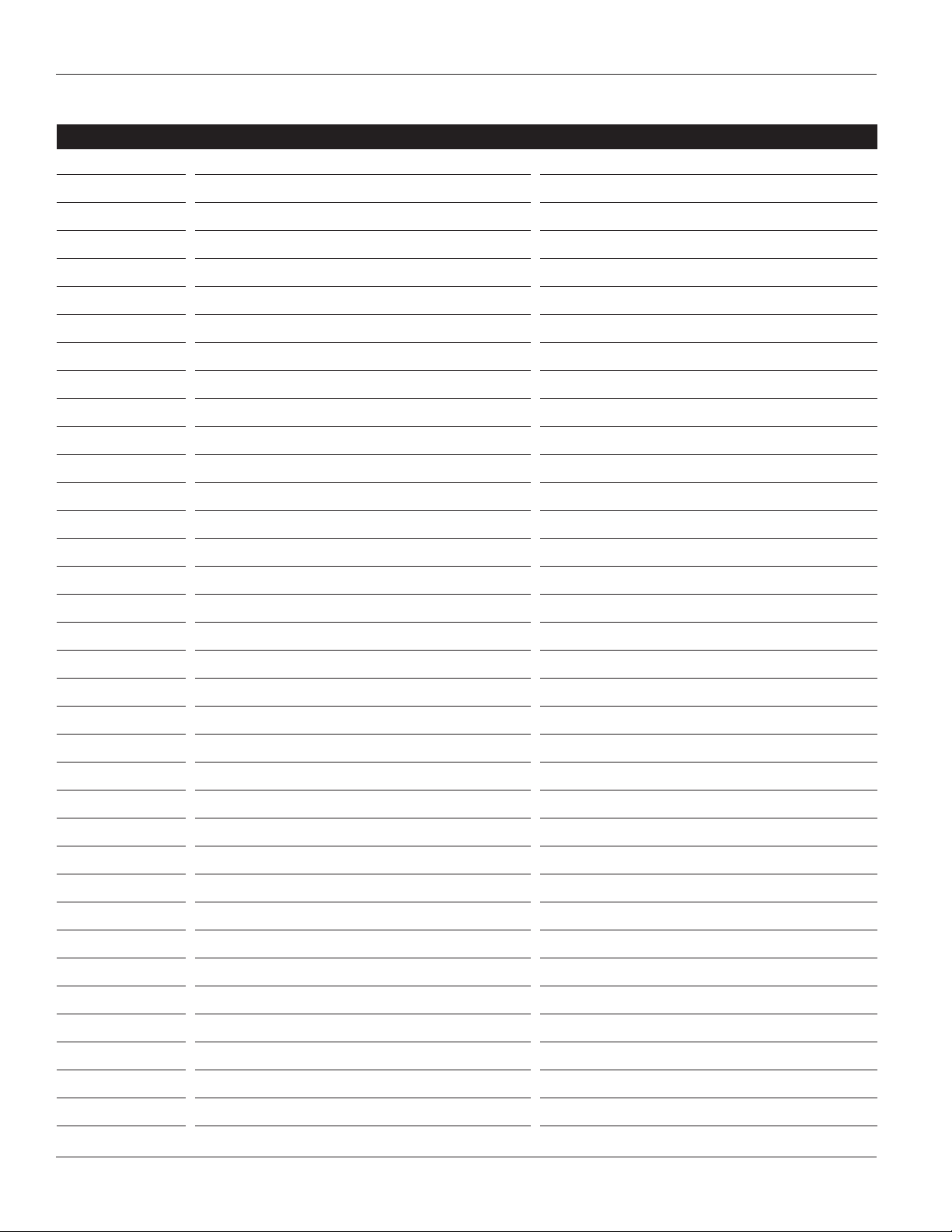

J1128, Type TXL

Ins.

GN5060, GN6575

8 AWG, SAE J1128,

GPTI

12 AWG, UL 1015/

16 AWG, SAE

UL 1230

Stranded Copper

Wire Lead

Specifications

GREEN

26

ALTERNATOR HOUSING

GENERATOR FRAME

WHITE

GROUND SCREW AT

GROUND SCREW AT

IDLE CONTROL

SOLENOID

IDLE CONTROL

CIRCUIT BOARD

ALTERNATOR

33

BLACK

33

AC2 AC1 TR1 TR2

IDLE CONTROL

SWITCH

ROTOR STATOR

EXCITATION

WINDING

CAPACITOR

BLACK

WHITE GFCI WIRE

32

BLACK

BREAKER

CIRCUIT

2-POLE

GFCI

CB1

32

BLACK

24

L1

30

GROUND SCREW IN

ALTERNATOR HOUSING

13

14

15

16

120V

MAIN WINDING

GREEN

BLACK BLACK

23

BLACK

N

1311121443

BROWN

BLUE

15

16

361718

TB1

WHITE

TB2

MAIN WINDING

120V

L2

N

ORANGE

ORANGE

WHITE

37

44

12V

AUXILLIARY WINDING

43 44

BLACK

HOUR METER

25, 26, 27, 28, 29,

30, 31, 34, 35, 45

23, 24, 28, 32, 33,

36, 37, 38, 39, 40,

42, 43, 44, 46

IGNITION MODULE

42

40

BLACK

PINK

per Schematic

Ground Wire at

Generator Frame

11, 12, 13, 14, 15,

16, 17, 18, 19, 20,

CARBURETOR

SOLENOID

ENGINE

41

39

YELLOW

YELLOW / WHITE

Wire Number

LOOP THROUGH COIL

GREEN GREEN

GREEN

30 31

45

29

GROUND SCREW AT

CONTROL PANEL

GREEN

Figure 2 - Wiring Diagram

BLACK WIRE HAS (2)

LOOPS THROUGH COIL

BROWN WIRE HAS (1)

CURRENT SENSING COIL

BREAKER

CIRCUIT

RECEPTACLE

BLACK

20A

CB3

35

20A DUPLEX

25

BROWN

19 35

26

BROWN

BLACK

19

45

28

BREAKER

CIRCUIT

27

BROWNBROWN

18

20A

29

ORANGE

17

20

CB2

ORANGE

RECEPTACLE

NEMA L15-30R

28

20 34

BLACK

RECEPTACLE

120 / 240 VOLT

25

WHITE

20A DUPLEX

27

GREEN

36

34

11

46

FUSE - 15A

37

39 46

RECTIFIER

38

AC

RED

38

ENGINE

CONTROL

SWITCH

WHITE

BLUE

12

31

40

42

41

www.chpower.com

9

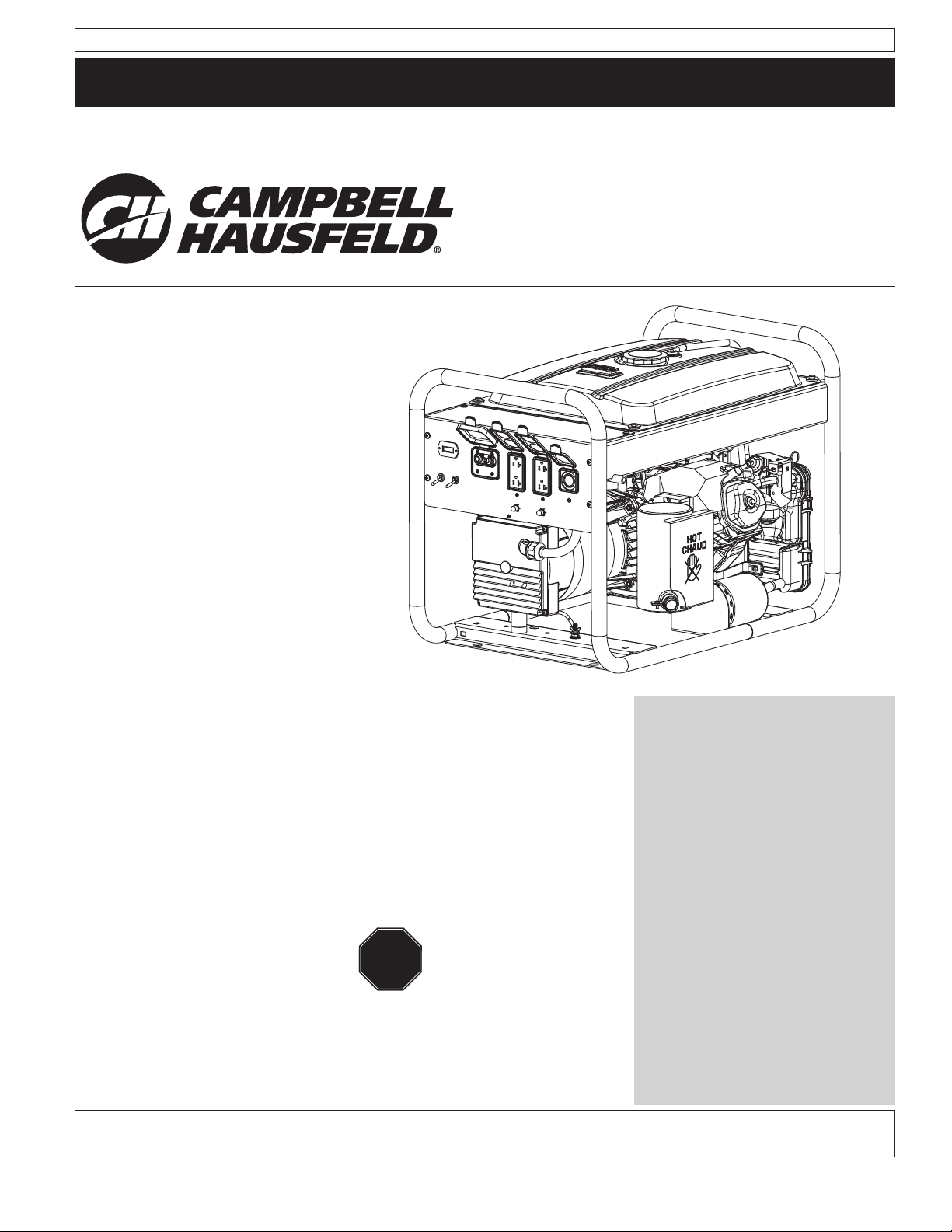

Page 10

Operating Instructions and Parts Manual

Generator Assembly

27

28

26

2

32

30

4

3

8

29

23

22

24

14

13

17

25

19

18

12

16

11

10

15

14

1

31

20

21

7

6

9

5

Figure 3

www.chpower.com

10

Page 11

For replacement parts or technical assistance, call 1-800-803-1436

GN5060, GN6575

Please provide following information:

- Model number

- Serial number (if any)

- Part description and number as shown in parts list

Address parts correspondence to:

Campbell Hausfeld

Attn: Customer Service

100 Mundy Memorial Dr.

Mt. Juliet, TN 37122 USA

Replacement Parts List

Ref.

No. Description Part Number Qty.

1 Generator Frame GN051081SJ 1

2 Honda Engine and Sincro Alternator Assembly See Page 12 1

3 1/4 inch ID Fuel Hose, 8-1/4 inch L, Carb. to Petcock (GN5060 Only)

4 3/8 inch Constant tension hose clamp (GN5060 Only) MJ111006AV 2

5 Hex Bolt, 3/8 - 16 UNC X 3 inch L

6 Fender Washer, 3/8 inch

7 ISO Mount Assembly PM004290AV 3

8 Hex Nut, 3/8 - 16 UNC

9 Hex Bolt, 3/8 - 16 UNC X 2-1/2 inch L

10 Hex Bolt, M8 - 1.25 X 70

11 ISO Mount Spacer GN051065AV 1

12 Ground Cable, 8 AWG SAE GN052305AV 1

13 Hex Bolt, 1/4 - 20 UNC X 3/4 inch L

14 Flange Nut, 1/4 - 20 UNC

15 Hex Bolt, 5/16 - 18 UNC X 1-1/4 inch L

16 Star Washer - 5/16 inch Internal / External Tooth

17 Flange Nut, 5/16 - 18 UNC

18 Flat Washer - 0.344 X 0.688 X 0.065

19 Wing Nut, 5/16 - 18 UNC

20 600cc Carbon Canister GN051031AV 1

21 Carriage Bolt - 1/4 - 20 UNC X 3/4 inch L

22 Control Panel Assembly (Includes ALL parts listed on page 14, plus all wiring and conduit) GN051111SJ 1

23 Pan Head Screw, 1/4 - 20 UNC X 3/4 inch L

24 Conduit, 0.62 inch ID, 6 inch L

25 Conduit, 0.62 inch ID, 18 inch L

26 Fuel Tank GN051030AV 1

27 Hex Bolt, 1/4 - 20 UNC X 1 inch L

28 Fender Washer - 1/4 inch

29 Grommet - 0.688 X 0.563 ID Hole X 0.063 Groove

30 1/4 inch ID Fuel Hose, 35 inch L (Tank to Carbon Canister)

31 1/2 inch ID Fuel Hose, 4 inch L (Carbon Canister to Engine)

32 Roll-over Valve GN051032AV 1

Warning Decal - Frame DK667841AV 1

Warning Decal (CPSC) - Fuel Tank DK667848AV 1

Warning Decal (Earth Ground) - Frame DK667849AV 1

Warning Decal (Fueling Process) - Fuel Tank DK667850AV 1

Warning Decal (Not sold in California) - Fuel Tank DK667851AV 1

Warning Decal (Spark Warning) - Frame DK667155AV 1

Warning Decal (EPA Certification) - Frame DK667500AV 1

★

Standard hardware item, available at local hardware stores

★

★

★

★

★

★

★

★

★

★

★

★

★

★

★

★

★

★

★

★

★

★

1

1

3

2

1

1

1

7

1

1

1

2

1

2

6

1

1

4

4

1

1

1

11

www.chpower.com

Page 12

Operating Instructions and Parts Manual

Alternator Assembly

10

8

1

4

3

7

14

5

6

16

13

20

25

18

26

15

11

5

12

8

2

9

17

24

23

22

19

21

Figure 4

www.chpower.com

21

Assembled muffler detail

showing flange hex nut

position.

12

Page 13

For replacement parts or technical assistance, call 1-800-803-1436

GN5060, GN6575

Please provide following information:

- Model number

- Serial number (if any)

- Part description and number as shown in parts list

Address parts correspondence to:

Campbell Hausfeld

Attn: Customer Service

100 Mundy Memorial Dr.

Mt. Juliet, TN 37122 USA

Replacement Parts List

Ref.

No. Description Part Number Qty.

1 Honda GX390 Low Profile Engine GN060001AV 1

Honda GX270 Low Profile Engine GN060000AV 1

2

3

4

5

6 Hex Bolt, 3/8 - 16UNC X 1.00L

7 3/8 inch Lock Washer

8

9

10

11

12

13

14

15

16 Elbow Connector- HEYCO 8425 GN051096AV 1

17 Honda Muffler

18 Muffler Bracket - Honda GX390 Engine GN051012KK 1

19 Flange Hex Nut, M8

20 Hex Bolt- 5/16 - 18 UNC X 0.75 L

21 Flange Hex Nut, 5/16 - 18 UNC

22 Hex Bolt, 3/8 - 16 UNC x 1-3/4 inch L

23 Flange Hex Nut, 3/8 -16 UNC

24 USDA Screen GN051013AV ▲ 1

25 Clamp, USDA Screen GN051014AD ▲ 1

26 Pan Head Self Tapping Screw (Muffler Clamp) GN051015AV ▲ 1

●

Sincro Alternator - 6.8 kVA, 60Hz GN051001SJ 1

■

Sincro Alternator - 5.2 kVA, 60Hz GN051000SJ 1

■ ●

Sincro Engine Adapter Not Available 1

■ ●

Hex Bolt, M8 x 25mm

■ ●

M8 NyLock Nut

■ ●

Screw, Pan Head, M5 X 10mm

■ ●

Sincro Rear Shield GN051016AV 1

■ ●

Capacitor - 35mf, 450V GW001016SV 1

●

Sincro Threaded Rod (6.8 kVA Alt.) GN051008AV 1

■

Sincro Threaded Rod (5.2 kVA Alt.) GN051025AV 1

■ ●

Sincro Rear Cover Kit GN051002SJ 1

■ ●

Sincro Round Hole Plug GN051009AV 1

■ ●

Sincro LH Louver GN051018AV 1

■ ●

Sincro RH Louver GN051017AV 1

Muffler Bracket - Honda GX270 Engine GN051011KK 1

★

★

★

★

★

▲

★

★

★

★

★

4

5

4

4

5

1

2

2

2

1

1

REPLACEMENT PARTS KITS

▲

Honda Muffler Kit GN051010SJ

SYMBOLS DEFINED

■

Included with GN051000SJ - Sincro Alternator (5.2 kVA)

●

Included with GN051001SJ - Sincro Alternator (6.8 kVA)

★

Standard hardware item, available at local hardware stores

13

www.chpower.com

Page 14

Operating Instructions and Parts Manual

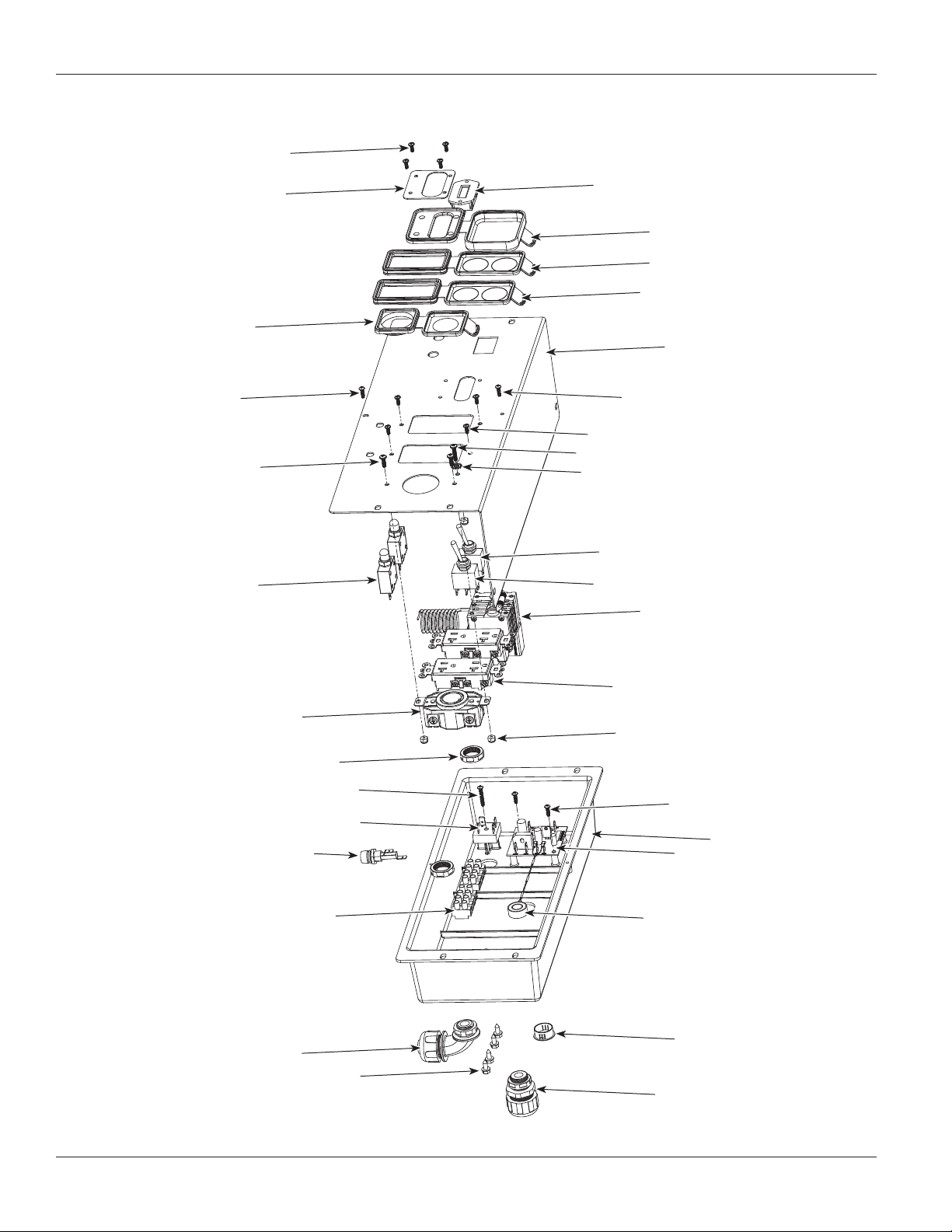

Control Panel Assembly

5

4

8

12

3 6

6

1

26

10

13

26

5

28

29

14

15

2

7

9

22

18

17

30

11

26

16

25

Figure 5

www.chpower.com

21

19

27

24

20

23

14

Page 15

For replacement parts or technical assistance, call 1-800-803-1436

GN5060, GN6575

Please provide following information:

- Model number

- Serial number (if any)

- Part description and number as shown in parts list

Address parts correspondence to:

Campbell Hausfeld

Attn: Customer Service

100 Mundy Memorial Dr.

Mt. Juliet, TN 37122 USA

Replacement Parts List

Ref.

No. Description Part Number Qty.

1 Control Panel GN051093AD 1

2 GFCI Circuit Breaker GN051042AV 1

3 Cover, GFCI Circuit Breaker GN051022AV 1

4 GFCI Cover Plate- Painted GN051024KK 1

5 Pan Head Screw, #6 - 32 X 3/8 inch L

6 Cover, Duplex Receptacle GN051021AV 2

7 Duplex Receptacle- 120V, 20 Amp GN003403AV 2

8 Cover, Twist Lock Receptacle GN051020AV 1

9 Twistlock Receptacle, 125 - 250V, 30 Amp GW004255AV 1

10 Pan Head Screw, #8 - 32 X 1/2 inch L

11 Nylock Nut, #8 - 32

12 Digital Hour Meter GN051094AV 1

13 Thermal Circuit Protector - Pushbutton GN051041AV 2

14 Engine Run-Stop Switch GW004258AV 1

15 Idle Control Switch PM351124AV 1

16 Rear Control Panel Cover GN051023AV 1

17 Bridge Rectifier, 200V, 15 Amp GN006651AV 1

18 Pan Head Screw, 8 - 18 HiLo X 1 inch L

19 Terminal Block GN051099AV 2

20 Tapping Screw, #10 X 1/2 inch L

21 Elbow Connector- Heyco 8425 GN051096AV 1

22 Connector Nut GN051097AV 2

23 Straight Connector - Heyco 8402 GN051095AV 1

24 Control Panel Hole Plug, 7/8 inch ID MJ106807AV 1

25 Idle Control Circuit Board GN051070AV 1

26 Pan Head Screw, #8 - HiLo X 1/2 inch L

27 Idle Control Current Sensing Coil GN051075AV 1

28 Pan Head Screw, #8-32 X 3/4 inch L

29 #8 Lock Washer, Internal / External Tooth

30 Fuse Holder HV010201AV 1

Fuse, 1-1/4 inch x 1/4 inch, 15 Amp (not shown)

★

Standard hardware item, available at local hardware stores

★

★

★

★

★

★

★

★

★

8

3

3

1

4

4

1

1

1

15

www.chpower.com

Page 16

Operating Instructions and Parts Manual

Limited Warranty

1. DURATION: From the date of purchase by the original purchaser as follows: Three Years.

2. WHO GIVES THIS WARRANTY (WARRANTOR): Campbell Hausfeld / Scott Fetzer Company, 100 Mundy Memorial Drive,

Mt. Juliet, TN 37122, Telephone: (800) 803-1436.

3. WHO RECEIVES THIS WARRANTY (PURCHASER): The original purchaser (other than for purposes of resale) of the Campbell

Hausfeld Industrial product.

4. WHAT PRODUCTS ARE COVERED BY THIS WARRANTY: This Campbell Hausfeld generator.

5. WHAT IS COVERED UNDER THIS WARRANTY: Parts and Labor to remedy substantial defects due to material and

workmanship during the first 3 years of ownership with the exceptions noted below. Parts only to remedy substantial

defects due to material and workmanship during remaining term of coverage with exceptions noted below.

6. WHAT IS NOT COVERED UNDER THIS WARRANTY:

A. Implied warranties, including those of merchantability and FITNESS FOR A PARTICULAR PURPOSE ARE LIMITED IN

DURATION TO THIS EXPRESS WARRANTY. After this period, all risks of loss, from whatever reason, shall be on the

purchaser. Some States do not allow limitation on how long an implied warranty lasts, so the above limitations may

not apply to you.

B. ANY INCIDENTAL, INDIRECT, OR CONSEQUENTIAL LOSS, DAMAGE, OR EXPENSE THAT MAY RESULT FROM ANY

DEFECT, FAILURE, OR MALFUNCTION OF THE CAMPBELL HAUSFELD INDUSTRIAL PRODUCT. Some States do not allow

limitations on how long an implied warranty lasts, so above limitations may not apply to you.

C. This warranty does not apply to any accessory items included with the product which are subject to wear from usage;

the repair or replacement of these items shall be at the expense of the owner.

D. Any failure that results from accident, purchaser’s abuse, neglect or failure to operate products in accordance with

instructions provided in the owner’s manual(s) supplied with product.

E. Pre-delivery service, e.g. assembly, oil or lubricants, and adjustment.

F. Gasoline engines and components are expressly excluded from coverage under this limited warranty. The Purchaser

must comply with the warranty given by the engine manufacturer which is supplied with the product.

7. RESPONSIBILITIES OF WARRANTOR UNDER THIS WARRANTY: Repair or replace, at Warrantor’s option, compressor or

component which is defective, has malfunctioned and/or failed to conform within the duration of the specific warranty

period.

8. RESPONSIBILITIES OF PURCHASER UNDER THIS WARRANTY:

A. Please call 800-803-1436 for warranty assistance.

B. Provide dated proof of purchase and maintenance records.

C. All generators must be delivered or shipped to the nearest Campbell Hausfeld Authorized Service Center. Freight

costs, if any, must be borne by the purchaser.

D. Use reasonable care in the operation and maintenance of the products as described in the owner’s manual(s).

9. WHEN WARRANTOR WILL PERFORM REPAIR OR REPLACEMENT UNDER THIS WARRANTY:

Repair or replacement will be scheduled and serviced according to the normal work flow at the servicing location, and

depending on the availability of replacement parts.

This Limited Warranty gives you specific legal rights and you may also have other rights which vary from state to state.

www.chpower.com

16

Page 17

Voir la Garantie à la page 32 pour de l’information importante sur l’utilisation commercial de ce produit.

Instructions d’Utilisation et Manual de Pièces GN5060, GN6575

Veuillez lire et conserver ces instructions. Lire attentivement avant de commencer à assembler, installer, faire fonctionner ou entretenir

l'appareil décrit. Protégez-vous et les autres en observant toutes les informations sur la sécurité. Négliger d'appliquer ces instructions peut

résulter en des blessures corporelles et/ou en des dommages matériels ! Conserver ces instructions pour références ultérieures.

Génératrice

Table des matières

Description . . . . . . . . . . . . . . . . . . . . .17

Déballage . . . . . . . . . . . . . . . . . . . . . .17

Spécifications. . . . . . . . . . . . . . . . . . . .17

Directives de Sécurité . . . . . . . . . . . . .18

Généralités sur la Sécurité . . . . . 18 - 19

Glossaire des Termes. . . . . . . . . . . . . .19

Pré-Fonctionnement . . . . . . . . . . 20 - 21

Fonctionnement . . . . . . . . . . . . . 21 - 22

Entretien . . . . . . . . . . . . . . . . . . . . . . .22

Entreposage . . . . . . . . . . . . . . . . . . . .22

Guide de Dépannage . . . . . . . . . 22 - 23

État de Service. . . . . . . . . . . . . . . . . . . 24

Schéma de Câblage. . . . . . . . . . . . . . .25

Assemblage du Générateur . . . . 26 - 27

Assemblage de l’Alternateur . . . 28 - 29

Assemblage du Panneau

de Commande. . . . . . . . . . . . . . . 30 - 31

Garantie. . . . . . . . . . . . . . . . . . . . . . . .32

Description

Ces générateurs Campbell Hausfeld sont

alimentés par des moteurs à essence.

Chaque appareil est doté de prises

de 120 V et de 230 V fournissant une

alimentation continue et régulière

pour la tâche en cours. Ces prises

sont protégées par des disjoncteurs

de fuite à la terre et des disjoncteurs

thermiques.

LIRE ET SUIVRE TOUTES LES

INSTRUCTIONS

CONSERVER CES INSTRUCTIONS

NE PAS JETER

MÉMENTO: Gardez votre preuve datée d'achat à fin de la garantie!

Joignez-la à ce manuel ou classez-la dans un dossier pour plus de sécurité.

© 2012 Campbell Hausfeld/Scott Fetzer

Déballage

Lors du déballage, l’examiner

soigneusement pour rechercher toute

trace de dommage susceptible de

s’être produit en cours de transport.

Assurer que tous raccords, boulons, etc.,

dégagés sont serrés avant de mettre

ce produit en service. Pour toutes

questions, pièces endommagées ou

manquantes, appeler le

1-800-803-1436 pour le service à la

clientèle. Prière d’avoir le numéro de

série, numéro de modèle et liste de

parties (avec les parties manquantes

encerclées) avant d’appeler.

NE PAS RENVOYER

ARRÊT!

LE PRODUIT AU

MARCHAND !

17 Fr

Specifications

Modèle GN5060

Engine . . . . . . . . . . . Honda GX270

Moteur . . . . . . . . . . . Honda GX270

Type de soupape. . . . . . . . . . . .OHV

Puissance / Type

de moteur . . . . . . . . . 270 cc/4 temps

Type de démarrage . . . . Rappel manuel

Type d’alternateur . . . 2 pôles, sans balai

Phase/Fréquence . . . . . . . . 1 PH/60 Hz

Puissance nominale

de l’alternateur . . . . . . . . . . 5,2 kVA

Bouchon de

réservoir d’essence. .22,7 litres [6 gallons]

Modèle GN6575

Moteur . . . . . . . . . . . Honda GX390

Type de soupape. . . . . . . . . . . .OHV

Puissance / Type

de moteur . . . . . . . . . 390 cc/4 temps

Type de démarrage . . . . Rappel manuel

Type d’alternateur . . . 2 pôles, sans balai

Phase/Fréquence . . . . . . . . 1 PH/60 Hz

Puissance nominale

de l’alternateur . . . . . . . . . . 6,8 KVA

Bouchon de

réservoir d’essence. .22,7 litres [6 gallons]

IN954800AV 3/12

Page 18

Instructions d’utilisation et Manual de Pièces

Directives de Sécurité

Ce manuel contient de l’information

très importante qui est fournie pour

la SÉCURITÉ et pour ÉVITER LES

PROBLÈMES D’ÉQUIPEMENT. Rechercher

les symboles suivants pour cette

information.

Danger indique

dangereuse imminente qui MÈNERA à

la mort ou à des blessures graves si elle

n’est pas évitée.

Avertissement

situation potentiellement dangereuse

qui, si elle n’est pas évitée, POURRAIT

mener à la mort ou à de graves

blessures.

Attention

situation potentiellement dangereuse

qui, si elle n’est pas évitée, PEUT mener

à des blessures mineures ou modérées.

Avis indique

importante qui pourrait endommager

l’équipement si elle n’est pas respectée.

REMARQUE : Information qui exige

une attention spéciale.

Généralités sur la Sécurité

PROPOSITION 65 DE CALIFORNIE

Les gaz

ce produit contiennent des substances

chimiques qui, selon l'État de Californie,

sont cancérigènes, et entraînent des

malformations congénitales ou autres

anomalies de l’appareil reproducteur.

Vous

créer de la poussière en

coupant, ponçant, perçant

ou meulant les matériaux

tels que le bois, la peinture, le métal, le

béton, le ciment ou autre maçonnerie.

Cette poussière contient souvent des

produits chimiques reconnus pour

causer le cancer, les déformations

congénitales ou autres problèmes de la

reproduction. Porter de l’équipement de

protection.

ÉMISSIONS

Les moteurs

règlements des émissions de l’EPA

des É.-U. pour le PÉHR/SORE (petit

équipement hors route), sont certifi és

conformes pour un fonctionnement

à l’essence sans plomb ordinaire,

et peuvent inclure les systèmes de

contrôle d’émissions suivants : (MM)

modifi cations de moteurs et (CCTV)

convertisseur catalytique à trois voies

(s’il y a lieu).

une situation

indique une

indique une

de l’information

d’échappement de

pouvez

conformes aux

L’utilisation d’un

à l’intérieur PEUT ENTRAÎNER LA

MORT EN QUELQUES MINUTES. Les

gaz d'échappement du générateur

contiennent du monoxyde de carbone. Il

s’agit d’un poison invisible et inodore.

• NE JAMAIS l'utiliser à l'intérieur

d'une maison ou d'un garage,

MÊME SI les portes et fenêtres sont

ouvertes.

• N'utiliser qu'À L'EXTÉRIEUR et loin

des fenêtres, portes et conduits

d'aération.

GÉNÉRALITÉS SUR LA SÉCURITÉ

• Lire et comprendre

toutes les instructions

avant de procéder

avec le démarrage

ou l’entretien de la génératrice.

Manque de suivre les précautions

ou instructions peut avoir comme

résultat, dommage à l’équipement

et/ou blessures personnelles graves.

Les instructions pour le moteur se

trouvent dans un autre manuel.

Conserver tout les manuels comme

référence.

LE CARBURANT ET

LES ÉMANATIONS

SONT EXTRÊMEMENT

INFLAMMABLES ! Laisser le moteur

refroidir pendant au moins deux (2)

minutes avant de remplir de carburant.

Ne pas utiliser de mélanges d’essence/

éthanol contenant plus de 15 %

d’éthanol.

Ne jamais

fonctionner cette génératrice

dans un atmosphère explosif

ou dans un endroit qui n’est

pas bien ventilé.

• Ne jamais utiliser cette génératrice

pour aucune application sauf

celles indiquées par le fabriquant.

Ne jamais faire fonctionner cette

génératrice sous des conditions

qui ne sont pas approvés par le

fabriquant. Ne jamais essayer

de modifier cette génératrice

générateur

faire

MANUEL

afin qu’elle fonctionne dans

une manière qui n’est pas

intentionnelle.

• Utiliser seulement les produits et

les pièces recommandés par le

fabriquant pour l’entretien ou la

réparation.

• Assurer que la génératrice est

mise à la terre avec sûreté à un

passage externe mis à la terre avant

d’utiliser. Se référer à la section

“Instructions Pour La Mise À La

Terre” pour les procédures corrects

de la mise à la terre.

• Seules les personnes bien

familiarisés avec les instructions

doivent êtres autorisés à faire

fonctionner la génératrice.

• Situer la génératrice sur une surface

plate et égale avant et pendant son

fonctionnement. La génératrice

ne devrait pas glisser ou bouger

pendant son fonctionnement.

• Tenir toutes personnes à l’écart

de la génératrice pendant son

fonctionnement.

• Ne pas permettre que les personnes

portant des vêtements flottants ou

des bijoux exécutent le démarrage

ou l’utilisation de la génératrice.

Les vêtements flottants et les

bijoux peuvent s’emmêler dans les

pièces mouvantes et endommager

l’équipement ou causer des

blessures personnelles.

• Tenir toutes personnes à l’écart

des pièces mouvantes et chaudes

pendant le fonctionnement.

• Assurer que tout les appareils sont

hors circuit avant de les brancher à

la génératrice.

• Toujours tenir la génératrice propre

et en bon état.

• Assurer que tout outils et appareils

électriques / ménagers sont en bon

état et sont correctement mis à la

terre. Utiliser les appareils qui ont

des cordons d’alimentation à trois

broches. Si un cordon prolongateur

est utilisé, assurer qu’il a trois

broches pour la mise à la terre.

Ne jamais faire

fonctionner cette

génératrice sur une surface trempe ou

dans la pluie.

Mettre le moteur

de la génératrice

hors circuit et déconnecter le fi l de la

bougie d’allumage avant de procéder à

n’importe quel service ou entretien au

modèle.

18 Fr

Page 19

GN5060, GN6575

Généralités sur la Sécurité

(Suite)

• Utiliser seulement de l’essence sans

plomb. Ne pas remplir le réservoir

d’essence tandis que le moteur est

en marche. Prendre des précautions

pour éviter de répandre du

carburant en remplissant le

réservoir. S’assurer que le bouchon

du réservoir d’essence est bien en

place avant de mettre le moteur

en marche. Nettoyer toute trace

de carburant répandu avant de

mettre le moteur en marche.

Laisser le moteur refroidir pendant

au moins deux (2) minutes avant

de remplir de carburant. Ne pas

ajouter de carburant si vous

fumez ou si l'appareil se trouve

à proximité d'étincelles ou de

flammes nues. Ne pas remplir le

réservoir - prévoir de l'espace pour

l'expansion du carburant. Toujours

garder l'embout en contact avec le

réservoir durant le remplissage.

• Cette génératrice peut être utilisée

pour service de secours en cas

d’urgence. En ce cas, un inverseur

manuel doit être installé entre

l’appareil de mésure du courant

électrique et la boîte de distribution

électrique. Cet interrupteur devrait

être installé par un électricien

autorisé.

Ne jamais mélanger

de l’huile avec de

l’essence pour ce moteur. Ce moteur

à quatre temps a été conçu pour le

fonctionnement à l’essence pur. Utiliser

l’huile seulement pour le graissage du

moteur.

SURFACES CHAUDES ! Les

surfaces chaudes entraînent

de graves brûlures cutanées.

Ne pas toucher le moteur, le silencieux

ou l’alternateur avant que l’appareil

n’ait refroidi complètement.

Toujours

garder

un extincteur à portée de

main durant l’utilisation de

l’appareil.

• Toutes les opérations d'installation,

d'entretien, de réparation et

d'utilisation de cet équipement

doivent être effectuées par du

personnel qualifié conformément

aux exigences des codes d'états,

nationaux et locaux.

Un usage

non

conforme des générateurs

électriques peut provoquer

des chocs électriques, des

blessures et la mort ! Prendre toutes

les précautions décrites dans ce manuel

pour réduire la possibilité de choc

électrique.

• Vérifier la propreté et l'état

de l'ensemble des composants

du générateur avant son

utilisation. S'assurer que la gaine

de l’ensemble des câbles et

cordons d'alimentation n'est pas

endommagée. Toujours réparer

ou remplacer les composants

endommagés avant d'utiliser le

générateur. Toujours conserver les

panneaux, écrans, etc. en place

durant l’utilisation du générateur.

• Toujours porter des vêtements

protecteurs, gants et chaussures

isolées secs.

• Toujours utiliser le générateur

dans un endroit propre, sec et

bien aéré. Ne pas faire fonctionner

le générateur dans des zones

humides, sujettes à la pluie ou

encore mal aérées.

• Ne jamais utiliser le générateur

comme surface de travail.

Si le générateur se

mouille pour une

quelconque raison, s’assurer qu’il

est entièrement propre et sec avant

d’entreprendre de l’utiliser !

• Toujours mettre l'équipement

hors tension avant de déplacer

l'appareil.

NORMES DE SÉCURITÉ

ADDITIONNELLES

Normes de sécurité et de santé

OSHA 29 CFR 1910, Superintendent of

Documents,

U.S. Government Printing Office,

Washington, D.C. 20402

Codes d’électricité nationaux

Norme NFPA 70 de la National Fire

Protection Association, Batterymarch

Park, Quincy, MA 02269

Glossaire des Termes

CC (centimètre cube) - Mesure du

volume du cylindre du moteur au-dessus

du piston mesuré avec le piston

entièrement rétracté par le vilebrequin.

Moteur à quatre temps - Moteur

à combustion interne où le piston

complète quatre temps distincts,

admission, compression, combustion

et détente durant deux révolutions

distinctes du vilebrequin du moteur.

R/min (RPM) - Révolutions par

minute Unité habituellement utilisée

pour mesurer la vitesse du rotor de

l’alternateur ou du vilebrequin du

moteur.

EPA - Environmental Protection

Agency (Agence de protection de

l’environnement des États-Unis).

CARB ou ARB - California

Environmental Protection Agency

Air Resources Board (conseil des

ressources atmosphériques de l’agence

de protection environnementale de la

Californie).

CEN - Code d'électricité national

UL - Underwriters Laboratories

ACNOR - Association canadienne de

normalisation

NEMA - National Electrical

Manufacturers Association (normes

pour les produits électroniques)

Alternateur - Appareil

électromécanique convertissant

une énergie mécanique en énergie

électrique sous forme de courant

alternatif.

Hertz (Hz) - Unité de fréquence de

courant alternatif mesurée en cycles à la

seconde.

Sans balayage - Alternateur qui crée

un champ magnétique dans le rotor

induisant un courant électrique de

conducteurs stationnaires enroulés

comme des serpentins. Par contre, les

générateurs à balayage échangent le

courant électrique du rotor au stator

par des balais de carbone à ressort qui

établissent un contact électrique par

l’intermédiaire des lames du collecteur.

CA ou « AC » (courant alternatif) -

Courant électrique qui inverse sa

direction périodiquement ou à une

certaine fréquence.

CC ou « DC » (courant continu) -

Courant électrique qui se déplace dans

une direction et qui est donc polarisé.

Volt (V) - Unité de mesure de travail

nécessaire pour déplacer une charge

électrique.

Ampère (A) ou (I) - Unité permettant

de définir le débit du courant

électrique.

Watt (W) - Unité de courant électrique

calculée par W = V x I ou W = volts x

ampères.

Kilowatt (KW) - Unité de mesure en

watts égale à W/1000. Par exemple :

5000 W = 5 KW.

19 Fr

Page 20

Instructions d’utilisation et Manual de Pièces

Glossaire des Termes (Suite)

Facteur de puissance (FP) - Rapport

de la puissance réelle à la charge à la

puissance apparente du circuit.

Kilo Volt-Ampère (KVA) - Unité

utilisée pour la puissance apparente

dans un circuit électrique. KVA = KW/FP.

Disjoncteur de fuite à la terre -

Disjoncteur qui s’ouvre avec la détection

d’une fuite de courant.

Disjoncteur thermique (DT) -

Disjoncteur qui s’ouvre lorsque le

courant dépasse la limite de courant du

disjoncteur.

Pré-Fonctionnement

EMPLACEMENT

Le choix du bon emplacement peut

considérablement augmenter la

performance, la fiabilité et la durée de

vie du générateur.

Pour obtenir les meilleurs résultats,

placer le générateur dans un

environnement propre et sec. La

poussière et la saleté qui s’infiltrent

dans l’appareil conservent l'humidité et

augmentent l'usure des pièces mobiles.

INSTRUCTIONS

Vérifier le niveau d'huile du moteur.

L’huile N’est PAS mélangée avec

l’essence, mais il faut une quantité

d’huile suffisante pour une lubrification

correcte du moteur. Se reporter

au Manuel du moteur pour les

spécifications SAE, API et la quantité de

remplissage. L’appareil est expédié sans

huile dans le moteur.

MISE À LA TERRE

1. Utiliser la borne de mise à la terre

et l’écrou papillon sur le bâti de la

génératrice pour le raccordement

du modèle à une source de terre

convenable. Fixer, avec sûreté, la

borne d’extrémité du fil de terre

à la borne de mise à la terre sur

le bâti de la génératrice. Serrer la

Figure 1

rondelle et l’écrou papillon situés

sur la borne d’extrémité du fil de

terre.

2. Le fil de terre devrait être fabriqué

du fil de calibre #8. Ne pas utiliser

un fil avec un numéro de calibre

plus haut, ceci indique un fil plus

mince qui ne fournira pas un

conduit de terre convenable.

3. L’autre bout du fil de terre doit être

fixé avec sûreté à une source de

terre approuvée.

Les sources de mise à la terre qui sont

approuvées par le National Electric

Code sont indiqués ci-dessous. Autres

sources peuvent êtres acceptables.

Se référer au National Electric Code

et aux règlements locaux pour plus

d’information concernant les sources

de mise à la terre. Si vous n’êtes pas

certains des règles ou des procédures,

consulter un électricien qualifié

(autorisé ou diplômé).

a. Un tuyau d’eau qsouterrain d’au

moins dix pieds en longueur.

b. Un tuyau souterrain inoxydable

d’au moins huit pieds de

longueur et 3/4 po de diamètre

c. Un tringle souterrain en acier ou

en fer d’au moins huit pieds de

longueur et 5/8 po de diamètre

d. Un tringle non-ferreux, d’au

moins huit pieds en longueur,

1/2 po en diamètre et approuvé

pour la mise à la terre

3.5 cm ou 35 mm [1-3/8 po]

Niveau de remplissage

d’essence

N’importe quel tringle ou tuyau qui est

utilisé pour la mise à la terre doit être

enfoncé à huit pieds de profondeur

ou enterré dans une tranchée aussi

profonde que possible.

RAVITAILLEMENT EN CARBURANT

(VOIR LA FIGURE 1)

1. Couper le moteur et attendre

2 minutes avant de remplir le

réservoir de carburant.

2. Retirer le bouchon et remplir le

réservoir d’essence jusqu’au bas du

col de remplissage, à environ

3,5 cm ou 35 mm [1-3/8 po] du

haut de l’ouverture du col de

remplissage.

3. Ne pas trop remplir le réservoir. Ceci

pourrait endommager la soupape

rotative et le réservoir à charbon

actif.

4. Réinstaller le bouchon d’essence en

s’assurant de le tourner dans le sens

horaire jusqu’à ce qu’il s’arrête.

DÉMARRAGE

1. Retirer toutes les charges

électriques des générateurs.

2. Tourner le levier du robinet de

purge de carburant se trouvant

sous le réservoir de carburant sur

la position verticale, de manière à

ouvrir le robinet.

3. Basculer l’interrupteur à bascule

du moteur (sur le panneau de

commande) sur la position ON

(MARCHE).

TABLEAU 1 - PROMEDIOS ESTIMADOS (VATIOS)

APPAREIL

DE CHARGE WATTS

Appareil de

climatisation

Laveuse 150-1500 Évantail 40-200 Réfrigérateur 190-2000 Aspirateur 200-300

Couveuse 100+ Congélateur 300-500 Poêlon 1200 Pompe à eau 1000-3000

Sécheuse de linge 5000-10,000 Réchaud 330-1100 Chaufferette 600-4800 Chauffe-eau 1000-5000

Cafetière 400-700 Fer à repasser 500-1500 Pompe de puisard 400-3000 Scie à main petite 1000-2000

Perceuse électrique

(petite)

2000-3000 Perceuse électrique

225-1000 Ampoule Selon la

APPAREIL

DE CHARGE WATTS

500-1000 Radio 50-200 Grille-pain 900-1700

(large)

classification

APPAREIL

DE CHARGE WATTS

Télévision 200-500 Scie à main large 1500-2500

APPAREIL

DE CHARGE WATTS

20 Fr

Page 21

GN5060, GN6575

Pré-Fonctionnement (Suite)

4. Le moteur est doté d’un étrangleur

automatique. Le mécanisme de

l’étrangleur possède toutefois

un surpassement manuel pour le

démarrage par temps extrêmement

froids. Pour ce type de démarrage,

tirer le fil de l’étrangleur; une

fois le moteur réchauffé, appuyer

sur l’étrangleur pour qu’il

retrouve sa position normale de

fonctionnement.

5. Tirer la corde de lancement d’un

mouvement souple et rapide.

6. Après chaque démarrage, laisser

le moteur tourner pendant 2 à 3

minutes sans charge.

La vitesse du

moteur est

préprogrammée pour fournir une

tension de sortie adéquate. Ne jamais

essayer de modifi er ou de régler la

vitesse du moteur ou la tension de

sortie.

RODAGE DU MOTEUR

Après le démarrage initial, procéder

avec les instructions de rodage fournit

par le fabriquant. Se référer au manuel

du moteur pour les procédures de

rodage.

ARRÊT

1. Arrêter et retirer tous les dispositifs

de charges électriques du

générateur.

2. Laisser le moteur tourner pendant

2 à 3 minutes sans charges

électriques.

3. Basculer l’interrupteur à bascule

du moteur (sur le panneau de

commande) sur la position OFF

(ARRÊT).

4. Vérifier que le générateur est

entièrement arrêté.

5. Tourner le levier du robinet de

purge de carburant se trouvant

sous le réservoir de carburant sur la

6. Laisser l’appareil refroidir avant

d’installer un quelconque couvercle.

COMMANDE DE RALENTIAUTOMATIQUE (S’IL Y A LIEU)

Certains appareils possèdent une

commande de ralenti-automatique

qui fait tourner le moteur au ralenti

lorsque le générateur n’est pas sollicité.

Le panneau de commande possède un

interrupteur à bascule à commande

de ralenti permettant d’activer ou de

désactiver ce mode.

1. Interrupteur à commande de

ralenti – MARCHE active la fonction

de ralenti-automatique tandis que

le moteur tourne automatiquement

au ralenti lorsqu’il n’y a pas de

charge.

2. Interrupteur à commande de

ralenti – ARRÊT désactive la

fonction de ralenti-automatique

tandis que le moteur tourne à plein

régime.

ARRÊT DE NIVEAU D’HUILE BAS

Un interrupteur d’arrêt de niveau

d’huile bas est fournit pour protéger

le moteur et la génératrice sur la

plupart des modèles à fonctionnement

prolongé. Quand le niveau d’huile

du moteur est trops bas pour son

fonctionnement, l’interrupteur d’arrêt

coupe le moteur. Si le niveau d’huile

est trops bas pendant le démarrage ,

l’interrupteur empêchera le démarrage

du moteur. S’il y a un problème avec le

démarrage, vérifier le niveau d’huile.

REMARQUE : Situer la génératrice

sur une surface plate. Si le modèle

génératrice n’est pas situé sur une

surface plate, l’interrupteur d’arrêt

de niveau d’huile bas peut empêcher

le démarrage, même s’il y a de l’huile

suffisant.

Fonctionnement

APPAREILS DE CHARGE

1. Tout appareils de charge et cordons

prolongateurs devraient utiliser

des bornes à trois broches. Se

référer au tableau suivant pour

les exigences de tailles de cordons

prolongateurs et de câbles.

2. Permettre que le moteur

fonctionne pour 2-3 minutes

avant d’y ajouter aucune charge

électrique.

3. Les prises de courant de 120

volts sont classifiées pour 15 A

et peuvent être utilisées dans

n’importe quelle combinaison de

charges de 120 volts et aussi avec

les charges de 240 volts à travers les

prises de 240 volts.

Les prises de courant de 240

volts sont classifiées pour 20 A

et peuvent être utilisées dans

n’importe quelle combinaison de

charges de 240 volts et aussi avec

des charges de 120 volts à travers

les prises de 120 volts.

La prise de courant 120/240 volts

(twist lock) sur quelque modèles

est classifiée pour 20 ou 30 A et

peut être utilisée dans n’importe

quelle combinaison de charges de

120 et 240 volts.

4. Les prises de courant individuelles

ne devraient pas être chargées plus

que la classification d’ampérage.

5. La charge totale à travers n’importe

quelle combinaison de prises ne

doit pas dépasser la classification de

limite de charge de la génératrice.

Se référer à la plaque indicatrice

sur la génératrice pour les

spécifications d’ampérage et de

puissance en watts.

6. Toujours couper et enlever les

charges avant le démarrage ou

avant de mettre le moteur de la

génératrice hors circuit.

position horizontale, de manière à

fermer le robinet.

TABLEAU 2 - CORDONS PROLONGATEURS

Longeur Maximum Recommandée (En Pieds)

Ampères Watts 120 V Watts 240 V #8 Fil #10 Fil #12 Fil #14 Fil #16 Fil

2.5 300 600 1000 600 375 250

5 600 1200 500 300 200 125

7.5 900 1800 350 200 125 100

10 1200 2400 250 150 100 50

15 1800 3600 150 100 65

20 2400 4800 175 125 75 50

25 3000 6000 150 100 60

30 3600 7200 125 65

40 4800 9600 90

21 Fr

Page 22

Instructions d’utilisation et Manual de Pièces

Fonctionnement (Suite)

7. Pour le raccordement de plusieurs

appareils de charge électrique,

raccorder et faire fonctionner

l’appareil qui exige le plus

de puissance en premier lieu.

Permettre que la génératrice se

stabilise, et ensuite raccorder

et faire fonctionner le prochain

appareil qui exige le plus de

puissance. L’appareil qui appel

le moins de puissance doit être

raccordé en dernier.

REMARQUE : Pour calculer l’appel du

courant, multiplier les volts et ampères.

Le résultat est la consommation en

watts.

Ne jamais dépasser la consommation

en watts maximale indiquée pour la

génératrice ou autre appareil individuel.

Se référer au manuel d’utilisation et sur

l’étiquette du produit pour déterminer

la consommation en watts de tout

appareils de charge électrique.

Si le classement actuel en watts n’est

pas disponible, utiliser le tableau

ci-dessous pour des renseignements

générals.

Les appareils qui engendrent la chaleur

pendant leur fonctionnement tels

que les chaufferettes, les ampoules

incandescents, moteurs et sèchecheveux ont un appel de courant plus

haut que les appareils qui engendrent

moins de chaleur tels que les ampoules

fluorescents, radios et horloges.

Les cordons d’alimentation et cordons

prolongateurs trops longs peuvent aussi

avoir un appel de courant additionnel.

Utiliser un cordon de longueur

minimum.

Se référer au tableau fournit pour les

limites maximales de longueur pour

cordons prolongateurs.

8. La protection de circuit est fournit

par un interupteur disjoncteur.

Le disjoncteur s’ouvre quand la

charge de la génératrice dépasse

sa capacité maximum ou dans

l’évenement d’un court-circuit. Si

le disjoncteur s’ouvre, suivre les

procédures suivants pour corriger le

problème :

a. Couper et débrancher tout

charges électriques.

b. Essayer de déterminer la source

du problème - surcharge ou

court-circuit.

c. Ne pas utiliser d’appareils qui

ont un court-circuit. Ne pas

surcharger la génératrice.

d. Appuyer sur le bouton du

disjoncteur pour le rajuster.

Un disjoncteur qui

cycle d’une manière

répétitive, indique un problème et peut

causer du dommage à la génératrice

ou aux appareils de charge. Ne pas

faire fonctionner la génératrice si

le disjoncteur cycle d’une manière

répétitive.

MONTAGE POUR USAGE DE RÉSERVE

Prenez des précautions pour empêcher

l’alimentation en revers dans

l’entreprise de service public. Ceci exige

l’isolement du système électrique. Suivre

les procédures suivants pour isoler le

système électrique :

1. Mettre hors circuit l’interrupteur du

système électrique principal avant

de raccorder la génératrice.

2. Un inverseur bidirectionnel doit

être installé dans le système

conformément aux normes

nationaux et locaux.

Toujours couper la

source d’énergie

principale avant d’effectuer un

raccordement temporaire de la

génératrice à un systéme électrique d’un

bâtiment.

L’installation d’une

génératrice comme

source électrique supplémentaire doit

être effectué par un électricien qualifié